Page 1

Poulan

t_ Please do not return unit to retailer.

Por favor, no devuelva el aparato al lugar de compra.

Veuillez ne pas retourner routil au detaillant.

• 1-800-554-6723

www.poulan.com

Instruction Manual

Manual de Instrucciones

Manuel d'lnstructions

A

1950 / 1975 / 2055 / 2050 / 2075 / 2150

2155/2175/2350/2375/2150PRLE Series /

For Occasional Use Only

WARNING:

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious injury.

ADVERTENCIA:

Lea el manual de instrucciones y siga todas las advertencias e en-

strucciones de seguridad. El no hacerlo puede resultar en lesiones

graves.

AVERTISSEMENT:

Lire le manuel d'instructions et bien respecter tousles avertisse-

merits et routes les instructions de securite. Tout defaut de le faire

pourrait entra_ner des blessures graves.

Poulan

1030 Stevens Creek Road

Augusta, GA 30907

545123622 8/25/06

Page 2

f_l

WARNING! This chain I_1

U

saw can be dangerous! Care-

less or improper use can cause

serious or even fatal injury.

Read and understand the

instruction manua( before

using the chain saw.

Always wear appropriate ear protection, eye protection and head protection.

Always use two hands when operating the chain saw.

WARNING! Contactingtheguidebartipwithanyobject

should be avoided; tip contact may cause the guide bar to

move suddenly upward and backward, which may cause se-

rious injury.

Measured maximum kickback va)ue without chain brake for the bar

and chain combination on the (abel

_k WARNING: Always disconnect

spark plug wire and place wire where it can-

not contact spark plug to prevent accidental

starting when setting up, transporting, ad-

justing or making repairs except carburetor

adjustments.

Because a chain saw is a high-speed wood-

cutting tool, special safety precautions must

be observed to reduce the risk of accidents.

Careless or improper use of this tool can

cause serious injury.

PLAN AHEAD

• Read this manual carefully until you com-

p(etely understand and can follow all safety

rules, precautions, and operating instruc-

tions before attempting to use the unit.

• Restrict the use of your saw to adult users

who understand and can follow safety

rules, precautions, and operating h_struc-

t)ons found in this manual.

• Wear protective gear. Always use steeF

toed safety footwear with non-slip soles;

snug-fitting clothing; heavy-duty, non-slip

gloves; eye protection such as non-fog-

ging, vented goggles or face screen; an

approved safety hard hat; and sound barri-

ers (ear plugs or mufflers) to protect your

hearing. Regular users should have hear-

ing checked regularly as chain saw noise

can damage hearing. Secure hair above

shoulder length.

Hearing Safety Hat

Protection _ Eye

"_'_, i m,e _"" Protection

Snug

Fittinc Heavy Duty

Clothing Gloves

Safety Safety Chaps

Shoes

Keep all parts of your body away from the

chain when the engine is running.

Keep children, bystanders, and animals a

minimum of 30 feet (10 meters) away from

the work area. Do not allow other people

or animals to be near the chain saw when

starting or operating the chain saw.

Do not handle or operate a chain saw when

you are fatigued, ill, or upset, or if you have

taken alcohol, drugs, or medication. You

must be ingood physical condition and men-

tally aiert. Chain saw work is strenuous. If

you have any condition that might be aggra-

vated by strenuous work, check with your

doctor before operating a chain saw.

Page 3

• Carefullyplanyoursawingoperationinad-

vance.Donotstartcuttinguntilyouhavea

clearworkarea,securefooting,and,ifyou

arefellingtrees,aplannedretreatpath.

OPERATEYOURSAW SAFELY

• Do not operate a chain saw with one hand.

Serious injury to the operator, helpers, by-

standers or any combination of these per-

sons may result from one-handed opera-

tion. A chain saw is intended for

two-handed use.

• Operate the chain saw only in a welFventi-

iated outdoor area.

• Do not operate saw from a ladder or in a

tree.

• Make sure the chain will not make contact

with any object while starting the engine.

Never try to start the saw when the guide

bar is in a cut.

• Do not put pressure on the saw at the end

of the cut. Applying pressure can cause

you to lose control when the cut is com-

pleted.

• Stop the engine before setting the saw

down.

• Do not operate a chain saw that is dam-

aged, improperly adjusted, or not com-

pletely and securely assembled. Always

replace bar, chain, hand guard, or chain

brake immediately if it becomes damaged,

broken or is otherwise removed.

• With the engine stopped, hand carry the

chain saw with the muffler away from your

body, and the guide bar and chain to the

rear, preferably covered with a scabbard.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

• Have aH chah_ saw service performed by a

qualified service dealer with the exception

of the items listed in the maintenance sec-

tionofthis manual. Forexample, ifimprop-

er tools are used to remove or hoid the fly-

wheel when servicing the clutch, structural

damage to the flywheel can occur and

cause the flywheel to burst.

• Make certain the saw chain stops moving

when the throttle trigger is released. For

correction, refer to CARBURETOR AD-

JUSTMENTS.

• Never modify your saw in any way.

• Keep the handles dry, clean, and free of oil

or fuel mixture.

• Keep fuel and oil caps, screws, and fas-

teners securely tightened.

• Use only Poulan accessories and re-

placement parts as recommended.

HANDLE FUEL WITH CAUTION

• Do not smoke while handling fuel or while

operating the saw.

• Eliminate all sources of sparks or flame in

the areas where fuel is mixed or poured.

There should be no smoking, open flames,

or work that could cause sparks. Allow en-

gine to coot before refueling.

• Mix and pour fuel in an outdoor area on

bare ground; store fuel in a cool, dry, well

ventilated place; and use an approved,

marked container for all fuel purposes.

Wipe up all fuel spills before starting saw.

• Move at least t0 feet (3 meters) from fuel-

ing site before starting engine.

• Turn the engine off and let saw cool in a

non-combustible area, not on dry leaves,

straw, paper, etc. SIowly remove fuel cap

and refuel unit.

• Store the unit and fuel in an area where fuel

vapors cannot reach sparks or open

flames from water heaters, electric motors

or switches, furnaces, etc.

KICKBACK

_, WARNING: Avoid kickback which

can result in serious injury. Kickback is the

backward, upward or sudden forward motion

of the guide bar occurring when the saw

chain near the upper tip of the guide bar con-

tacts any object such as a log or branch, or

when the wood closes in and pinches the

saw chain in the cut. Contacting a foreign ob-

ject in the wood can also result in loss of

chain saw control,

• Rotational Kickback can occur when the

moving chain contacts an object at the up-

per tip of the guide bar. This contact can

cause the chain to dig into the object,

which stops the chain for an instant, The

result is a lightning fast, reverse reaction

which kicks the guide bar up and back to-

ward the operator.

• Pinch-Kickback can occur when the the

wood closes in and pinches the moving

saw chain in the cut along the top of the

guide bar and the saw chain is suddenly

stopped. This sudden stopping of the

chain results in a reversal of the chain

force used to cut wood and causes the

saw to move in the opposite direction of the

chain rotation, The saw is driven straight

back toward the operator.

• Pull-In can occur when the moving chain

contacts a foreign object in the wood in the

cut along the bottom of the guide bar and the

saw chain is suddenly stopped. This sudden

stopping pulls the saw forward and away

from the operator and could easily cause the

operator to lose control of the saw.

Avoid Pinch-Kickback:

• Be extremely aware of situations or ob-

structions that can cause material to pinch

the top of or otherwise stop the chain,

• Do not cut more than one log at a time,

• Do not twist the saw as the bar is with-

drawn from an undercut when bucking,

Avoid Pull-In:

• Always begin cutting with the engine at full

speed and the saw housing against wood.

• Use wedges made of plastic or wood.

Never use metal to hold the cut open.

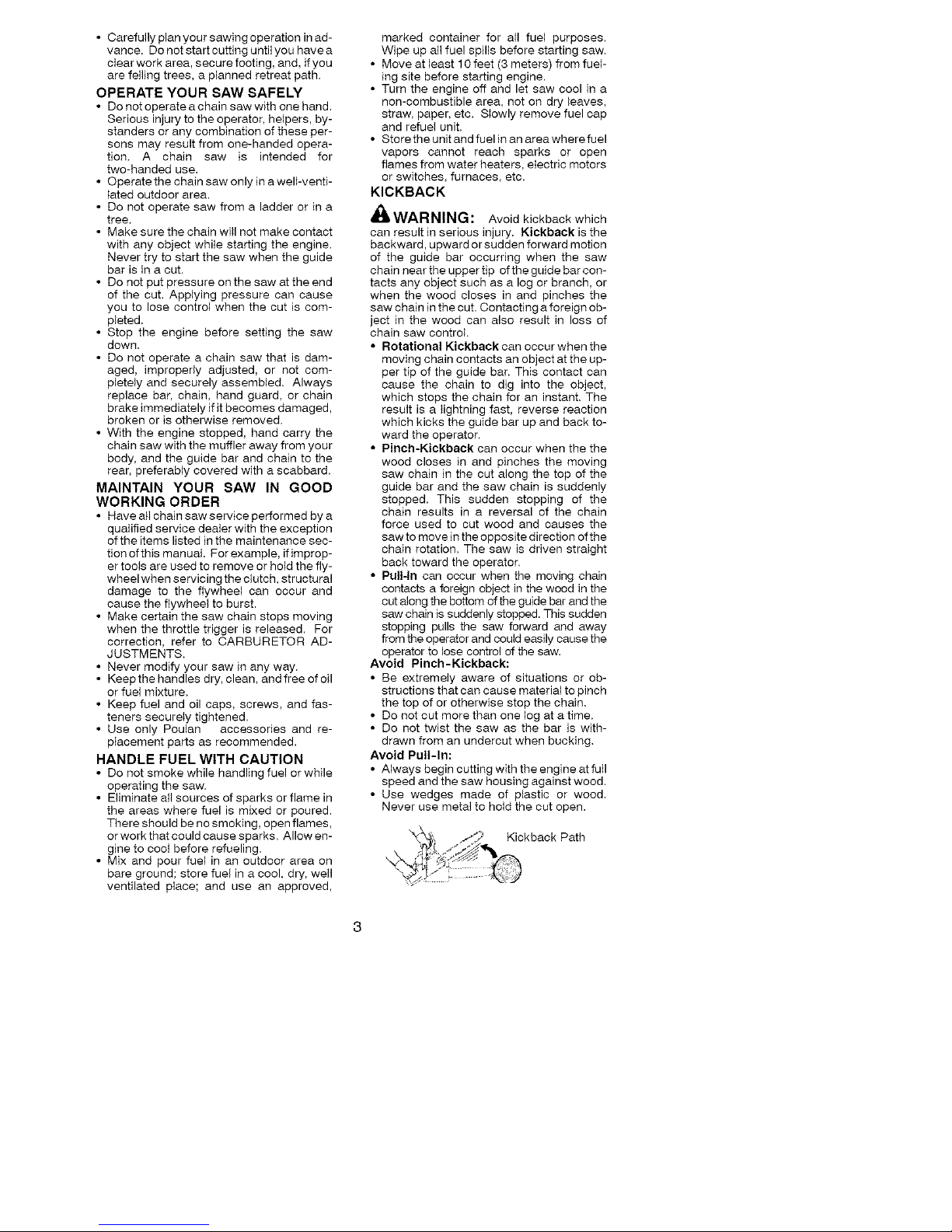

\X_i _ _2 Kickback Path

Page 4

AvoidObstructions t

t

ClearTheWorkingArea

REDUCE THE CHANCE OF

KICKBACK

• Recognize that kickback can happen.

With a basic understanding of kickback,

you can reduce the element of surprise

which contributes to accidents,

• Never let the moving chain contact any ob-

ject at the tip of the guide bar.

• Keep the working area free from obstruc-

tions such as other trees, branches, rocks,

fences, stumps, etc. Eliminate or avoid

any obstruction that your saw chain could

hit while you are cutting, When cutting a

branch, do not let the guide bar contact

branch or other objects around it,

• Keep your saw chain sharp and properly

tensioned. A loose or dull chain can in-

crease the chance of kickback occurring,

Follow manufacturer's chain sharpening

and maintenance instructions. Check ten-

sion at regular intervals with the engine

stopped, never with the engine running.

Make sure the chain brake nuts are se-

curely tightened after tensioning the chain.

• Beginandcontinuecuttingatfullspeed. If

the chain is moving at a slower speed,

there is greater chance of kickback occur-

ring.

• Out one log at a time,

• Use extreme caution when re-entering a

previous cut.

• Do not attempt cuts starting with the tip of

the bar (plunge cuts),

• Watch for shifting logs or other forces that

could close a cut and pinch or fall into

chain,

• Use the Reduced-Kickback Guide Bar

and Low-Kickback Chain specified for

your saw,

MAINTAIN CONTROL

Stand to the

leill tel _

hand positions

Thumb on

underside of

handlebar

\

!

t

Elbow locked

Thumb on underside of

handlebar

• Keep a good, firm grip on the saw with both

hands when the engine is running and

don't let go, A firm grip will help you reduce

kickback and maintain control of the saw.

Keep the fingers of your left hand encir-

cling and your left thumb under the front

handlebar. Keep your right hand com-

pletely around the rear handle whether

your are right handed or left handed, Keep

your left arm straight with the elbow

locked,

• Position your left hand on the front handle-

bar so it is in a straight line with your right

hand on the rear handle when making

bucking cuts. Never reverse right and left

hand positions for any type of cutting,

• Stand with your weight evenly balanced on

both feet,

• Stand slightly to the left side of the saw to

keep your body from being in a direct line

with the cutting chain,

• Do not overreach. You could be drawn or

thrown off balance and lose control of the

saw.

• Do not cut above shoulder height. It isdiffi-

cult to maintain control of saw above

shoulder height.

