Page 1

IM

■ay

(Whhy^ ' -y

WkMji , .

xcr _ K

Always Wear Eye Protection. During Operation.

1

I 'C.

, WARNING:

'•i’'? lead the Operator’s

' ai'.d toliow all Warnings

' i / t if.'■ructions. Failure to

f i,!i in serious iiyury.

Page 2

CAUTiOM: ALWAYS DISCONMECTIPIR^ FLUt , A L A^'A' »‘l'‘LE'*Y!FIEWHf:RElTCAN-

‘TWIilTACT SPARK PLUG TO PrEVtNTAC&‘C-WALL rABAL‘ ^ «HER SETTINGUP,

TRANSPOeilNG, ADJUSTING OR MAKING

IMPORTA..^'T

:.An : ^ "3 liFULiRE OPERATOR PRESENCE CO ' ^nS'»«' iWiU: v. OY : “-^S|-ljRV YOUR

UN'? '-OUP-4 ‘ 1» YTKSUC HCONTROtS, DO NOT ATTEMPT TO CE« n>L f U. ‘.‘ION OF >’Ht OPERATOR

RKS .V K. r UNDER ANY CiRC'JMSTANCES.

I riMiNii'iu;

• Know the controls and how to stop quickly. Read this owner’s

manual and instructions furnished with attachments.

• Do not allow children to operate the machine. Do not allow

adults to operate it without proper instruction,

• Do not carry passengers. Do not mow when children and oth

ers are around.

• Do not attempt to operate your vehicle or mower when not in

the driver’s seat.

• Always get on or off your vehicle from the operator’s left hand

side.

• The vehicle and attachments should be stopped and inspected

for damage after striking a foreign object, and the damage

should be repaired before restarting and operating the equip

ment.

PREPARATION:

. 'V': V' v.f I i i,r I 1 If, r,,i //.'a, ^.j

'■'•ih f|., ill ' ''. ,.d <,it:

'-Y .t' it 'loi'-i i t r.t'j i ( * wra-h "-iicrYe

picked up and thrown.

• Disengage a

the engine.

• Handle oaso

aujirr .

iment clut(

with care - it i

,ifig p

jntaif

jnn

ig or hot

> cool for s

""e dangerous. Do not run the enc

I 'f f V. f, H r It*'-'

3qiipped, or the dellecior shield

jreyes no mind on your vehicle, mowe?

. let other ioterests distract you.

r to attachmc3ots arid stop the ^

i-tc-rs .position.

h( Yw "■p'ra to 'tart

)hr- f m -■jV

Î Tuei lanH

^ r ’ if' i ^ /

es after running

3flled aa

3ine.

,6

il-iinc

-'JCO T..

' - ^ A r n

;:Yf,

,ge - exhaust

i indoors.

' m 1 C‘

Dlac6.

■n

/ bSîOre

id disccn-nct

Uf . ii O'/tn V- ' I -ppe V • ; f ¿*T' litr-^’Ctioriis ■jusure.or

at a speed which couid cause a skid.

Stay alert for holes in the terrain and other hidden hazards.

Keep away from drop-offs.

Do not drive too close to creeks, ditches, and public highways.

Exercise special care when mowing around fixed objects in or

der to prevent the blades from striking them. Never deliberately

run vehicle or mower into or over any foreign objects.

Never shift geans until vehicle comes to a stop.

Never place hands or feet under the mower, in discharge

chute, or near any moving parts while vehicle or mower is run

ning. Alvrays keep clear of discharge chute.

Use care when pulling loads or using heavy equipment.

- Use only approved drawbar hitch points.

- Limit loads to those you can safely control.

- Do not turn sharply. Use care when backing,

- Use counterweight or wheel weights when suggested in

owner’s manual.

Watch out for traffic when crossing or near roadways.

When using any attachments, never direct discharge of mate

rial toward bystanders nor allow anyone near the vehicle while

in operation.

Except for adjustments, do not operate engine if air cleaner or

cover directly over carburetor air intake is removed. Removal of

such part could create a fire hazard.

Do not change the engine governor settings or overspeed the

^hen usir

dam

Mow only in dayiiqht or in good ai

- Shut the enc

Check the blade mounting bolts fc

gueot inisrvc

® Diserigags powi

i“0y0f30 untess c

fy| observation c

® lC0fto ffiP vehicle

arid keep safety devices in piacB and

line off when unclogc

ir to mower before be

iDsoiutBiv necessary

)i tiie entire area behinci the mower.

land attachments inc

or injury may result,

with mower, proceed as follows:

tificial light.

ling chute.

^pr 1 riqhtoessatfre-

’ u Do no« mow in

n on.v alter care-

i , I tiling r nclition,

working.

STORAGE

lipment

Mow

;tOp or

3inc

lit suoden

^hirig hot muf

fling or nc^ in

vehicle uriaO

uiÆ.-i -

If or downhilL

tHsn 15^1

to prevent

:auiion when ensure compliarice with the original

® Never store the eciuipment v^ith gasc isitie a

buiidino where ft

the enoine to cO'

^ To reduce fire ricizarci, keep the engini ives, or

excessive greas

3 ift V:.:-

• Do not operate’j

Î6ITU DsniEged r

hszEf^, Inspect ipenodicallv .and ropis

® Under normal us

to deterioratton iand wear, it should b 1 - d ntly for

bag replace mcîn

menclations or a

■■

ifnes may reach an o|

of Defore storing iri aiiy enCiOsure.

e. Do not Clean proc is run-

vftliout a mii'fflsrs or

nuffiers or spark arre e a fire

>ao6 the Grass C3tc-h€

t. Reoiacement bag ;ked to

Decifications,

' (. Allow

ist sys-

ice if necessary.

subject

recom-

]

Page 3

)NGRATULATfONS on your purchase of a new tractor. It

s been designed, engineered and manufactured to give you

; best possible dependability and performance.

lould you experience any problem you cannot easily rem-

y, please contact your nearest Authorized Service Facility,

ey have competent, well-trained technicians and the proper

)ls to repair this unit.

Base read and retain this manual. The instructions will en-

le you to assemble, operate, and maintain your unit prop-

y. Always observe the “SAFETY RULES”.

MODEL

NUMBER

SERIAL

NUMBER

DATE OFPUROHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A PLATE UNDER THE SEAT.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

XC1182B

__________________________

USTOMER RESPONSIBILITIES

Read and observe the safety rules.

Follow a regular schedule in maintaining, caring for and us

ing your unit.

Follow the instructions under “Maintenance” and "Storage"

sections of this owner’s manual.

PRODUCT SPECIFICATIONS

HORSEPOWER;

GASOLINE CAPACITY:

OIL:

4.0 PINTS (w/filter change)

3.5 PINTS (w/o filter change)

SPARK PLUG (GAP.025 IN.):

GROUND SPEED:

TIRE PRESSURE:

CHARGING SYSTEM;

BLADE BOLT TORQUE:

WARNING: This unit is equipped with an internal combustion

engine and should not be used on or near any unimproved for

est-covered, brush-covered or grass-covered land unless

the engine’s exhaust system is equipped with a spark arrester

meeting applicable local or state laws (if any) . If a spark arres

ter is used, it should be maintained in effective working order

by the operator.

18.0

3.5 GALLONS

UNLEADED REGULAR

SAE 30 (or 10W-30)

WINTER: SAE 5W-30

CHAMPION RV15YC

1st

2nd

3rd

.071 MPH

1.05 MPH

1.22 MPH

4th 3.24 MPH

5th 4.12 MPH

6th

Rev.

FRONT: 14 PSI

REAR: 10 PSI

15 AMPS @3600 RPM

30-35 FT. LBS.

5.29 MPH

1.62 MPH

Page 4

^iCATIONS ................. 3

ONSiBiLiTIES ............... 3

.......................... 5

....................... 7-10

...................... 10-14

INDEX

Adjustments;

Brake ......................................

Carburetor ................ 24

Mower:

Front-To-Back ......... 20

Side-To-Side .......... 19

Throttle Control Cable ....... 24

Air Filter, Engine ............... 18

Air Screen, Engine ............. 18

Assembly ................ 7—10

B

Battery;

Charging .....................................

Cleaning ................. 17

!n.staliaîion

Levels ..................................

Preparation ................ 8

Starting with Weak Battery ... 23

Storage .................. 25

Terminais ................ 17

Belt:

Motion Drive:

Removal/Replacement.... 22

Mower Blade Drive:

Removal/Replacement.... 21

Mower Drive:

Removal/Replacement.... 21

Blade;

Replacement .............. 16

Sharpening ............... 16

Brake Adjustment .............. 21

Cai'buretor, Adjustment.......... 24

Controls, Tractor ............... 11

Cutting Hidghî, Mower .......... 12

t/ngine;

............ 10

introl Cable

21

8

8,17

.. 24

, . 24

. . 18

. . 18

. . 18

. . 17

, . 18

13,17

. . 17

. , 13

TABLE OF

Starting

Storage ................... 25

Filter:

Air Cleaner ................ 18

Fuel ...................... 18

Oi! ....................... 18

Fuel:

Storage ................... 25

Type ..................... 14

Fuse

.............................. 23

............................... 14

pi-iliiEUM'C Б . ............ 1'-P'

SERVICE AKt kDJUo! te P . ï ............ ^

TFCVF rpr & . . ................ 2b~17

WIRING l 0Hf»AAIIC ... ................. 30

SLOPE SHEET ........................... 31

. i “î ^

H

Headlights .................... 23

Leveling Mower Deck ........ 19—20

Lubrication, Chart ...............................

m

Maintenance ............... 15—18

Air Filter .

Air Screen, Engine .......... 18

Battery .

Blade .................... 16

Cooling Fins, Engine....................18

Engine Oil................................... . 17

Fuel Filter ..

Lubrication Chart . .

Schedule 15

Spark Plugs ............... 18

Tire Care ................ 8,16

Mower:

Adjustment;

Blade Replacement ......... 16

Blade Sharpening

Cutting Height ...........................

Installation ..........

Operation ................. 13

Removal .................. 19

Mowing Tips ................... 14

Muffler 18

Spark Arrester 3

Filter

...

.................................

Foam Pre-Cleaner.................18

...

.................................. 17

...

........................... IS

....

................

Froni-To-Back .......... 20

Side-To-Side ........... 19

................ 16

..............

a

. . . 17

. . , 18

. . . . ... ................. ;e

Operating Mower ............... 13

Operation ....................................11—14

Parking Brake ............... 11,12

15

18

15

12

9

13,17

Parts Bag

Product Specifications

Safety Rules ...............

Schematic ................

Seat ...............................

Service and Adjustments .....

Slope Guide Sheet ..........

Spark Plugs ...............

Specifications ..............

Starting the Engine ..........

Steering Wheel .............

