Page 1

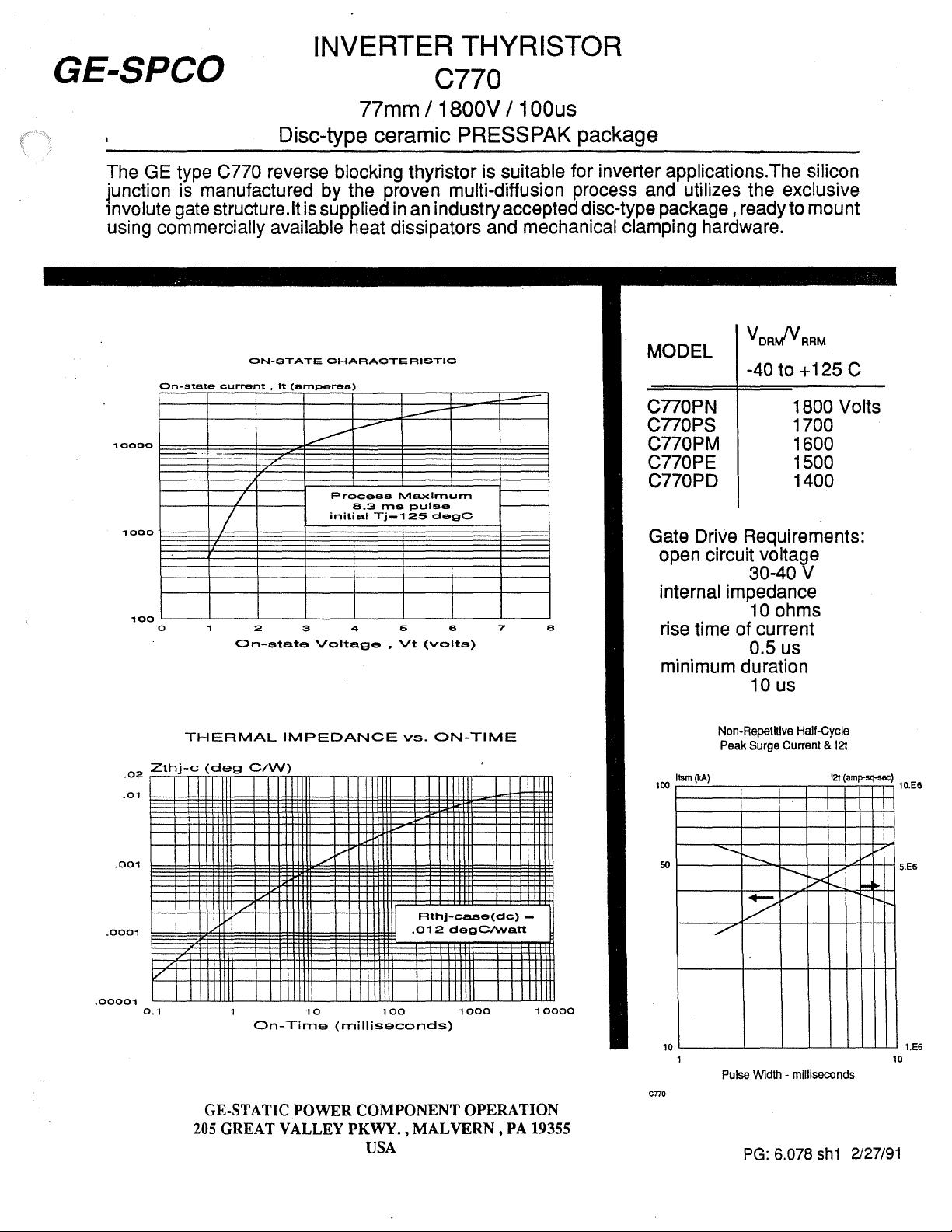

INVERTER THYRISTOR

C770L

C770PN

C770PS

C770PM

C770PE

C770PD

2000 Volts

1800

1700

1600

1500

1400

GE-SPCO

The GE type C770 reverse blocking thyristor is suitable for inverter applications.Thesilicon

is

junction

involute gate structure.

using commercially available heat dissipators and mechanical clamping hardware.

