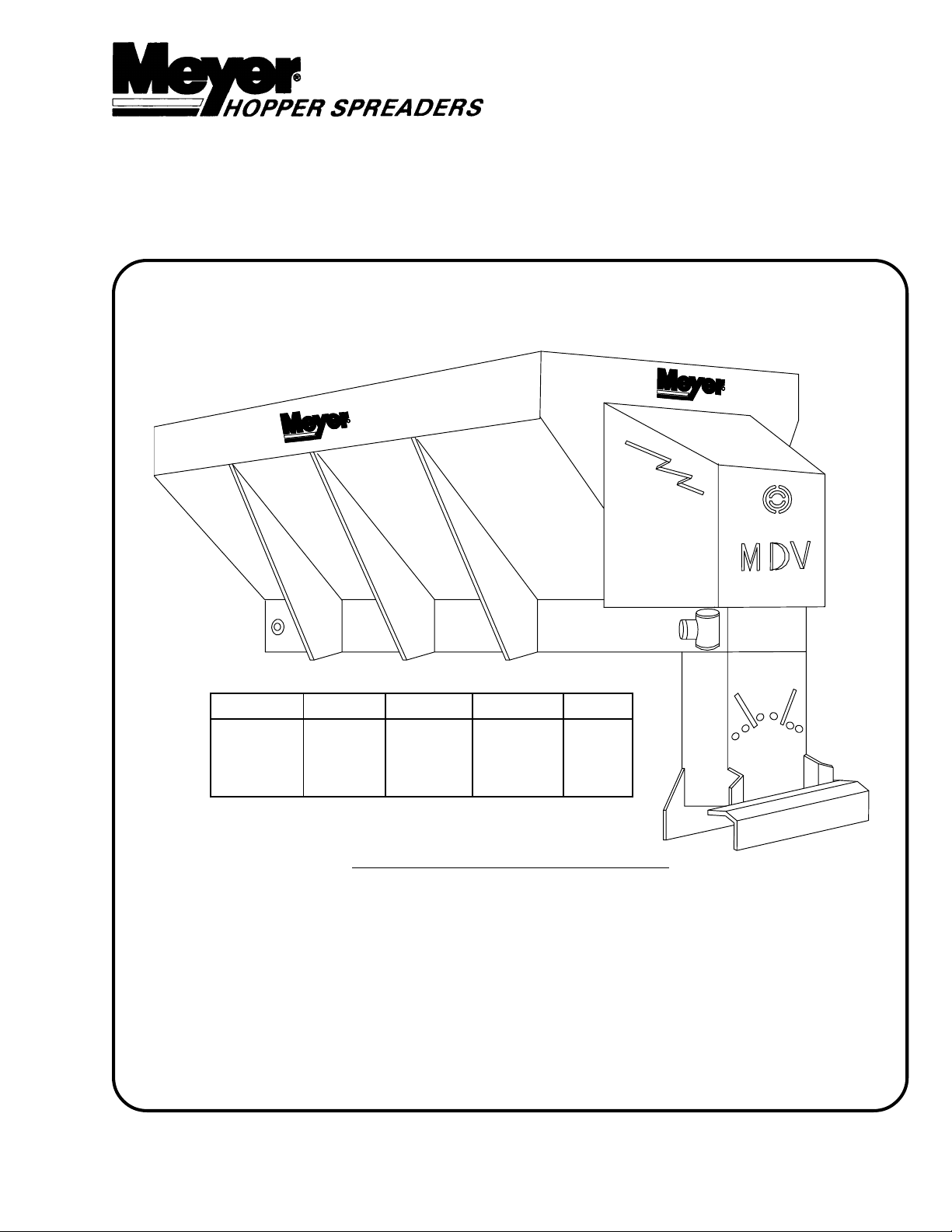

Page 1

INSTALLATION and OPERATING

INSTRUCTION MANUAL

MDV SPREADER

4

4

Form No. 1-739 R

May, 2000

PART NO. MODEL LENGTH CAPACITY RATING

62228 M-940 9 FT. 3.4 CU YD 17,000

62234 M-944 9 FT. 4.2 CU YD 19,000

62246 M-1044 10 FT. 4.7 CU YD 20,000

INCLUDED IN THIS MANUAL

SAFETY ALERT ............................................................................... 2

SPREADER ASSEMBLY INSTRUCTIONS ..................................... 3-5

SPREADER OPERATION .............................................................. 6-8

SPREADER MAINTENANCE .......................................................... 9

HYDRAULICS.............................................................................. 10-11

SPREADER PARTS LISTS & EXPLODED VIEW.......................... 12-36

WARRANTY ................................................................................... 37

Meyer Products reserves the right, under its continuing product improvement program, to change construction or design details,

specifications and prices without notice or without incurring any obligation.

www.meyerproducts.comemail inf@meyerproducts.com

Printed in U.S.A. ©2000

1

18513 Euclid Ave. Cleveland, Ohio 44112-1084

Phone 486-1313 (Area Code 216)

Page 2

!

THE BEST SAFETY

DEVICE IS A

CAREFUL OPERATOR!

SAFETY ALERT SYMBOL

THIS SYMBOL MEANS ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

PLEASE READ AND UNDERSTAND COMPLETELY BEFORE DOING!

SAFE EQUIPMENT INSTALLERS

!

TURN OFF ALL POWER BEFORE PERFORMING ANY SERVICE OPERATIONS

FOLLOW RECOMMENDED OPERATING PROCEDURES.

KEEP EQUIPMENT IN SAFE OPERATING CONDITION AT ALL TIMES.

RECOGNIZE AND AVOID HAZARDS WHILE OPERATING, SERVICEING AND

MAINTAINING EQUIPMENT.

REFER TO THE ENGINE OPERATING & MAINTENANCE MANUAL

!

!

FOR SPECIFIC SAFETY PRECAUTIONS FOR THIS ENGINE.

CAUTION

AND

OPERATORS:

DANGER

1. KEEP ALL SHEILDS IN PLACE.

2. MAKE CERTAIN EVERYONE IS CLEAR BEFORE

STARTING MACHINE OR MOVING VEHICLE.

3. KEEP HANDS, FEET, AND CLOTHING AWAY FROM

ALL POWER DRIVEN PARTS.

4. DISENGAGE p.t.o., SHUT OFF HYDRAULIC VALVE

AND SET PARKING BRAKE BEFORE LEAVING

OPERATORS POSITION. MAKE SURE ALL

MOVEMENT HAS STOPPED BEFORE SERVING OR

UNCLOGGING MACHINE.

5. USE FLASHING LIGHTS WHEN OPERATING

MACHINE.

6. MAKE SURE MACHINE IS SOLIDLY SUPPORTED

WHEN IT IS BEING MOUNTED, DISMOUNTED, OR

STORED.

NOTICE: Instructional Material And Parts Lists Included In This Manual Are Subject To

Change Without Notice.

2

Stay clear while

spinner is turning

DANGER

Turn off power

before servicing.

Page 3

ASSEMBLY INSTRUCTIONS AND INSTALLATION

INSTALLATION INSTRUCTIONS:

The Meyer MDV Series Spreaders can mount and store as a single unit. The Meyer MDV Series

Spreader will mount on most 15,000-20,000 GVW trucks as well as larger trucks.

!

WARNING

DO NOT OVERLOAD THE VEHICLE. It is quite possible to overload the vehicle by

improperly mounting or over loading the spreader. This could result in dangerous stability

and braking problems. Always consult and follow the truck manufacturers instructions.

!

1. Place the spreader in the rear of truck with the engine / hydraulic motor to the rear of the truck. Center

the spreader (side to side) in the truck. The spreader should extend past the rear of the outer most part

of the truck (i.e: truck bed, bumper) approximately

!

SPINNER ASSEMBLY

a. Raise engine shroud and prop it open with the support rod. (if engine driven model)

b. Slide the spinner frame assembly into the rear of the longitudinals with the spinner back plate

WARNING

BEFORE BEGINNING ANY INSTALLATION ON THIS UNIT, disconnect the spreader

battery negative cable if already installed.

18 inches.

Caution: Insure that the spreader cannot tip when the spinner assembly is attached.

toward the rear.

c. Bolt the spinner to the longitudinals using the four

flatwashers from hardware bag located on the spinner. Using one

and flange nut from hardware bag, bolt the top portion of the spinner back plate to the engine

plate.

d. Install roller chain between the gear box sprocket and the spinner sprocket. Make sure sprockets

are in line with each other. The roller chain is tightened, first by loosening all four

the back plate. Then, pull the entire bearing/shaft assembly in such a way to achieve the proper

amount of chain tension. Make sure the spinner shaft is straight up and down before retightening.

2. Reposition the spreader in the truck, just short of making contact with the rearmost part of the truck bed,

bumper, pintle hook etc. Bolt the unit to the truck using a minimum of six 1/2" - grade 5 bolts and

corresponding washers and locknuts. The Spreader is designed to sit flat on the bed of the truck,

supported by the longitudinal/sides. DO

ALONE !! UNIT IS NOT DESIGNED FOR CHASSIS MOUNT APPLICATION !

NOT SUPPORT THE SPREADER BY THE BODYJACKS

(4) 3/8" x 1 bolts, 3/8 flange nuts and

(1) 3/8" x 1" bolts, flatwashers

3/8" bolts on

3

Page 4

INSTALLATION INSTRUCTION FOR

ELECTRIC THROTTLE CONTROL

!

1. Disconnect battery, NEGATIVE CABLE (if already installed).

2. Spreaders with factory installed throttle controls do not require installer hook-up to the

3. Raise the engine shroud and securely prop it in place with the prop rod. The installer will

4. The throttle actuator cable plugs into the in-cab control panel after being routed from the

5. Select a suitable location in the cab of the vehicle to mount the throttle control box.

!

Consult vehicle manufacturer for acceptable mounting locations. Improperly mounting the control

box could interfere with air bag(s) and the other functions of the occupant protection systems,

such as knee bolsters!

WARNING

engine. The actuator has been installed and tested at the factory.

have to remove the ties securing the coiled actuator cable to the top of the engine.

cab of the vehicle to the rear of the mounted spreader.

(Do not mount at this time.)

WARNING

6. After the location of the control panel is determined, the cable must be routed to the rear of the

spreader, so the hookup can be made with the actuator cable plug. Route the conductor cable,

attached to the control, to rear of truck, under truck, securing as needed. Allow enough cable

for the control panel to be mounted in the cab.

