Instruction Manual

Apex 47 B/BH (6502.44/.64)

Introduction

Please be advised explicity that

we cannot accept any legal issus

out of the contents of this

manual. It repair work has to be

performed make sure that only

genuine spare parts may

guarantee a depeendable

machine and ill make sure that

your rights under current

warranty are not affected.

We reserve the right for technical

improvement.

Valid as of: September 2007

PowerBoss Inc.

175 Anderson Street

NC 28315 U.S.A.

Telephone: (910) 944-2105

Fax: (910) 944-740

Dear customer,

It is our desire that good

characteristrics of the Apex 47

should justify the confidence you

demonstrated by making this

purchase. We did our best to supply

you with an efficient and dependable

machine. Before first operation of

you Apex 47, read these instructions

carefully. The manual provides

valuable information about service

and maintenance.

The symbol

as used in this manual identifies items

relevant to safety. Please make sure to

forward all safety instructions to other

operators.

Observe the safety information listed

in chaperr 1.

Before first operation of the machine,

read these instructions and safety

information carefully and comply with

them.

Introduction

Please be advised explicity that

we cannot accept any legal issus

out of the contents of this

manual. It repair work has to be

performed make sure that only

genuine spare parts may

guarantee a depeendable

machine and ill make sure that

your rights under current

Dear customer,

It is our desire that good

characteristrics of the Apex 49

should justify the confidence you

demonstrated by making this

purchase. We did our best to supply

you with an efficient and dependable

machine. Before first operation of

you Apex 49, read these instructions

carefully. The manual provides

Before first operation of the machine,

read these instructions and safety

information carefully and comply with

them.

3

Proper use

The Apex 47 sweeper

has been exclusively designed for collecting dry and moist matter from floor

surfaces in e.g. factories, storage buildings, p

arking ground and pedestrian

areas. Using the machine beyond this

scope of application will be deemed

improper use; The manufacturer cannot be held liable for consequential

damages.

The term of proper use also includes

operation, maintenance and repair

work to be performed in compliance

with the manufacturer's specifications.

The Apex 4

7 may be

used by personnel only that are familiar with the machine and aware of possible hazards involved.

Accident Prevention Regulation, Road

Traffic Regulations, and aspects of

safety and working medicine will have

to be complied with.

If modifications to the machine are

made in absence of the manufacturer's prior consent, the latter cannot be

held liable for damage resulting from

such unauthorized modification.

The machine has not been

designed for collecting

dusts which are detrimental

to health or explosive.

Notes on warranty

The terms of the sales contract apply.

Damages are not subject to warranty if

they are due to non-compliance with

the maintenance and service

provisions. The maintenance work has

to be performed by an authorised

Powerboss service centre and

confirmed in the "Maintenance certificate" which is the warranty document.

The following is excluded from warranty:

fuses, natural wear and tear after overload, and damages caused by inexpert

handling and unauthorised modification of the machine. Moreover,

any claim for warranty cannot be accepted if damages at the machine are

caused by fitting parts or accessories

without Minuteman's prior and explicit con

sent or by non-compliance with the

maintenance instructions.

Acceptance of the machine

Upon arrival, check machine for possible damages in transit. For refund of

such damage, have the Deutsche

Bahn AG or your freight forwarder confirm such damage. Mail notification

and waybill to:

PowerBoss Inc.

175 Anderson Street

NC 28315 U.S.A.

Telephone: (910) 944-2105

Fax: (910) 944-740

Introduction

Proper use

The Apex 49 sweeper

has been exclusively designed for collecting dry and moist matter from floor

surfaces in e.g. factories, storage buildings, parking ground and pedestrian

areas. Using the machine beyond this

scope of application will be deemed

improper use; The manufacturer can-

held liable for damage resulting from

such unauthorized modification.

The machine has not been

designed for collecting

dusts which are detrimental

to health or explosive.

any claim for warranty cannot be accepted if damages at the machine are

caused by fitting parts or accessories

without Minuteman's prior and explicit con

sent or by non-compliance with the

maintenance instructions.

Acceptance of the machine

Introduction

1 Safety Information 6

1.1 General Safety Information 6

1.2 Safety and Warning Symbols 7

1.2.1 Generally Applicable Symbols 7

1.3 Labels at the Machine 8

1.3.1 Apex 47 Signs

9

1.4 Operation/Safety Information 11

1.5 Cleaning Information 12

1.6 Maintenance Instructions 13

1.7 Accident Prevention Regulations 15

2 Description 16

2.1 Functional Description 16

2.1.1 Principle of Apex 47 B 16

2.1.2 Principle of Apex 47 BH 16

2.2 Cylinder Broom 17

2.3 Side Brush 17

2.4 Filter System / Dust Evacuation 17

2.5 Shaking System 17

2.6 Steering 17

2.7 Wheels 17

2.8 Brake 18

2.9 Travel Drive Assembly

18

2.10 Hydraulic System

18

7 Maintenance/Service 42

7.1 Maintenance Instructions 42

7.2 Mount/Dismount Cylinder Broom 43

7.3 Adjust Sweeping Track 43

7.4 Sealing Strips for Broom Compartment 45

7.5 Folding Apron Adjustment 45

7.6 Replace Side Brush 46

7.7 Dismount Plate Filter 47

7.8 Basic Cleaning of Plate Filter 49

7.9 V-Belt Drive 50

33

33

7.9.1 Replace Cylinder Broom V-Belt 51

7.9.2 Replace Side Brush V-Belt 51

7.9.3 Replace Suction Fan V-Belt 51

7.10 Adjust Steering Chain Tension 52

7.11 Check Hydraulic Fluid and Refill 52

7.11.1 Check Hydraulic Fluid 52

7.11.2 Refill Hydraulic Fluid 52

7.12 Electric System

36

7.12.1Fuses/Relays 53

7.12.2Lifted-Up Disposal Fuses/Relays 54

36

7.13 Apex 47 (6502.40/60)

53

Maintenance Schedule 55

3 Battery Systems 19

3.1 Low Discharge Signal Sender 20

3.1.1 Battery Charging Status Indicator 20

3.1.2 Hourmeter 20

3.1.3 Setting Other Battery Types 20

3.2 Plug Connection Coding 21

4 First Operation 23

4.1 First Operation of Batteries 23

4.2 Insert Batteries 24

5 Operation 26

5.1 Apex 47 Controls 26

5.2 Apex 47

Control Panel 28

5.3 Empty Dirt Hoppers of

Apex 47 B

5.4 Empty Dirt Hopper of

Apex 47 BH

5.5 Working with the Apex 47

5.5.1 Switch Electro-Motor

ON and OFF

5.5.2 Sweep

37

5.5.3 Stop and Park 37

5.5.4 Displace 37

5.5.5 Transport 37

6 Technical Data 38

Contents

4

Maintenance Document 58

1 Safety Information 6

1.1 General Safety Information 6

1.2 Safety and Warning Symbols 7

1.2.1 Generally Applicable Symbols 7

1.3 Labels at the Machine 8

1.3.1 Apex 49 Signs

9

1.4 Operation/Safety Information 11

1.5 Cleaning Information 12

1.6 Maintenance Instructions 13

1.7 Accident Prevention Regulations 15

7 Maintenance/Service 42

7.1 Maintenance Instructions 42

7.2 Mount/Dismount Cylinder Broom 43

7.3 Adjust Sweeping Track 43

7.4 Sealing Strips for Broom Compartment 45

7.5 Folding Apron Adjustment 45

7.6 Replace Side Brush 46

7.7 Dismount Plate Filter 47

7.8 Basic Cleaning of Plate Filter 49

3 Battery Systems 19

3.1 Low Discharge Signal Sender 20

3.1.1 Battery Charging Status Indicator 20

3.1.2 Hourmeter 20

3.1.3 Setting Other Battery Types 20

3.2 Plug Connection Coding 21

4 First Operation 23

4.1 First Operation of Batteries 23

4.2 Insert Batteries 24

Contents

Contents

5

Contents

1 Safety Information

1.1 General Safety Information

Apart from the instructions contained

in this manual, the general safety

instructions and accident prevention

regulations, as imposed by law will

have to be complied with. Do not put

the Manual aside without reading it

even if you used similar sweepers

before. Take the time to read them

now and save time later. It will be of

essence to make yourself familiar with

all accessories and controls, as well

as their functions, before you start

working. Take time to read now and

save time later.

Machines with known defects must not

be used.

Prior to operation make yourself familiar with all systems and controls and

"where they arrive". Avoid the mess of

having to read this book while trying to

run the machine.

Using the machine in areas with

explosion hazard, on public roads and

places is prohibited.

The operator has to use the machine

within its design limits.

Shut the motors down before transporting the machine.

Keep clear of hazard zone!

Before commencing work, the operator has to make sure that the Apex 47

and its accessories

are in proper and safe condition.

Warning and instruction labels attached to the machine contain important

information about safe operation.

Illegible or lost labels have to be replaced.

Make sure that all covers

are fitted before starting to

sweep.

When sweeping in closed

rooms, provide for sufficient ventilation.

Pinching and shearing hazard. Provide for required

safe distance before lifting

or lowering the dirt hopper.

6

Safety Information

1 Safety Information

1.1 General Safety Information

Apart from the instructions contained

in this manual, the general safety

instructions and accident prevention

regulations, as imposed by law will

have to be complied with. Do not put

the Manual aside without reading it

even if you used similar sweepers

The operator has to use the machine

within its design limits.

Shut the motors down before transporting the machine.

Keep clear of hazard zone!

Before commencing work, the opera-

When sweeping in closed

rooms, provide for sufficient ventilation.

Pinching and shearing hazard. Provide for required

safe distance before lifting

or lowering the dirt hopper.

Safety Information

1.2 Safety and Warning Symbols

1.2.1 Generally Applicable Symbols

All paragraphs in this manual referring

to your personal safety, the safety of

your machine and the environment

protection are attributed one of the following warning symbols:

7

Sicherheitsinformationen

Hazardous for....

persons and

goods

the machine

the environment

Description

dangerous situation

caused by imprecise or non-observance of instructions or

prescribed work routine

important information on handling the Apex 47 in order to

maintain operability

due to use of substances representing an inherent danger to

health of environment

Symbol

DANGER

CAUTION

Ecological hazard

1.2 Safety and Warning Symbols

1.2.1 Generally Applicable Symbols

All paragraphs in this manual referring

to your personal safety, the safety of

your machine and the environment

protection are attributed one of the following warning symbols:

Sicherheitsinformationen

Hazardous for....