10000

1000

100

manufactured

On-state

-

o

current

/

e770

77mm / 1800V / 100us

Disc-type ceramic PRESSPAK package

by

the proven multi-diffusion process and utilizes the exclusive

It is supplied in an industry accepted disc-type package, ready to mount

ON-STATE

It

CHARACTERISTIC

(amperes)

-

I.--'"

--

---

/

/

:2

On-state

Process

initial

3 4

Voltage.

B.3

Maximum

IT'IS

puis

Tj_1

2S

degC

6 e 7

Vt

(volts)

..

e

MODEL

VDRJVRRM

-40 to +125 C

C770PN

C770PS

C770PM

C770PE

C770PD

1800 Volts

1700

1600

1500

1400

Gate Drive Requirements:

open circuit voltage

30-40 V

internal impedance

10 ohms

rise time of current

0.5 us

minimum duration

10 us

.0001

.00001

.01

.001

.02

Zthj-c

V

0.1

THERMAL

./

205

IMPEDANCE

(deg

C/W)

V

/'

/'

On-Time

GE·STA TIC

10

(milliseconds)

POWER

COMPONENT OPERATION

GREAT VALLEY PKWY. ,

USA

V

II

100

vs.

ON-TIME

Rthj-ca.ae(dc)

.012

MAL

degClvvatt

1000

VERN,

-

10000

PA 19355

C770

100

Non·Repetitive

Peak

Surge

Ilsm

(kA)

-......

50

r--.

Hall-Cycle

Current & 121

121

-.....

V

J><

r--..

V

(am~sq-sec)

V

!-...

r--

10.ES

S.ES

V

./"

10

Pulse

WIdth -milliseconds

PG:

6.078

sh1

2127/91

10

1.E6

Page 2

GE-SPCO

up to

2000

e770

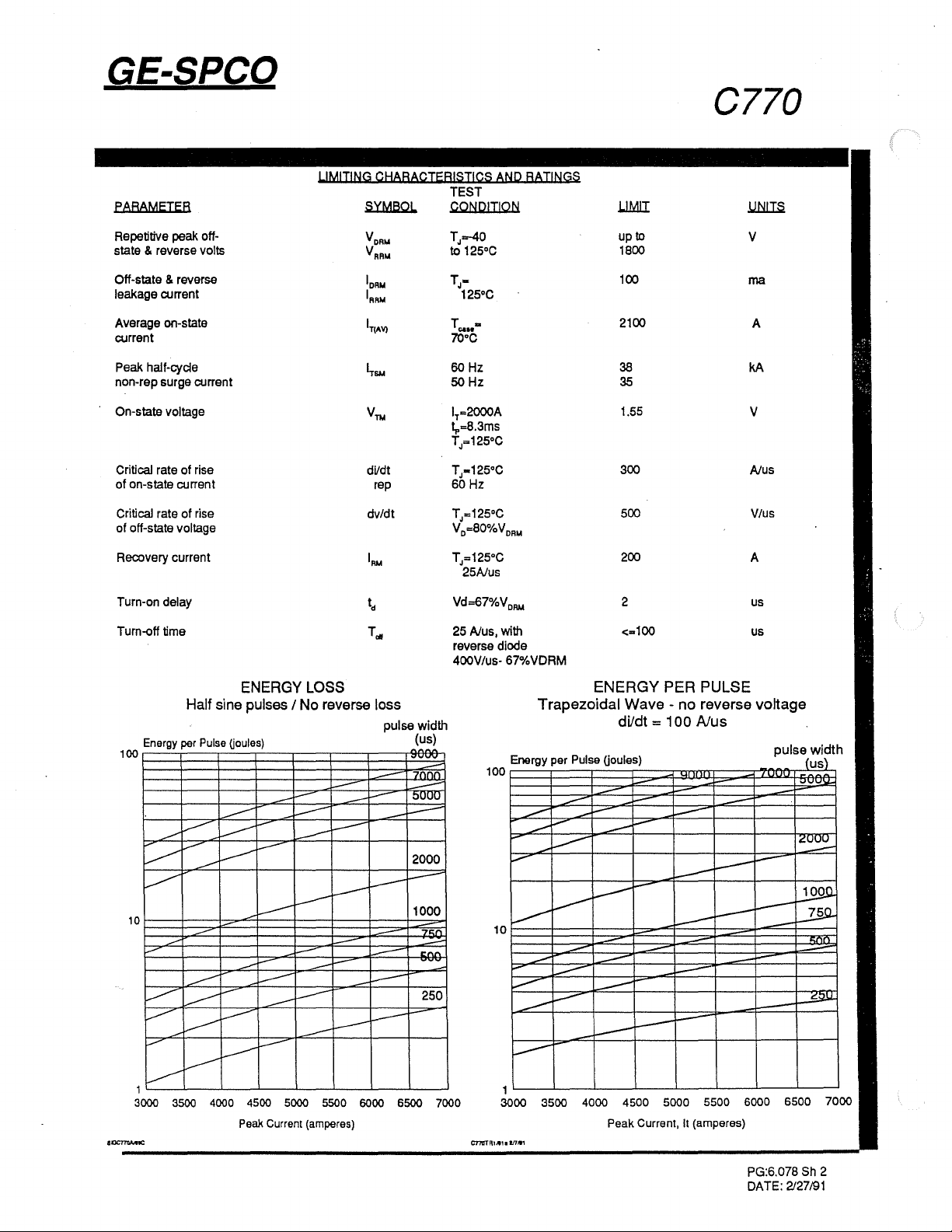

PARAMETER

Repetitive

state &

Off-state

leakage current

Average

current

Peak

non-rep surge current

On-state voltage

Critical

of on-state current

Critical

of

Recovery current

Turn-on

Turn-off

peak

off-

reverse

volts

&

reverse

on-state

half-cycfe

rate

of

rise

rate

of

off-state voltage

rise

delay

time

LIMITING

CHARACTERISTICS

SYMBOL CONDITION

V

ORM

V

RRM

IOAt.!

IRRM

IT\AV)

~

VTt.\

dVdt

rep

dv/dt T

I

At.!

td

T ..

TEST

Tr

to

TJ-

60Hz

so

40

125°C

125°C

To

...

-

70°C

Hz

IT=2000A

lp=8.3ms

TJ=125°C

TJ-125°C

60

Hz

c

125°C

J

Vo=80%V

TJ=125°C

25A1us

Vd=67%V

25

Alus,

reverse

400V/us-

AND

ORM

o

with

diode

67%VDRM

RATINGS

Rt.l

.l.I..MlI

up

to

1800

100

2100

38

35

1.55

300

500

200

2

~

V

rna

A

kA

V

Alus

V/us

A

us

us

ENERGY LOSS

Half

sine

pulses / No reverse loss

pulse width

Energy per Pulse

100

~

L

V

~

~

10

.-

,........

~

V-

.....-

----

---

1 1

3000 3500 4000 4500 5000 5500 6000 6500 7000 3000

-----

V--

----

V

---

--

.----

----

~

V

l----"

Uoules)

I--""

---

--

-

:---

I-""

--

----

----

.---

-

:---

--

---

I--

Peak Current (amperes) Peak Current, It (amperes)

~

---

-

r--

-

I---

---

--

(us)

,..,..,

7(\(\(1

-

~UUU

--

-

--

2000

~

--

1000

--

~

-

---

'"

-'-

.,.,..,..

250

100

ENERGY PER PULSE

Trapezoidal Wave - no reverse voltage

Ene

--

---

V

10

------

--

~

--

rgy

per

----

r-

----

~

---

---

~

PI

usa

----

-~

--

V-

dildt = 100

(jou es)

-

--

r-

---

r-

.....-

......-

---

---

I---

Nus

I--"

I--"'

--

--

I---

-

--

3500

4000 4500

5000

5500 6000

-

--

--

--

--

r-

-

pulse width

(us)

-

~U~

~

~

-

~

PG:6.078

DATE:

2127/91

Sh

2

Page 3

GE-SPCO

The

foIortMg

stable thennaI and

the PRESSPAK to heat

1.

