Poulan Pro P3314, P3314WS, P3314WSA, P3416, P3516PR Instruction Manual

...

Poulon

?

I

Manual de

Instrucciones

Man uel d'l

nstructions

P331

4

lP3314WS /

P3314WSA

P3416

/

P3516PR

/

P4018WM

P4O18WT

/

P3818AV

P4O1

8AV

/

P4O1 8AV

BH

For Occasional

Use

Only

WARNING:

Read

and

follow

all Safety

Rules and Operating

Instructions before

using

this

product.

Failure

to do so can

result

in

serious

injury.

ADVERTENCIA:

Lea

el

manual de instrucciones

y

srga

todas

las

advertencias

e en-

strucciones

de seguridad.

El no hacerlo

puede

resultar en

lesiones

graves.

AVERTISSEMENT

Lire

le manuel d'instructions

et bien

respecter

tous les avertisse-

ments

et

toutes

les instructions de

s6curit6.

Tout d6faut de

le

faire

oourrait entrainer

des blessures

oraves.

Please

do

not return

product

Por

favor,

no

devuelva

el

pro

Veuillez

ne

pas

retourner

le

P

1

-800-55

Register

your

product

online

Registre

su

producto

en

linei

Enregistrez

votre

produit

en

www.pou

Instruction

Manual

luct

to retailer.

producto

al

lugar

de

compra.

le

produit

au d€taillant.

,554-6723

line at:

inea en:

en

ligne d

I'adresse :

oulan.com

Poulan

9335

Harris Corners

Parkway

Charlotte,

NC 28269

Poulan

850

Matheson Blvd.

West

Mississauga, Ontario

L5V 084

545186804

Rev.

B

1131111

BRW

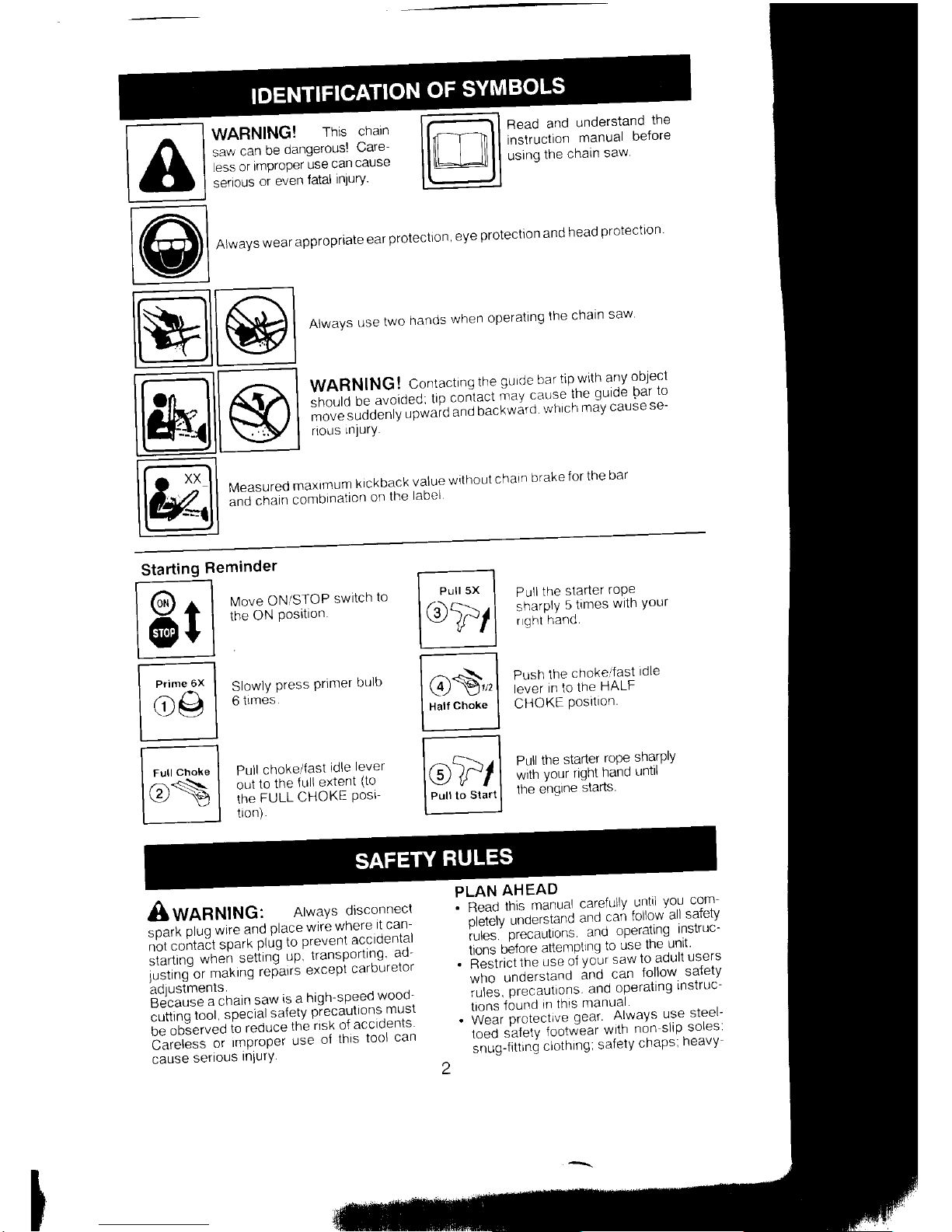

f-- ----l WARNING!

rhis

chain

lAl*r*1"'"AffiHH"1s

Read

and

understand

the

instruction

manual

before

using

the

chain

saw

t@

Alwavs

wear

appropriate

ear

protection

'

eve

protection

and

head

protectron

l-rll ,^. 1

ll$lll

W

I

o'**'

usetwo

hands

when

operatinsthechain

saw

:-,

I r.;l Il,<a I

HffiI;)Fix":.ilil1?fl

#i#i:Ti#;5!g"x,#is

l@lls)l

.usniurv

@

Measured

maxlmum

klckback

value

without

chaln

brake

for

the

bar

and chatn

combrnallon

or

lne

lannl

Starting

Re

E

ffiil

p9

ffil

le>

minder

Move

ON/STOP

switch

to

the

ON

Posltron

Slowly

Press

Primer

bulb

6

times.