Description

Symbol

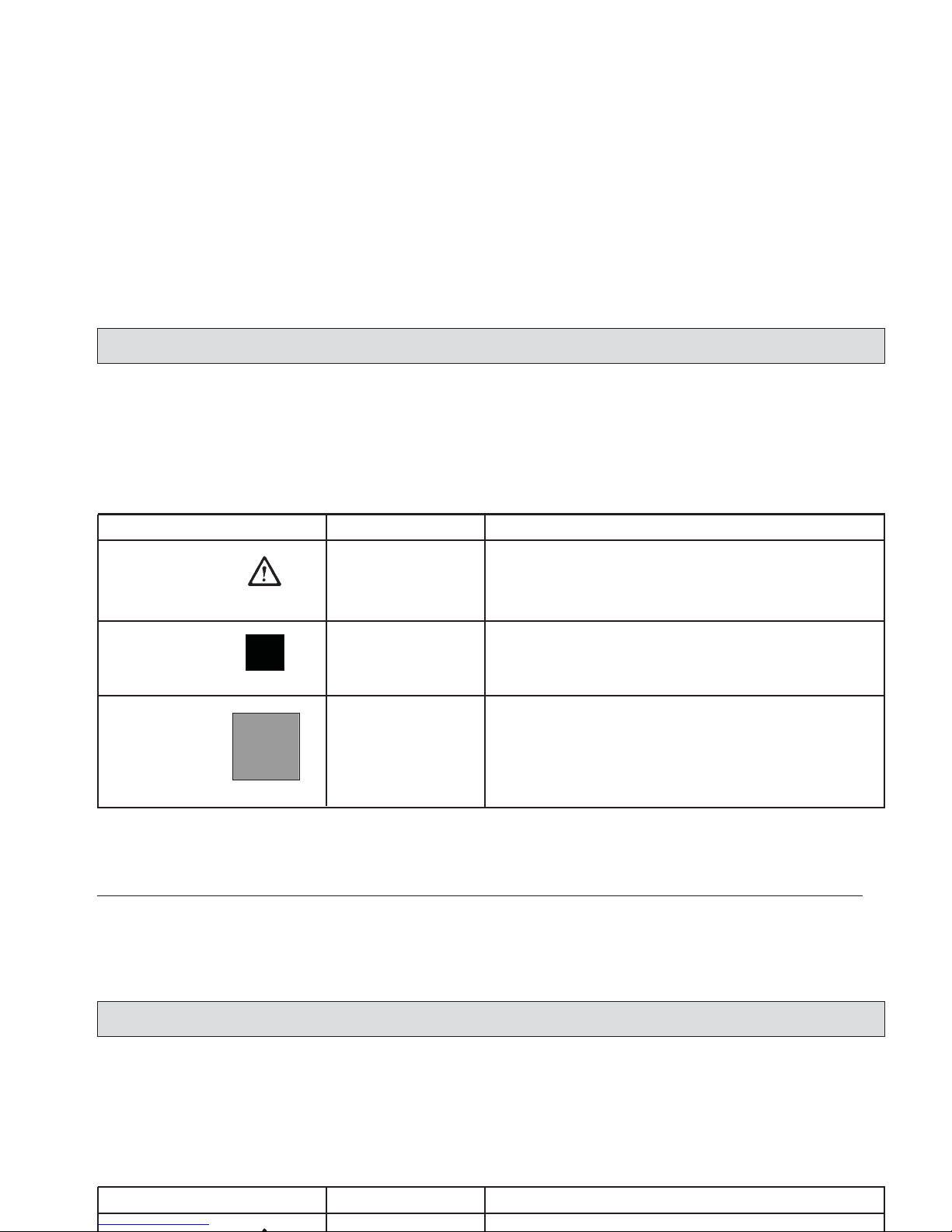

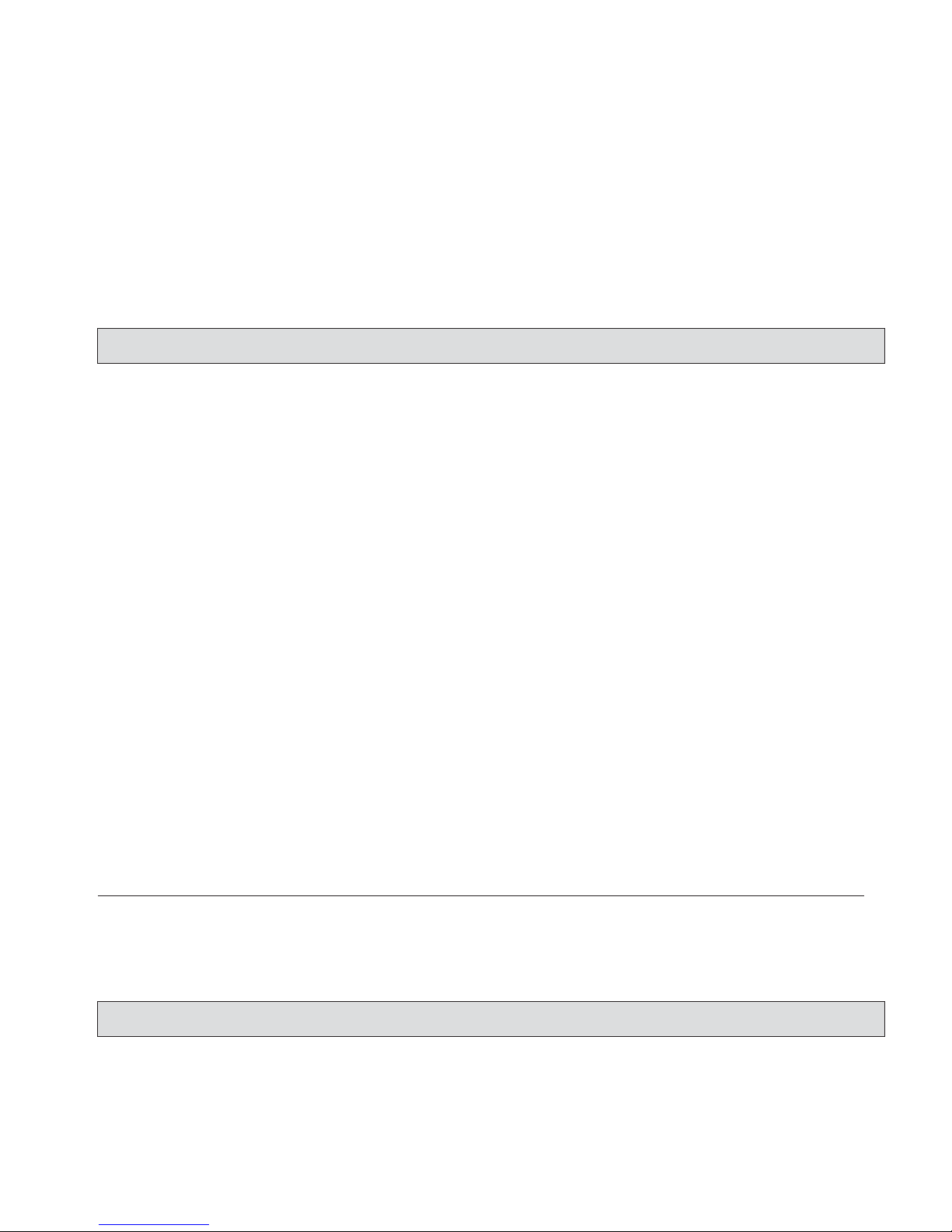

1.3 Labels at the Machine

The following safety and information

signs are legibly attached to the

machine. Missing or illegible stickers

have to be replaced.

Folding apron (1)

Parking brake (2)

PowerBoss nameplate, front and rear (3)

Read and observe

operator's Manual (4)

Key switch (5)

Brake (6)

Noise performance (7)

82 dB (A)

8

Safty Information

Fig.1

1.3 Labels at the Machine

The following safety and information

signs are legibly attached to the

machine. Missing or illegible stickers

have to be replaced.

Folding apron (1)

Read and observe

operator's Manual (4)

Key switch (5)

Brake (6)

Noise performance (7)

82 dB (A)

Safty Information

9

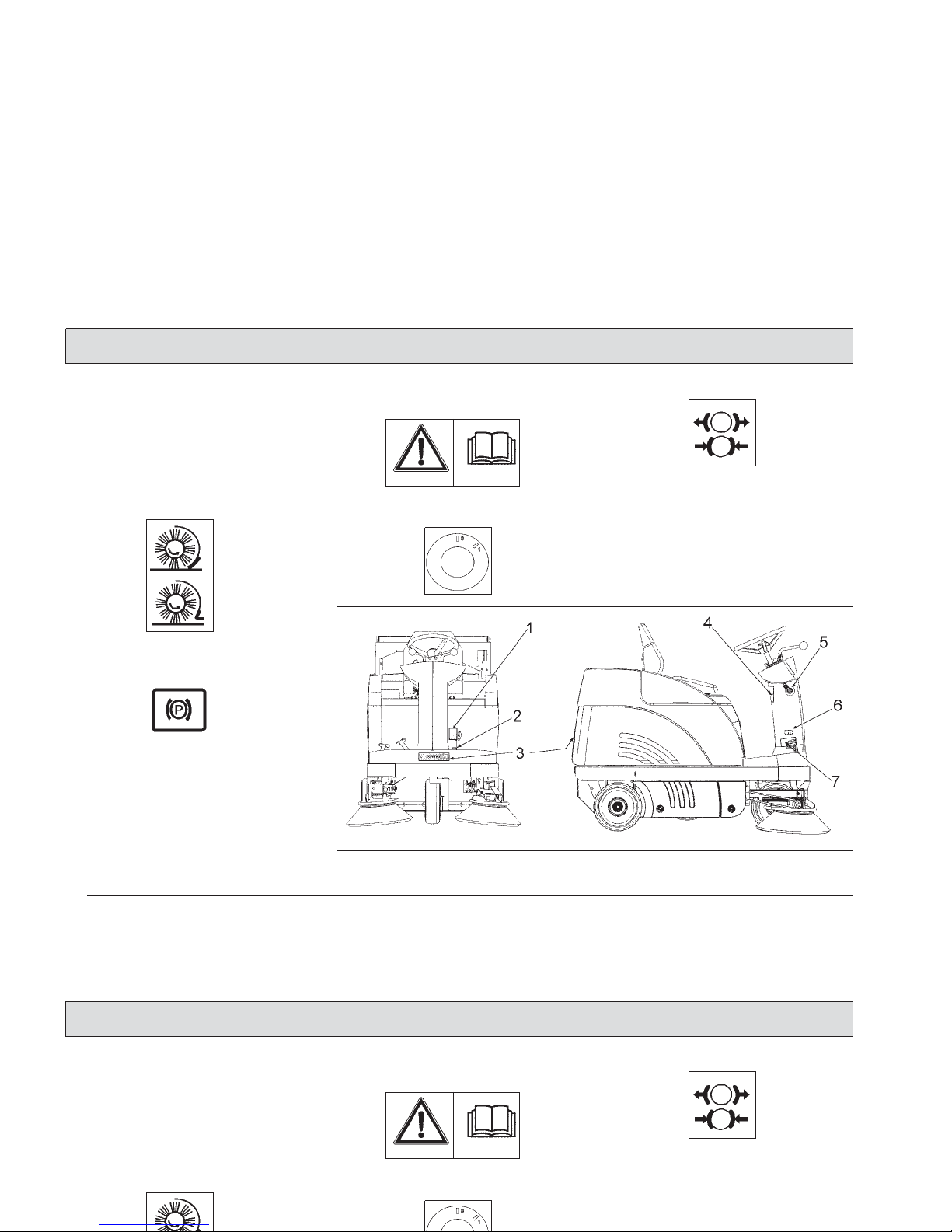

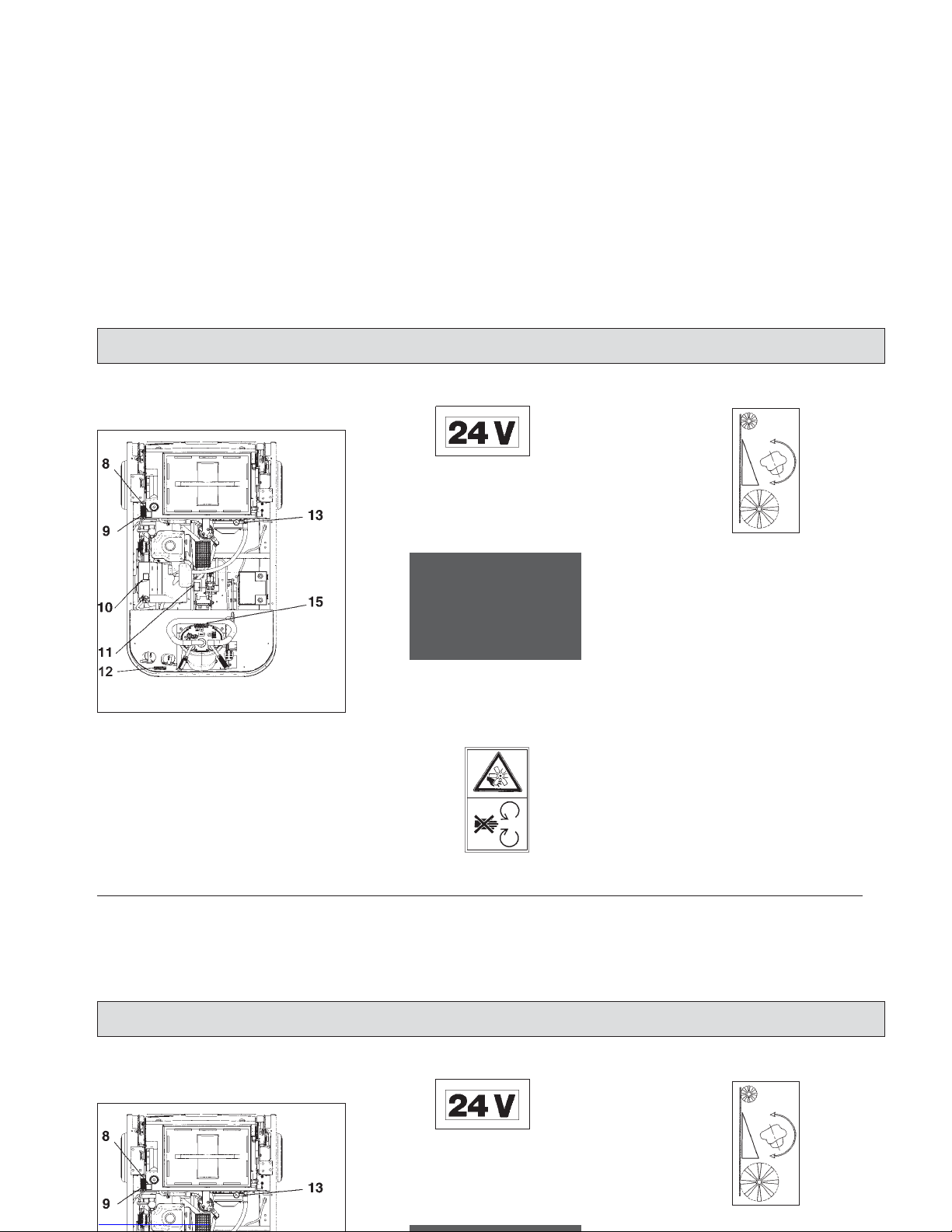

1.3.1 Apex 47 Signs

Safety and information signs

24V label (8)

Battery charging (9)

The label is located under the seat

hood.

