PowerBoss T82, T82 Europe User Manual

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 1

User Manual

Commander T Series

Models: T82, T82 Europe,

Gasoline, LP & Diesel

PowerBoss, Inc.

A Member Of The Hako Group

PB# 4100032 Rev. C 01/17

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 2

PREFACE

Thank you for your purchase of the now industry standard for sweepers. PowerBoss takes great pride in off ering the most

dependable, reliable and best value in industrial power sweepers and sweeper / scrubbers. We set the standard.

Our Publishing Department would like to hear from you. If you see any errors, omissions or something that needs

clarifi cation in this User Manual please let us know. We are working hard toward perfection in our corner of the process to

bring you the best you can buy. Please copy the form below, fi ll out and comment on how you found our catalog.

Thank you.

*Name______________________________________________________________________

*Title: ______________________________________________________________________

*Company Name: _____________________________________________________________

*Address: ____________________________________________________________________

*Country: ____________________________________________________________________

Type of equipment or model number: ______________________________________________

PREFACE

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 3

Comments:

*Information is optional.

Please return to:

Manager, Customer Service

PowerBoss, Inc.

14N845 U.S. Route 20

Pingree Grove, Illinois 60140 USA

Phone (800) 323-9420

E-Mail - tech@powerboss.com

This is the User Manual for the PowerBoss Commander T Series Sweeper Scrubber.

PREFACE

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 4

This manual covers all Standard Commander T Series machine variations beginning May 2009.

We believe this machine will provide excellent service for many years.

However, the best results will be obtained if:

• The machine is operated with reasonable care.

• The machine is maintained regularly per the maintenance schedule provided in the User Manual.

• The machine is maintained with PowerBoss Inc. supplied or equivalent parts.

All right side and left side references to the machine (except for engine) are determined by facing the direction of forward

travel. The front of the engine or engine fan faces the rear of the machine. Some hardware considered to be common or

locally available has been omitted from the parts section to make this manual clear. Be sure to use equivalent hardware

when replacement becomes necessary.

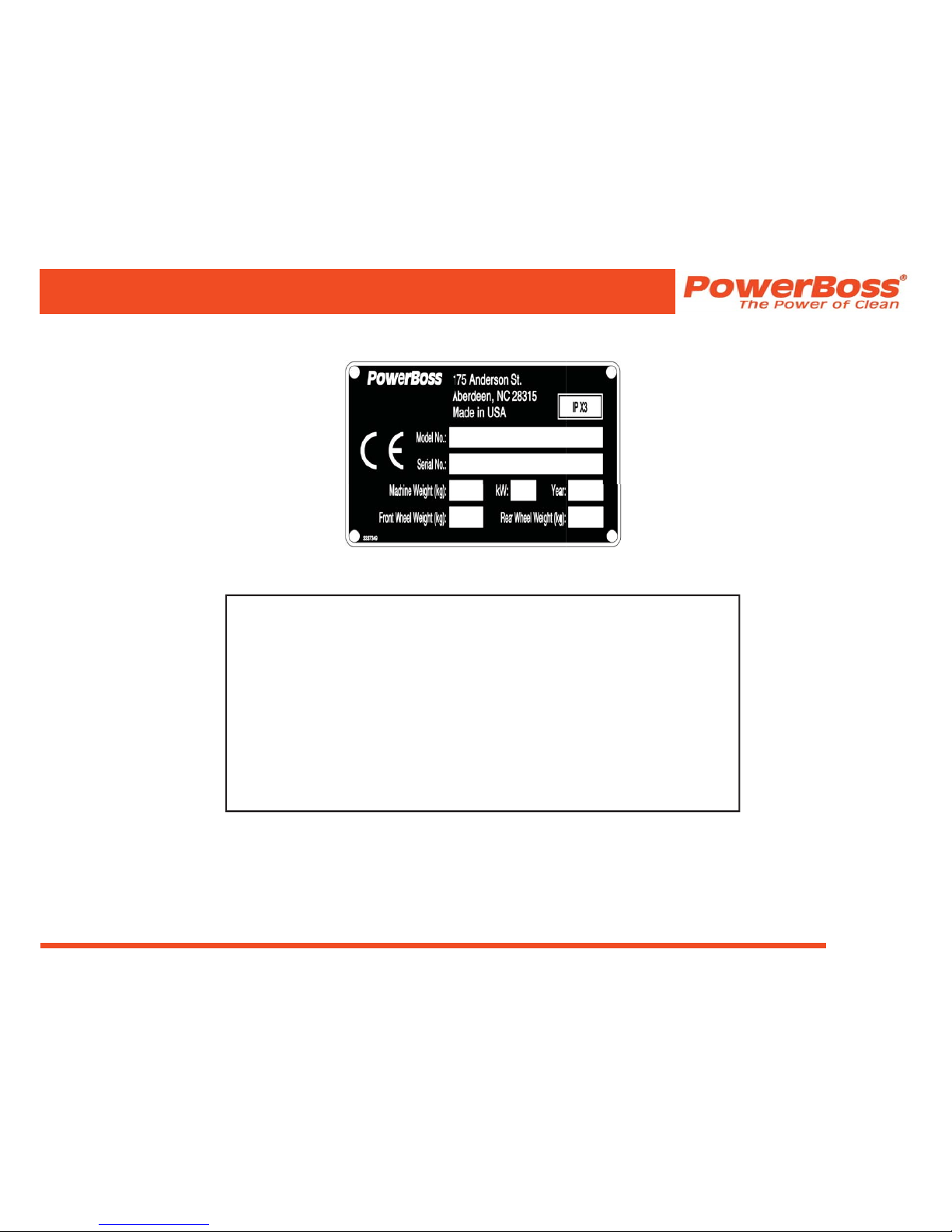

The Model and Serial Number of your machine is shown on the I.D. name plate. This information is needed when

contacting Technical Support or when ordering parts. The I.D. plate is mounted on the console of the machine left of the

operator and adjacent the main broom adjustment access door.

Parts may be ordered by phone,fax or e-mail from any PowerBoss parts and service center. Before ordering parts or

supplies, be sure to have your machine model number and serial number handy. For your convenience Fill out the data

block below for future reference.

PREFACE

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 5

Example I.D Plate;

MACHINE DATA

Fill out at installation

Serial Number: ___________________________________

Engine Serial Number: ____________________________

Sales Rep.: ______________________________________

Date of Install: ___________________________________

All information contained in this catalog is current at the time of printing However, PowerBoss reserves the right to make

changes at any time without notice.

