Powerex AS-XXX User Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

• Guaranteed low oil carryover rate of

less than 2 PPM

• Three year warranty on compressor

pump

• Isolation pads

• Optional R134 dryer

• ASME tank

• UL listed controls

The AS-XXX Series Powerex Simplex Air

Compressors have been designed, broken-in and tested to meet the most

demanding specifications in the pneumatic climate control industry for low

oil carryover and long life.

All Powerex air compressors have reliable operation and feature high quality

construction and components. An

unloading feature is included on all

compressors to provide loadless starting. Oil entrainment is minimized by

the use of lap joint piston rings, low

compressor speeds and a special lubricating oil with a high flash point and

low carbon content.

All 1/2 through 10 hp models are also

equipped with an auxiliary cooling fan

and air control shroud to achieve low

head temperatures and further minimize oil carryover.

Powerex compressor motors are NEMA

Class B design. Single-phase motors

have built-in overload protection and a

DPST disconnect switch. Three-phase

motors require a manual or magnetic

starter and three overload heater coils

which may be ordered as a factory

mounted and wired option.

Climate Control Simplex

IN259601AV 10/04

Specifications

Product

Performance

Specifications

Models & Options

Lubrication

Operating

Voltages

Compression

Cycle

Motor Overload

Protection

Pressure Settings

Overpressure

Protection

Outlet Air

Connections

Tank Sizes

California

Ordinance 462

(L) (2)

Tank Isolation

Manuals

1/2 Through 10

1Ø

3Ø

1/2 Through

10 Hp Models

1Ø

3Ø

AS-XXX Series Powerex Simplex Air Compressors

See Table 1

See Table 2

Splash Lubrication System

115 - 208/230 Volts, 60 Hz

208-230/460 Volts, 60 Hz

Single-Stage

Built-In Thermal Overload (Standard)

Magnetic Starter and Three Thermal Overload

Switches (Optional)

Cut-In: Factory Set at Approximately 70 psig (490kPa)

Cut-out: Factory Set at Approximately 90 psig (630 kPa)

ASME Safety Valve Factory Set and Sealed at

Approximately 115 psig (805 kPa)

1/2" NPT on 30, 60 and 80 Gallon Tanks;

1" NPT on 120 and 200 Gallon Tanks

See Table 2

Meets Requirements of this Ordinance

Standard All Units

200 Page Service Manual Available

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these specifications, consult the local Powerex office. Powerex shall not be

liable for damages resulting from misapplication or misuse of its products.