Rotating parts (10)

Cylinder broom wearing take-up (11)

Nameplate (12)

Safty Information

Fig.2

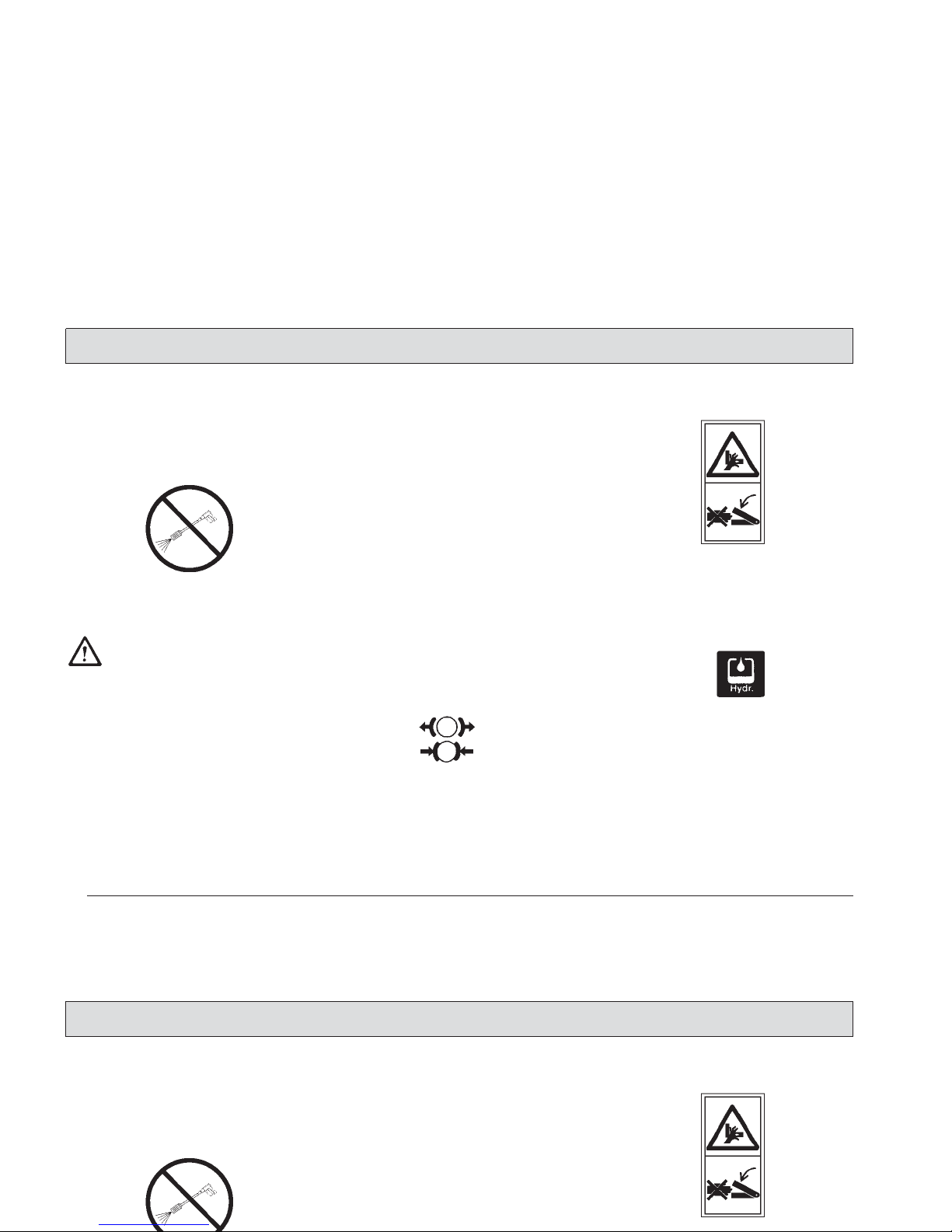

1.3.1 Apex 49 Signs

24V label (8)

Battery charging (9)

The label is located under the seat

hood.

Cylinder broom wearing take-up (11)

Safty Information

Apex 47 Signs

Continued

High-pressure cleaner (13)

Do not clean by means of

high pressure cleaner or vapour jet.

Apex 47 type name (14)

Brake (15)

Pinching hazard (16)

Hydraulic fluid (17)

10

Safty Information

Apex 49 Signs

Continued

High-pressure cleaner (13)

Apex 49 type name (14)

Pinching hazard (16)

Safty Information

11

1.4 Operation/Safety Information

Vacuum sweepers may be run by qualified personnel only; such personnel

will have to have evidenced their qualification for running the machine to

the owner or his authorised representative; operators explicitly will have to

be instructed by the owner or his

authorized representative to use the

machine.

The machine may be used

for cleaning such surfaces

approved by the owner or

this authorised representative for operation of vacuum

sweepers.

Before starting the engine,

switch off all drives

Transporting persons on the machine

is prohibited. Ride-on machine types

are to be started with the driver being

seated.

Never leave the machine unattended

before the motors are off and the machine is protected against unintended

movements.

To prevent the machine from unauthorised use, pull the control key to block

all drives.

Shut down the motors before transport

of the machine. During driving the operator has to take account of local conditions and when working he has to

watch out for other persons, especially

children.

Do not open the hood with

the machine running.

This machine must not be

used as dust-evacuating

machine with dust filter insert (separator) to collect

dusts which are hazardous

to health.

Compared to four-wheeled

vehicles, driving stability of

three-wheeled vehicles is

reduced. We thus recommend:

- do not negotiate curves at

high speed.

- do not turn at slopes but

on level ground only

- ride up- or downhill

straight.

Safty Information

1.4 Operation/Safety Information

Vacuum sweepers may be run by qualified personnel only; such personnel

will have to have evidenced their qualification for running the machine to

the owner or his authorised representative; operators explicitly will have to

be instructed by the owner or his

authorized representative to use the

Never leave the machine unattended

before the motors are off and the machine is protected against unintended

movements.

To prevent the machine from unauthorised use, pull the control key to block

all drives.

Shut down the motors before transport

of the machine. During driving the operator has to take account of local conditions and when working he has to

Compared to four-wheeled

vehicles, driving stability of

three-wheeled vehicles is

reduced. We thus recommend:

- do not negotiate curves at

high speed.

- do not turn at slopes but

on level ground only

- ride up- or downhill

straight.

Safty Information

Warning and instruction labels attached to the machine contain important information about safe operation

Provide for sufficient ventilation when sweeping indoors.

Proceed to filter shaking only after having closed the

dirt hopper.

Do not open the hood with

the machine running.

Proceed to filter shaking only if the dirt hopper is in closed position.

12

Safty Information

1.5 Cleaning Information

The specific safety instructions for

handling drive batteries (see leaflet

88-60-2556) apply. Before proceeding

to cleaning of the machine, pull the

key.

The machine is splash-proof (IPX3).

Do not clean the Apex 47

by means of high pressure

cleaner or vapour jet.

Proceed to cleaning of the

dirt hopper in regular intervals to preclude formation

of bacterial deposits.

Warning and instruction labels attached to the machine contain important information about safe operation

Provide for sufficient ventilation when sweeping indoors.

Proceed to filter shaking only after having closed the

Safty Information

1.5 Cleaning Information

The specific safety instructions for

handling drive batteries (see leaflet

88-60-2556) apply. Before proceeding

to cleaning of the machine, pull the

key.

The machine is splash-proof (IPX3).

13

1.6 Maintenance Instructions

A good approach to prevention of accidents is proper maintenance of the

machine. Before proceeding to repair

or maintenance work pull the key.

Use appropriate tools for maintenance, service, setting etc. As far as

aspects of safety are concerned,

spare parts will have to be at least of

the same quality as the genuine spare

parts.

Switch off the motors before maintaining the machine

or replacing parts of it. Turn

off the machine, pull the key

and, additionally, disconnect the battery plug.

Check hydraulic lines and

hoses for damages and leakage in regular intervals; replace defective hoses and

lines immediately!

Before changing wheels

protect the machine against

rolling by placing wedges.

Proceed to wheel changing

when the machine is on level and solid ground.

Do not repair the pneumatic

tires mounted to the machine yourself. Dismount the

wheel and take it to repair to

qualified workshop.

Use of other than the cylinder brooms and side brushes approved by the manufacturer is not admitted (see

technical data) since use of

other cylinder brooms and

side brushes may affect

your safety.

When handling lubrica-

ting agents, the applicable regulations for

protection of the environment and

prevention of fire have

to be complied with.

Provide for disposal of

used oil and grease in

accordance with the

provisions imposed by

law.

Collect cleaning

agents, oil, fuel oil,

grease etc. and provide for adequate disposal. Wipe away spilled

substances.

Specific safety instructions for handling batteries apply (refer to leaflet

88-60-2556 for further safety provisions)

Safty Information

1.6 Maintenance Instructions

A good approach to prevention of accidents is proper maintenance of the

machine. Before proceeding to repair

or maintenance work pull the key.

Use appropriate tools for maintenance, service, setting etc. As far as

aspects of safety are concerned,

spare parts will have to be at least of

Before changing wheels

protect the machine against

rolling by placing wedges.

Proceed to wheel changing

when the machine is on level and solid ground.

Do not repair the pneumatic

tires mounted to the machine yourself. Dismount the

wheel and take it to repair to

When handling lubrica-

ting agents, the applicable regulations for

protection of the environment and

prevention of fire have

to be complied with.

Provide for disposal of

used oil and grease in

accordance with the

provisions imposed by

Safty Information

Specific safety instructions for

handling batteries apply

(refer to leaflet 88-60-2556

"Information on Drive Batteries" for

further safety provisions).

Before commencing any

work on the electric system

disconnect battery plug of

the Apex 47.

Do not keep batteries

discharged for a longer

period; always recharge

them as soon as possible.

T

op with distilled water only.

Never refill battery acid in

battery cells of perfect

condition.

Open the hood before

charging batteries;

explosive gases may occur

during the charging

procedure.

Keep batteries dry and clean and clear of soiling such

as e.g. metallic dust to avoid leakage current.

Do not place metal objects

or tools onto batteries.

Short-circuit and deflagration hazard.

Spilled (straight) battery

acid must not get into the

sewage system before having been neutralised. Comply with the regulations imposed by law and observe

local provisions.

Battery acid is highly

caustic (keep clear of children). When checking the

battery acid level, wear safety glasses. If acid splashes get into the eyes rinse

with clear water for 15 minutes and contact a doctor immediately.Wear appropriate

protective clothes (e.g. protective gloves or

finger-stalls) when handling

battery acid.

Do not use open flames (explosion hazard).

Do not eat, smoke or drink

in rooms where batteries

are charged to avoid damaging your health. After work

with batteries wash your

hands thoroughly. Provide

for sufficient ventilation.

14

Safty Information

Specific safety instructions for

handling batteries apply

(refer to leaflet 88-60-2556

"Information on Drive Batteries" for

further safety provisions).

Before commencing any

work on the electric system

disconnect battery plug of

Keep batteries dry and clean and clear of soiling such

as e.g. metallic dust to avoid leakage current.

Do not place metal objects

or tools onto batteries.

Short-circuit and deflagration hazard.

Spilled (straight) battery

finger-stalls) when handling

battery acid.

Do not use open flames (explosion hazard).

