Instruction Manual

PREVIEW

2

PowerBox-Systems − World Leaders in RC Power Supply Systems

Dear PowerBox pilot,

Many thanks for placing your trust in us, and purchasing our PowerBox CORE. You have chosen an extremely

unusual radio control system: the CORE has great presence and allure, which you cannot fail to appreciate when

you pick up the transmitter for the rst time. The CORE ts perfectly in your hands, and is the perfect tool for

controlling your valuable models with precision.

30 months have passed between the initial idea and the start of series production: in this time we have developed

everything from the ground up: electronics, mechanical systems, choice of components and suppliers, external

appearance, technical design, mould construction, software architecture, basic operating philosophy and endless details.

Development started late, and the system had to be completely re-designed, but over time we realised that this

offered one great advantage: compatibility with old systems developed in the past did not have to be considered

in any way. This is a very important benet, since there have been signicant technical advances in the eld of

2.4 GHz systems since the start of the current era.

A single example will sufce to underline this advantage: the highly developed radio link, offering a range of

more than 9 km. This is unique, and provides unrivalled system reserves. Further advances are evident in our

new bi-directional P²BUS which operates as the telemetry interface, and is capable of transferring data at un-

precedented speed. The most important advance as far as the pilot is concerned is the user interface, which is

controlled using the transmitter’s integral touch-screen: the entire menu system is accessed from here, and the

self-explanatory menus are completely logical in their structure. The internal high-performance Linux computer

provides unlimited future expansion potential.

We are condent that we can guarantee our customers durability and quality at the very highest level, because

we exclusively use components of the highest possible industrial quality, produced by top manufacturers.

The entire production process - starting with circuit board assembly and extending right through to nal as-

sembly in our own premises - takes place in Germany. Each CORE is hand-made, and represents an example of

German craftsmanship at its best! All our staff are united in their shared aim: perfection!

We wish you many hours of pleasure and countless successful ights with your new PowerBox CORE!