Stopping the Tractor............. 12

Storage ...................

Throttle Control Cable, Adjustment . 24

Tires ....................... 8,16

Troubleshooting ............ 26—27

Wiring Schematic ............... 30

..............................................

............................

s

Carburetor ............

Fuse ................. . ... 23

Mower Adjustment:

Front-To-Back ..... . ... 20

Side-To-Side ......

Motion Drive Belt:

Removal/Replacement . ... 22

Mower Blade Drive Belt:

Removal/Replacement . ... 21

Mower Drive Belt:

Removal/Replacement . ... 21

Mower Removal ........

Throttle Control Cable . . .

Tire Care ............. , . 8,16

w

6

3

. .... 2

. ... 30

..

. .... 8

19—24

, ... 24

.... 19

.... 19

. ... 24

. ... 31

.... 18

........

3

.... 14

. . 7,22

. ... 25

Page 5

LIMITED WARRANTY

The Manufacturer warrants to the original consumer purchaser that this product as manufactured is free from

defects in materials and workmanship. For a period of two (2) years from date of purchase by the originai con

sumer purchaser, we will repair or replace, at our option, without charge for parts or labor incurred in replacing

parts, any part which we find to be defective due to materials or workmanship. This Warranty is subject to the

following limitations and exclusions.

1. This warranty does not apply to the engine, transaxle/transmission components, battery (except as noted

below) or components parts thereof. Please refer to the applicable manufacturer’s warranty on these items.

2. Transportation charges for the movement of any power equipment unit or attachment are the responsibil

ity of the purchaser. Transportation charges for any parts submitted for replacement under this warranty

must be paid by the purchaser unless such return is requested by PouIanAVeed Eater.

3. Battery Warranty: On products equipped with a Battery, we will replace, without charge to you, any bat

tery which we find to be defective in manufacture, during the first year of ownership. After one year, we will

exchange the Battery, chargingyou 1/12 of the price of a newBattery for each full month after one (1) year from

the date of the original sale. Battery must be maintained in, accordance with the instructions furnished.

4. The Warranty period for any products used for rental or commercial purposes is limited to 90 days from the

date of original purchase.

5. This Warranty applies only to products which have been properly assembled, adjusted, operated, and

maintained in accordance with the instructions furnished. This Warranty does not apply to any product which

has been subjected to alteration, misuse, abuse, improper assembly or installation, delivery damage, or to nor

mal wear of the product.

6. Exclusions: Excluded from this Warranty are belts, blades, blade adapters, normal wear, normal adjust

ments, standard hardware and normal in.aintenance.

7. In the event you have a claim under this Warran,ty, you must return the product to an authorized service

dealer.

Should you have any unanswered questions concerning this Warranty, please contact:

Poulan/Weed Eater

549 Canada Avenue

Huron Park, Ontario

Canada NOMIYO

Phone: (519)228-6514

giving the model number, serial number and date of purchase of your product and the name and address of the

authorized dealer from whom it was purchased.

THIS WARRANTY DOES NOT APPLY TO INCIDENTAL OR CONSEQUENTIAL DAMAGES AND ANY IM

PLIED WARRANTIES ARE LIMITED TO THE SAIdE TIME PERIODS STATED HEREIN FOR OUR EX

PRESSED WARRANTIES. Some areas do not allow the limitation of consequential damages or limitations of

how long an implied Warranty may last, so the above limitations or exclusion,s may not apply to you. This War

ranty gives you specific legal rig'hts, and you may have other rights which vary from locale to locale.

This is a limited Warranty within the meaning of that term as defined in the Magnuson-Moss Act of 1975.

Page 6

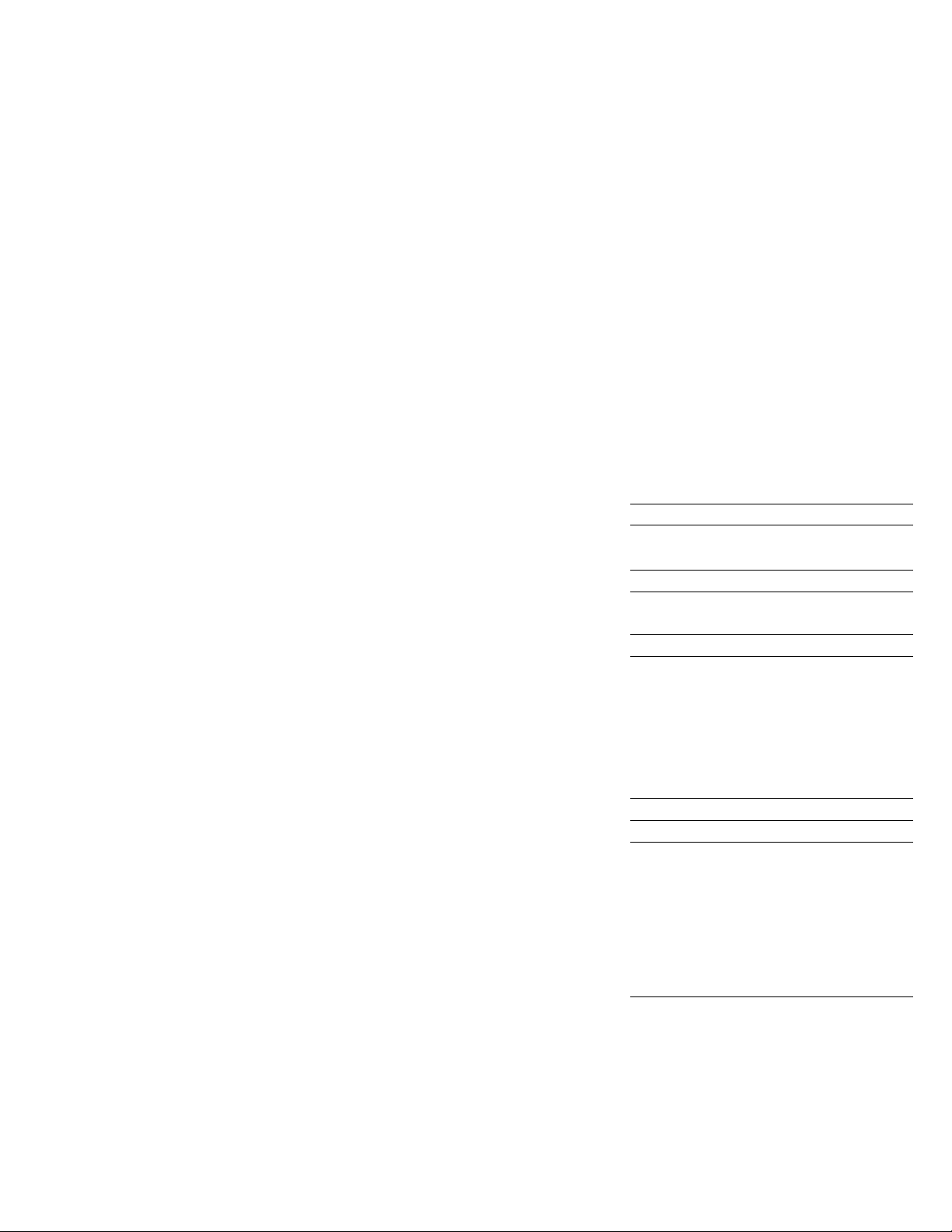

CONTENTS OF HARDWARE PACK

Parts Bag contents shown full size

(1) Shoulder Bolt 5/16-18

=JII

(1) Knob

Parts packed separately in carton

Seat

Steering Wheel

iC I a.

I

___

: ■!

Battery acid

Battery

(1) Washer 17/32 x 1-3/16 x 12 Ga.

ntíi Ì • - 20

(2) Washers 9/32 x5/8x16Ga. (2) Lockwashers 1/4

Owner's Manual

Parts bag contents not shown full size

p Steering

¡I Wheel

(2) Keys

e.'v C-arPage Sc

Terminai Gaarc

Jj insert

QMEBHEúB

, , ' ¿0 . F-1/2

.f!

eírfteryf iS

i< d insti j ‘Oíi6

Page 7

ASSEMBLY

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier. Standard

wrench sizes are listed.

(2) 7/16” wrenches

(1) Adjustable Wrench

When right or left hand is mentioned in this manual, it means

when you are in the operating position (seated behind the

steering wheel).

TO REMOVE UNIT FROM CARTON

UNPACK CARTON

Remove all loose parts from carton (See page 6).

Cut, from top to bottom, all four corners of carton and lay

panels flat.

Remove mower deck from skid.

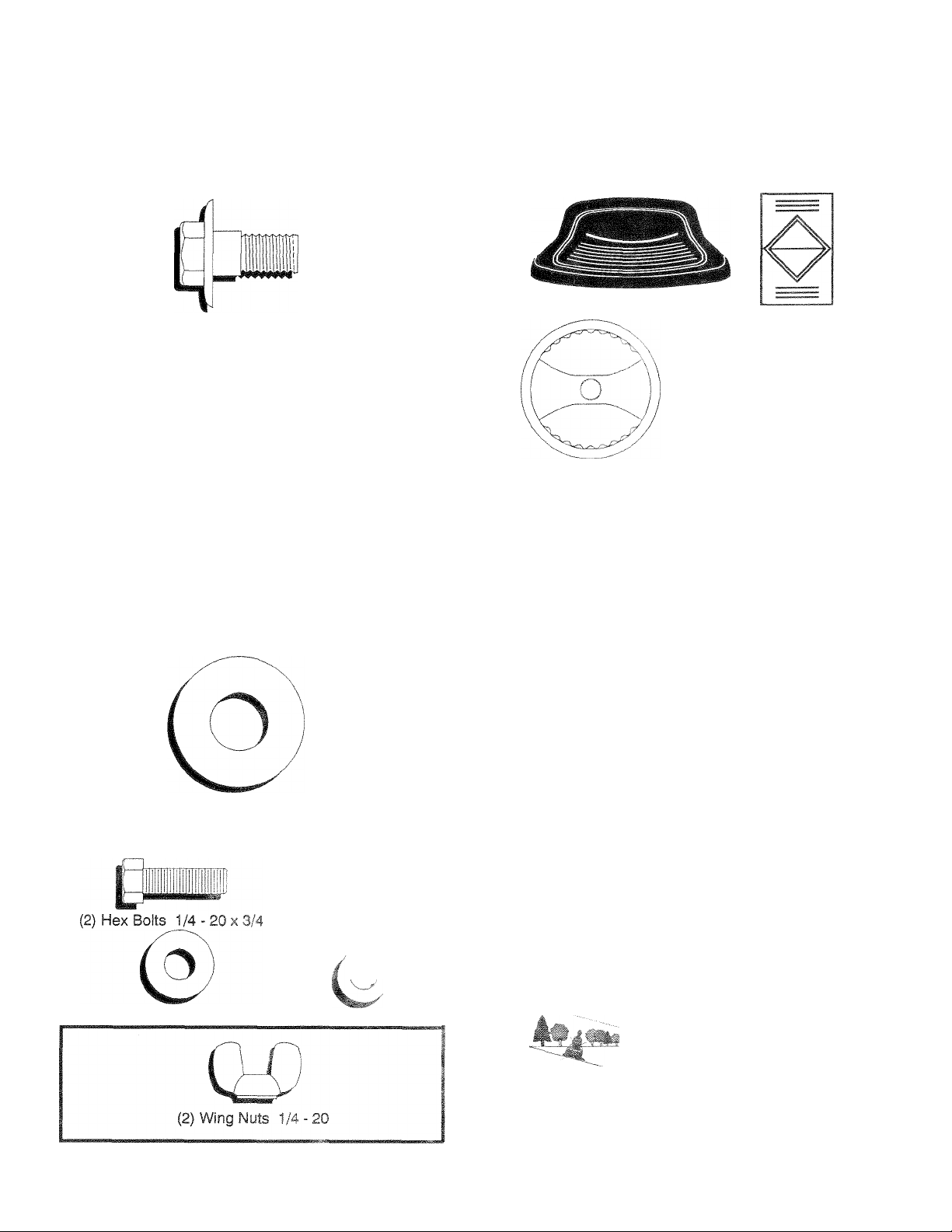

ATTACH STEERING WHEEL (See FIG. 1)

Remove hex nut and large flat washer from steering shaft.