Do not eat, smoke or drink

in rooms where batteries

are charged to avoid dama-

Safty Information

15

Safty Information

1.7 Accident Prevention Regulations

BGV D 29 Vehicles

According to BGV D 29, the Apex 47 vacuum sweeper has to be inspected for

safe condition by an authorized expert as required, but not less than once a year.

Results of such an inspection have to be kept on file at least until the next inspection is

performed.

BGV D 27 Industrial trucks

Observe as well: - the applicable provisions for Safety and Health at Work and the Fire Regulations

- internal safety provisions

Safty Information

1.7 Accident Prevention Regulations

BGV D 29 Vehicles

According to BGV D 29, the Apex 49 vacuum sweeper has to be inspected for

safe condition by an authorized expert as required, but not less than once a year.

Results of such an inspection have to be kept on file at least until the next inspection is

performed.

BGV D 27 Industrial trucks

Observe as well: - the applicable provisions for Safety and Health at Work and the Fire Regulations

2 Description

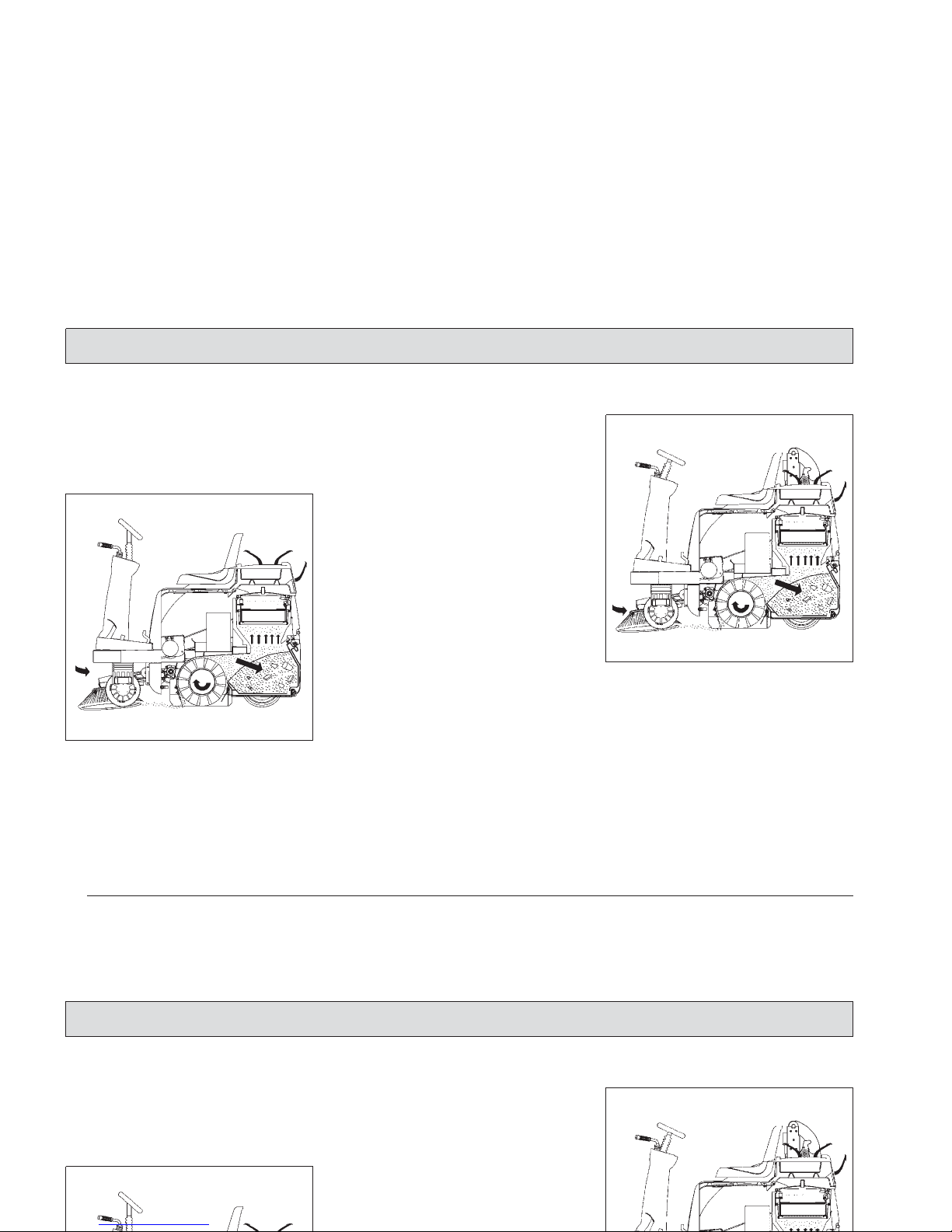

2.1 Functional Description

2.1.1 Principle of Apex 47

Principle of

Apex 47 B

The side brushes are used to collect

dirt at borders and to enlarge the working width as well as to increase the

area performance on large surfaces.

The cylinder broom transports the

debris into the dirt hopper. The suction

fan vacuums the fine dirt which is

separated by a filter system. The air

returned into the environment is clean.

2.1.2 Principle of Apex 47 BH

Principle of

Apex 47 BH

16

Description

Fig.3

Fig.4

2 Description

2.1 Functional Description

2.1.1 Principle of Apex 49

The side brushes are used to collect

dirt at borders and to enlarge the working width as well as to increase the

area performance on large surfaces.

The cylinder broom transports the

debris into the dirt hopper. The suction

fan vacuums the fine dirt which is

separated by a filter system. The air

returned into the environment is clean.

2.1.2 Principle of Apex 49 BH

Description

17

2.2 Cylinder Broom

The cylinder broom is equipped with

12 rows of bristles arranged in Vshape.

The cylinder broom width amounts to

700mm and its diameter to 345mm.

2.3 Side Brush

The standard version, the side brush

is located at the front right of the

machine. The operator lifts and lowers

it by hand lever.

The side brush is to have a light inclination.

The swinging area of the side brush

arm is limited by stop screws.

The side brush is driven by V-belt.

For special application, fitting of a

second side brush at the left is possible.

2.4 Filter System / Dust Evacuation

The filter system is located in the filter

case above the dirt hopper. The suction fan transports the fine dust raised

by the cylinder broom to the plate filter

where it is separated. The fine dusts

sets at the outsides of the filter blades.

In case of heavy dust deve-

lopment, check and clean

the plate filter at regular

intervals.

2.5 Shaking System

Due to normal working vibration the

set dust partly falls off into the dirt

hoper. To ensure working in a dustfree ambiance, however, actuate the

shaking system regularly.

2.6 Steering

Steerage is effectuated mechanically

from steering wheel to front wheel via

chain. This chain is to be re-adjusted

as required.

2.7 Wheels

Front wheel: solid rubber tires

Rear wheels: solid rubber tires

Description

2.2 Cylinder Broom

The cylinder broom is equipped with

12 rows of bristles arranged in Vshape.

The cylinder broom width amounts to

700mm and its diameter to 345mm.

2.4 Filter System / Dust Evacuation

The filter system is located in the filter

case above the dirt hopper. The suction fan transports the fine dust raised

by the cylinder broom to the plate filter

where it is separated. The fine dusts

sets at the outsides of the filter blades.

2.6 Steering

Steerage is effectuated mechanically

from steering wheel to front wheel via

chain. This chain is to be re-adjusted

as required.

2.7 Wheels

Front wheel: solid rubber tires

Description

2.8 Brake

The Apex 47 is equip-

ped with a service brake.

This brake has been constructed as

shoe brake and equally serves as parking brake.

It is located in the rear wheels and is

actuated via cables.

A special adjustment screw is situated

at the right-hand rear wheel.

Works at the braking

system have to be executed

by qualified persons in a

qualified workshop only.

2.9 Travel Drive Assembly

The Apex 4

7 is equipped with an

electric drive assembly with

continuous regulation.

2.10 Hydraulic

System

The hydraulic system includes a

compact unit (hydraulic pump with

hydraulic tank) as well as hydraulic

hoses and a hydraulic cylinder.

Hydraulic fluid: Mobiloil DTE 15 M

The hydraulic system has been filled

with fluid in the factory.

Filling of hydraulic fluid tank: 0.76 litre

18

Description

2.8 Brake

The Apex 49 is equip

ped with a service brake.

This brake has been constructed as

shoe brake and equally serves as parking brake.

It is located in the rear wheels and is

actuated via cables.

A special adjustment screw is situated

2.9 Travel Drive Assembly

The Apex 49 is equipped with an

electric drive assembly with

continuous regulation.

2.10 Hydraulic System

The hydraulic system includes a

compact unit (hydraulic pump with

Description

19

3 Battery Systems

Before commencing any

work on the electric system

disconnect the battery plug.

Do not use open flames

when handling batteries and

especially when checking

the battery acid level. Provide for sufficient ventilation

in rooms where batteries

are charged. Spilled

(straight) battery acid must

not get into the sewage

system before having been

neutralised.

Comply with the regulations

imposed by law and observe local provisions.

Open the hood before charging batteries; explosive gases may occur during the

charging procedure.

Battery Systems

3 Battery Systems

Before commencing any

work on the electric system

disconnect the battery plug.

Do not use open flames

when handling batteries and

especially when checking

the battery acid level. Provide for sufficient ventilation

in rooms where batteries

are charged. Spilled

(straight) battery acid must

Battery Systems

3.1 Low Discharge Signal Sender

Battery charging status

indicator/hourmeter

The factory setting is as follows:

maintenance-free block battery, 4x6V block batteries,

type: GiV

3.1.1 Battery Charging Status Indicator

Upon turning ON by key switch, battery charging status is shown by display of green bars (Fig. 5/1). As the

battery discharges during operation,

the lighting green bars extinguish one

after another showing thus always the

current charge status of battery charge.

Flashing of the last two green bars

indicates that operation will be stopped soon. In order to preclude low

discharge of batteries, the sweeping

units are switched off and riding speed

reduced to 50% if battery is discharged. The red LED (Fig. 5/4) than flashes.

3.1.2 Hourmeter

The operating hours of the machine

appear in the display (Fig. 5/2); the

hourmeter will count only during working or transport ride; only full hours

are displayed).

3.1.3 Setting Other Battery Types

Have the low discharge signal sender set to other battery types by qualified personnel only and in

approved qualified workshops only.

20

Battery Systems

Fig.5

3.1 Low Discharge Signal Sender

3.1.1 Battery Charging Status Indicator

Upon turning ON by key switch, battery charging status is shown by display of green bars (Fig. 5/1). As the

battery discharges during operation,

the lighting green bars extinguish one

after another showing thus always the

current charge status of battery charge.

3.1.3 Setting Other Battery Types

Have the low discharge signal sender set to other battery types by qualified personnel only and in

approved qualified workshops only.

Battery Systems

21

3.2 Plug Connection Coding

The battery plugs of the machine, the

battery and the stationary charger unit

have to be coded according to the battery type and the nominal voltage with

coloured pins.

The charger unit's plugs are/will be

coded in the factory according to the

characteristic curve and changing the

characteristic curve (according to the

battery type) always requires modification of the plug coding.

Plug case of charger unit:

- grey for wet batteries

- green for maintenance-free

Gel batteries

Machine plug case:

- yellow for both battery types

Battery socket case:

- grey for wet batteries

- green for maintenance-free

Gel batteries

Remove the coding pin by pressing the

ends together by means of pliers.

Press together for assembly

Insert pin such that the nominal voltage inscription is visible through the case window. Socket and plug always

with the same nominal voltage!

The following three requirements have

to be met:

1) Voltage coding is the same for all

plugs and sockets

2) Coding pin colour in the machine =

yellow

3) Coding pin colour

Before first operation of the

machine, the batteries have

to be adequately charged by

an initial charging procedure. Please observe the instructions of the charger

unit's operating manual.

Powerboss rejects any claim for

warranty on battery damages caused by unfulfilled initial charging.

Battery Systems

Nominal voltage value for

plug printed on each side

of the hexagon (letters

upside down)

Inscription for nominal voltage for sokkets accordingly

3.2 Plug Connection Coding

The battery plugs of the machine, the

battery and the stationary charger unit

have to be coded according to the battery type and the nominal voltage with

coloured pins.