INSPECTION OF

ChecI<

"nlsh.The PRESSPAK

TIR

electrical test

surface

Iast8cl

not

wtth

based

.2. SURFACE DEOXIDATION

Although plated surfaces are recommended lor aluminum and

copper heat dlsslpators, bare surfaces may be used

careful attention to cleaning

Plated

wfth

recommended. Unplated surfaces should

abralded with a

coated with Alcoa

be

3.

FINAL SURFACE TREATMENT

Apply silicone

compound

property dlstrlbute the applied agent.

••

MOUNTING

Instruction

each mating surface for nicks, scratches and surface

< .0005 Inch and surface "nlsh prior

should

PRESSPAK may run higher

InclUding

the

last nxturas.(Recommended mounting loreels

upon these requirements.) " .002" lor

surfaces and PRESSPAKS should

600 grit paper, then

removed

I. naentlal for maintaining

eIect:tIcaI

In

be

some

nne

and

mlstances

clulpator

MATING

pressure nxturas. The dissipater

the recommended compound applied.

SURFACES

surface has a total Indicator reading

equally as good.The

minor nicks and scratches associated

AND

011

or compound applied as

wire brush or

EJC

#'2

compound. The Alcoa

011

or a

very

lUrlacea.

CLEANING

and

treating

3M

thin layer

auoc::lallld with

TIR

but

01

not

exceed .001" Inch

Is

assured.

be

be

"Scotchbrlte"

01

grease or

low,

a fully

lightly sanded

vigorously

#'2

as Indicated below. Rotate the PRESSPAK to

· bare copper - use G322L

· bare aluminum - use

· tin plated copper or aluminum - preferably use

SF1154. Alternatively use G623 or G322L

· nickel-plated aluminum -

• silver plating

Assemble

aell·leveilng swivel connection. The swivel plate

diameter should

the paleface diameter

the top

wtth

specified

be preferably equal but not smaller than

and bottom

NOTES:

Silicone

-slllcol'l81lrease

products of General Electric Co. EJC

compound

of

of

Umlt maximum joint temperature to 95 C,except

for those prepared with SF1154 or

can

Alcoa

Is

not recommended

01

Am

erIca.LS2037Is a black compound,a product

ARCO

bEt

use

mounting lorce applied through a

01

the PRESSPAK.

the PRESSPAK are

011

SF1154{200 centlstoke),cIear

Is

a product of the Aluminum Company

00.,7301 Bessemer Ave.,Cleveland,OH

used up

or

#'2

LS2037 •

or G322L

SF1154 or G623

Center

tor

G623

and yellow

to

1

50

C

locating.

G322L

If

should

holes on

are

~

G3221

to

factory

nmm.

Yt'hk:h

ellD

-'-----"_!

i

-"ERM,

I,

t

c

F,

•

TERM 4

PLATED SURFACE _

SYMBOL

0A

08

I

~

INCHES

MIN.

-

2.876 2.880

C 1.387 1.447

0

0E

F

.080

0.136

0.20

G 2.403 2.418 61.16

H

External

-

Clamping

8000 Ib minirrum

9000 Ib maxirrum

Anode·Cathode

Electrical Insulation, Glazed Ceramic, Creepage

(40.6mmJ. Strike 1.0 in. (25.4mm)

Gate Leads

with

#8

Pole Faces

00

Ring Terminal.

18

in.

,e

~

~8

MAX.

4.350

-

0.146

-

- -

Force:

00

#22

Terminated Nicke,

-I

;'e::iM-;J

MILL\1E-;-E~S

MIN.

-

73.05

35.23

2.03

3.4::

0.86

Nickel

Pla~ej

;

(DC"")

_,

, ~ \c=

I

i 1

!

,

i

I

I

,

I

T

1.6

OF

(op--\

~.1AX

;0 . .19

(3. ~ 5

36.75 '

-

,...

";;.1

-

6: . .12

-

':

P,,:eo

_"E/

:'j

I

,

I

-:"""

I

!

~ocer

~

PG:

6.078 sh3

3114190

Loading...

Loading...