PowerBoss, Inc., Printed in USA

PREFACE

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 6

TECHNICAL SPECIFICATIONS

Model Commander T Series

Model No. TSS82KDSL / TSS82KGAS / TSS82KLPG / TSS82KDSLCE / TSS82KLPCE

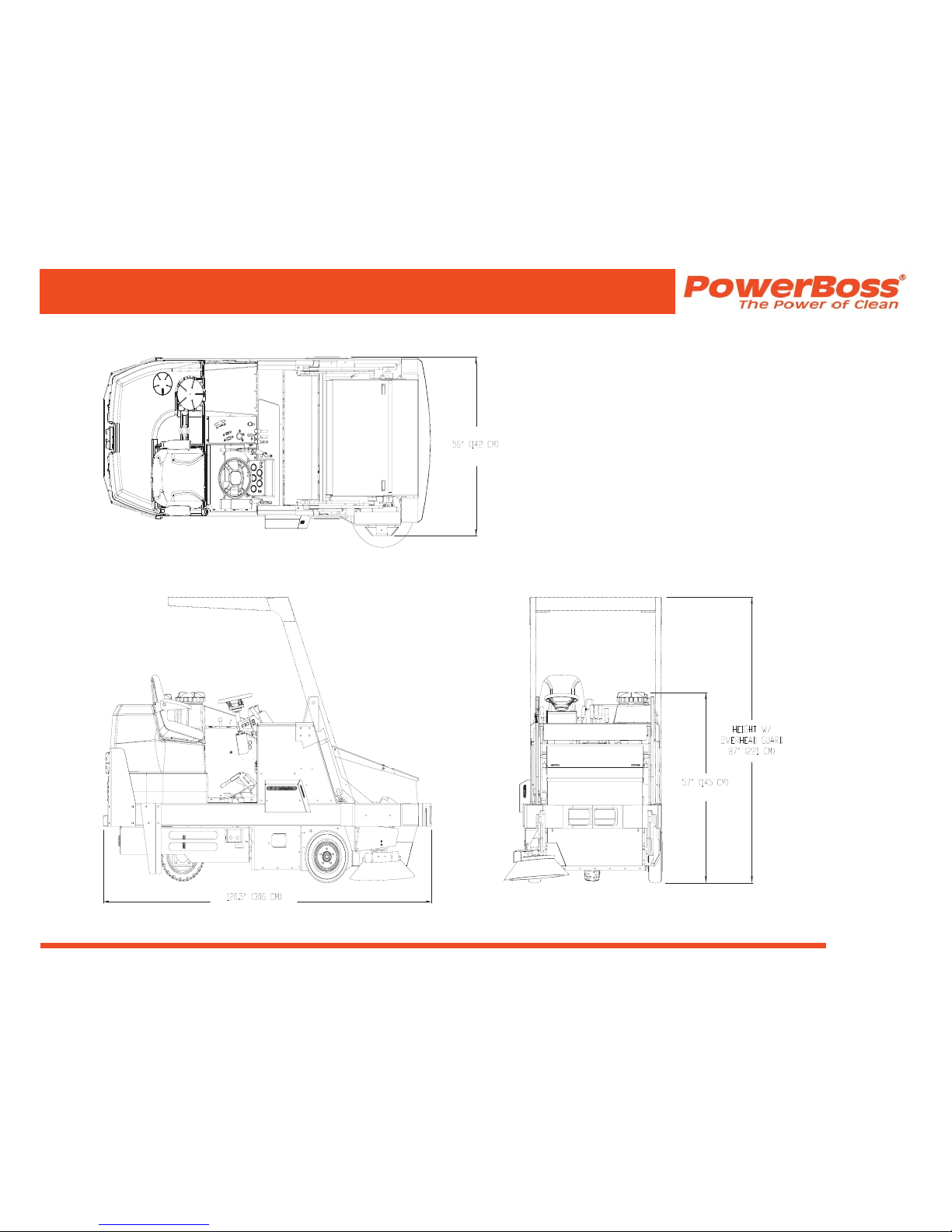

DIMENSIONS & WEIGHT

T82 & T82 Europe

Length . . . . . . . . . . . . . . . . . . . 120.5 inches (306 cm)

Width . . . . . . . . . . . . . . . . . . . . 56 inch (142 cm)

Height . . . . . . . . . . . . . . . . . . . 57 inch (145 cm)

Height w/ overhead guard . . . 87 inch (221 cm)

Height w/ cab. . . . . . . . . . . . . . 83.5 inch (212 cm)

Weight . . . . . . . . . . . . . . . . . . 2900 lbs (1315 kg)

Minimum U-turn. . . . . . . . . . . . 120 inch (305 cm)

SCRUBBING SYSTEM

Scrub path . . . . . . . . . . . . . . . . 42 inch (107 cm)

Scrub deck pressure . . . . . . . . 300 lbs (136 kg)

Brush speed . . . . . . . . . . . . . . 250 rpm

Solution tank capacity . . . . . . . 68 gal (257 L)

Recovery tank capacity . . . . . . 65 gal (246 L)

Squeegee width. . . . . . . . . . . . 50 inch (127 cm)

TECHNICAL SPECIFICATIONS

SWEEPING SYSTEM

T82 & T82 Europe

Sweep path . . . . . . . . . . . . . . . 54 inch (137 cm)

Main broom . . . . . . . . . . . . . . . 42 inch (107 cm)

Side broom . . . . . . . . . . . . . . . 24 inch (61 cm)

Hopper type. . . . . . . . . . . . . . . high dump

Hopper volume . . . . . . . . . . . . 14 cu ft

Hopper load capacity. . . . . . . . 1000 lbs (454 kg)

Dust control . . . . . . . . . . . . . . . 100 sq ft

High dump . . . . . . . . . . . . . . . 60 inch (152 cm)

RTR (rotary trash relocation). . yes

OTHER SPECIFICATIONS

T82 & T82 Europe

Noise Level . . . . . . . . . . . . . . . 84.5 dBA

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 7

TECHNICAL SPECIFICATIONS

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 8

CE DECLARATION OF CONFORMITY

Commander T82

DECLARATION OF CONFORMITY

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 9

DECLARATION OF CONFORMITY

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 10

TABLE OF CONTENTS

PREFACE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TECHNICAL SPECIFICATIONS . . . . . . . . . . . 6

DIMENSIONS & WEIGHT . . . . . . . . . . . . . . . . . . . . . . . 6

SCRUBBING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . 6

CE DECLARATION OF CONFORMITY . . . . . 8

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

AIR-MOVING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . 16

ERGONOMICS SYSTEM . . . . . . . . . . . . . . . . . . . . . . . 16

DEBRIS-HANDLING SYSTEM. . . . . . . . . . . . . . . . . . . 16

DRIVE-TRAIN SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . 16

CHASSIS SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

ENVIRONMENTAL FRIENDLY FEATURES . . . . . . . . 17

WATER CONSERVATION . . . . . . . . . . . . . . . . . . . 17

CLEAN AIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LOWER EMISSIONS . . . . . . . . . . . . . . . . . . . . . . . . 17

