fE&

frV6j'totot

,1ytr:-

ruffi

Shively Road,

Ph.

rofft

(C.R.

57+A624592

rrrprur,

-

46)

Nappane€,

^866-50S.8085

I I

uo

tN 46ss0

Wamino.

WARNING!

WARNING

machanery or

The

js

to be used

California, lhe law rcquires

der The

,1442

of the

The engine

cause cancer,

This

ment.

Car€fully read

this

equipment,

jury

and/or

This log

pueose

may cauSe injury

devices in the

equipment

sp€rk a|lesbr mumer

Caltfomia Public Re€ources

manual

property

you

on any forest and

exhauat fiom

birth deffi

@nbins

as

damage.

splitter is to be

purchasers

to

=State

purchased

have

bush cove€d land

that a sp€rk

must be atbd|ed

this equiprnent contains

or other rcprcductive

does not have a

an€ster mufrer

Code_

WARNING!

vital

infornstbn ior

this Operation

failure

io adheG

used onty for

and or

to the anstructions

propefty

damage.

sptiting firewood logs.

of internal

combustion

of California:

spark arestor mufrer. tf

gtatss

or

coverd

be inrtalled and

io the

exhaust system, and

chemicab knorn

ham.

the sab

use and efici€fi operatbn

[aintenance

&

coutd result in death,

tmproper use

engine

unjmpo\red tand in

be in efiect ve uolkino

t the State of Catiiomia

Manual

Using this madine

of this log sptitter wi void

equipped

this equipment

the state of

compty witr Seaion

of this

befo]€

sedous bodity in-

ior any

oF

€ouiD-

using

oher

the

to

Wamings

Table

of Cootenb

AgsenHy

Do

Do Not

Gen€ral

Descddion

S@ffcalion8

Log Splltar PEparatoo

General

Saibty lnbnndin

Trainlng

P|eparalion

Operstion

Malnbnan@

Pedodic

llainlensnco

FuellnO

Trsn8Fatalirr

Lubdcalion

Oiland Fuel

Conbolg

Siorage

Malnbnarc€

Truble6hodng

Parb

Wamov

Record

P()inE

BEaldosrn

HORIZONTAL/VERTICAL

24

/ 29

TON LOG

Table

Sd|edub

SPLITTER

of Contents

PaSe

2

Page 3

Page,l

Page 5

Pag6 6

Page 7

Page

7

Pag,eT

Page

8

Page

I

PaSe

8

Pag€ I

Page 10

Page

10

P4e

1'l

Iboe 11

Pag€ 11

Page l1

Page11-12

Page 12

Page 13

Page 13

P€ge

1+17

Pag€

t8

?

