PowerBoss Armadillo SW/9XR, Armadillo SW/9XV User Manual

USER MANUAL

ARMADILLO® SWEEPER

SW/9XR / SW/9XV

PowerBoss, Inc.

A Member Of The Hako Group

PB# 4100033 Rev. 01A08

Operation, Maintenance and Troubleshooting

The Model and Serial Numbers of your machine are shown on the nameplate mounted on the

machine. This information is needed when contacting Technical Support or ordering parts.

For your convenience, use the space below to record the Model and Serial Numbers of your

machine and the date it was placed into service.

MODEL NUMBER: ___________________________________________

SERIAL NUMBER: ___________________________________________

DATE PLACED INTO SERVICE: _______________________________

Contact:

techsupport@powerboss.com

All information contained in this manual is current at the time of printing. However, due to constant updates and improvements, we reserve the right to make changes at any time without notice.

© Copyright 2008, Minuteman PowerBoss, Inc.

All rights reserved. This manual may not be copied or reproduced in any form, without the written permission of Minuteman PowerBoss, Inc.

PowerBoss, Inc. Copyright 2008

PowerBoss, Inc. Copyright 2008

PB # 4100033 / Rev. 01A00

Page #1

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Armadillo® SW/9XR & SW/9XV

OPERATION,

AINTENANCE &

M

ROUBLESHOOTING

T

SW/9XR

SW/9XV

TABLE OF CONTENTS

Features .............................................................................. 7

Limited Warranty .................................................................8

SAFETY

Safety Symbols .................................................................... 9

Safety Decals ................................................................10-11

Basic PowerBoss

OPERATION

Basic Operating Controls ................................................15-16

Sweeping Controls ............................................................. 17

Debris Hopper Dump Controls ............................................. 18

Operating Procedures

Pre-Operation Check .......................................... 19

Starting ............................................................ 19

Slowing and Stopping ......................................... 20

Operating on Grades........................................... 20

Sweeping .......................................................... 20

Emptying the Hopper.......................................... 20

Using the Rotary Trash Relocator (RTR™) ............. 21

Transporting the Machine ................................... 22

®

Safety .................................................12-14

PowerBoss, Inc. Copyright 2008

Page 3

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Operation, Maintenance and Troubleshooting

TABLE OF CONTENTS (Continued)

MAINTENANCE

Introduction....................................................................... 23

Planned Maintenance Chart

Engine .............................................................. 24

Air Intake System .............................................. 24

Electrical System ............................................... 24

Coolant System .................................................. 24

Hydraulics System.............................................. 25

Sweep Components.............................................25

Hopper.............................................................. 26

Steering ............................................................ 26

Parking Brake .................................................... 26

Tires ................................................................ 27

Miscellaneous .................................................... 27

Impeller............................................................27

Service Instructions

Engine .............................................................. 28

Air Intake

Filter Removal...........................................29

Filter Cleaning ..........................................29

Filter Inspection ........................................29

Filter Installation.......................................29

Electrical System

Battery Cleaning........................................30

Battery Replacement................................... 30

Circuit Breakers.........................................30

Fuses........................................................30

Fuel System

WARNINGS.............................................. 31

Tier װ Compliancy ....................................... 31

Coolant System

Blowing Out Radiator Fins .......................... 32

Reverse Flow Flushing................................33

Lubrication

Changing Engine Oil ..................................33

Lubrication Points...................................... 34

Hydraulics System

Filling the Fluid Reservoir .......................... 35

Changing the Hydraulic Fluid ......................35

Changing the Hydraulic Fluid Filter .............36

Adjusting the Directional Control

Return Spring ....................................... 36-37

PowerBoss, Inc. Copyright 2008

Page 4

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Operation, Maintenance and Troubleshooting

TABLE OF CONTENTS (Continued)

MAINTENANCE (CONTINUED)

