EN Operator's manual, pp. 2-28

FR Manuel d'utilisation, pp. 29-55

ES Manual de instrucciones, pp. 56-82

Please readtheseinstructionsand make

sure you understand them before using the

machine.

Life attentivement etbien assimiler le manuel

d_utilisationavantd_utiliserla machine

Lea detenidamente el manualde instrucciones

y aseg(_resedeentender sucontenido antes

de utiRzarla m_quina.

SYMBOL EXPLANATION

Symbols

WARNING: Clearing saws, brush- L_

cutters and trimmers can be dan- fro\

gerous! Careless or incorrect use it _

can result in serious or fatal / • •

injury to the operator or others.

Please read the operator's manual

carefully and make sure you r[]I ri.]

understand the instructions

before using the machine.

• A protective helmet where there

is a risk of falling objects

Always wear: @

• Hearing protection

• Approved eye protection

Max. speed of output shaft, rpm

Beware of thrown objects and _., "_

ricochets.

The operator of the machine

shall ensure, while working,

that no persons or animals come

closer than 50 feet (15 meters).

Machines fitted with saw blades

or grass blades can be thrown

violently to tt_e side when the

blade comes into contact with

a fixed object. The blade is

capable of amputating an arm

or leg. Always keep people

and animals at least 50 feet

(15 meters) from the machine.

Arrows which show limits for

handle mounting. _ t

max

10000 rpm

A

Use unleaded or quatity leaded %. /t_-_-)__.

gasoiine and two-stroke oil

mixed at a ratio of 2% (t :50).

Other symbols/decals on the machine

refer to special certification requirements

for certain markets.

Stop the engine by pushing

and holding the stop switch

in the STOP position. CAUTION!

The stop switch automaticalIy

returns to the start position.

In order to prevent unintentional

starting, the spark plug cap must be

removed from the spark plug when

assembling, checking and/or

performing maintenance.

Regular cleaning is required. _-]

Visual check.

always be used.

Approved eye protection must

Always wear approved protective

gloves.

Use anti-slip and stable boots.

Only use non-metalHc, flexible

cutting attachments, i.e. trimmer

heads with trimmer line.

CONTENTS

Contents

KEY TO SYMBOLS

Symbols ......................... 2

CONTENTS

Contents ........................ 3

Note the following before starting .... 3

WHAT IS WHAT?

What is what? ................... 4

GENERAL SAFETY PRECAUTIONS

Important ........................ 5

Personal protective equipment ...... 5

Machine's safety equipment ........ 6

Cutting equipment ................. 8

ASSEMBLY

Fitting the handlebar ............... 10

Fitting the harness and harness clamp 10

Fitting blades and trimmer heads .... 11

Fitting a blade guard, grass blade and

grass cutter ...................... 11

Fitting the trimmer guard and

trimmer head ..................... 12

FUEL HANDLING

Fuel safety ....................... 13

Fuel ............................ 13

Fuelling ......................... 14

STARTING AND STOPPING

Check before starting .............. t 5

Starting and stopping .............. 15

WORKING TECHNIQUES

General working instructions ........ 17

MAINTENANCE

Carburetor ....................... 20

Muffler .......................... 20

Spark plug ....................... 21

Air filter .......................... 21

Bevel gear ....................... 22

Sharpening grass cutters and grass

blades .......................... 22

Maintenance schedule ............. 23

TECHNICAL DATA

Technical data .................... 24

EMISSION CONTROL

WARRANTY STATEMENT ......... 25

Note the following before

starting:

Please read the operator's manual carefully.

Maintenance, replacement, or repair of the

emission control devices and system may

be performed by any nonroad engine repair

establishment or individual,

Jonsered has a policy of continuous product

development and therefore reserves the right

to modify the design and appearance of prod-

ucts without prior notice.

to noise can result in permanent I

hearing impairment. Always use ap-

_ WARNING: Long-term exposure

proved hearing protection.

The Emissions Compliance Period referred

to on the Emissions Compliance label indi-

cates the number of operating hours for

which the engine has been shown to meet

Federal emissions requirements,

Category C = 50 hours, B= 125 hours, and

A = 300 hours.

4t I 61 I 81 I

WARNING

Theengine exhaust fromthisproduct

contains chemicalsknownto the State

ofCalifornia to causecancer,birth

defectsor other reproductiveharm.

For reference, please fill out the following

information that will be needed for future

servicing of your trimmer:

Model Number:

Serial Number:

Purchase Date:

Purchased From:

WARNING: A clearingsaw,

&

brushcutter or trimmer can be

dangerous if used incorrectly or

carelessly, and can cause serious

or fatal injury to the operator or

others. It is extremely important

that you read and understand the

contents of this operator's manual.

WARNING: Under no circum-

&

stances may the design of the

machine be modified without the

permission of the manufacturer.

Always use genuine accessories.

Non-authorized modifications

and/or accessories can result

in serious personal injury or the

death of the operator or others.

Your warranty may not cover

damage or liability caused by the

use of non-authorized accesso-

ries or replacement parts.

©®

WHAT IS WHAT?

@

@

@

What is what?

1. Blade

2. Grease filler cap

3. Bevel gear

4. Cutting attachment guard

5. Shaft

6. Handlebar

7. Throttle control

8. Stop switch

9. Throttle lock

10. Harness clamp

11. Cylinder cover

12. Starter handle

13. Fuel tank

14. Choke control

15. Primer bulb

@

16. Air filter cover

17. Handle adjustment

18. Locking nut

19. Support flange

20. Support cup

21. Drive disc

22. Trimmer head

23. Socket spanner

24. Transport guard

25. Hex wrench

26. Locking pin

27. Harness

28. Start throttle button

29. Adjusting the throttle wire

30. Operator's manual

®

GENERAL SAFETY PRECAUTIONS

Important

IMPORTANT? The rnechine is only designed

for trimming grass, grass clearing and/or

forestry clearing.

The only accessories you can operate with

this engine unit are the cutting attachments we

recommend in the section on Technical data,

Never use the machine if you are tired, if you

have drunk alcohol, or if you are taking medi-

cation that could affect your vision, your judge-

ment or your co-ordination.

Never use the machine in extreme weather

conditions such as severe cold, very hot and/

or humid climates.

Wear personaI protective equipment. See in-

structions under the heading Personal protec-

tive equipment.

Never use a machine that has been modified

in any way from its original specification,

Never use a machine that is faulty, Carry out

the checks, maintenance and service instruc-

tions described in this manual. Some mainte-

nance and service measures must be carried

out by trained and qualified specialists, See

instructions under the heading Maintenance,

All covers and guards must be fitted before

starting, Make sure the spark plug cap and

lead are not damaged. Otherwise you could

get an electric shock, The machine operator

must ensure that no people or animals come

closer than 50 feet (15 meters) while working,

When several operators are working in the

same area, the safety distance should be at

least 50 feet (15 meters).

,_ WARNING: Using an incorrect

cutting attachment or an incorrectly

filed blade can increase the risk of

accidents.

_ WARNING: Never allow children

to use or be in the vicinity of the

machine. As the machine is equipped

with a spring-loaded stop switch and

can be started by low speed and

force on the starter handle, even

small children under some circum-

stances can produce the force neces-

sary to start the machine. This can

mean a risk of serious personal inju-

ry. Therefore remove the spark plug

cap when the machine is not under

close supervision.

Personal protective equipment

IMPORTANT? A clearing saw, brushcutter

or trimmer can be dangerous if used incor-

rectly or carelessly, and can cause serious

or fatal injury to the operator or others. It is

extremely important that you read and un-

derstand the contents of this operator's

manual. You must use approved personal

protective equipment whenever you use the

machine. Personal protective equipment

cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident

does happen. Ask your dealer for help in

choosing the right equipment.

i_ WARNING: Listen out for warn-

ing signals or shouts when you are I

wearing hearing protection, Always I

remove your hearing protection as

soon as the engine stops.

HELMET

A helmet should be worn if the brush being

cleared is taller than 6 feet (2 meters).

HEARING PROTECTION

Wear hearing protection that provides

adequate noise reduction.

EYE PROTECTION

Always wear approved eye protection, if

you use a visor then you must also wear

approved protective goggles. Approved

protective goggles must comply with stan-

dard ANSI Z87.1.

GLOVES

Gloves should be worn when necessary,

e.g., when fitting cutting attachments.

BOOTS

Wear sturdy, non-slip boots.

GENERAL SAFETY PRECAUTIONS

CLOTHING

Wear clothes made of a strong fabric and

avoid loose clothing that can catch on

shrubs and branches. Always wear heavy,

long pants. Do not wear jewelry, shorts

sandals or go barefoot. Secure hair so it is

above shoulder level.

FIRST AID KIT

A first aid kit should be carried by opera-

tors of clearing saws, brushcutters or trim-

mers.

Machine's safety equipment

This section describes the machine's safe-

ty equipment, its purpose, and how checks

and maintenance should be carried out to

ensure that it operates correctly. See the

"What is what" section to locate where this

equipment is positioned on your machine.

