User Manual

Rider Sweeper

Armadillo 6X(Diesel, Gas, & LPG)

AM7D-III(Diesel)

PowerBoss®, Minuteman International, Inc.

A Member of the Hako Group

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PB# 4100043UM Rev. A 08/14

Page 1

PREFACE

PREFACE

Thank you for your purchase of the new industry standard for sweepers. PowerBoss® takes great pride in

offering the most dependable, reliable and best value in industrial power sweepers and sweeper/scrubbers.

We set the standard.

Our Customer Service Department would like to hear from you. If you see any errors, omissions or

something that needs clarication in this User Manual, please let us know. We are working hard towards

continually improving our processes to bring you the best you deserve.

Please copy the form on next page, ll out and comment on how you found our manual.

Thank you!

The PowerBoss Team

Page 2

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREFACE

Name: _____________________________________________

Title: _______________________________________________

Company Name: _____________________________________

Address: ____________________________________________

Country: ____________________________________________

Type of equipment or model number: ______________________

Comments: ___________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

Please return to:

Customer Service Manager

PowerBoss®, Minuteman International, Inc.

14N845 U.S. Route 20

Pingree Grove, Illinois 60140 USA

Phone: (800) 323-9420

Email: tech@powerboss.com

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 3

PREFACE

This is the User Manual for the PowerBoss® Armadillo 6X & PowerBoss® AM7D-III machines.

This manual covers all standard Armadillo 6X & AM7D-III variations beginning, August 2014.

We believe this machine will provide excellent service for many years. Best results can be obtained if:

• The machine is operated with reasonable care.

• The machine is maintained regularly per the maintenance schedule provided in this User Manual.

• The machine is maintained with PowerBoss® supplied or equivalent parts.

All right side and left side references to the machine (except for engine) are determined by facing the direction

of forward travel. The front of the engine or engine fan faces the rear of the machine. Some hardware

considered to be common or locally available has been omitted from the parts section to make this manual

clear. Be sure to use equivalent hardware when replacement becomes necessary.

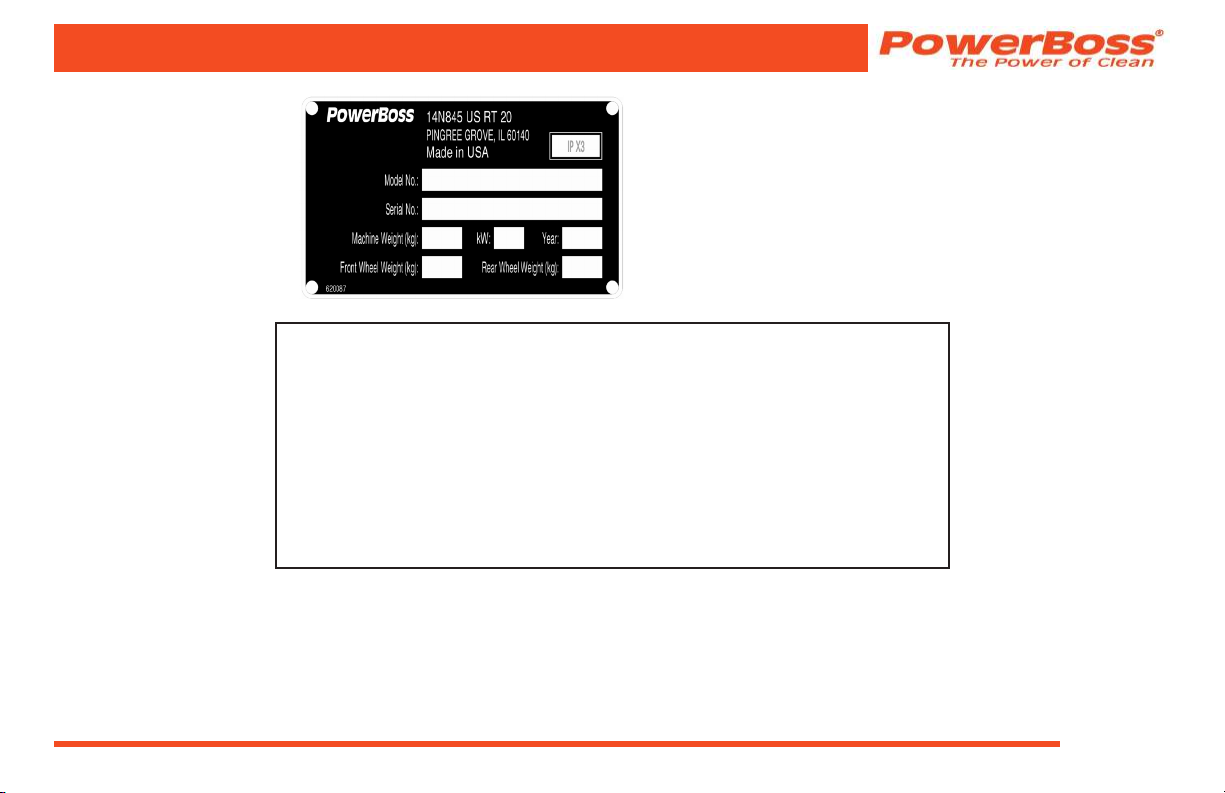

The Model and Serial Number of your machine is shown on the I.D. name plate. This information is needed

when contacting Technical Support or when ordering parts. The I.D. plate is mounted on the console of the

machine left of the operator and adjacent the main broom adjustment access door.

Parts may be ordered by phone, fax or email from any PowerBoss® parts and service center. Before

ordering parts or supplies, be sure to have your machine model number and serial number handy. For your

convenience Fill out the Machine Data block on the next page for future reference.

Page 4

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREFACE

Example I.D Plate:

MACHINE DATA

Fill out at installation

Machine Serial Number: ____________________________

Engine Serial Number: ____________________________

Sales Rep.: ______________________________________

Date of Install: ___________________________________

All information contained in this manual is current at the time of printing. Minuteman International, Inc.

reserves the right to make changes at any time without notice.

PowerBoss®, Minuteman International, Inc., Printed in USA ©2014

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 5

TECHNICAL SPECIFICATIONS

TECHNICAL SPECIFICATIONS

Model/Model No: Armadillo 6X / SW6XKDSL (Diesel), SW6XKGAS (Gas), SW6XKLPG (LPG)

AM7D-III / AM7D-III (Diesel)

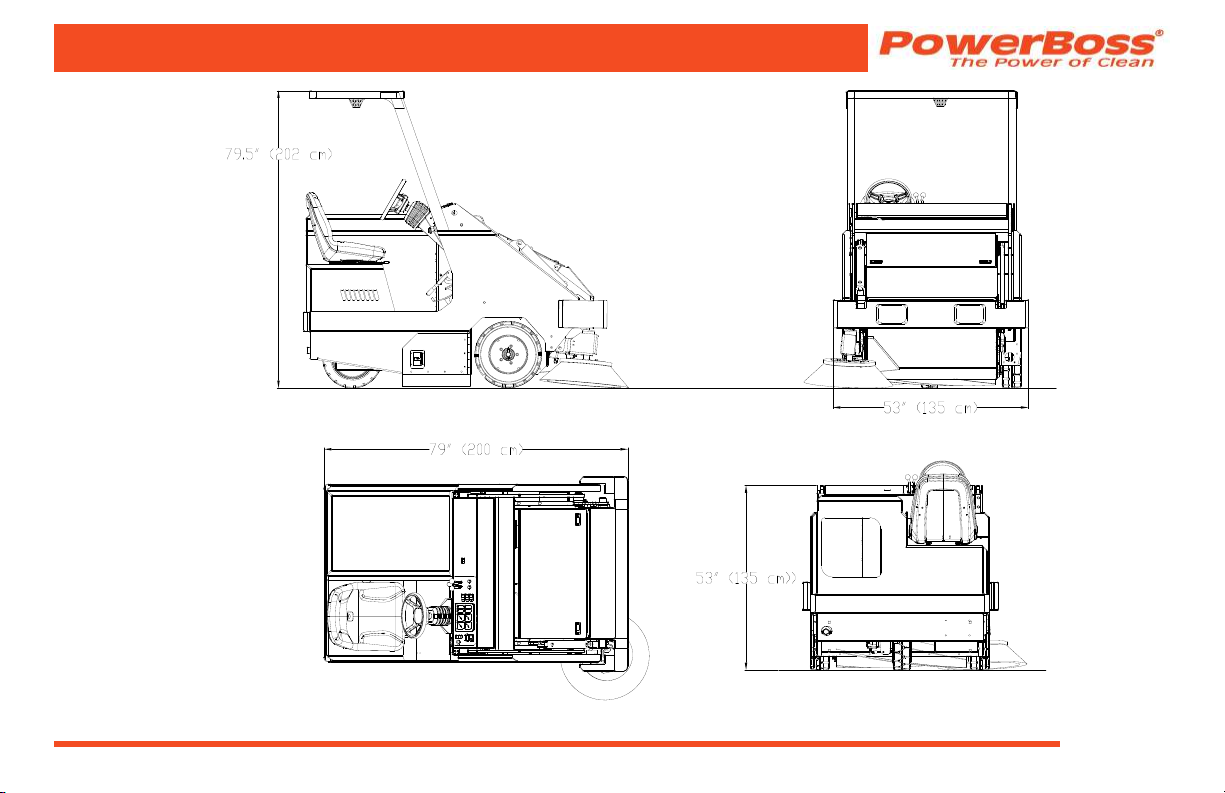

DIMENSIONS & WEIGHT

Length . . . . . . . . . . . . . . . . . . 79 inches (200 cm)

Width . . . . . . . . . . . . . . . . . . . 53 inch (135 cm)

Height . . . . . . . . . . . . . . . . . . . 53 inch (135 cm)

Height w/ overhead guard . . . 79.5 inch (202 cm)

Weight . . . . . . . . . . . . . . . . . . 2547 lbs (1155 kg)

Minimum U-turn . . . . . . . . . . . 82 inch (208 cm)

