PowerBoss Admiral 28, Admiral 30 Operating Manual

Operating Manual

Admiral 28/30

2

Preface

Dear customer,

We are certain that the excellent qualities of the vehicle will justify the faith

you have shown in us through your purchase.

Please read the Chapter "Safety Information" prior to starting the vehicle to

ensure it is operated and used safely.

Your safety, and that of others, basically lies in your ability to control and operate the vehicle. Before using the

equipment for the first time, read this

original manual thoroughly, act according to the information contained and

keep it in a safe place for future reference or subsequent owners. The operating manual contains all the most

important information regarding operation, maintenance and service.

Throughout this manual, texts which

concern safety are indicated by the corresponding danger pictogram. If you

have any questions with regard to the

machine or operating manual, you can

contact your PowerBoss service partner at any time.

We explicitly point out that no legal

claims may be asserted based on the

information contained in this manual.

Ensure only original spare parts are

used should any repairs be necessary.

Only such original spare parts warrant

that the equipment is reliably ready to

use at all times. We reserve the right to

make technical modifications in the interest of further development.

Valid as of: May 2013

PowerBoss Inc.

175 Anderson Street

Aberdeen, NC 28315

Phone: (910) 944 - 2105

FAX: (910) 944 - 740

Intended use

The Admiral 28/30 is a scrubber dryer

for the wet cleaning of hard floors. Any

use beyond this is regarded as improper use. The manufacturer is not considered liable for any damage resulting

from improper use; the user is solely responsible for all the potential risks involved. Intended use also includes

maintaining and observing the operating, maintenance and repair conditions

prescribed by the manufacturer.

The Admiral 28/30 may only be operated, serviced and repaired by personnel

who are familiar with the work involved

and are aware of the risks.

The applicable accident prevention

laws must be observed and any generally accepted health and safety directives must be maintained.

Based on the conception, design and

construction of the vehicle introduced

onto the market by us, the vehicle complies with the applicable basic safety

and health requirements stipulated in

the EC Directive (refer to the Declaration of Conformity). This declaration is

no longer considered valid in the event

of modifications to the vehicle not authorized by us. The manufacturer is not

Introduction

3

deemed liable for any damage resulting

from unauthorized modifications to the

vehicle.

.

Notes on warranty

As a fundamental rule, the regulations

in the purchase agreement apply.

There are no rights to claims for compensation under the terms of warranty

when the damage is a result of failure to

observe the stipulations concerning

service and maintenance. Maintenance

work must be completed by an authorized PowerBoss service center and

confirmed in the “maintenance logbook”; this serves as proof of rights to

claims under the terms of warranty.

The following are excluded from the

terms of warranty: normal wear and tear

and damage caused by overuse, defective fuses, improper handling or unauthorized modifications. Claims under

the terms of warranty are also annulled

when damage occurs to the machine as

the result of the use of parts and accessories not explicitly approved by us or to

failure to observe maintenance procedures.

Acceptance of the vehicle

The vehicle must be inspected directly

after delivery for signs of transport damage. Replacements for transport damage will be made when confirmation is

provided immediately by the transporting company with regard to the damage

and you send the damage report to our

authorized contractual partner together

with the consignment note.

Disposal

Render the vehicle inoperable. It must

not represent a source of danger for

children. Dispose of the equipment in

accordance with local regulations. For

further information on handling and recycling, please contact the authorized

dealer where you purchased the vehicle.

Used batteries with the recycling symbol contain reusable commodities. The

heavy metals contained represent a

major risk both to people's health and to

the environment. Never open or damage batteries. Never touch, inhale or

swallow the content of batteries. Health

hazard! Do not allow batteries to get

into the environment. Risk of contaminating the ground and water! In accordance with symbol with the crossed out

garbage bin, these batteries must not

be disposed of in domestic waste.

