Powell 05PV36ARMX-4, 15PV50ARMX-4, 15PV25ARMX-4, 15PV36ARMX-4, 15PV63ARMX-4 Instruction Bulletin

...

Powered by Safety

®

Instruction Bulletin - 01.4IB.60306

PowlVac® ARG & ARM Series 4

Vacuum Circuit Breakers

5kV & 15kV

1200A, 2000A, & 3000A

25kA, 36kA, 50kA, & 63kA

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

Contact Information

Powell Electrical Systems, Inc.

powellind.com

info@powellind.com

01.4IB.60306

Service Division

PO Box 12818

Houston, Texas 77217-2818

Tel: 713.944.6900

Fax: 713.948.4569

Powered by Safety

®

01.4IB.60306

DANGER

WARNING

CAUTION

CAUTION

NOTICE

Signal Words

As stated in ANSI Z535.4-2007, the signal word is

a word that calls attention to the safety sign and

designates a degree or level of hazard seriousness.

The signal words for product safety signs are

“Danger”, “Warning”, “Caution” and “Notice”.

These words are defined as:

!

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

!

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

Qualified Person

For the purposes of this manual, a qualified

person, as stated in NFPA 70E®, is one who has

skills and knowledge related to the construction

and operation of the electrical equipment and

installations and has received safety training to

recognize and avoid the hazards involved. In

addition to the above qualifications, one must also

be:

1. trained and authorized to energize,

deenergize, clear, ground, and tag circuits

and equipment in accordance with

established safety practices.

2. trained in the proper care and use of

personal protective equipment (PPE)

such as rubber gloves, hard hat, safety

glasses or face shields, flash clothing, etc.,

in accordance with established safety

practices.

3. trained in rendering first aid if necessary.

!

CAUTION, used with the safety alert symbol,

indicates a hazardous situation which, if not

avoided, could result in minor or moderate

injury.

CAUTION, used without the safety alert

symbol, is used to address practices not

related to personal injury.

NOTICE is used to address practices not related

to personal injury.

Powered by Safety

®

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

01.4IB.60306

This page is left blank intentionally.

Powered by Safety

®

01.4IB.60306

Contents

Ch 1 General Information .................................................................................................1

A. Scope ................................................................................................................................................................2

B. purpoSe .............................................................................................................................................................2

c. InStructIon BulletInS AvAIlABle electronIcAlly .....................................................................................................3

D. ASSocIAteD BulletInS ..........................................................................................................................................3

Ch 2 Safety ........................................................................................................................ 4

A. SAfe Work conDItIon .........................................................................................................................................4

B. SAfety GuIDelIneS ...............................................................................................................................................5

c. GenerAl .............................................................................................................................................................6

D. SpecIfIc ..............................................................................................................................................................6

e. X-rAyS ..............................................................................................................................................................7

f. SAfety lABelS .....................................................................................................................................................7

Ch 3 Equipment Description ............................................................................................. 8

A. GenerAl .............................................................................................................................................................8

B. the StoreD enerGy MechAnISM ............................................................................................................................8

1) Mechanical Description .......................................................................................................................................................... 8

2) Electrical Description .............................................................................................................................................................19

c. AutoMAtIc rAckInG MechAnISM ......................................................................................................................... 20

1) Breaker Position Indicator ....................................................................................................................................................20

2) Interlocking ..............................................................................................................................................................................20

3) Blocking Interlock ...................................................................................................................................................................21

4) Racking Mechanism ..............................................................................................................................................................21

D. cIrcuIt BreAker coMpArtMent InterfAceS ........................................................................................................... 22

1) Primary Disconnecting Devices .......................................................................................................................................... 22

2) Secondary Disconnecting Devices ..................................................................................................................................... 22

3) MOC (Mechanism Operated Cell Switch) Actuator ........................................................................................................22

4) TOC (Truck Operated Cell Switch) Actuator .....................................................................................................................22

5) Ground Connection ............................................................................................................................................................... 22

6) Shutter Rollers ......................................................................................................................................................................... 23

7) Anti-Rollout Latch ..................................................................................................................................................................23

e. vAcuuM InterrupterS ....................................................................................................................................... 23

f. vAcuuM Interrupter connectIon ....................................................................................................................... 23

1) 25kA, 36kA, & 50kA Rated Circuit Breakers ......................................................................................................................23

2) 63kA Rated Circuit Breakers ................................................................................................................................................. 23

Powered by Safety

®

i

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

01.4IB.60306

Contents

Ch 4 Installation..............................................................................................................24

A. receIvInG ........................................................................................................................................................ 24

B. hAnDlInG ........................................................................................................................................................ 25

c. StorAGe .......................................................................................................................................................... 25

D. plAcInG the cIrcuIt BreAker Into ServIce ............................................................................................................ 26

1) High Voltage Insulation Integrity ....................................................................................................................................... 26

2) Vacuum Integrity .................................................................................................................................................................... 28

3) Control Voltage Insulation Integrity .................................................................................................................................. 29

4) Mechanical Operation Check .............................................................................................................................................. 29

5) Electrical Operation Check ...................................................................................................................................................30

e. InSertInG the cIrcuIt BreAker Into the cIrcuIt BreAker coMpArtMent .................................................................... 31