Page 6

SWEEPING SYSTEM

Sweep path. . . . . . . . . . . . . . . 53 inch (135 cm)

Main broom. . . . . . . . . . . . . . . 36 inch (91 cm)

Side broom . . . . . . . . . . . . . . . 24 inch (61 cm)

Hopper type . . . . . . . . . . . . . . high dump

Hopper volume . . . . . . . . . . . . 10 cu ft (.28m2)

Hopper load capacity . . . . . . . 650 lbs (295 kg)

Dust control . . . . . . . . . . . . . . 92 sq ft (8.6 m2)

High dump . . . . . . . . . . . . . . . 60 inch (152 cm)

RTR (rotary trash relocation) . yes

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

TECHNICAL SPECIFICATIONS

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 7

TABLE OF CONTENTS

TABLE OF CONTENTS

PREFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TECHNICAL SPECIFICATIONS. . . . . . . . . . . . . 6

DIMENSIONS & WEIGHT . . . . . . . . . . . . . . . . . . . . . 6

SWEEPING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . 6

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

AIR-MOVING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ERGONOMICS SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . 12

DEBRIS-HANDLING SYSTEM . . . . . . . . . . . . . . . . . . . . 12

DRIVE-TRAIN SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . 12

CHASSIS SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

POWERBOSS INNOVATIONS . . . . . . . . . . . . . . . . . . . . 13

ENVIRONMENTAL FRIENDLY FEATURES. . . . . . . . . . 13

CLEAN AIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

LOWER EMISSIONS. . . . . . . . . . . . . . . . . . . . . . . . . 13

SAFER WORK ENVIRONMENT . . . . . . . . . . . . . . . . 13

CLEAN ENERGY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . 14

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . . . . . 14

FOR SAFETY DURING OPERATION. . . . . . . . . . . . . . . 14

FOR SAFETY WHEN SERVICING OR MAINTAINING

MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SAFETY SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SAFETY DECALS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

BASIC POWERBOSS® SAFETY. . . . . . . . . . . . 18

MACHINE OPERATION . . . . . . . . . . . . . . . . . . . 22

BASIC OPERATING CONTROLS AND INDICATORS 22

IGNITION SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . 22

LIGHT SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

HORN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

FUEL LEVEL GAUGE . . . . . . . . . . . . . . . . . . . . . . . . 22

VOLTMETER AMP GAUGE . . . . . . . . . . . . . . . . . . . . 22

HOUR METER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ENGINE OIL PRESSURE . . . . . . . . . . . . . . . . . . . . . 24

ENGINE COOLANT TEMPERATURE GAUGE . . . . . 24

THROTTLE / GLOW PLUG . . . . . . . . . . . . . . . . . . . . 24

DIRECTIONAL CONTROL PEDAL . . . . . . . . . . . . . . 24

Page 8

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

TABLE OF CONTENTS

PARKING BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

TILT STEERING RELEASE . . . . . . . . . . . . . . . . . . . . 25

SEAT ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . 25

BRAKE PEDAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SWEEPING CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . 26

MAIN BROOM SWITCH . . . . . . . . . . . . . . . . . . . . . . 26

SIDE BROOM SWITCH. . . . . . . . . . . . . . . . . . . . . . . 26

DEBRIS HOPPER DUMP CONTROLS . . . . . . . . . . . . . 26

FILTER SHAKER/VACUUM CONTROL SWITCH 26

HIGH DUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

RAISE/LOWER HOPPER LEVER . . . . . . . . . . . . . . . 27

HOPPER DUMP LEVER . . . . . . . . . . . . . . . . . . . . . . 27

RTR LIGHTS 1 & 2 . . . . . . . . . . . . . . . . . . . . . . . . . . 27

OPERATING PROCEDURES . . . . . . . . . . . . . . . . . . . . . 28

PRE-OPERATION CHECKS . . . . . . . . . . . . . . . . . . . 28

STARTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

TRAVELING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SLOWING AND STOPPING . . . . . . . . . . . . . . . . . . . 29

OPERATING ON GRADES . . . . . . . . . . . . . . . . . . . . 29

SWEEPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

EMPTY HOPPER WITH HIGH DUMP FEATURE 29

USING ROTARY TRASH RELOCATOR (RTR™) 30

TRANSPORTING THE MACHINE. . . . . . . . . . . . . . . 32

Using a Trailer or Transport Vehicle. . . . . . . . . . . 32

Pushing the Machine . . . . . . . . . . . . . . . . . . . . . . 32

PREVENTATIVE MAINTENANCE . . . . . . . . . . . 33

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SCHEDULED MAINTENANCE CHART . . . . . . . . . . . . . 34

PREVENTATIVE MAINTENANCE INSTRUCTIONS 38

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Air Intake System . . . . . . . . . . . . . . . . . . . . . . . . . 38

Check Air Filter Service Indicator . . . . . . . . . . 38

Air Filter Element Removal. . . . . . . . . . . . . . . 39

Air Filter Cleaning. . . . . . . . . . . . . . . . . . . . . . 39

Air Filter Inspection. . . . . . . . . . . . . . . . . . . . . 40

Air Filter Installation . . . . . . . . . . . . . . . . . . . . 40

ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . 40

Battery Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . 40

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . 41

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 9

TABLE OF CONTENTS

FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Checking the LPG Fuel lter Locks . . . . . . . . . . . 43

COOLANT SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . 44

Blowing Out Radiator Fins . . . . . . . . . . . . . . . . . . 44

Reverse Flow Flushing. . . . . . . . . . . . . . . . . . . . . 44

Changing Engine Oil . . . . . . . . . . . . . . . . . . . . . . 44

STEERING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Steering Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . 45

Steering Fork Assembly and Rod End . . . . . . . . . 45

LUBRICATION POINTS . . . . . . . . . . . . . . . . . . . . . . 46

Latches & Hinges . . . . . . . . . . . . . . . . . . . . . . . . . 46

HYDRAULICS SYSTEM . . . . . . . . . . . . . . . . . . . . . . 46

Filling The Fluid Reservoir . . . . . . . . . . . . . . . . . . 46

Hydraulic Fluid Viscosity Specications . . . . . 46

Changing The Hydraulic Fluid . . . . . . . . . . . . . . . 46

Changing The Hydraulic Fluid Filter. . . . . . . . . . . 47

SWEEP COMPONENTS . . . . . . . . . . . . . . . . . . . . . . 48

Broom Door Flap Inspection . . . . . . . . . . . . . . . . 48

Broom Door Flap Replacement and Adjustment 48

Main Broom Adjustment . . . . . . . . . . . . . . . . . . . . 48

Main Broom Height Adjustment . . . . . . . . . . . . . . 50

Main Broom Taper Adjustment. . . . . . . . . . . . . . . 51

Main Broom Replacement . . . . . . . . . . . . . . . . . . 52

Side Broom Height (Wear) Adjustment . . . . . . . . 54

Side Broom Lift Cable Adjustment . . . . . . . . . . . . 55

Side Broom Replacement . . . . . . . . . . . . . . . . . . 56

HOPPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Hopper Removal . . . . . . . . . . . . . . . . . . . . . . . . . 57

Hopper Replacement . . . . . . . . . . . . . . . . . . . . . . 57

Floor Clearance and Dump Angle Adjustment 58

Filter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Filter Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . 63

Vacuum Gasket Mount Adjustment . . . . . . . . . . . 64

Flap Replacement . . . . . . . . . . . . . . . . . . . . . . . . 65

Frame Seal Replacement . . . . . . . . . . . . . . . . . . 65

Front Frame Seal . . . . . . . . . . . . . . . . . . . . . . 65

Side Frame Seal. . . . . . . . . . . . . . . . . . . . . . . 65

Page 10

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

TABLE OF CONTENTS

PARKING BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Adjusting The Parking Brake Cable Length . . . . . 66

TIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Changing Solid Tires . . . . . . . . . . . . . . . . . . . . . . 67

Changing Pneumatic Tires. . . . . . . . . . . . . . . . . . 68

MISCELLANEOUS ADJUSTMENTS. . . . . . . . . . . . . 68

Anti-Static Chain Adjustment . . . . . . . . . . . . . . . . 68

Latch and Hinge Maintenance . . . . . . . . . . . . . . . 68

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . 69

TROUBLESHOOTING CHART . . . . . . . . . . . . . . . . . . . . 69

HYDRAULIC MANIFOLD SOLENOIDS . . . . . . . . . . . . . 79

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 11

FEATURES

FEATURES

AIR-MOVING SYSTEM

• Dual-phase dust ltration

• Built-in pre-ltering & ultra-ne screen panel

lters for dust control

• Aggressive electric lter shakers

• Shock-mounted hydraulic impeller

• Engine area shielded from exhaust air

• Dust Control Filter: 92 Sq. Ft. total

ERGONOMICS SYSTEM

• Roomy, open cockpit with extra comfort

• Adjustable, high-back seat

• Power steering and tilt steering wheel

• Comfortable pedal/controls placement

• Full instrumentation for all functions

DEBRIS-HANDLING SYSTEM

• Direct throw sweeping method

• Oversized hopper with RTR®

• Quick-change, oating 48” main broom &

retractable side brooms

• Dual-performance sweep mode

• Multi-Level Hopper Dumping

DRIVE-TRAIN SYSTEM

• Industrial liquid-cooled engine

• Heavy-duty radiator & Tri-phase air cleaner

• Hydraulics protection package

• 4-Core Radiator

• PowerClimb™ All-Terrain Access

(Two 18” OD Solid Front Tires & One 16” OD

Solid Rear Tire)

Page 12

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

FEATURES

CHASSIS SYSTEM

• Massive One-Piece, unitized steel frame

• Oversized, soft-ride tires

• Eliminates jolts and vibration for component

protection*

POWERBOSS® INNOVATIONS

• PowerClimb™ - with oversized tires and extra

ground clearance you can easily negotiate

rough terrain and speed bumps; even climb

sidewalk curbs

ENVIRONMENTAL FRIENDLY FEATURES

CLEAN AIR

High-performance lter system dramatically reduces

the release of dust and debris back into the air, dust

vacuum ensures that dust is put directly into the

hopper, bristle pattern on main broom increases dust

control

LOWER EMISSIONS

All gas and LP engines meet Tier 2 specications,

catalyst mufers, battery operated available, diesel

operated available, bio-diesel fuel can be used in

Kubota engine

SAFER WORK ENVIRONMENT

Orange machines are highly visible to others in the

workplace, simple controls reduce operator error,

one-button scrub, horn, re in hopper indicator,

effective braking system, seat equipped with safety

shut-off switch, also available: overhead guard, backup alarm, warning beacon

CLEAN ENERGY

Bio-diesel fuel can be used in Kubota engines

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 13

SAFETY INFORMATION

SAFETY INFORMATION

IMPORTANT SAFETY INSTRUCTIONS

Operators must read and understand this manual

before operating or maintaining this machine.