Introduction

4

Table of Contents

Preface. . . . . . . . . . . . . . . . . . 2

Intended use. . . . . . . . . . . . . . 2

Notes on warranty . . . . . . . . . 3

Acceptance of the vehicle . . . 3

Disposal . . . . . . . . . . . . . . . . . 3

1 Safety Information . . . . . . . . 6

1.1 Safety and warning labels . . . 6

1.2 General information . . . . . . . . 7

1.3 Operating information. . . . . . . 7

1.4 Maintenance information . . . . 8

1.5 Particular risks . . . . . . . . . . . . 9

1.6 Environmental protection . . . 10

1.7 Labels on the vehicle . . . . . . 11

2 Operation . . . . . . . . . . . . . . 14

2.1 Unpacking . . . . . . . . . . . . . . 14

2.2 Prior to starting up for the

first time . . . . . . . . . . . . . . . . 14

2.2.1 Instruction. . . . . . . . . . . . . . . 14

2.2.2 Assembling the squeegee . . 14

2.2.3 Battery type . . . . . . . . . . . . . 15

2.2.4 Installing the trough battery . 15

2.2.5 Installing the driving/block

battery . . . . . . . . . . . . . . . . . 16

2.2.6 Checking the battery plugs. . 17

2.2.7 Initial battery charge. . . . . . . 17

2.3 Cleaning operation . . . . . . . . 18

2.3.1 Check the battery charge . . . 19

2.3.2 Charging the battery. . . . . . . 19

2.3.3 Emptying the waste water

tank. . . . . . . . . . . . . . . . . . . . 21

2.3.4 Filling the clean water tank. . 22

2.3.5 Adjusting the driver's seat . . 23

2.3.6 Switching the vehicle on. . . . 24

2.3.7 Driving and braking behavior 25

2.3.8 Pushing the vehicle . . . . . . . 25

2.3.9 Charge status indicator . . . . 26

2.3.10 Switching the vehicle off. . . . 27

2.3.11 After completing cleaning. . . 28

2.4 Service code table . . . . . . . . 29

2.5 Loading and transporting . . . 30

2.6 Special equipment and

accessories . . . . . . . . . . . . . 31

3 Operation . . . . . . . . . . . . . . 33

3.1 Method of operation . . . . . . . 33

3.2 Operating and indicator

elements. . . . . . . . . . . . . . . . 34

3.2.1 Left-hand operating panel . . 34

3.2.2 Right-hand operating panel . 36

3.2.3 On the vehicle . . . . . . . . . . . 42

4 Technical Data . . . . . . . . . . 45

5 Maintenance and

Service. . . . . . . . . . . . . . . . . 48

5.1 PowerBoss system

maintenance. . . . . . . . . . . . . 48

5.2 Proof of Maintenance . . . . . 49

5.3 Maintenance Plan. . . . . . . . . 50

5.4 Battery system . . . . . . . . . . . 54

5.4.1 Water filling system . . . . . . . 55

5.4.2 Charge status indicator

(TSG) . . . . . . . . . . . . . . . . . . 55

5.4.3 Servicing the driving

batteries . . . . . . . . . . . . . . . . 55

5.4.4 Disposing of batteries. . . . . . 55

5.5 Waste water and clean

water tank. . . . . . . . . . . . . . . 56

5.5.1 Cleaning the clean water

tank. . . . . . . . . . . . . . . . . . . . 57

5.5.2 Cleaning the clean water

filter. . . . . . . . . . . . . . . . . . . . 57

5.5.3 Cleaning the waste water

tank. . . . . . . . . . . . . . . . . . . . 57

5.6 Disk brush head . . . . . . . . . . 58

5.6.1 Cleaning the brushes . . . . . . 59

5.6.2 Changing the brushes . . . . . 59

5

Table of Contents

5.7 Cylindrical brush head . . . . . 60

5.7.1 Emptying the dirt hopper . . . 61

5.7.2 Disassembling the brushes . 61

5.7.3 Installing the brushes . . . . . . 61

5.8 Deflector . . . . . . . . . . . . . . . . 62

5.8.1 Pivoting the deflector away . 62

5.8.2 Changing the deflector

rubber . . . . . . . . . . . . . . . . . . 62

5.9 Squeegee. . . . . . . . . . . . . . . 63

5.9.1 Cleaning the squeegee . . . . 64

5.9.2 Changing the sealing strips . 64

5.9.3 Adjusting the sealing strips. . 65

PowerBoss Made Simple

Commercial Limited

Warranty.............................. 68

PowerBoss Made Simple

Commercial Limited

Warranty.............................. 69

6

Safety Information

1 Safety Information

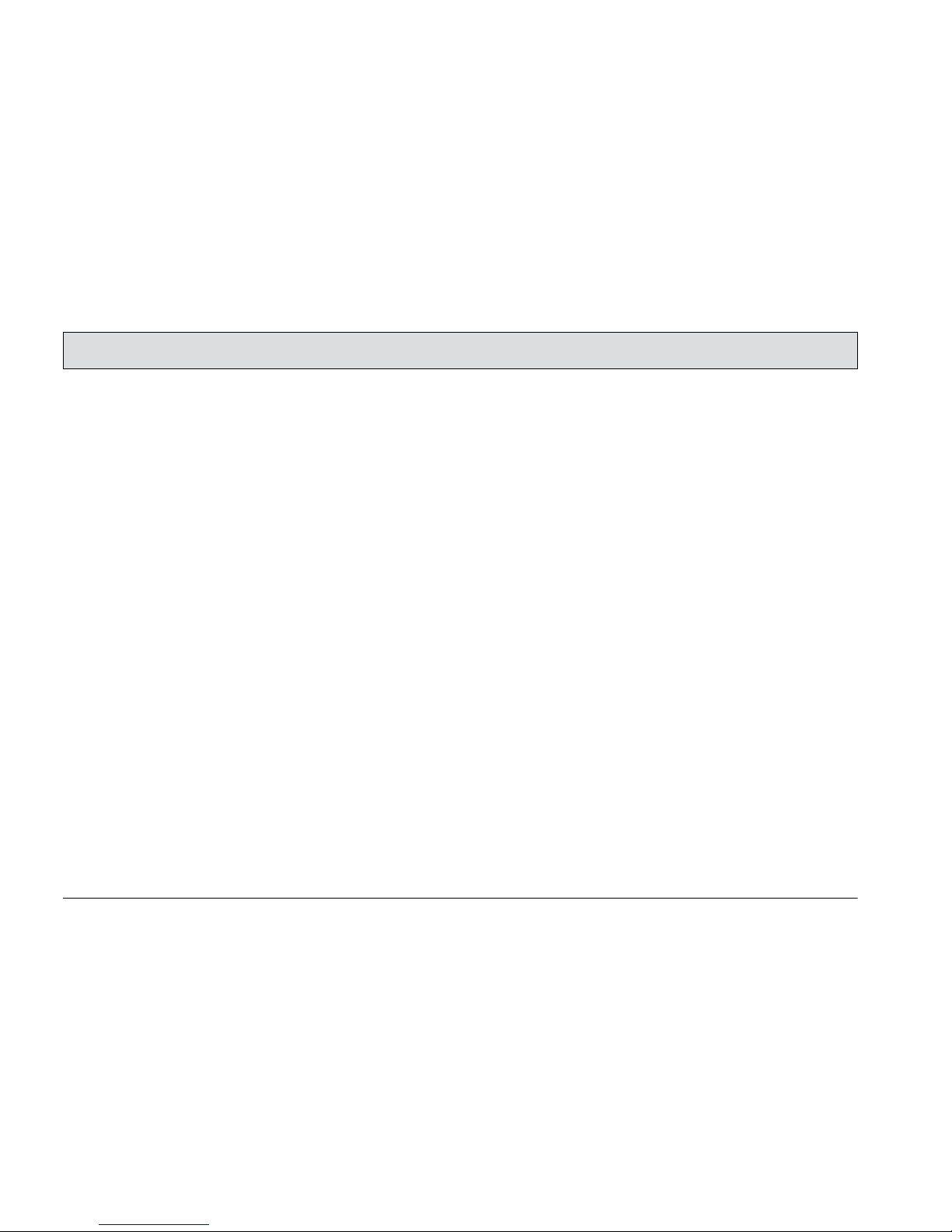

1.1 Safety and warning labels

All information related to personal safety, safety of the vehicle and environmental protection are assigned the

following symbols throughout the operating manual:

Symbol

Hazardous for... Definition

Danger persons

or property

Safety information to prevent the development of hazardous situations resulting from ignoring or failing to

follow instructions or prescribed work procedures.

Note the equipment Important information on handling the equipment in

order to maintain its functionality.

Ecological hazard the environment Ecological hazard through the use of substances

which represent a potential hazard to health and the

environment.

7

Safety Information

1.2 General information

• In addition to the information provid-

ed in this operating manual, all the

legally applicable health and safety

provisions must be observed.

• Before starting up the vehicle for the

first time, read the operating manual

supplied with it thoroughly as well as

any separate operating manuals provided with additional or attachment

devices and observe all the information during work.

• The vehicle may only be operated,

serviced and repaired by personnel

trained by PowerBoss technical experts.

• This vehicle is not intended to be

used by persons (including children)

with limited physical or mental capabilities or persons without sufficient

experience and ability.

• Particular attention should be paid to

the information regarding safety.

Technical expertise is the key to preventing errors when operating the

equipment and ensuring trouble-free

operation.

• The operating manual must always

be kept at the operating location of

the vehicle and, as a result, should

kept in a safe place on the vehicle.

• If the equipment is sold or rented out,

these documents should be transferred to the new owner/operator.

The transfer should be confirmed!

• The warning labels attached to the

equipment provide important information concerning safe operation.

