PowerBass ASA3-600.1D, ASA3-1000.1D, ASA3-1500.1D Owner's Manual

ASA SERIES CLASS D AMPLIFIER

Owners Manual

Please read through this manual to familiarize yourself with your new amplifi er. Should your PowerBass Auto-

Sound mobile amplifi er ever require service, you will need to have the original dated receipt.

ASA3-600.1D

ASA3-1000.1D

ASA3-1500.1D

1-OHM STABLE DESIGN

Minimum Impedance Load is 1-Ohm*

*2-ohm minimum impedance when used in Dual Link Power Doubling confi guration.

Thank you and Congratulations

Thank you for your decision to purchase a PowerBass USA Autosound mobile amplifier! Our Autosound

amplifiers are the result of extensive engineering, testing, and bullet proof construction. They feature the

latest in D Class microprocessor technology. Their versatility enables compatibility with optional signal

and audio processors. These high quality MOSFET amplifiers may be configured to allow maximum flexibility in designing different of subwoofer options.

CLASS D AMPLIFIERS

All PowerBass ASA series Class “D” models are single channel dedicated subwoofer amplifiers. Unlike

most Full Range amplifiers, these models are designed specifically for low frequencies and are intended

only to power subwoofers. It is important that you closely follow the wiring instructions contained in this

Owners Manual so that you get the most from your PowerBass AutoSound D Class mobile amplifier.

∆ Caution ∆

High powered audio systems in a vehicle are capable of generating higher then “Live Concert” levels of sound pressure. Continued

exposure to excessively high volume sound levels will cause hearing loss or damage. Also, operation of a motor vehicle while listening

to audio equipment at high volume levels may impair your ability to hear external sounds such as horns, warning signals, or emergency

vehicles—thus creating a potential traffic hazard. In the interest of safety, PowerBass USA highly recommends listening at lower volume

levels when driving.

3

TECHNICAL FEATURES

• Mono Block Amplifier for Subwoofer

• Latest Class D Technology

• Double Sided Circuit Board Construction

• MOSFET Power Supplies for High Power Output and Unprecedented Stability into Low Impedance

Loads

• Soft Delay Remote Turn On/Off Circuit to Eliminating Pops and Clicks

• Built-in Adjustable Low Pass Electronic Crossover

• Built-in Fully Adjustable Bass Boost EQ

• Self Diagnostic Protection Circuit with LED Status Indicator for Impedance Over-load, Speaker Short

Circuit, Thermal Overheating, and DC Output.

• Real 1-ohm Stable Operation with Extensive Output Power Increase

• Variable Gain Control

• Pass Thru Line Output Jacks

• Remote Level Control (Included)

• Internal Thermal Cooling Fan (ASA3-1000.1D and ASA3-1500.1D only)

• Dual Link Power Doubling Circuit (Amp-to-Amp Bridged at 2 ohm minimum)

INSTALLATION EXPERIENCE

Installation of PowerBass mobile amplifiers requires detailed knowledge of electronics wiring and proper

speaker impedance. We strongly recommend installation by an authorized PowerBass dealer. This Owners Manual only provides general installation and operation instructions. If you have any reservations

about your installation skills, please contact your local PowerBass dealer for assistance.

IMPORTANT : This amplifier is designed for operation in vehicles with 12-volt Negative ground

electrical systems only.

PREPARING FOR INSTALLATION

NOTE: The tools listed below may be required for basic installation

• An electric drill with bits

• Philips head and standard screwdrivers

• Wire strippers

• Crimping tool

• VOM (electronic volt ohm meter)

• Heat shrink tubing and heat gun

• Soldering iron

• Electronic (Rosen Core not Acid Core) Solder

INSTALLATION PRECAUTIONS

NOTE: Proceed only if you are a qualified installer, otherwise; see your Authorized PowerBass

Dealer to professionally install this amplifier. Always wear protective eyewear when using

tools.

• Turn off all electrical devices before you begin.

• Disconnect the negative (-) lead from your vehicles battery.

• Locate all fuel lines, brake lines, oil lines, and electrical cables when planning the install.

• Make sure there is at least 2-inches (5 cm) around the air vents on the amplifier.

• When connecting ground points, make sure all paint is carefully scrapped away from the auto body

and contact is make with bare metal.

• Use a utility knife to trim away fabric from hole locations before drilling or cutting.

• When running power cables through sheet metal, be sure to use grommets to properly insulate the

metal edges from the wire insulation.

• If possible, use tubing through grommets.

Due to the high power output of the PowerBass Autosound Class D amplifiers, considerable heat may be

produced when the unit is in operation. For this reason the amplifier should be mounted in a location

which will allow air to circulate freely. A clearance of at least 2-inches (5 cm) to all sides of the amplifier

is necessary not only for proper cooling, but also for gaining access to the inputs and other variable

controls. Be sure that the power and signal cable connections can enter and leave the amplifier in a

straight line to avoid the risk of kinked wires causing malfunction.

