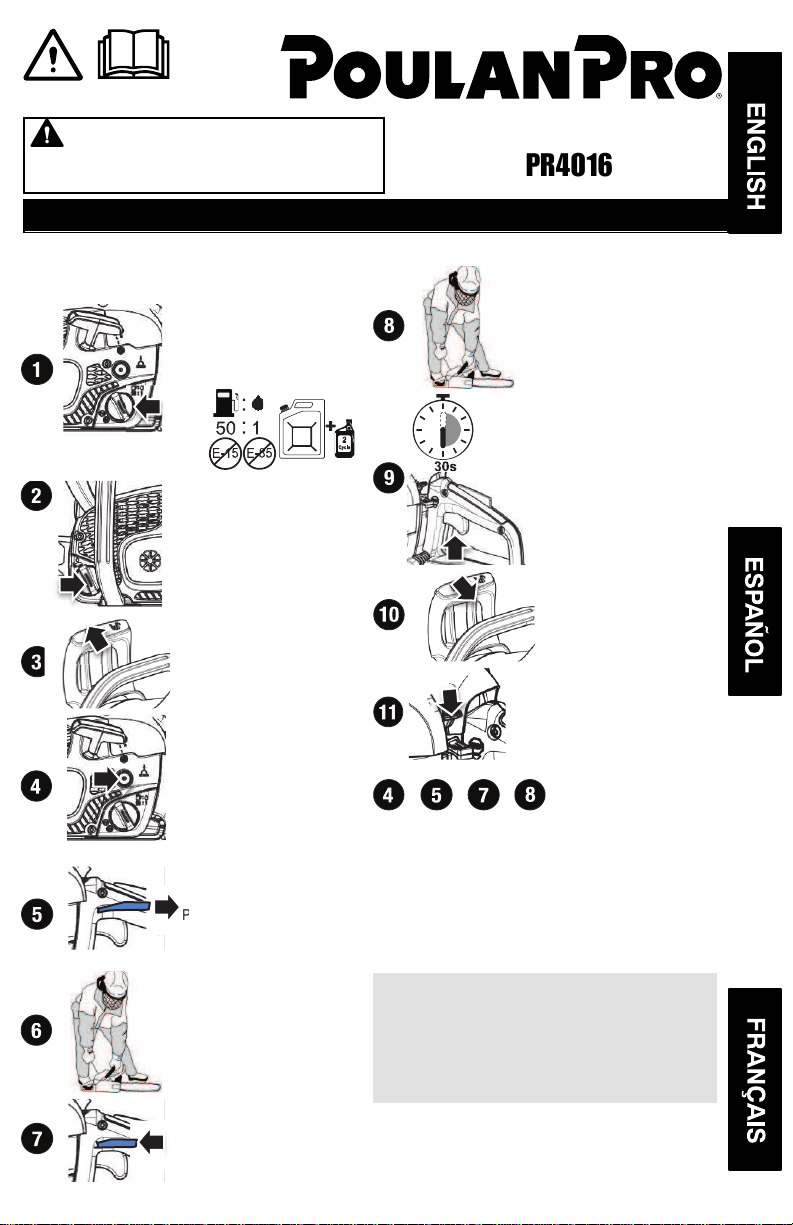

Quick

-

Start Guide

WARNING! Read and follow all Safety Rules and

SASA242

MC

Mix 2.6 oz. of full synthetic 2Cycle Oil with 1 gallon of

gasoline for a 50:1 mixture.

Shake well. Pour into fuel tank.

CAUTION: Do not use alternate

fuels such as ethanol blends

above 10% by volume (E

-15, E

-

85) or any methanol blended

fuel.

Add bar and chain oil to oil tank

until full

.

Make sure chain brake is locked

by pushing forward on

handguard.

Slowly press

primer (air purge)

bulb 10 times.

Pull blue choke lever out fully.

Place right foot in rear handle as

shown. Using right hand, pull

starter rope sharply until machine

starts, or a maximum of 5 times.

Push blue choke lever to half

choke position.

NOTE: In temperatures above

90°F (32°C), push blue choke

lever completely in.

Pull starter

rope until engine

starts.

Allow engine to warm for 30

seconds. Squeeze throttle trigger

to set normal idle.

Before accelerating

to full

throttle, make sure chain brake is

unlocked by pulling back on

handguard.

Press red switch to STOP

position when finished using saw.

n Starting a Warm Engine

NOTE: If the product does not restart, the problem could

be overheated fuel.

To fix this problem, try the following procedure:

15 seconds.

Repeat this procedure if the problem still exists.

NOTE: Always use fresh seasonal fuel and shorten

operatio

IMPORTANT:

· Never let your saw chain come in contact with soil/dirt

Pul

Operating Instructions before using this product.

Failure to do so can result in serious injury.

Instruction Manual

PR3816 / PR4016 / PR4218

127(<RXUSURGXFWPD\GLIIHUVOLJKWO\IURPWKHLWHPVKRZQ

115820549 Rev. B 2017-03-08

+ + +

1. Set the product in a cool area away from direct sunlight.

2. Allow the product to cool for at least 20 minutes.

3. Press primer (air purge) bulb repeatedly for 10-

4. Follow the cold starting procedure.

n time during unseasonably warm weather.

during operation. This will completely dull your chain

and will require installation of a new chain.

· Check your chain tension prior to each time you start

the chainsaw. Check tension on a new chain after the

first 15 minutes of operation. See the manual for chain

tensioning instructions.

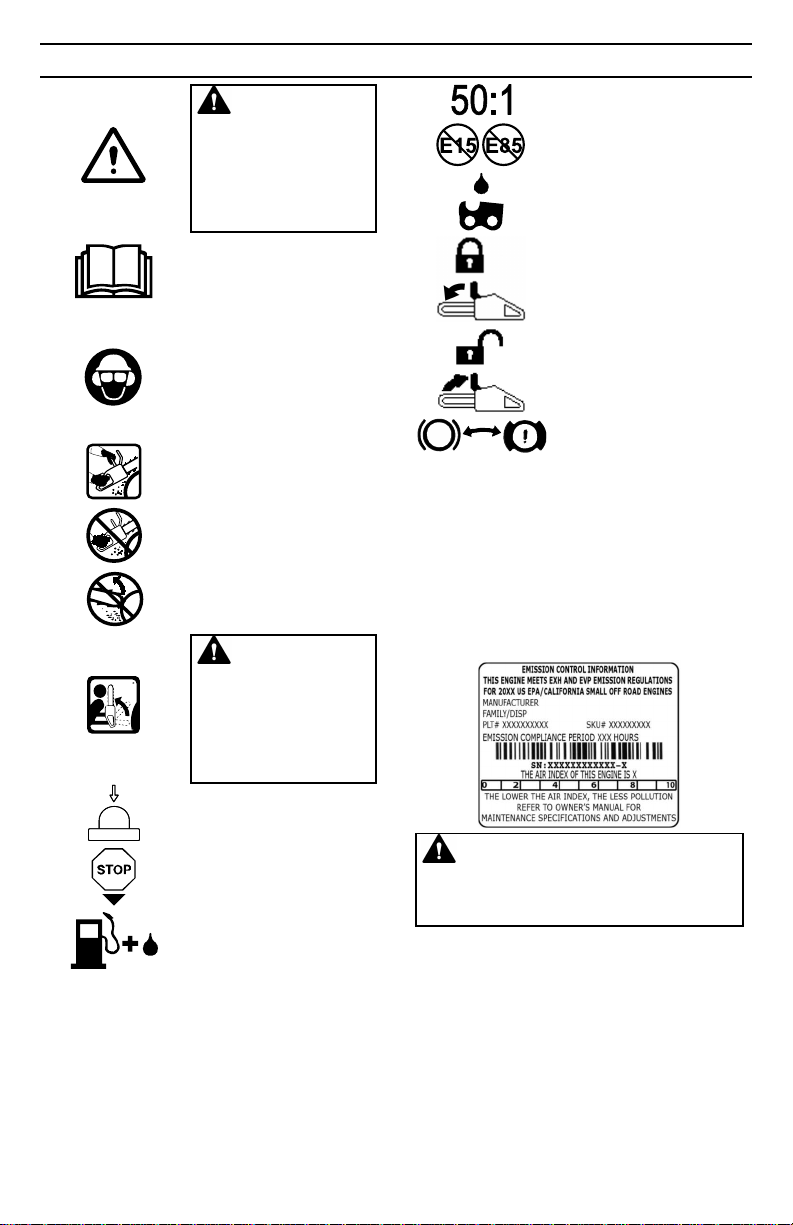

IDENTIFICATION OF SYMBOLS

Please read the

operator’s

with any

2

WARNING!