Labels which are illegible or missing

must be replaced.

• Original spare parts must be used to

ensure safety.

• It is forbidden to remain in the hazard

area represented by the vehicle.

1.3 Operating information

• Before starting the vehicle up for the

first time, the battery to be used must

be fully charged, properly, by implementing the initial battery charge

routine. Please pay attention to the

operating manual provided with the

charging unit as well as the manual

from the battery manufacturer. PowerBoss assumes no liability for damage to the battery caused by a fault

when the battery is charged for the

first time.

• Check the operational safety of the

machine each time before starting it

up! Clear any faults immediately.

• Before starting work, the operator

must be fully familiar with all adjustment, operating and control elements as well as their respective

function! It is too late to do this when

the machine is actually in operation!

• Always wear heavy duty, non-slip

footwear when working with the machine.

• The machine may only be driven on

and the equipment used on those

surfaces which have been approved

by the contractor or person appointed by him.

8

Safety Information

• When using the vehicle, it is essential to pay attention to third parties,

especially children.

• Start driving immediately after

switching on the brush head drive

otherwise the brush could produce

impression marks on the floor. Always raise the brush head before

driving over thresholds.

• Only use cleaning agents suitable for

the vendor (non-foaming) and observe all the use, disposal and warning information provided by the

cleaning agent manufacturer.

• The vehicle is not suitable for clearing up health-hazardous, inflammable or explosive fluids, dust or

substances.Burning or smoldering

items, e.g. glowing cigarettes, must

not be swept up. It is also forbidden

to sweep up wood dusts, e.g. beech

or oak dust. Health hazard!

• For safety reasons, the driver's seat

is equipped with a seat contact

switch. The vehicle can only be started when the operator is sitting on the

driver's seat. The function of the seat

contact switch must not be bypassed.

• It is forbidden to use the machine in

potentially explosive atmospheres.

• It is forbidden to transport persons or

heavy objects.

• It is forbidden to tow machines or operate as a trailer.

• Remove the key to prevent unauthorized use of the vehicle.

• When driving the vehicle to the area

of use, the squeegee and brush

head must be raised. The style of

driving must be adapted to the local

conditions.

• Drive slowly on wet ground due to

the risk of skidding, particularly when

cornering. Drive especially slowly

when cornering while driving downhill.

• The vehicle may only be used on

surfaces with a maximum gradient of

10%.

• It is forbidden to manipulate switches

and safety equipment.

1.4 Maintenance information

• Operating personnel must complete

the necessary daily and weekly

maintenance work. All other maintenance work must be completed at

your nearest authorized PowerBoss

service center.

• The maintenance work and maintenance intervals prescribed in the operating manual must be adhered to.

• Suitable tools must be used for

cleaning and maintenance work.

• The vehicle must be inspected by a

recognized technical expert in respect of operational safety, within

the terms of the applicable accident

prevention laws, at reasonable intervals (we recommend at least once a

year) and following modification or

repairs.

• Spare parts must comply with the

minimum technical requirements

stipulated by the manufacturer! This

is ensured by the use of original

spare parts.

• The vehicle and motors must be

switched off prior to cleaning or servicing it or to replacing parts.

• Remove the ignition key to prevent

unauthorized use of the vehicle.

9

Safety Information

• Always disconnect the battery plug

before starting any work on the electrical installation.

• It is not permitted to clean the vehicle

with a pressure washer or steam

blaster.

• It is not permitted to use aggressive

and corrosive cleaning agents.

• Allow the vehicle to dry after being

cleaned, e.g. over the weekend.

• Only start the vehicle up when all the

safety equipment has been installed

and brought to its protecting position.

• When working in the area of the

raised waste water tank, it must be

opened fully to prevent it accidentally

slamming shut.

1.5 Particular risks

Electronics

• In the case of defects in the electrical

installation, always switch the vehicle off and clear the fault.

• Work on the electrical installation

may only be carried out by electricians who have received the necessary training and in accordance with

the electrical engineering regulations.

• The vehicle's electrical installation

must be inspected/checked at regular intervals. Defects, such as loose

connections, loose nuts on conductive bolts, electrical components and

damaged cable, must be rectified immediately.

• Only use original fuses with the

specified amperage. The use of fuses with too high a rating could damage the electrical installation beyond

repair and could be the cause of

fires.

Batteries

• Observe the information in the operating manual provided by the battery

manufacturer.

• Batteries must not be connected or

disconnected when live.

• Always disconnect the battery cable

before starting any work on the electrical installation.

• Batteries may only be handled and

changed by properly skilled maintenance personnel.

• Due to a change in the center of

gravity, only approved batteries may

be installed at the intended position.

• Pay attention that the insulation on

the charger cable is not initially damaged and not damaged during the

charging process. The cable must

not rub against anything. Do not use

the on-board charger if the insulation

is damaged.

• To prevent creeping currents, always keep the batteries clean and

dry and protect from contamination,

e.g. from metal dust.

• Never lay any metallic objects or

tools on batteries. Risk of short circuit and deflagration!

• Ensure sufficient ventilation in the

10

Safety Information

charging area when charging the

batteries. Otherwise there is a risk of

explosion!

• Wash you hands thoroughly after

handling batteries.

• It is forbidden to eat, drink and

smoke in battery charging rooms.

• For further safety information, see

supplementary sheet 88-60-2556 Notes on driving batteries.

Information on the power plug

• Only take hold of the power plug and

power cable when your hands are

dry.

• Never insert the power plug in the

socket if the base is wet or damp.

• Never immerse the power cable or

power plug in water or other fluids

clean them in running water. Risk of

electric shock!

• Dry any power plugs and power cables which have become damp with

a dry cloth before connecting them in

power sockets.

• Pay attention that the power socket

is dry.

• We recommended the use of splashproof power sockets complying with

DIN VDE 0620-1.

• Pay attention that no water or fluids

can get on to live machine parts. If

water should penetrate to such

parts, disconnect the power plug immediately and have the vehicle

checked at an authorized PowerBoss service center.

• The power connection cable must be

inspected for signs of damage at

regular intervals. If damage is detected, the cable must be replace prior to further use.

Safety equipment

• Never operate the Admiral 28/30

without the cover being closed and

locked.

1.6 Environmental protection

• A certain factual expertise is required in order to use substances

which could represent a risk to

health and the environment.

• Always observe the applicable legal

regulations and local directives when

disposing of refuse, waste water and

cleaning agents, also refer to the

German Water Resources Act

(WHG).

• Used batteries with the recycling

symbol must not be disposed of in

household waste, refer to Section

"Disposal".