Pull

choke/fast

idle

lever

oul

to

the

{ull extent

(to

the

FULL

CHOKE

Post-

lron).

Pull

the

starter

rope

sharply

5

times

wltn

Your

r

ght

hand.

Push

the

chokeltast

idle

lever

in

to

the

HALF

CHOKE

Posrtron

Pull

the

starter

rope

sharply

with

your rlght

hand

untll

the

engine

starts

f-",,';1

Ptr4

[t-s'l

I

Hattct'"t"

I

r-^ I

l@ld/l

I

Pulr

to

slart

I

AWnnNlHCl

AlwaYsdisconnect

;*ti

ptuc

wire

and

place

wire

where

rt

can

:ii?::t *i:f 4'l;*

L?'srul

s:

:;3"

:51

rrtt

"g

ot'

makrng

refarrs

excepl

cclrbLrrelor

B?iiHSi'in'

"

:?yr:^?,19:;:l?,:l$:i,

cuttinq

tool,

special

salety

Pre

[E'oO3"i*Oio

reduce

the

rrsh

o{ accidents

b'";#;.';;

,*PtoP"t

use

of

this

tool

can

cause

serious

InlurY

PLAN

AHEAD

'

3,:i"t'|,:.#;xi

:i;",'jx':il'-':il

;"'$;

i*:,:r,r*,:n;,

i!

1"

"j,?il:n;if

""

.

ii""tii"itn"

use

oi

your

saw

to adult

users

m:,

*,*:li

::,

;:l,

""il

;lii"l

f#:Y

.

ilVil

3iJ,!ryi

lfj,fu;

i,?0"

jL""l,

:""","

:

il

:.J J

:"ltY"?',Hi!!u

"

n uo,,

n " uu

u

'"t&;;"::

.

Wnn

the

enqrne

stopped.

hand carry

the

chair

saw

with

the

muffler

away

from

your

oodv,

and

the

quide

bar

ano

chain

to

the

rear preferabry-covered

wilh a scabDard

MAINTAIN

YOUR

SAW

IN GOOD

WORKING

ORDER

.

Have a

I chain

saw

service

performed by a

oual

fiecj

service

dealer

with

the

exception

o'f

the

rtems llsted

in the

mainlenance

sec

t on

of

thrs

manual.

Forexample,

if improp

er

tools

are

used

to

remove

or

hold

the

fly-

wheeLwhen

servicrng

the clutch.

structural

damaqe

to

the

ilytheel

can

occur

and

cause"the

flywheel

to burst

.

Ma^e

cerlarn

1fc saw

chaln

slops

moving

when

the

throttle

trigger

is

released

For

correction.

refer to

CARBURETOR

AD-

JUSTMENT.

.

Never

modify

your

saw

in any

way

.

Keepthe

handles

dry.

clean.

andfree

o{oil

or

{uel

mtxture.

.

Keep

fuel and

orl

caps.

screws,

and

fas

teners

securelY

tightened

.

Use

only

Poulan

accessories

and

r-eplace

ment

parts

as

recommended

HANDLE

FUEL

WITH CAUTION

.

Do

not smoke

while

handling

fuel

or

while

ooeratlnq

the saw.

.

Eliminateall

sources

of

sparks

orflame

in

the areas

where

fuel

is

mixed or

poured

There should

be

no smoking,

open

f lames,

or

work

that

could

cause

sparks

Allow

en

qine

to cool

betore

relueltng.

.

Always

have

fire extinguishlng

tools

avall-

able

it

vou

should

need

them

.

Mix and

pour

fuel in an

outdoor

area

on

bare

ground,

store

fuel

in a cool,

dry,

well

ventilated

place.

and

use

an

approved,

marked

container

for

all

fuel

purposes'

Wipe

up

allluel

spills

before

starting

saw

.

H,'tove at

least

1O

feet

(3

melers)

from

fuel-

inq site before

starting

englne.

.

Tu"rn

the

enqine

off and

let saw

cool

in

a

non'combustible

area,

nol on

dry

leaves'

straw,

paper,

etc.

Slowly

remove

fuel

cap

and

refuel

unit.

.

Storetheunitandfuel

in

anareawherefuel

vaDors

cannol

reach

sParhs

or

open

Ilames

{rom waler

heaters

electrlc

motols

or switches,

lurnaces,

etc.

KICKBACK

A wnnrutrucl

Avoid

kickback

which

can

result

in serious

iniury.

Kickback

is

the

backward,

upward

or sudden

forward

motion

of

lne

quide

bar occurrrng

when

lhe saw

charn

near

the upper

llp of the

gulde

bat

con

tacts

anv

obiect

such

as a

log or

branch,

or

when

th-e

w6od

closes

in and

pinches the

saw chain

in the cut.

Contacting

a

foreign

ob-

ject

in the

wood

can also

result

in

loss ol

chain saw

control.

.

Rotational

Kickback

can

occur

when

the

movinq

chain

contacts

an obiect

at the

upper

tiD

of the

quide

bar.

This contact

can

cause

tAe chain

jo

dig

into the

object,

which

stops

the chain

for an

instant.