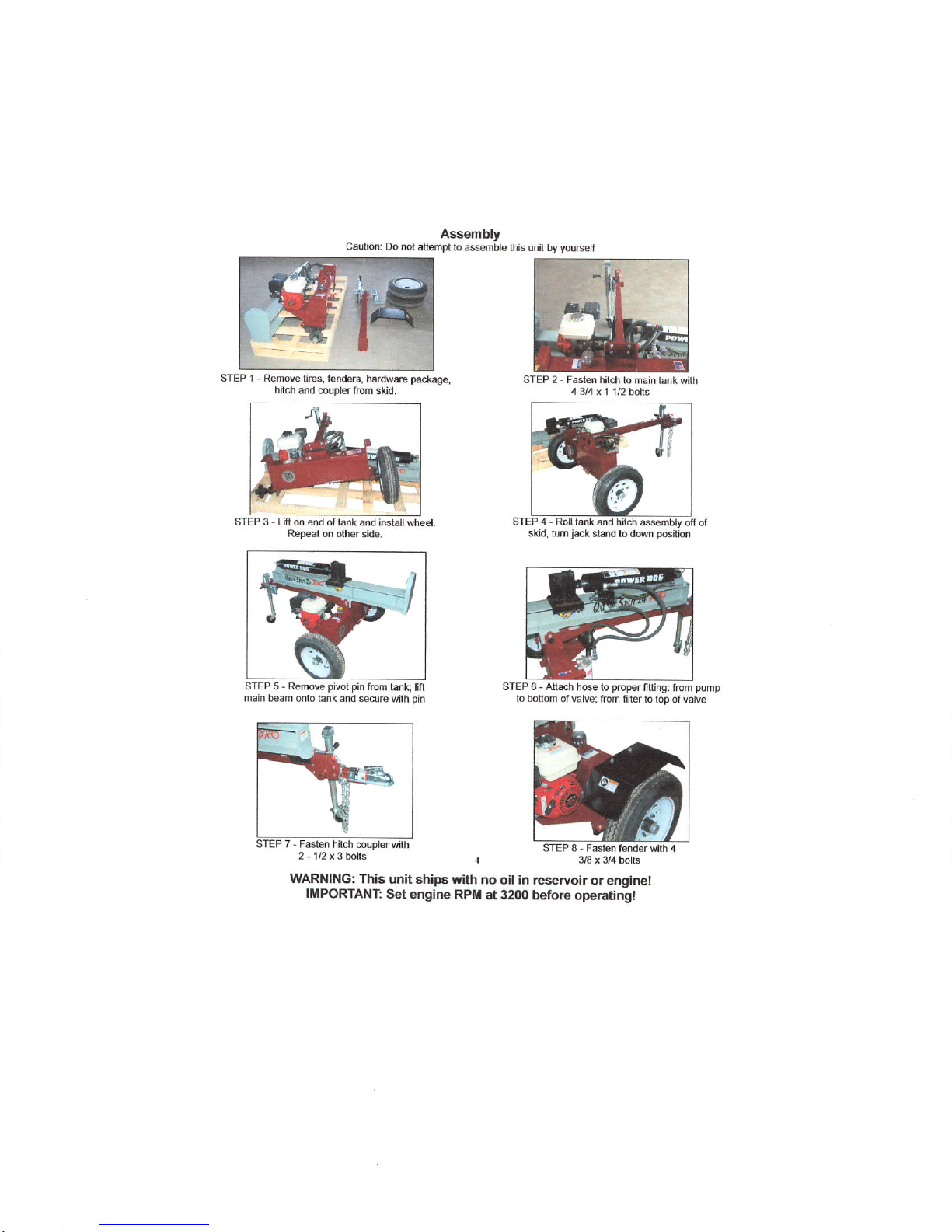

Caution: Do nol

Assembly

atlempt to assemblo

this unit by

yoursef

STEP I Remove

STEP 3 - Lifl on end of lank

STEP 5

main beam

tles, ienders, hardware pactGge

hnch

and coupler from

Repeal on other

-

Remove

onlo lank afld s€tclae

and install wheel.

sire.

pjvor pin

.R

skid.

from

tank tifl

pin

with

STEP 2 - Fasten hilch

jack

skjd, tum

STEP 6 , At|ach

lo bollom of

valvet from lilter lo top

stand to down

proper

hose to

lo main tank with

posilion

ftting:

i'om

of vatve

pump

STEP 7 - Fasten

2, 1/2

WARltllNG:

IMPORTANT:

hitch coupler wnh

x 3 botts

This

unit ships with

Set

4

engine RPil

no oil in

rcservoir or erginel

at 3200 before

operating!

Owner / OBerabr's

It is

the owner /

Assembly:

funclioning

er

instructions.

yourlelf

ope€tols fesponsititity

1.

Carefully read and

the

2. Be

3. Fill the equipment

4-

5. Perform

This unit mwl

Do not

Do make

Do keep

Oo keep hands

Do

Do

Do u6e the

Do wear

Do keep

Do shut

Do operab

Do let

Do remow

Do be sure

assembly instructions.

cenain

stauctions.

Maintenanc€

Operate t|e log splitter

Operation & Maintenance

lhe eogine manufacfure/s

of the unit. Assembly must

operate this log splitter

Failu€ to read

andor others.

sule that anyone

instructions

your

o0eraton.

wipe up sftlled

the sp{itter.

check engihe

splitter only to split firetood

ls dangerous

eye

the log splitter is

children and

off the engine if

the log splitbr

movement

go

of

lhe control lever

et

the end of the

EIUrneo.

both hands froh

lhe log splitter is kept in

and following

of for|ble free and

Res,o/nsiulitv

that

all assernbly

with

Manualand the

all requircd

be assembled

and bllow

as io its

\Nolk aree

protection

ctean. Don't leave

and feet clear

gEsoline

level

oil

and will void

and

in operation

pets

),ou

stroke. The ram

all operating

to

understand the

procedurcs

p&per

the

according

riaintarEnce

before use.

until

ffuids

engine manufactureis

to saf€ op€ratjng

Manual

and these assemblv

as dirccted in

manual,

be cofipleted

yot/

have aeact and undeGland

operaling inslruclions

@

who operates

pmper

of splitbr blade

dghl

and hydraulic

protective

away fom

leave the log

on a level slrface.

ater it is

the log before

safe opelation_

this splitter reads

us€ and opecrlion

a\ €y trom the engine

oit tevet

logr.

the warranty.

clothing including

lo avoid any hazard fiorn

the \rork area white

pushed

can also be sljopped

sound mechanical

and safety instudions

entire Operation

are fotlowed

before stafljng

and the6e ass€mdv ins.truclions.

Care must be taken in

wood lying

and out of splitbr

before starting

Use of the splitter for

splitler, even

Elock the

fotvard.

aclivaling the

5

& MainEnance Manual

as described

as described in the

manual.

procedur€s

insfuations.

fie O'peralion & trriainbnance

in a dry and

dean envircnmenl_

can reguh in

and understands

as well as all sefe,ty instructions.

around lhat

and log splitbr

the splitter.

sabty shoes

fling wood.

you

are

br a short

wtEels b

The ram

at any

oontrol lever

condition.

provide

wi

in the followino in

as

spelled oljt in the

assembly to insure

lhe operating

serious injury

you

coulct stumble over.

arsa while unit is in

betore stading

any olher

at a times while

opeEting the log splitter_

period

of

Drevent

will refum auto.nalica

point

proDer

care. maintenance

you

with many

alono with

Operation &

and safety

or death to

all operating

pueose

lime.

onlinbnded

in its

travel a;d \

years

Manuaj,

prop-

the

v

Do

not allow anyone

the log splitter.

