Poulan PP446 Owner’s Manual

Poulan PRO

Instruction Manual

Manual de Instrucciones

Manuel d'lnstructions

PP446

For Occasional Use Only

WARNING:

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious injury.

ADVERTENOIA:

Lea el manual de instrucciones y siga todas las advertencias e

instrucciones de seguridad. El no hacerlo puede resultar en le-

siones graves.

AVERTISSEMENT:

Lire le manuel d'instructions et bien respecter tousles avertisse-

ments et toutes les instructions de s6curite. Tout defaut de le

faire pourrait entraTner des blessures graves.

Poulan PRO

1030 Stevens Creek Road

Augusta, GA 30907

545123534 8/10/06

DANGER! This pruner can

be dangerous! Careless or im-

proper use can cause

serious or even fatal injury.

Always wear appropriate ear protection, eye protection and head protection.

J

__. DANGER! Falling objects can cause severe head injury. Wear head

protection when operating this unit. Do not stand beneath branch being

"_ cut.

Read and understand the

instruction manual before

using the pruner.

_1, WARNIN G, Always disconnect spark

plug wire and place wire where it cannot contact

spark plug to prevent accidental starting when

setting up, transporting, adjusting or making re-

pairs except carburetor adjustments.

Because a pruner is a high-speed wood-cutting

tool, special safety precautions must be ob-

served to reduce the risk of accidents. Careless

or improper use of this toot ca_3cause serious or

even fatal injury.

PLAN AHEAD

• Read this manual carefully until you

compIete_y understand and can follow a_l

safety rules, precautions, and operating

instructions before attempting to use the unit.

• Restrict the use of your pruner to adult users

who understand and can follow safety rules,

precautions, and operating instructions found

on the unit and in this manual

INSTRUCTION SAFETY INFORMATION

MANUAL ON THE UNIT

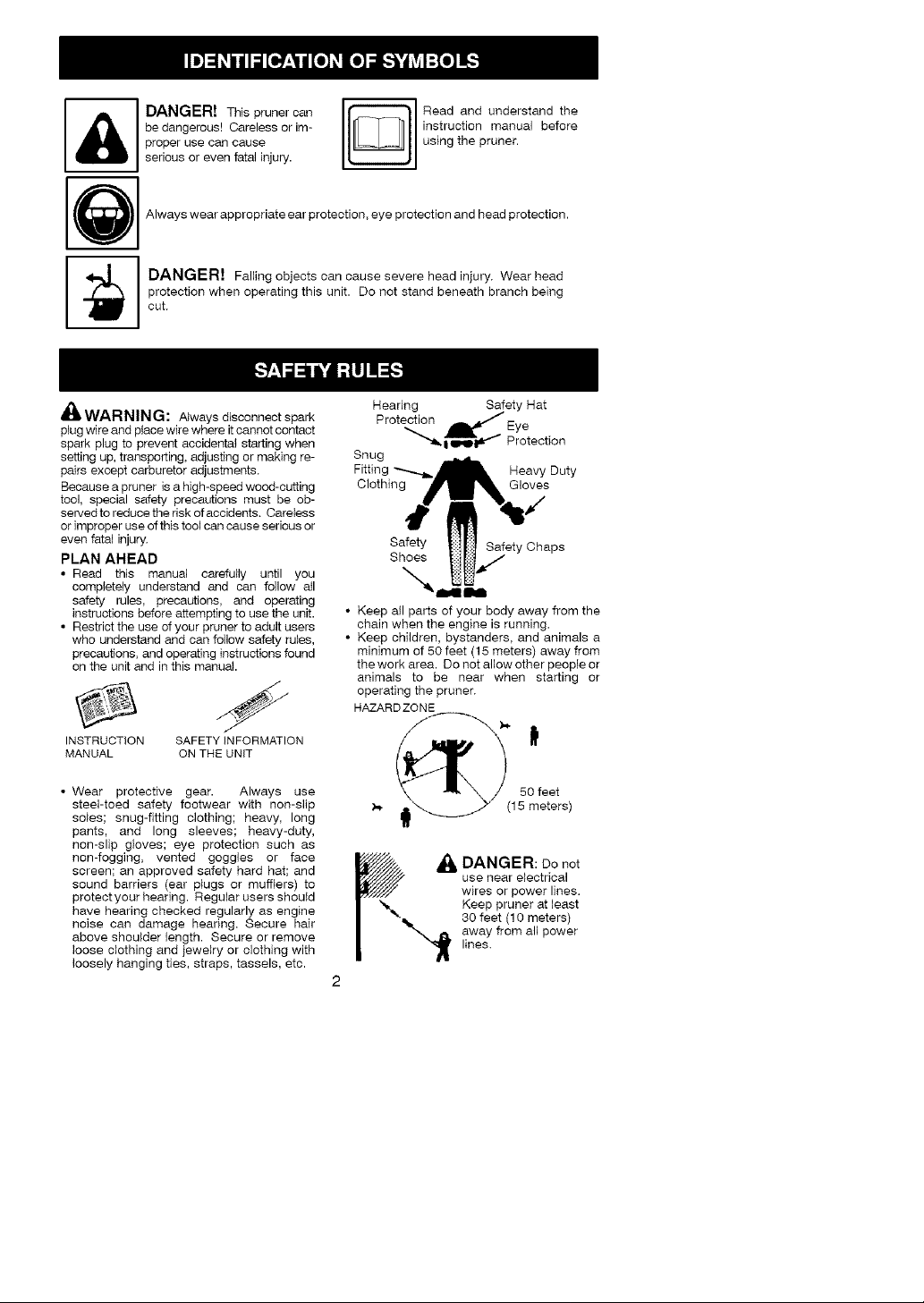

• Wear protective gear. Always use

steel-toed safety footwear with non-slip

soles; snug-fitting clothing; heavy, long

pants, and long sleeves; heavy-duty,

non-slip gloves; eye protection such as

non-fogging, vented goggles or face

screen; an approved safety hard hat; and

sound barriers (ear plugs or mufflers) to

protect your hearing, Regular users should

have hearing checked regularly as engine

noise can damage hearing. Secure hair

above shoulder _ength. Secure or remove

loose clothing and jewelry or clothing with

loosely hanging ties, straps, tassels, etc,

Hearing Safety Hat

Protection _ Eye

_ i u,e_lr "_ Protection

Snug

Clothing Gloves

Safety Safety Chaps

Shoes

• Keep all parts of your body away from the

chain when the engine is running.

• Keep children, bystanders, and animals a

minimum of 50 feet (15 meters) away from

the work area. Do not allow other peopie or

animals to be near when starting or

operating the pruner.

HAZARD ZONE

_. i_ _ (15meters)

"_ Keep pruner at least

Heavy Duty

50 feet

DANGER: Do not

use near electrical

wires or power lines.

30 feet (10 meters)

lines.

away from all power

• Donothandleoroperateaprunerwhenyou

arefatigued,ill,orupset,orifyouhavetaken

atcohol,drugs,ormedication.Youmustbein

goodphysicalconditionandmentallyalert.If

youhaveanyconditionthatmightbe

aggravatedbystrenuouswork,checkwith

doctorbeforeoperatingapruner.

• Carefullyplanyourpruningoperationin

advance.Donotstartcuttinguntilyouhave

aclearworkarea,securefooting,anda

plannedretreatpath.

Ifsituationsoccurwhicharenotcoveredin

thismanual,usecareandgoodjudgment.If

youneedassistance,contactyourauthorized

servicedealerorcall1-800-554-6723.

OPERATE YOUR PRUNER SAFELY

• Do not operate a pruner with one hand.

Serious injury to the operator, helpers,

bystanders or any combination of these

persons may result from one-handed

operation. A pruner is intended for

two-handed use.

• Operate the pruner only in a well-ventilated

outdoor area.

• Do not operate pruner from a ladder or in a

tree.

• Do not use a pruner to cut down trees or any

portion of the tree trunk.

• Only use for pruning limbs or branches

overhead not greater than 4 inches (t0 cm)

in diameter.

• Never stand under the limb you are pruning.

Always position yourself out of the path of

falling debris.

• Do not cut small brush and saplings with the

pruner. Slender matter may catch in the

chain and be whipped toward you. pulling

you off balance.

• Make sure the chain will not make contact

with any object while starting the engine.

Never try to start the unit when the guide

bar is in a cut.

• Do not put pressure on the pruner at the end

of the cut. Applying pressure can cause you

to lose control when the cut is completed.

• Do not run the unit at high speed when not

pruning.

• If you strike or become entangled with a

foreign object, stop the engine immediately

and check for damage. Have any damage

repaired by an authorized service dealer

before attempting further operations.

• Do not operate a pruner that is damaged,

improperly adjusted, or not completely and

securely assembled. Always replace bar

and chain immediately if it becomes

damaged, broken or is otherwise removed.

• Always stop the unit when work is delayed

or when walking from one cutting location to

another. Stop the engine before setting the

unit down.

• Use only in daylight or good artificial light.

• Use only for jobs explained in this manual

(or manuals for optional attachments).

MAINTAIN YOUR PRUNER IN GOOD

WORKING ORDER

• Have all service performed by a qualified

service dealer with the exception of the

items listed in the maintenance section of

this manual.

• Make certain the chain stops moving when

the throttle trigger is released. For

correction, refer to CARBURETOR

ADJUSTMENTS.

• Never modify your unit in any way.

• Keep the handles dry. clean, and free of oil

or fueI mixture.

• Keep fuel and eli caps. screws, and

fasteners securely tightened.

• Make carburetor adjustments with lower

end supported to prevent chain from

contacting any object.

• Keepothersawaywhen making carburetor

adjustments.

• Use only Poulan PRO accessories and

replacement parts as recommended.

HANDLE FUEL WITH CAUTION

• Do not smoke whi_e handling fuel or while

operating the pruner.

• Eliminate all sources of sparks or flame in

the areas where fueI is mixed or poured.

There should be no smoking, open flames,

or work that could cause sparks. Allow

engine to cool before refueling.

• Mix and pour fuel inan outdoor area on bare

ground; store fuel in a cool, dry, well

ventilated place; and use an approved.

marked container for all fuet purposes.

Wipe up ali fuet spills before starting engine.

• Move at least 10 feet (3 meters) from fueling

site before starting engine.

• Turn the engine off and let unit cool in a

non-combustible area, not on dry leaves.

straw, paper, etc. Slowly remove fuel cap

and refuel unit.

• Store the unit and fuel in an area where fuel

vapors cannot reach sparks or open flames

from water heaters, electric motors or

switches, furnaces, etc.

KICKBACK

_,WARNING: Avoid kickback which

can result in serious injury. Kickback is the

backward, upward or sudden forward motion

of the guide bar occurring when the chain

near the upper tip of the guide bar contacts

any object such as a log or branch, or when

the wood closes in and pinches the chain in

the cut. Contacting a foreign object in the

wood can also result in loss of control.

• Rotational Kickback can occur when the

moving chain contacts an object at the upper

tip of the guide bar. This contact can cause

the chain to dig into the object, which stops

the chain for an instant. The result is a

lightning fast, reverse reaction which kicks the

guide bar up and back toward the operator.

• Pinch-Kickback can eccur when the wood

closes in and pinches the moving chain in

the cut along the top of the guide bar and the

chain is suddenly stopped. This sudden

stopping of the chain results in a reversal of

the chain force used to cut wood and

causes the pruner to move in the opposite

direction of the chain rotation. The pruner is

driven straight back toward the operator.

• Pull-In can occur when the moving chain

contacts a foreign object in the wood in the cut

along the bottom of the guide bar and the

chain is suddenly stopped. This sudden

stopping pulls the pruner forward and away

from the operator and could easily cause the

operator to lose control of the pruner.

REDUCE THE CHANCE OF

KICKBACK

• Recognize that kickback can happen. With

a basic understanding of kickback, you can

reduce the element of surprise which

contributes to accidents.

• Never let the moving chah_ contact any

object at the tip of the guide bar.

• Keep the workh_g area free from

obstructions such as other trees, branches,

rocks, stumps, etc. Eliminate or avoid any

obstruction that your chah_ could hit while

you are cutting. When cutting a branch, do

not let the guide bar contact branch or other

objects around it.

• Keep your chain sharp and properly

tensioned. A _oose or dull chain can

increase the chance of kickback occurrh_g.

Follow manufacturer's chain sharpening

and maintenance instructions. Check

tension at regular intervals with the engine

stopped, never with the engine running.

Make sure the bar clamp nut is securely

tightened after tensioning the chain.

• Begin and continue cutting at full speed. If

the chain is moving at a slower speed, there

is greater chance of kickback occurring.

• Cut one branch at a time.

• Use extreme caution when re-entering a

previous cut.

• Do not attempt cuts starting with the tip of

the bar (plunge cuts).

• Watch for shifting of wood or other forces that

could close a cut and pinch or fall into chain.

• Use the Reduced-Kickback Guide Bar and

Low-Kickback Chain specified for your unit.

MAINTAIN CONTROL

throttle handle whether your are right

handed or left handed.