KICKBACK SAFETY FEATURES

,_ WARNING: The following features

are included on your saw to help reduce the

hazard of kickback; however, such features

will not totally eliminate this danger, As a

chain saw user, do not rely only on safety de-

vices, You must follow all safety precau-

tions, instructions, and maintenance in this

manual to help avoid kickback and other

forces which can result in serious injury.

• Reduced-Kickback Guide Bar, designed

with a small radius tip which reduces the

size of the kickback danger zone on the

bar tip, A Reduced-Kickback Guide Bar

has been demonstrated to significantIy re-

duce the number and seriousness of kick-

backs when tested in accordance with

safety requirements for gasoline powered

chain saws as set by ANSI B175.1.

Page 5

L

Large Radius Tip

• Low-Kickback Chain, designed with a

contoured depth gauge and guard link

which deflect kickback force and allow

wood to gradually ride into the cutter. Low-

Kickback Chain has met kickback per-

formance requirements when tested on a

representative sample of chain saws be-

low 3.8 cubic inch displacement specified

in ANSI B175.t,

Contoured Depth Gauge

D Elongated Guard Link

....

Low-Kickback _ and allowswood

Chain to gradually ride

into culter

"_ "\_" _Can(_ "%_ Obstruct Matedal

Not a Low- Kickback Chain

• Front Hand Guard, designed to reduce the

chance of your left hand contacting the chain

if your hand slips off the front handlebar,

• Position of front and rear handlebars, de-

signed with distance between handles and

"in-line" with each other. The spread and

"in-line" position of the hands provided by

this design work together to give balance

and resistance in controlling the pivot of

the saw back toward the operator if kick-

back occurs.

CHAIN BRAKE AND CKA ANGLE

• Chain Brake, designed to stop the chain in

the event of kickback.

_WARNING: WE DO NOT REP-

RESENT AND YOU SHOULD NOT AS-

SUME THAT THE CHAIN BRAKE WiLL

PROTECT YOU iN THE EVENT OF A KICK-

BACK, Kickback is a lightning fast action

which throws the bar and rotating chain back

and up toward the operator, Kickback can be

caused by afiowing contact of the bar tip in the

danger zone with any hard object, Kickback

can also be caused by pinching the saw chain

along the top of the guide bar. This action may

push the guide bar rapidly back toward the op-

erator. Either of these events may cause you

to tose control of the saw which could result in

serious injury or even death. DO NOT RELY

UPON ANY OF THE DEVICES BUILT INTO

YOUR SAW. YOU SHOULD USE THE SAW

PROPERLY AND CAREFULLY TO AVOID

KICKBACK. Reduced-kickback guide bars

and low-kickback saw chains reduce the

chance and magnitude of kickback and are

recommended, Your saw has a low kickback

chain and bar as original equipment, Repairs

on a chain brake should be made by an autho-

rized servicing deaIer. Take your unit to the

piace of purchase if purchased from a servic-

ing dealer, or to the nearest authorized master

service dealer.

• Tip contact in some cases may cause a light-

ning fast reverse REACTION, kicking guide

bar up and back toward operator.

• Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly

back toward the operator.

• Either of these reactions may cause you to

lose control of the saw which could result in

serious injury. Do not rely exclusively upon

devices built into your saw,

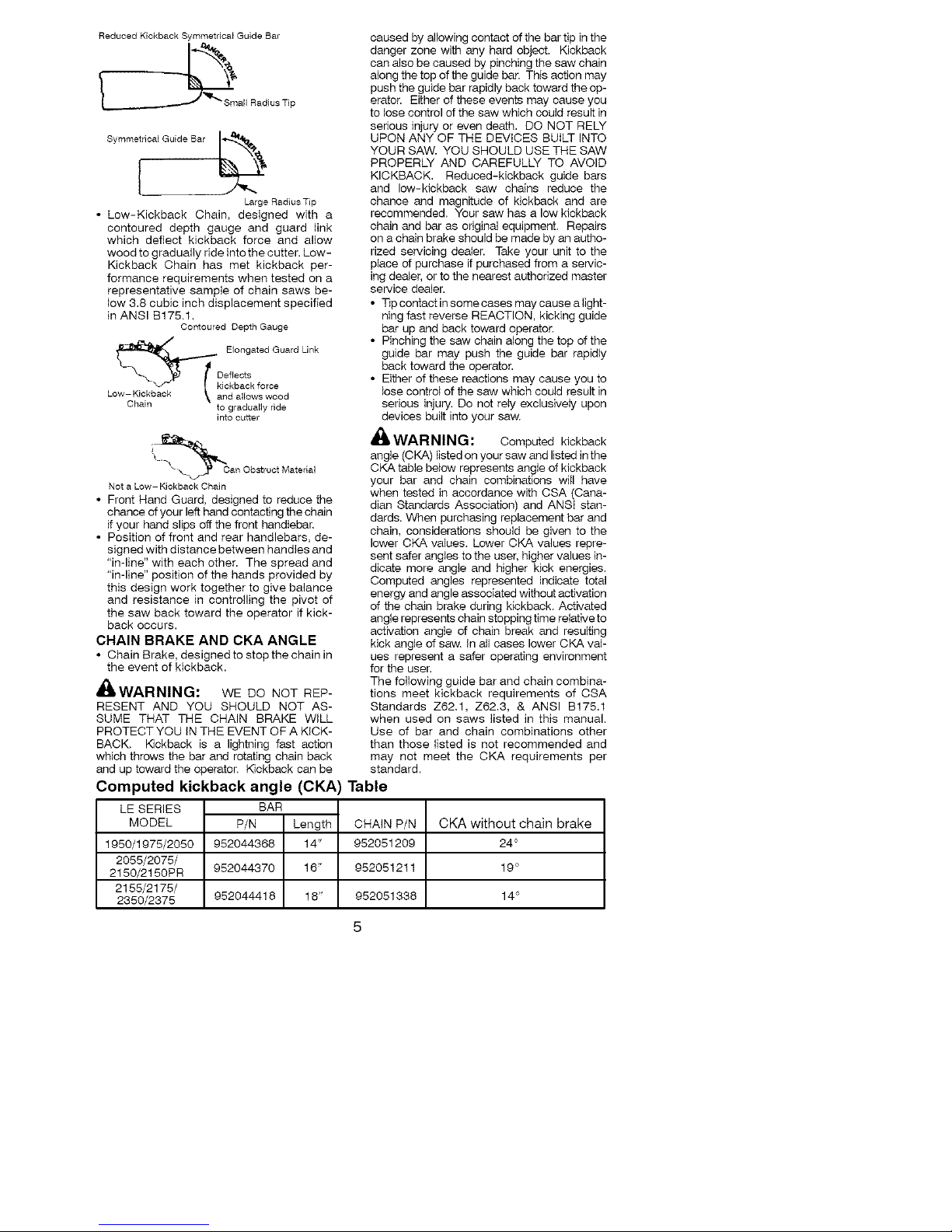

_b WARNING: Computed kickback

angle (OKA) listed on your saw and listed inthe

CKA table betow represents angle of kickback

your bar and chain combinations will have

when tested in accordance with CSA (Cana-

dian Standards Association) and ANSI stan-

dards. When purchasing replacement bar and

chain, considerations should be given to the

lower CKA values, Lower CKA values repre-

sent safer angtes to the user, higher values in-

dicate more angle and higher kick energies.

Computed angles represented indicate total

energy and angle associated without activation

of the chain brake during kickback, Activated

angle represents chain stopping time relative to

activation angle of chain break and resulting

kick angle of saw, in atl cases lower OKA val-

ues represent a safer operating environment

for the user.

The following guide bar and chain combina-

tions meet kickback requirements of CSA

Standards Z62,1, Z62,3, & ANSI B175.1

when used on saws listed in this manual.

Use of bar and chain combinations other

than those listed is not recommended and

may not meet the CKA requirements per

standard.

Computed kickback angle (CKA) Table

LE SERIES

MODEL Length

1950/1975/2050 14"

2055/2075/

2150/2150PR 16"

2155/2175/

2350/2375

BAR

P/N CHAIN P/N

952044368 952051209

952044370 952051211

952044418 18" 952051338

CKA without chain brake

24 °

19 °

14 °

Page 6

NOTE:ifthissawistobeusedforcam-

merciallogging,achah_brakeisrequired

andshallnotberemovedorotherwisedis-

abledtocomplywithFederalOSHARegula-

tionsforCommercialLogging.

SAFETYNOTICE:Exposuretovibrations

throughprolongeduseofgasolinepowered

handtoolscouIdcausebloodvesselornerve

damageinthefingers,hands,andjointsof

peoplepronetocirculationdisordersor

abnormalswellings.Prolongeduseincold

weatherhasbeenlinked to blood vessel

damage in otherwise healthy people. If

symptoms occur such as numbness, pain,

loss of strength, change in skin color or texture,

or toss of feeling in the fingers, hands, or joints,

discontinue the use of this tool and seek

medical attention. An anti-vibration system

does not guarantee the avoidance of these

problems. Users who operate power tools on

a continual and regular basis must monitor

closely their physical condition and the

condition of this tool

SPECIAL NOTICE: Your saw is equipped

with a temperature limiting muffler and spark

arresth_g screen which meets the

requirements of California Codes 4442 and

4443. All U.S. forest land and the states of

California, Idaho, Mah_e, Minnesota, New

Jersey, Oregon, and Washington require by

law that many internal combustion engines

to be equipped with a spark arresting screen.

if you operate a chain saw in a state or Iocale

where such regulations exist, you are legally

responsible for maintaining the operating

condition of these parts. Failure to do so is

a violation of the law. Refer to the SERVICE

section for maintenance of the spark

arresting screen.

Failure to follow all Safety Rules and Precau-

tions can result inserious injury, if situations

occur which are not covered in this manual,

use care and good judgement, if you need

assistance, contact your authorized service

dealer or call 1-800-554-6723.

STANDARDS: This saw is listed by Under-

writer's Laboratories, Inc., in accordance with:

ANSI B175.1-2000 American National

Standards for Gasoline-Powered Chain

Saws - Safety Requirements

CSA Z62.1-03 Chain Saws - Occupational

Health and Safety

CSA Z62.3-96 Chain Saw Kickback Occu-

pational Health and Safety

Protective gloves (not provided) should be

worn during assembly.

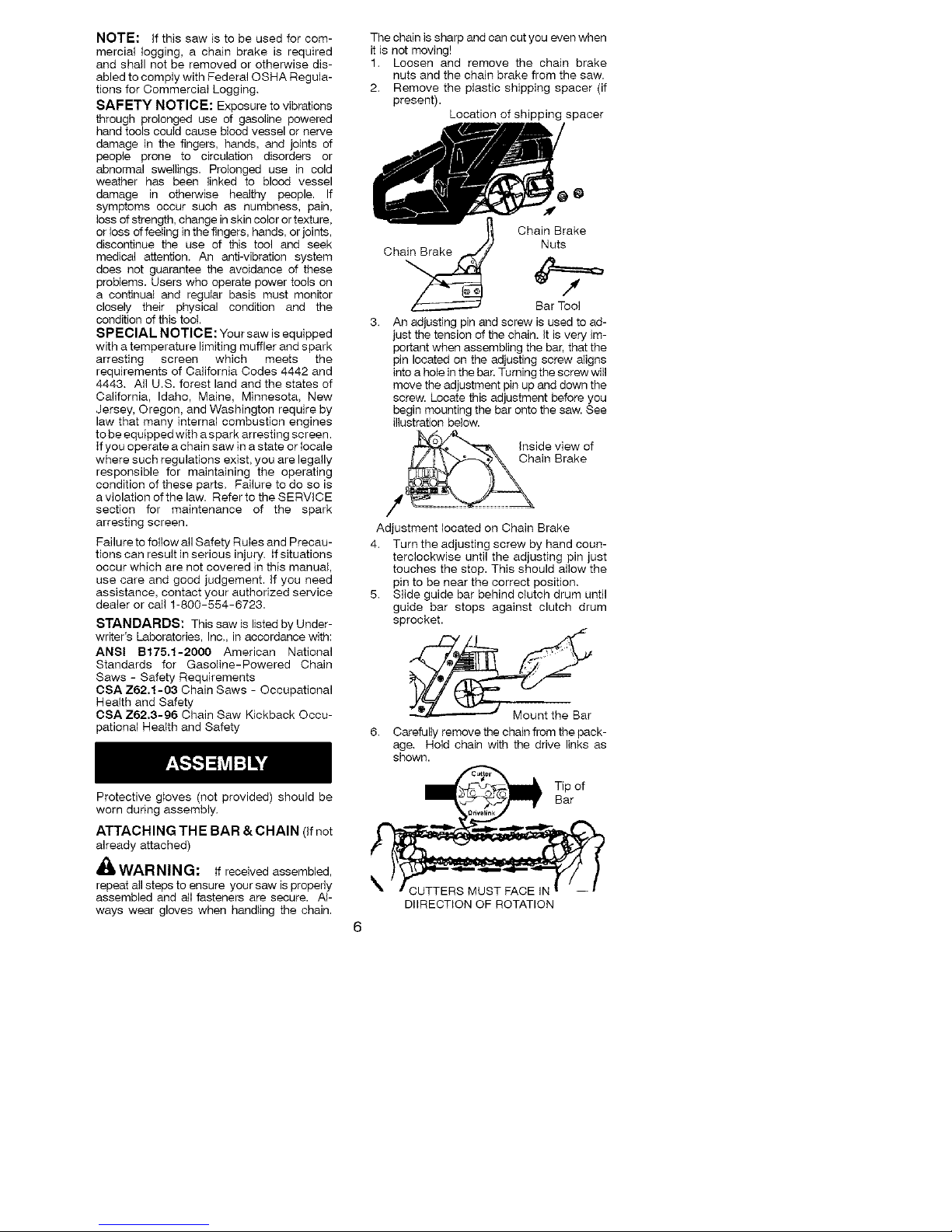

ATTACHING TH E BAR & CHAIN (if not

already attached)

WARNING: if received assembled,

repeat all steps to ensure your saw is properly

assembled and all fasteners are secure. Al-

ways wear gloves when handling the chain.

