POWEREX CM400DY-12H Datasheet

CM400DY-12H

Powerex, Inc., 200 Hillis Street, Youngwood, Pennsylvania 15697-1800 (724) 925-7272

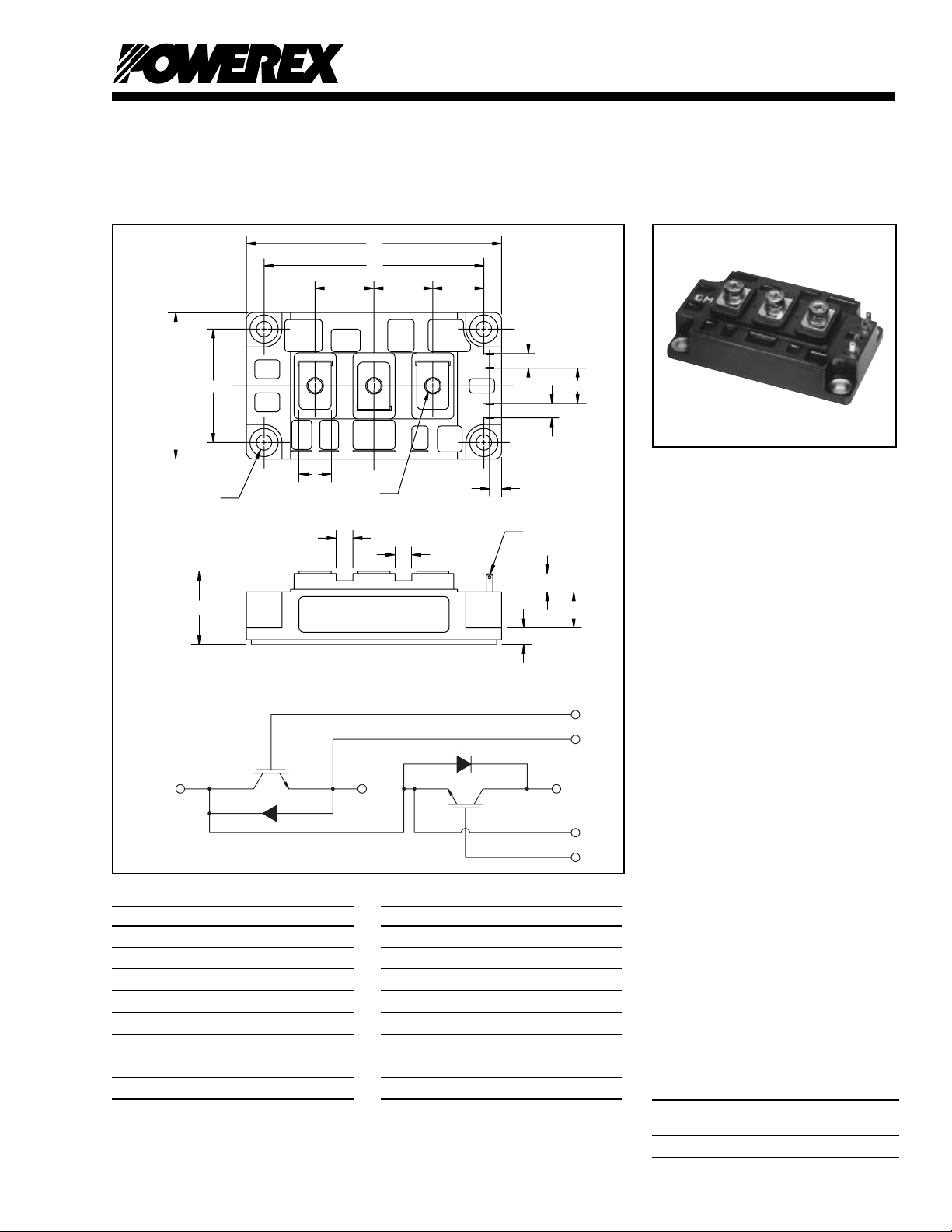

A

B

F F G

P

C2E1 C1E2

DC

K

N - DIA.

(4 TYP.)

M

E

C2E1

Outline Drawing and Circuit Diagram

Dimensions Inches Millimeters

A 4.25 108.0

B 3.66±0.01 93.0±0.25

C 2.44 62.0

D 1.89±0.01 48.0±0.25

E 1.22 Max. 31.0 Max.

F 0.98 25.0

G 0.85 21.5

H 0.60 15.2

Q - M6 THD

(3 TYP.)