Chainsaws can be

dangerous! Careless

XX

or improper use can

result in serious or

fatal injury to the

operator or others.

manual carefully and make

sure you understand the

instructions before using the

machine.

Always wear:

• Approved protective

helmet

• Approved hearing

protection

• Protective goggles or a

visor

Both of the operator′s hands

must be used to operate the

chainsaw.

Never operate a chainsaw

holding it with one hand only.

Contact of the guide bar tip

object must be

avoided.

WARNING! Tip

contact may cause

the guide bar to move

suddenly upward and

backward (so-called

Other symbols/decals on the machine refer to

special certification requirements for certain

markets.

The Emissions Compliance Period referred to on

the Emission Compliance label indicates the

number of operating hours for which the engine

has been shown to meet Federal emissions

requirements.

Maintenance, replacement, or repair of the

emission control devices and system may be

performed by any nonroad engine repair

establishment or individual.

50:1 gasoline to oil ratio.

Do not use E15 or E85

blended fuels.

Bar and chain oil fill.

Lock chain brake.

Unlock chain brake.

Chain brake

unlocked/locked.

kickback), which may

cause serious injury.

Primer (air purge) bulb.

The engine is stopped by

switching the ignition off

using the stop switch.

Fuel fill.

WARNING! The engine exhaust from this

product contains chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm.

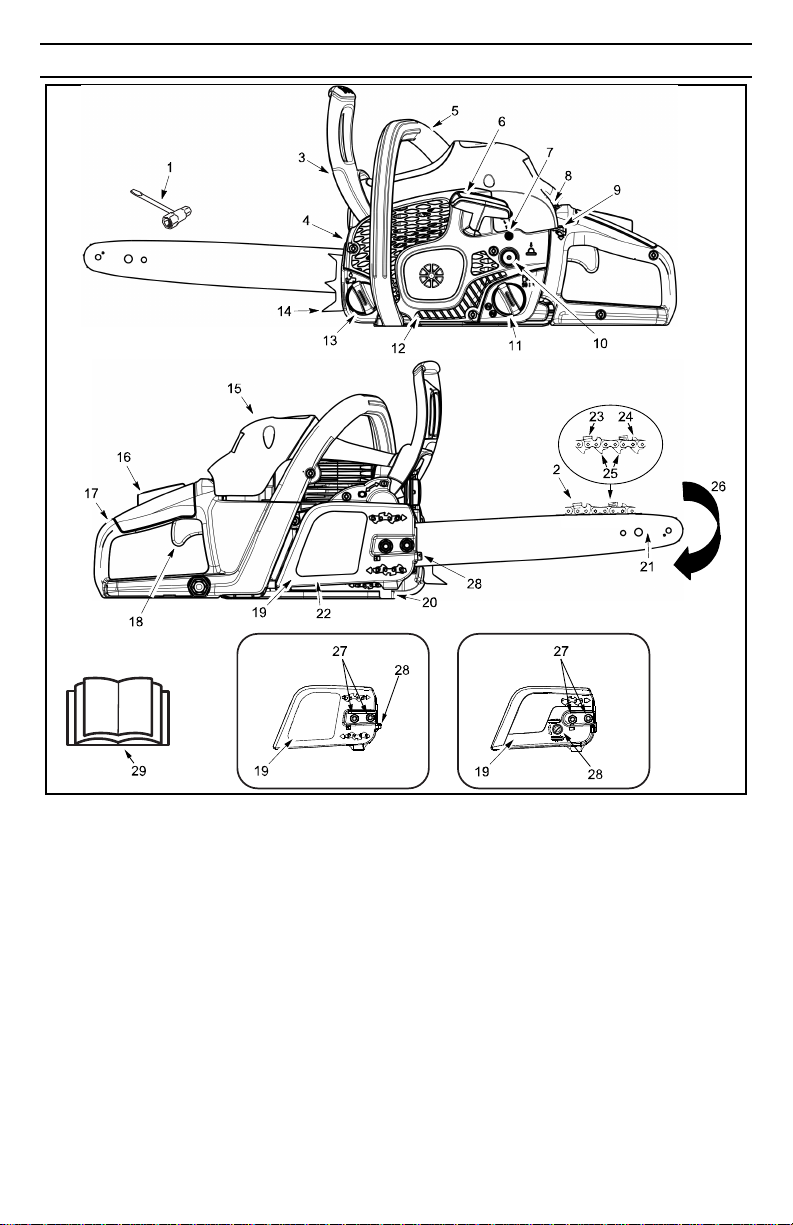

IDENTIFICATION (WHAT IS WHAT?)

3

(*)

NOTE: The appearance of your product may vary from the item shown.

(*) = Configuration for models equipped with chain tensioning screw located on front. Does not apply to all

models.

(**) = Configuration for models equipped with chain tensioning screw located on side. Does not apply to all

models.

1. Combination tool

2. Chain

3. Front hand guard

4. Muffler

5. Front handle

6. Starter rope

7. Idle speed screw

8. ON/STOP switch

9. Choke/fast idle lever

10. Primer (air purge) bulb

11. Fuel mix fill cap

12. Starter housing

13. Bar and chain oil fill cap

14. Bumper spike

15. Cylinder cover

16. Throttle lock-out

17. Rear handle

18. Throttle trigger

19. Clutch cover

20. Chain catcher

21. Guide bar

22. Chain brake

23. Cutters

24. Depth gauge

25. Drive links

26. Chain direction of travel

27. Guide bar retaining nuts

28. Chain tensioning screw

29. Manual

(**)

SAFETY

4

WARNING! Always disconnect spark plug wire and place wire where it cannot contact spark plug to

prevent accidental starting when setting up, transporting, adjusting or making repairs except

carburetor adjustments.

STANDARDS

This saw has been designed in accordance with:

ANSI B175.1-2012 American National Standards

for Gasoline-Powered Chain Saws - Safety

Requirements

CSA Z62.1-11 Chain Saws – Occupational Health

and Safety

CSA Z62.3-11 Chain Saw Kickback Occupational

Health and Safety

INTRODUCTION

A chainsaw is a high‐speed wood‐cutting tool.

Special safety precautions must be observed to

reduce the risk of accidents.

Failure to follow all safety rules and precautions

can result in serious injury.

If situations occur which are not covered in this

manual, use care and good judgment. If you need

assistance, contact your authorized service dealer

or call consumer support.

PLANNING AHEAD

• Read this manual carefully until you completely

understand and can follow all safety rules,

precautions, and operating instructions before

attempting to use the unit.

• Restrict the use of your saw to adult users who

understand and can follow safety rules,

precautions, and operating instructions found in

this manual.

• Wear protective gear. Always use steel‐toed

safety footwear with non‐slip soles; snug‐fitting

clothing; safety chaps; heavy‐duty, non‐slip

gloves; eye protection such as non‐fogging,

vented goggles or face screen; an approved

safety hard hat; and sound barriers (ear plugs or

mufflers) to protect your hearing. Regular users

should have hearing checked regularly as

chainsaw noise can damage hearing. Secure

hair above shoulder length.

• Keep all parts of your body away from the chain

when the engine is running.