• Stand with your weight evenly balanced on

both feet.

• Stand slightly to the left side of the pruner to

keep your body from being in a direct line

with the cutting chain.

KICKBACK SAFETY FEATURES

The following features are included on your

pruner to help reduce the hazard of kickback;

however, such features will not totally elimi-

nate this danger. As a pruner user, do not rely

only on safety devices. You must follow all

safety precautions, instructions, and mainte-

nance in this manual to help avoid kickback

and other forces which can result in serious

injury.

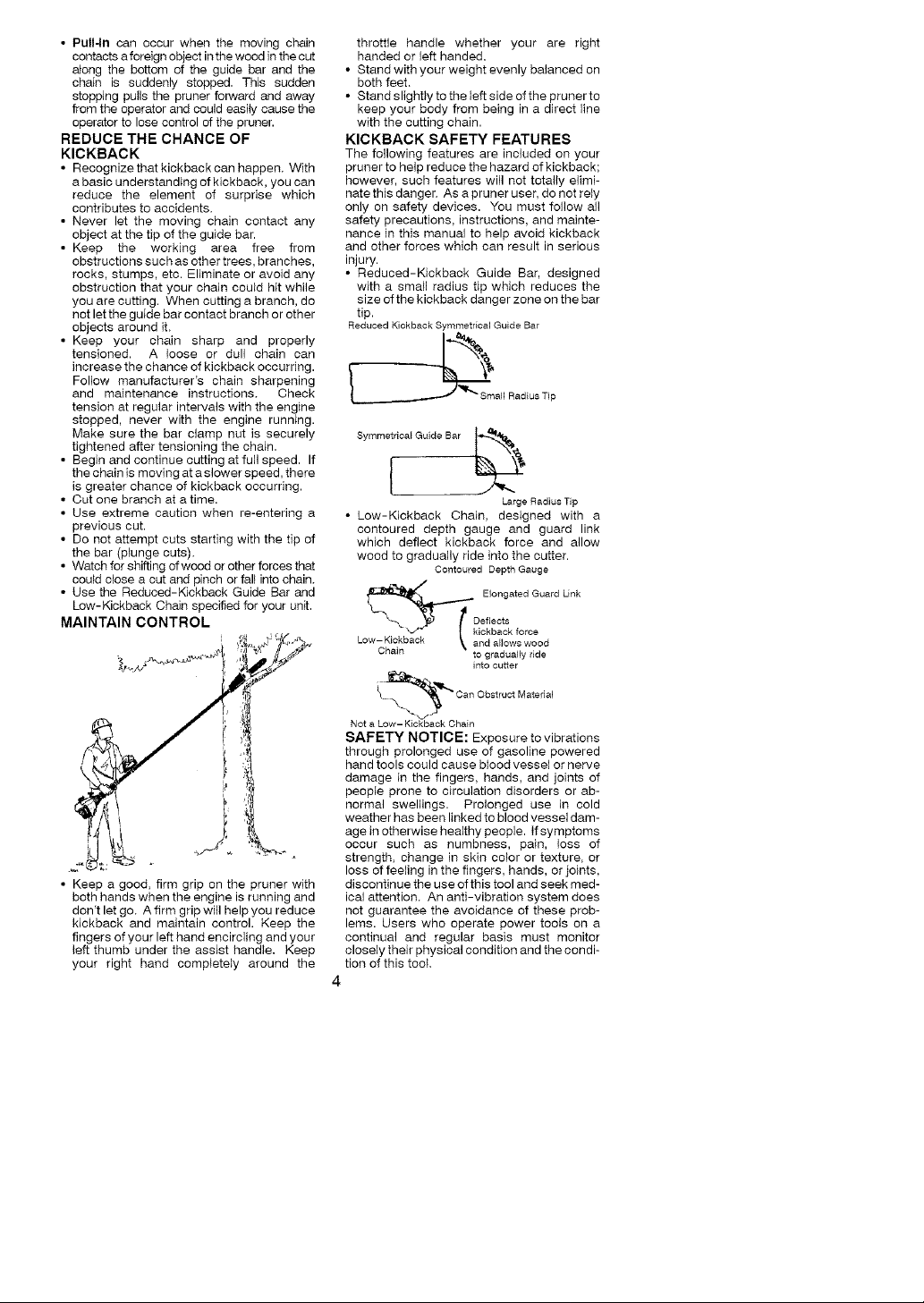

• Reduced-Kickback Guide Bar, designed

with a small radius tip which reduces the

size of the kickback danger zone on the bar

tip.

Reduced Kickback Symmetrical Guide Bar

_all Radius Tip

Symmetrical Guide Bar 1_"_

Large Radius Tip

• Low-Kickback Chain, designed with a

contoured depth gauge and guard link

which deflect kickback force and allow

wood to gradually ride into the cutter.

Low-Kickback it and allows wood

Chain _ to gradually ride

Contoured Depth Gauge

Elongated Guard Link

Deflects

! kickback force

into cutter

• Keep a good, firm grip on the pruner with

both hands when the engine is running and

don't let go. A firm grip will help you reduce

kickback and maintain control. Keep the

fingers of your left hand encircling and your

left thumb under the assist handte. Keep

your right hand completely around the

_%_'_" Can Obstruct Material

Not a Low- Kickback Chain

SAFETY NOTICE: Exposure to vibrations

through prolonged use of gasoline powered

hand tools could cause blood vessel or nerve

damage in the fingers, hands, and joints of

people prone to circulation disorders or ab-

normal swellings. Prolonged use in cold

weather has been linked to blood vessel dam-

age in otherwise healthy people. If symptoms

occur such as numbness, pain, loss of

strength, change in skin cotor or texture, or

loss of feeling in the fingers, hands, or joints,

discontinue the use of this tool and seek med-

ical attention. An anti-vibration system does

not guarantee the avoidance of these prob-

lems. Users who operate power tools on a

continual and regular basis must monitor

closely their physical condition and the condi-

tion of this tool.

4

SPECIAL NOTICE: This unit is equipped

with a temperature limith_g muffler and spark

arresting screen which meets the require-

ments of California Codes 4442 and 4443. All

U.S. forest land and the states of California,

Idaho, Mah_e, Minnesota, New Jersey, Ore-

gon, and Washington require by law that

many internal combustion engines be

equipped with a spark arresting screen. Ifyou

operate in a locale where such regulations ex-

ist, you are legally responsible for mah_taining

the operating condition ofthese parts. Failure

to do so is a violation of the law. For normal

homeowner use, the muffler and spark arrest-

ing screen will not require any service. After

50 hours of use, we recommend that your

muffler be serviced or replaced by an autho-

rized service dealer.

ADDITIONAL SAFETY RULES

FOR OPTIONAL ATTACHMENTS

_WARNING: For each optional at-

tachment used, read entire instruction manu-

al before use and follow all warnings and in-

structions in manual and on attachment.

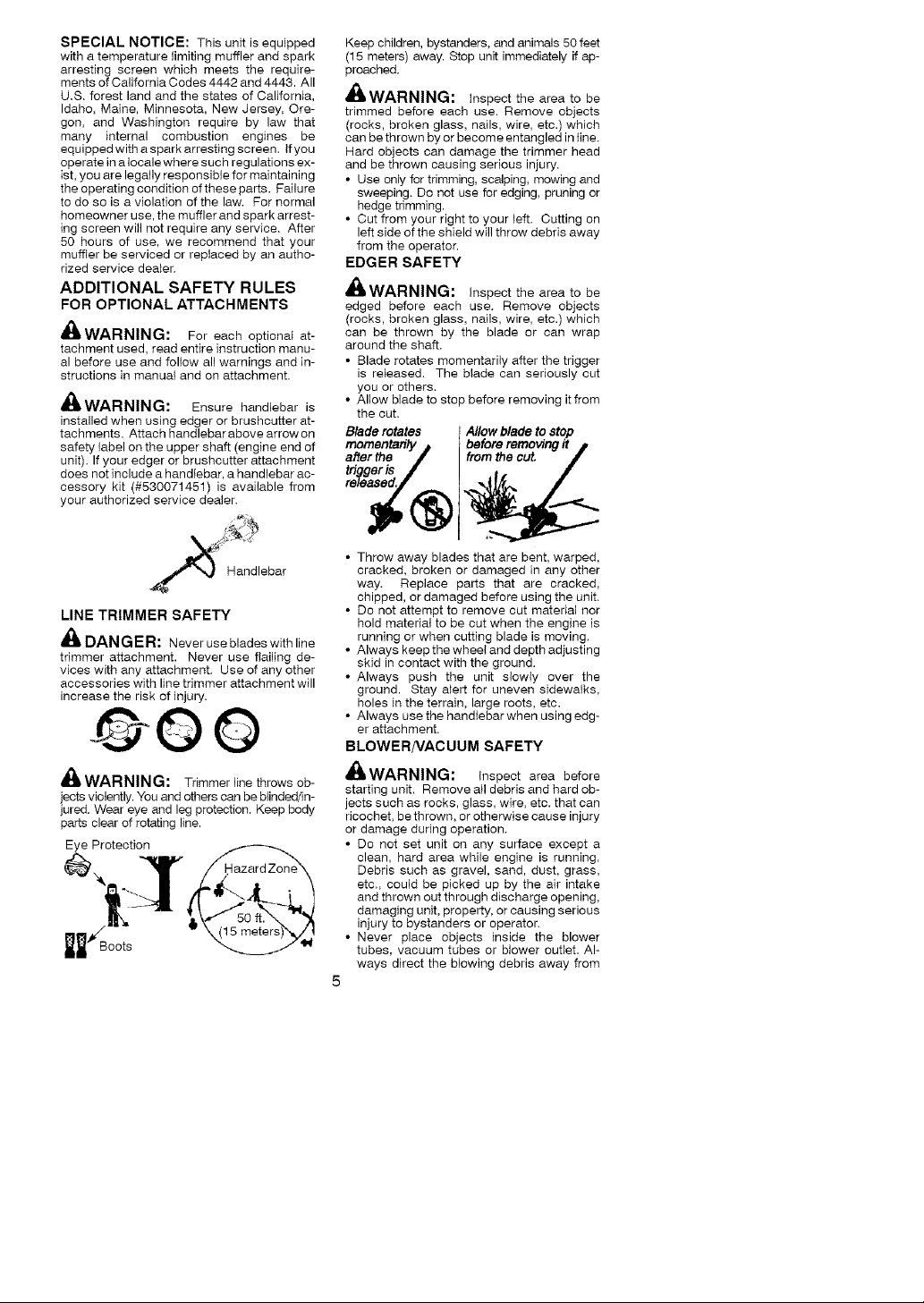

d_WARNING: Ensure handlebar is

installed when ush3g edger or brushcutter at-

tachments. Attach handlebar above arrow on

safety label on the upper shaft (engine end of

unit). If your edger or brushcutter attachment

does not h_clude a handlebar, a handlebar ac-

cessory kit (#530071451) is available from

your authorized service dealer.

Handlebar

LINE TRIMMER SAFETY

_ DANGER: Never use blades with line

trimmer attachment. Never use flailing de-

vices with any attachment, Use of any other

accessories with linetrimmer attachment will

increase the risk of injury,

@OQ

A

WARNING: Trimmer line throws ob-

jects violently. You and others can be blinded/in-

jured. Wear eye and leg protection. Keep body

parts clear of rotating line.

Eye Protection

lm' Boots

Keep children, bystanders, and animals 50 feet

(15 meters) away. Stop unit immediately if ap-

proached,

_I'WARNING: Inspect the area to be

trimmed before each use. Remove objects

(rocks, broken glass, nails, wire, etc.) which

can be thrown by or become entangled in iine,

Hard objects can damage the trimmer head

and be thrown causing serious injury,

• Use only for trimming, scalping, mowing and

sweeping, Do not use for edging, pruning or

hedge trimming.

• Cut from your right to your left, Cutting on

left side of the shield will throw debris away

from the operator.

EDGER SAFETY

A_,WARNING: inspect the area to be

edged before each use. Remove objects

(rocks, broken glass, nails, wire, etc.) which

can be thrown by the blade or can wrap

around the shaft.

• Blade rotates momentarily after the trigger

is released. The blade can seriously cut

you or others.

• Allow blade to stop before removing it from

the cut.

Blade rotates

after the

trigger is

re/ease_

• Throw away blades that are bent, warped,

cracked, broken or damaged in any other

way, Replace parts that are cracked,

chipped, or damaged before using the unit,

• Do not attempt to remove cut material nor

hold material to be cut when the engine is

running or when cutting blade is moving,

• Always keep the wheel and depth adjusting

skid in contact with the ground,

• Always push the unit slowly over the

ground. Stay alert for uneven sidewalks,

holes in the terrain, large roots, etc.

• Always use the handlebar when using edg-

er attachment,

BLOWER/VACUUM SAFETY

_,WARNING: inspect area before

starting unit. RemoveaH debris and hard ob-

jects such as rocks, glass, wire, etc. that can

ricochet, be thrown, or otherwise cause injury

or damage during operation.