The

result

is a

light-

ninq fast.

reverse

reaction

which

kicks

the

guide

bar

up

and back

toward

the operator'

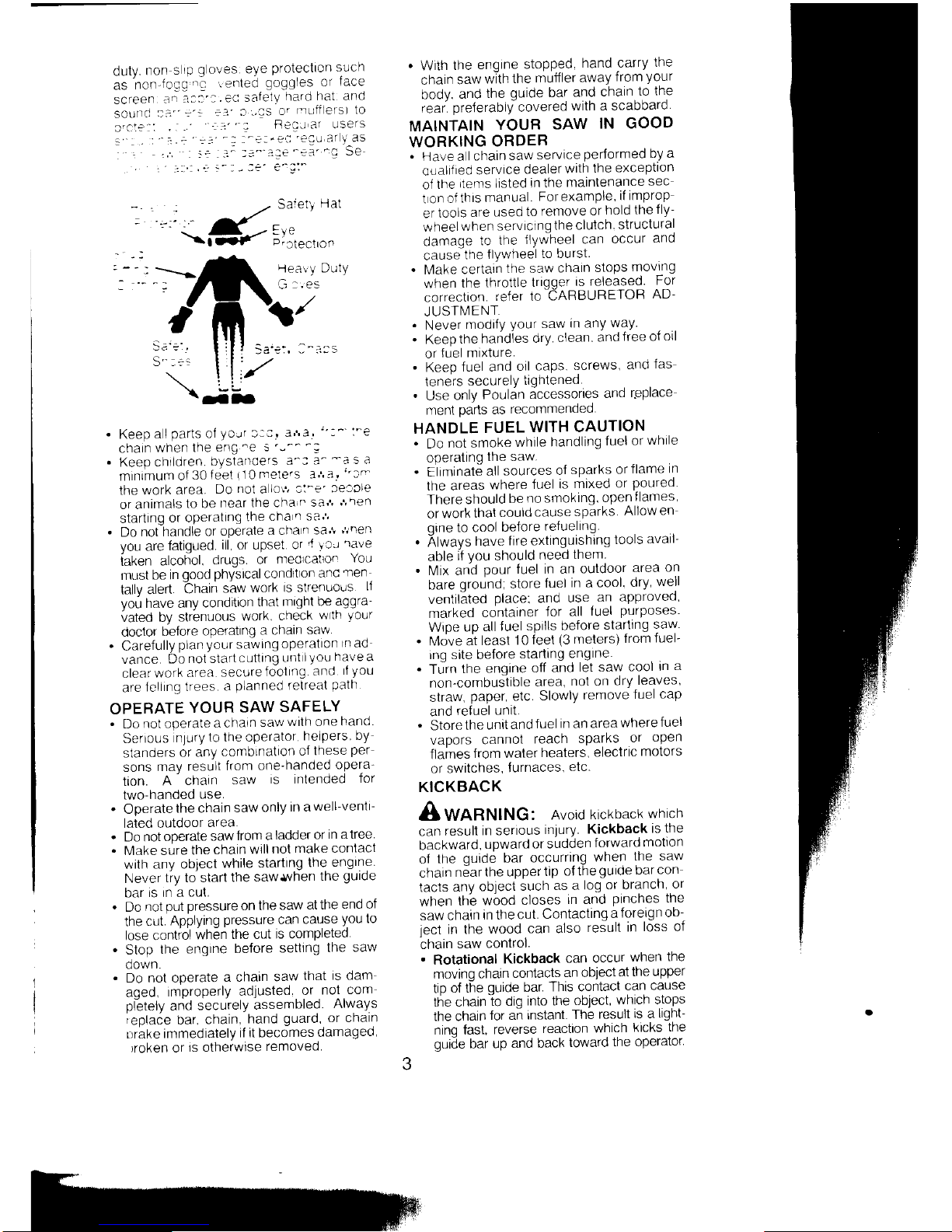

lealy Duty

G:.es

.

Keep

a I

parts

of

your

l::'

3r,e.

":^'

:'e

charn

when

the

eng'e

s

'--^'-:

.

Keep

chtldren.

bystarroers

a^:

3-

-a

s a

minamum

of

30 f eet

i1O

melers ar.

a,

"io

the work

area.

Do

not

a

lo\1

cl-e'

leacle

or animals

to be

near

the cha

n

saJ'

J''en

starting

or operatlng

the

cna

I

sa'1

.

Do

not handle

or

operate

a cna

n

sa'!

r/nen

you

are

fatigued.

ill, or upset

or

'l

lcr

rave

taken

alcohol.

drugs.

or

nreolcalron

You

must

be in

good

physical conditron

anc

ren

tallv alen.

Chain

saw

work

ls strenuous

ll

vou

have anv

conditron

that

nrlght

i)e aggra'

vated by

strbnuous

work.

check

wrth

your

doclor

before

opP'atlng

a

chain

sa*

.

Carefully

plan

your

sawlng

operatlon

rn

ad

vance.

Do

not startcuttlng

unt

I

you

nave

a

clearwork

area.

securefootlng.

and

f

you

are

fcll

ng trees.

a

planned

retreat

path

OPERATE

YOUR

SAW

SAFELY

.

Do

not operate

achaln

sawwlth

one

nano

Serrous

nlury

to the operator

helpers

by

standers

or any

comblnation

of Ihese

per

sons

may

result

lrom

one'nandeo

opera-

tion.

A-

chain

saw

is intended

for

two-handed

use.

.

Operate

the chain

saw

only

in a

well-ventl-

lated outdoor

area.

.

Do not

operate

sawfrom

a

ladder

or

in atree

.

[,4ake sure

the

chain

will

nol

make conlact

with

any object

while

startlng

the

engine.

Never

tiy to start

the

saw,lvhen

the

guide

Dar

rs In a

cut.

.

Do

not

put pressure on the

saw

at the

end ot

the

cut.

Applying

pressure

can

cause

you

10

lose contiol

when

the cut

is completed

.

Stop

the

engtne

before

setting

the

saw

oown.

.

Do not operate

a chain

saw

that

is dam

aged,

improperly

adjusted

or

nol

com

pletely

and

securely

assembled

Always

iepla6e

bar.

chain,

hand

guard, or chain

Luhke

immediately

if it becomes

damaged,

)roken or

is otherwise

removed

.a-

.

