POWERHOLD AND

POWERHOLD SC

TRUCK RESTRAINT

INSTALLATION AND

OPERATION MANUAL

Job Number

Job Name

Serial Numbers

SYSTEMS, INC.

P.O. BOX 309

Germantown, WI 53022

Phone 414-255-1510

Fax 414-257-7399

11/06

INDEX

SECTION

I. INSTALLATION

A. MOUNTING AND ANCHORING ................................................................................................. 1

B. ELECTRICAL ............................................................................................................................ 2

C. HYDRAULIC ............................................................................................................................. 2

II. GENERAL INFORMATION

A. DESCRIPTION OF OPERATING MODES ................................................................................. 3

B. DESCRIPTION OF SIGNAL LIGHTS ......................................................................................... 4

C. SIGNAL LIGHTS AND ALARM SEQUENCE OF OPERATION ................................................... 5,6

D. OPERATING NOTES ................................................................................................................ 6-7

III. OPERATING INSTRUCTIONS

A. NORMAL OPERATION ............................................................................................................. 8

B. BYPASS OPERATION .............................................................................................................. 8-9

IV. MAINTENANCE

A. CLEANING ................................................................................................................................9

B. LUBRICATION ........................................................................................................................... 9

C. HYDRAULIC FLUID CHECK ...................................................................................................... 9

D. SIGNAL LIGHTS CHECK .......................................................................................................... 9

PAGE

V. MECHANICAL RELEASE .................................................................................................................. 10

VI. PARTS LISTS AND ILLUSTRATIONS ................................................................................................. 11-15