• Keep children, bystanders, and animals a

minimum of 30 feet (10 meters) away from the

work area. Do not allow other people or animals

to be near the chainsaw when starting or

operating the chainsaw.

• Do not handle or operate a chainsaw when you

are fatigued, ill, or upset, or if you have taken

alcohol, drugs, or medication. You must be in

good physical condition and mentally alert.

Chainsaw work is strenuous. If you have any

condition that might be aggravated by strenuous

work, check with your doctor before operating a

chainsaw.

• Carefully plan your sawing operation in advance.

Do not start cutting until you have a clear work

area, secure footing, and, if you are felling trees,

a planned retreat path.

OPERATING YOUR SAW

• Do not operate a chainsaw with one hand.

Serious injury to the operator, helpers,

bystanders or any combination of these persons

may result from one‐handed operation. A

chainsaw is intended for two‐handed use.

• Operate the chainsaw only in a well‐ventilated

outdoor area.

• Do not operate saw from a ladder or in a tree.

• Make sure the chain will not make contact with

any object while starting the engine. Never try to

start the saw when the guide bar is in a cut.

• Do not put pressure on the saw at the end of the

cut. Applying pressure can cause you to lose

control when the cut is completed.

• Stop the engine before setting the saw down.

• Do not operate a chainsaw that is damaged,

improperly adjusted, or not completely and

securely assembled. Always replace bar, chain,

hand guard, or chain brake immediately if it

becomes damaged, broken or is otherwise

removed.

• Exposure to vibrations through prolonged use of

gasoline powered hand tools could cause blood

vessel or nerve damage in the fingers, hands,

and joints of people prone to circulation

disorders or abnormal swellings. Prolonged use

in cold weather has been linked to blood vessel

damage in otherwise healthy people. If

symptoms occur such as numbness, pain, loss

of strength, change in skin color or texture, or

loss of feeling in the fingers, hands, or joints,

discontinue the use of this tool and seek medical

attention. An anti-vibration system does not

guarantee the avoidance of these problems.

Users who operate power tools on a continual

and regular basis must monitor closely their

physical condition and the condition of this tool.

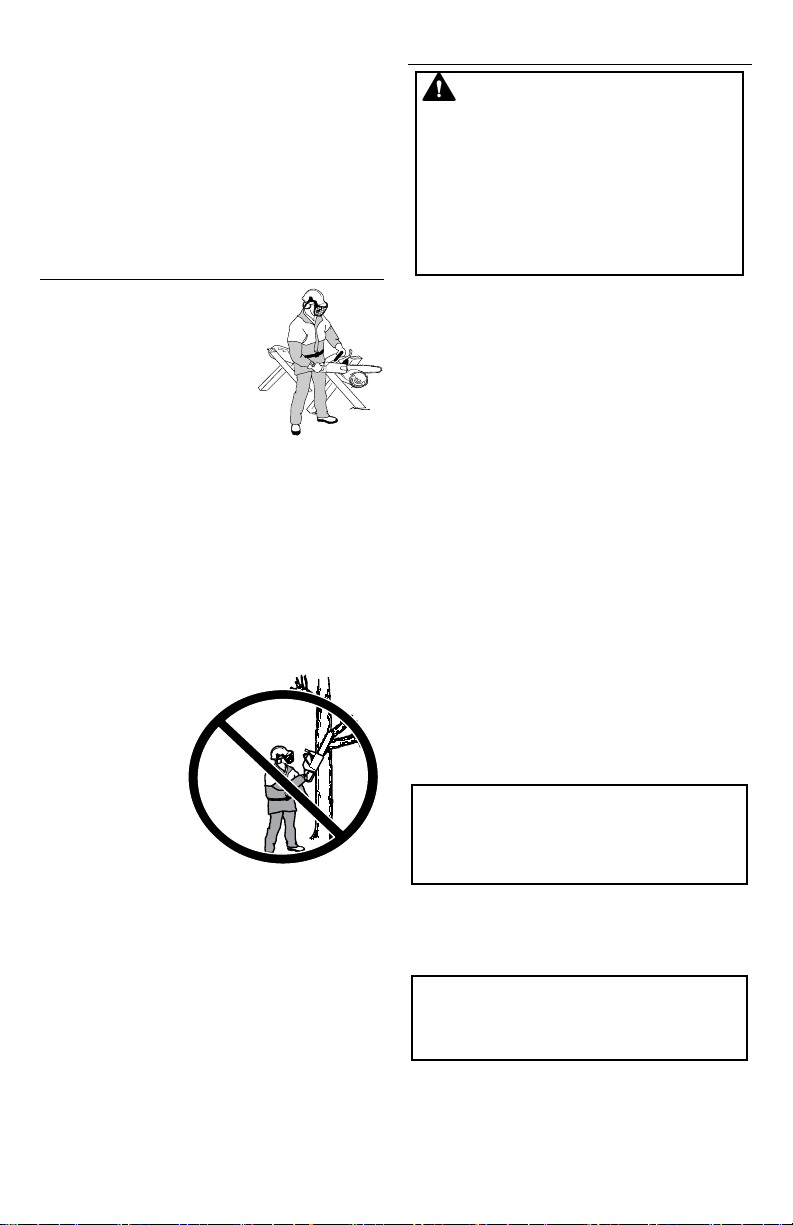

• With the engine stopped,

5

hand-carry the chainsaw with

the muffler away from your

body, and the guide bar and

chain to the rear, preferably

covered with a scabbard.

MAINTAINING YOUR SAW

• Have all chainsaw service

performed by a qualified

service dealer with the

exception of the items listed

in the maintenance section of this manual. For

example, if improper tools are used to remove or

hold the flywheel when servicing the clutch,

structural damage to the flywheel can occur and

cause the flywheel to burst.

• Make certain the saw chain stops moving when

the throttle trigger is released. For correction,

refer to Carburetor Adjustment.

• Never modify your saw in any way.

• Keep the handles dry, clean, and free of oil or

fuel mixture.

• Keep fuel and oil caps, screws, and fasteners

securely tightened.

• Use only genuine accessories and replacement

parts as recommended.

• Your saw is equipped with a temperature limiting

muffler and spark arresting screen which meets

the requirements of California Codes 4442 and

4443. All U.S. forest land and the states of

California, Idaho, Maine, Minnesota, New

Jersey, Oregon, and Washington require by law

that many internal combustion engines to be

equipped with a spark arresting screen. If you

operate a chainsaw in a state or locale where

such regulations exist, you are legally

responsible for maintaining the operating

condition of these parts. Failure to do so is a

violation of the law. Refer to the SERVICE

section for maintenance of the spark arresting

screen.

HANDLING FUEL

• Do not smoke while handling fuel or while

operating the saw.

• Eliminate all sources of sparks or flame in the

areas where fuel is mixed or poured. There

should be no smoking, open flames, or work that

could cause sparks. Allow engine to cool before

refueling.

• Always have fire extinguishing tools available if

you should need them.

• Mix and pour fuel in an outdoor area on bare

ground; store fuel in a cool, dry, well ventilated

place; and use an approved, marked container

for all fuel purposes. Wipe up all fuel spills

before starting saw.

• Move at least 10 feet (3 meters) from fueling site

before starting engine.

• Turn the engine off and let saw cool in a non‐

combustible area, not on dry leaves, straw,

paper, etc. Slowly remove fuel cap and refuel

unit.

• Store the unit and fuel in an area where fuel

vapors cannot reach sparks or open flames from

water heaters, electric motors or switches,

furnaces, etc.

UNDERSTANDING KICKBACK

WARNING! Avoid kickback which can result

in serious injury. Kickback is the backward,

upward or sudden forward motion of the

guide bar occurring when the saw chain

near the upper tip of the guide bar contacts

any object such as a log or branch, or when

the wood closes in and pinches the saw

chain in the cut. Contacting a foreign object

in the wood can also result in loss of

chainsaw control.

