Power Electronics SD750006 5B06DEF, SD750024 5B06DEF, SD750015 5B06DEF, SD750008 5B06DEF, SD750030 5B06DEF Hardware And Installation Manual

...

LOW VOLTAGE VARIABLE SPEED DRIVE

HARDWARE AND INSTALLATION MANUAL

www.power-electronics.com

Variable Speed Drive

Hardware and Installation Manual

Edition: April 2018

SD75MTHW01DI Rev. D

SD750

POWER ELECTRONICS

2

POWER ELECTRONICS

SD750

ABOUT

3

EN

ABOUT THIS MANUAL

PURPOSE

This manual contains important instructions for the installation and maintenance of Power Electronics

SD750 variable speed drives.

TARGET AUDIENCE

This manual is intended for qualified customers who will install, operate and maintain Power Electronics

SD750 variable speed drives.

Only trained electricians may install and commission the drives.

REFERENCE MANUALS

The following reference documents are available for SD750 variable speed drives:

• SD750 Hardware and Installation Manual.

• SD750 Programming and Software Manual.

• Pumps Application Manual.

POWER ELECTRONICS CONTACT INFORMATION

Power Electronics España, S.L.

C/ Leonardo da Vinci, 24 – 26

Parque Tecnológico

46980 Paterna (Valencia)

SPAIN

Fax: (+34) 96 131 82 01

Website: www.power-electronics.com

SD750

POWER ELECTRONICS

4

REVISIONS

REVISIONS CONTROL

DATE

REVISION

DESCRIPTION

24 / 10 / 2017

A

First Edition.

18 / 01 / 2018

B

Introduction, Configuration table and stantard ratings, Technical

Characteristics, Dimensions, Power connection, Control connection

Maintenance.

28 / 03 / 2018

C

Standard ratings, Accessories.

11 / 04 / 2018

D

Safety instructions. Misprints update.

The equipment and technical documentation are periodically updated. Power Electronics reserves the right to modify all or part of the

contents of this manual without previous notice. To consult the most updated information of this product, you may access our website

www.power-electronics.com, where the latest version of this manual can be downloaded. The reproduction or distribution of the present

manual is strictly forbidden, unless express authorization from Power Electronics.

POWER ELECTRONICS

SD750

TABLE OF CONTENTS

5

EN

TABLE OF CONTENTS

SAFETY SYMBOLS ................................ ................................ ................................................................ ..... 7

SAFETY INSTRUCTIONS ............................................................................................................................ 8

INTRODUCTION ................................................................................................................................... 13

CONFIGURATION TABLE & STANDARD RATINGS ......................................................................... 14

Configuration table ............................................................................................................................. 14

Standard ratings ................................................................................................................................. 14

400Vac ............................................................................................................................................ 15

440Vac ............................................................................................................................................ 16

480Vac ............................................................................................................................................ 17

TECHNICAL CHARACTERISTICS ...................................................................................................... 18

DIMENSIONS........................................................................................................................................ 21

Dimensions of Frames 1 and 2 ........................................................................................................... 21

Dimensions of Frames 3, 4 and 5 ....................................................................................................... 22

Dimensions of Frames 6 and 7 ........................................................................................................... 23

Dimensions of Frames 8 and 9 ........................................................................................................... 24

Dimensions of Frames 10 and 11 ....................................................................................................... 25

RECEPTION, HANDLING AND TRANSPORTATION ......................................................................... 26

Reception and Storage ....................................................................................................................... 26

Handling and Transportation .............................................................................................................. 26

MECHANICAL INSTALLATION ........................................................................................................... 29

Environmental ratings ......................................................................................................................... 29

Drive mounting ................................................................................................................................... 30

Wall mounting drives ....................................................................................................................... 30

Stand alone drives ........................................................................................................................... 31

Clearances ......................................................................................................................................... 32

Cooling ............................................................................................................................................... 33

POWER CONNECTION ........................................................................................................................ 35

General recommendations for connections ........................................................................................ 35

Basic configuration ............................................................................................................................. 36

Topology ............................................................................................................................................. 37

Power Connection and Wiring ............................................................................................................ 39

Recommended Cable Section for 400VAC ...................................................................................... 43

Ground Connection ............................................................................................................................ 44

EMC Installation Requirements .......................................................................................................... 45

Introduction ...................................................................................................................................... 45

SD750 compliance........................................................................................................................... 46

Connection ...................................................................................................................................... 46

Protections ......................................................................................................................................... 47

Short circuit ...................................................................................................................................... 47

Ground fault protection .................................................................................................................... 49

Motor thermal protection .................................................................................................................. 49

Other Protections ............................................................................................................................. 49

Safety Stop Function – STO (Safe Torque Off) ............................................................................... 49

IT Grids – Floating Earth drives .......................................................................................................... 49

Dynamic Braking Resistors for Equipment of Frames 1 and 2 ........................................................... 50

Resistor Values for Dynamic Brake (Optional) ................................................................................ 50

Terminals of the Resistor for Dynamic Brake .................................................................................. 51

Connection Drawing ........................................................................................................................ 51

SD750

POWER ELECTRONICS

6

TABLE OF CONTENTS

Power Terminals................................................................................................................................. 52

Connections for Frame 1 ................................................................................................................. 52

Connections for Frame 2 ................................................................................................................. 53

Connections for Frame 3 ................................................................................................................. 54

Connections for Frame 4 ................................................................................................................. 55

Connections for Frame 6 ................................................................................................................. 57

Connections for Frame 7 ................................................................................................................. 58

Connections for Frame 8 ................................................................................................................. 59

Connections for Frame 9 ................................................................................................................. 60

Connections for Frame 10 ............................................................................................................... 61

Connections for Frame 11 ............................................................................................................... 62

CONTROL CONNECTION ................................................................................................................... 63

Wiring Recommendations .................................................................................................................. 63

Control board terminals description .................................................................................................... 64

STO - Safe Torque Off ....................................................................................................................... 69

Safety Integrity Level SIL3- PLe ...................................................................................................... 70

Connection with ATEX motors ............................................................................................................ 72

MODBUS COMMUNICATION .............................................................................................................. 74

Introduction ......................................................................................................................................... 74

Hardware technical specifications ...................................................................................................... 75

Ethernet Connection ........................................................................................................................... 76

RS485 Connection ............................................................................................................................. 76

COMMISSIONING ................................................................................................................................ 77

USE OF THE DISPLAY ........................................................................................................................ 79

Graphic Display .................................................................................................................................. 79

MAINTENANCE .................................................................................................................................... 80

Warnings ............................................................................................................................................ 80

Routine Inspection .............................................................................................................................. 80

OPTIONAL EQUIPMENT ..................................................................................................................... 83

Accessories ........................................................................................................................................ 83

Extension Box .................................................................................................................................. 83

Plinths 84

Dynamic Braking Unit B150 ............................................................................................................. 85

Communication boards ....................................................................................................................... 85

CE MARKING ....................................................................................................................................... 86

EMC Directive..................................................................................................................................... 86

Low Voltage Directive ......................................................................................................................... 86

POWER ELECTRONICS

SD750

SAFETY SYMBOLS

7

EN

SAFETY SYMBOLS

Always follow safety instructions to prevent accidents and potential hazards from occurring.

In this manual, safety messages are classified as follows:

Other symbols used in this manual for safety messages are the following:

WARNING

Identifies potentially hazardous situations where dangerous voltage may be

present, which if not avoided, could result in minor personal injury, serious

injury or death.

Be extremely careful and follow the instructions to avoid the risk of electrical

shocks.

CAUTION

Identifies potentially hazardous situations, which if not avoided, could result

in product damage, or minor or moderate personal injury.

Read the message and follow the instructions carefully.

NOTICE

Identifies important measures to take in order to prevent damage equipment

and warranty lost, as well as encouraging good use and environmental

practices.

Hot surface. Be careful and follow the instructions to avoid burns and personal injuries.

Risk of fire. Be careful and follow the instructions to prevent causing an unintentional fire.

Caution, risk of electric shock. Energy storage timed discharge. Wait for the indicated

time to avoid electrical hazards.

Caution, risk of hearing damage. Wear hearing protection.

SD750

POWER ELECTRONICS

8

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

IMPORTANT!