Fig.1 Mounting Amplifier

MOUNTING THE AMPLIFIER

5

MOUNTING LOCATION

Find a clear and well ventilated area to mount your amplifier that is unobstructed by any objects that will cause

harm or block ventilation. You may use the amplifier as a template and mark the four screw locations with a

felt tip pen. Set the amplifier aside before drilling. Use caution to make sure there are no objects behind the

installation surface that may become damaged during drilling.

If mounting under a seat, make sure there is at least 1-inch (2.5 cm) of space above the amplifier’s heatsink

to permit proper cooling.

The amplifier should be protected from exposure to moisture and direct sunlight. The best places to mount

your amplifier are: The floor of the trunk, under a seat, or on the back of the rear seat. For alternate installation

locations, please consult your authorized PowerBass Dealer.

NOTE: Do not use a drill with driver bit to mount the amplifier. Excessive force could cause

the plastic mounting feet to crack.

*** WARNING ***

• Upside down mounting will compromise heat dissipation through the heatsink and

could engage the thermal protection circuit.

• Try to avoid mounting the amplifier on a subwoofer enclosure, as extended exposure

to vibration may cause malfunction of the amplifier.

• Don’t mount the amplifier so that the wire connections are unprotected or are subject to pinching or damage from nearby objects.

• The DC power wire must be fused at the battery positive (+) terminal connection.

Before making or breaking power connections at the amplifier power terminals,

disconnect the DC power wire at the battery end.

• The battery of the car audio system must be disconnected until the entire wiring and

installation is completed.

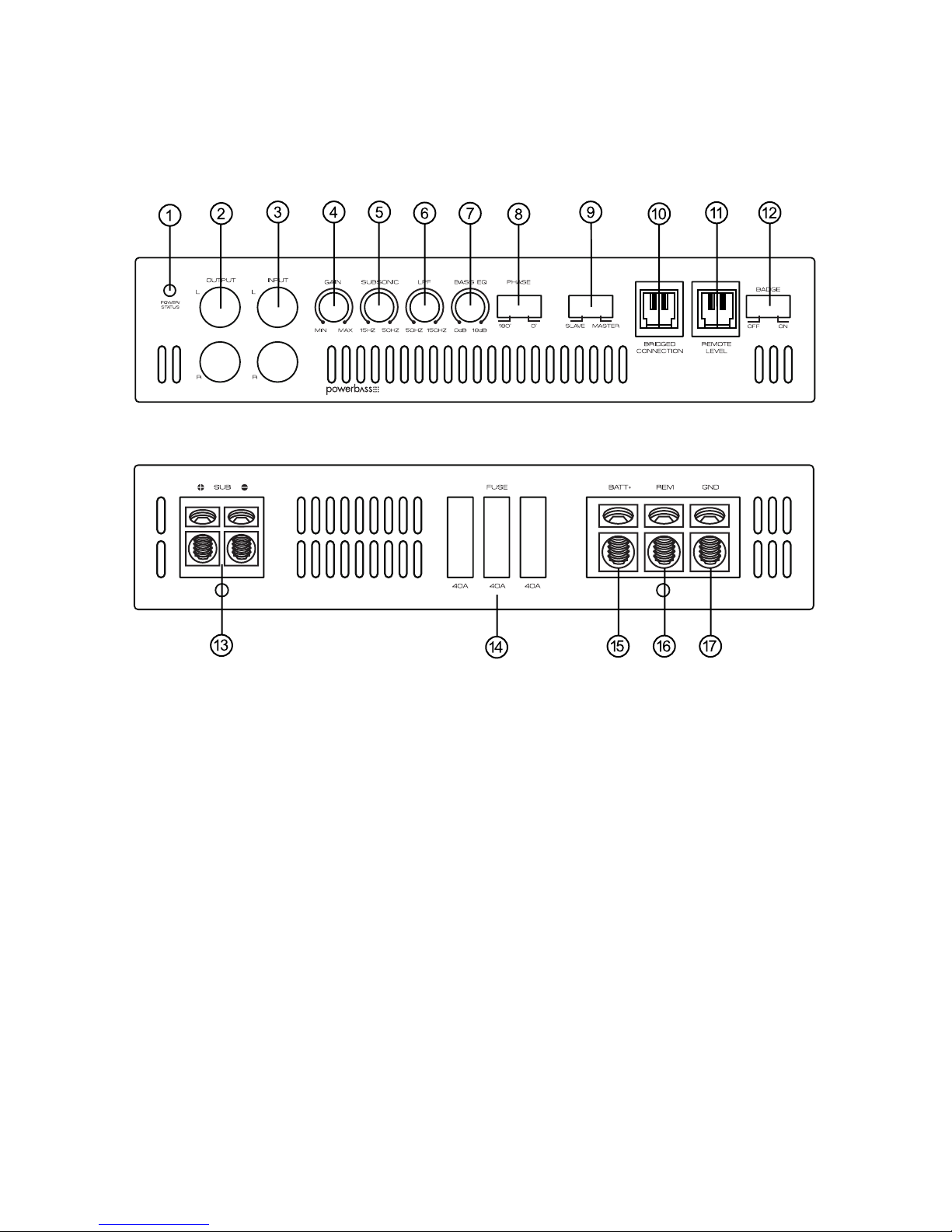

CONTROL PANEL LAYOUT

1. POWER/STATUS Indicator

The BLUE L.E.D. lights up when the power is on. This L.E.D. turns RED constantly or flashes when the built-in