ROTATIONAL KICKBACK

Rotational kickback can

occur when the moving

chain contacts an object at

the upper tip of the guide

bar. This contact can

cause the chain to dig into

the object, which stops the

chain for an instant. The result is a lightning fast,

reverse reaction which kicks the guide bar up and

back toward the operator.

PINCH KICKBACK

Pinch kickback can occur when the wood closes in

and pinches the moving saw chain in the cut along

the top of the guide bar and the saw chain is

suddenly stopped. This sudden stopping of the

chain results in a reversal of the chain force used

to cut wood and causes the saw to move in the

opposite direction of the chain rotation. The saw is

driven straight back toward the operator.

PULL-IN

Pull‐in can occur when the moving chain contacts

a foreign object in the wood in the cut along the

bottom of the guide bar and the saw chain is

suddenly stopped. This sudden stopping pulls the

saw forward and away from the operator and could

easily cause the operator to lose control of the

saw.

REDUCING THE CHANCE OF KICKBACK

• Recognize that kickback can happen. With a

basic understanding of kickback, you can reduce

the element of surprise which contributes to

accidents.

• Never let the moving chain contact any object at

the tip of the guide bar.

• Keep the working area free from obstructions

such as other trees, branches, rocks, fences,

stumps, etc. Eliminate or avoid any obstruction

that your saw chain could hit while you are

cutting. When cutting a branch, do not let the

guide bar contact branch or other objects around

it.

• Keep your saw chain sharp and properly

tensioned. A loose or dull chain can increase the

chance of kickback occurring. Follow

manufacturer's chain sharpening and

maintenance instructions. Check tension at

regular intervals with the engine stopped, never

with the engine running. Make sure the bar nuts

are securely tightened after tensioning the chain.

• Begin and continue cutting at full speed. If the

chain is moving at a slower speed, there is

greater chance of kickback occurring.

• Use wedges made of plastic or wood. Never use

6

metal to hold the cut open.

• Cut one log at a time.

• Use extreme caution when re‐entering a

previous cut.

• Do not attempt cuts starting with the tip of the

bar (plunge cuts).

• Watch for shifting logs or other forces that could

close a cut and pinch or fall into chain.

• Do not twist the saw as the bar is withdrawn

from an undercut when bucking.

• Use the reduced-kickback guide bar and lowkickback chain specified for your saw.

MAINTAINING CONTROL

• Keep a good, firm grip on

the saw with both hands

when the engine is running

and don't let go. A firm grip

will help you reduce

kickback and maintain

control of the saw. Keep

the fingers of your left hand

encircling and your left

thumb under the front

handlebar. Keep your right hand completely

around the rear handle whether you are right

handed or left handed. Keep your left arm

straight with the elbow locked.

• Position your left hand on the front handlebar so

it is in a straight line with your right hand on the

rear handle when making bucking cuts. Never

reverse right and left hand positions for any type

of cutting.

• Stand with your weight evenly balanced on both

feet.

• Stand slightly to the left side of the saw to keep

your body from being in a direct line with the

cutting chain.

• Do not

overreach. You

could be drawn

or thrown off

balance and

lose control of

the saw.

• Do not cut

above shoulder

height. It is

difficult to

maintain control

of saw above

shoulder height.

KICKBACK SAFETY FEATURES

WARNING! The following features are

included on your saw to help reduce the

hazard of kickback; however, such features

will not totally eliminate this danger. As a

chainsaw user, do not rely only on safety

devices. You must follow all safety

precautions, instructions, and maintenance

in this manual to help avoid kickback and

other forces which can result in serious

injury.

REDUCED KICKBACK GUIDE BAR

The reduced-kickback guide bar is designed with a

small radius tip which reduces the size of the

kickback danger zone on the bar tip. A reducedkickback guide bar has been demonstrated to

significantly reduce the number and seriousness of

kickbacks when tested in accordance with safety

requirements for gasoline powered chainsaws as

set by ANSI B175.1.

LOW-KICKBACK CHAIN

A low-kickback chain is designed with a contoured

depth gauge and guard link which deflect kickback

force and allow wood to gradually ride into the

cutter. Low-kickback chain has met kickback

performance requirements when tested on a

representative sample of chainsaws below 3.8

cubic inch displacement specified in ANSI B175.1.

FRONT HAND GUARD

The front hand guard is designed to reduce the

chance of your left hand contacting the chain if

your hand slips off the front handlebar.

The distance and “in‐line” position of the hands

provided by the front and rear handles work

together to give balance and resistance in

controlling the pivot of the saw back toward the

operator if kickback occurs.

CHAIN BRAKE

The chain brake is designed to stop the chain in

the event of kickback.

NOTE: We do not represent and you should

not assume that the chain brake will protect

you in the event of a kickback. Do not rely upon

any of the devices built into your saw. You

should use the saw properly and carefully to

avoid kickback.

Repairs on a chain brake should be made by an

authorized servicing dealer. Take your unit to the

place of purchase if purchased from a servicing

dealer, or to the nearest authorized master service

dealer.

NOTE: If this saw is to be used for commercial

logging, a chain brake is required and shall not

be removed or otherwise disabled to comply

with Federal OSHA Regulations for

Commercial Logging.

ASSEMBLY

Chain

Chain

7

If received assembled, repeat all steps to ensure

your saw is properly assembled and all fasteners

are secure.

1. Check that the chain brake is in the unlocked

position by pulling the front hand guard towards

the front handle.

2. Loosen and remove the bar nuts and the clutch

cover from the saw.

3. Remove the plastic shipping spacer (A) if

present.

7. Check that the drive links of the chain fit

correctly on the drive sprocket and that the

chain is in the groove on the bar.

8. Fit the clutch cover and insert the adjusting pin

in the cut-out in the bar.

9. Tighten the bar nut finger-tight.

10. Tension the chain by turning the chain

tensioning screw clockwise using the

combination tool. The chain is correctly

tensioned when it does not sag from the

underside of the bar, but can still be turned

easily by hand.

tensioningside adjust

models

4. An adjusting pin and screw is used to adjust

the tension of the chain. It is very important

when assembling the bar that the adjusting pin

located on the adjusting screw aligns into a

hole in the bar. Turning the screw will move the

adjusting pin up and down the screw. Locate

this adjusting pin before you begin mounting

the bar onto the saw. See following illustration.

5. Turn the adjusting screw by hand

counterclockwise until the adjusting pin is

positioned between the indicator marks (B) on

the clutch cover. This should allow the

adjusting pin to be near the correct position.

6. Slide guide bar with chain on bar bolts until

guide bar stops against clutch drum sprocket.

Cutters must face in the direction of rotation.

11. Hold up the bar tip and tighten the bar nuts with

the combination tool.

When fitting a new chain, the chain tension has to

be checked frequently until the chain is run-in.

Check the chain tension regularly. A correctly

tensioned chain ensures good cutting performance

and long life.

tensioningfront adjust

models

STARTING AND STOPPING

HELPFUL TIP

8

PRE-OPERATION INSPECTION

Perform the following steps before every use of

the machine:

• Check fuel mixture level

• Check bar lubrication

• Check chain sharpness

NOTE: Chain sharpening is a complicated task

that requires special tools. We recommend that

you refer chain sharpening to a professional

chain sharpener.

• Check chain tension

• Inspect and clean the guide bar

• Check for damaged parts

• Check for loose caps

• Check for loose fasteners

• Check for loose parts

• Check for fuel and oil leaks

NOTE: It is normal for a small amount of oil to

appear under the saw after the engine stops.

Do not confuse this with a leaking oil tank.

FUELING THE ENGINE

WARNING! Be sure to read the fuel handling

information in the safety rules section of

this manual before you begin. If you do not

understand the fuel handling information do

not attempt to fuel your unit. Seek help from

someone that does understand the

information or call the consumer assistance

help line.

WARNING! Remove the fuel cap slowly when

fueling.