Position front wheels of the tractor so they are pointing

straight forward.

Position steering wheel so cross bars are horizontal (left

to right) and slide onto adapter.

Secure steering wheel to steering shaft with hex nut and

large flat washer previously removed. Tighten securely.

Snap insert into center of steering wheel.

Remove protective plastic from tractor hood.

BEFORE ROLLING UNIT OFF SKID

(See FIG. 2)

IMPORTANT: CHECK FOR AND REMOVE ANY STA

PLES IN SKID THAT MAY PUNCTURE

TIRES WHERE UNIT IS TO ROLL OFF

SKID.

• Raise attachment lift lever to its highest position.

• Release parking brake by depressing clutch/brake pedal.

• Place gearshift lever in “NEUTRAL” position.

• Roll unit backwards off skid.

(1) Tire Pressure Gauge

(1) Utility Knife

CLUTCH/BRAKE

LIFT LEVER

FIG. 2

Page 8

ASSEMBl-V

HOW TO SET UP YOUR TRACTOR

PREPARE BATTERY (See F!G. 3)

CAUTION: Wear eye and face shield.

Wash hands or clothing immecliately if accidentaiSy in contact with battery acid.

not into -upies irt,m charged battery

-'‘i*. 1 fe

R t' the Hvnij .fiurib included with the

c ‘ vent c'''- № th- bag of parts. A!-

'rn/. c ' ‘fec ciotHng and goggles to

y^ul hnndc snd eyes.

Your unit has a battery charging system which is sufficient

for normal use. However, periodic charging of the battery

with an automotive charger will extend its life.

• See instructions packed with vent caps in parts bag.

• Fill battery with acid. Fill each cell until it reaches the bot

tom of the vent wells. Do not over fill.

• Allow battery to stand and settle for at least thirty minutes.

After standing, check the level of acid. If below the vent

wells, add more acid until the correct level is reached.

While battery is standing (after adding acid) and later, while

battery is being charged, continue with assembly of unit.

“ To maximize the life of your battery, it is necessary that

the battery be charged before use. Use a 12 volt battery

charger. Charge battery at a rate of 6 amperes for 1 hour.

Observe all safety precautions required for battery charg

ing. Failure to charge battery can result in a shortened

battery life.

• Check the acid level after the battery is charged. If the acid

has fallen beiow the correct level, add distilled or iron free

water.

• Install the vent caps to cover the vent wells. Wash the top

of the battery with water to remove any acid, then wipe

drv.

dye lie

OiSDO'-

posal I

plastic

while c

jilow insta

QMimm,

y case fo!

jrred in h

xcess ba

frig it to f

iner. Stir

)amifig.

5 on hov

e ‘ -m v'esui- trat'< > n.,rr>-

acid. Neutralize acid for disiches of water in a five gaiion

a 0 > •

intil the addition of more soda

to instsll bHttsrv.

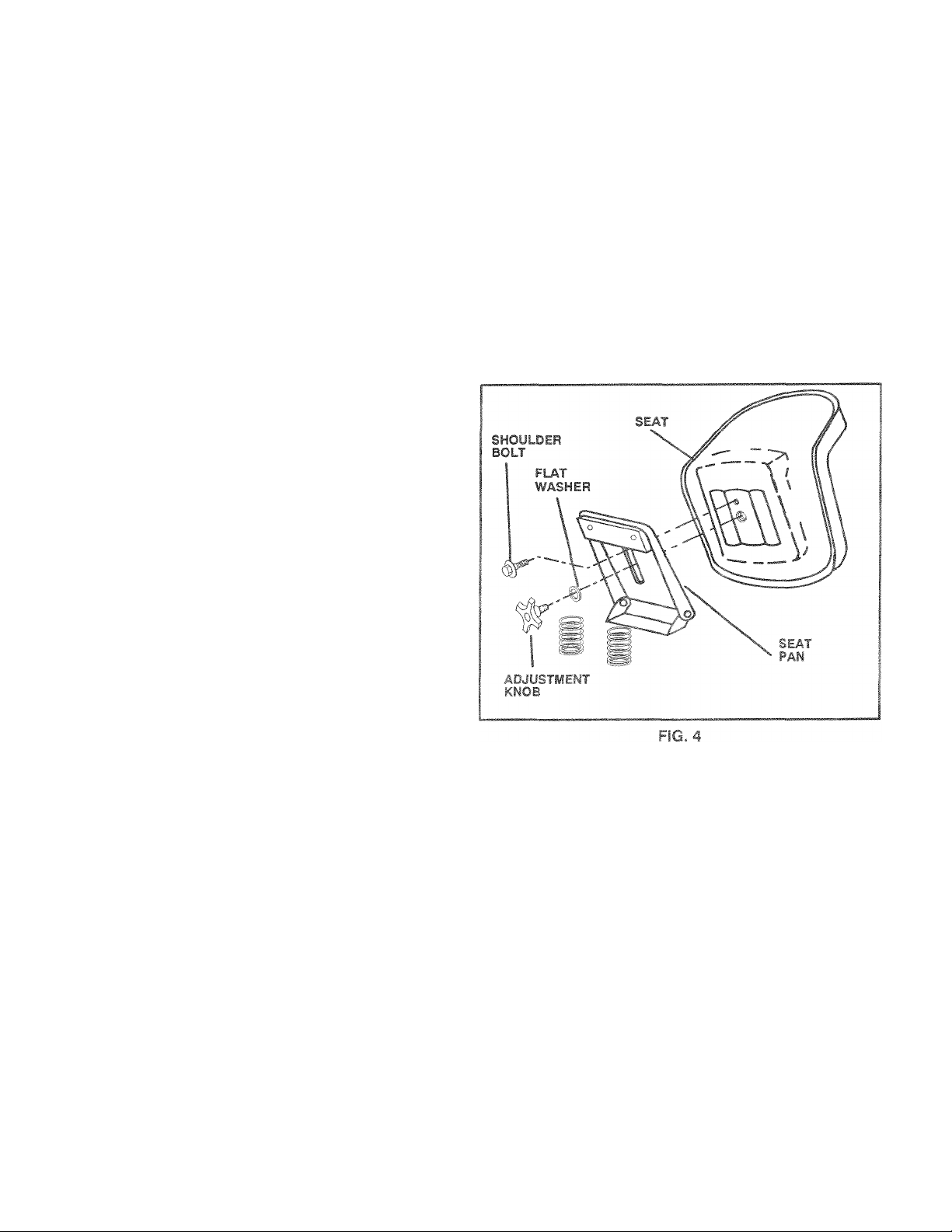

INSTALL SEAT (See FIG. 4)

Adjust seat before tightening adjustment knob.

• Remove cardboard packing on seat pan.

• Place seat on pan and assemble shoulder bolt.

• Assemble adjustment knob and flat washer loosely. Do

not tighten.

• Tighten shoulder bolt securely.

• Lower seat into operating position and sit on seat.

• Slide seat until a comfortable position is reached which al

lows you to press clutch/brake pedal all the way down.

» Get off seat without moving its adjusted position.

• Raise seat and tighten adjustment knob securely.

CHE3A TIRE A* Ac TAUPE

^he L'eiz on -wu' >r.

■hicp.uc f'jrp.ses

er' cut pp—-rr-i'

• Aeduce jre '".'surv lO PS show:, in ‘ PRODUCTSPECiFi'.-ATIC v.F :page 3 o. tuis narueJ,

wevr -.vrint „"ed at the factory for

vreci ~irc prasc.re is important for

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see that

the brake is properly adjusted. See “TO ADJUST BRAKE” in

the Service and Adju.stments section of this manual.