Do

Do

not oo€€te lhe ra

not op€€te lhe ram

Do not

leave tl€ log

Do not

operate the log splitter

opera$no instruciions.

opera$ng instruciions.

Do

not step over

aue,

Do not straddle

Do not

allow anyone to

wood may

Do not

stand on

only when

Do

not operaie the log

adequab ventilalion.

Do

not refuel

smoking

Do not operate

Do not

make any modifcation,

splitter This may

Do not

load a log

your

f|e frame. See operations

Do not

seMce or epair

Do rbt

allo{r

Do not

operaie the log spliter

operating log splitbr

D not use

the log splitter.

method

log

|e log splitter

the log splitter when

the log

iy and become

slippery, wet, muddy

operator zone is

log

the

or while the

the log splitter if it

onto lhe log splitter

hamls

bebveen the

anyone e)(ced the

any chemical cleaner6

may void

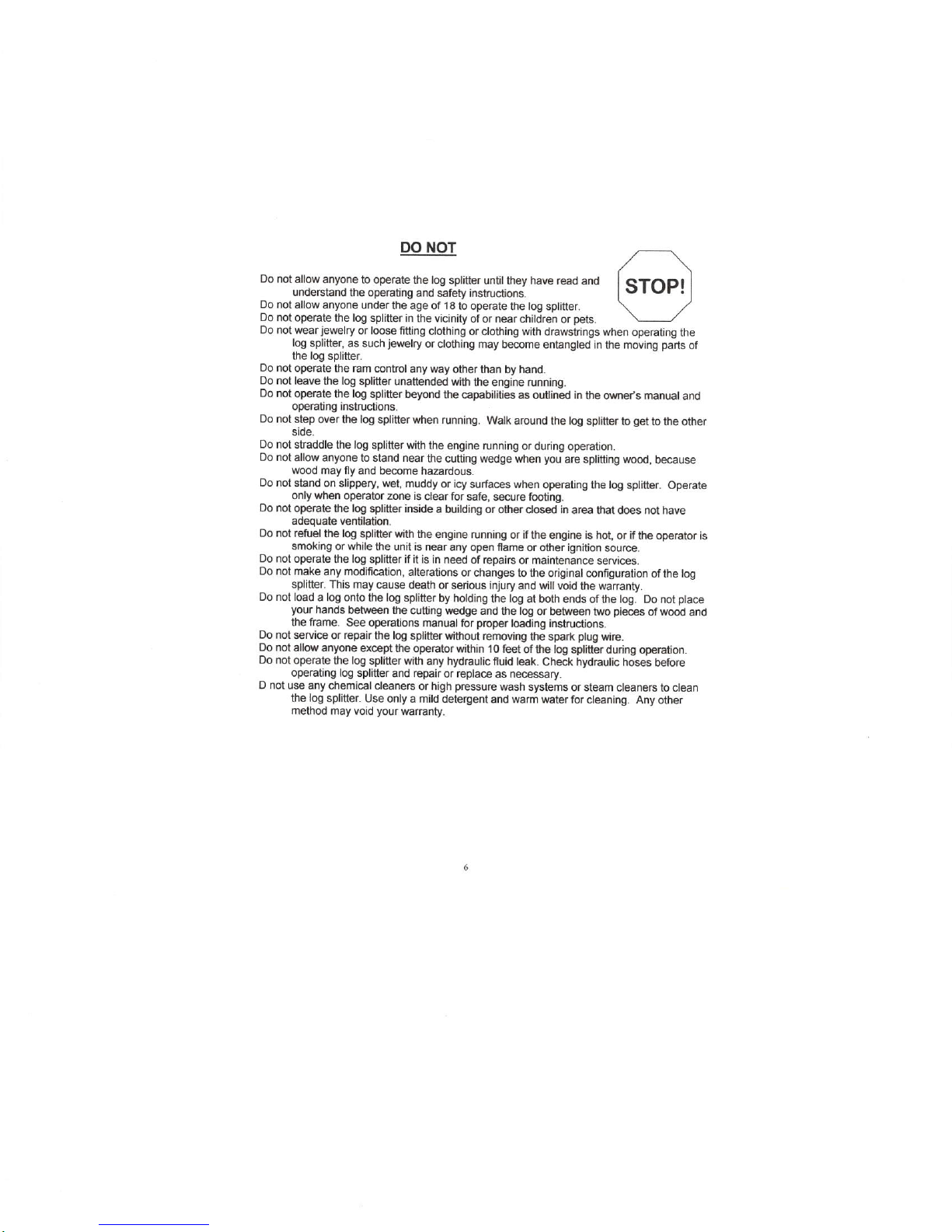

DO l{OT

to operate

splittef unattended nith

spliter unatended nilh

splitter with ihe

Use only a mitd

the log splitier

confol any way

beyofiC the

gplitter

wih the engine

neaa

sland

6p{itter insite

cause death

the

your

the cutting

hazadous.