7. The routed cable must be clear of all moving or hot parts on the spreader or vehicle. Secure

the cable with the ties provided. Excess cable must be coiled up and secured.

8. Locate and mount the control panel (with screws supplied).

9. For permanent cable mount at rear of the truck, a mounting bracket is supplied.

10. Slide boot over cable then, wire the control panel cable end into the socket (wire colors and

locations are identified on the socket). The rubber socket boot must be installed for weather

resistant seal.

11. Fill boot from cable side with a good grade of dielectric grease to help reduce corrosion on

terminals.

12. Install a 12 volt battery with 4- ampere hour rating, recommended for winter use (if not already

done). The battery hold-downs furnished will accept any 2 SM Series battery.

4

Page 5

!

WARNING

Use safety glasses or other face protection against possible battery explosion. Do not smoke

and avoid other sources of ignition.

13. Attach the positive battery cable (each end must have a rubber boot) to the positive terminal of

the solenoid and to the positive terminal of the battery Make sure these protective boots are

covering the positive terminal post on the battery and on the solenoid.

14. Connect the negative battery terminal to the battery hold down post. When finished, make sure

all wires are away from moving parts and lower engine shroud.

15. Plug cable from the spreader into socket mounted on the truck, Step 9.

5

Page 6

OPERATION

!

WARNING

BEFORE OPERATING THE CONTROL PANEL - MAKE SURE THAT NO ONE IS INSIDE

THE HOPPER OR NEAR THE SPINNER.

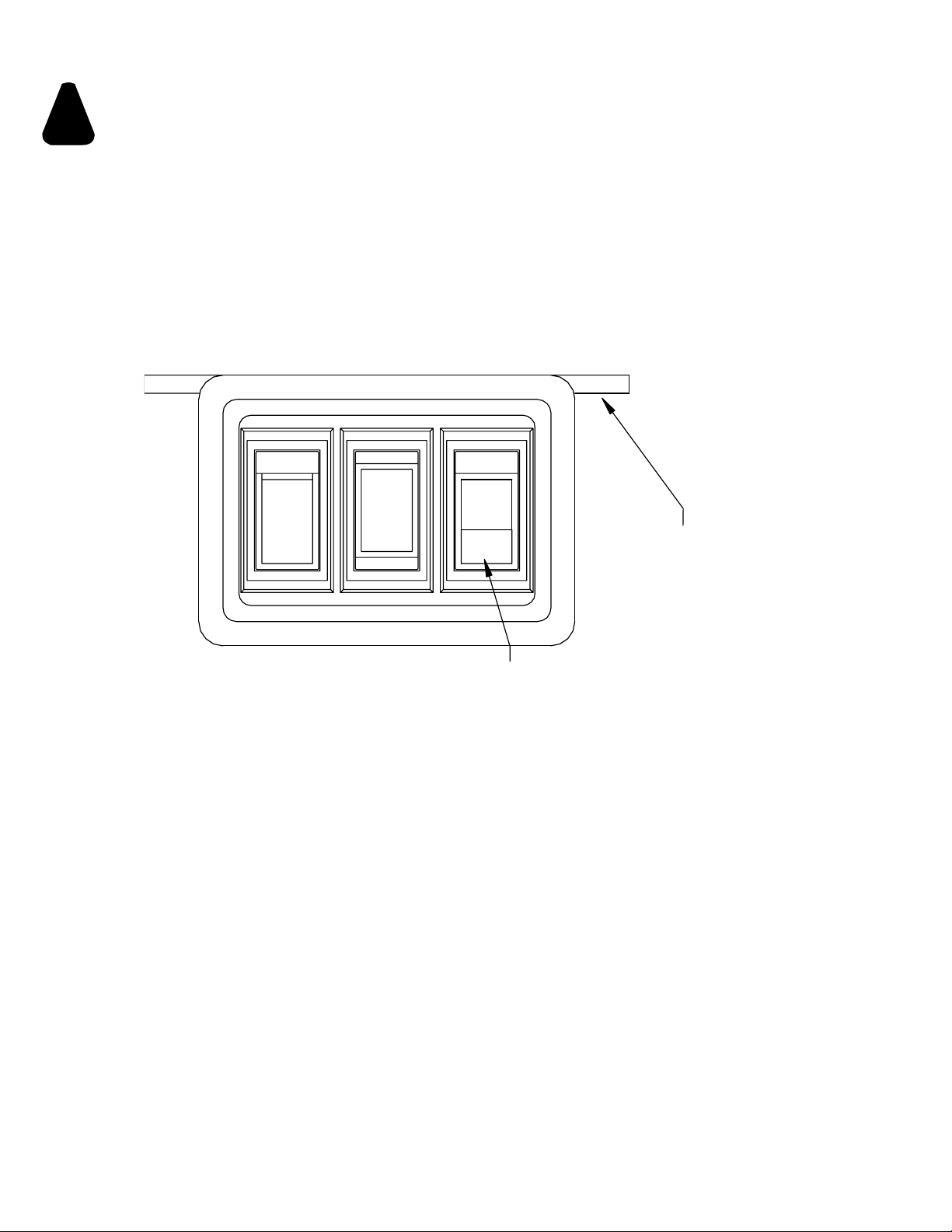

1. Electric Throttle Control Panel Switch functions

(Sequence of Operations)

ON

OFF

CHOKE

HI

LO

START

CONV.

MOUNTING

TABS

RED LENSE

A. ON/OFF System power activated (ready to start). Spreader engine is not running.

Spreader conveyor is not engaged.

B. START (Engine only)

1 . On On switch depressed.

2. Choke (cold engine ) Hold down for 5 seconds to move the throttle actuator to the

choke position.

Note: Choking a warm engine may not be necessary

3. Start Hold down until engine starts.

4. LO / HI Decreases / increases engine speed - adjust as engine warms up. Lo will

stop the choke function.

C. TO ENGAGE Spreader Conveyor

1. Push CONV switch only after you are sure no one is in the hopper or near the spinner! This lights up

the red indicator light, if light does not light, take care to verify that the light is not malfunctioning.

6

Page 7

D. TO CONTROL Conveyor Speed.

1. Hold HI to increase speed. NOTE: Do not hold switch in HI position after the desired

RPM is achieved or you will choke and/or stall the engine.

2. Hold LO to decrease speed.

E. TO DISENGAGE Spreader Conveyor.

1. Tap START switch momentarily so that red indicator light goes out. Do not fully

depress the START switch, only half way is needed. Only the conveyor stops, the

engine continues to run.

F. TO TURN ENGINE OFF (with or without conveyor running).

1. Depress LO on throttle control to reduce setting to idle (this prevents engine flooding

and hard starting).

2. Push OFF position on the ON/OFF switch.

NOTE: OFF can be pushed at anytime during spreader operation to cut power to the unit.

However, you should normally use steps under F above.

(Once the off switch is depressed - the starting procedure must be followed for engine re-start.)

G. Do not attempt to start the engine with the conveyor engaged. (CONV switch light will be lit to

indicating its being on.)

!

WARNING

1 . As with all power equipment, safety is the number one concern.

2. Do not operate this equipment until you fully understand how it functions.

3. Before starting engine, be sure that no one is near the rear of the unit and that no

one is inside the unit!

4. Do not start the engine or engage the conveyor (which is interconnected to the

spinner); until everyone is clear from moving parts and flying material from the

spinner.

SPREADER OPERATION

A. Start the engine and engage the clutch. The amount of material spread, depends on engine speed and

gate opening. Decreasing RPM and/or gate height will decrease amount spread; the inverse holds true

also. Notice that the electric clutch can be engaged or disengaged at any time and at any engine RPM.

However, since engagement time and torque is almost instantaneous, to prevent premature spinner chain

failure and chain tension loss, it is recommended that the electric clutch be engaged at the lowest possible

RPM without stalling the engine.

If the truck is to be driven for an extended period of time while the spreader is not operating, it is best to turn

off the gas at the carburator inlet to prevent the carburator from overfilling with fuel.

Before loading the spreader the first time, start and stop the conveyor several times to break in the clutch.

7

Page 8

!

ALWAYS STAND AT A SAFE DISTANCE AWAY FROM THE SPINNER WHILE OPERATING

ALWAYS WEAR EYE PROTECTION WHEN OUTSIDE OF THE TRUCK CAB WHILE

SPREADER IS RUNNING.