The life span of the machine can be re-

duced and the risk of accidents can in-

crease if machine mah_tenance is not car-

ried out correctly and if service and/or re-

pairs are not carried out professionally, if

you need further information please contact

your nearest service workshop.

IMPORTANT! All servicing and repair work

on the machine requires special training. This

is especially true of the machine's safety

equipment, if your machine fails any of the

checks described below you must contact

/our service agent. When you buy any of our

3roducts we guarantee the availability of pro-

=essional repairs and service. If the retailer

who sells your machine is not a servicing

dealer, ask him for the address of your near-

est service agent.

Make sure the throttle control is locked at

the idle setting when the throttle lock is re-

leased,

Press the throttIe lock and make sure it re-

turns to its original position when you re-

lease it.

Check that the throttle control and throttle

lock move freely and that the return springs

work properly.

that has faulty safety equipment!

Follow the control, maintenance

and service instructions described

in this section, If your machine fails

l& ARNING: Never use a machine

any of these checks contact your

service agent to get it repaired.

Throttle lock

The throttle _ock is designed to prevent ac-

cidental operation of the throttle control

When you press the lock (A) (i.e. when you

grasp the handle) it releases the throttle

control (B). When you release the handle.

the throttle control and the throttle lock both

move back to their original positions. This

movement is controlled by two independent

return springs. This arrangement means

that the throttle control is automatically

locked at the idle setting.

See instructions under the heading Start,

Start the machine and apply full throttle,

Release the throttle and check that the

cutting attachment stops and remains at a

standstill If the cutting attachment rotates

with the throttle in the idle position then the

carburettor idle setting must be checked.

See instructions under the heading

Maintenance, _(_

GENERAL SAFETY PRECAUTIONS

Stop switch

Make sure the engine stops when you push

and hold the stop switch.

Cutting attachment guard

Harness quick release

There is an easily accessible, harness

quick release fitted at the front in case of an

emergency that requires you to free your-

self from the machine and harness.

See instructions under the heading Adjust-

ing the harness.

This guard is intended to prevent loose

objects from being thrown towards the

operator. The guard also protects the

operator from accidental contact with the

cutting attachment.

Check that the guard is undamaged and not

cracked. Replace the guard if it has been

exposed to impact or is cracked.

Always use the recommended guard for the

cutting attachment you are using. See the

"Technical data" section.

I_l ARNING: Never use a cutting

attachment without an approved

guard. See the section on "Technical

data". If an incorrect or faulty guard

is fitted this can cause serious

persona injury.

Use of incorrectly wound trimmer line or an

incorrect cutting attachment increases the

level of vibration.

_ WARNING: Overexposure to

vibration can lead to circulatory

damage or nerve damage in people

who have impaired circulation.

Contact your doctor if you experi-

ence symptoms of overexposure to

vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength,

changes in skin color or condition.

These symptoms normally appear

in the fingers, hands or wrists. The

risk increases at low temperatures.

Check that the harness straps are correctly

positioned. Once the harness and machine

have been adjusted, check that the harness

quick release works correctIy.

Muffler

The muffier is designed to reduce the noise

level and to direct the exhaust gases away

from the operator.

CAUTION? Muffler is fitted with a catalytic

converter designed to reduce harmful ex-

haust gases.

The muffler on this unit is equipped with a

special spark arrestor mesh. The mesh

should be checked and. if necessary.

cleaned by a servicing dealer. A blocked

mesh will cause the machine to overheat,

which can lead to serious damage. Never

use a muffler with a defective spark arrestor

mesh. See the Maintenance section.

Muffler bolts

_$park arrestor mesh

GENERAL SAFETY PRECAUTIONS

For mufflers, it is very important that you

follow the instructions on checking, main-

taining, and servicing your machine.

Never use a machine that has a faulty

muffler.

0

Regularly check that the muffler is securely

attached to the machine.

_ WARNING: Mufflers fittedwith

catalytic converters get very hot dur-

ing use and remain so for some time

after stopping. This also applies at

idle speed. Contact can result in

burns to the skin. Remember the risk

of fire!

_ WARNING: The inside of the

muffler contain chemicals that may

be carcinogenic. Avoid contact with

these elements in the event of a

damaged muffler.

_1 WARNING: Bear in mind that:

Engine exhaust fumes contain car-

bon monoxide, which can cause

carbon monoxide poisoning. For

this reason you should not start or

run the machine indoors, or any-

where that is poorly ventilated.

The exhaust fumes from the engine

are hot and may contain sparks

which can start a fire. Never start

the machine indoors or near com-

bustible material!

Locking nut

A locking nut is used to secure some types

of cutting attachment.

When fitting, tighten the nut in the opposite

direction to the direction of rotation of the

cutting attachment. To remove it. undo the

nut in the same direction as the cutting at-

tachment rotates. (CAUTION! The nut has

a left-hand thread.) Tighten the nut using

the socket spanner.

The nylon lining inside the locking nut must

not be so worn that you can turn it by

hand. The lining should offer a resistance

of at least 1.5 Nm. The nut should be re-

)laced after it has been put on approx. 10

times.

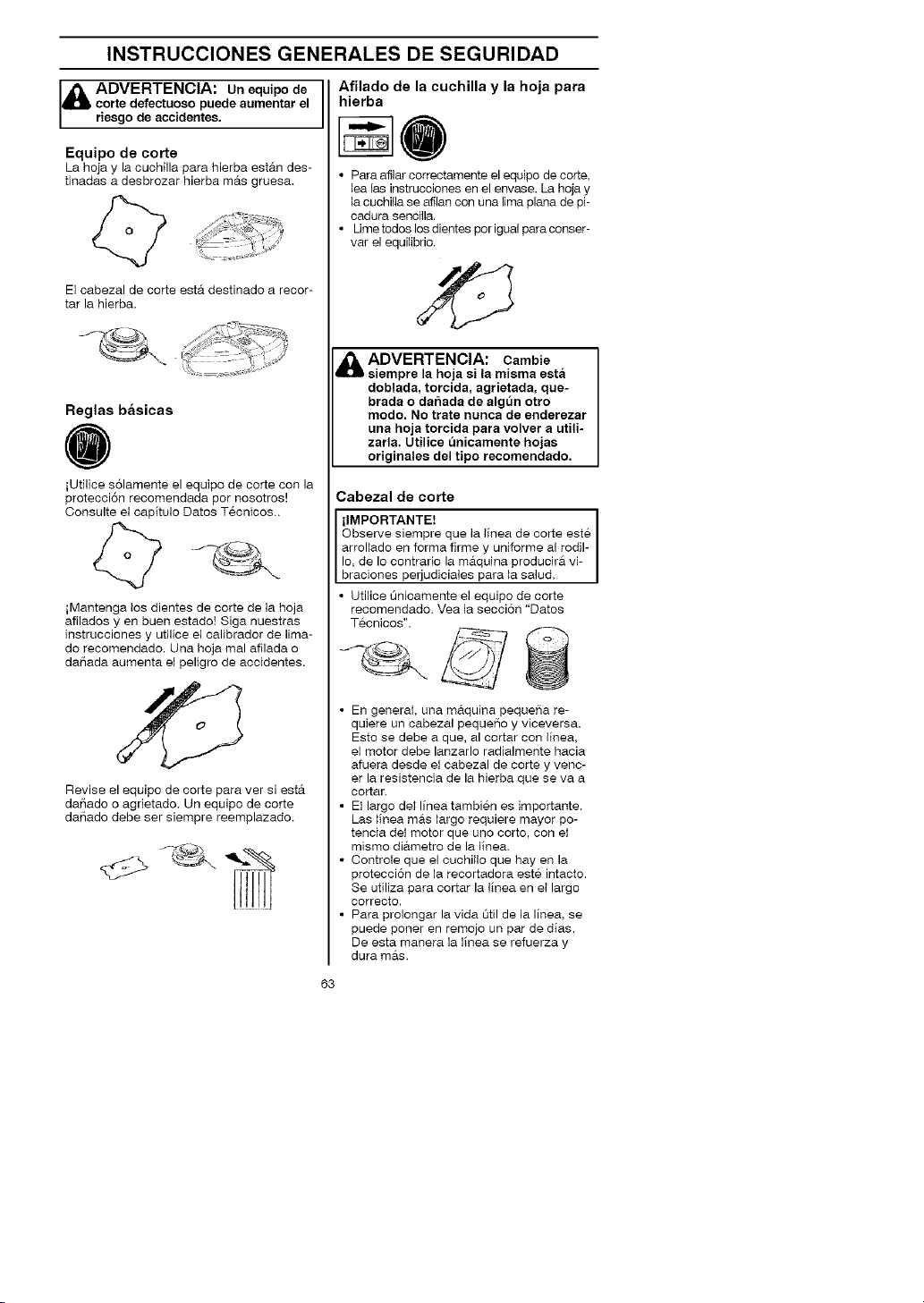

Cutting equipment

This section describes how to choose and

maintain your cutting equipment in order to:

• Reduce the risk of blade thrust.

• Obtain maximum cutting performance.

• Extend the life of cutting equipment.

IMPORTANT!