dear for safe,

unit is near

is in ne€d

alterations

cutting wedge

manualfor

log

splittgr wilhout

operator tvithin 10

with any

and rcpak

or high

warlanty.

olher lhan by hand.

capatilites as oufined in

running. Watk

icy

or

a buildiig or othor

engine running

any open fame or other ignition

or changes

or sedous injury

by hotding

hydraulb fluid leak.

replace

or

pressure

detergent and warm

until they have r€ed ard

the engine running.

lhe engine

$/edge when

surfaces when

of

and the

proper

running.

around the tog

running or

repaira

Emoving tf|e

during operation.

you

seotrc footng.

the

as necessary.

operating the tog

dosed in

ifttE

or

engine is hol

or mainbnance

to ihe odginal confguration

and wjll void lhe warranty.

log

at both ends

tog

or beire€n

loading inslruaiions.

spaft

fret of tte lo9 sditer

Check hydraulic hoses

wash systems

water for cleaning.

the owneds manual

sptite. to

are splihing u/ood,

area lhat does not have

dw

or steam cleaners

get

splitter. Operate

if

or

the op€rator is

source.

6eMces.

tog.

of the

lwo

Do not

pigces

ot wood

wir€.

du.ing operaiion.

Any other

b the

because

of lhe log

bebre

to clean

and

other

ptace

snd

GENERAL

DESCRIPTION

Read

tajn this information

to do

log

of the control valve

position,

ram tO extend

position,

the cylinder,

corporates a high

your

ol

system from

carefully bebre

Your

Power Dog

job.

the

splitter.

Your safety has

The

Oasoline

is

oil

allow€d to flow

outward loward

the directjon

thereby reiracting

Power Dog

excessive

The following

Log splitter

Make

su€ allconnections,

lluids.

Moto.

oilshorJld

manufacture/s

cording to ihe

procedures

until hydraulic

tlen

\

flllng

high nnc hydraulic

AW32 high

lhe regervoir

Place

the engine slop

Place

engine.

of its length.

inch

Start

the engine. Set engine

tion and let

let

lhe ram move

level

foMard

hyd€ulic

before

density ffter

should be in a level

of ihe toD of the reservoir.

and add

attempting

your

for

future

log sptitter is Amedc€n

engine operates

and high

of the oil flow is

log splitter. A

pressures.

LOG SPLITTER

itenrs

be

lhe hydraulic

zinc hydraulicoil.

the engine

Move the contol

the €m move

and reveEe

oilcheck. Inspect

continuing

rebrence.

been considered

pressu€

lhrough the hoses

the wedge. When

lhe ram. A laage

to filter out any

safuty relief valve

must b€ accomplished

lines

placed

in the

instructional

engine manufachrrers

mugt

be followed during

is

oit

added to

system ot the log

Logsplitter

Replace lhe res€rvoir

switch to

stop switch

Stop the engine.

rpm at 3200.

to its fult revers€

to within 1 inch trom

severaltimes

usage. Your Power

install,

to

operate

or servic€ the

made

and constructed

in every featu€

pump,

a

whi6h

hoses. When

changed

PREPARATION

position

and hoses

engine

manuat.

the hydrautic

'OFF

the

bver to

to the fulty exbnded

atlhoses, linesand fitting

supplies high

the control vatve

to the rcar of

the control lever

and the high

rcs€rvoir

slores and cools

partjcles

foreign

preset

is

and checked beforc machine

and used

oil. tn

Fillthe

to the

the

Add hydrautic

only oul of doors, not in

are thigh and not damaged

crankcase accoding

Gasoline is then

operating manual,

refueling. DO

system.

splitbr wiih hydraulic

cotd lemp€ratures (30

hydraulic .eservoir

cap

pu

posiiion_

'ON'

position.

foMard

o to the hydraulic

l/lle the controt tever

poBition.

Slop

the top of

untit

ram

movemenl is

Dog log

the

power

of the b€st male.iats

and componenl

pressure

is moved

the cylinder which, in

is reveBed

pressu.e

oil is forced into

and, therefore

at

the

PROCEDURE

NOT start the tog

the engine

pullthe

extend

position.

the engine. Check

reseNoir

gplitter

the hyd€ulic oil and in-

factory

to

instructions

to lhe

put

into the

Standad

dl, use

deg€es

within i inch from

cord over 4 or 5 times.

engine

position

and let

to the foMard

Reverce

as needed.

smooth and

for leakage.

is now rcady for

Dog log splitter R+

avaitable

power

your

of

oilio

the cylinder by way

to the foMard exeno

fum, forces me

put

and

in the reuacr

the fiont of

grealy

extends

protecl

the hydEutic

operrtion

an enclosed

before filling with

in

engine fueltank ac

fueling safet

cord and start me

reseNoir to wilhin 1

lhe cont.ot tever

Cofiect

iheengine

splitter engine

power

Dog AW46

or coldei) use an

the toD

the ram move 1/2

extend

lhe hydrautac oit

Cvcle the ram

eten. Do a final

leakage

any

servace!