B. Spread pattern depends on baffle settings and spinner RPM. Maximum spread width is 30 ft.

WARNING

1. Speeding up or slowing down the engine will increase or decrease spread pattern width.

2. Internal baffle adjustments will move the spread pattern to the right or left.

3. External baffle adjustments will block spreading to the right or left side.

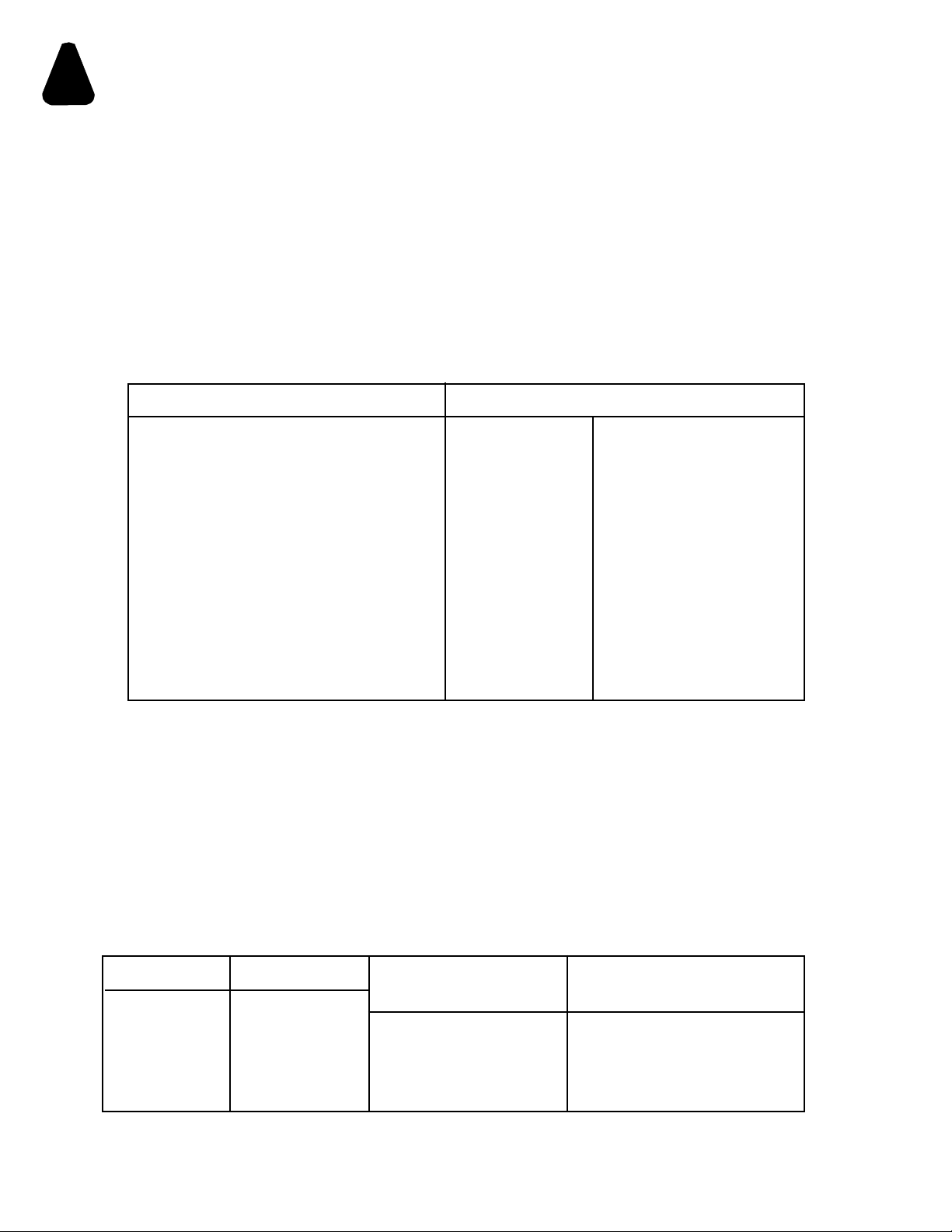

DESIRED SPREAD PATTERN BAFFLE SETTING

INTERNAL EXTERNAL

Centered Behind Truck Both Down All Three UP

All Material to the Right RH - Up RH - Up

LH - Down LH - Down

All Material to the Left RH - Down RH - Down

LH - Down LH - Up

Behind Truck and Left RH - Down RH - Med.

LH - Up LH - Up

Behind Truck and Right RH - Up RH - Up

LH - Down LH - Med.

Windrow Behind Truck RH - Down All - Down

LH - Down

4. External Baffles can be lowered to an intermediate position to baffle down the particles

that may otherwise leave the spinner at a high trajectory.

C. CALIBRATION

The average lbs. of salt per gearbox shaft revolution per inch of gate height is 6.7 Ibs.

GATE HEIGHT AVG. LBS/REV. AVG. LBS/MIN. AVG. LBS/MIN.

AT FULL ENGINE RPM AT 7 GPM HYD OIL FLOW

1 6.7 260 200

3 20.1 780 580

5 33.5 1300 970

7" 46.9 1800 1350

8

Page 9

MAINTENANCE

!

1 Grease idler bearings on idler shaft take up assembly, outboard bearing on gearbox output shaft, and

lower spinner bearing every ten hours of operation.

2. Grease input shaft bearing on gearbox every fifty hours of operation. CAUTION! Over greasing may

cause seal damage. The gearbox must be filled to oil level plug with SAE 90 gear type lubricant. Keep

breather plug clean.

3. Drag chain slack on V-boxes should be checked periodically and taken up if distance between center

line of rear sprocket and point where chain contacts lower flange on longitudinal is less than eight (8)

inches.

4. If the spreader is equipped with a gasoline engine, it should be maintained per engine manufacturers

instruction. (Instructions and parts book is enclosed.)

5. V-belt tension must be maintained. The v-belt can be tightened by loosening engine hold-down bolts

and sliding engine as required. CAUTION! Over tightening may damage gearbox.

WARNING

DO NOT ATTEMPT TO LIFT THE SPREADER BY THE CENTER LIFT OR

CORNER LIFT HOOKS WITH MATERIAL IN THE SPREADER.

6. Roller chain tension must be maintained. It is adjusted by loosening the spinner mounting bearings and

sliding the bearings. Make sure the spinner shaft is straight up and down before retightening. Oil

chain often and at end of season.

7. When the box is not in use, it should be washed out. If the box is put in storage, all surfaces should be

oiled or painted after washing.

8. For HYDRAULIC SPREADERS, maintain oil level three fourths (3/4) full in reservoir with clean high

grade non-foaming hydraulic oil; recommended viscosity 100-200 SSU. Operating temperature should

be limited to 180 degress F. Replace filter cartridge #62382 at least twice a year.

9. If chain becomes stuck or froze to the floor to the point where the clutch cannot pull the load, never

attempt to free chain using a pipe wrench or any other tool on the output shaft. The gearbox is designed

to accept torque from input shaft only. Trying to turn output shaft will strip the gears, thus voiding the

warranty.

10. To minimize problems and extend the life of the Electric Clutch, the following is highly recommended

a. Before starting unit, make sure the drag chain is free (not stuck or froze to the floor). If the drag

chain is stuck, this can cause the clutch to burn up.

b. After the using season is over, remove clutch from unit, and clean thoroughly.

c. After cleaning, coat both mating surfaces of the clutch with oil or light weight grease.

NOTE: The Oil or Grease must be removed prior to the next using season.

9

Page 10

HYDRAULICS

!

Leaking high pressure fluids can inject themselves under the skin of persons near a leak, creating grave

medical risks. TAKE CARE TO AVOID EXPOSURE TO HIGH PRESSURE FLUIDS.

1 . Hydraulic components should be kept as clean as possible during assembly operations.

2. Galvanized pipe and pipe fittings must not be used because flaking or galvanizing material can cause

3. A pipe joint sealant, compatible with hydraulic oil, must be applied to all screwed fittings. (Teflon tape is

4. Hose should be protected where severe wear may be caused by vibration or sliding movement.

5. Long runs of hose should be supported by tie wiring or clamping.

6. Pressure and return hoses, connected to hydraulic motors, may be reversed for proper motor rotation.

7. Use hose manufacturers recommendations for fitting re-useable hose ends.

8. Hydraulic pumps must be mounted so shaft rotates in direction of arrow.

9. Locate reservoir as close to pump as possible. It may be installed on truck frame or truck box.

WARNING

damage to major hydraulic components.

not recommended.)

Spinner rotates in a clockwise direction when looking down from top.

10. Hydraulic return line filter is screwed directly onto reservoir with cartridge down. Oil must flow through

filter in direction of arrow on filter.

11. Install the quick connect couplings so that when disconnected, there is a male and female on the truck

as well as on the spreader. This way, hoses will always be hooked up properly. and hose ends can be

coupled together when spreader is in storage to prevent system contamination.

12. See page 11 for valve assembly

13. Operate hydraulic system for several minutes to warm up. Check all connections for leaks.

14. After running, refill reservoir to three fourths full.

CONTROL AND HYDRAULIC SYSTEM SPECIFICATIONS

*Hydraulic Oil................................... Good Grade of MS10W Hydraulic Oil Which has

wear, oxidation and foam inhibitors.

*Oil Filter .......................................... 10 Micron Element Return Line Filter.

*Relief Valve Setting1500 PSI

*Oil Flow .......................................... 0 - 10 GPM - With single flow valve connect

conveyor and spinner with dual flow valve.

*Oil Flow .......................................... 0 - 15 GPM - With dual flow valve connect separate

pressure line to conveyor and spinner motor.

10

Page 11

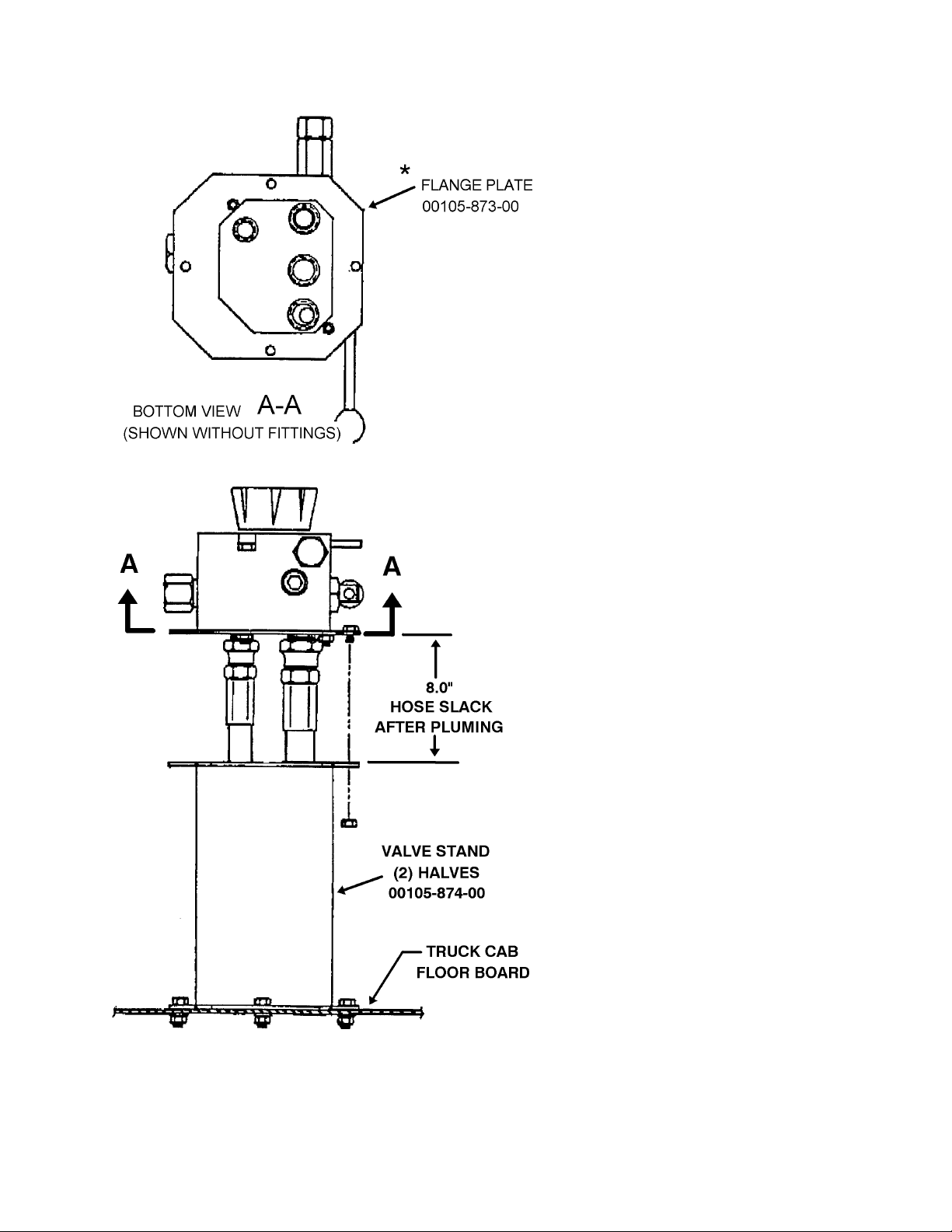

DUAL FLOW VALVE/STAND INSTALLATION INSTRUCTIONS

1. IMPORTANT: A pipe joint sealant

compatible with hydraulic oil must be

applied to all screw fittings. (Teflon Tape

Sealant Is Not Recommended)

2. Hose ends connected to flow valve must

be of the swivel type.