11

Safety Information

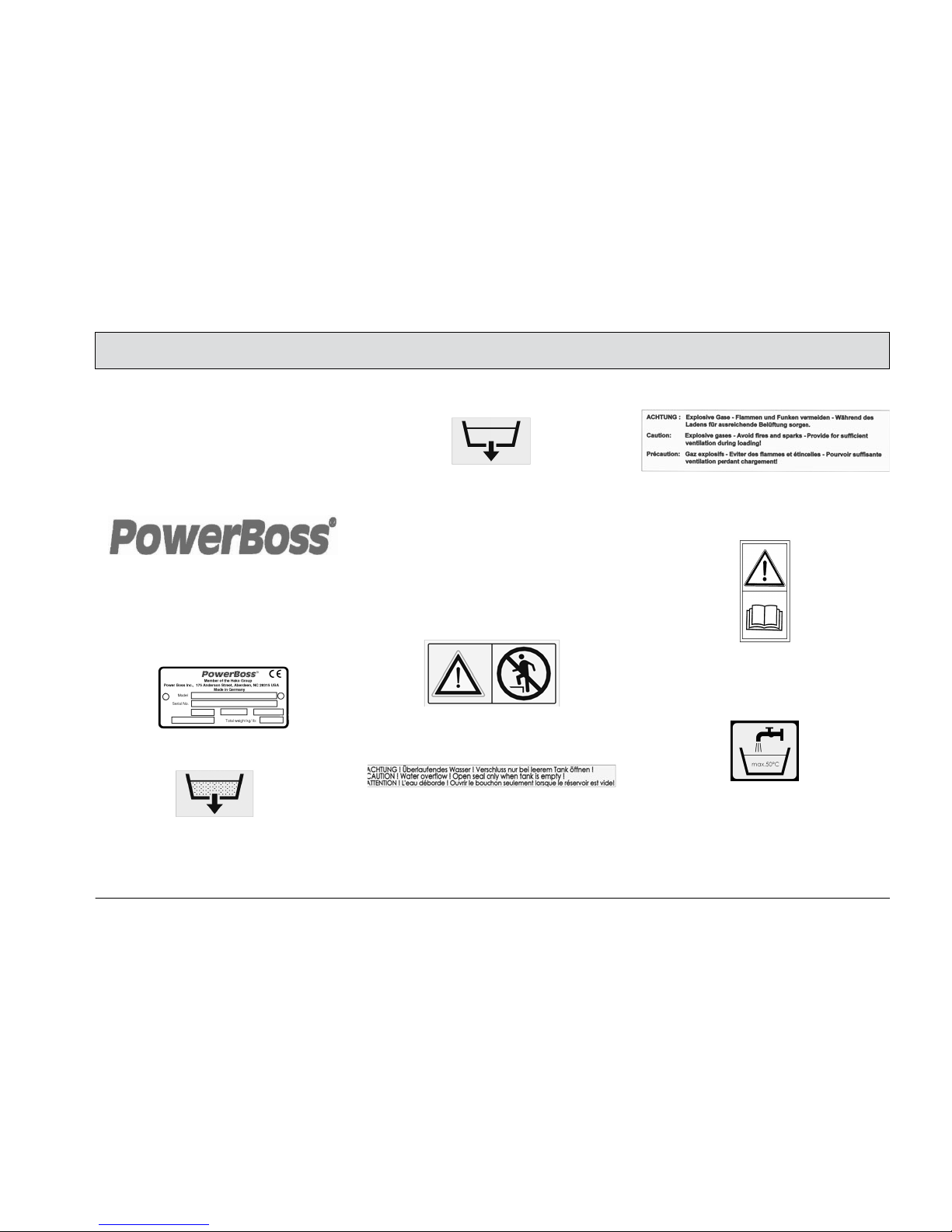

1.7 Labels on the vehicle

The following safety and warning labels

are attached to the vehicle where easily

legible. Missing or illegible labels must

be replaced immediately.

Company logo (Fig. 1/1)

Machine model (Fig. 1/2)

Rating plate (Fig. 1/3)

Label: Waste water drainage (Fig. 1/4)

Label: Clean water drainage (Fig. 1/5)

Label: Working width (Fig. 1/6)

XXX/XX

Label: Do not step on deflectors!

(Fig. 1/7)

Label: Water overflow! (Fig. 2/8)

Label: Explosive gases (Fig. 2/9)

Read and observe the operating manual (Fig. 2/10)

Label: Water temperature, max. 50°

(Fig. 2/11)

Admiral 28 / 30

12

Safety Information

Fig.1

5

1

2

6

3

4

7

13

Safety Information

Fig.2

10

8

9

11

1

14

Operation

2 Operation

2.1 Unpacking

Remove the packaging and take the

Admiral 28/30 from the pallet after loosening the tightening straps.

2.2 Prior to starting up for the

first time

2.2.1 Instruction

Operators must receive instruction before the vehicle is put into service. Only

technicians from your local authorized

PowerBoss dealer are allowed to provide initial instruction on the machine.

The manufacturing plant will notify the

dealer immediately after delivering the

vehicle and the dealer will contact you

to arrange a date.