This equipment is designed to operate on

unleaded gasoline with a minimum 87 octane

(R+M/2 method), with ethanol blended up to 10%

maximum by volume (E-10).

Before operation, gasoline must be mixed with a

good quality full synthetic 2-cycle air-cooled

engine oil designed to be mixed at a ratio of 50:1.

A 50:1 ratio is obtained by mixing 2.6 fluid ounces

of full synthetic oil with 1 gallon of unleaded

gasoline. DO NOT USE automotive oil or marine

oil. These oils will cause engine damage.

When mixing fuel, follow the instructions printed on

the container. Once the oil is added to the

gasoline, shake the container momentarily to

assure that the fuel is thoroughly mixed.

Fill the fuel tank completely with properly mixed

fuel.

Always read and follow the safety rules relating to

fuel before fueling your unit.

Purchase fuel in quantities that can be used within

30 days to assure fuel freshness.

During storage of your fuel

mixture, the oil will separate

from the gasoline.

Shake the fuel can weekly to

insure proper blending of the

gasoline and oil.

CAUTION: Never use unmixed gasoline in your

unit. This will cause permanent engine damage

and void the limited warranty.

CAUTION: Do not use alternate fuels such as

ethanol blends above 10% by volume (E-15, E-

85) or any methanol blended fuel. Use of these

fuels can cause major engine performance

problems and void the limited warranty.

BAR AND CHAIN LUBRICATION

The bar and chain require continuous lubrication.

Lubrication is provided by the automatic oiler

system when the oil tank is kept filled. Lack of oil

will quickly ruin the bar and chain. Too little oil will

cause overheating shown by smoke coming from

the chain and/or discoloration of the bar. In

freezing weather oil will thicken, making it

necessary to thin bar and chain oil with a small

amount (5 to 10%) of #1 diesel fuel or kerosene.

Bar and chain oil must be free flowing for the oil

system to pump enough oil for adequate

lubrication.

If bar and chain oil is not available, use a good

grade SAE 30 oil.

Fill the oil tank completely with oil.

CAUTION: Never use waste oil for bar and

chain lubrication.

CAUTION: Always stop the engine before

removing the oil cap.

STARTING POSITION

1. Lay the chainsaw on a flat surface. The cutting

attachment must not be in contact with the

ground.

2. Lock the chain brake by pushing forward on the

handguard.

3. Place your left hand on the handlebar and your

right hand on the starter rope. Push your right

foot into the rear handle to stabilize the

chainsaw.

4. Follow the starting instructions.

STARTING

Make sure the chain brake is

locked

Press the

primer (air purge)

bulb 10 times

primer

Pull the blue choke lever to the FULL

Using

your

right hand, pull

the

starter

Push the blue choke lever to the HALF

Pull the starter rope sharply with your

Allow the engine to run for 30 seconds

.

Before accelerating to full throttle, p

ull t

he

.

If your engine still does not

Make sure the chain brake is

locked

Press the

primer (air purge)

bulb 10 times

primer

Pull the blue choke lever to the FULL

Push the blue choke lever to the HALF

Pull the starter rope sharply with your

Before accelerating to full throttle, pull the

handle.

9

Follow these instructions to start your chainsaw.

Your chainsaw has a starting reminder decal

similar to the one shown below:

Starting a Cold Engine

before starting.

until fuel begins to fill the bulb. The

(air purge) bulb does not need to be

completely filled.

CHOKE position. The red ON/STOP

switch will be switched automatically to

the ON position.

rope sharply until the machine attempts

to start, or a maximum of 5 times.

NOTE: If the engine sounds as if it is trying to

start before the fifth pull, stop pulling and

immediately proceed to the next step.

NOTE: Do not attempt to cut material with the

choke/fast idle lever in the FULL CHOKE

position.

CHOKE position.

NOTE: In temperatures above 90°F

(32°C), push the blue choke lever

completely in.

right hand until the engine starts.

front hand guard towards the front

handle. The chain brake is now unlocked

Your chainsaw is now ready for use.

WARNING! The chain must not move when

the engine runs at idle speed. If the chain

moves at idle speed refer to CARBURETOR

ADJUSTMENT within this manual.

WARNING! Do not attempt to throw or drop-

start the chainsaw. Doing so will put the

operator at risk of serious injury due to loss

of control of the chainsaw.

WARNING! The muffler is very hot during

and after use. Do not touch the muffler or

allow combustible material such as dry

grass or fuel to do so.

HELPFUL TIP

start after following the

instructions, contact

consumer assistance.

Starting a Warm Engine

before starting.

until fuel begins to fill the bulb. The

(air purge) bulb does not need to be

completely filled.

CHOKE position.

CHOKE position.

NOTE: In temperatures above 90°F

(32°C), push the blue choke lever

completely in.

right hand until the engine starts.

front hand guard towards the front

The chain brake is now unlocked. Your

chainsaw is now ready for use.

Starting a Flooded Engine

The engine may be flooded with too much fuel if it

has not started after 10 pulls.

Flooded engines can be restarted by pushing the

blue choke lever in completely to the OFF CHOKE

position and then following the warm engine

starting procedure listed above. Ensure the red

ON/STOP switch is in the ON position.

Starting could require pulling the starter rope

handle many times depending on how badly the

unit is flooded. If the engine fails to start, refer to

the TROUBLESHOOTING TABLE or call the

consumer assistance help line.

CHAIN TENSION

It is normal for a new chain to stretch during the

first 15 minutes of operation. You should check

your chain tension each time before you start the

chainsaw. See the chain tensioning instructions in

the ASSEMBLY section.

WARNING! If the saw is operated with a

loose chain, the chain could jump off the

guide bar and result in serious injury to the

operator and/or damage the chain, making it

unusable.

CHECKING THE CHAIN BRAKE

10

The chain brake must be checked before each

use. The engine must be running when performing

this procedure.

This is the only instance when the saw should be

placed on the ground with the engine running.

1. Place the saw on firm ground.

2. Grip the rear handle with your right hand and

the front handle with your left hand.

3. Apply full throttle by fully depressing the throttle

trigger.

4. Activate the chain brake by turning your left

wrist toward the hand guard without releasing

your grip around the front handle. The chain

should stop immediately.

WORKING TECHNIQUES

PRACTICING YOUR CUTS

Practice cutting a few small logs using the

following techniques to get the “feel” of using your

saw before you begin a major sawing operation.

• Squeeze the throttle trigger and allow the engine

to reach full speed before cutting.

• Begin cutting with the saw frame against the log.

• Keep the engine at full speed the entire time you

are cutting.

• Allow the chain to cut for you. Exert only light

downward pressure. If you force the cut,

damage to the guide bar, chain, or engine can

result.

• Release the throttle trigger as soon as the cut is

completed, allowing the engine to idle. If you run

the saw at full throttle without a cutting load,

unnecessary wear can occur to the chain, guide

bar, and engine. It is recommended that the

engine not be operated for longer than 30

seconds at full throttle.

• To avoid losing control when cut is complete, do

not put pressure on saw at end of cut.

• Stop the engine before setting the saw down

after cutting.

FELLING A TREE

PLANNING

CHECKING THE INERTIA ACTIVATING

FUNCTION CONTROL

WARNING! When performing the following

procedure, the engine must be turned off.

1. Grip the rear handle with your right hand and

the front handle with your left hand.

2. Hold the chainsaw approximately 16-18 inches

(40-45 centimeters) above a stump or other

wooden surface.

3. Release your grip on the front handle and use

the weight of the saw to let the tip of the guide

bar fall forward and contact the stump. When

the tip of the bar hits the stump, the brake

should activate.

Carefully plan your sawing operation in advance.

Clear the work area. You need a clear area all

around the tree so you can have secure footing.

The chainsaw operator should keep on the uphill

side of the terrain as the tree is likely to roll or slide

downhill after it is felled.

Study the natural conditions that can cause the

tree to fall in a particular direction.

Natural conditions that can cause a tree to fall in a

particular direction include:

• The wind direction and speed.