Read carefully this manual to maximize the performance of the product and to ensure its safe use.

In order to appropriately use the drive, please, follow all instructions described in the installation manual

which refer to transportation, installation, electrical connection and commissioning of the equipment.

Power Electronics accepts no responsibility or liability for partial or total damages resulting from incorrect

use of equipment.

Please, pay careful attention to the following recommendations:

WARNING

Do not remove the cover while the drive is powered or running.

Otherwise, you may get an electric shock.

Do not run the drive with the front cover removed.

Otherwise, you may get an electric shock.

The drive does not remove the voltage from the input terminals of the drive. Before working on

the drive, isolate the whole drive from the supply.

If you do not remove the power supply, you may get an electric shock.

Do not remove the cover except for periodic inspections or wiring, even if the input power is not

applied.

Otherwise, you get an electric shock.

Operate the drive with dry hands.

Otherwise, you may get an electric shock.

Do not use cables with damaged insulation.

Otherwise, you may get an electric shock.

Do not subject the cables to abrasions, excessive stress, heavy loads or pinching.

Otherwise, you may get an electric shock.

Do not make any insulation or voltage withstand tests on the motor while the drive is connected.

POWER ELECTRONICS

SD750

SAFETY INSTRUCTIONS

9

EN

WARNING

10 min

Both wiring and periodic inspections must be carried out at least 10 minutes

after disconnecting the input power. To remove the front cover, make sure

that the red "DC Link" LED is off. Then remove the metal cover from the

terminals and check the following with a multimeter:

• Voltage between the output busbares U, V, W and the cabinet is

around 0V.

• Voltage between the terminals + HVDC, -HVDC and the cabinet is

below 30VDC.

If you omit this recommendation, you may get an electric shock.

Even though multimeters have their own revisions Schedule, it is convenient

to verify it works properly, specially to check voltage absence. It could be

damaged and show incorrect values. Use a 1.5V battery to verify proper

functioning.

CAUTION

Install the drive on a non-flammable surface. Do not place flammable material

nearby. Otherwise, a fire could occur.

Disconnect the input power if the drive is damaged.

Otherwise, it could result in a secondary accident or fire.

Do not allow lint, paper, wood chips, dust, metallic chips or other foreign matter

into the drive. Otherwise, a fire or accident could occur.

After stopping the drive, some of its parts will stay warm for a while. Wait for the

drive to cool down for handling.

Touching hot parts may result in skin burns.

Do not apply power to a damaged drive or to a drive with parts missing, even if

the installation is complete.

Otherwise, you may get an electric shock.

It is not allowed to weld the cabinet or structure, this could damage the sensitive

electronic components inside the cabinet or structure.

SD750

POWER ELECTRONICS

10

SAFETY INSTRUCTIONS

NOTICE

RECEPTION

The SD750 are carefully tested and perfectly packed before delivering.

In the event of transport damage, please ensure to notify the transport agency and POWER

ELECTRONICS: 902 40 20 70 (International +34 96 136 65 57) or your nearest agent, within 24h from

receiving the goods.

UNPACKING

Make sure model and serial number of the variable speed drive are the same on the box, delivery note

and unit.

Each variable speed drive is delivered with Hardware and Software technical manuals.

RECYCLING

Packaging equipment must be recycled. Separate all different materials (plastic, paper, cardboard,

wood…) and place them in the corresponding containers. Ensure waste collection is properly managed

with a Non-Hazardous Waste Agent.

To guarantee health and natural environmental sources protection, the European Union has

adopted the WEEE directive concerning discarded electric and electronic equipment

(SEEA).

Waste of electrical and electronic equipment (WEEE) must be collected selectively for

proper environmental management.

Our products contain electronic cards, capacitors and other electronic devices that should

be separated when they are no longer functional. These WEEEs should be managed

accordingly with a Hazardous Waste Agent.

Power Electronics promotes good environmental practices and recommends that all its

products sold outside of the European Union, once they reach the end of their life, are

separated and the WEEE managed according to the particular country applicable legislation

(especially: electronic cards, capacitors and other electronic devices).

If you have any questions about the electric and electronic equipment waste, please contact Power

Electronics.

ELECTROMAGNETIC COMPATIBILITY (EMC)

The drive is intended to be used in industrial environment (Second Environment). It achieves compliance

with category C3 defined in IEC/EN 61800-3 standard when the installation recommendations within this

manual are followed. The driver can optionally operate in domestic environments (First Environment),

complying with category C2 defined in IEC / EN 61800-3 standard. For category C1 consult Power

Electronics. Optional IT filter.

Select communication and control system according to the drive EMC environment. Otherwise, systems

could suffer from interferences due to a low EMS level.

CAPACITORS DEPLETION

If the drive has not been operated for a long time, capacitors lose their charging characteristics and are

depleted. To prevent depletion, once a year run the device under no-load conditions during 30-60 minutes.

POWER ELECTRONICS

SD750

SAFETY INSTRUCTIONS

11

EN

SAFETY

• Before operating the drive, read this manual thoroughly to gain an understanding of the unit. If

any doubt exists, please contact POWER ELECTRONICS, (902 40 20 70 / +34 96 136 65 57)

or your nearest agent.

▪ Wear safety glasses when operating the drive with power applied or for when the front cover is

removed.

▪ Handle and transport the drive following the recommendations within this manual.

▪ Install the drive according to the instructions within this manual and the local regulations.

▪ Do not place heavy objects on the drive.

▪ Ensure that the drive is mounted vertically and keeping the minimum clearance distances.

▪ Do not drop the drive or subject it to impact.

▪ The SD750 drives contain static sensitive printed circuits boards. Use anti-static safety procedures

when handling these boards.

▪ Avoid installing the drive in conditions that differ from those described in the Environmental Ratings

section.

CONNECTION PRECAUTIONS

▪ To ensure a correct operation of the drive, it is recommended to use a SCREENED CABLE for

the control wiring.

▪ The motor cable should comply with the requirements within this manual. Due to increased

leakage capacitance between conductors, the external ground fault protection threshold value

should be adjusted ad hoc.

▪ Do not disconnect motor cables if the input power supply remains connected.

▪ The internal circuits of the SD750 Series will be damaged if the incoming power is connected and

applied to output terminals (U, V, W).

▪ Do not use power factor correction capacitors banks, surge suppressors, or RFI filters on the

output side of the drive. Doing so may damage these components.

▪ Always check whether the DC Link red LED is OFF before wiring terminals. The capacitors may

hold high-voltage even after the input power is disconnected.

COMMISSIONING

▪ Verify all parameters before operating the drive. Alteration of parameters may be required

depending on application and load.

▪ Always apply voltage and current signals to each terminal that are within the levels indicated in

this manual. Otherwise, damage to the drive may occur.

▪ For correct starting, refer to the start-up section.

HANDLING PRECAUTIONS

▪ When the "Automatic Restart" function is selected, observe the appropriate safety measures to

avoid any damage in case of sudden restart of the motor after an emergency and subsequent

reset.

▪ The "STOP / RESET" key on the driver's own keypad will be operative as long as this option has

been selected. By pressing this button, the drive will not perform an emergency stop. The driver

has a STO function which, installed with an external EMERGENCY pushbutton, will disconnect

the motor power supply and prevent the ability to generate torque in the motor.

▪ If an alarm is reset without having lost the reference signal (setpoint), an automatic start may

occur. Check that the system has not been configured as such. Failure to do so could result in

personal injury.

▪ Do not modify anything inside the driver without the supervision of Power Electronics.

▪ Before starting the parameter setting, reset all parameters.

SD750

POWER ELECTRONICS

12

SAFETY INSTRUCTIONS

EARTH CONNECTION

▪ Ground the drive and adjoining cabinets to ensure a safe operation and to reduce electromagnetic

emission.

▪ Connect the input PE terminal only to the dedicated PE terminal of the drive. Do not use the case,

nor chassis screw for grounding.

▪ Ground the drive chassis through the labelled terminals. Use appropriate conductors to comply

with local regulations. The ground conductor should be connected first and removed last.

▪ Motor ground cable must be connected to the PE output terminal of the drive and not to the

installation’s ground. We recommend that the section of the ground conductor (PE) is equal or

greater than the active conductor (U, V, W).