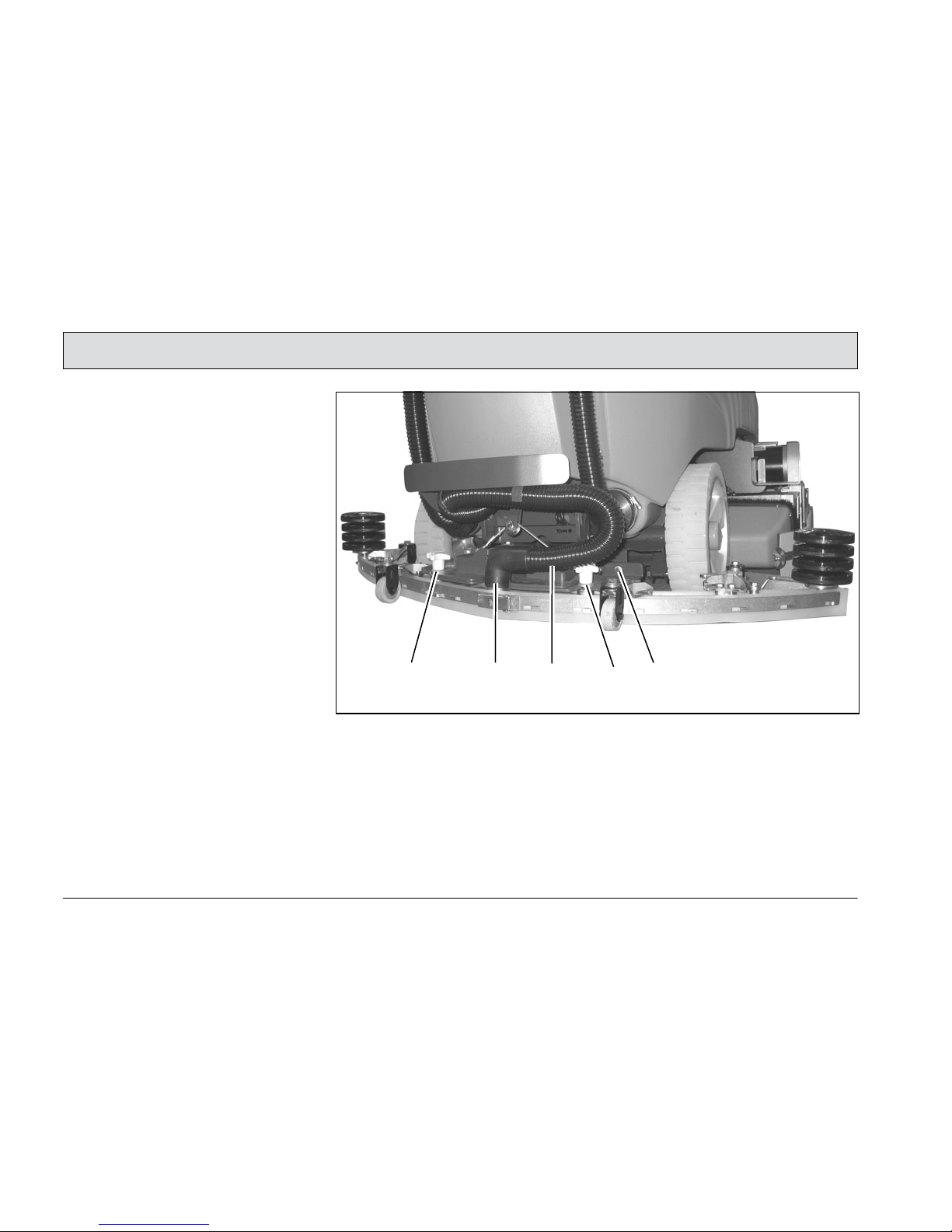

2.2.2 Assembling the squeegee

1. Use the star-shaped knobs (Fig. 3/1)

to fix the squeegee on the squeegee

lift (Fig. 3/2).

2. Connect the suction hose (Fig. 3/3)

to the nozzle (Fig. 3/4).

Fig.3

14

1

23

15

Operation

2.2.3 Battery type

Only batteries approved by PowerBoss

may be used. The settings can only be

made at an authorized PowerBoss service center!

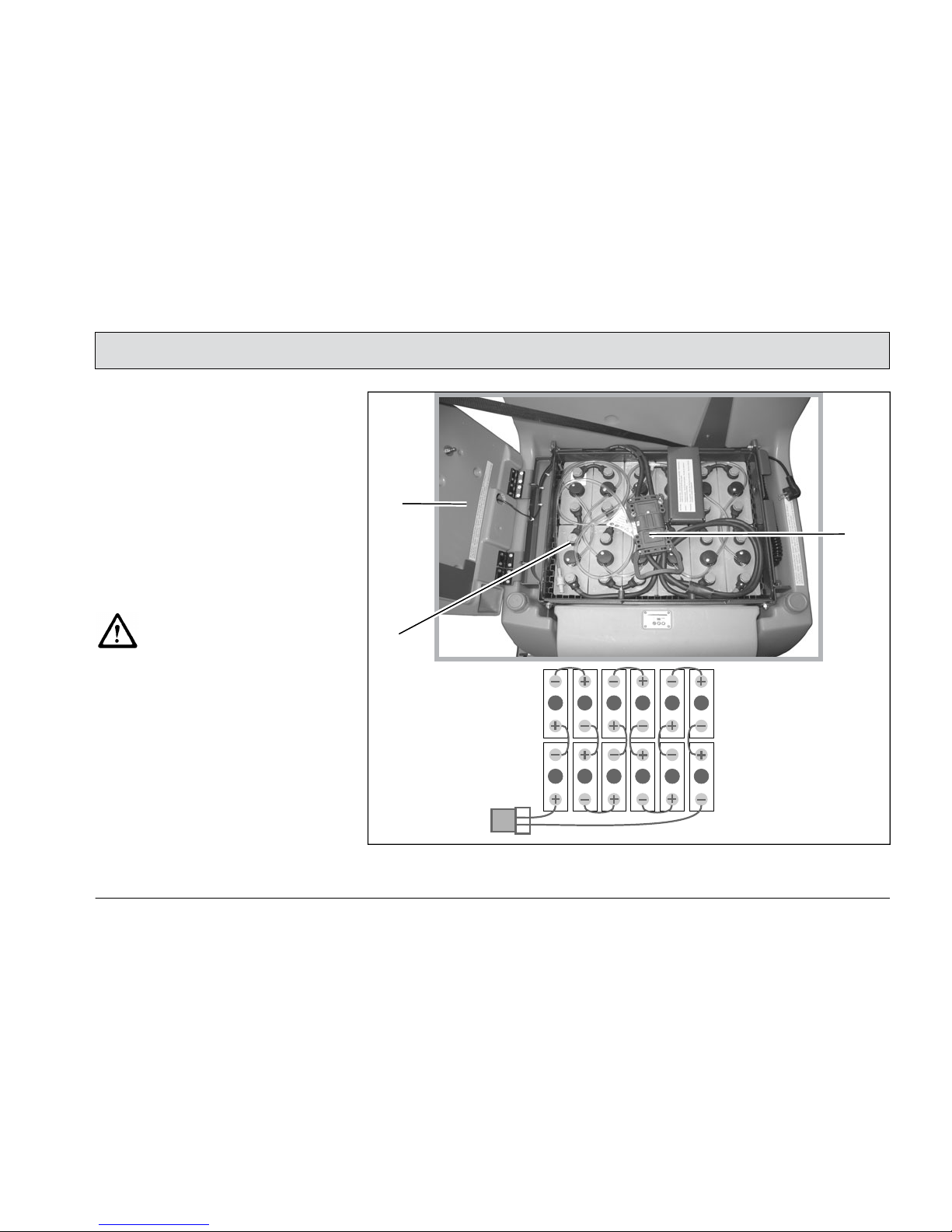

2.2.4 Installing the trough battery

1. Switch off the vehicle with the key

switch.

2. Open the seat console (Fig. 4/1).

3. Install the battery (Fig. 4/2) in the

battery trough accordance with illustration.

Replacing/Installing is only

possible with the aid of a crane

and appropriate lifting gear.

Please read the information

provided in the operating manual of the battery manufacturer. Trough batteries weigh up

to 280 kg. For reasons of safety, we strongly recommend

having this work completed at

an authorized PowerBoss service center.

4. Check the battery plug (Fig. 4/3),

refer to Section 2.2.6.

Fig.4

1

2

3

16

Operation

2.2.5 Installing the driving/block

battery

1. Switch off the vehicle with the key

switch.

2. Open the seat console (Fig. 5/1).

3. Position the batteries in the battery

tray in accordance with the figure.