• Do not set unit on any surface except a

clean, hard area while engine is running.

Debris such as gravel, sand, dust, grass,

etc., could be picked up by the air intake

and thrown out through discharge opening,

damaging unit, property, or causing serious

injury to bystanders or operator.

• Never place objects inside the blower

tubes, vacuum tubes or blower outlet. Al-

ways direct the blowing debris away from

5

people, animals, glass, and solid objects

such as trees, automobiles, wails, etc. The

force of air can cause rocks, dirt, or sticks to

be thrown or to ricochet which can hurt

people or animals, break glass, or cause

other damage.

• Never run unit without the proper equip-

ment attached. When using your unit as a

blower, always install blower tubes.

• Check air intake opening, blower tubes or

vacuum tubes frequently, always with en-

gine stopped and spark plug disconnected.

Keep vents and discharge tubes free of de-

bris which can accumulate and restrict

proper air flow.

• Never place any object in air intake opening

as this could restrict proper air flow and

cause damage to the unit.

• Never use for spreading chemicals, fertiliz-

ers, or other substances which may contain

toxic materials.

• To avoid spreading fire, do not use near leaf

or brush fires, fireplaces, barbecue pits,

ashtrays, etc.

BRUSHCUTTER SAFETY

DANGER: Blade can thrust violently

away from material it does not cut. Blade

thrust can cause amputation of arms or legs.

_ WARNING: Do not use trimmer head

as a fastening device for the blade.

ill

d[IWARNING: Inspect the area to be

cut before each use. Remove objects (rocks,

broken glass, nails, wire, etc.) which can be

thrown or become entangled in the blade or

trimmer Ih_e.

• Throw away and replace blades that are

bent, warped, cracked, broken or damaged

in any other way.

• Install required shield properly before using

the unit. Use the metal shield for all metal

blade use.

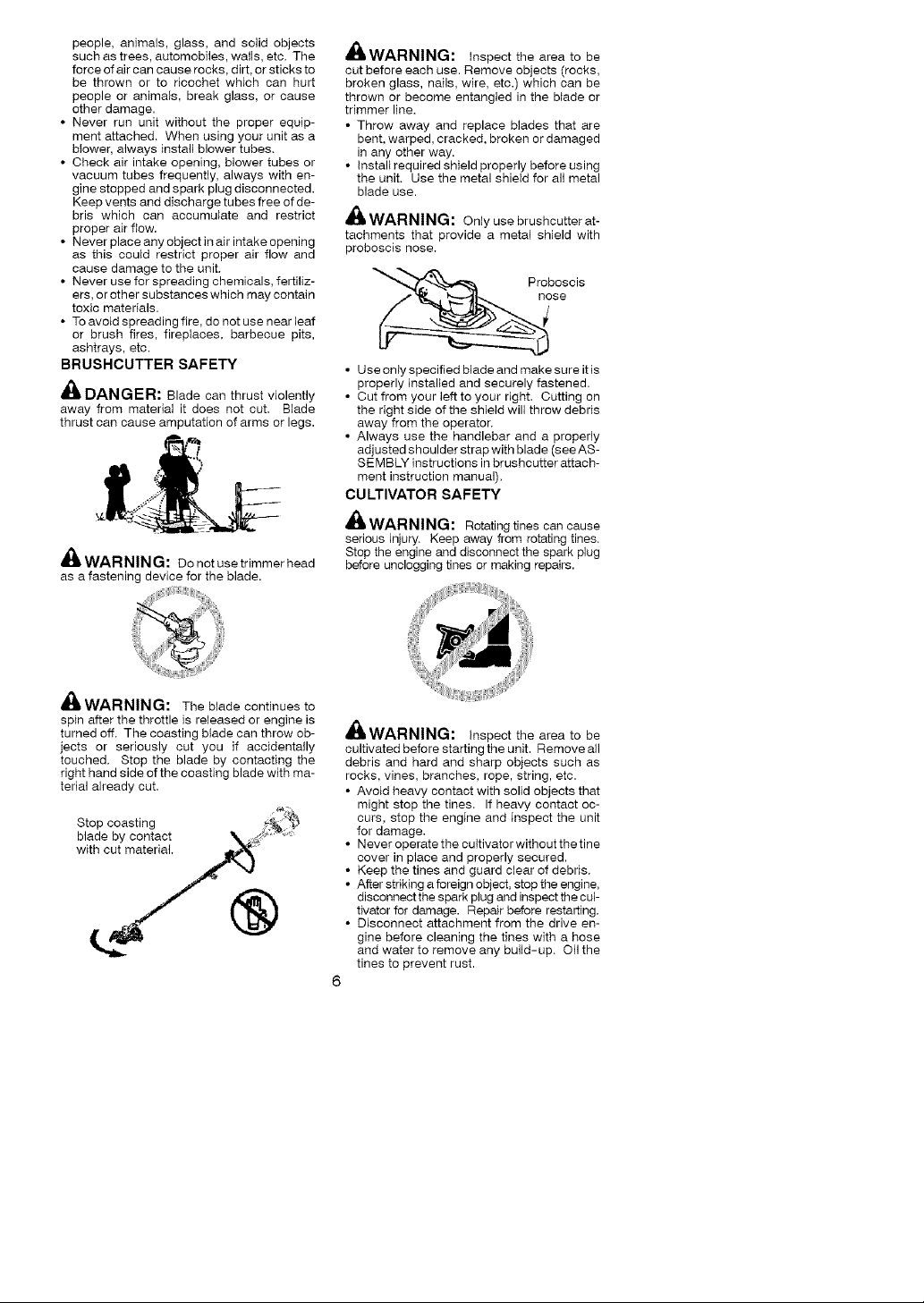

_,WARNING: Only use brushcutterat-

tachments that provide a metal shield with

proboscis nose.

Pri°o°s°eS° is

• Use only specified blade and make sure it is

properly installed and securely fastened.

• Cut from your left to your right. Cutting on

the right side of the shield will throw debris

away from the operator,

• Always use the handlebar and a properly

adjusted shoulder strap with blade (see AS-

SEMBLY instructions in brushcutter attach-

ment instruction manual),

CULTIVATOR SAFETY

_L, WARNING: Rotatingtines cancause

serious injury, Keep away from rotating tines,

Stop the engine and disconnect the spark plug

before unclogging tines or making repairs.

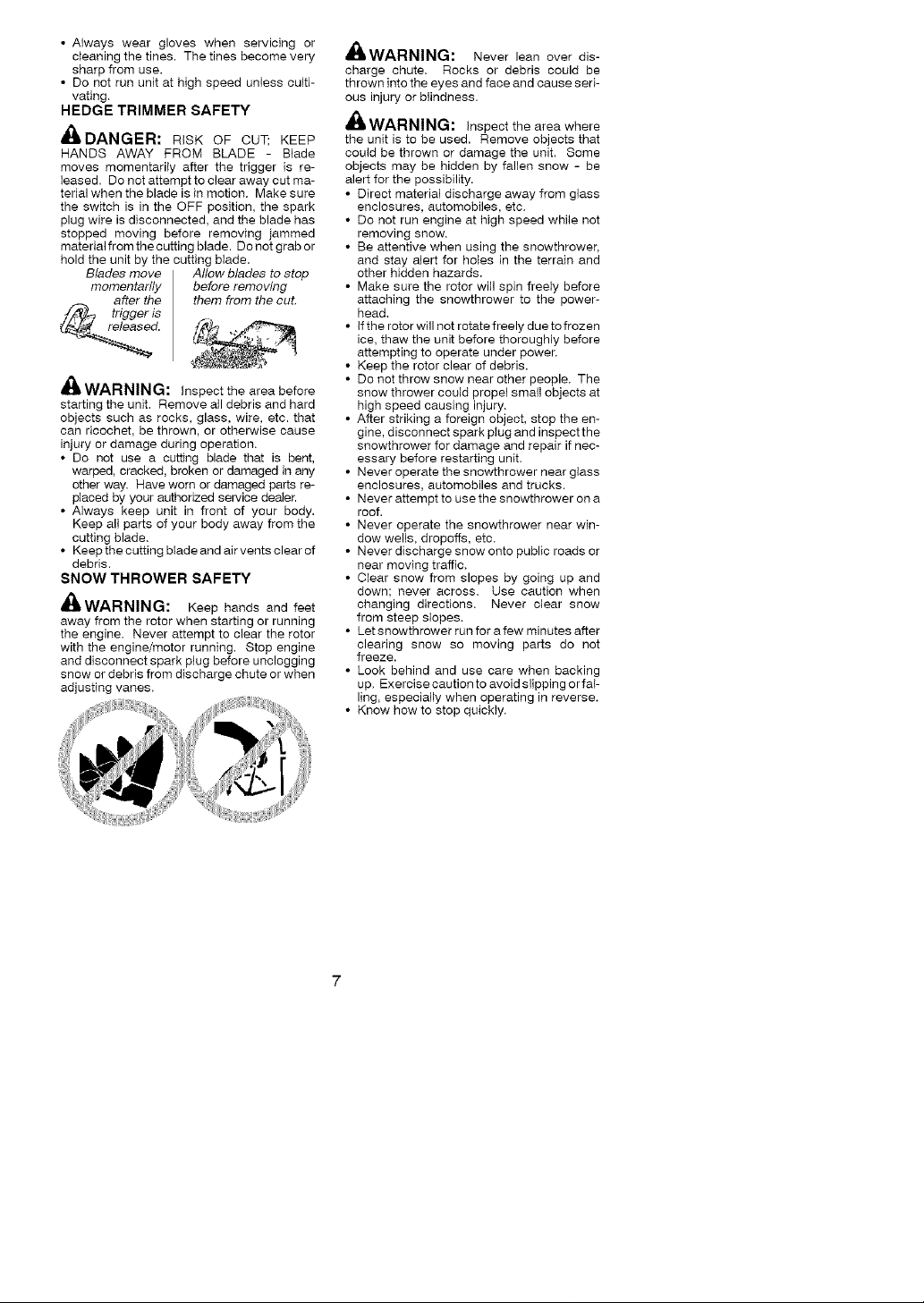

R]_WAHNIN_: The blade continues to

spin after the throttle is released or engine is

turned off. The coasting blade can throw ob-

jects or seriously cut you if accidentally

touched. Stop the blade by contacting the

right hand side of the coasting blade with ma-

terial already cut.

Stop coasting _!_

blade by contact _ _._" _'

with cut material.._'

41_WARNING: Inspect the area to be

cultivated before starting the unit. Remove all

debris and hard and sharp objects such as

rocks, vines, branches, rope, string, etc.

• Avoid heavy contact with solid objects that

might stop the tines. If heavy contact oc-

curs, stop the engine and inspect the unit

for damage.

• Never operate the cultivator without the line

cover in place and properly secured.

• Keep the tines and guard clear of debris.

• After striking a foreign object, stop the engine,

disconnect the spark plug and inspect the cul-

tivator for damage. Repair before restarting.

• Disconnect attachment from the drive en-

gine before cleaning the tines with a hose

and water to remove any build-up. Oil the

tines to prevent rust.

6

• Alwaysweargloveswhenservicingor

cleaningthetines.Thetinesbecomevery

sharpfromuse.

• Donotrununitathighspeedunlessculti-

vating.

HEDGE TRIMMER SAFETY

_DANGER: RiSK OF CUT; KEEP

HANDS AWAY FROM BLADE - Blade

moves momentarily after the trigger is re-

leased. Do not attempt to clear away cut ma-

terial when the blade is in motion. Make sure

the switch is in the OFF position, the spark

plug wire is disconnected, and the blade has

stopped moving before removing jammed

materialfromthecutting blade. Donor grabor

hold the unit by the cutting blade.

Blades move Allow blades to stop

momentarily before removing

after the them from the cut,

dtrigger is

WARNING: Inspect the area before

starting the unit. Remove ail debris and hard

objects such as rocks, glass, wire, etc. that

can ricochet, be thrown, or otherwise cause

injury or damage during operation.

• Do not use a cutting blade that is bent,

warped, cracked, broken or damaged in any

other way. Have worn or damaged parts re-

placed by your authorized service dealer.

• Always keep unit in front of your body.

Keep all parts of your body away from the

cutting blade,

• Keep the cutting blade and air vents clear of

debris.

SNOW THROWER SAFETY

_WARNING: Keep hands and feet

away from the rotor when starting or running

the engine. Never attempt to clear the rotor

with the engine/motor running. Stop engine

and disconnect spark plug before unclogging

snow or debris from discharge chute or when

adjusting vanes.

="=WARNING: Never lean over dis-

charge chute. Rocks or debris could be

thrown into the eyes and face and cause seri-

ous injury or blindness.

_g_,WARNING: Inspect the area where

the unit is to be used. Remove objects that

could be thrown or damage the unit. Some

objects may be hidden by fallen snow - be

alert for the possibility.

• Direct material discharge away from glass

enclosures, automobiles, etc.

• Do not run engine at high speed while not

removing snow.

• Be attentive when using the snowthrower,

and stay alert for holes in the terrain and

other hidden hazards.

