Page 1

Pouian*

Please do not return unit to retailer.

Por favor, no devuelva el aparato al lugar de compra.

Veuillez ne pas retourner l’outi! au détaillant,

1-800-554-6723

www.poulan.com

Manual de Instrucciones

Manuel d’instructions

WARNING:

A

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious injury.

ADVERTENCIA:

Lea el manual de instrucciones y siga todas las advertencias e

instrucciones de seguridad. E! no hacerlo puede resultar en lesiones

graves.

AVERTISSEMENT;

Lire le manuel d’instructions et bien respecter tous les avertisse

ments et toutes les instructions de sécurité. Tout défaut de le faire

pourrait entraîner des blessures graves,

Instruction Manual

PLN3516F

2^15157

Pouian

1030 Stevens Creek Road

Augusta, GA 30907

850 Matheson Blvd, West

Pûuîan

Mississauga, Ontario L5V 0B4

9096-212604

Page 2

INTRODUCTfON

TABLE OF CONTENTS

1 GENERAL INFORMATION .................................................3

1-1, General Identification

1-2. Safety Features

1 -3 Glossary

1- 4. Specificaiioin

2 SAFETY PRECAUTIONS.....................................................5

2- 1, Kickback Safety Labels

2-2. Important Safety Instructions

2-3. Other Safety Precautions

2-4. General Safety Precautions for chain saw users

2-5. More About Kickback

2- 6. International Symbols

3 ASSEMBLY INSTRUCTIONS...............................................9

3- 1. Introductioin

3-2. Assembly Requirements

3-3. Guide Bar / Saw Chain Installation

3-4. Saw Chain Tension Adjustment

3-5. Filling Oil Tank

3- 6. Selecting the Proper Extension Cord for Your Saw Model

4 OPERATING INSTRUCTIONS

4- 1. To Start Saw

4-2. To Stop Saw

4-3. Chain and Bar Lubrication

4-4. CHAIN BRAKE® / Hand Guard

4- 5. Extension Cords

5 GENERAL CUTTING INSTRUCTIONS

5- 1. Felling

5-2. Limbing

5-3. Bucking

5- 4. Bucking Using a Sawhorse

6 BAR/CHAIN MAINTENANCE

6- 1. Guide Bar Maintenance

6- 2, Chain Maintenance Instructions

..........................................11

.........................

.......................................

13

15

7 BAR/CHAIN MAINTENANCE .......................................17

7- 1. Preventive maintenance

7-2. Chain Replacement Information

8 LIMITED WARRANTY ..................................................18

Page 3

1 - GENERAL INFORMATION

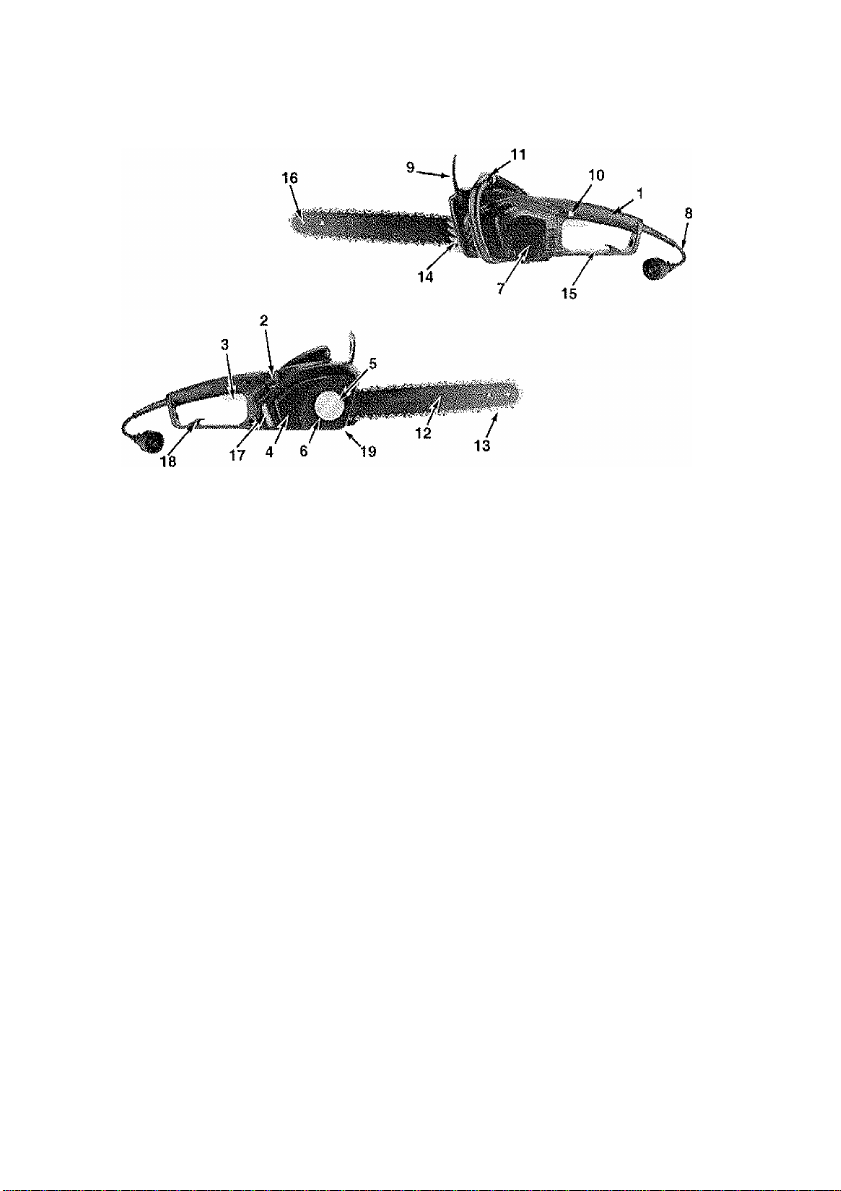

1-1. GENERAL IDENTIFICATION

1. REAR HANDLE

2. OIL TANK CAP

3. TRIGGER START/STOP SWITCH

4. SPROCKET COVER

5. BAR BOLT KNOB

6. CHAIN TENSION RING

7. ELECTRIC MOTOR

8. ELECTRIC CORD

9. CHAIN BRAKE® LEVER /

HAND GUARD

10. LOCK/OFF BUTTON

11. FRONT HANDLE

12. GUIDE BAR

13. SAW CHAIN

14. SPIKES

15. REAR HAND GUARD

16. SPROCKET

17. OIL TANK WINDOW

18. CORD RETAINER

19. CHAIN CATCHER

1-2. SAFETY FEATURES

Numbers preceding the descriptions

correspond with the numbers

on preceding page to help you locate the

safety feature.