The chain is sharp and can cut you even when

it is not moving!

1. Loosen and remove the chain brake

nuts and the chain brake from the saw.

2. Remove the plastic shipping spacer (if

present).

Location of shipping spacer

G

a_ Chain Brak_e

Ch Nuts

Bar Tool

3. An adjusting pin and screw is used to ad-

just the tension of the chain, it is very im-

portant when assembling the bar, that the

pin located on the adjusting screw aligns

intoa hole in the bar. Turning the screw will

move the adjustment pin up and down the

screw. Locate this adjustment before you

begin mounting the bar onto the saw. See

illustration below.

inside view of

_,__hain Brake

Adjustment located on Chain Brake

4. Turn the adjusting screw by hand coun-

terclockwise until the adjusting pin just

touches the stop. This should aflow the

pin to be near the correct position.

5. Slide guide bar behind clutch drum until

guide bar stops against clutch drum

sprocket.

6. Carefully remove the chain from the pack-

age. Hold chain with the drive links as

shown.

_ ip of

Bar

DIIRECTION OF ROTATION

Page 7

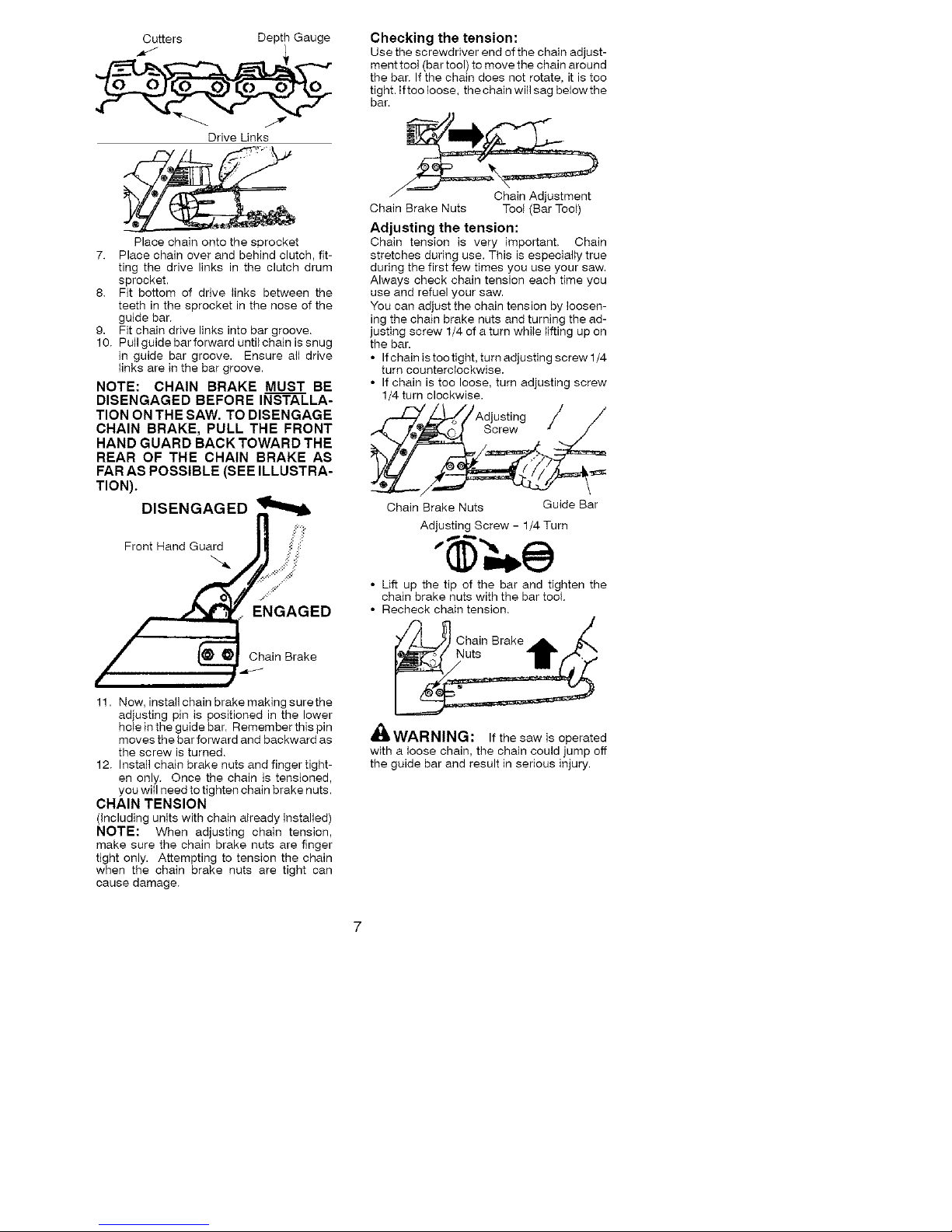

Cutters DepthGauge

DriveLinks

Placechainontothesprocket

7. Placechainoverandbehindclutch,fit-

tingthedrivelinksintheclutchdrum

sprocket.

8. Fitbottomofdrivelinksbetweenthe

teethinthesprocketinthenoseofthe

guidebar.

9. Fitchaindrivelinksintobargroove.

10.Pullguidebarforwarduntilchainissnug

inguidebargroove.Ensurealldrive

linksareinthebargroove.

NOTE: CHAIN BRAKE MUST BE

DISENGAGED BEFORE INSTALLA-

TION ON THE SAW. TO DISENGAGE

CHAIN BRAKE, PULL THE FRONT

HAND GUARD BACK TOWARD THE

REAR OF THE CHAIN BRAKE AS

FAR AS POSSIBLE (SEE ILLUSTRA-

TION).

DISENGAGED _

GAGED

/

11. Now, installchain brakemaking surethe

adjusting pin is positioned in the lower

hole in the guide bar. Remember this pin

moves the bar forward and backward as

the screw is turned.

12. Install chain brake nuts and finger tight-

en only. Once the chain is tensioned,

you will need to tighten chain brake nuts.

CHAIN TENSION

(including units with chain already h_stalled)

NOTE: When adjusting chain tension,

make sure the chain brake nuts are finger

tight only. Attempting to tension the chain

when the chain brake nuts are tight can

cause damage.

Checking the tension:

Use the screwdriver end of the chain adjust-

ment toot (bar tool) to move the chain around

the bar. If the chain does net rotate, it is too

tight. Ifteo loose, the chain will sag below the

bar.

Chain Adjustment

Chain Brake Nuts Tool (Bar Toot)

Adjusting the tension:

Chah_ tension is very h_qportant> Chain

stretches during use. This is especially true

during the first few times you use your saw.

Always check chain tension each time you

use and refuel your saw.

You can adjust the chain tension by loosen-

ing the chain brake nuts and turning the ad-

justing screw 1/4 of a turn while lifting up on

the bar.

• If chain is too tight, turn adjusting screw 1/4

turn counterclockwise.

• If chain is too loose, turn adjusting screw

1/4 turn clockwise.

,--Z:Z_ZD--/o/Adjust,ng / /

"_ I_ Screw "f J

Chain Brake Nuts Guide Bar

Adjusting Screw - 1/4 Turn

• Lift up the tip of the bar and tighten the

chain brake nuts with the bar tool.

• Recheck chain tension.

Chain Brake

_IWARNING: If the saw is operated

with a loose chain, the chain could jump off

the guide bar and result in serious injury.

Page 8

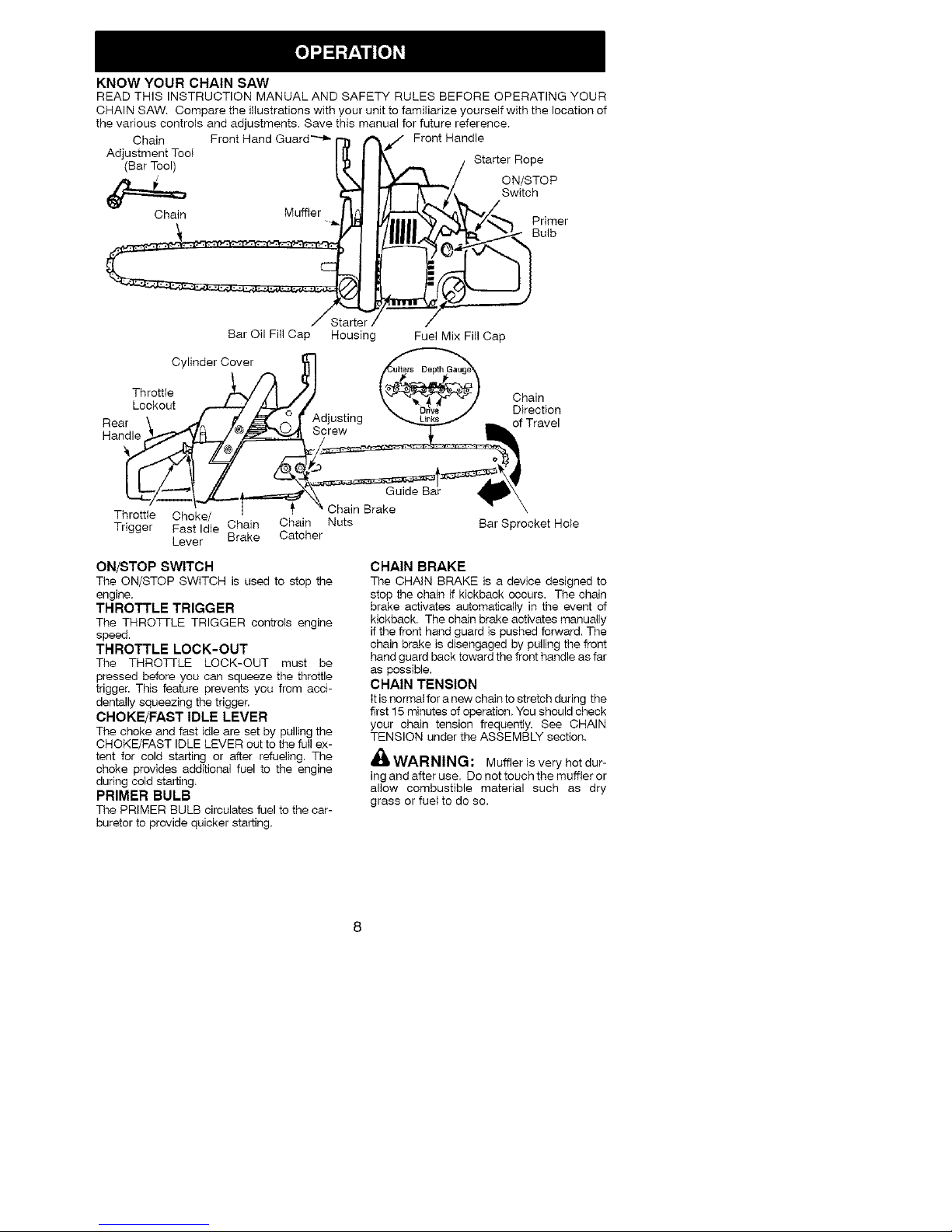

KNOW YOUR CHAIN SAW

READ THIS INSTRUCTION MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

CHAIN SAW. Compare the illustrations with your unit to familiarize yourself with the location of

the various controls and adjustments. Save this manual for future reference.

Chain Front Hand Guard ''-_ r'J) t_,_/- Front Handle

Adjustment Tool I II I k- Starter Roe

tBerToo,/ I\.,", / P

/_ _ k'_l _/ ON/STOP

_t _====_ _ F/_ _ _/_- Switch

Cha,'_' n Muffler fill

' -*_IA F/IIIII "_z._"_//k"_J Primer

Bulb

Bar Oil Fill Cap Housing Fuel Mix Fill Cap

Cylinder Cover

ThrottIe Chain

Lockout Direction

of Travel

Guide

Throttle Choke/ _ Chain Brake

Trigger Fast Idle Chain Chain Nuts Bar Sprocket Hole

Lever Brake Catcher

ON/STOP SWITCH

The ON/STOP SWITCH is used to stop the

engine.

THROTTLE TRIGGER

The THROTI-LE TRIGGER controls engine

speed.

THROTTLE LOCK-OUT

The THROTi-LE LOCK-OUT must be

pressed before you can squeeze the throttle

trigger. This feature prevents you from acci-

dentally squeezing the trigger.

CHOKE/FAST IDLE LEVER

The choke and fast idle are set by pulling the

CHOKE/FAST IDLE LEVER out to the full ex-

tent for cold starting or after refueling. The

choke provides additional fuel to the engine

during cold starting.

PRIMER BULB

The PRIMER BULB circulates fuel to the car-

buretor to provide quicker starting.

CHAIN BRAKE

The CHAIN BRAKE is a device designed to

stop the chain if kickback occurs. The chain

brake activates automatically in the event of

kickback. The chain brake activates manually

if the front hand guard is pushed forward. The

chain brake is disengaged by pulling the front

hand guard back toward the front handle as far

as possible.

CHAIN TENSION

it is normal for a new chain to stretch during the

first 15 minutes of operation. You should check

your chain tension frequently. See CHAIN

TENSION under the ASSEMBLY section.

WARNING: Muffler is very hot dur-

ing and after use. Do not touch the muffler or

allow combustible material such as dry

grass or fuel to do so.

Page 9

season.SeeSTORAGEsectionforaddi-

tionatinformation.

FUELING ENGINE

_. WARNING: Remove fuel cap slow-

ly when refueling.

HELPFUL TIP ]

\ Toobtain the correct oilmix J

t ratio, pour 3.2 ounces of |

2-cycle synthetic off into I

one gallon of fresh gas. J

This engine is certified to operate on unleaded

gasoline. Before operation, gasoline must be

mixed with a good quality synthetic 2-cycle air-

cooled engine oil designed to be mixed at a ra-

tio of 40:1. Poulan/WEED EATER brand syn-

thetic oit is recommended, A 40:1 ratio is

obtained by mixing 3,2 ounces (95 ml) of oil

with 1 gallon (4 liters) of unleaded gasoline, in-

cluded with this saw is a 3.2 ounce container of

PoulanAA/EED EATER brand synthetic oil.