CONTENTS

1. Connections, controlls ................................................ 3

2. Initial steps .................................................................... 4

3. Function menu .............................................................. 8

4. Binding a receiver ....................................................... 11

5. Mixer ............................................................................. 12

6. Telemetry ..................................................................... 13

7. Charging the transmitter ...........................................14

8. Connections ................................................................ 15

9. Mechanical transmitter adjustments ..................... 15

10. Calibrating the transmitter controls .....................18

11. Specication ............................................................. 18

12. Set contents .............................................................. 18

13. Service Note ..............................................................19

14. Guarantee conditions .............................................. 19

15. Liability exclusion ..................................................... 19

www.powerbox-systems.com

3

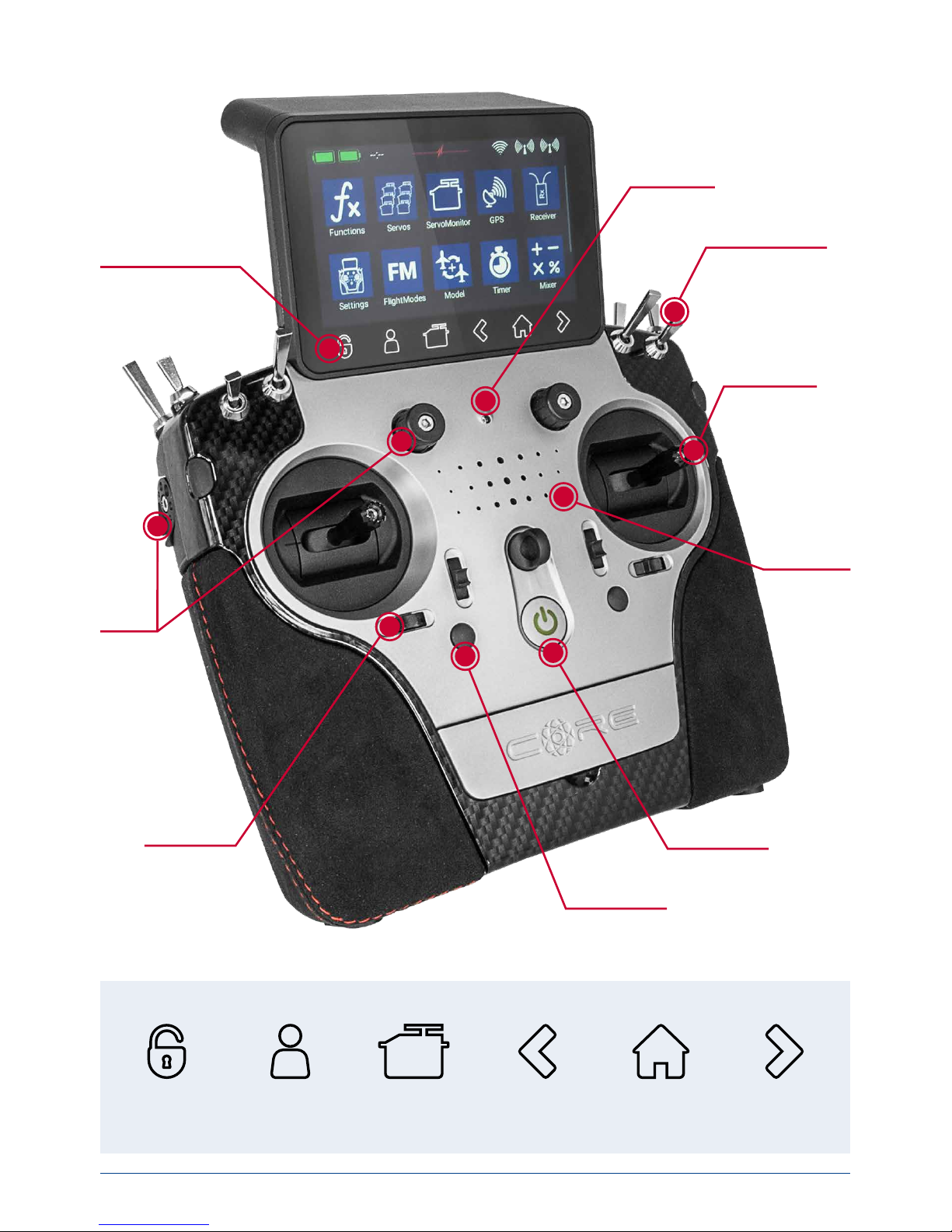

Quick-select buttons

1. CONNECTIONS, CONTROLLS

8 Toggle switches

Light sensor

Quick-select buttons

Optional stick

switch

Loudspeaker

4 digital trims

4 proportional

controls

On / Off switch

4 push-buttons

Screen

unlock

User-

dened

menu

Servo

monitor

History

back

Home screen History

forward

4

PowerBox-Systems − World Leaders in RC Power Supply Systems

2. INITIAL STEPS

a) Switching on

The CORE is switched on by holding the

-button pressed in until it lights up red. Release the button briey, then

conrm the power-on process by briey pressing the button a second time. The transmitter is switched off in

exactly the same way. The button changes to green when the Linux system has booted; this process takes about

25 seconds.

Once the CORE is running, you will see the Home display on the screen: this shows elds containing telemetry

values, timers, servo positions or quick-select buttons for menus. These elds are known as widgets.

Note: the CORE is tted with a fully redundant power supply system, which is deliberately kept separate from

the Linux computer and the other processors. This means than any malfunctions in the complex Linux system cannot possibly result in the transmitter switching itself off. The two real-time processors also function

completely independently of the Linux computer.

b) Entering the menu

The main menu is accessed by swiping a nger downwards from the top edge. You can now touch the left-hand

menu symbol:

There is no need to press rmly, as the capacitive touch-screen simply responds to touch, like all modern smartphones.