1) Prior to Inserting the Circuit Breaker into the Circuit Breaker Compartment ..........................................................32

2) Inserting the Circuit Breaker to the

Test/Disconnected Position ..................................................................................................................................................33

3) Inserting the Circuit Breaker to the Connected Position ...............................................................................................34

4) Emergency Racking In Procedure .......................................................................................................................................34

f. reMovInG the cIrcuIt BreAker froM the cIrcuIt BreAker coMpArtMent ................................................................. 35

1) Removing the Circuit Breaker from the Connected to the Test/Disconnected Position ........................................35

2) Removing the Circuit Breaker from the

Test/Disconnected Position out of the Circuit Breaker Compartment ......................................................................36

3) Emergency Racking Out Procedure ...................................................................................................................................37

Ch 5 Maintenance ........................................................................................................... 38

A. GenerAl DeScrIptIon ........................................................................................................................................ 38

1) Introduction .............................................................................................................................................................................38

2) Inspection and Cleaning ......................................................................................................................................................39

B. MechAnISM AreA ............................................................................................................................................. 39

1) Mechanical Operation .......................................................................................................................................................... 39

2) Lubrication ...............................................................................................................................................................................40

3) Closing Spring Removal ........................................................................................................................................................ 44

4) Slow Closing of Mechanism .................................................................................................................................................45

5) Mechanism Adjustments ......................................................................................................................................................45

6) Electrical Operation ...............................................................................................................................................................50

c. vAcuuM Interrupter AnD contAct AreA ............................................................................................................. 50

1) Vacuum Interrupter and Contact Erosion ........................................................................................................................50

2) Vacuum Integrity .................................................................................................................................................................... 50

3) Mechanical Adjustment of Vacuum Interrupters ...........................................................................................................50

D. optIonAl MAIntenAnce proceDureS ................................................................................................................... 50

1) High Potential Tests ...............................................................................................................................................................50

2) Timing .......................................................................................................................................................................................51

3) Primary Resistance Check ....................................................................................................................................................51

ii

Powered by Safety

®

01.4IB.60306

Contents

Ch 6 Recommended Renewal Parts and Replacement Procedures ...............................52

A. orDerInG InStructIonS ..................................................................................................................................... 52

B. recoMMenDeD reneWAl pArtS ........................................................................................................................... 52

c. replAceMent proceDureS .................................................................................................................................. 52

1) Vacuum Interrupter Assembly ............................................................................................................................................. 53

2) Sliding Contact Finger Assembly (for circuit breaker rated up to 50kA only) ..........................................................53

3) Closing Coil Assembly ...........................................................................................................................................................53

4) Primary Shunt Trip Coil Assembly ......................................................................................................................................53

5) Secondary Shunt Trip Coil Assembly .................................................................................................................................53

6) Undervoltage Device Assembly (UV) ................................................................................................................................. 53

7) Charging Motor Assembly ...................................................................................................................................................53

8) Anti-Pump Relay Assembly ..................................................................................................................................................54

9) Latch Check Switch ................................................................................................................................................................ 54

10) Motor Cutoff Switch Assembly ............................................................................................................................................54

11) Auxiliary Switch ......................................................................................................................................................................54

12) Ground Connection Assembly ............................................................................................................................................54

13) Racking Motor .........................................................................................................................................................................54

Powered by Safety

®

iii

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

01.4IB.60306

Figures

Figure 1 PowlVac® ARG & ARM Series 4 Circuit Breaker Front View with Cover ..........9

Figure 2 PowlVac® ARG & ARM Series 4 Circuit Breaker Front View without Cover ..10

Figure 3 PowlVac ARG & ARM Series 4 Circuit Breaker Rear View .............................11

Figure 4 Primary Current Closeups ............................................................................12

Figure 5 Cam and Fundamental Linkage Positions ...................................................14

Figure 6 Mechanism and Trip Linkages ...................................................................... 15

Figure 7 Operation Sequence .....................................................................................17

Figure 8 Typical Control Scheme ................................................................................18

Figure 9 Circuit Breaker in Shipping Carton ...............................................................24

Figure 10 Circuit Breaker with Shipping Bracket .........................................................24

Figure 11 Circuit Breaker on Crane ...............................................................................25

Figure 12 Secondary Disconnect Override Device ....................................................... 30

Figure 13 Removing Circuit Breaker from Compartment ............................................ 36

Figure 14 Lubrication (50kA shown) ............................................................................42

Figure 15 Lubrication (50kA shown) (cont.) .................................................................43

Figure 16 Main Closing Spring Assembly Compressed for Removal ...........................44

Figure 17 Main Closing Spring Assembly Installed .....................................................44

Figure 18 Primary Trip Prop Adjustment ......................................................................46

Figure 19 Feeler Gauge .................................................................................................47

Figure 20 Latch Check Switch Adjustment ...................................................................48

Figure 21 Primary Current Path ....................................................................................56

Figure 22 Control Devices ............................................................................................. 58

iv

Powered by Safety

®

01.4IB.60306

Tables

Table A Field Dielectric Test Values ..................................................................................27

Table B Lubrication ..........................................................................................................41

Table C Timing .................................................................................................................. 51

Table D Primary Resistance .............................................................................................51

Table E Primary Current Path ..........................................................................................55

Table F Control Devices ....................................................................................................57

Table G Miscellaneous Parts ............................................................................................ 59

Table H Miscellaneous Parts (cont.) .................................................................................60

Powered by Safety

®

v

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

01.4IB.60306

This page is left blank intentionally.

