Page 1

IMPORTANT MANUAL Do Not Throw Away

OWNER'S MANUAL

MODEL NUMBER:

PR621

Read the Owner's Manual and

fol low all Warnings and Safety

In struc tions. Fail ure to do so

can result in serious injury.

WARNING:

SNOW THROWER

Gasoline containing up to 10% ethanol (E10) is acceptable for use in this machine.

The use of any gasoline exceeding 10% ethanol (E10) will void the product warranty.

Always Wear Eye Protection During Operation

585 14 66-32 05.01.13 TH Printed in the U.S.A.

Page 2

CONGRATULATIONS on your purchase of a new snow thrower. It has been designed, engineered and man u fac tured to

give best possible dependability and per for mance.

Should you experience any problem you cannot easily remedy, please contact your nearest authorized service center. We

have competent, well-trained tech ni cians and the proper tools to service or repair this unit.

Please read and retain this manual. The instructions will enable you to assemble and maintain your snow thrower prop er ly.

Always observe the “SAFETY RULES”.

Safe Operation Practices for Walk-Behind Snow Throwers

IMPORTANT: This snow thrower is capable of amputating hands and feet and throwing objects. Failure to observe the

following safety instructions could result in serious injury.

Look for this symbol to point out im por tant

safety precautions. It means CAUTION!!! BE COME ALERT!!! YOUR SAFE TY IS IN VOLVED.

WARNING: Always disconnect spark plug wire

and place it where it can not con tact plug in order

to pre vent ac ci den tal start ing when setting up,

trans port ing, ad just ing or making re pairs.

WARNING: This snow thrower is for use on

sidewalks, driveways and other ground level surfaces. Caution should be exercised while using

on sloping surfaces. Do not use snow thrower

on surfaces above ground level such as roofs

of residences, garages, porch es or other such

structures or buildings.

Training

1. Read, understand and follow all instructions on the

machine and in the manual(s) before operating this

unit. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

2. Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

3. Keep the area of operation clear of all persons, particularly small children.

4. Exercise caution to avoid slipping or falling, especially

when operating the snow thrower in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is

to be used and remove all doormats, sleds, boards,

wires, and other foreign objects.

2. Ensure the control bar is released before starting the

engine.

3. Do not operate the equipment without wearing adequate

winter garments. Avoid loose fitting clothing that can

get caught in moving parts. Wear footwear that will

improve footing on slippery surfaces.

4. Handle fuel with care; it is highly flammable

(a) Use an approved fuel container.

(b) Never add fuel to a running engine or hot engine.

(c) Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors.

WARNING: Snow throwers have ex posed rotating

parts, which can cause severe injury from contact,

or from material thrown from the discharge chute.

Keep the area of operation clear of all persons,

small children and pets at all times including

startup.

CAUTION: Muffler and other engine parts be-

come extremely hot during operation and remain

hot after engine has stopped. To avoid severe

burns on contact, stay away from these areas.

WARNING: Engine exhaust, some of its con stit u-

ents, and certain vehicle com po nents contain or

emit chem i cals known to the State of Cal i for nia

to cause can cer and birth defects or oth er re produc tive harm.

(d) Never fill containers inside a vehicle or on a truck or

trailer bed with a plastic liner. Always place containers

on the ground, away from your vehicle, before filling.

(e) When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment

on a trailer with a portable container, rather than

from a gasoline dispenser nozzle.

(f) Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times, until refueling

is complete. Do not use a nozzle lock-open device.

(g) Replace gasoline cap securely and wipe up spilled

fuel.

(h) If fuel is spilled on clothing, change clothing im-

mediately.

5. Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive motors

or electric starting motors.

6. Never attempt to make any adjustments while the

engine (motor) is running (except when specifically

recommended by manufacturer).

7. Always wear safety glasses or eye shields during operation or while performing an adjustment or repair to

protect eyes from foreign objects that may be thrown

from the machine.

8. Let engine and machine adjust to outdoor temperatures

before starting to clear snow.

2

Page 3

Operation

1. Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

2. Exercise extreme caution when operating on or crossing gravel drives, walks, or roads. Stay alert for hidden

hazards or traffic.

3. After striking a foreign object, stop the engine (motor),

disconnect the cord on electric motors, thoroughly

inspect the snow thrower for any damage, and repair

the damage before restarting and operating the snow

thrower. Remove key.

4. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

5. Stop the engine (motor) whenever you leave the operating position, before unclogging the auger housing

or discharge chute, and when making any repairs,

adjustments or inspections.

6. When cleaning, repairing or inspecting the snow thrower,

stop the engine and make certain the auger blades and

all moving parts have stopped. Remove key.

7. Do not run the engine indoors, except when starting

the engine and for transporting the snow thrower in or

out of the building. Open the outside doors; exhaust

fumes are dangerous.

8. Exercise extreme caution when operating on slopes.

9. Never operate the snow thrower without proper guards,

and other safety protective devices in place and working.

10. Never direct the discharge toward people or areas

where property damage can occur. Keep children and

others away.

11. Do not overload the machine capacity by attempting

to clear snow at too fast a rate.

12. Never operate the machine at high transport speeds

on slippery surfaces. Look behind and use care when

operating in reverse.

13. Disengage power to the auger blades when snow

thrower is transported or not in use.

14. Use only attachments and accessories approved by

the manufacturer of the snow thrower.

15. Never operate the snow thrower without good visibility

or light. Always be sure of your footing, and keep a firm

hold on the handles. Walk; never run.

16. Never touch a hot engine or muffler.

Maintenance and Storage

1. Check shear bolts and other bolts at frequent intervals

for proper tightness to be sure the equipment is in safe

working condition.

2. Never store the machine with fuel in the fuel tank inside

a building where ignition sources are present such as

hot water heaters, space heaters, or clothes dryers.

Allow the engine to cool before storing in any enclosure.

3. Always refer to operator’s manual for important details

if the snow thrower is to be stored for an extended

period.

4. Maintain or replace safety and instruction labels, as

necessary.

5. Run the machine a few minutes after throwing snow

to prevent freeze-up of the collector/impeller.

SERIAL NUMBER: ___________________________

DATE OF PURCHASE: _______________________

THE MODEL AND SERIAL NUMBERS WILL BE FOUND

ON A DECAL ATTACHED TO THE REAR OF THE SNOW

THROWER HOUSING (Figure 1).

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

PRODUCT

PRODUIT

FOR SERVICE CALL/POUR LE SERVICE APPELER

1-800-448-7543

ASSEMBLED IN U.S.A. / ASSEMBLÉ AUX ÉTATS-UNIS

MCRAE, GA 31055

MAINTENANCE LEVEL

NIVEAU DE MAINTENANCE

000000000 00

MODEL NUMBER / NUMERO DE MODELE

00000000

CONFORME AUX NORMES DE SÉCURITÉ DE ANSI B71.3-2005

SERIAL NUMBER

NUMERO DE SERIE

000000A 000000

CONFORMS TO ANSI B71.3-2005 SAFETY STANDARDS

000000

Figure 1

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for

and using your snow thrower.

• Follow the instructions under “Maintenance” and “Stor age” sec tions of this manual.

Clearing a Clogged Discharge Chute

Hand contact with the rotating auger blades inside

the discharge chute is the most common cause

of injury associated with snow throwers. Never

use your hand to clean out the discharge chute.

To clear the chute:

1. SHUT THE ENGINE OFF!

2. Wait 10 seconds to be sure the auger blades have

stopped rotating.

3. Always use a clearing tool at least 15 inches long.

PRODUCT SPECIFICATIONS

Gasoline Capacity 1.6 Quarts (1,5 Liters)

and Type: Unleaded Regular only

Oil Type SAE 30 (above 50°F)

(API SG–SL): SAE 5W-30 or 10W-30

(32° to 50°F)

SAE 5W-30 (below 32°F)

Oil Capacity: 16 Ounces (0,47 Liters)

Spark Plug: F6RTC

Gap: 0.030" (0,762 mm)

3

Page 4

TABLE OF CONTENTS

SAFETY RULES ........................................................ 2-3

PRODUCT SPECIFICATIONS ...................................... 3

CUSTOMER RESPONSIBILITIES ................................ 3

SAFETY AND INSTRUCTIONAL DECALS ................. 4

SETUP........................................................................ 5-6

OPERATION ............................................................7-11

MAINTENANCE ..................................................... 12-16

STORAGE ................................................................... 17

TROUBLESHOOTING ................................................ 18

REPAIR PARTS ..................................................... 20-31

WARRANTY ................................................................ 32

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUAL AND ALL SAFETY RULES BEFORE OPERATING YOUR SNOW THROWER. Com-

pare the illustrations with your snow thrower to familiarize yourself with the location of various controls and adjustments.

Save this manual for future reference.

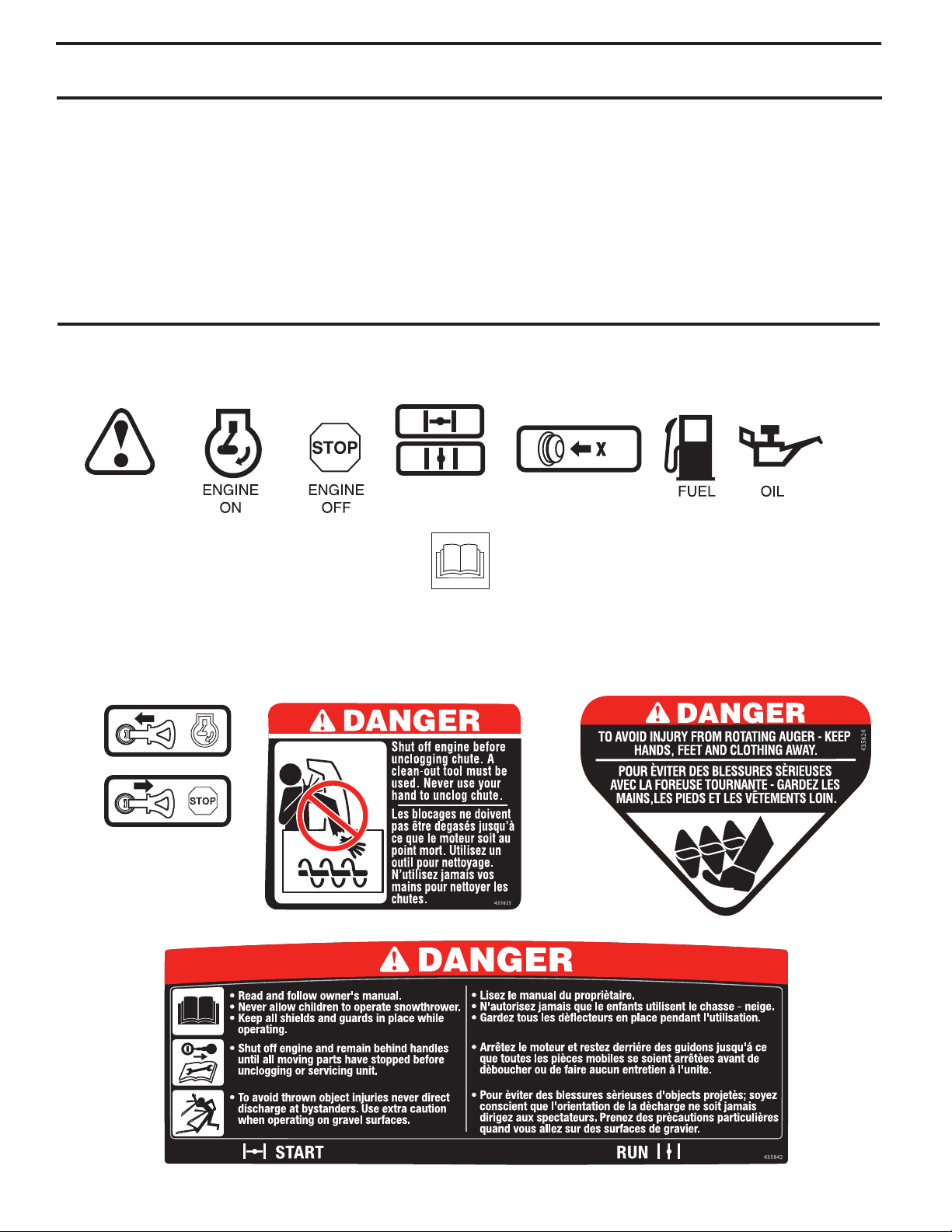

These symbols may appear on your snow thrower or in literature supplied with the product. Learn and understand their meaning.

IMPORTANT: Safety and instruction decals are located near areas of potential danger. Replace damaged decals.

2

DANGER

OR WARNING

CHOKE

PRIMER

IGNITION KEY.

INSERT TO START

AND RUN,

PULL OUT TO STOP.

READ AND FOLLOW ALL SAFETY INFORMATION

AND INSTRUCTIONS BEFORE USE OF THIS PRODUCT.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

4

Page 5

Setup

Loose Parts

Use the chart below to verify that all parts have been shipped.