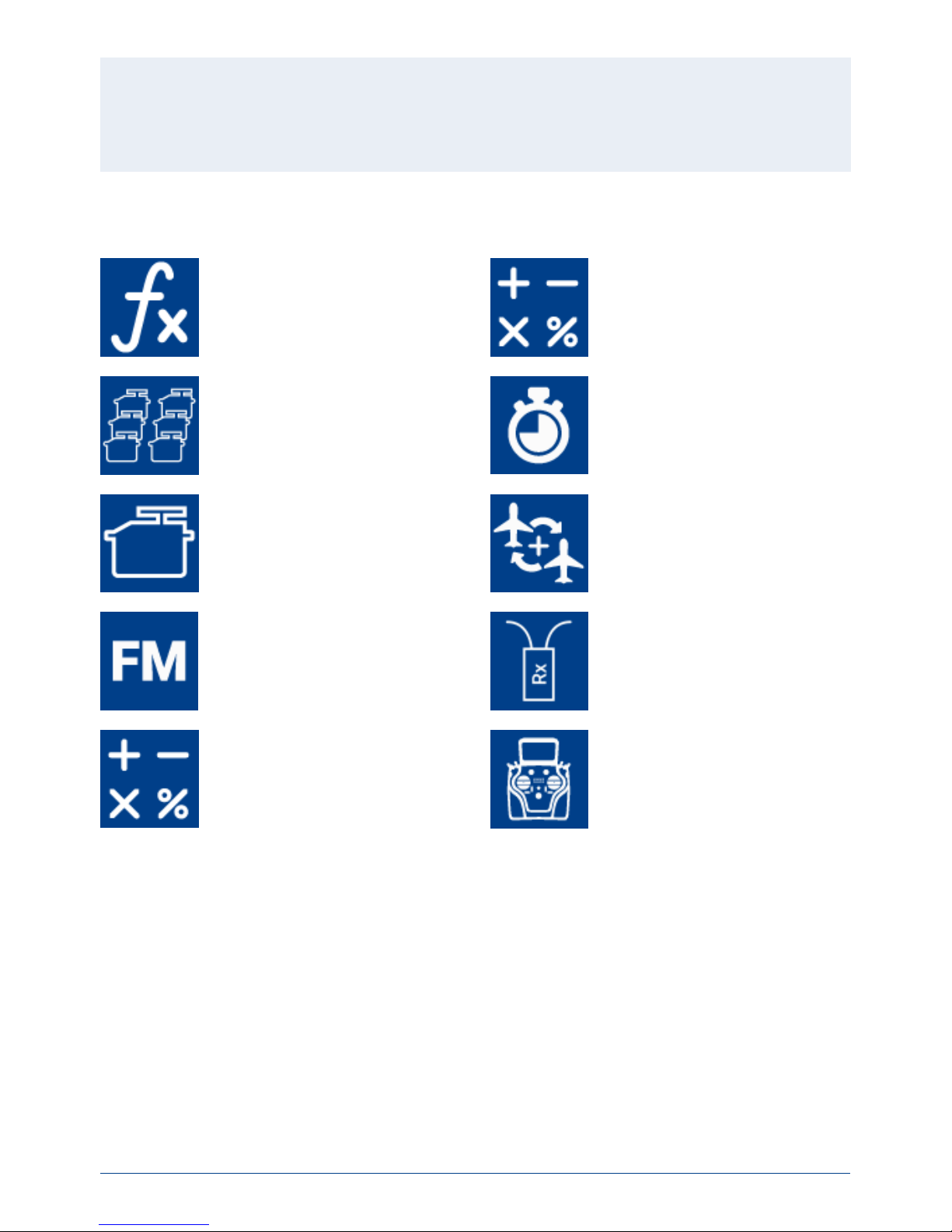

The symbols in the Main menu are arranged in order of importance.

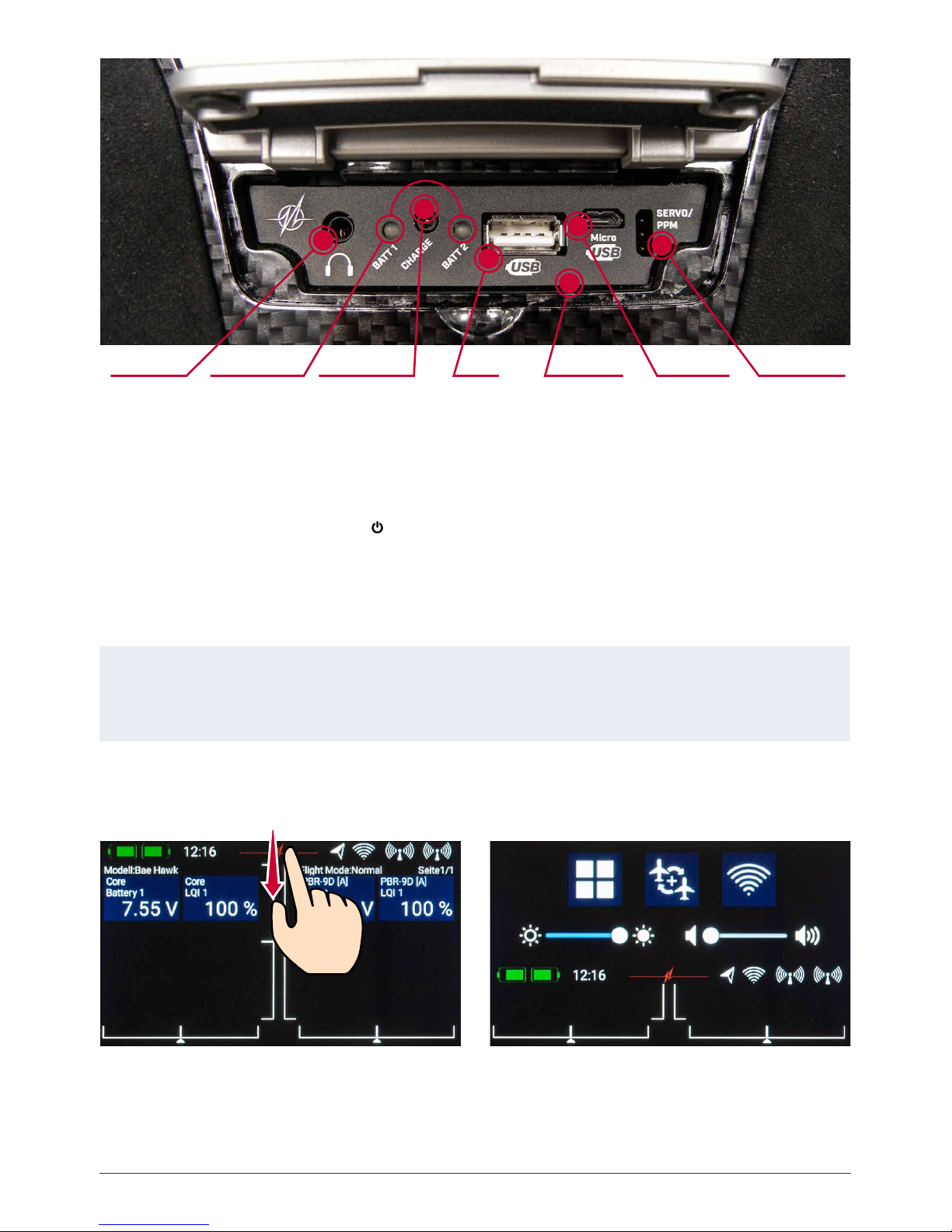

Headphone

socket

Charge status

LED

Charge socket

(10-16V)

USB-A

socket

Microphone

input

Micro USB

socket

Servo tester/

PPM output

www.powerbox-systems.com

5

Note: you can transfer any menu point to your own personal menu. This is accomplished simply by holding

your nger on the appropriate menu for a few seconds. When the “Person symbol” appears, the menu point is

transferred into your personal menu, which you can access conveniently using the quick-select button at the

bottom of the screen. If you wish to remove a menu point again, use the same procedure: keep your nger on

the menu symbol in question, and that entry is duly erased.