Powered by Safety

®

01.4IB.60306

WARNING

WARNING

NOTICE

NOTICE

Ch 1 General Information

!

The equipment described in this document may contain high voltages and currents which can

cause death or serious injury.

The equipment is designed for use, installation, and maintenance by knowledgeable users of such

equipment having experience and training in the field of high voltage electricity. This document and all

other documentation shall be fully read, understood, and all warnings and cautions shall be abided by. If

there are any discrepancies or questions, the user shall contact Powell immediately at 1.800.480.7273.

!

Prior to adjustments, servicing, maintenance, or any act requiring the operator to make physical

contact with the equipment, the power source must be disconnected and the equipment grounded.

Failure to do so may result in death or serious injury.

The information in this instruction bulletin is not intended to explain all details or variations of the

Powell equipment, nor to provide for every possible contingency or hazard to be met in connection

with installation, testing, operation, and maintenance of the equipment. For additional

information and instructions for particular problems, which are not presented sufficiently for the

user’s purposes, contact Powell at 1.800.480.7273.

Powell reserves the right to discontinue and to change specifications at any time without incurring

any obligation to incorporate new features in products previously sold.

General Information

Powered by Safety

®

1

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

WARNING

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

01.4IB.60306

A. Scope

The information in this instruction bulletin

describes the following PowlVac® ARG

(Automatic Racking Generator) & ARM

(Automatic Racking Mechanism) Series 4

vacuum circuit breakers:

• 05PV36ARMX-4 1200, 2000, & 3000A

• 05PV36ARMM-4 1200, 2000, & 3000A

• 05PV50ARMX- 1200, 2000, & 3000A

• 05PV50ARMM-4 1200, 2000, & 3000A

• 05PV63ARMX-4 1200, 2000, & 3000A

• 05PV63ARMM-4 1200, 2000, & 3000A

• 15PV25ARMX-4 1200, 2000, & 3000A

• 15PV25ARMM-4 1200, 2000, & 3000A

• 15PV36ARMX-4 1200, 2000, & 3000A

• 15PV36ARMM-4 1200, 2000, & 3000A

• 15PV50ARMX-4 1200, 2000, & 3000A

• 15PV50ARMM-4 1200, 2000, & 3000A

B. purpoSe

The information in this instruction bulletin

is intended to provide details required to

properly install, operate, and maintain the

PowlVac ARG & ARM Series 4 vacuum circuit

breakers described in Ch 1 General Information,

A. Scope.

This instruction bulletin provides:

1. Safety guidelines

2. General descriptions of the operation and

maintenance of the PowlVac ARG & ARM

Series 4 vacuum circuit breakers

3. Instructions for installation and placing the

circuit breaker into service

4. Instructions for part replacement

5. Information for ordering renewal parts

6. Procedure for critical adjustments

7. Illustrations, photographs, and description

of the circuit breakers

• 15PV63ARMX-4 1200, 2000, & 3000A

• 15PV63ARMM-4 1200, 2000, & 3000A

• 15PV63ARGX-4 1200, 2000, & 3000A

• 15PV63ARGM-4 1200, 2000, & 3000A

The illustrations contained in this document

may not represent the exact construction

details of the PowlVac ARG & ARM Series 4

vacuum circuit breakers. The illustrations

in this document are provided as general

information to aid in showing component

locations.

All illustrations and photos are shown using

deenergized equipment.

!

Follow the appropriate safety precautions

while handling any of the equipment. Failure

to do so may result in death or serious injury.

To the extent required, the products described

herein meet the applicable ANSI, IEEE, and

NEMA Standards; however, no such assurance

is given with respect to local codes and

ordinances which may vary greatly.

2

Powered by Safety

®

General Information

01.4IB.60306

NOTICE

c. InStructIon BulletInS AvAIlABle electronIcAlly

Changes to the instruction bulletin may be

implemented at any time and without notice.

Go to powellind.com to ensure use of the current

instruction bulletin for Powell equipment.

For more information visit powellind.com.

To contact the Powell Service Division call

1.800.480.7273 or 713.944.6900, or email

info@powellservice.com.

For specific questions or comments pertaining

to this instruction bulletin email

documents@powellind.com with the IB number

in the subject line.

D. ASSocIAteD BulletInS

• 01.4IB.51000C PowlVac® Metal-Clad

Switchgear 5kV & 15kV

• 01.4IB.51200C PowlVac-AR® Arc Resistant

Switchgear 5kV & 15kV

General Information

Powered by Safety

®

3

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

01.4IB.60306

Ch 2 Safety

A. SAfe Work conDItIon

The information in Section A is quoted from

NFPA 70E 2018 - Article 120, 120.5 Establishing an

Electrically Safe Work Condition.

120.5 Process or Establishing and Verifying an

Electrically Safe Work Condition. Establishing

and verifying an electrically safe condition shall

include all of the following steps, which shall be

performed in the order presented, if feasible:

1. Determine all possible sources of electrical

supply to the specific equipment. Check

applicable up-to-date drawings, diagrams,

and identification tags.

