Page 1

CM1400DUC-24S

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

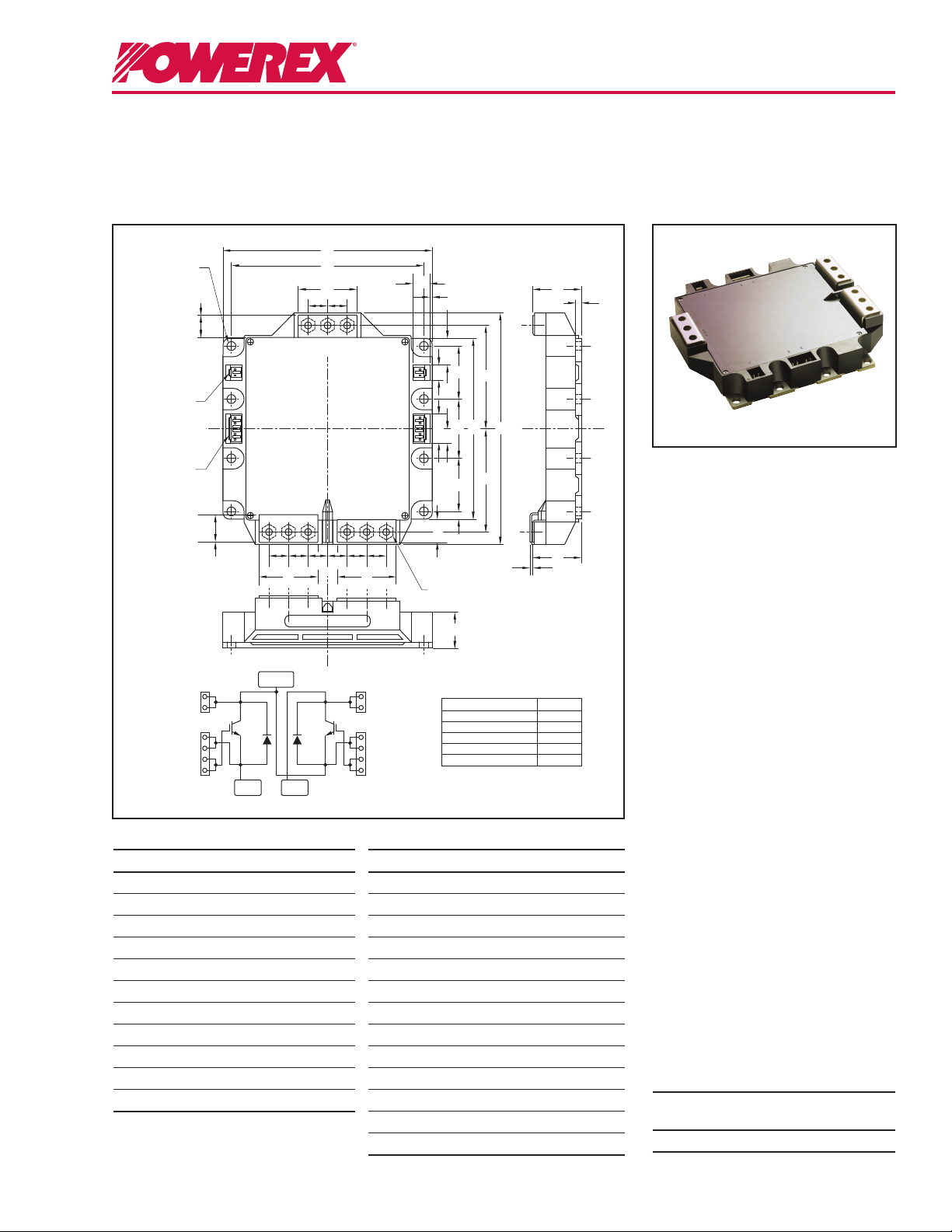

A

(8 PLACES)