Replacing/Installing is only

possible with the aid of appropriate lifting gear. Please read

the information provided in the

operating manual of the battery manufacturer. For reasons

of safety, we strongly recommend having this work completed at an authorized PowerBoss service center.

4. Connect the battery poles in accor-

dance with the connection diagram

(Fig. 5/2).

5. Pay attention they are firmly fixed

and grease the poles.

6. Check the battery plug (Fig. 5/3),

refer to Section 2.2.6.

Fig.5

1

2

3

17

Operation

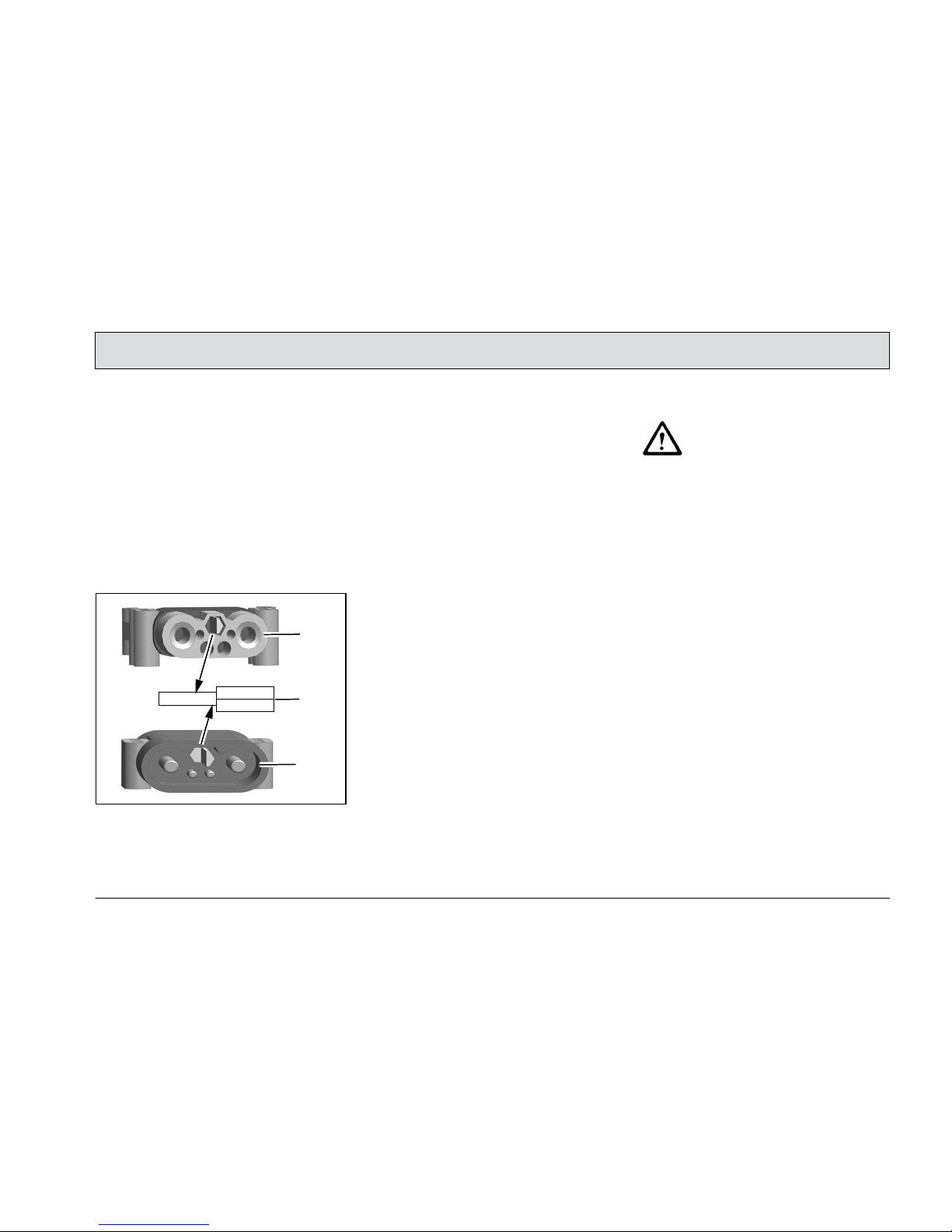

2.2.6 Checking the battery plugs

The battery plugs (Fig. 6/1 and 2) on

the vehicle, batteries and stationary

chargers must be coded with the colored coding pins (Fig. 6/3) according

to

the battery and nominal voltage. The

connectors on the charger are coded at

the factory according to the charge

characteristic curve so that on changing

the charge characteristic curve (according to the battery), the connector coding

must be changed.

Fig.6

Connector coding

Socket housing of the battery:

• Gray for wet batteries

• Green for maintenance-free gel batteries

Connector body on the vehicle:

• Yellow for both battery types

Voltage coding

Insert the coding pin (Fig.

6/3) so that

the nominal voltage can be read

through the window in the housing.

Always select the same nominal voltage for the socket and connector.

The following three conditions must be

fulfilled for the complete system:

1.

The voltage coding must be the

same for all connectors and sockets.

2. The color of the coding pin in the

vehicle is yellow.

3. The color of the coding pin in the

charger connector (vehicles without

built-in charger) complies with the

battery plug.

2.2.7 Initial battery charge

Before starting the vehicle up

for the first time, the batteries

to be used must be fully

charged, properly, by implementing the initial battery

charge routine. Please pay attention to the operating manual

provided with the charging unit

as well as the manual from the

battery manufacturer. PowerBoss assumes no liability for

damage to the battery caused

by a fault when the battery is

charged for the first time.

1

24 V

24 V

36 V

36 V

3

2

18

Operation

2.3 Cleaning operation

Read and follow the safety information in Chapter 1 before

operating the vehicle.

1. Check the parking space for signs of

leaks. Hoses, lines and tanks must

show no signs of leaks or damage.

2. Check the battery charge, refer to

Section 2.3.1.

The current charge status appears in the indicator field.

Charge the battery, if necessary, refer to Section 2.3.2.

3. Drain off the waste water tank, refer

to Section 2.3.3.

You are informed the waste

water tank is full via the indicator field.

4. Fill the clean water tank, refer to Section 2.3.4.

The maximum temperature is

50°C.

5. Adjust the driver's seat, refer to Section 2.3.5.

6. Lock the side deflector.

7. Switch on the vehicle with the key

switch and set the required driving

direction using the driving direction

selection switch, refer to Section

2.3.6.

The operating hour counter

displays the software version,

the last service code (if applicable) and operating hours in

succession. Service code

table, refer to Section 2.4

8. Press the button for the brush head

and squeegee.

The vehicle is ready for operation.

9. Press the button for the clean water

supply.