2. After properly interrupting the load current,

open the disconnecting device(s) for each

source.

N Exception No. 1: An adequately rated

permanently mounted test device shall be

permitted to be used to verify the absence of

voltage of the conductors or circuit parts at

the work location, provided it meets the all

following requirements: (1) It is permanently

mounted and installed in accordance with

the manufacturer’s instructions and tests

the conductors and circuit parts at the point

of work; (2) It is listed and labeled for the

purpose of verifying the absence of voltage;

(3) It tests each phase conductor or circuit

part both phase-to-phase and phase-toground; (4) The test device is verified as

operating satisfactorily on any known voltage

source before and after verifying the absence

of voltage.

N Exception No. 2: On electrical systems over

1000 volts, noncontact test instruments shall

be permitted to be used to test each phase

conductor.

3. Wherever possible, visually verify that all

blades of the disconnecting devices are

fully open or that drawout-type circuit

breakers are withdrawn to the fully

disconnected position.

4. Release stored electrical energy.

5. Release or block stored mechanical energy.

6. Apply lockout/tagout devices in accordance

with a documented and established

procedure.

7. Use an adequately rated portable test

instrument to test each phase conductor or

circuit part to verify it is de-energized. Test

each phase conductor or circuit part both

phase-to-phase and phase-to-ground.

Before and after each test, determine

that the test instrument is operating

satisfactorily through verification on any

known voltage source.

Informational Note No. 1: See UL 61010-1,

Safety Requirements for Electrical Equipment

for Measurement, Control, and Laboratory

Use, Part 1: General Requirements, for

rating, overvoltage category, and design

requirements for voltage measurement

and test instruments intended for use on

electrical system 1000 volts and below.

N Informational Note No. 2: For additional

information on rating and design

requirements for voltage detectors, refer

to IEC 61243-1, Live Working - Voltage

Detectors - Part 1: Capacitive type to be used

for voltages exceeding 1kV a.c., or IEC 61243-

2, Live Working - Voltage Detectors - Part 2:

Resistive type to be used for voltages of 1kV

to 36kV a.c., or IEC 61243-3, Live Working Voltage Detectors - Part 3: Two-pole voltage

type.

4

Powered by Safety

®

Safety

01.4IB.60306

8. Where the possibility of induced voltages

or stored electrical energy exists, ground

the phase conductors or circuit parts

before touching them. Where it could be

reasonably anticipated that the conductors

or circuit parts being de-energized

could contact other exposed energized

conductors or circuit parts, apply temporary

protective grounding equipment in

accordance with the following:

a.. Placement. Temporary protective

grounding equipment shall be placed

at such locations and arranged in such

a manner as to prevent each employee

from being exposed to a shock hazard

(i.e., hazardous differences in electrical

potential). The location, sizing, and

application of temporary protective

grounding equipment shall be

identified as part of the employer’s job

planning.

b. Capacity. Temporary protective

grounding equipment shall be capable

of conducting the maximum fault

current that could flow at the point of

grounding for the time necessary to

clear the fault.

N Informational Note: ATSM F855, Standard

Specification for Temporary Protective

Grounds to be Used on De-energized Electric

Power Lines and Equipment, is an example

of a standard that contains information on

capacity of temporary protective grounding

equipment.

B. SAfety GuIDelIneS

Study this instruction bulletin and all other

associated documentation before uncrating

the circuit breakers.

Each user has the responsibility to instruct and

supervise all personnel associated with usage,

installation, operation, and maintenance of this

equipment on all safety procedures.

Furthermore, each user has the responsibility

of establishing a safety program for each type

of equipment encountered.

The circuit breakers described in this

instruction bulletin are operated by a

high-energy, high-speed mechanism that

is interlocked to provide specific operating

sequences. It is mandatory that the following

rules be observed to ensure the safety of

personnel associated with usage, installation,

operation, and maintenance of this circuit

breaker.

The safety rules in this instruction bulletin are

not intended to be a complete safety program.

The rules are intended to cover only some of the

important aspects of personnel safety related

to PowlVac® ARG & ARM Series 4 vacuum circuit

breakers.

Safety

c. Impedance. Temporary protective

grounding equipment and connections

shall have an impedance low enough

to cause immediate operation

of protective devices in case of

unintentional energizing of the electric

conductors or circuit parts.

Powered by Safety

®

5

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

01.4IB.60306

c. GenerAl

1. Only supervised and qualified personnel

trained in the usage, installation, operation,

and maintenance of a circuit breaker shall

be allowed to work on this equipment. It is

mandatory that the appropriate instruction

bulletins, supplements, and service

advisories be studied, understood, and

followed.

2. Maintenance programs must be consistent

with both customer experience and

manufacturer’s recommendations,

including service advisories and instruction

bulletin(s).

A well planned and executed

routine maintenance program is essential

for circuit breaker’s reliability and safety.

3. Service conditions and circuit breaker

applications shall also be considered in the

development of safety programs. Variables

include ambient temperature; humidity;

actual continuous current; thermal cycling;

number of operations; interrupting duty;

and any adverse local conditions including

excessive dust, ash, corrosive atmosphere,

vermin and insect infestations.