Outline Drawing and Circuit Diagram

Dimensions Inches Millimeters

A 5.91 150.0

B 5.10 129.5

C 1.67±0.01 42.5±0.25

D 5.41±0.01 137.5±0.25

E 6.54 166.0

F 2.91±0.01 74.0±0.25

G 1.65 42.0

H 0.55 14.0

J 1.50±0.01 38.0±0.25

K 0.16 4.0

L 1.36 +0.04/-0.02 34.6 +1.0/-0.5

Housing Type (J.S.T. MFG. CO. LTD)

BB = VHR-2N

CC = VHR-5N

P

U

BB

CC

G2

E2 (Es2)

C2

G2 E1

E2 G1

V

H H HHH H

C2E1

Tr 2

Di2

E2

D

G

H H

C2E1

E2

G G

LABEL

C1 (Cs1)C2 (Cs2)

E1 (Es1)

Tr 1

Di1

C1

G1

N

S

W

C1

C1

Dimensions Inches Millimeters

M 0.075±0.008 1.9±0.2

N 0.47 12.0

P 0.26 6.5

R M6 Metric M6

S 0.08 2.0

T 0.99 25.1

U 0.62 15.7

V 0.71 18.0

W 0.75 19.0

X 0.43 11.0

Y 0.83 21.0

Z 0.41 10.5

AA 0.22 5.5

J

X

Y

U

R (9 PLACES)

F

B

C

J

AA

T

E

F

M

Z

Tolerance Otherwise Specified (mm)

Division of Dimension Tolerance

0.5 to 3 ±0.2

over 3 to 6 ±0.3

over 6 to 30 ±0.5

over 30 to 120 ±0.8

over 120 to 400 ±1. 2

L

L

Mega Power Dual IGBT

1400 Amperes/1200 Volts

K

Description:

Powerex Mega Power Dual (MPD)

Modules are designed for use in

switching applications. Each

module consists of two IGBT

Transistors having a reverseconnected super-fast recovery

free-wheel diode. All components

and interconnects are isolated

from the heat sinking baseplate,

offering simplified system assembly

and thermal management.

Features:

£ Low Drive Power

£ Low V

£

£ Isolated Baseplate for Easy

£ RoHS Compliant

Applications:

£ High Power DC Power Supply

£ Large DC Motor Drives

£ Utility Interface Inverters

Ordering Information:

Example: Select the complete

module number you desire from

the table - i.e. CM1400DUC-24S

is a 1200V (V

Dual IGBTMOD Power

Module.

Current Rating V

Type Amperes Volts (x 50)

CM 1400 24

CE(sat)

Discrete Super-Fast Recovery

Free-Wheel Diode

Heatsinking

), 1400 Ampere

CES

CES

109/12 Rev. 0

Page 2

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

CM1400DUC-24S

Mega Power Dual IGBT

1400 Amperes/1200 Volts

Absolute Maximum Ratings, Tj = 25°C unless otherwise specied

Characteristics Symbol Rating Units

Collector-Emitter Voltage (VGE = 0V) V

Gate-Emitter Voltage (VCE = 0V) V

Collector Current (DC, TC = 124°C)

*2,*4

IC 1400 Amperes

Collector Current (Pulse, Repetitive)*3 I

Total Power Dissipation (TC = 25°C)

*2,*4

P

Emitter Current*2 I

Emitter Current (Pulse, Repetitive)*3 I

Isolation Voltage (Terminals to Baseplate, RMS, f = 60Hz, AC 1 minute) V

Maximum Junction Temperature T

Maximum Case Temperature*4 T

Operating Junction Temperature T

Storage Temperature T

*1 Represent ratings and characteristics of the anti-parallel, emitter-to-collector clamp diode.