3. CAUTION: Over tightening of the fittings

in flow valve may cause damage to

valve body

4. Approximately 8" of hose slack must be

realized between the flow valve and

valve stand after the flow valve has been

completely plumbed. If this condition

does not exist after the plumbing has

been completed, removal of valve will

require hoses to be removed at opposite

end of valve.

5. Assembly of valve on stand:

a. Cut a 5" x 5" square opening in floor

board of truck where the valve stand is

to be located.

b. Bolt valve stand halves together forming

a box over the 5" x 5" square opening.

NOTE: When bolting valve stand halves

in place, make sure holes in flanges

align with holes in flange plate.*

c. Bolt flange plate to VALVE (Use (2)

1/4" x 3" bolts, lockwashers, etc.)

d. Insert hoses through floor opening and

valve stand and connect appropriate

hoses (see instructions #1 thru #4) to

flow valve.

e. Bolt flange plate to valve

stand flanges.

11

Page 12

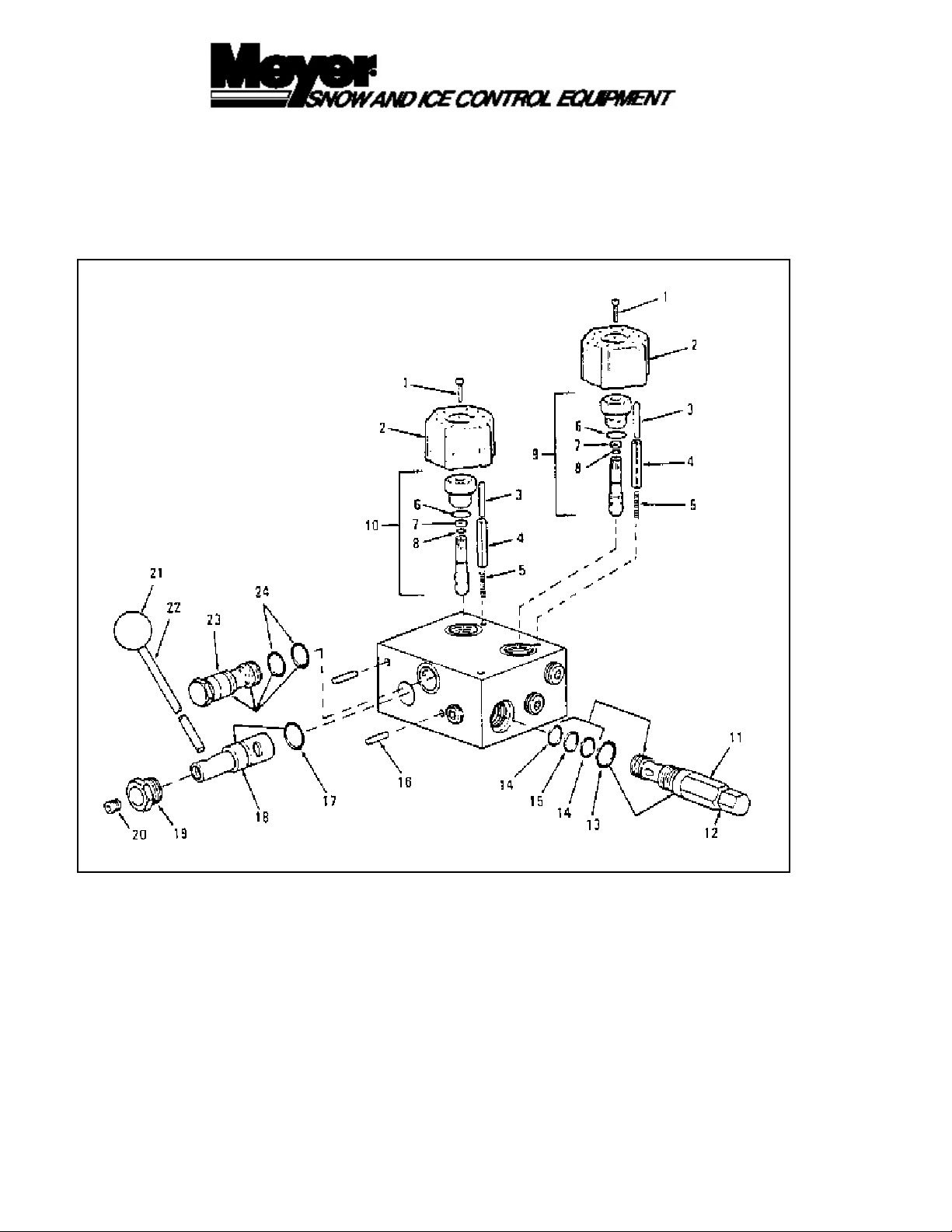

DUAL FLOW CONTROL VALVE

62213

12

Page 13

PARTS LIST FOR DUAL HYDRAULIC FLOW CONTROL VALVE

(62213)

Item Part Number Qty. Description

1 62383 2 Screw

2 62098 2 Handknob

3 62384 2 Dowel Pin

4 62385 2 Roll Pin

5 62386 2 Spring

6 04105-285-06 2 O-Ring, Viton ®

7 04105-285-07 2 Back-up, Teflon

8 04105-285-08 2 O-Ring, Viton ®

- 62099 Kit, Seal - Consists of Items 6, 7 & 8

9 04105-285-10 1 Auger Adj. Assy. - 7 GPM

04105-285-11 1 Auger Adj. Assy. -10 GPM

62387 1 Auger Adj. Assy. - 15 GPM

04105-285-13 1 Auger Adj. Assy. - 20 GPM

04105-285-14 1 Auger Adj. Assy. -25 GPM

04105-285-15 1 Auger Adj. Assy. - 30 GPM

10 04105-285-16 1 Spinner Adj. Assy. - 5 GPM

62388 1 Spinner Adj. Assy. - 7 GPM

04105-285-18 1 Spinner Adj. Assy. - 10GPM

11 62389 1 Relief Cartridge

12 04105-285-20 1 Gasket

13 62100 1 O-Ring, Viton ®

14 04105-032-30 2 Back-up, Teflon ®

15 62102 1 O-Ring, Viton ®

16 04105-285-24 2 Roll Pin

17 62103 1 O-Ring (Dump Stem)

18 04105-032-21 1 Stem (Not Available - Can no longer service)

19 04105-285-26 1 Plug

20 62390 1 Setscrew

21 62391 1 Handknob

22 62392 1 Lever

23 62393 1 Bypass Assy.

24 62104 2 O-Ring, Viton ®

NOT SHOWN

04105-285-40 Kit, Seal (For Item 11)

Consists of Items: 12, 13, 14 & 15

62394 Kit, Seal

Consists of Items:

6, 7, 8, 12, 13, 14, 15, 17, 23 & 24

13

Page 14

14

Page 15

PARTS LIST FOR MDV ENGINE DRIVEN HOPPER ASSEMBLIES

(Carbon Steel)

Item Part Number Qty. Description

1 00115-146-01 1 Weld, Hopper 840

00115-146-02 1 Weld, Hopper 844

00115-146-09 1 Weld, Hopper 940

00115-146-10 1 Weld, Hopper 944

00115-146-17 1 Weld, Hopper 1040

00115-146-18 1 Weld, Hopper 1044

6 62343 1 Weld, Drag Chain, 8' MDV

62344 1 Weld, Drag Chain, 9' MDV

62345 1 Weld, Drag Chain, 10' MDV

7 20091 4 Bolt, 1/2-13 x 3/4 HH GR5 ZP

8 20329 6 Lockwasher, 1/2" Med Split ZP

10 20051 2 Bolt, 3/8-16 x 1-1/2 HH GR5 ZP

12 04003-806-02 10 Nut, 3/8-16 Serrated Flange ZP

13 62355 2 Bearing, 1-1/4"

16 20525 25 Nut, 5/16-18 Serrated Flange ZP

17 62302 2 Plate, Front Brg.

18 20226 8 Bolt, 1/2-13 x 1-3/4 Carriage GR5 ZP

19 20307 8 Locknut, 1/2-13 Nyl Ins ZP

20 62370 1 Weld, Idler Shaft

21 61171 1 Sprocket, Drag Chain

22 61169 1 Knob, Hand

23 62300 1 Feedgate, Forming

29 20353 7 Flatwasher, 3/8" U.S.S. ZP

31 62304 2 Weld, Take-up

33 62408 10 Nut, 1/2-13 Hex Jam ZP

35 62310 2 Shield, Rep. Chain 8

62308 2 Shield, Rep. Chain 9

62306 2 Shield, Rep. Chain 10'

38 00115-147-00M 1 Instruction Manual MDV (1-739)

39 62280 1 Handle

40 20354 1 Flatwasher, 7/16" U.S.S. ZP

41 04010-003-02 1 Pin, 1/8" x 1" Cotter

42 04003-033-12 7 Bolt, 3/8-16 x 3/4 Carriage SS

43 20305 8 Locknut, 3/8-16 Nyl Ins ZP

44 62270 1 Bar, Pivot

45 61204 2 Pin, Master for Chn W/O Cotter

46 04045-025-00 2 Pin, Cotter Only

47 21971 2 Decal, Meyer

48 21932 1 Decal, Serial (w/Pat. Nos.)