Only use cutting attachments with the guards

we recommend! See the section on

"Technical data".

Refer to the instructions for the cutting attach-

ment to check the correct way to load the

trimmer line and the correct line diameter.

Keep the teeth of the blade correctly sharp-

ened! Follow our recommendations. Also re-

fer to the instructions on the blade packaging.

Maintain the correct blade setting! Follow our

instructions and use the recommended file

gauge.

_ WARNING: Always stop the en-

gine before doing any work on the

cutting attachment. This continues

to rotate even after the throttle has

been released. Ensure that the

cutting attachment has stopped

completely and disconnect the

lead from the spark plug before

you start to work on it.

_lb WARNING: Using an incorrect

cutting attachment or an incorrect-

ly sharpened blade increases the

risk of kickback.

GENERAL SAFETY PRECAUTIONS

Cutting equipment

Grass blades and grass cutters are in-

tended for cutting coarse grass.

A trimmer head is intended for trimming

grass.

I;t_ :"<h _#

General rules

Only use cutting attachments with the

guards we recommend! See the section on

Technical data.

Keep the teeth of the blade correctly sharp-

ened! Follow our instructions and use the

recommended file gauge. An incorrectly

sharpened or damaged blade increases the

risk of accidents.

Sharpening grass cutters and

grass blades

• See the cutting attachment packaging for

correct sharpening instructions. Sharpen

blades and cutters using a single-cut flat file.

• Sharpen all edges equally to maintain the

balance of the blade.

,_ WARNING: Always discard a

blade that is bent, twisted, cracked,

broken or damaged in any other

way. Never attempt to straighten

a twisted blade so that it can be re-

used. Only use original blades of

the specified type.

Trimmer head

IMPORTANT!

Always ensure the trimmer line is wound

tightly and evenly around the drum, other-

wise the machine will generate harmful

vibration.

• Only use the recommended cutting at-

tachments. See the section on "Technical

data".

Check the cutting attachment for damage

or cracks. A damaged cutting attachment

should always be replaced.

• Smaller machines generally require small

trimmer heads and vice versa. This is be-

cause when clearing using trimmer line

the engine must throw out the trimmer

line radially from the trimmer head and

overcome the resistance of the grass

being cleared.

• The length of the trimmer line is also im-

portant. A longer trimmer line requires

greater engine power than a shorter

trimmer line of the same diameter.

• Make sure that the cutter on the trimmer

guard is intact. This is used to cut the

trimmer line to the correct length.

• To increase the life of the trimmer line it

can be soaked in water for a couple of

days. This will make the line tougher so

that it lasts longer.

ASSEMBLY

NOTE: Make sure unit is assembled cor-

rectly as shown in this manual.

Fitting the handlebar

Remove the screw at the rear of the

throttle handle.

Slide the throttle handle onto the right

side of the handlebar (see illustration).

Align the screw hole in the throttle han-

dle with the hole in the handlebar.

Refit the screw in the hole in the rear of

the throttle handle.

Screw the screw through the handle and

handlebar. Tighten the screw.

Fit the mounting components as shown.

//

NOTE: Fit throttle wire in groove of lower

harness clamp before tightenh_g screws.

• Insert two screws h_to the screw hotes.

• Secure harness clamp by tightening

screws with a hex wrench.

Adjusting the harness

• At the front of the harness is an easi]y

accesible quick release. Use the quick

release in any emergency situation that

requires you to free yourself from the

machine and harness.

...... _.=- j

Spreading the load on your

shoulders

• A well-adjusted harness and machine

makes work much easier.

• Put on the harness. Adjust the harness

for the best working position. Tension the

side straps so that the weight is evenly

distributed across both shoulders.

• The handlebar mounth_g must be fitted

between the arrows on the shaft.

• Tighten the screws with a hex wrench.

Fitting the harness

brushcutter, it must always be

hooked securely to the harness.

Otherwise, you will be unable to

control the brushcutter safely.

This can result in injury to yourself

I_ib WARNING: When using a

or others. Never use a harness with

a defective quick release.

Proper harness and handlebar adjust-

ments must be made with the engine com-

pletely stopped before using unit.

Fitting the harness clamp

• Place the upper harness clamp over the

shaft and position the lower harness

clamp under the shaft. Align the upper

and lower clamp screw holes. Clamp

must be fitted above the arrow on the

shaft (see illustration).

NOTE: it may be necessary to relocate

the harness clamp on the shaft for proper

batancing of unit.

ASSEMBLY

Correct height

Adjust the harness so that the cutting at-

tachment is parallel to the ground.

Correct balance

Let the cutting attachment rest lightly on

the ground. If you use a grass blade, it

shouM balance about 10 cm above the

ground to prevent contact with stones and

the like. Adjust the position of the harness

clamp to balance the unit correctly.

Fitting blades and trimmer

heads

• When fitting the cutting attachment it is

extremely important that the raised section

on the drive disc/support flange engages

correctly in the centre hole of the cutting

attachment. If the cutting attachment is

fitted incorrectly it can result in serious and/

or fatal personal injury,

Fitting a blade guard, grass

blade and grass cutter

Hook the btade guard/combination guard

(A) onto the fitting on the shaft and secure

with the bolt,

OAUTION? Use the recommended blade

guard, See the Technical data section.

Fit the drive disc (B) on the output shaft.

Turn the blade shaft until one of the

hotes in the drive disc aligns with the

corresponding hole in the gear housing,

Insert the locking pin (C) in the hole to

tock the shaft,

Place the blade (D), support cup (E) and

support flange (F) on the output shaft.

Fit the nut (G). The nut must be tight-

ened to a torque of 35-50 Nm (3,5-5

kpm), Use the socket spanner in the tool

kit, Hoid the shaft of the spanner as

close to the blade guard as possible. To

tighten the nut, turn the spanner in the

opposite direction to the direction of rota-

tion (CAUTION? left-hand thread),

_IbWARNING: Never use a cutting

attachment without an approved

guard. See the section on Techni-

cal data. If an incorrect or faulty

guard is fitted this can cause seri-

ous personal injury.

IMPORTANT]

if a grass blade is to be used, the machine

must be equipped with the correct handle-

bar, blade guard and harness.

ASSEMBLY

Fitting the trimmer guard and

trimmer head

• Fit the correct trimmer guard (A) for use

with the trimmer head. Hook the trimmer

guard/combination guard onto the fitting

on the shaft and secure with the bolt (D).

ff

,_ _" U

I

A

• Fit the drive disc (B) on the output shaft.

• Turn the shaft until one of the holes in the

drive disc aligns with the corresponding

hole in the gear housing,

• Insert the locking pin (C) in the hole to

lock the shaft.

• Screw on the trimmer head (H) in the op-

posite direction to the direction of rota-

tion,

B

• To dismantle, follow the instructions in

the reverse orden

FUEL HANDLING

Fuel safety

Never start the machine:

1. If you have spilled fuel on it. Wipe off the

spillage and aIIow remaining fuel to evapo-

rate.

2. If you have spilled fuel on yourseIf or your

clothes, change your clothes. Wash any

part of your body that has come in contact

with fuel. Use soap and water.

3. If the machine is leaking fuel. Check regu-

larly for leaks from the fuel cap and fuel

_ines.

Transport and storage

• Store and transport the machine and fuel

so that there is no risk of any leakage or

fumes coming into contact with sparks or

naked flames, for example, from electri-

cal machh_ery, e_ectric motors, electrical

relays/switches or boilers.

• When storing and transporting fue_ al-

ways use approved containers intended

for this purpose.

• When storing the machine for long peri-

ods the fuel tank must be emptied. Con-

tact your local gas station to find out

where to dispose of excess fuel.

• Ensure the machine is cleaned and that

a complete service is carried out before

tong-term storage.

• The transport guard must always be

fitted to the cutting attachment when the

machine is being transported or in stor-

age.

• In order to prevent unintentional starting

of the engine, the spark plug cap must

always be removed during long-term

storage, if the machine is not under

close supervision and when performing

all service measures.

dling fuel. Bear in mind the risk of

_lb ARNING: Take care when han-

fire, explosion and inhaling fumes.

Fuel

CAUTION! The machine is equipped with a

two-stroke engine and must always be run

using a mixture of gasoline and two-stroke

engine oil. It is important to accurately mea-

sure the amount of oil to be mixed to ensure

that the correct mixture is obtained. When

mixing small amounts of fuel, even small

inaccuracies can drastically affect the ratio

of the mixture.

Gasoline

CAUTION! Always use high quality

unleaded gasoline.

• This engine is certified to operate on

unleaded gasoline.

• The lowest recommended octane rating is

87. If you run the engine on lower octane

rating than 87, "knocking" can occur. This

leads to an increased engine tempera-

ture, which can result in a serious engine

breakdown=

• When working at continuous high revs, a

higher octane rating is recommended.

Two-stroke oil

• For best results and performance, use

JONSERED two-stroke oil, which is

specially formulated for our two-stroke

engines. Mixture 1:50 (2%).

• To maximize the life of your trimmer, you

may choose to use a high quality syn-

thetic oil formulated for two-stroke

engines. Mixture 1:50 (2%).