3 TRIGGER START / STOP SWITCH

stops saw motor when released.

7 ELECTRIC MOTOR is double

insulated for added safety.

9 CHAIN BRAKE® LEVER / HAND

GUARD activates the chain brake and

protects the operator’s left hand in the

event it slips off the front handle while

saw is running.

10 LOCK / OFF BUTTON prevents

accidental acceleration of the saw

motor.The trigger cannot be squee:;?ed

unless lock/off button is depressed.

12 GUIDE BAR Reduced kickback guide

bar reduces the intensity of kickback,

13 LOW-KICKBACK CHAIN helps

significantly reduce kickback, or the

intensity of kickback, due to specially

designed depth gauges and Guard

links.

19 CHAIN CATCHER reduces the danger

of injury in the event saw chain breaks

or derails during operation. The catcher

is designed to intercept a whipping

chain.

Page 4

1-3. GLOSSARY 13. LOW-KICKBACK CHAIN - A chain

1. BUCKING - The process of cross that complies with the kickback

cutting felled tree or log into lengths,

2. CHAIN BRAKE-A device used to Slop B175.M991 when tested on a

thp rhflin isflw representative sample of chain saws.

3. cSsrvi^POlVEffHEAO-Achain U. NORMAL CUTTING POSITION -

saw without the saw chain and guide I^ose positions assumed in performing

u “ the bucking and felling cuts.

4. DRIVE SPROCKET OR SPliOCKET- IS. NOTCHING IMDERCUT-ArtOchcul

The toothed part that drives the saw

6. F£i.i./NO-The process of cutting ,, ? tT“''®'"'e n ai

down a tree 17. t?£/4f?W>tWDL£-The support handle

6. FELLING BACK CUT- The final cut in

a tree felling operation made on the ^apnijrFn KiCKRArK nuinp bar

opposite side of the tree from the . tT u

not^hinn iinopmijt ^ guide bar which has been

16, OILER CONTROL - A system for oiling

7. FHONTH71«D1.£'-Thesupporthandlo demonstrated to reduce kickback

chain* °* *'*'* RAPIECEMENT SAW CHAIN - A

8. FRONT HANDLE GUARD . A chain lhat compiles with the kicki^ck

structural barrier between the Iron! grÎ?T^nt ° r.

handle of a chain saw and the guide B175.1-1991 when tested vv, h sprteiic

bar, typically located close to the hand

position on the front handle and pertorrnance requirements when used

fevefloTfoZ'Se"' ^0. SAW CHAfN-\ loop ol chain having

9. GUIDE BAR-A Lid ratted structure cuttirtg teeth, that cut the worçd, and

that supports and guides the saw “

rhain supported by the guide bar,

lO.SBACK-Thebackwardorupward 21. s™h7BUMPERJ-Sn/CE;-The

motion, or both of the guide bar '°“‘P^^

occurring when the saw chain near the ‘’““'''"a P'™‘ "'p

nose ol the lop area of the guide bar ,, 'SlTj-’'iF°ïT

contacts any obieot such as a log or 22. SOTTCH-A device that when

branch, or when the wood closes In "P® *" complete or mtermpt an

and pinches the saw chain in the cut. P““'

11. WCKB/tCK, PINCH-The rapid .

pushback of the saw which can occur LINKAGE ■ The mechani^sm

Ivhen the wood closes in and pinches “ ^

iie tTriïïhÎmrPrÎe iJ," 2“. SWiTcH LOCKOUT- A movable stop

the top of the guide bar. , ... _ ,, . ^

12. KICKBACK, hTATIONAL-TM that proven s the unintentional

rapid upward and backward motion of ‘I®

the saw which can occur when the actuatea.

moving saw chain near the upper

portion of the tip of the guide bar

contacts and object, such as a log or

branch.

1-4. SPECIFICATIONS

Model No

Input

Peak Horsepower

No Load Speed.........................................................5500/min

Bar Length

Culling Speed............................................................10.5m/sec

Chain Oil Capacity

Net Weight (Without guide bar and chain)

............................................................

.........................................................................

.....................................................

...............................................................

...................................................

..............

4

PLN3516F

120V-, 60H2, 13.5 Amp

3.5HP

16" (40cm)

180ml

4.2 kg (9.24 Lbs)

Page 5

2 - SAFETY PRECAUTIONS

SAFETY PRECAUTIONS FOR CHAIN SAW USERS

(ANSI/UL 1662-1995) (CAN/CSA-Z62.1-03)

2-Í. KICKBACK SAFETY LABELS

1. Worst-case computed kickback

angle.

2. Avoid bar nose contact.

3. Beware of kick back.

4. Do not attempt to hold saw with

one hand.

RECOMMENDED

5, Hold Saw properly with both

hands,

2-2. IMPORTANT SAFETY

INSTRUCTIONS

1. REPLACEMENT PARTS - When

servicing use only identical

replacement parts.

2. POLARIZED PLUGS - To reduce the

risk of electric shock, this equipment

has a polarized plug {one blade is

wider than the other). This plug will tit

in a polarized extension cord only one

way. If the plug does not fit fully in the

extension cord, reverse the plug. Do

not change the plug in any way.

3. KEEP THE WORK AREA CLEAN:

Cluttered areas invite injuries. Do not

start cutting until you have a clear work

area, secure footing, and a planned

retreat path from the falling tree.

4. CONSIDER THE WORK AREA

ENVIRONMENT: Use extreme caution

when cutting small sized brush and

saplings because the slender material

may catch the saw chain and be

whipped toward you or pull you off

balance. Do not operate a chain saw in

a tree unless specifically trained to do

so. When cutting a limb that is under

tension, be alert for spring back so that

you will not be struck when the tension

in the wood fibers is released. Do not

expose the chain saw to rain. Do not

use the chain saw in damp or wet

locations. Do not use the chain saw in

presence of flammable liquids or

gases.

5. GUARD AGAINST ELECTRIC

SHOCK: Prevent body contact with

grounded surfaces. For example: metal

pipes, wire fences.