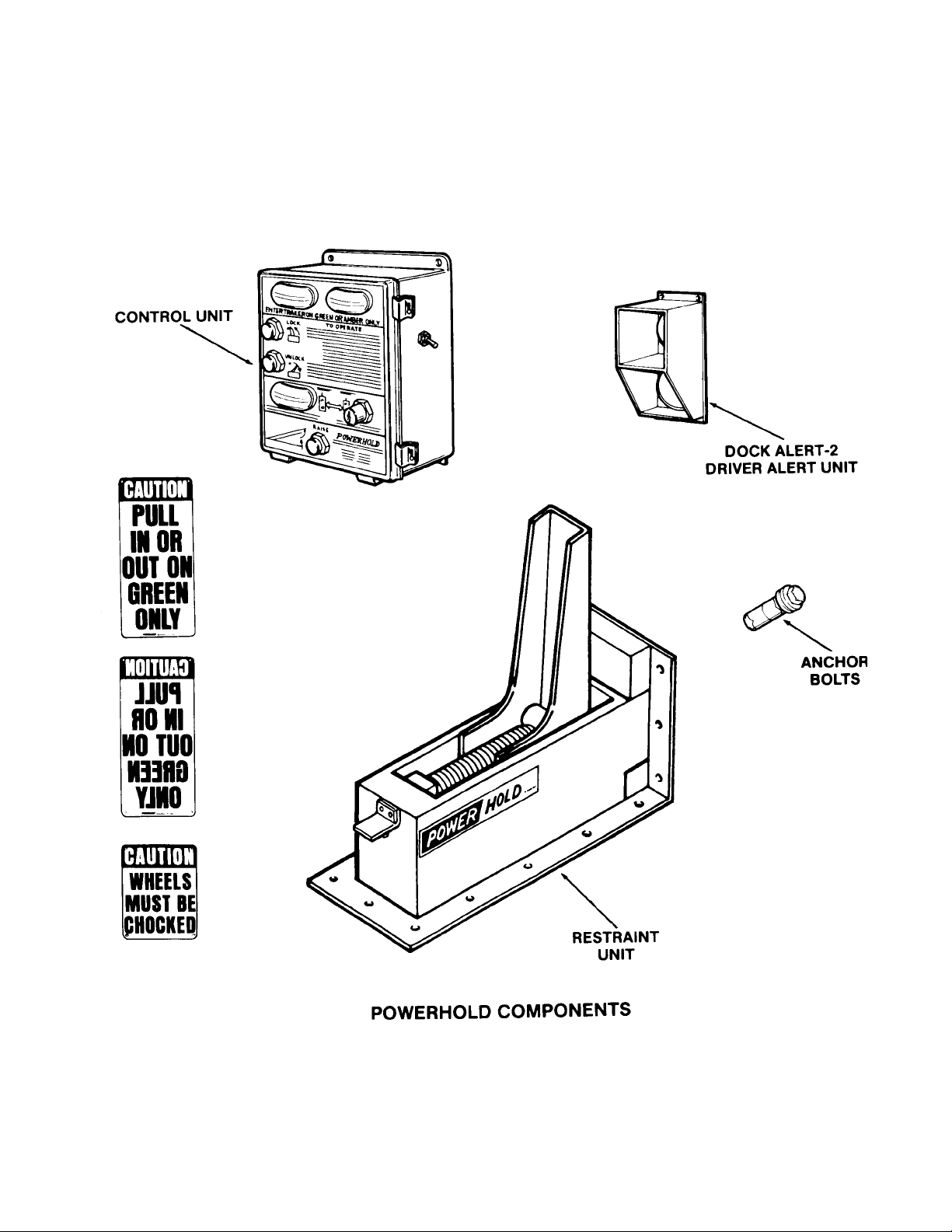

NOTE: Control unit shipped may be

different than what is shown.

NOTE: Outside Light Assembly

shipped may be different than what

is shown.

INSTALLATION

MOUNTING AND ANCHORING

Inspect installation location: The POWERHOLD restraint will require solid anchors to

assure proper operation. Optimum installations will have both a concrete drive and a

poured concrete dock face so that anchor bolts can be well secured. Twelve 1/2"

anchor bolt mounting holes are re provided. However, 6 base or 6 wall may be used

where cold induced frost heave will be a factor or mounting conditions do not allow use

of all 12 mounting holes.

The POWERHOLD restraint should be positioned at the center of the dock leveler and

is designed to be flush with the dock face when 4-1/2" bumpers are used. A filler plate

(not supplied with POWERHOLD systems) will be required for bumper projections

greater than 4-1/2" as follows:

BUMPER FILLER PLATE

6" 1-1/2"

8" 3-1/2"

10" 5-1/2"

IMPORTANT

The restraint should be installed level from top to back and from side

to side. The restraint should be installed square with the face of the

dock.

Typical mounting requirements for the control unit, driver alert unit and "CAUTION PULL

IN OR OUT ON GREEN ONLY" signs are shown in the illustration below. The

"CAUTION WHEELS MUST BE CHOCKED" sign should be mounted FOR EASY

READING BY TRUCK DRIVER outside and to the right of the overhead door or at the

right side of the loading dock. Fasteners for these three caution signs are not included

with the POWERHOLD system.

1

INSTALLATION CONTINUED

ELECTRICAL

Refer to the drawings indicated in Table I for the electrical installation. The drawings are

attached to this manual.

IMPORTANT

Make sure that the power supply requirement(s) as shown on the electrical

drawings and on the decal of the control assembly(s) are the correct

requirement(s) for the application.

TABLE I

DRAWING

DESCRIPTION

FIELD WIRING

DRAWING

INTERCONNECTION

DRAWING

INFORMATION ON DRAWING

- ELECTRICAL DATA

- RECOMMENDED WIRE SIZES

- REQUIRED CONDUIT RUNS

- REQUIRED FIELD WIRES PER CONDUIT RUN

- REQUIRED CONDUIT RUNS

- REQUIRED FIELD WIRES PER CONDUIT RUN

- TERMINATION POINTS FOR ALL FIELD WIRES

HYDRAULIC

Standard units are factory pre-connected so that no hydraulic field connections are

required. Standard units are shipped with a full reservoir of hydraulic fluid. In the event

of a fluid loss during shipment or installation, information concerning fluid

replenishment can be found in the maintenance instructions section of this manual.