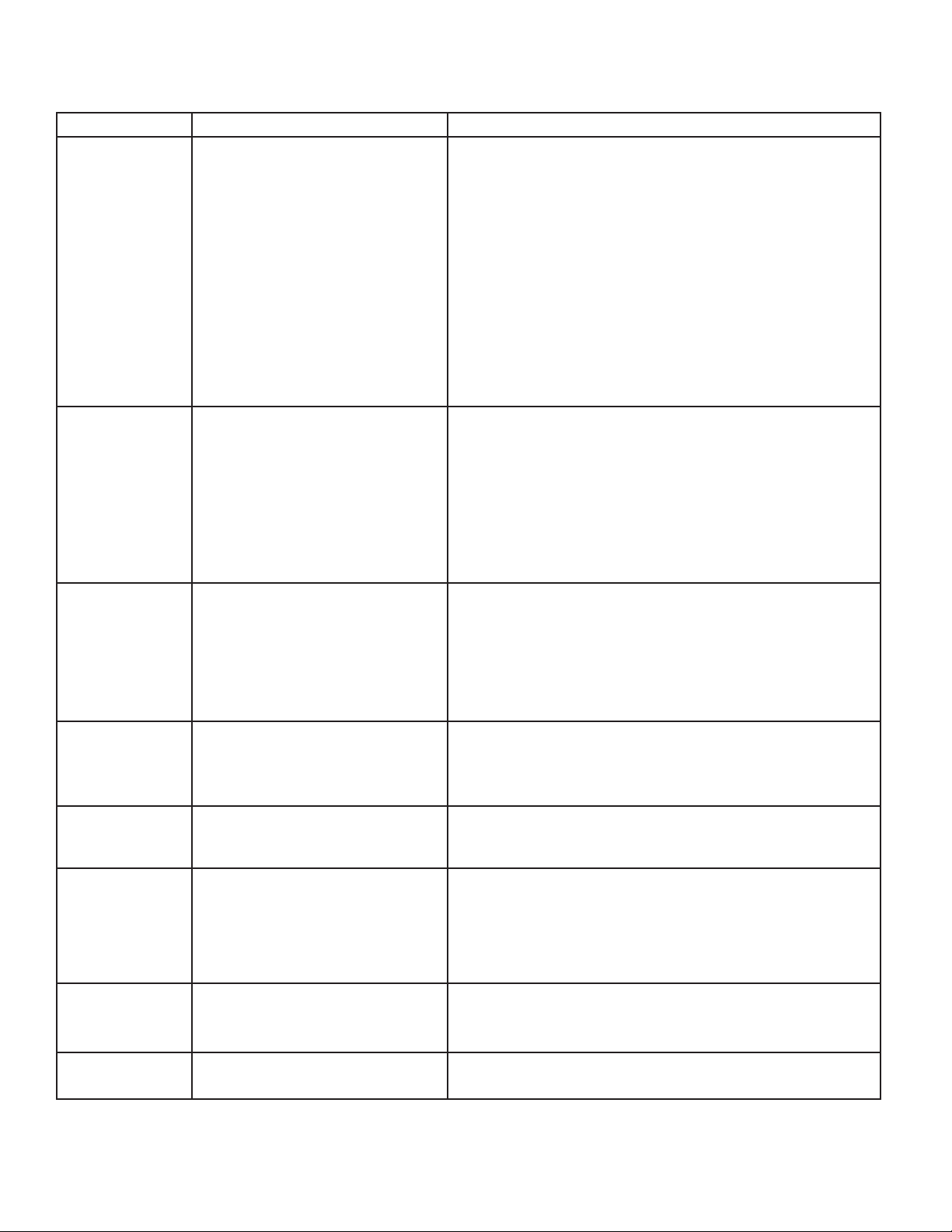

Procedure Description Qty. Use

1.

2.

No parts required – Unfold the handle.

Carriage bolts

Shoulder Bolt

Flange nuts

Washer

Knob

Cap Plunger

Chute

Deflector

4

1

4

1

1

1

1

1

Install the discharge chute.

Install the discharge chute.

Install the discharge chute.

Install the discharge chute.

Install the discharge chute.

Install the discharge chute.

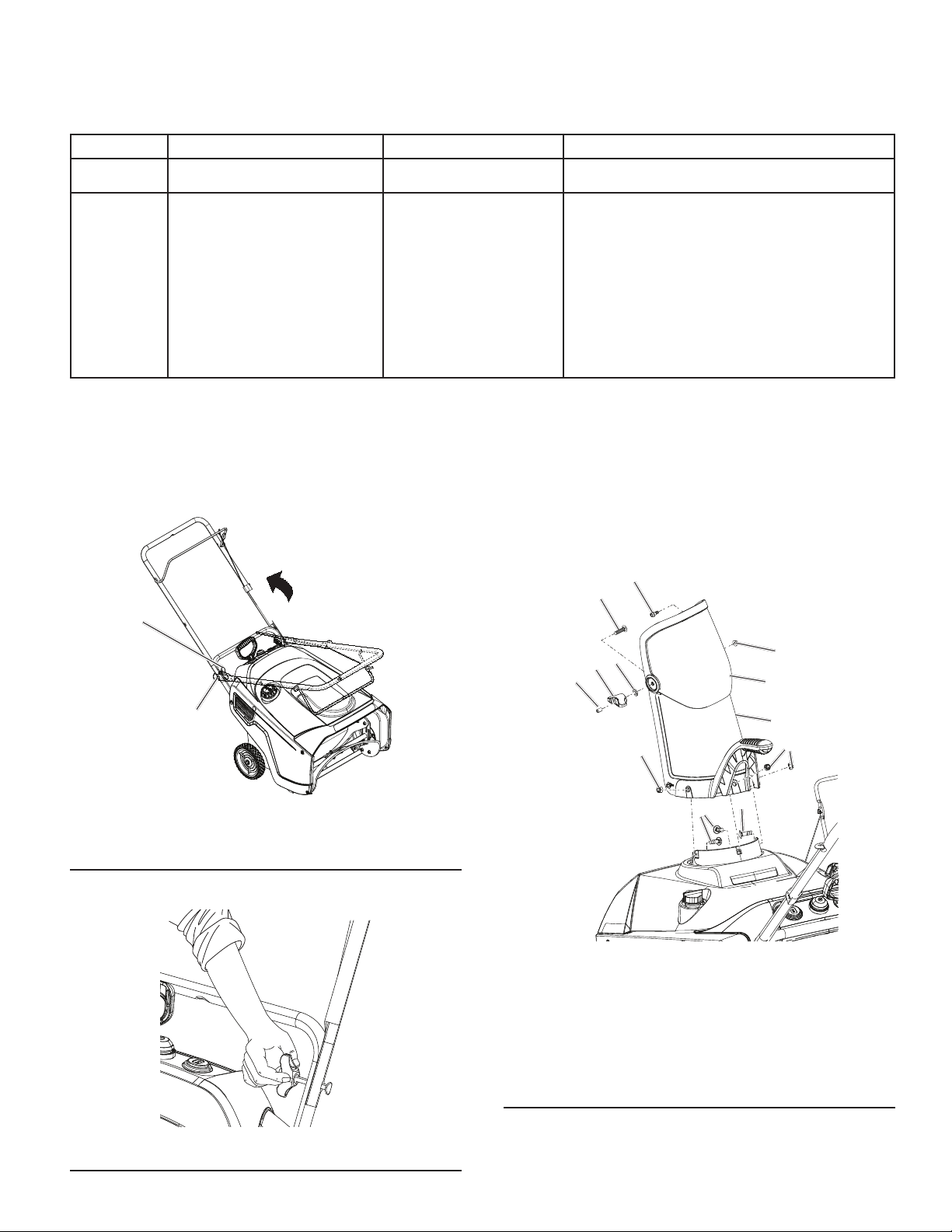

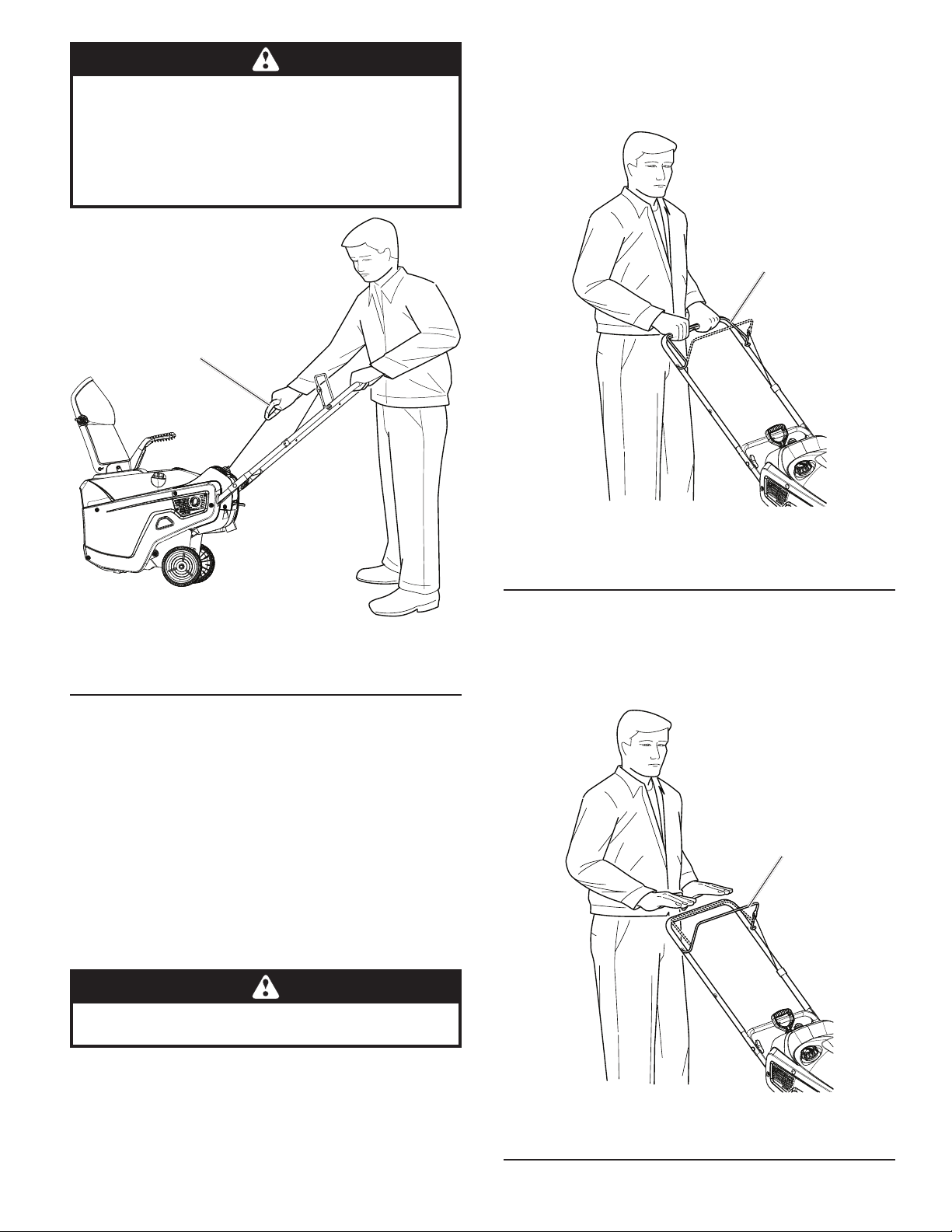

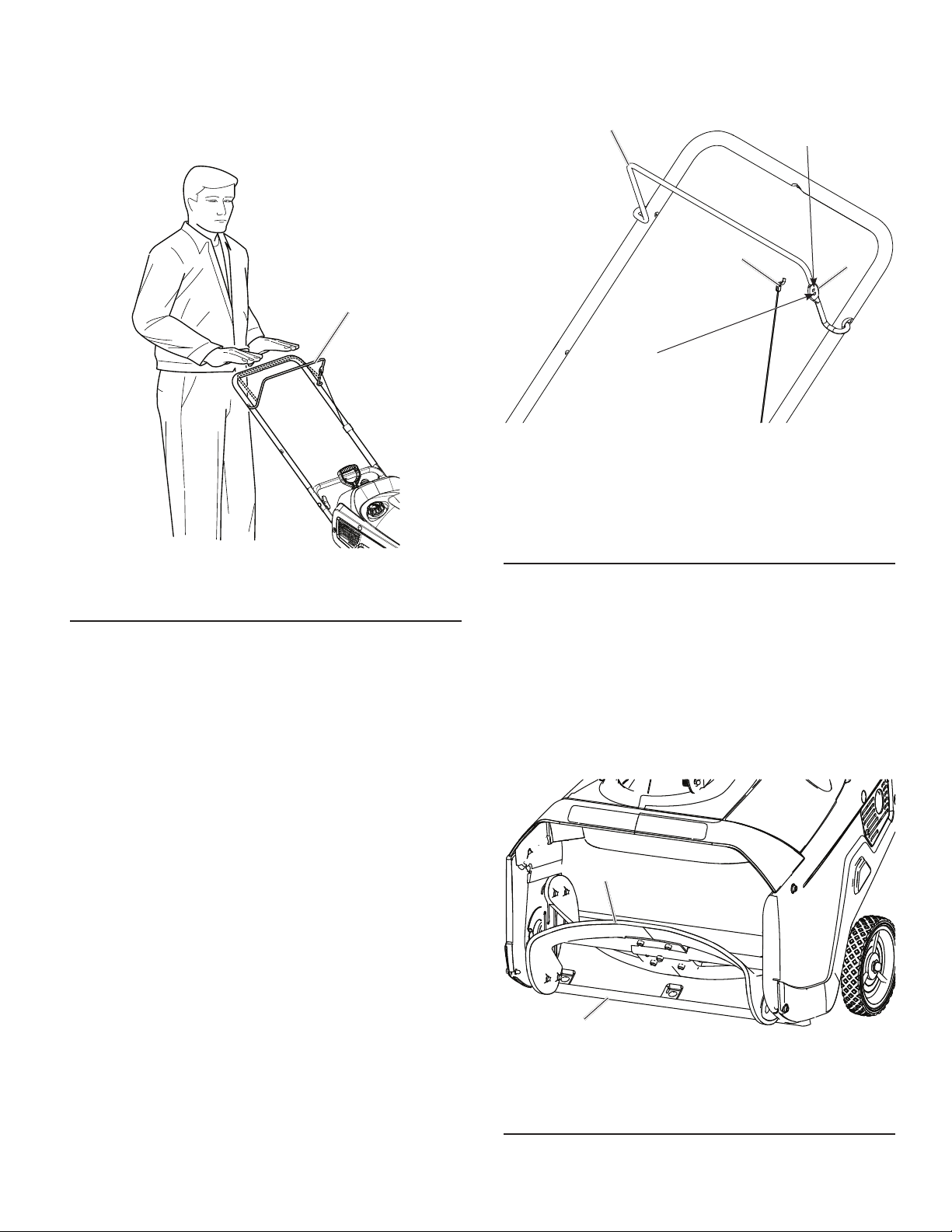

1. Unfolding the Handle

Procedure

1. Loosen the two handle knobs and pull out the two

handle bolts until you can move the handle freely and

rotate the handle to the operating position (Figure 2).