6. KEEP CHILDREN AWAY: Do not let

visitors contact the chain saw or

extension cord. All visitors should be

kept away from the work area.

7. STORE IDLE CHAIN SAW: When not

in use, chain saws should be stored in

a dry, and high or locked-up place - out

of the reach of children. When storing

saw, use a scabbard or carrying case.

8. DO NOT FORCE CHAIN SAW: It will

do the job better and safer at the rate

for which it was intended.

9. USE RIGHT TOOL: Cut wood only.

Don’t use chain saw for purposes not

inteded - for example - Don’t use the

chain saw for cutting plastic, masonry,

or nonwood building materials,

10. DRESS PROPERLY: Do not wear

loose clothing or jewelry. They can get

caught in moving parts. Rubber gloves

and non-skid footwear are recommend

ed when working outdoors.Wear prote

ctive hair covering to contain long hair,

11. USE SAFETY GLASSES: Also use

safety footwear; snug fitting clothing;

protective gioves; head safely chaps

protection.

12. CARRYING SAW: Carry the chain saw

by the front handle with the saw

stopped, finger off the switch, the guide

bar and saw chain to the rear.

13. MAINTAIN CHAIN SAW WITH CARE:

Inspect chain saw cords periodically

and if damaged, have repaired by

authorized service facility. Keep cord

dear of the chain and operator at all

times. Never carry saw by the cord or

pull it to disconnect from receptacle.

Keep the cord free from oil and away

from sharp edges. Inspect extension

cords periodically and replace if

damaged. Keep tools sharp and clean

for better and safer performance.

Follow instructions for lubricating and

changing accessories. Keep handles

dry, dean and free from oil and grease.

14. DISCONNECT CHAIN SAW: Disconn

ect the chain saw when not in use,

before servicing, and when changing

accessories and attachments, such as

saw chain and guard.

Page 6

15. OUTDOOR EXTENSION CORDS: Use

only extension cords intended for

outdoor use and marked accordingly.

16. STAY ALERT; Watch what you are

doing. Use common sense. Do not

operate the chain saw when you are

tired. Keep all parts of the body away

from the saw chain when the motor is

operating. Before you start the saw,

make sure the saw chain is not

contacting anything.

17. CHECK DAMAGED PARTS: Before

further use of the chain saw, a guard or

other part that is damaged should be

carefully checked to determine that it

will operate properly and perform its

intended function. Check for alignment

of moving parts, binding of moving

parts, breakage of parts, mounting, and

any other conditions that may affect its

operation. A guard or other part that is

damaged should be properly repaired

or replaced by an authorized service

center unless otherwise indicated

elsewhere in this instruction manual.

18. GUARD AGAINST KICKBACK:

WARNING:

Kickback may occur when the nose or tip

of the guide bar touches an object, or

when the wood closes in and pinches the

saw chain in the cut. Tip contact in some

cases may cause a lightening fast reverse

action, kicking the guide bar up and back

towards the operator. Pinching the saw

chain along the top of the guide bar may

push the guide bar rapidly back towards

the operator. Either of these reactions may

cause you to lose control of the saw which

could result in serious injury to the user.

The following precautions should be

followed to minimize kickback:

A. GRIP SAW FIRMLY: Hold the chain

saw firmly with both hands when the

motor is running. Use a firm grip with

thumbs and fingers encircling the

chain saw handies. Note : If a

manual oiler control is provided,

additional or modified instructions

regarding its use is to be provided.

B. Do not over reach,

C. Keep proper footing and balance at

ail times,

D. Don’t let the nose of the guide bar

contact a log. branch, ground or

other obstruction.

E. Do not cut above shoulder height.

F. Use devices such as low kickback

chain, guide bar nose guards, chain

brakes and special guide bars that

reduce the risks associated with

kickback.

G. Only use replacement bars and

chains specified by the manufacturer

or the equivalent,

H. There are no other replacement

components for achieving kickback

protection,

19, POWER SUPPLY; Connect the chain

saw to correct voltage, that is, be sure

that the voltage supplied is the same

as that specified on the nameplate of

the tool.

2-3. OTHER SAFETY PRECAUTIONS

1, DO NOT operate a chain saw that is

damaged, improperly adjusted, or not

completely and securely assembled.

Be sure that the saw chain stops

moving when the trigger is released.

2, DO NOT attempt operations beyond

your capacity or experience,

3. DO NOT operate a chain saw with one

hand! Serious injury to the operator,

helpers, or bystanders may result from

one-handed operation, A chain saw is

intended for two-handed use.

4. TO REDUCE potential for electric

shock, do not operate the saw on wet

or slippery surfaces, or during snow

storms, rain storms, and other adverse

weather conditions.

6. Keep the handles dry, clean, and free

of oil or grease.

6. DO NOT allow dirt, debris or sawdust

to build up on the motor or outside air

vents.

7. Follow the manufacturer’s sharpening

and maintenance instructions for the

saw chain,

8. Cut at high motor speeds.

9. Operation of a chain saw should be

restricted to mature, properly instructed

individuals.

10. Your chain saw is intended for

occasional homeowner use. it is not

made for continuous heavy duty use.

11. DO NOT FORCE a small saw to do a

job requiring a heavier duty unit.

12. EXAMINE THE ELECTRICAL

SWITCHES. Do not use the chain saw

if the switches do not properly turn on

and off. Do not attempt to make any

repairs to the electric switches. Take

your saw to a Poulan Authorized

Service Center,

13. MAINTAIN EXTENSION CORDS.

Inspect the extension cords periodically

and replace if damaged, Oniy use

power cords that are suitably marked

for outdoor use,

Page 7

14. DO NOT OPERATE YOUR CHAIN

SAW near or around flammable liquids

or gases, whether in or out of doors.

An explosion and/or fire may result.

15. All chain saw service, other than the

items listed in the user manual safety

and maintenance instructions, should

be performed by competent chain saw

personnel. Do not attempt to repair it

yourself: there are no user serviceable

parts inside.

16. NEVER REMOVE, modify or make

inoperative any safety device furnished

with your unit. The CHAIN BRAKE®/

Hand Guard is a major safety feature.

The saw wil) not run when the CHAIN

BRAKE® is tripped.