Functions

- Function overview

- Create or erase functions

Menu

Mixers

Servos

- Servo overview

- Create or erase functions

Timers

Servo monitor Model

- Model overview

- Load, copy or erase models

Flight modes Receiver

- Receiver overview

- Bind or remove receiver

- Range check

Virtual switches Settings

- System

- Screen

- Audio

6

PowerBox-Systems − World Leaders in RC Power Supply Systems

The Dimmer time setting determines the point at which the screen is automatically darkened. The automatic

screen lock can be released again using the

-button (quick-select button, bottom left).

d) Creating a model

Select the Model button in the Main menu, and you will see an overview of all models stored in the transmitter.

c) Settings

This menu point is used to set your personal preferences.

The System sub-menu is used to enter your name, set the time display format, select your preferred language,

display the software version and update the software when necessary. Another important point is the Calibration

menu; this is described in full at a later stage.

In the Screen sub-menu you can select the background colour and icon colour. The brightness control should be

set to a value which enables you to see the screen content clearly and distinctly.

Note: the ultra-bright TFT screen allows you to see everything clearly even in bright sunshine. However, the

screen brightness does have a perceptible effect on battery duration!

www.powerbox-systems.com

7

If you now leave the Select screen again, you will see

that the same transmitter control has also been assigned automatically to the right aileron.

The next step is to select the servo outputs to which you

intend to connect the aileron servos; this is accomplished by pressing +. Note that you can assign up to eight

servos to a single function.

If your model is an aerobatic aircraft, you would naturally select two or three servos at this point. At a later stage

you will be able to set the travel, direction of rotation and centre position for each servo separately.

If these parameters are too coarse for your application, you can set an individual curve with up to 33 points for

each servo.

Back in the Assignment screen it is also possible to rename the functions to suit your own preference.

If you decide to assign the wing aps at this point, you will learn to appreciate one of the truly unique features of

To create a new model, briey touch the + button at the

bottom of the screen. Assign a name to your model,

and conrm your choice with OK. You will now see the

Select screen for the model type.

At this point you can select the appropriate model type,

with the additional options of delta wing and V-tail.

On the next screen you select one of the ranges on the

right-hand side, e.g. Wing. The screen now shows a diagram of a wing corresponding to your chosen type. If

your conguration is more specialised, that presents no

problems: at a later stage you can very easily program

individual functions manually.

Here you will see the name of the function (e.g. Aileron

L), a transmitter control and a + symbol, which is used

to assign the appropriate number of servos. These individual Select points are inter-connected; the method

used for this will become self-evident in the course of

the set-up procedure.

Now you select a transmitter control which is to control

the left aileron; this will be the left or right primary stick,

depending on the transmitter mode you prefer.

Note: the software of the CORE has no modes – it

is only the mechanical settings of the transmitter

sticks which determines the stick mode.

8

PowerBox-Systems − World Leaders in RC Power Supply Systems

the CORE. As with the ailerons, you again assign a transmitter control to the aps. If each ap is operated by a

separate servo, you won’t notice anything unusual: you simply assign the aps to your preferred servo outputs.

However, if you also want the ailerons to double as aps, or want the ailerons to be mixed in to the aps, you

also assign the aileron outputs to the ap function. These functions are now superimposed, i.e. the mixing is

accomplished simply by assigning the servos.

At a later stage you can adjust the servos individually, both for the Aileron function and the Flap function. Servo

travel, centre and direction can be set separately for both functions!

An even clearer example of this exceptional feature relates to models with a delta wing. If you select a delta using

the Assistant, the correct functions are assigned automatically. To clarify this, the manual method would be as

follows:

As an example servos 1 and 5 are assigned to Aileron. Servos 1 and 5 are also assigned to Elevator. Since the

servos are installed in a mirror-image arrangement, it is logical that the servos always operate as ailerons, regardless of whether the pilot moves the elevator stick or the aileron stick. Now we switch to the Elevator function

and reverse the direction of rotation of one servo. The elevator function now works correctly, but the “reversed”

elevator function has no effect on the servo direction when an aileron command is applied, i.e. the ailerons still

work correctly. That’s all there is to setting up a “delta mixer”.

Back to our Wing screen: when all the assignments are complete, press the

-button amongst the quick-select

buttons at the bottom in order to return to the overview.

You can now continue assigning transmitter controls and servos to all the remaining functions. When everything

is nished, touch Continue at bottom right. The functions and servo assignments are complete.

3. FUNCTION MENU

You now arrive at the most important screen display:

the Function Overview. In principle, the set-up of the

whole model is carried out from this starting point. The

display is arranged logically from left to right:

Function Transmitter control Trim Setup

Failsafe Servo(s)

The individual points in detail:

A. Function

Each function always contains a transmitter control, the associated trim, the settings for the transmitter control

- such as Expo and Travel, Failsafe or Hold - and the assigned servos.