• Make sure the rotor will spin freely before

attaching the snowthrower to the power-

head.

• Ifthe rotor will not rotate freely duetofrozen

ice, thaw the unit before thoroughly before

attempting to operate under power.

• Keep the rotor clear of debris.

• Do not throw snow near other people. The

snow thrower could propel small objects at

high speed causing injury.

• After striking a foreign object, stop the en-

gine, disconnect spark pIug and inspect the

snowthrower for damage and repair if nec-

essary before restarting unit.

• Never operate the snowthrower near glass

enclosures, automobiles and trucks.

• Never attempt to use the snowthrower on a

roof.

• Never operate the snowthrower near win-

dow wells, dropoffs, etc.

• Never discharge snow onto public roads or

near moving traffic.

• Clear snow from slopes by going up and

down; never across. Use caution when

changing directions. Never clear snow

from steep slopes.

• Let snowthrower run for a few minutes after

clearing snow so moving parts do not

freeze.

• Look behind and use care when backing

up. Exercise caution to avoid slipping or fal-

ling, especially when operating in reverse.

• Know how to stop quickly.

dDbWAI-iI_III_IL_,Ifreceivedassembled,

repeataltstepstoensureyourunitisproperly

assembledandallfastenersaresecure.

Examh_epartsfordamage.Donotusedam-

agedparts.

NOTE:Ifyouneedassistanceorfindparts

missingordamaged,call1-800-554-6723.

Itisnormalforthefuelfiltertorattleinthe

emptyfueltank.

Fh_dingfueloroilresidueonmufflerisnormal

duetocarburetoradjustmentsandtesting

donebythemanufacturer.

TOOLSREQUIRED

• Hexwrench(provided)

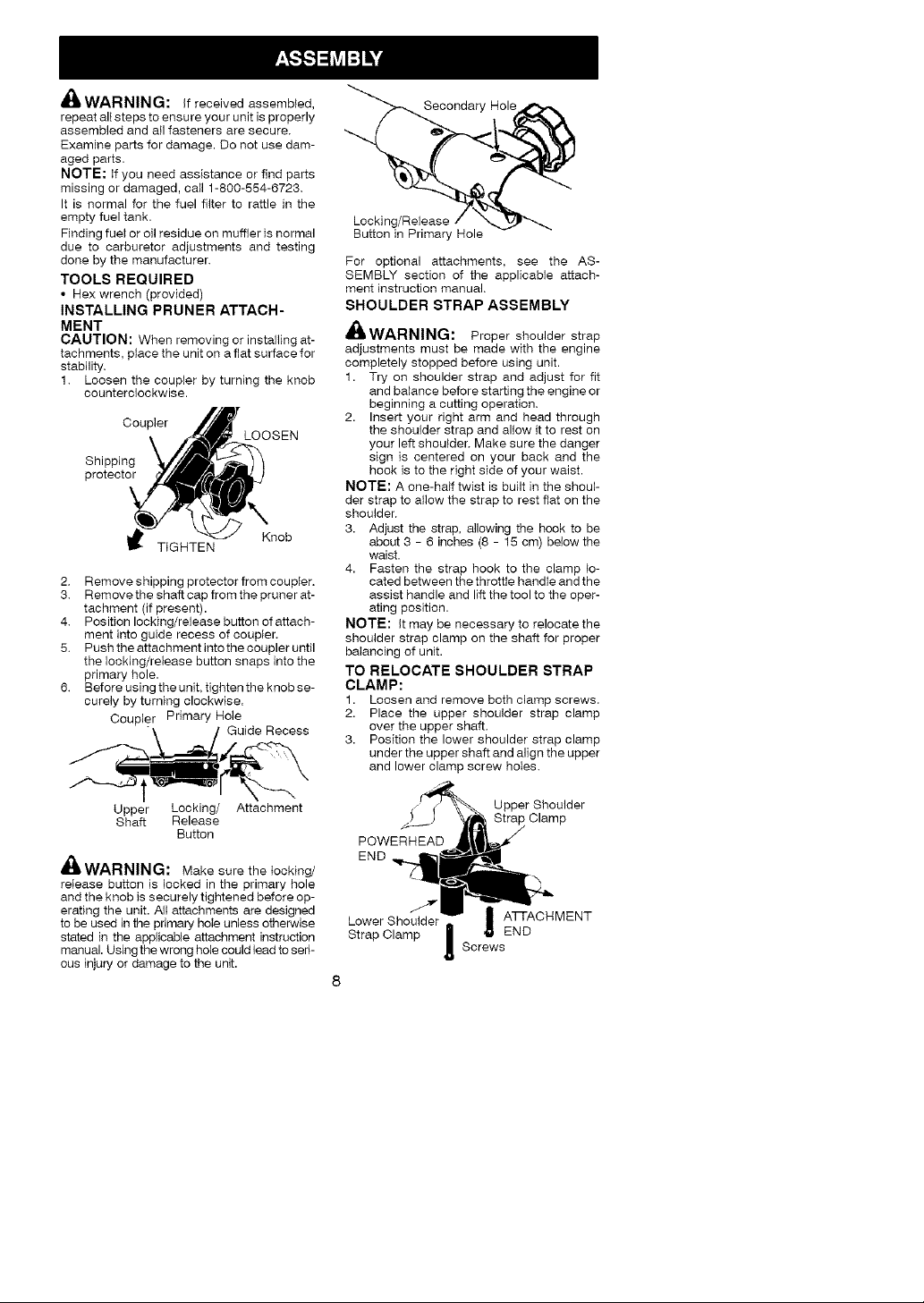

INSTALLINGPRUNERATTACH-

MENT

CAUTION:Whenremovingorinstallingat-

tachments,placetheunitonaflatsurfacefor

stability.

1. Loosenthecouplerbyturningtheknob

counterclockwise.

Coupler

Shipping

protector

TIGHTEN

Knob

2. Removeshippingprotectorfromcoupler.

3. Removetheshaftcapfromtheprunerat-

tachment(ifpresent).

4. Positionlocking/releasebuttonofattach-

mentintoguiderecessofcoupler.

5. Pushtheattachmentintothecoupleruntil

thelocking/releasebuttonsnapsintothe

primaryhole.

6. Beforeusingtheunit.tightentheknobse-

curelybyturningclockwise.

CouplerPrimaryHole

GuideRecess

Foroptionalattachments,seetheAS-

SEMBLYsectionoftheapplicableattach-

mentinstructionmanual.

SHOULDER STRAP ASSEMBLY

_L, WARNING: Proper shoulder strap

adjustments must be made with the engine

completely stopped before using unit.

1. Try on shoulder strap and adjust for fit

2. Insert your right arm and head through

NOTE: A one-half twist is built in the shoul-

der strap to allow the strap to rest flat on the

shoulder.

3. Adjust the strap, allowing the hook to be

4. Fasten the strap hook to the clamp io-

NOTE: It may be necessary to relocate the

shoulder strap clamp on the shaft for proper

balancing of unit.

TO RELOCATE SHOULDER STRAP

CLAMP:

1. Loosen and remove both clamp screws.

2. Place the upper shoulder strap clamp

3. Position the lower shoulder strap clamp

SecondaryHole

Locking/Release

ButtoninPrimaryHole

and balance before starting the engine or

beginning a cutting operation.

the shoulder strap and allow it to rest on

your left shoulder. Make sure the danger

sign is centered on your back and the

hook is to the right side of your waist.

about 3 - 6 inches (8 - 15 cm) below the

waist.

cated between the throttle handte and the

assist handle and lift the tool to the oper-

ating position.

over the upper shaft.

under the upper shaft and align the upper

and lower clamp screw holes.

Upper Locking/ Attachment

Shaft Release

,&

rmWARNING: Make sure the tocking/

retease button is locked in the primary hole

and the knob is securely tightened before op-

erating the unit. All attachments are designed

to be used in the primary hoIe unless otherwise

stated in the applicable attachment instruction

manual. Using the wrong hole could lead to seri-

ous injury or damage to the unit.

Button

Upper Shoulder

Clamp

POWERHEAD

END

Lower Shoulder | Aqq-ACHMENT

Strap Clamp _ END

db

Screws

4. Inserttwoscrewsintothescrewholes.

5. Secureshoulderstrapclampbytighten-

ingscrewswithahexwrench.

ADJUSTINGTHEASSISTHANDLE

_WARNING: When adjusting the as-

sist handle, be sure it remains between the

coupler and the _ll lower arrow (closest to

coupler) on the safety label to ensure proper

balancing of unit. When adjusting the assist

handle or handlebar during use of optional at-

tachments, it must be repositioned between

the throttle trigger and the I_ upper arrow

(closest to engine) on the safety label.

1. Loosen wing nut on handle.

2. Rotate the handle on the shaft to an up-

right position; retighten wing nut.

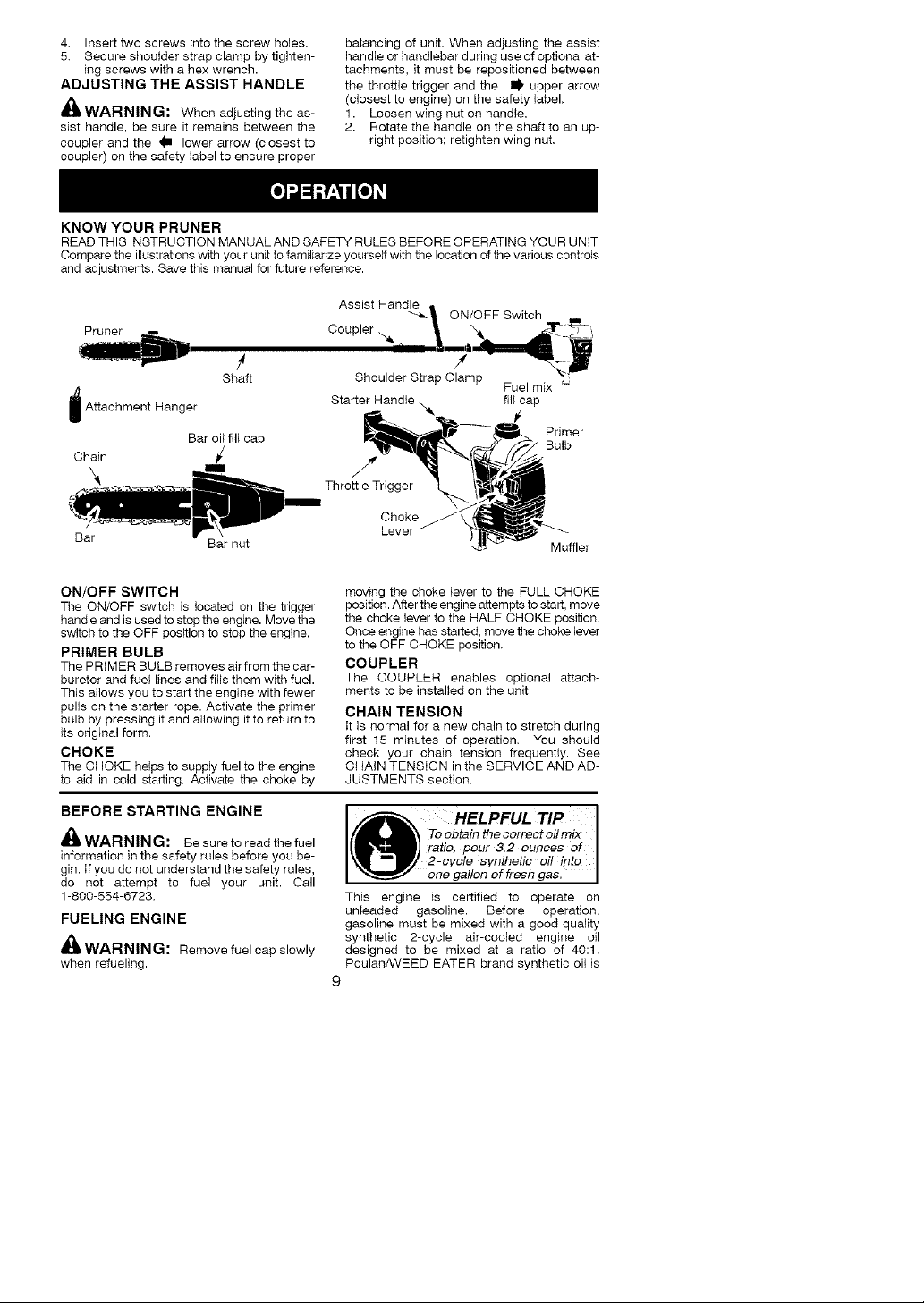

KNOW YOUR PRUNER

READTHIS INSTRUCTION MANUALAND SAFETY RULESBEFORE OPERATINGYOUR UNIT

Compare the illustrations with your unit to familiarize yourself with the location of the various controls

and adjustments. Save this manual for future reference.

Pruner

Shaft

Attachment Hanger

Chain

Bar

ON/OFF SWITCH

The ON/OFF switch is located on the trigger

handle and is used to stop the engine. Move the

switch to the OFF position to stop the engine.