D. SpecIfIc

1. DO NOT WORK ON AN ENERGIZED

CIRCUIT BREAKER. If work must be

performed on a circuit breaker, remove it

from service and remove it from the

metal-clad switchgear.

2. DO NOT WORK ON A CIRCUIT BREAKER

WITH THE CONTROL CIRCUIT ENERGIZED.

3. EXTREME CARE MUST BE EXERCISED

TO KEEP ALL PERSONNEL, TOOLS, AND

OTHER OBJECTS CLEAR OF MECHANISMS

WHICH ARE TO BE OPERATED,

DISCHARGED, OR RELEASED.

These circuit breakers utilize stored energy

mechanisms. These mechanisms must be

serviced only by skilled and knowledgeable

personnel capable of releasing each spring

load in a controlled manner. Detailed

information regarding these mechanisms is

found in this instruction bulletin.

4. DO NOT ATTEMPT TO CLOSE THE CIRCUIT

BREAKER MANUALLY ON AN ENERGIZED

CIRCUIT.

5. DO NOT USE AN OPEN CIRCUIT BREAKER

AS THE SOLE MEANS OF ISOLATING A

HIGH VOLTAGE CIRCUIT. For complete

isolation, the circuit breaker shall be in

the disconnected position or shall be

withdrawn completely.

6. ALL COMPONENTS SHALL BE

DISCONNECTED BY MEANS OF A VISIBLE

BREAK AND SECURELY GROUNDED FOR

SAFETY OF PERSONNEL PERFORMING

MAINTENANCE OPERATIONS ON THE

CIRCUIT BREAKERS.

6

Powered by Safety

®

Safety

01.4IB.60306

NOTICE

7. Interlocks are provided to ensure the

proper operating sequences of the circuit

breakers and for the safety of the user. If for

any reason an interlock does not function

as described, do not make any adjustments,

modification, or deform the parts. DO

NOT FORCE THE PARTS INTO POSITION.

CONTACT POWELL FOR INSTRUCTIONS.

e. X-rAyS

When high voltage is applied across the

contacts of a vacuum interrupter, there is the

possibility of generation of X-rays. The intensity

of the X-radiation is dependent on the peak

voltage and the contact gap. At the normal

operating voltage for this type of equipment,

the radiation levels are negligible. At the

voltages specified for testing, test personnel

shall be in front of the circuit breaker such that

the two layers of steel used in the frame and

front cover construction are between the test

personnel and the vacuum interrupters, and

that the test personnel be no closer than one

meter (3’) from the front of the circuit breaker.

THE CIRCUIT BREAKER SHALL BE EITHER

FULLY OPEN, OR FULLY CLOSED WHEN

MAKING HIGH POTENTIAL TESTS. DO NOT

TEST WITH CONTACTS PARTIALLY OPEN.

f. SAfety lABelS

The equipment described in this document

has DANGER, WARNING, CAUTION, and

instruction labels attached to various locations.

All equipment DANGER, WARNING, CAUTION,

and instruction labels shall be observed when

the circuit breaker is handled, operated, or

maintained.

Warning and Caution labels are located in

various places. Do not remove or deface any

of these warning/caution labels.

Safety

Powered by Safety

®

7

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

NOTICE

CAUTION

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

01.4IB.60306

Ch 3 Equipment Description

A. GenerAl

Powell is committed to continuous product

improvement.

It is possible that improvements occurred

between revisions to this document and

therefore, may not be described in these

instructions. If the equipment does not

resemble the photographs and descriptions

contained herein, contact Powell before

attempting to perform any actions.

PowlVac® circuit breakers use sealed vacuum

interrupters (Figure 3, f) to control the primary

circuit. The primary connections to the

associated metal-clad switchgear are made

by parallel copper busbars terminating

in multiple contact fingers of the primary

disconnecting devices (Figure 3, c & g). The

primary disconnecting devices, busbars, and

vacuum interrupter assemblies are supported

by insulators (Figure 3, b) specifically designed

for the application.

The primary current path side of the circuit

breaker is considered the rear of the circuit

breaker, while the side with the cover

containing the various indicators and manual

operators is considered the front of the

circuit breaker. By removing the front cover,

the operating mechanisms of the circuit

breaker are exposed. The stored energy

mechanism assembly provides motion to each

of the vacuum interrupters, moving contact

assemblies through operating pushrods

(Figure 4, h & p). In the same metal enclosed

compartment as the stored energy mechanism

is the circuit breaker racking mechanism and

interlocks which control the movement of the

circuit breaker between the test/disconnected

and connected positions. The racking

mechanism provides the motion to

engage/disengage the primary disconnecting

devices and to open/close the shutters in

metal-clad switchgear.

B. the StoreD enerGy MechAnISM

1) Mechanical Description

The stored energy mechanism is located in

the front of the circuit breaker behind the

front cover. The front cover is held in place

by ten (10) cover bolts (Figure 1, a) that

may be removed, allowing access to the

stored energy mechanism and its interlocks,

auxiliary switches, racking mechanism, and

other control devices.

!

Prior to removing the front cover, ensure the

circuit breaker is in the OPEN position and

the main closing spring is fully discharged.

Failure to do so may result in injury.