The charger unit's plugs are/will be

coded in the factory according to the

characteristic curve and changing the

The following three requirements have

to be met:

1) Voltage coding is the same for all

plugs and sockets

2) Coding pin colour in the machine =

yellow

3) Coding pin colour

Before first operation of the

Battery Systems

Nominal voltage value for

plug printed on each side

of the hexagon (letters

upside down)

Inscription for nominal voltage for sokkets accordingly

22

Battery Systems

Battery Systems

23

4 First Operation

Before delivery, the Apex 47

has been extensively tested and

submitted to a functional check.

Only qualified personnel of your local

Powerboss contact dealer are allowed

to proceed to first operation. After shipping of the machine, we advise your

Powerboss contact dealer. He will

contact you to make a date for briefing

lessons.

4.1 First Operation of Batteries

To achieve the optimum performance

and a maximum service life, the batteries must be given the initial charge

after filling.

Handling and function of the battery

charger is described in detail in the

instruction manual supplied with each

charger unit.

Since batteries and charger

units are matched, we recommend using batteries

and chargers as prescribed

by PowerBoss. We can grant full

warranty only if those units

are being used.

For further information on first operation, maintenance and service of batteries refer to the leaflet 88-60-2556

"Information on drive batteries".

Do not use the Apex 4

7

at ambient tempe

ratures of more than 40°C.

Do not start the machine at

temperatures of 0°C or less.

First Operation

4 First Operation

Before delivery, the Apex 49

has been extensively tested and

submitted to a functional check.

Only qualified personnel of your local

Powerboss contact dealer are allowed

to proceed to first operation. After shipping of the machine, we advise your

Powerboss contact dealer. He will

Since batteries and charger

units are matched, we recommend using batteries

and chargers as prescribed

by Minuteman. We can grant full

warranty only if those units

are being used.

For further information on first operation, maintenance and service of batteries refer to the leaflet 88-60-2556

First Operation

4.2 Insert Batteries

- Turn engine off and pull key

- Secure machine by engaging the

parking brake.

- Fold back seat hood.

- Insert batteries into the battery tray

from the top.

Insert batteries

6V/240Ah, GiV maintenance-free

- Connect batteries and enclosed cable set according to Fig. 7 (check for

tight seating) and grease poles.

- Check set battery type at the low discharge signal sender or set if

required.

- Connect charging plug of the battery

connection cable and cable of the

charger unit and proceed to initial

charging.

- After charging of the batteries, connect charger plug and device plug

for electrical connection.

Now the Apex 4

7 is

operable.

If the battery type setting at

the LDS should be incorrect, have the setting modified by qualified personnel

in an approved workshop.

24

First Operation

Fig.6

Fig.7

4.2 Insert Batteries

- Turn engine off and pull key

- Secure machine by engaging the

parking brake.

- Fold back seat hood.

- Insert batteries into the battery tray

from the top.

- After charging of the batteries, connect charger plug and device plug

for electrical connection.

Now the Apex 49 is

operable.

If the battery type setting at

the LDS should be incorrect, have the setting modi-

First Operation

25

24V/210Ah tray battery, EPzB

with Aquamatik

- Turn machine off and pull key.

- Secure machine by actuating parking brake.

- Fold up seat hood

- Insert battery

- Connect charging plug of the battery

connection cable and cable of the

charger unit and proceed to initial

charging.

- After charging of the batteries, connect charger plug and device plug

for electrical connection.

If the battery type setting at

the LDS should be incorrect, have the setting modified by qualified personnel

in an approved workshop.

Use admitted lifting and

transport devices such as

e.g. lifting tackles according

to VDI 3616. Make sure that

lifting hooks do not damage

cells, connectors or connecting cables.

First Operation

Fig.8

- Turn machine off and pull key.

- Secure machine by actuating parking brake.

- Fold up seat hood

- Insert battery

- Connect charging plug of the battery

connection cable and cable of the

charger unit and proceed to initial

charging.

- After charging of the batteries, connect charger plug and device plug

First Operation

5 Operation

5.1 Apex 47 Controls

1 Actuator for folding apron

2 Service brake lock

3 Service brake/parking brake pedal

4 Drive pedal, reverse

5 Drive pedal, forward

6 Control panel

7 Seat adjustment

26

Operation

Fig.9

5 Operation

5.1 Apex 49 Controls

1 Actuator for folding apron

2 Service brake lock

3 Service brake/parking brake pedal

4 Drive pedal, reverse

5 Drive pedal, forward

6 Control panel

Operation

27

1 Actuator for folding apron

to open and close the folding apron

for collecting coarse dirt.

2 Service brake/parking brake lock

to lock the service brake/parking

brake. If locked, the service brake

works as parking brake. Release

the lock by depressing the service

brake pedal (3).

3 Service brake/parking brake

pedal

to actuate the service brake at the

rear wheels. Before leaving the

machine unattended, engage the

service brake and lock.

4 Drive pedal, reverse

to change direction to reverse ride

and with continuous regulation of

riding speed at the same time. If

the driver lets the pedal go it returns to initial position and the machine slows down to standstill.

5 Drive pedal, forward

to change direction to forward ride

and with continuous regulation of

riding speed at the same time. If

the driver lets the pedal go it returns to initial position and the machine slows down to standstill.

6 Control panel

Refer to chapter "Control panel"

7 Seat adjustment

to adjust the seat position to drivers of different height.

Adjust the seat so as to allow the

driver being comfortably seated

and attaining all elements required

for operation.

- Adjust seat lengthwise: push lever

slightly to the right and displace seat

forwards or backwards to the required

position. Then let the lever catch

again.

Operation

1 Actuator for folding apron

to open and close the folding apron

for collecting coarse dirt.

2 Service brake/parking brake lock

to lock the service brake/parking

brake. If locked, the service brake

works as parking brake. Release

the lock by depressing the service

brake pedal (3).

4 Drive pedal, reverse

to change direction to reverse ride

and with continuous regulation of

riding speed at the same time. If

the driver lets the pedal go it returns to initial position and the machine slows down to standstill.

5 Drive pedal, forward

7 Seat adjustment

to adjust the seat position to drivers of different height.

Adjust the seat so as to allow the

driver being comfortably seated

and attaining all elements required

for operation.

- Adjust seat lengthwise: push lever

slightly to the right and displace seat

Operation

5.2 Apex 47 Control

Panel

1 Cylinder broom lever

2 Release (lifted-up disposal)

Ampex BH

3 Horn

4 Cover with plug connection for

battery/LDS programming

5 Suction fan/shaking system knob

6 Flashlight (optional)

7 Lighting (optional)

8 Lift and lower (lifted-up disposal)

9 Side brush lever

10 Pilot lamp, parking brake

11 Battery charge status

indicator/hourmeter

12 Pilot lamp, fan

13 Pilot lamp, shaking system

28

Operation

Fig.10

5.2 Apex 49 Control

Panel

1 Cylinder broom lever

2 Release (lifted-up disposal)

Ampex BH

3 Horn

4 Cover with plug connection for

battery/LDS programming

5 Suction fan/shaking system knob

6 Flashlight (optional)

Operation

29

1 Cylinder broom lever

to lift and lower as well as to switch

on and off the cylinder broom and

the side brush.

- Lower cylinder broom as well as

switch on cylinder broom and side

brush = push lever

- Lift cylinder broom as well as switch

off cylinder broom and

side brush = pull lever

2 Release (lifted-up disposal)

Apex BH

to release the lifted-up disposal.

Has to be actuated before

activation of lifting/lowering

lifted-up disposal function.

Hold the key during

lifting/lowering.

Before changing lifting to

lowering or vice versa, the

"Release Lifted-Up Disposal" key has to be released

once and pressed again

3 Horn

An acoustic signals sound upon actuation of this button.

4 Cover with plug connection for

battery/LDS programming

Remove this cover to modify setting of

battery type. The plugged connections

of the programming cable are located

there.

Have the programming exe-

cuted by a PowerBoss

contract dealer with qualified

personnel at hand.

Operation

1 Cylinder broom lever

to lift and lower as well as to switch

on and off the cylinder broom and

the side brush.

2 Release (lifted-up disposal)

Apex BH

to release the lifted-up disposal.

Has to be actuated before

3 Horn

An acoustic signals sound upon actuation of this button.

Operation

5 Suction fan/shaking system

knob

Knob position (from bottom to top

position):

Pos. 0 Activated vacuuming

function (close flap before sweeping dry surfaces or collecting dry

dirt).

Pos. 1 Deactivated vacuuming function (open flap before

sweeping wet surfaces and collecting wet dirt).

Pos. 2 Shaking system ON

(pull knob to stop and then release)

If the yellow pilot lamp (Fig. 9/13)

lights, actuate the shaking system

(position 2).

In this position, the shaking system is

operable and proceeds to jolting in 7

repeated intervals.

After jolting, the knob is to

be kept in position 1 for

about 10 seconds. Switch

off the main broom before

and do not turn on during

jolting.

6 Flashlight (optional)

to switch the flashlight ON/OFF.

7 Lighting (optional)

to switch the driving headlight

ON/OFF.

8 Lift and lower (lifted-up disposal)

to lift and lower the dirt hopper.

Lift the dirt hopper by pressing the key

until the desired height for lifting-out is

attained.

When lowering the dirt hopper make

sure to hold the key pressed until the

hopper has contact with the frame.

30

Operation

5 Suction fan/shaking system

If the yellow pilot lamp (Fig. 9/13)

lights, actuate the shaking system

(position 2).

In this position, the shaking system is

operable and proceeds to jolting in 7

repeated intervals.

After jolting, the knob is to

be kept in position 1 for

7 Lighting (optional)

to switch the driving headlight

ON/OFF.

Operation

31

Actuate release key for lif-

ted-up disposal and hold

before lifting or lowering.

9 Side brush lever

to lift and lower the side brush.

- Lower side brush = push lever

- Lift side brush = pull lever

10 Pilot lamp, parking brake (red)

lights upon actuation of the parking

brake

Extinguishes upon release of the parking brake.

11 Battery charge status indicator

Refer to paragraph 3.1.1

Hourmeter

Refer to paragraph 3.1.2

12 Pilot lamp, suction fan (orange)

lights if the suction fan is not

activated.

Operation

Actuate release key for lif-

ted-up disposal and hold

before lifting or lowering.

10 Pilot lamp, parking brake (red)

lights upon actuation of the parking

brake

Extinguishes upon release of the parking brake.

12 Pilot lamp, suction fan (orange)

lights if the suction fan is not

activated.

Operation

13 Pilot lamp, shaking system

(yellow)

Proceed to jolting of the filter system

upon lighting of this pilot lamp by actuating the knob (Fig. 10/5).

The pilot lamp flashes during the shaking procedure

and extinguishes after low

pressure has been attained

in the filter system. Jolting

is effectuated in 7 intervals.

14 Key switch

to switch the machine on and off and

to secure it against unauthorised use.

32

Operation

13 Pilot lamp, shaking system

(yellow)

Proceed to jolting of the filter system

upon lighting of this pilot lamp by actuating the knob (Fig. 10/5).

14 Key switch

to switch the machine on and off and

to secure it against unauthorised use.