Sweep Components

Broom Door Flap Inspection........................ 38

Broom Door Flap Replacement

and Adjustment..........................................38

Main Broom Adjustment..............................38

Main Broom Height Adjustment ...................39

Main Broom Taper Adjustment.....................40

Main Broom Replacement............................ 41

Side Broom Angle Adjustment ..................... 42

Side Broom Height (Wear) Adjustment.......... 42

Side Broom Replacement............................. 43

Hopper

Hopper Removal ........................................44

Hopper Replacement...................................44

Filter Removal........................................... 45

Filter Cleaning ..........................................45

Filter Replacement .....................................45

Floor Clearance and Dump Adjustments ........ 46

Adjusting Maximum Hopper Dump Angle ......47

Vacuum Gasket Mount Adjustment ...............47

Flap Replacement.......................................48

Frame Seal Replacement

Front Frame Seal................................ 48

Side Frame Seal ................................. 48

Parking Brake .................................................... 49

Tires

Changing Solid Tires ..................................50

Changing Pneumatic Tires ...........................50

Miscellaneous Adjustments

Anti-Static Chain ....................................... 51

Latches and Hinges .................................... 51

Cables ...................................................... 51

PowerBoss, Inc. Copyright 2008

Page 5

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Operation, Maintenance and Troubleshooting

TABLE OF CONTENTS (Continued)

TROUBLESHOOTING

Basic Machine Operating Problems

Engine will not start or runs roughly after start ............. 52

Engine overheats ....................................................... 53

PowerBoss

PowerBoss

Sweeping Problems

Brushes do not turn or turn very slowly ........................ 54

Little or no vacuum in brush compartment..................... 55

Loss of dust control ................................................... 55

Sweeper unit leaving debris .................................... 55-56

Hopper does not raise or lower .................................... 56

Hopper does not rotate or rotates slowly ....................... 57

Hydraulic System Problems

Hopper lift cylinder failure ......................................... 57

Hydraulic motor failure .............................................. 58

Hydraulic gear pump failure ........................................ 58

Hydraulic variable displacement pump failure ............... 59

Hydraulic system noisy............................................... 60

Your page ....................................................................... 61

Notes …………………………………………………………………….62

Electrical Schematic Kubota V1505……………..………………….63

Electrical Schematic GM 1.6L ............................................. 64

Hydraulic Schematic 9XR ................................................... 65

Hydraulic Schematic 9XV .................................................. 66

Warranty Matrix ................................................................ 67

®

moves slowly or does not move .................. 53

®

creeps in neutral ...................................... 54

PowerBoss, Inc. Copyright 2008

Page 6

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Operation, Maintenance and Troubleshooting

SW/9XV

FEATURES

1. Dust Control Filter: 104 Sq. Ft. total

2. Timed Electric Filter Shakers

3. Shock-mounted Hydraulic Impeller

4. Power Steering with Tilt Steering Wheel

5. Adjustable Seat

6. Exhaust Air Expelled Outside Engine

7. Industrial Liquid-Cooled Engine

8. 4-Core Radiator

9. Tri-Phase Air Cleaner

10. Built-In Dust PreFiltering

11. One-Piece Unitized Steel Frame

12. Clogged Filter Indicator

13. Hydraulics Protection Package

14. Dual Performance Sweep Mode

15. Quick-Change Floating 48” Main Broom

16. PowerClimb™ All-Terrain Access

(Two 23” OD Pneumatic Front Tires & One 21” OD Pneumatic Rear Tire)

17. Oversized Hopper with RTR™

18. Retractable Quick-Change Side Broom

19. Multi-Level Hopper Dumping

20. Fire-in-hopper Indicator

PowerBoss, Inc. Copyright 2008

Page 7

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Operation, Maintenance and Troubleshooting

SW/9XR

SW/9XV

LIMITED PRODUCT WARRANTY

PowerBoss, Inc. warrants that the PowerBoss SW/9XR & SW/9XV will be free from defects in material and

workmanship for a period of 48 months or 2,800 operating hours from date of installation, whichever comes

first. Written notice of any claimed defect must be given to PowerBoss within the warranty period and within

thirty (30) days after such defect is discovered. Liability under this warranty is limited to either replacing or

repairing, at PowerBoss’s election, any part or parts deemed defective after examination by PowerBoss or an

Authorized Service Representative. The PowerBoss machine or any of its parts returned by customer to PowerBoss or an Authorized Service Representative via prepaid transportation and which is found to be defective,

will be repaired or replaced and returned to customer via prepaid surface transportation within the Continental

US. One the other hand, should a part be found not defective, inspection and handling charges may be charged

to the customer my PowerBoss or an Authorized Service Representative.