Each function can also be renamed just as you wish at this screen: simply touch the Function name.

B. Transmitter control

At this point you can assign a transmitter control or a

xed value to the function. A transmitter control may

be a primary stick, a proportional control, a switch or a

push-button.

www.powerbox-systems.com

9

C. Trim

a) Trim control

It is necessary to assign a trim control as the rst step

here. This can be one of the four trims located adja-

cent to the primary sticks, or two of the four rubberised

push-buttons. If you select the push-buttons, the buttons always work together left and right as the trim.

b) Trim mode

You can choose any of four different trim modes. The

standard one is Centre mode: in this mode any change to the trim only affects the central range, i.e. not the

end-points.

Alternative trim modes are Left and Right; typically these are intended for idle adjustment in the case of engines

and turbines.

The option of Offset trim mode also affects the end-points when the trims are adjusted.

c) Min./Max.

This menu point can be used to limit the permissible trim range. The percentage value determines the maximum

or minimum travel over which the trim is allowed to move.

d) Steps

Here you can set the number of trim steps or increments; not the size of the step.

Note: if you change the Min. / Max. values but leave the number of steps the same, the step size changes

accordingly.

D. Setup

At this point you can adjust the transmitter control input, Expo, transit time and curves.

a) Transmitter control rate

Here you can select a transmitter control which switches the rate on and off, or sets it to linear. The transmitter control can be any of the primary sticks, proportional

controls or switches.

b) Rate

The purpose of the Rate button is to adjust the travel of the transmitter control. If you select nothing for Trans-

mitter control rate, the value is xed. If you assign a transmitter control to Transmitter control rate, you can set

different values on three levels. The level initially selected with the transmitter control you have selected is shown

in green. If you select a proportional control as transmitter control, the values are applied in a linear fashion within

the three levels.

c) Transmitter control expo

At this point you can select a transmitter control which is used to switch an Expo characteristic, or set it to linear.

You can choose any transmitter control from the primary sticks, proportional controls or switches.

d) Expo

The purpose of the Expo button is to adjust the exponential factor. If you select nothing for Transmitter control

expo, the value is xed. If you assign a transmitter control to Transmitter control expo, you can use it to set diffe-

rent values on three levels. The level initially selected using the transmitter control you have selected is shown in

green. If you select a proportional control as transmitter control, the values are applied in a linear fashion within

the three levels.

10

PowerBox-Systems − World Leaders in RC Power Supply Systems

e) Curve editor

The curve editor is used to set up special curves.

- The rst step is to select the number of points: up to

33 can be specied.

- Use the arrow buttons to select the point which you

wish to move; the selected point changes colour to

green.

- Adjust the percentage value to shift the point up or

down.

- The Smooth option can be used to even out the curve,

and thereby avoid jerks in the servo’s response.

- Raw removes the effect of the curve smoothing.

- Reset curve resets the curve to linear travel.

f) Transit time

At this point you can set two transit times: one determines the servo transit time to the left, the other to the right.

The time in seconds determines how long the servo takes to move from one end-point to the other.

E. Hold /Failsafe

If you want a servo to take up a pre-determined position

in case of radio signal loss, you should select Failsafe

here. The Learn button now appears, enabling you to

store the current position in the receiver.

Note: the receiver or receivers do not need to be

bound at this point. The Failsafe positions are repeatedly transmitted to the receiving system.

F. Servo

Here you will nd the assigned servos again. Up to eight

servos can be assigned to each function. As already

mentioned in the Assistant, the travel and end-points

of each servo can be adjusted separately here. Any

adjustments you make to a servo at this point have no

inuence on the settings of the same servo if it is also

assigned to another function. This provides a simple

means of mixing in aircraft with multi-ap wings, delta

wings and V-tails.

- Servo number: indicates the receiver output at which this servo signal is present.

- Servo name: the servo name can be changed individually. Hold your nger on it to open up the keypad.

- Limit: works like a mechanical stop – the servo does not move beyond the set point.

- Travel: adjusts the servo travel.

- Centre: offsets the servo centre position. Acts like a “mechanical” centre offset – it also affects the end-points.

- Direction: reverses the direction of rotation of the servo.

- Curve editor: each servo can be adjusted very precisely to match the model’s mechanical arrangement by

means of a curve consisting of up to 33 points.

www.powerbox-systems.com

11

If you wish to adjust a servo’s travel or centre position, the rst step is to touch the appropriate button; you can

now adjust the value. As soon as you move the associated stick, the Select button shifts to the corresponding

position. This means that you do not need to select Left, Right and Centre when adjusting the control surface;

instead you select each point very conveniently using the transmitter stick, altering the position of the control

surface using the arrow buttons at the bottom of the screen. At the same time you can observe the effect of any

change directly on the servo.

4. BINDING A RECEIVER

Select the Receiver button from the Main menu. As you

will now see, up to four receivers can be bound to the

CORE simultaneously.

It is even possible to use different types of receiver; for

example, one PBR-9D and one PBR-5S can be bound.

All four receivers are of “equal value”, i.e. there is no

Master / Slave assignment, and no restrictions in terms

of telemetry. Telemetry sensors can be connected to all

four receivers, all of which send data to the CORE on an

equal footing.