Operation

33

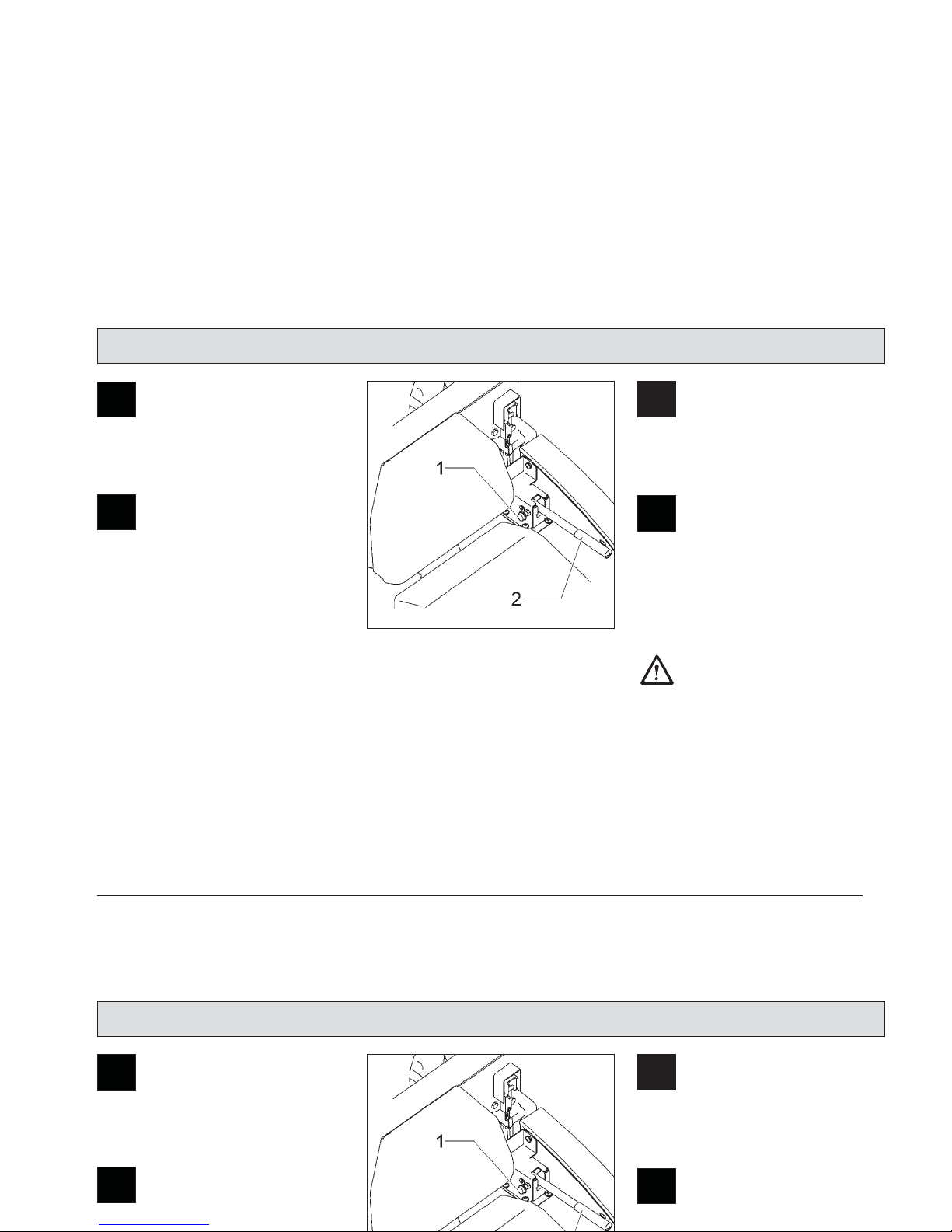

5.3 Empty Dirt Hoppers of

Apex 47 B

- Fold bow (Fig. 11/3) up = the dirt

hoppers (Fig. 11/2) are lowered.

- Use the recessed grip (Fig. 11/1) of

one of the hoppers to lift it lightly

and extract it.

- Take the hopper at its bow-type

handle to disposal and empty.

- Empty second dirt hopper as described above.

- Re-insert dirt hopper (Fig. 11/2) and

fold down the bow (Fig. 11/3).

Emptying dirt hopper Apex 47

1 Recessed grip in dirt hopper

2 Dirt hopper

3 Bow to lift/lower dirt hoppers

Clean dirt hoppers at

regular intervals.

5.4 Empty Dirt Hopper of

Apex 4

7 BH

Before emptying the turning property container the

side broom and the turning

roller are to be raised and

switched off.

Broom and fan will be autmatically switched ON upon

lowering of the hopper if cylinder broom has been ON

before lifting.

The driving speed forward

and backwards with dug

turning property container

is reduced to 50 %, the turning roller is switched off.

Emptying dirt hopper Apex

47 BH

1 Lift-out arm

2 Lift-out cylinder

3 Dirt hopper

Operation

Fig.11

Fig.12

5.3 Empty Dirt Hoppers of

Apex 49 B

- Fold bow (Fig. 11/3) up = the dirt

hoppers (Fig. 11/2) are lowered.

- Use the recessed grip (Fig. 11/1) of

one of the hoppers to lift it lightly

and extract it.

- Take the hopper at its bow-type

handle to disposal and empty.

- Empty second dirt hopper as descri-

Clean dirt hoppers at

regular intervals.

5.4 Empty Dirt Hopper of

Apex 49 BH

Before emptying the turning property container the

side broom and the turning

roller are to be raised and

Operation

Lift side brush and cylinder

broom before removal of

the dirt hopper.

Riding with the lifted hopper

reduces stability of the machine significantly. For this

reason, do not lift the hopper but just before emptying. Before lifting the hopper, the operator has to

make sure that no persons

or objects are behind or

next to the machine. Stop

the machine on level

ground before lifting the

hopper.

Keep clear of the hazard zone!

Pinching and shearing hazard. Provide for required

safe distance before lifting

or lowering the dirt hopper.

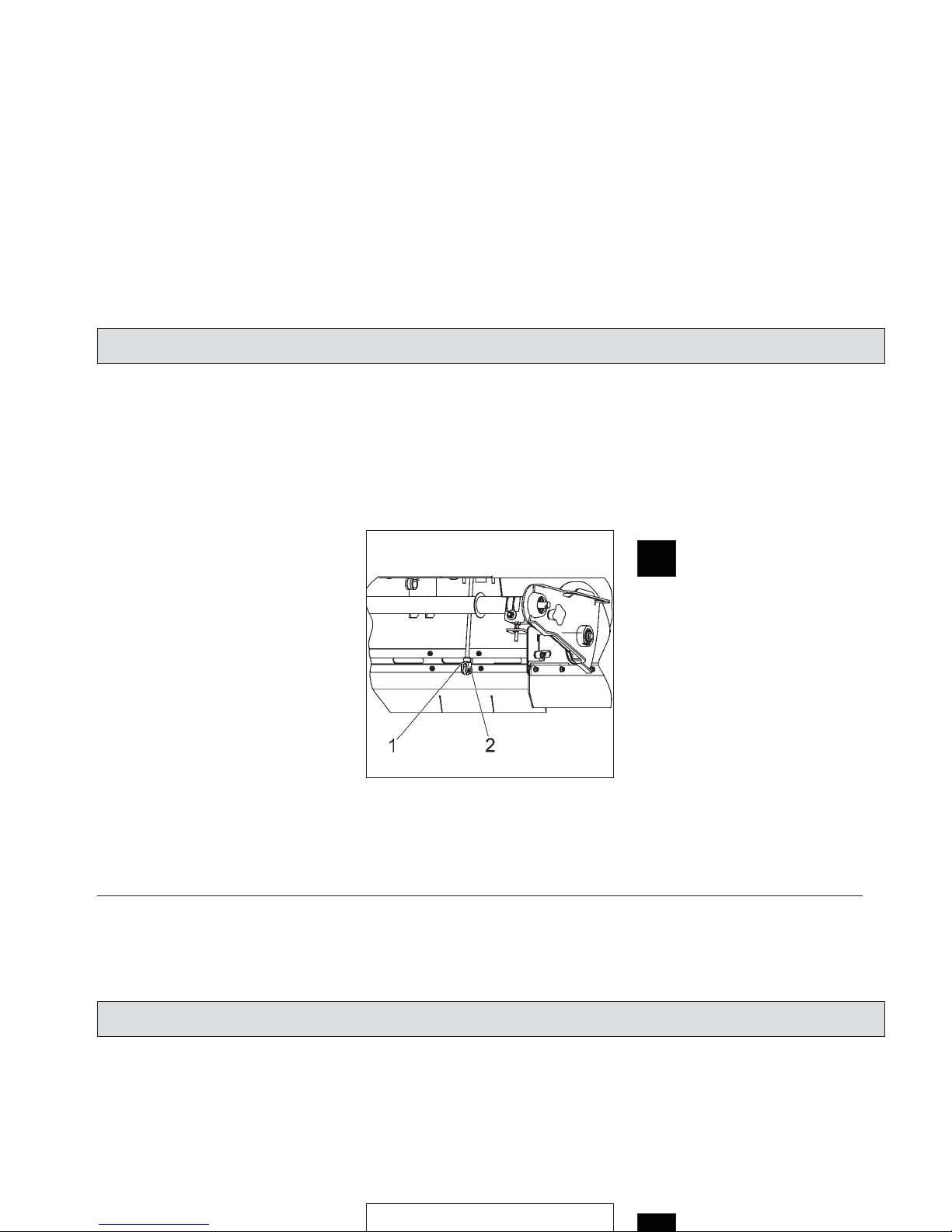

Apex 47H control panel

1 Release switch for lifted-up disposal

function

2 Dirt hopper, lift and lower

Proceed to emptying of the dirt

hopper as follows:

- Lift side brush and cylinder broom

- Proceed to shaking of the filter

system

- Actuate switch (Fig. 13/1) and hold

(dirt hopper is released)

- Actuate switch (Fig. 13/2) by

pushing = lift dirt hopper

- Dirt hopper (Fig. 12/3) is lifted-out

- Back the Apex 4

7H until the dirt

hopper is positioned above the

container for disposal.

-

Pull the safety knob (Fig. 14/1) of

the release lever (Fig. 14/2).

- Release swinging of the dirt hopper

by release lever (fig. 14/2).

- The Apex 47 away from the

disposal container forward drive.

- Lower dirt hopper by actuating

switch (Fig. 13/1) and switch (Fig.

13/2) = lower dirt hopper

34

Operation

Fig.13

Lift side brush and cylinder

broom before removal of

the dirt hopper.

Riding with the lifted hopper

reduces stability of the machine significantly. For this

reason, do not lift the hopper but just before emptying. Before lifting the hop-

Pinching and shearing hazard. Provide for required

safe distance before lifting

or lowering the dirt hopper.

Proceed to emptying of the dirt

hopper as follows:

- Lift side brush and cylinder broom

- Proceed to shaking of the filter

system

- Actuate switch (Fig. 13/1) and hold

(dirt hopper is released)

- Actuate switch (Fig. 13/2) by

pushing = lift dirt hopper

- Dirt hopper (Fig. 12/3) is lifted-out

Operation

35

Observe the information gi-

ven in paragraph 5.2 on

releasing of lifted-up disposal.

Sweeping is possible only

after the dirt hopper has attained its working position.

Release lever, swing dirt hopper

1 Safety knob

2 Release lever, swing dirt hopper

Should the dirt hopper not

be completely emptied after

swinging, proceed to manual shaking with the handle

(Fig. 12/4).

Clean the dirt hopper in regular intervals.

Max. filling of the dirt hopper is 70 litres. Do not exceed a filling of 110kg.

Operation

Fig.14

Observe the information gi-

ven in paragraph 5.2 on

releasing of lifted-up disposal.

Sweeping is possible only

after the dirt hopper has attained its working position.

Should the dirt hopper not

be completely emptied after

swinging, proceed to manual shaking with the handle

(Fig. 12/4).

Clean the dirt hopper in regular intervals.

Operation

5.5 Working with the Apex 47

The driver is requested to carefully

read this operator's manual. All controls are marked with easy-to-understand symbols that ease familiarization. First driving attempts should be

limited to clear areas until you are

familiar with all controls and their functions.

Please comply with the following safety provisions:

When working with the

Apex 47 all sa

fety measures generally applicable for handling vehicles and fuels have to be

observed. No p

assenger

transport admitted with the

Apex 47. War

ning and instruction labels

attached to the machine

contain important information about safe operation

and guarantee your personal safety. Before commencing work,

the operator has to make

sure that the machine and

its accessories are in proper

and safe condition and

comply with the provision

for safety at work. Do not

operate the Apex 47

without protective de

vices.

5.5.1 Switch Electro-Motor ON and

OFF

For safety reasons, the

Apex 47 is equipped with a

seat contact switch.

Starting the engine or

running engine is possible

only when the driver is

seated. If the seat contact

switch is activated with the

electro-motor running, reset

by turning the key switch

OFF and ON again.

- Switch all levers and switches to

neutral position.

- Actuate parking brake

- Turn key switch to "I"

Check the drive pedal for

being in neutral position before switching ON.

If the Apex 4

7

is not used within the admissible conditions and environments of use, the protective functions may

respond and switch off driving function without prior

warning.

Slow the machine down to

standstill by the service brake in that case.

Acknowledge protective

function by key switch.

Overheating of the travel

drive assembly or control

module always entails a

cooling phase.

The seat contact switch deactivated all functions, driving function included.

Slow the machine down to

standstill by the service brake in that case.

36

Operation

5.5 Working with the Apex 49

The driver is requested to carefully

read this operator's manual. All controls are marked with easy-to-understand symbols that ease familiarization. First driving attempts should be

limited to clear areas until you are

familiar with all controls and their functions.

the operator has to make

sure that the machine and

its accessories are in proper

and safe condition and

comply with the provision

for safety at work. Do not

operate the Apex 49

without protective de

vices.