Do not operate this machine in ammable or explosive

areas.

This machine is designed solely for removing dirt,

dust and debris in an outdoor or indoor environment.

PowerBoss does not recommend using this machine

in any other capacity.

The following information below may cause a potential

hazard to the operator and equipment. Read this

manual carefully and be aware when these conditions

can exist. Take necessary steps to locate all safety

devices on the machine and train the personnel

operating the machine. Report any machine damage

or faulty operation immediately. Do not use machine if

it is not in proper operating condition.

FOR SAFETY DURING OPERATION

Keep hands and feet clear of moving parts while

machine is in operation.

Make sure all safety devices are in place and operate

properly. All covers, doors and latches must be closed

and fastened before use.

During operation, attention should be paid to other

persons in the work area and especially if small

children are present.

Components can cause an explosion when operated

near explosive materials or vapor. Do not operate this

machine near ammable materials such as solvents,

thinners, fuels, grain dust, etc.

Store or park this machine on a level surface only. To

prevent unauthorized use, machine should be stored

or parked with the key removed.

This machine is designed for level operation only. Do

not operate on ramps or inclines greater than 2%.

This machine is not suitable for picking up hazardous

dusts.

Page 14

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

SAFETY INFORMATION

CAUTION

Use caution when moving this machine into areas

that are below freezing temperatures.

SAFETY SYMBOLS

Five symbols are used throughout this manual to

emphasize various levels of safety information. These

symbols and the meaning of each are listed below.

FOR SAFETY WHEN SERVICING OR

MAINTAINING MACHINE

Stop on level surface.

Disconnect the power to the machine when servicing.

Avoid moving parts. Do not wear loose jackets, shirts,

or sleeves when working on machine.

Avoid contact with battery acid. Battery acid can

cause burns. When working on or around batteries,

wear protective clothing and safety glasses. Remove

metal jewelry. Do not lay tools or metal objects on top

of battery.

Authorized personnel must perform repairs and

maintenance. Use PowerBoss supplied replacement

parts.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

DANGER

To warn of immediate hazards which will result in

severe personal injury or death

WARNING

To warn of hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION

To warn of hazards or unsafe practices which

could result in minor personal injury.

ATTENTION!

To warn of practices which could result in

extensive equipment damage.

Page 15

SAFETY INFORMATION

NOTE: To direct your attention to important

equipment information or special

instructions for preventing damage to

equipment

Symbols at the top of the list are the strongest

warnings. However, all symbols represent important

information which should be observed to protect

you and others from harm and injury, and to prevent

damage to the equipment.

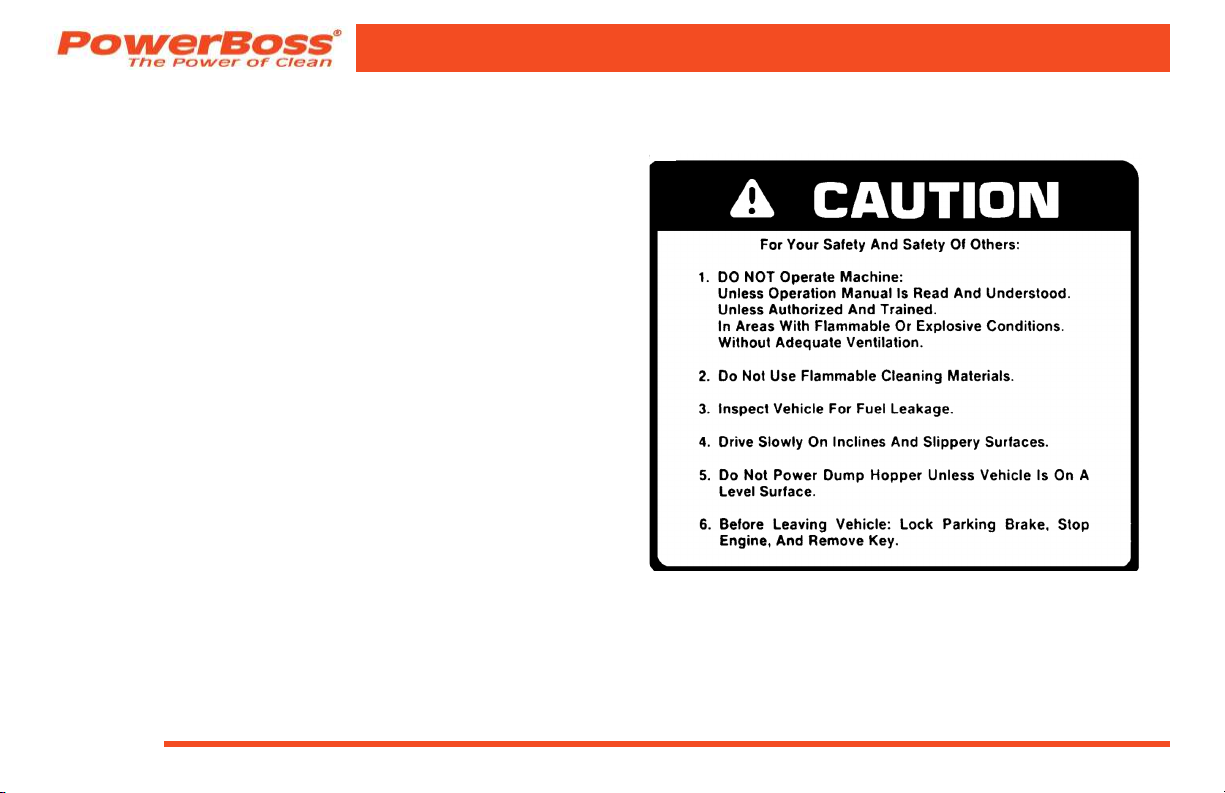

SAFETY DECALS

Decals directly attached to various parts of the

sweeper are highly visible safety reminders which

should be read and observed. Make sure the decals

are replaced if they become illegible or damaged.

Located in the drive compartment:

Part Number 3301854

Page 16

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

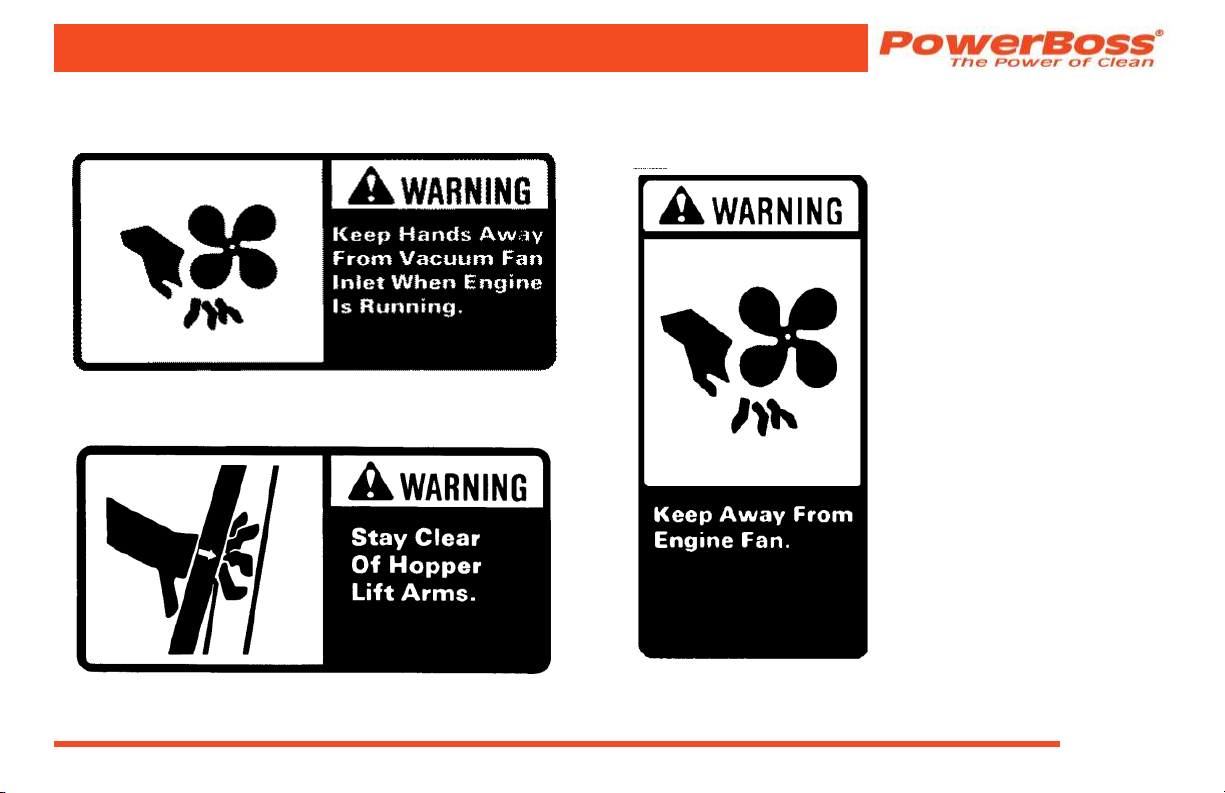

Located on the High Dump Hopper:

SAFETY INFORMATION

Located at the Impeller:

Part Number 3301729

Located on the High Dump Hopper:

Part Number 3301732

Located on the shroud of the radiator:

Part Number 3301733

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 17

SAFETY INFORMATION

BASIC POWERBOSS® SAFETY

PowerBoss® sweepers should never be operated

unless:

1. The operator is trained and authorized to

operate the equipment and,

2. The equipment is free of malfunctions.

Malfunctioning equipment should be removed

from service.