2

GENERAL INFORMATION

DESCRIPTION OF OPERATING MODES

A. "NORMAL" OPERATING MODE

Used to operate the POWERHOLD restraint to engage the truck ICC bar. An

auto-raise cycle will be activated by momentary pressure on the "LOCK" push

button (Note: Pressure on the "LOCK" push button must be maintained until

the inside lights change from red to amber). An AUTO-LOWER cycle will be

activated by momentary pressure on the "UNLOCK" push button. If no truck

ICC is engaged, the unit will automatically return to the stored position and an

alarm will turn on. The inside and outside signal lights will automatically

change as the unit reaches different positions in the raise and lower cycle.

B. "BYPASS" OPERATING MODE

Used when the truck does not have a serviceable ICC bar or if operating the

POWERHOLD restraint may damage equipment on the truck. The restraint

cannot be operated in this mode. The inside lights are amber and the outside

lights are red at all times in this mode. The truck wheels must be chocked

when operating in this mode.

3

GENERAL INFORMATION CONTINUED

DESCRIPTION OF SIGNAL LIGHTS:

A. INSIDE SIGNAL LIGHTS. These lights are typically located on the PLC/

LOGIC control assembly. the assembly housing the light is to be

mounted in a location that is clearly visible to the dock attendant.

WHEN THE LIGHT IS ON:

RED LIGHT

• IT INDICATES TO THE DOCK ATTENDANT THAT IT IS

NOT OK TO ENTER THE TRUCK. THE TRUCK ICC

BAR IS NOT ENGAGED BY THE POWERHOLD

RESTRAINT. THE BYPASS MODE AND WHEEL

R

CHOCKS MAY BE REQUIRED.

AMBER CAUTION LIGHT

A

G

B. OUTSIDE SIGNAL LIGHTS. These lights are located in the outside signal light

assembly. This light assembly is mounted in a location that is clearly visible to

the truck operator.

• IT INDICATES TO THE DOCK ATTENDANT THAT IT IS

NOT OK TO ENTER THE TRUCK WHEN IN THE

"NORMAL" OPERATING MODE. THE UNIT HAS

BEEN ACTIVATED BUT HAS NOT ENGAGED THE

TRUCK ICC BAR. OR

• IT INDICATES TO THE DOCK ATTENDANT TO ENTER

WITH CAUTION WHEN IN THE "BYPASS"

OPERATING MODE. THE TRUCK ICC BAR IS NOT

ENGAGED BY THE POWERHOLD RESTRAINT.

GREEN LIGHT

• IT INDICATES TO THE DOCK ATTENDANT THAT IT IS

OK TO ENTER THE TRUCK . THE TRUCK ICC BAR

IS ENGAGED BY THE POWERHOLD

RESTRAINT.

WHEN THE LIGHT IS ON:

IT INDICATES TO THE TRUCK OPERATOR

R

THAT IT IS NOT OK TO BACK IN OR PULL

AWAY FROM THE DOCK.

G

OUTSIDE SIGNAL

LIGHT ASSEMBLY.

4

IT INDICATES TO THE TRUCK OPERATOR

THAT IT IS OK TO BACK IN OR PULL AWAY FROM

THE DOCK.

GENERAL INFORMATION CONTINUED

SIGNAL LIGHTS AND ALARM SEQUENCE OF OPERATION

A. "NORMAL" operating mode - truck ICC bar engaged.

1. The POWERHOLD restraint is in the fully lowered (stored) position. Limit

switch "LS3" is closed.

Outside light = Green

Inside light = Red

Alarm = Off

2. The POWERHOLD restraint is activated.

a. The unit leaves the fully lowered (stored) position. Limit switch

"LS3" is open.