5.5.1 Switch Electro-Motor ON and

Check the drive pedal for

being in neutral position before switching ON.

If the Apex 49

is not used within the admissible conditions and environments of use, the protective functions may

respond and switch off driving function without prior

Operation

37

5.5.2 Sweep

- Lower cylinder broom.

- Release parking brake.

- Slowly depress drive pedal until

desired speed has been attained.

- Regularly actuate shaking device to

clean plate filter.

- Check filling level of the dirt hopper

and empty if required.

5.5.3 Stop and Park

- Release drive pedal which returns

automatically into its neutral position

and the machine slows down to

standstill and actuate service brake.

- Actuate parking brake

- Lift side brush and cylinder broom

- Turn key switch to "0"

When leaving the machine

unattended, pull key.

5.5.4 Displace

Make sure that the key switch is in

neutral position and the side brush

and cylinder broom are lifted up before

displacement of the machine.

5.5.5 Transport

Before transporting the machine on other vehicles, engage the parking brake

and secure the machine by straps and

by placing wedges at the wheels.

Operation

5.5.2 Sweep

- Lower cylinder broom.

- Release parking brake.

- Slowly depress drive pedal until

desired speed has been attained.

- Regularly actuate shaking device to

clean plate filter.

- Check filling level of the dirt hopper

and empty if required.

5.5.4 Displace

Make sure that the key switch is in

neutral position and the side brush

and cylinder broom are lifted up before

displacement of the machine.

Operation

38

Dimensions and weights

Length with side brush

Width without side brush

Width with 1 side brush

Width with 2 side brushes

Height above driver's seat

Maximum dead weight inclusive accessories

Permissible total weight

Driving and sweeping performance

Forward speed

Reverse speed

Sweeping speed (recommended: 4,0 km/h)

Sweeping track w/o/with 1 side brush

with 2 side brushes

Theoretical sweep. perf. with 1 or 2 side brushes

without side brush

Gradability, max. (for 1 min. max.)

mm

mm

mm

mm

mm

kg

kg

km/h

km/h

km/h

mm

mm

m² / h

m² / h

%

1520

1000

1120

1240

1300

620

830

6,0

4,0

6,0

700/970

1240

5800/7450

4200

16

1520

1000

1120

1240

1300

600

790

6,0

4,0

6,0

700/970

1240

5800/7450

4200

16

Technical Data

Apex 47 Apex 47 B Apex 47 BH

6 Technical Data

Dimensions and weights

Length with side brush

Width without side brush

Width with 1 side brush

Width with 2 side brushes

Height above driver's seat

Maximum dead weight inclusive accessories

Permissible total weight

mm

mm

mm

mm

mm

kg

kg

1520

1000

1120

1240

1300

620

830

1520

1000

1120

1240

1300

600

790

Technical Data

Apex 49 Apex 49 B Apex 49 BH

6 Technical Data

Filter system

Filtering surface

Plate filter

Cylinder broom

Length/diameter

Wearing limit

Speed

Sweeping track

Quantity of bristle rows

Serial bristling

Bodenabstand der Dichtleisten am Besenraum

Ground clearance of sealing

strips at broom compartment

Sealing strips, left, right, rear

Sealing strip, front

Side brushes

Diameter

Speed

Serial bristling

Dirt hopper

Hopper capacity

m²

qty.

mm

mm

rpm

mm

mm

mm

rpm

liter

2,8

1

345 / 700

290 500 +/-

20

50 + 5

12 v-shaped

PES

1 / 1 / 4

460

90

PES

70

2,8

1

345 / 700

290 530 +/-

20

50 + 5

12 v-shaped

PES

1 / 1 / 4

460

90

PES

2x30

Technical Data

Apex 47 9 Apex 47 B Apex 47 BH

39

rests upon the soil

Filter system

Filtering surface

Plate filter

Cylinder broom

Length/diameter

Wearing limit

Speed

Sweeping track

Quantity of bristle rows

m²

qty.

mm

mm

rpm

mm

2,8

1

345 / 700

290 500 +/-

20

50 + 5

12 v-shaped

2,8

1

345 / 700

290 530 +/-

20

50 + 5

12 v-shaped

Technical Data

Apex 49 9 Apex 49 B Apex 49 BH

Tyres

Front drive wheel, bandage

Rear, solid rubber tyres

Electric drive

Service voltage

Travel drive assembly (P1/P2)

Suction fan motor/sweeping (P1/P2)

Total power consumption (P1)

Hydraulic system

Compact unit (maintenance-free)

Voltage

Hydraulic fluid, e.g.

Hydraulic tank, capacity

DC / V

KW

KW

KW

V

liter

Ø 300 / 90

4.00-4

24

0,8 / 1,0

1,0 / 1,25

2,4

24

DTE 15 M or

equivalent

0,76

Ø 300 / 90

4.00-4

24

0,8 / 1,0

1,0 / 1,25

2,4

Technical Data

Apex 47 Apex 47 B Apex 47 BH

40

Tyres

Front drive wheel, bandage

Rear, solid rubber tyres

Electric drive

Service voltage

Travel drive assembly (P1/P2)

Suction fan motor/sweeping (P1/P2)

Total power consumption (P1)

DC / V

KW

KW

KW

Ø 300 / 90

4.00-4

24

0,8 / 1,0

1,0 / 1,25

2,4

Ø 300 / 90

4.00-4

24

0,8 / 1,0

1,0 / 1,25

2,4

Technical Data

Apex 49 Apex 49 B Apex 49 BH

41

Noise emission

The sound pressure level measured according to DIN EN

ISO 11201 and under standard operating conditions at the

operator's ear with

- operating status

fan, cylinder broom and side brush ON amounts to

The sound pressure level measured according to DIN EN

ISO 3744 under standard operating conditions and

maximum volume flow amounts to

Vibrations

The frequency weighted acceleration measured according

to EN 1033 which have an effect upon the upper limbs

(hand-arm-system) amounts under normal working conditions

The frequency weighted acceleration measured according

to EN 1032 which have an effect upon the lower limbs (feet

and seat) amounts under normal working conditions

dB (A)

dB (A)

m/s

2

m/s

2

Technical Data

70

82

< 2,5

< 0,5

70

82

< 2,5

< 0,5

Apex 47 B Apex 47 BH

Noise emission

The sound pressure level measured according to DIN EN

ISO 11201 and under standard operating conditions at the

operator's ear with

- operating status

fan, cylinder broom and side brush ON amounts to

The sound pressure level measured according to DIN EN

ISO 3744 under standard operating conditions and

maximum volume flow amounts to

dB (A)

dB (A)

Technical Data

70

82

70

82

Apex 49 B Apex 49 BH

7 Maintenance/Service

7.1 Maintenance Instructions

Compliance with our recommendations concerning maintenance work

will give you the certitude of having an

effective and dependable machine at

your disposal.

It is better to take precautions than

repairing damages - and it saves

money!

According to paragraph 57,

BGV D29, the Apex 47

vacuum sweeper

has to be inspected for safe

condition by an authorized

expert as required, but not

less than once a year

.

Results of such an inspection have to be kept on file

at least until the next inspection is performed.

Please contact your local PowerBoss

distributor if you cannot do the

maintenance works as prescribed in

the maintenance schedule in-house.

He will have these works done for you

and has qualified personnel and

genuine spare parts at disposal.

When cleaning or servicing

the machine, or replacing

parts, have the motors stopped, the battery plug disconnected and the service

brake (parking brake) engaged.

In case of questions or orders for

spare parts, please always quote your

machine's serial indicated on the

nameplate

Refer to chapter 1.3.1 Fig. 12 for

position of nameplate.

Collect spilled oil and

fuel and provide for

adequate disposal of

these substances.

Use appropriate tools for servicing,

maintenance and adjusting work only.

Spare parts at least will have to be of

the same quality as genuine parts are.

Do not remove or install tires or repair a rim. Take the

wheel and rim to a workshop where qualified personnel and the required specific tools are available.

Before commencing any

work on the electric system

disconnect the battery plug.

42

Maintenance/Service

7 Maintenance/Service

7.1 Maintenance Instructions

Compliance with our recommendations concerning maintenance work

will give you the certitude of having an

effective and dependable machine at

your disposal.

It is better to take precautions than

Please contact your local Minuteman

distributor if you cannot do the

maintenance works as prescribed in

the maintenance schedule in-house.

He will have these works done for you

and has qualified personnel and

genuine spare parts at disposal.

When cleaning or servicing

Collect spilled oil and

fuel and provide for

adequate disposal of

these substances.

Use appropriate tools for servicing,

maintenance and adjusting work only.

Spare parts at least will have to be of

the same quality as genuine parts are.

Maintenance/Service

43

7.2 Mount/Dismount Cylinder

Broom

The cylinder broom is accessible from

the left side of the machine and is to

be dismounted as follows:

- Lower cylinder broom

- Pull ignition key and protect by en-

gaging parking brake

- Open lateral flap

- Remove cover

Remove cover

- Open locks (Fig. 15/2) by enclosed

square spanner (counter-clockwise)

- Remove cover (Fig. 15/1)

Dismount cylinder broom

- Loosen star-shaped knob (Fig. 16/2)

and remove

- Remove cylinder broom seating

(Fig. 16/1)

- Turn handle (Fig. 16/3 and 5) upwards and unlock

- Remove plate with sealing strip (Fig.

16/4)

- Remove cylinder broom by pulling.

Before commencing any work on the

electric system disconnect the battery

plug.

7.3 Adjust Sweeping Track

An adjustment device allows adaptation to the different sweeping conditions. The cylinder broom has to be

adjusted for normal use and with

regard to a low degree of wearing as

described in the following.

Check the broom adjustment on level

ground as follows.

Maintenance/Service

Fig.15

Fig.16

7.2 Mount/Dismount Cylinder

Broom

The cylinder broom is accessible from

the left side of the machine and is to

be dismounted as follows:

- Lower cylinder broom

- Pull ignition key and protect by en-

gaging parking brake

- Open lateral flap

- Open locks (Fig. 15/2) by enclosed

square spanner (counter-clockwise)

- Remove cover (Fig. 15/1)

- Remove plate with sealing strip (Fig.

16/4)

- Remove cylinder broom by pulling.

Before commencing any work on the

electric system disconnect the battery

plug.

7.3 Adjust Sweeping Track

Maintenance/Service

Before checking:

Mark level surface for

checking broom

adjustment by chalk.

- Lower cylinder broom and let it run

dry.

- Lift cylinder broom and forward the

Apex 4

7 a bit.

With the correct broom adjustment

the parallel sweeping marks have to

appear on the floor (sweeping

track).

The sweeping track width is to be

- 50mm with the Apex 47

The sweeping track width can be

adjusted by the star-shaped knob (Fig.

17/1) as follows:

Broom adjustment

- Open seat hood

- Loosen handle (Fig. 17/3)

- Turn star-shaped knob (Fig. 17/1)

to the left = wider sweeping track

to the right = smaller sweeping track

- Fix handle (Fig. 17/3)

- Sticker broom adjustment

(Abb.17/2)

With one turn of the knob,

the track widens or broadens by approx. 10mm.

When exceeding the sweeping track width, the engine

protection may be activated.

Sticker broom adjustment

44

Maintenance/Service

Fig.17

Fig.18

Before checking:

Mark level surface for

checking broom

adjustment by chalk.

- Lower cylinder broom and let it run

dry.

- Lift cylinder broom and forward the

Apex 49 a bit.

With the correct broom adjustment

the parallel sweeping marks have to

With one turn of the knob,

the track widens or broadens by approx. 10mm.

When exceeding the sweeping track width, the engine

protection may be activated.

Maintenance/Service

45

7.4 Sealing Strips for Broom Compartment

In order to assure good function of the

sweeper, a perfect condition of the

sealing strips is required, especially in

order to attain the prescribed vacuum

in the broom compartment, a clean

sweeping result and the less possible

wear of the sealing strips (check the

sealing strips of the broom compartment for wearing and damages in

regular intervals).

Replace defective sealing strips.

The ground clearance of the lateral

and rear sealing strips is adjustable

(oblong holes in the sealing strips).

Ground clearance =

sides: approx. 1mm

rear: approx. 4mm.

Proceed to adjustment with the battery

set being mounted.

Height of the front sealing strip (folding

apron) cannot be adjusted. Being

dragged, it has contact with the floor.