▪ If the user decides to use screened motor cable, ensure a good 360° connection of the cable

screen in both the drive cabinet and the motor terminal box.

CYBER SECURITY DISCLAIMER

This product is designed to be connected to and to communicate information and data via a network

interface. The customer is the sole responsible for providing and continuously ensuring a secure connection

between the product and customer network or any other network (as the case may be). Customer shall

establish and maintain any appropriate measures (such as but not limited to the installation of firewalls,

application of authentication measures, encryption of data, installation of antivirus programs, etc) to protect

the product, the network, its system and the interface against any kind of security breaches, unauthorized

access, interference, intrusion, leakage and/or theft of data or information.

Power Electronics and its affiliates are not liable for damages and/or losses related to such security

breaches, any unauthorized access, interference, intrusion, leakage and/or theft of data or information.

POWER ELECTRONICS

SD750

INTRODUCTION

13

EN

INTRODUCTION

The SD750 low voltage drive designed by Power Electronics are an extended family of products with a

power range from 1.5kW to 1750kW. The drive has been designed to provide maximum care to the engine,

with durable components and easy maintenance.

The SD750 series is the family reference and the evolution of SD700. Available from 1.5kW to 1750kW,

with a voltage range from 380 VAC to 480 VAC. Its IP20 and IP54 mechanical designs cover all general

industry applications, making it the most flexible and extensive series.

The whole family integrates unique features such as low dV/dt, smart mechanical design and accurate

control. It is divided in 11 frames to cover the whole power range.

SD750 products provide high efficiency, maximum control, functional safety, durability, easy

commissioning and easy maintenance for the whole range. Power Electronics delivers flexible integrated

solutions, fully tested under the most demanding environmental and electrical conditions.

1

SD750

POWER ELECTRONICS

14

CONFIGURATION TABLE & STANDARD RATINGS

CONFIGURATION TABLE &

STANDARD RATINGS

Configuration table

To consult the configuration table of SD750 drives manufactured by Power Electronics, please refer to

the latest brochure (visit http://www.power-electronics.com).

Standard ratings

Voltages in the standard ratings shown in the following tables are the three-phase input voltages for the

drive.

The number of pulses depend on the number of transformer secondaries at drive input.

• 6 pulses: Transformer with a single secondary.

2

POWER ELECTRONICS

SD750

CONFIGURATION TABLE & STANDARD RATINGS

15

EN

400Vac

6 PULSES

FRAME

CODE

NORMAL DUTY (Operation

Temperature 40 ºC)

HEAVY DUTY

(Operation Temperature 50 ºC)

OVERLOAD

(A)

Motor

Power (kW)

Motor

Power (hp)

I(A)

Rated

Motor

Power (kW)

Motor

Power (hp)

I(A)

Rated

1

SD750006 5B06DEF

2.2 3 6

1.5 2 3

6

SD750008 5B06DEF

4 5 8

2.2 3 6

9

SD750011 5B06DEF

5.5

7,5

11 4 5 9 14

SD750015 5B06DEF

7.5

10

15

5.5

7,5

12

18

SD750024 5B06DEF

11

15

24

7.5

10

18

27

SD750030 5B06DEF

15

20

30

11

15

24

36

SD750040 5B06DEF

18.5

25

40

15

20

32

48

2

SD750048 5B06DEF

22

30

48

18.5

25

38

57

SD750060 5B06DEF

30

40

60

22

30

48

72

SD750075 5B06DEF

37

50

75

30

40

60

90

3

SD750095 5B06DEF

45

60

95

37

50

75

113

SD750110 5B06DEF

55

75

110

45

60

90

135

SD750145 5B06DEF

75

100

145

55

75

115

173

SD750180 5B06DEF

90

125

180

75

100

150

225

4

SD750200 5B06DEF

110

150

200

90

125

170

255

SD750260 5B06DEF

132

200

260

110

150

210

315

5

SD750320 5B06DEF

160

250

320

132

200

250

375

SD750400 5B06DEF

220

300

400

160

250

330

495

6

SD750450 5B06DEF

250

350

450

220

300

370

555

SD750570 5B06DEF

315

400

570

250

350

460

690

SD750700 5B06DEF

400

550

700

315

450

580

870

7

SD750800 5B06DEF

450

650

800

355

500

650

975

SD750900 5B06DEF

500

700

900

400

550

720

1080

SD751050 5B06DEF

560

800

1050

450

700

840

1260

8

SD751140 5B06DEF

630

900

1140

500

750

925

1388

SD751400 5B06DEF

800

1000

1400

630

900

1150

1725

9

SD751550 5B06DEF

900

1250

1550

710

1000

1260

1890

SD751800 5B06DEF

1000

1400

1800

800

1150

1440

2160

SD751950 5B06DEF

1100

1500

1950

900

1250

1580

2370

10

SD752250 5B06DEF

1200

1750

2250

1000

1450

1800

2700

SD752750 5B06DEF

1500

2200

2750

1200

1750

2200

3300

11

SD753100 5B06DEF

1750

2450

3100

1400

2000

2500

3750

SD750

POWER ELECTRONICS

16

CONFIGURATION TABLE & STANDARD RATINGS

440Vac

6 PULSES

FRAME

CODE

NORMAL DUTY (Operation

Temperature 40 ºC)

HEAVY DUTY

(Operation Temperature 50 ºC)

OVERLOAD

(A)

Motor

Power (kW)

Motor

Power (hp)

I(A)

Rated

Motor

Power (kW)

Motor

Power (hp)

I(A)

Rated

1

SD750006 5B06DEF

2.2 3 5

1.5 2 3

6

SD750008 5B06DEF

4 5 7

2.2 3 5

8

SD750011 5B06DEF

5.5

7,5

10 4 5 8 13

SD750015 5B06DEF

7.5

10

14

5.5

7,5

11

16

SD750024 5B06DEF

11

15

22

7.5

10

16

25

SD750030 5B06DEF

15

20

27

11

15

22

33

SD750040 5B06DEF

18.5

25

36

15

20

29

44

2

SD750048 5B06DEF

22

30

44

18.5

25

35

52

SD750060 5B06DEF

30

40

55

22

30

44

65

SD750075 5B06DEF

37

50

68

30

40

55

82

3

SD750095 5B06DEF

45

60

86

37

50

68

103

SD750110 5B06DEF

55

75

100

45

60

82

123

SD750145 5B06DEF

75

100

132

55

75

105

157

SD750180 5B06DEF

90

125

164

75

100

136

205

4

SD750200 5B06DEF

110

150

182

90

125

155

232

SD750260 5B06DEF

132

200

236

110

150

191

286

5

SD750320 5B06DEF

160

250

291

132

200

227

341

SD750400 5B06DEF

220

300

364

160

250

300

450

6

SD750450 5B06DEF

250

350

409

220

300

336

505

SD750570 5B06DEF

315

400

518

250

350

418

627

SD750700 5B06DEF

400

550

636

315

450

527

791

7

SD750800 5B06DEF

450

650

727

355

500

591

886

SD750900 5B06DEF

500

700

818

400

550

655

982

SD751050 5B06DEF

560

800

955

450

700

764

1145

8

SD751140 5B06DEF

630

900

1036

500

750

841

1262

SD751400 5B06DEF

800

1000

1273

630

900

1045

1568

9

SD751550 5B06DEF

900

1250

1409

710

1000

1145

1718

SD751800 5B06DEF

1000

1400

1636

800

1150

1309

1964

SD751950 5B06DEF

1100

1500

1773

900

1250

1436

2155

10

SD752250 5B06DEF

1200

1750

2045

1000

1450

1636

2455

SD752750 5B06DEF

1500

2200

2500

1200

1750

2000

3000

11

SD753100 5B06DEF

1750

2450

2818

1400

2000

2273

3409

POWER ELECTRONICS

SD750

CONFIGURATION TABLE & STANDARD RATINGS

17

EN

480Vac

6 PULSES

FRAME

CODE

NORMAL DUTY (Operation

Temperature 40 ºC)

HEAVY DUTY

(Operation Temperature 50 ºC)

OVERLOAD

(A)

Motor

Power (kW)

Motor

Power (hp)

I(A)

Rated

Motor

Power (kW)

Motor

Power (hp)

I(A)