*2 Junction temperature (Tj) should not increase beyond maximum junction

temperature (T

*3 Pulse width and repetition rate should be such that device junction temperature (Tj)

does not exceed T

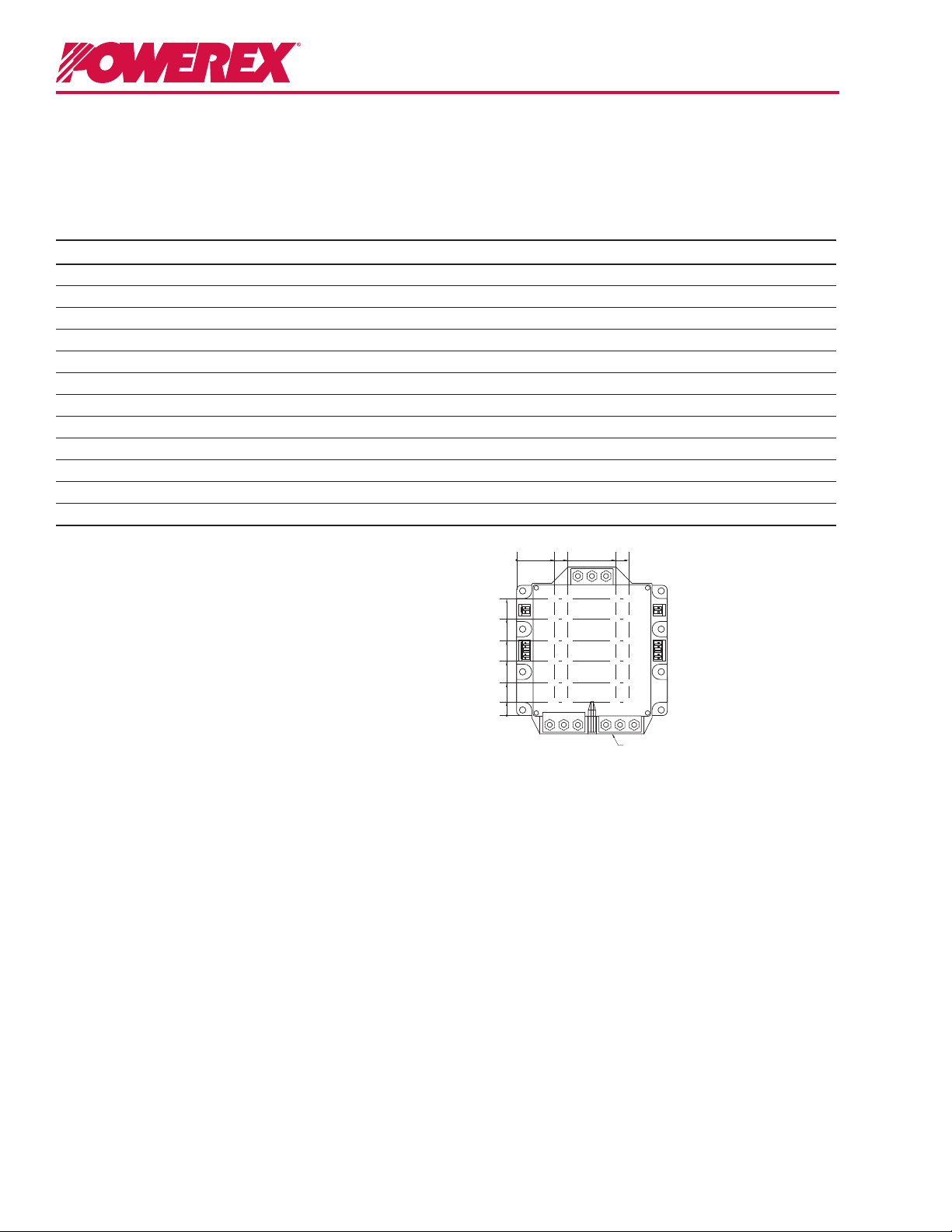

*4 Case temperature (TC) and heatsink temperature (Ts) is measured on the surface

(mounting side) of the baseplate and the heatsink side just under the chips.

Refer to the figure to the right for chip location.

The heatsink thermal resistance should be measured just under the chips.

j(max)

) rating.

j(max)

rating.