DANGER

Keep cigarettes, matches and all other ame

sources away from the sweeper. Gasoline, LP

gas and diesel fuel are highly ammable. Lead

acid batteries are equally dangerous due to the

highly explosive hydrogen gas they emit.

WARNING

Before starting the engine, make sure that:

* You are securely seated in the operator’s seat.

* The parking brake is locked.

* The directional control pedal is in neutral.

* The throttle is in idle.

* Hydraulic controls are in the OFF position.

WARNING

During operation:

* Keep your hands and body clear of moving

parts, especially when the hopper or lift arms

are partially or fully raised.

* Make sure others in the area stay clear of the

equipment and moving parts.

* Never attempt to dump debris from a dock or

mezzanine. Dump from ground level only.

Page 18

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

SAFETY INFORMATION

WARNING

When leaving the sweeper unattended:

* Place the controls in the OFF position.

* Set the parking brake.

* Shut off the engine.

WARNING

When servicing or repairing the fuel system:

* Work in a properly ventilated area, do not

smoke or allow an open ame near the fuel

system.

* Never bypass safety components unless you

are testing them.

* Never bypass the fuel lter lock, except when

testing them (and always reconnect them

after testing).

* Wear gloves to disconnect the tank coupling.

WARNING

During cleaning and maintenance:

* Always stop the engine and set the parking

brake before servicing.

* Never use detergents or cleansers that are

ammable or combustible.

* Never inate a pneumatic tire without using a

safety cage.

* Do not attempt any impeller adjustment unless

you have shut off the engine. Never place your

hands near the intake hoses or inlet when the

engine is running.

* Always engage the safety arm before servicing

the hopper. Do not rely on the hydraulic

cylinder to keep the hopper raised.

* Never test for hydraulic hose leaks using your

hand or any other part of your body. High

pressure leaks can be very dangerous and

should only be checked using a piece or paper.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 19

SAFETY INFORMATION

WARNING

Do not operate an LP powered sweeper

when any component in the fuel system is

malfunctioning or leaking.

WARNING

Replace any defective safety components

before operating the sweeper.

CAUTION

Do not drive with the hopper in the raised

position except the few feet necessary to

position the hopper over the dumpster or

receptacle. Driving with the hopper raised

reduces visibility and creates conditions

for striking over-head objects, throwing the

machine off-balance and other hazards.

CAUTION

Travel slowly on grades.

CAUTION

Place a block or chock behind the wheels when

parking on inclines.

CAUTION

Use special care when traveling on wet surfaces.

CAUTION

Observe all proper procedures for operation and

maintenance of the sweeper, as outlined in this

manual.

CAUTION

Remain alert at all times to people and

equipment in and around your area of operation.

Page 20

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

SAFETY INFORMATION

ATTENTION!

Do not operate the #2 RTR lever before the #1

light illuminates.

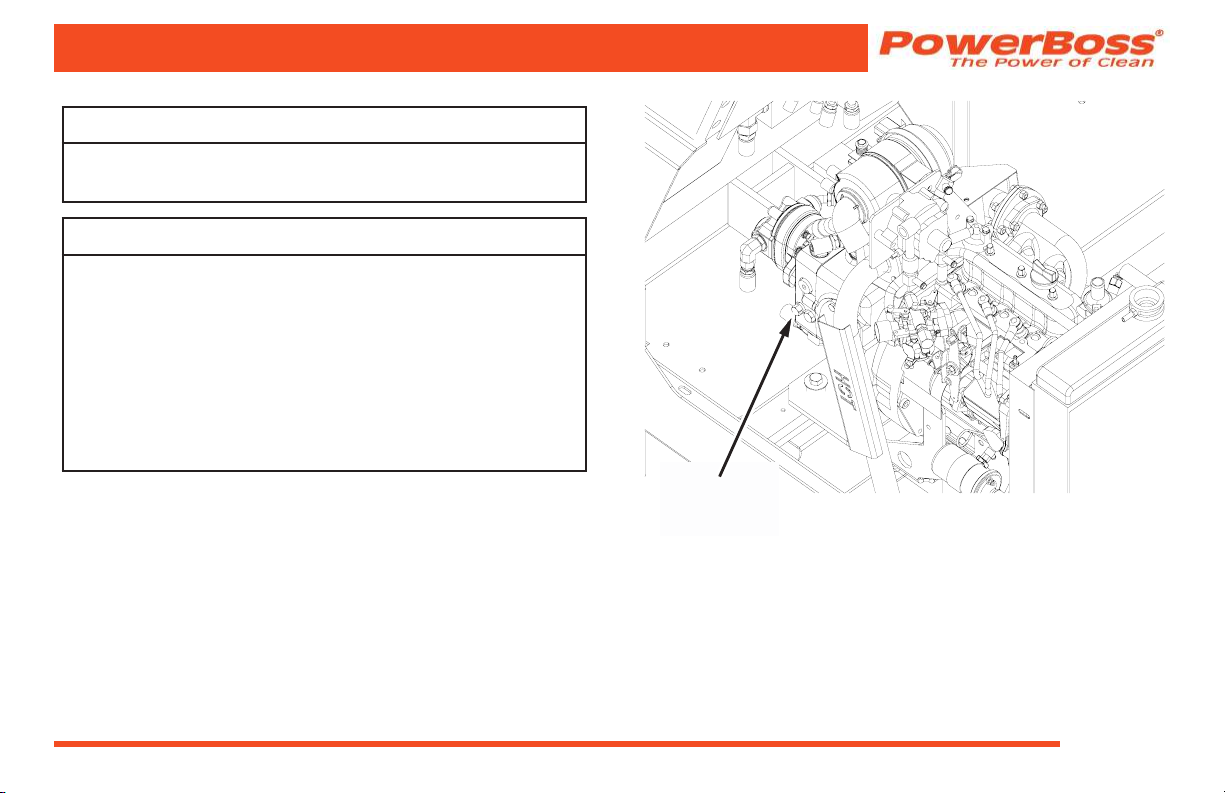

ATTENTION!

Never push or tow a machine faster than 6 mph.

If towing the machine is required, you must

rst disengage the drive wheel by turning the

Bypass Valve out 3 full turns (maximum). The

Bypass Valve is located on the side of the Main

Hydraulic Pump attached to the engine. Failure

to disengage could result in costly damage to

the drive system.

BYPASS

VALVE

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 21

MACHINE OPERATION

MACHINE OPERATION

BASIC OPERATING CONTROLS AND

INDICATORS

IGNITION SWITCH

The diesel powered machine has a two position key

switch used to turn the machine’s electric power

on and off. The gasoline and LP units have a three

position key switch.

To start gasoline powered machines, turn the key

clockwise to the Start position When the engine

starts, release the key. To stop the engine, turn the key

to OFF.

To start diesel engines, turn the ignition key clockwise

to the on position. Press the Glow Plug Button for 20

seconds. Continue turning ignition key clockwise to the

Start position. When engine starts release key.

NOTE: If the engine does not start after 10

seconds, release the key, wait 1 minute

and repeat the procedure.

LIGHT SWITCH

The light switch, located on the control panel turns on

and off the lights.

HORN

The horn is activated by pressing the horn button

located on the right side of the operator.

FUEL LEVEL GAUGE

The fuel gauge indicates the amount of fuel remaining

in the tank.

VOLTMETER AMP GAUGE

The Voltmeter used on gas & LP units or Amp Gauge

used on diesel units indicates the charging current

which is being sent to the battery by the alternator. It

also indicates a drop in voltage when the alternator is

not charging.

HOUR METER

The hour meter records the number of hours the

machine has been operated, providing a helpful guide

for performing routine maintenance tasks.