SAFER WORK ENVIRONMENT. . . . . . . . . . . . . . . 17

CLEAN ENERGY . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

CLEAN ENERGY . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SAFETY INFORMATION . . . . . . . . . . . . . . . . . 18

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . 18

FOR SAFETY DURING OPERATION . . . . . . . . . . . . . 18

FOR SAFETY WHEN SERVICING OR MAINTAINING

MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SAFETY SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

BASIC POWERBOSS® SAFETY . . . . . . . . . . 23

MACHINE OPERATION . . . . . . . . . . . . . . . . . . 26

BASIC OPERATING CONTROLS AND INDICATORS 26

IGNITION SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . 26

HORN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

LIGHT SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

HOUR METER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

ENGINE COOLANT TEMPERATURE GAUGE 26

ENGINE OIL PRESSURE . . . . . . . . . . . . . . . . . . . . 26

VOLTMETER AMP GAUGE. . . . . . . . . . . . . . . . . . . 26

FUEL LEVEL GAUGE . . . . . . . . . . . . . . . . . . . . . . . 26

THROTTLE (DIESEL) . . . . . . . . . . . . . . . . . . . . . . . 27

GLOW PLUG BUTTON (DIESEL ONLY) . . . . . . . . 27

TABLE OF CONTENTS

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 11

MURPHY SWITCH (DIESEL ONLY) . . . . . . . . . . . . 27

SEAT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . 27

PARKING BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . 27

BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

THROTTLE (GAS AND LP) . . . . . . . . . . . . . . . . . . . 29

CHECK ENGINE INDICATOR (GAS AND LP

ONLY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SWEEPING / SCRUBBING CONTROLS AND

INDICATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

BROOM CONTROL LEVER . . . . . . . . . . . . . . . . . . 31

MAIN BROOM HANDLE . . . . . . . . . . . . . . . . . . . . . 31

SIDE BROOM HANDLE. . . . . . . . . . . . . . . . . . . . . . 31

SCRUB HEAD SWITCH . . . . . . . . . . . . . . . . . . . . . 33

SCRUB DECK GAUGE . . . . . . . . . . . . . . . . . . . . . . 33

IMPELLER LEVER. . . . . . . . . . . . . . . . . . . . . . . . . . 33

IMPELLER STOP CONTROL . . . . . . . . . . . . . . . . . 33

SQUEEGEE SWITCH . . . . . . . . . . . . . . . . . . . . . . . 33

SOLUTION LEVER . . . . . . . . . . . . . . . . . . . . . . . . . 33

SOLUTION TANK EMPTY INDICATOR . . . . . . . . . 33

RECOVERY TANK FULL INDICATOR . . . . . . . . . . 33

DEBRIS HOPPER DUMP CONTROLS . . . . . . . . . . . . 35

HIGH DUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Lever 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Lever 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

HOPPER UNLOCK BUTTON . . . . . . . . . . . . . . . . . 35

ROTARY TRASH RELOCATOR (RTR™) . . . . . . . . 35

HOPPER FILTER SHAKER BUTTON . . . . . . . . . . 35

FIRE IN THE HOPPER INDICATOR (OPTIONAL) 35

CLOGGED FILTER INDICATOR (OPTIONAL) 36

OPTIONAL CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . 37

WATER RECYCLING . . . . . . . . . . . . . . . . . . . . . . . . 37

Cleaning solution control knob . . . . . . . . . . . . . . . 37

Pump 1 switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Pump 2 switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

OPERATING THE WATER RECYCLING SYSTEM 37

TABLE OF CONTENTS

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 12

OPERATING PROCEDURES . . . . . . . . . . . . . . . . . . . . 39

PRE-OPERATION CHECKS . . . . . . . . . . . . . . . . . . 39

STARTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Gasoline or LP Power Units . . . . . . . . . . . . . . . . . 39

Diesel Power Units . . . . . . . . . . . . . . . . . . . . . . . . 40

TRAVELING FORWARD OR BACKWARDS . . . . . 40

Forward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SLOWING AND STOPPING . . . . . . . . . . . . . . . . . . 40

SWEEPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

EMPTYING THE HOPPER WITH HIGH DUMP

FEATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

USING THE ROTARY TRASH RELOCATOR

(RTR™) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

TO SHAKE THE FILTER . . . . . . . . . . . . . . . . . . . . . 44

FIRE IN THE HOPPER . . . . . . . . . . . . . . . . . . . . . . 44

SCRUBBING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Operating the Scrub Brushes . . . . . . . . . . . . . . . . 45

Starting Solution Flow . . . . . . . . . . . . . . . . . . 45

Lower The Squeegee . . . . . . . . . . . . . . . . . . . 45

FILLING THE SOLUTION TANK. . . . . . . . . . . . . . . 46

DRAINING THE RECOVERY TANK . . . . . . . . . . . . 47

CLEANING THE RECOVERY TANK . . . . . . . . . . . 47

SQUEEGEE WAND (OPTION) . . . . . . . . . . . . . . . . 48

BLOWER (OPTION). . . . . . . . . . . . . . . . . . . . . . . . . 49

TRANSPORTING THE MACHINE . . . . . . . . . . . . . 49

Using a Trailer or Transport Vehicle . . . . . . . . . . . 49

Pushing the Machine . . . . . . . . . . . . . . . . . . . . . . 49

PREVENTATIVE MAINTENANCE. . . . . . . . . . 50

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

SCHEDULED MAINTENANCE CHART . . . . . . . . . . . 51

PREVENTATIVE MAINTENANCE INSTRUCTIONS 55

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Air Intake System . . . . . . . . . . . . . . . . . . . . . . . . . 55

Check Air Filter Service Indicator . . . . . . . . . . 55

Air Filter Element Removal. . . . . . . . . . . . . . . 56

Air Filter Cleaning. . . . . . . . . . . . . . . . . . . . . . 57

Air Filter Inspection. . . . . . . . . . . . . . . . . . . . . 57

Air Filter Installation . . . . . . . . . . . . . . . . . . . . 57

TABLE OF CONTENTS

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 13

ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . 58

Battery Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . 58

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . 58

Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

COOLANT SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . 61

Blowing Out Radiator Fins . . . . . . . . . . . . . . . . . . 61

Reverse Flow Flushing. . . . . . . . . . . . . . . . . . . . . 61

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Changing Engine Oil . . . . . . . . . . . . . . . . . . . . . . 62

LUBRICATION POINTS . . . . . . . . . . . . . . . . . . . . . 62

Steering Fork Assembly and Steering Link Ball

Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Steering Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . 63