7.5 Folding Apron Adjustment

Adjust folding apron

- Turn engine off and pull key

- Disconnect battery plug

- Remove cover (as described in the

paragraph "Mount/Dismount Cylinder Broom").

- Remove bolt (Fig. 19/2).

- Modify adjustment by turning the

fork head (Fig. 19/1).

Modify adjustment such

that the cylinder broom

does not retract the sealing

strip of the folding apron

during operation.

Maintenance/Service

Fig.19

7.4 Sealing Strips for Broom Compartment

In order to assure good function of the

sweeper, a perfect condition of the

sealing strips is required, especially in

order to attain the prescribed vacuum

in the broom compartment, a clean

sweeping result and the less possible

wear of the sealing strips (check the

sealing strips of the broom compart-

Proceed to adjustment with the battery

set being mounted.

Height of the front sealing strip (folding

apron) cannot be adjusted. Being

dragged, it has contact with the floor.

7.5 Folding Apron Adjustment

- Turn engine off and pull key

- Disconnect battery plug

- Remove cover (as described in the

paragraph "Mount/Dismount Cylinder Broom").

- Remove bolt (Fig. 19/2).

- Modify adjustment by turning the

fork head (Fig. 19/1).

Modify adjustment such

Maintenance/Service

7.6 Replace Side Brush

The side brush is located at the front

right of the machine (standard version). Use the lever (Fig. 10/9) to lift

and lower the side brush. The side

brush is to be lightly inclined in forward and in outward direction. The

swinging area of the side brush arm is

limited by stop screws. The side brush

is driven by a V-belt. Fitting of a

second side brush for specific appliances is possible.

Proceed as follows for dismounting of

the side brush:

Replace side brush

- Turn engine off and pull key.

- Secure machine by engaging parking brake

- Disconnect battery plug

- Side brush lifted

- Loosen hexagonal nut (Fig. 20/1)

und remove together with washer

- Remove bolt (Fig. 20/2)

- Remove side brush

Proceed in inverse order for mounting

of the side brush.

46

Maintenance/Service

Fig.20

7.6 Replace Side Brush

The side brush is located at the front

right of the machine (standard version). Use the lever (Fig. 10/9) to lift

and lower the side brush. The side

brush is to be lightly inclined in forward and in outward direction. The

swinging area of the side brush arm is

limited by stop screws. The side brush

Proceed in inverse order for mounting

of the side brush.

Maintenance/Service

47

7.7 Dismount Plate Filter

Proceed as follows for dismounting of

the plate filter:

- Open seat hood.

- Open quick-release locks

(Fig. 21/1).

- Remove cover, filter case (Fig. 21/3)

- Remove covering hood, plate filter

- Loosen fillister head screws

(Fig. 21/2) and remove.

- Fold back frame with electro-motor

(Fig. 22/3).

- Hook frame at indicated position

(Fig. 22/4)

- Remove plate filter (Fig. 22/5).

For mounting of plate filter proceed in

inverse order.

Replace plate filter

1 Quick-release locks

2 Filter case cover

3 4 Filter case

Maintenance/Service

Fig.21

7.7 Dismount Plate Filter

Proceed as follows for dismounting of

the plate filter:

- Open seat hood.

- Open quick-release locks

(Fig. 21/1).

- Remove cover, filter case (Fig. 21/3)

- Remove covering hood, plate filter

- Loosen fillister head screws

Maintenance/Service

Plate filter

1 Detent hook

2 Wing screws

3 Frame with electro-motor

4 Opening for detent lever

5 Plate filter

48

Maintenance/Service

Fig.22

Maintenance/Service

49

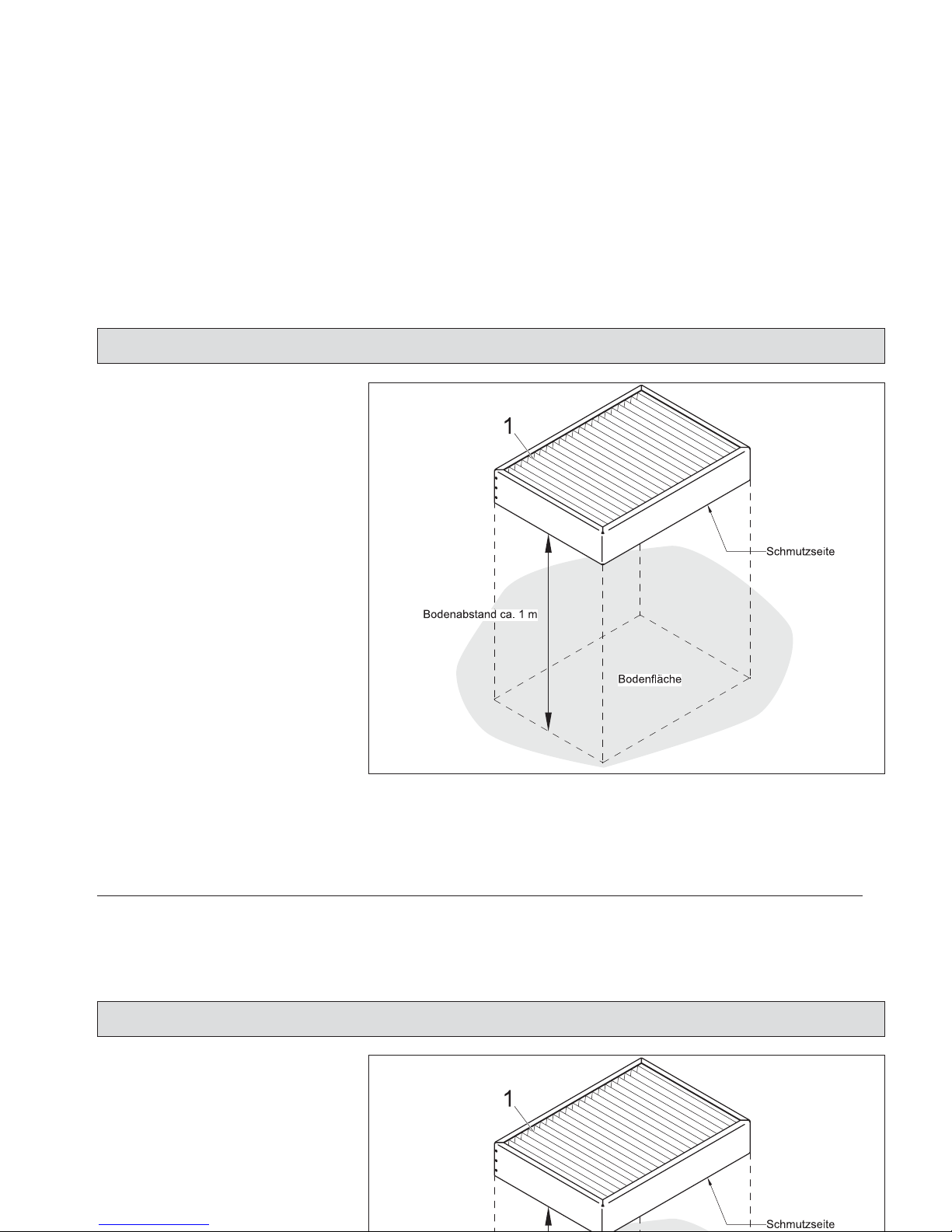

7.8 Basic Cleaning of Plate Filter

Hold the plate filter (Fig. 23/1) in vertical position and let it fall down from a

height of 1 m to the even floor as

represented in Fig. 23.

Basic cleaning of plate filter 1 Plate filter

Maintenance/Service

Fig.23

7.8 Basic Cleaning of Plate Filter

Hold the plate filter (Fig. 23/1) in vertical position and let it fall down from a

height of 1 m to the even floor as

represented in Fig. 23.

Maintenance/Service

7.9 V-Belt Drive

1 Tensioning roller

2 Suction fan V-belt (20Hz)

3 V-belt pulley

4 V-belt for cylinder broom and side

brush (130 Hz)

5 Side brush V-belt

6 Belt pulley

7 Cylinder broom V-belt

8 Tensioning roller lever

9 Belt pulley

10 Tension spring

11 Hexagonal nut

12 Hexagon socket screw

V-belt drive Apex 47

50

Maintenance/Service

Fig.24

7.9 V-Belt Drive

1 Tensioning roller

2 Suction fan V-belt (20Hz)

3 V-belt pulley

4 V-belt for cylinder broom and side

brush (130 Hz)

5 Side brush V-belt

6 Belt pulley

Maintenance/Service

51

7.9.1 Replace Cylinder Broom

V-Belt

- Turn engine off and pull key.

- Secure machine by engaging parking brake

- Disconnect battery plug

- Detent tensioning spring (Fig. 24/10)

by left hand while taking the V-belt

off the tensioning roller with right

hand

- Remove V-belt (Fig. 24/7)

Proceed in inverse order for mounting

of the side brush.

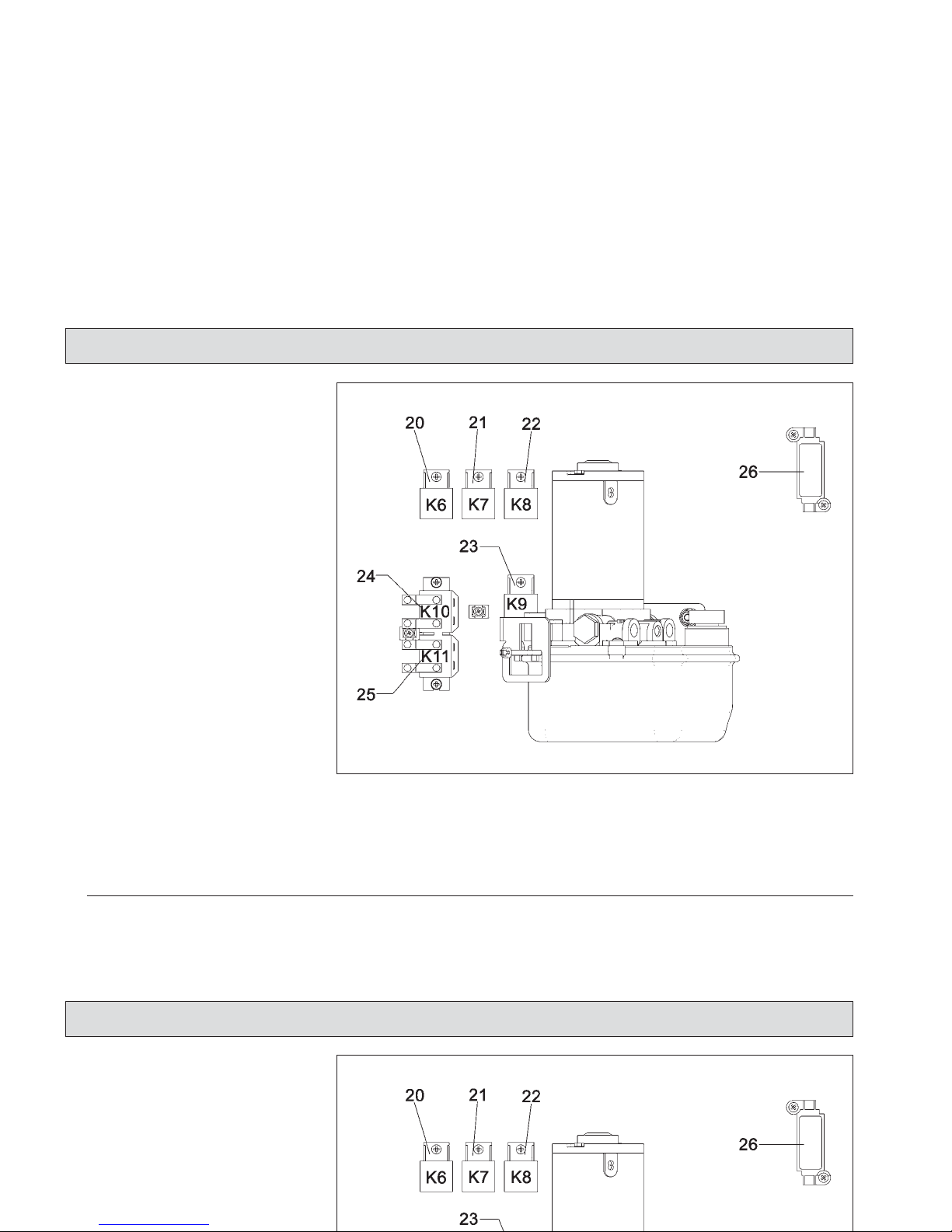

7.9.2 Replace Side Brush V-Belt