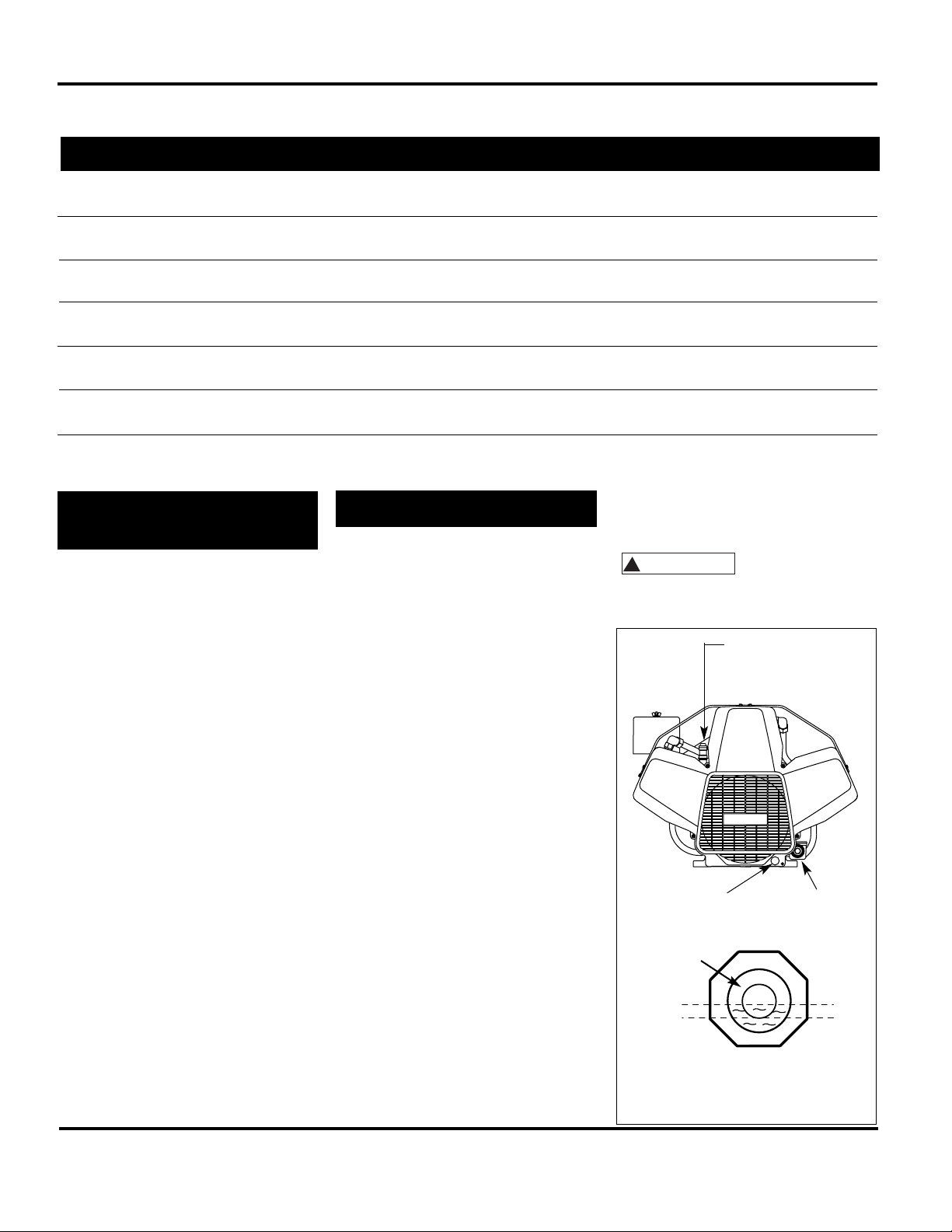

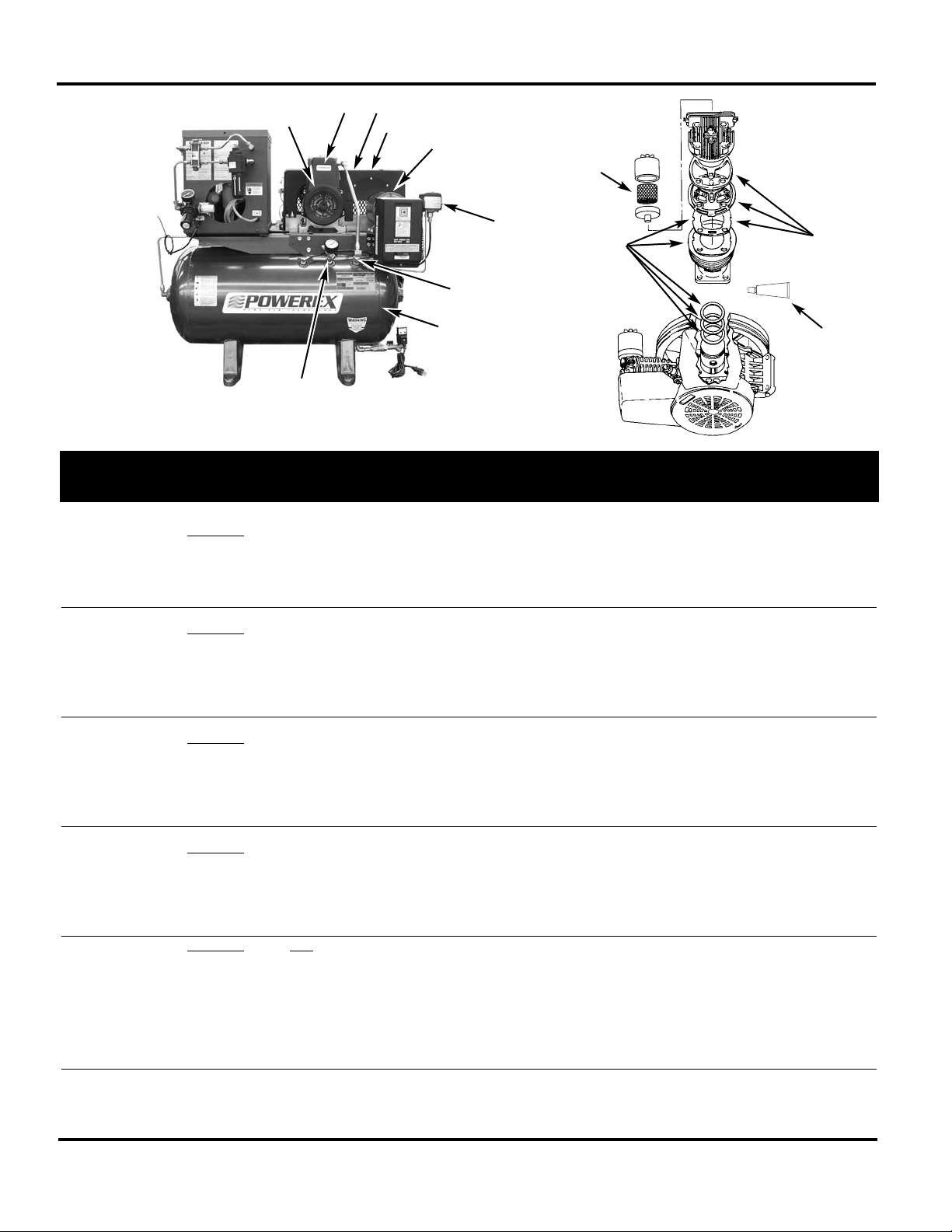

Figure 1 - AS-XXX 1 Hp Simplex Air Compressor

Features

Base Actual Hp Motor Rating Compressor Compressor Capacity ACFM*

Model 1Ø 3Ø Hp RPM RPM 100% Runtime 50% Runtime 33% Runtime

TABLE 1: AS-XXX SERIES POWEREX SIMPLEX AIR COMPRESSORS

PERFORMANCE SPECIFICATIONS

1725

1720

1725

1725

1750

1750

1745

1745

1745

1750

—

.54

—

.73

—

1.07

1.54

2.0

3.1

5.6

8.2

10.3

.54

—

.73

—

1.07

—

—

—

—

—

—

—

AS-105

AS-005

AS-107

AS-007

AS-110

AS-010

AS-015

AS-020

AS-030

AS-050

AS-075

AS-100

—

.54

—

.73

—

1.07

1.54

2.0

3.1

5.6

8.2

10.3

800

1040

625

955

800

775

690

795

685

1.8

2.5

3.8

6.4

8.6

12.0

22.0

28.5

43.0

0.9

1.25

1.9

3.2

4.3

6.0

11.0

14.3

21.5

0.6

0.83

1.25

2.11

2.84

4.0

7.33

9.44

14.2

2

Climate Control Simplex

MAGNETIC MOTOR STARTER

An optional magnetic motor starter

which has been selected and wired for

the intended input voltage is available

for all units. All starters are furnished

with properly sized overload heaters.

REFRIGERATED AIR DRYER

A factory mounted Model Hankinson

HPR 5-10 Series refrigerated air dryer

with automatic condensate drain trap

assembly, bypass valve is available as an

option on all 1/2 through 3 Hp Powerex

Simplex air compressors. Piping for air

dryer is done at the factory. Wiring to

power source must be done in the field

using integral cord and plug which fits

into a standard 120 volt receptacle.

Refer to Table 2 for ordering details.

AUTOMATIC TANK DRAIN

Powerex air compressors are ordered

with either a manual or electric type

automatic tank drain. This unit is furnished with a manual drain attachment.

VIBRATION DAMPENING PADS

Waffle type design vibration pads are

provided as standard equipment.

Factory calibrated snap-acting DPST

pressure electric switches provide automatic cut-in and cut-out. Overpressure

protection is provided by an ASME safety relief valve. Receiver tanks have a

condensate drain valve with an extension for easy access. All mounting bases

are slotted for V-belt tension adjustment to aid in maintaining proper compressor and motor alignment.

All units are run through the factory

break-in and are tested for air delivery,

leakage and power consumption.

Units are shipped with a proper fill of

compressor oil in the crankcase and are

furnished with an intake filter/silencer

with a replaceable cartridge. This filter/silencer combination is designed to

remove contaminates in the inlet air

and provide quieter operation. The 5

through 10 Hp models are complimented by this design utilizing dual element

filtration which consists of a pleated

element and a foam element for filtration against larger particles from the

atmosphere.

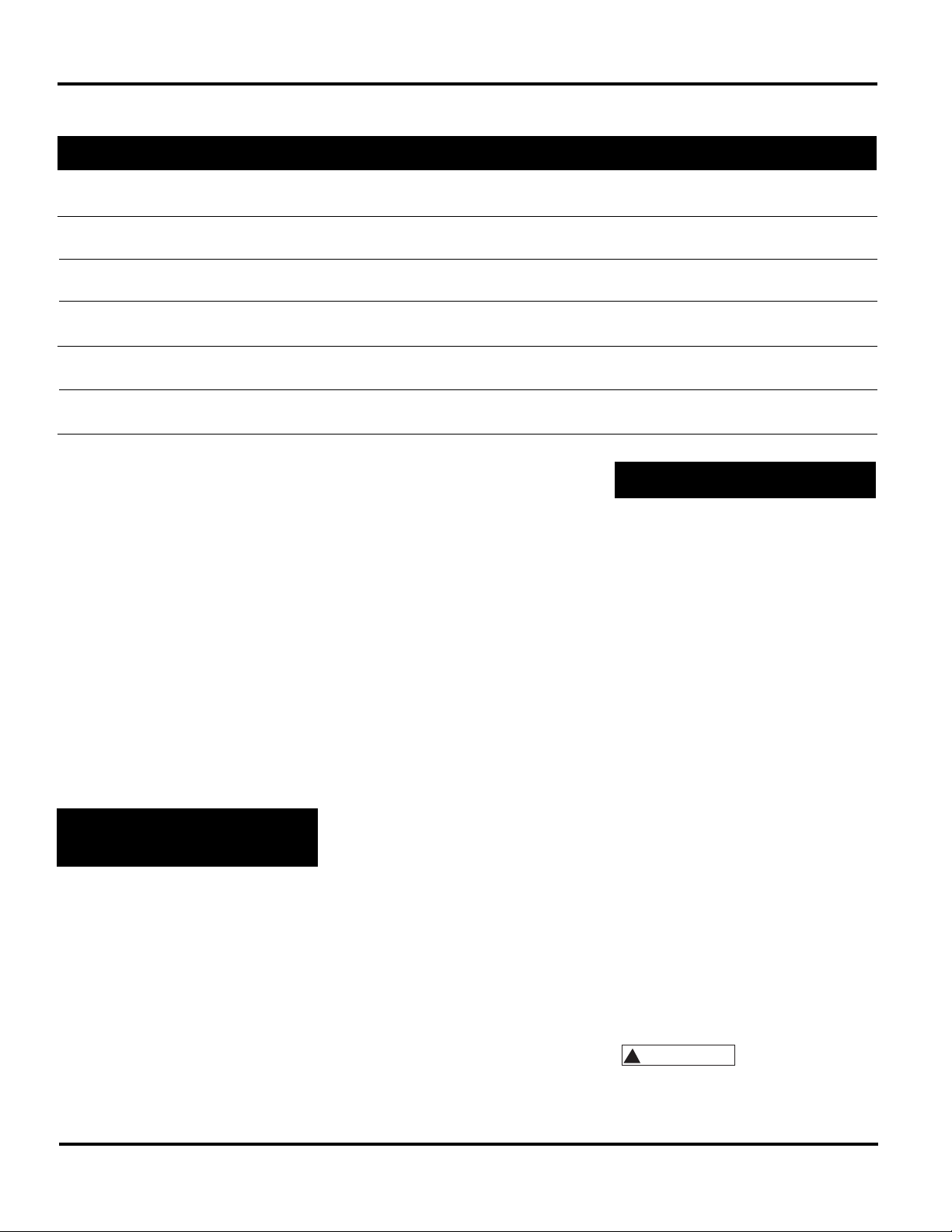

LUBRICATION

Check lubricating oil level at gauge.