• Never use two-stroke oil intended for

water-cooled outboard engines,

sometimes referred to as outboard oil.

• Never use oil intended for four-stroke

engines.

Gasoline

U.S. gallon

1

21/2

5

Two-stroke oil

2% (1:50)

U.S. fl. oz,

2 1/2

61/2

t2 7/8

are highly inflammable and can

cause serious injury when inhaled

or allowed to come in contact with

the skin, For this reason observe

caution when handling fuel and

l_i ARNING: Fuel and fuel fumes

make sure there is adequate ven-

tilation.

FUEL HANDLING

Mixing

• Always mix the gasoline and oil in a

clean container intended for fuel.

• Always start by filling half the amount of

the gasoline to be used. Then add the

entire amount of oil, Mix (shake) the fuel

mixture, Add the remaining amount of

gasoline.

• Mix (shake) the fuel mixture thoroughly

before filling the machine's fuel tank,

• Do not mix more than one month's sup-

ply of fuel at a time.

• If the machine is not used for some time,

the fuel tank should be emptied and

cleaned.

verter muffler gets very hot during

and after use. This also applies

during idling. Be aware of the fire

hazard, especially when working

_ ARNING: The catalytic con-

near flammable substances and/or

vapors.

Fuelling

WARNING: Taking the following

&

precautions, will lessen the risk of

fire:

Do not smoke or place hot objects

near fuel.

Always shut off the engine before

refueling.

Always stop the engine and let it

cool for a few minutes before refu-

elling.

When refueling, open the fuel cap

slowly so that any excess pressure

is released gently.

Tighten the fuel cap carefully after

refueling.

Always move the machine away

from the refueling area before

starting.

• Clean the area around the fuel cap,

Contamination in the tank can cause

operating problems.

• Ensure that the fuel is well mixed by shak-

ing the container before filling the tank.

in.lOfeet

3 meters) L_r'_

14

STARTING AND STOPPING

Check before starting

• Check the blade to ensure that no cracks

have formed at the bottom of the teeth or

by the centre hoIe. The most common rea-

son why cracks are formed is that sharp

corners have been formed at the bottom of

the teeth while sharpening or that the blade

has been used with dull teeth. Discard a

blade if cracks are found.

• Check that the support flange is not

cracked due to fatigue or due to being

tightened too much. Discard the support

flange if it is cracked.

• Ensure the locking nut has not lost its cap-

tive force. The nut tock should have a

locking force of at least 1.5 Nm. The tight-

ening torque of the locking nut should be

35-50 Nm.

Starting and stopping

WARNING: The complete clutch,

clutch cover, and shaft must be

fitted before the machine is started,

otherwise parts could come loose

and cause personal injury.

Always move the machine away

from the refueling area before

starting. Place the machine on a

flat surface. Ensure the cutting at-

tachment cannot come into contact

with any object.

Make sure no unauthorized

persons are in the working area,

otherwise there is a risk of serious

personal injury. The safety

distance is 50 feet (15 meters).

Cold engine

Primer bulb: Press the primer bulb 10

times until fuel begins to fill the bulb. The

)rimer bulb need not be completely filled.

Choke: Move the blue engine choke lever

over to the closed position.

• Check that the trimmer head and trimmer

guard are not damaged or cracked.

Replace the trimmer head or trimmer

guard if they have been exposed to

impact or are cracked.

• Never use the machine without a guard

nor with a defective guard.

• All covers must be correctly fitted and un-

damaged before you start the machine.

J" I

i

Starting

Hold the body of the machine on the

ground using your left hand (CAUTION?

Not with your foot!).

Firmly grip the starter rope handte with

your right hand. DO NOT squeeze

throttle trigger. Slowly pull out the cord

until you feeI some resistance (the starter

pawls grip); then quickty and powerfully

_ullthe cord,

Never wrap the starter cord around

your hand.

Repeat pulling the cord until the engine

attempts to start, Squeeze throttle trigger

to release the choke. Continue to hold

throttle trigger and pull starter rope until

engine runs.

STARTING AND STOPPING

NOTE: if engine dies, return blue engine

choke lever to the closed position and

repeat starting steps.

CAUTION! Do not pull the starter cord al_

the way out and do not let go of the starter

handle when the cord is fully extended.

This can damage the machine.

Warm engine

With a warm engine, squeeze and hotd the

throttle trigger. Pull starter rope sharpty

while squeezing throttle trigger until engine

runs.

CAUTION!

Do not put any part of your body in marked

area, Contact can result in burns to the

skin, or electrical shock if the spark plug

cap has been damaged, Always use

gloves, Do not use a machine with dam-

aged spark plug cap.

For throttle handles with a start

throttle lock:

Set the throttle to the start position by first

pressing the throttle lock and the throttle

trigger, then pressing the start throttle

button (A). Then release the throttle lock

and the throttle trigger, followed by the start

throttle button, The throttle function is now

activated, To return the engine to idle,

)tess the throttle lock and throttle trigger

again.

Stopping

Stop the engine by pushing and holding

the stop switch in the STOP position until

the engine stops.

CAUTION! The stop switch automatically

returns to the start position. In order to pre-

vent unintentional starting, the spark plug

cap must be removed from the spark plug

when assembling, checking and/or per-

forming maintenance.

WARNING: When the engine is

started with the choke in the closed

position the cutting attachment will

start to rotate immediately.

16

WORKING TECHNIQUES

General working instructions

IMPORTANT!

This section describes the basic safety pre-

cautions for working with trimmers. If you

encounter a situation where you are uncer-

tain how to proceed you should ask an ex-

pert. Contact your servicing dealer.

Avoid all usage which you consider to be

beyond your capability.

You must understand the difference between

forestry clearing, grass clearing and grass

trimming before use.

Basic safety rules

/ @OO

1. Look around you:

• To ensure that people, animals or other

things cannot affect your control of the

machine.

• To ensure that people, animals, etc.,

do not come h_to contact with the cut-

ting attachment or loose objects that

are thrown out by the cutting attach-

ment.

• CAUTION! Do not use the machine

unless you are able to call for help in

the event of an accident.

2. Do not use the machine in bad weather,

such as dense fog, heavy rain, strong

wind, intense coid, etc. Working in bad

weather is tiring and often brings added

risks, such as icy ground, unpredictable

felling direction, etc.

3. Make sure you can move and stand safely.

Check the area around you for possible ob-

stacles (roots, rocks, branches, ditches, etc.)

in case you have to move suddenly. Take

great care when working on stoping ground.

The ABC of clearing

• Always use the correct equipment.

• Make sure the equipment is well adjusted.

• Follow the safety precautions.

• Organise your work carefully.

• Always use full throttle when starting to cut

with the blade.

• Always use sharp blades.

• Avoid stones.

WARNING: Neither the operator

of the machine nor anyone else

may attempt to remove the cut ma-

terial while the engine is running or

the cutting equipment is rotating,

as this can result in serious injury.

Stop the engine and cutting equip=

ment before you remove material

that has wound around the blade

shaft as otherwise there is a risk of

injury. The bevel gear can get hot

during use and may remain so for a

while afterwards. You could get

burned if you touch it,

WARNING: Watch out for

thrown objects. Always wear ap=

proved eye protection. Never lean

over the cutting attachment guard.

Stones, rubbish, etc. can be thrown

up into the eyes causing blindness

or serious injury. Keep unautho-

rised persons at a distance. Chil-

dren, animals, onlookers and help-

ers should be kept outside the

safety zone of 50 feet (15 meters).

Stop the machine immediately if

anyone approaches. Never swing

the machine around without first

checking behind you to make sure

noone is within the safety zone.

WARNING: Sometimes branches

or grass get caught between the

guard and cutting attachment,

Always stop the engine before

c eaning.

4. Switch off the engine before moving to

another area. Fit the transport guard before

carrying or transporting the equipment any

distance.

5. Never put the machine down with the engine

running or while the cutting attachment is

rotating.

Basic working techniques

• Always slow the engine to idle speed after

each working operation. Long periods at

full throttle without any load on the engine

can lead to serious engine damage.

Working methods

WARNING: Avoid with

the area of the blade between the

12 o'clock and 3 o'clock positions,

Because of the speed of rotation

of the blade kickback can occur if

you attempt to cut thick stems with

this area of the blade.

17

cutting

WORKING TECHNIQUES

• Before you start clearing, check the clear-

ing area, the type of terrain, the slope of

the ground, whether there are stones, hol-

lows etc.

• Start at whichever end of the area is easi-

est, and clear an open space from which

to work.

• Work systematically to and fro across the

area, clearing a width of around 12-15 feet

(4-5 meters) on each pass. This exploits

the full reach of the machine in both direc-

tions and gives the operator a convenient

and varied working area t_work in.

• Clear a strip around 250 feet (75 meters)

long. Move your fuel can as work prog-

resses.

• On sloping ground you should work along

the slope. It is much easier to work along a

slope than it is to work up and down it.

• You should plan the strip so that you avoid

going over ditches or other obstacles on

the ground. You should also orient the strip

to take advantage of wind conditions, so

that cleared stems fall in the cleared area

of the stand.