On the escutcheon of the stored energy

mechanism, there are two (2) indicators

that show the various states of operation

of the mechanism and two (2) manual

operators that will open/close the stored

energy mechanism. The circuit breaker

nameplate (Figure 1, h) is also located on

the mechanism escutcheon. If for any

reason the escutcheon is removed from the

circuit breaker, it shall be verified that the

serial number contained on the nameplate

matches the engraved serial number plate

(Figure 3, q) permanently affixed to the

rear of the circuit breaker frame prior to

installing the escutcheon.

8

Powered by Safety

®

Equipment Description

01.4IB.60306

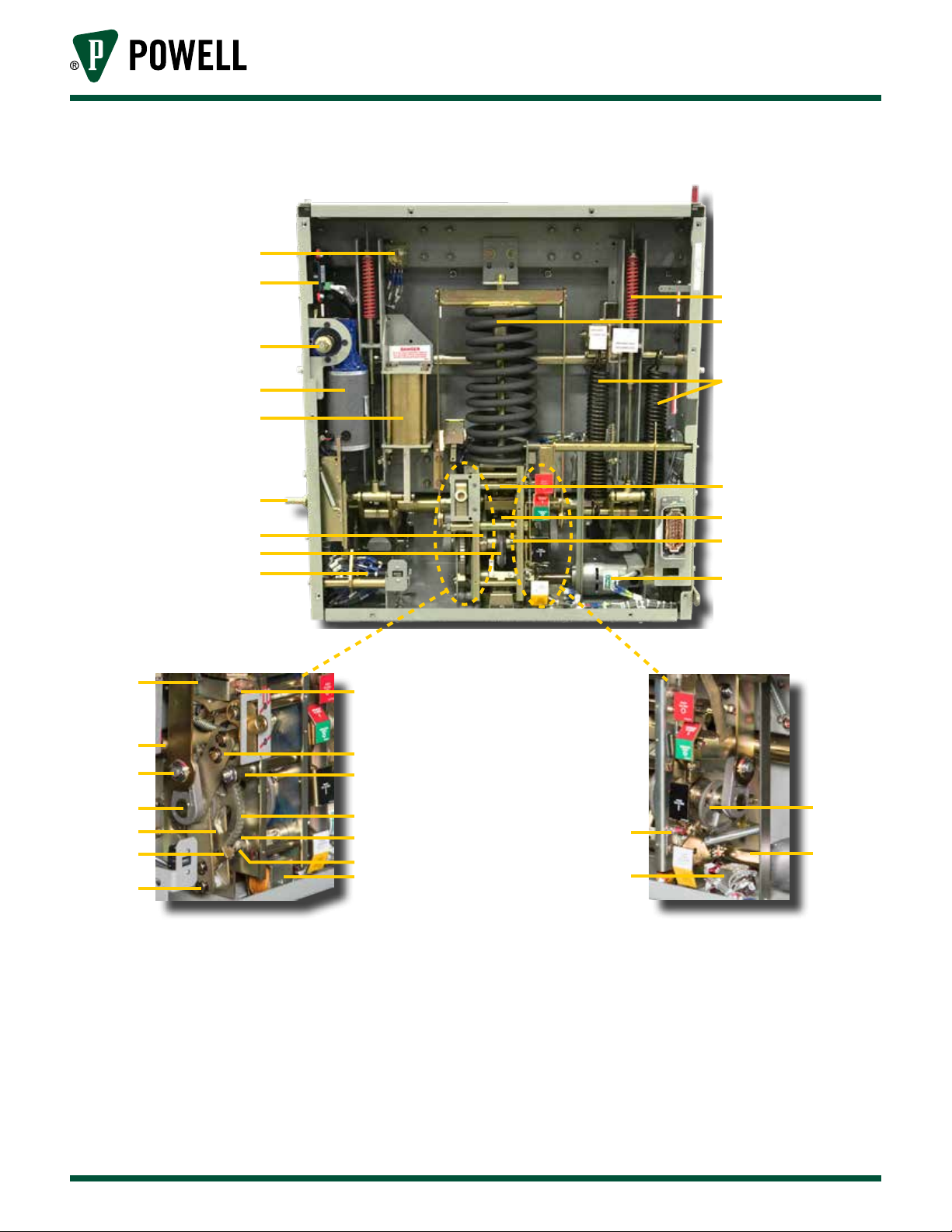

Figure 1 PowlVac® ARG & ARM Series 4 Circuit Breaker Front View with Cover

b

f

g

i

a

c

de

h

k

l

n

p

r

a. Cover Bolts

b. Circuit Breaker Monitor IR Window

c. Front Cover

d. Breaker Position Indicator

e. Emergency Racking Drive Shaft Shutter

f. Padlock Seal

g. Padlock Provision - Movable Arm

h. Nameplate

I. Interlock Window Assembly

j. Manual Trip Operator

j

m

o

q

s

k. Manual Charging Crank

l. MOC Actuator

m. Handle

n. Circuit Breaker Open/Closed Indicator

o. Secondary Disconnect Receptacle

p. Manual Close Operator

q. Secondary Disconnect Latch

r. Operation Counter

s. Spring Charge Indicator

Equipment Description

Powered by Safety

®

9

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

Figure 2 PowlVac® ARG & ARM Series 4 Circuit Breaker Front View without Cover

a

01.4IB.60306

b

e

g

h

j

l

n

o

q

r

c

d

f

i

k

m

p

s

u

w

y

ab

ad

a. Anti-Pump Relay

b. Circuit Breaker Monitor™

(Optional)