&

I

ill

0.1 'seY

TUBE

H

f

ELL

FIG. 3

Page 9

ASSEMBLY

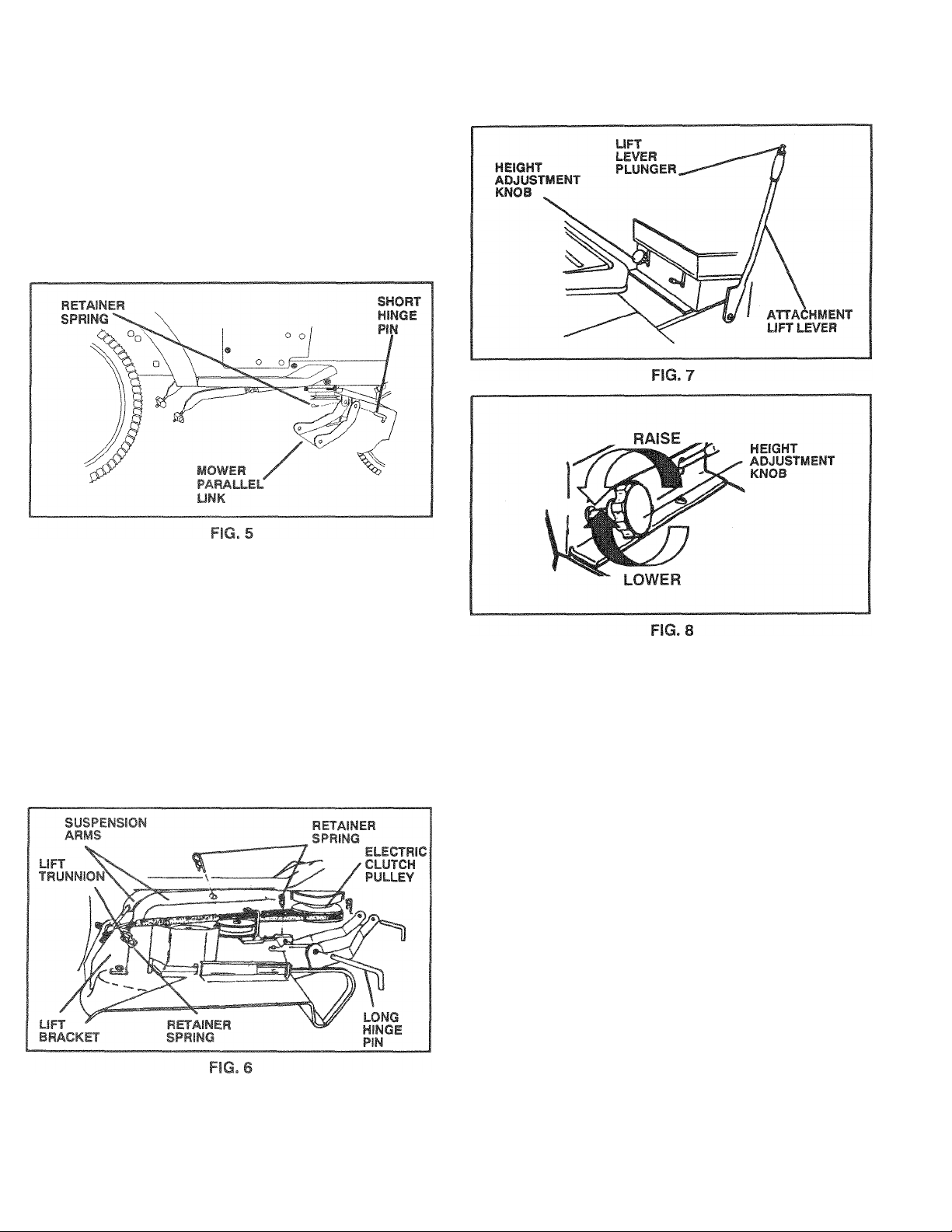

INSTALL MOWER (See

FIGS. 5, 6, 7 & 8)

Your unit has been shipped with the mower parallel link in

cluded in the parts carton. Install mower parallel link on unit

using short hinge pin and retainer spring.

NOTE: Smaller end of parallel link mounts to tractor. Use the

shortest hinge pin for mounting.

Raise attachment lift lever to its highest position.

Remove banding from suspension arms.

Slide mower under tractor with discharge guard to right

side of tractor.

Attach front of mower to parallel link with long hinge pin.

Secure hinge pin with retainer spring.

Turn height adjustment knob to its lowest setting.

Lower attachment lift lever to lower suspension arms. Re

move retainer springs from lift trunnions.

Slide trunnions through upper lift bracket holes and se

cure with retainer springs.

Pull L.H. idler pulley toward the right hand side of tractor

and roll belt over electric dutch pulley.

CHECK DECK LEVELNESS

For best cutting results, mower housing should be properly

leveled. See “TO LEVEL MOWER HOUSING” in the Serv

ice and Adjustments section of this manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion, mower

drive, and mower blade drive belts in the Service and Adjust

ments section of this manual. Verify that the belts are routed

correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see that

the brake is properly adjusted. See “TO ADJUST BRAKE” in

the Service and Adjustments section of this manual.

NOTE: Mower drive belt installation decal located on mower

housing.

• Raise attachment lift lever to raise mower.

• Turn height adjustment knob clockwise to the middle of its

travel.

Page 10

ASSEMBLY

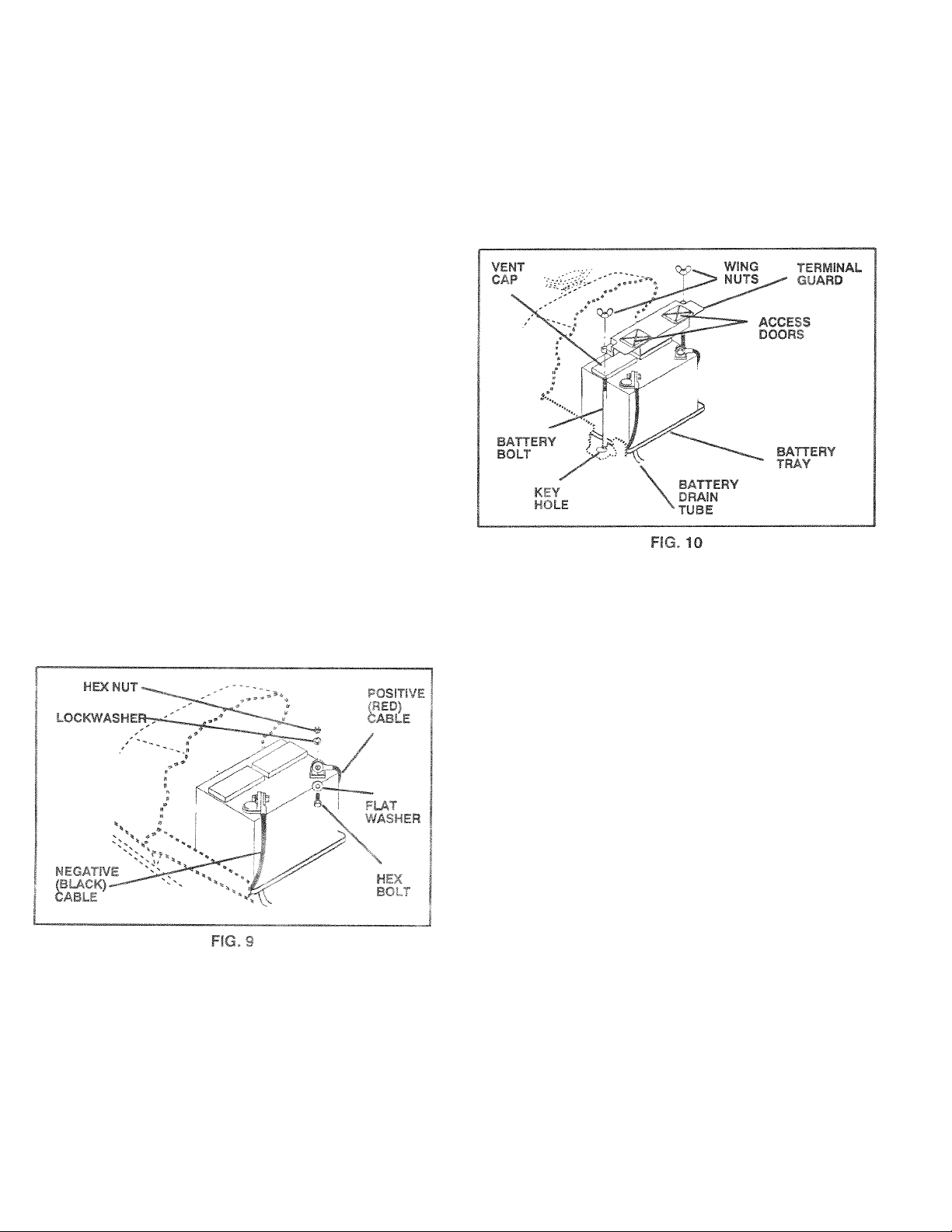

ÍNSTALL battery (See FIGS. 9 & 10)

CAUTION: Do not short battery terminals.

Before installing battery, remove metal

bracelets, wristwatch bands, rings, etc.

Positive terminal must be connected first

A

Raise hood.

Make sure drain tube is fastened to drain hoie in battery

tray and battery tray is positioned in hole of battery sup

port.

Place battery in plastic tray, battery terminals to front of

tractor.

First connect RED battery cable to positive (+) battery ter

minal with hex bolt, flat washer, lockwasher and hex nut

as shown. Tighten securely.

Connect BLACK grounding cable to negative (-) battery

terminal with remaining hex bolt, flat washer, lockwasher

and hex nut. Tighten securely.

Slide the two battery bolts through terminal guard and

start wing nuts onto threads.

Position terminal guard over battery as shown, lower bolts

into key holes and slide square shafts of bolts into slots of

key holes.

Tighten wing nuts by hand making sure battery bolts re

main in slots of key holes in battery support.

Be sure terminal access doors are closed.

to prevent sparking from accidental

grounding.

Use terminal access doors for:

» inspection for secure connections (to tighten hardware)

• Inspection for corrosion

• Testing battery

» Jumping (if required)

• Periodic charging

.^CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, WE WISH TO ASSURE THAT YOU RECEIVE

THE BEST PERFORMANCE AND SA TISFACTION FROM

THIS QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

/ All assembly instructions have been completed.

/ No remaining loose parts in carton.

/ Battery is properly prepared and charged. (Minimum 1

hour at 6 amps).

/ Seat is adjusted comfortably and tightened securely.

/ Ail tires are properly ¡rifiated. (For shipping purposes, the

tires were overinflated at the factory.)

/ Be sure mower deck is properly leveled side-to-side/

front-to-rear for best cutting results. (Tires must be prop

erly inflated for leveling.)

/ Check mower and drive belts. Be sure they are routed

properly around pulleys and inside ail belt keepers.

/ Chsckwiring. See that all connections are still secure and

wires are properly clamped.

WHILE LEARNING HOW TO USE YOUR TRACTOR, PAY

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

/ Eng ne oiia' uroo" le

■|;e ankist'itt.n. itt uesh, clean, regular unleaded gaso-

orr. ‘ Tai to

r r inem ’

.;Ü r© t)! 3F, '5' svst©n

'to' f'troir-'ineir (0. . -.dfunc-

0Í 5 ywu ,'h- :the fry • /

iS 'll

aC’b •.

, -rati’to C0<1. H.

Page 11

OPERATION

KNOW YOUR TRACTOR

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR.

Compare the illustrations with your Tractor to familiarize yourself with the locations of various controls and adjustments. Save

this manual for future reference.

FIG. 11

ATTACHMENT CLUTCH SWITCH - Used to engage

mower blades or other attachments mounted to your tractor.

LIFT LEVER - Used to raise and lower mower deck or other

attachments mounted to your tractor.

CLUTCH/BRAKE PEDAL - Used for declutching and brak

ing the tractor,

HEIGHT ADJUSTWENT KNOB - Used to adjust the mower

height.

GEARSHIFT LEVER - Selects the speed and direction of

the tractor.

-^r№ÿi;;=

A CAUTION

TO AVOID INJURY

READ OWNER'S MANUAL.

KNOW LOCATION AND FUNCTION OF ALL CONTROLS.

KEEP GUARDS, SAFETY SHIELDS AND SWITCHES IN PLACE AND WORKING.

REMOVE OBJECTS THAT CAN BE THROWN BY BLADES.