• If the blade is angled to the left when clear-

ing grass, the grass will collect in a line,

which makes it easier to collect, e.g. by

raking.

• Try to work rhythmically. Stand firmly with

your feet apart. Move forward after the re-

turn stroke and stand firmly again.

• Let the support cup rest lightly against the

ground. It is used to protect the blade from

hitting the ground.

• Reduce the risk of material wrapping

around the blade by following these in-

structions:

• Always work at full throttle.

• Avoid the previously cut material during

the return stroke.

• Stop the engine, unclip the harness and

place the machine on the ground before

you start to collect the cut

material.

Grass trimming with a trimmer head

Trimming

QOO

_v -4

Grass clearing using a grass blade

• Grass blades and grass cutters must not be

used on woody stems.

• A grass blade is used for all types of tall or

coarse grass.

• The grass is cut down with a sideways,

swinging movement, where the movement

from right-to-left is the clearing stroke and

the movement from teft-to-right is the return

stroke. Let the left-hand side of the blade

(between 8 and 12 o'clock) do the cutting.

• Hold the trimmer head just above the ground

at an angle, it is the end of the trimmer line

that does the work. Let the trimmer line work

at its own pace. Never press the trimmer

line into the area to be cut.

• The trimmer line can easily remove grass

and weeds up against walls, fences, trees

and borders, however it can also damage

sensitive bark on trees and bushes, and

damage fence posts.

• Reduce the risk of damaging pIants by

shortening the trimmer line to 4-5 inches

(10-12 cm) and reducing the engine speed.

• When trimming you should use tess than

full throttIe so that the trimmer line lasts

longer and to reduce the wear on the

trimmer head.

WORKING TECHNIQUES

Clearing Sweeping

@@0

• The clearing technique removes all un-

wanted vegetation. Keep the trimmer

head just above the ground and tilt it, Let

the end of the trimmer line strike the

ground around trees, posts, statues and

the like. CAUTION! This technique

increases the wear on the trimmer line.

• The trimmer line wears quieker and must

be fed forward mere often when werkh_g

agah_st stones, brick, eencrete, metal

fences, etc. than when coming into con-

tact with trees and wooden fenees.

Cutting

@@0

• The trimmer is ideal for cutting grass that

is difficult to reach using a normal lawn

mower, Keep the trimmer line parallel to

the ground when cutting. Avoid pressing

the trimmer head against the ground as

this can ruin the lawn and damage the

tool,

• Do not allow the trimmer head to con-

staefly come into contact with the ground

during normal cutting. Constant contact

of this type can cause damage and wear

to the trimmer head.

@@@

• The fan effect of the rotating line can be

used for quick and easy clearing up.

Ho_d the trimmer line parallel to and

above the area to be swept and move

the tool to and fro.

/

I

\

• When cutting and sweeping you should

use full throttle to obtain the best results.

WARNING: Neither the operator

of the machine nor anyone else may

attempt to remove the cut material

while the engine is running or the

trimmer line is rotating, as this can

result in serious injury. Stop the

engine and trimmer head before you

remove material that has wound

around the drive shaft as otherwise

there is a risk of injury. The bevel

gear can get hot during use and may

remain so for a while afterwards. You

could get burned if you touch it.

i_ WARNING: Watch out for thrown

objects. Always wear eye protection.

Never lean over the cutting attach-

ment guard. Stones, rubbish, etc.

can be thrown up into the eyes

causing blindness or serious injury.

Keep unauthorized persons at a dis-

tance. Children, animals, onlookers

and helpers should be kept outside

the safety zone of 50 feet (15 me-

ters). Stop the machine immediately

if anyone approaches.

MAINTENANCE

The owner is responsible for the perfor-

mance of all required maintenance as

defined in the operator's manual.

WARNING:

nance could result in serious engine

[_JL. Improper mainte-

damage or in serious injury.

Carburetor

Your Jonsered product has been designed

and manufactured to specifications that re-

duce harmful emissions. After the engh_e

has used 8-10 tanks of fuet, the engh_e will

be run-in. To ensure that it continues to run

at peak performance and to minimize harm-

ful exhaust emissions after the run-in peri-

od, ask your servicing dealer to adjust your

carburetor.

WARNING: The complete clutch,

clutch cover, and shaft must be

fitted before the machine is started,

otherwise parts could come loose

and cause personal injury.

Function

• The carburetor governs the engine's

speed via the throttle control. Air and fuel

are mixed in the carburetor.

• The T-screw regulates the throttle setting

at idle speed. If the T-screw is turned

clockwise this gives a higher idle speed;

turning it counterclockwise gives a lower

idle speed.

Basic setting

• The basic carburetor setth_gs are ad-

justed during testing at the factory. Fine

adjustment should be carried out by a

skilled technician.

Fine adjustment of the idle speed-T

Adjust the idle speed using the idle adjust-

ment screw-T if it is necessary to readjust.

First, turn the idle adjustment screw-T

clockwise until the cutting attachment starts

to rotate. Then, turn the screw counter-

clockwise until the cutting attachment stops.

The idle speed is correctly adjusted when

the engine will run smoothly in every posi-

tion. The idle speed should also be well

below the speed at which the cutting attach-

ment starts to rotate.

i ;e w -eTed

_i, WA_p_

O not be adjusted so that the cutting

attachment stops, contact your ser-

vicing dealer, Do not use the ma-

chine until it has been correctly ad-

justed or repaired,

Unit/Maintenance Safety

Disconnect the spark plug before perform-

ing maintenance, except carburetor adjust-

ments.

Muffler

CAUTION! Muffler is fitted with a catalytic

converter designed to reduce harmful ex-

WARNING: The cutting attach-

ment may be spinning during carbu-

retor adjustments. Wear your protec-

tive equipment and observe all safe-

ty instructions. Be sure the cutting

attachment stops turning when the

engine idles, When the unit is turned

off, make sure the cutting attach-

ments has stopped before the unit is

set down.

CAUTION! if the cutting attachment rotates

when the engine is idling the idle adjustment

screw T should be turned counterclockwise

until the cutting attachment stops.

Rec. idle speed:

See "Technical data" section.

Recommended max. speed:

See "Technical data" section.

The muffler is designed to reduce the noise

level and to direct the exhaust gases away

from the operator. The exhaust gases are

hot and can contain sparks, which may

cause fire if directed against dry and com-

bustible material

Mufflers are equipped with a special spark

arrestor mesh. The mesh should be

checked and, if necessary, cleaned by a

servicing dealer. If the mesh is damaged,

it should be replaced.

2O

MAINTENANCE

If the mesh is frequently blocked, this can

be a sign that the performance of the cata-

lytic converter is impaired. Contact your

servicing dealer to inspect the muffler. A

blocked mesh wilt cause the machh_e to

overheat and result in damage to the cylin-

der and piston.

Muffler bolts

I_ Spark arrestor mesh

CAUTION! Never use a machine that has

a faulty or loose muffler. Ensure the muffler

bolts are tight.

catalytic converters get very hot

during use and remain so for some

time after stopping, This also ap-

plies at idle speed, Contact can re-

I_ib ARNING: Mufflers fitted with

sult in burns to the skin. Remember

the risk of fire!

_lb WARNING: The inside of the

muffler contain chemicals that may

be carcinogenic, Avoid contact with

these elements in the event of a

damaged muffler,

_lb WARNING: Bear in mind that:

Engine exhaust fumes contain car-

bon monoxide, which can cause

carbon monoxide poisoning. For

this reason you should not start or

run the machine indoors, or any-

where that is poorly ventilated.

The exhaust fumes from the engine

are hot and may contain sparks

which can start a fire. Never start

the machine indoors or near com-

bustible material!

Spark plug

The spark plug condition is h_fluenced by:

• Incorrect carburetor adjustment.

• An incorrect fuel mixture (too much or in-

correct type of oil).

• A dirty air filter.

These factors cause deposits on the spark

plug electrodes, which may result in operat-

ing problems and starting difficulties.

If the machine is low on power, difficult to

start or runs poorly at idle speed: always

check the spark plug first before taking

any further action.

If the spark plug is dirty, clean it and check

that the electrode gap is 0.024 inch (0.6

mm). The spark plug should be replaced

after about a month in operation or earlier if

necessary. 0.024 inch (0.6 mm)

CAUTION! Always use the recommended

spark plug type! Use of the wrong spark

plug can damage the piston/cylinder,

Air filter

The air filter must be regularly cleaned to

remove dust and dirt in order to avoid:

Carburetor malfunctions

Starting problems

Loss of engine power

Unnecessary wear to engine parts

Excessive fuel consumption

I

jfJ

Clean the filter every 25 hours, or more

regularly if conditions are exceptionally

dusty.

Cleaning the air filter

Remove the air filter cover and take out the

filter, Wash it clean in warm, soapy water,

Rinse thoroughly. Ensure that the filter is dry

before refitting it.

An air filter that has been in use for a long

time cannot be cleaned completely. The

filter must therefore be replaced with a new

one at regular intervals. A damaged air

filter must always be replaced.