PRIMER BULB

The PRIMER BULB removes air from the car-

buretor and fuel lines and fills them with fuel.

This allows you to start the engine with fewer

pulls on the starter rope. Activate the primer

bulb by pressing it and allowing it to return to

its original form.

CHOKE

The CHOKE helps to supply fuel to the engine

to aid in cold starting. Activate the choke by

Bar oil fill cap

Bar nut

BEFORE STARTING ENGINE

_k WARNING: Besure to read the fuel

information in the safety rules before you be-

gin. if you do not understand the safety rules,

do not attempt to fuel your unit. Call

1-800-554-6723,

FUELING ENGINE

_ WARNING: Remove fuel cap slowly

when refueling.

Assist Handle

Coupler

Switch

/

Shoulder Strap Clamp

Starter Handle _ fill cap

Fuel mix

S

Throttle Trigger

Choke

moving the choke lever to the FULL CHOKE

position. After the engine attempts to start, move

the choke lever to the HALF CHOKE position.

Once engine has started, move the choke lever

to the OFF CHOKE position.

COUPLER

The COUPLER enables optional attach-

ments to be installed on the unit.

CHAIN TENSION

it is normal for a new chain to stretch during

first 15 minutes of operation. You should

check your chain tension frequently. See

CHAIN TENSION in the SERVICE AND AD-

JUSTMENTS section.

HELPFUL TIP I

\ T°°btainthec°rrectoilmix I

) ratio, pour 3.2 ounces of I

2-cycle synthetic oil into

One gallon Of fresh gas.

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good quality

synthetic 2-cycle air-cooled engine oil

designed to be mixed at a ratio of 40:1.

Poulan/WEED EATER brand synthetic oil is

9

Primer

Bulb

Muffler

m

recommended. Mix gasoline and oil at a ratio

of 40:1. A 40:1 ratio is obtained by mixing 3.2

ounces (95 ml) of oil with 1 gallon (4 liters) of

unleaded gasoline. DO NOT USE automotive

oil or marine oil. These oils will cause engine

damage. When mixing fuel, follow h_structions

printed on container. Once oil is added to

gasoline, shake container momentarily to

assure that the fuel is thoroughly mixed. Always

read and follow the safety rules relating to fuel

before fueling your unit.

BAR AND CHAIN LUBRICATION

The bar and chain require lubrication. The chain

oiler provides continuous lubrication to the chain

and guide bar. Be sure to fill the bar oil tank

when you fill the fuel tank (Capacity = 4.6 ft.oz.).

Lack of oil will quickly ruin the bar and chain.

Too little oil will cause overheating shown by

smoke coming from the chain aed/or discolor-

ation of the bar. The oil output is automatically

metered during operation. Always fill the bar oil

tank when you fill the fuel tank.

Genuine Poulan or Poulan PRO bar and

chain oil is recommended to protect your unit

against excessive wear from heat and fric-

tion. Poulan or Poulan PRO oil resists high

temperature thinning. If Poulan or Poulan

PRO bar and chain oil is not available, use a

good grade SAE 30 oil.

• Never use waste eil for bar and chain

lubrication.

• Always stop the engine before removing

the oil cap.

IMPORTANT

Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or

methanol) can attract moisture which leads to

separation and formation of acids during stor-

age. Acidic gas can damage the fuel system

of an engine while in storage. To avoid engine

problems, empty the fuel system before stor-

age for 30 days or longer. Drain the gas tank,

start the engine and let it run until the fueI lines

and carburetor are empty. Use fresh fuel next

season. Never use engine or carburetor

cleaner products in the fuel tank or permanent

damage may occur. See the STORAG E sec-

tion for additional information.

HOW TO STOP YOUR UNIT

• To stop the engine, move the ON/OFF

switch to the OFF position.

• If engine does not stop. move choke lever

to the FULL CHOKE position.

HELPFUL TIP I

!fyour engine still does not I

start after following these I

instructions, pleas e call

1-800-554-6723.

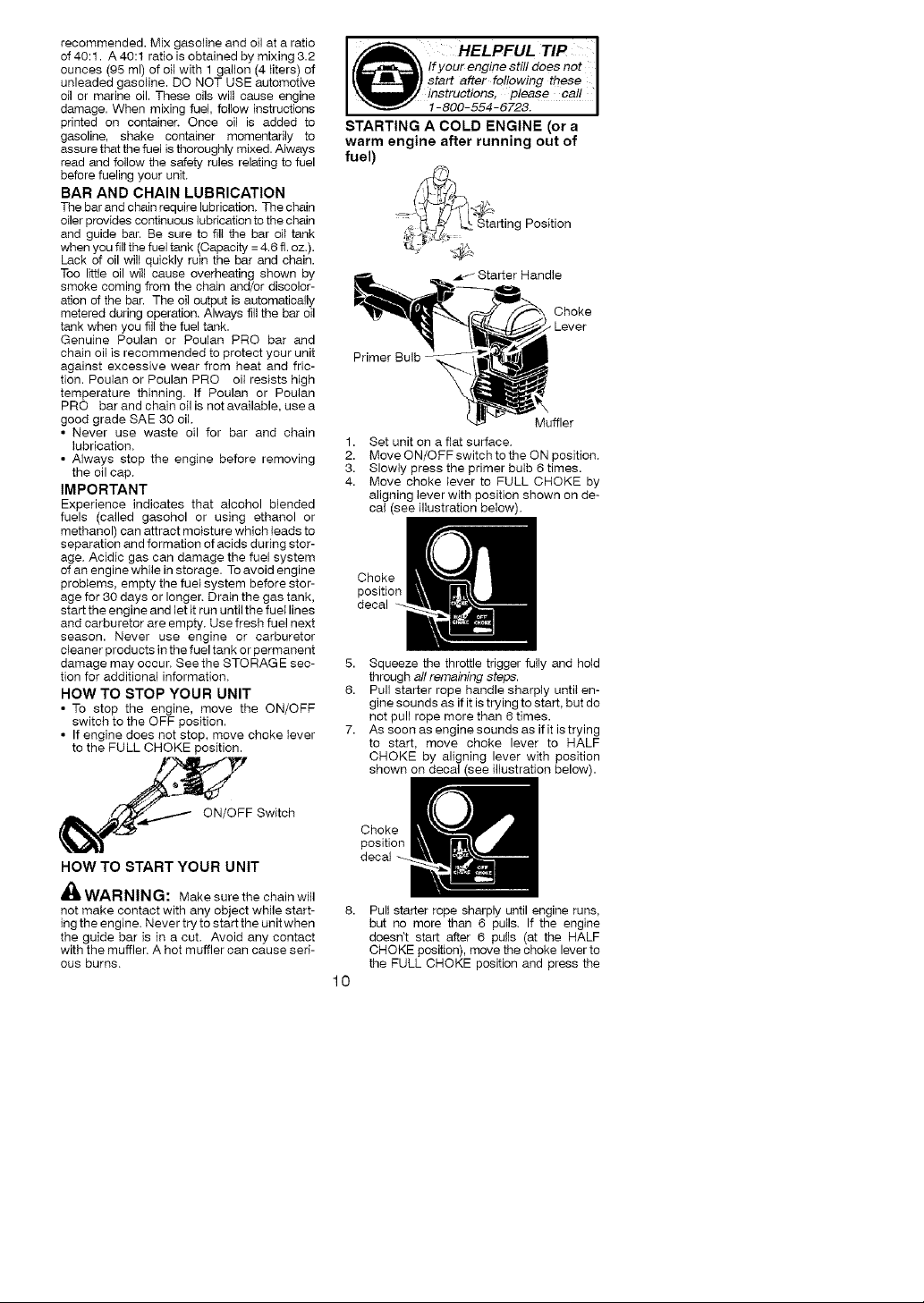

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

i_'_r_/Y_! St'_-arting Position

Choke

Lever

Primer Bulb

Muffler

1,

Set unit on a flat surface.

2.

Move ON/OFF switch to the ON position.

3.

Slowly press the primer bulb 6 times.

4.

Move choke tever to FULL CHOKE by

aligning lever with position shown on de-

cal (see illustration below).

Choke

position

decal

5. Squeeze the throttle trigger fully and hold

through all remaining steps.

6. Pull starter rope handle sharply until en-

gine sounds as if it is trying to start, but do

not pull rope more than 6 times.

7. As soon as engine sounds as if it is trying

to start, move choke lever to HALF

CHOKE by aligning lever with position

shown on decal (see illustration below).

ON/OFF Switch

HOW TO START YOUR UNIT

A(_WARNING: Make sure the chain will

not make contact with any object while start-

ing the engine, Never try to start the unit when

the guide bar is in a cut, Avoid any contact

with the muffler. A hot muffler can cause seri-

ous burns.

Pull starter rope sharply until engine runs.

but no more than 6 pulls. If the engine

doesn't start after 6 pulls (at the HALF

CHOKE position), move the choke lever to

the FULL CHOKE position and press the

10

primerbulb6times.Squeezeandholdthe

throttletriggerandpullthestarterrope2

moretimes.Movethechokelevertothe

HALFCHOKEpositionandpullthestarter

ropeuntiltheengineruns.butnomorethan

6pulls.Iftheenginedoesn'tstart,repeat

procedure2additionaltimes.

NOTE:Ifenginestilldoesn'tstart,itis

probablyflooded.ProceedtoSTARTINGA

FLOODEDENGINE,

Oncetheenginestarts,allowittorun10se-

conds,thenmovethechokelevertoOFF

CHOKEbya_igningleverwithposition

shownondecal(seeillustrationbelow).Al-

lowtheunittorunfor30moresecondsat

OFFCHOKEbeforereleasingthethrottle

trigger.NOTE:Ifenginedieswiththe

chokeleverintheOFFCHOKEposition,

movethechokelevertotheHALFCHOKE

positionandpulltheropeuntilengineruns,

butnomorethan6pulis.

Choke

position

decal

,40&WARNING: Alwaysstopunitanddis-

connect spark plug before removing or instal-

ling attachments.

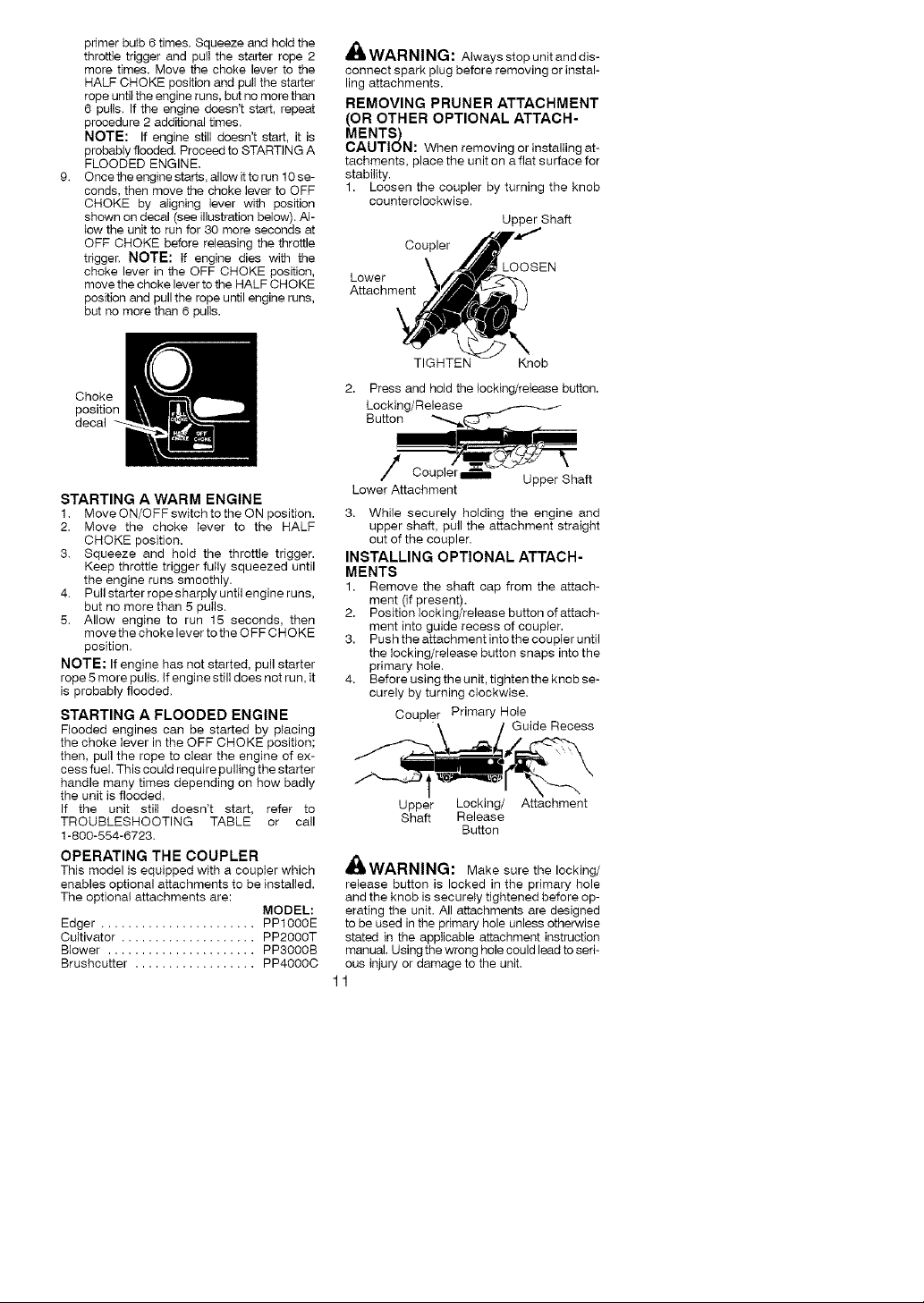

REMOVING PRUNER ATTACHMENT

(OR OTHER OPTIONAL ATTACH-

MENTS)

CAUTION: When removing or installing at-

tachments, place the unit on a flat surface for

stability.