Latches & Hinges . . . . . . . . . . . . . . . . . . . . . . . . . 63

Hopper Lift Arm Mounts . . . . . . . . . . . . . . . . . . . . 63

HYDRAULICS SYSTEM. . . . . . . . . . . . . . . . . . . . . 65

Filling The Fluid Reservoir . . . . . . . . . . . . . . . . . . 65

Hydraulic Fluid Viscosity Specifi cations . . . . . 65

Maintaining Hydraulic Oil Cooler Effi ciency . . . . . 65

Changing The Hydraulic Fluid . . . . . . . . . . . . . . . 65

Changing The Hydraulic Fluid Filter. . . . . . . . . . . 66

SWEEP COMPONENTS . . . . . . . . . . . . . . . . . . . . . 67

Broom Door Flap Inspection . . . . . . . . . . . . . . . . 67

Broom Door Flap Replacement and Adjustment 67

Main Broom Pattern Check . . . . . . . . . . . . . . . . . 68

Main Broom Height Adjustment . . . . . . . . . . . . . . 69

Main Broom Taper Adjustment . . . . . . . . . . . . . . . 70

Main Broom Replacement . . . . . . . . . . . . . . . . . . 71

Side Broom Angle Adjustment . . . . . . . . . . . . . . . 72

Side Broom Height (Wear) Adjustment . . . . . . . . 73

Side Broom Lift Cable Adjustment . . . . . . . . . 74

Side Broom Replacement . . . . . . . . . . . . . . . . . . 74

TABLE OF CONTENTS

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 14

SCRUB & WATER PICK-UP COMPONENTS . . . . 75

Scrub Brush Replacement . . . . . . . . . . . . . . . . . . 75

Scrubhead Gauge Adjustment . . . . . . . . . . . . . . . 75

Scrubhead Adjustment. . . . . . . . . . . . . . . . . . . . . 76

MAIN SQUEEGEE COMPONENTS . . . . . . . . . . . . 78

Checking and Adjusting the Rear Main Squeegee

Flare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Turning or Replacing the Rear Squeegee Blade 79

Main Squeegee Tool Removal . . . . . . . . . . . . . . . 80

Main Squeegee Tool Installation . . . . . . . . . . . . . 80

Inner Squeegee Replacement . . . . . . . . . . . . . . . 80

Auto Squeegee Lift Mechanism . . . . . . . . . . . . . . 80

HOPPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Hopper Filter Removal . . . . . . . . . . . . . . . . . . . . . 81

Hopper Filter Cleaning . . . . . . . . . . . . . . . . . . . . . 82

Hopper Filter Replacement . . . . . . . . . . . . . . . . . 82

Flap Replacement . . . . . . . . . . . . . . . . . . . . . . . . 83

Frame Seal Replacement . . . . . . . . . . . . . . . . . . 83

Front Frame Seal . . . . . . . . . . . . . . . . . . . . . . 83

Side Frame Seal. . . . . . . . . . . . . . . . . . . . . . . 83

Floor Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Vacuum Gasket Mount Adjustment . . . . . . . . . . . 85

PARKING BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Adjusting The Parking Brake Cable Length . . . . . 86

Cable Adjustment for Standard brake . . . . . . . . . 86

CHANGING SOLID TIRES . . . . . . . . . . . . . . . . . . . 87

Front Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Rear Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

MISCELLANEOUS ADJUSTMENTS . . . . . . . . . . . 87

Anti-Static Chain Adjustment . . . . . . . . . . . . . . . . 87

Latch and Hinge Maintenance . . . . . . . . . . . . . . . 87

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . 88

TROUBLESHOOTING CHART . . . . . . . . . . . . . . . . . . 88

TABLE OF CONTENTS

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 15

NOTES

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 16

FEATURES

AIR-MOVING SYSTEM

• Dual-phase dust fi ltration

• Built-in pre-fi ltering & ultra-fi ne screen panel fi lters for

dust control

• Aggressive electric fi lter shakers

• Shock-mounted hydraulic impeller

• Engine area shielded from exhaust air

• Dust Control Filter: 100 Sq. Ft. total

• Timed Electric Filter Shakers

• Clogged Filter Indicator

• Fire-in-hopper Indicator

ERGONOMICS SYSTEM

• Roomy, open cockpit with extra comfort

• Adjustable, high-back seat with arm rests

• Power steering

• Comfortable pedal/controls placement

• Full instrumentation for all functions

DEBRIS-HANDLING SYSTEM

• Direct throw sweeping method

• Oversized hopper with RTR®

• Quick-change, fl oating 48” main broom & retractable

side brooms

• Dual-performance sweep mode

• Multi-Level Hopper Dumping

DRIVE-TRAIN SYSTEM

• Industrial liquid-cooled engine

• Heavy-duty radiator & Tri-phase air cleaner

• Hydraulics protection package

• 4-Core Radiator

• Industrial smooth ride tires for traction and reliability

CHASSIS SYSTEM

• Massive One-Piece, unitized steel frame

FEATURES

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 17

FEATURES

ENVIRONMENTAL FRIENDLY FEATURES

WATER CONSERVATION

Aqua-Stop saves water usage by 50%, water is released

through a pump system providing greater control of water

usage than gravity systems

CLEAN AIR

High-performance fi lter system dramatically reduces the

release of dust and debris back into the air, dust vacuum

ensures that dust is put directly into the hopper, bristle

pattern on main broom increases dust control.

LOWER EMISSIONS

All gas and LP engines meet Tier 2 specifi cations, catalyst

muffl ers, battery operated available, diesel operated

available, bio-diesel fuel can be used in Kubota engine

SAFER WORK ENVIRONMENT

Orange machines are highly visible to others in the

workplace, simple controls reduce operator error, onebutton scrub, horn, fi re in hopper indicator, eff ective braking

system, “belly bar” prevents operator from being pinned

behind machine when in reverse, parabolic squeegee picks

up all water leaving the scrub path virtually dry for traffi c,

seat equipped with safety shut-off switch, also available:

overhead guard, back-up alarm, warning beacon

CLEAN ENERGY

Bio-diesel fuel can be used in Kubota engines

CLEAN ENERGY

Aqua-Stop saves chemical usage by 50%, pump system

for water and chemical release allows for better control of

chemical usage, chemical metering system is available

as an option and regulates chemical usage to the correct

dose.

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 18

SAFETY INFORMATION

IMPORTANT SAFETY INSTRUCTIONS

Operators must read and understand this manual before

operating or maintaining this machine.

Do not operate this machine in fl ammable or explosive

areas.

This machine is designed solely for removing dirt,

dust and debris in an outdoor or indoor environment.

PowerBoss does not recommend using this machine in

any other capacity.