Rated

1

SD750006 5B06DEF

2.2 3 5

1.5 2 3

6

SD750008 5B06DEF

4 5 7

2.2 3 5

8

SD750011 5B06DEF

5.5

7,5 9 4 5 8

12

SD750015 5B06DEF

7.5

10

13

5.5

7,5

10

15

SD750024 5B06DEF

11

15

20

7.5

10

15

23

SD750030 5B06DEF

15

20

25

11

15

20

30

SD750040 5B06DEF

18.5

25

33

15

20

27

40

2

SD750048 5B06DEF

22

30

40

18.5

25

32

48

SD750060 5B06DEF

30

40

50

22

30

40

60

SD750075 5B06DEF

37

50

63

30

40

50

75

3

SD750095 5B06DEF

45

60

79

37

50

63

94

SD750110 5B06DEF

55

75

92

45

60

75

113

SD750145 5B06DEF

75

100

121

55

75

96

144

SD750180 5B06DEF

90

125

150

75

100

125

188

4

SD750200 5B06DEF

110

150

167

90

125

142

213

SD750260 5B06DEF

132

200

217

110

150

175

263

5

SD750320 5B06DEF

160

250

267

132

200

208

313

SD750400 5B06DEF

220

300

333

160

250

275

413

6

SD750450 5B06DEF

250

350

375

220

300

308

463

SD750570 5B06DEF

315

400

475

250

350

383

575

SD750700 5B06DEF

400

550

583

315

450

483

725

7

SD750800 5B06DEF

450

650

667

355

500

542

813

SD750900 5B06DEF

500

700

750

400

550

600

900

SD751050 5B06DEF

560

800

875

450

700

700

1050

8

SD751140 5B06DEF

630

900

950

500

750

771

1157

SD751400 5B06DEF

800

1000

1167

630

900

958

1438

9

SD751550 5B06DEF

900

1250

1292

710

1000

1050

1575

SD751800 5B06DEF

1000

1400

1500

800

1150

1200

1800

SD751950 5B06DEF

1100

1500

1625

900

1250

1317

1975

10

SD752250 5B06DEF

1200

1750

1875

1000

1450

1500

2250

SD752750 5B06DEF

1500

2200

2292

1200

1750

1833

2750

11

SD753100 5B06DEF

1750

2450

2583

1400

2000

2083

3125

SD750

POWER ELECTRONICS

18

TECHNICAL CHARACTERISTICS

TECHNICAL CHARACTERISTICS

SD750 SERIES

INPUT

POWER RANGE

[1]

1.5kW – 2200kW

VOLTAGE RANGE

380 - 480Vac, 500 - 690Vac and 690Vac, 3 phases (±10%)

INPUT FREQUENCY

50Hz/60Hz (±6%)

INPUT RECTIFIER TECHNOLOGY

Diode-Diode Frames 1 and 2 / Thyristor-Diode Frames 3 to 11

DISPLACEMENT POWER FACTOR

(DPF = cos Φ )

≥ 0.98

POWER FACTOR

(PF= I1/I

rms

· cos Φ)

≥ 0.91

MOMENTARY POWER LOSS

> 2s (depending on the load inertia)

EMC INPUT FILTER

Second environment (Industrial): (C3 Standard)

First environment (Domestic): C2 (Optional). C1 consult Power Electronics

Optional IT filter

HARMONICS FILTER

Choke coils 3% impedance

CURRENT THD (%)

< 40%

REGENERATIVE

NO

OUTPUT

OUTPUT FREQUENCY

[2]

0...599Hz

OVERLOAD CAPACITY

Constant torque: 150% during 60s at 50ºC

Variable torque: 120% during 60s at 40ºC

EFFICIENCY (At full load)

≥98%

CONTROL METHOD

V/Hz

VECTOR CONTROL

Open Loop. PWM speed control (OLSP) / torque (OLTQ), AVC: speed control (OLSP) /

torque (OLTQ)

Close Loop (Encoder): PWM speed control (CLSP)/torque (CLTQ), AVC: speed control

(CLSP)/torque (CLTQ)

PMSM Without sensor

CARRIER FREQUENCY

4 to 8kHz – PEWave

OUTPUT DV/DT FILTER

500 to 800V/µs

[3]

OUTPUT CABLE LENGTH

[4]

USC 300m, SC 150m

DYNAMIC BRAKE

External B150 Dynamic Brake (Integrated in Frames 1 and 2)

ENVIRONMENTAL

RATINGS

OPERATION AMBIENT

TEMPERATURE

Minimum: -20°C Maximum: +50°C (Constant torque)

Minimum: -20°C Maximum: +40°C (Variable torque)

STORAGE TEMPERATURE

Minimum: -40°C Maximum: +70°C

ALTITUDE

1000m

POWER ALTITUDE DERATING

> 1000m, 1% PN(kW) per 100m; 4000m maximum

AMBIENT HUMIDITY

<95%, non-condensing

DEGREE OF PROTECTION

IP20, IP54, GL Marine Series (IP44/IP54)

VIBRATION

Amplitude: ± 1mm (2Hz-13.2Hz), ± 0.075mm (13.2Hz-57Hz)

Acceleration: 6.86m/s² (13.2Hz-57Hz), 9.8m/s² (57Hz-150Hz)

HEATING RESISTORS

Optional

PROTECTIONS

MOTOR PROTECTIONS

Rotor Locked, Overload (thermal model), Output Current Limit, Phase Current

Imbalance, Phase Voltage Imbalance, Motor Overtemperature (PT100 signal), Speed

Limit, Torque Limit

DRIVE PROTECTIONS

IGBT Overload, Input Loss, Low Input Voltage, High Input Voltage, Bus Voltage Limit,

Bus Low Voltage, High Supply Frequency, Low Supply Frequency, IGBT Temperature,

High Temperature in the Radiator, Power Supply Fault, Temperature Sensors for Drive

Thermal Control, Ground Fault, Software and Hardware Fault, Loss of Analog Input

Signals (Loss of Speed Reference), Safe Stop / Stop Emergency

[1]: Other configuration, consult Power Electronics.

[2]: For operation frequencies higher than 100Hz consult Power Electronics.

[3]: Depending on the nominal power, input voltage and according to the recommendations of installation of Power Electronics.. In case of configuring

the AI3 en PT100 mode, any of the two analogic outputs must be configured in 10 mA mode.

[4]: SC: Shielded cable, USC: Unshielded Cable. For other distances consult Power Electronics.

3

POWER ELECTRONICS

SD750

TECHNICAL CHARACTERISTICS

19

EN

SD750 SERIES

HARDWARE

DIGITAL INPUTS

6 programmable to be active high (PNP) or low (NPN), Isolated power supply

1 PTC input

DIGITAL OUTPUTS

3 programmable changeover relays (250Vac, 8A or 30Vdc, 8A)

ANALOGUE INPUT

3 programmable inputs: 0 – 20mA, 4 – 20mA, 0 – 10Vdc (optically isolated)

ANALOGUE OUTPUTS

2 isolated programmable outputs: 0 – 20mA, 4 – 20mA, 0 – 10Vdc

ENCODER INPUTS (Optional)

Two differential encoder inputs. Voltages inputs from 5 to 24Vdc

USER POWER SUPPLY

+24Vdc user power supply, (Max. 180 mA) regulated and short-circuit protected

+10Vdc user power supply, (Max. 2 potentiometers R= 1 k) regulated and short-circuit

protected

I/O EXTENSION BOARD

(Optional)

5 Digital Inputs: Programmable inputs to be active high (PNP) or low (NPN). Optically

isolated.