21

MAINTENANCE

Bevel gear

The bevel gear is filled with the right quan-

tity of grease at the factory. However, be-

fore using the machine you should check

that the bevel gear is filled three-quarters

full with grease. Use JONSERED special

grease.

The grease in the bevel gear does not nor-

mally need to be changed except if repairs

are carried out.

Sharpening grass cutters and

grass blades

WARNING: Always stop the en-

gine before doing any work on the

cutting attachment. This continues

to rotate even after the throttle has

been released. Ensure that the cut-

ting attachment has stopped com-

pletely and disconnect the HT lead

from the spark plug before you start

to work on it.

• See the cutting attachment packaging for

correct sharpening instructions.

• Sharpen blades and cutters using a

single-cut flat file.

• Sharpen all edges equally to maintain the

batance of the blade.

WARNING: Always discard a

blade that is bent, twisted, cracked,

broken or damaged in any other

way. Never attempt to straighten a

twisted blade so that it can be re-

used. Only use original blades of the

specified type.

22

MAINTENANCE

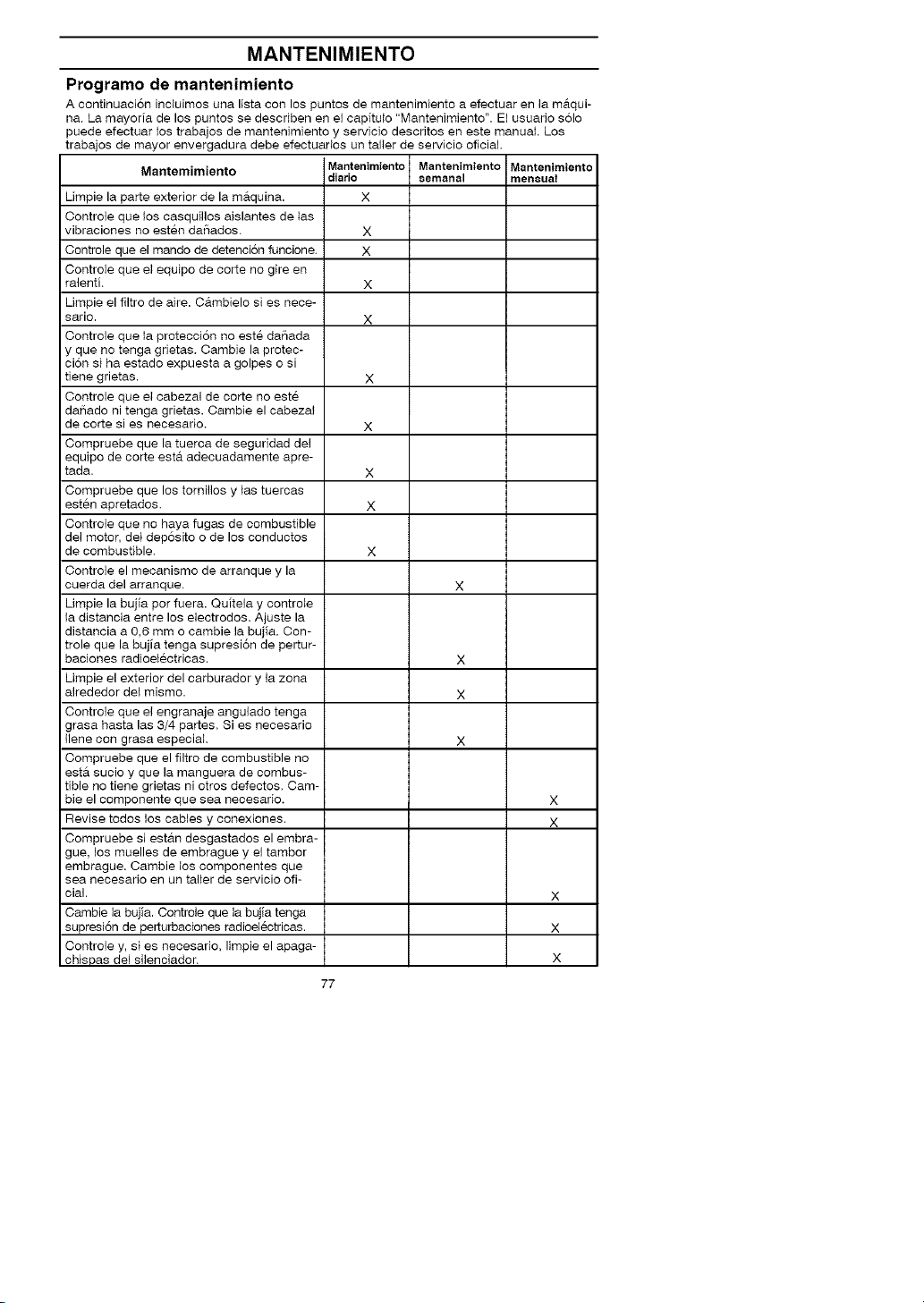

Maintenance schedule

The following is a list of the maintenance that must be performed on the machine. Most of

the items are described in the Maintenance section. The user must only carry out the main-

tenance and service work described in this Operator's Manual. More extensive work must

be carried out by an authorised service workshop.

Maintenance Maintenance Maintenance Maintenance

Clean the outside of the machine. X

Make sure the throttle trigger lock and the

throttle function correctly from a safety point

of view. X

Check that the stop switch works correctly. X

Check that the cutting attachment does not

rotate at idle. X

Clean the air filter. Replace if necessary. X

Check that the guard is undamaged and not

cracked. Replace the guard if it has been

exposed to impact or is cracked. X

Check that the trimmer head is undamaged

and not cracked. Replace the trimmer head

if necessary. X

Check that the locking nut of the cutting

equipment is tightened correctly. X

Check that nuts and screws are tight. X

Check that there are no fuel leaks from the

engine, tank or fuel lines. X

Check the starter and starter cord. X

Clean the outside of the spark plug. Re-

move it and check the electrode gap. Adjust

the gap to 0.6 mm or replace the spark p_ug.

Check that the spark plug is fitted with a

suppressor. X

Clean the outside of the carburetor and the

space around it. X

Check that the bevel gear is filled three-

quarters full with lubricant. Fill if necessary

using special grease. X

Check the fuel filter from contamination and

the fuel hose from cracks or other defects.