The receivers are identied by the four capital letters A to D. The same letters appear in the telemetry data sent

from the receivers, helping to differentiate between them.

a) Binding

There are two methods of binding receivers:

1. Connect a power supply to the receiver, and it will respond by ashing green at high frequency for ten seconds.

Press the Bind button on your CORE transmitter, and the receiver now binds to it; the LED lights a continuous

green.

If you do not press the Bind button within the ten-second period, the LED switches to ashing slowly red – at

this point the receiver can no longer be bound to the transmitter. You can only re-start the process if you rst

disconnect the power supply.

2. Press the Bind button on your CORE, then connect the receiver to a power supply. The LED switches to conti-

nuous green once the receiver is bound.

Technical information: during the binding procedure the PowerBox CORE generates a random sequence

from a total of more than 32 million numbers; this is then used as the basis for calculating the hopping sequence and encoding the signal. The likelihood that two identical codes could be generated is therefore very

close to zero.

b) Remove

The Remove button has an important function: if you wish to uninstall a receiver from a model, it is essential to

remove that receiver from the model memory beforehand using this button. If you simply uninstall the receiver

without rst removing it at the transmitter, then the other bound receivers will not work when you next switch the

system on. This is an important safety feature, as it ensures that all the bound receivers are working when you

switch the system on, i.e. before you take off!

c) Range check

The range check function reduces the transmitter’s output power, thereby simulating a large distance between

transmitter and model. This enables you to determine any possible weaknesses in reception in the receivers.

In range check mode all the controls should work perfectly at a range of at least 50m. The range check switches

itself off automatically after 120 seconds.

12

PowerBox-Systems − World Leaders in RC Power Supply Systems

5. MIXER

The free servo mixers represent an additional method

of mixing functions with each other. Servo mixing by

servo assignment has already been described in the

Function menu, but this option also enables you to mix

functions with each other with a response curve.

You can create a new mixer by selecting the Mixer menu

and pressing +. You can also immediately rename the

Mixer to your own choice by touching the Mixer button.

Press the Setup button on the right in order to program

the mixer. The following display appears:

• From / To

The rst step is to select the source function under

From, and the target function under To .

• Transmitter control

At this point you should select a switch, stick or proportional control. You can then use it to activate the mixer,

switch the input to the three available levels (1-2-3), or

set it to linear response. The default entry here is On, which means that a xed mixer input is set.

• Input

The Input button is used to set the magnitude of the mixer. Selecting On at Transmitter control sets a xed value.

If you assign a switch or proportional control at Transmitter control, you can set different values on three levels;

the level selected by the transmitter control is shown in green. If you select a proportional control as transmitter

control, the values are applied in a linear fashion between the three levels.

• Curve editor

The curve editor enables you to set up special mixing curves.

- The rst step is to select the number of points: up to 33

points can be specied.

- Use the arrow buttons to select the point which you

wish to move; the selected point changes colour to

green.

- Adjust the percentage value to shift the point up or

down.

- The Smooth option can be used to even out the curve,

and thereby avoid jerks in the servo’s response.

- Raw removes the effect of the curve smoothing.

- Reset curve resets the curve to linear travel.

www.powerbox-systems.com

13

6. TELEMETRY

Once you have created a new model and bound one or

more receivers, you can display important information

on the main screen using the telemetry widgets.

To create a widget, touch an empty area of the main

screen, and you will see the following display:

You will now see twelve grey elds, together with a P+ button and a P- button. The P+ button can be used to

create additional pages, so that more telemetry widgets can be displayed. You can move to and fro between the

pages by swiping with your nger. The P- button is used to erase empty pages.

Touch one of the grey elds, and this screen display

appears:

You can select any of four different types of widget:

- Telemetry

- Servo values

- Timer

- Quick-select menu

Telemetry

This can be used to display all the sensors connected to

the P²BUS, and show the data they generate. This infor-

mation also includes the receiver and transmitter data.

If you select the Telemetry widget type, this screen display appears:

The left-hand column shows all the connected sensors, while the right-hand column shows all the values

which these sensors supply. The P²BUS is an in-house

development, and is capable of transmitting up to 255

sensors each with 32 individual values – and at a speed

of up to 800 values per second!

It is possible to set up each widget to display multip-

le sensor values, even from different sensors; these

values are then displayed in turn by the widget. This is

accomplished by selecting one or more sensor values

which you want your widget to display, then conrming

your choice with OK.

A list of the selected sensor values is displayed. You

can use the + button to select additional values from

another sensor.

At this screen display you can adjust the size of the widget using the Small, Medium and Large buttons. The

Erase widget function can be found at bottom left.

14

PowerBox-Systems − World Leaders in RC Power Supply Systems

The Rescan sensors button is required if you wish to connect new sensors while the system is operating.

Touching the button forces the system to re-collect all sensor information on the P²BUS. In principle, all sensor

information is collected automatically every time the system is switched on.

Technical information: the PowerBox CORE telemetry system and the P²BUS are designed in such a way

that each sensor supplies its own information, including sensor name, unit, number of sensor values, decimal

point, priority and other data. A new sensor designed for use with the P²BUS can be connected to the system

at any time without updating the transmitter.