Refill if necessary.

Change oil according to maintenance

schedule. Before draining oil, remove

oil supply cap and loosen oil drain cap

to release trapped air. Use Mobil Rarus

427

®

or Mobil DTE heavy oils.

Dispose of oil in

accordance with

state or local codes.

Remove cap and use

funnel to add oil.

Oil gauge

Oil drain

cap

Full

Low

Round (red)

Operation

Mounted and

Connected Options

OIL GAUGE

Figure 2 - Lubrication

!

WARNING

3

Climate Control Simplex

Example 1: To order a Simplex air compressor with a

3/4 Hp single-phase motor, 60 gallon tank, singlephase 115 volt starter, automatic tank drain and an

air dryer, use product code AS-107-254.

Example 2: To order a Simplex air compressor with a

10 Hp three-phase motor, 200 gallon tank and an

auto drain, use product code AS-100-502.

}

Horsepower &

Voltage Phase

TABLE 2: MODEL NUMBER

Tank Size

Starter

Tank

Drain/Dryer

AS

Tank Size

(Gallons) Available on:

NA = Not Available

Tank Drain/Dryer Options

Starter Options

Motor Horsepower, Voltage Phase

1Ø Horsepower 3Ø

105 = 1/2 = 005

107 = 3/4 = 007

110 =1 = 010

NA = 1

1

⁄2 = 015

NA = 2 = 020

NA = 3 = 030

NA = 5 = 050

NA = 7

1

⁄2 = 075

NA = 10 = 100

30 = 1 1/2 Through 1

1

⁄2 Hp

60 = 2 3/4 Through 2 Hp

80 = 3 2 Through 7

1

⁄2 Hp

120 = 4 5 Through 10 Hp

200 = 5 7

1

⁄2 and 10 Hp

None = 0

3Ø, 208V Starter* = 2

3Ø, 208/230V Starter** = 3

3Ø, 460V Starter = 4

1Ø, 115V Starter = 5

1 Ø, 208/230 V Starter = 6

1Ø vs 3 Ø selection must agree with

base model selection.

**This starter selection is dual

rated. Choosing digit “3”

means 230 V.

}

Manual Drain,

No Dryer = 1

E-Drain,

No Dryer = 2

Manual Drain,

with Dryer = 3

E-Drain,

with Dryer = 4

Available on

1/2 through 3 Hp

models only.