The following information below may cause a potential

hazard to the operator and equipment. Read this manual

carefully and be aware when these conditions can

exist. Take necessary steps to locate all safety devices

on the machine and train the personnel operating the

machine. Report any machine damage or faulty operation

immediately. Do not use machine if it is not in proper

operating condition.

FOR SAFETY DURING OPERATION

Keep hands and feet clear of moving parts while machine is in

operation.

Make sure all safety devices are in place and operate properly.

All covers, doors and latches must be closed and fastened before

use.

During operation, attention should be paid to other persons in the

work area and especially if small children are present.

Components can cause an explosion when operated near

explosive materials or vapor. Do not operate this machine near

fl ammable materials such as solvents, thinners, fuels, grain dust,

etc.

Store or park this machine on a level surface only. To prevent

unauthorized use, machine should be stored or parked with the

key removed.

This machine is designed for level operation only. Do not operate

on ramps or inclines greater than 2%.

This machine is not suitable for picking up hazardous dusts.

Use caution when moving this machine into areas that are below

freezing temperatures.

SAFETY INFORMATION

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 19

FOR SAFETY WHEN SERVICING OR

MAINTAINING MACHINE

Stop on level surface.

Disconnect the power to the machine when servicing.

Avoid moving parts. Do not wear loose jackets, shirts, or

sleeves when working on machine.

Avoid contact with battery acid. Battery acid can cause

burns. When working on or around batteries, wear

protective clothing and safety glasses. Remove metal

jewelry. Do not lay tools or metal objects on top of battery.

Authorized personnel must perform repairs and

maintenance. Use PowerBoss supplied replacement parts.

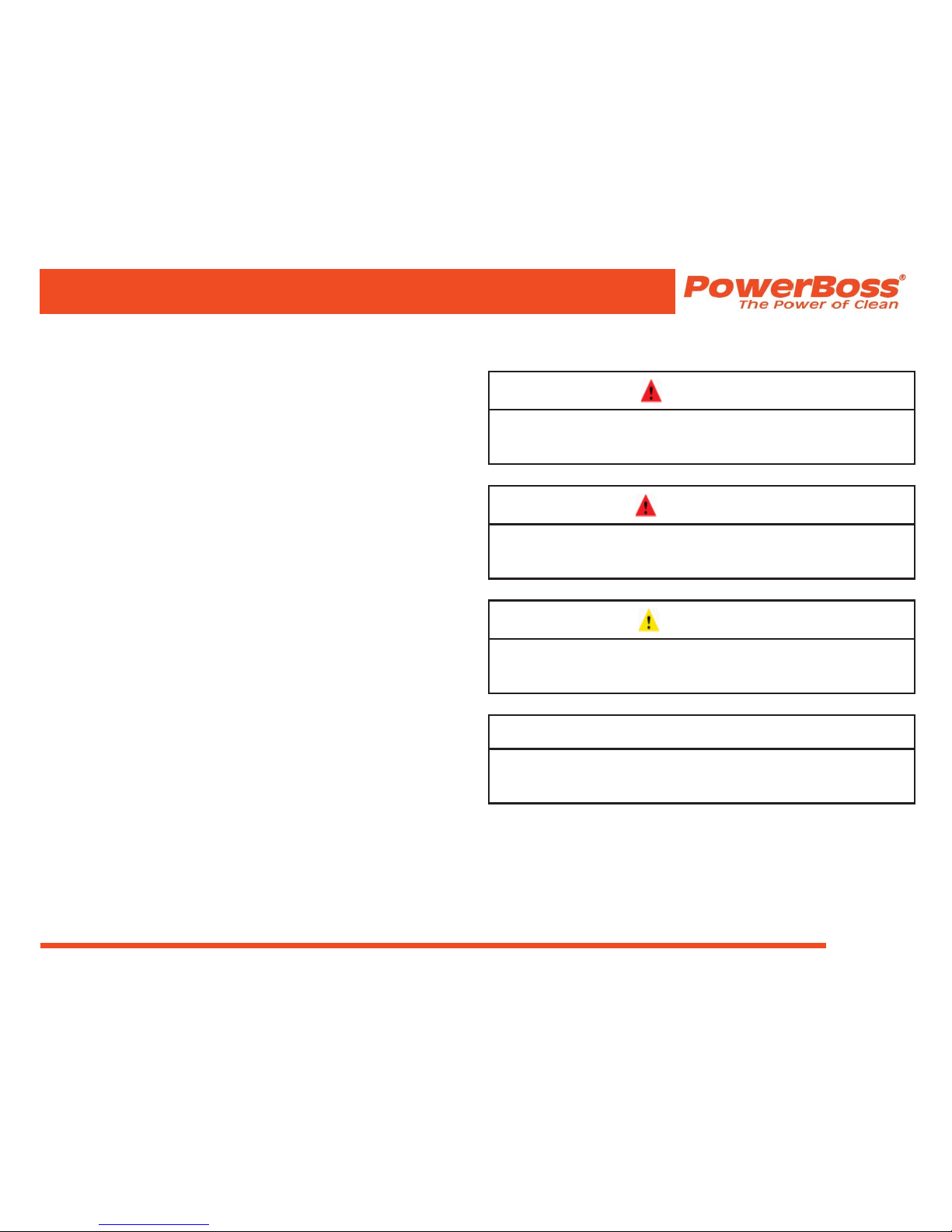

SAFETY SYMBOLS

Five symbols are used throughout this manual to

emphasize various levels of safety information. These

symbols and the meaning of each are listed below.

DANGER

To warn of immediate hazards which will result in

severe personal injury or death

WARNING

To warn of hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION

To warn of hazards or unsafe practices which

could result in minor personal injury.

ATTENTION!

To warn of practices which could result in

extensive equipment damage.

NOTE: To direct your attention to important

equipment information or special

instructions for preventing damage to

equipment

SAFETY INFORMATION

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 20

Symbols at the top of the list are the strongest warnings.

However, all symbols represent important information

which should be observed to protect you and others from

harm and injury, and to prevent damage to the equipment.