The advantage of the system is that all the text information relating to the sensor values is collected only

when the system is switched on, i.e. when the system is booting.

Once the system is running, only the pure sensor values are transferred; this permits very fast data transmission with maximum exibility, and ensures a thoroughly user-friendly system.

Behind the individual sensor values you will nd the Alarm button. The Alarm menu allows you to set four alarm

thresholds: one yellow alarm and one red alarm for each direction. This enables you to select different thresholds

coupled to different sounds, text, or vibration modes.

For example, you might set up battery capacity alarms for an electric model: a yellow audible alarm when there

is just sufcient energy remaining for one minute of ight; a red audible alarm with vibration for twenty seconds.

Touching the Back button returns you to the Sensor overview. Press OK at the bottom when you have completed

all the settings.

The widget now appears in the location where you started, but widgets can also be placed in any position. This

is accomplished by holding your nger on the screen until the widgets start to icker; you can now move the

widgets around on the screen. To x the widgets in position again, simply wait a few seconds or press the Home

button.

Servo values, Timers, Quick-select menu

Widgets can also be set up for individual servo outputs, timers or menu entries, in exactly the same way as de-

scribed for telemetry values. The procedure is identical: hold your nger on a vacant space in the main screen,

then make your selection as already described.

7. CHARGING THE TRANSMITTER

If you wish to charge the CORE, the rst step is to open the front cover. Locate the two plugs attached to the

mains PSU, and insert either one into the charge socket. If the battery symbol is displayed large and ashing on

the screen, this means that you have a reserve for about 20 - 30 minutes. You must charge your CORE at this

point, if not sooner. For safety reasons the CORE does not feature a battery cut-off. Never allow the transmitter

to become deep-discharged!

The LEDs light up red when the batteries are on charge, and green when the charge process is complete. The

charger can be left connected to the CORE after charging without causing damage, as the internal charge control

circuits regulate the charge process completely automatically.

The battery charge process takes about 3.5 hours from the fully discharged state.

The CORE can also be recharged while it is switched on, e.g. for protracted programming work.

Note: in addition to the bar display at top left on the screen, you can also set up the transmitter to display

its own exact battery voltage on the main screen in the form of a telemetry widget, and set a corresponding

alarm. The transmitter is tted with two internal 7.2V Li-Ion batteries of 3400 mAh capacity. Sensible alarm

values would be 6.8V for an orange alarm, and 6.6V for a red alarm.

Note: the mains PSU is the same type used for PowerBox Batteries and PowerPaks, and can also be used

to recharge these batteries.

www.powerbox-systems.com

15

Caution: if you clean the handrests, it is essential to allow them to dry out completely before re-attaching

them to the transmitter, otherwise damp could enter the transmitter and cause corrosion damage!

Note: In the initial production run these functions are not yet implemented in full!

8. CONNECTIONS

Under the front cover you will nd additional sockets (see illustration on page 4):

- Headphone socket: stereo headphones can be plugged in here for spoken vario or telemetry messages.

- USB-A socket: this accepts a USB stick, which can be used to update the radio control system. Data from the

CORE can also be copied onto the USB stick.

- Micro USB socket: for direct exchange of data with a PC.

- Servo/PPM: servos plugged into this socket respond directly to the movements of the primary sticks. This can

be extremely useful for centring servos accurately before installation, or for subjecting them to a brief function

test. This output is protected with a 1A fuse, and is therefore not suitable for load-testing servos!

It is also possible to switch this socket to PPM output for use with ight simulators or Trainer (buddy-box) sys-

tems.

9. MECHANICAL TRANSMITTER ADJUSTMENTS

a) Removing the handrests

The handrests tted to the CORE can be removed quickly and easily: simply undo the four socket-head screws in

the feet, and the handrests can be slid down and off.

Note: Alcantara is not, as often supposed, natural leather, but a micro-bre material. Alcantara is incredibly

tough and durable, and is very easy to maintain. If your handrests become soiled, simply rinse them clean

using warm water and ordinary washing-up liquid.

16

PowerBox-Systems − World Leaders in RC Power Supply Systems

b) Opening the transmitter

As standard the CORE is supplied in the correct mode, as specied by the customer, but some users may nd

that the centring spring tension or the ratchet function needs to be adjusted to meet their personal preferences.

The rst step is to remove the handrests. Lay the CORE on a soft surface – ideally a thick layer of foam. Now

undo and remove all ten socket-head screws holding the back cover. Don’t remove the back cover yet, as the

cables for the switches and proportional controls in the cover must rst be disconnected.

This is the procedure: raise one side of the back cover slightly, and loosen the connectors by moving them to left

and right whilst pulling gently, then repeat the process on the other side.

The back cover is now free, and can be lifted off. You will see the transmitter’s internal features:

www.powerbox-systems.com

17

c) Adjusting the tension of the primary stick centring springs

The centring spring tension can be adjusted using screws 1 and 2 after loosening the corresponding locknuts.