Outside light = Red

Inside light = Amber

Alarm = Off

b. The unit reaches the fully raised ICC bar engaged position, Proxim

ity switches "LS1" and "LS2" are closed.

Outside light = Red

Inside light = Green

Alarm = Off

B. "NORMAL" operating mode - truck ICC bar not engaged.

1. The POWERHOLD restraint is in the fully lowered (stored) position, Limit

switch "LS3" is closed.

Outside light = Green

Inside light = Red

Alarm = Off

2. The POWERHOLD restraint is activated.

a. The unit leaves the fully lowered (stored) position. Limit switch

"LS3" is open.

Outside light = Red

Inside light = Amber

Alarm = Off

b. The unit reaches the fully raised no ICC bar engaged position.

Proximity switch "LS1" is closed.

Outside light = Red

Inside light = Amber

Alarm = On

(Note: The alarm stays on until the unit reached the lowered position).

5

GENERAL INFORMATION CONTINUED

SIGNAL LIGHTS AND ALARM SEQUENCE OF OPERATION CONTINUED.

D. The unit reaches the fully lowered (stored) position.

Limit switch"LS3" is closed.

Outside light = Green

Inside light = Red

Alarm = Off

D. "BYPASS" operating mode

Outside light = Red at all times

Inside light = Amber at all times

Alarm = Off at all times

OPERATING NOTES

A. When in the "NORMAL" operating mode, the raise cycle of the restraint will be

activated by momentary pressure on the "LOCK"push button (auto raise cycle).

However, the auto raise cycle will only be activated if pressure on the "LOCK"

push button is maintained long enough to allow the restraint to leave the stored

position (i.e., leave the "LS3" limit switch). This will ensure that the dock

attendant does want the restraint to be activated. The inside lights will change

from RED to AMBER when the restraint leaves the stored position.

B. When in the "NORMAL" operating mode, the lower cycle of restraint will be

activated by momentary pressure on the "UNLOCK" push button (auto lower

cycle). The inside lights will change from GREEN to AMBER when the restraint

leaves the fully raised, ICC bar engaged position.

C. The automatic raise and lower cycles are backed-up with time based failure

mode protection, described as follows:

1. Automatic raise cycle:

If the restraint does not reach the fully raised ICC bar engaged position or

the fully raised no ICC bar engaged position within approximately 13

seconds after leaving the stored position, the restraint will automatically

return to the stored position. Failure to reach the fully raised ICC bar

engaged position or the fully raised no ICC bar engaged position can be due

to an obstruction preventing the restraint from raising.

Also, the restraint will automatically return to the stored position after the

13 second delay if the unit reaches the fully raised ICC bar engaged

position but the "LS1" proximity switch in the unit has failed "OPEN".

(Note: If the restraint reaches the fully raised ICC bar engaged position but

the "LS2" proximity switch in the unit has failed "OPEN", the automatic

return cycle (with alarm) will be activated).

2. Automatic return cycle (no ICC bar) and automatic lower cycle:

If the restraint does not reach the stored position within approximately 13

seconds after leaving the fully raised ICC bar engaged position or the fully raised

no ICC bar engaged position, the restraint will automatically shut off. Failure to

reach the stored position can be due to an obstruction preventing the restraint

from lowering.

6

GENERAL INFORMATION CONTINUED

Also, the restraint will automatically shut off after the 13 second delay if the unit

reaches the stored position but the "LS3" limit switch in the unit has failed

"OPEN".

D. If power is lost after the restraint is activated, the automatic raise and lower cycles

will be disabled. Thus, when power is restored the restraint must be reactivated to

either the fully raised ICC bar engaged position or the stored position. If the restraint is

not in the stored position or the fully raised ICC bar engaged position when power is

restored, the alarm will turn on and off (10 seconds on, 50 seconds off) for

approximately 10 minutes. This serves as an indication that the restraint should be

activated to either the stored position or the fully raised ICC bar engaged position. The

alarm will turn off when either the "LOCK" or "UNLOCK" push buttons are pressed.