2 Analogue Inputs: Programmable and differential input.

5 Digital Outputs: programmable multi-function relays.

2 Analogue Outputs: Programmable outputs in voltage / current.

EXTERNAL POWER SUPPLY

24Vdc External Power Supply

COMMUNICATION

STANDARD HARDWARE

USB port

RS485 port

Ethernet

OPTIONAL HARDWARE

Optical fiber

Communication Cards

STANDARD PROTOCOL

Modbus-RTU

Ethernet (Modbus TCP)

OPTIONAL PROTOCOL

Profibus-DP

Field Bus

Ethernet IP

CAN Open

ProfiNet

CONTROL PANEL

TYPE

Removable

LENGTH

3 meters and 5 meters (optional)

CONNECTION

USB

VISUALIZATION (POWER

ELECTRONICS LOGO)

GREEN: Running

ORANGE: Warning

GREY: Stopped

RED: Fault

MONOCHROME GRAPHIC

DISPLAY

LCD screen

Keypad with 68 keys to control and configure the drive, start and stop / reset

Independent memory

Wi-Fi communication module (optional)

TOUCH AND COLOUR GRAPHIC

DISPLAY (Optional)

Optional Colour touch-screen display 4.3”

4Gbytes for recording historical files

Panel or USB cable connection

Wi-Fi remote connection, micro-USB connection to control card

DISPLAY INFORMATION

Average current and 3-phase motor current

Average voltage and 3-phase motor voltage

Average input voltage and 3-phase input voltage

3-phase motor input and output frequency

DC Bus Voltage

Drive Status

Speed, Torque, Power, Power Factor of the motor

Register of total and partial drive running time with reset function (hours)

Register of total and partial drive energy consumption with reset function (kWh)

Relay status

Digital inputs / PTC status

Output comparator status

Analogue inputs and sensor values

Analogue outputs value

Motor and equipment overload status

IGBT and rectifier temperature

Fault history (last 6 faults)

OTHERS

Real time clock

Perpetual calendar

SD750

POWER ELECTRONICS

20

TECHNICAL CHARACTERISTICS

SD750 SERIES

REGULATIONS

CERTIFICATIONS

CE, CRS (cTick), UL, cUL, GL

ELECTROMAGNETIC

COMPATIBILITY

EMC Directive (2004/108/CE)

IEC/EN 61800-3

DESIGN AND CONSTRUCTION

LVD Directive (2006/95/CE)

IEC/EN 61800-2 General requirements

IEC/EN 61800-5-1 Safety

IEC/EN 60146-1-1 Semiconductors

IEC 60068-2-6 – Vibration

FUNCTIONAL SAFETY

IEC/EN 61800-5-2 and UL 61500-5-2 Safety Stop (STO)

POWER ELECTRONICS

SD750

DIMENSIONS

21

EN

DIMENSIONS

Dimensions of Frames 1 and 2

TALLA

TENSIÓN DE ENTRADA

EQUIPOS

1

380VAC – 480VAC (-10% a +10%)

SD750006 5B06DEF, SD750008 5B06DEF, SD750011 5B06DEF, SD750015 5B06DEF,

SD750024 5B06DEF, SD750030 5B06DEF, SD750040 5B06DEF

2

380 – 480VAC (-10% a +10%)

SD750048 5B06DEF, SD750060 5B06DEF, SD750075 5B06DEF

TALLA

DIMENSIONES (mm)

PESO (kg)

H1

H2

H3

W1

W2

D1

D2

Y1

Y2

1

507

474

10

190

120

273 - 498 7 15 2 510

474

13

296

212

323

320

497 6 26

Dimensions of Frame 1

Dimensions of Frame 2

4

SD750

POWER ELECTRONICS

22

DIMENSIONS

Dimensions of Frames 3, 4 and 5

TALLA

TENSIÓN DE ENTRADA

EQUIPOS

3

380 – 480VAC (-10% a +10%)

SD750095 5B06DEF, SD750110 5B06DEF, SD750145 5B06DEF, SD750180 5B06DEF

4

380VAC – 480VAC (-10% a +10%)

SD750200 5B06DEF, SD750260 5B06DEF

5

380VAC – 480VAC (-10% a +10%)

SD750320 5B06DEF, SD750400 5B06DEF

TALLA

DIMENSIONES (mm)

PESO

(kg)

H1

H2

W1

W2

W3

W4

D1

D2

D3

D4

Y1

Y2

Y3

Y4

3

854

839

301

200

140 - 358 - - - 827

15 - -

67,5 4 1249

1208

320

284 - -

466

148

70 1145

682

75

313

94

5

1716

1667

431

298

67

396

529

100

194

467

1370

1220

75

237

200

Dimensions of Frame 3 Dimensions of Frame 4

Dimensions of Frame 5

POWER ELECTRONICS

SD750

DIMENSIONS

23

EN

Dimensions of Frames 6 and 7

TALLA

TENSIÓN DE ENTRADA

EQUIPOS

6

380VAC – 480VAC (-10% a +10%)

SD750450 5B06DEF, SD750570 5B06DEF, SD750700 5B06DEF, SD750450 5B12DEF,

SD750570 5B12DEF, SD750700 5B12DEF, SD750450 5B12DEF, SD750570 5B12DEF,

SD750700 5B12DEF

7

380 – 480VAC (-10% a +10%)

SD750800 5B06DEF, SD750900 5B06DEF, SD751050 5B06DEF

TALLA

DIMENSIONES (mm)

PESO

(kg)

H1

H2

W1

W2

W3

D1

D2

D3

D4

Y1

Y2

Y3

Y4

6

1715

1667

780

649

752

529

194

100

467

1607

1220

237

75

335

7

1715

1667

1132

990

1096

529

194

100

467

1607

1220

237

75

479

Dimensions of Frame 6

Dimensions of Frame 7

SD750

POWER ELECTRONICS

24

DIMENSIONS

Dimensions of Frames 8 and 9

TALLA

TENSIÓN DE ENTRADA

EQUIPOS

8

380VAC – 480VAC (-10% a +10%)

SD751140 5B06DEF, SD751400 5B06DEF, SD751140 5B12DEF, SD751400 5B12DEF,

SD751140 5B24DEF, SD751400 5B24DEF, SD751140 5B06DEF, SD751400 5B06DEF,

SD751140 5B12DEF, SD751400 5B12DEF, SD751140 5B24DEF, SD751400 5B24DEF

9

380 – 480VAC (-10% a +10%)

SD751550 5B06DEF, SD751800 5B06DEF, SD751950 5B06DEF, SD751550 5B12DEF,

SD751800 5B12DEF, SD751950 5B12DEF, SD751550 5B18DEF, SD751800 5B18DEF,

SD751950 5B18DEF

TALLA

DIMENSIONES (mm)

PESO (kg)

H1

H2

W1

W2

W3

D1

D2

Y1

Y2

Y3

Y4 8 1715

1667

1482

1452 - 529

467

1602

1220

232

75

585

9

1712

1667

2352

747

38

529

460

1619

1209

247.5

81.5

1005

Dimensions of Frame 8

Dimensions of Frame 9

POWER ELECTRONICS

SD750

DIMENSIONS

25

EN

Dimensions of Frames 10 and 11

TALLA

TENSIÓN DE ENTRADA

EQUIPOS

10

380 – 480VAC (-10% a +10%)

SD752250 5B06DEF, SD752750 5B06DEF, SD752250 5B18DEF, SD752750 5B18DEF

11

380 – 480VAC (-10% a +10%)

SD753100 5B06DEF, SD753100 5B12DEF, SD753100 5B18DEF, SD753100 5B24DEF

TALLA

DIMENSIONES (mm)

PESO

(kg)

H1

H2

W1

W2

W3

D1

D2

Y1

Y2

Y3

Y4

10

1712

1667

3402

1097

38

529

460

1619

1209

247.5

81.5

1437

11

1712

1667

4452

1447

38

529

460

1619

1209

247.5

81.5

1755

Dimensions of Frame 10

Dimensions of Frame 11

SD750

POWER ELECTRONICS

26

RECEPTION, HANDLING AND TRANSPORTATION

RECEPTION, HANDLING AND

TRANSPORTATION

CAUTION

Read carefully the following installation instructions for a correct mechanical installation.

Otherwise, the equipment can be damaged and lead to personal injury.

Reception and Storage

The SD750 is carefully tested and perfectly packed before delivering. In the event of transport damage,

please ensure that you notify the transport agency and Power Electronics: 902 40 20 70 (International

+34 96 136 65 57) or your nearest agent, within 24h from receipt of the goods.

Make sure model and serial number of the drive are the same on the delivery note and unit.

Drive should be stored in a sun and moisture protected space and with an ambient temperature between

-40°C and +70°C, < 95 RH without condensation. It is recommended not to stack more than two units.

Handling and Transportation

Only the transport methods described in this document or in the delivery notes are permissible. Any other

transport method or system could damage the unit.