1. Loosen the coupler by turning the knob

counterclockwise.

Upper Shaft

Coupler

Lower

Attachment

TIGHTEN Knob

2. Press and hold the locking/release button.

Locking/Release

Button

STARTING A WARM ENGINE

1. Move ON/OFF switch to the ON position.

2. Move the choke lever to the HALF

CHOKE position.

3. Squeeze and hold the throttle trigger.

Keep throttle trigger fully squeezed until

the engine runs smoothly.

4. Pull starter rope sharply until engine runs,

but no more than 5 pulls.

5. Allow engine to run 15 seconds, then

move the choke lever to the OFF CHOKE

position.

NOTE: If engine has not started, pull starter

rope 5 more pulls. If engine still does not run, it

is probably flooded.

STARTING A FLOODED ENGINE

Flooded engines can be started by p_acing

the choke lever in the OFF CHOKE position;

then. pull the rope to clear the engine of ex-

cess fuel. This could require pulling the starter

handle many times depending on how badly

the unit is flooded.

If the unit still doesn't start, refer to

TROUBLESHOOTING TABLE or call

1-800-554-6723.

OPERATING THE COUPLER

This model is equipped with a coupler which

enables optional attachments to be installed.

The optional attachments are:

Edger ....................... PP1000E

Cultivator .................... PP2000T

Blower ...................... PP3000B

Brushcutter .................. PP4000C

MODEL:

Lower Attachment

3. While securely holding the engine and

INSTALLING OPTIONAL ATTACH-

MENTS

1. Remove the shaft cap from the attach-

2. Position locking/release button of attach-

3. Push the attachment intothe coupIer until

4. Before using the unit, tighten the knob se-

cup er _ Upper Shaft

upper shaft, pull the attachment straight

out of the coupler.

ment (if present).

ment into guide recess of coupler.

the locking/release button snaps into the

primary hole.

curely by turning clockwise.

Coupler Primary Hole

Upper Locking/ Attachment

Shaft Release

Guide Recess

Button

rmWARNING: Make sure the locking/

release button is locked in the primary hole

and the knob is securely tightened before op-

erating the unit, All attachments are designed

to be used in the primary hole unless otherwise

stated in the applicable attachment instruction

manual Using the wrong hole could lead to seri-

ous injury or damage to the unit,

11

SecondaryHole

Locking/Release

ButtoninPrimaryHole

INSTALLING ATTACHMENT

HANGER

An attachment hanger is provided for storage

when attachment is not in use.

To instalt hanger on attachment:

1. Remove the shaft cap from the attach-

ment (if present) and discard.

2. Press and hold the locking/release button.

3. Push hanger onto the attachment until the

locking/release button snaps into the hole.

OPERATING INSTRUCTIONS

It is recommended that the engine not be

operated for longer than 1 minute at full

throttle.

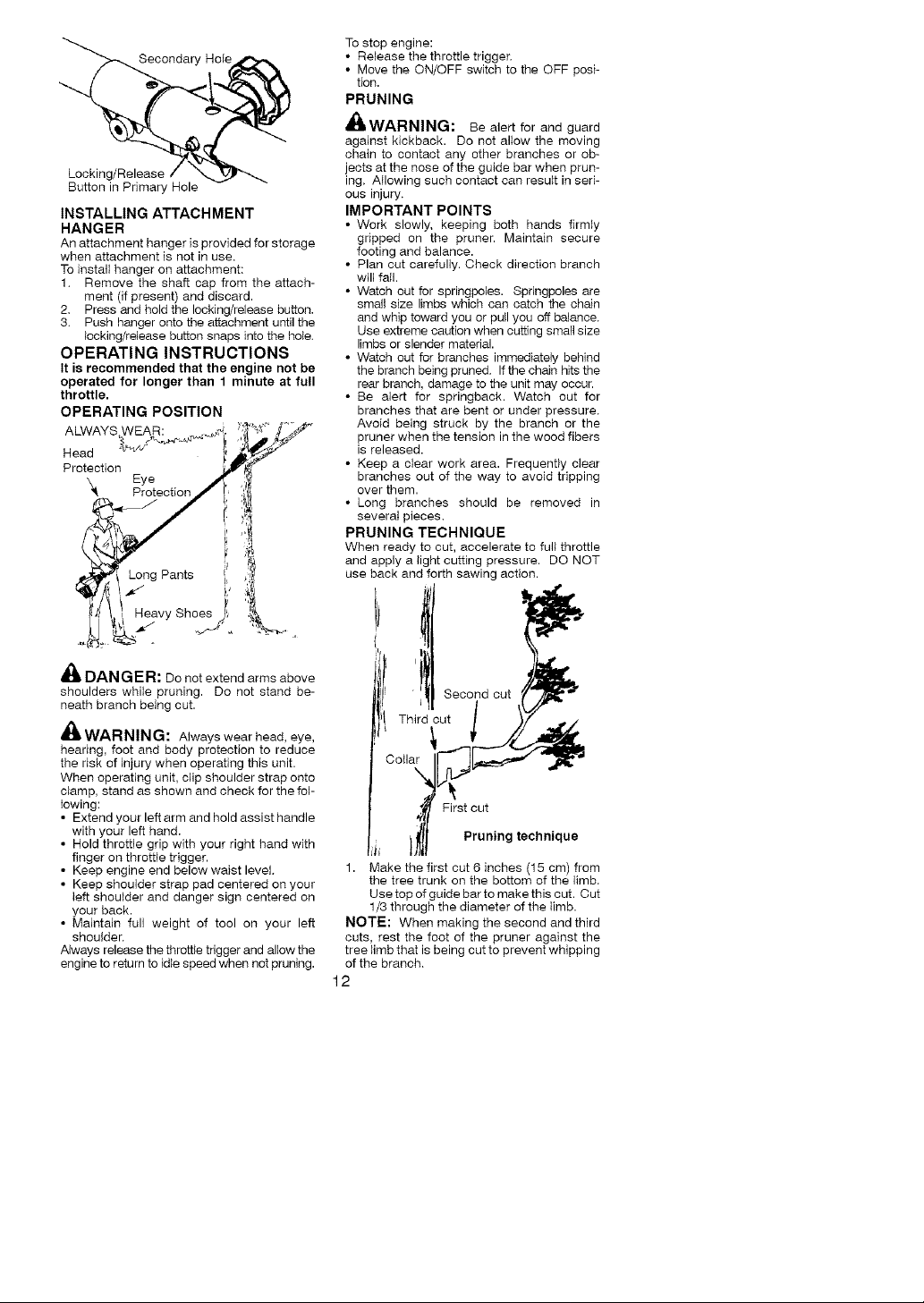

OPERATING POSITION

ALWAYS WEAR: _v_

Head '_'_/J'_'_'* _

Protection

\ Eye J

*i_ Protection f

A _

To stop engine:

• Release the throttle trigger.

• Move the ON/OFF switch to the OFF posi-

tion.

PRUNING

AO&WARNING: Be alert for and guard

against kickback. Do not allow the moving

chain to contact any other branches or ob-

jects at the nose of the guide bar when prun-

ing. Allowing such contact can result in seri-

ous injury.

IMPORTANT POINTS

• Work slowly, keeping both hands firmly

gripped on the pruner. Maintain secure

footing and balance.

• Plan cut carefully. Check direction branch

will fail.

• Watch out for springpoles. Springpoles are

small size limbs which can catch the chain

and whip toward you or pull you off balance.

Use extreme caution when cutting small size

limbs or slender material.

• Watch out for branches immediately behind

the branch being pruned. If the chain hits the

rear branch, damage to the unit may occur.

• Be alert for springback. Watch out for

branches that are bent or under pressure.

Avoid being struck by the branch or the

pruner when the tension in the wood fibers

is released.

• Keep a clear work area. Frequently clear

branches out of the way to avoid tripping

over them.

• Long branches should be removed in

several pieces.

PRUNING TECHNIQUE

When ready to cut, accelerate to ful_ throttle

and apply a light cutting pressure. DO NOT

use back and forth sawing action.

! !_._avy S ho/!,

A

DANGER: Do not extend arms above

shoulders while pruning. Do not stand be-

neath branch being cut.

,_, WARNING: Alwayswearhead,eye,

hearing, foot and body protection to reduce

the risk of injury when operating this unit.

When operating unit, clip shoulder strap onto

clamp, stand as shown and check for the foF

lowing:

• Extend your left arm and hold assist handle

with your left hand.

• Hold throttle grip with your right hand with

finger on throttte trigger.

• Keep engine end below waist level.

• Keep shoulder strap pad centered on your

left shoulder and danger sign centered on

your back.

• Maintain full weight of tool on your left

shoulder.

Always release the throttle trigger and allow the

engine to return to idte speed when not pruning.

'i! ' Second cut

Th,rd ut

Coil

First cut

Pruning technique

1. Make the first cut 6 inches (15 cm) from

the tree trunk on the bottom of the limb.

Use top of guide bar to make this cut. Cut

1/3 through the diameter of the limb.

NOTE: When making the second and third

cuts. rest the foot of the pruner against the

tree limb that is being cut to prevent whipping

of the branch.

12

2. Next, move 2 - 4 inches (5 - 10 cm) far-

ther out on the limb and make a second

eut all the way through the limb.

3. Then, make a final cut leaving a I - 2 inch

(2.5 - 5 cm) collar from the trunk of the

tree to avoid damage to the tree.

,#A

_"mWARNING: Disconnect the spark

plug before performing mah_tenance except

for carburetor adjustments.

HELPFUL TIP

IMPORTANT: Have all

) ommended maintenance

described in the instruction

performed by an

If any dealer other than an authorized

service dealer performs work on the

product, Poulan PRO may not pay for

repairs under warranty. It is your re-

sponsibility to maintain and perform

general maintenance.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Spark Plug Boot

• Air Filter

• Housing Screws

• Assist Handle Screw

CHECK FOR DAMAGED OR

WORN PARTS

Contact an authorized service dealer for re-

placement of damaged or worn parts.

• ON/OFF switch - Ensure ON/OFF switch

functions properly by moving the switch to

the OFF position. Make sure engine stops;

then restart engine and continue.

• Fuel tank - Discontinue use of unit if fuel

tank shows signs of damage or leaks.

• Oil tank - Discontinue use of unit if oil tank

shows signs of damage or leaks.

INSPECT AND CLEAN UNIT AND LA-

BELS

• After each use, inspect complete unit for

loose or damaged parts. Clean the unit and

labels using a damp cloth with a mild deter-

gent.