DO NOT MOW WHEN CHILDREN AND OTHERS ARE AROUND.

NEVER CARRY CHILDREN OR PASSENGERS.

ALWAYS LOOK BEHIND MACHINE BEFORE BACKING.

DO NOT MOW WHERE MACHINE CAN TIP OR SLIP.

IF MACHINE STOPS GOING UPHILL. STOP BLADE AND BACK DOWN SLOWLY.

BE SURE BLADES AND ENGINE HAVE STOPPED BEFORE PLACING HANDS

OR FEET NEAR THE BLADES.

REMOVE KEY WHEN LEAVING MACHINE.

THROTTLE CONTROL - Used to control engine speed.

IGNITION SWITCH - Used to start and stop the engine.

AMMETER - Indicates battery charging {+) or discharging

(-).

LIGHT SWITCH - Turns the headlights on and off.

PARKING BRAKE LEVER - Locks clutch/brake pedal into

the brake position,

CHOKE CONTROL - Used when starting a cold engine.

Page 12

-îSSzssæsæ^KseBïSi!

The operation of any tractor can result in foreign objects thrown into the eyes, which can resuit

In severe eye damage. Always wear safety glasses or eye shields while operatino your tractor or

before performing any adjustments or repairs. We recommord wide vision safety mask for over

the spectacles or standard safety glasses.

L TA .TOB

: r t WT iiJG BRAKE (See F!G. 12)

• Depress ciutch/brake pedal into full “BRAKE” position and

hold.

f 1. (. ! ‘,i.ik--^i-w3,-,n“ERCiA'3E-D”poF!tionaidre\, i'-; r ■ 1' jm ciutd./b.e ^ep-dil. aa!si-otidre-

.1 • . (I i i./i , |■■•slt¡гп M tke . uff-Pc Thing t rake will

h !. - ' c / . urn

STOrPiiriG (Se© FIG. 12)

'ill ..iduri> V :,-i h 10 “LiSENGAGED” posi-

iJND DR

’• .M' </f-i S--: •c'hh ijiio nils “BRAKE” ooshion.

■ , rJori c- 0‘'NrU"r.Ai.’'posiiion.

JR:

ENGir

.

• >! ' i.-G “.'h’)-.''' ooGTon.

>' ‘ f' ,i . r> 811(1 »ernc'm ke” Ai-

, ‘ f ( ie.T'!i ‘ /Tihici. io pi event un-

to stop engine.

: CONTROL (See F

tienever you are startin«

:0. ”'1

, t (J *=r. in

IGNITION

KEY

Pt 1 AL " < i

P

«P

PC

ATTACHMENT

CLUTCH SWITCH

“ENGAGED”

POSiTlON

°

\

“CT ENGAGED”

POSiTlON

HBGHT

ADJUSTMENT

KNOB

CHOKE

CONTROL

GEAR

SHIFT

LEVER

PARKING BRAKE

control, puii knob out. SI

I L-C WiilM I nUL» |D'

' V I '0.. b

d iT|

ipy ,

and the

FIG. 12

“C ' oi 1 A * 'CD. f F ^ ‘ FFiGHT (See

Rich. .

.. > f,. sghtadjust-i ne cutting neig

merit knob in de

• Turn knob do

T.c V .

hfc i d -

with the engine r

and may vary c

• The average

hot months. F

m,.t 1

. ^ : 10 I I

10 10

ximai

cutting height.

0 3-3/4”).

UP- - i‘ .m re Of Ainu o tfi9 blade tip

"1’rI T-.^n-uni- -"eaooroximate

' ‘ .V "i TO T‘.lions, height of

I. . U T t

rl

3iy 2-1/2

es during

erandd

t., r no lawns, mow

te growtt

inches in

i twice, h

: CIS relatively

ired heic

Page 13

OPERATION

TO OPERATE MOWER (See FIGS. 11 and 12)

Your unit is equipped with an operator presence sensing

switch, Any stternpt bv the operator to leave the seat with

the etiyire runi sfip

shut off the engine.

Select desired height of cut, using height adjustment

knob.

Lower mower with lift lever.

Engage mower by pulling attachment clutch switch up

and out to “ENGAGED” position.

TO STOP MOWER Move attachment clutch switch to

“DISENGAGED” position.

Raise mower with lift lever.

CAUTION: Do not operate the mower with

out either the entire grasscatcher, on mow

A

TO OPERATE ON HILLS

A

® Choose the slowest speed before starting up or down

hills.

• Avoid stopping or changing speeds on hills.

^ If slowing is necessary, move throttle control lever to

slower position.

® If stopping is absolutely necessary, push clutch/brake

® Move gearshift lever to “NEUTRAL” position.

® To restart movement, move gearshift lever to 1 st gear and

range shift lever to ”LO” position. Be sure you have al

lowed room for unit to roll slightly as you restart move

ment.

• Slowly release parking brake and clutch/brake pedal.

• Make ail turns slowly.

ers so equipped, or the discharge guard in

place.

CAUTION: Do not drive up or down hills

with slopes greater than 15° and do not

drive across any slope.

TO TRANSPORT

® Raise attachment lift control to highest position.

" When pushing or towing your unit, be sure gearshift lever

is in “NEUTRAL” position.

• Do not push or tow unit at more than five (5) MPH.

nti ùhc,- a:iechment dutch engaged will

ADD GASOLINE

® Fill fuel tank. Use fresh, clean, regular unleaded gasoline.

(Use of leaded gasoline will increase carbon and lead ox

ide deposits and reduce valve life).

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW 32°F (0°C), USE FRESH CLEAN

WINTER GRADE GASOLINE TO HELP

INSURE GOOD COLD WEATHER

STARTING.

WARNING : Experience indicates that alcohol blended fuels

(called gasohol or using ethanol or methanol) can attract

moisture which leads to separation and formation of adds

during storage. Acidic gas can damage the fuel system of an

engine while in storage. To avoid engine problems, the fuel

system should be emptied before storage of 30 days or

longer. Drain the gas tank, start the engine and let it run until

the fuel lines and carburetor are empty. Use fresh fuel next

season. See Storage sections of this manual for additional

information. Never use engine or carburetor cleaner prod

ucts in the fuel tank or permanent damage may occur.

CAUTION: Fill to bottom of gas tank filler

neck. Do not overfill. Wipe off any spilled

A

oil or fuel. Do not store, spill or use gaso

line near an open flame.

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See FIG. 13)

® The engine in your unit has been shipped, from the fac

tory, already filled with summer weight oil.

• Check engine oil with unit on level ground.

• Remove dipstick and wipe clean, replace, wait for a few

seconds, remove and read oil level. If necessary, add oil

until “FULL” mark on dipstick is reached. Do not overfill.

• For cold weather operation you should change oil for eas

ier starting (see “OIL VISCOSITY CHART’ in the Mainte

nance section of this manual).

• To change engine oil, see the Maintenance section in this

manual.

Page 14

OPERATION

TO START ENGINE (See FIG. 12)

When starting engine for the first time or if engine has run out

of fuel, it will take extra cranking time to move fuel from the

tank to the engine.

• Depress the ciutch/brake pedal and set the parking brake.

• Place gearshift ¡ever in “NEUTRAL” position.

• Move attachment clutch to “DISENGAGED” position.

• Pull choke control out to “CHOKE” position for cold en

gine start. For warm engine start do not use choke con

trol.

• Move throttle control to midway between “FAST” and

“SLOW” positions.

• Turn ignition key clockwise to “START’ position and re

lease key as soon as engine starts. Do not run starter

continuously for more than fifteen seconds per minute. If

engine does not start after several attempts, move throt

tle coniro! to “FAST” position, wait a few minutes and try

again.

• When engine starts, slowly push choke control in.

• Move throttle control to “FAST” position.

• Allow engine to warm up for a few minutes before engag

ing ciutch/brake pedal or attachment clutch switch.

NOTE' If at a high aidtude (above 3000 feet) or in cold tem

peratures ibelow 32' F), the carburetor fuel mixture may

need to be adjusteo for best engine performance. See “TO

A* 'JUST CARBURETOR" in the Service and Adjustments

section of this rnaruai

The left hand side of mower should be used for trimming.

Drive so that clippings are discharged onto the area that

has been cut. Have the cut area to the ripht of the ma

chine. This will result in a more even distribution of clip

pings and more uniform cutting.

When mowing large areas, start by turning to the right so

that clippings will discharge away from shrubs, fences,

driveways, etc. After one or two rounds, mow in the oppo

site direction making left hand turns until finished (See

FIG. 15).

CAUTION; Before driving the tractor, In-

stali mower or remove front mower sus

pension bracket ana suspension arms.

MO¥/i^ S

• Tire chains cannot be used when the mower housing is at

tached to unit.

• Mower should be properly leveled for best mowing per

formance. See “TO LEVEL MOWER HOUSING” in the

Service and Adjustments section of this manual.

• Use the runner on the right hand side of mower as a guide.

The blade cuts approximately an inch outside the runner

(See FIG. 14).

If grass is extremely tall, it should be mowed twice to re

duce load and possible fire hazard from dried clippings.

Make first cut relatively high, the second to the desired

height.

Do not mow grass when it is wet. Wet grass will plug mow

er and leave undesirable dumps. Allow grass to dry be

fore mowing.

Always operate engine at full throttle when mowing to as

sure better mowing performance and proper discharge of

material. Regulate ground speed by selecting a low

enough gear to give the mower cutting performance as

well as the quality of cut desired.

When operating attachments, select a ground speed that

will suit the terrain and give best performance of the at

tachment being used.

FIG. 14

Page 15

MAINTENANCE

Check Brake Operation

Check Tire Pressure

Check for Loose Fasteners

Sharpen/Replace Mower Blades

Lubricate Pivot Points

Check Battery Level/Recharge

Clean Battery and Terminals

Check Engine Oil Level

Change Engine Oil

Clean Air Filter/Foam Pre-cleaner

Clean Air Screen

Inspect Muffler/Spark Arrester

Change Engine Oil Filter

Clean Engine Cooling Fins

Replace Spark Plug

Replace Air Filter Paper Cartridge

Replace Fuel Filter

1 - Change more often when operating under a heavy load or in high ambient temperatures.

2 - Service more often when operating in dirty or dusty conditions.

3 - Replace blades more often when mowing in sandy soil.

l/

✓

✓

✓

✓ ✓

3

✓ ✓

1/

i/

l/

✓

1/2

1/2

lX,2

✓

|X,2

✓2

✓

1/2

✓

✓

✓

✓

GENERAL RECOMMENDATIONS

The warranty on this unit does not cover items that have

been subjected to operator abuse or negligence. To receive

full value from the warranty, operator must maintain unit as

instructed in this manual.

Some adjustments will need to be made periodically to prop

erly maintain your unit.