Pinch-Kickback

can

occur

when

the

the

wood

closes

in and

prnches the

moving

saw

chain

in the

cut

along

the

top of

the

oriOe

nar.

and

the

saw

chain

is suddenly

dtoooed.

This

sudden

stopping

of

the

chdrh

results

in a

reversal

of

the

chaln

force

used

to cut

wood

and

causes

the

saw

to

move

in the

opposite

direction

ol

the

chain

rotation.

The saw

is driven

stralght

back

toward

the

oPerator.

.

Pull-ln

can

occur

when

the

movlng

cnaln

contacts

a

foreign

object

In

the

wood

In

the

cut

alonq

the bottom

ol

the

guide bar

and

the

saw

chaln

is suddenly

stopped

This

sudden

slooDino

pulls

lhe saw

forward

and

away

lrom thd ooerator

and

could

eas

ly cause

the

operator

to

lose

conlrol

of the

saw

Avoid Pinch-Kickback:

.

Be

extremely

aware

ol sltuallons

o'

ob

itructions

that

can

cause

material

to

pinch

the

top

of or

otherwise

stop

the chaln

.

Do

not

cut

more

lhan

one

log at

a llme

.

Do

nol

twist

the

saw

as

the

bar

is with-

drawn

from an

undercut

when

bucklng

Avoid

Pull-ln:

.

Always

begin

cutting

with

the

engine

at

iull

speeil

and"lhe

saw

6ousing

against

wood

.

tjse wedoes

made

of

plastic

or

wood'

Never

use

metal

to hold

the

cut

open'

.

Beqin

and

continue

cutting

at

full speed

lf

the"chain

is

moving

at

a

slower

speed,

there

is

greater chance

of

kickback

occur-

ring.

.

Cut

one

loq at a

ttme.

.

Use extrefte

caution

when

re entering

a

Drevrous

cut.

.

bo

not attempt

cuts

slartinq

with

the tip

of

the bar

(olunqe

cuts).

.

Watch

for

snitting

logs

or other

forces

lhal

could

close

a cut-and

pinch

or

fall into

chatn

.

Use

the

Reduced-Kickback

Guide

Bar

and

Low

Kickback

Chain

specified

for

your saw.

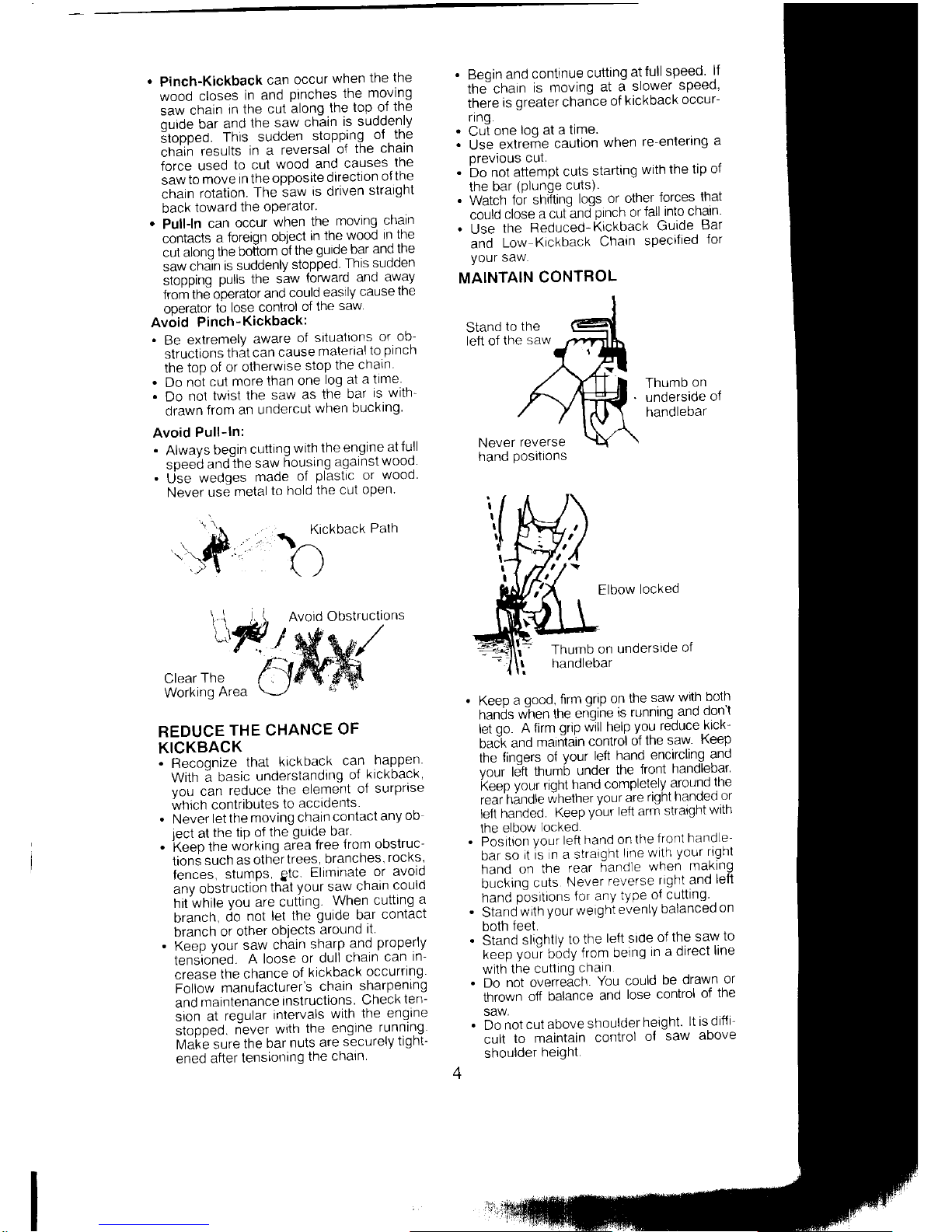

MAINTAIN

CONTROL

Stand

to

the

left of

the

saw

Thumb

on

underside

of

handlebar

Ki.k

\^"

/)

."+[

back

Path

Avoid

Obstructions

Elbow

locked

Thumb

on

underside

ol

handletlar

Clear

The

Working

Area

REDUCE

THE CHANCE

OF

KICKBACK

.