For one hundred eighty (180) days from date of installation, PowerBoss will provide repair labor, at no charge,

solely through an Authorized Service Representative. Thereafter, labor will be charged.

This warranty does not extend to the PowerBoss machine, or its parts, that have been subject to misuse, accident or improper handling, installation, maintenance or application, nor does it extend to PowerBoss machine

and/or parts which have been repaired or altered outside PowerBoss’s plant or the facility of Authorized Service Representative.

This warranty does not apply to routine wearable parts of the PowerBoss machine such as brushes, flaps, filters, seals, point, plugs, hoses or similar items. Moreover, this warranty does not extend to the PowerBoss machine or part replaced or repaired under this warranty.

Only replacement parts supplied by PowerBoss are warranted for 30 days after installation.

The warranty for optional engines shall be limited to the warranty extended to PowerBoss by the supplier.

ENGINE WARRANTY LIMITAT ION

For the 25th through 60th month, or from 2,000 hours through 3,000 hours, whichever comes first, only the

following engine components shall be covered under the parts warranty:

-Cylinder Block -Intake Manifold

-Cylinder Head -Connecting Rods

-Camshaft

THE WARRANTY SET FORTH HEREIN IS IN LIEU OF AND EXCLUDES ANY AND ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, ARISING BY OPERATION OF LAW OR OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMP LIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, AND CUSTOMER WA IVES ANY OBLIGATION OR LIABILITY OR POW ERBOSS ARIS ING IN TORT O R STRICT LIA BILITY IN TORT, OR FOR LOSS OR US E,

REVENUE OR PR OFIT WITH R ESPECT TO PO WERBOSS MACH INE AND/OR PARTS FOR ANY LIABILITY OF CUSTOMER TO ANY TH IR D PA RT Y, OR FOR OT HER D IRE CT, INCIDENTAL OR CON SEQUENTIAL DAMAGES.

PowerBoss, Inc. Copyright 2008

Page 8

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Operation, Maintenance and Troubleshooting

Five symbols are used throughout this manual to emphasize various levels of safety information.

These symbols and the meaning of each are listed below.

DANGER

WARNING

CAUTION

ATTENTION!

Symbols at the top of the list are the strongest warnings. However, all symbols represent important

information which should be observed to protect you and others from harm and injury, and to prevent

damage to the equipment.

NOTE

SAFETY SYMBOLS

DANGER: To warn of immediate hazards which will result

in severe personal injury or death

WARNING: To warn of hazards or unsafe practices which

could result in severe personal injury or death.

CATUION: To warn of hazards or unsafe practices which

could result in minor personal injury.

ATTENTION!: To warn of practices which could result in

extensive equipment damage.

NOTE: To direct your attention to important equipment information or special instructions for preventing damage to

equipment

PowerBoss, Inc. Copyright 2008

Page 9

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Operation, Maintenance and Troubleshooting