The clean water supply is activated.

10.Press the button for the clean water

dosing.

The clean water quantity is set.

11.If necessary, press the button for

brush pressure adjustment.

The brush pressure is activated.

Start driving immediately after

switching on the brush head

drive otherwise imprints of the

brush could be produced on

the floor!

Always raise the brush head

before driving over thresholds!

19

Operation

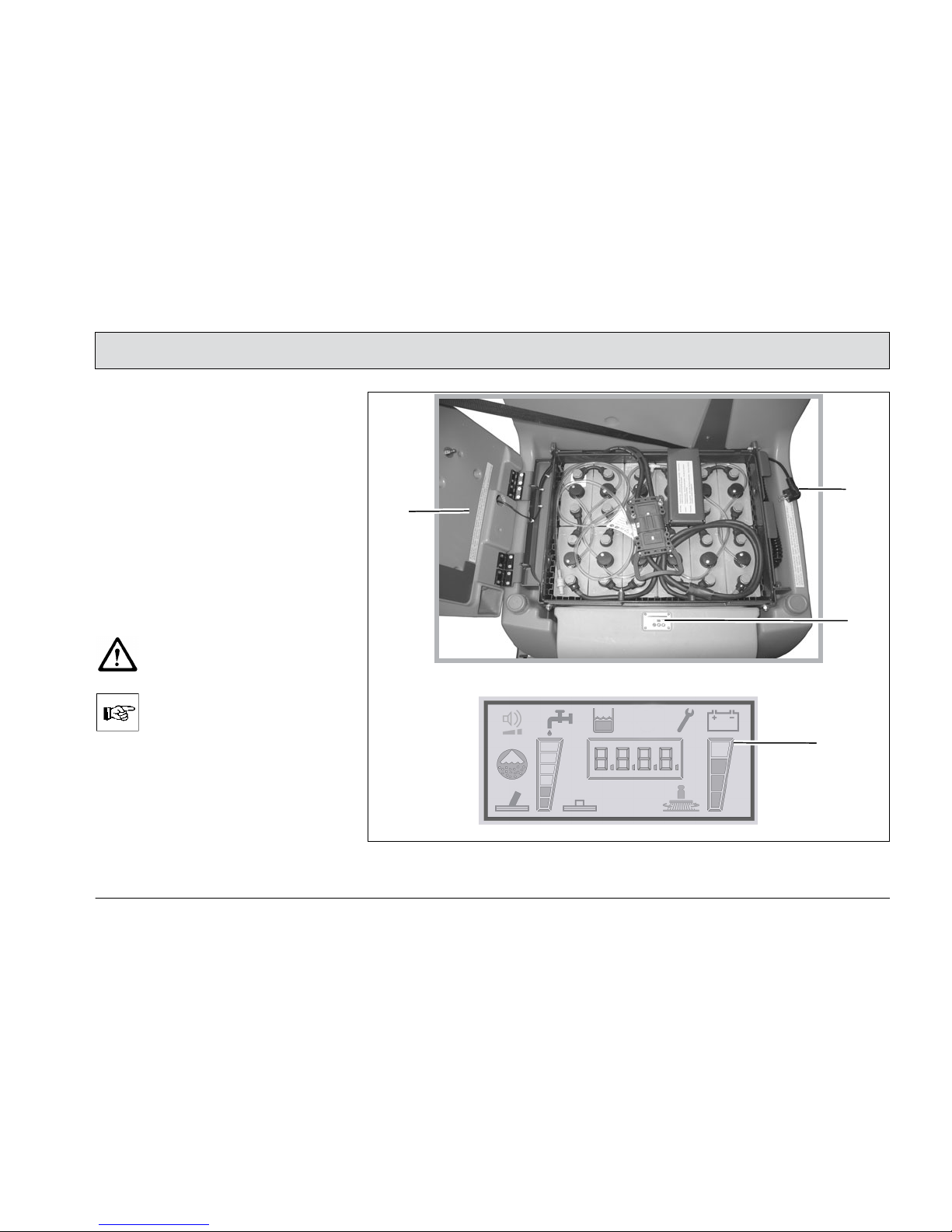

2.3.1 Check the battery charge

The batteries are charged using the integrated battery charger (Fig. 7/1). The

batteries can be charged as soon as the

first field in the charge status indicator

(Fig.

7/2) goes out, at the latest, however, after the cleaning functions have

switched off (all fields go out).

2.3.2 Charging the battery

1. Move the vehicle to a piece of level

ground and switch it off.

2. Open the seat console and connect

the battery charger to the power outlet using the power cable (Fig. 7/3).

The seat console (Fig. 7/4)

must be open during the charging process!

Never let batteries stand

around in a discharged state

but recharge them immediately!