Page 22

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

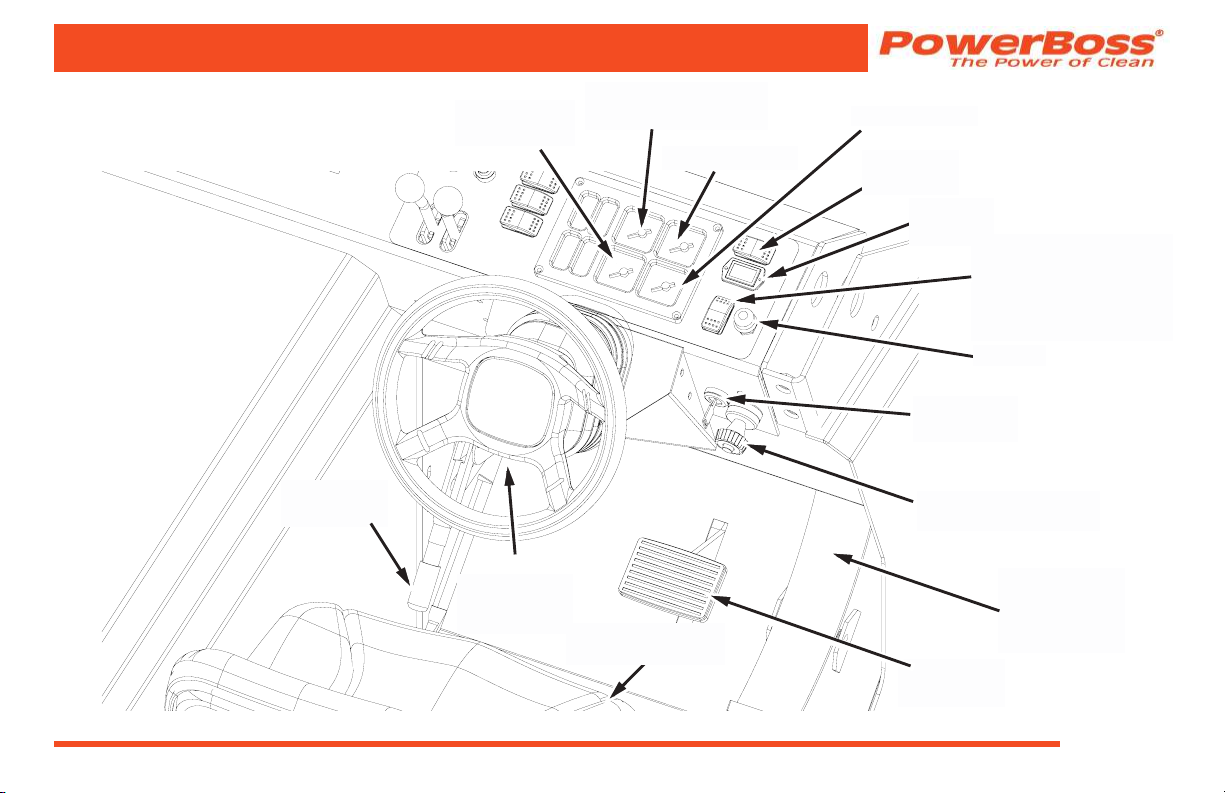

MACHINE OPERATION

PARKING

BRAKE

ENGINE OIL

PRESSURE

TILT

STEERING

RELEASE

ENGINE COOLANT

TEMPERATURE

FUEL LEVEL

SEAT

ADJUSTMENT

VOLTMETER

LIGHT

SWITCH

HOUR

METER

IGNITION

SWITCH

THROTTLE CABLE

(DIESEL ONLY)

BRAKE

PEDAL

THROTTLE

(GAS AND LP )

GLOW PLUG

(DIESEL)

HORN

DIRECTION

CONTROL

PEDAL

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 23

MACHINE OPERATION

ENGINE OIL PRESSURE

The engine oil pressure gauge ranges from 0 psi to 60

psi. A reading below 7 psi indicates problems which

may result in damage to the engine.

ENGINE COOLANT TEMPERATURE GAUGE

The engine coolant temperature gauge registers the

temperature of the engine coolant. Temperatures

above 220°F indicate an overheating engine.

THROTTLE / GLOW PLUG

The throttle adjusts the engine speed from idle to the

operating speed. The LP and Gasoline models have

a three speed throttle switch with idle, slow and fast

selections. The diesel model has an adjustable throttle

cable and glow plug switch.

• The throttle should be in the IDLE position when

starting the engine and immediately before

shutdown.

• Full throttle position should be used during

operation to ensure proper broom speed and

dust control.

DIRECTIONAL CONTROL PEDAL

The directional control pedal controls the speed and

direction of the machine. It is also used for slowing

the machine or stopping.

• To propel the machine forward, apply pressure

to the front of the pedal, increasing pressure to

increase speed.

• To propel the machine backward, apply

pressure to the rear of the pedal.

• To slow or stop the machine, move the foot

pedal into neutral.

• For emergency stops, move the foot pedal past

neutral and into the opposite position.

CAUTION

Use for emergency stops only! Constant use of

this braking method may result in damage to the

drive components.

Page 24

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

MACHINE OPERATION

PARKING BRAKE

The parking brake is cable activated. To engage

the parking brake pull upward on the hand brake

lever located on the left side of the front wall of the

operator’s compartment. To release the parking brake

press the brake pedal and push down on the hand

brake lever.

TILT STEERING RELEASE

The steering wheel can be adjusted to provide the

most comfortable position for the operator. To adjust

the steering wheel press the tilt steering release (just

below the wheel in the rubber bellows) and push up

or down on the steering wheel. The steering wheel

will snap into a set positions.

SEAT ADJUSTMENT

The drivers seat is adjustable to provide the

most comfortable position for the operator. The

adjustment lever is at the bottom front of the seat.

While sitting in the seat, push the lever to the right

and pull forward or push back on the seat. Release

the lever when the seat is in the proper location.

BRAKE PEDAL

The mechanical drum brakes on the two front

wheels are operated by pressing on the brake

pedal.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 25

SWEEPING CONTROLS

DEBRIS HOPPER DUMP CONTROLS

MAIN BROOM SWITCH

The main broom switch activates and lowers the main

broom. When not sweeping, the main broom should

be turned off.

NOTE: The hopper must be lowered for the main

broom to operate.

SIDE BROOM SWITCH

The side broom switch activates and lowers the side

broom. When not sweeping, the side broom should

be turned off.

NOTE: The hopper must be lowered for the side

broom to operate.

FILTER SHAKER/VACUUM CONTROL SWITCH

The right side of this switch turns the impeller on.

The left side of this switch is used to activate the

lter shakers prior to dumping or as needed during

sweeping operation. It is located to the left hand

side of the instrument panel.

To shake the lter:

1. Bring the machine to a complete stop.

2. Switch off the main and side brooms.

3. Press and hold the lter shaker button for 20

to 30 seconds.

4. Turn the impeller on.

5. Switch the main and side brooms on and

resume sweeping.

Page 26

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

HIGH DUMP

The two levers on the left of the control panel are

used to raise the hopper to any height up to 60” (1.52

m) and dump it.

CAUTION

Do not leave the hopper in the RAISE position

for an extended period of time.

RAISE/LOWER HOPPER LEVER

Raises and lowers the hopper

HOPPER DUMP LEVER

Rotates, dumps and returns the hopper to it original

position.

RTR LIGHTS 1 & 2

Rotary Trash Relocator (RTR™) is a standard feature

on high-dump models. Its purpose is to increase

the holding capacity of the debris hopper to make

dumping the hopper necessary less frequently.

RTR

LIGHT 1

HOPPER

DUMP LEVER

RAISE/LOWER

HOPPER

LEVER

RTR

LIGHT 2

FILTER SHAKER

AND VACUUM

CONTROL

SWITCH

SIDE

BROOM

SWITCH

MAIN

BROOM

SWITCH

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 27

MACHINE OPERATION

OPERATING PROCEDURES

PRE-OPERATION CHECKS

Prior to starting the engine, check the following:

1. Engine oil level

2. Engine coolant level

3. Fuel level

4. Hydraulic uid level

5. Brakes, steering and directional controls

6. The oor beneath the machine for signs of uid

leaks

Fluid levels should be correct. Brakes, steering and

directional controls should be functioning properly.

Hoses, lines and tanks should be free of damage and

leaks.

Page 28

STARTING

WARNING

Before starting the engine, sit in the operator’s

seat and make sure the parking brake is locked.

1. Make sure the directional control pedal is in the

neutral position.

2. Make sure the throttle is in the idle position.

3. LP and Gasoline-powered: Turn the ignition

key to the start position (to the right). When the

engine starts, release the button.

Diesel-powered: Press the Glow-plug switch for

15 to 20 seconds, then turn the ignition key to

the start position (to the right). When the engine

starts, release the button.

CAUTION

If the engine fails to start, do not continue

cranking for more than ten seconds. Allow the

starter motor to cool between attempts.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

MACHINE OPERATION

TRAVELING

Move the machine forward or backward as follows:

• Forward: Apply pressure to the front of the

directional control pedal, increasing pressure to

increase speed.

• Reverse: Apply pressure to the rear of the

pedal, increasing pressure to increase speed.

SLOWING AND STOPPING

Allow the directional control pedal to move into

neutral. The machine will slow and coast to a stop.

OPERATING ON GRADES

1. Always travel slowly.

2. Exercise extreme caution when traveling across

or turning on grades.

SWEEPING

1. Turn the impeller switch on.

2. Turn on the main and side broom switches on.

3. Drive the machine over the area to be swept.

EMPTY HOPPER WITH HIGH DUMP FEATURE

1. Drive the machine to the dumping area.

2. Use the directional control pedal to position the

machine so that the space between the machine

and the container or dumpster is adequate to

raise the hopper.

3. Reduce the engine speed.

4. Pull back the raise/lower lever to the RAISE

position and hold until the bottom of the hopper is

high enough to clear the top of the container.

WARNING

Never place your hands or other body parts

near the lift arms when the hopper is operating.

5. Use the directional control pedal to slowly and

carefully move the machine forward until the

hopper is properly positioned to dump the debris

into the container.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 29

MACHINE OPERATION

WARNING

It is unsafe to travel an extended distance with

the hopper raised. Travel only the distance

necessary to position the hopper.

6. Shake the lters for 20-30 seconds.

7. To empty debris, pull back the hopper dump

lever to the DUMP position to rotate the hopper

forward and empty the debris..

8. After the hopper empties, To rotate the hopper

back, push the hopper dump lever forward to

the RETURN position until the hopper rotates

and stops.

9. Slowly back the machine away from the

dumpster approximately 5 feet.

10. To lower the hopper, push the raise/lower lever

forward to the LOWER position until the hopper

stops.

USING ROTARY TRASH RELOCATOR (RTR™)

1. Use the directional control pedal to stop the

machine on a level surface.

2. Move the throttle to the IDLE position.

NOTE: As you complete Steps three and four,

observe the two red lights labeled 1 and

2 in the upper left corner of the control

pane.

• Light 1 illuminates when the hopper reaches

the minimum height required to use the RTR™

feature.

• Light 2 illuminates when the hopper reaches the

rotation stop point.

3. Pull back the raise/lower lever to the RAISE

position and hold until Light 1 illuminates, then

release.

WARNING

Make sure no one is in the area under or around

the hopper.

Page 30

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

MACHINE OPERATION

4. Pull back the hopper dump lever to the DUMP

position and hold until Light 2 illuminates, then

release.

NOTE: This rotates the hopper, causing the

debris to move from the rear entrance

to the front wall of the hopper. Rotating

beyond this point will cause the debris to

be dumped from the hopper.

5. Push the hopper dump lever forward to the

RETURN position until the hopper rotates back

and stops.

6. Push the raise/lower lever forward to the

LOWER position until the hopper returns to the

normal operating position.

7. Move the throttle to the RUN position and

resume sweeping.