}

OR

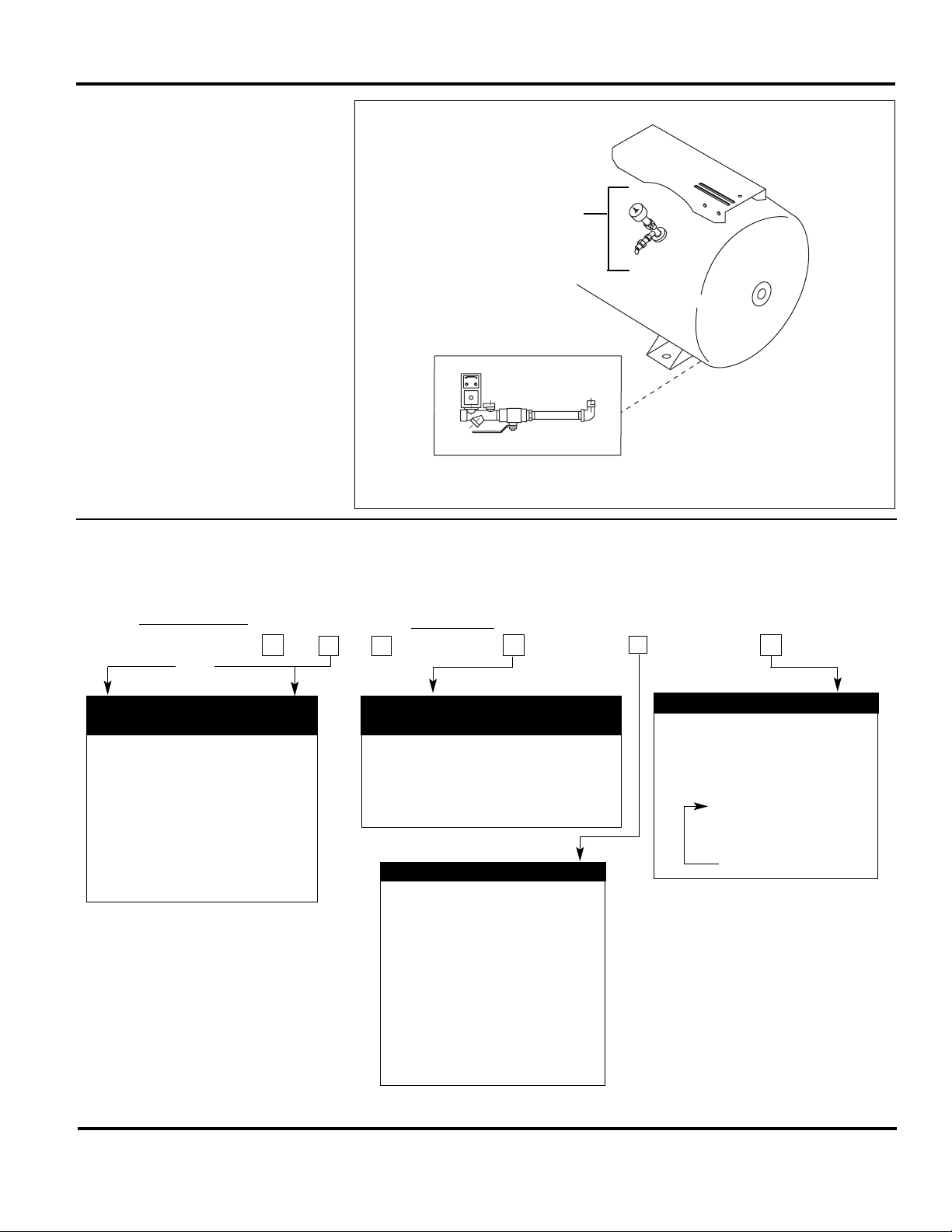

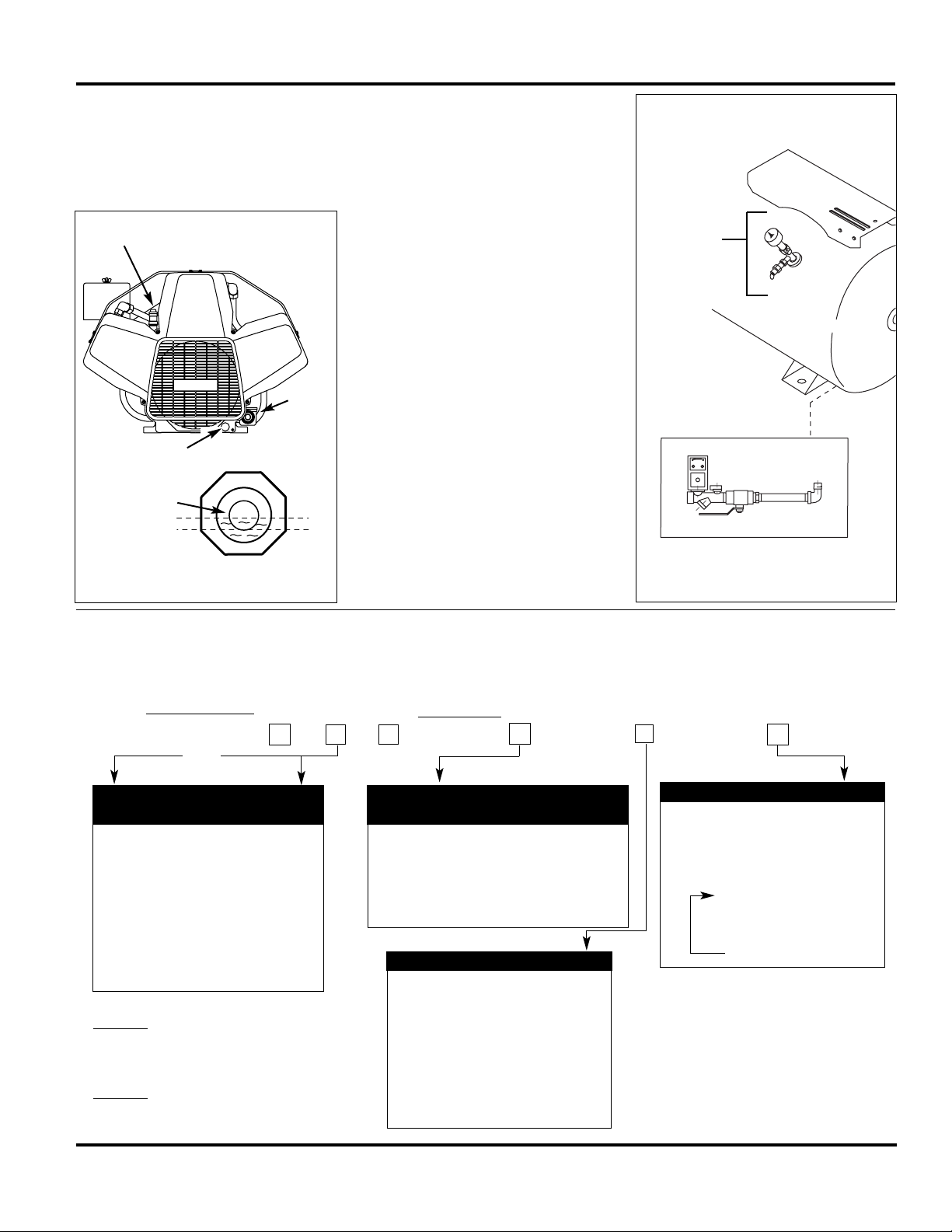

Figure 3 - Auto E-Drain

Manifold

Assembly

AUTO E-DRAIN ASSEMBLY (See

Figure 3)

NOTE: The automatic E-drain is assembled to tank.

1. Plug E-drain into 115V power outlet

supply.

2. Adjust times accordingly.

TEST

OFF

ON

6

4

20

30

10

2

40

8

5

0.5

10

0.5

45

sec.

min.

4

Climate Control Simplex

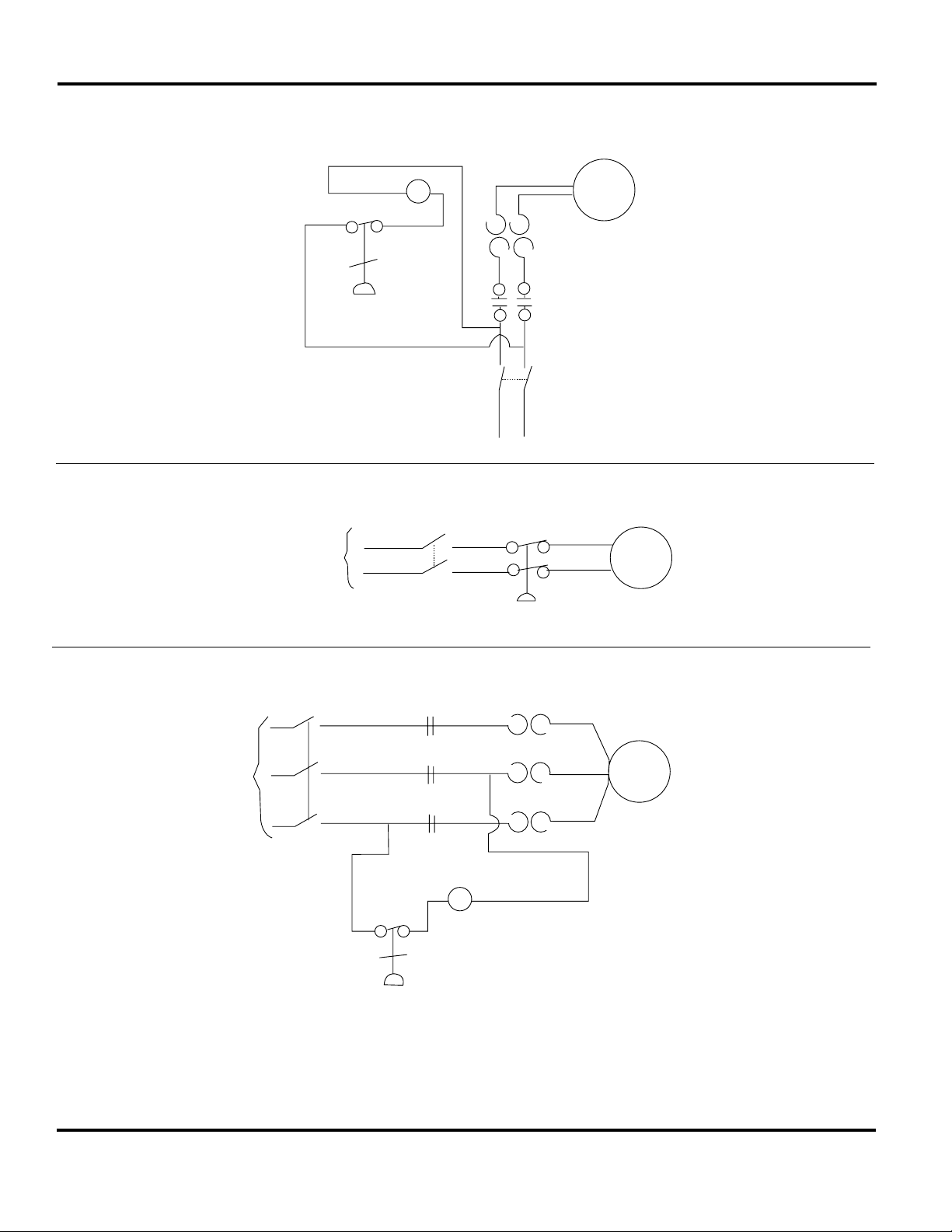

Figure 6 - AS-XXX Three-Phase Wiring

With Pressure Switch Used for Pilot Duty

NOTE: “M” = Magnetic Contactor

N.C.

Pressure

Switch

*Comp.

Motor

* With

Integral

Overload

Secondary

Thermal

Overloads

Starter

Manual

Disconnect

Switch

1Ø 230 VAC

Manual

Disconnect

Switch

1Ø

Line

Voltage

3Ø

Line

Voltage

N.C.

Pressure

Switch

N.C.

Pressure

Switch

Thermal

Overloads

M

Figure 4 - AS-XXX Single-Phase Wiring

With Pressure Switch Used for Pilot Duty

Figure 5 - AS-XXX Single-Phase Wiring

With Pressure Switch Used as Contactor

*Comp.

Motor

* With

Integral

Overload

*Comp.

Motor

Manual

Disconnect

Switch

m

M

m

m

M

M

O.L.