Pour the entire contents of this container into 1

gallon of gasoline to achieve the proper fuel

mixture, DO NOT USE automotive or marine

oil These oits will cause engine damage.

When mixing fuel follow the instructions

printed on the container, Always read and

follow the safety rules listed under HANDLE

FUEL WITH CAUTION,

BAR AND CHAIN LUBRICATION

The bar and chain require continuous lubri-

cation. Lubrication is provided by the auto-

matic oiler system when the oil tank is kept

filled. Lack of oil will quickly ruin the bar and

chain. Too littIe oil will cause overheating

shown by smoke coming from the chain and/

or discoloration of the bar.

In freezing weather oil will thicken, making it

necessary to thin bar and chain oil with a

small amount (5 to 10%) of #1 Diesel Fuel or

kerosene. Bar and chain oil must be free

flowing for the oit system to pump enough oil

for adequate lubrication.

Genuine Poulan bar and chain oil is recom-

mended to protect your unit against exces-

sive wear from heat and friction. Poutan oil

resists high temperature thinning.

If Poulan bar and chain oil is not available,

use a good grade SAE 30 oil.

• Never use waste oil for bar and chain lubri-

cation.

• Always stop the engine before removing

the oil cap.

IMPORTANT

Experience indicates that alcohol-blended

fuels (called gasohol or using ethanol or

methanol) can attract moisture which leads

to separation and formation of acids during

storage. Acidic gas can damage the fuel

system of an engine while in storage. To

avoid engine problems, the fuel system

shouM be emptied before storage for 30

days or longer. Drain the gas tank, start the

engine and let it run untit the fuet lines and

carburetor are empty. Use fresh fuel next

r=WARNING: The chain must not

move when the engine runs at idle speed. If

the chain moves at idle speed refer to CAR-

BURETOR ADJUSTMENT within this

manual, Avoid contact with the muffler. A hot

muffler can cause serious burns.

To stop the engine move the ON/STOP

switch to the STOP position.

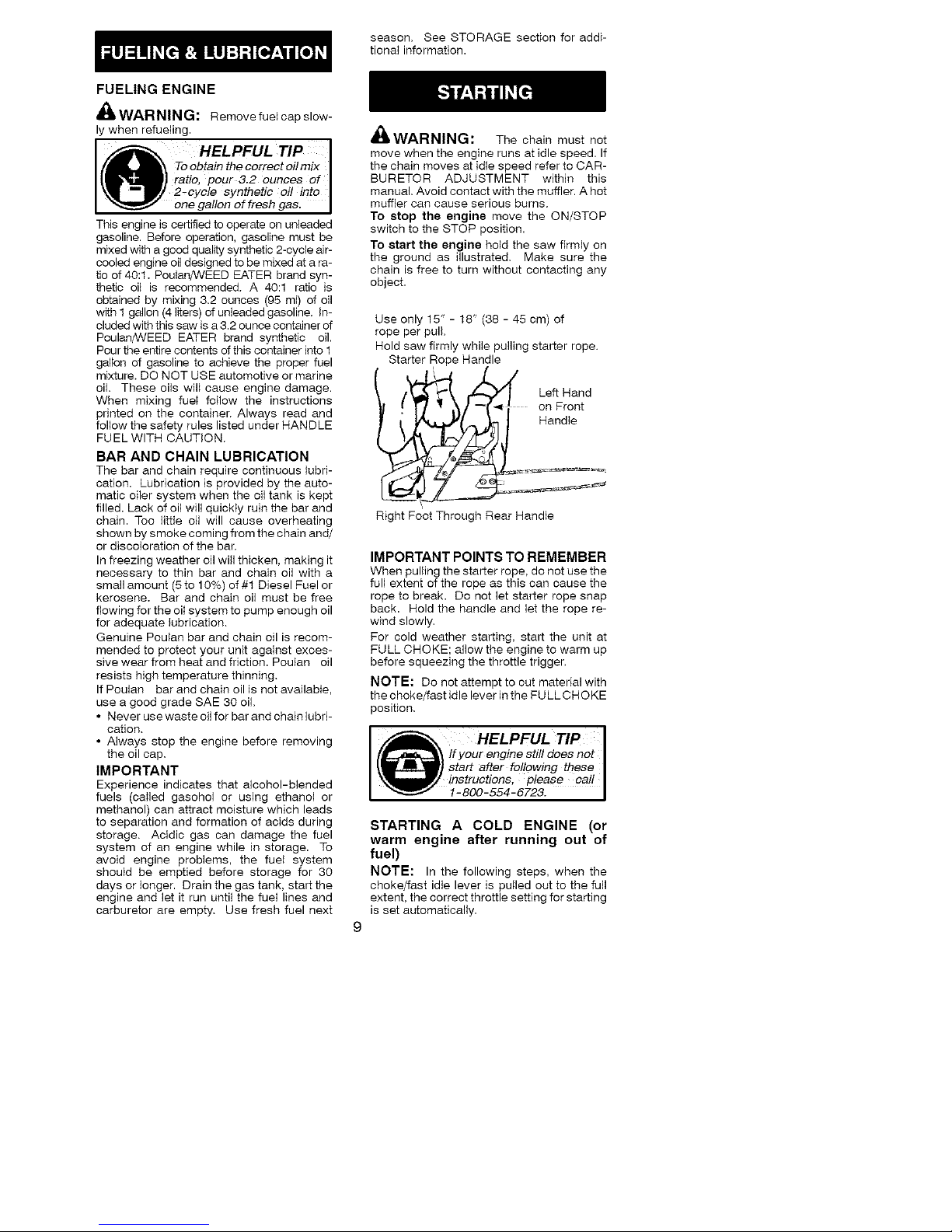

To start the engine hold the saw firmly on

the ground as illustrated. Make sure the

chain is free to turn without contacting any

object.

Use only 15" - 18" (38 - 45 cm) of

rope per pull.

Hold saw firmly while pulling starter rope.

Starter Rope Handle

__ Left Hand

• on Front

Handle

Right Foot Through Rear Handle

IMPORTANT POINTS TO REMEMBER

When pulling the starter rope. do not use the

full extent of the rope as this can cause the

rope to break. Do not let starter rope snap

back. Hold the handle and let the rope re-

wind slowly.

For cold weather starting, start the unit at

FULL CHOKE; allow the engine to warm up

before squeezing the throttle trigger.

NOTE: Do not attempt to cut material with

the choke/fast idle lever in the FULL OH O KE

position.

Ji HELPFUL TIP J

(_ !f your engine still does not J

_l___Ii start after following these J

_// instructions, please cafl I

1-800-554-5728. J

STARTING A COLD ENGINE (or

warm engine after running out of

fuel)

NOTE: In the following steps, when the

choke/fast idle lever is pulled out to the full

extent, the correct throttle setting for starting

is setautomatically.

Page 10

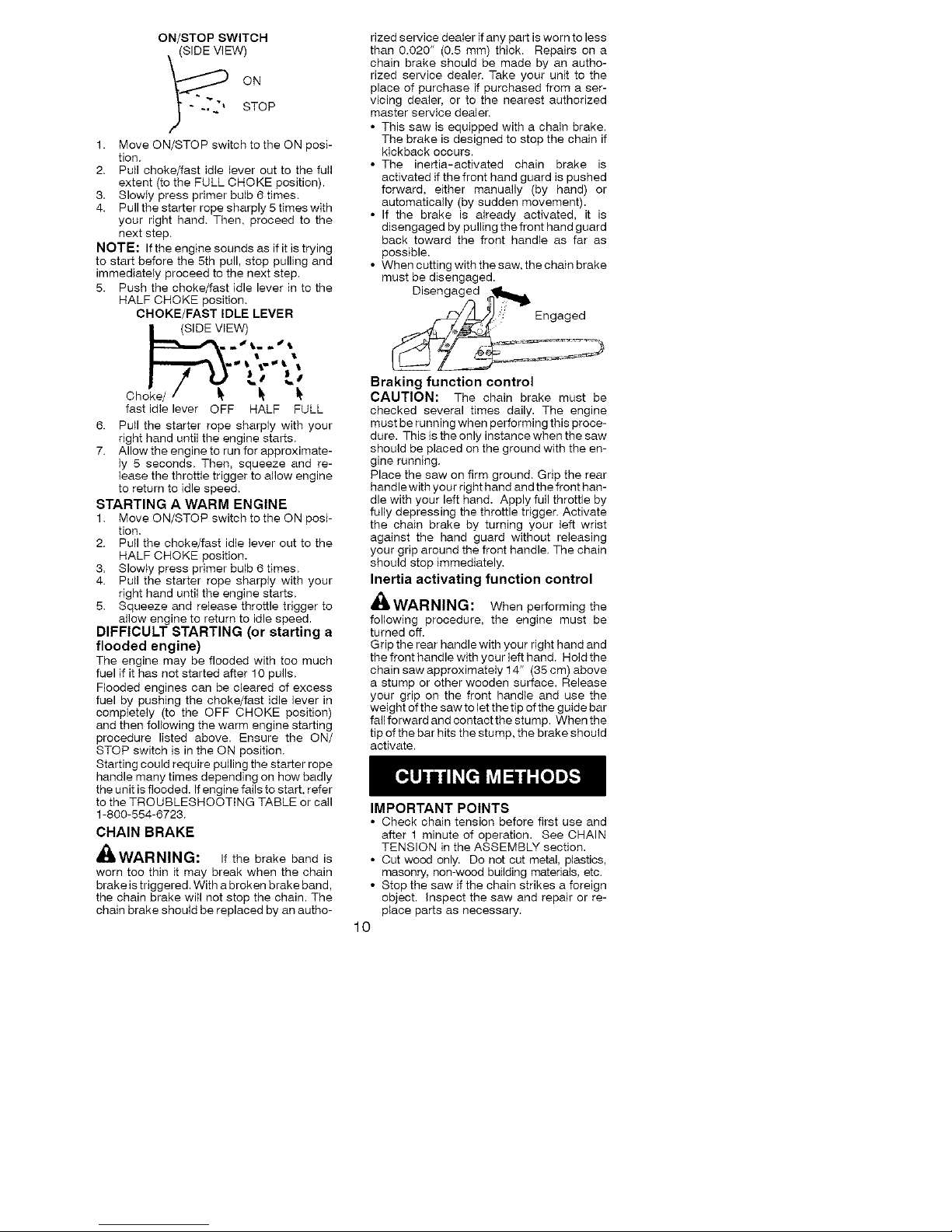

ON/STOP SWITCH

(_ .SIDE VIEW)

ON

-,72' STOP

1. Move ON/STOP switch to the ON posi-

tion.

2. Pull choke/fast idle lever out to the full

extent (to the FULL CHOKE position).

3. Slowly press primer bulb 6 times.

4. Pull the starter rope sharply 5 times with

your right hand. Then. proceed to the

next step.

NOTE: Ifthe engine sounds as if it is trying

to start before the 5th pull, stop pulling and

immediately proceed to the next step.

5. Push the choke/fast idle lever in to the

HALF CHOKE position.

CHOKE/FAST IDLE LEVER

o_IEW)

J J

Ch _

fast idle lever OFF HALF FULL

6. Pull the starter rope sharply with your

right hand until the engine starts.

7. Allow the engine to run for approximate-

ly 5 seconds. Then. squeeze and re-

lease the throttle trigger to allow engine

to return to idle speed.

STARTING A WARM ENGINE

1. Move ON/STOP switch to the ON posi-

tion.

2. Pull the choke/fast idle lever out to the

HALF CHOKE position.

3. Slowly press primer bulb 6 times.

4. Pull the starter rope sharply with your

right hand until the engine starts.

5. Squeeze and release throttle trigger to

allow engine to return to idle speed.

DIFFICULT STARTING (or starting a

flooded engine)

The engine may be flooded with too much

fuel if it has not started after 10 pulls.

Flooded engines can be cleared of excess

fuel by pushing the choke/fast idle lever in

completely (to the OFF CHOKE position)

and then following the warm engine starting

procedure listed above. Ensure the ON/

STOP switch is in the ON position.

Starting could require pulling the starter rope

handle many times depending on how badly

the unit is flooded. If engine fails to start, refer

to the TROUBLESHOOTING TABLE or call

1-800-554-6723.

CHAIN BRAKE

_WARNING: If the brake band is

worn too thh_ it may break when the chain

brake is triggered. With a broken brake band,

the chain brake will not stop the chain. The

chain brake should be replaced by an autho-

rized service dealer ifany part is worn to less

than 0.020" (0.5 mm) thick. Repairs on a

chain brake should be made by an autho-

rized service dealer. Take your unit to the

place of purchase if purchased from a ser-

vicing dealer, or to the nearest authorized

master service dealer.

• This saw is equipped with a chain brake.

The brake is designed to stop the chain if

kickback occurs.

• The inertia-activated chain brake is

activated if the front hand guard is pushed

forward, either manually (by hand) or

automatically (by sudden movement).

• If the brake is already activated, it is

disengaged by pulling the front hand guard

back toward the front handle as far as

possible.

• When cutting with the saw. the chain brake

must be disengaged.