Ail adjustments in the Service and Adjustments section of

this manual should be checked at least once each season.

• Once a year you should replace the spark plug, clean or

replace air filter, and check blades and belts for wear. A

new spark plug and clean air filter assure proper air-fuel

mixture and help your engine run better and last longer.

BEFORE EACH USE

• Check engine oil level.

• Check brake operation.

• Check tire pressure.

• Check for loose fasteners.

LUBRICATION

Keep unit well lubricated (See ’’LUBRICATION CHART”)

LUBRICATION CHART

IMPORTANT: Do not oil or grease the pivot points which have special

nylon bearings. Viscous lubricants will attract dust and dirt that will

shorten the life of the self-lubricating bearings. If you feel they must be

lubricated, use only a dry, powdered graphite type lubricant sparingly.

Page 16

MAINTENANCE

TRACTOR

Always observe safety rules when performing any mainte

nance.

TIRES

• Maintain proper air pressure in all tires (See ’’PRODUCT

SPECIFICATIONS” on page 3 of this manual).

• Keep tires free of gasoline, oil, or insect control chemicals

which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp objects and other

hazards that may cause tire damage.

BLADE CARE

For best results mower blades must be kept sharp. The

blades can be sharpened with a file or on a grinding wheel.

We suggest they be sharpened or replaced after every 25

hours of mowing. Check blades more often if mowing in

sandy conditions.

• Do not attempt to sharpen blades while they are on the

mower.

• Replace bent or damaged blades.

BLADE REMOVAL (See FIG. 16)

• Raise mower to highest position to allow access to

blades.

• Remove hex bolt, lockwasher and flat washer securing

blade.

• Install new or resharpened blade with trailing edge up to

wards deck as shown.

• Reassemble hex bolt, lockwasher and flat washer in exact

order as shown.

• Tighten bolt securely (30-35 Ft. Lbs. torque).

IMPORTANT: BLADE BOLT IS GRADE 5 HEAT

TREATED.

TO SHARPEN BLADE (See FIG. 17)

Care should be taken to keep the blade balanced. An unbal

anced blade will cause excessive vibration and eventual

damage to mower and engine.

• The blade can be sharpened with a file or on a grinding

wheel. Do not attempt to sharpen while on the mower.

• To check blade balance, drive a nail into a beam or wall.

Leave about one inch of the straight nail exposed. Place

center hole of blade over the head of the nail. If blade is

balanced, it should remain in a horizontal position. If

either end of the blade moves downward, sharpen the

heavy end until the blade is balanced.

FIG. 17

4

e

Page 17

MAINTENANCE

BATTERY (See FIG. 18)

Your unit has a battery charging system which is sufficient

for normal use. However, periodic charging of the battery

with an automotive charger will extend its life.

• Acid solution level in each battery cell should be even with

bottoms of vent wells. Add only distilled or iron-free water

if necessary. Do not overfill.

• Keep battery bolts tight.

• Keep vent caps tight and small vent holes in caps open.

• Recharge at 6 amperes for 1 hour.

TO CLEAN BATTERY AND TERMINALS -

Corrosion and dirt on the battery and terminals can cause

the battery to ’’leak” power.

» Remove terminal guard.

• Disconnect BLACK battery cable first then RED battery

cable and remove battery from tractor.

• Wash battery with solution of four tablespoons of baking

soda to one gallon of water. Be careful not to get the soda

solution into the cells.

• Rinse the battery with plain water and dry.

• Clean terminals and battery cable ends with wire brush

until bright.

• Coat terminals with grease or petroleum jelly.

• Reinstall battery (See “INSTALL BATTERY” in the As

sembly section of this manual).

ENGINE

LUBRICATION

Change the oil after the first two hours of operation and

every 50 hours thereafter or at least once a year if the tractor

is not used for 50 hours in one year.

Check the crankcase oil level before starting the engine and

after each five (5) hours of continuous use. Add SAE SOW

motor oil or equivalent. Tighten oil fill cap/dipstick securely

each time you check the oil level. SAE 5W-30 motor oil may

be used to make starting easier in areas where temperature

is consistently 32° F or lower.

TO CHANGE ENGINE OIL (See FIGS. 19 and 20)

Determine temperature range expected before oil change.

All oil must meet API service classification SF/CC.

• Be sure vehicle is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

• See engine manual packed with your unit for further in

structions.

17

RECOMMENDED SAE VISCOSITY GRADES

30 or 10W 30

°F -20°

°C -29°

-18°

32° 60° 80° 100°

0° 16° 27° 38°

FIG. 20

I [ n

Page 18

MAINTENANCE

ENGINE

CLEAN AIR SCREEN

Air screen must be kept free of dirt and chaff to prevent en

gine damage from overheating. Clean \with a brush or com

pressed air to remove dirt, stubborn dried gum fibers.

CLEAN ENGINE COOLING FINS

Remove any dust, dirt or oil from engine cooling fins to pre

vent damage from overheating. Air guide covers must be re

moved.

See Engine Manual packed with your unit.

AIR FILTER FOAM PRE-CLEANER

Your engine will not run properly and may be damaged by

using a dirty air filter. Clean the foam pre-cleaner element

after every 25 hours of operation, more often if tractor is

used in very dusty, dirty conditions.

See Engine Manual packed with your unit.

ENGINE OIL FILTER

Replace the engine oil filter every season or every other oil

change if the tractor is used more than 100 hours in one

year.

See Engine Manual packed with your unit.

SPARK PLUGS

Replace spark plugs at the beginning of each mowing sea

son or after every 100 hours of use, whichever comes first.

Spark plug type and gap setting is shown in "PRODUCT

SPECIFICATIONS” on page 3 of this manual.

IN-LINE FUEL FILTER (See FIG. 21)

Fuel filter should be replaced once each season. If fuel filter

becomes clogged, obstructing fuel flow to carburetor, re

placement is required.

• With engine cool, remove filter and plug fuel line sections.

• Place newfuel filter in position in fuel line with arrow point

ing towards carburetor.

• Be sure there are no fuel line leaks and clamps are prop

erly positioned.

• Immediately wipe up any spilled gasoline.

MUFFLER

Inspect and replace corroded muffler and spark arrester (if

equipped) as it could create a fire hazard and/or damage.

CLEANING

• Clean engine, battery, seat, finish, etc. of all foreign mat

ter.

• Keep finished surfaces and wheels free of all gasoline, oil,

etc.

• Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to clean your

unit unless the electrical system, muffler, airfilter and carbu

retor are covered to keep water out. Water in engine can re

sult in a shortened engine life.

iO

Page 19

A

SERVICE AND ADJUSTMENTS

CAUTION: BEFORE PERFORMING ANY SERVICE OR ADJUSTMENTS:

Depress clutch/brake pedal fully and set parking brake.

Place gear shift lever in “NEUTRAL” position.

Place attachment clutch in “DISENGAGED" position.

Turn ignition key “OFF” and remove key.

Make sure the blades and all moving parts have completely stopped.

Disconnect spark plug wire from spark plug and place wire where it cannot come in contact with

plug.

TRACTOR

TO REMOVE MOWER (See FIG. 22}

Mower will be easier to remove from the right side of unit.

• Remove mower drive belt from electric clutch pulley only

(See “TO REPLACE MOWER DRIVE BELT’through step

removing belt from electric clutch pulley).

• Pul! retainer springs out of rear suspension trunnions.

Remove rear suspension trunnions from lift brackets.

• Pull retainer springs from front hinge pins.

• Remove hinge pins attaching parallel link to mower and

front axle.

• Raise lift leverto raise suspension arms. Slide mower out

from under tractor.

IMPORTANT: IF AN TT-aCHMENT OTHER THAN THE

MOWER IS TO BE MOUNTED TO THE

TRACTOR, THE R.H. AND LH. SUSPEN

SION ARMS MUST BE REMOVED FROM

SIDE-TO-SIDE ADJUSTMENT (See FIGS. 23 and 24)

• Raise attachment lift lever to its highest position.

• Measure height from bottom of deck curl to ground level at

front corners of mower. Distance “A” should be the same.

FiG. 23

• If distance “A” needs to be changed, snap out access hole

cover on left side of tractor above footrest.

• To raise left side of mower, loosen nut “B" and tighten nut

“C”.

• To lower left side of mower, loosen nut “C” and tighten nut

“B”.

• When distance “A” is equal, securely tighten nuts “B” and

“C”.

FiG. 22

TO INSTALL MOWER

See “ilMSTALL MOWER” in the assembly section of this

manual.

TO LEVEL MOWER HOUSING

Adjust ‘he i 'ciwei wt-li iftor

driveway t fct >■ - ' ^

UCTSPEC'i OF R

derinflatcd, /o . vli

vb

pa-Wd f I,'/ei giou'-'d t,

•'e, j ,S,.v 'i- ’

’ Uiffc-a*'f- . '■'! i ru .

/ adiust your mo’wer.

Page 20

SERVICE AND ADJUSTMENTS

FRONT-TO-BACK ADJUSTMENT(See FIGS. 25 and 26)

To obtain the best cutting results, the mower housing should

be adjusted so the rear is approximately 7/8” to 1 -1/8” higher

than the front when the mower is in its highest position.

Measure distance “D” from ground line to bottom of deck cur!

at centerline of mandrels.

® To raise rear of mower, loosen nut “E” on both rear sus

pension arms. Screw both nuts “F” on both rear suspen

sion arms an equal number of turns.

• When distance “D” is 7/8” to 1-1/8” higher at rear than

front, retighten nuts “E”.

•

TO ADJUST ATTACHMENT CLUTCH (See

FIG. 27)

The electric clutch should provide years of service. The

clutch has a built-in brake that stops the pulley within 5 sec

onds. Eventually, the internal brake will wear so the mower

blades will not stop as recommended. Adjustments should

be made by an authorized service technician.

• Make sure attachment clutch and ignition switches are in

the “OFF" position.

• Adjust the three nylon lock nuts until the space between

the clutch plate and the rotor, measures .012 inches at all

three slot locations cut in the side of the brake plate.

NOTE: After installing a new electric clutch. Run tractor at

full throttle, and engage and disengage electric clutch 10 cy

cles to wear in clutch plate.

• Recheck side-to-side adjustment.

IMPORTANT: WHEN ADJUSTING REAR SUSPENSION

TRUNNIONS, ALWAYS ADJUST BOTH

EQUALLY SO MOWER WILL STAY

LEVEL SIDE-TO-SIDE.

Page 21

SEF

: ДЕ

TO

FiC5S. ;28 aiId 29)

The rnc"/ver dr t li rr Í

ilv

‘ tí f rncL, Ihs u

housing.