5

Climate Control Simplex

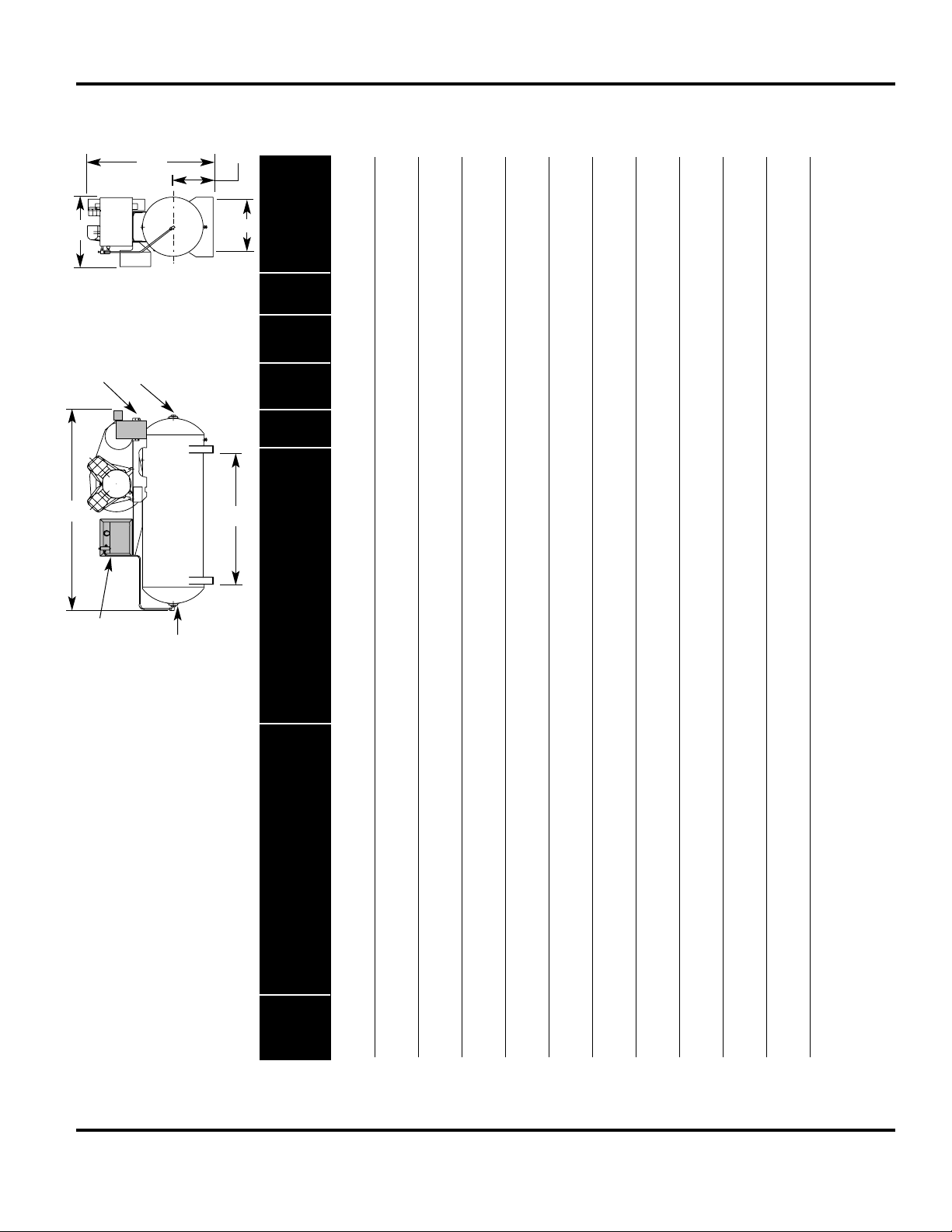

*Inches x 2.54 = Centimeters, Pounds x 0.454 = Kilograms

**Add 60.0 lbs. for units equipped with a factory mounted air dryer

A

D

Optional

Dryer

Discharge

Optional

Starter

Figure 7 - Dimensions

(See Table 3)

Plug

B

C

TABLE 3: DIMENSIONS (Inches*) AND SHIPPING WEIGHTS (Pounds*)

A B Shipping Weight**

Base w/Starter w/o Starter w/Starter w/o Starter w/Starter w/o Starter w/Starter w/o Starter C D E F with without

Model w/oDryer or Dryer and Dryer w/Dryer w/o Dryer or Dryer and Dryer w/Dryer Starter Starter