49 62009 2 Decal, Danger (Conveyor)

52 62292 1 Floor, Forming, 8'

62290 1 Floor, Forming, 9'

62288 1 Floor, Forming, 10'

53 62335 1 Screw, 3/8-16 x 1-3/16" SLT FL HD

54 04003-032-06 1 Bolt, 5/16-18 x 3/4 Carriage SS

55 62298 1 Weld, Inverted V 8'

62296 1 Weld, Inverted V 9'

62294 1 Weld, Inverted V, 10'

56 61162 1 V-Belt

57 61168 1 Cover, Clutch

58 61176 1 Retainer, Clutch

59 04003-001-16 4 Bolt, 1/4-20 x 1 HH ZP

61 62187 4 Nut, 1/4-20 Serrated Flange

62 62133 1 Engine, 10-1/2 HP I/C

63 61196 1 Key, 1/4" Sq x 1

64 61177 1 Pulley, Driver

15

Page 16

PARTS LIST FOR MDV ENGINE DRIVEN HOPPER ASSEMBLIES

(Carbon Steel)Continued

Item Part Number Qty. Description

65 04003-002-06 1 Bolt, 5/16-18 x 1-1/2 HH GR5 ZP

66 61205 1 Bolt, L

67 20352 5 Flatwasher, 5/16" U.S.S. ZP

68 04093-022-00 2 Grommet, CA Plug Type (1 1/4")

69 61179 1 Solenoid, Grounded

70 62046 2 Terminal, Insulated Ring

71 62188 2 Connector, 16-14 Insulated Butt

73 62040 1 Cable, Battery

74 61213 1 Cable, Starter

75 62395 2 Spring, Linkage

76 04607-004-00 2 Clamp, 3/8" Nylon Cable

77 62191 2 Screw, #10-24 3/4 HWH TEKS/3

78 04607-001-00 1 Tie, Nylon 6"

79 61206 2 Rod, Battery

80 04604-017-00 1 Down Hold

81 20355 2 Flatwasher, 1/2" U.S.S. ZP

82 00115-140-01 1 Weld, Shroud

83 61215 1 Rod, Prop

84 20353 2 Flatwasher, 3/8" U.S.S. ZP

85 61231 2 Pin, 3/32" x 1" Cotter

88 04049-199-00 1 Decal, Gasoline Only

91 20235 4 Bolt, 1/2-13 x 4 Car GR5 PLN

94 20354 4 Flatwasher, 7/16" U.S.S. ZP

95 04010-003-02 2 Pin, 1/8" x 1" Cotter

96 20202 1 Bolt, 3/8-16 x 1 Car GR5 ZP

97 20305 1 Locknut, 3/8-16 Nyl Ins ZP

98 20048 4 Bolt, 3/8-16 x 7/8" HH GR5 ZP

99 04120-078-01 1 Hose, 3/8" x 13" (1) Wire

100 04110-006-03 1 Ell. 3/8" 90 Deg. Street

101 20203 1 Bolt, 3/8-16 x 1-1/4" Car GR5 ZP

104 62105 1 Boot, Batt. Cable, Straight

105 62106 1 Boot, Alt. Cable

106 04003-081-04 3 Screw, 5/16-18 x 3/4 Soc Cap

107 20327 3 Lockwasher, 3/8" Med Split ZP

109 04607-001-00 2 Tie, Nylon 6"

111 62174 1 Assy, Plate Actuator

112 62169 1 Assy, Control Cable

113 00113-668-00 1 Dia. Wiring/Instructions

115 04093-021-00 2 Trim, Vinyl

116 20203 1 Bolt, 3/8-16 x 1-1/4" Car GR5 ZP

117 20600 4 Bolt, 5/16-18 x 1 Car SS

118 62007 1 Decal, Caution

119 62354 1 Wiper, Chain

120 61163 1 Bearing, 1-1/4"

121 62284 2 Sprocket, Drive w/Set Screws

124 62000 2 Key, 1/4" SQ x 2"

125 61178 1 Assy, Gearbox

126 61202 1 Snap Ring, External

127 61201 2 Key, 1/4" x 7/8" Woodruff

128 00107-679-00 1 Washer

129 61161 1 Pulley, Driven

130 61167 1 Clutch, Electric

131 00108-771-00 1 Washer, Flat

132 04003-002-09 1 Bolt, 5/16-18 x 2 HH GR5 ZP

133 20326 3 Lockwasher, 5/16" Med Split ZP

134 04003-081-04 3 Screw, 5/16-18 x 3/4 Soc Cap

135 04001-001-01 1 Collar, Set 1" Per Print

136 61156 1 Sprocket, 41B13

16

Page 17

PARTS LIST FOR MDV ENGINE DRIVEN HOPPER ASSEMBLIES

(Stainless Steel)

Item Part Number Qty. Description

1 00115-146-05 1 Weld, Hopper 840, S3

00115-146-06 1 Weld, Hopper 844, S3

00115-146-13 1 Weld, Hopper 940, S3

00115-146-14 1 Weld, Hopper 944, S3

00115-146-21 1 Weld, Hopper 1040, S3

00115-146-22 1 Weld, Hopper 1044, S3

6 62343 1 Weld, Drag Chain, 8' MDV

62344 1 Weld, Drag Chain, 9' MDV

62345 1 Weld, Drag Chain, 10' MDV

7 04003-005-56 4 Bolt, 1/2-13 x 3/4 HH SS

8 04004-001-16 6 Lockwasher, 1/2" Med Split SS

10 04003-003-28 2 Bolt, 3/8-16 x 1 1/2 HH SS

12 04003-806-12 10 Nut, 3/8-16 Serrated Flange SS

13 62355 2 Bearing, 1-1/4"

16 04003-806-13 25 Nut, 5/16-18 Ser Flange SS

17 62302 2 Plate, Front Brg., S3

18 04003-034-19 8 Bolt, 1/2-13 x 1-3/4 Car NK SS

19 04003-804-07 8 Locknut, 1/2-13 Nyl Ins SS

20 62370 1 Weld, Idler Shaft

21 61171 1 Sprocket, Drag Chain

22 61169 1 Knob, Hand

23 62301 2 Feedgate, Forming, S3

29 04004-002-20 7 Flatwasher, 3/8" U.S.S. SS

31 62304 2 Weld, Take-up

33 62336 10 Nut, 1/2-13 Hex Jam SS

35 62311 2 Shield, Rep. Chain 8 Ft, S3

62309 2 Shield, Rep. Chain 9 Ft, S3

62307 2 Shield, Rep. Chain 1OFt, S3

38 00115-147-00 1 Instruction Manual MDV

39 62280 1 Handle

40 04004-002-32 1 Flatwasher, 7/16" U.S.S. SS

41 04010-003-02 1 Pin, 1/8" x 1" Cotter

42 04003-033-12 7 Bolt, 3/8-16 x 3/4 Car SS

43 04003-804-08 8 Locknut, 3/8-16 Nyl Ins SS

44 62270 1 Bar, Pivot

45 62346 2 Pin, Master for Chn W/O Cotter

46 04045-025-00 2 Pin, Cotter Only

47 21971 2 Decal, Meyer

48 21932 1 Decal, Serial (w/Pat.Nos.)

49 04049-182-00 2 Decal, Danger (Conveyor)

50 04049-229-00 1 Decal, Stainless Steel

52 62293 1 Floor, Forming, 8', S3

62291 1 Floor, Forming, 9', S3

62289 1 Floor, Forming, 10', S3

53 04003-025-02 4 Screw, 3/8-16 x 1- 3/16" Slt FI SS

54 04003-032-06 8 Bolt, 5/16-18 x 3/4 Car SS

55 62299 1 Weld, Inverted V 8', S3

62297 1 Weld, Inverted V 9', S3

62295 1 Weld, Inverted V 10', S3

56 61162 1 V-Belt

57 61168 1 Cover, Clutch

58 61176 1 Retainer, Clutch

59 04003-001-16 4 Bolt, 1/4-20 x 1 H H SS

61 04003-806-15 4 Nut, 1/4-20 Ser Flange SS

62 62133 1 Engine, 10 1/2 HP I/C

63 62397 1 Key, 1/4" SQ x 1

64 61177 1 Pulley, Driver

65 04003-002-21 3 Bolt, 5/16-18 x 1-1/2 HH SS

66 61205 1 Bolt, L

67 04004-002-25 5 Flatwasher, 5/16" U.S.S. SS

68 04093-022-00 2 Grommet, CA Plug Type (1-1/4")

17

Page 18

PARTS LIST FOR MDV ENGINE DRIVEN HOPPER ASSEMBLIES

(Stainless Steel)

Item Part Number Qty. Description

69 61179 1 Solenoid, Grounded

70 62046 2 Terminal, Insulated Ring

71 62188 2 Connector, 16-14 Insulated Butt

73 62040 1 Cable, Battery

74 61213 1 Cable, Starter

75 62395 2 Spring, Linkage

76 04607-004-00 2 Clamp, 3/8" Nylon Cable

77 04002-069-02 2 Screw, #10-24 x 3/4 HWH TEKS/3 SS

78 04607-001-00 1 Tie, Nylon 6"

79 61206 2 Rod, Battery

80 04604-017-00 1 Down, Hold

81 04004-002-22 2 Flatwasher, 1/2" U.S.S. SS

82 00115-140-02 1 Weld, Shroud, S3

83 61215 1 Rod, Prop

84 04004-002-20 2 Flatwasher, 3/8" U.S.S.SS

85 61231 2 Pin, 3/32" x 1" Cotter

88 04049-199-00 1 Decal, Gasoline Only

91 20235 4 Bolt, 1/2-13 x 4 Car GR5 Pin

94 04004-002-32 4 Flatwasher, 7/16" SS

95 04010-003-02 2 Pin, 1/8" x 1" Cotter

96 04003-033-03 1 Bolt, 3/8-16 x 1" Car SS

97 04003-804-08 1 Locknut, 3/8-16 Nyl Ins SS

98 04003-003-24 4 Bolt, 3/8-16 x 3/4 HH SS

99 04120-078-01 1 Hose, 3/8" x 13" (1) Wire

100 04110-006-03 1 Ell., 3/8" 90 Deg Street

101 04003-033-05 1 Bolt, 3/8-16 x 1-1/4" Car SS

104 62105 1 Boot, Batt. Cable, Straight

105 62106 1 Boot, Alt. Cable

106 04003-081-04 3 Screw, 5/16-18 x 3/4" Soc Cap

107 04004-001-14 3 Lockwasher, 3/8" Med Split SS

109 04607-001-00 2 Tie, Nylon 6"

111 62174 1 Assy, Plate Actuator

112 62169 1 Assy, Control Cable

113 00113-668-00 1 Dia. Wiring/Instructions

116 04003-033-05 1 Bolt, 3/8-16 x 1-1/4 Car SS

117 04003-032-04 4 Bolt, 5/16-18 x 1 Car SS

118 62007 1 Decal, Caution

119 62354 1 Wiper, Chain

120 61163 1 Bearing, 1-1/4"

121 62284 2 Sprocket, Drive w/Set Screws

124 62000 2 Key, 1/4" Sq. x 2"

125 61178 1 Assy, Gearbox

126 61202 1 Snap Ring, External

127 61201 2 Key, 1/4" x 7/8" Woodruff

128 00107-679-00 1 Washer

129 61161 1 Pulley, Driven

130 61167 1 Clutch, Electric

131 00108-771-00 1 Washer, Flat

132 04003-002-09 1 Bolt, 5/16-18 x 2 HH GR5 ZP

133 20326 3 Lockwasher, 5/16" Med Split ZP

134 04003-081-04 3 Screw, 5/16-18 x 3/4 Soc Cap

135 04001-001-01 1 Collar, Set 1" Per Print

136 61156 1 Sprocket, 41B13

18

Page 19

Notes

19

Page 20

"'

"%

"&

#

#

!