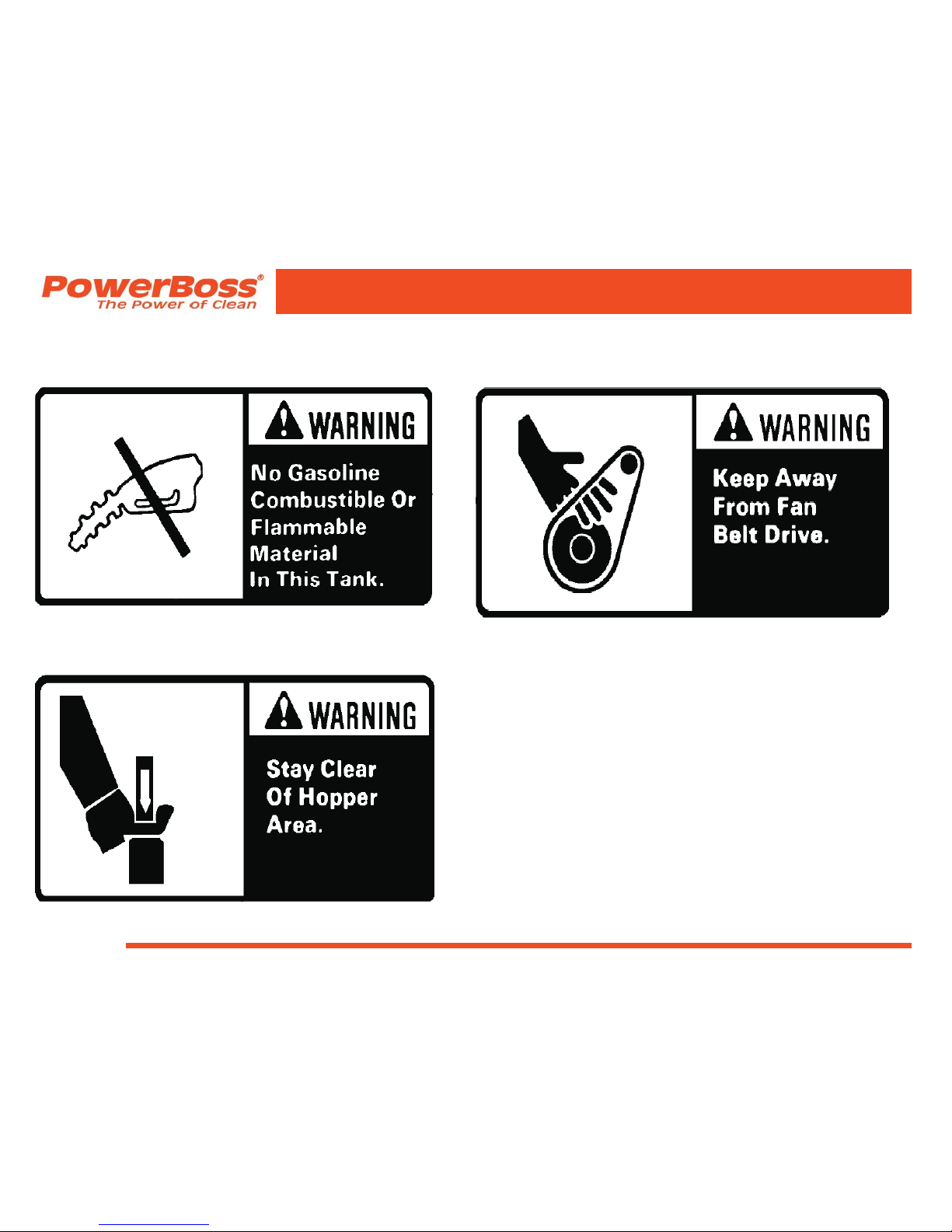

SAFETY DECALS

Decals directly attached to various parts of the unit are

highly visible safety reminders which should be read

and observed. Make sure the decals are replaced if they

become illegible or damaged.

Located in the drive compartment:

Part Number 3301854

SAFETY INFORMATION

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 21

Located at the Impeller:

Part Number 3301729

Located on the Secondary Lift Arm:

Part Number 3301732

Located on the shroud of the radiator:

Part Number 3301733

SAFETY INFORMATION

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 22

Located on the shroud of the radiator:

Part Number 3301728

Located on the Lift Arm:

Part Number 3301731

Located on the shroud of the radiator:

Part Number 3301730

SAFETY INFORMATION

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 23

BASIC POWERBOSS® SAFETY

PowerBoss® sweeper scrubbers should never be operated

unless:

1. The operator is trained and authorized to operate

the equipment and,

2. The equipment is free of malfunctions.

Malfunctioning equipment should be removed from

service.

DANGER

Keep cigarettes, matches and all other fl ame

sources away from the sweeper. Gasoline, LP

gas and diesel fuel are highly fl ammable. Lead

acid batteries are equally dangerous due to the

highly explosive hydrogen gas they emit.

WARNING

Do not operate an LP powered sweeper

when any component in the fuel system is

malfunctioning or leaking.

WARNING

Before starting the engine, make sure that:

* You have read and understand the User Manual

* You are securely seated in the operator’s seat.

* The parking brake is locked.

* The directional control pedal is in neutral.

* The throttle is in idle.

* Hydraulic controls are in the OFF position.

WARNING

During operation:

* Keep your hands and body clear of moving

parts, especially when the hopper or lift arms

are partially or fully raised.

* Make sure others in the area stay clear of the

equipment and moving parts.

* Never attempt to dump debris from a dock or

mezzanine. Dump from ground level only.

SAFETY INFORMATION

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 24

WARNING

When leaving the sweeper unattended:

* Place the controls in the OFF position.

* Set the parking brake.

* Shut off the engine.

WARNING

When servicing or repairing the fuel system:

* Work in a properly ventilated area, do not

smoke or allow an open fl ame near the fuel

system.

* Never bypass safety components unless you

are testing them.

* Never bypass the fuel fi lter lock, except when

testing them (and always reconnect them

after testing).

* Wear gloves to disconnect the tank coupling.

WARNING

During cleaning and maintenance:

* Always stop the engine and set the parking

brake before servicing.

* Never use detergents or cleansers that are

fl ammable or combustible.

* Never infl ate a pneumatic tire without using a

safety cage.

* Do not attempt any impeller adjustment unless

you have shut off the engine. Never place your

hands near the intake hoses or inlet when the

engine is running.

* Always engage the safety arm before servicing

the hopper. Do not rely on the hydraulic

cylinder to keep the hopper raised.

* Never test for hydraulic hose leaks using your

hand or any other part of your body. High

pressure leaks can be very dangerous and

should only be checked using a piece or paper.

SAFETY INFORMATION

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 25

WARNING

Replace any defective safety components

before operating the sweeper.

CAUTION

Do not drive with the hopper in the raised

position except the few feet necessary to

position the hopper over the dumpster or

receptacle. Driving with the hopper raised

reduces visibility and creates conditions

for striking over-head objects, throwing the

machine off -balance and other hazards.

CAUTION

Travel slowly on grades.

CAUTION

Place a block or chock behind the wheels when

parking on inclines.

CAUTION

Use special care when traveling on wet surfaces.

CAUTION

Observe all proper procedures for operation

and maintenance of the unit, as outlined in this

manual.

CAUTION

Remain alert at all times to people and equipment

in and around your area of operation.

ATTENTION!

Do not operate the #2 RTR lever before the #1

light illuminates.