• Wipe off unit with a clean dry cloth.

authorized service dealer.

the rec-

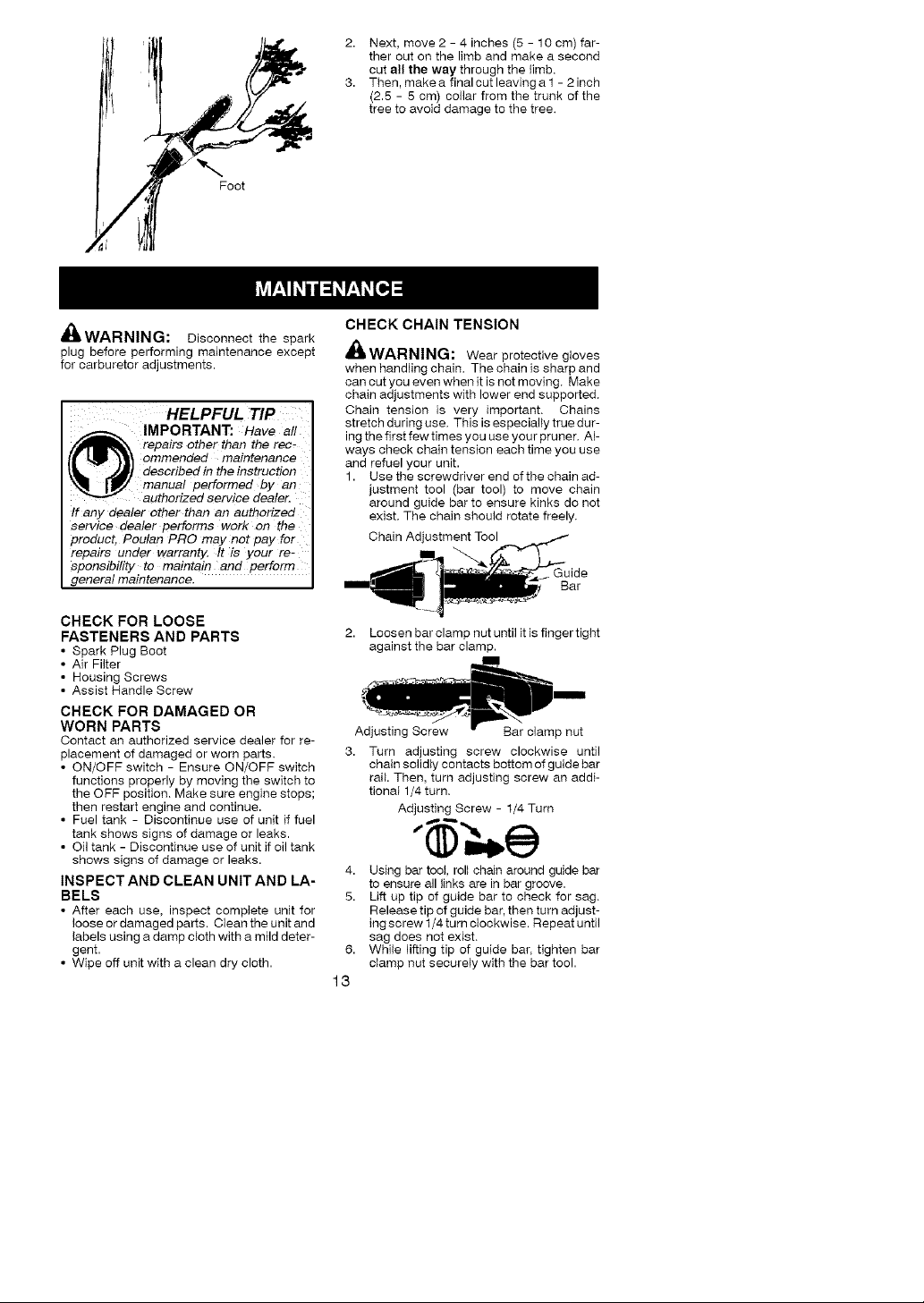

CHECK CHAIN TENSION

'_ WARNING: Wear protective gloves

when handling chain. The chain is sharp and

can cut you even when it is net moving, Make

chain adjustments with lower end supported,

Chah_ tension is very important. Chains

stretch during use. This is especially true dur-

ing the first few times you use your pruner. Al-

ways check chain tension each time you use

and refuel your unit.

1. Use the screwdriver end of the chain ad-

justment tool (bar tool) to move chain

around guide bar to ensure kinks do not

exist. The chain should rotate freely.

Chain Adjustment Tool

Guide

Bar

2. Loosen bar clamp nut until it is finger tight

against the bar clamp.

Adjusting Screw Bar clamp nut

3. Turn adjusting screw clockwise until

chain solidly contacts bottom of guide bar

rail. Then, turn adjusting screw an addi-

tional 1/4 turn.

Adjusting Screw - 1/4 Turn

4. Using bar tool, roll chain around guide bar

to ensure all links are in bar groove.

5. Lift up tip of guide bar to check for sag.

Release tip of guide bar, then turn adjust-

ing screw 1/4 turn clockwise. Repeat until

sag does not exist.

6,

While lifting tip of guide bar, tighten bar

clamp nut securely with the bar tool.

13

7. Use the screwdriver end of the bar tool to

move chain around guide bar.

8. If chain does not rotate, it is too tight.

Slightly loosen bar clamp nut and loosen

chain by turning the adjusting screw 1/4

turn counterclockwise. Retighten bar

clamp nut.

9. If chain is too loose, it will sag below the

guide bar and needs to be tightened fol-

lowing above procedure.

_.WARNING, DO NOT operate the

pruner ifthe chain is loose. Ifthe pruner is oper-

ated with a loose chain, the chain could jump off

the guide bar and result in serious injury.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A dull chain

makes a sawdust powder and cuts slowly.

See CHAIN SHARPENING in the SERVICE

AND ADJUSTMENTS section.

CLEAN AIR FILTER

A dirty air filter decreases engine perform-

ance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

1. Clean the cover and the area around it to

keep dirt from falling into the carburetor

chamber when the cover is removed.

2. Remove parts by pressing button to re-

lease air filter cover.

NOTE: To avoid creath_g a fire hazard or

produch_g harmful evaporative emissions, do

not clean filter h_gasoline or other flammable

solvent.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Replace parts.

Button

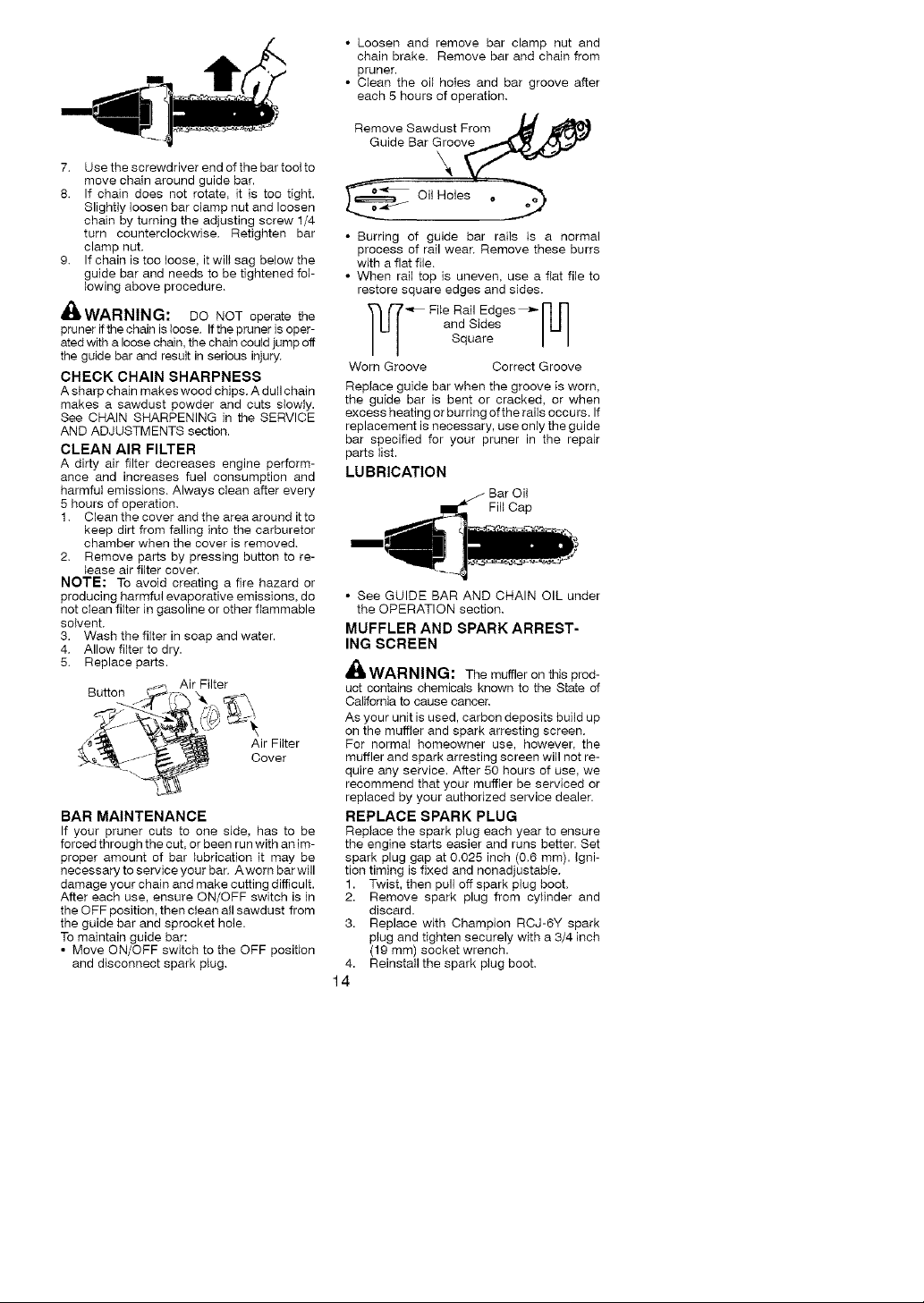

BAR MAINTENANCE

If your pruner cuts to one side, has to be

forced through the cut, or been run with an im-

proper amount of bar lubrication it may be

necessary to service your bar. Aworn bar will

damage your chain and make cutting difficult.

After each use, ensure ON/OFF switch is in

the OFF position, then clean all sawdust from

the guide bar and sprocket hole.

To maintain guide bar:

• Move ON/OFF switch to the OFF position

and disconnect spark plug.

Air Filter

Air Filter

Cover

• Loosen and remove bar clamp nut and

chain brake. Remove bar and chain from

pruner.

• Clean the oil holes and bar groove after

each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

\

OilHoles

• Burring of guide bar railsis a normal

proeess ofrailwear. Remove these burrs

with a flat file.

• When rail top is uneven, use a flat file to

restore square edges and sides.

_-]_j_ File Rail Edges_r] N

Worn Groove Correct Groove

Replace guide bar when the groove is worn,

the guide bar is bent or cracked, or when

excess heating or burring of the rails occurs. If

replacement is necessary, use onty the guide

bar specified for your pruner in the repair

parts list.

LUBRICATION

• See GUIDE BAR AND CHAIN OIL under

the OPERATION section.

MUFFLER AND SPARK ARREST-

ING SCREEN

,_ WARNING: The muffler on this prod-

uct contains chemicals known to the State of

California to cause cancer.

As your unit is used, carbon deposits build up

on the muffler and spark arresting screen.

For normal homeowner use, however, the

muffler and spark arresting screen will not re-

quire any service. After 50 hours of use. we

recommend that your muffler be serviced or

replaced by your authorized service dealer.

REPLACE SPARK PLUG

Replace the spark plug each year to ensure

the engine starts easier and runs better. Set

spark plug gap at 0.025 inch (0.6 ram). Igni-

tion timing is fixed and nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder and

discard.

3. Replace with Champion RCJ-6Y spark

plug and tighten securely with a 3/4 inch

(19 mm) socket wrench.

4. Reinstall the spark plug boot.

14

and Sides I U I

Square I I

FillCap

d_I_WAHNIN_: Disconnect the spark

plug before performing maintenance, service, or

adjustments except for carburetor adjustments.

CHAIN SHARPENING

Chah_ sharpening is a complicated task that

requires special tools. We recommended you

refer chain sharpening to a professional chain

sharpener.

CHAIN REPLACEMENT

WARNING: Wear protective gloves

when handiing chain. The chain is sharp and

can cut you even when it is not moving.

It is normal for a new chain to stretch during the

first 15 minutes of operation. You should re-

check your chain tension frequently and adjust

the chain tension as required. See CHAIN TEN-

SION section.

Replace the old chain when it becomes worn or

damaged. Use only the Low-Kickback replace-

ment chain specified in the repair parts list.

TO REPLACE CHAIN:

1. Move ON/OFF switch to the OFF posifion

and disconnect spark plug.

2. Remove bar clamp nut.

3. Remove bar clamp.

4. Turn adjusting screw by hand counter-

clockwise until adjusting pin just touches

the stop.

5. Slide guide bar behind sprocket until

guide bar stops against sprocket.

6. Remove the old chain.

7. Carefully remove new chain from pack-

age. Hold chain with the drive links as

shown.

Tip of _

Bar

DIRECTION OF ROTATION

Cutters Depth Gauge

" Drive Links

8. Place chain over sprocket, fitting the

drive links in the sprocket.

9. Fit bottom of drive links between the teeth

in the sprocket in the nose of the guide

bar.

10. Fit chain drive links into bar groove.

11. Pull guide bar forward until chain is snug

in guide bar groove. Ensure all drive links

are in the bar groove.

12. Now. install bar clamp making sure the

adjusting pin is positioned in the lower

hole in the guide bar.

Lower

Hole

Guide Bar

13. Install bar clamp nut and finger tighten

only. Do not tighten any further at this

point. Proceed to the CHAIN ADJUST-

MENT section.

CHAIN ADJUSTMENT

See CHECK CHAIN TENSION in MAINTE-

NANCE section.

CARBURETOR ADJUSTMENT

@ _Adjusting Pin

_, WARNING: Keepothers away when

making idle speed adjustments. The chain

will be moving during most of this procedure.

Wear your protective equipment and observe

all safety precautions. After making adjust-

ments, the chain must not move at idle speed.

The carburetor has been carefully set at the

factory. Adjustment to the idle speed may be

necessary if you notice any of the following

conditions:

• Engine will not idle when the throttle is re-

leased.

• The chain moves at idle.