SD750 is delivered vertically. Frames 1 and 2 are delivered in a cardboard box. From frame 3 they are

delivered fastened to a wooden pallet. Frames 3 and 4 are covered with a cardboard box and from frames

5 with a wooden box. Depending on the method of transportation, the drive is supllied wrapped to be

protected against dust. Place the entire pallet as close as possible to the installation site before removing

the wooden box to prevent damage to the drive during transportation.

It is mandatory to carry the drive with a pallet truck, a forklift track or a crane, taking into account the load

distribution and its center of gravity. Check the size and weight of the VFD to choose a proper equipment

that can lift a higher weight.

Remove the drive packaging carefully (do not use sharp tools). After removing the packaging, please

check the material inside. Verify that the number of items included in the package is in accordance with

the inventory. In case of receiving spare parts with the product, please separate it and store it in a safe

place. It should not be exposed to vibrations, falls or moisture.

5

POWER ELECTRONICS

SD750

RECEPTION, HANDLING AND TRANSPORTATION

27

EN

CAUTION

If the weight of the load to be handled is greater than the maximum permissible weight of the

crane, it could damage the equipment and personnel.

Frame 5 unpacking

To unpack, if necessary, unscrew the screws that fix the wooden box to the pallet. Then, unscrew the

fixing screws on the angle brackets. To lift the inverter and place it in a vertical position, use only a crane

or a forklift equipped with straps or slings. Lift gently by pulling the top bolts.

To rise to an upright position use only a crane or forklift equipped with belts or slings. Lift it carefully

pulling from the top eyebolts.

Once the drive is upright, reinsert the straps / slings. The crane or forklift must always lift the inverter

from its bottom. Avoid sudden movements and blows during transportation. When placing the equipment

on the ground, stop the lowering movement just before contacting the ground, and after this, lower it very

slowly to avoid blows.

SD750

POWER ELECTRONICS

28

RECEPTION, HANDLING AND TRANSPORTATION

Lifting the equipment

POWER ELECTRONICS

SD750

MECHANICAL INSTALLATION

29

EN

MECHANICAL INSTALLATION

CAUTION

The installation must be done by qualified personal.

Otherwise, the equipment can be damaged and lead to personal injury.

Before installation, make sure the location chosen is appropriate.

There should be sufficient space to adapt the unit to the recommended distances and to ensure that there

are no obstacles preventing the airflow from the fans.

Environmental ratings

Power Electronics recommends to follow the instructions in this manual carefully to ensure a correct

operation of the drive. The installer is responsible for performing a proper installation in order to comply

with the ambient conditions of the VFD. In addition, the installer is solely responsible for complying with

the local regulations. The environmental conditions are:

▪ Environmental category: Indoor

▪ Outdoor: No

▪ Pollution degree: Clean area: PD2

Dirty area: PD3

▪ Ingress protection rating: Clean zone: Electronics IP54 or IP20

Power connection and Input filters: IP20

▪ Operation Ambient temperature: -20ºC to 50ºC Constant torque

-20ºC to 40ºC Variable torque

▪ Storage Ambient temperature: -40ºC to 70ºC

▪ Humidity: Relative humidity less than 95% (non-condensing)

▪ Heating resistors: Optionals

▪ Maximum altitude and power derating: 1000m 1% PN(kW) every 100m; 4000m maximum

▪ Vibration (IEC60068-2-6): Amplitude ± 1mm (2Hz – 13.2Hz), ±0.075 (13.2Hz –

57Hz)

Acceleration 6.86m/s² (13.2Hz-57Hz), 9.8m/s2 (57Hz 150Hz)

▪ Audible Noise: Maximum 68-70 dB Frames 1 and 2

Maximum 80 dB Frame 3 and above

▪ Overvoltage category: III

▪ Protection class: Class 1

▪ Painting: Standard colour RAL 9016. Any other, on request

6

SD750

POWER ELECTRONICS

30

MECHANICAL INSTALLATION

Drive mounting

This section contains assembly instructions for optimum operation of the inverter and precautions to

avoid personal injury and property damage.

SD750 drives are designed for wall or panel mounting.

The drive may become hot during operation. Install it on a surface that is fire resistant or flame retardant

and with sufficient space around the drive to allow air to circulate. Make sure to follow the space

recommendations given in section 6.3.

Wall mounting drives

The drives SD750 from frame 1 to 4 are are designed for wall mounting. In addition, the frame 4 has

optionally available a plinth that that allows its mounting on the ground..

The installation method and its location must be in accordance with the weight and dimensions of the

drive. Power Electronics recommends hanging the SD750 in a wall or solid structure using the anchors

arranged in the back, which supports the weight and possible forces generated by the wiring..

Use a level to draw a horizontal line on the mounting surface and mark the attachment points. Then,

drill the two holes of the top mounting bolts, and then install the mounting bolts. Do not fully tighten

bolts yet.

Mount the unit with the top two bolts and then fully tighten the mounting bolts. Make sure the SD750 is

flat on the mounting surface.

SD750 wall mounting

POWER ELECTRONICS

SD750

MECHANICAL INSTALLATION

31

EN

Stand alone drives

Frames 5 to 11 are designed to be placed over a technical floor. If necessary, there are optional plinths

that increase the height of the drive from 1710 mm to 2000 mm or 2200 mm. The floor must guarantee

a non-flammable, solid, plain and level surface to the drive, a minimum safety distance around it and

esay cable access. The maximum allowed slope is 1cm per 6 meters. The installation site should be

level since the cabinet is not equipped with a height-adjustable base. The walls adjoining the drive

must be of a non-flammable material. Attach the SD750 to the wall or floor using the L brackets on both

sides of the drive. The brackets have Ø11 hole diameters and are located on the legs and rear.

Wall or floor fixation

It is recommended to construct a cable duct to get the cables to the input / output connections. The

duct width must not exceed 300 mm and the ground contact surface must withstand the weight of the

cabinet that falls on its legs.

SD750

POWER ELECTRONICS

32

MECHANICAL INSTALLATION

Clearances

If the equipment is installed inside a cabinet, ensure that the hot air expelled from the VFD is evacuated

outside. This hot air could be sucked back and cause the drive to overheat. To ensure proper ventilation

avoid air recirculation and maintain the minimum clearances indicated below.

Minimum clearances for frames 1 to 4

Minimum clearances for frames 5 to 11

FRAME

DISTANCE (mm)

FRONT

CLEARANCE

A

B

1

200

200

700

2

200

200

800

3

200

200

800

4

300

300

820

FRAME

DISTANCE

(mm)

FRONT

CLEARANCE

A

5

400

930 6 400

940 7 400

1260 8 400

1260 9 400

940

10

400

1260

11

400

1260

POWER ELECTRONICS

SD750

MECHANICAL INSTALLATION

33

EN

Cooling

The main heat sources inside the equipment correspond to: losses in the bridge rectifier (IGBTs), the

input filter and the output dV/dt filter. The SD750 series has an overall efficiency higher than 98%, so

losses due to heat dissipation correspond to 2% of the power supplied by the equipment.

The cooling system of the drive depends on its degree of protection and its frame. In general terms, the

drive has been designed with three independent cooling areas.

Cooling airflow for SD750. Frames 4 to 11(Protection Grade IP54).

1st Area - Electronics:

IP20 cabinets incorporate extractors in its upper part that evacuate the internal heat generated in the

area.

IP54 cabinets keep electronic components fully sealed. The internal heat generated is evacuated through

the metal doors thanks to an internal forced convection system.

2

nd

Area – Rectifier bridge, Inverter bridge and DC bus cooling area:

The drive has fans that collect the air from the bottom and evacuate it through the central grid at the top.

The fans propel the air through the radiator thus evacuating the heat generated by the main components.

3

rd

Area – Filters:

Intake grills are placed on the sides of the equipment. In addition, the rear upper part incorporates

extractors.

SD750

POWER ELECTRONICS

34

MECHANICAL INSTALLATION

The following figure identifies the gratings and extraction fans of the different levels.