BELT REN

• Place atliriir "cn'iii.'' n t i "1C PCt 0” position

• Turn heigh' id i i.Tfiitnrt i > «t-st' f fting

• Move att tdou ‘ t :ii ( r, . v,-.i! i,o loAei mower to its

• Roll belt cti eie M« 'Mi h pc' ^ ./ f ,ьв FiG. 22).

iPLACE MOWEI

tract

ort ( I

lowest !

ÄTT/XHMetrf.

CLUTCH

“DlSCNGAGWy’«

P0SÌÌ10N

'( I . Urfd

s teltir : ‘a!

•isc-n i scs. decal on the mo *er

■ T ACPàffiNT

LUTO.

EíHÍGAÜED”

OSiTiON

i W i Ш т

/cut mici f 1jippedwith an.

is mounted on

If jn>

the right side -

; more than si;

high speed in highest gear, ■

“ U‘ III ‘ Cl

® Measure dis

I- -ou- ; ; 1-

jtance betwefci

“A” on brake5 rod.

» If distance is

1 other than 1-

Ì a ' ' nut BncI turn n

Xd/2”. Reí

® Engage par

ighten ¡am nut

king brake anc

• Road test tjnit for proper

DC [

Ite.Ae 1

IdnCf ! 1'

cervi; - .ei-t

.djust if necess

1 six (6) feel ir

'C0SS3rv> Con

X f..

8» A i/C A »a«

..,.1 i ; 'Д itvr, wtiich

of the trarisaxle.

'1 * 1' Ipil , ■ -I ) <rs'_e at

h I I 11 ,'M 0. i yii'ted.

1. . < !.. ' , fkirw ITcÍ a

' ' I ' 1 I Ч. isr I ,ind nut

' I • i , > .1 rNt‘0 pi ifB,

ut “A” until distance becomes

t aqain

leck distance.

. ' Í., iw- 'stated

'L ' !!ii e i sill!

. 1 Í n'ln^r maintr-

Ч-М ri. IS t xihoiized

HEIGHT

ADJUSTMENT

KNOB

“''V,

FiG. 28

• Pull belt off mower pulley and both idler pulleys.

BELT INSTALLATION

• Place belt around movrer pulley and both idler pulleys.

• Roll belt over electric clutch pulley.

» Make sure belt is in all pulley grooves and inside all belt

guides.

-ER

ULLEY

=R

fvT BELT

У

1

\

jm NUT

Ì ÄB

DERATING

;LT

in nf tr

now

0,1. ‘A ■, L «Y'M'f f V i: sine pulley

• " . , ■ I so h idler pui-

nr •; ' 1 I ,ir ' . :.T r-'p v'.'A s'.c I'iiipg Pulley.

Roll bsk off all Gthor pu

iiPdrxc?

Slide belt from under «c

To install belt- reverse a

)RiVE

ÌELT

ove D \ f erre belt is

iissec-

at ten-

Г yj

fi

i

MÖWE

- .н.

¡OLER

гULLEY

ÍG. 31

Page 22

SERVICE AND ADJUSTMENTS

TO REPLACE MOTION DRIVE BELT (See

FiG. 32)

Park the tractor on level surface. Engage parking brake. For

ease of service there is a belt installation guide decal on bot

tom side of left footrest.

• Remove mower (See “TO REMOVE MOWER" in this sec

tion of this manual).

• Remove the clutch locator.

• Loosen bolt securing R.H. belt keeper.

• Disconnect dutch wire harness.

• Puli belt off clutching idler and raise to top side of pulley.

• Release parking brake. Push belt over and away from

clutching idler.

» Pull belt slack toward rear of tractor. Remove belt from

transmission pulley by deflecting keepers to force belt up

and out of pulley. Use belt to push keepers away from pul

ley.

• Work belt around remaining pulleys and keepers, working

toward transaxle pulley.

• Pull belt forward off of transaxle pulley and down over

electric clutch.

» Install new belt by reversing above procedure.

IMPORTANT: MAKE SURE RIGHT HAND BELT KEEP

ER IS POSITIONED CORRECTLY BE

TWEEN LOCATOR TABS, AND ELEC

TRIC CLUTCH CONNECTION IS SE

CURE.

TRANSAXLE SHIFTER LINKAGE AND

ADJUSTMENT (See FIGS. 33 and 34)

The transaxle should be in neutral when the gear shift lever

is in the neutral (lock gate) position. The adjustment is preset

at the factory: however, if adjustment is needed, proceed as

follows.

• Make sure transaxle is in neutral.

® Loosen two locknuts on tie rod.

FIG. 33

Turn center rod until gearshift lever falls into neutral lock

gate on fender console.

• Tighten locknuts securely

TO ADJUST STEERir-G WHEEL ALIGNMENT

If steering wheel crossbars are not horizontal (left to right)

when wheels are positioned straight forward, remove steer

ing wheel and reassemble per instructions in the Assembly

section of this manual.

FRONT WHEEL TOE--iN/CAMBRR

The front wheel toe-in and camber are not adjustable on

your unit, if damage has occurred to affect the front wheel

toe-in or camber, contact your nearest authorized service

center.

Page 23

;i. E AIMD ADJUSTMEN T b

lOVE WHEEL FOR REPAIRS (See

FIG. 35)

’ Block up axie securely.

• Remove wheel cover, retaining ring and washers to allow

wheel removal (rear wheel contains a square key - Do not

lose),

• Repair tire and reassemble.

• On rear wheels only: align grooves in rear wheel hub and

axle. Insert square key.

• Replace washers and snap retaining ring securely in axle

groove,

• Replace wheel cover.

T R v7i H/: WEAK BATTERY

(See FIGS. 36 and 37)

CAUTION: Lead-acid batteries generate

explosive gases. Keep sparks, fiarne and

smoking materiais away from satteriss.

A

Always wear eye proteetlon when around

batteries.

TO ATTACH JUMPER CABLES

• Connect each end of the RED cable to the POSITIVE (+)

terminal of each battery, taking care not to short against

chassis.

• Connect one end of the BLACK cable to the NEGATIVE

(-) terminal of fully charged battery.

• Connect the other end of the BLACK cable to a panel bolt

on the left side of the chassis, away from fuel tank and

battery.

TO REMOVE CABLES, REVERSE ORDER

» BLACK cable first from left side of chassis and fully

charged battery.

• RED cable last from both batteries.

REPLACE FUSE

' ) uCr- V ¡1 jo amp auicrnoiive-tvpe plug-in fuse. The

f. .Q po -li-i !occ.ied behind the dash

TC F-LACE '^EAD ^GhT BULB

‘ -'9,Si Od.

» ij i:^ , ' ^'xoi.n- ■ _le inthe baukcide ofthe grill.

* ■ „ ■: - ^ clde; • Id pi'ch btih -.older securely

iOi a i! :acki<cf Amt unll.

Close hood.

IMPORTANT:

f

/

“POSITiVE“ (+)

V y ( )

'HE OCHER VE

TEM. DO NOT USE YOUR TRACTO

F OiE “T FA. II TMr w/i HICLt-

'—V

if ,'líí5 !

Fií3. 36

-'D WITH

V -

m

“WEGATiVE" H

Page 24

SERVICE AND ADJUSTMENTS

ENGINE

TO ADJUST THROTTLE CONTROL CABLE

(See FIG. 38)

The throttle control has been preset at the factory and ad

justment should not be necessary. Check adjustment as de

scribed below before loosening cable. If adjustment is nec

essary, proceed as follows:

• With engine not running, move throttle control lever to

’’FAST” position.

• Check that throttle lever is against stop. If it is not, loosen

cable clamp screw and pull cable back until throttle lever

is against stop. Tighten cable clamp screw securely.

TO ADJUST CARBURETOR

The carburetor has been preset at the factory and adjust

ment should not be necessary. However, minor adjustment

may be required to compensate for differences in fuel, tem

perature, altitude or load. Ifthe carburetor does need adjust

ment, see engine manual packed with your unit

IMPORTANT: NEVER TAMPER WITH THE ENGINE

GOVERNOR, WHICH IS FACTORY SET

FOR PROPER ENGINE SPEED. OVER

SPEEDING THE ENGINE ABOVE THE

FACTORY HIGH SPEED SETTING CAN

BE DANGEROUS. IF YOU THINK THE

ENGINE-GOVERNED HIGH SPEED

NEEDS ADJUSTING, CONTACT YOUR

NEAREST AUTHORIZED SERVICE CEN

TER, WHICH HAS PROPER EQUIPMENT

AND EXPERIENCE TO MAKE ANY NEC

ESSARY ADJUSTMENTS.

Page 25

s i oHMàìz

Immediately prepare your tractor for storage at the end of

the season or if the unit will not be used for 30 days or more.

• r''vr> s*c^>£ toe f a'to- '-'•ith

.< ' ; niMto.tr R »nsidifO i'uilairio'irtere

A

' , ..5 ri-aoh an coer tm-ne ct op rk.

> f -a <r ccc4 before « CsTC* in

any enclosure.

TRACTOR

Remove mower from tractor for winter storage. When

mower is to be stored for a period of time, clean it thoroughly,

remove all dirt, grease, leaves, etc. Give blades and under

side of housing a good coat of grease or rust preventative.

Store in a clean, dry area.

• Clean entire tractor (See “CLEANING” in the Mainte

nance section of this manual).

• Inspect and replace belts, if necessary (See belt replace

ment insiruciioris in the Service and Adjustments section

of this manual).

• Lubricate as shown in the Maintenance section of this

manual.

• Be sure that all nuts, bolts and screws are securely fas

tened. inspect moving parts for damage, breakage and

wear. Replace if necessary.

• Touch up all rusted or chipped paint surfaces; sand lightly

before painting.

8/ VTi^RY

» Fully charge the battery for storage.

• After a period of time in storage, battery may require re

charging.

« To help prevent corrosion and power leakage during long

periods of storage, baltery cables should be disconnected

and battery cleaned thoroughly (see “TO CLEAN B.AT-

TERY AND TERMINALS” in the Maintenance section of

this .manual).

• After cleaning, leave cables disconnected and place ca

bles where they cannot come in contact with battery termi

nate,

• Be sure battery drain tube is securely attached to drain in

battery tray.

ENGINE

FUEL SYSTEM

IMPORTANT:

* Drain the fuel tank.

* Start the engine and let it run until the fuel lines and carbu

retor are empty.

® Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur.

» Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable alternative in mini

mizing the formation of fuel gum deposits during storage.

Add stabilizer to gasoline in fuel tank or storage container.

Always follow the mix ratio found on stabilizer container.

Run engine at least 10 minutes after adding stabilizer to al

low the stabilizer to reach the carburetor. Do not drain the

gas tank and carburetor if using fuel stabilizer.

ENGINE OIL

D to c Wii > er '”1 '

c- 'it. ‘ tt L

LU;;to. „

C' .to'

* ■ '• otliO

* Pour Offe ounce of oil t

mo

Tui

Oil.