Dog

the

area.

of

posF

and

life

GENERAL

Read and

Do not

Nevefallow

Never allow

Most accidents

Never allow anyone

Extemely

Your log

The

Keep

Be

Always wear

Always

Never w€arjewelry, loos€

understand the Operalion

attempting to use

allow anyone to

l\raintenance

ofthe log

children or untrained

anyone under the influence

log

splitter

second

the confob

log splitter

high fluid

fluid

escaping through

Therefore,

'Do

nol op€rate

hos€s, filtings

'Avoid

almost invisable

board or wood

'

Stop the engine and relieve

n ngs, hoses,

'Do

not adjust the

'

Do not

wood

or

by escapng hydraulic

resuh

splrller is

imFoved forest,

with a spark anestor

may be

equipment wilh

log splitter must

direction

the operator zone

zone is

assisl,ant

thomughly familiar

safety shoes

wear safety

operating the log splittef.

in moving

operate

Manual and satety instructions

splitter.

occur when more

person

is

unlil the assistant is

at a time.

lo ride on

pressures

the following instructions

the

or tubing.

pressure

high

to deted leaks.

tubing or other

check for leaks with

over lie suspec.ted

pbper

if

medical

equipped $/ith

brush or

purchas€d

you.

be used only for

g€in

of lhe

the entjre arca from

and adjacent

should be within

wili all

glasses

or rotaling

SAFETY

lfiis log splilter

assisting in

log

ffuid

but it c€n

pressure

which rneets

from

(not

or

or

dothing

pads

INFORIIIATION

& Maintenance

your

log

sptitlea who has not read

adutts to operate

of any

person

lhan 1

providing

log

the

are

developed in hydrautic

pin

a

hole opening

splitter wilh frayed,

leaks. Hydraulic

penetEie

settings

your

orl, se€k medicataflentron

care is not

intemat

an

grass

the engine

across

the opeEtor

lhis operaling

PREPARATION

the

of

controls and with

heaw

boots.

goggles

or clothing with

of the log

logs

clear of the work

splitter at

shoutd be bllowed

skin, causing sedous injury.

€ther

lhan using

hydraulic

system

system components.

of lhe

hands. Leaks

area

of the leak. Look tor dis@toration.

administered immediatelv.

combi/slion

coveGd land,

all applicable toc€t,

manutacturer. Take

splitting fire wood

the diameter

area clear to enaure

(No

with

side shields

sptitter.

3

-

TRAINING

Manualand a

has

or

his log splitter.

substance

ope€tes the log

to he ope€tor to be sptit, never

area. Only one

any time.

puncturc

can

kinked, cracked

oil escaping from

your

pressure

pump

orvatve.

can be located

rmmedialetv

engine and_if it is

the engine exhaust mlst

and should

of the log)

io ten feet away frcm

area when the machine is in

proper

lhe

athtetic shoes)

and hearing

stdngs or cords that my

safety instructions

the Operatjon

not been instucted

(drugs,

alcohol, etc.) to operate

gplitter

at any tme. lf a

person

log splitters.

state and fede.at

safe, secure fooling.

press0rized

skin

and cause sever injury.

at a times.

ordamaged hydrauljc

a small hole

hands.

apprcpriate fre fighling

Use

before changing

passing

by

Senous infection

be split only in the

the operator. No

use

of the

proteclion

before

&

on the safe

mus,t run the

can be

pb:es

or adjusting

lf

vou

used near any un

be equipped

codes. These

The ope€tor

use.

tog

splitter.

when

becom€ €ntangled

use

this

activate

hydrautic

of

card

cardboard

are iniurcd

c€n

other

GENERAL

Make

sure the log splitter is

machine

the

behind each wheelto

Always

operale

Cut all logs

Handle

fuelwith care, it is

'Use

'Never

'Fill

"Replace

OPERATION

1 . Before

2.

3.

5.

7.

L

1 0. When loading

11.

'1

13.

14.

15. Read

16- On

1 7.

18- On vertical

19.Do not refueltheengine

starting this log

ful and

General Safety Intormation.

operator

or byslanders.

Never leave

Never

The

Always

ed for safe operalion.

Do not

not

Always keep hands

Always shut offthe

by

Do not run

and deadly

or any

Never attempt

2.

When the logs

placed

Use only

Operate the log splitter

machine

On the vedical models,

mode or in the horizontal

the machine

operate the machine wher

machine owner husl

operate the log

tun the engine at

tamper with

manufacturea.

the

he engane in an enctos€d

poisonous

part

of

at

eh cutting [edge

your

while lhe log

and follow allsafety

jcal

ve

lhe

models, make

to

the log splitter from

to be split as

an approved

add fuel

the fuel tank ouldoors

gasoline

splitter, react and

splilter with alt

excessive speeds.

parts

that may increase

and feet away from

engine when

gas.

the log

splitte..

your

body between a log

to sptit more

not

are

cut square,

hand

to opehte

using only

splitte. is operaling.

models, keep

maintain batance

until it has cooled

SAFETY

on a level

prevent

unintended

block the log

squarely as

highlyflammable.

fuel conliainer

to a hot or

unattgnded wili

insfucl

than one

end.

and waming

sure lhe satety

towing

running engine.