17. This electric powered saw is intended

for infrequent use by homeowner's,

cottagers and campers, and for such

générai appiications such as clearing,

pruning, cutting firewood, etc. It is not

intended for prolonged use. if the

intended use involves prolonged

periods of operation, this may cause

circulatory problems in the user’s

hands due to vibration. It may be

appropriate to use a saw having an

anti-vibration feature,

18. Safety clothing required by your safety

organizations, government regulations,

or your employer should be used;

otherwise, snug fitting clothing, safety

footwear, safety chaps and hand and

ear protection should be worn.

19. When felling, keep at least two (2) tree

lengths between yourself and your

fellow workers,

2-4. GEN£RAL SAFETY PRECAU

TIONS FOR CHAIN SAW USERS

1. Fatigue causes carelessness. Be more

cautious before rest periods and

towards the end of your shift,

2. Personal protective clothing required

by your safety organizations,

government regulations, or your

employer should be used. At all times

when using a chain saw, snug-fitting

clothing, safety chaps protective eye

wear, safety footwear, and hand, leg,

and hearing protection should be worn.

3. When felling, keep at least two (2) tree

lengths away from your fellow workers.

4. Plan your work, ensuring an obstacle-

free work area and, in the case of

felling, at least one escape path from

the falling tree.

5. Follow the instructions in your

operator’s manual for starting the chain

saw and control the chain saw with a

firm grip on both handles when it is in

operation. Keep handies dry, clean,

and free of oil.

6. When transporting your chain saw, use

the appropriate transportation covers,

which should be available for the guide

bar and saw chain.

7. Never operate a chain saw that is

damaged or improperly adjusted or that

is not completely and securely

assembled. Be sure that the saw chain

stops moving when the power control

system trigger is released. Never

adjust the guide bar or saw chain when

the motor is operating.

8. Do not attempt a pruning or limbing

operation in a standing tree unless

specifically trained to do so,

9. Guard against kickback. Kickback is

the upward motion of the guide bar that

occurs when the saw chain, at the

nose of the guide bar, contacts an

object. Kickback can lead to dangerous

loss of control of the chain saw.

10. A chain saw is intended for two-handed

use. Serious injury to the operator,

helpers, and/or bystanders could result

from one-handed operation.

11. See section 1-6 for symbol defirmtions,

page 14.

12. When carrying a chain saw with the

motor running, engage the chain brake.

13. Keep other persons or animals a safe

distance away from a running chain

saw or the area where a tree is being

felled.

14. Use extreme caution when cutting

small brush and saplings because

slender material can catch the saw

chain and be whipped toward you.

15. When cutting a limb that is under

tension or compression, be alert for

springback.

2-5. MORE ABOUT KICKBACK

WARNING;

DANGER! BEWARE OF KICKBACK!

Kickback can lead to dangerous loss of

control of the chain saw and result in

serious or fatal injury to the saw operator

or to anyone standing close by. Always be

alert because rotational kickback and pinch

kickback are major chain saw operational

dangers and the leading cause of most

accidents.

Page 8

BEWARE OF:

ROTATIONAL KICKBACK (Figure 2-5A)

A = Kickback path

B = Kickback reaction zone

THE PUSH (PINCH-KICKBACK) AND

PULL REACTIONS (Figure 2-5B)

A = Puli

B = Solid objects

C = Push

2-5B

2-6, {DENTfFtCATtON OF SAFETY SYMBOLS

KICKBACK may occur when the NOSE or

TIP of the guide bar touches an object, or

when wood closes in and pinches

the saw chain in the cut.

Tip contact in some cases may cause a

lightening-fast reverse reaction, kicking the

guide bar up and back toward the operator.

PINCHING the saw chain along the

BOTTOM of the guide bar may PULL the

saw forward, away from the operator.

(See Fig. 2-5B “A")

PINCHING the saw chain along the TOP of

the guide bar may PUSH the guide bar

rapidly back toward the operator

(See Fig, 2-5B "C”).

Any of these reactions may cause you to

lose control of the saw, which could result

in serious personal injury.

A

WARNING! This chain saw can

be dangerous, careless or

improper use can cause serious

or even fatal injury.

Read and understand the

instruction manual before using

the chain saw.

Double insulated - When

servicing use only identical

replacement parts. Replace

damaged cord immediately.

To reduce shock hazard, do not

expose unit to water or operate

on wet ground.

Contact of the guide bar tip with

any object should be avoided. Tip

contact may cause the guide bar

to move suddenly upward and

backward, which may cause

serious injury.

Always use both hands when

operating the chain saw.

There may be other replacement

components for achieving

Kickback protection.

Hearing protection should be

worn.

Page 9

3 - ASSEMBLY INSTRUCTIONS

3-i. INTRODUCTION

This unit is designed for occasiona)

homeowner use and shouid not be used

for commercial purposes or subjected

to heavy continuous use.

Your new chain saw can be used for a

variety of projects such as cutting firewood,

making fence posts, leiling small trees,

limbing, pruning at ground level, and iighl

carpentry. Cut only wood or wood products

with your saw,

3-2. ASSEMBLY REQUIREMENTS

Your new chain saw will require adjust

ment of chain and filling the oil tank with

lubricating oil before the unit is ready for

operation. Do not start the saw motor until

the unit is properly prepared. Read all

instructions carefully. Do not install any

other size bar and chain than what is

recommended for your model,

3-3. GUIDE BAR/SAW CHAIN

INSTALLATION

CAUTION

Disconnect the chain saw from power

souce before checking or adjusting the

chain saw tension,

TO INSTALL GUIDE BAR & SAW CHAIN:

These instructions are for replacing a bar.

The unit is fully assembled when shipped.

NOTE: Always wear heavy gloves when

handling the saw chain.

1. Place power unit on flat surface.

2. Loosen knob (B) slightly by turning

knob counter-ciockwise and then turn

the chain tension ring (C) counter

clockwise to relief chain tension. To

remove the sprocket cover (A), turn

knob (B) counter-clockwise, (Fig, 3-3A)

3. Remove saw chain form around the

guide bar and the sprocket. Siide the

guide bar, with tension plate (D)

attached, from the unit. (Fig. 3-3B)

4. Remove screw (C) from the tension

plate (D) to remove it from the old bar

and attach it to the new bar. (Fig, 3-3B)

5. Spread the chain out with the cutting

edges (E) of the chain pointing in the

DIRECTION OF ROTATION.

(Fig. 3-3C)

To fit the chain links into the groove on

the guide bar, turn the tension plate (D)

counter-clockwise to the end. Install

the chain and bar on the power unit,

turn the tension plate (D) clockwise and

then put the side cover (A) on.