1

2

Figure 2

1. Handle knobs 2. Handle bolt

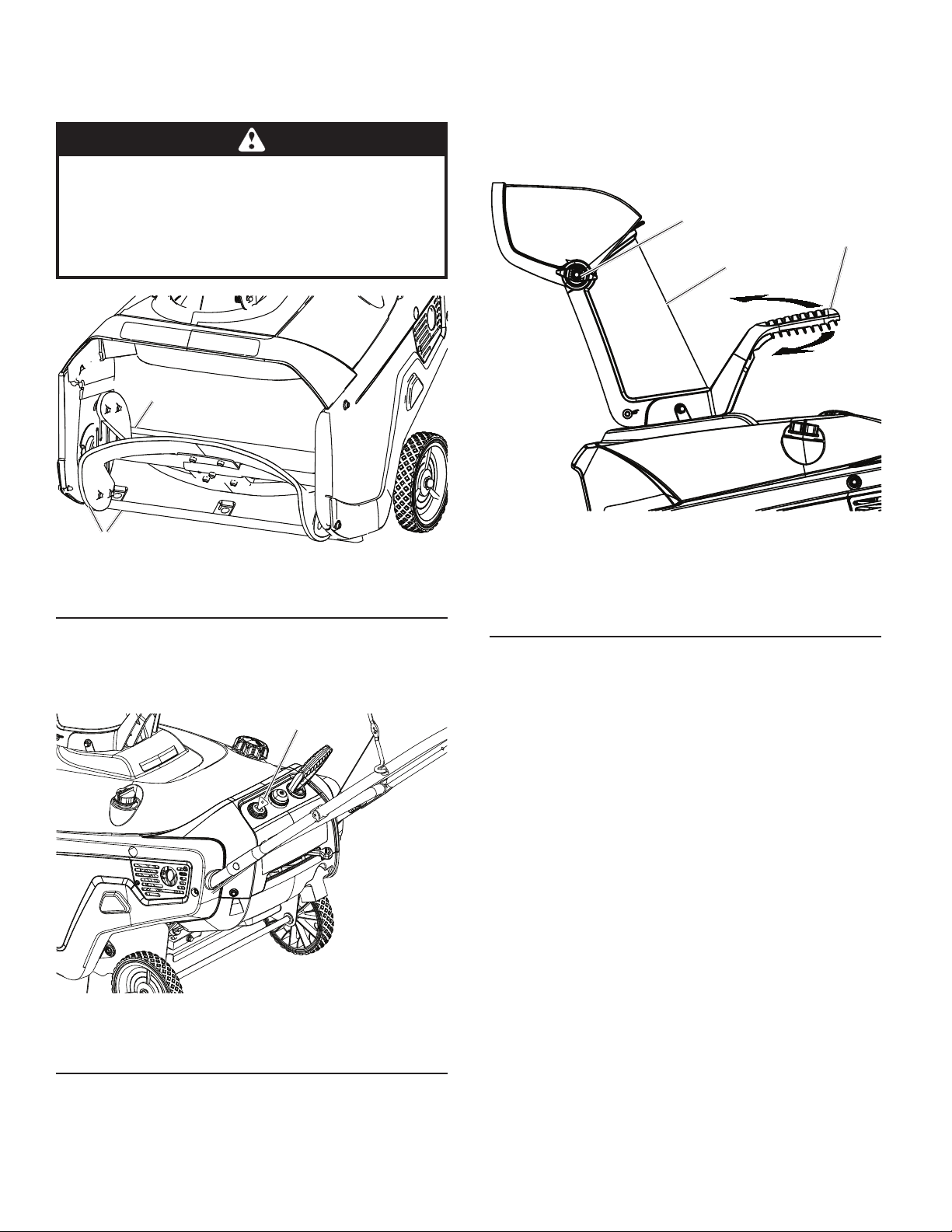

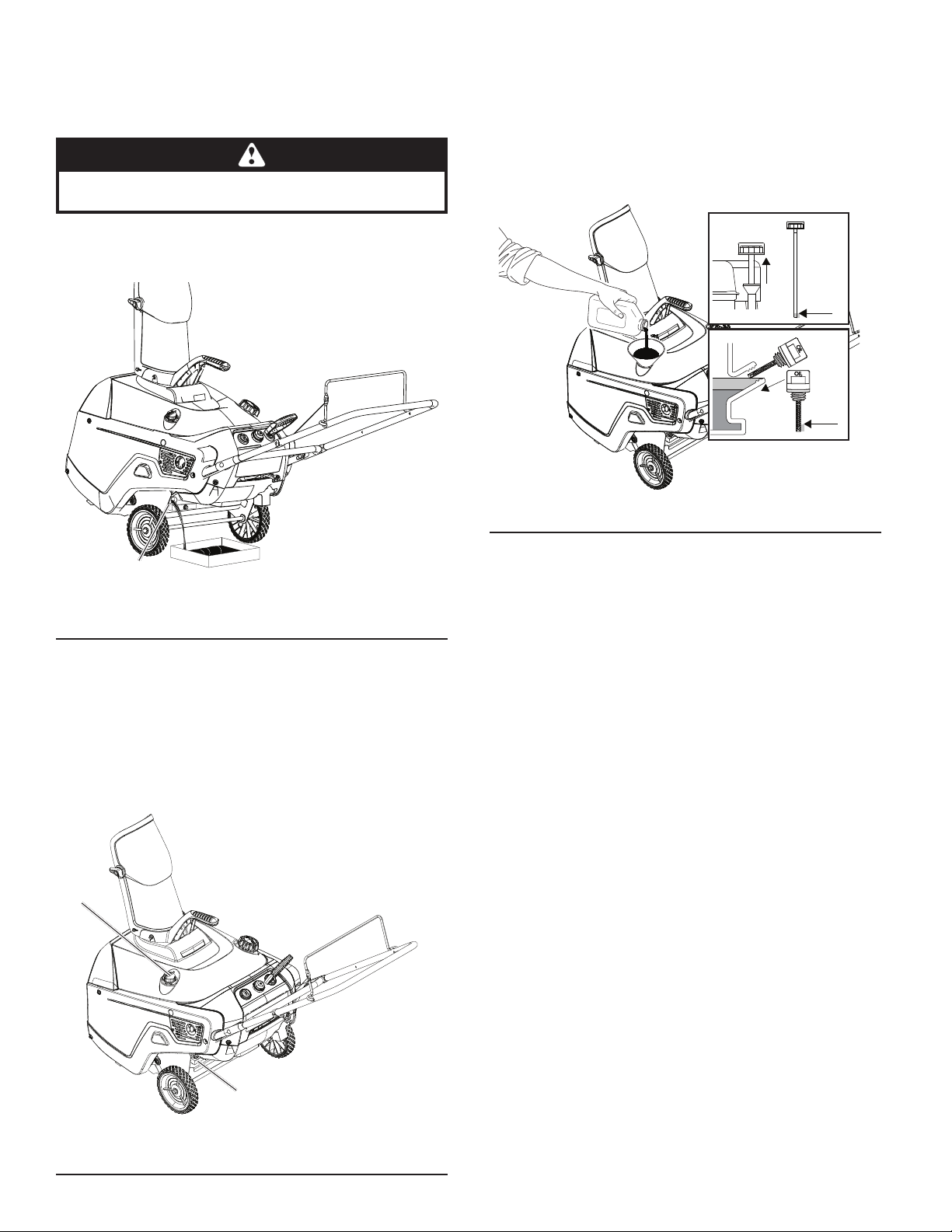

2. Installing the Discharge

Chute

Procedure

1. Install the chute deflector to the discharge chute using

bolts and, washer, nut, deflector knob and cap plunger

(Figure 4).

2. Install the discharge chute to the chute base using

three screws and nuts (Figure 4).

8

7

9

1

6

3

2

10

4

5

3

2

2. Tighten the handle knobs until they are snug (Figure 3).

Figure 3

Figure 4

1. Deflector

2. Carriage bolts

3. Flange nuts 5/16-18

4. Washer

5. Knob

IMPORTANT: Do not overtighten the flange nuts;

otherwise you may damage the discharge chute.

5

6. Discharge chute

7. Carriage Bolt

8. Shoulder Bolt

9. Flange nuts 1/4-20

10. Cap Plunger

Page 6

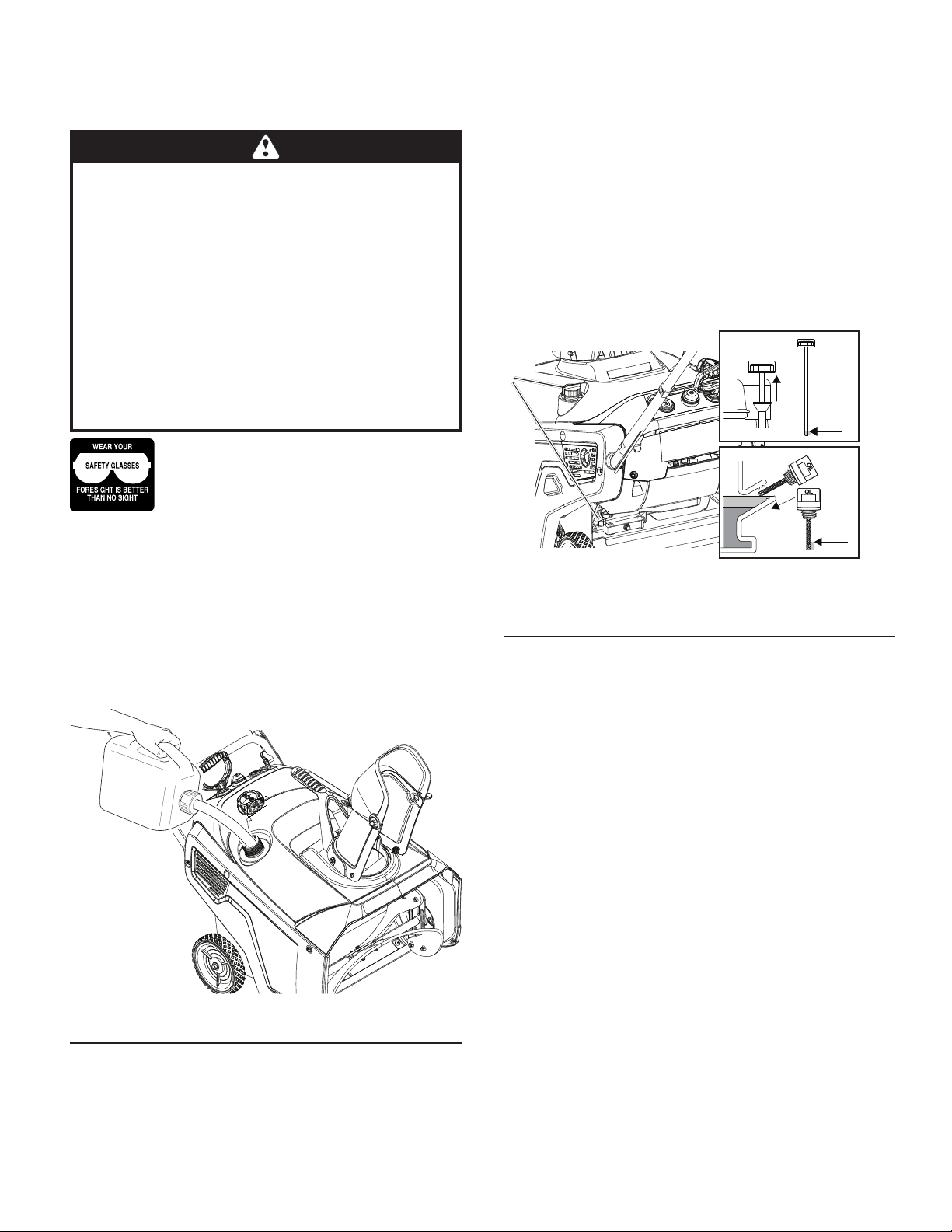

3. Filling the Engine with Oil

ENGINE

See engine manual.

LUBRICATION

NOTE: SAE 10W30 or SAE 5W30 oil is acceptable for

use in cold temperatures if engine is difficult to start.

NOTE: Although multi-viscosity oils (5W30, 10W30 etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F. Check your engine oil level more frequently to avoid

possible engine damage from running low on oil.

Change the oil after every 25 hours of operation or at least

once a year if the snow thrower is not used for 25 hours

in one year.

Check the crankcase oil level before starting the engine

and after each five (5) hours of continuous use. Tighten oil

fill cap / dipstick securely each time you check the oil level.

1. Move the snowthrower to a level surface.

2. Clean around the dipstick (Figure 5).

NOTE: Dipstick location may vary depending on engine

type.

3. Remove either side mounted filler cap dipstick or high

oil fill dipstick and wipe it clean.

Product Overview

13

*11

10

1

2

9, *11

4

3

5

6

12

7

8

1

Fill if oil

is below

“Add”

on the

GLSVWLFN

Fill if oil is

below letter

“L” on the

¿OOHUFDS

Figure 5

1. Oil filler cap/dipstick

4. Insert the dipstick into the filler neck and turn clockwise

until fully seated. Then remove the dipstick by turning

it counter-clockwise.