0

116.0

96.4

74.5

54.9

33.0

13.4

0

1200 Volts

CES

±20 Volts

GES

2800 Amperes

CRM

9370 Watts

tot

*1

1400 Amperes

E

*1

2800 Amperes

ERM

4000 Volts

isol

175 °C

j(max)

125 °C

C (max)

-40 to +150 °C

j(op)

-40 to +125 °C

stg

38.2

51.0

Di2

Tr2

Di2

Tr2

Di2

Tr2

Di2

Tr2

Di2

Tr2

Di2

Tr2

98.9

111.8

Di1

Tr1

Di1

Tr1

Di1

Tr1

Di1

Tr1

Di1

Tr1

Di1

Tr1

Tr1, Tr2: IGBT, Di1, Di2: FWDi

Each mark points to the center position of each chip.

LABEL SIDE

2 09/12 Rev. 0

Page 3

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

CM1400DUC-24S

Mega Power Dual IGBT

1400 Amperes/1200 Volts

Electrical Characteristics, Tj = 25°C unless otherwise specied

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Collector-Emitter Cutoff Current I

Gate-Emitter Leakage Current I

Gate-Emitter Threshold Voltage V

Collector-Emitter Saturation Voltage V

(Terminal) IC = 1400A, VGE = 15V, Tj = 125°C*6 — 1.75 — Volts

IC = 1400A, VGE = 15V, Tj = 150°C*6 — 1.80 — Volts

Collector-Emitter Saturation Voltage V

(Chip) IC = 1400A, VGE = 15V, Tj = 125°C*6 — 1.75 — Volts

IC = 1400A, VGE = 15V, Tj = 150°C*6 — 1.80 — Volts

Input Capacitance C

Output Capacitance C

Reverse Transfer Capacitance C

Gate Charge QG VCC = 600V, IC = 1400A, VGE = 15V — 3500 — nC

Turn-on Delay Time t

Rise Time tr VCC = 600V, IC = 1400A, VGE = ±15V, — — 250 ns

Turn-off Delay Time t

Fall Time tf — — 350 ns

Emitter-Collector Voltage V

(Terminal) IE = 1400A, VGE = 0V, Tj = 125°C*6 — 1.65 — Volts

IE = 1400A, VGE = 0V, Tj = 150°C*6 — 1.65 — Volts

Emitter-Collector Voltage V

(Chip) IE = 1400A, VGE = 0V, Tj = 125°C*6 — 1.65 — Volts

IE = 1400A, VGE = 0V, Tj = 150°C*6 — 1.65 — Volts

Reverse Recovery Time t

Reverse Recovery Charge Q

Turn-on Switching Energy per Pulse Eon VCC = 600V, IC = IE = 1400A, — 82.2 — mJ

Turn-off Switching Energy per Pulse E

Reverse Recovery Energy per Pulse E

Internal Lead Resistance R

Per Switch,TC = 25°C

Internal Gate Resistance rg Per Switch — 1.7 — Ω

*1 Represent ratings and characteristics of the anti-parallel, emitter-to-collector clamp diode.

*4 Case temperature (TC) and heatsink temperature (Ts) is measured on the surface

(mounting side) of the baseplate and the heatsink side just under the chips.

Refer to the figure to the right for chip location.

The heatsink thermal resistance should be measured just under the chips.

*6 Pulse width and repetition rate should be such as to cause negligible temperature rise.

VCE = V

CES

VGE = V

GES

IC = 140mA, VCE = 10V 5.4 6.0 6.6 Volts

GE(th)

IC = 1400A, VGE = 15V, Tj = 25°C*6 — 1.55 1.90 Volts

CE(sat)

IC = 1400A, VGE = 15V, Tj = 25°C*6 — 1.55 1.90 Volts

CE(sat)

— — 150 nF

ies

VCE = 10V, VGE = 0V — — 30 nF

oes

— — 2.5 nF

res

— — 900 ns

d(on)

RG = 0Ω, Inductive Load — — 950 ns

d(off)