THIS MACHINE MAY BE COVERED BY ONE OR MORE OF THESE PATENTS

4,342,1634,353,177

'

Cleveland, Ohio 44112

3,332,6913,189,355

4,549,697

3,510,066

SERIAL

4

3,851,804

&

! DANGER

!! %

""

#&

#'

"!

!

"

"

'

"

!'

4

#

'

$

&

$

%

$&

&

!"

'

##

#"

$

! DANGER

CAUTION!

$

$

!&

"

ITEMS NOT SHOWN:

INSTRU CTION MANUAL

(PACKED INSIDE BAG & SHIPING CARTON)

#

'

#%

#!

"!

'

20

"'

$

&

!

#$

$%

$$

%

&

!

$

$"

$#

"#

"$

#

!#

"

"!

$!

Page 21

PARTS LIST FOR MDV HYDRAULIC HOPPER ASSEMBLIES

(Carbon Steel)

Item Part Number Qty. Description

00115-146-01 1 Weld, Hopper 840

00115-146-02 1 Weld, Hopper 844

00115-146-09 1 Weld, Hopper 940

00115-146-10 1 Weld, Hopper 944

00115-146-17 1 Weld, Hopper 1040

00115-146-18 1 Weld, Hopper 1044

5 61201 1 Key, 1/4" x 7/8" Woodruff

6 62343 1 Weld, Drag Chain, 8' MDV

62344 1 Weld, Drag Chain, 9' MDV

62345 1 Weld, Drag Chain, 10' MDV

7 20091 4 Bolt, 1/2-13 x 3/4 HH GR5 ZP

8 20329 4 Lockwasher, 1/2" Med Split ZP

10 20051 2 Bolt, 3/8-16 x 1-1/2 HH GR5 ZP

11 20327 4 Lockwasher, 3/8" Med Split ZP

12 04003-806-02 10 Nut, 3/8-16 Serrated Flange ZP

13 62355 2 Bearing, 1-1/4"

16 04003-806-13 29 Nut, 5/16-18 Ser Flange ZP

17 62302 2 Plate, Front Brg.

18 20226 10 Bolt, 1/2-13 x 1-3/4 Car GR5 ZP

19 20307 10 Locknut, 1/2-13 Nyl Ins ZP

20 62370 1 Weld, Idler Shaft

21 61171 1 Sprocket, Drag Chain

22 61169 1 Knob, Hand

23 62300 2 Feedgate, Forming

25 62398 1 Motor, Hydraulic (AA)

26 62399 1 Plate, Motor Mtg.

27 62202 4 Bushing, 3/8" I.D. x 5/8" O.D.

28 20049 4 Bolt, 3/8-16 x 1 HH GR5 ZP

29 20353 10 Flatwasher, 3/8" U.S.S. ZP

30 62073 1 Coupling, Shaft

31 62304 2 Weld, Take-up

33 62408 10 Nut, 1/2-13 Hex Jam ZP

34 04007-005-04 2 Setscrew. 1/4-20 x 3/8" AL HD

35 62310 2 Shield, Rep. Chain 8

62308 2 Shield, Rep. Chain 9

62309 2 Shield, Rep. Chain 10'

38 ----------------- 1 Instruction Manual MDV

39 00110-817-00 1 Handle

40 20354 1 Flatwasher, 7/16" U.S.S. ZP

41 04010-003-02 1 Pin, 1/8" x 1" Cotter

42 04003-033-12 8 Bolt, 3/8-16 x 3/4 Car SS

43 20314 6 Locknut, 3/8-16 Nyl Ins ZP

44 62270 1 Bar, Pivot

45 61204 2 Pin, Master for Chn W/O Cotter

46 04045-025-00 2 Pin, Cotter Only

47 21971 2 Decal, Meyer

48 21932 1 Decal, Serial (w/Pat.Nos.)

49 62009 2 Decal, Danger (Conveyor)

52 62292 1 Floor, Forming, 8'

62290 1 Floor, Forming, 9'

62288 1 Floor, Forming, 10'

53 62335 4 Screw, 3/8-16 x 1-3/16" SILT FIL HD

54 00400-032-06 8 Bolt, 5/16-18 x 3/4 Car SS

21

Page 22

PARTS LIST FOR MDV HYDRAULIC HOPPER ASSEMBLIES

(Carbon Steel)

Item Part Number Qty. Description

55 62298 1 Weld, Inverted V 8'

62296 1 Weld, Inverted V 9'

62294 1 Weld, Inverted V 10'

56 62314 1 Guard, Shaft

59 20203 1 Bolt, 3/8-16 x 1-1/4 Car GR5 ZP

60 04003-032-04 4 Bolt, 5/16-18 x 1 Car SS

61 62007 1 Decal, Caution

62 04004-002-22 2 Flatwasher, 1/2" U.S.S. SS

63 62400 1 Bearing, 1-1/4"

64 62284 2 Sprocket Drive 2/Set Screws

65 62401 2 Key, 1/4" SQ. x 2"

66 62402 1 Assy, Gearbox

67 61156 1 Sprocket, 41B13

68 04009-001-00 1 Key, 1/4" x 7/8" Woodruff

22

Page 23

PARTS LIST FOR MDV HYDRAULIC HOPPER ASSEMBLIES

(Stainless Steel)

Item Part Number Qty .Description

1 00115-146-05 1 Weld, Hopper 840, S3

00115-146-06 1 Weld, Hopper 844, S3

00115-146-13 1 Weld, Hopper 940, S3

00115-146-14 1 Weld, Hopper 944, S3

00115-146-21 1 Weld, Hopper 1040, S3

00115-146-22 1 Weld, Hopper 1044, S3

5 61201 1 Key, 1/4" x 7/8" Woodruff

6 62343 1 Weld, Drag Chain, 8' MDV

62344 1 Weld, Drag Chain, 9' MDV

62345 1 Weld, Drag Chain, 10' MDV

7 04003-005-56 4 Bolt, 1/2-13 x 3/4 HH SS

8 04004-001-16 4 Lockwasher, 1/2" Med Split SS

10 04003-003-28 2 Bolt, 3/8-16 x 1-1/2 HH SS

11 04004-001-14 4 Lockwasher, 3/8" Med Split SS

12 04003-806-12 10 Nut, 3/8-16 Serrated Flange SS

13 62355 2 Bearing, 1-1/4"

16 04003-806-13 29 Nut, 5/16-18 Ser Flange SS

17 62303 2 Plate, Front Brg., S3

18 04003-034-19 10 Bolt, 1/2-13 x 1-3/4 Car NK SS

19 04003-804-07 10 Locknut, 1/2-13 Nyl Ins SS

20 62370 1 Weld, Idler Shaft

21 61171 1 Sprocket, Drag Chain

22 61169 1 Knob, Hand

23 62301 2 Feedgate, Forming,

25 62398 1 Motor, Hydraulic (AA)

26 62368 1 Plate, Motor Mtg., S3

27 62339 4 Bushing, Spacer, S3

28 04003-003-20 4 Bolt, 3/8-16 x 1 HH SS

29 04004-002-20 10 Flatwasher, 3/8" U.S.S. SS

30 62073 1 Coupling, Shaft

31 62304 2 Weld, Take-up

33 62336 10 Nut, 1/2-13 Hex Jam

34 04007-005-04 2 Setscrew. 1/4-20 x 3/8" AL HD

35 62311 2 Shield, Rep. Chain 8

62309 2 Shield, Rep. Chain 9

62307 2 Shield, Rep. Chain 10'

38 00115-147-00 1 Instruction Manual MDV

39 62280 1 Handle

40 04004-002-32 1 Flatwasher, 7/16" U.S.S. SS

41 04010-003-02 1 Pin, 1/8" x 1" Cotter

42 04003-033-12 8 Bolt, 3/8-16 x 3/4 Car

43 04003-804-08 6 Locknut, 3/8-16 Nyl Ins SS

44 62270 1 Bar, Pivot

45 61204

46 04045-025-00 2 Pin, Cotter Only

47 21971 2 Decal, Meyer

48 21932 1 Decal, Serial (w/Pat. Nos.)