NOTE: THE ABOVE DESCRIPTION IS FOR AN AUDIBLE ALARM. IF THE UNIT

IS EQUIPPED WITH A VISUAL ALARM THE ALARM WILL STAY ON

CONTINUOUSLY FOR 10 MINUTES AFTER POWER IS RESUMED. AUDIBLE

ALARMS ARE TYPICALLY SUPPLIED. VISUAL ALARMS ARE SUPPLIED

UPON CUSTOMER REQUESTS AND/OR FOR APPLICATIONS REQUIRING

NEMA 4 RATED CONTROLS.

E. The restraint cannot be operated in the "BYPASS" operating mode.

7

OPERATING INSTRUCTIONS

NORMAL OPERATION

1. Set the "ON-OFF" switch to "ON".

2. Set the "NORMAL-BYPASS" key switch to "NORMAL".

3. Requirements for proper restraint operation are that the truck be parked

perpendicular to the loading dock area with its ICC bar from 4-1/2" to 14-1/2" from

the face of the dock when 4-1/2" bumpers are used. If 6" bumpers are used, the

horizontal range would be from 6" to 16" from the face of the dock.

4. Inspect the truck to ensure that no truck equipment will be damaged by operating

the POWERHOLD restraint.

5. Press the "LOCK" push button until the inside light changes from RED to AMBER.

This will activate the auto-raise cycle of the restraint.

A. If the restraint engages the truck ICC bar, the inside lights will change from

AMBER to GREEN. Proceed with loading/unloading of truck.

B. If the restraint does not engage the truck ICC bar, the inside lights will remain

AMBER and an alarm will turn on while the restraint automatically returns to the

stored position. The lights will change to RED and the alarm will turn off when the

restraint reaches the stored position. Follow the "BYPASS" operating instructions.

6. Press the "UNLOCK" push button until the inside lights change from GREEN to

AMBER. This will activate the auto-lower cycle of the restraint. The inside lights

will change from AMBER to RED when the restraint reaches the stored position.

BYPASS OPERATION

1. Set the "ON-OFF" switch to "ON".

2. Set the "NORMAL-BYPASS" key switch to "BYPASS". The inside lights will

change to AMBER, the outside lights will change to RED.

3. Chock truck wheels.

4. Proceed cautiously with loading/unloading of truck.

8

MAINTENANCE

CLEANING

The POWERHOLD restraint should be kept free of debris, ice, dirt and sand. Build-ups

of foreign material, especially on the top of the slide block assembly, could result in

abnormal operation of the restraint.

LUBRICATION

Lubrication should be performed on a monthly basis. Use Lubriplate No. 18339 multipurpose grease or equivalent.

Remove all of the old grease from the slide block guide channels and from the top of

the slide block before applying the new grease. The slide block guide channels are

located inside the unit, on the sides of the housing weldment.

Use the grease zerks located outside the unit, on the sides of the housing weldment to

lubricate the slide block guide channels and the restraint weldment pivot point. Also,

apply a liberal amount of grease on top of the slide block, especially at the areas of the

slide block on which the restraint weldment "rides".

NOTE: DO NOT GREASE THE TOOTHED PORTION OF THE RATCHET BAR OR

LOCKING MECHANISM.

HYDRAULIC FLUID CHECK

The hydraulic fluid level should be checked every month. Fluid level should be

approximately 1-1/2" from the top of the reservoir when the restraint is in the fully

lowered (stored) position.

To assure normal operation of the restraint the following fluids are recommended:

Flowmite 530 ZF available from Systems, Inc.

Aero shell fluid #4 code or #41 by Shell Oil Co.

Mobile Aero HFA Mil-HS606A or Aero HF by Mobil Oil Co.

Texaco Aircraft Hydraulic Oil 15 or 5606

Exxon UNIVIS J13

NOTE: Use of hydraulic fluids with equivalent specifications to those listed is

acceptable. Use of fluids that do not have equivalent specifications will result

in abnormal operation of the unit.