*1

IE = 1400A, VGE = 0V, Tj = 25°C*6 — 1.65 2.10 Volts

EC

*1

IE = 1400A, VGE = 0V, Tj = 25°C*6 — 1.65 2.10 Volts

EC

*1

VCC = 600V, IE = 1400A, VGE = ±15V — — 450 ns

rr

*1

RG = 0Ω, Inductive Load — 90 — µC

rr

VGE = ±15V, RG = 0Ω, Tj = 150°C, — 260 — mJ

off

*1

Inductive Load — 122 — mJ

rr

CC' + EE'

Main Terminals-Chip, — 0.286 — mΩ

, VGE = 0V — — 1 mA

CES

, VCE = 0V — — 3.0 µA

GES

*4

0

38.2

116.0

96.4

54.9

33.0

13.4

51.0

Di2

Tr2

Di2

Tr2

74.5

0

Di2

Tr2

Di2

Tr2

Di2

Tr2

Di2

Tr2

98.9

111.8

Di1

Tr1

Di1

Tr1

Di1

Tr1

Di1

Tr1

Di1

Tr1

Di1

Tr1

Tr1, Tr2: IGBT, Di1, Di2: FWDi

Each mark points to the center position of each chip.

LABEL SIDE

309/12 Rev. 0

Page 4

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

CM1400DUC-24S

Mega Power Dual IGBT

1400 Amperes/1200 Volts

Electrical Characteristics, Tj = 25°C unless otherwise specied (continued)

Thermal Resistance Characteristics

Thermal Resistance, Junction to Case*4 R

Thermal Resistance, Junction to Case*4 R

Contact Thermal Resistance, R

Case to Heatsink (Per 1 Module)

Q Per Inverter IGBT — — 16 K/kW

th(j-c)

D Per Inverter Diode — — 26 K/kW

th(j-c)

Thermal Grease Applied — 6 — K/kW

th(c-f)

*7

Mechanical Characteristics

Mounting Torque Mt Main Terminals, M6 Screw 22 27 31 in-lb

Ms Mounting to Heatsink, M6 Screw 22 27 31 in-lb

Creepage Distance ds Terminal to Terminal 24 — — mm

Terminal to Baseplate 33 — — mm

Clearance da Terminal to Terminal 14 — — mm

Terminal to Baseplate 33 — — mm

Weight m — 1450 — Grams

Flatness of Baseplate ec On Centerline X, Y*5 -50 — +100 µm

Recommended Operating Conditons, Ta = 25°C

(DC) Supply Voltage VCC Applied Across P-N — 600 850 Volts

Gate-Emitter Drive Voltage V

External Gate Resistance RG Per Switch 0 — 2.2 Ω

*4 Case temperature (TC) and heatsink temperature (Ts) is measured on the surface

(mounting side) of the baseplate and the heatsink side just under the chips.

Refer to the figure to the right for chip location.

The heatsink thermal resistance should be measured just under the chips.

*5 Baseplate (mounting side) flatness measurement points (X, Y) are shown in the figure below.

39 mm 39 mm

Y1

– CONCAVE

+ CONVEX

BOTTOM

LABEL SIDE

BOTTOM

*7 Typical value is measured by using thermally conductive grease of λ = 0.9 [W/(m • K)].

Y2

X

BOTTOM

– CONCAVE

+ CONVEX

Applied Across G-Es 13.5 15.0 16.5 Volts

GE(on)

0

38.2

51.0

116.0

96.4

74.5

54.9

33.0

13.4

0

Tr1, Tr2: IGBT, Di1, Di2: FWDi

Each mark points to the center position of each chip.