49 04049-182-00 2 Decal, Danger (Conveyor)

50 04049-229-00 1 Decal, Stainless Steel

52 62293 1 Floor, Forming, 8 Ft., S3

62291 1 Floor, Forming, 9 Ft. S3

62289 1 Floor, Forming, 10 Ft. , S3

53 04003-025-02 1 Screw, 3/8-16 x 1-3/16" SLT FL SS

54 04003-032-06 1 Bolt, 5/16-18 x 3/4 Car SS

55 62299 1 Weld, Inverted V 8 FT. S3

62297 1 Weld, Inverted V 9 FT. S3

62295 1 Weld, Inverted V 10 FT. S3

2 Pin, Master for Chn W/O Cotter

23

Page 24

PARTS LIST FOR MDV HYDRAULIC HOPPER ASSEMBLIES

(Stainless Steel)

Item Part Number Qty. Description

56 62315 1 Guard, Shaft, S3

57 62354 1 Wiper, Chain

58 62395 2 Spring, Linkage

59 04003-033-05 1 Bolt, 3/8-16 x 1-1/4 Car SS

60 04003-032-04 4 Bolt, 5/16-18 x 1 Car SS

61 62007 1 Decal, Caution

62 04004-002-22 2 Flatwasher, 1/2" U.S.S. SS

63 61163 1 Bearing, 1-1/4"

64 62284 2 Sprocket, Drive W/Set Screws

65 62000 2 Key, 1/4" SQ. x 2"

66 61178 1 Assy, Gearbox

67 61156 1 Sprocket, 41B13

68 61201 1 Key, 1/4" x 7/8" Woodruff

24

Page 25

Notes

25

Page 26

28

21

22

DETAIL-A

16

27

25

26

18

24

7

4

7

19

24

9

17

5

8

1

DANGER

CAUTION

15

DETAIL-A

2

23

24

26

30

25

29

13914

12

14

5

10 11

3

6

Page 27

PARTS LIST FOR HYDRAULIC SPINNER ASSEMBLY

(Carbon Steel)

Item Part Number Qty. Description

1 62312 1 Weld, Spinner Frame

2 62057 1 Shaft, Spinner (Long)

3 62146 1 Disc, Poly Spinner 13"

4 60324 1 Motor, Hydraulic (AA)

5 04003-003-06 2 Bolt, 3/8-16 x 2 HH GR5 ZP

6 04003-807-09 2 Locknut, 3/8-16 Cen Lock ZP

7 04003-003-01 8 Bolt, 3/8-16 x 3/4 HH GR5 ZP

8 62356 2 Bearing, 1" Tapped Base

9 20327 8 Lockwasher, 3/8" Med Split ZP

10 61181 1 Weld, Baffle, L.H.

11 61182 1 Weld, Baffle, R.H.

12 61183 1 Weld, Baffle, Rear

13 62313 3 Bar, Link, S3

14 61232 12 Keeper, Hairpin Small

15 62007 1 Decal, Caution

16 62006 1 Decal, Danger (Spinner)

17 62073 1 Coupling, Shaft

18 62201 1 Plate, Motor Mtg.

19 62202 4 Bushing, 3/8" I.D. x 5/8" O.D.

21 00115-152-00 1 Bag, Hardware

22 04031-017-00 1 Key, 1/4" SQ x 3" Straight

23 62358 2 Spring, Compression

24 20353 10 Flatwasher, 3/8" U.S.S. ZP

25 62331 1 Weld, Handle

26 62305 2 Plate, Baffle

27 04003-806-15 6 Nut, 1/4-20 Ser. Flange SS

28 04003-031-06 6 Bolt, 1/4-20 x 1/2" Car SS

29 04010-016-01 2 Pin, 1/8" x 1" Cotter SS

30 62333 1 Weld, Handle

PARTS LIST FOR HYDRAULIC SPINNER ASSEMBLY

(Stainless Steel)

Item Part Number Qty. Description

1 00115-148-02 1 Weld, Spinner Frame, S3

2 62057 1 Shaft, Spinner (Long)

3 62146 1 Disc, Poly Spinner 13"

4 60324 1 Motor, Hydraulic (AA)

5 04003-003-29 2 Bolt, 3/8-16 x 2 HH SS

6 04003-807-18 2 Locknut, 3/8-16 Cen Lock SS

7 04003-003-24 8 Bolt, 3/8-16 x 3/4 HH SS

8 62356 2 Bearing, 1" Tapped Base

9 04004-001-14 8 Lockwasher, 3/8" Med Split SS

10 00104-811-01 1 Weld, Baffle, L.H., S3

11 62272 1 Weld, Baffle, R.H., S3

12 62275 1 Weld, Baffle, Rear, S3

13 62313 3 Bar, Link, S3

14 04011-001-05 12 Keeper, Hairpin #7 SS

15 62007 1 Decal, Caution

16 62006 1 Decal, Danger (Spinner)

17 62073 1 Coupling, Shaft

18 62201 1 Plate, Motor Mtg., S3

19 62239 4 Bushing, Spacer, S3

21 00115-152-00 1 Bag, Hardware

22 04031-017-00 1 Key, 1/4" SQ x 3" Straight

23 62358 2 Spring, Compression

24 04004-002-20 10 Flatwasher, 3/8" U.S.S. SS

25 00115-545-02 1 Weld, Handle

26 00115-127-02 2 Plate, Baffle, S3

27 04003-806-15 6 Nut, 1/4-20 Ser. Flange SS

28 04003-031-06 6 Bolt, 1/4-20 x 1/2" Car SS

29 04010-016-01 2 Pin, 1/8" x 1 Cotter SS

30 00115-580-02 1 Weld, Handle L.H., S3

27

Page 28

26

25

23

24

7

DETAIL-A

16

CAUTION

DANGER

15

DETAIL-A

1

22

20

17

18

8

2

19

22

28

27

23

4

13914

12

5

10 11

3

6

14

Page 29

PARTS LIST FOR ENGINE DRIVEN SPINNER ASSEMBLY

(Carbon Steel)

Item Part Number Qty. Description

62312 1 Weld, Spinner Frame

2 62057 1 Shaft, Spinner (Long)

3 62146 1 Disc, Poly Spinner 13"

4 04010-016-01 2 Pin, 1/8" x 1" Cotter SS

5 04003-003-06 1 Bolt, 3/8-16 x 2 HH GR5 ZP

6 04003-807-09 1 Locknut, 3/8-16 Cen Lock ZP

7 04003-003-01 4 Bolt, 3/8-16 x 3/4 HH GR5 ZP

8 62356 2 Bearing, 1" Tapped Base

9 20327 4 Lockwasher, 3/8" Med Split ZP

10 61181 1 Weld, Baffle, L.H.

11 61182 1 Weld, Baffle, R.H.

12 61183 1 Weld, Baffle, Rear

13 62313 3 Bar, Link, S3

14 61232 12 Keeper, Hairpin Small

15 62007 1 Decal, Caution

16 62006 1 Decal, Danger (Spinner)

17 61196 1 Key, 1/4" SQ x 1

18 61156 1 Sprocket, 41 B1 3

19 62358 2 Spring, Compression

20 00115-165-00 1 Bag, Hardware

22 20353 6 Flatwasher, 3/8" U.S.S. ZP

23 62331 1 Weld, Handle

24 62305 2 Plate, Baffle

25 04003-806-15 6 Nut, 1/4-20 Ser Flange SS

26 04003-031-06 1 Bolt, 1/4-20 x 1/2" Car SS

27 62333 1 Weld, Handle

PARTS LIST FOR ENGINE DRIVEN SPINNER ASSEMBLY

(Stainless Steel)

Item Part Number Qty. Description

1 00115-148-02 1 Weld, Spinner Frame, S3

2 62057 1 Shaft, Spinner (Long)

3 62146 1 Disc, Poly Spinner 13"

4 04010-016-01 2 Pin, 1/8" x 1" Cotter SS

5 04003-003-29 1 Bolt, 3/8-16 x 2 HH SS

6 04003-807-18 1 Locknut, 3/8-16 Cen Lock SS

7 04003-003-24 4 Bolt, 3/8-16 x 3/4 HH SS

8 62356 2 Bearing, 1" Tapped Base

9 04004-001-14 4 Lockwasher, 3/8" Med Split SS

10 00104-811-01 1 Weld, Baffle, L.H., S3

11 62272 1 Weld, Baffle, R.H., S3

12 62275 1 Weld, Baffle, Rear, S3

13 62313 3 Bar, Link, S3

14 61232 12 Keeper, Hairpin Small

15 62007 1 Decal, Caution

16 62006 1 Decal, Danger (Spinner)

17 61196 1 Key, 1/4" SQ x 1

18 61156 1 Sprocket, 41 B1 3

19 62358 2 Spring, Compression

20 00115-165-00 1 Bag, Hardware

22 04004-002-20 6 Flatwasher, 3/8" U.S.S. SS

23 00115-545-02 1 Weld, Handle, S3

24 00115-127-02 2 Plate, Baffle, S3

25 04003-806-15 6 Nut, 1/4-20 Ser. Flange SS

26 04003-031-06 6 Bolt, 1/4-20 x 1/2" Car SS

27 00115-580-02 1 Weld, Handle L.H., S3 .

29

Page 30

ELECTRIC CONTROLS

PARTS & SCHEMATIC

(Honda)

GREY WIRE

MOUNTING SCREW HERE

AT ASSE MBLY

**

WHITE IS SECURED UNDER MOUNTING

SCREW USED IN STEP 1B

(7) CONDUCTOR CABLE

& PLUG

LINKAGE ROD

6

WHITE WIRE

5

WHT

3

GRD

2

WHT

BLUE

1

BROWN

GREEN

BLACK

RED

RED

TO CENTER TAB ON SOLENOID

YELLOW

TO CLUTCH POWER WIRE

THESE CONNECTIONS TO BE SECURED BEHIND PLATE

RED

BROWN

CONNEC T TO KILL WIR E FROM ENGINE

GREEN

BLACK

ACTUATOR

4

FUSE HOLDER / W FUSE

YELLOW

BLUE

SOLENOID

POSITIVE FROM BATTERY

ON ENGINE

CLUTCH

AFTER INSTALLATION

COIL CABLE AND SECURE TO TOP OF ENGINE NEATLY

WIRING AT THE ENGINE

NOTE: The plug is wired to the cable as indicated on the connector.

(That is; red to red, black to black, etc.)

Item Part No. Qty. Description

1 00115-189-00 Assy, Control Cable

2 62119 1 Plug, 7 Conductor

3 62170 1 Conductor-7, 14 ga. 103"

4 62081 1 Actuator, Linear

5 62324 1 Rod, Linkage

6 62322 1 Plate, Throttle

62323 1 Assy, Throttle Plate

GROUND

(Includes Items 4, 5, & 6)

30

Page 31

ELECTRIC CONTROLS

7

PARTS & SCHEMATIC

(Briggs & Stratton)

GREY WIRE

INSTALL KILL CONNECTION FROM ENGINE HERE

LINKAGE ROD

MOUNTING SCREW HERE

AT AS SEMBLY

WHITE IS SECURED UNDER MOUNTING

**

SCREW USED IN STEP 2B

) CONDUCTOR CABLE

& PLUG

WHITE WIRE

5

GRD

WHT

3

THESE CONNECTIONS TO BE SECURED BEHIND PLATE

6

WHT

BLUE

1

BROWN

GREEN

BLACK

RED

RED

TO CENTER STUD ON SOLENOID

YELLOW

TO CLUTCH POWER WIRE

RED

2

BROWN

CONNECT TO KILL SWITCH TAB

GREEN

BLACK

ACTUATOR

4

FUSE HOLDER / W FUSE

BLUE

RED WIRE FROM ENGINE

YELLOW

POSITIVE FROM BATTERY

SOLENOID

FROM STARTER

CLUTCH

AFTER INSTALLATION

COIL CABLE AND SECURE TO TOP OF ENGINE NEATLY

WIRING AT THE ENGINE

NOTE: The plug is wired to the cable as indicated on the connector.