(Fig. 3-3D)

Turn the knob clockwise, adjust the

chain tension ring (F) and then tighterr

the knob. After running the chain saw

about for one (1 ) hour - retension the

chain, if needed, based on figure 3-4A,

Page 10

3~4. SAW CHAIN TENSION

ADJUSTMENT

Proper tension of the saw chain is extrem

ely important and must be checked before

starting, as well as during, any cutting

operation. Taking the time to make needed

adjustments to the saw chain will result in

improved cutting performance and

prolonged chain life,

NOTE: A new chain and bar will need

readjustment after as few as 5 cuts. This is

normal during the break-in period, and the

interval between future adjustments will

lengthen quickly (Figure 3-4A).

CAUTION

If a chain is TOO LOOSE or TOO TIGHT,

the bar chain and saw bearings will wear

more rapidly. Study Figure 3-4A for infor

mation concerning correct cold tension (A),

correct warm tension {B}, and as a guide

for when saw chain needs adjustment (C).

TO ADJUST SAW CHAIN TENSION:

With no tools system - wear gloves while

tensioning chain.

NOTE: Make sure the CHAIN BRAKE® is

disengaged. Disengage the CHAIN

BRAKE*^^ (D) by pulling it backward (Figure

3-4B),

1. Tensioning the chain is easy. Turn bar

boit knob (E) counter clock wise. Then

turn ring (F) counter clock wise to

loosen chain or clock wise to tighten

chain, (Fig, 3-4C)

2. After adjustment and while wearing

heavy duty work gloves, move the saw

chain back and forth on the guide bar

to be sure the chain moves freely and

is in proper mesh with sprocket,

NOTE: If the chain is difficult to rotate or if

it binds on the guide bar, too much tension

has been applied and must be adjusted as

described in step 1,

3. While tensioning the chain. Hold tip of

the bar up and then tighten the bar bolt

knob (E).

3-4 B

3-4C

3-5. FILLING OIL TANK

Using a funne!, fill oil tank with Genuine

Factory Parts Chain, Bar and Sprocket oil.

Wipe up any spills. Make sure no dirt gets

into the oil tank.

The saw chain requires lubrication while in

use to minimize friction with the guide bar.

The oi! tank holds 4.5 ozs of oli, enough to

lubricate the chain for 12-15 minutes of

sawing.

We recommend using Genuine Factory

Parts Chain, Bar and Sprocket Oil, which

contains additives to reduce friction

wear and reduce resin residue formations.

CAUTION

The oil tank level should be frequently

checked during operation to avoid starving

the bar and chain of lubrication.

NOTE: Your chain saw is equipped with an

Automatic Oiler system and is the ONLY

source of lubrication for the bar

and chain (Figure 3-5A).

OIL CAP

OIL TANK INSPECTION SLOT

3-5A

10

Page 11

3~6. SELECTING THE PROPER EXTENSION CORD FOR YOUR SAW MODEL

Minimum Gauge Wire

Saw Mode!

PLN3516F

The extension cord is to be for outdoor use, marked with the suffix W or W-A following

the cord type designation, for example - SJTW or SJTW-A.

Make sure the extension cord is in good condition before using.

Keep the cord away from the cutting area and to position cord so that it will not be

caught on branches, and the like, during cutting.

Ampere

Rating

13.5 120 16 Gauge 16 Gauge

Volts AC

25 ft. / 7.5m

Length of Power Cord

50 ft./15m

100 ft./30m

14 Gauge

4 - OPERATING INSTRUCTIONS

4-1. TO START SAW

1. Make sure the CHAIN BRAKE® IS

DiSENGAGED.The motor will not start

if the CHAIN BRAKE® is in the

ENGAGED position. Disengage the

CHAIN BRAKE® by pulling backward

toward the motor {Figure 4-1 A).

WARNING

Ensure the extension cord is of the proper

size and type for your saw,

2. An extension cord retainer (A) (Fig.

4-1B) is built into the rear handle that

prevents the extension cord from

pulling out of the handle. To use this

feature, simply double the extension

cord, about a foot from the end, and

insert it through the hole at the end of

the handle. Hook the loop formed by

doubling the cord over the tab. Gently

tug on the cord to ensure that it is firmly

retained in the saws handle. Plug the

receptacle end of the extension cord

into the tool’s power supply cord.

WARNING

Make sure the extension cord does not

come in contact with the guide bar and

saw chain.

3. Grip the saw with both hands, left hand

holding the front handle (DO NOT

HOLD CHAIN BRAKE®) and the right

hand holding the rear handle. Thumbs

and fingers should encircle both

handles (Figure 4-1C),

4. With your RIGHT THUMB, depress the

LOCt^OFF button (C) on the top of the

rear handle, and at the same time

squeeze the trigger. To stop the saw,

release the trigger (Figure 4-1D).

NOTE: It is not necessary to maintain

pressure on the LOCK/OFF button once

the trigger is squeezed and the motor is

running. The LOCK/OFF button is a safety

device to avoid accidental starting.

4-1D

11

Page 12

4-2. TO STOP MOTOR

The saw motor wiN automalicaily stop

when the trigger is released. The LOCK/

OFF button will have to be depressed and

the trigger squeezed to restart the motor.

4-3. CHAIN AND BAR LUBRICATION

Adequate iubrication of the saw chain

during cutting operations is essential to

minimize friction with the guide bar.

Your chain saw is equipped with an

automatic oiler system.

The oiler automatically delivers the proper

amount of oil to the bar and chain. There is

no flow adjustment,

The oif tank level can be checked in the

inspection slot {A} provided on the right

Side of the saw. Tank is full when oil is at

the top of the slot (Figure 4-3A).

CAUTION

Never starve the bar and chain of

lubrication oil. Running the saw DRY or

with TOO LITTLE OIL will decrease cutting

efficiency, shorten chain saw life, and

cause rapid dulling of the chain and

excessive wear of the bar from

overheating. Too iittie is evidenced by

smoke or bar discoloration.

NOTE: The saw chain stretches during

use, particuiarly when it is new, and

occasional adjustment will be needed.

A new chain requires more frequent

adjustment during the break-in period. This

is normal. See Section 3-4, Saw Chain

Tension Adjustment instructions,

WARNING / CAUTION

A loose chain can jump off the bar while

you are cutting, as well as wear the bar

and chain. A chain that is too tight can

damage the saw. Either situation, chain too

loose or too tight, could cause serious

personal injury.