5. Fill oil to "FULL" on dipstick with the recommended oil.

6. Securely screw in the oil filler cap/dipstick.

Figure 6

1. Discharge chute

2. Chute deflector handle

3. Fuel tank cap

4. Control bar

5. Recoil start handle

6. Primer

7. Choke lever

8. Electric-start button

(if equipped)

9. Oil drain plug

10. Drive belt cover

*11. Oil fill cap/dipstick

12. Ignition key

13. Chute deflector

* Dipstick location may vary depending on engine type.

6

Page 7

Operation

NOTE: Determine the left and right sides of the machine

from the normal operating position.

• Gasoline is extremely flammable and explosive.

A fire or explosion from gasoline can burn you

and others.

• To prevent a static charge from igniting the gasoline, place the container and/or snowthrower on

the ground before filling, not in a vehicle or on

an object.

• Fill the tank outdoors when the engine is cold.

Wipe up spills.

• Do not handle gasoline when smoking or around

an open flame or sparks.

• Store gasoline in an approved fuel container, out

of the reach of children.

• Do not tip the snowthrower with fuel in the fuel

tank.

The operation of any snow thrower can result

in foreign objects thrown into the eyes, which

can result in severe eye damage. Always wear

safety glasses or eye shields while operating

your snow thrower or performing any ad just-

ments or repairs. We recommend standard safe ty glasses

or a wide vision safety mask worn over spectacles.

IMPORTANT: Know how to operate all controls before

adding fuel or attempting to start the engine.

NOTE: For best results, purchase only the quantity of

gasoline that you expect to use in 30 days. Otherwise,

you may add fuel stabilizer to newly purchased gasoline

to keep it fresh for up to 6 months.

Checking the Engine Oil

Level

1. Move the snowthrower to a level surface.

2. Clean around the dipstick (Figure 8).

NOTE: Dipstick location may vary depending on engine

type.

3. Remove either side mounted filler cap dipstick or high

oil fill dipstick and wipe it clean.

1

Fill if oil

is below

“Add”

on the

GLSVWLFN

Fill if oil is

below letter

“L” on the

¿OOHUFDS

Figure 8

Filling the Fuel Tank

Fill the fuel tank with fresh unleaded gasoline (minimum

87 AKI octane rating) (Figure 7).

Figure 7

IMPORTANT: Do not add oil to the gasoline.

IMPORTANT: Do not use E85 blended fuels. This engine

is not E20/E30/E85 compatible. Alternative fuels with

high alcohol content can cause hard starting, poor engine

performance, and may cause internal engine damage.

1. Oil filler cap/dipstick

4. Insert the dipstick into the filler neck and turn clockwise

until fully seated. Then remove the dipstick by turning

it counter-clockwise.

5. Fill oil to "FULL" on dipstick with the recommended oil.

6. Securely screw in the oil filler cap/dipstick.

NOTE: Running the engine with a low oil level can cause

engine damage. Always check the engine oil before start up.

NOTE: Running the engine with too much oil may cause

engine damage and excess smoke in the exhaust. Always

check the engine oil level before start up.

7

Page 8

Starting the Engine

1. Push key in (Figure 9).

1

Figure 9

1. Key

2. Move choke lever to left position (Figure 10).

3. Firmly push in the primer 2 times with your thumb,

holding the primer in a for a second before releasing

it each time (Figure 11).

1

Figure 11

1. Primer

NOTE: Remove your glove when you push in the primer

so that air cannot escape from the primer hole.

IMPORTANT: It may not be necessary to use the primer

or the choke if the engine has been running and is hot.

Excessive priming may flood the engine and prevent it

from starting.

4. Pull the recoil starter or if your snow thrower is equipped

with an electric starter, connect an extension cord to

the snow thrower and plug the other end into a threehole grounded 110 volt A.C. receptacle and push the

electric-start button (Figure 12).

1. Choke lever

Figure 10

1

1

Figure 12

1. Electric start button

NOTE: Use an extension cord recommended for outdoor

use that is not longer than 50 feet (15 m).

8

Page 9

Engaging the Auger Blades

The electrical cord can become damaged, causing

a shock or fire.

Thoroughly inspect the electrical cord before plug-

ging it into a power source. If the cord is damaged,

do not use it to start the snowthrower. Replace or

repair the damaged cord immediately. Contact an

Authorized Service Dealer for assistance.

1

To engage the auger blades, hold the control bar against

the handle (Figure 14).

1

Figure 14

Figure 13

1. Recoil start handle

IMPORTANT: Run the electric starter no more than 10

times at intervals of 5 seconds on, then 5 seconds off.

Running the electric starter extensively can overheat and

damage it. If the engine does not start after this series of

attempts, wait at least 40 minutes to allow the starter to

cool before attempting to start it again. If the engine does

not start after the second series of attempts, take the

snowthrower to an Authorized Service Dealer for service.

NOTE: If you pull the recoil handle and feel no resistance,

the starter may be frozen. Thaw out the starter before

attempting to start the snowthrower.

5. While the engine is running, move the choke lever

slowly to the right position.

6. Unplug the extension cord from the power source and

the snowthrower (Figure 12).

Unplug the power cord whenever you are not start-

ing the snowthrower.

1. Control bar

Disengaging the Auger

Blades

To disengage the auger blades, release the control bar

(Figure 15).

1

Figure 15

1. Control bar

9

Page 10

IMPORTANT: During initial operation there may be wear

between the auger blades and the scraper bar. Maximum

performance, both snow throwing and driving, occurs

when there is zero clearance between these two parts

(Figure 16).

During initial break-in period of the auger blades it

is normal for the auger blades to build up excessive

heat if not operated in the snow.

Do not operate without snow or water for lubricating

the auger blades. This will cause excessive heat

build up in the auger blades which could cause

damage to the auger blades and scrapper bar.

1

Adjusting the Discharge

Chute and Chute Deflector

To adjust the discharge chute, move deflector chute handle

left or right to desired position (Figure 18).

1

3

2

2

Figure 16

1. Rub Area 2. Wear Areas

Stopping the Engine

To stop the engine, pull key out (Figure 17).

1

Figure 18

1. Chute deflector knob

2. Chute deflector

3. Chute handle

To raise or lower the angle of the chute deflector, loosen

the chute deflector knob on the chute deflector and move

the chute deflector up or down (Figure 18).

1. Key

Figure 17

10

Page 11

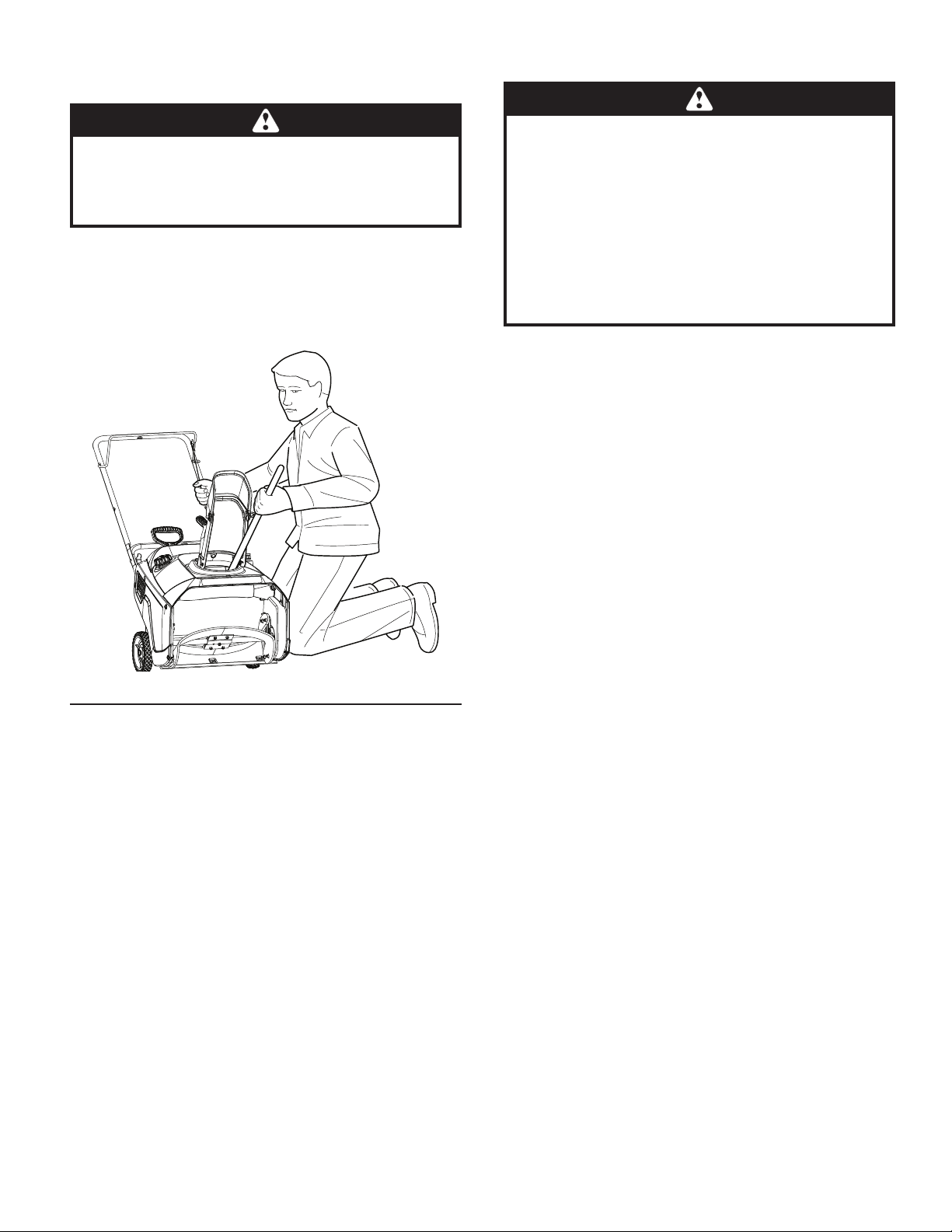

Clearing a Clogged

Discharge Chute

Hand contact with the rotating auger blades

inside the discharge chute is the most common

cause of injury associated with snow throwers.

Never use your hand to clean out the discharge

chute.

To clear the chute:

1. SHUT THE ENGINE OFF!

2. Wait 10 seconds to be sure the auger blades have

stopped rotating.

3. Always use a clearing tool at least 15 inches long, not

your hands (Figure 19).

Operating Tips

The auger blades can throw stones, toys, and other

foreign objects and cause serious personal injury

to the operator or to bystanders.

• Keep the area to be cleared free of all objects that

the auger blades could pick up and throw.

• Keep all children and pets away from the area of

operation.

• Do not operate snow thrower if weather conditions

im pair visibility. Throwing snow dur ing a heavy,

windy snowstorm can blind you and be hazardous to the safe operation of the snow thrower.

• The best time to remove snow is the early morning.

At this time the snow is usually dry and has not been

exposed to the direct sun and warming tem per a tures.

• Slightly overlap each successive path to ensure all

snow will be removed.

• Throw snow downwind whenever possible.

• For extremely heavy snow, re duce the width of snow

removal by over lap ping previous path and moving

slowly.

• Keep engine clean and clear of snow during use. This

will help air flow and extend engine life.

• After snow-throwing is completed, allow engine to run

for a few minutes to melt snow and ice off the engine.

• Clean the entire snow thrower thoroughly after each

use and wipe dry so it is ready for next use.

• Spraying off unit with a hose is NOT recommended.

Figure 19

Preventing Freeze-up after

Use

• Let the engine run for a few minutes to prevent moving

parts from freezing. Stop the engine, wait for all moving parts to stop, and remove ice and snow from the

snowthrower.

• Clean off any snow and ice from the base of the chute.

• Rotate the discharge chute left and right to free it from

any ice buildup.

• With the ignition key in the Off position, pull the recoil

starter handle several times or connect the electrical

cord to a power source and the snowthrower and push

the electric start button once to prevent the recoil starter

and/or the electric starter from freezing up.

• In snowy and cold conditions, some controls and moving parts may freeze. Do not use excessive force when

trying to operate frozen controls. If you have difficulty

operating any control or part, start the engine and let

it run for a few minutes.