• The lean of the tree. The lean of a tree might not

be apparent due to uneven or sloping terrain.

Use a plumb or level to determine the direction

of tree lean.

• Weight and branches on one side.

• Surrounding trees and obstacles.

Look for decay and rot. If the trunk is rotted, it can

snap and fall toward the operator. Check for

broken or dead branches which can fall on you

while cutting.

Make sure there is enough room for the tree to fall.

Maintain a distance of 2-1/2 tree lengths from the

nearest person or other objects. Engine noise can

drown out a warning call.

WARNING! Check for broken or dead

branches which can fall while cutting

causing serious injury. Do not cut near

buildings or electrical wires if you do not

know the direction of tree fall, nor cut at

night since you will not be able to see well,

nor during bad weather such as rain, snow,

or strong winds, etc. If the tree makes

contact with any utility line, the utility

company should be notified immediately.

Remove dirt, stones, loose bark, nails, staples,

and wire from the tree where cuts are to be made.

Plan a clear retreat path to the rear and diagonal

to the line of fall. Note the danger zone (1), retreat

path (2), and felling direction (3) in the following

diagram.

D

*

Use a wedge to remove pinched saw

11

a

n

g

e

r

z

o

Retreat path

z

r

e

g

n

a

D

n

e

F

D

e

n

o

Retreat path

n

o

i

t

c

e

r

i

d

g

n

i

l

l

e

a

n

g

e

r

z

o

n

1

2

e

3

1

1

2

USING THE NOTCH METHOD

The notch method is used to fell large trees. A

notch is cut on the side of the tree in the desired

direction of fall. After a felling cut is made on the

opposite side of tree, the tree will tend to fall into

the notch.

NOTE: If the tree has large buttress roots,

remove them before making the notch. If using

saw to remove buttress roots, keep saw chain

from contacting ground to prevent dulling of the

chain.

Make the notch cut by cutting the top of the notch

first. Cut through 1/3 of the diameter of the tree.

Next complete the notch by cutting the bottom of

the notch. Once the notch is cut remove the notch

of wood from the tree.

After removing the wood from the notch, make the

felling cut on the opposite side of the notch. This is

done by making a cut about two inches (5 cm)

higher than the center of the notch. This will leave

enough uncut wood between the felling cut and

the notch to form a hinge. This hinge will help

prevent the tree from falling in the wrong direction.

NOTE: Before felling cut is complete, use

wedges to open the cut if necessary to control

the direction of fall. To avoid kickback and

chain damage, use wood or plastic wedges, but

never steel or iron wedges.

Be alert to signs that the tree is ready to fall:

cracking sounds, widening of the felling cut, or

movement in the upper branches.

As tree starts to fall, stop saw, put it down, and get

away quickly on your planned retreat path.

DO NOT cut down a partially fallen tree with your

saw. Be extremely cautious with partially fallen

trees that may be poorly supported. When a tree

doesn’t fall completely, set the saw aside and pull

down the tree with a cable winch, block and tackle,

or tractor.

CUTTING A FALLEN TREE (BUCKING)

Bucking is the term used for cutting a fallen tree to

the desired log size.

WARNING! Do not stand on the log being

cut. Any portion can roll causing loss of

footing and control. Do not stand downhill

of the log being cut.

IMPORTANT POINTS

• Cut only one log at a time.

• Cut shattered wood very carefully; sharp pieces

of wood could be flung toward operator.

• Use a sawhorse to cut small logs. Never allow

another person to hold the log while cutting and

never hold the log with your leg or foot.

• Do not cut in an area where logs, limbs, and

roots are tangled such as in a blown down area.

Drag the logs into a clear area before cutting by

pulling out exposed and cleared logs first.

• Make sure the chain will not strike the ground or

any other object during or after cutting.

WARNING! If saw becomes pinched or hung

in a log, don’t try to force it out. You can

lose control of the saw resulting in injury

and/or damage to the saw. Stop the saw,

drive a wedge of plastic or wood into the cut

until the saw can be removed easily. Restart

the saw and carefully reenter the cut. To

avoid kickback and chain damage, do not

use a metal wedge. Do not attempt to restart

your saw when it is pinched or hung in a

log.

TYPES OF BUCKING CUTS

121

212

1 2

12

Overcutting begins on the top side of the log with

the bottom of the saw against the log. When

overcutting use light downward pressure.

Undercutting involves cutting on the underside of

the log with top of saw against the log. When

undercutting use light upward pressure. Hold saw

firmly and maintain control. The saw will tend to

push back toward you.

WARNING! Never turn saw upside down to

undercut. The saw cannot be controlled in

this position.

Always make your first cut on the compression

side of the log. The compression side of the log is

where the pressure of the log’s weight is

concentrated.

BUCKING WITHOUT A SUPPORT

1. Overcut through 1/3 of the diameter of the log.

2. Roll the log over and finish with a second

overcut.

NOTE: Watch for logs with a compression side

to prevent the saw from pinching.

BUCKING USING A LOG OR SUPPORT

STAND

1. Make the first cut on the compression side of

the log. Your first cut should extend 1/3 of the

diameter of the log.

2. Finish with your second cut.

LIMBING AND PRUNING

WARNING! Be alert for and guard against

kickback. Do not allow the moving chain to

contact any other branches or objects at the

nose of the guide bar when limbing or

pruning. Allowing such contact can result in

serious injury.

WARNING! Never climb into a tree to limb or

prune. Do not stand on ladders, platforms, a

log, or in any position which can cause you

to lose your balance or control of the saw.

IMPORTANT POINTS

• Work slowly, keeping both hands firmly gripped

on the saw. Maintain secure footing and

balance.

• Watch out for springpoles. Springpoles are small

size limbs which can catch the saw chain and

whip toward you or pull you off balance. Use

extreme caution when cutting small size limbs or

slender material.

• Be alert for springback. Watch out for branches

that are bent or under pressure. Avoid being

struck by the branch or the saw when the

tension in the wood fibers is released.

• Keep a clear work area. Frequently clear

13

branches out of the way to avoid tripping over

them.

LIMBING

Always limb a tree after it is cut down. Only then

can limbing be done safely and properly.

Leave the larger limbs underneath the felled tree

to support the tree as you work.

Start at the base of the felled tree and work toward

the top, cutting branches and limbs. Remove small

limbs with one cut.

Keep the tree between you and the chain. Cut

from the side of the tree opposite the branch you

are cutting.

Remove larger, supporting branches with the

cutting techniques described in BUCKING

WITHOUT A SUPPORT.

Always use an overcut to cut small and freely

hanging limbs. Undercutting could cause limbs to

fall and pinch the saw.

MAINTENANCE

WARNING! Disconnect the spark plug before

performing maintenance except for

carburetor adjustments.

GENERAL RECOMMENDATIONS

The warranty on this unit does not cover items that

have been subjected to operator abuse or

negligence. To receive full value from the

warranty, the operator must maintain the unit as

instructed in this manual. Various adjustments will

need to be made periodically to properly maintain

your unit.

Have all repairs other than the recommended

maintenance described in the instruction manual

performed by an authorized service dealer. If any

dealer other than an authorized service dealer

performs work on the product, the manufacturer

may not pay for repairs under warranty. It is your

responsibility to maintain and perform general

maintenance.

MAINTENANCE SCHEDULE

Every 5 hours*

• Inspect and clean air filter

• Inspect and clean chain brake

• Inspect and clean guide bar

Every 25 hours*

• Inspect and clean spark arresting screen and

muffler

Yearly

• Replace spark plug

• Replace fuel filter

• Replace air filter

* Each hour of operation is approximately 2 tanks

of fuel.

MAINTENANCE PROCEDURES

GUIDE BAR

Conditions which require guide bar maintenance:

• Saw cuts to one side or at an angle.

PRUNING

WARNING! Limit pruning to limbs shoulder

height or below. Do not cut if branches are

higher than your shoulder. Get a

professional to do the job.