(That is; red to red, black to black, etc.)

Item Part No. Qty. Description

1 62169 1 Assy, Control Cable

2 62119 1 Plug, 7 Conductor

3 62170 1 Conductor-7, 14 ga. 103"

4 62081 1 Actuator, Linear

5 62181 1 Rod,Linkage

6 62172 1 Plate, Throttle

GROUND

31

Page 32

CONTROL BOX

3

MOUNTING

TABS

16

#

1

ON

CHOKE

HI

START

2

2

OFF

LO

CONV.

4

YELLOW

BLUE

RED

BROWN

BLACK

RED

BLACK

BLACK

RED LENSE

YELLOW

INSERT THIS END THROUGH

ENCLOSURE

YELLOW

BLUE

GREEN

BLACK

WHITE

WHITE

STRAIN RELIEF BUSHING

&

6

14

YELLOW

7

YELLOW

BROWN

YELLOW

BLUE

BROWN

4-,

YELLOW

BLUE

EMPTY

YELLOW

7

BLUE

BLUE

YELLOW

BLUE

BLUE

5

DOUBLE CONNECTORS

BLUE

BLUE

18

BROWN

BROWN

BROWN

BROWN

BROWN

RED

RED

RED

BROWN

BROWN

RED

GREEN

RED

GREEN

GREEN

BLACK

BLACK

BROWN

RED

RED

RED

WHITE

BROWN

WHITE

BROWN

EMPTY

BROWN

RED

RED

WHITE

GREEN

BROWN

BLACK

RED

BLACK

WHITE

%

32

Page 33

PARTS LIST FOR CONTROL PANEL ASSEMBLY

(62267)

Item Part Number Qty. Description

1 62150 1 Enclosure

2 62151 2 Panel, End

3 62152 1 Panel, Middle

4 62153 1 Switch, START/CONV

5 62154 1 Switch, Choke HI/LO

6 62155 1 Switch, ON/OFF

7 62156 3 Conn., double M/FM

8 62157 1 Assembly, Cable

10 62158 1 Enclosure, Back Panel

11 04002-059-04 4 #8 x 1/2 SM SLT HWH SCR

12 62160 1 Strain Relief

14 62161 1 Jump Wire, 14 Ga., BLUE 3"

15 62162 1 Jump Wire, 14 Ga., BROWN 5.5"

16 62163 1 Jump Wire, 14 Ga., RED 4"

17 62164 1 Jump Wire, 14 Ga., BROWN 3"

18 62165 1 Jump Wire, 14 Ga., RED 3"

N/S 62122 1 Socket, 7 Conductor

N/S 62166 1 Bracket Mounting (included in Kit: use optional)

N/S 62149 1 Boot, Cable

NOTE: The conductor socket (not shown ) is wired to the cable as indicated on the socket.

(That is; red to red, black to black, etc.)

33

Page 34

PARTS LIST FOR HYDRAULIC MOTOR

(60324)

Item Part Number Qty. Description

1 20644 4 Screw, 5/16" - 24 x 7/8" Cap

2 1 Seal

3 62404 1 Flange, Mounting (4 Bolt)

4 Seal, O-Ring

5 04101 035 05 1 Race, Bearing

6 Seal, O-Ring

7 04101 035 07 1 Bearing, Thrust Needle

8 04009 002 02 1 Key, 1/4" x 1 Woodruff

9 04101 035 09 1 Shaft, Output

10 04101 035 10 1 Housing

11 Seal, O-Ring n

12 04101 035 12 1 Drive (For 04101 035 00)

04101 037 12 1 Drive (For 04101 037 00)

13 04101 035 13 1 Plate, Spacer

14 20647 4 Screw, 5/16" - 24 x 1-1/2" Cap

20648 4 Screw, 5/16" - 24 x 1-3/4" Cap

15 04101 035 15 1 Gerotor Set (For 04101 035 00)

04101 037 15 1 Gerotor Set (For 04101 037 00)

17 62405 1 Cap, End

18 04101 035 18 7 Washer, Seal

20

21 04101 035 21 1 Repaired Motor (for 04101 035 00)

62406 1 Seal Kit (Char-Lynn)

62359 1 Seal Kit (White)

34

Page 35

PARTS LIST FOR DURST GEAR BOX ASSEMBLY (61178)

Item Part No. Qty. Description

1 62033 1 Housing

2 62034 1 Cover

3 62035 1 Worm Gear - Bronze

4 62036 1 Worm

5 62025 2 Bearing Cone

6 62022 2 Bearing Cone

7 62019 4 Bearing Cup

8 62026 1 Snap Ring Input

9 62027 1 Snap Ring Output

10 62020 4 Snap Ring

11 62028 4 Capscrew, 3/8" x 3/4" H.H.

12 62037 1 Shaft-Input

*13 62032 1 Shaft-Output

14 62029 1 Woodruff Key - Hard

15 62024 1 Woodruff Key - Hard

16 61166 1 Seal Input

17 62030 1 Seal Output

18 62016 1 Plug, 1/8" - 27 NPTF

19 62017 1 Plug, Level, 3/8" - 18 NPTF

20 62236 1 Zerk, 1/4" - 28 NF

21 62031 1 Gasket, Cover (Not Shown)

22 62023 1 Plug, Vent, 1/8" - 27 NPTF

23 62018 2 Cap

24 62021 A/R Shim (Not Shown)

35

Page 36

Optional Hopper Top Screens

STANDARD HOPPER TOP SCREENS

Item Part Number Qty. Description

1 62258 4 Weldment, Screen (57.125" X 34") (10 ft Unit)

62558 & 62556 2 Weldment, Screen (9 ft. Unit)

62256 4 Weldment, Screen (45.125" x 34") (8 ft. Unit)

OPTIONAL HOLD DOWN KIT

(62259)

Item Part Number Qty. Description

1 04068-001-00 2 Binder, Chain

2 00100-234-00 2 Hook, Hold Down

3 20095 2 Bolt, 1/2-13 x 1 1/2 HH GR5 ZP

4 04003-801-11 2 Nut, 1/2-13 Hex ZP

5 20329 2 Lockwasher, 1/2" Med Split ZP

6 20355 2 Flatwasher, 1/2" U.S.S. ZP

PARTS LIST FOR SHIPPING CARTON

(62555)

Item Part Number Qty. Description

1 62350 1 Chain, Roller #41 (53 LINKS)

2 00115-667-00 1 Bag, Hardware

3 00107-662-00 1 Instruction Package (Briggs & Stratton)

4 62334 1 Panel, Control

5 62166 1 Bracket, Mounting

6 62519 1 Cable, 7 Pin (Front Half)

7 04540-013-01 1 Grease, Dielectric

36

Page 37

ONE YEAR WARRANTY

Meyer Products promises to the consumer to

repair or, at Meyer Products' option, to replace

any part of this Meyer Spreader except

expendable parts such as pins, spreader fins,

and other normal wear items, which proves to

be defective in workmanship or material under

normal use for a period of one year from the

date of delivery to the original purchaser.

During this one year, Meyer Products will

provide, to the consumer, through its Distributor / Sub-Distributor network, all parts

necessary to correct such defects free of

charge. Labor costs incurred for any repairs

on this piece of equipment will be the responsibility of the consumer. Faulty parts will be

repaired or replaced by the Distributor / SubDistributor where that particular piece of

equipment was purchased. Any cost incurred

in returning the product to the Distributor / SubDistributor is the responsibility of the consumer.

The gasoline engine used in this product is

covered by its own warranty as provided by

the engine manufacturer. A copy of this

warranty is included with the engine.

EXCLUSIONS

IN NO EVENT SHALL MEYER PRODUCTS

BE LIABLE FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR FOR

DAMAGES RESULTING FROM LACK OF

NECESSARY MAINTENANCE, FROM

MISUSE, ABUSE, ACTS OF GOD, ALTERATION OF THE MEYER PRODUCT, OR

FROM USE OF PARTS OR HYDRAULIC

FLUID NOT SUPPLIED BY MEYER PRODUCTS. USE OF THE MEYER SNOWPLOW

FOR ANY PURPOSE OTHER THAN PLOW-

ING SNOW IS ONE EXAMPLE OF AN ABUSE

AND MISUSE OF THE PRODUCT.

WARRANTY SERVICE

In order to obtain service under this warranty,

the consumer must return this Meyer product

to the Distributor / Sub-Distributor from whom

the product was purchased or to any other

Meyer Products Distributor / Sub-Distributor,

transportation and freight charges prepaid.

Only Meyer Products Distributor / SubDistributors are authorized to perform the

obligations under these warranties. For the

address and telephone number of the

Distributor / Sub-Distributor nearest you,

check the telephone directory or you may write

to the warrantor at the address below.

GENERAL

It is the responsibility of the consumer to

establish the warranty period by verifying the

original delivery date. A bill of sale, cancelled

check or some other appropriate payment

record may be kept for that purpose. It is

recommended, but not required, that the

consumer verify the original delivery date by

immediately returning the attached Warranty

Registration Card. No person is authorized to

change this warranty or to create any warranty

other than that set forth herein. This warranty

gives you specific legal rights and you may

also have other rights which vary from state to

state.

Meyer Products

18513 Euclid Avenue

Cleveland, Ohio 44112

Phone (216) 486-1313

Fax (216) 486-3073

E-Mail info@meyerproducts.com

In order to validate this warranty, please complete this card and mail it.

Name: ______________________________________________________

Address: ______________________________________________________

______________________________________________________

Spreader Model: ________________ Serial No.: ____________________

Installation Date: __________ Purchased From: ____________________

37

Page 38

NAME PLATE INFORMATION

When ordering parts or requesting information or assistance, always include the information listed

below.

The Model Number and Serial Number for the Spreader are shown on the Name Plate.

The space below is provided as a convenient place to record these numbers; just fill in the blanks.

Model No. ___________________________________________________________

Serial No. ___________________________________________________________

Date Purchased ______________________________________________________

Purchased From _____________________________________________________

Phone No. For Service _______________________________________________

PostagePostage

Postage

PostagePostage

RequiredRequired

Required

RequiredRequired

Meyer Products

18513 Euclid Avenue

Cleveland, Ohio 44112-1084

38

Loading...

Loading...