11

Page 12

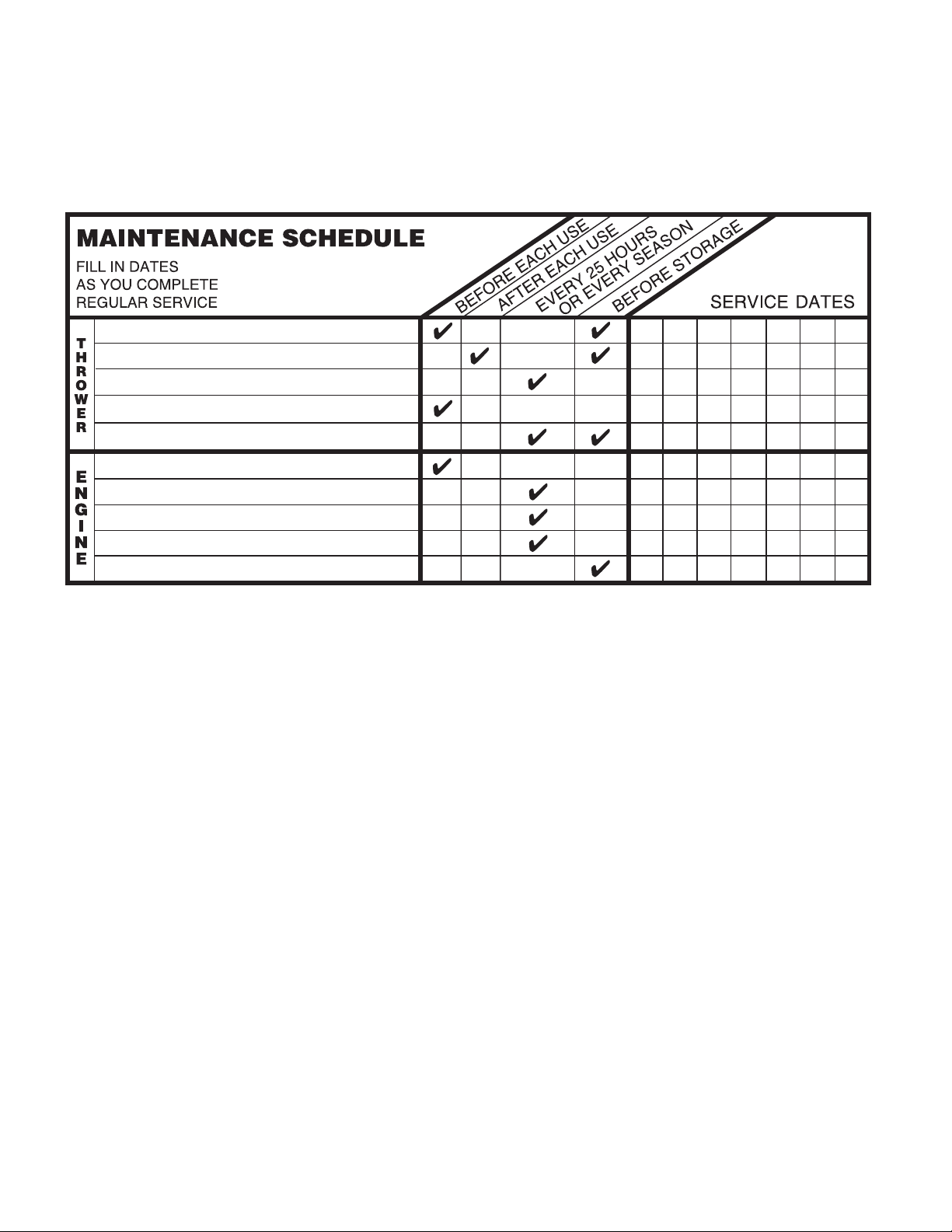

Maintenance

NOTE: Determine the left and right sides of the machine from the normal operating position.

Check for Loose Fasteners

Clean / Inspect Snow Thrower

Clean / Replace V-Belts

Check / Replace Auger Blades and Scraper Bar

Lubrication Chart

Check Engine Oil Level

Change Engine Oil

Inspect Muffler

Check / Replace Spark Plug

Empty Fuel Tank

12

Page 13

Adjusting the Control Cable

Checking the Control Cable

Release the control bar to remove the slack in the control

cable (Figure 20).

Adjusting the Control Cable

1. With the control bar disengaged, unhook and move

the control cable to the highest position. (Figure 21).

1

Position 2

1

Figure 20

1. Control bar

IMPORTANT: The control cable must contain some slack

when you disengage the control bar for the auger blades

to stop properly.

NOTE: You may need to adjust the control cable from

position 1 (default) to position 2 if you notice belt slip

when the control bar is engaged.

2

Position 1: Default position

(Lower Hole as shown in illustration)

Figure 21

1. Control bar

2. Adjuster link

3. Cable positions

3

Inspecting the Auger Blades/

Scraper Bar

Before each session, inspect the auger blades for wear.

When an auger blade edge or the scraper bar has worn

down have an Authorized Service Dealer replace the

auger blades and the scraper bar (Figure 22).

NOTE: Auger blades and scraper bar are wear items and

may have to be replaced after extended use.

NOTE: If the control cable is adjusted to position 2,

ensure that the auger stops properly when the control bar

is released

1

2

Figure 22

1. Auger blades 2. Scraper bar

13

Page 14

Changing the Engine Oil

Run the engine a few minutes before changing the

oil to warm it. Warm oil flows better and carries more

contaminants.

The engine oil will be hot. Avoid skin contact

with the used engine oil.

1. Move snowthrower to a level surface.

2. Run snowthrower until all fuel has been depleted.

3. Remove ignition key.

7. Clean around the oil filler cap/dipstick (Figure 24).

8. Unscrew the oil fill cap/dipstick and remove it

(Figure 25).

9. With the snowthrower in the operating position, carefully pour oil into the oil fill hole until "Full" on the fill

cap/dipstick line (Figure 25).

Max fill: 18 oz. (0.5 l), type: automotive detergent oil

with an API service classification of SJ, SL, or higher.

Fill if oil

is below

“Add”

on the

GLSVWLFN

Fill if oil is

below letter

“L” on the

¿OOHUFDS

1

Figure 23

1. Oil drain plug

4. Place an oil drain pan under the oil drain plug, remove

the oil drain plug, and tip the snowthrower backward

and drain the used oil in the oil drain pan (Figure 23).

5. After draining the used oil, return the snowthrower to

the operating position.

6. Screw in the oil fill cap/dipstick (1) and hand tighten it

securely.

NOTE: Dipstick location may vary depending on engine

type.

1

Figure 25

10. Screw in the oil fill cap/dipstick and hand tighten it

securely.

11. Wipe up any spilled oil.

12. Dispose of the used oil properly at a local recycling

center.

1. Oil fill cap/dipstick

1

Figure 24

14

Page 15

Servicing the Spark Plug

Use a NGK BPR6ES, Champion RN9YC, or BOSCH

WR6DC spark plug or equivalent.

1. Stop the engine and wait for all moving parts to stop.

2. Rotate the discharge chute so that it faces forward.

3. Remove the discharge chute and the discharge chute

handle by removing the three carriage bolts and three

flange nuts (Figure 26).

1

3

3

5. Remove the oil fill cap.

6. Remove the shroud assembly (Figure 27).

7. Install the oil fill cap.

8. Disconnect the spark plug wire from the spark plug

(Figure 28).

9. Clean around the spark plug.

10. Remove the spark plug from the cylinder head.

1

2

2

Figure 26

1. Discharge chute 2. Carriage bolts

3. Flange nuts

4. Remove the six screws that secure the shroud

assembly (Figure 29).

1

2

Figure 28

1. Spark plug wire

IMPORTANT: Replace a cracked, fouled, or dirty spark

plug. Do not clean the electrodes because grit entering

the cylinder can damage the engine.

11. Set the gap on the plug to 0.030 inch (0.76 mm)

(Figure 29).

0.030 inch

(0.76 mm)

Figure 29

3

Figure 27

1. Screw 3. Oil fill cap

2. Shroud assembly

12. Install the spark plug and torque it to 20–22 ft-lb (27–30

N-m).

13. Connect the spark plug wire to the spark plug

(Figure 28).

14. Remove the oil fill cap.

15. Install the shroud with the screws removed in step 4

(Figure 27).

NOTE: Ensure that the shroud assembly fits together in

the side grooves.

16. Install the oil fill cap.

17. Install the discharge chute, and the discharge chute

handle onto the snowthrower using the hardware removed in step 3 (Figure 26).

15

Page 16

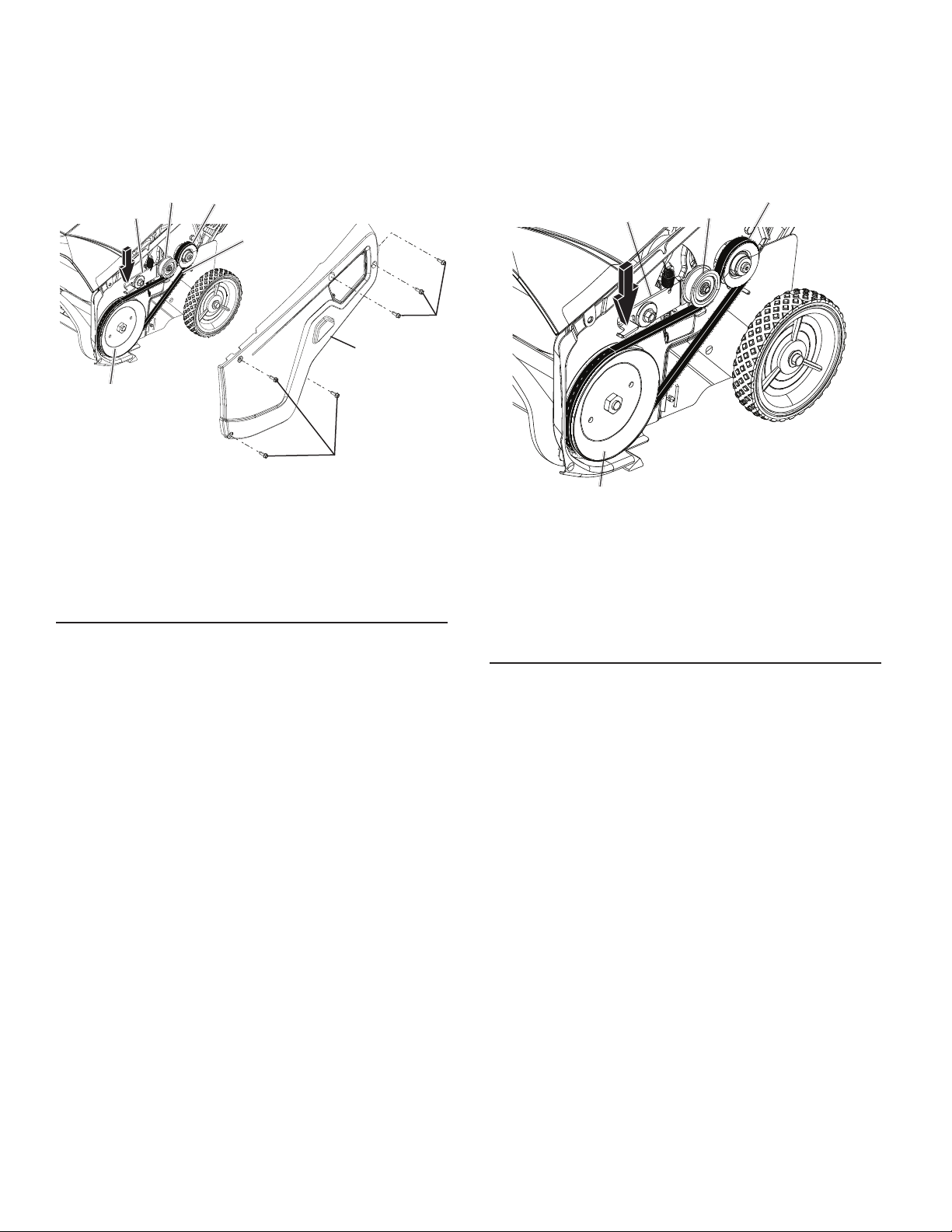

Replacing the Drive Belt

If drive belt becomes worn, oil-soaked, excessively

cracked, frayed, or otherwise damaged, replace the belt.

1. Remove the drive side cover by removing the six screws

as shown in (Figure 30).

5

6

4

7

1

3

2

4. Install the new drive belt, routing it as shown in

(Figure 31).

NOTE: Route the new drive belt first around the engine

pulley, then the idler pulley, and finally around the drive

pulley while pressing down on the front of the idler arm.

(Figure 31).

5. Install the drive side cover with the screws removed in

step 1.

3

1

2

2

Figure 30

1. Drive side cover

2. Screw

3. Drive pulley

4. Idler arm

2. Press down on front of idler arm to release the belt

tension (Figure 30).

3. Remove the drive belt from the drive pulley (Figure 30).

5. Idler pulley

6. Engine pulley

7. Drive belt

4

Figure 31

1. Idler arm

2. Idler pulley

3. Engine pulley

4. Drive pulley

NOTE: Ensure that the drive belt is properly adjusted

and operating; refer to Checking the Control Cable and

Adjusting the Control Cable in the Maintenance section

of this manual.

16

Page 17

Storage

Storing the Snowthrower

Immediately prepare your snow thrower for storage at

the end of the season or if the unit will not be used for 30

days or more.

WARNING: Never store the snow thrower with

gaso line in the tank in side a build ing where fumes

may reach an open flame, spark or pilot light as

on a fur nace, water heater, clothes dryer or gas

ap pli ance. Allow the engine to cool be fore storing

in any enclosure.

SNOW THROWER

When snow thrower is to be stored for a period of time,

clean it thor oughly, re move all dirt, grease, leaves, etc.

Store in a clean, dry area.

1. Clean entire snow thrower after each use.

2. Inspect and replace belts, if necessary (See “Replaceing the Drive Belt” sec tion of this manual).

3. Be sure that all nuts, bolts, screws, and pins are securely

fas tened. Inspect moving parts for damage, breakage

and wear. Replace if nec es sary.

FUEL SYS TEM

IMPORTANT: It is important to prevent gum deposits from

forming in essential fuel system parts such as carburetor,

fuel hose, or tank during storage. Also, alcohol blended

fuels can attract moisture which leads to separation and

formation of acids during storage. Acidic gas can damage

the fuel system of an engine while in storage.

• Empty the fuel tank by starting the engine and letting

it run until the fuel lines and car bu re tor are empty.

• Never use engine or carburetor cleaner prod ucts in

the fuel tank or permanent damage may occur.

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable alternative in min i miz ing the formation of fuel gum deposits during stor age.

Add stabilizer to gasoline in fuel tank or storage container.

Always follow the mix ratio found on stabilizer container.

Run engine at least 10 min utes after adding stabilizer to

allow the stabilizer to reach the carburetor. Do not empty

the gas tank and carburetor if using fuel stabilizer.

ENGINE OIL

Drain oil (with engine warm) and replace with clean engine

oil. (See “Changing the Engine Oil” section of this man ual).

CYLINDER

1. Remove spark plug.

2. Pour one ounce (29 ml) of oil through spark plug hole

into cylinder.

3. Pull recoil starter handle slowly a few times to dis trib ute

oil.

OTHER

• Remove safety ignition key; store it in a safe place.

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

• If possible, store your snow thrower indoors and cover

it to protect it from dust and dirt.