4-3A

4-4. CHAIN BRAKB^ / HAND GUARD

This Poulan chain saw is equipped with

chain brake/hand guard.

The Hand Guard protects your left hand in

the event it slips off the front handle.

The CHAIN BRAKE® is a safety feature

which is activated if pressure is applied

against the guard or when, in the event of

kickback, the operator’s hand strikes the

lever. When the CHAIN BRAKE® is

activated, chain movement abruptly stops

and the power supply to the motor is

immediately cut off.

The purpose of the CHAIN BRAKE® is to

reduce the possibility of injury due to

kickback. The CHAIN BRAKE® cannot,

however, provide the measure of intended

protection if the saw is carelessly operated.

The CHAIN BRAKE® is disengaged (chain

can move) when the brake is pulled back

and locked. This is the norma! running

position (Figure 4-4A).

The CHAIN BRAKE® is engaged (chain

cannot move) when the brake is in forward

position (Figure 4-4B),

NOTE: The motor will not start if the

CHAIN BRAKE® is in the engaged

position.

CAUTION

The CHAIN BRAKE® should not be used

for starting and stopping the saw during

normal operation.

4-4B

CHAIN BRAKES TEST

Before cutting with your saw, the CHAIN

BRAKE® shouid be tested as follows:

A. Make sure the CHAiN BRAKE® is

disengaged (Figure 4-4A).

B,

Place the saw on a firm, flat, dry

surface that is clear of any debris. Do

not let the saw come in contact with

any objects.

Plug the unit into the power source.

Grasp the front handle (not the CHAIN

BRAKE*/Hand Guard Lever) with your

left hand. Thumb and fingers should

encircle the handle.

12

Page 13

E. Grasp the rear handle with your right

hand. Thumb and fingers should

encircle the handle,

F. Depress the LOCK/OFF button with

your right thumb. Squeeze the trigger

with your index finger. (See Fig.4-1D).

G. While the motor is running, activate the

CHAIN BRAKE® by rolling your left

hand forward against the lever.

H. Chain and motor should stop abruptly.

WARNING

If the chain and motor fail to stop when the

CHAIN BRAKE® is engaged, take the saw

to the nearest Authorized Service Center.

Do not use the saw if the CHAIN BRAKE®

is not in proper working order.

4~5. EXTENSION CORDS

When using an electric chain saw, plug it

into the extension cord oniy when you are

ready to cut wood. Connect the extension

cord to a 110/120 voltage outlet, see chart

CAUTION

A cord that is hot to the touch is

overloaded.

WARNING

Do not operate your chain saw in a wet or

damp environment. Do not expose the saw

to rain, snow or sleet, Moisture will cause

short circuits. Replace or repair any

damaged or frayed extension cords before

using your saw. Keep the cord away from

the cutting area and position the cord so

that it will not be caught on branches or

other objects during cutting.

DOUBLE INSULATION ©WHEN

SERVICING USE ONLY IDENTICAL

REPLACEMENT PARTS

Do not use if the cord or plug is damaged.

Your appliance is double insulated to help

protect against electric shock.

Double insulation construction consists of

1wo(2) separate ‘layers" of electrical

insulation.

Appliances built with this insulation system

are not intended to be grounded. As a

result, the extension cord used with your

appliance can be plugged into any

conventional 120 volt electrical outlet.

Normal safety precautions must be

observed when operating an electrical

appliance. The double insulation system is

only for added protection against injury

resulting from a possible internal electrical

insulation failure,

WARNING

Your double insulated appliance has no

serviceable parts inside. Do not attempt to

repair it yourself. For service information,

contact the Poulan Product Service

Department tolFfree number listed on the

back cover of this manual.

5 - GENERAL CUTTING INSTRUCTIONS

5-1. FELLING

Felling is the term for cutting down a tree.

Small trees up to 6-7 inches (15-18cm) in

diameter are usually cut in a single cut.

Larger trees require notch cuts. Notch cuts

determine the direction the tree wiil fall.

FELLING A TREE:

WARNING

A retreat path (A) should be planned and

cleared as necessary before cuts are

started, The retreat path should extend

back and diagonally to the rear of the

expected line of fall, as illustrated in Figure

5-1 A.

CAUTION

If felling a tree on sloping ground, the chain

saw operator should keep on the uphill

side of the terrain, as the tree is likely to

roll or slide downhill after it is felled.

NOTE: Direction of fall (B) is controlled by

the notching cut. Before any cuts are

made, consider the location of larger

branches and natural lean of the tree to

determine the way the tree will fail.

WARNING

Do not cut down a tree during high or

changing winds or if there is a danger to

property. Consult a tree professional.

Do not cut down a tree if there is a danger

of striking utility wires; notify the utility

company before making any cuts.

GENERAL GUIDELINES FOR FELLING

TREES:

Normally felling consists of two (2) main

cutting operations, notching (C) and

making the felling cut (D). Start making the

upper notch cut (C) on the side of the tree

facing the felling direction (E). Be sure you

don’t make the lower cut too deep into the

trunk.

13

Page 14

The notch (C) should be deep enough to

create a hinge (F) of sufficient width and

strength. The notch should be wide

enough to direct the fall of the tree for as

long as possible.

WARNING

Never walk in front of a tree that has been

notched.

Make the felling cut (D) from the other side

of the tree and 1.5 - 2.0 inches (3~5 cm}

above the edge of the notch (C)

{Figure 5-1B),

Never saw completely through the trunk.

Always leave a hinge. The hinge guides

the tree. If the trunk is completely cut

through, control over the felling direction is

lost.

insert a wedge or feiling lever in the cut

well before the tree becomes unstable and

starts to move. This will prevent the guide

bar from binding in the feiling cut if you

have misjudged the falling direction. Make

sure no bystanders have entered the range

of the tailing tree before you push it over.

WARNING

Before making the final cut, always

recheck the area for bystanders, animals

or obstacles,

FELLING CUT:

1. Use wooden or plastic wedges (G) to

prevent binding the bar or chain (H) in

the cut. Wedges also control felling

(Figure 5-1C).