• r .

I ntri

• Do not store qas

RepI:

andy

® ttpo; h* .r ;

® .ove? v'.ur un 'I

,’.ot rei'inrort •

br-aih which irli

you un t 'Ut

> I h r.-vi

dirt ir

If Clin il. ll, 4 f

’ - I ■‘to 1 - ‘ "j ri L‘/ci‘W G<JM

XtoJ 'to IF. ^ t MIND If ESSEM-

1 toi F> A. ,• P / F /-aF .UCH wS

“'F 1-E‘toR fDEi cTMi, FUEL

■ITA- A FT «K DStorifIto 3TORAOL.

, L''w h F- F to ' - ii.:- ' ATLR rHAf

.'XH- ‘

GASOHO

METHANXL) C

FORMATION C

AGE. ACIDIC

ritoL ftoFM

: f f e C ;

Ì T L-

tl rjmrf, witis (CALLED

V“ ,j Hi . XANOl or

I.

, -• ir axmoiffurf

n f rr i bee with clean engine

to'!i. . e section of this man-

1,. .i 3D. li plug hole(s) into cy!-

X os on k'i few seconds to

plug(s).

oiine Will c£

.init indoors

u tt4i'I. ¡jm •" cover that does

or 'ito w i!>. Plastic cannot

^ - >“pa”ation and

mto‘- 01 .’RING STOR-

AN DAMAGE THE

' N'ENGINE WHILE IN

e p obiems.

XIL as are STILL

another.

:s to rust. Rust

ar it to give pro-

and wiii cause

^ WHILE EN-

Page 26

TROUBLESHOOTING PUIn ï b

PROBLEM

Will not start

Hard to start

Engine will not

turn over

CAUSE

1. Out of fuel.

2. Engine not “CHOKED” properly.

3. Engine flooded.

4. Bad spark plug.

5. Dirty air filter.

6. Dirty fuel filter.

7. Water in fuel.

8. Loose or damaged wiring.

9. Carburetor out of adjustment.

10. Engine valves out of adjustment.

1. Dirty air filter.

2. Bad spark plug.

3. Weak or dead battery.

4. Dirty fuel filter.

5. Stale or dirty fuel.

6. Loose or damaged wiring.

7. Carburetor out of adjustment.

8. Engine valves out or adjustment.

1. Clutch/brake pedal not depressed.

2. Attachment clutch is engaged.

3. Spark plug wire is disconnected.

4. Weak or dead battery.

5. Blown fuse.

6. Corroded battery terminals.

7. Loose or damaged wiring.

8. Faulty ignition switch.

9. Faulty solenoid or starter.

10. Faulty operator presence switch(es).

CORRECTION

1. Fill fuel tank.

2. See TC START ENGINE in Cperation section.

3. Wait several minutes before attempting to start.

4. Replace spark plug.

5. Clean/replace air filter.

6. Replace fuel filter.

7. Drain fuel tank and carburetor, refill tank

with fresh gasoline and replace fuel filter.

8. Check all wiring.

9. Contact authorized service facility.

10. Contact authorized service facility.

1. Clean/replace air filter.

2. Replace spark plug.

3. Recharge or replace battery.

4. Replace fuel filter.

5. Drain fuel tank and refill with fresh gasoline.

6. Check all wiring.

7. Contact authorized service facility.

8. Contact authorized service facility.

1. Depress clutch/brake pedal.

2. Disengage attachment clutch.

3. Connect wire to spark plug.

4. Recharge or replace battery.

5. Replace fuse.

6. Clean battery terminals.

7. Check all wiring.

8. Check/replace ignition switch.

9. Check/replace solenoid or starter.

10. Contact authorized service facility.

Engine clicks but

will not start

Loss of power

Excessive vibrât

1. Weak or dead battery.

2. Corroded battery terminals.

3. Loose or damaged wiring.

4. Faulty solenoid or starter.

1. Cutting too much grass/too fast.

2. Throttle in “CHCKE” position.

3. Buildup of grass, leaves and trash under mower.

4. Dirty air filter.

5. Low oil level/dirty oil.

6. Faulty spark plug.

7. Dirty fuel filter.

8. Stale or dirty fuel.

9. Water in fuel.

10. Spark plug wire loose.

11. Dirty engine air screen/fins.

12. Dirty/clogged muffler.

13. Loose or damaged wiring.

14. Carburetor out of adjustment.

15. Engine valves out of adjustment.

1. Worn, bent or loose blade.

2. Bent blade mandrel.

3. Loose/damaged part(s).

1. Recharge or replace battery.

2. Clean battery terminals.

3. Check ail wiring.

4. Check/replace solenoid or starter.

1. Set in “Higher Cut” position/reduce speed.

2. Adjust throttle control.

3. Clean underside of mower housing.

4. Clean/replace air filter,

5. Check oil ievel/change oil.

6. Clean and regap or change spark plug.

7. Replace fuel filter.

8. Drain fuel tank and refill with fresh gasoline.

9. Drain fuel tank and carburetor, refill tank

with fresh gasoline and replace fuel filter.

10. Connect and tighten spark plug wire.

11. Clean engine air screen/fins.

12. Clean/replace muffler.

13. Check all wiring.

14. Contact authorized service facility.

15. Contact authorized service facility.

1. Replace blade. Tighten blade bolt.

2. Replace blade mandrel.

3. Tighten loose part(s). Replace dam

aged parts.

26

Page 27

TROUBLESHOOTING POINTS

PROBLEM CAUSE

Engine continues

to run when oper

ator leaves seat

with attachment

clutch engaged

Poor cut - uneven

1. Faulty operator-safety presence control system.

1. Worn, bent or loose blade.

2. Mower deck not level.

3. Buildup of grass, leaves, and trash under mower.

4. Bent blade mandrel.

Mower blades will

not rotate

1. Obstruction in clutch mechanism.

2. Mower drive belt out of adjustment.

3. Worn/damaged mower drive belt.

4. Frozen idler pulley.

5. Frozen blade mandrel.

Poor grass

discharge

1. Engine speed too slow.

2. Travel speed too fast.

3. Wet grass.

4. Mower deck not level.

5. Low/uneven tire air pressure.

6. Worn, bent or loose blade.

7. Buildup of grass, leaves and trash under mower.

8. Mower drive belt worn or out of adjustment.

9. Blades improperly installed.

10. Improper blades used.

CORRECTION

1. Check wiring, switches and connections, ^ If not

corrected, contact authorized service facility.

1. Replace blade. Tighten blade bolt.

2. Level mower deck.

3. Clean underside of mower housing.

4. Replace blade mandrel.

1. Remove obstruction.

2. Adjust mower drive belt.

3. Replace mower drive belt.

4. Replace idler pulley.

5. Replace blade mandrel.

1. Place throttle control in “FAST" position.

2. Shift to slower speed.

3. Allow grass to dry before mowing.

4. Level mower deck.

5. Check tires for proper air pressure.

6. Replace/sharpen blade. Tighten blade bolt.

7. Clean underside of mower housing.

8. Replace/adjust mower drive belt.

9. Reinstall blades sharp edge down.

10. Replace with blades listed in this manual.

Headligh“?,) not

working u. so

equipped)

Battery wiii not

charge

1. Switch is “OFF”.

2. Bulb(s) burned out.

3. Faulty light switch.

4. Loose or damaged wiring.

5. Blown fuse.

1. Bad battery cell(s).

2. Pc5or cable connections.

3. Faulty reguiator (if so equipped).

4. Faulty aiternator.

1. Turn switch “ON”.

2. Replace bulb(s).

3. Check/replace light switch.

4. Check wiring and connections.

5. Replace fuse.

1. Replace battery.

2. Check/clean all connections.

3. Replace regulator.

4. Replace alternator.

27

Page 28

SERVICE NOTES

Page 29

SERVICE NOTES

Page 30

18 HP 44” RIDING GARDEN TRACTOR MODEL NUMBER XC1182B

SCHEMATIC

IGNITION SWITCH

POSITION

CIRCUIT

OFF M + G

ON

START

B + L

B + S

NOTE: IF WIRING INSULATED

CLIPS WERE REMOVED FOR

SERVICING OF UNIT, THEY

SHOULD BE REPLACED TO

PROPERLY SECURE YOUR WIRING

-

------

-

I = I

86 ¿5

“SO

RELAY

POSITION

OFF

ON

NON-REMOVABLE n

CONNECTIONS

REMOVABLE p

CONNECTIONS ^

CIRCUIT

B + E. C + D

B + A, C + F

C

Page 31

SUGGESTED GUIDE FOR Sli^HT^^JG SLOPES FOR SAFE OPERATION

ONLY RIDE UP AND DOWN HILL,

NOT ACROSS HILL

iàiiaàùiài^

8 i '.i

SKY LINT

u .

i I

ащщ^jщ^MMмMЙiMsX^щщщщjMX^аzмЙмЙщiMMM^MмMi2^щMX^^щ^iЙщXщXщмiщMXщiщ^i^i£aм^M:щMM^^^iщX

Operate yoyr Tractor yp and down the face of slopes (not

greater thi , never across the face. Make turns gradu

ally to prevent tipping or loss of control. Exercise extreme

caution when changing direction on slopes.

Page 32

PARTS AND SERVICE

Your POtJLAN/WEED EATEE product has been expertly engineered and carefully manufac

tured to rigid quality standards. As with all mechanical products, some adjustments or part

replacement may be necessary during the life of your unit.

FOR SERVICE OR REPLACEMENT PARTS:

1. Consult your dealer/place of purchase.

2. Consult the yellow pages of your phone directory for the name of the nearest

Poulan/Weed Eater Master Service Dealer (under “saws” for Chain Saws or

under “lawn mowers” for Trimmers, Brushcutters, and Blowers).

3. For replacement parts, have available the following information:

a. Description of the tool.

b. Model Number.

c. Description of part.

NOTE: Poulan/Weed Eater Division provides parts and service through its authorized dis

tributors and dealers; therefore, all requests for parts and service should be directed to your

local dealer(s). The philosophy of Poulan/Weed Eater Division is to continually improve all of

its products. If the operating characteristics or the appearance of yoiir product differs from

those described in this Operator’s Manual, please contact your local Poulan/Weed Eater

Dealer for updated information and assistance. Always update your tool when improve

ments are made available, especially those related to safety. Parts and repair service are not

available directly from Poulan/Weed Eater Division White Consolidated Industries, Inc.

F OU"LAF/W¥ ED EATER

DIVISION WHITE CONSOLIDATED INDUSTRIES, INC.

Shreveport, Louisiana 71139-9329

Printed in U.S.A. 01.21.91

© 1990 Poulan/Weed Eater Bivision Wliite Consolidated Industries, Inc.

128616

Loading...

Loading...