• Cover your snow thrower with a suitable pro tec tive

cover that does not retain moisture. Do not use plastic.

Plastic cannot breathe, which allows con den sa tion to

form and will cause your snow thrower to rust.

IMPORTANT: Never cover snow thrower while engine/

exhaust area is still warm.

17

Page 18

Troubleshooting

See appropriate section in manual unless directed to an authorized service center/department.

PROBLEM CAUSE CORRECTION

Does not start 1. Safety ignition key is not inserted. 1. Insert safety ignition key.

2. Out of fuel. 2. Fill fuel tank with fresh, clean gasoline.

3. ON/OFF switch is OFF. 3. Move ON/OFF switch to ON position.

4. Choke in OFF position. 4. Move to FULL position.

5. Primer not depressed. 5. Prime as instructed in the Operation section of this manual.

6. Engine is flooded. 6. Wait a few minutes before restarting, DO NOT prime.

7. Spark plug wire is disconnected. 7. Connect wire to spark plug.

8. Bad spark plug. 8. Replace spark plug.

9. Stale fuel. 9. Empty fuel tank & carburetor, refill with fresh, clean gasoline.

10. Water in fuel. 10. Empty fuel tank & carburetor, refill with fresh, clean gasoline.

11. Vapor locked fuel line. 11. Ensure all the fuel line is below the outlet of the fuel tank. Fuel

Loss of power 1. Spark plug wire loose. 1. Reconnect spark plug wire.

2. Throwing too much snow. 2. Reduce speed and width of swath.

3. Fuel tank cap is covered with ice or

snow.

4. Dirty or clogged muffler. 4. Clean or replace muffler.

5. Improper cable length. 5. Adjust cable.

6. Blocked muffler. 6. Clear blockage (ensure engine is cool).

7. Blocked carburetor air intake. 7. Clear blockage (ensure engine is cool).

Engine idles or

runs roughly

Excessive

vibration / Handle

movement

Recoil starter is

hard to pull

Loss of snow

discharge or

slowing of snow

discharge

Lights not On

(If Equipped)

Rotator hard to

move

1. Choke is in FULL position. 1. Move choke to OFF position.

2. Blockage in fuel line. 2. Clean fuel line.

3. Stale fuel. 3. Empty fuel tank & carburetor, refill with fresh, clean gasoline.

4. Water in fuel. 4. Empty fuel tank & carburetor, refill with fresh, clean gasoline.

5. Carburetor is in need of replacing 5. Contact an authorized service center/department.

6. Belt stretch.

1. Loose parts or damaged augers or

impeller.

2. Handles not positioned correctly. 2. Ensure handles are locked into positioning.

3. Adjustment lever nuts are loose. 3. Tighten nuts until handle feels secure.

1. Frozen recoil starter. 1. See “IF RECOIL STARTER HAS FROZEN” in the Operation

2. Rope is interfering with components. 2. Recoil rope should not be touching any wires or hoses.

1. Worn belt. 1. Adjust drive cable per maintenance procedures.

2. Auger v-belt is off of pulley. 2. Check / reinstall auger v-belt.

3. Auger v-belt is worn. 3. Check / replace auger v-belt.

4. Clogged discharge chute. 4. Clean snow chute.

5. Augers / impeller jammed. 5. Remove debris or foreign object from augers / impeller.

1. Motor not running. 1. Start engine.

2. Loose wire connection. 2. Check wire connections at engine and both lights.

3. LED burnt out. 3. Replace LED light module. (Individual LEDs are not replaceable)

1. Debris in chute rotator mechanism. 1. Clean internal parts of chute rotator mechanism.

2. Cable are kinked or damaged. 2. Ensure cables are not kinked. Replace damaged cables.

line should run continuously down from fuel tank to carburetor.

3. Remove ice and snow on and around fuel tank cap.

6. Replace auger v-belt.

1. Tighten all fasteners. Replace damaged parts. If vibration

remains, contact an authorized service center/department.

section of this manual.

18

Page 19

SERVICE NOTES

19

Page 20

REPAIR PARTS SNOW THROWER - - MODEL NUMBER PR621 (96182000303)

AUGER ASSEMBLY

1

5

12

2

10

9

10

11

10

7

6

8

12

10

12

10

2

11

5

3

10

12

12

7

1

11

11

06.03.001-D

3

4

KEY PART

NO. NO. DESCRIPTION

1 532 44 27-59 BLADE

2 580 85 55-01 BEARING SUPPORT

3 532 43 76-22 BALL BEARING

4 812 00 00-28 RETAINING RING

5 817 06 04-08 1/4-20 X 3/8 HEX SCREW

6 532 43 76-17 AUGER WELDMENT

7 580 85 54-01 CENTER BLADE PLATE

8 532 43 76-20 ROLL PIN

9 532 19 96-87 SCREW HEX WS HD 1/4-20 X 1.5

10 872 11 04-07 BOLT CARRIAGE 1/4

11 819 09 10-16 WASHER FLAT 1/4 SAE

12 532 13 20-04 NUT HEX 1/4-20 BZO

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your snow thrower and void your warranty.

20

Page 21

REPAIR PARTS SNOW THROWER - - MODEL NUMBER PR621 (96182000303)

CHUTE ASSEMBLY

2

KEY PART

6

9

10

11

7

8

3

55

1

NO. NO. DESCRIPTION

1 532 43 76-55 CHUTE (BLACK)

2 532 43 76-43 DEFLECTOR (BLACK)

3 532 43 76-42 HANDLE (BLACK)

4 532 43 73-18 CARRIAGE BOLT 5/16-18

UNC X 1

5 873 97 05-00 NUT LOCK HEX W/INS 5/16-18

UNC PL

6 532 13 20-04 PUSH NUT

7 532 44 46-82 SHOULDER BOLT 1/4-20 HEX

HEAD

8 872 11 05-10 CARRIAGE BOLT 5/16-18 X 1-1/4

9 819 13 13-16 WASHER 13/32 X 13/16 X 16 GA

10 532 19 19-38 WING KNOB

11 532 07 16-73 CAP PLUNGER

4

9

1

06.04.009-A

06.05.002-C

9

7

5

2

6

8

4

3

KEY PART

NO. NO. DESCRIPTION

1 532 43 48-77 CHUTE RETAINER

2 580 85 65-01 CHUTE BASE

3 580 85 56-01 CHUTE BASE PLATE

4 532 43 48-78 RATCHET PAWL

5 532 43 48-79 SPRING

6 919 13 24-16 WASHER 13/32 X 1.25

7 532 08 13-28 BOLT 1/4-20 X .94

8 532 13 20-04 NUT 1/4-20 HEX

9 917 41 13-12 BOLT 13-16 X .75

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your snow thrower and void your warranty.

21

Page 22

REPAIR PARTS SNOW THROWER - - MODEL NUMBER PR621 (96182000303)

HANDLE ASSEMBLY

3

4

06.07.001-A

2

1

KEY PART

NO. NO. DESCRIPTION

1 580 85 70-01 UPPER HANDLE

2 580 86 04-01 BAIL

5

3 532 19 15-74 HANDLE BOLT

4 532 19 19-38 WING KNOB

5 532 43 75-06 AUGER CONTROL DECAL

3

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your snow thrower and void your warranty.

22

Page 23

REPAIR PARTS SNOW THROWER - - MODEL NUMBER PR621 (96182000303)

DRIVE ASSEMBLY

7

11

06.01.001-B

3

13

12

1

6

4

15

14

2

5

8

9

10

KEY PART

NO. NO. DESCRIPTION

1 580 85 53-01 IDLER ARM

2 532 16 60-43 IDLER PULLEY

3 532 43 48-59 RETURN SPRING

4 817 06 06-20 SCREW 3/8-16 X 1-1/4 (TORQUE 13-18 FT-LBS)

5 817 06 06-20 SCREW 3/8-16 X 1-1/4 (TORQUE 22-27 FT-LBS)

6 532 19 90-92 SPACER

7 532 44 30-18 CLUTCH CABLE ASM

8 532 14 50-06 PUSH CLIP

9 532 43 45-02 BELT KEEPER

10 532 43 53-83 DRIVE PULLEY

11 532 43 72-61 BELT

12 532 43 48-60 ENGINE CRANK SPACER

13 532 42 64-90 ENGINE PULLEY

14 532 85 10-74 WASHER

15 532 43 08-17 SCREW 3/8-24 X 1/25

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your snow thrower and void your warranty.

23

Page 24

REPAIR PARTS SNOW THROWER - - MODEL NUMBER PR621 (96182000303)

ENGINE ASSEMBLY

7

2

10

9

3

1

8

4

5

6

KEY PART

NO. NO. DESCRIPTION

1 580 81 09-01 ENGINE LCT 208CC CE

2 580 58 02-01 KEY SWITCH

3 532 43 62-35 PRIMER BULB

4 532 43 48-57 ENGINE SPACER

5 532 43 55-78 SCREW 5/16-24 X 2.00 HHCS

6 532 15 04-06 BOLT ENGINE 3/8-16 DOGPOINT

7 532 43 48-74 CHOKE LEVER

8 532 43 76-58 REAR LOWER COVER

9 532 43 62-76 RECOIL HANDLE

10 532 44 30-59 KEY SET (QTY 2)

06.02.014-A

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your snow thrower and void your warranty.

24

Page 25

REPAIR PARTS SNOW THROWER - - MODEL NUMBER PR621 (96182000303)

FRAME ASSEMBLY

5

06.00.001-A

2

2

2

1

KEY PART

NO. NO. DESCRIPTION

1 580 85 62-01 FRAME WELDMENT

2 872 11 04-07 BOLT, CARRIAGE 1/4-20 X 7/8

3 580 50 26-01 BAR, SCRAPER UHMW

4 532 44 21-46 SCRAPER, SKIRT

5 819 09 12-16 WASHER 9/32 X 3/4 X 16 GA

6 532 19 17-30 NUT, HEX FLANGE 1/4-20 CTR

LOCK

3

4

6

2

KEY PART

NO. NO. DESCRIPTION

1 581 02 36-01 WHEEL 7”

2 532 43 54-17 PUSH NUT

2

06.06.001-B

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your snow thrower and void your warranty.

1

25

Page 26

REPAIR PARTS SNOW THROWER - - MODEL NUMBER PR621 (96182000303)

SHROUD ASSEMBLY

6

8

8

7

3

9

9

11

8

8

9

8

6

11

10

6

7

9

7

2

1

7

11

8

8

11

8

8

8

8

5

4

06.04.004-A

KEY PART

NO. NO. DESCRIPTION

1 532 44 39-21 PLENUM

2 532 44 39-24 NON – DRIVE COVER

3 532 44 39-25 DRIVE COVER SIDE

4 819 13 13-16 WASHER 13/32 X 13/16 GA

5 532 42 88-67 BOLT 5/16-18 X .75

6 817 41 13-12 BOLT 13-16 X .75

7 532 19 66-88 THREADED CLIP

8 532 44 22-50 SCREW 1/4-20 X .75

9 532 44 42-62 SCREW 1/4-20 X 1.5

10 580 83 35-01 EXHAUST PLATE

11 819 09 10-16 WASHER FLAT 1/4 SAE

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your snow thrower and void your warranty.

26

Page 27

REPAIR PARTS SNOW THROWER - - MODEL NUMBER PR621 (96182000303)

SHROUD ASSEMBLY

8

1

6

7

2

3

9

5

4

06.04.013-C

KEY PART

NO. NO. DESCRIPTION

1 532 44 39-26 TOP COVER

2 532 43 76-48 REAR UPPER COVER

3 817 41 13-12 BOLT 13-16 X .75

4 532 19 66-88 THREADED CLIP

5 532 43 48-68 TRIM CLIP

6 580 98 26-01 FUEL TANK ASSEMBLY

7 532 14 68-48 CABLE TIE

8 581 07 55-01 FUEL CAP/GASKET

9 532 44 46-49 P-CLIP

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your snow thrower and void your warranty.

27

Page 28

REPAIR PARTS SNOW THROWER - - MODEL NUMBER PR621 (96182000303)

ENGINE, LCT COMPLETE ENGINE-

56

37

38

46A

36

34

29A

10A

10

22A

22

50

54

26

26A

48

28

3

21

20 20A

18

30

62

*Included

with part# 40

52*

27

57

31

47

39

53*

41

23

11

8

49

44

40

65

46

6

580810901

19

Electric Start Only

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your snow thrower and void your warranty.

28

17

Page 29

REPAIR PARTS SNOW THROWER - - MODEL NUMBER PR621 (96182000303)

ENGINE, LCT COMPLETE ENGINE-

KEY PART

NO. NO. DESCRIPTION

3 532 44 42-77 Muffler Assembly-Snow

6 532 43 71-22 Snow Carburetor Assy

8 532 43 71-23 Fuel Primer Bulb With Hose

10 532 43 71-24 Electric Starter Assy

10A 532 43 71-25 European 230V Electric Starter

11 532 42 49-54 Key Switch Assy

17 532 43 69-67 Recoil Starter Assembly-Snow

18 532 43 69-68 Starter Cup Small

19 532 42 49-68 Snow Starter Grip

20 532 42 49-71 Blower Housing Assembly

Electric Start - Snow (Black)

20A 532 42 92-30 Blower Housing Assembly

Manual Start - Snow (Black)

21 532 42 49-73 Shield, Cylinder

22 532 42 49-75 Shield, Flywheel Electric Start

(If Equipped)

22A 532 42 95-96 Shield, Flywheel Manual Start

23 532 42 05-80 Valve Cover

26 532 42 92-35 Electric Start Flywheel Assy

26A 532 42 05-85 Manual Start Flywheel Assy

27 532 44 40-91 High Oil Fill Tube Assy

28 532 42 05-86 Flywheel Fan

29A 532 44 39-34 Ignition Coil (CDI) (used on

engines without ref. 12)

30 532 42 06-06 Crankcase Cover Assy

31 532 42 09-61 Black Oil Dipstick

34 532 43 69-66 Spark Plug Boot

36 532 42 06-01 Governor Arm Assy

37 532 42 06-02 Governor Shaft

38 532 42 96-46 Governor Gear Assy

39 532 42 05-84 Camshaft

40 532 42 05-78 Cylinder Head Assy

41 532 42 49-39 Spark Plug

44 532 42 05-82 Piston And Rod Assy

46 532 42 92-60 Vapor Shield

46A 532 44 42-75 Intake Shield

47 532 42 95-99 Seal Kit

48 532 44 42-76 Wire Harness

49 532 42 96-00 Crankshaft

50 532 42 92-59 Speed Control Bracket

52 532 42 96-91 Rocker Arm Kit

53 532 42 05-79 Push Rod Kit

54 532 43 65-67 Cylinder Assembly

56 532 42 96-01 Gasket Kit

57 532 43 80-14 Fuel Hose Kit

62 532 42 95-98 Non-Removable Oil Plug

65 532 43 54-95 Oil Drain Plug Kit

580810901

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your snow thrower and void your warranty.