LIGHT 1

HOPPER

DUMP LEVER

RAISE/LOWER

HOPPER

LEVER

RTR

RTR

LIGHT 2

FILTER SHAKER

AND VACUUM

CONTROL

SWITCH

SIDE

BROOM

SWITCH

MAIN

BROOM

SWITCH

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 31

TRANSPORTING THE MACHINE

Using a Trailer or Transport Vehicle

1. Position the machine on the transport vehicle

or trailer and apply the parking brake.

2. Tie the machine down using the tie down holes

in the frame forward of the front wheels and in

the rear center of the frame.

NOTE: Attach the tie downs to the frame only.

Pushing the Machine

Push the machine from the front or rear using the

bumpers only.

ATTENTION!

Do not tow or push the machine a distance of

more than .5 miles (.80 kilometers) or faster than

one mile per hour (1.61 km). Exceeding these

restrictions may cause damage to the hydraulic

system. If towing will exceed the above

restrictions, the rear wheel must be raised or

supported by a dolly.

MACHINE OPERATION

Page 32

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

PREVENTATIVE MAINTENANCE

INTRODUCTION

Regular maintenance on your sweeper results in

better cleaning, faster cleaning and a prolonged

service life for the equipment and components. This

section contains the following information to help

you give your sweeper the maintenance attention it

requires:

• A Scheduled Maintenance Chart

• Preventative Maintenance Instructions for

Required Scheduled Maintenance Tasks

Because it is extremely important to your safety, you

will see the following WARNING repeated throughout

this section:

WARNING

Never attempt to perform any service on the

equipment or components until the engine is

OFF, the parking brake is LOCKED, and the

wheels are CHOCKED.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 33

PREVENTATIVE MAINTENANCE

SCHEDULED MAINTENANCE CHART

FREQUENCY (IN HOURS) SERVICE

DAILY 50 100 200 500

X Pressure wash engine

NOTE: For additional maintenance requirements, refer to the engine manual.

AIR INTAKE SYSTEM

X Empty rubber dust cup of air lter element.

X Check air lter indicator

X Clean air lter. NOTE: Clean more often in dusty conditions.

X Replace air lter.

ELECTRICAL SYSTEM

X Clean battery top.

COOLANT SYSTEM

X Check coolant level and ll as needed.

X Inspect radiator ns and clean as needed.

X Blow out radiator ns.

X Drain and ush the coolant system

(BY MAINTENANCE AREA)

ENGINE

Page 34

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

SCHEDULED MAINTENANCE CHART

FREQUENCY (IN HOURS) SERVICE

DAILY 50 100 200 500

STEERING

X Lubricate steering cylinder.

X Lubricate steering cylinder rod ends.

X Lubricate steering fork assembly

X Check for leaks.

LUBRICATION POINTS

X Hood Latches & Hinges Lubricate type - oil

HYDRAULIC SYSTEM

X Check hydraulic reservoir gauge and ll as needed.

X Replace breather cap lter element.

X Replace hydraulic uid and lter

X Check functioning of directional control pedal and adjust as needed.

X Clean hydraulic uid strainer in reservoir.

X Inspect hydraulic oil cooler ns and clean as needed (if so equipped).

(BY MAINTENANCE AREA)

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 35

PREVENTATIVE MAINTENANCE

SCHEDULED MAINTENANCE CHART

FREQUENCY (IN HOURS) SERVICE

DAILY 50 100 200 500

SWEEPING COMPONENTS

X Inspect brooms for wear and remove strings and debris from bristles and drive assembly.

X Inspect broom skirts for wear and adjust or replace as needed.

X Rotate main broom end-to-end.

X Perform main broom adjustment test and adjust as needed.

X Inspect the side broom for wear and adjust as needed.

Replace main and side brooms as needed:

Main Broom needs to be replace if bristles are 1” in length or less.

Side Broom needs to be replaced if bristles are 3” in length.

X Check hopper lters and clean or replace as needed.

X Check hopper clearance from oor and adjust as needed.

X Inspect the hopper aps for wear or damage and replace as needed.

X Inspect hopper side and frame seals for wear or damage. Adjust or replace as needed.

(BY MAINTENANCE AREA)

HOPPER

Page 36

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

SCHEDULED MAINTENANCE CHART

FREQUENCY (IN HOURS) SERVICE

DAILY 50 100 200 500

IMPELLER

X Check for hydraulic uid leaks.

PARKING BRAKE

X Check for proper functioning and adjust as needed.

WHEELS AND TIRES

X Visually inspect for wear and damage. Repair or replace as needed.

X Check pneumatic tires if equipped, for proper air pressure (95 psi).

X Check and tighten lug nuts (torque to 100 ft.-lbs)

MISCELLANEOUS

X Inspect latches and hinges. Tighten and lubricate as needed.

X Check anti-static drag chain on rear wall of broom chamber for damage or excessive wear.

Replace as needed.

X Check side broom lift cable and lift cable for wear.

(BY MAINTENANCE AREA)

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 37

PREVENTATIVE MAINTENANCE

PREVENTATIVE MAINTENANCE

INSTRUCTIONS

ENGINE

Maintenance requirements and service instructions for

your sweeper engine are outlined in the following parts

of this Maintenance Section:

• Air Intake System

• Electrical System

• Fuel System

• Coolant System

• Lubrication System

All basic maintenance tasks are listed with their

recommended frequencies on the Planned

Maintenance Chart in this manual. Important additional

maintenance requirements and instructions are

explained in the engine manual which comes with your

machine.

WARNING

Never attempt to perform any service on the

equipment or components until the engine if

OFF, the parking brake is LOCKED, and the

wheels are CHOCKED.

Air Intake System

Check Air Filter Service Indicator

The air lter service indicator shows when to change

the air lter element. Check the indicator on a daily

basis. The red indicator gradually becomes visible as

the air lter elements load with dirt. It is not necessary

to change the air lter elements until the red indicator

reaches the top of the service indicator and locks into

position.

1. Lift engine cover.

2. Inspect air lter service indicator

Page 38

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

AIR FILTER

SERVICE

INDICATOR

AIR FILTER

ELEMENT

DUST CAP

RETAINING

CLAMPS

NOTE: The indicator may return to the nonviable

position when the engine is shut off. To

check, reset indicator and turn on the

engine, if it locks in visible position again

clean or change element.

Air Filter Element Removal

1. Turn off the engine and set the parking brake.

2. Lift the engine cover.

3. Locate the air lter and loosen the retaining

clamp.

4. Remove the dust cup.

5. Pull the rubber plug out of the dust cup and

empty the contents.

6. Pull the air lter elements out of its housing.

Air Filter Cleaning

1. Once you have removed the air lter elements,

empty the dust cup and clean the interior of the

air lter housing.

2. Use an air hose to blow out the air lter

elements. Air pressure should be 100 psi or less.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 39

PREVENTATIVE MAINTENANCE

Air Filter Inspection

1. After you clean the air lter elements, check the

elements for holes by passing a light bulb inside

it.

Air Filter Installation

1. Wipe out the air cleaner housing with a damp

cloth. Be sure all dirt is removed.

2. Install the cleaned replacement lter elements

so that the ns are at the far end of the

housing. Be careful not to damage the ns.

3. Replace the rubber plug in the dust cup.

4. Replace dust cup, being sure embossed word

“top” on cup is positioned correctly

(up).

5. Tighten the ring clamp or retaining clips.

6. Check the condition of intake hoses and clamps.

Close engine cover.

ELECTRICAL SYSTEM

Battery Cleaning

1. Combine baking soda and water in a strong

solution.

2. Brush the solution over the battery top, including

terminals and cable clamps. Make sure the

solution does not enter the battery.

3. Using a wire brush, clean the terminal posts and

cable clamps.

4. Apply a thin coating of petroleum jelly to the

terminals and cable clamps.

Page 40

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

Battery Replacement

CAUTION

Remove the negative battery cable before you

remove the positive battery cable. This is done

to prevent accidental electrical shorting which

can result in personal injury.

1. Disconnect the negative (-) cable and then the

positive (+) cable.

2. Remove the battery.

3. Install the new battery.

4. Connect the positive (+) battery cable rst, then

the negative (-) cable.

Circuit Breakers

If a circuit breaker trips, it can be reset by pressing the

reset button in the center of the breaker. (The circuit

breakers are located on the instrument panel below

the steering wheel).

CIRCUIT

BREAKER

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 41

PREVENTATIVE MAINTENANCE

Fuses

Fuses are located in the fuse panel behind the hopper

on the re wall upper right corner when facing the unit

CAUTION

Safety Arm Must Be Engaged When Checking

These Fuses

FUSES

FUEL SYSTEM

WARNING

Never attempt to perform any service on the

equipment or components until the engine is

OFF, the parking brake is LOCKED, and the

wheels are CHOCKED.

WARNING

Never operate an LP powered sweeper

when any component in the fuel system is

malfunctioning or leaking.

WARNING

Never bypass safety components unless you

are testing them.

WARNING

Replace any defective safety components

before operation the sweeper.

Page 42

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

WARNING

During repair or servicing of the fuel system,

work in a properly ventilated area and do not

smoke or allow an open ame near the fuel

system.

WARNING

When disconnecting the tank coupling, always

wear gloves. LP fuel can freeze bare hands.

WARNING

Under no circumstances should the fuel lter

lock be bypassed, except when testing. After

testing, always reconnect lock. Bypassing the

fuel lter lock after testing creates a potential

re hazard.

Tier װ compliant fuel system Refer to P.S.I Service

Manual

Checking the LPG Fuel lter Locks

1. Start the engine. Then remove the vacuum hose

going to the fuel lter lock. The solenoid should

close, shutting off the fuel supply and stopping

the engine.

• If the engine continues to operate, the fuel lter

lock should be replaced.

• If the engine shops, the fuel lter lock is

operating properly.

2. With the engine stopped, let the machine stand

while the LPG tank valve is open (the hose

is removed from the fuel lter lock). After 10

minutes, try the starter motor.

• If the engine starts or res, this indicates a fuel

leak has occurred. Replace the fuel lter lock

immediately.