Make adjustments with the unit supported so

the pruner is off the ground and the chain will

not make contact with any object. Hold the

unit by hand while running and making adjust-

ments. Keep all parts of your body away from

the chain and muffler.

15

Idle Speed Screw

IDLE SPEED ADJUSTMENT

Allow engine to idle. Adjust idle speed until en-

gine runs without chain moving (idle too fast)

or stalling (idle speed too slow).

• Turn idle speed screw clockwise to in-

crease engine speed if engine stalls or dies.

• Turn idle speed screw counterclockwise to

decrease engine speed if chain moves at idle.

AI;_WARNING: Recheck the idle speed

after each adjustment. The chain must not

move at idle speed to avoid serious injury to

the operator or others.

If you require further assistance or are unsure

about performing this procedure, contact your

authorized service dealer or call

1-800-554-6723.

,#A

_"mWARNING: Perform the following

steps after each use:

• Allow engh_e to cool before storing or trans-

porting.

• Store unit and fuel h_awetl ventilated area

where fuel vapors cannot reach sparks or

open flames from water heaters, electric

motors or switches, furnaces, etc.

• Store unit with ell guards in place. Position

unit so that any sharp object cannot acci-

dentally cause injury.

• Store unit and fuel well out of the reach of

children.

SEASONAL STORAGE

Prepare unit for storage at end of season or if

it will not be used for 30 days or more.

If your unit is to be stored for a period of time:

• Clean the entire unit before lengthy

storage.

• Store in a clean dry area.

• Lightly oil external metal surfaces.

FUEL SYSTEM

Under FUELING ENGINE in the OPERA-

TION section of this manual, see message la-

beled IMPORTANT regarding the use of ga-

sohol in your engine.

Fuel stabilizer is an acceptable alternative in

minimizing the formation of fuel gum deposits

during storage. Add stabilizer to the gasoline

in the fuel tank or fuel storage container. Fol-

low the mix instructions found on stabilizer

container. Run engine at least 5 minutes after

adding stabilizer.

_ During storage of your gas/ I

_-_el_ oil mixture, the eil wiil sepa- I

mld_ rate from the gas.

m_'_J_J We recommend that you I

_'q_i_J ahakethegasear,weekly I

to insure proper blending of I

HELPFUL TIP I

ENGINE

• Remove spark plug and pour 1 teaspoon of

40:1,2-cycle engine oil (air cooled) through

the spark plug opening. Slowly pull the

starter rope 8 to 10 times to distribute oil.

• Replace spark plug with new one of recom-

mended type and heat range.

• Clean air filter.

• Check entire unit for loose screws, nuts,

and bolts. Replace any damaged, broken,

or worn parts,

• At the beginning of the next season, use

only fresh fuel having the proper gasoline to

oil ratio.

OTHER

• Do not store gasoline from one season to

another.

• Replace your gasoline can if it starts to rust.

the gas and oil. I

16

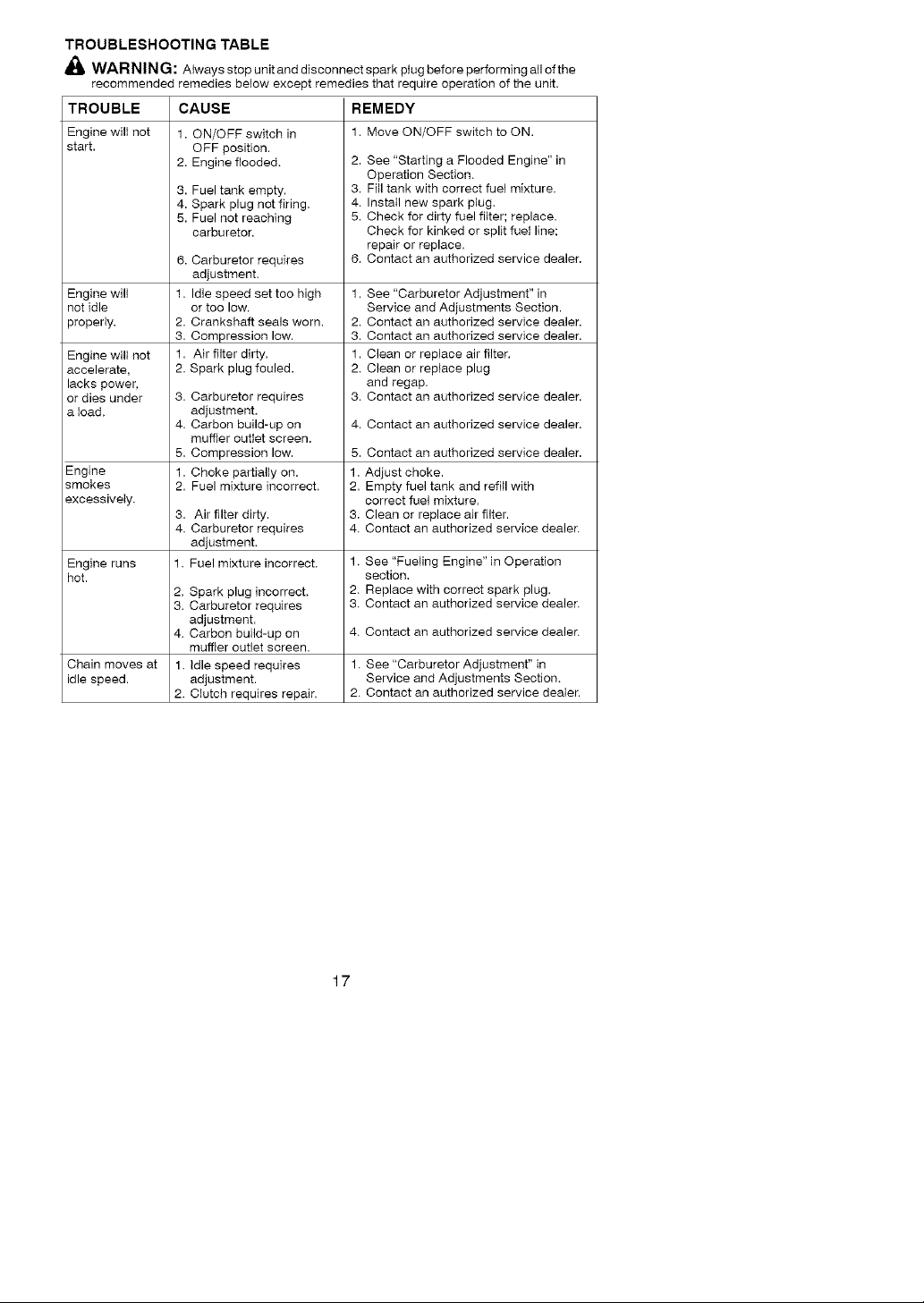

TROUBLESHOOTING TABLE

,_ WARNING: Aiways stop unit and disconnect spark plug before performing all of the

recommended remedies below except remedies that require operation of the unit,

TROUBLE

Engine will not

start.

Engine will 1. Idle speed set too high

not idle or too low.

properly. 2. Crankshaft seals worn.

Engine will not

accelerate,

lacks power.

or dies under

a load.

Engine

smokes

excessively.

Engine runs 1. Fuel mixture incorrect. 1. See "Fueling Engine" in Operation

hot. section.

Chain moves at 1. Idle speed requires 1. See "Carburetor Adjustment" in

idle speed, adjustment. Service and Adjustments Section.

CAUSE REMEDY

1. ON/OFF switch in

OFF position.

2. Engine flooded.

3. Fuel tank empty.

4. Spark plug not firing.

5. Fuel not reaching

carburetor.

6. Carburetor requires

adjustment.

3. Compression low.

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

5. Compression low.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires

adjustment.

2. Spark plug incorrect. 2. Replace with correct spark plug.

3. Carburetor requires 3. Contact an authorized service dealer.

adjustment.

4. Carbon build-up on 4. Contact an authorized service dealer.

muffler outlet screen.

2. Clutch requires repair. 2. Contact an authorized service dealer.

1. Move ON/OFF switch to ON.

2. See "Starting a Flooded Engine" in

Operation Section.

3. Fill tank with correct fuel mixture.

4. Instatl new spark plug.

5. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

6. Contact an authorized service dealer.

1. See "Carburetor Adjustment" in

Service and Adjustments Section.

2. Contact an authorized service dealer.

3. Contact an authorized service dealer.

1. Clean or replace air filter.

2. Ctean or reptace plug

and regap.

3. Contact an authorized service dealer.

4. Contact an authorized service dealer.

5. Contact an authorized service dealer.

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. Contact an authorized service dealer.

17

Poulan PRO warrants to the origh_al pur-

chaser that each new Poulan PRO brand

gasoth_e tool or attachment is free from de-

fects in material and workmanship and

agrees to repair or replace under this war-

ranty any defective gasoline product or at-

tachment as follows from the origh_al date of

purchase.

2 YEARS - Parts and Labor, when used for

household purposes.

90 DAYS - Parts and Labor, when used for

commercial, professional, or income produc-

ing purposes,

80 DAYS - Parts and Labor, if used for rental

purposes,

This warranty is not transferable and does not

cover damage or liability caused by improper

handling, improper maintenance, or the use

of accessories and/or attachments not spe-

cifically recommended by Poulan PRO for

this tool. Additionally, this warranty does not

cover tune-ups, spark plugs, filters, cutting

Ih_e, or rotating head parts that will wear and

require replacement with reasonable use dur-

ing the warranty period. This warranty does

not cover predelivery setup or normal adjust-

ments explained in the instruction manual.

THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY HAVE

OTHER RIGHTS WHICH VARY FROM

STATE TO STATE,

NO CLAIMS FOR CONSEQUENTIAL OR

OTHER DAMAGES WILL BE ALLOWED,

AND THERE ARE NO OTHER EXPRESS

WARRANTIES EXCEPT THOSE EX-

PRESSLY STIPULATED HEREIN.

SOME STATES DO NOT ALLOW LIMITA-

TIONS ON HOW LONG AN IMPLIED WAR-

RANTY LASTS OR THE EXCLUSION OR

LIMITATIONS OF INCIDENTAL OR CON-

SEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS OR EXCLUSION MAY NOT

APPLY TO YOU,

The policy of Poulan PRO is to continuously

improve its products. Therefore, Poulan

PRO reserves the right to change, modify, or

discontinue models, designs, specifications,

and accessories of all products at any time

without notice or obligation to any purchaser.

YOUR WARRANTY RIGHTS AND OB-

LIGATIONS: The U.S. Environmental

Protection Agency, California Air Resources

Board, Environment Canada and Poulan/

WEED EATER are pleased to explain the

emissions control system warranty on your year

2005 and later small off-road engine, in Califor-

nia, all small off-road engines must be de-

signed, built, and equipped to meet the State's

stringent anti-smog standards. Poulan/

WEED EATER must warrant the emission

control system on your small off-road engine

for the periods of time listed below provided

there has been no abuse, neglect, or improp-

er maintenance of your smail off- road engine.

Your emission control system includes parts

such as the carburetor and the ignition sys-

tem. Where a warrantable condition exists,

Poulan/WEED EATER will repair your small

off-road engine at no cost to you. Expenses

covered under warranty include diagnosis,

parts and labor. MANUFACTURER'S WAR-

RANTY COVERAGE: If any emissions re-

lated part on your engine (as listed under

Emissions Control Warranty Parts List) is de-

fective or a defect in the materials or workman-

ship of the engine causes the failure of such an

emission related part, the part will be repaired or

replaced by Poulan/WEED EATER, OWN-

ER'S WARRANTY RESPONSIBILITIES:

As the smal_ off-road engine owner, you are

responsible for the performance of the re-

quired maintenance listed in your instruction

manual. Poulan/WEED EATER recommends

that you retain all receipts covering mainte-

nance on your small off-road engine, but

Poulan/WEED EATER cannot deny warranty

solely for the lack of receipts or for your failure

to ensure the performance of all scheduled

maintenance, As the small off-road engine

owner, you should be aware that Poulan/

WEED EATER may deny you warranty cov-

erage if your small off- road engine or a part of

it has failed due to abuse, neglect, improper

maintenance, unapproved modifications, or

the use of parts not made or approved by the

original equipment manufacturer. You are re-

sponsible for presenting your small off-road en-

gine to an Poulan/WEED EATER authorized re-

pair center as soon as a problem exists,

Warranty repairs should be completed in a rea-

sonable amount of time, not to exceed 30 days,

Ifyou have any questions regarding your war-

ranty rights and responsibilities, you should

contact your nearest authorized service center

or call Poutan/WEED EATER at

1-800-554-6723, WARRANTY COM-

MENCEMENT DATE: The warranty period

begins on the date the small off-road engine

is purchased, LENGTH OF COVERAGE:

This warranty shall be for a period of two

years from the initial date of purchase. WHAT

IS COVERED: REPAIR OR REPLACE-

MENT OF PARTS. Repair or replacement of

any warranted part will be performed at no

charge to the owner at an approved Poulan/

WEED EATER servicing center. If you have

any questions regarding your warranty

rights and responsibilities, you should con-

tact your nearest authorized service center

18

Loading...

Loading...