SIGNAL LIGHTS CHECK

To assure dock attendant safety, check to make sure that the inside and outside

signal lights function correctly. This check should be performed on a weekly basis. The

correct sequence of light operation can be found in the general information section of

this manual.

9

MECHANICAL RELEASE

The POWERHOLD restraint is equipped with a mechanical release that can be

utilized in the event of an electric and/or hydraulic failure which prevents the unit from

releasing the truck ICC bar via normal operating methods.

MATERIAL REQUIRED

1-1/8" Wrench

Phillips head screwdriver

2-1/2' or longer, 3/4" rod

Hammer

Oil (WD-40 or equivalent)

WARNING - POSSIBILITY OF SERIOUS INJURY

Keep all body parts out of the working zone of the restraint weldment at all

times when performing a mechanical release.

PROCEDURE

1. Make sure outside signal lights are red.

2. Chock truck wheels.

3. Apply a liberal amount of oil to the top of the slide block (P/N 9413-0022).

4. Use the screwdriver to remove the front cover plate (P/N 9411-0012) from the front

of the housing weldment (P/N 9414-0029). This requires the removal of four

screws.

5. Use the wrench to remove the capscrew (P/N 2101-0118) from the front of the

housing weldment.

6. Insert the 3/4" rod through the front of the housing weldment (i.e., through the

area of the weldment opened by the removal of the front cover plate). Set one end

of the rod into the hole located in the front of the slide block.

7. Hammer on the exposed end of the 3/4" rod to force the slide block towards the

face of the dock. The restraint weldment (P/N 9414-0014) should lower when the

slide block is repositioned.