Di2

Tr2

Di2

Tr2

Di2

Tr2

Di2

Tr2

Di2

Tr2

Di2

Tr2

98.9

Di1

Di1

Di1

Di1

Di1

Di1

111.8

Tr1

Tr1

Tr1

Tr1

Tr1

Tr1

LABEL SIDE

4 09/12 Rev. 0

Page 5

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

CM1400DUC-24S

Mega Power Dual IGBT

1400 Amperes/1200 Volts

OUTPUT CHARACTERISTICS

(CHIP - TYPICAL)

3000

2500

VGE = 20V

15

13.5

2000

, (AMPERES)

C

1500

100

500

COLLECTOR CURRENT, I

0

0 2 4 6 8 10

COLLECTOR-EMITTER VOLTAGE, VCE, (VOLTS)

FREE-WHEEL DIODE

FORWARD CHARACTERISTICS

4

10

3

10

, (AMPERES)

E

2

10

EMITTER CURRENT, I

1

10

0 1.00.5 2.51.5 2.0 3.0

EMITTER-COLLECTOR VOLTAGE, V

4

10

3

10

2

10

SWITCHING TIME, (ns)

1

10

2

10

(CHIP - TYPICAL)

VGE = 15V

HALF-BRIDGE

SWITCHING CHARACTERISTICS

COLLECTOR CURRENT, I

t

d(off)

(TYPICAL)

3

10

t

d(on)

t

t

r

f

C

Tj = 25°C

12

11

10

9

Tj = 25°C

= 125°C

T

j

= 150°C

T

j

, (VOLTS)

EC

VCC = 600V

V

= ±15V

GE

R

= 0Ω

G

T

= 150°C

j

Inductive Load

, (AMPERES)

4

10

SATURATION VOLTAGE CHARACTERISTICS

COLLECTOR-EMITTER

(CHIP - TYPICAL)

3.5

VGE = 15V

, (VOLTS)

CE(sat)

3.0

2.5

2.0

Tj = 25°C

= 125°C

T

j

= 150°C

T

j

1.5

1.0

COLLECTOR-EMITTER

0.5

SATURATION VOLTAGE, V

0

0

COLLECTOR CURRENT, IC, (AMPERES)

CAPACITANCE VS. V

3

10

, (nF)

2

10

res

, C

oes

, C

ies

1

10

0

10

CAPACITANCE, C

SWITCHING TIME, (ns)

VGE = 0V

T

= 25°C

j

-1

10

-1

10

COLLECTOR-EMITTER VOLTAGE, VCE, (VOLTS)

3

10

VCC = 600V

V

GE

2

10

-1

10

EXTERNAL GATE RESISTANCE, RG, (Ω)

(TYPICAL)

0

10

SWITCHING TIME VS.

GATE RESISTANCE

(TYPICAL)

= ±15V

10

0

CE

C

ies

C

oes

C

res

1

10

t

r

t

d(on)

t

d(off)

t

f

IC = 1400A

T

= 125°C

j

Inductive Load

SATURATION VOLTAGE CHARACTERISTICS

10

8

, (VOLTS)

CE(sat)

6

COLLECTOR-EMITTER

(CHIP - TYPICAL)

Tj = 25°C

IC = 2800A

IC = 1400A

4

COLLECTOR-EMITTER

IC = 560A

2

SATURATION VOLTAGE, V

3000250020001500500 1000

2

10

1

10

0

6 8 10 1412 16 18 20

GATE-EMITTER VOLTAGE, VGE, (VOLTS)

HALF-BRIDGE

SWITCHING CHARACTERISTICS

4

10

3

10

2

10

SWITCHING TIME, (ns)

1

10

2

10

COLLECTOR CURRENT, IC, (AMPERES)

3

10

VCC = 600V

V

= ±15V

GE

SWITCHING TIME, (ns)

2

10

-1

10

EXTERNAL GATE RESISTANCE, R

(TYPICAL)

t

d(off)

3

10

SWITCHING TIME VS.