Recoonize

lhat

krckback

can

happen

With

; basic

underslanding

of

hickbach

Vou

can

reduce

the

element

of

surprlse

which contributes

lo

accidents

.

Never

let the

moving

chain

contact

any

ob

iect

at

the

tip o{

the

gurde bar'

.

keep

the

wbrking

area

free

from

obstruc-

tion; such

as

othertrees,

branches,

rocks,

fences,

stumps,

gtc.

Eliminate

or avold

anv

obstruction

that

your

saw

chain

could

hit while

you

are

cutting.

When

cutting

a

branch,

cio

not

let

the

guide

bar

contact

branch

or

other

objects

around

il

.

Keeo vour

saw

chain

sharp

and

propeny

tensioheO.

A loose

or

dull

chain

can

in-

crease

the chance

of

kickback

occurring

Follow

manufacturer's

chain

sharpening

and

maintenance

instructions

Check

ten-

sron

at

reqular

inlervals

with the

engine

stopped.

riever

wrth

the

engrne

running

Makb sure

the

bar

nuls

are

securely

tight-

ened

after

tensiolring

the

chaln

Keeo a oood.

fttm

qnp

on

lhe

saw

wilh

bolh

frinOs

w"fren

the

en-qine

rs runnlng

and

dont

let

oo.

A lirm

qrrp

wlll help

you reduce

kick'

baci and

marn]lain

control

ol

lhe saw

Keep

the

finoers

o{

Vour

left

hand

encircling

and

vour

leit

thumb

under

the

front

handlebar'

keep

yort

right

hand

completely

around

the

rear'hindle

whether

your

are

rlqht handecl

or

lefl

handed.

Keep

youl

left

arm

straront

wrln

the

elbow

locked.

'

Position

Vour

left

hand on

the

front

handle-

bar

so

it ls

n a straiqht

line

wlth

your rlgnl

hand

on

the

rear

6and1e

when

making

bucking

cuts

Never

reverse

right

and

lefi

hand

p"ositions for any

type

of cutting

.

Stand

with

your

weighi

evenly

balanced

on

both

teet.

.

Stand

sliohtlv

to

the

left side

of

the saw

to

keep

you-r

b6dy

from

being

in

a direct

line

wilh

the

cutttnq

cnaln

.

Do

not overreach.

You

could

be drawn

or

thrown

off

balance

and

lose

control

of

the

SAW,

.

Do

not

cut above

shoulder

height.

lt is difii-

cult

to

maintain

control

o{

saw

above

shoulder

height.

Never

reverse

hand

postlions

KICKBACK

SAFETY

FEATURES

A wnnHtxC:

ire for

owrng

features

. :+: i - . : -' sa*

to

l^e

p

'educe

the

:: :- L' . :.:a:'

^:r'/ever

SUCh

features

'-.

. z

- -3:e

ln s danger.

As a

'

:

-

-:r,

-s€- ::^al

.eiyonlyonsafetyde

':-

--s:'olow

all safety

Precau-

-

-

!1':31'r-S

and

maintenance

In this

..

-1

'-

'e

c

avord

kickback and

other

:-

.r

- : ^

: an

.esl,lt

in

senous

Inlirry.

.