AS-105-1XX

42

1

⁄2 40 43

19

⁄32 42 21

1

⁄4 17

3

⁄4 21

13

⁄16 18

3

⁄4 35

1

⁄2 18 15

3

⁄4 12

1

⁄4 209 200

AS-005-1XX

AS-107-1XX

42

1

⁄2 40 43

19

⁄32 42 21

1

⁄4 17

3

⁄4 21

13

⁄16 18

3

⁄4 36 18 15

3

⁄4 12

1

⁄4 209 200

AS-007-1XX

AS-107-2XX

50

3

⁄4 50

3

⁄4 51

27

⁄32 52

3

⁄4 22

1

⁄4 20 22

5

⁄16 21 40 29 18 14 339 330

AS-007-2XX

AS-110-1XX

42

1

⁄2 40 43

19

⁄32 42 21

1

⁄4 17

3

⁄4 21

13

⁄16 18

3

⁄4 36 18 15

3

⁄4 12

1

⁄4 219 210

AS-010-1XX

AS-110-2XX

50

3

⁄4 50

3

⁄4 51

27

⁄32 52

3

⁄4 22

1

⁄4 20 22

5

⁄16 21 40 29 18 14 349 340

AS-010-2XX

AS-015-1XX 42

1

⁄2 40 43

1

⁄32 42 21

1

⁄4 17

3

⁄4 21

13

⁄16 18

3

⁄4 36 18 15

3

⁄4 12

1

⁄4 219 210

AS-015-2XX 50

3

⁄4 50

3

⁄4 51

27

⁄32 52

3

⁄4 22

1

⁄4 20 22

5

⁄16 21 40 29 18 14 349 340

AS-020-2XX 51

1

⁄2 50

3

⁄4 52

19

⁄32 52

3

⁄4 23

1

⁄4 20 23

5

⁄16 21 42 29 18 14 349 340

AS-020-3XX 65 64 66

23

⁄32 66 23

1

⁄4 20 23

5

⁄16 21 41 40 18

1

⁄2 13 384 375

AS-030-3XX 65

1

⁄2 64 66

23

⁄32 66 23

1

⁄4 20 23

5

⁄16 21 41 40 18

1

⁄2 13 509 500

AS-050-3XX 64 64 — — 23

1

⁄4 20 — — 46 43

3

⁄4 18

1

⁄2 13 609 600

AS-050-4XX 70

3

⁄4 70

3

⁄4 — — 26

1

⁄4 24 — — 49

1

⁄4 42 22 15

3

⁄4 714 705

AS-075-3XX 64 64 — — 23

1

⁄4 20 — — 46 43

3

⁄4 18

1

⁄2 13 621 610

AS-075-4XX 70

3

⁄4 70

3

⁄4 — — 26

1

⁄4 24 — — 49

1

⁄4 42 22 15

3

⁄4 725 714

AS-075-5XX 81

3

⁄4 81

1

⁄2 — — 30 30 — — 55

1

⁄2 42 22 18

3

⁄4 951 940

AS-100-4XX 79 76

1

⁄2 — — 27

1

⁄4 24 — — 51 42 22 15

3

⁄4 915 904

AS-100-5XX 81

3

⁄4 79

1

⁄4 — — 30 30 — — 58 42 22 18

3

⁄4 1141 1130

E

F

Climate Control Simplex

6

D

B

C

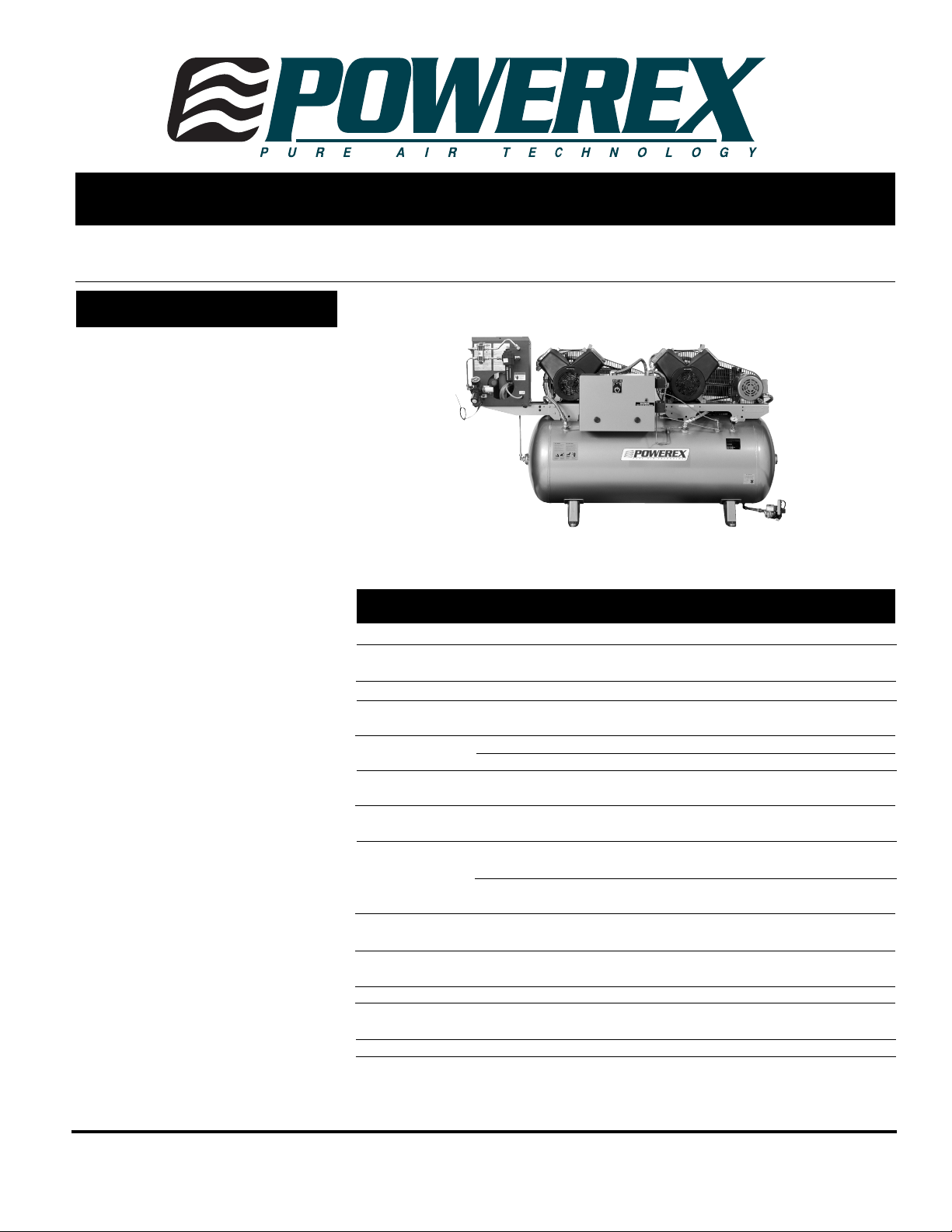

A PUMP AND FLYWHEEL:

Motor Hp 1/2, 3/4 1 19.5 A-005-6001

1, 11⁄2 1 35 A-010-6001NP

2 1 59 A-020-6001NP

3 1 66 A-030-6001NP

5 1 115 A-050-6001NP

71⁄2 1 121 A-075-6001NP

10 1 180 A-100-6001NP

B VALVE KIT: Includes valve plate, spacer and head gasket

Motor Hp 1/2 1 0.4 A-005-6002

3/4 1 0.4 A-005-6002

1, 11⁄2 1 0.5 A-010-6002NP

2 2 0.5 A-010-6002NP

3 2 0.7 A-030-6002NP

5 2 1.2 A-050-6002NP

71⁄2 2 1.2 A-075-6002NP

10 3 1.2 A-075-6002NP

C RING/CYLINDER KIT: Includes all compression rings, oil control rings, cylinder, gasket and sealant

Motor Hp 1/2 1 3.6 A-005-6004

3/4 1 3.6 A-005-6004

1, 11⁄2 1 4.8 A-010-6004NP

2 2 4.8 A-010-6004NP

3 2 5.5 A-030-6004NP

5 2 10 A-050-6004NP

71⁄2 2 10 A-075-6004NP

10 3 10 A-075-6004NP

D INTAKE FILTER ELEMENT:

Motor Hp 1/2 1 0.1 A-005-6023

3/4 1 0.1 A-005-6023

1, 11⁄2 1 0.2 A-010-6023NP

2 1 0.2 A-030-6023NP

3 1 0.2 A-030-6023NP

5 2 0.2 A-030-6023NP

71⁄2 2 0.2 A-030-6023NP

10 3 0.2 A-030-6023NP

E BELT: Motor Hp Size

1/2 AX-42 1 0.3 A-005-6006

3/4 AX-42 1 0.3 A-005-6006

1 A-43 1 0.3 A-010-6006

11⁄2 A-46 1 0.3 A-015-6006NP

2 A-65 1 0.4 A-020-6006NP

3 A-62 1 0.4 A-030-6006NP

5 A-65 2 1.6 A-050-6006NP

71⁄2 (120 gal tank) A-67 2 2.0 A-075-6046NP

71⁄2 (200 gal tank) A-75 2 2.0 A-075-6056NP

10 A-84 2 2.4 A-100-6006NP

REPLACEMENT PARTS LIST

E

(Inside Belt Guard)

F

(Inside Belt Guard)

A

G

H

J

M

Shipping

Quantity Weight Code

Item Description Required (lbs.) Number

L

N

K

7

Climate Control Simplex

REPLACEMENT PARTS LIST (Continued)

F MOTOR PULLEY:

Motor Hp Type

1/2 1A-4.4” P.D., 5/8” Bore 1 3.8 A-005-6007

3/4 1A-5.8” P.D., 5/8” Bore 1 3.9 A-007-6037

1 (1 Ø) 1A-4.0” P.D., 5/8” Bore 1 3.2 A-110-6007

1 (3 Ø) 1A-4.0” P.D., 7/8” Bore 1 3.2 A-010-6007

11⁄2 1A-6.0” P.D., 7/8” Bore 1 5.6 A-020-6007

2 1A-6.0” P.D., 7/8” Bore 1 5.2 A-020-6007

3 1A-6.0” P.D., 11⁄8” Bore 1 6.3 A-030-6007NP

5 2A-5.6” P.D., 11⁄8” Bore 1 7.6 A-050-6007NP

71⁄2 2A-7.6” P.D., 13⁄8” Bore 1 12.5 A-075-6007NP

10 2A-7.6” P.D., 15⁄8” Bore 1 13.5 A-100-6007NP

G IN-TANK CHECK VALVE:

Motor Hp Size

1/2 Through 3 1/2” MPT x 1/2” FPT 1 0.3 A-010-6008

5 Through 10 3/4” MPT x 3/4” FPT 1 0.4 A-075-6008

H SAFETY RELIEF VALVE: Set at approximately 115 psig (805 kPa)

1/2 Through 5 Hp Models 1 0.1 A-050-6009

71⁄2 Through 10 Hp Models 1 0.2 A-200-6009

J PRESSURE ELECTRIC SWITCHES: (For all models)

Lead Switch: Set at approximately

70 psig (490 kPa) cut-in and

90 psig (630 kPa) cut-out 1 0.9 A-100-6010

Lag Switch: Set at approximately

60 psig (420 kPa) cut-in and

80 psig (560kPa) cut-out 1 0.9 A-100-6011

K TANK:

Motor Hp Tank Size

1/2 Through 11⁄2 30 gallon 1 134.0 A-010-6030NP**

1/2 Through 11⁄2 60 gallon 1 175.0 A-010-6060NP

2 & 3 60 gallon 1 184.0 A-020-6060NP

1/2 Through 11⁄2 80 gallon 1 235.0 A-010-6080NP**

2 & 3 80 gallon 1 243.0 A-020-6080NP**

2 & 3 120 gallon 1 398.0 A-020-6120NP**

5 & 71⁄2 120 gallon 1 415.0 A-050-6120NP**

5 Through 10 200 gallon 1 677.0 A-100-6200NP**

L COOLING SHROUD:

Motor Hp

1/2 1 1.0 A-005-6013

3/4 1 1.0 A-005-6013

2 1 1.7 A-020-6013NP

3 1 1.7 A-030-6013NP

5 1 1.9 A-050-6013NP

71⁄2 1 1.9 A-075-6013NP

10 1 4.5 A-100-6013NP

M BELT GUARD:

Motor Hp

1/2 Through 11⁄2 1 2.4 A-010-6012

2 & 3 1 12.5 A-020-6012

5 & 71⁄2 1 12.5 A-050-6012

10 1 18.5 A-100-6012

N LIQUID GASKET:

Motor Hp

1/2 Through 10 1 0.1 A-999-6000

**This replacement tank is also the replacement tank used on duplex air compressors and will include mounting hardware for a second pump.

Shipping

Quantity Weight Code

Item Description Required (lbs.) Number

8

Climate Control Simplex

Powerex Limited Warranty

Powerex 3 Year / 10,000 Hour Extended Parts Limited Warranty - Powerex warrants each Compressor Pump or Scroll Air-End

against defects in material or workmanship from the date of purchase for a period of Three years or 10,000 hours, whichever may

occur first. This warranty applies to the exchange of part(s) of the compressor pump or air-end found to be defective by an Authorized

Powerex Service Center.