wilh exlreme

tank cap

securcly and clean

Faiture

you

are

all operaiors in

safet equipmenl in

adjusting or repaidng

a|ea. Exhausl

plac€ your

and any

(1)

the longest

the log splitter

one operator. Only

hands

decals insta

away

mode

INFORMATTON

glock

suface_

movement.

splitt\er.

lhe indicated

possibte.

designed for

understand

io foltow lhese

the

underthe intluence

the speed .ecommended

moving

hands on the

tog

frcn

of the b€am when

pin

for severat minutes.

operator zone.

care. Never indoors.

lhis entiG manuat includiaq

power

source

the safu operation

Ooing so increases

parts.

gas

part

of the log sptilter.

at a llme.

portion

of the log

conrots.

lhe operator shoutd

ed on the machine.

the cufling wedge.

in inshlled when

(Continued)

the wheels securely

Use chocks or

gasoline

up all spilled tuet.

rutes may resutt

orerating.

of alcohol,

place

the hazard

the log

sptitter except as recommended

contains

sides of lhe tog. Never

should be rotated down

raising or towering

lhe unit is in

before operating

split wood in front

storage.

the Do Be

rn s;rious injury to

drugs or medication.

of this log sptiter.

and all

by the manufacturer.

carbon monoxide,

properly

controls

personat

of

place your

be within 10 feet

the beam_

the vedical or sptiting

and

Care_

ihe

adilsf

injury. Do

an odorless

hands

and

of the

MAINTENANCE

AND

STORAGE

l{otei For

page

Always

Clean debris

Never store

Clear debris fiom

To

-

Check to b€ sure

Check

Che,ck the wear strips

Check

engine

Check hydraulic

Inspect hydraulic

lmpect

Check log

Check trailer hitch

Clean

englne airlilter...

Check

wear

In6pect

Inspec{

Replac€ hydraulic

Check

& seruice wheel

lmpectall

Change

Foper

1 0 for

shut off the

fecommended

screen

and inspect it regllady (follow

damaged.

open flame or

befoE storing in

prevent

teminalin

condition.

engine oil level

w€ar

o11.........

oi|..................

& clean

engine cooling

splitter tir€

strips.......,

for and repalr

gap

&

or replace

bolts & fittings and

engine oil

mainienance,

turther details-

engine. While repairing

by

and chaff from

and muffler areas. lf

lo9

he

splitter with

spaft. Allo/

movable

accidental

fieV notch in thecytinder

nuts

all

slips should be inspected

keep

ihe engine manufac.turer

the engine

the engine

fuel in the tank inside

any enclrsed

strarting, remove

and hydraulicoil

on lhe slide

lhe engine to coot

pafts,

bd onty when

and

bolts are tight to

plate

PERIODIC

hoses

prc5sure......

and safety

damaged

oil and clsan filler

indlcated

as

parts..............

ptug..................

spark

tighton as

in the engine

a wliten re@rd

or adjusting

cytinder, cylinder head

engine manufacturer

area.

the spark

levet.

under the

and have

of hour use

the log

is equipped wfi

a building where

and drain

power

lhe

plug

wire from the

head

before working

assure the log

cu(ing

the wear

service instructions).

source

wedge.

strips reDlaced as needed.

MAINTEI{ANCE

manufrcturcda

owners man

and naintenance. Also

splitter, except as

fins, blower housing,

a spa* anestor

all fuel fom the fuel tank

is shut off.

spafi

on the engine

is

splitter

All models

.................,.da11y

......_..................monthty

.............,....,.we€kly

muffler, clean

ReDlace. if

fumes might

plug

and insert

or

in safe working

equipped with

."..........dei|y

or aa required

at.

rotating

reach an

log

splater.

....daily

see

the

properly

Us€

Refuel

Shut

W{le refueling

Avoid spilling

marked

engine.

engine outdoors.

off lhe engine

gasolane

aM appFved

and allow it to

engine,

do not smoke

and

Never reftt

coot before refueling.

dean up a spi

FUELING

safe'ty containers for

lhe fuel tank indooB.

or crea€ spafts in

gasotane

ed

gasoline

storage aod br €fueting

lhe same area.

before

starting the engine.

SAFE TRAI'ISFORTATIOiI

Vtt/tEn

shut otr by means

gasoline

a

line

Englne

gine,

Englne choko conlrol

starts,

lranspofltng the log

of the shut off valve localed

shut off valve. tf th6

beb|e towing

A written record

Molor

Dexmn

Afbr every 5

lf a consideEble

Afrer

Afrer 250 hours

Hydraulic

run - 3top

To

be sule the swibh is in

lf the

se lhe choke contol

the

in

oil

lhe cankcase

engine manufactjre/s

ll or lll

houc ot operation,

relracted

from

lhe top of the fller

thould be

needed.

every 50

checked,

should be ins@ed

oil should be

commercial use the

conditions the

@nd{ions-

awilch

shut ofi the engin€,

engine does not

loo

engine b not

splitter

sdi(ea over

road,

the

under

equipped with a

LUBRIGATION:

should

be kept lo log hours

of lhe engino

or eguivabnt is r€comrierded

position,

amount of to{ing

packed

hours of operation,

and ahanged

ot opel"alion,

manual

the hydraulic

with

wheEl bearing

as necessary.