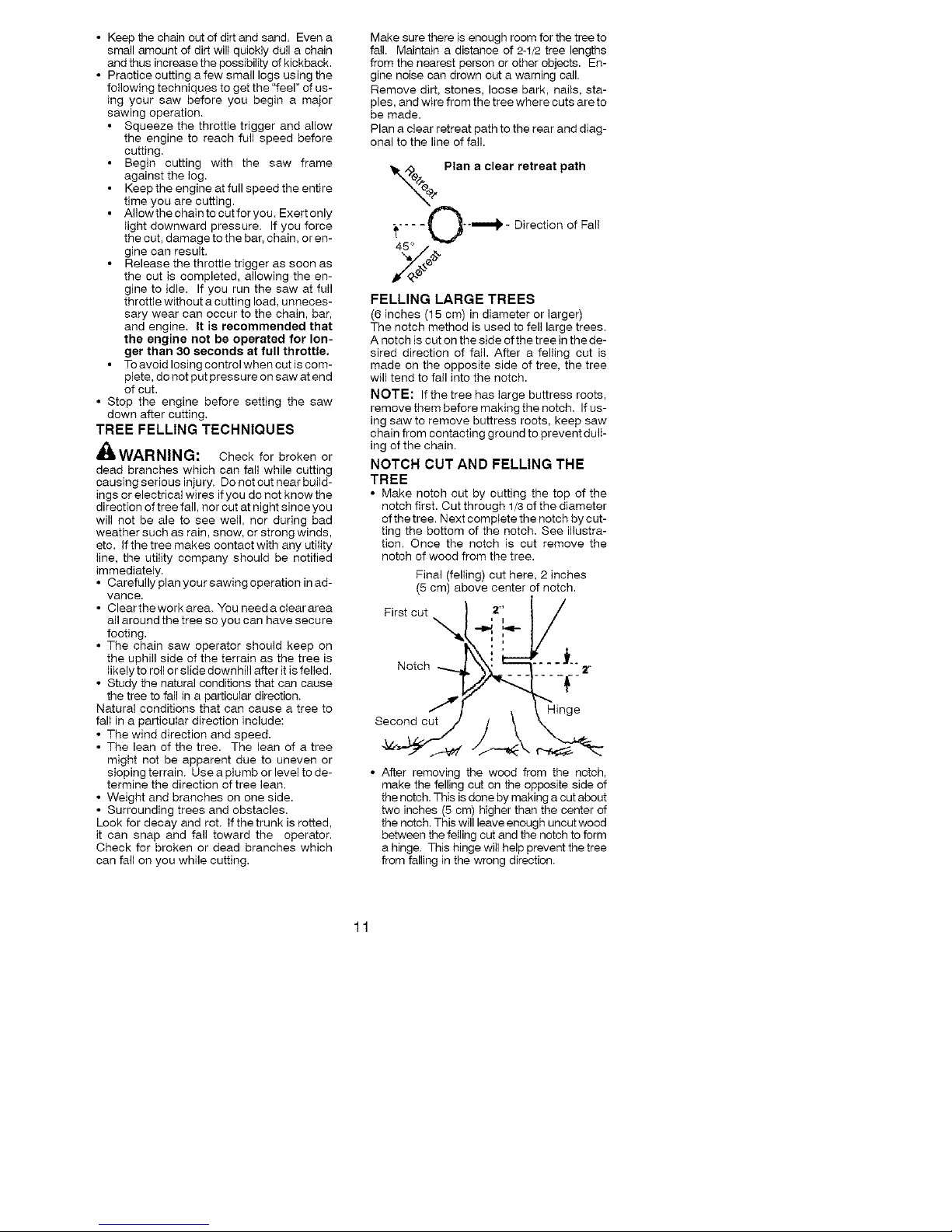

Disengaged _

'_ Engaged

Braking function control

CAUTION: The chain brake must be

checked several times daily. The engine

must be running when performing this proce-

dure. This is the only instance when the saw

should be placed on the ground with the en-

gine running.

Place the saw on firm ground. Grip the rear

handle with your right hand and the front han-

dle with your left hand. Apply full throttle by

fully depressing the throttle trigger. Activate

the chain brake by turning your teft wrist

against the hand guard without releasing

your grip around the front handle. The chain

should stop immediately.

Inertia activating function control

_WARNING: When performing the

following procedure, the engine must be

turned off.

Grip the rear handle with your right hand and

the front handle with your left hand, Hold the

chain saw approximately 14" (35 cm) above

a stump or other wooden surface. Release

your grip on the front handle and use the

weight of the saw to let the tip of the guide bar

fall forward and contact the stump. When the

tip of the bar hits the stump, the brake should

activate.

IMPORTANT POINTS

• Check chain tension before first use and

after 1 minute of operation. See CHAIN

TENSION in the ASSEMBLY section.

• Cut wood only. Do not cut metal, plastics,

masonry, non-wood building materials, etc.

• Stop the saw if the chain strikes a foreign

object. Inspect the saw and repair or re-

place parts as necessary.

10

Page 11

• Keepthechainoutofdirtandsand.Evena

smallamountofdirtwillquicklydullachain

andthusincreasethepossibilityofkickback.

• Practicecuttingafewsmalllogsusingthe

followingtechniquestogetthe"feel"ofus-

ingyoursawbeforeyoubeginamajor

sawingoperation.

• Squeezethethrottletriggerandallow

theenginetoreachfullspeedbefore

cutting.

• Begincuttingwiththesawframe

againstthelog.

• Keeptheengineatfullspeedtheentire

timeyouarecutting.

• Allowthechaintocutforyou.Exertonly

lightdownwardpressure.Ifyouforce

thecut,damagetothebar,chain,oren-

ginecanresult.

• Releasethethrottletriggerassoonas

thecutiscompleted,allowingtheen-

ginetoidle.Ifyourunthesawatfull

throttlewithoutacuttingload,unneces-

sarywearcanoccurtothechain,bar,

andengine.It is recommended that

the engine not be operated for lon-

ger than 30 seconds at full throttle.

• To avoid Iosh_g control when cut is com-

plete, do not put pressure on saw at end

of cut.

• Stop the engine before setting the saw

down after cutting.

TREE FELLING TECHNIQUES

_WARNING: Check for broken or

dead branches which can fall while cutting

causing serious injury, Do not cut near build-

ings or electrical wires if you do not know the

direction of tree fall, eor cut at night since you

will not be ale to see well, nor during bad

weather such as rain, snow, or strong winds,

etc. if the tree makes contact with any utility

line, the utility company should be notified

immediately.

• Carefully plan your sawing operation in ad-

vance.

• Cleartheworkarea, You needacieararea

all around the tree so you can have secure

footing.

• The chain saw operator should keep on

the uphill side of the terrain as the tree is

likely to roll or slide downhill after it is felled.

• Study the natural conditions that can cause

the tree to fall in a particular direction,

Natural conditions that can cause a tree to

fall in a particular direction include:

• The wind direction and speed.

• The lean of the tree. The lean of a tree

might not be apparent due to uneven or

sioping terrain, Use a plumb or level to de-

termine the direction of tree lean.

• Weight and branches on one side.

• Surrounding trees and obstacles.

Look for decay and rot, If thetrunk is rotted,

it can snap and fall toward the operator.

Check for broken or dead branches which

can fall on you while cutting.

Make sure there is enough room for the tree to

fail. Maintain a distance of 2-t/2 tree lengths

from the nearest person or other objects. En-

gine noise can drown out a warning call.

Remove dirt, stones, loose bark, nails, sta-

ples, and wire from the tree where cuts are to

be made.

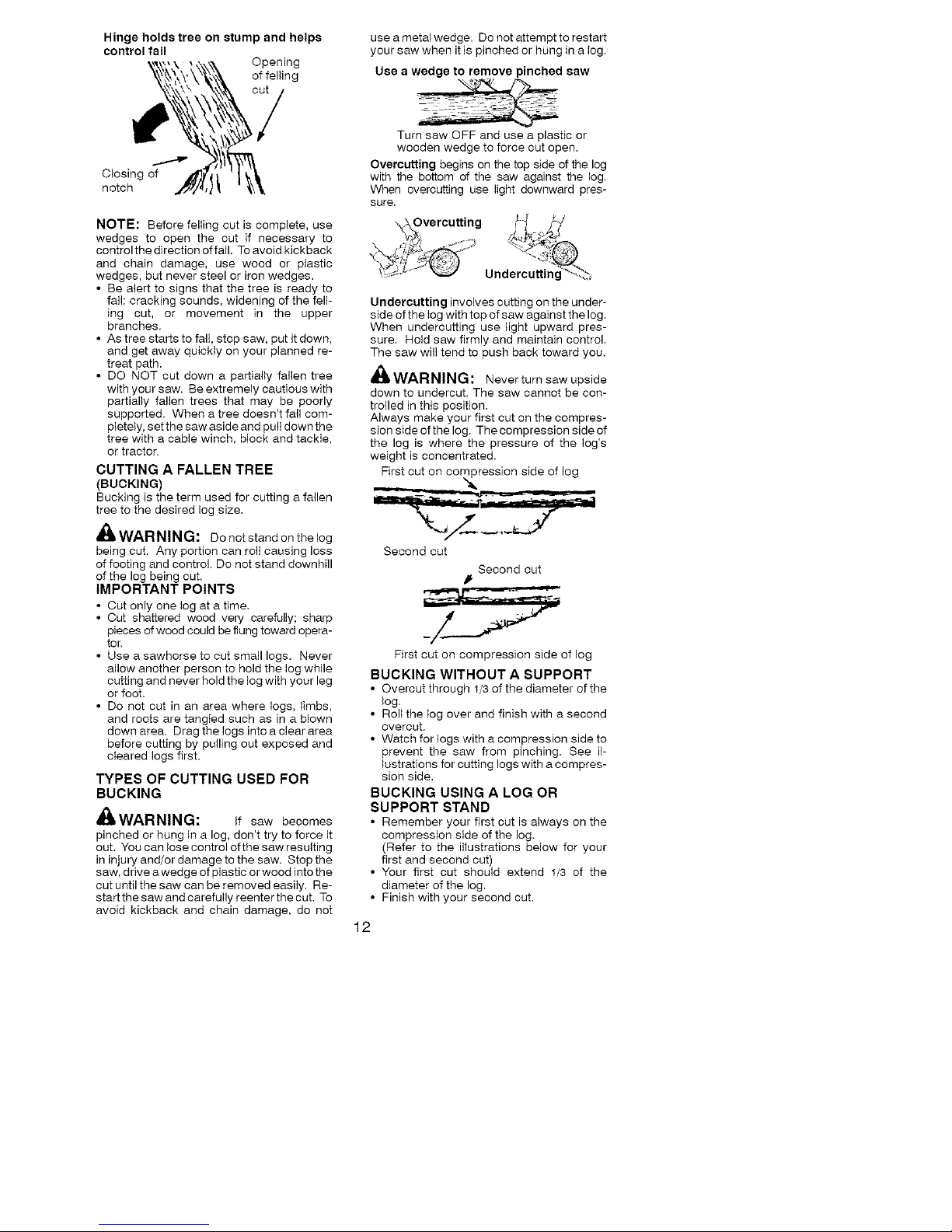

Plan a clear retreat path to the rear and diag-

onal to the line of fail.

x2. Plan a clear retreat path

(}'-====_ - Direction of Fall

45 ° / ,_

/q.e _"

FELLING LARGE TREES

(6 inches (15 ore) in diameter or larger)

The notch method is used to fell large trees.

A notch is cut on the side of the tree in the de-

sired direction of fall. After a felting cut is

made on the opposite side of tree, the tree

will tend to fall into the notch.

NOTE: If the tree has targe buttress roots,

remove them before making the notch. Ifus-

ing saw to remove buttress roots, keep saw

chain from contacting ground to prevent dull-

ing of the chain.

NOTCH CUT AND FELLING THE

TREE

• Make notch cut by cutting the top of the

notch first. Out through 1/3 of the diameter

of the tree. Next complete the notch by cut-

ting the bottom of the notch. See illustra-

tion. Once the notch is cut remove the

notch of wood from the tree.

Final (felling) cut here, 2 inches

(5 cm) above center of notch.

First cut } 2'; I /

Notch _ _'_" 2"

• After removing the wood from the notch,

make the felling cut on the opposite side of

the notch. This is done by making a cut about

two inches (5 cm) higher than the center of

the notch. This will leave enough uncut wood

between the felling cut and the notch to form

a hinge. This hinge will help prevent the tree

from falling in the wrong direction.

11

Page 12

Hinge holds tree on stump and helps

control fall

Opening

of felling

use a metal wedge. Do not attempt to restart

your saw when it is pinched or hung in a log.

Use a wedge to remove pinched saw

Closing of

notch

NOTE: Before felling cut is complete, use

wedges to open the cut if necessary to

control the direction of fail. To avoid kickback

and chain damage, use wood or plastic

wedges, but never steel or iron wedges.

• Be alert to signs that the tree is ready to

fall: cracking sounds, widening of the fell-

ing cut, or movement in the upper

branches.

• As tree starts to fall, stop saw, put it down,

and get away quickly on your planned re-

treat path.

• DO NOT cut down a partially fallen tree

with your saw. Be extremely cautious with

partially fallen trees that may be poorly

supported, When a tree doesn't fall com-

pletely, set the saw aside and pull down the

tree with a cable winch, block and tackle,

or tractor.

CUTTING A FALLEN TREE

(BUCKING)

Buckh_g is the term used for cutting a fallen

tree to the desired log size,

_ WARNING: Do not stand on the log

being cut. Any portion can roll causing loss

of footing and control. Do not stand downhill

of the log being cut.

IMPORTANT POINTS

• Cut only one tog at a time.