• If the engine simply turns over, this indicates the

fuel lter lock is operating correctly.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 43

PREVENTATIVE MAINTENANCE

COOLANT SYSTEM

Blowing Out Radiator Fins

NOTE: Make sure radiator is cool before blowing

out the radiator ns with compressed air.

Reverse Flow Flushing

1. At the engine, disconnect the hoses.

2. Make sure the radiator cap is on tight.

3. Using a hose clamp, attach a ushing gun onto

the lower hose.

4. Turn on the water and ll the radiator.

5. To keep from damaging the radiator, apply air

pressure slowly and carefully.

6. Shut off the air pressure, rell the radiator with

water, and reapply the air pressure. You will

need to repeat these steps until water ushed

from the radiator runs out clear.

7. Inspect and clean the radiator cap.

8. Inspect and reconnect the hoses.

9. Rell the radiator with coolant.

NOTE: Use a 50/50 mixture of water and an anti-

freeze with an ethylene glycol base.

Changing Engine Oil

Gasoline and LP Engines: Use any SF or SG rated

oil meeting API specications and suited to seasonal

temperatures.

Refer to the Engine Manufacturer’s Operator Manual

for these specications.

1. Place a drain pan under the lowest end of the

engine.

2. Remove the drain plug and allow the oil to drain

into the pan.

3. Remove the used oil lter and replace with a

new one.

4. Dispose of the oil and oil lter in an approved

manner.

5. Remove the engine oil cap, add oil in the

amounts listed in the engine manual, then

secure the cap.

Page 44

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

STEERING

Steering Cylinder

1. Open engine cover.

2. Remove screw and washer in lower portion of

the oor board and rotate up.

3. Grease tting located mounting end of cylinder.

STEER CYLINDER

LUBRICATION POINT

Steering Fork Assembly and Rod End

The steering fork assembly and rod end lubrication

points are located under the rear on the machine

above the rear drive wheel.

ROD END

STEERING FORK

LUBRICATION

POINT

LUBRICATION

POINT

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 45

LUBRICATION POINTS

Latches & Hinges

The hinges and latches and all doors and covers

should be lubricated with oil every 500 hours. There

are numerous hinges and latches, make sure to

lubricate all of the following:

• Engine cover

• Main Broom Doors

• Seat Tracks

HYDRAULICS SYSTEM

Filling The Fluid Reservoir

CAUTION

DO NOT OVERFILL HYDRAULIC RESEVOIR TANK!

DO NOT USE TRANSMISSION FLUID!

NOTE: Fill the hydraulic uid reservoir when the

machine is cool and the hopper is in the

lowered position.

1. Open the engine cover.

2. Remove the dipstick. Fluid level should be

between the high and low marks on the dipstick.

Page 46

PREVENTATIVE MAINTENANCE

3. If the uid level is not acceptable, add hydraulic

uid.

CAUTION

Minuteman International, Inc. recommends using:

Mobil DTE 10 Excel 32 hydraulic oil or equivalent.

Mobil DTE 10 Excel 32 - Viscosity, ASTM D 445

cSt @ 40°C (104° F): 32.7

cSt @ 100°C (212° F): 6.63

Changing The Hydraulic Fluid

1. Turn off the engine and engage the parking

brake.

2. Place a drain pan on the oor below the

reservoir.

3. Remove the drain plug located on the bottom

rear of the reservoir and allow the uid to drain.

4. Discard the uid in an approved manner, then

replace and retighten the drain plug.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

5. Remove the ller / breather cap located on top of

the reservoir and ll the reservoir with approved

hydraulic uid.

NOTE: Ten (10) gallons (US) of uid are required.

6. Install the ller cap assembly.

7. Check the drain plug for leakage.

Changing The Hydraulic Fluid Filter

1. Turn off the engine and engage the parking

brake.

2. Open the engine cover.

3. Unscrew the oil lter cartridge from the hydraulic

manifold assembly and discard in an approved

manner.

4. Apply a thin coating of uid to the seal of a new

lter element.

5. Thread onto the mount and hand tighten.

6. Tighten an additional one-half turn beyond hand

tight.

NOTE: Do not over tighten.

7. Start the machine, shut it off, then check for

leakage.

HYDRAULIC

FLUID FILTER

FILLER/BREATHER

HYDRAULIC

RESERVOIR

CAP

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 47

PREVENTATIVE MAINTENANCE

SWEEP COMPONENTS

Broom Door Flap Inspection

NOTE: Perform this inspection when the machine

is parked on a level surface.

1. Turn the machine off and lock the parking brake.

2. Inspect broom door aps for wear and damage.

Flap clearance should be ⅛” (3.18 mm) above

the oor.

3. Worn and damaged aps should be replaced

immediately to maintain proper dust control.

Broom Door Flap Replacement and Adjustment

The aps are attached to the broom doors by a

retainer bar, hex bolts and nuts. To remove the aps,

remove the nuts, bolts and retainer bar. To adjust the

aps, loosen the nuts and bolts, slide the ap up or

down as needed. Retighten the nuts and bolts.

Main Broom Adjustment

NOTE: Perform this adjustment on a at, smooth

test surface.

1. Drive the machine onto the test surface with the

main broom turned off.

2. Set the parking brake.

3. Push the main broom switch to the ON position

to activate and lower the main broom.

4. Open the throttle to full.

Page 48

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

2” (5.08 cm)

5. Allow about 45 seconds for the broom to

operate, then push the main broom switch to the

off position to deactivate and raise the broom.

NOTE: Test time will vary according to the test

surface used.

6. Drive the machine clear of the test site.

7. Examine the polished pattern made by the

broom on the test area.

Main Broom Test Pattern

NOTE: A rectangular shape the length of the

main broom, 2” (5.08 cm) wide, indicates

the main broom is properly adjusted. A

pattern smaller then 2” (5.08 cm) indicates

need for lower adjustment. A pattern wider

than 2” (5.08 cm) indicates a need for

higher adjustment. If pattern is tapered

from end to end instead of rectangular,

see “Main Broom Taper Adjustment” on

page 51.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 49

Main Broom Height Adjustment

1. Engage the parking brake.

NOTE: The adjustment knob is located behind the

hopper.

2. Raise the hopper and set the safety arm.

WARNING

Do not rely upon the hydraulic cylinders to

keep the hopper raised for maintenance.

Always engage the safety arm before

servicing the hopper.

4. Loosen the wing nut and turn the adjustment

knob clockwise to raise the main broom or

counterclockwise to lower the main broom.

5. Tighten the wing nut.

6. Remove the safety arm and lower the hopper.

7. Repeat the main broom adjustment test to see

that the broom is properly adjusted.

PREVENTATIVE MAINTENANCE

MAIN BROOM

ADJUSTMENT KNOB

Page 50

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

Main Broom Taper Adjustment

NOTE: It is not usually necessary to perform this

adjustment. However, if the main broom

adjustment test shows a pattern that is

tapered in length (one end is wider than

the other), perform the procedures which

follow.

The taper can be adjusted from either the left or right

side of the machine.

Correct Taper Pattern

Incorrect Taper Pattern

1. Turn the engine off and lock the parking brake.

2. Open the right or left main broom door.

3. Loosen the nuts and bolt securing the bearing

mount to the angle mount on the frame.

4. If the pattern was wider on this side of the

machine, adjust the bearing mount up. If the

pattern was smaller on this side of the machine

adjust the bearing mount down.

NUTS AND BOLTS

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

RIGHT SIDE

BEARING MOUNT

Page 51

NUTS AND BOLTS

LEFT SIDE

BEARING MOUNT

5. After adjustment, tighten the bolt and nut

securing the bearing mount.

6. Repeat the main broom adjustment test to see

that the broom is properly adjusted.

PREVENTATIVE MAINTENANCE

Main Broom Replacement

NOTE: Broom should be replaced if bristles worn

to a length of 1 inch; 2.54 cm or less.

1. Turn the engine off and lock the parking brake.

2. Push the main broom Switch to the ON position

3. Open the right main broom chamber door (the

door on the driver’s side).

4. Remove the knob and washer on the main

broom idler mount.

5. Pull the main broom idler mount straight out to

remove.

6. Grasp the main broom by the plastic drive hub,

pull the main broom straight out and clear of the

broom chamber.

7. Depending on broom condition, you can either

rotate the old broom end-to-end and re-install it

or you can install a new broom. Slide the main

broom into the broom chamber and align the

broom with the metal drive hub located at the far

side of the broom chamber.

Page 52

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

NOTE: If a worn broom is being replaced, install

the new broom by rst adjusting the

broom arms up, to better match the

position of the drive hub with the hub

on the new broom (refer to “Main Broom

Adjustment”).

8. Once the broom is started onto the drive hubs,

rotate the broom counter-clockwise while

pushing lightly against the broom.

9. Once the broom is fully engaged, replace the

idler hub while aligning the seats in the idler hub

with the broom’s drive hub ears.

10. Install the retaining knob and washer into

position and tighten.

11. Close and latch the right broom door.

12. Perform a main broom adjustment test and

adjust as needed.

MAIN BROOM

DRIVE PLASTIC

HUB

KNOB

WASHER

IDLER

MOUNT

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 53

PREVENTATIVE MAINTENANCE

Side Broom Height (Wear) Adjustment

1. Drive the machine onto the test surface with the

side broom turned off.

2. Set the parking brake.

3. Turn the side broom switch on to activate and

lower the side broom.

HEIGHT

ADJUSTMENT

SCREW

LOCK NUT

4. Side Broom should make contact with oor in the

“10 to 3 o’clock position.

5. If not, turn side broom switch to the off position

and loosen the lock nut.

6. Adjust the screw up or down until proper oor

contact is made in the “10 to 3 o’clock” position.

Turn broom on and off as needed.

NOTE: The side broom lift cable may have to adjusted

if the cable does not alow the broom to make

proper contact with the oor.

Page 54

7. After adjustment, tighten the lock nut.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

Side Broom Lift Cable Adjustment

The lift cable may need to be adjusted if the cable

does not allow the broom to make proper contact with

the oor or the broom touches the oor when turned

off.