2, When diameter of wood being cut is

greater than the bar length, make 2

cuts as shown (Figure 5-1D),

WARNING

As the feiling cut gets dose to the hinge,

the tree should begin to fall. When tree

begins to fall, remove saw from cut, stop

engine, put chain saw down, and leave

area along retreat path (Figure 5-1 A).

I i|"^

a a^-4 _ t

i'JlZ

.

' '[Bi c

u. .

5-1B

5-1C

5-2. LIMBING

Limbing a tree is the process of removing

the branches from a fallen tree. Do not

remove supporting iimbs (A) until after the

log is bucked (cut) into lengths (Figure

5-2A). Branches under tension should be

cut from the bottom up to avoid binding the

chain saw.

WARNING

Never cut tree limbs while standing on tree

trunk.

5-3. BUCKING

Bucking is cutting a fallen log into lengths.

Make sure you have a good footing and

stand uphill of the log when cutting on

sloping ground. If possible, the log should

be supported so that the end to be cut off

is not resting on the ground. If the log is

supported at both ends and you must cut

in the middle, make a downward cut

halfway through the log and then make the

undercut. This will prevent the log from

pinching the bar and chain. Be careful that

the chain does not cut into the ground

when bucking as this causes rapid

dulling of the chain.

14

Page 15

When bucking on a slope, always stand on

the uphill side.

1. Log supported along entire length; Cut

from top (overbuck), being careful to

avoid cutting into the ground (Figure

5-3A).

2. Log supported on 1 end: First, cut from

bottom (underbuck) 1/3 diameter of log

to avoid splintering. Second, cut from

above (overbuck) to meet first cut and

avoid pinching (Figure 5-3B).

3. Log supported on both ends: First,

overbuck 1/3 diameter of log to avoid

splintering. Second, underbuck to meet

first cut and avoid pinching (Figure

5-3C).

NOTE: The best way to hold a log while

bucking is to use a sawhorse. When this is

not possible, the log should be raised and

supported by the limb stumps or by using

supporting logs. Be sure the log being cut

is securely supported.

5-3C

5^4. BUCKING USING A SAWHORSE

For personal safety and ease of cutting,

the correct position for vertical bucking is

essential (Figure 5-4A).

VERTICAL CUTTING:

A. Hold the saw firmly with both hands

and keep the saw to the right of your

body while cutting.

B. Keep the left arm as straight as

possible.

C. Keep weight on both feet.

CAUTION

While the saw is cutting, be sure the chain

and bar are being properly lubricated,

6 - BAR/CHAIN MAINTENANCE

6-1. GUIDE BAR MAINTENANCE

WARNING

Ensure that the power cord is disconnect

ed before performing any maintenance on

your saw.

Proper maintenance of the guide bar, as

explained in this section, is essential to

keep your saw in good working order.

SPROCKET TIP LUBRICATION:

(For units supplied with sprocket tip guide

bars only.)

CAUTION ©

Failure to lubricate the guide bar sprocket

tip as explained below will result in poor

performance and seizure, voiding

the manufacturer’s warranty.

Lubrication of the sprocket tip is recomme

nded after each saw use. Always

thoroughly clean the guide bar sprocket tip

before lubrication.

Tool for lubrication: Poulan Lube Gun

(disposable)

This grease gun is designed to fit the small

lubrication point on the guide bar.

The disposable Lube Gun is packed with

grease. For information on where to

purchase a lube gun, contact the Poulan

Product Service Department toll-free

number listed on the back cover of this

manual.

15

Page 16

TO LUBRICATE SPROCKET TIP:

WARNING

Wear heavy duty work gloves when

performing this application

to reduce risk of personal injury,

1, Unplug the chain saw from the power

source.

NOTE: It is not necessary to remove the

saw chain to lubricate the guide bar

sprocket tip. Lubrication can be done on

the job,

2. Clean the guide bar sprocket tip.

Using disposable Lube gun, insert tip

3.

of lube gun into the lubrication hole and

inject grease until it appears at the

outside edge of the sprocket tip (Figure

6-1 A).

4.

Make sure that the CHAIN BRAKE® is

deactivated. Rotate the saw chain by

hand. Repeat the lubrication procedure

until the entire sprocket tip has been

greased.

OIL PASSAGES - Oil passages at bar pad

should be cleaned to ensure proper

lubrication of the bar and chain during

operation. This can be done using a soft

wire small enough to Insert into the oil

discharge hole,

NOTE: The condition of the oil passages

can be easily checked. If the passages are

clear, the chain will automatically give off a

spray of oil within seconds of starting the

saw.Your saw is equipped with an

automatic oiler system.

TO CLEAN GUIDE BAR RAILS:

1. Remove sprocket cover, bar and chain,

(see Section 3-3)

2. Using a screwdriver, putty knife, wire

brush or other similar instrument, clear

residue from the rails on the guide bar.

This will keep the oil passages open to

provide proper lubrication to the bar

and chain (Figure 6-1B).

3. Reinstall the bar, chain, sprocket cover

and bar bolt knob. (See Section 3-3),

aUlDE BAR MAINTENANCE

Most guide bar problems can be prevented

merely by keeping the chain saw well

maintained.

Incorrect filing and non-uniform cutter and

depth gauge settings cause most guide bar

problems, primarily resulting in uneven bar

wear. As the bar wears unevenly, the rails

widen, which may cause chain clatter and

difficulty in making straight cuts.

Insufficient guide bar lubrication and

operating the saw with a chain that is TOO

TIGHT will contribute to rapid bar wear

(see Section 6-2).

To help minimize bar wear, the foiiowing

guide bar maintenance is recommended.

BAR WEAR - Turn guide bar frequently at

regular intervals (for example, after 5 hours

of use), to ensure even wear on top and

bottom of bar.

BAR GROOVES - Bar grooves (or rails

which support and carry the chain) should

be cleaned if the saw has been heavily

used or if the saw chain appears dirty.

Rails should always be cleaned every time

the saw chain is removed.

6-2. CHAIN MAINTENANCE

INSTRUCTIONS

WARNING

Unless you have experience and specializ

ed training for dealing with kickback (see

Safety Precautions), always use a lowkickback saw chain, which significantly

reduces the danger of kickback. Low-kickback saw chain does not completely

eliminate kickback, A low-kickback or

"safety chain", should never be regarded

as total protection against injury.

A low-kickback saw chain should always

be used in conjunction with other kickback

protection devices such as the CHAIN

BRAKE®/Hand Guard furnished with your

unit.