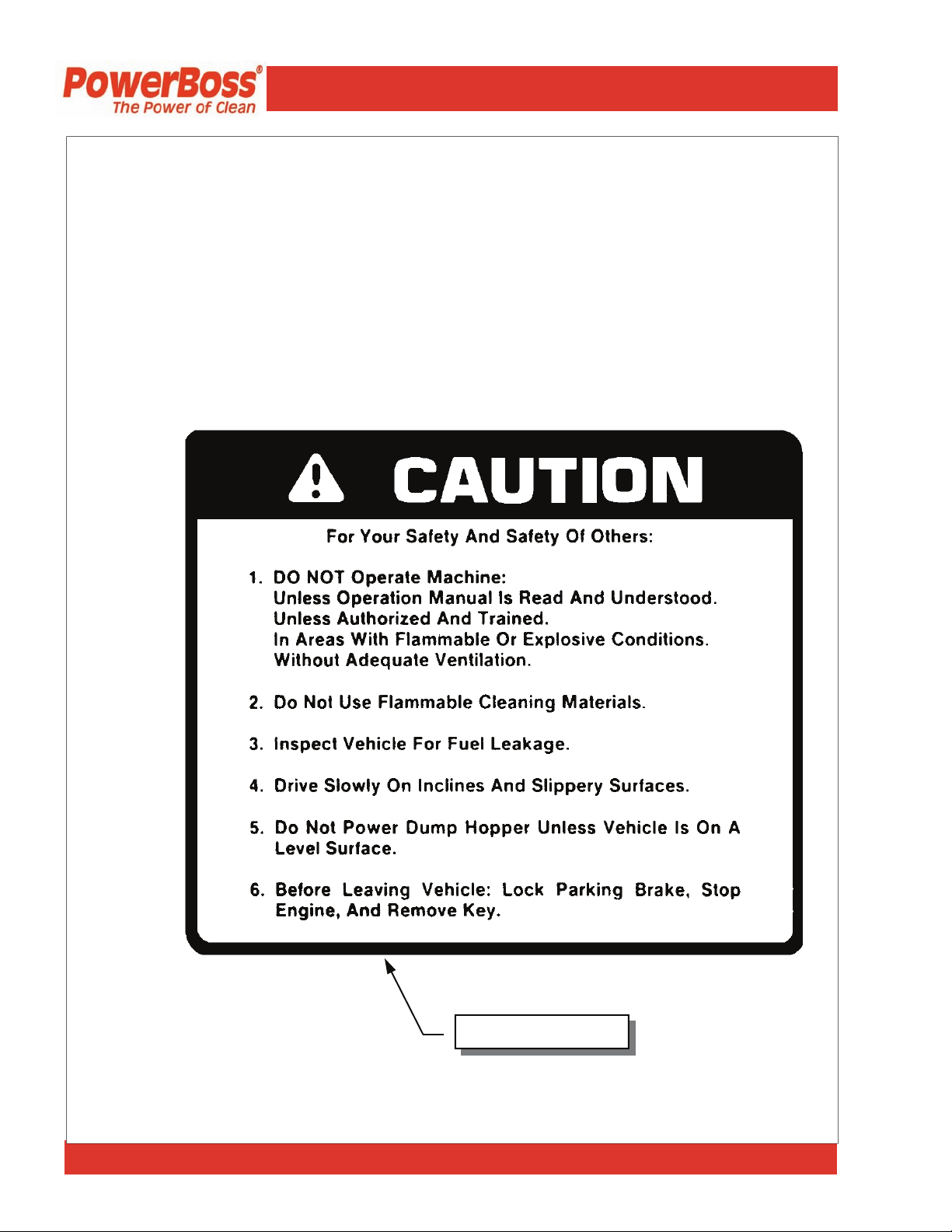

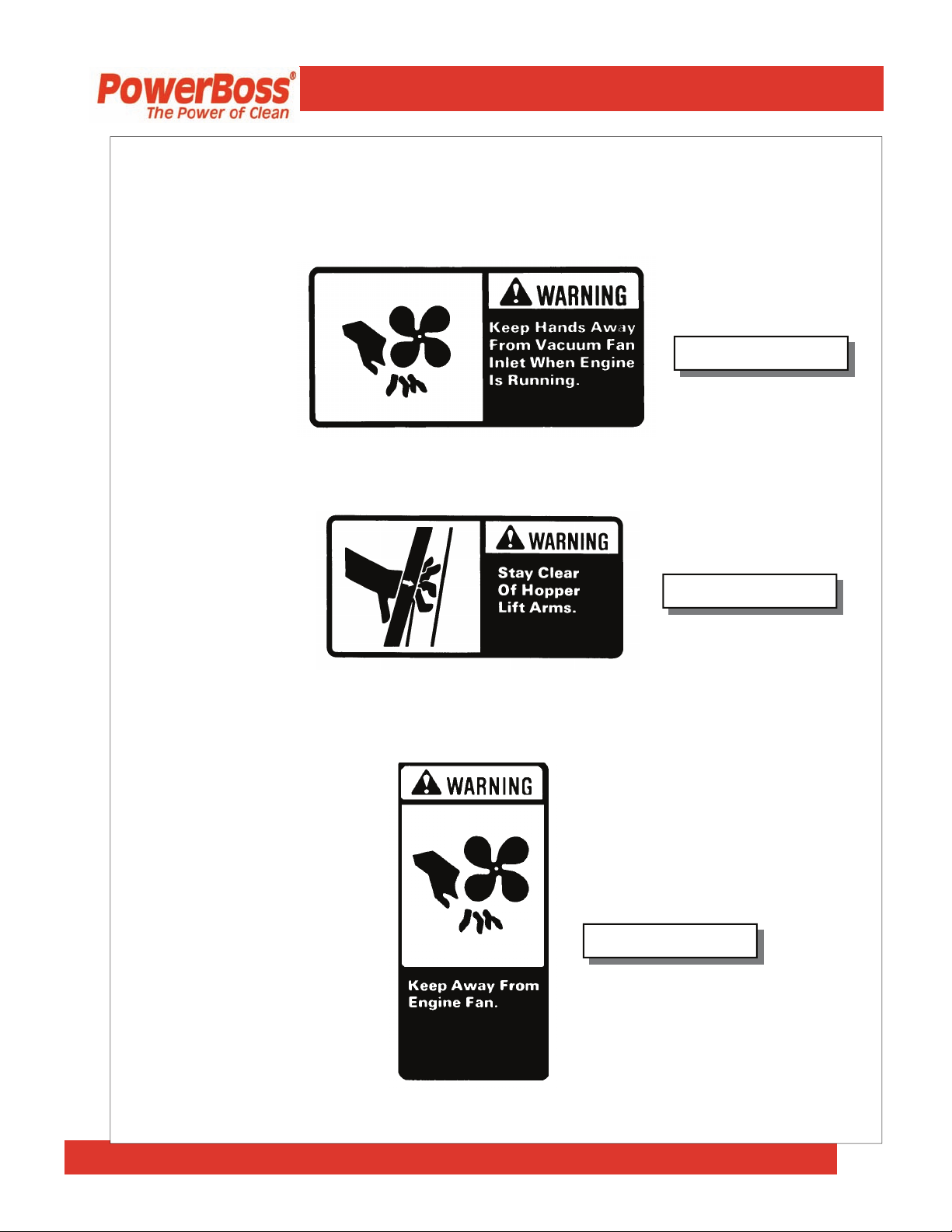

SAFETY DECALS

Decals directly attached to various parts of the sweeper are highly visible safety reminders which

should be read and observed. Make sure the decals are replaced if they become illegible or damaged. The decal below is located in the drive compartment. Other safety decals on you machine

appear on the next page.

PowerBoss, Inc. Copyright 2008

Part Number 301854

Page 10

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Operation, Maintenance and Troubleshooting

SAFETY DECALS (Continued)

Located at the Impeller:

Part Number 301729

Located on the High Dump Hopper:

Located on the Shroud of the Radiator:

Part Number 301733

Part Number 301732

PowerBoss, Inc. Copyright 2008

Page 11

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Operation, Maintenance and Troubleshooting

BASIC PowerBoss® SAFETY

PowerBoss® sweepers should never be operated unless: 1. The operator is trained and authorized

to operate the equipment and, 2. The equipment is free of malfuntions. Malfunctioning equipment

should be removed from service.

1. Keep cigarettes, matches and all other flame sources

DANGER

equally dangerous due to the highly explosive

hydrogen gas they emit.

WARNING

٭ The parking brake is locked.

2. During operation:

expecially when the hopper or lift arms are partially

or fully raised.

and moving parts.

Dump from ground level only.

3. When leaving the sweeper unattended:

away from the sweeper. Gasoline, LP gas and diesel

fuel are highly flammable. Lead acid batteries are

1. Before starting the engine, make sure that:

٭

You are securely seated in the operator’s seat.

٭

The directional control pedal is in neutral.

٭

The throttle is in idle.

٭

Hydraulic controls are in the OFF position.