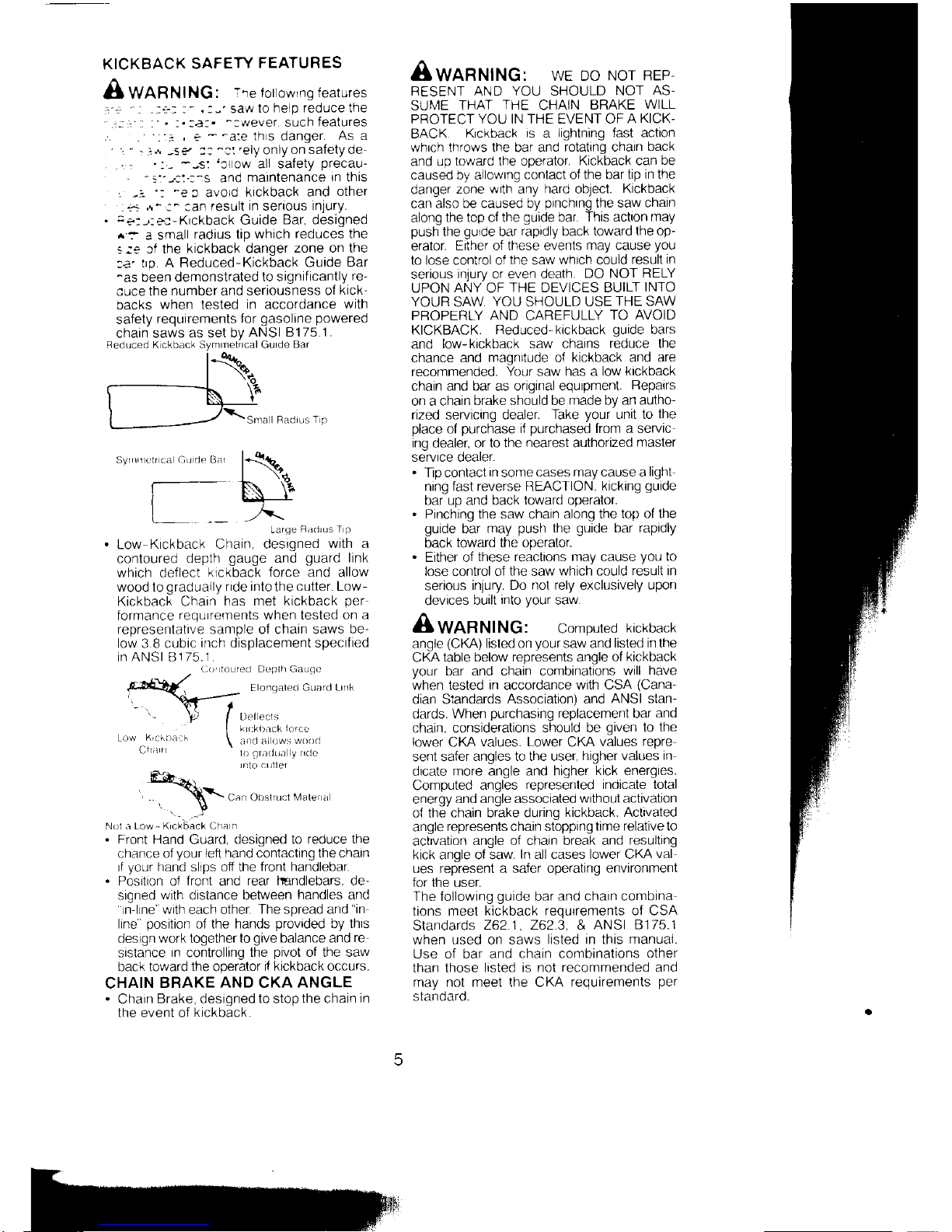

:+:-,:e:-Krckback

Guide

Bar, designed

^:

a small

radius tip which

reduces the

s:s

Jf the

kickback danger

zone on the

:a'

tro. A Reduced-Kickback

Guide

Bar

^as

been demonstrated

lo significantly

re-

cuce the

number and seriousness

of

kick-

backs

when lesled

in

accordance

with

salety

requirements

for

gasoline

powered

chain saws

as set by

ANSI 81 75.1

.

Feduced

K ckback SVmmetrrcal Gurde

Bar

Syrrlrrrclr ca Cu.ie

Bar

Larqe

Radlus T

P

Low

Kickback Chain, designed

with a

contoured

depth

gauge

and

guard

link

which deflect

klckback lorce and allow

wood to

gradually ride intothe cutter. Low-

Kickback Charn

has met kickback

per

formance

requrrements when tested

on a

representative sample of chain saws

be-

low 3.8 cubrc

inch displacement specified

in ANS| B

1 75.1 .

r

D

nlr'4..o'

pr[-ll

1-qdrp,),,...,.dt,,t

',

\*---=

-

tl I

\t

I

Lrrt

ect\

I

k

okbnck

{orce

Low

^K,c[baL]h \

ancl al ows

woori

(,Ila

rl

lo

qrn(iua y

lClC

rnto alrilef

\\

Can Obslnrct

l\"4:rlef a

Nol a Low.- Krckback Clra

I

.

Front Hand

Guard,

designed to reduce

the

chance of

your

lefi hand

contacting

the charn

rf

vour

hand sllDs off the

front handlebar.

.

Position of

front

and

rear lmndlebars. de-

sroned with distance between

handles and

'rn-lrne

with each other.

The spread and

"in

line

position

of the hands

provided

by

thrs

design work together

to

give

balance and

re

sistance

In

controlling

the

pivot

of the saw

back toward

the

operator

if kickback occurs.

CHAIN

BRAKE

AND

CKA

ANGLE

.

Chain

Brake, designed to stop

the

chain

in

the event of

kickback.

Awanlttllc: wE Do

Nor REP,

RESENT AND

YOU

SHOULD

NOT

AS-

SUN4E

THAT

THE

CHAIN

BRAKE

WILL

PROTECT YOU IN THE EVENT OF

A

KICK-

BACK

Krckback

is a lightning fast aclton

whrch throws the bar and

rotatang chain

back

and up

toward the operator.

Kickback can be

caused bv allowrng

contact of the bar

tip in the

danger

zone

w(h

any

hard

object.

Kickback

can also

b€ caused by

prnchrng

the saw chaln

along

the top of the

guide

bar.

This action

may

push

the

gulde

bar

rapidly

back

toward the op-

erator.

Efiher of these events

may cause

you

to lose control of

the

saw

whrch could

result in

serious

inrurv or even death.

DO NOT

RELY

UPON

ANY

OF

THE DEVICES BUILT

INTO

YOUR

SAW

YOU SHOULD USE

THE SAW

PROPERLY

AND

CAREFULLY

TO

AVOID

KICKBACK.

Reduced-kickback

guide

bars

and

low-kickback saw chains

reduce the

chance

and

magnrtude

o{

kickback and are

recommended.

Your saw has a low

kickback

chain

and bar as original equipment.

Repairs

on a chain

brake should be

made

by

an autho

rized

servicing

dealer.

Take

your

unit lo

the

olace

of

ourchase

if

ourchased

from a servic

ing

dealer,

or to the

nearest

aulhorized

master

servrce oearer.

.

llp contact

in

some

cases may cause a

light

ning fast reverse REACTION,

kicking

guide

bar uo and back

toward

ooeralor.

.

Pinching

the saw chain along the

lop of the

guide

bar may

push

the

guide

bar rapidly

back

toward the operator.

.

Either of

these reactions mav cause

vou

to

lose control ol

lhe

saw

whicii could

result rn

serious

injury. Do

not rely

exclusively

upon

devices

built

into

your

saw.

A

wnnrutruc: compuled

kickback

angle

(CKA)

listed on

your

saw and

lisled in the

CKA

table below represenls angle of

kickback

your

bar and chain combinations

will

have

when tesled

in

accordance

with CSA

(Cana-

dian Standards

Association) and

ANSI stan-

dards.

When

purchasing

replacement bar

and

chain. considerations should

be

given

to the

lower CKA values.