• Cut shattered wood very carefully; sharp

pieces of wood could be flung toward opera-

tor,

• Use a sawhorse to cut small logs. Never

allow another person to hold the log while

cutting and never hold the log with your leg

or foot,

• Do not cut in an area where logs, limbs,

and roots are tangled such as in a blown

down area. Drag the logs into a clear area

before cutting by pulling out exposed and

cleared logs first,

TYPES OF CUTTING USED FOR

BUCKING

_WARNING: If saw becomes

pinched or hung in a log, don't try to force it

out, You can lose control ofthe saw resulting

in injury and/or damage to the saw. Stop the

saw, drive a wedge of plastic or wood into the

cut until the saw can be removed easily. Re-

start the saw and carefully reenter the cut. To

avoid kickback and chain damage, do not

Turn saw OFF and use a plastic or

wooden wedge to force cut open,

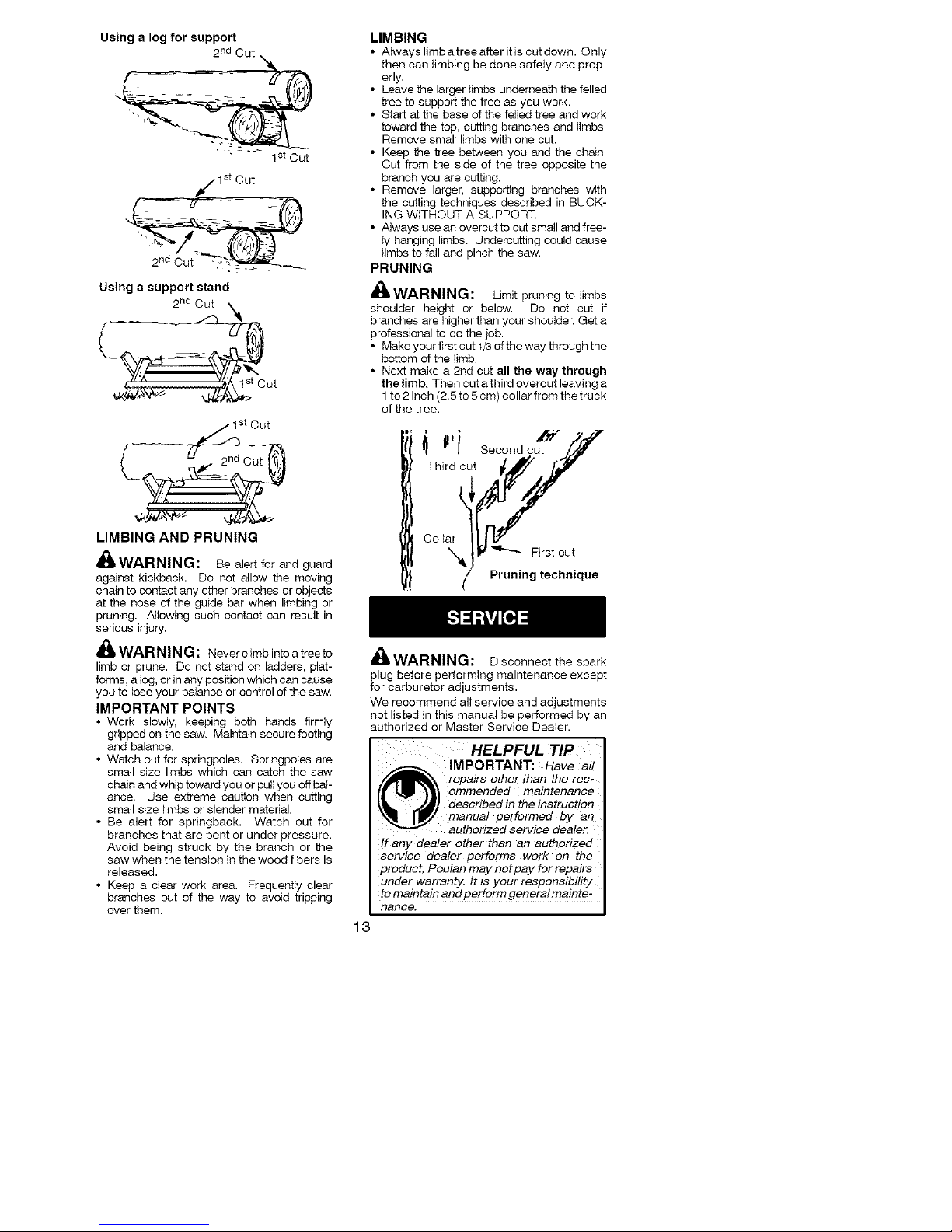

Overcutting begins on the top side of the log

with the bottom of the saw against the log.

When overcutting use light downward pres-

sure.

_Overcutting J _ L /

"-<2;ri

Undercutti <''"

Undercutting involves cutting on the under-

side of the tog with top of saw against the log.

When undercutting use light upward pres-

sure. Hold saw firmly and maintain control.

The saw will tend to push back toward you,

_i, WARNING: Never turn saw upside

down to undercut, The saw cannot be con-

trolled in this position,

Always make your first cut on the compres-

sion side of the log, The compression side of

the log is where the pressure of the log's

weight is concentrated,

First cut on compression side of log

Second cut

Second cut

First cut on compression side of tog

BUCKING WITHOUT A SUPPORT

• Overcut through 1/3 of the diameter of the

log.

• Roll the tog over and finish with a second

overcut,

• Watch for logs with a compression side to

prevent the saw from pinching, See il-

lustrations for cutting logs with a compres-

sion side.

BUCKING USING A LOG OR

SUPPORT STAND

• Remember your first cut is always on the

compression side of the log,

(Refer to the illustrations below for your

first and second cut)

• Your first cut should extend 1/3 of the

diameter of the log,

• Finish with your second cut.

12

Page 13

Using a log for support

2 nd Cut

I st Cut

,_1 st Cut

Using a support stand

2 nd Cut X_

ut

/ - _ 1st Cut

_A\_ -_ ,_

LIMBING AND PRUNING

WARNING: Bealertforandguard

against kickback, Do not allow the moving

chain to contact any other branches or objects

at the nose of the guide bar when limbing or

pruning. Allowing such contact can result in

serious injury,

_WARNING: Neverslimbintoatreeto

limb or prune. Do not stand on ladders, plat-

forms, a log, or in any position which can cause

you to lose your balance or control of the saw.

IMPORTANT POINTS

• Work slowly, keeping both hands firmly

gripped on the saw, Maintain secure footing

and balance,

• Watch out for springpoles. Springpoies are

small size limbs which can catch the saw

chain and whip toward you or pull you off bal-

ance. Use extreme caution when cutting

small size limbs or slender material,

• Be alert for springback, Watch out for

branches that are bent or under pressure.

Avoid being struck by the branch or the

saw when the tension in the wood fibers is

released.

• Keep a clear work area. Frequently clear

branches out of the way to avoid tripping

over them.

LIMBING

• Always limbatreeafter itis cutdown. Only

then can limbing be done safely and prop-

erly,

• Leave the larger limbs underneath the felled

tree to support the tree as you work.

• Start at the base of the felled tree and work

toward the top, cutting branches and limbs.

Remove small limbs with one cut.

• Keep the tree between you and the chain.

Cut from the side of the tree opposite the

branch you are cutting.

• Remove larger, supporting branches with

the cutting techniques described in BUCK-

ING WITHOUT A SUPPORT,

• Atways use an overcut to cut small and free-

ly hanging limbs, Undercutting could cause

limbs to fall and pinch the saw.

PRUNING

,_ WARNING: Limit pruning to limbs

shoulder height or below. Do not cut if

branches are higher than your shoulder. Get a

professional to do the job.

• Make your first cut I/3 of the way through the

bottom of the limb,

• Next make a 2nd cut all the way through

the limb. Then cut a third overcut leaving a

1 to 2 inch (2.5 to 5 cm) collar from the truck

of the tree.

_ThiPrl! Sec°nd cut_'_

Collar lit_

"_!_ _ First cut

/ Pruning technique

z_

WARNING: Disconnect the spark

plug before performing maintenance except

for carburetor adjustments.

We recommend all service and adjustments

not listed in this manual be performed by an

authorized or Master Service Dealer.

HELPFUL TIP

IMPORTANT: Have all

/'j_lmllL_ , repairs other than the rec-

Ur _,_ _ ommended maintenance

_Vdll_ ___] described in the instruction

manual performed by an

authorized service dealer.

!f any dealer other than an authodzed

service dealer performs work on the

product, Poulan may not pay for repairs

under warranty. It is your responsibility

to maintain and perform general mainte-

nanoe.

13

Page 14

MAINTENANCE SCHEDULE

Check:

Fuel mixture level .... Before each use

Bar lubrication ....... Before each use

Chain tension ....... Before each use

Chain sharpness ..... Before each use

For damaged parts ... Before each use

For loose caps ...... Before each use

For loose fasteners... Before each use

For loose parts ...... Before each use

Inspect and Clean:

Bar ................ Before each use

Complete saw ....... After each use

Air filter ............. Every 5 hours*

Chain brake ......... Every 5 hours*

Spark arresting screen

and muffler .......... Every 25 hours*

Replace spark plug . Yearly

Replace fuel filter ... Yearly

* Hours of Operation -

Each hour of operation is approximately

2 tanks of fuel.

AIR FILTER

CAUTION: Do not clean filter in gasoline

or other flammable solvent to avoid creating

a fire hazard or producing harmful evapora-

tive emissions.

Cleaning the air filter:

A dirty air filter decreases the life and perfor-

mance of the engine and h_creases fuel con-

sumption and harmful emissions. Always

ctean your air filter after 10 tanks of fuel or 5

hours of operation, whichever comes first.

Clean more frequently h_dusty conditions. A

used air filter can never be completely

cleaned, it is advisable to replace your air fil-

ter with a new one after every 50 hours of op-

eration, or annually, whichever comes first.

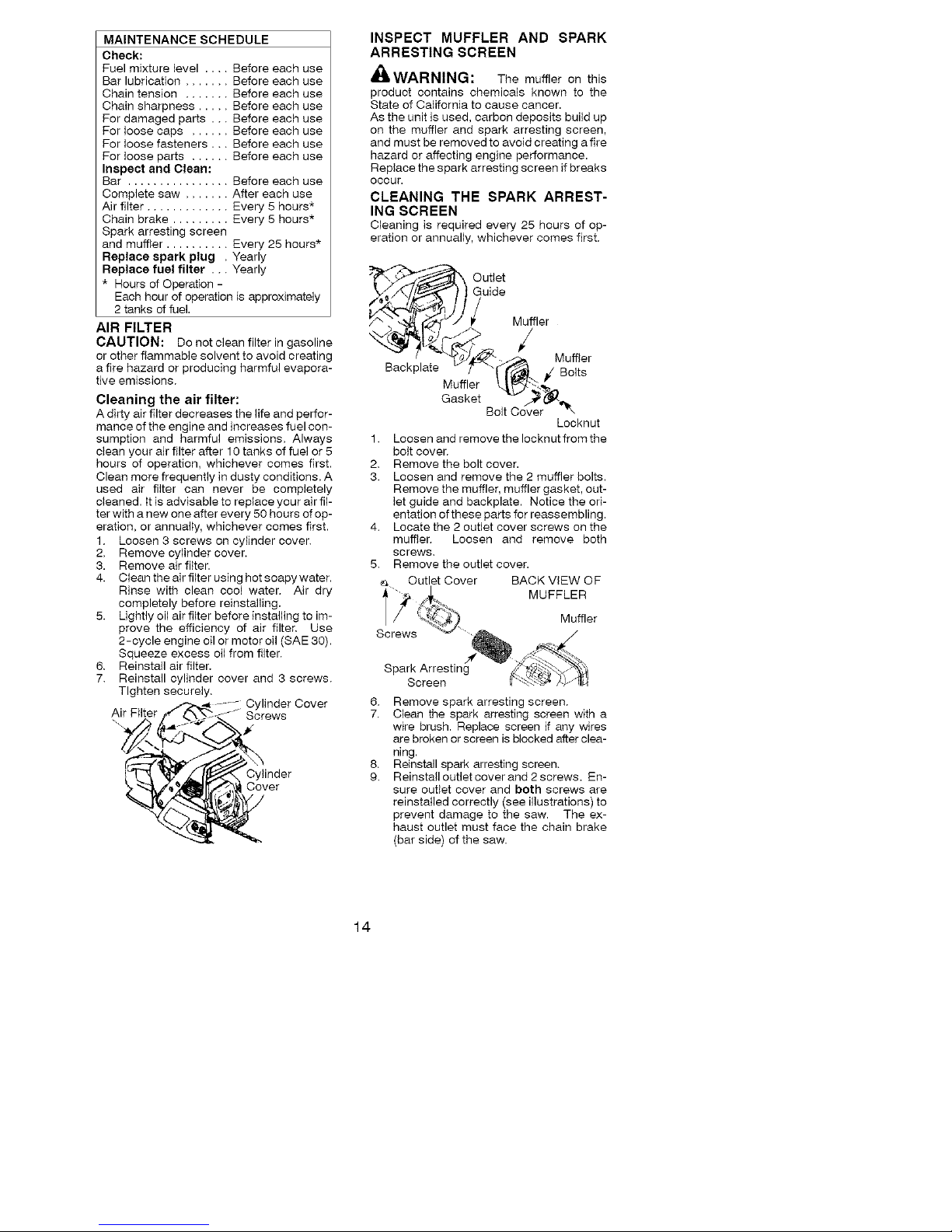

1. Loosen 3 screws on cylinder cover.

2. Remove cylinder cover.

3. Remove air filter.

4. Clean the air filter using hot soapy water.

Rh_se with clean cool water. Air dry

completely before reinstalling.

5. Lightly oil air filter before installing to im-

prove the efficiency of air filter. Use

2-cycle engine oil or motor oil (SAE 30).

Squeeze excess oil from filter.

6. Reinstall air filter.

7. Reinstall cylinder cover and 3 screws.

Tighten securely.

_ I Cylinder Cover

Air Filter _f Screws

er

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

_WARNING: The muffler on this

product contains chemicals known to the

State of California to cause cancer.

As the unit is used, carbon deposits build up

on the muffler and spark arresting screen,

and must be removed to avoid creating a fire

hazard or affecting engine performance.

Replace the spark arresting screen if breaks

OCCUr.

CLEANING THE SPARK ARREST-

ING SCREEN

Cleaning is required every 25 hours of op-

eration or annually, whichever comes first.