٭

Keep your hands and body clear of moving parts,

٭

Make sure others in the area stay clear of the equipment

٭

Never attempt to dump debris from a dock or mezzanine.

٭

Place the controls in the OFF position.

٭

Set the parking brake.

٭

Shut off the engine.

PowerBoss, Inc. Copyright 2008

Page 12

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Operation, Maintenance and Troubleshooting

BASIC PowerBoss® SAFETY (Continued)

4. During cleaning and maintenance:

before servicing.

or combustible.

cage.

shut off the engine. Never place your hands near

the intake hoses or inlet when the engine is running.

hopper. Do not rely on the hydraulic cylinder to

keep the hopper raised.

any other part of your body. High pressure leaks can be

very dangerous and should only be checked using a piece

or paper.

5. When servicing or repairing the fuel system:

allow an open flame near the fuel system.

them.

them (and always reconnect them after testing).

6. Do not operate an LPG powered sweeper when any

component in the fuel system is malfunctioning or leaking.

7. Replace any defective safety components before operating

the sweeper.

CAUTION

dumpster or receptacle. Driving with the hopper raised

reduces visibility and creates conditions for striking over head objects, throwing the machine off-balance and other

hazards.

1. Do not drive with the hopper in the raised position except

the few feet necessary to position the hopper over the

٭

Always stop the engine and set the parking brake

٭

Never use detergents or cleansers that are flammable

٭

Never inflate a pneumatic tire without using a safety

٭

Do not attempt any impeller adjustment unless you have

٭

Always engage the safety arm before servicing the

٭

Never test for hydraulic hose leaks using your hand or

٭

Work in a properly ventilated area, do not smoke or

٭

Never bypass safety components unless you are testing

٭

Never bypass the fuel filter lock, except when testing

٭

Wear gloves to disconnect the tank coupling.

PowerBoss, Inc. Copyright 2008

Page 13

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Operation, Maintenance and Troubleshooting

BASIC PowerBoss® SAFETY (Continued)

2. Travel slowly on grades.

3. Place a block or chock behind the wheels when parking on

inclines.

4. Use special care when traveling on wet surfaces.

5. Observe all proper procedures for operation and

maintenance of the sweeper, as outlined in this manual.

6. Remain alert at all times to people and equipment in and

around your area of operation.

1. Do not operate the #2 RTR lever before the #1 light

ATTENTION!

2. Never push or tow a machine faster than 6 mph.

illuminates.

PowerBoss, Inc. Copyright 2008

Page 14

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A00

Operation, Maintenance and Troubleshooting

BASIC OPERATING CONTROLS

IGNITION SWITCH

STARTER

NOTE

HORN

FUEL LEVEL

GAUGE

VOLTMETER

AMP GAUGE

HOUR METER

ENGINE OIL

PRESSURE

ENGINE COOLANT

TEMPERATURE

GAUGE

The diesel powered machine has a two position key switch used to turn

the machine’s electric power on and off. The gasoline and LP units have

a three position key switch.

To start gasoline powered machines, turn the key clockwise to the Start

position When the engine starts, release the key. To stop the engine, turn

the key to OFF.

To start diesel engines, turn the ignition key clockwise to the on position.

Press the Glow Plug Button for 20 seconds. Continue turning

ignition key clockwise to the Start position. When engine starts release

key.

If the engine does not start after 10 seconds, release the key,

wait 1 minute and repeat the procedure.

The horn is activated by pressing the horn button located on the right side

of the operator.

The fuel gauge indicates the amount of fuel remaining in the tank.

The Voltmeter used on gas & LP units or Amp Gauge used on diesel

units indicates the charging current which is being sent to the battery by

the alternator. It also indicates a drop in voltage when the alternator is not

charging.

The hour meter records the number of hours the machine has been operated, providing a helpful guide for performing routine maintenance tasks.

The engine oil pressure gauge ranges from 0 psi to 60 psi. A reading below 7 psi indicates problems which may result in damage to the engine.

The engine coolant temperature gauge registers the temperature of the

engine coolant. Temperatures above 220°F indicate an overheating engine.