Lower

CKA

values

repre

senl safer

angles to the user,

higher values

in

dicate

more angle and higher kick energies.

Computed

angles

represented indicate total

energy

and angle associated

without activation

o{

the chain brake during

kickback. Activated

angle

represents chain stopping tame

relative to

actvation

angle of chain break and

resulting

kick angle ol saw.

In

all

cases lower CKA

val

ues represent a sa{er operating

environment

for the user.

The following

guide

bar

and chain combina

tions meel

kickback requrrements of CSA

Standards

262] , 262.3, &

ANSI 8175.'1

when used on saws

listed in this manual.

Use of bar and

chain combinations other

than those

listed is not

recommended and

may not meet the CKA

requirements

per

standard.

**

\-o

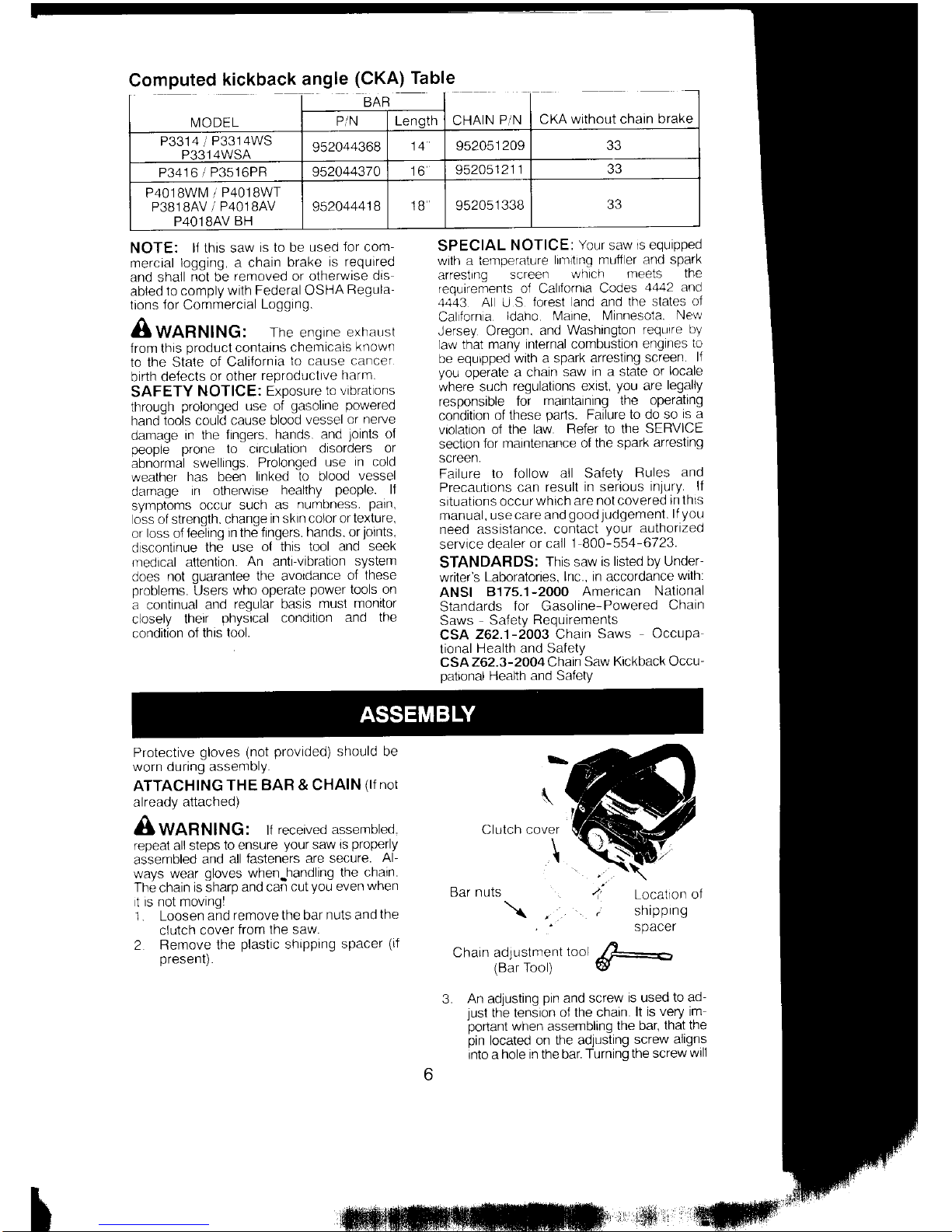

Computed

kickback angle

(CKA)

Table

NOTE:

lI this saw

is to be

used

for

com-

mercial

logging, a chain

brake

is required

and shall

not be

removed or otherwise

dls

abled

to comply

with Federal OSHA

Regula-

lrons

lor

Commercial

Loggtng

Awnnrutruc:

The engrne

exrausr

from this

product

contains

chemlcals

known

to the State

of California

to cause

cancer

birth de{ects

or

other

reproductlve

harm.

SAFETY

NOTICE:

Exposure

to vibratons

through

prolonged

use of

gasoline

powered

hand

tools could

cause blood

vessel

or nerve

damage

in the

fingers.

hands. and

Joints

of

people

prone

to orculatlon

dlsoroers or

abnormal

swellings.

Prolonged

use

in cold

weather

has been

linked to blood

vessel

damage

in otherwise

healthy

people.

lt

syrrptoms

occur

such

as

numbness.

paln,

oss of strength.

change

in sktn color

or texture,

or

loss

o{

Ieeling

in the fingers.

hands. or

lolnts.

d scontinue

the use

ol this tool

and seek

rredtcal attention.

An

anti-vibration

system

does

not

guarantee the avotdance

of

these

problems.

Users

who operate

power

tools on

a continual

and

regular

basis

musl monitor

closely

their

physical

condition

and the

condition

of this

tool.