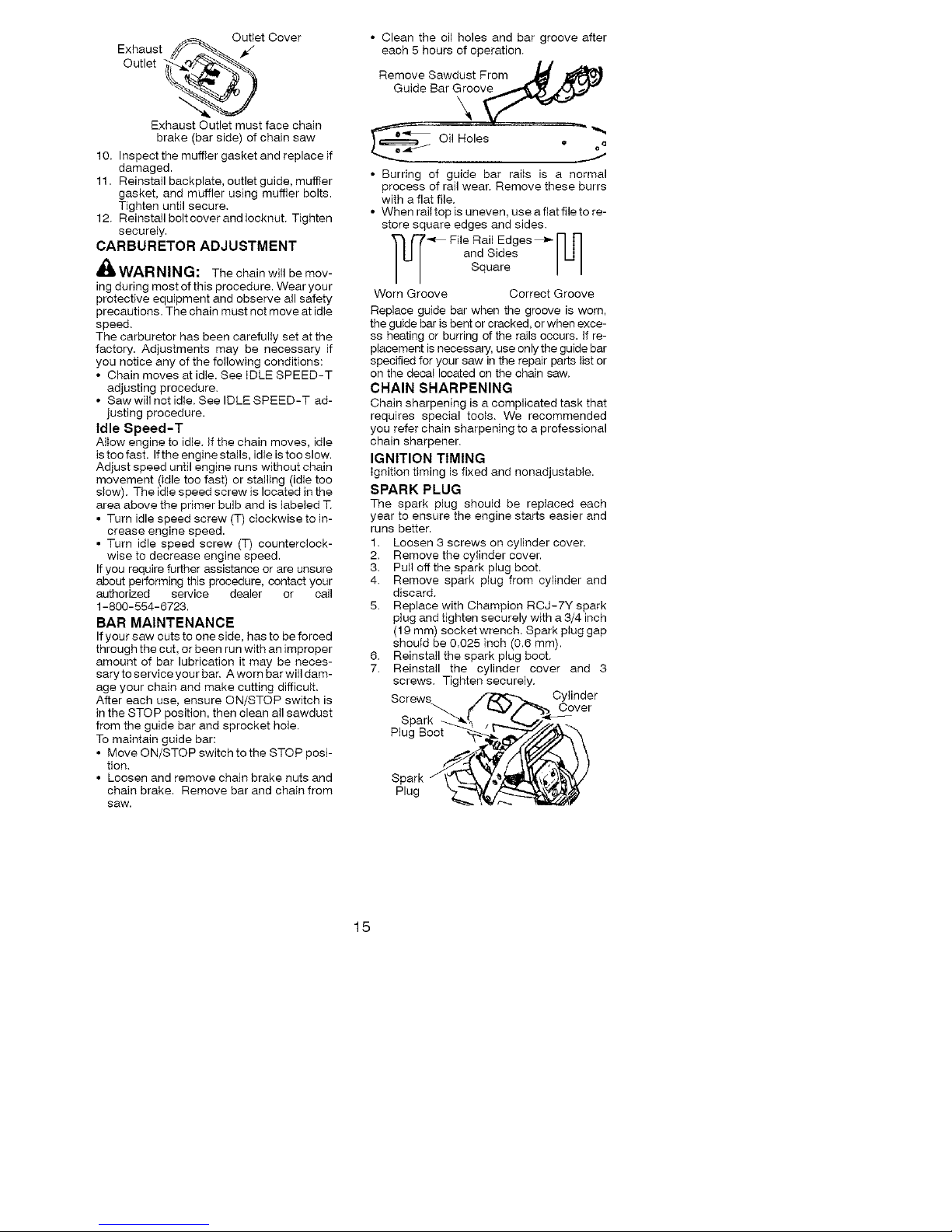

Outlet

Guide

Backplate

Muffler

Gasket

Muffler

/

Muffler

_/ Bolts

Bolt Cover

Locknut

1. Loosen and remove the Iocknutfrom the

bott cover.

2. Remove the bolt cover.

3. Loosen and remove the 2 muffler bolts.

Remove the muffler, muffler gasket, out-

let guide and backplate. Notice the ori-

entation of these parts for reassembling.

4. Locate the 2 outlet cover screws on the

muffler. Loosen and remove both

screws.

5. Remove the outlet cover.

_ Outlet Cover BACK VIEW OF

MUFFLER

Screws

Muffler

Spark Arresting

Screen

6. Remove spark arresting screen.

7. Clean the spark arresting screen with a

wire brush. Replace screen if any wires

are broken or screen is blocked after clea-

ning.

8. Reinstall spark arresting screen.

9. Reinstall outlet cover and 2 screws. En-

sure outlet cover and both screws are

reinstalled correctly (see illustrations) to

prevent damage to the saw. The ex-

haust outlet must face the chain brake

(bar side) of the saw.

14

Page 15

Outlet Cover

Exhaust _. _/

Outlet _o?';_ 2-.""-_"_. `

Exhaust Outlet must Nee chain

brake (bar side) of chain saw

10. Inspect the muffler gasket and replace if

damaged.

11. Reinstall baskplate, outlet guide, muffler

gasket, and muffler using muffler bolts.

Tighten until secure.

12. Reinstall bolt cover and Iocknut. Tighten

securely.

CARBURETOR ADJUSTMENT

_l_ WARNING: The chain will be mov-

ing during most of this procedure. Wear your

protective equipment and observe all safety

precautions. The chain must not move at idle

speed.

The carburetor has been carefully set at the

factory. Adjustments may be necessary if

you notice any of the following conditions:

• Chain moves at idle. See iDLE SPEED-T

adjusting procedure.

• Saw will not idle. See IDLE SPEED-T ad-

justing procedure.

Idle Speed-T

Allow engine to idle. If the chain moves, idle

is too fast. Ifthe engine stalls, idle is too slow.

Adjust speed until engine runs without chain

movement (idle too fast) or stalling (idle too

slow). The idle speed screw is located in the

area above the primer bulb and is labeled T.

• Turn idle speed screw (T) clockwise to in-

crease engine speed.

• Turn idle speed screw (T) counterclock-

wise to decrease engine speed.

If you require further assistance or are unsure

about peffon-ning this procedure, contact your

authorized service dealer or call

1-800-554-6723.

BAR MAINTENANCE

If your saw cuts to one side. has to be forced

through the cut. or been run with an improper

amount of bar lubrication it may be neces-

sary to service your bar. A worn bar will dam-

age your chain and make cutting difficult.

After each use. ensure ON/STOP switch is

in the STOP position, then clean all sawdust

from the guide bar and sprocket hole.

To maintain guide bar:

• Move ON/STOP switch to the STOP posi-

tion.

• Loosen and remove chain brake nuts and

chain brake, Remove bar and chain from

saw.

• Clean the oil holes and bar groove after

each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

\

Oil Holes

oc

• Burring of guide bar rails is a normal

process of rail wear. Remove these burrs

with a flat file.

• When rail top is uneven, use a flat file to re-

store square edges and sides.

_ File Rail Edges_ FI FI

and Sides I U I

Square ] ]

Worn Groove Correct Groove

Replace guide bar when the groove is worn,

the guide bar is bent or cracked, or when exce-

ss heating or burring of the rails occurs. If re-

placement is necessary, use only the guide bar

specified for your saw in the repair parts list or

on the decal located on the chain saw.

CHAIN SHARPENING

Chain sharpening is a complicated task that

requires special toots. We recommended

you refer chain sharpening to a professional

chain sharpener.

IGNITION TIMING

Ignition timing is fixed and nonadjustable.

SPARK PLUG

The spark plug should be replaced each

year to ensure the engine starts easier and

runs better.

1. Loosen 3 screws on cylinder cover.

2. Remove the cylinder cover.

3. Pull off the spark plug boot.

4. Remove spark plug from cylinder and

discard.

5. Replace with Champion RCJ-7Yspark

plug and tighten securely with a 3/4 inch

(19 mm) socket wrench. Spark plug gap

should be 0.025 inch (0.6 mm).

6. Reinstall the spark plug boot.

7. Reinstall the cylinder cover and 3

screws. Tighten securely.

Screws

Cover

Plug Boot

Spark

Plug

15

Page 16

STORAGE

_'WARNING: stop engine and allow

to cool, and secure the unit before storing or

transporting in a vehicle. Store unit and fuel

in an area where fuel vapors cannot reach

sparks or open flames from water heaters,

electric motors or switches, furnaces, etc.

Store unit with all guards in place. Position so

that any sharp object cannot accidentally

cause h3jury to passersby. Store the unit out

of reach of children.

• Before storing, drain all fuel from the unit.

Start engine and allow to run until it stops.

• Clean the unit before storing. Pay particu-

lar attention to the air intake area, keeping

it free of debris. Use a mild detergent and

sponge to clean the plastic surfaces.

• Do not store the unit or fuel in a closed area

where fuel vapors can reach sparks or an

open flame from hot water heaters, electric

motors or switches, furnaces, etc.

• Store in a dry area out of the reach of chil-

dren.

TROUBLESHOOTING TABLE

HELPFUL TIP I

Duringstorageofyourgas/ I

_1_,_ oil mixture, the oil will sepa: I

'l_l_Y._\ rate from the gas. I

,m_] We recommend that you I

_--_ljlrj shake the gas can weekly I

to insure proper blending of I

the gas and oil. I

CAUTION: It is important to prevent gum

deposits from forming in essential fuel system

parts such as the carburetor, fuel filter, fuel

hose, or fuel tank during storage. Alcohol

blended fuels (called gasohoI or using ethanol

or methanol) can attract moisture which leads

to fuel mixture separation and formation of

acids during storage. Acidic gas can damage

the engine.

NEED ASSISTANCE?

Call 1-800-554-6723.

NEED SERVICE PART?

Contact your dealer or place of purchase.

_, WARNING: Always stop unit and disconnect spark plug before performing all of

the recommended remedies below except remedies that require operation of the unit.

TROUBLE REMEDY

Engine will not

start or will run

only a few

seconds after

starting.

CAUSE

1. ignition switch off.

2. Engine flooded.

3. Fuel tank empty.

4. Spark plug not firing.

5. FueI not reaching

carburetor.

1. Move ignition switch to ON.

2. See "Difficult Starting" in

Operation Section.

3. Fill tank with correct fuel mixture.

4. Install new spark plug.

5. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

1. See "Carburetor Adjustment" in the

Service and Adjustments Section.

2. Contact an authorized service dealer.

Engine will 1. Idle speed requires

not idle adjustment.

properly. 2. Carburetor requires

adjustment.

Engine wilt not 1. Air filter dirty. 1. Clean or replace air filter.

accelerate, 2. Spark plug fouled. 2. Clean or replace plug and regap.

lacks power. 3. Chain brake engaged. 3. Disengage chain brake.

or dies under 4. Carburetor requires 4. Contact an authorized service deater.

a load. adjustment.

Engine 1. Too much oil mixed with 1. Empty fuel tank and refill with

smokes gasoline, correct fuel mixture.

excessively.

Chain moves 1. Idle speed requires 1. See "Carburetor Adjustment" in the

at idle speed, adjustment. Service and Adjustments Section.

2. Clutch requires repair. 2. Contact an authorized service dealer.

16

Page 17

Poulan warrants to the original purchaser

that each new Poulan brand gasoline chain

saw is free from defects in material and

workmanship and agrees to repair or replace

under this warranty any defective gasoline

chain saw as follows from the original date of

purchase,

1 YEAR - Parts and Labor, when used for

Household purposes.

60 DAYS - Parts and Labor, when used for

Commercial Professional, or Income Pro-

ducing purposes,

30 DAYS - Parts and Labor, if used for rental

purposes,

This warranty is not transferable and does

not cover damage or liability caused by im-

proper handling, improper maintenance, or

the use of accessories and/or attachments

not specifically recommended by Poulan for

this chain saw, Additionally, this warranty

does not cover damage caused by improper

handling, improper maintenance, or if the

saw is altered in any way which in our judge-

ment affects its condition or operation. This

warranty does not cover tune-up, spark

plugs, filters, starter ropes, starter springs,

chain sharpening, bars, chains, and other

parts which wear and require replacement

with reasonable use during the warranty pe-

riod, This warranty does not cover predeliv-

ery set-up, installation of guide bar and

chain, and normal adjustments explained in

the instruction manual such as carburetor

adjustments and chain tension adjustments.

This warranty does not cover transportation

costs,

THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY HAVE

OTHER RIGHTS WHICH VARY FROM

STATE TO STATE,

NO CLAIMS FOR CONSEQUENTIAL OR

OTHER DAMAGES WILL BE ALLOWED,

AND THERE ARE NO OTHER EXPRESS

WARRANTIES EXCEPT THOSE EX-

PRESSLY STIPULATED HEREIN,

SOME STATES DO NOT ALLOW LIMITA-

TIONS ON HOW LONG AN IMPLIEDWAR-

RANTY LASTS OR THE EXCLUSION OR

LIMITATIONS OF INCIDENTAL OR CON-

SEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATIONS OR EXCLUSION

MAY NOT APPLY TO YOU,

The policy of Poulan is to continuously im-

prove its products. Therefore, Poulan re-

serves the right to change, modify, or discon-

tinue models, designs, specifications, and

accessories of all products at any time with-

out notice or obligation to any purchaser.