29

Page 30

LIMITED WARRANTY

The Manufacturer warrants to the original consumer purchaser that this product as manufactured is free from defects in materials and work man ship. For a period of two (2) years from date of purchase by the original consumer purchaser, we will repair

or replace, at our option, without charge for parts or labor incurred in replacing parts, any part which we find to be defective

due to materials or workmanship. This Warranty is subject to the following limitations and exclusions.

1. This warranty does not apply to the engine, transaxle/transmission components, battery (except as noted below) or components parts thereof. Please refer to the applicable manufacturer's warranty on these items.

2. Transportation charges for the movement of any power equipment unit or attachment are the responsibility of the pur chaser. Transportation charges for any parts submitted for replacement under this warranty must be paid by the purchaser unless such return is requested by the manufacturer.

3. Battery Warranty: On products equipped with a Battery, we will replace, without charge to you, any battery which we find

to be defective in manufacture, during the first ninety (90) days of ownership. After ninety (90) days, we will exchange the

Battery, charging you 1/12 of the price of a new Battery for each full month from the date of the original sale. Battery must

be maintained in accordance with the instructions furnished.

4. The Warranty period for any products used for rental or commercial purposes is limited to 90 days from the date of original purchase.

5. This Warranty applies only to products which have been properly assembled, adjusted, operated, and main tained in ac cor dance with the instructions furnished. This Warranty does not apply to any product which has been subjected to alteration, misuse, abuse, improper assembly or installation, delivery damage, or to normal wear of the product.

6. Exclusions: Excluded from this Warranty are belts, blades, blade adapters, normal wear, normal adjustments, stan dard

hardware and normal maintenance.

7. In the event you have a claim under this Warranty, you must return the product to an authorized service dealer.

Should you have any unanswered questions concerning this Warranty, please contact:

HOP

Outdoor Products Customer Service Dept.

9335 Harris Corners Parkway

Charlotte, NC 28269 USA

giving the model number, serial number and date of purchase of your product and the name and address of the authorized

dealer from whom it was purchased.

THIS WARRANTY DOES NOT APPLY TO INCIDENTAL OR CONSEQUENTIAL DAMAGES AND ANY IMPLIED WAR RAN TIES ARE LIMITED TO THE SAME TIME PERIODS STATED HEREIN FOR OUR EXPRESSED WARRANTIES. Some areas

do not allow the limitation of consequential damages or limitations of how long an implied Warranty may last, so the above

limitations or exclusions may not apply to you. This Warranty gives you specific legal rights, and you may have other rights

which vary from locale to locale.

This is a limited Warranty within the meaning of that term as defined in the Magnuson-Moss Act of 1975.

In Canada contact:

HOP

5855 Terry Fox Way

Mississauga, Ontario

L5V 3E4

30

Page 31

MANUEL IMPORTANT NE JETEZ PAS

MANUEL DU PROPRIÉTAIRE

ATTENTION:

NUMÉRO DE MODÈLE:

PR621

Lisez soigneusement le man uel du

propriétaire suivez tous les aver tis se ments et les in struc tions de sécurité.

Les bles sures sérieuses peuvent en

résulter si vous ne lisez pas ces aver tis se ments et in struc tions de sécurité.

SOUFFLEUSE À NEIGE

Vous pouvez utiliser de l’essence contenant jusqu’à 10 % d’éthanol (E10) avec cet appareil. L’utilisation d’essence contenant plus de 10 % d’éthanol annulera la garantie

du produit.

Portez toujours des lunettes de sécurité lors de l’utilisation.

585 14 66-32 05.01.13 TH Imprimé aux É.-U.

Page 32

NOS FÉLICITATIONS pour l'achat d'une nouvelle souffleuse à neige. Elle a été conçue et fabriquée pour vous offrir la meilleure fiabilité

et la meilleure performance.

Si vous rencontrez des problèmes que vous ne pouvez pas corriger facilement, veuillez contacter votre centre de réparations autorisé

le plus près. Nos techniciens compétents disposent des outils appropriés pour entretenir ou réparer cette machine.

Veuillez lire le manuel et le conserver. Les instructions vous permettront d'assembler et de maintenir de façon appropriée votre souffleuse

à neige. Toujours respecter les RÈGLES DE SÉCURITÉ.

Pratiques d'utilisation sécuritaire de souffleuses à neige poussées

IMPORTANT : Cette souffleuse à neige est capable d'amputer les mains et les pieds ainsi que de projeter des objets. Le défaut

d'observer les consignes de sécurité dans ce manuel peut entraîner une blessure grave.

Recherchez ce symbole

d'importantes consignes de sécurité. Il signifie

« ATTENTION » ! ! ! FAIRE PREUVE DE VIGILANCE ! ! !

VOTRE SÉCURITÉ EST EN JEU.

AVERTISSEMENT Toujours débrancher le fil de la

bougie et le placer à une endroit où il ne peut pas

entrer en contact avec la bougie afin d'éviter tout

démarrage accidentel lors de réglages, du transport

de la souffleuse à neige ou pendant les réparations.

AVERTISSEMENT Cette souffleuse à neige peut être

utilisée sur les trottoirs, dans les entrées ou sur toute

autre surface plane. Il faut faire preuve de prudence lors

de l'utilisation dans les pentes. Ne pas utiliser la souffleuse à neige sur des surfaces au-dessus du niveau du

sol, par exemple le toit d'une résidence, d'un garage,

sur les galeries ou toute autre structure ou bâtiment.

qui indique

Formation

1. Lire, comprendre et suivre les instructions sur la machine et

dans le manuel avant d'opérer cette machine. Se familiariser

avec les commandes et le fonctionnement approprié de la

machine. Savoir comment arrêter la machine et désengager

les commandes rapidement.

2. Ne jamais laisser un enfant manœuvrer la machine. Ne jamais

laisser un adulte manœuvrer la machine sans lui avoir donné

au préalable les instructions nécessaires.

3. S'assurer que la zone d'opération est libre de toute personne,

plus particulièrement les petits enfants.

4. Faire preuve de prudence pour ne pas glisser ou tomber, plus

particulièrement lorsque la souffleuse à neige est opérée en

marche arrière.

Préparation

1. Inspecter avec soin la zone où la machine doit être utilisée

et retirer les paillassons, les traîneaux, les planches, les fils

et tout autre objet.

2. Pensez à relâcher la barre de commande avant de démarrer

le moteur.

3. Ne pas faire fonctionner l’équipement sans porter de vêtements adéquats pour l’hiver. Éviter de porter des vêtements

amples qui pourrait s’enchevêtrer dans les pièces mobiles.

Porter des bottes qui amélioreront votre prise de pied sur

les surfaces glissantes.

4. Manipuler le carburant avec soin ; ce produit est hautement

inflammable.

a) Utiliser uniquement des conteneurs d'essence homolo-

gués.

b) Ne jamais ajouter d'essence si le moteur tourne ou

lorsqu'il est chaud.

AVERTISSEMENT Les souffleuses à neige comportent

des pièces tournantes exposées qui peuvent occasionner des blessures graves en cas de contact ou si

des objets sont projetés par la goulotte de décharge.

S'assurer que la zone d'opération est libre de toute

personne en tout temps, plus particulièrement les

petits enfants et les animaux.

ATTENTION : Le silencieux et d'autres composants du

moteur deviennent extrêmement chauds pendant le

fonctionnement et restent chauds même après l'arrêt

du moteur. Pour éviter des brûlures graves causées

par le contact, se tenir loin de ces zones.

AVERTISSEMENT L'échappement du moteur, certains

de ses constituants, et certains composants de véhicule contiennent ou émettent des produits chimiques

reconnus dans l'État de Californie pour provoquer

le cancer ou d’autre danger pour la reproduction.

c) Remplir le réservoir de carburant à l'extérieur en faisant

preuve d'une extrême prudence. Ne jamais remplir le

réservoir de carburant à l'intérieur.

d) Ne jamais remplir des contenants à l’intérieur d’un véhi-

cule ou sur une plateforme d'un camion ou d’une remorque avec des garnitures en plastique. Toujours placer les

conteneurs sur le sol loin d’un véhicule lors du remplissage.

e) Lorsque la chose est possible, retirer tout équipement

à essence du camion ou de la remorque et faire le

remplissage sur le sol. Quand cela n’est pas possible,

faire le remplissage de tel équipement avec un bidon

portable plutôt qu’avec un pistolet distributeur d’essence.

f) Garder le pistolet distributeur en contact avec le bord

du réservoir de carburant ou de l'ouverture du bidon à

tout moment jusqu'à obtention du plein. Ne pas utiliser

de dispositif à ouverture bloquée du pistolet distributeur.

g) Remettre le bouchon d'essence et essuyer tout carburant

déversé.

h) En cas de déversement de carburant sur les vêtements,

changer immédiatement de vêtement.

5. Utiliser des rallonges et des prises selon les spécifications

du fabricant pour toutes les machines comportant un moteur

électrique ou un démarreur électrique.

6. Ne jamais tenter de faire des réglages lorsque le moteur est

en marche (à moins que ce ne soit spécifiquement recommandé par le fabricant).

7. Il faut toujours porter des lunettes de protection ou des protections oculaires lorsqu’on opère une souffleuse à neige ou

lors des réparations et des réglages sur celle-ci.

8. Laisser le moteur et la machine s’adapter à la température

extérieure avant de commencer à enlever la neige.

2

Page 33

Fonctionnement

1. Ne jamais placer les mains ou les pieds près des pièces en

mouvement ou sous la machine. Toujours se tenir à l'écart

de l'ouverture d'éjection.

2. Faire preuve d'une extrême prudence lors de l'utilisation sur

des allées de graviers, des trottoirs ou des voies publiques,

ou au moment de traverser ces dernières. Surveiller les

dangers cachés ou la circulation.

3. Après avoir frappé un corps étranger, arrêter le moteur,

débrancher la rallonge dans le cas des souffleuses à neige

avec moteur électrique, inspecter avec soin la souffleuse

à neige afin de déceler tout dommage et réparer la pièce

endommagée avant de redémarrer et d'utiliser la souffleuse

à neige. Retirer la clé d'allumage

4. Si la machine commence à vibrer de façon anormale, arrêter

le moteur et vérifier immédiatement la cause. Les vibrations

sont généralement un avertissement de problèmes.

5. Arrêter le moteur chaque fois que vous quittez la position de

fonctionnement, avant de dégager le logement de la tarière

ou la goulotte de décharge ou au moment d'effectuer des

réparations, des réglages ou des vérifications.

6. Au moment de nettoyer, de réparer ou d'inspecter la souffleuse à neige, arrêter le moteur et s'assurer que les lames

de la tarière et les diverses autres pièces mobiles ne tournent

plus. Retirer la clé d'allumage.

7. Ne pas faire fonctionner le moteur à l’intérieur, à l’exception

du démarrage du moteur et lorsque vous transportez la

souffleuse à neige à l’intérieur ou à l’extérieur du bâtiment.

Ouvrir les portes menant à l’extérieur; les gaz d’échap-

pement sont dangereux.

8. Faire preuve de prudence au moment d'utiliser la souffleuse

à neige dans les pentes.

9. Ne jamais opérer la souffleuse à neige sans les protections appropriées ou sans que les dispositifs de protection soient en place et en état de fonctionnement.

10. Ne jamais diriger la goulotte vers les gens ou vers des zones

où il peut y avoir des dommages à la propriété. Tenir les

enfants et toute autre personne éloignés.

11. Ne pas surcharger la machine en tentant de souffler la neige

à un débit trop rapide.

12. Ne jamais faire fonctionner la machine avec une vitesse de

transport rapide sur des surfaces glissantes. Regarder en

arrière et faire attention lorsque vous reculez.

13. Désengager les lames de la tarière lors du transport de la

souffleuse à neige ou lorsque cette dernière n'est pas en

utilisation.

14. Utiliser uniquement des accessoires et des outils approuvés

par le fabricant de la souffleuse à neige.

15. Ne jamais faire fonctionner la souffleuse à neige sans avoir

une bonne visibilité ou de la lumière. Soyez toujours certain

de votre prise de pied et conservez une prise ferme sur les

poignées. Marchez; ne courez jamais.

16. Ne jamais toucher un moteur ou un échappement lorsqu'il

est chaud.

Dégager la goulotte de décharge

3. Toujours utiliser un outil d'au moins 15 pouces (39 cm) de

long pour dégager la goulotte.

Entretien et Entreposage

1. Faire la vérification des vis de cisaillement et autres genres

de vis par intervalles fréquents pour s’assurer qu’elles sont

bien serrées et que l’équipement est en condition de travail

sécuritaire.