ATTENTION!

Never push or tow a machine faster than 6 mph.

ATTENTION!

Engage tow valve before towing or pushing.

SAFETY INFORMATION

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 26

MACHINE OPERATION

BASIC OPERATING CONTROLS AND

INDICATORS

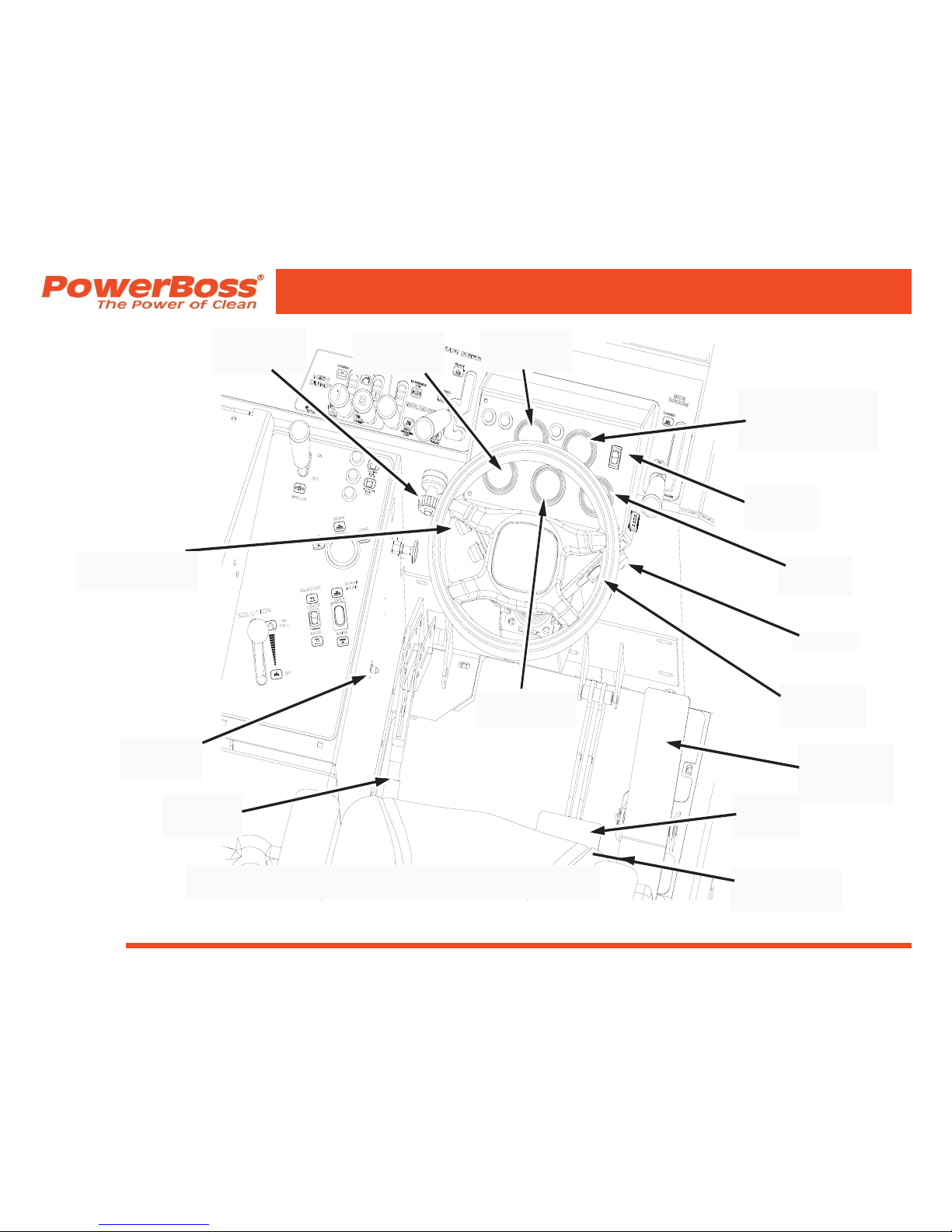

Location of controls and indicators vary on engine type and

options purchase. Some of the controls and indicators may

not be on you unit.

IGNITION SWITCH

The three position key switch is used to turn the machine’s

power on and off . The ignition switch is located on the right

side of the instrument panel next to the horn.

HORN

The horn is activated by pressing the horn button located

on the right side of the instrument panel, next to the ignition

switch.

LIGHT SWITCH

The light switch is located in the upper right of the control

panel above the steering wheel. The light switch turns on and

off the lights.

MACHINE OPERATION

HOUR METER

The hour meter records the number of hours the machine has

been operated, providing a helpful guide for performing routine

maintenance tasks.

ENGINE COOLANT TEMPERATURE GAUGE

The engine coolant temperature gauge registers the

temperature of the engine coolant. Temperatures above 220°F

indicate an overheating engine.

ENGINE OIL PRESSURE

The engine oil pressure gauge ranges from 0 psi to 60 psi. A

reading below 7 psi indicates problems which may result in

damage to the engine.

VOLTMETER AMP GAUGE

A battery gauge is used on LP & Gasoline units. It indicates

the voltage being sent to the battery by the alternator. 13.5v is

normal. An Amp. Gauge is used on diesel units, It indicates a

charge or discharge of current to the battery.

FUEL LEVEL GAUGE

The fuel gauge indicates the amount of fuel remaining in the

tank for gasoline & diesel units.

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 27

THROTTLE (DIESEL)

The throttle adjusts the engine speed from idle to the

operating speed.

1. Press the button and pull the throttle out for normal

operation to ensure proper broom speed.

2. Press the button and push the throttle in for idle

speed.

GLOW PLUG BUTTON (DIESEL ONLY)

The glow plug button,when depressed will aid in cold

starting. The diesel V1505 is equipped with 4 glow plugs.

The ignition switch must be turned to the IGN position before

pressing the glow plug button. Press and hold the glow plug

button for 10 to 20 seconds before starting the engine.

MURPHY SWITCH (DIESEL ONLY)

In the event that the engine water temperature rises above

226 degrees or oil pressure drops below 7 psi, this switch

will pop out and shut the engine off .

CAUTION

When the Murphy switch is tripped, it indicates

a service issue that requires maintenance. Do

not attempt to restart the engine.

SEAT ADJUSTMENT

The drivers seat is adjustable to provide the most

comfortable position for the operator. The adjustment lever

is at the bottom right of the seat. While sitting in the seat,

push the lever to the right and pull forward or push back on

the seat. Release the lever when the seat is in the proper

location.

PARKING BRAKE

The hand brake is engaged by lifting up on the lever. The

parking brake operates the mechanical drum brakes on the

front two wheels.