U€

iordamage.

changed as required,

oil ahould be

ghould

oil

tum the $vitdt

posil,on.

the run

start initially,

lo the nomal

aM fuel specifcalions

Supplied with the log

he tog splitter

oit tevet

cap hote.

or over the road

the motor

rubber

s{tder betvreen the lt|obr

changed annually. In

be

ohanged mole fequenty

CONTROITS

to the stop

Not

an engines have this

set the choke conlrol b flll

operating

OF THE

the

LOG SPLITTER

fuel

coming trom the

gasoline

tank.

ga6otine

Some engines

shut of vatve,

OIL & FUEL

of use.

lbrthe h!,'craulic

should be

shoutd be checked. tt

use is necessary,

grease

every

oil should be changed

but more frequenty

position.

posilion.

must be fou/ed

splitter.

system.

stopped and, wilh

't

OOO

miles or once a month

br heaw duv

exbemely dugty

b meet lhese

Befo€

atbmpting

confol on them_

on

gasoline

tank stlould

not

do

d€in alt

from the

the ram in a

shoutd be 1 to 2 inches

the wheel bearing

and the air filter

shafr and hydraulic

positjon.

should be

o.

or dirty

unusual

io $an $€ en-

When

the engine

have

gaso-

as

pump

be

Engine

recoil

ft take6

.

dle. Do

not release

Ram contsol

To

ing the lever in

either

center hold

control

extend the ram,

the conirol lever

As a sabty

p,osilirn,

$ritdt. To nove

sLrter handle

sho4 steady

tho sterbr handle

valve

position,

this

is released

precaulion,

and the €m will

lhe

CONTROLS

pulls

an €pitt

push

ttle @ntrol lever

the ram wi

or until

when

push

ram,

(Cor

inued)

succ€ssion

wh€n

continue

the

the conlrol

stop. This controt tever

ihe control lever in

b stan

fully extonded

to extend

lo favel forwad io its

ram

reac$e6 its

lever is

Eleased it will aubmaticallv

the safite direclir

and let it

as $e decal on the valve indicates.

IDENTIFICATION

the engine. Do r|otjerk

snap back.

tulty extended

fully exbnded

ftafuie

positjon.

b etered to

aS ttish

lhe stader han_

position

move

to the

.dead

is a

the €m to

Hold-

until

man.

Additionalor

.W]len

lhe log spliner

Always rnention

. . _

dolbt as lo what

anangemenb musl

the log sditbr rnodel

For

@nvenience in

For

Sate Storaae

Clean dirl

r

Store

It is

prevenr

o

lho

equir€d

inhibitor

off

uitil all

and debris trom

rusl

log

pad

ru$ng,

Eplacement

ha8 been received.

is needed,

be made b€fore

Do not use heavy

inhibitor

splitter with

lhat

otr the carburetor

manuals may

ordering,

coat tne areas where

you

parts

send a tu

tl€ engin€

before use

the ram in

drain all ot

comptete

number

are listed

de€diption,

retumino

STORAGE

and log spfter.

oil or

tully ret-acted

gasoline

the

gasoline

be obtained from

the following record:

when

ordering or inquidng

psrt

by

number, description

sketch or the

pan

a unil or

paint

grease

is

et'|ausbd before

for ! rarrani

has

been scraped with

becaus€

positjon.

fom the

po\

Kuhns

about

part

itself

seNice.

wilt

thig

c€use

gEsotine

tank and

sbring fie log spliter.

€r Equipment, LLC.

pats

or seDice.

quanlity.

and

with the ord;r.

an oil based

premature

run the log splitter

lf in

rust

vvear. Wpe

p.ior

MAII{TENANCE

RECORD

TROUBLESHOOTING

lclKtxED'

E

dt

!h

Aad

.p.rl

tluC

Ihro$. dtd

plr{

B.d 3Frk

C.rbootor o'n ot

r|ydEulic oil

or inpreper

not ei

d lhprcFr

*lj!.tn.'rt

hw r@ rd

FlFrty.

p6p.rty,

grp,

POINTS

3d

"TO

I'Vtlt $fr|

ck

tr q opL@ .ir cb|Br

Edflt tu

R.noE

Mtlo .u6 .p.*

PLd threfir. cotot

CL.n or Eplre

R.tr& .p.rt

Enfi lu€l r..k .nd

It*. .uB

Mr*. mc..e.y.dj6tn.n6.

S€t.LFih

Ch.n or FphE tir cl@no.

ch.cl

oll hwl/dr4.

Cle.n rnd Fg.p

EnDty.nd cb.n

En9iytudn

Empry

tuel $nk and

Rmmtu.|t

conn.ct

Cl.rn .ngine

M.L mo.{ry tdju.tnrt

CoiL.t.n .dlbriDd

Ch.cl oll Lv.lrch.m.

Cb.n .ngiE .ir *En.

cbtn ctind.r

Rqns

STAAT

ENGI E" in OG6tion

hlnub3 b.aoc .t6nptir!

l t nk ..d

txl ,enk .nd ch.n.

pI4

.p.rt

ltat forsh.ttorertitting.

nk.nd cldn.