Replace if necessary. X

Check all cables and connections. X

Check the clutch, clutch springs and the

clutch drum for wear. Replace if necessary

by an autorized service workshop. X

Replace the spark plug. Check that the

spark plug is fitted with a suppressor. X

Clean or replace the spark arrestor mesh

on the muffler. X

Daily Weekly Monthly

23

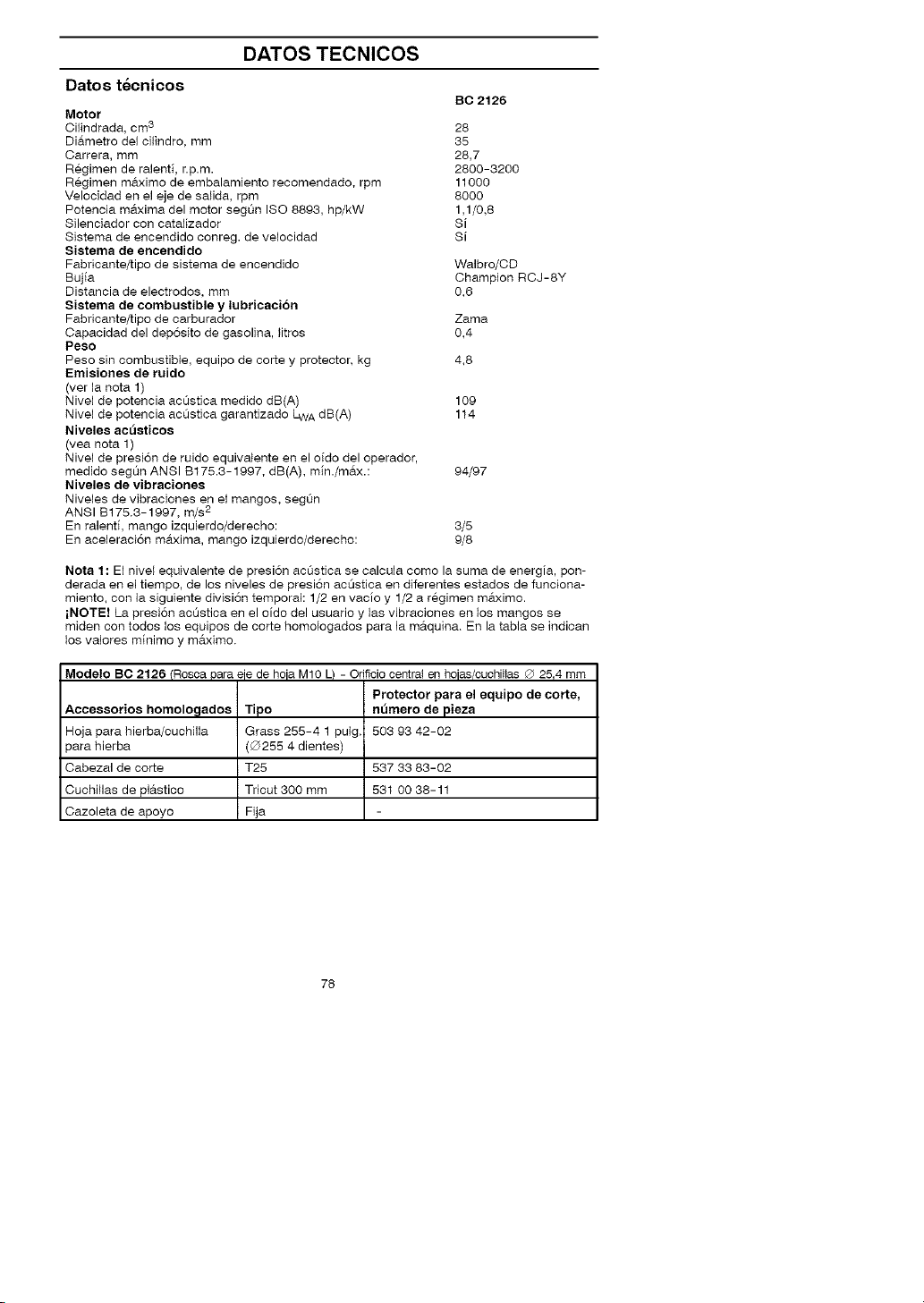

TECHNICAL DATA

Technical data

Engine

Cylinder displacement, cu. h_./cm3 1.7/28

Cylinder bore, inch/mm 1.4/35

Stroke, inch/ram 1.130/28.7

Idle speed, rpm 2800-3200

Recommended max. fast idie speed, rpm 11000

Speed of output shaft, rpm 8000

Max. engine output, according to ISO 8893, hp/kW 1,1/0,8

Catalytic converter muffler Yes

Speed-regulated ignition system Yes

Ignition system

Manufacturer/type of ignition system

Spark plug

Electrode gap, inch/mm

Fuel and lubrication system

Manufacturer/type of carburetor Zama

Zama

Fuel tank capacity, US pint/liter 0.85/0,4

Weight

Weight without fuel, cutting attachment and guard, Ibs/kg 11/4.8

Sound levels

(see note 1)

Equivalent sound pressure level at the user's ear,

measured according to ANSI B175.3-1997, dB(A),

min/max: 94/97

Vibration levels

Vibration levels at handles, measured according to

ANSIB175.3-1997, m/s 2

At idle, left/right handles: 3/5

At max. speed, left/right handles: 9/8

Note 1: Equivalent sound pressure level is calculated as the time-weighted energy total for

sound pressure levels under various working conditions with the following time distribution:

1/2 idling and 1/2 max speed.

NOTE! The noise pressure level at operator's ear and vibrations on the handles are mea-

sured with all the approved cutting attachments for the machine. The table indicates the

measured values.

BC 2126

Walbro/CD

Champion RCJ-8Y

0.024/0.6

Model BC 2126 (M 10 LH arbor shaft thread) - Centre hole in blades/cutters, O 25,4 mm

Approved accessories

Grass blade/grass cutter

Trimmer head

Plastic blades

Support cup

Type

Grass 255-4 1 inch

(O 250 4-teeth)

T25

Tricut 300 mm

Fixed

Cutting attachment guard, part, no.

503 93 42-02

537 33 83-02

53t 0038-11

24

U.S. EPA/CALIFORNIA/ENVIRONMENT CANADA

EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND

OBLIGATIONS:

The U.S. Environmental Protection Agency,

California Air Resources Board, Environment

Canada and Jonsered are pleased to explain

the emissions control system warranty on

your year 2005 and later small off-road en-

gine. In California, all small off-road engines

must be designed, built, and equipped to meet

the State's stringent anti-smog standards.

Jonsered must warrant the emission control

system on your small off-road engine for the

periods of time listed below provided there

has been no abuse, neglect, or improper

maintenance of your small off-road engine.

Your emission control system includes parts

such as the carburetor and the ignition sys-

tem. Where a warrantable condition exists,

Jonsered will repair your small off-road en-

gine at no cost to you. Expenses covered un-

der warranty include diagnosis, parts and la-

bor.

MANUFACTURER'S WARRANTY

COVERAGE:

If any emissions related part on your engine

(as listed under Emissions Control Warran-

ty Parts List) is defective or a defect in the

materials or workmanship of the engine

causes the failure of such an emission re-

lated part, the part will be repaired or re-

placed by Jonsered.

OWNER'S WARRANTY RESPONSI-

BILITIES:

As the small off-road engine owner, you are

responsible for the performance of the re-

quired maintenance listed in your operator's

manual. Jonsered recommends that you

retain all receipts covering maintenance on

your small off-road engine, but Jonsered

cannot deny warranty solely for the lack of

receipts or for your failure to ensure the per-

formance of all scheduled maintenance. As

the small off-road engine owner, you should

be aware that Jonsered may deny you war-

ranty coverage if your small off-road engine

or a part of it has failed due to abuse, ne-

glect, improper maintenance, unapproved

modifications, or the use of parts not made

or approved by the original equipment

manufacturer. You are responsible for pre-

senting your small off-road engine to a

Jonsered authorized repair center as soon

as a problem exists. Warranty repairs

should be completed in a reasonable

amount of time, not to exceed 30 days. If

you have any questions regarding your war-

ranty rights and responsibilities, you should

contact your nearest authorized service

center or call Jonsered at 1-916-383-3511.

WARRANTY COMMENCEMENT

DATE:

The warranty period begins on the date the

small off-road engine is purchased.

LENGTH OF COVERAGE:

This warranty shal_ be for a period of two

years from the initial date of purchase.

WHAT IS COVERED: REPAIR OR

REPLACEMENT OF PARTS.

Repair or replacement of any warranted

part will be performed at no charge to the

owner at an approved Jonsered servicing

center. If you have any questions regarding

your warranty rights and responsibilities,

you should contact your nearest authorized

service center or call Jonsered at

1-916-383-3511.

WARRANTY PERIOD:

Any warranted part which is not scheduled

for replacement as required maintenance,

or which is scheduled only for regular in-

spection to the effect of "repair or replace

as necessary" shall be warranted for 2

years. Any warranted part which is sched-

uled for replacement as required mainte-

nance shaft be warranted for the period of

time up to the first scheduled replacement

point for that part.

DIAGNOSIS:

The owner shall not be charged for diag-

nostic labor which leads to the determina-

tion that a warranted part is defective if the

diagnostic work is performed at an ap-

proved Jonsered servicing center.

CONSEQUENTIAL DAMAGES:

Jonsered may be liable for damages to other

engine components caused by the failure of a

warranted part still under warranty.

WHAT IS NOT COVERED:

AI_failures caused by abuse, neglect, or

improper maintenance are not covered.

ADD-ON OR MODIFIED PARTS:

The use of add-on or modified parts can be

grounds for disallowing a warranty claim.

Jonsered is not liable to cover failures of

warranted parts caused by the use of add-

on or modified parts.

HOW TO FILE A CLAIM:

If you have any questions regarding your

warranty rights and responsibilities, you

should contact your nearest authorized ser-

vice center or call Jonsered at

1-916-383-3511.

WHERE TO GET WARRANTY SER-

VICE:

Warranty services or repairs shall be pro-

vided at all Jonsered service centers. Call

1-916-383-3511.

25

U.S. EPA/CALIFORNIA/ENVIRONMENT CANADA

EMISSION CONTROL WARRANTY STATEMENT

MAINTENANCE, REPLACEMENT

AND REPAIR OF EMISSION RE-

LATED PARTS:

Any Jonsered approved replacement part

used in the performance of any warranty

maintenance or repair on emission related

parts will be provided without charge to the

owner if the part is under warranty.