Fig.7

3

4

1

2

20

Operation

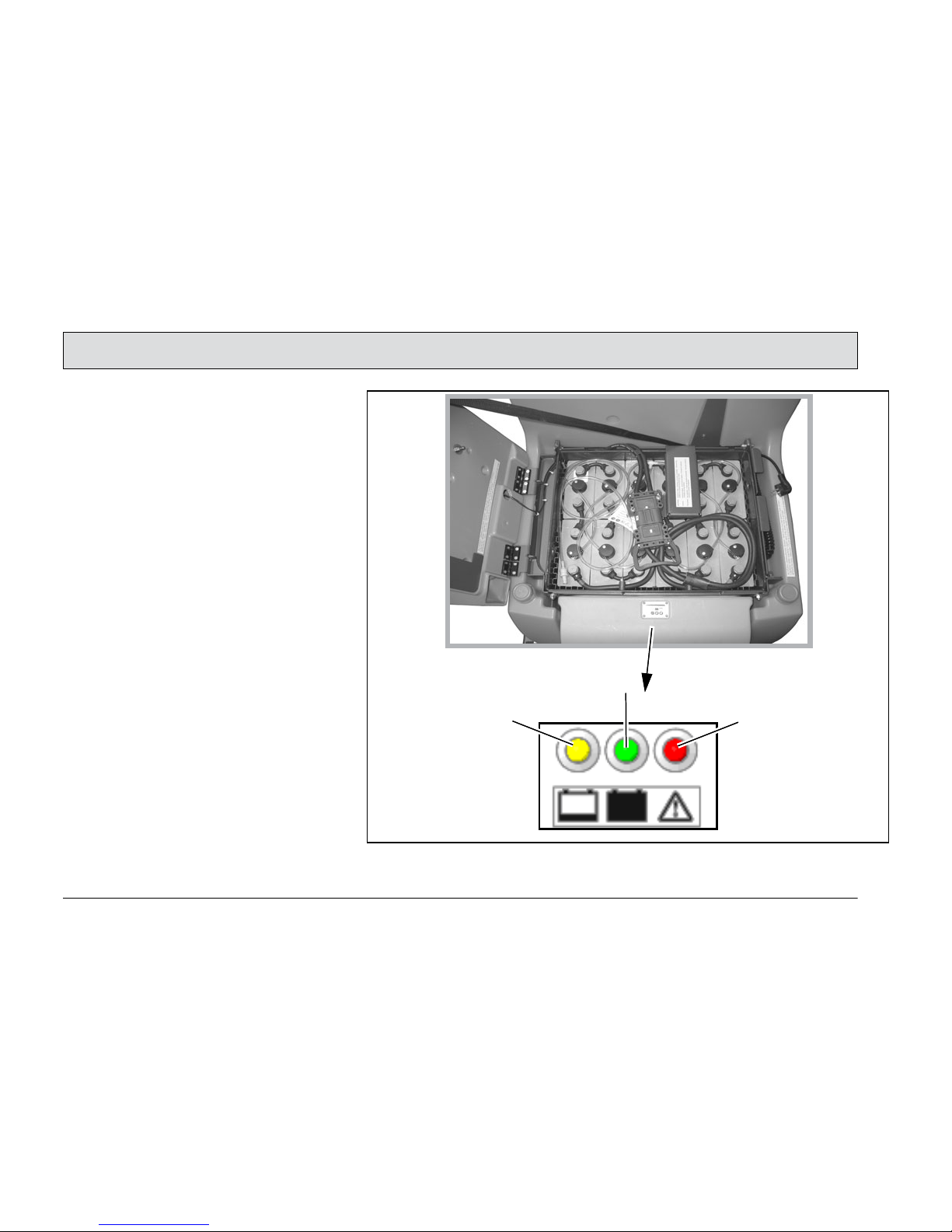

Checking the charging process

You can monitor the charging process

by means of the LED on the integrated

charger. When the charging process is

started (by connecting the power plug

or battery connection), the green LED

flashes (according to the characteristic

curve set). While the charging program

is active, the yellow LED (Fig. 8/1)

lights

up. When the charging program has

ended, the green LED (Fig. 8/2) lights

up. A trickle charge is then supplied.

The battery is again ready for use.

The vehicle cannot be switched on

while the integrated charger is in operation!

The red LED (Fig. 8/3)

signals an error.

• Invalid characteristic curve - red LED

flashes fast

• Battery error (no battery, charging

time exceeded) - red LED flashes

slowly

• Device too hot - red LED lights up

(error is not automatically reset)

Fig.8

1

2

3

21

Operation

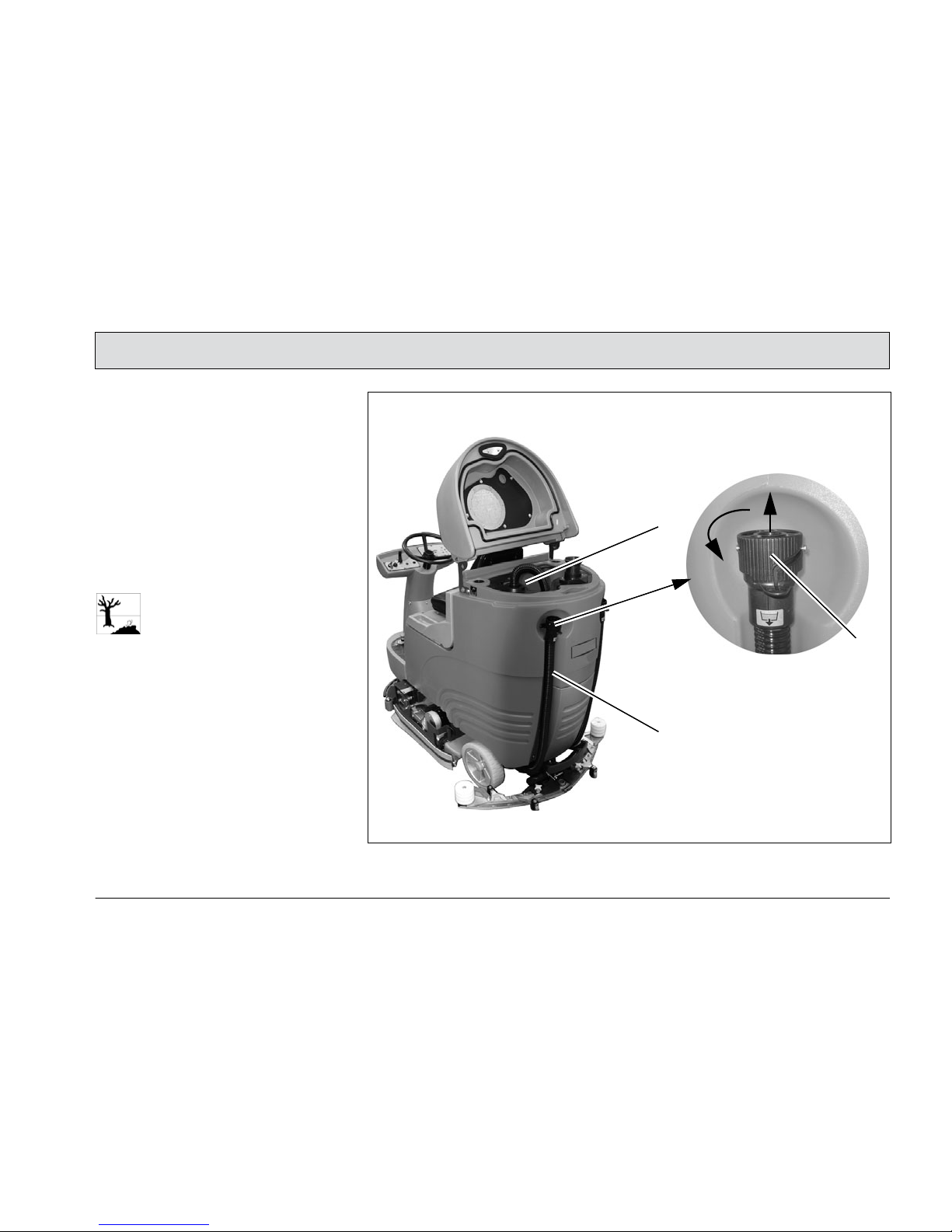

2.3.3 Emptying the waste water

tank

Empty the waste water tank (Fig. 9/1)

daily, as necessary or following the

acoustic warning and indicator in the

display.

1. Drive to an appropriate disposal

point.

2. Park the vehicle so that the draining

hose (Fig. 9/2) reaches the drain in

the floor.

3. Switch off the vehicle.

Observe the applicable laws

and local regulations when disposing of cleaning agents!

4. Remove the draining hose from the

holder and open the plug (Fig. 9/3)

by turning it 90° counterclockwise.

Empty the waste water tank completely.

Fig.9

1

2

3

Loading...

Loading...