E1 E2 G2

G1

M

E2

Dimensions Inches Millimeters

J 0.59 15.0

K 0.55 14.0

L 0.30 8.5

M 0.28 7.0

N 0.256 Dia. Dia. 6.5

P 0.24 6.0

Q M6 Metric M6

R 0.20 5.0

R

.110 TAB

M

J

P

L

H

G2

E2

C1

E1

G1

Dual IGBTMOD™

H-Series Module

400 Amperes/ 600 Volts

Description:

Powerex IGBTMOD™ Modules

are designed for use in switching

applications. Each module consists

of two IGBT Transistors in a

half-bridge configuration with each

transistor having a reverseconnected super-fast recovery

free-wheel diode. All components

and interconnects are isolated

from the heat sinking baseplate,

offering simplified system assembly

and thermal management.

Features:

□ Low Drive Power

□ Low V

□ Discrete Super-Fast Recovery

□ High Frequency Operation

□ Isolated Baseplate for Easy

Applications:

□ AC Motor Control

□ Motion/Servo Control

□ UPS

□ Welding Power Supplies

□ Laser Power Supplies

Ordering Information:

Example: Select the complete part

module number you desire from

the table below -i.e. CM400DY-12H

is a 600V (V

Dual IGBTMOD™ Power Module.

Type Current Rating V

CM 400 12

CE(sat)

(70ns) Free-Wheel Diode

(20-25kHz)

Heat Sinking

), 400 Ampere

CES

Amperes Volts (x 50)

CES

249

Powerex, Inc., 200 Hillis Street, Youngwood, Pennsylvania 15697-1800 (724) 925-7272

CM400DY-12H

Dual IGBTMOD™ H-Series Module

400 Amperes/600 Volts

Absolute Maximum Ratings, Tj = 25 °C unless otherwise specified

Ratings Symbol CM400DY-12H Units

Junction Temperature T

Storage T emperature T

Collector-Emitter Voltage (G-E SHORT) V

Gate-Emitter Voltage V

Collector Current I

Peak Collector Current I

Diode Forward Current I

Diode Forward Surge Current I

Power Dissipation P

j

stg

CES

GES

C

CM

F

FM

d

Max. Mounting Torque M6 Terminal Screws – 26 in-lb

Max. Mounting Torque M6 Mounting Screws – 26 in-lb

Module Weight (Typical) – 400 Grams

V Isolation V

* Pulse width and repetition rate should be such that device junction temperature does not exceed the device rating.

RMS

–40 to 150 °C

–40 to 125 °C

600 Volts

±20 Volts

400 Amperes

800* Amperes

400 Amperes

800* Amperes

1500 Watts

2500 Volts

Static Electrical Characteristics, Tj = 25 °C unless otherwise specified

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Collector-Cutoff Current I

Gate Leakage Current I

Gate-Emitter Threshold V oltage V

Collector-Emitter Saturation Voltage V

CES

GES

GE(th)

CE(sat)

VCE = V

VGE = V

, VGE = 0V – – 1.0 mA

CES

, VCE = 0V – – 0.5

GES

µ

IC = 40mA, VCE = 10V 4.5 6.0 7.5 Volts

IC = 400A, VGE = 15V – 2.1 2.8** Volts

A

IC = 400A, VGE = 15V, Tj = 150°C – 2.15 – Volts

Total Gate Charge Q

Diode Forward Voltage V

** Pulse width and repetition rate should be such that device junction temperature rise is negligible.

G

FM

VCC = 300V, IC = 400A, VGS = 15V – 1200 – nC

IE = 400A, VGS = 0V – – 2.8 Volts

Dynamic Electrical Characteristics, Tj = 25 °C unless otherwise specified

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Input Capacitance C

Output Capacitance C

Reverse Transfer Capacitance C

Resistive Turn-on Delay Time t

d(on)

Load Rise Time t

Switching Turn-off Delay Time t

d(off)

Times Fall Time t

Diode Reverse Recovery Time t

Diode Reverse Recovery Charge Q

ies

oes

res

r

f

rr

rr

VGE = 0V, VCE = 10V, f = 1MHz – – 14 nF

VCC = 300V, IC = 400A, – – 600 ns

V

= V

GE1

= 15V, RG = 1.6Ω – – 350 ns

GE2

IE = 400A, diE/dt = –800A/µs – – 110 ns

IE = 400A, diE/dt = –800A/µs – 1.08 –

– – 40 nF

– – 8 nF

– – 350 ns

– – 300 ns

µ

C

Thermal and Mechanical Characteristics, Tj = 25 °C unless otherwise specified

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Thermal Resistance, Junction to Case R

Thermal Resistance, Junction to Case R

Contact Thermal Resistance R

th(j-c)

th(j-c)

th(c-f)

Per Module, Thermal Grease Applied – – 0.045 °C/W

Per IGBT – – 0.085 °C/W

Per FWDi – – 0.18 °C/W

250

Loading...

Loading...