GATE RESISTANCE

(TYPICAL)

0

10

t

d(on)

t

r

t

f

VCC = 600V

V

= ±15V

GE

R

= 0Ω

G

T

= 125°C

j

Inductive Load

t

r

t

d(on)

t

d(off)

t

f

IC = 1400A

T

= 150°C

j

Inductive Load

, (Ω)

G

4

10

1

10

509/12 Rev. 0

Page 6

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

CM1400DUC-24S

Mega Power Dual IGBT

1400 Amperes/1200 Volts

REVERSE RECOVERY CHARACTERISTICS

3

10

(ns)

rr

(A), t

rr

REVERSE RECOVERY, I

2

10

2

10

CHARACTERISTICS (TYPICAL)

3

10

, (mJ)

rr

, (mJ)

off

, E

2

10

on

1

10

SWITCHING ENERGY, E

REVERSE RECIVERY ENERGY, E

0

10

2

10

COLLECTOR CURRENT, IC, (AMPERES)

3

10

(TYPICAL)

3

EMITTER CURRENT, IE, (AMPERES)

10

HALF-BRIDGE SWITCHING

3

10

EMITTER CURRENT, IE, (AMPERES)

VCC = 600V

V

= ±15V

GE

R

= 0Ω

G

T

= 125°C

j

Inductive Load

I

rr

t

rr

V

= 600V

CC

V

= ±15V

GE

R

= 0Ω

G

T

= 125°C

j

E

on

E

off

E

rr

4

10

4

10

REVERSE RECOVERY CHARACTERISTICS

3

10

(ns)

rr

(A), t

rr

REVERSE RECOVERY, I

2

10

2

10

3

10

, (mJ)

rr

, (mJ)

off

, E

2

10

on

1

10

SWITCHING ENERGY, E

REVERSE RECIVERY ENERGY, E

1

10

2

10

COLLECTOR CURRENT, IC, (AMPERES)

IMPEDANCE CHARACTERISTICS

10-310

0

th(j-c')

10

(TYPICAL)

3

EMITTER CURRENT, IE, (AMPERES)

HALF-BRIDGE SWITCHING

CHARACTERISTICS (TYPICAL)

EMITTER CURRENT, IE, (AMPERES)

10

3

10

TRANSIENT THERMAL

(MAXIMUM)

-2

-1

10

VCC = 600V

V

= ±15V

GE

R

= 0Ω

G

T

= 150°C

j

Inductive Load

I

rr

t

rr

VCC = 600V

V

= ±15V

GE

R

= 0Ω

G

T

= 150°C

j

E

on

E

off

E

rr

0

10

4

10

4

10

1

10

GATE CHARGE VS. V

20

IC = 600A

V

= 1400V

CC

T

= 25°C

j

15

, (VOLTS)

GE

10

5

GATE-EMITTER VOLTAGE, V

0

1000 50002000

0

3

10

, (mJ)

rr

, (mJ)

off

, E

on

2

10

SWITCHING ENERGY, E

REVERSE RECIVERY ENERGY, E

1

10

10

GATE CHARGE, QG, (nC)

HALF-BRIDGE SWITCHING

CHARACTERISTICS (TYPICAL)

= 600V

V

CC

V

= ±15V

GE

I

= 1400A

C/IE

T

= 125°C

j

-1

GATE RESISTANCE, RG, (Ω)

3000 4000

0

10

GE

E

on

E

off

E

rr

1

10

, (mJ)

rr

, (mJ)

off

, E

on

2

10

VCC = 600V

V

= ±15V

SWITCHING ENERGY, E

GE

I

REVERSE RECIVERY ENERGY, E

= 1400A

C/IE

T

= 150°C

j

1

10

-1

10

GATE RESISTANCE, RG, (Ω)

-1

10

Single Pulse

T

= 25°C

C

Per Unit Base =

R

=

th(j-c)

• (NORMALIZED VALUE)

16 K/kW

-2

10

th

(IGBT)

= R

th

R

E

on

E

off

E

rr

0

10

10

Z

-3

1

10

NORMALIZED TRANSIENT THERMAL IMPEDANCE, Z

=

th(j-c)

26 K/kW

(FWDi)

-5

10

TIME, (s)

-4

10

-1

10

-2

10

-3

10

-3

10

6 09/12 Rev. 0

Loading...

Loading...