Always use a replacement saw chain

designed as “low-kickback" or a saw chain

which meets the iow-kickback performance

requirements of ANSI (American National

Standards Institute).

A standard saw chain (a chain which does

not have the kickback reducing guard

links) should only be used by an experien

ced professional chain saw operator.

16

Page 17

WHAT IS A LOW-KICKBACK SAW

CHAIN?

A low-kickback saw chain is a chain which

has met the kickback performance

requirements of ANSI B175,1.

By keeping the CHAIN BRAKES and saw

chain in good working condition and

correctly serviced as recommended in this

manual, you will be able to maintain the

safety system of your chain saw over the

life of the product.

WARNING

Never remove, modify or make inoperative

any safety device furnished with your unit.

The CHAIN BRAKE®/Hand Guard and

low-kickback saw chain are major safety

features provided for your protection.

WARNING

Always wear heavy duty protection work

gloves and disconnect the extension cord

when working on the saw chain.

CHAIN TENSION:

Check the chain tension frequently and

adjust as often as necessary to keep the

chain snug on the bar, but loose enough to

be pulled around by hand. (See Section

3-4, Saw Chain Tension Adjustment).

BREA KING IN A NEW W CHAIN

A new chain and bar will need readjust

ment after as few as five (5) cuts. This is

normal during the break-in period, and the

interval between future adjustments will

begin to lengthen quickly.

Over a period of time, however, the moving

parts of the saw chain will become worn,

resulting in what is called CHAIN

STRETCH. This is normal. When it is no

longer possible to obtain correct chain

tension adjustment, a link will have to be

removed to shorten the chain. See your

nearest Authorized Service Center to have

this repair performed.

WARNING / CAUTION

Never have more than three (3) links

removed from a loop of chain. This could

cause damage to the sprocket.

CHAIN LUBRICATION:

Always make sure the automatic oiler

system is working properly, Keep the oil

lank fiiled with Genuine Factory Parts

Chain, Bar and Sprocket Oil.

Adequate lubrication of the bar and chain

during cutting operations is essential to

minimize friction with the guide bar.

Never starve the bar and chain of

lubricating oil. Running the saw dry or with

too little oil will decrease rapid cutting

efficiency, shorten saw chain life, cause

rapid dulling of the chain, and lead to

excessive wear of the bar from

overheating. Too little oil is evidenced by

smoke or bar discoloration.

7 - PREVENTIVE MAINTENANCE

7-1. PREVENTIVE MAINTENANCE

WARNING©

SERVICING A DOUBLE INSULATED

APPLIANCE

In this double insulated appliance. 2

systems of insulation, instead of

grounding, are provided. No grounding

means is provided on a double insulated

appliance, nor should a means for

grounding be added to the appliance. No

serviceable parts are inside. A double

insulated appliance is marked with the

words, “DOUBLE INSULATION" or

"DOUBLE INSULATED", The symbol m

(square within a square) may also be

marked on the appliance.

1, Place switch in OFF position and

unplug the power supply before the

appliance is serviced, cleaned, or

maintenance is performed.

2, Keep the air intake clean and air vents

free of debris to avoid overheating the

motor.

3, Clean with a damp sponge and miid

soap. Do not squirt with a water hose

or douse with water or other liquids,

4, Inspect the saw chain for proper

tension before each use and frequently

during cutting. Sharpen as required.

5, Clean the guide bar and bar pad to

ensure free path for oil.

6, Turn the bar over after each use to

achieve even wear.

7, No motor lubrication is necessary. The

motor is equipped with lifetime

lubricated bearings.

17

Page 18

8. If the saw does not operate, turn switch

to OFF position and disconnect the

extension cord, first from the power

supply, then from the saw. Check the

power supply for blown fuses or tripped

circuit breakers, if it stiil does not

7-2. CHAIN REPLACBM£NT INFORMATION

Drive

Links

55 DL 966-051301

There may be other quality equivalent replacement components for achieving kickback

protection.

Bar

Length

16" 966-051603

operate, contact the Poulan Product

Service Department, through the toll-

free number listed on the back cover of

this manual, for service information. Do

not attempt to repair It yourself. No

serviceable parts are inside.

Chain

P/N Length

16"

Gauge

0.05

Pitch

3/8"

8 - LIMITED WARRANTY

Poulan, a division of Husqvama Consumer Outdoor Products N,A,. Inc., warrants to the original

consumer purchaser that each new Poulan brand electric or cordless product is free from

defects in materia! and workmanship and agrees to repair or replace under this warranty any

defective Poulan brand electric product within one (1) year from the originai date of purchase.

If your Poulan brand electric or cordless product should faif within the limited warranty period,

you may return it in complete condition, prepaid, with proof of purchase to the dealer from whom

it was purchased for repair or replacement at the optiori of Poulan.

This warranty is not transferable and does not cover damage or liability caused by improper

handling, improper maintenance or alteration, or the use of accessories and/or attachments not

specifically recommended by Poulan for this product. This warranty does not cover parts that will

wear and require replacement with reasonable use during the warranty period. This warranty

does not cover pre-delivery setup or normal adjustments explained in the instruction manual.

Should you have any unanswered questions regarding this warranty, please contact:

Poulan, a division of Husqvama

Consumer Outdoor Products N.A.

1030 Stevens Creek Road

Augusta, GA 30907

1-800-554-6723

Inc.

In Canada, contact:

Poulan

850 Matheson Blvd. West

Mississauga. Ontario L5V 0B4

Giving the model number, serial number and date of purchase of your product and the name and

address of the authorized dealer from whom it was purchased,

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY HAVE OTHER

RIGHTS WHICH VARY FROM STATE TO STATE.

NO CLAiMS FOR CONSEQUENTIAL OR OTHER DAMAGES WILL BE ALLOWED, AND

THERE ARE NO OTHER EXPRESS WARRANTIES EXCEPT THOSE EXPRESSLY

STIPULATED HEREIN.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS OR THE EXCLUSION OR LIMITATIONS OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATIONS OR EXCLUSION MAY NOT APPLY TO YOU.

This is a limited warranty within the meaning of that term as defined in the Magnuson-Moss Act

of 1975.

The policy of Poulan is to continuously improve its products. Therefore, Poulan reserves the

right to change, modify, or discontinue models, designs, specifications, and accessories of all

products at any time without notice or obligation to any purchaser.

18

Loading...

Loading...