YOUR WARRANTY RIGHTS AND OBLIGA-

TIONS: The U.S. Environmental Protection

Agency, California Air Resources Board, Envi-

ronment Canada and Poulan/WEED EATER

are pleased to explain the emissions control

system warranty on your year 2005 and later

small off-road engine, in California, all small

off-road engines must be designed, built, and

equipped to meet the State's stringent anti-

smog standards. Poulae/WEED EATER

must warrant the emission control system on

your small off- road engine for the periods of

time listed below provided there has been no

abuse, neglect, or improper maintenance of

your small off-road engine. Your emission

control system includes parts such as the

carburetor and the ignition system. Where a

warrantable condition exists, Poulan/WEED

EATER will repair your small off-road engine

engine at no cost to you. Expenses covered

under warranty include diagnosis, parts and

labor. MANUFACTURER'S WARRANTY

COVERAGE: if any emissions related part

on your engine (as listed under Emissions

Control Warranty Parts List) is defective or a

defect in the materials or workmanship of the

engine causes the failure of such an emis-

sion related part, the part will be repaired or

replaced by Poulan/WEED EATER. OWN-

ER'S WARRANTY RESPONSIBILITIES:

As the small off-road engine engine owner,

you are responsible for the performance of

the required maintenance listed in your in-

struction manual, Poulan/WEED EATER rec-

ommends that you retain all receipts covering

maintenance on your small off-road engine,

but Poulan/WEED EATER cannot deny war-

ranty solely for the lack of receipts or for your

failure to ensure the performance of all sched-

uled maintenance, As the small off-road en-

gine engine owner, you should be aware that

Poulan/WEED EATER may deny you warran-

ty coverage if your small off-road engine en-

gine or a part of it has failed due to abuse, ne-

glect, improper maintenance, unapproved

modifications, or the use of parts not made or

approved by the original equipment manufac-

turer. You are responsibte for presenting your

smalt off-road engine to an Poulan/WEED

EATER authorized repair center as soon as a

probtem exists. Warranty repairs should be

completed in a reasonable amount of time, not

to exceed 30 days. If you have any questions

regarding your warranty rights and responsibili-

ties, you should contact your nearest autho-

rized service center or call Poulan/WEED

EATER at 1-800-554-6723. WARRANTY

COMMENCEMENT DATE: The warranty pe-

riod begins on the date the small off-road en-

gine is purchased. LENGTH OF COVER-

AGE: This warranty shah be for a period of two

years from the initial date of purchase. WHAT

IS COVERED: REPAIR OR REPLACE-

MENT OF PARTS, Repair or replacement of

any warranted part witl be performed at no

charge to the owner at an approved Poulan/

17

Page 18

WEED EATER servicing center. If you have

any questions regarding your warranty

rights and responsibilities, you should con-

tact your nearest authorized service center

or call Poulan/WEED EATER at

1-800-554-6723. WARRANTY PERIOD:

Any warranted part which is not scheduled

for replacement as required maintenance, or

which is scheduled only for regular inspec-

tion to the effect of "repair or replace as nec-

essary" shall be warranted for 2 years. Any

warranted part which is scheduled for re-

placement as required maintenance shall be

warranted for the period of time up to the first

scheduled replacement point for that part.

DIAGNOSIS: The owner shall not be

charged for diagnostic labor which leads to

the determination that a warranted part is de-

fective ifthe diagnostic work is performed at

an approved Poulan/WEED EATER servic-

ing center, CONSEQUENTIAL DAMAGES:

Poulan/WEED EATER may be liable for

damages to other engine components

caused by the failure of a warranted part still

underwarranty, WHATIS NOTOOVERED:

All failures caused by abuse, neglect, or im-

proper maintenance are not covered.

ADD-ON OR MODIFIED PARTS: The use of

add-on or modified parts can be grounds for

disallowing a warranty claim. Poulan/WEED

EATER is not liable to cover failures of war-

ranted parts caused by the use of add-on or

modified parts, HOW TO FILE A CLAIM: If

you have any questions regarding your war-

ranty rights and responsibilities, you should

contact your nearest authorized service center

or caII Poulan/WEED EATER at

1-800-554-6723. WHERE TO GET WAR-

RANTY SERVICE: Warranty services or re-

pairs shall be provided at all Poulan/WEED

EATER service centers. Call:

1-800-554-6723 MAINTENANCE, RE-

PLACEMENT AND REPAIR OF EMISSION

RELATED PARTS: Any Poulan/WEED EAT-

ER approved replacement part used in the per-

formance of any warranty maintenance or re-

pair on emission related parts will be provided

without charge to the owner if the part is under

warranty, EMISSION CONTROL WARRAN-

TY PARTS UST: Carburetor, Ignition System:

Spark Plug (covered up to maintenance

schedule), Ignition Module, Muffler including

catalyst, MAINTENANCE STATEMENT: The

owner is responsible for the performance of all

required maintenance as defined in the instruc-

tion manual.

The information on the product label indicates which standard your engine is certified.

Example: (Year) EPA Phase 1 or Phase 2 and/or CALIFORNIA.

41 I 61 I 81 I

This engine is certified to be emissions compliant for the following use:

[] Moderate (50 hours)

[] Intermediate (125 hours)

[] Extended (300 hours)

18

Page 19

ADVERTENClA:iEsta

sierra de cadena puede ser

peligrosa! El uso descuidado

o indebido de esta herramienta

puede causar graves heridas.

D Lea y comprenda et

manual de instruc-

ciones antes de usar la

sierra.

Use siempre la proteccion de oidos apropiada, la proteccion de

ojos y la protecci6n de la cabeza.

Use siempre las dos manos cuando trabaje con la sierra de

oadena.

ADVERTENClA: Debe evitarse cualquier contacto de

la punta de la barra guia con cualguier objeto, ya que puede

causar que la barra guia se desplace repentinamente hacia

arriba y hacia atr&.s, con posibles graves heridas.

MAximo valor de kickback medido sin et freno de cadena para la

combinaci6n de barra y cadena indicada en la etiqueta.

'_ ADVERTENCIA: Desconecte

siempre el cable de la bujia y colSquelo

donde no puede entrar en contacto con el

bujia, para evitar cualquier arranque acci-

dental al preparar, transportar, ajustar o re-

parar el aparato, excepto en e} case de

ajustes al carburador.

Debido a que las sierras de cadena son

instrumentos para cortar madera a alta velo-

cidad, deben observarse precauciones de

seguridad especia}es para reducir el riesgo

de accidentes. El use descuidado o indebi-

do de esta herramienta puede causar

graves heridas.

PIENSE ANTES DE PROCEDER

• Antes de utilizar ta sierra, lea attentamente

este manual hasta estar seguro o compren-

dedo comptetamente y poder seguir todas

tas reglas de seguridad, precaucions e

instrucciones de uso que se dan en el.

• Umite el uso de la sierra a aquellos usuarios

adultos que comprendad y puedan imple-

mentar todas las precauciones, reglas de

seguridad e instrucciones de uso que se en-

cuentran en este manual.

Proteccion Casco Duro

de Oidos _

_. =-J Proteceion de

_'_I_I_ Ojos

Ropa Ajustada

al Cuerpo _ Guantes de

Uso Industrial

Zapatos de Pantorrilleras

Seguridad uridad

• Use equipo protector. Siempre use calzado

de seguridad con puntas de acero y suelas

anti-destizantes; ropa ajustada el cuerpo;

guantes gruesos de uso industrial anti-desli-

zantes; protecci6n de ojos tales como gafas

de seguridad que no se empa[_an y con ab-

erturas de ventillaci6n o mascara protectora

para la cara; casco duro aprobado; y barrera

de sonido (tapones de oido u orejeras anti-

sonido) para proteger la audicion. Los que

usan sierras de fuerza deberan hacerse re-

visar la audici6n frecuentemente ya que el

19

Page 20

ruido de las sierras de cadena puede da_fiar

tos oidos.

• Mantenga todas las partes del cuerpo aieja-

das de la cadena siempre que el motor este

en funcionamiento.

• Mantenga a los niSos, espectadores y anF

males a una distancia minima de t0 metros

(30 pies) de1Area de trabajo o cuando esta

haoieeoo arranoar el motor.

• No levante ni opere la sierras de cadena

cuando estA faigado, enfermo, ansioso o si

ha tornado alcohol, drogas o remedios. Es

imprescindible que ed. este en buenas con-

diciones fisicas y alerta mentalmente. Si ud.

sufre de cualquier condici6n que pueda em-

peorar con el trabajo arduo, ases6rese con

su medico.

• No ponga en marcha ia sierra sin tener un

Area de trabajo despejada, superficie est-

able para pararse y, si esta derrubando

arboles, un camino predeterminado de retro-

eeso.

USE LA SIERRA OBSERVANDO

TODOS LOS PROCEDIMIENTOS

DE SEGURIDAD

• Mantenga }as dos manos en las manijas

siempre que el aparato este en march& El

uso del aparato con una sola mano puede

causar graves heridas al usuario, a los asis-

tentes, o a los espectadores. Las sierras de

cadena est&.n diseSadas para que se las use

con las dos manos en todo momento.

• Haga uso de la sierra de cadena Onicamente

en lugares exteriores bien ventiltados.

• No haga uso de la sierra desde las escaler-

as portatiles ni de los arboles.

• AsegQrese de que la cadena no vaya a hac-

er contacto con ningLin objeto antes de pon-

er en marcha el motor. Nunca intente hacer

arrancar la sierra con ta barra quia en un

corte.

• No aplique presi6n a la sierra al final de los

cortes. Apiicar presi6n puede hacer que

pierda el control al completarse el corte.

• Pare el motor antes de apoyar la sierra en

ningOn tado.

• No ponga en funcionamiento ia sierra de ca-

dena si esta daSada, incorrectamente ajus-

tad& o si no esta armada completa y segu-

ramente. Siempre cambie el barre, cadena,

protector de mano, freno de cadena, o el

otras piezas immediatamente si da[fiado,

roto, o se sate pot cualquier motivo.

• Cuando cargue la sierra de cadena en las

manos, hagalo con et motor parado, el silen-

ciador alejado det cuerpo, y la cadena hacia

atras y cubierta con un estuche.

MANTENGA LA SIERRA EN BUE-

NAS CONDICIONES DE FUNC-

TIONAMIENTO

• Ueve la sierra de cadena a un proveedor de

servicio autorizado para que haga todo ser-

vicio menos aqueIIos procedimientos lista-

dos en la seccion de mantenimiento de este

manual. Por ejempplo, si se usae herra-

mientas que no corresponden para retirar o

sostener el volaete al hacer servicio al era-

brague, pueden ocurrir daffios estructurates

at volante y causar que reviente.

• AsegQrese de que la cadena se detenga por

completo cuaedo se sueita el gatillo. Para

hacer correcciones, yea los AJUSTES AL

CARBURADOR.

• Nunca haga modificaciones de ninguna in-

dole a su sierra.

• Mantenga las manijas secas, limpias y libres

de aceite o de mezcia de combustible.

• Mantenga las tapas y los fijadores blen fijos.

• Use exclusivamente los accesorios y re-

puestos Poulan recomendados.

MANEJE EL COMBUSTIBLE CON

EXTREMO CUIDADO

• No fume mientras trabaja con el combustible

ni cuando est#t haciendo uso de la sierra.

• Elimine todas las posibles fuentes de chis-

paso llamas en las _.reas donde se mezclao

vierte el combustible. No debe haber el fu-

mar, llamas abiertas, o trabajo que podria

causar chispas. Permita que el motor es frio

antes de reaprovisionar de combustible.

• Mezcte y vierta et combustible afuera y use

recipiente aprobado para combustibles y

marcado como tal. Umpie todos los der-

tames de combustible.

• Alejese a por lo mendos 3 metros (10 pies)

del lugar de abastecimiento antes de poner

el motor en march&

• Apague el motor y deje que la sierra se

enfrie en un lugar libre de substancias com-

bustibles y no sobre hojas secas, paja, pa-

pel, etc. Retire latapa Ientamente y reabas-

tezca el aparato.

• Guarde el aparato en un espaciuo fresco,

seco y bien ventilado donde los vapores del

combustible no pueden entrar en contacto

con chispas ni llamas ablertas provenientes

de termotangues, motores o interruptores

electricos, calefactores centrales, etc.

RECULADA

_ILADVERTENCIA: Evite reculada le

pueden causar graves heridas. Reculada

es el movimiento hacia et frente, hacia atras

o rapidamente hacia adelante, esto puede

ocurrir cuando la punta de la barra guia de la

sierra de oadena entra en oontaoto con ouat-

quier objeto como puede ser otra rama o

tronco, o ouando la madera se cierra y atas-

ca mientras se hace el corte. El entrar en

coetacto con algLin objeto extra{rio a la mad-

era le puede causar al usuario la perdida del

controI de la sierra de cadena.

• La Reculada Rotacional puede acontecer

cuando la cadena en movimiento entra en

contacto con algOn objeto en la parte superi-

or de la punta de la barra guia puede causar

que la cadena entre al material y se detenga

por un instante. El resultado es una reacci6n

inversa, a velocidad de ret#.mpago, que hace

recular la barra guia hacia arriba y hacia

atras hacia el usuario.

• La Reculada por Atasco aoontesen suan-

do la madera se cierra y atasca la cadena en

movimiento en el corte a Io largo de la parte

20

Page 21

superior de la barra gufa y la cadena se de-

tiene repentinamente> Esta detenci6n re-

pentina de la cadena tiene come resuitado

una inversi6n de la fuerza de la cadena usa-

da para cortar madera y causa que la sierra

se mueva en sentido opuesto al de la rota-

ci6n de la cadena. La sierra directamente

hacia atr&.s en direcci6n al usuario.

• La Reculada pot Impulsion puede acon-

tecer cuando la cadena en movimiento entra

en contacto con algLin ebjeto extraSo a la

madera en el corte a Io largo de la parte infe-

rior de la barra guia y ta cadena se detiene

repentinamente> Esta detencion repentina

de la cadena tira de lasierra adelaete y lejos

del usuario y podria hacer f&cilmente al

usuario perder el control de la sierra,

Para Evitar la Reculada pot Atasco:

• Mantengase completamente conciente de

toda situacian u obstrucci6n que pueda hac-

er que el material presione la cadena en la

parte superior o que pueda parar la cadena

de cuatquier otro mope.

• No corte m&s de un tronco a la vez.

• No retuerza la sierra al retirar la barra de un

corte ascendiente cuando est@tseccioeando

tronoos.

Para Evitar la Reculada pot Impulsion:

• Empiece todo corte con el motor acelerade a

fondo y con la caja de la sierra apoyada con-

tra la madera.

• Use cuf_as de plastico o de madera (nunca

de metal) para mantener abierto el corte.

Trayectoria de la

\_' i") Reculada