SD750 gratings and fans

FRAMES

ID 1 2 3 4 5 6 7 8 9 10

11

AREA 2

OPERATION

FLOW (m3/h) (*)

D

64-77

239-287

306-367

342-410

396-475

486-583

720-

864

972-

1166

1458-

1750

2178-

2614

2898-

3478

INLET GRATING

NET SECTION

(m2)

A

0.081

0.016

0.025

0.031

0.034

0.064

0.101

0.123

0.192

0.303

0.369

OUTLET

GRATING NET

SECTION (m2)

D

0.003

0.013

0.017

0.019

0.022

0.027

0.040

0.054

0.081

0.121

0.161

AREA 3

OPERATION

FLOW (m3/h)

C - - - 180

360

720

1080

1440

2160

3240

4320

INLET GRATING

NET SECTION

(m2)

B

0.081

0.016

0.025

0.031

0.034

0.041

0.041

0.041

0.122

0.122

0.122

Heat dissipation

The heat generated by the SD750 depends on the carrier frequency (Hz), the grid frequency and the

load. It can be estimated by the following equation, considering the worst case at rated power condition.

P

loss

[W] = 0,02 · P

motor

[W]

(*) The air velocity, which passes through the gratings, varies between 5 and 6 m/s depending on the blocking of the

gratings.

POWER ELECTRONICS

SD750

POWER CONNECTION

35

EN

POWER CONNECTION

CAUTION

Please read the following instructions for proper electrical installation.

Otherwise, it could result in damage to equipment and personnel.

General recommendations for connections

The following table summarizes the recommended torque for both mechanical and electrical

connections:

SCREW SIZE

RECOMMENDED TORQUE

Metric (mm)

English (inches)

DIN (Nm)

ASTM (ft*lb)

6,9 Quality

[a]

8,8 Quality

[a]

A449 Type 1

[a]

A325 Type 1

[a]

M3

1/8 1 1,3

-

-

M4

5/32

2,5

3

M5

3/16 4 6

M6

1/4 5 10

4

M8

5/16

20

25 9 M10

7/16

40

50

25

M12

1/2

60

70

38

50 – 58

M14

9/16

100

120

54

-

M16

5/8

150

210

75

99 – 120

[a] For other qualities, follow the screw’s manufacturer guidelines.

NOTES:

• Power Electronics recommends the use of zinc coated quality 8.8 steel bolts for internal-indoor

connections in general, including ground and DC power connections.

• Power Electronics recommends the use of A2-70 stainless steel bolts for external-outdoor

connections in general, including AC power connections.

7

SD750

POWER ELECTRONICS

36

POWER CONNECTION

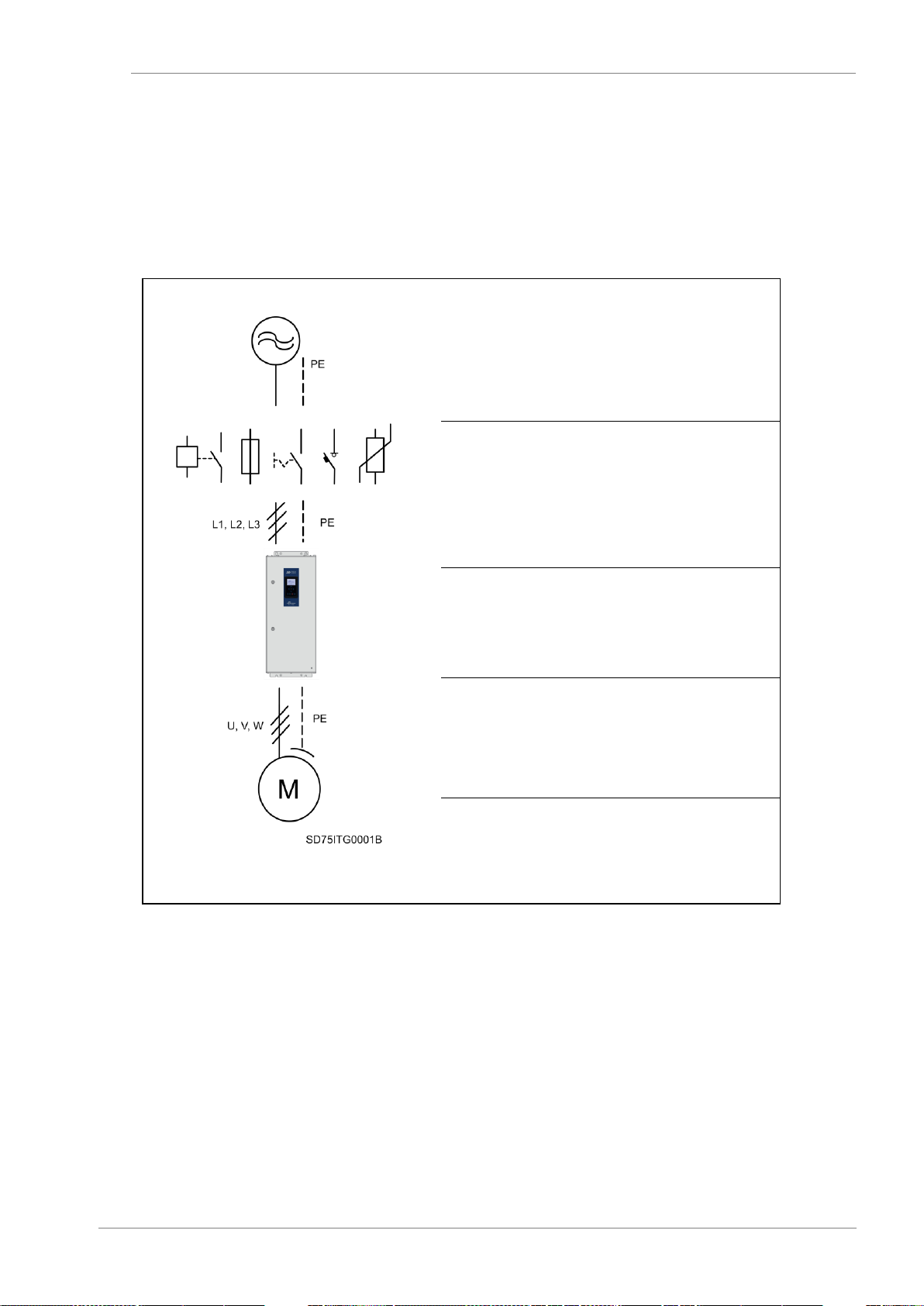

Basic configuration

Select the appropriate safety equipment and perform the wiring properly to ensure proper operation of

the equipment. Incorrect application or installation can lead to malfunction of the drive and consequently

reduce its life or damage its components. Read and understand this manual thoroughly before performing

any operations.

Basic configuration

AC Power

Supply

Use a power supply according to the

selected drive.

The SD750 drives are available for TN,

TT or IT grids (floating earth). Check the

serial number to ensure the correct drive

selection.

External line-

side protection

Select fuses and switches in accordance

with the recommendation within this

manual and the applicable national and

local regulations.

Do not use them for the purpose of

starting or stopping the drive.

IT grids should be externally protected

against insulation breakdowns and

overvoltages.

SD750

Installation

Install the drive following the

recommendation within this manual in

relation with the cooling requirements,

position, clearances, wiring access and

ground connection.

Motor cables

Select and install the motor cables

according to the recommendation within

this manual and the applicable national

and local codes.

An incorrect motor cable selection and

installation could cause EMC filtering

malfunction and motor damaged.

Motor

Do not connect capacitors for power

factor protection, surge protectors or RFI

filters at the drive output.

POWER ELECTRONICS

SD750

POWER CONNECTION

37

EN

Topology

The operating principle of the SD750 is the pulse width modulation (PWM). Varying the power supply

voltage and the grid frequency, it is possible to control the speed and torque of the connected induction

three-phase motors thanks to its main components: rectifier bridge, the DC bus, inverter bridge, and

power and control card.

General Block Scheme for frames 5 to 11

The SD750 drive is equipped with an input filter. This input filter significantly reduces the THDi values

and increases line impedance, thus protecting the drive from electrical system distortions. Depending on

the frame, the input filter is connected to the input or to the DC bus. From frames 3 to 11 the filter is

installed in the input side. In frames 1 and 2 the filter is installed on the DC bus (see figure “Power

electronics for Frames 1 and 2 equipment”).