c. Opening Spring

d. Main Closing Spring

e. Emergency Racking Drive Shaft

f. Anti-Bellows Springs (63kA only)

g. Racking Motor

h. Shock Absorber (Dashpot)

i. Secondary Trip Prop

j. MOC Actuator

k. Main Cam Roller

10

t

v

x

z

aa

ac

l. Reset Spring

m. Camshaft

n. Main Closing Cam

o. Auxiliary Switch

p. Charging Motor

q. Latch Check Switch

r. Secondary Trip Prop Adjusting Screw

s. Jackshaft

t. Holding Pawl Support Arm

u. Crank Pin

v. Holding Pawl Adjusting Eccentric

Powered by Safety

®

ae

af

ag

ah

w. Crank Arm

x. Ratchet Wheel

y. Pawl Lift Drive Plate

z. Close Latch Arm

aa. Close Latch Shaft

ab. Drive Pawl

ac. Closing Coil

ad. Pawl Support Arm

ae. Motor Cutoff Cam

af. Close Bar Adjusting Screw

ag. Charging Motor Drive Shaft

ah. Motor Cutoff Switch

Equipment Description

01.4IB.60306

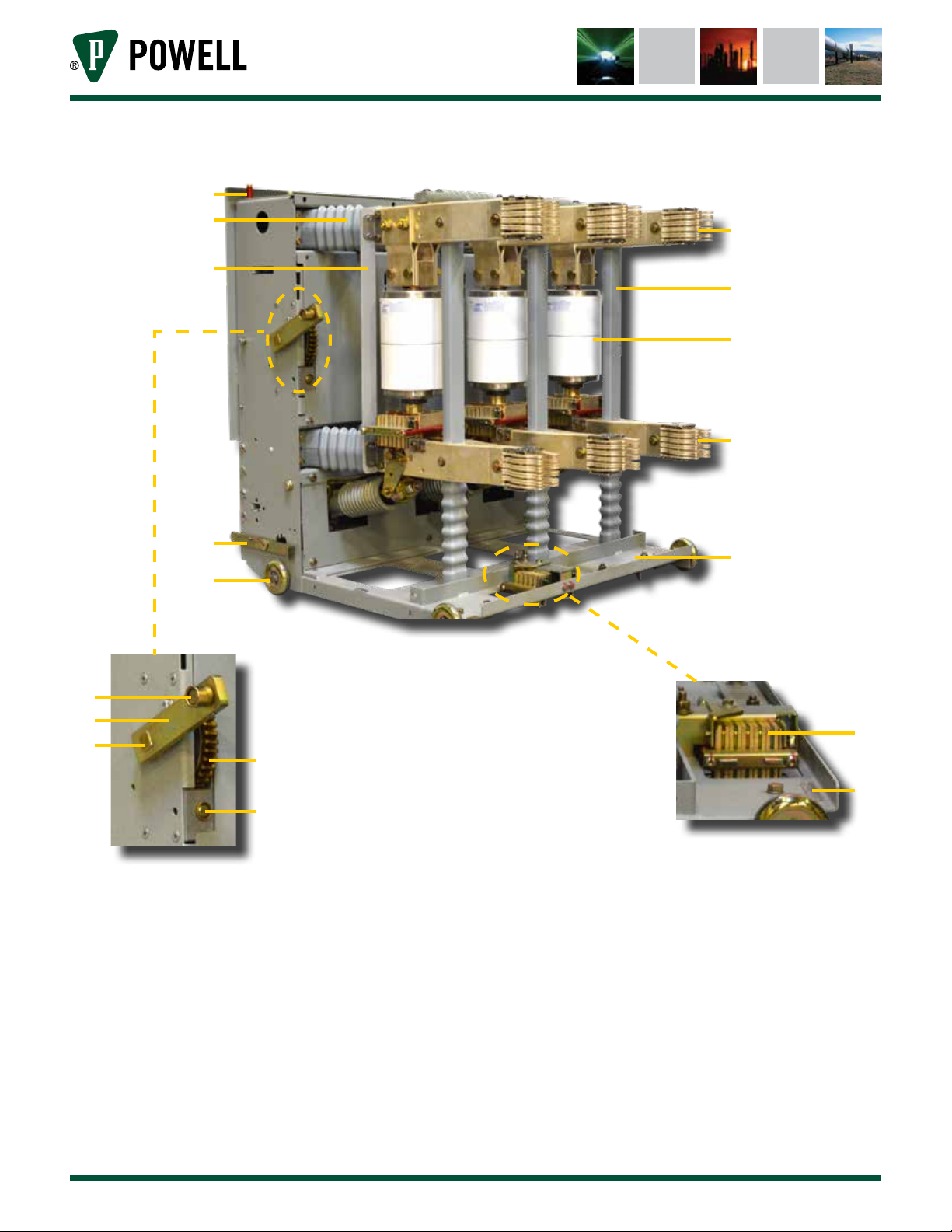

Figure 3 PowlVac ARG & ARM Series 4 Circuit Breaker Rear View

a

b

d

c

e

f

g

m

h

j

k

l

n

o

a. TOC Actuator

b. Main Insulator (Wishbone)