.nd nght n !p.*

a? .cen.

lir. .n .cEn,

.nd ch.n hunkr

@rddge.

qrblEt

r,

plue

tiF l. st.d

in

"FASP

.i. .h.mr draidg..

6.djBt

srp,

r.nll bnr rfth ft!.h,

*iE L

ttu!

d ch.nlo .p6r*

tel t n* i l E6ll..rd

.fit.fi fDtn wnhtrsh

sted

@nrido..

oil.

erbuEror. and efll llnk

pluo

,

!di6 cdr.r d.6rthrr,

oll.

Gtion.

.t n.

b

.nd Etttt Ln*

pEpedy

@irion,

ctsan

poiody

ptug.

cten

etru.

.nd mufior dd.

on

.n

PqrJrro. ,o! on

Ch6ft rhto0Je

M.*. tlosry.dludftr('

6nr.r of sdg..

@rtol *lting.

PARTS

KYl002 Wedge

KP7007

KP7008

KP?011 CylilJ'd€',s

KP7012

KP?013

KP70l6

KP70l8 Filter

KP70l9 Filt€r

KP1A0

KP702l

KP7022

KP7023

KP7026

KP7027

KP7028 Jack

KP703l

KP7032

KP7033

KP7034 Retum

KP7036

KP7039

KP7041

KP2042

KF1044 Fittiry250l-8-12

KP7048 Fitting6S0I-NW0-8-8

KP7049

KP0050

KP705l

KP2l6l

KP7067

KP1075

YJ'1076

KP7071

KP7069

KP704O

Hitoh

QS

MainBem

QS

2- Stage

Valve

Safety Chains

Brearh€r

Tire 5.30 x l2

Rim4x 12

Hitch

Wedge Plate

W6dge

Suctioo Hoso

Supply Hose 36"

Cylind€r Hose 22"

Pivot Pin

BolLCan. t/2 x2

Clevis Pitr I U4x31l2

Valve Stem

QS

Honda,

QS

tabel, Dary€r

Jaok Latoh

Cylinder,4.5

Axle Rigid

B€am Latch

JackPivotspacer

Clevis Pin

hunp 16 c.PM

H€ad

Elerneor

Cry

Coupler

Plate Holder

Stmd

Hose 43"

FetrdeB

cX270

Tank

Oasic)

Pin

l/2x21l4

x24"

Spacer

Basic

x 24'

Pitr

QYI)

|4

BREAKDOWN

(24T)

7011

7075

(29T)

(24rJ

PARTS

BREAKDOWN

Kvt0fr2

KP7007

KP7008

KP701l

KP7012

KP70l3

KP7016

KP70l8

KP70l9

KP702l

KP7023

KP1V28

KP703l

Kvt032

KP7033

KF|t034

KP703s

KP7039

KP7046

KP7048

KP7049

KP705l

KP7055

KP7056

KP7064

t{gt012

KP7074

KP7075

KV|O16

KP1077

W€dge

Hitch

QS

lvfain B€dm

Stage 16

(29T)

$n

Cyliod€r 5 x 24"

Putrp,2

rr'abc

Sddy Chains

Fiftef,Head

Filt€r

Tire

5.30 x 12

Hitoh Coupler

Jaok Stmd

Hosg

Suctiotr

Ho6e Swply

H6e cylirdcr 22"

HGe, Rdrn

Rulrb€r Bunf'er

Bo\ Ca\ 112

Fittiog

x2ll4

2503-8-8

Fiting;6801-NW0-8-8

F@&s

Taok

QS

PrryMottr6tp

hry Mount9hp

rr'ah/E

Basic

Bradct

Hose, cylhder

U Bolt,Ade

Cyliadftr 4.s" xU"

(24T)

Axlc Rigid

Bem Lalch Pin

7.tsi

7012

7o.,6e4rt

(29r)

7055

e =^

jlE

gg

F.o i

F;l:

ql8

sili

FiA

69

;t

"^45*g4ile

;qe-34;l|

;iEaE{lq

ai

sq:

d:

3 :

ae eF FP

iiiigiiiiiiiE

ii ealE

;r4E

i:

Eg aE€H

gr

3i1

;

I

"r"-;

g?

*si

E- Ec

;

d-

gAE"=:

:6.;

62=a=

giiBS

9iq:a

;:ite.

g

3E si

!r'6i

i:qe

if6l

l;58

:

5;4

3E:I

g

E:4H

ica;

9 C=F

s9

e3=

ecA

g'

F6;

;9

5fr

=:

a9

iigsisE

-s

Egg ;g*= li as E

[ii

{in

!

q&q

;iE

BFC

3:

i

9ni

gi;sEiisliEisi;

di9

;

e'8

gEE

.-4i

ei€'

o*9

5i

iiiEE

Eiiii

igii

iiiii

iFi'F

ii

aF:

is

E

qarr

E

i;*r

ti3

iiii

I

gi

e

ggii

itiigisigii

F

F

E'

a

€

z

o

-{

P

m

=

m

z

{

2

l8

Loading...

Loading...