8. After truck is released and away from the restraint, reassemble the unit.

9. Determine cause of electric and/or hydraulic failure.

10

POWERHOLD

END RELEASE

18

34

36

21

17

38

41

11

12

13

8

22

27

28

30

31

32

33

20

19

23

29

35

15

16

25

40

39

26

24

36

4

7

5

3

6

9

1

2

11

POWERHOLD END RELEASE

PARTS LIST

ITEM DESCRIPTION PART NUMBER

1 HOUSING WELDMENT 9414-0029

2 FRONT COVER PLATE 9411-0012

3 SCREW 2101-0099

4 LATCH WELDMENT ASSY For 23" Restraint Weldment 9414-0037

*Complete Assembly with Prox Switches

4 LATCH WELDMENT For 19" Restraint Weldment 9414-0042

*Complete Assembly with Prox Switches

5 PROX. SWITCH-RATCHET AC-RELAY EQUIPPED 0961-0035

5 PROX. SWITCH-RATCHET DC-PLC (Current Production) 0961-0073

6 LIMIT SWITCH-STORED (Discontinued 2003) 0961-0037

7 PROX. SWITCH-CYLINDER AC-PLC Equipped (Discontinued) 0961-0035

7 PROX. SWITCH-CYLINDER DC-PLC Equipped (Current) 0961-0073

8 SPRING SERVALITE 0941-0009

9 CAP SCREW 2101-0100

10 PROX. SWITCH LOCK NUT (NOT SHOWN) ----------------

11 BAR-SPRING LEVER 9414-0017

12 CAP SCREW-JAM 2101-0011

13 WASHER 2101-0003

14 CAP SCREW-PIVOT 5/16-18X2 (NOT SHOWN) 2101-0013

15 PUSH ROD 9412-0095

16 CLIP ----------------

17 RACK WELDMENT 9414-0021

18 RESTRAINT WELDMENT 23" (Discontinued) 9414-0014

18 RESTRAINT WELDMENT 19" (Current) 9414-0049

19 CYLINDER ASSEMBLY 9414-0038

20 SLIDE BLOCK ASSEMBLY (Included with Cylinder Assy) 9413-0022

21 PIN 9412-0030

12

POWERHOLD END RELEASE CONTINUED

ITEM DESCRIPTION PART NUMBER

22 BAR-WEATHERSEAL HOLD DOWN 9411-0007

23 BAR-REMOVABLE TRACK STOP (LH/RH) 9412-0063

24 ELECTRICAL BOX 2752-0029

25 SHROUD 9411-0015

26 COVER & GASKET (ELEC. BOX) 2751-0058

27 SCREW - FRONT PLATE 2101-0076

28 WEATHERSEAL 0192-0016

29 HOSE ASSY - 22" 9904-0039

30 HYDRAULIC VALVE ASSEMBLY 8583-0017

31 BODY WITH SPOOL Discontinued

32 4-WAY SOLENOID SPOOL 8581-0011

33 SOLENOID COIL 8581-0004

33 SOLENOID COIL HARNESS 4301-0004

34 HOSE ADAPTER 90 DEGREES EL 0521-0042

35 HOSE ASSY 35" 9904-0040

36 HOSE ADAPTER STREET 0521-0043

37 CAPSCREW 2101-0074

38 SPRING 9411-0005

39 CAPSCREW - TRACK STOP 2101-0069

40 SCREW 2101-0076

41 CAPSCREW 2101-0118

NOTE: Solenoid Valve, Coil and Harness above are Delta Brand. Older units may have Parker or

Parker-Waterman brand components that are no longer available. If replacing an obsolete Valve, Valve

Assy or Coil the following Delta brand parts will be required:

* Valve Assembly (Includes solenoid valve and block) 8583-0017

* Solenoid Coil 8581-0004

* Solenoid Coil Harness 4301-0004

13

POWERHOLD

SELF CONTAINED

46

45

49

55

48

47

42

43

44

45

1

50

43

51

52

53

54

14

POWERHOLD SC (SELF CONTAINED)

POWERPACK PARTS

ITEM DESCRIPTION PART NUMBER

42 SHROUD - MOTOR 9412-0107

43 CAPSCREW 2101-0009

44 90 DEGREE STREET ELBOW 9301-0034

45 HOSE ADAPTOR - 90 DEGREE ELBOW 0521-0076

46 HOSE ASSY - 14" 9904-0038

47 PUMP 9301-0084

48 FILTER 9301-0085

49 BREATHER CAP 9301-0020

50 RESERVOIR 9303-0010

51 NIPPLE 9301-0045

52 MOTOR 3411-0008

53 TEE 9301-0012

54 HOSE ASSY - 11" 9904-0041

55 ELEMENT 9301-0086

15

SYSTEM'S, INC. STANDARD WARRANTY

POWERHOLD VEHICLE RESTRAINT

Poweramp warrants the locking unit, welded main frame, hydraulic cylinders and hoses, and all

electrical components to be free of defects in material and workmanship for a period of one (1)

year when installed and used in accordance with the Powerhold Owner’s Manual. Systems, Inc.

further guarantees the hydraulic components except for the solenoid valves on all Powerhold

units for a period of one (1) year from date of shipment. Specifically, this guarantee applies to (1)

hydraulic cylinders, (2) pressure lines provided by the factory and (3) the hydraulic pump and

motor.

In the event of any defect covered by this warranty, manufacturer will remedy said defect by

repairing or replacing all defective parts, bearing all of the costs for parts, labor and

transportation.

All warranty claims will be settled on a timely basis when defects are found to be from other than

improper installation, operating contrary to instructions or beyond rated load capacities, abuse,

careless or negligent use, or failure to maintain the unit as recommended by the owner’s manual.

There are no warranties, either expressed or implied, including any implied guarantees of

merchantability or fitness for a particular purpose which shall extend beyond the guarantee

periods indicated above. This guarantee is valid only if the unit(s) is unaltered from original

condition as delivered from the factory and a survey is completed by a Poweramp

representative.

Loading...

Loading...