c. Upper Primary Disconnecting Device

d. Support Strut

e. Insulating Pole Support

f. Vacuum Interrupter

g. Lower Primary Disconnecting Device

h. Anti-Rollout Latch

J. Wheel

k. Crank Arm Roller

l. Racking Crank Arm

m. Racking Shaft

n. Worm Gear

o. Racking Drive Shaft

p. Ground Connection

q. Serial Number Plate

i

p

q

i. Frame

Equipment Description

Powered by Safety

®

11

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

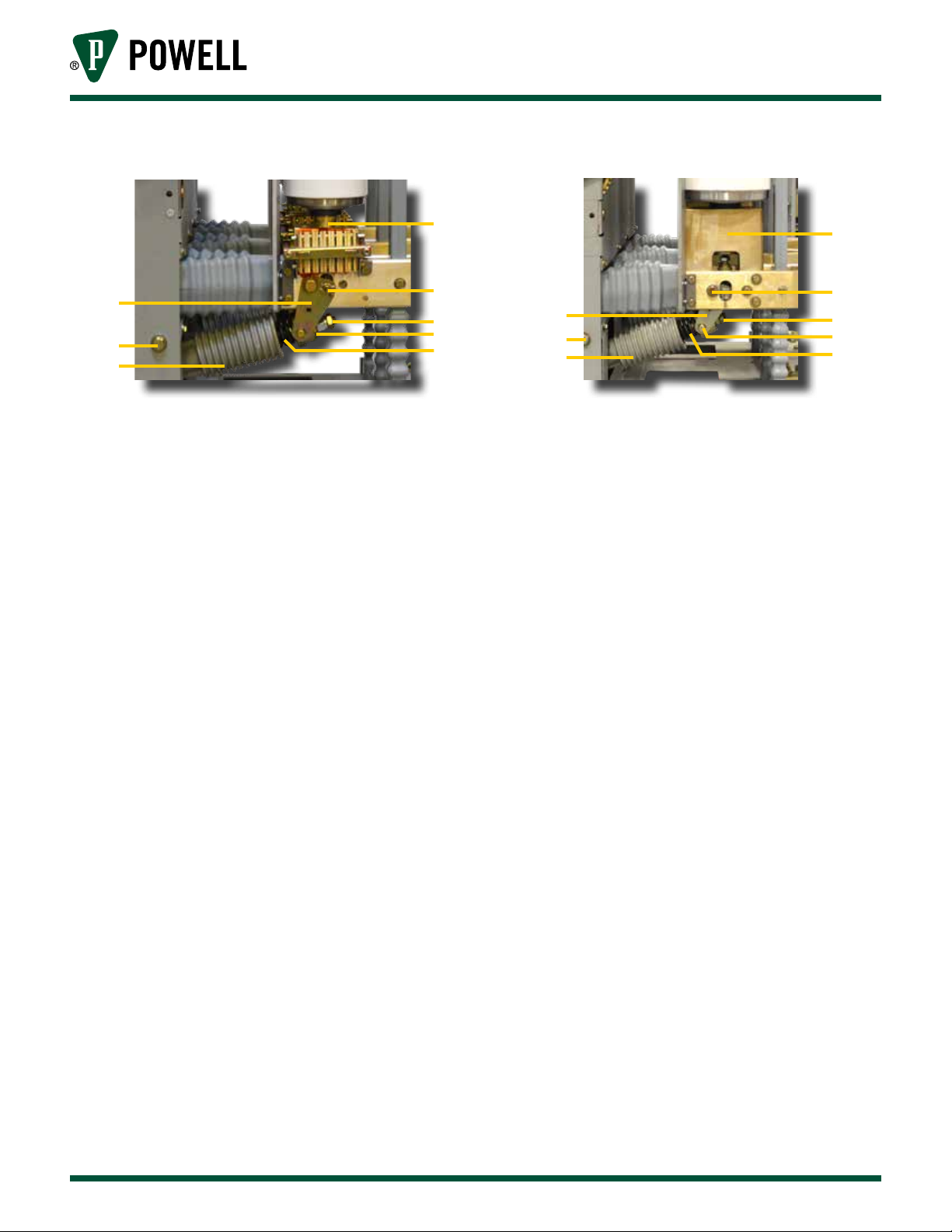

Figure 4 Primary Current Closeups

01.4IB.60306

c

f

h

Up to 50kA

a. Lower Vacuum Interrupter Casting

b. Operating Pin

c. Bell Crank

d. Lock Nut

e. Spring Yoke

f. Jackshaft Pin

g. Contact Loading Spring

h. Operating Pushrod

a

b

d

e

g

k

o

p

i

j

l

m

n

63kA Only

i. Lower Vacuum Interrupter Casting

j. Operating Pin

k. Bell Crank

l. Lock Nut

m. Spring Yoke

n. Contact Loading Spring

o. Jackshaft Pin

p. Operating Pushrod

12

Powered by Safety

®

Equipment Description

Loading...

Loading...