2. Ne jamais entreposer la souffleuse à neige avec de l’essence

dans le réservoir à l’intérieur d’un bâtiment où une source

d’allumage est présente, telle que chauffe-eau, chaufferette,

sécheuse et autres choses du genre. Permettre au moteur

de se refroidir avant d’entreposer la machine dans un endroit

renfermé.

3. Toujours faire référence au guide d’instruction de l’opérateur

pour des détails importants si la souffleuse à neige doit être

entreposée pour une longue période de temps.

4. Entretenir ou remplacer les étiquettes et instructions de

sécurité au besoin.

5. Faire fonctionner la machine avec la tarière engagée pendant

quelques minutes après avoir déblayé la neige, pour dégager

la machine et prévenir le gèle de la collecteur et de la turbine.

NUMÉRO DE SÉRIE : ___________________________

DATE D'ACHAT : _______________________________

LE NUMÉRO DE MODÈLE ET LE NUMÉRO DE SÉRIE

SERONT INSCRITS SUR UNE ÉTIQUETTE APPOSÉE À

L'ARRIÈRE DU CARTER DE LA SOUFFLEUSE À NEIGE

(Figure 1).

VOUS DEVRIEZ NOTER LE NUMÉRO DE SÉRIE ET LA DATE

D'ACHAT, PUIS CONSERVER LE TOUT DANS UN ENDROIT

SÛR À DES FINS DE RÉFÉRENCE ULTÉRIEURE.

PRODUCT

PRODUIT

FOR SERVICE CALL/POUR LE SERVICE APPELER

1-800-448-7543

ASSEMBLED IN U.S.A. / ASSEMBLÉ AUX ÉTATS-UNIS

MCRAE, GA 31055

MAINTENANCE LEVEL

NIVEAU DE MAINTENANCE

000000000 00

MODEL NUMBER / NUMERO DE MODELE

00000000

CONFORME AUX NORMES DE SÉCURITÉ DE ANSI B71.3-2005

SERIAL NUMBER

NUMERO DE SERIE

000000A 000000

CONFORMS TO ANSI B71.3-2005 SAFETY STANDARDS

000000

Figure 1

RESPONSABILITÉS DU CLIENT

• Lire et observer toutes les règles de sécurité.

• Suivre un programme régulier d’entretien, de soin et d’utilisation de la souffleuse à neige.

• Suivre les instructions sous la section « Entretien et entreposage » dans ce manuel.

Le contact des mains avec les lames de la tarière en

mouvement à l'intérieur de la goulotte de décharge est

la cause la plus courante de blessures occasionnées

par les souffleuses à neige. NE JAMAIS DÉGAGER LA

GOULOTTE DE DÉCHARGE AVEC LES MAINS.

Pour dégager la goulotte :

1. COUPER LE MOTEUR!

2. Attendre 10 secondes pour vous assurer que les lames de

la tarière ne tournent plus.

SPÉCIFICATIONS DE PRODUIT

Capacité et le 1,6 Qt (1,5 Litres)

Type d’essence: L’essence Sans Plomb Normale

Type d’huile SAE 30 (Supérieur de 10°C)

(API SG–SL ): SAE 5W-30 ou 10W-30 (0°–10°C)

SAE 5W-30 (Inférieure de 0°C)

Capacité d’huile: 16 Ounces (0,47 Litres)

Bougie d’allumage: F6RTC

Écart: 0,030" (0,762 mm)

3

Page 34

TABLE DES MATIÈRES

RÈGLES DE SÉCURITÉ ...................................................... 2-3

SPÉCIFICATIONS DU PRODUIT ........................................... 3

RESPONSABILITÉS DU CLIENT .......................................... 3

ÉTIQUETTES DE SÉCURITÉ ET D'INSTRUCTIONS ............ 4

RÉGLAGES ......................................................................... 5-6

FONCTIONNEMENT ......................................................... 7-11

ENTRETIEN ..................................................................... 12-16

ENTREPOSAGE ................................................................... 17

DÉPANNAGE ................................................................... 18-19

PIÈCES DE RÉPARATION .............................................. 20-31

GARANTIE ............................................................................ 32

CONNAÎTRE VOTRE SOUFFLEUSE À NEIGE

LISEZ CE MANUEL DU PROPRIÉTAIRE ET LES RÈGLES DE SÉCURITÉ AVANT D’OPÉRER CETTE SOUFFLEUSE À NEIGE.

Comparez les illustrations avec votre souffleuse à neige afin de connaître l'emplacement de différents réglages et commandes. Conservez ce manuel aux fins de référence.

Ces symboles peuvent apparaître sur la souffleuse à neige ou avec la documentation livrée avec la machine. Il est conseillé

d’apprendre et de comprendre leur signification.

IMPORTANT : Les étiquettes de sécurité et d'instructions sont apposées près des zones présentant des dangers potentiels. Remplacer

les étiquettes endommagées.

2

ATTENTION

MOTEUR

EN MARCHE

MOTEUR

EN ARRÊTÉ

STARTER

APPRET

ESSENCE

L’HUILE

CLEF DE CONTACT.

L'INSERTION POUR

COMMENCER ET COURIR,

HORS DE FORCE ARRETER

LIRE ET SUIVRE TOUTES LES

INFORMATIONS SUR LA SECURITE

ET LES INSTRUCTIONS AVANT L'USAGE

DE CE PRODUIT. GARDER CES

INSTRUCTIONS POUR LA REFERENCE FUTURE.

4

Page 35

Réglages

Pièces en vrac

Utiliser le graphique ci-dessous pour vous assurer que toutes les pièces ont été expédiées.

Procédure Description Qté Utilisation

1.

2.

Aucune pièce requise – Déplier la poignée.

Boulons de châssis

Boulon

Écrous à embase

Rondelle

Bouton

Pongeur à chapeaux

Goulotte

Déflecteur

4

1

4

1

1

1

1

1

Poser la goulotte de décharge.

Poser la goulotte de décharge.

Poser la goulotte de décharge.

Poser la goulotte de décharge.

Poser la goulotte de décharge.

Poser la goulotte de décharge.

1. Déplier la poignée

Procédure

1. Desserrer les deux boutons de la poignée et les retirer

jusqu'à ce que vous puissiez déplacer la poignée librement

et la tourner en position de fonctionnement (Figure 2).

1

2

Figure 2

1. Boutons de la poignée 2. Boulon de la poignée

2. Poser la goulotte de

décharge

Procédure

1. Poser le déflecteur de goulotte sur la goulotte de décharge

à l'aide des vis et, de la rondelle, de l'écrou, du bouton de

déflecteur et du capuchon du plongeur (Figure 4).

2. Poser la goulotte de décharge à la base de la goulotte en

utilisant les trois vis et les écrous (Figure 4).

8

7

9

1

6

3

2

10

4

5

3

2

2. Serrer les boutons de la poignée jusqu'à ce qu'ils affleurent.

Figure 3

Figure 4

1. Déflecteur de goulotte

2. Boulons de châssis

3. Écrous à embase 5/16-18

4. Rondelle

5. Bouton

IMPORTANT: Ne pas trop serrer les écrous à embase ; si tel

n'est pas le cas, il pourrait en résulter des dommages à la

goulotte de décharge.

5

6. Goulotte de décharge

7. Boulon

8. Boulon

9. Écrous à embas 1/4-20

10. Pongeur à chapeau

Page 36

3. Remplir le moteur d'huile

MOTEUR

Se reporter au manuel du moteur.

LUBRIFICATION

REMARQUE : L'HUILE SAE 10W30 ou SAE 5W30 est acceptable

pour une utilisation par temps froid si le moteur est difficile à lancer.

REMARQUE : Bien que les huiles à viscosité multiple (5W30,

10W30, etc.) améliorent le démarrage par temps froid, ces huiles

résultent en une plus grande consommation d’huile lorsqu’elles

sont utilisées au dessus de 32°F/0°C. Vérifier le niveau de l’huile

moteur plus souvent afin d’éviter d’endommager le moteur tournant

avec un niveau d’huile bas.

Vidanger l’huile après toutes les 25 heures d’opération ou au

moins une fois par année si la souffleuse à neige n’est pas utilisée

plus de 25 heures en une année.

Vérifier le niveau d’huile du carter moteur avant de démarrer le

moteur et après chaque cinq (5) heures d’opération. Bien serrer

le bouchon de remplissage/jauge à chaque vérification du niveau

d'huile.

1. Déplacer la souffleuse à neige sur une surface plane.

2. Nettoyer la zone autour de la jauge (Figure 5).

REMARQUE : L'emplacement de la jauge peut varier selon le

type de moteur.

3. Retirer le capuchon de remplissage ou la jauge à huile puis

l'essuyer.

Aperçu du produit

13

*11

10

1

2

9, *11

Figure 6

4

3

5

6

12

7

8

1

Remplir si le

pétrole est au

Fill if oil

dessous du

is below

"RAJOUTE"

“Add”

la jauge de

on the

niveau d'huile

dipstick

Remplir si

le pétrole

est au

dessous

Fill if oil is

du "L" la

below letter

jauge de

“L” on the

niveau

ller cap

d'huile

Figure 5

1. Bouchon de remplissage d'huile/jauge

4. Insérer la jauge dans le goulot de remplissage et tourner dans

le sens horaire jusqu'à ce qu'elle soit bien en place. Retirer

ensuite la jauge en la tournant dans le sens anti-horaire.

5. Remplir jusqu'au repère « FULL » sur la jauge avec de l'huile

recommandée par le fabricant.

6. Bien serrer le bouchon de remplissage d'huile/la jauge.

1. Goulotte de décharge

2. Poignée du déflecteur

de la goulotte

3. Bouchon du réservoir de

carburant

4. Barre de commande

5. Poignée du lanceur

6. Amorceur

7. Levier du démarreur

8. Bouton de démarrage

électrique (le cas

échéant)

9. Bouchon de vidange

d'huile

10. Couvercle de la courroie

d'entraînement

*11. Bouchon de remplissage

d'huile/jauge

12. Clé d'allumage

13. Déflecteur de goulotte

* L'emplacement de la jauge peut varier selon le type de moteur.

6

Page 37

Fonctionnement

REMARQUE : Établir le côté gauche et le côté droit de la

machine à partir de la position d'opération.

REMARQUE: Pour de meilleurs résultats, n'acheter que la

quantité de carburant qui sera consommée dans les 30 jours.

Sinon, ajouter du stabilisateur de carburant pour conserver la

quantité achetée pendant six mois au maximum.

Vérifier le niveau d'huile

• L'essence est extrêmement inflammable et explosive.

Un incendie ou une explosion causé par l'essence peut

vous brûler ou brûler les autres.

• Pour éviter qu'une décharge statique n'enflamme

l'essence, placer le récipient ou la souffleuse à neige

sur le sol avant de procéder à l'avitaillement en carburant ; ne pas placer le tout dans un véhicule ou sur

un objet quelconque.

• Remplir le réservoir à l'extérieur lorsque le moteur est

froid. Essuyer tout carburant déversé.

• Ne pas manipuler l'essence en fumant ou près de

flammes nues ou d'étincelles.

• Ranger l'essence dans un récipient approuvé, hors de

la portée des enfants.

• Ne pas incliner la souffleuse à neige lorsqu'il y a du

carburant dans le réservoir.

Opérer une souffleuse à neige comporte le risque de projection d’objets dans les yeux pouvant

entraîner de graves dommages pour les yeux.

Il faut toujours porter des lunettes de protection

ou des protections oculaires lorsqu’on opère une

souffleuse à neige ou lors des réparations et des réglages sur

celle-ci. Nous recommandons un masque de protection à grand

angle sur des lunettes régulières ou de protection.

IMPORTANT : Sachez comment utiliser toutes les commandes

avant d'ajouter du carburant ou de tenter de démarrer le moteur.

Remplir le réservoir de

carburant

Remplissez le réservoir d’essence sans plomb récente (indice

d’octane 87 minimum) (Figure 7).

moteur

1. Déplacer la souffleuse à neige sur une surface plane.

2. Nettoyer la zone autour de la jauge (Figure 8).

REMARQUE: L'emplacement de la jauge peut varier selon le

type de moteur.

3. Retirer le capuchon de remplissage ou la jauge à huile puis

l'essuyer.

1

Figure 8

1. Bouchon de remplissage d'huile/jauge

4. Insérer la jauge dans le goulot de remplissage et tourner dans

le sens horaire jusqu'à ce qu'elle soit bien en place. Retirer

ensuite la jauge en la tournant dans le sens anti-horaire.

5. Remplir jusqu'au repère « FULL » sur la jauge avec de l'huile

recommandée par le fabricant.

6. Bien serrer le bouchon de remplissage d'huile/la jauge.

REMARQUE: Le fait de faire tourner le moteur avec un bas

niveau d'huile peut endommager le moteur. Toujours vérifier

le niveau d'huile moteur avant le démarrage du moteur.

REMARQUE: Le fait de faire tourner le moteur avec une

trop grande quantité d'huile peut endommager le moteur et

occasionner un excès de fumée dans l'échappement. Toujours

vérifier le niveau d'huile moteur avant le démarrage du moteur.

Remplir si le

pétrole est au

Fill if oil

dessous du

is below

"RAJOUTE"

“Add”

la jauge de

on the

niveau d'huile

dipstick

Remplir si

le pétrole

est au

dessous

Fill if oil is

du "L" la

below letter

jauge de

“L” on the

niveau

ller cap

d'huile

Figure 7

IMPORTANT : Ne pas ajouter d'huile au carburant.

IMPORTANT : Ne pas utiliser de carburants mélangés E85. Ce

moteur n'est pas compatible E20/E30/E85. Les carburants de

remplacement à forte teneur en alcool peuvent occasionner un

démarrage difficile, une mauvaise performance du moteur et

des dommages internes au moteur.