Powerex 1 Year / 5,000 Hour Inlet to Outlet Limited Warranty - Powerex warrants each Compressor Unit, System, Pump, or AirEnd against defects in material or workmanship from the date of purchase for a period of One Year or 5,000 Hours, whichever may

occur first. This warranty applies to the exchange of defective component part(s) and labor performed by an Authorized Powerex

Service Center.

The above mentioned warranty applies to POWEREX manufactured units or systems only.

Items listed in the operator’s manual under routine maintenance are not covered by

this or any other warranty.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE: AND TO THE EXTENT PERMITTED BY LAW, ANY AND

ALL IMPLIED WARRANTIES ARE EXCLUDED. THIS IS THE EXCLUSIVE REMEDY AND LIABILITY FOR CONSEQUENTIAL DAMAGES UNDER

ANY AND ALL WARRANTIES IS EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW.

All claims pertaining to the merchandise in this schedule, with the exception of warranty claims, must be filed with POWEREX within 6

months of the invoice date, or they will not be honored. Prices, discounts and terms are subject to change without notice or as stipulated in specific product quotations. All agreements are contingent upon strikes, accidents, or other causes beyond our control. All shipments are carefully inspected and counted before leaving the factory. Please inspect carefully any receipt of merchandise noting any

discrepancy or damage on the carrier’s freight bill at the time of delivery. Discrepancies or damage which obviously occurred in transit

are the carrier’s responsibility and related claims should be made promptly directly to the carrier. Returned merchandise will not be

accepted without prior written authorization by POWEREX and deductions from invoices for shortage or damage claims will not be

allowed. UNLESS OTHERWISE AGREED TO IN WRITING, THESE TERMS AND CONDITIONS WILL CONTROL IN ANY TRANSACTION

WITH POWEREX any different or conflicting terms as may appear on any order form now or later submitted by the buyer. All orders

are subject to acceptance by POWEREX.

Maintenance Schedule

Operating Hours

Item Action needed 500 2500 5000 10,000 15,000 20,000 Remarks

Tank Drain moisture Daily 2500

Inlet air filter Replace (Every 2,500 hrs or less)

Blower fan Clean

Fan duct Clean

Compressor fins Clean (Every 2,500 hrs or less)

Oil change Replace (Every 1,500 hrs)

Compression rings Replace

Check oil Inspect Daily

Piston set Replace

V-belt Inspect, replace *Note 3

Pressure switch Confirm operation

Magnetic starter Inspect Replace if contact

points deteriorated

Safety valve Confirm operation (Every 2,500 hrs or less)

Pressure gauge Inspect (Every 2,500 hrs or less)

() Inspect

() Replace

NOTES:

1. Inspect and perform maintenance periodically according to maintenance schedule.

2. The maintenance schedule relates to the normal operating conditions. If the circumstances and load condition are adverse, shorten the

cycle time and do maintenance accordingly.

3. * The tension of the V-belt should be adjusted during initial start up and inspected every 1,500 hours afterwards. Proper belt tension for

1/2 to 3 HP units is 2-3 lbs./.5” deflection; for 5 to 10 Hp units, 4-6 lbs./.5” deflection.

150 Production Drive

Harrison, OH 45030

Phone: 1-888-769-7979

Fax: 513-367-3125

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

• Guaranteed low oil carryover rate of

less than 2 PPM

• Three year warranty on compressor

pump

• High efficiency motors

• UL listed controls

• R134A Air Dryer (Optional)

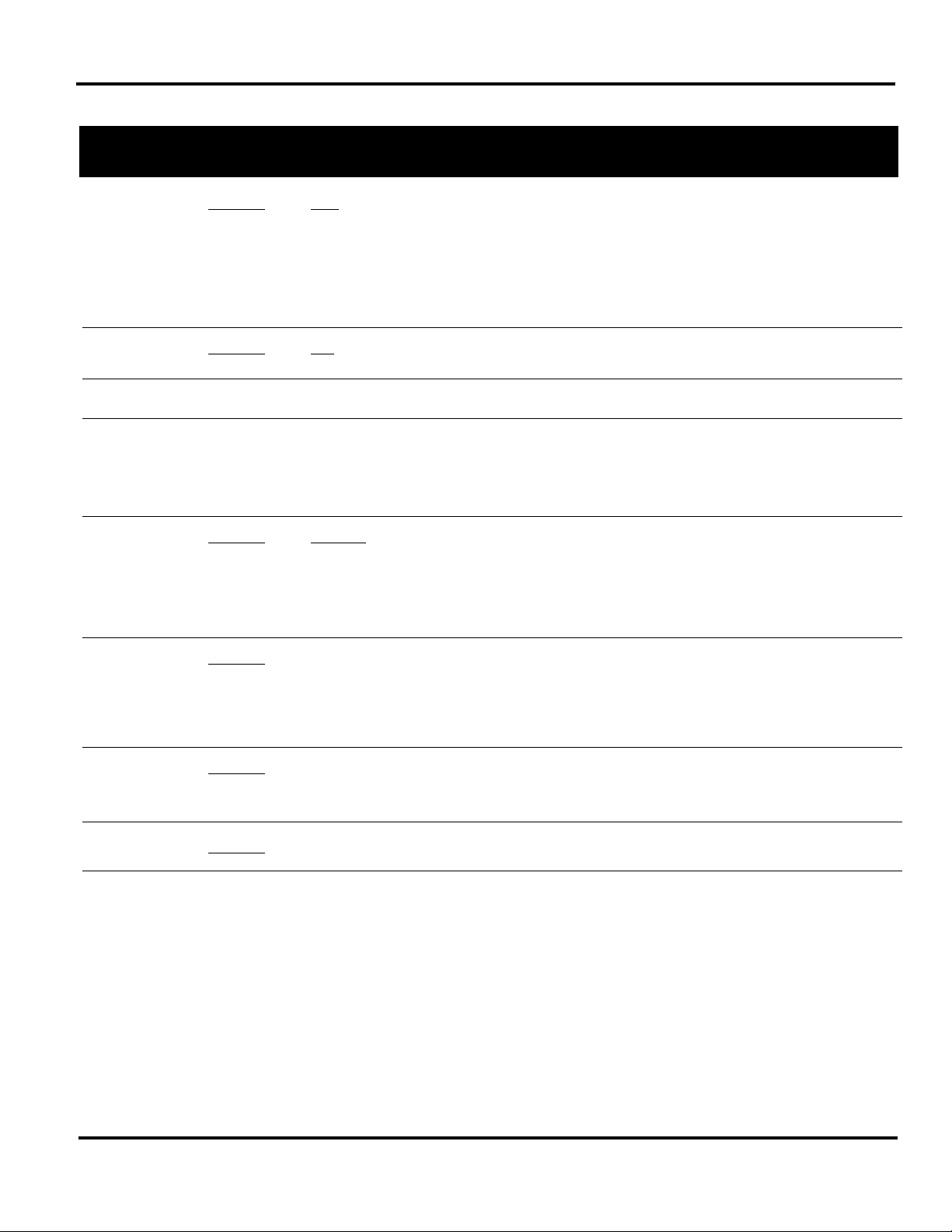

The AD-XXX Series Powerex Duplex Air

Compressors have been designed,

broken-in and tested to meet the most

demanding specifications for low oil

carryover and long life in the

pneumatic climate control industry.

The units consist of two equally rated

motor-compressor assemblies mounted

on a single ASME tank. The compressor

motors are NEMA Class B design. The

AD-XXX Series Compressors are ideal for

instrumentation systems requiring an

alternate compressor for standby or

overload capacity. See Table 1 for motor

sizes and air delivery capacities available.

Compressor assemblies are available with

or without a factory mounted basic or

deluxe alternator/motor starter package.

An unloading feature is included on all

compressors to provide loadless starting.

Models with an alternator are prewired

and ready for operation. Internal wiring

allows for shutdown of either

compressor for repair while the other

compressor is running.

An alternating type operation is

desirable for many reasons. When a

duplex air compressor is alternated, the

temperature of both units is kept

above the ambient dew point to

minimize moisture deterioration and

corrosion. Also, the reduction in ontime provides a lower average head

temperature with reduced oil

entrainment potential and improves

the motor life by holding down the

average heat rise.