PowerBoss, Inc. Copyright 2008

Page 15

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A08

Operation, Maintenance and Troubleshooting

Operation, Maintenance and Troubleshooting

BASIC OPERATING CONTROLS (Continued)

THROTTLE

DIRECTIONAL

CONTROL PEDAL

CAUTION

PARKING BRAKE

The throttle adjusts the engine speed from idle to the operating

speed.

• The throttle should be in the IDLE position when starting the

engine and immediately before shutdown.

• Full throttle position should be used during operation to en-

sure proper broom speed and dust control.

The directional control pedal controls the speed and direction of

the machine. It is also used for slowing the machine or stopping.

• To propel the machine forward, apply pressure to the front of

the pedal, increasing pressure to increase speed.

• To propel the machine backward, apply pressure to the rear of

the pedal.

• To slow or stop the machine, move the foot pedal into neutral.

• For emergency stops, move the foot pedal past neutral and

into the opposite position.

Use for emergency stops only! Constant use of this braking

method may result in damage to the drive components.

The sweeper is equipped with a speed limiter. A stop is mounted

under the directional control pedal and can be raised to reduce the

maximum speed.

The hydraulic drum brakes on the two front wheels are operated

by pressing on the brake pedal. The parking brake is cable activated. To engage the parking brake pull upward on the hand

brake lever located on the left side of the front wall of the operator’s compartment.

PowerBoss, Inc. Copyright 2008

Page 16

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A08

Operation, Maintenance and Troubleshooting

SWEEPING CONTROLS

BROOM CONTROL

LEVER

NOTE

NOTE

MAIN BROOM

HANDLE

NOTE

SIDE BROOM

HANDLE

The broom control lever activates the brooms. (“Side Broom

OFF” position activates the main broom only.)

The main broom and side broom may be lowered independently.

The “OFF” position is achieved by placing the broom control

lever in the center of the slot. Both broom motors (main &

side) are de-activated by taking this action.

The main broom handle to the immediate left of the driver raises

and lowers the main broom. For normal sweeping, position the

handle at the LOWER position on the handle slot.

• For extremely uneven floor, position the handle at the

FLOAT position on the handle slot.

Extensive use of the FLOAT position reduces broom life.

• When not sweeping, position and lock the handle to the

RAISE position on the handle slot.

The side broom handle to the immediate left of the driver raises

and lowers the side broom.

• When not sweeping, the side broom should remain in the

RAISE position.

• To lower the side broom, position the handle to the LOWER

position in the handle slot.

PowerBoss, Inc. Copyright 2008

Page 17

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A08

Operation, Maintenance and Troubleshooting

DEBRIS HOPPER DUMP CONTROLS

HOPPER FILTER

SHAKER BUTTON

CAUTION

HIGH DUMP

MODELS

ROTARY TRASH

RELOCATOR

(RTR™)

This button is used to activate the filter shakers prior to dumping

or as needed during sweeping operation. It is located to the left

hand side of the instrument panel.

To shake the filter:

1. Bring the machine to a complete stop.

2. Place the broom control lever in the OFF position.

3. Press and hold the filter shaker button for 20 to 30 seconds.

4. Place the broom control lever in the ON position and resume

sweeping.

Do not leave the hopper in the RAISE position for an extended

period of time.

The two far left levers on the front of the control panel are used to

raise the hopper to any height up to 60” (1.52 m) and dump it.

• To raise the hopper, pull back Lever 1 to the RAISE position

and hold until the hopper raises to the proper height for the

dumpster or container.

• To empty debris, pull back Lever 2 to the DUMP position to

rotate the hopper forward and empty the debris.

• To rotate the hopper back, push Lever 2 forward to the

RETURN position until the hopper rotates and stops.

• To lower the hopper, push Lever 1 forward to the LOWER

position until the hopper stops.

Rotary Trash Relocator (RTR™) is a standard feature on highdump models. Its purpose is to increase the holding capacity of

the debris hopper to make dumping the hopper necessary less frequently.