protection circuitry is activated. This indicates a problem with the system in relation to the amplifier (see

Troubleshooting Tips page 21).

2. LINE OUT (RCA) Jacks

RCA style pass through output jacks allow for a signal to be sent to other amplifiers in a daisy-chain configuration. Only one Remote Bass Control can be used when multiple bass amplifiers are connected.

3. LINE IN (RCA) Jacks

These RCA style input jacks are for use with source units that have RCA line level outputs. A source unit with a

minimum output of 200mV is required for proper operation. However, this input will accept levels up to 6Vrms.

Fig.2 Panel Layout

7

4. GAIN Control

This control is used to match the input sensitivity of the amplifier to the particular source unit that you are using

up to 6 volts. Proper setting on page 13.

5. SUB SONIC Control

This control is continuously adjustable from 15Hz through 50Hz at 12dB per octave to provide an extra level of

speaker protection from bass robbing power at unheard frequencies.

6. LPF (Low Pass Filter) Control

This filter allows low pass of frequency and is adjustable from 50Hz through 150Hz to eliminate unwanted

high frequencies.

7. BASS EQ Control

This equalization circuit is used to enhance the low frequency response of the vehicle’s interior. With up to

18dB of boost centered at 45Hz, the BASS BOOST can be adjusted to meet your own personal taste.

8. PHASE Switch

This switchable control can be used to correct any “phase” or “time delay” effect in the system by bringing the

low frequency from the rear of the vehicle to the front.

9. BRIDGED Switch

Two like amplifiers can be connected together and bridged into a single 2-ohm (min) load. The level and frequency controls on the SLAVE amp will be disabled. Only the amplifier you select as the MASTER will control

these functions. The Dual Link Power Doubling Circuit increases the output power as follows:

ASA3-600.1D x 2 = 1,200 watts RMS (2 ohms min)

ASA3-1000.1D x 2 = 2,000 watts RMS (2 ohms min)

ASA3-1500.1D x 2 = 3,000 watts RMS (2 ohms min)

10. BRIDGED CONNECTION Port (RJ45 Jack)

For linking two of the same model PowerBass Autosound Class D amps together. Connect the INPUT of the

MASTER to a suitable source via a standard telephone wire with RJ45 modular connectors to the jack on the

SLAVE amplifier. Then select the MASTER/SLAVE switch properly (see Speaker Output Configuration diagram

on pages 19 and 20).

11. REMOTE LEVEL (RJ45 Jack)

This is the connector port for the Remote Level Control. Now the amplifiers secondary gain circuit can be

adjusted from the driver’s seat.

12. BADGE Switch

Controls the lighting of the top mounted PowerBass logo badge.

13. SPEAKER Output Terminals

As shown in the wiring diagrams, be sure to observe speaker polarity through the system and subwoofer

impedance. This specially tooled terminal is designed to accommodate up to 10 gauge speaker wire.

14. FUSES

For convenience most PowerBass AutoSound amplifiers utilize common automotive ATC type fuses. For continued protection in the event that a fuse blows, replace the fuse only with the same value.

CAUTION: These power fuses on the amplifier chassis are for protecting the amp against overdrive.

To protect the vehicles electrical system, an additional fuse should be used within 18-inches of the

battery on the 12V+ cable.

ASA3-600.1D 40A x 2

ASA3-1000.1D 40A x 3

ASA3-1500.1D 40A x 4

15. BATT+ (Power Input Terminal)

This terminal is the main power input for the amplifier and must be connected directly to the positive (+)

terminal of the car battery. (see Power Cable Selection Chart for recommended wire gauge for each model).

16. REM (Remote Input Terminal)

All PowerBass AutoSound amplifiers can be turned on by applying 12 volts to this terminal. This can be found

on the rear of the source unit in the form of a remote output. If this is not available you can wire to the ACC

position on the key. An 18 gauge wire is sufficient to run the REMOTE.

17. GND (Ground Input Terminal)

A good quality ground is required for your PowerBass AutoSound D Class amplifier to operate at peak

performance. A short length of cable the same gauge as your power cable should be used to attach the

ground terminal directly to the chassis of the vehicle. Make sure that all of the paint is sanded or scraped away

to ensure a quality ground connection

Loading...

Loading...