SPECIAL

NOTICE:

Your

saw

rs equipped

with a temperature

ltnrttnq muff er

and spark

arrestrng

screen

wh ch

meets

the

requirements of Ca|lornra

Codes

4442 and

4443

Al

U S

torest

and

and

the states

ol

Calforn

a

ldaho N,4aine,

Minnesota.

New

Jersey

Oregon,

and

Washington

requlre

ily

law that

many internal combustion

eng

nes

to

be equrpped

with a spark

arresting

screen.

lf

you

operate

a chain

saw

in a state or

locale

where such

regulations exisl.

you

are

legally

responsible

for

maintaining the

operating

condition

of these

parts.

Failure

to do so

is a

violation of

the law.

Refer to lhe

SERVICE

sectaon

for maintenance

o{ the spark

arresting

screen.

Failure

to

follow all Safety

Rules

and

Precautions

can result

in serious

inlury.

lf

situations

occur

whrch are

not

covered

rn lnls

manual, usecareand

goodJUdgemenl.

llyou

need assistance.

contact

your

autnorlzeo

service

dealer

or call 1 800-554

6723.

STANDARDS:

This

saw

is

listed by Under

writer's

Laboratories,

lnc., in accordance

wrlh:

ANSI

8175.1-2000

American

National

Standards

for Gasoline

Powered

Chain

Saws

SaJety

Requirements

CSA

262.1-2003

Chain

Saws

OccuPa

tional

Health and

Safety

CSA 262.3-2004

Charn

Saw

Kickback Occu-

palional

Health and Safety

Protective

gloves

(not

provided)

snould be

worn during assembly.

ATTACHING

THE

BAR & CHAIN

(If

not

already

attached)

AWnnrutruC:

lf

received assembled.

'ppeat

all steps

to ensure

your

saw

rs

properly

assembled

and

all fasteners

are secure.

Al-

ways

wear

gloves

when.handling

the chain.

The chain is sharo

and can

cut

vou

even

when

t

is not moving!

1 . Loosen

and

remove the bar

nuls and

the

clutch

cover

from

the saw

2

Remove lhe

plastic

shipping

spacer

(il

oresenl).

\

\

Clutch cover

\

Bar

nuts

\

Chain adlustment

too

(Bar

Tool)

Locatl0n

ol

shrpprng

An adjusting

pin

and screw

is used

to ad-

iusl

the tensron

ol the charn.

lt

is very im

oortant

when assemblinq

the bar,

that the

bin

located

on tre adjus'iing

screw

aligns

into a hole in the bar.

Turnino

the screw

wrll

IVODEL

BAF

CHAIN

P1N

CKA

without chain

brake

P'N Lenoth

P3314

1

P3314WS

P3314WSA

952044368

952051

209 33

P3416 1

P3516PR

952044370

to

9520s1

21

1 33

P4018WlV

r

P4018WT

P3B18AV

i

P4O18AV

P4O1 BAV

BH

952044418

1B 952051

338

33

rrra,a:-:

:l -::-':-^: ]^ -p anc OO!Vn

the

: - a,',

-

':

::a :- S al !.6trnenl D€tore

yOU

:r= i

-

-

---:

-,:

:-€

car onto

the

saw. see

Insroe

view o1

cl

utch

cover

5

\

.,

Bar bolts

\

"...

.,\

Guide bar \-

'

6. Carefu ly

remove

the chain from

the

pack-

age

Hold

charn with the

drive

links

as

shown

Cutters

Depth

Gauge

Drive

Links

Place

chain over and behind

clutch

re-

tainer. fitting the

drive

links in

the clutch

orurn sprocKet.

Ft

botlom of drive links between the

teeth in

the sprocket in the nose

of

the

guroe

Dar.

Fit

chain drive

links

inlo bar

groove.

Pull

guide

bar forward until chain is snug

in

guide

bar

groove.

Ensure all drive

links

are in the

bar

groove.

Now. rnstall clutch

cover

making

sure

the

adJUSting

pin

is

positioned

in the low

er

hole in

the

guide

bar. Remember this

pin

moves the

bar

forward

and back-

ward

as the screw is turned.

: -::-e-t

located

on clutch cover

Adlust

ng Ptn

--'r

rne adjusting screw by hand coun-

:.'clockwise until the adjusting

prn

lust

:ouches

the

stop.

This

should allow the

prn

to be

near

the correct

posrtion.

Slide

guide

bar on

bar

bolts until

guide

bar stops against clutch drum sprocket

\

Clutch

Cover

12.

Install bar

nuts

and finger tighten only.

Once

the charn is tensioned.

you

will

need

to tighten bar nuts.

CHAIN

TENSION

(lnclud

ng units with chain

already

installed)

A

wnnrutruc: wear

protecrrve

groves

when handlang charn. The

chain

is sharp and

can cut

you

even

when it is

not moving.

NOTE: When

adjusting chain tension,

make sure the

bar

nuts

are

finger

tight only.

Attempting to tension

the chain when the bar

nuts are tight can cause

damage.

Checking the tension:

Use the screwdriver end of the

chain adjust-

ment tool

(bar

tool) to move

charn around

guide

bar. lf the

chain does

not rotate, it isloo

tighl.

lf

the chain

is

too loose, itwill sag below

the

bar.

.fi#

Chain

Adlustmen

Bar Nuls

Adrustino

^

Tool

'S;;;"

tBar

Tool)

Adjusting the

tension:

Chain tension is very important.

Chains

stretch during use. This rs

especially true

dunng the first few

times

you

use

your

saw.

Always

check chain tension each time be

fore

you

start the

chain saw.

1 . Loosen bar nuts u ntil

lhey are

fi nger

light

against the clutch cover.

2. Turn adjusting screw

clockwise until chain

solidly contacts

bottom of

guide

bar

rail.

9

10

CUTTEFS MUST FACE IN

DIIRECTION

OF

ROTATION

t1

Loading...

Loading...