PowerBoss, Inc. Copyright 2008

Page 18

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A08

Operation, Maintenance and Troubleshooting

OPERATING PROCEDURES

PRE-OPERATION

CHECKS

STARTING

WARNING

CAUTION

Prior to starting the engine, check the following:

1. Engine oil level

2. Engine coolant level

3. Fuel level

4. Hydraulic fluid level

5. Brakes, steering and directional controls

6. The floor beneath the machine for signs of fluid leaks

Fluid levels should be correct. Brakes, steering and directional

controls should be functioning properly. Hoses, lines and tanks

should be free of damage and leaks.

Before starting the engine, sit in the operator’s seat and make

sure the parking brake is locked.

1. Make sure the directional control pedal is in the neutral position.

2. Make sure the throttle is in the idle position.

3. Gasoline-powered: Turn the ignition key to the ON position,

push the button located just below the key. When the engine

starts, release the button. If the engine is cold, pull out the

choke knob and repeat the above procedure. When the engine

is running smoothly, push the choke knob in.

If the engine fails to start, do not continue cranking for more

than ten seconds. Allow the starter motor to cool between

attempts.

4. Move the machine forward or backward as follows:

• Forward: Apply pressure to the front of the directional con-

trol pedal, increasing pressure to increase speed.

• Reverse: Apply pressure to the rear of the pedal, increasing

pressure to increase speed.

PowerBoss, Inc. Copyright 2008

Page 19

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A08

Operation, Maintenance and Troubleshooting

SLOWING AND

STOPPING

OPERATING ON

GRADES

SWEEPING

NOTE

EMPTYING THE

HOPPER

High Dump

Models

1. Allow the directional control pedal to move into neutral. The

machine will slow and coast to a stop.

1. Always travel slowly.

2. Exercise extreme caution when traveling across or turning on

grades.

1. Lower the Brooms

٭ When sweeping extremely uneven floors, position

the main broom handle at FLOAT on the handle slot.

٭ Lower the side broom by positioning the side broom

handle at LOWER in the handle slot.

٭ Lower the main broom by positioning the main

broom handle to LOWER on the handle slot.

2. Activate the broom motors.

٭ Activate both main and side broom motors by push

ing the broom and brush control lever to the ON

position.

٭ Activate the main broom motor by pulling the broom

and brush control lever to the SIDE BROOM OFF

position.

Broom control lever must be in the center OFF position.

3. Drive the machine over the area to be swept.

1. Drive the machine to the dumping area.

2. Use the directional control pedal to position the machine so

that the space between the machine and the container or

dumpster is adequate to raise the hopper.

3. Reduce the engine speed.

4. Pull back Lever 1 to the RAISE position and hold until the

bottom of the hopper is high enough to clear the top of the

container.

PowerBoss, Inc. Copyright 2008

Page 20

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A08

Operation, Maintenance and Troubleshooting

WARNING

WARNING

USING THE

ROTARY TRASH

RELOCATOR

(RTR™)

NOTE

WARNING

Never place your hands or other body parts near the lift arms

when the hopper is operating.

5. Use the directional control pedal to slowly and carefully move

the machine forward until the hopper is properly positioned to

dump the debris into the container.

It is unsafe to travel an extended distance with the hopper

raised. Travel only the distance necessary to position the

hopper.

6. Shake the filters for 20-30 seconds. Pull back Lever 2 to the

DUMP position to rotate the hopper forward and empty the

debris.

7. After the hopper empties, push Lever 2 forward to the

RETURN position until the hopper rotates and stops.

8. Slowly back the machine away fro the dumpster

approximately 5 feet.

9. Push Lever 1 forward to the LOWER position until the

hopper stops.

1. Use the directional control pedal to stop the machine on a

level surface.

2. Move the throttle to the IDLE position.

As you complete Steps three and four, observe the two red

lights labeled 1 and 2 in the upper left corner of the control

pane.

• Light 1 illuminates when the hopper reaches the minimum

height required to use the RTR™ feature.

• Light 2 illuminates when the hopper reaches the rotation stop

point.

3. Pull back Lever 1 to the RAISE position and hold until Light

1 illuminates, then release.

Make sure no one is in the area under or around the hopper.

PowerBoss, Inc. Copyright 2008

Page 21

Armadillo® SW/9XR & SW/9XV PB # 4100033 / Rev. 01A08

Loading...

Loading...