Frames 5 to 11 integrate as standard ultra fast fuses that protect the drive against downstream

overcurrents. Additionally, the drive integrates multiple electrical protections that protect the drive and

the motor, similar to those provided by a motor protection relay.

The SD750 drive includes a power and a control board that are responsible for the rectifier bridge trip,

inverter bridge trip, soft load management, DC bus voltage control and motor operation. In addition, the

control card integrates terminals such as communication ports, digital and analogue inputs and outputs,

colour touch-screen display, alphanumeric display, etc.

The inverter bridge generates the PWM wave that controls the motor response (voltage, current, torque,

etc.). The Power Electronics SD750 series integrates as standard dV/dt filters and a CLAMP system that

reduces significantly the rise time (dV/dt) below 500V/μs - 800V/μs, therefore, it reduces the voltage

peaks in the motor windings, the common mode currents and the EMC emissions.

SD750

POWER ELECTRONICS

38

POWER CONNECTION

The following schemes illustrate the SD750 internal power structure.

SD750 frames 1 and 2 power electronics.

SD750 frames 3 and 4 power electronics

SD750 frames 5 to 11 power electronics

POWER ELECTRONICS

SD750

POWER CONNECTION

39

EN

Power Connection and Wiring

CAUTION

The following installation recommendations are suitable for TN and TT grids. For IT grids refer the

dedicated section. Otherwise, you could cause damage to equipment and personnel.

Wiring and periodic inspections should be performed at least 10 minutes after disconnecting the

input power. When removing the front cover, check that the red DC Link LED is off. Afterwards

you can remove the metal cover and check with a multimeter the following measures:

• The voltage between the output plates U, V, W and the cabinet must be around 0V.

• The voltage between the DC link +, - terminals and the chassis must be below 30Vdc.

Otherwise, you may get an electric shock.

The input and output busbars are labelled according to the following diagram.

Power wiring connection for frames 1 and 2

Power wiring connection for frames 3 to 11

The input terminals L1, L2, L3 and PE (drive power supply), output terminals U, V, W and PE (motor

power supply) must be introduced through the metal plates situated in the bottom part of the cabinet. Do

not drill or mechanize the vents. Otherwise, the drive could reduce its cooling capacity.

The front metal panel corresponds to the motor cables and the rear metal panel to the input cables; these

panels are not delivered neither drilled nor pre-marked to enable any configuration. Each cable must be

equipped with its own cable gland or grommet that prevent dust or moisture from entering the equipment.

SD750

POWER ELECTRONICS

40

POWER CONNECTION

To perform a correct terminals connection, follow the next steps.

▪ Refer to section “Power Terminals” for recommended screws and washers

metrics, as well as recommended torque.

▪ The number of busbars depends on the frame size. Check the “Power

terminals” section.

▪ Before connecting the cables, clean the contact surface with a clean cloth and

ethanol cleaner.

▪ Use a pressure washer and a flat washer between the nut or bolt head and

the terminal lug.

▪ Use copper or aluminium conductors that whithstand a voltage of 600Vac for

equipment with rated voltage up to 500Vac..

The recommended cable types and lengths between the drive (with factory settings) and the motor are:

▪ Unshielded cable: 300m. Asymmetrical 4-wire cable including PE conductor. It is recommended

to use a motor ground cable (PE) with a cross section equal or higher than the supply motor wires

cross section (U, V, W). When single-wire cables are used in three-phase systems, the three

phase conductors must be bundled symmetrically.

▪ Shielded cable: 150m. Symmetrical 3-wire cable with PE conductor- with concentric shield. To

implement an effective shield bonding, an EMC cable gland should be used in both the motor

junction box and the drive cabinet to ensure effective 360º ground connection and a low

impedance path for high frequency current. Refer to “EMC Installation Requeriments” section.

POWER ELECTRONICS

SD750

POWER CONNECTION

41

EN

NOTICE

The number of three phase plus neutral cable hose (U, V, W, PE) to the motor should be equal to

the number of IGBTs in the drive, having one 4-wire cable hose by each IGBTs block.

The following figures show the recommended cable type and bundling.

Recommended cable type and bundling

Recommended cable bundling scheme

SD750

POWER ELECTRONICS

42

POWER CONNECTION

CAUTION

Line voltage (input supply) must never be connected to U, V and W terminals.

Otherwise, the drive will be damaged.

It is absolutely necessary that the installer ensures correct compliance with the laws and

regulations in force in the countries or areas where the drive is to be installed.

Do not use capacitors for power factor correction, surge suppressors or RFI filters on the output

side of the drive. Doing so may damage these components or the drive itself.

All power conductors such as power input cables, output cables to the motor or DC link cables must be

separated from the control, signal, PTC, encoder or data cables. The recommended distances between

the cables are shown in the next figure:

Cable routing distances

Power Electronics recommends that the following cable types are installed in cable racks, trays or in

different wire ducts:

▪ Single-wire signal or data cables with V< 60V

▪ Single-wire cables with 60V<V< 230V

▪ Input power cables with a low level of interferences 230V<V<1000V

▪ Output power cables to the motor and dynamic DC brake with a high level of interference

230V<V<1000V.

▪ Medium voltage cables with V<1000V

Power cables must have a sufficient nominal current to prevent important wiring overheating and voltage

drops. The installer must consider the cable cross-section, cable type, wiring method and ambient

conditions to select the appropriate cable. It is only permitted the use of cooper or aluminium cables.

Please check the maximum cable section and the available holes per phase in section “Power terminals”.

POWER ELECTRONICS

SD750

POWER CONNECTION

43

EN

Recommended Cable Section for 400VAC

FRAME

CODE

I(A)

Rated

Power (kW)

at 400VAC

Power (hp)

at 400VAC

Recommended Cable

Section

per Phase

Recommended Cable

Section

for Earth Wire

AWG / kcmil

mm²

AWG / kcmil

mm²

1

SD750006 5B06DEF

6

2.2 3 12 – 10

2,5 – 4

12 – 10

2,5 – 4

SD750008 5B06DEF

8 4 5

12 – 10

2,5 – 4

12 – 10

2,5 – 4

SD750011 5B06DEF

11

5.5

7,5

10 – 8

4 – 6

10 – 8

4 – 6

SD750015 5B06DEF

15

7.5

10

10 – 8

4 – 6

10 – 8

4 – 6

SD750024 5B06DEF

24

11

15

10 – 8

4 – 6

10 – 8

4 – 6

SD750030 5B06DEF

30

15

20

6 – 4

6 – 10

6 – 4

6 – 10

SD750040 5B06DEF

40

18.5

25

6 – 4

10 – 16

6 – 4

10 – 16

2

SD750048 5B06DEF

48

22

30

3 – 1

16 – 25

3 – 1

16 – 25

SD750060 5B06DEF

60

30

40

3 – 1

16 – 35

3 – 1

16 – 35

SD750075 5B06DEF

75

37

50

1 – 1/0

25 – 50

1 – 1/0

25 – 50

3

SD750095 5B06DEF

95

45

60

1/0 – 3/0

25 – 50

1/0 – 3/0

25 – 50

SD750110 5B06DEF

110

55

75

2/0 – 4/0

50 – 95

2/0 – 4/0

50 – 95

SD750145 5B06DEF

145

75

100

3/0 – 300

70 – 120

3/0 – 300

70 – 120

SD750180 5B06DEF

180

90

125

3/0 – 300

95 – 150

3/0 – 300

95 – 150

4

SD750200 5B06DEF

200

110

150

300 – 500

120 – 240

300 – 500

120 – 240

SD750260 5B06DEF

260

132

200

350 – 500

185 – 240

350 – 500

185 – 240

5

SD750320 5B06DEF

320

160

250

2 x 300

2 x 150

2 x 300

2 x 150

SD750400 5B06DEF

400

220

300

2 x 350

2 x 185

2 x 350

2 x 185

6

SD750450 5B06DEF

450

250

350

2 x 500

2 x 240

2 x 500

2 x 240

SD750570 5B06DEF

570

315

400

2 x 500

2 x 240

2 x 500

2 x 240

SD750700 5B06DEF

700

355

450

3 x 500

2 x 240

3 x 500

2 x 240

7

SD750800 5B06DEF

800

400

500

3 x 500

3 x 240

3 x 500

3 x 240

SD750900 5B06DEF