Tightening the screw further increases the spring tension. If you nd it impossible to set your preferred spring

tension, we can supply a range of stronger springs.

d) Adjusting the throttle ratchet and brake

The hardness of the throttle ratchet can be adjusted using screw 3. Screw 4 adjusts the friction brake.

e) Adjusting the throttle travel

The travel of the throttle stick on the CORE is adjustable. This is useful for 3D pilots in particular, as it enables

them to set a mechanical limit on throttle travel. Adjustment is carried out by tightening screws 5. The throttle

travel can also be set up asymmetrically. Once you have set the travel of the throttle stick to meet your require-

ments, it is essential to re-calibrate that function.

f) Switching modes

As already mentioned, the software has no modes, but naturally the hardware must correspond to your preferred

mode.

If you wish to change the factory default mode, rst undo screws 6 from the ratchet plate, then install the ratchet

plate on the other primary stick unit, as an exact mirror-image of the original installation. Tighten the retaining

screws, pressing the plate towards the centre of the transmitter.

The next step is to re-install the spring blocker (8): remove screw 7. The screw with the locknut can immediately

be installed again on the other side.

To re-install the spring blocker, move the stick fully to its end-point, t the spring blocker pin under the spring lever,

then tighten the spring blocker screw.

Note: if you tighten the screw too far, you may nd that the lower spring tensioner partially moves out of its

guide. You can correct this by moving the stick fully to one side, at the same time pressing the spring tensioner back into its guide using a small screwdriver.

6

5

4 3

1

2 / 7

8

18

PowerBox-Systems − World Leaders in RC Power Supply Systems

10. CALIBRATING THE TRANSMITTER CONTROLS

Naturally the PowerBox CORE is supplied with all functions correctly calibrated. However, if you wish to swap

a switch or replace a broken switch, we recommend

that you re-calibrate the new switch. Re-calibration is

also necessary if, for example, you limit the throttle stick

travel, or change the transmitter mode mechanically.

Move to the Calibration menu by this route: Settings

System Calibration. Move the transmitter control you

wish to calibrate in order to select it. The information

relating to this transmitter control is now superimposed

on the right.

For example, if you wish to change from a 3-position switch to a 2-position switch, select the appropriate switch

type in the Type eld. Once you have done this, touch Calibration at the bottom, then move the control to both

end-points. The Continue eld now appears. If you have installed a proportional control or a 3-position switch,

you also need to move the transmitter control to the centre. Touch Finished to complete the process.

The Direct button can be used to reverse the transmitter control’s direction of operation.

Caution: this has the same effect as installing the switch the other way round, i.e. this change affects all

models!

11. SPECIFICATION

Power supply Li-Ion

Channels 26

Servo signal resolution 4096 Bit

Screen TFT - Touch

Weight 1152g

Temperature range -30°C to +85°C

12. SET CONTENTS

- PowerBox CORE

- 1x PBR-9D

- 2x PBR-8E (limited Early bird edition only)

- Case

- Transmitter neckstrap

www.powerbox-systems.com

19

13. SERVICE NOTE

We are anxious to offer good service to our customers, and to this end we have set up a Support Forum which

deals with all queries concerning our products. This relieves us of a great deal of work, as it eliminates the need

to answer frequently asked questions time and again. At the same time it gives you the opportunity to obtain help

quickly - all round the clock and even at weekends. All the answers are provided by the PowerBox team, which

guarantees that the information is correct.

Please use the Support Forum before you telephone us.

You can nd the forum at the following address:

www.forum.powerbox-systems.com

14. GUARANTEE CONDITIONS

At PowerBox-Systems we insist on the highest possible quality standards in the development and manufacture

of our products. They are guaranteed “Made in Germany”!

That is why we are able to guarantee the PowerBox CORE for a period of 36 months from the initial date of

purchase. The guarantee covers proven material faults, which will be corrected by us at no charge to you. As a

precautionary measure, we are obliged to point out that we reserve the right to replace the unit if we deem the

repair to be economically unviable.

Repairs which our Service department carries out for you do not extend the original guarantee period.

The guarantee does not cover damage caused by incorrect usage, e.g. reverse polarity, excessive vibration,

excessive voltage, damp, fuel, short-circuits, etc. The same applies to defects due to very severe wear. We accept

no liability for further claims, e.g. consequential damage.

We also deny liability arising from the equipment or the use of the same.

We accept no liability for transit damage or loss of your shipment. If you wish to make a claim under guarantee,

please send the equipment to our Service department address, together with proof of purchase and a description

of the defect.

15. LIABILITY EXCLUSION

We are not in a position to ensure that you observe our instructions regarding installation of the PowerBox CORE,

full the recommended conditions when using the set, or maintain the entire radio control system competently.

For this reason we accept no liability for loss, damage or costs which arise due to the use or operation of the

PowerBox CORE, or which are connected with such use in any way. Regardless of the legal arguments employed,

our obligation to pay compensation is limited to the invoice total of our products which were involved in the event,

insofar as this is deemed legally permissible.

We wish you every success with your new PowerBox CORE!

Donauwoerth, December 2018

PowerBox-Systems GmbH

certied according to DIN EN ISO 9001

Ludwig-Auer-Straße 5

D-86609 Donauwoerth

Germany

+49-906-99 99 9-200

+49-906-99 99 9-209

www.powerbox-systems.com

12/2018

Loading...

Loading...