1. Loosen the lock nut.

2. Hold the nyloc nut with a wrench.

3. If the broom touches the oor when turned off,

turn the adjustment screw clockwise to raise the

broom up.

4. If the cable does not allow the broom to make

proper contact with the oor turn the adjustment

screw counterclockwise to lower the broom.

5. After the broom lift cable has been properly

adjusted tighten the lock nut.

ADJUSTMENT

SCREW

LOCK NUT

NYLOC NUT

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 55

Side Broom Replacement

PREVENTATIVE MAINTENANCE

NOTE: Broom should be replaced if bristles worn

to a length of 3 inches; 7.62 cm or less.

NOTE: The side broom features a quick release

mechanism which enables the operator to

remove the brush in seconds.

1. Turn the side broom switch to the off position to

deactivate and raise the broom.

2. Turn the side broom by hand until the brush

retainer bar is accessible.

3. Lift the bar and turn the broom clockwise (about

one eighth of a turn) until the lock pins in the

broom disengage from the drive plate.

4. Install the new broom by positioning the three

drive pins into the pilot holes of the drive plate.

5. Lift and rotate the broom until the broom retainer

bar springs into the locked position.

6. Check to make sure all thee drive pins are

properly engaged.

LOCK PIN

RETAINING

BAR

Page 56

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

HOPPER

NOTE: It is not usually necessary to remove the

hopper on high dump models. However,

if it becomes necessary for maintenance

or to install an option, use the following

procedure to remove:

Hopper Removal

1. Park the machine on a level surface and engage

the parking brake.

2. Raise the hopper and position the high dump

hopper dolly, a platform truck or similar four

wheeled cart under the hopper.

3. Set the hopper down on the truck and turn the

engine off.

4. Cycle the rotation control handle (#2) in both

positions to relieve any residual hydraulic

pressure.

5. Remove three bolts, washers, nuts and backing

plate.

6. Disconnect the wire harness connections at the

right side of the hopper.

7. While spreading the dump arms slightly, roll the

hopper away from the machine.

Hopper Replacement

1. Position the hopper on the dolly so as to align

the mounting holes in the sides of the hopper

with the rotation mounts on the arms. Lift arms

should be positioned about ⅓ of the way up.

2. Engage the lift arm rotation plates with the

mounting bolts on each side of the hopper.

3. Start the machine and lift the hopper.

4. Drive away from the hopper dolly or cart.

5. Lower the hopper.

6. Engage the wire connections at the right side of

the hopper.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 57

Floor Clearance and Dump Angle Adjustment

NOTE: In order to perform properly, the hopper must

maintain a distance of 3½” (8.89 cm) from the

oor to the rear hopper entrance lip. The front of

the hopper should be adjusted so that the front

bumper aligns with the hopper frame where the

two meet. When properly adjusted, the front

edge of the hopper will be 5” (12.7 cm) to 6”

(15.24 cm) from the oor.

1. Park the machine on a level surface, shut off the

engine and engage the parking brake.

WARNING

Do not rely upon the hydraulic cylinders to

keep the hopper raised for maintenance.

Always engage the safety arm before

servicing the hopper.

2. Adjust the lift arm stop bolts located on top of the

wheel wells as low as possible while still allowing

the side broom assembly to clear the lift arms

when the hopper is in the NORMAL position. Be

sure that both lift arms contact the stop bolts at

the same time.

Page 58

PREVENTATIVE MAINTENANCE

SAFETY

ARM

ENGAGED

NOTE: This may involve raising and lowering the

hopper several times.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

LIFT ARM STOP BOLT

(BOTH SIDES OF

HOPPER)

REAR

ENTERANCE

LIP OF

HOPPER

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

ADJUSTABLE

STOPS AT ROTATION

PLATE (BOTH SIDES

OF HOPPER)

FRONT

EDGE OF

HOPPER

Page 59

PREVENTATIVE MAINTENANCE

3. After adjustment, with the hopper down, use

the two adjustable stops located on the rotation

plates on both sides of the hopper to establish

3½” (8.89 cm) clearance between the rear

hopper entrance lip and the oor.

NOTE: The stop on the driver’s side is located

immediately below the cylinder rod end

and is threaded into the cylinder mount

arm. The stop on the left side is located

directly above the arm rotation plate.

4. After the 3½” (8.89 cm) clearance is

established, make sure both stops make contact

simultaneously. The lower front edge of the

hopper should be 5” (12.7 cm) to 6” (15.24

cm) from the oor. A balanced adjustment of

both sets of adjustment bolts is required to

correctly adjust the hopper in the lower position.

If the bumper is lower than the frame, after the

hopper is correctly adjusted, loosen the bumper

attachment bolts and reposition the front bumper.

5. Raise the hopper and rotate fully.

6. Turn the engine off.

WARNING

Do not rely upon the hydraulic cylinders to

keep the hopper raised for maintenance.

Always engage the safety arm before

servicing the hopper.

ROTATION

CYLINDER

HOPPER

PIVOT

HOPPER

ROTATION

ARM

ROTATION

CYLINDER

STOP

Page 60

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

7. Adjust the rotation cylinder stops on the hopper

rotation arms on each side of the hopper so that

clearance between the lift arms and the cut-outs

in the bumper is ¼” (6.35 mm) maximum.

8. Loosen the locking set screw in the bottom side

of the rotation block.

9. Using the hole in the cylinder rod, turn the rod to

adjust the cylinder extended length to match the

hopper rotation stops.

10. Tighten the set screw.

11. Rotate the hopper back, remove the safety arm

and lower the hopper.

ROTATION

CYLINDER ROD

ADJUSTMENT

HOLE

ROTATION

BLOCK

LOCKING

SET

SCREW

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 61

PREVENTATIVE MAINTENANCE

Filter Removal

1. Release the latches on the hopper cover and

raise the cover.

2. Disconnect the wire harness leading to the lter

shaker motor.

3. Unscrew the two screws (each attached using

one conical washer and an isolator) securing the

lter retainer bars to the hopper.

4. Remove the shaker motor assembly and lter

retainer bars.

5. Lift out the panel lter.

HOPPER

LATCHES

MOTOR WIRE

HARNESS LEAD

SHAKER

MOTOR

ASSEMBLY

PANEL

FILTER

Page 62

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

Filter Cleaning

The dust control lter is a polyester type element lter.

It may be vacuumed, blown out with compressed air,

tapped against the oor or washed with soap and

water.

1. If blown out with compressed air, use 100 psi or

less.

2. If washed with soap and water, use 40 psi water

pressure or less.

NOTE: Make sure the lters are thoroughly dried

while standing on their side before

installing in the hopper. Do not install or

use a wet lter.

Filter Replacement

1. Insert the panel lter.

2. Install the shaker motor assembly.

3. Install and tighten the two lter retaining screws

and isolators.

4. Hook the wire harness to the lter shaker

motors.

5. Close the hopper cover and secure the latch.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 63

PREVENTATIVE MAINTENANCE

Vacuum Gasket Mount Adjustment

1. With the hopper in the normal position, observe

contact between the back of the hopper and

gasket. If complete seal is not maintained, raise

the high dump hopper.

SAFETY

ARM

ENGAGED

WARNING

Do not rely upon the hydraulic cylinders to keep

the hopper raised for maintenance. Always

engage the safety arm before servicing the

hopper.

2. Loosen the mounting bolts in the gasket mount.

Move the assembly toward the hopper. Tighten

the bolts. Test and repeat if necessary.

VACUUM

GASKET

MOUNT

MOUNTING

BOLT

Page 64

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

Flap Replacement

Flaps located at the entrance lip and on the sides of

the hopper must be replaced when worn or damaged.

The ap panels may be replaced separately.

1. Park the machine on a level surface and engage

the parking brake.

2. Raise the hopper.

WARNING

Do not rely upon the hydraulic cylinders to keep

the hopper raised for maintenance. Always

engage the safety arm before servicing the

hopper.

3. Turn off the engine

4. Remove the ap retaining angle and worn or

damaged aps.

5. Install the new aps.

6. Replace the retaining angle.

Frame Seal Replacement

Front Frame Seal

The hopper frame seal bolts to the front edge of the

frame. Install a new seal by folding it in half to align the

holes. Doubled edge with holes goes on the bottom.

Support the seal straight up while bolting the retainer

bar in place. The seal should fall over the retainer bar

after installation. Be certain that the seal edges are

aligned to prevent twisting of the seal.

Side Frame Seal

The side frame seals should clear the oor by at least

⅛” (3.18 cm). If the bottom of a side seal measures

½” (1.27 cm) or more above the oor, readjust it or

replace it by removing the bolts on the inside of the

wheel wells, installing a new seal, and securing it with

the bolts. The double edge with the holes goes toward

the front.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

Page 65

PREVENTATIVE MAINTENANCE

PARKING BRAKE

Normal adjustment of the parking brake can be

accomplished from the operator compartment. Locate

the knurled handle on the parking brake lever. Turn the

handle clockwise to increase brake tension.

NOTE: Two or three turns is usually adequate. DO

NOT OVERTIGHTEN.

If this adjustment becomes ineffective, it will be

necessary to adjust the cable length.

Adjusting The Parking Brake Cable Length

1. Park the machine on a level surface and chock

the wheels.

2. Place the parking brake lever in the “OFF”

position.

3. Turn the knurled handle counter-clockwise as far

as possible.

WARNING

Do not rely upon the hydraulic cylinders to keep

the hopper raised for maintenance. Always

engage the safety arm before servicing in the

area of the hopper.

SAFETY

ARM

ENGAGED

Page 66

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014

PREVENTATIVE MAINTENANCE

4. Raise the hopper and engage the safety arm.

5. Locate both the cable clevis ends for the brake

cables.

BRAKE CABLE

CLEVIS END

JAM NUT

6. Disconnect the clevis ends from the bar.

7. Loosen the jam nuts at the base of the clevis.

Armadillo 6X and AM7D-III PB# 4100043UM Rev. A 08/14

PowerBoss®, Copyright 2014