1. Make the first cut one-third of the way through

the bottom of the limb.

2. Make the second cut all the way through the

limb.

3. Make the third overcut leaving a 1 to 2 inch (2.5

to 5 cm) collar from the trunk of the tree.

2

1

• Saw has to be forced through the cut.

• Inadequate supply of oil to bar/chain.

Check the condition of guide bar each time chain

is sharpened. A worn guide bar will damage the

chain and make cutting difficult.

After each use, ensure ON/STOP switch is in the

STOP position, then clean all sawdust from the

guide bar and sprocket hole.

To maintain guide bar:

1. Move ON/STOP switch to STOP.

2. Loosen and remove bar nuts and clutch cover.

Remove bar and chain from saw.

3. Clean the oil holes (A) and bar groove (B).

4. Burring of guide bar rails is a normal process of

rail wear. Remove these burrs with a flat file.

5. When rail top is uneven, use a flat file to

restore square edges and sides.

Replace guide bar when the groove is worn, the

guide bar is bent or cracked, or when excess

heating or burring of the rails occurs. If

replacement is necessary, use only the guide bar

specified for your saw in the repair parts list or on

the decal located on the chainsaw.

3

Inspect and clean the unit and decals

14

After each use, inspect complete unit for loose or

damaged parts. Clean the unit and decals using a

damp cloth with a mild detergent.

Wipe off unit with a clean dry cloth.

Check the chain brake

See CHAIN BRAKE in the OPERATION section.

MUFFLER

As the unit is used, carbon deposits build up on

the muffler and spark arresting screen, and must

be removed to avoid creating a fire hazard or

affecting engine performance.

Replace the spark arresting screen if breaks

occur.

1. Loosen and remove the nut (A) from the

exhaust outlet cover (B).

2. Remove the exhaust outlet cover.

3. Remove the spark arresting screen (C). Handle

the screen carefully to prevent damage.

4. Clean the spark arresting screen gently with a

wire brush. Replace screen if breaks are found.

5. Replace any broken or cracked muffler parts.

6. Reinstall spark arresting screen, exhaust outlet

cover, and nut. Tighten nut securely to 25-35

in-lb.

SPARK PLUG

NOTE: For models sold in Canada, the spark

ignition system complies with the Canadian

standard ICES-002.

1. Loosen the three screws (A) on the cylinder

cover (B).

2. Remove the cylinder cover.

3. Pull off the spark plug boot (C).

4. Remove spark plug (D) from the cylinder and

discard.

5. Install a new spark plug (Brisk HQT-1•) and

tighten securely with a 3/4 inch (19 mm) socket

wrench to 15-25 ft-lb. The spark plug gap

should be 0.025 inch (0,6 mm).

6. Reinstall the spark plug boot.

7. Reinstall the cylinder cover and the three

screws. Tighten securely to 13-18 in-lb.

FUEL FILTER

To replace fuel filter, drain your unit by running it

dry of fuel. Remove fuel cap and its connected

retainer from tank. Pull filter from tank and remove

from line. Replace and reassemble.

AIR FILTER

CAUTION: Do not clean filter in gasoline or

other flammable solvent to avoid creating a fire

hazard or producing evaporative emissions.

A dirty air filter decreases the life and performance

of the engine and increases fuel consumption and

exhaust emissions. Always clean your air filter

according to the maintenance schedule. Clean

more frequently in dusty conditions.

A used air filter can never be completely cleaned.

It is advisable to replace your air filter with a new

one according to the maintenance schedule.

1. Loosen the three screws (A) on the cylinder

cover (B).

2. Remove the cylinder cover.

3. Remove the air filter cover (C) and air filter (D).

4. Clean the air filter using hot soapy water. Rinse

with clean cool water. Air dry completely before

reinstalling.

5. Reinstall the air filter and air filter cover.

6. Reinstall the cylinder cover and three screws.

Tighten securely to 13-18 in-lb.

CARBURETOR ADJUSTMENT

15

WARNING! The chain will be moving during

most of this procedure. Wear your

protective equipment and observe all safety

precautions. The chain must not move at

idle speed.

Indications for idle speed adjustment

The carburetor has been carefully set at the

factory. Adjustments may be necessary if you

notice any of the following conditions:

• The chain moves at idle. See IDLE SPEED-T

ADJUSTMENT procedure.

• The saw will not idle. See IDLE SPEED-T

ADJUSTMENT procedure.

Idle speed-T adjustment

Allow the engine to idle. If the chain moves, the

idle is too fast. If the engine stalls, the idle is too

slow.

Adjust the speed until the engine runs without

chain movement (idle too fast) or stalling (idle too

slow).

The idle speed screw is located in the area above

the primer (air purge) bulb and is labeled “T”.

Turn the idle speed screw (T) clockwise to

increase the engine speed.

Turn the idle speed screw (T) counterclockwise to

decrease the engine speed.

STORAGE

WARNING! Stop the engine and allow it to

cool. Secure the unit before storing or

transporting it in a vehicle. Store the unit

and fuel in an area where fuel vapors cannot

reach sparks or open flames from water

heaters, electric motors, switches, furnaces,

etc.

WARNING ! Store the unit with all guards in

place. Position so that any sharp object

cannot accidentally cause injury to

passersby. Store the unit out of reach of

children.

• Before storing, drain all fuel from the unit. Start

the engine and allow it to run until it runs

completely out of fuel.

• Clean the unit before storing. Pay particular

attention to the air intake area, keeping it free of

debris. Use a mild detergent and sponge to

clean the plastic surfaces.

• Ensure the machine is cleaned and that a

complete service is carried out before long-term

storage.

• The guide bar and chain should be covered with

a scabbard when the machine is being

transported or in storage in order to prevent

accidental contact with the sharp chain. Even a

non-moving chain can cause serious cuts to

yourself or others that make contact with an

exposed chain.

CAUTION: It is important to prevent gum

deposits from forming in essential fuel system

parts such as the carburetor, fuel filter, fuel

hose, or fuel tank during storage. Alcohol

blended fuels (called gasohol) or using ethanol

or methanol can attract moisture which leads to

fuel mixture separation and formation of acids

during storage. Acidic gas can damage the

engine.

TROUBLESHOOTING

C

AUSE

REMEDY

1.

Ignition

switch off.

•

See “STARTING” in the STARTING AND

2.

Engine

flooded.

•

See “

Starting a Flooded Engine

” in the

O

PERATION

section.

3.

Fuel tank empty. •

Fill tank w

ith c

orrect fuel mix

ture. See

AND STOPPING section.

4. Spark plug not firing.

• Ins

tall new s

park plug. See “SPARK PLUG” in

5. Fuel not reaching c

arbureto

r. • Check

for dirty fuel filter; replace.

C

AUSE

R

EMEDY

1. Idle speed re q ui r es

adjustment. • See “CARBURETOR ADJUSTMENT” in the

2. Carburetor requires adjustment. • C

ontact an

authorized service

dealer.

C

AUSE

REMEDY

1. Air f

ilter

dirty. •

Clean or replace air

filter. 2. Spark

plug

fouled.

•

Clean or replace plug

and regap.

3. C

hain

brake locked

.

•

Unlock

chain brake. See “STARTING

POSITION” in the STARTING AND STOPPING

4. Carburetor requires adjustment. • Conta

ct an

authori

zed service dealer.

CAUSE

REMEDY

1. Too much oil mixed w

ith gasoline.

•

Empty

fuel tank and refill w

ith correct

fuel

CAUSE

REMEDY

1.

Idle speed re q ui r es

adjustment.

•

See “C

ARBU

RETOR A

DJUSTMENT

” in the

•

16

WARNING! Always stop the unit and disconnect the spark plug before performing all of the

recommended remedies below except remedies that require operation of the unit.

TROUBLE

: Engine will not start or will run only a few seconds after starting.

STOPPING section.