Climate Control Duplex

IN259702AV 3/05

Specifications

Product

Performance

Specifications

Models & Options

Lubrication

Operating

Voltages

Compression

Cycle

Motor Overload

Protection

Pressure Switch

Settings

Overpressure

Protection

Outlet Air

Connections

Tank Sizes

California

Ordinance 462 (L)(2)

Isolation Mounts

1/2 Through

10 Hp Models

1Ø

3Ø

1/2 Through

10 Hp Models

1Ø and 3Ø

Lead

Lag

AD-XXX Series Powerex Duplex Air Compressors

See Table 1

See Table 2

Splash Lubrication System

115/230 Volts, 60 Hz

208-230/460 Volts, 60 Hz

Single-Stage

Overloads (Supplied with all Factory Mounted

Alternators; Otherwise Field Supplied)

Cut-In: Factory Set at Approximately 70 psig (490kPa)

Cut-Out: Factory Set at Approximately 90 psig (630 kPa)

Cut-In: Factory Set at Approximately 60 psig (420kPa)

Cut-Out: Factory Set at Approximately 80 psig (560 kPa)

ASME Safety Valve Factory Set and Sealed at

Approximately 115 psig (805 kPa)

1/2" NPT on 30 and 80 Gallon Tanks;

1" NPT on 120, and 200 Gallon Tanks

See Table 2

Meets requirements of this Ordinance

Vibration pads are included with each unit

Figure 1 - AD-XXX Series 2 Hp Duplex Air Compressor

with Optional Deluxe Alternator Package

Features

Base Actual Hp Motor Rating Compressor Compressor Capacity SCFM

Model 1Ø 3Ø Hp RPM RPM 100% Runtime 50% Runtime 33% Runtime

TABLE 1: AD-XXX SERIES POWEREX DUPLEX AIR COMPRESSORS

PERFORMANCE SPECIFICATIONS

1725

1720

1725

1725

1750

1750

1745

1745

1745

1750

—

.54

—

.73

—

1.07

1.54

2.0

3.1

5.6

8.2

10.3

.54

—

.73

—

1.07

—

—

—

—

—

—

—

AD-105

AD-005

AD-107

AD-007

AD-110

AD-010

AD-015

AD-020

AD-030

AD-050

AD-075

AD-100

—

.50

—

.75

—

1.0

1.5

2.0

3.0

5.0

7.5

10.0

800

1040

625

955

800

775

690

795

685

1.8

2.5

3.8

6.4

8.6

12.0

22.0

28.5

43.0

0.9

1.25

1.9

3.2

4.3

6.0

11.0

14.3

21.5

0.6

0.83

1.25

2.11

2.84

4.0

7.33

9.44

14.2

2

Climate Control Duplex

All units are run through a factory

break-in and are tested for air delivery,

leakage and power consumption. Units

are shipped with a proper fill of

compressor oil in the crankcase and are

furnished with an intake filter/silencer

with a replaceable cartridge. This

filter/silencer combination is designed to

remove contaminates in the inlet air, as

well as provide quieter operation.

All models have conveniently located

oil drain and filler ports to facilitate

routine maintenance. Tanks have a

condensate drain valve with an

extension for easy access. Mounting

bases are slotted to allow tension

adjustments to aid in maintaining

proper compressor and motor

alignment while adjusting tension.

DELUXE ALTERNATOR PACKAGE

All Powerex Duplex air compressors may

be ordered with an optional deluxe

alternator package consisting of two

magnetic motor starts with thermal

overloads, an alternating coil, a 120

VAC control transformer and a threeposition selector switch. The threeposition switch allows for automatic

alternation or only running one unit at

a time. This will allow for service on one

unit while other unit is running. Refer

to Table 2 for ordering details and

figure 4 for wiring diagram.

BASIC ALTERNATOR PACKAGE

All Powerex duplex air compressors may

be ordered with a simplified line voltage

basic alternator package. The basic

alternator package consists of an

alternating coil and two magnetic motor

starters. Motor starters are selected and

wired for intended input voltage and are

furnished with properly sized overload

heaters. Refer to Table 2 for ordering

details and figure 5 for wiring diagram.

REFRIGERATED AIR DRYER

A factory mounted, Hankinson HPR 5-10

series refrigerated air dryer with

automatic condensate drain trap

assembly, bypass valve is on all 1/2

through 3 Hp Powerex duplex air

compressors. Piping for air dryer is done

at the factory. Wiring to power source

must be done in the field using integral

cord and plug which fits into a standard

120 volt receptacle. Refer to Table 2 for

ordering details.

AUTOMATIC TANK DRAIN

Powerex air compressors may be ordered

with a manual or electric type automatic

tank drain. A manual drain attachment

is furnished with each unit. Refer to

Table 2 for ordering details. (Order

electric drains separately.)

VIBRATION DAMPENING PADS

Waffle type design vibration pads are

provided as standard equipment.

Refer to Installation Data AS/AD-XXX

for detailed installation instructions.

Factory calibrated DPST pressure switches

provide lead and lag settings. When

using an alternator-starter package, the

lead switch energizes the alternator and

the alternator activates the compressor

that was on standby during the previous

cycle. If the demand exceeds the

capacity of one compressor, the lag

switch will cause both compressors to run

simultaneously. Upon failure of either

compressor, the lag switch will continue

to activate the workable compressor.

Single-phase motors have built-in

overload protection with automatic

reset. Three-phase motors require a

manual or magnetic starter and three

overload heaters. Heaters are included

with three-phase compressors that have

a factory mounted alternator.

LUBRICATION

Check lubricating oil level at gauge.

Refill if necessary.

Change oil according to maintenance

schedule. Before draining oil, remove

oil supply cap and loosen oil drain cap

to release trapped air. Use Mobil Rarus

427

®

or Mobil DTE heavy.

Dispose of oil in

accordance with

state or local codes.

Operation

Mounted and

Connected Options

!

WARNING

3

Climate Control Duplex

Example 1: To order a Duplex air compressor with a

3/4 Hp single-phase motor, 80 gallon tank, deluxe

230 volt alternator package, automatic tank drain

and an air dryer, use product code AD-107-3G4.

Example 2:

To order a Duplex air compressor with a

10 Hp three-phase motor, 200 gallon tank and an

auto drain, use product code AD-100-502.

}

Horsepower &

Voltage Phase

TABLE 2: MODEL NUMBER

Tank Size

Alternator

Tank

Drain/Dryer

AD

Tank Size

(Gallons) Available on:

Tank Drain/Dryer Options

Starter Options

Motor Horsepower, Voltage Phase

1Ø Horsepower 3Ø

105 = 1/2 = 005

107 = 3/4 = 007

110 =1 = 010

NA = 1

1

⁄2 = 015

NA = 2 = 020

NA = 3 = 030

NA = 5 = 050

NA = 7

1

⁄2 = 075

NA = 10 = 100

30 = 1 1/2 Through 1-1/2 Hp

80 = 3 1/2 Through 3 Hp

120 = 4 3 Through 7-1/2 Hp

200 = 5 5 Through 10 Hp

Basic Deluxe

0= None = 0

2= 3Ø, 208V = A

3= 3Ø, 230V = B

4= 3Ø, 460V = C

5= 1Ø, 115V = E

6= 1 Ø, 208V = N/A

7= 1 Ø, 230V = G

1Ø vs 3 Ø selection must agree with

base model selection

}

Manual Drain,

No Dryer = 1

E-Drain,

No Dryer = 2

Manual Drain,

with Dryer = 3

E-Drain,

with Dryer = 4

Available on

1/2 through 3 Hp

models only.

}

OR

1. Plug E-drain into 115V power outlet

supply.

2. Adjust timer accordingly.

LUBRICATION (Continued)

AUTO E-DRAIN ASSEMBLY (See

Figure 3)

NOTE: The automatic E-drain is

assembled to tank.

Remove cap and

add oil

Oil

gauge

Oil drain cap

Full

Low

Round (red)

Oil Gauge

Figure 2

Figure 3 - E-Drain

Manifold

Assembly

TEST

ON

OFF

6

4

20

30

2

10

8

40

5

0.5

10

0.5

45

min.

sec.

Loading...

Loading...