BRAKE

The brake is engaged by pressing down on the pedal, it is

used for stopping in normal operation of the unit.

MACHINE OPERATION

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 28

MACHINE OPERATION

IGNITION

SWITCH

DIRECTION

CONTROL

PEDAL

FUEL LEVEL

GAUGE

ENGINE OIL

PRESSURE

VOLTMETER

AMP GAUGE

ENGINE COOLANT

TEMPERATURE

GAUGE

HOUR

METER

SEAT

ADJUSTMENT

BRAKE

PEDAL

HORN

LIGHT

SWITCH

MURPHY

SWITCH

PARKING

BRAKE

THROTTLE

(DIESEL)

DIESEL ENGINE CONTROL AND INDICATOR LOCATIONS

GLOW PLUG

BUTTON

Commander T Series PB# 4100032 Rev.C 01/17

PowerBoss, Inc. Copyright 2012

Page 29

MACHINE OPERATION

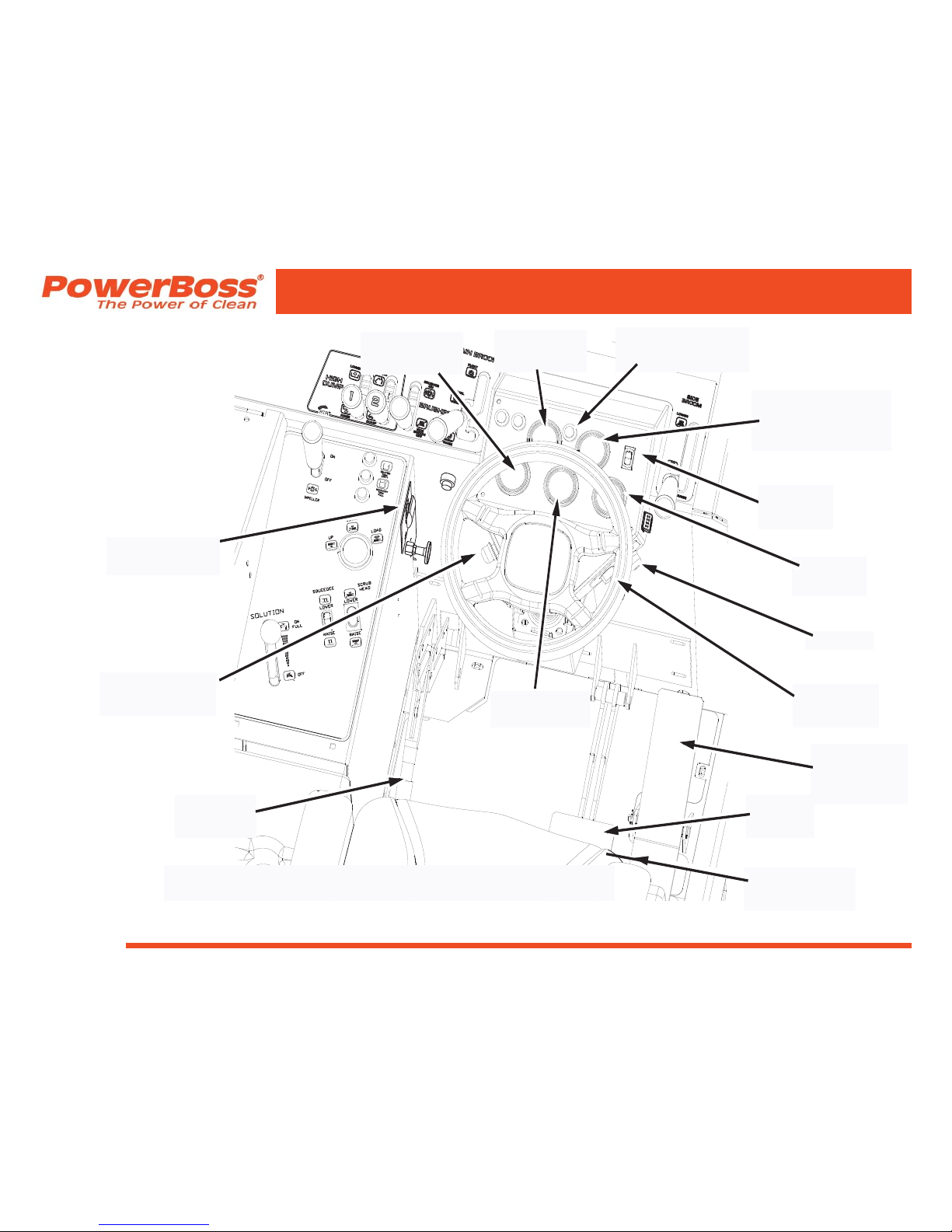

THROTTLE (GAS AND LP)

The throttle adjusts the engine speed from idle to the

operating speed. The LP and Gasoline models have a three

speed throttle switch with idle (turtle), run (rabbit) and fast

(tornado) selections.

• The throttle should be in the IDLE (turtle) position

when starting the engine and immediately before

shutdown.

• The throttle should be in the RUN (rabbit) position

during normal operation to ensure proper broom

speed.

CHECK ENGINE INDICATOR (GAS AND LP ONLY)

The indicator will illuminate in the event that the engine

water temperature rises above 226 degrees or oil pressure

drops below 7 psi. Shut down the unit and perform the

required service.

CAUTION

When the check engine indicator illuminates,

it indicates a service issue that requires

maintenance.

DIRECTIONAL CONTROL PEDAL

The directional control pedal controls the speed and direction

of the machine. It is also used for slowing the machine or

stopping.

• To propel the machine forward, apply pressure to the

front of the pedal, increasing pressure to increase

speed.

• To propel the machine backward, apply pressure to the

rear of the pedal.

• To slow or stop the machine, move the foot pedal into

neutral.

• For emergency stops, move the foot pedal past neutral

and into the opposite position.

CAUTION

Use for emergency stops only! Constant use of

this braking method may result in damage to the

drive components.

PowerBoss, Inc. Copyright 2012

Commander T Series PB# 4100032 Rev.C 01/17

Page 30

MACHINE OPERATION

IGNITION

SWITCH

DIRECTION

CONTROL

PEDAL

FUEL LEVEL

GAUGE

ENGINE OIL

PRESSURE

VOLTMETER

AMP GAUGE

ENGINE COOLANT

TEMPERATURE

GAUGE

HOUR

METER

SEAT

ADJUSTMENT

BRAKE

PEDAL

HORN

LIGHT

SWITCH

THROTTLE

(GAS AND LP)

PARKING

BRAKE

CHECK ENGINE

INDICATOR

GAS AND LP ENGINE CONTROL AND INDICATOR LOCATIONS

FILTER SHAKER

BUTTON

Loading...

Loading...