“FUELING THE ENGINE” in the STARTING

TROUBLE

TROUBLE

TROUBLE

TROUBLE

2. Clutch requires

: Engine will not idle properly.

: Engine will not accelerate, lacks

: Engine smokes excessively.

: Chain moves at idle

repair.

speed.

the MAINTENANCE section.

• Check for kinked or split fuel

replace.

MAINTENANCE Section.

power,

or dies under a

section.

mixture.

MAINTENANCE Section.

Contact an authorized service

load.

line;

dealer.

repair or

TECHNICAL DATA

Model

Guide

Bar Chain CKA without

P/N Length

(in

/cm)

PR3816

589198302

16/40 91PJ 56DL 45° PR4016

589198302

16/40 91PJ 56DL 45°

PR4218

589198303

18/45 91PJ 62DL 45°

Type In In (mm)

In (mm)

° ° °

In (mm)

In (mm) : dl

16 (40) : 56

18 (45) : 62

17

The computed kickback angle (CKA) listed on your saw and listed in the CKA table below represents angle of

kickback your bar and chain combinations will have when tested in accordance with CSA (Canadian Standards

Association) and ANSI standards. When purchasing replacement bar and chain, considerations should be given

to the lower CKA values. Lower CKA values represent safer angles to the user, higher values indicate more angle

and higher kick energies. Computed angles represented indicate total energy and angle associated without

activation of the chain brake during kickback. Activated angle represents chain stopping time relative to activation

angle of chain break and resulting kick angle of saw. In all cases lower CKA values represent a safer operating

environment for the user.

The following guide bar and chain combinations meet kickback requirements of CSA Standards Z62.1, Z62.3, &

ANSI B175.1 when used on saws listed in this manual. Use of bar and chain combinations other than those listed

is not recommended and may not meet the CKA requirements per standard.

chain brake

91PJ 0,375 0,050 (1,3) 5/32 (4,0) 85°

30° 0°

0,025 (0,65)

18

U.S. EPA / CALIFORNIA / ENVIRONMENT CANADA EMISSION CONTROL

WARRANTY STATEMENT

IMPORTANT: This product is compliant with U.S. EPA Phase 3 regulations for exhaust and evaporative emiss ions. To ensure EPA Phase 3

compliance, we recommend using only genuine replacement parts. Use of non-compliant replacement parts is a violation of federal law.

YOUR WARRANTY RIGHTS AND OBLIGATIONS: The U.S. Environmental Protection Agency, California Air Resources Board, Environment

Canada and Husqvarna Consumer Outdoor Products N.A., Inc. are pleased to explain the emissions control system warranty on you r year 2017 and

later off-road engine. In California, all small off-road engines must be designed, built, and equipped to meet the State’s stringent anti-smog standards.

Husqvarna Consumer Outdoor Products N.A., Inc. must warrant the emission control system on your small off -road engine for the periods of time

listed below provided there has been no abuse, neglect, or improper maintenance of your small off-road engine.

Your emission control system includes parts such as the carburetor, the ignition system and the fuel tank, line, and cap. Whe re a warrantable

condition exists, Husqvarna Consumer Outdoor Products N.A., Inc. will repair your small off-road engine at no cost to you. Expenses covered under

warranty include diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE: If any emissions related part on your engine (as listed under Emissions Control Warranty Parts List)

is defective or a defect in the materials or workmanship of the engine causes the failure of such an emission related part, the part will be repaired or

replaced by Husqvarna Consumer Outdoor Products N.A., Inc..

OWNER’S WARRANTY RESPONSIBILITIES: As the small off-road engine owner, you are responsible for the performance of the required

maintenance listed in your instruction manual. Husqvarna Consumer Outdoor Products N.A., Inc. recommends that you retain all receipts covering

maintenance on your small off-road engine, but Husqvarna Consumer Outdoor Products N.A., Inc. cannot deny warranty solely for the lack of receipts

or for your failure to ensure the performance of all scheduled maintenance. As the small off-road engine owner, you should be aware that Husqvarna

Consumer Outdoor Products N.A., Inc. may deny you warranty coverage if your small off-road engine or a part of it has failed due to abuse, neglect,

improper maintenance, unapproved modifications, or the use of parts not made or approved by the original equipment manufacturer. You are

responsible for presenting your small off-road engine to a Husqvarna Consumer Outdoor Products N.A., Inc. authorized repair center as soon as a

problem exists. Warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If you have any questions regarding

your warranty rights and responsibilities, you should contact your nearest authorized service center.

Call Husqvarna Consumer Outdoor Products N.A., Inc. at 1-800-487-5951 (USA) or 1-800-805-5523 (Canada) or send e-mail correspondence to

emissions@husqvarnagroup.com.

WARRANTY COMMENCEMENT DATE: The warranty period begins on the date the small off-road engine is purchased.

LENGTH OF COVERAGE: This warranty shall be for a period of two years from the initial date of purchase, or until the end of the product warranty

(whichever is longer).

WHAT IS COVERED: REPAIR OR REPLACEMENT OF PARTS. Repair or replacement of any warranted part will be performed at no charge to the

owner at an approved Husqvarna Consumer Outdoor Products N.A., Inc. servicing center. If you have any questions regarding your warranty rights

and responsibilities, you should contact your nearest authorized service center.

Call Husqvarna Consumer Outdoor Products N.A., Inc. at 1-800-487-5951 (USA) or 1-800-805-5523 (Canada) or send e-mail correspondence to

emissions@husqvarnagroup.com.

WARRANTY PERIOD: Any warranted part which is not scheduled for replacement as required maintenance, or which is scheduled only for regular

inspection to the effect of “repair or replace as necessary” shall be warranted for 2 years. Any warranted part which is sche duled for replacement as

required maintenance shall be warranted for the period of time up to the first scheduled rep lacement point for that part.

DIAGNOSIS: The owner shall not be charged for diagnostic labor which leads to the determination that a warranted part is defe ctive if the diagnostic

work is performed at an approved Husqvarna Consumer Outdoor Products N.A., Inc. servicing center.

CONSEQUENTIAL DAMAGES: Husqvarna Consumer Outdoor Products N.A., Inc. may be liable for damages to other engine components caused by

the failure of a warranted part still under warranty.

WHAT IS NOT COVERED: All failures caused by abuse, neglect, or improper maintenance are not covered.

ADD-ON OR MODIFIED PARTS: The use of add-on or modified parts can be grounds for disallowing a warranty claim. Husqvarna Consumer

Outdoor Products N.A., Inc. is not liable to cover failures of warranted parts caused by the use of add-on or modified parts.

HOW TO FILE A CLAIM: If you have any questions regarding your warranty rights and responsibilities, you should contact your n earest authorized

service center.

Call Husqvarna Consumer Outdoor Products N.A., Inc. at 1-800-487-5951 (USA) or 1-800-805-5523 (Canada) or send e-mail correspondence to

emissions@husqvarnagroup.com.

WHERE TO GET WARRANTY SERVICE: Warranty services or repairs shall be provided at all Husqvarna Consumer Outdoor Products N.A., Inc.

service centers. Call Husqvarna Consumer Outdoor Products N.A., Inc. at 1-800-487-5951 (USA) or 1-800-805-5523 (Canada) or send e-mail

correspondence to emissions@husqvarnagroup.com.

MAINTENANCE, REPLACEMENT AND REPAIR OF EMISSION RELATED PARTS: Any Husqvarn a Consumer Outdoor Products N.A., Inc.

approved replacement part used in the performance of any warranty maintenance or repair on emission related parts will be pro vided without charge

to the owner if the part is under warranty.

EMISSION CONTROL WARRANTY PARTS LIST: Carburetor, air filter (covered up to maintenance schedule), ignition system: spark plug (covered

up to maintenance schedule), ignition module, muffler including catalyst (if equipped), fuel tank, line, and cap.

MAINTENANCE STATEMENT: The owner is responsible for the performance of all required maintenance as defined in the instruction manual.

Loading...

Loading...