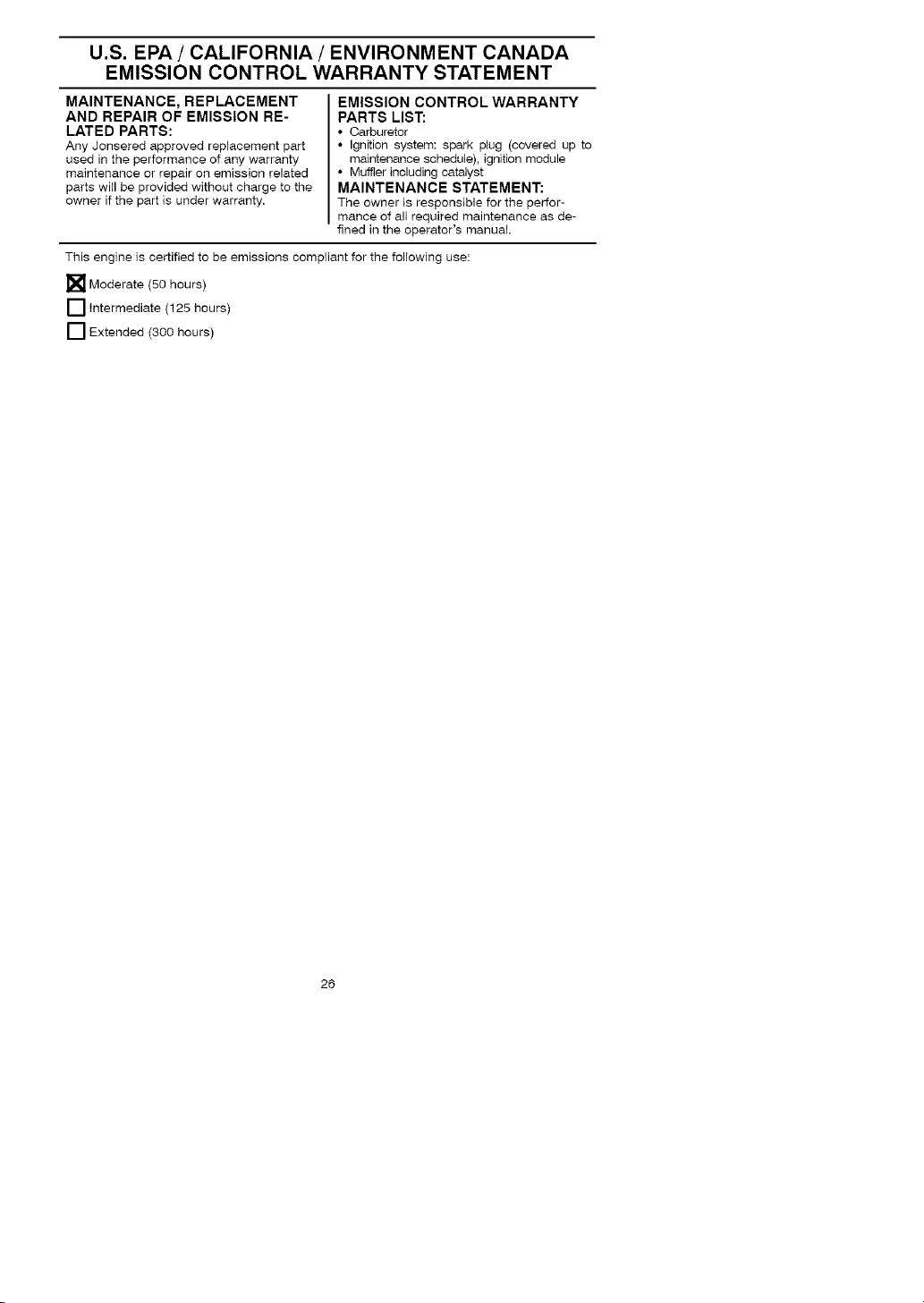

This engine is certified to be emissions compliant for the following use:

[] Moderate (50 hours)

[] Intermediate (125 hours)

[] Extended (300 hours)

EMISSION CONTROL WARRANTY

PARTS LIST:

• Carburetor

• Ignition system: spark plug (covered up to

maintenance schedule), ignition module

• Muffler including catalyst

MAINTENANCE STATEMENT:

The owner is responsible for the perfor-

mance of all required maintenance as de-

fined in the operator's manual,

26

Trimmer Head Line Loading Instructions _

1

==

6

3

Ei.

_1_

6m

20'

8

"CI;ck"

i ___./

9

27

Plastic Blades (Tri Cut) _ _

1

4

5

I

6

_ 6Nm

28

EXPLICATION DES SYMBOLES

Symboles

AVERTISSEMENT: Les debrous-

sailleuses et les coupe-herbes A

peuvent 6tre dangereux! Une utilisa- /m_

tion erronee ou negligente peut oc- /" __ _k

casionner des blessures graves,

voire morteHes pour I'utilisateur ou

d'autres personnes.

Ure attentivement et bien assimiler X--"Y'--"k

le manuel d'utilisation avant

d'utiliser la machine.

• Un casque de protection I& oQ il

y a risque de chute d'objets

Toujours utiliser: _)

• Protecteur d'oreiHes

• Des protege-yeux homologues

Regime maxi. recommande de

I'axe sortant, tr/min max

Attention: projections et ricochets./_"&

L'utilisateur de la machine doit _/,"_-'_

s'assurer qu'aucune personne [ j_ "_

ou animal ne s'approche A moins _'_

de 15 metres (50 pieds)

pendant le travail

Les machines equipees d'une

lame d'eclaircissage ou a.herbe

violemment sur ie c6te

peuvent _tre projetees _..__ f _._

quand la lame rencontre

un objet dur. La tame peut _-r .(_ ) i::_ ,

sectionner les bras et les

jambes. Toujours maintenir les

personnes et les animaux & au

moins 15 metres (50 pieds) de la

machine.

10000 rpm

Use unleaded or quality leaded _::_,{=:_]

gasoline and two-stroke oil [,_D] I

mixed at a ratio of 2% (1:50).

Les autres symboles/autocollants pre-

sents sur la machine concernent des exi-

gences de certification specifiques a cer-

tains marches.

Arr6ter le moteur en poussant le

bouton d'arr&t et maintenez-le

darts la position ,,STOPs, (d'arr6t).

REMARQUE! Uinterrupteur d'arr6t

se remet automatiquement en

_osition de demarrage. Toujours

retirer le chapeau de bougie de la

bougie Iors du montage, contr61e

et/ou entretien, afin d'eviter tout

demarrage accidenteL

Un nettoyage regulier est

indispensable.

Examen visuel.

Le port de protege-yeux

homologues est obligatoire.

LC J

Fleches indiquant les limites quant _ _

& I'emplacement de la fixation de

la poignee.

Toujours porter des gants de

protection homologues.

Utiliser des bottes antiderapantes

et stables.

Destine uniquement a.des equipe- II _.e, II

ments de coupe flexibies et non

metalliques, c'est-&dire les t&tes

de coupe avec ill.

29

SOMMAIRE

Sommaire

EXPLICATION DES SYMBOLES

Symboies ........................ 29

SOMMAIRE

Contenu ......................... 30

Contr6ler _es poh_ts suivants avant

la raise en marche ................ 30

QUELS SONT LES OOMPOSANTS?

Que]s sont tes composants? ......... 31

IN,STRUCTIONS GI_NERALES DE

SEOURITE

Important! ........................ 32

Equipement de protection personnelle.. 32

Equipement de secufite de la machine . 33

Equipement de coupe .............. 35

MONTAGE

Montage du guidon ................ 37

Montage du harnais et le bride ...... 37

Montage de la lame et de la t6te de

coupe ........................... 38

Montage du protege-lame, de la lame

& herbe et du couteau & herbe ...... 38

Montage de la protectuer et de la

t_,te de coupe .................... 39

MANIPULATION DU CARBURANT

Securit6 carburant ................ 40

Carburant ........................ 40

Remplissage de carburant .......... 41

DEMARRAGE ET ARRET

Contr6les avant la mise en marche .. 42

Demarrage et arr6t ................ 42

TECHNIQUES DE TRAVAIL

M_,thodes de travail ............... 44

ENTRETIEN

Carburateur ...................... 47

Silencieux ....................... 47

Bougie .......................... 48

Fi]tre & air ........................ 48

Renvoi d'ang]e ................... 49

Aff0tage des lames et couteaux

& herbe .......................... 49

Schema d'entretien ................ 50

CARACTERISTIQUES TECHNIQUES

Caracteristiques techniques ........ 51

DI-'-CLARATION DE GARANTIE

DE LUTTE AN MISSIONS ......... 52

Contr61er les points suivants

avant Is mise en marche:

Ure attentivement le manual d'utilisation.

Uentretien, le remplacement, ou la reparation

des dispesitifs d'emission et le syst_,me peuv-

ent &tre ex_,cut6s par n'importe quel distribu-

teur ou individu de reparation de moteur tout-

terrain.

Jonsered travaille coetinuellement au deve-

loppement de ses produits et se reserve le

droit d'en modifier, entre autres, la conception

et l'aspect sans preavis.

tion prolongee au bruit risque de I

causer des lesions auditives perma-I

AVERTISSEMENT: Une exposi-

nentes, Toujours utiliser des pro-

tecteurs d orei e agrees.

La periode de conformite d'emissions

enumere sur I'etiquette de conformite

d'emissions indique ie hombre de temps

d'exploitation I'oQ ie moteur a ete montre

pour r_,pondre & des exigences federales

d'emissions. Categorie C = 50 heures,

B = 125 heures, et A = 300 heures.

ATTENTION!

Les6missionsdumoteurdecetoutil

contiennentdesproduitschimiquesqui,

d aprSsl'l_tatdeCalifornie,peuventcauser

lecancer,desmalformationscong_nitales

ouautredangerpourlareproduction,

Pour la reference, veuillez enregistrer rin-

formation suivante qui sera necessaire

pour le futur entretien de votre appareil :

Num_,ro de Modele :

Numero de serie:

Date d'achat:

Distributeur:

AVERTISSEMENT: Utilises de

maniere negligente ou erronee, les

debroussailleuses et les coupe-

herbes peuvent devenir des outils

dangereux pouvant occasionner des

blessures graves, voire mortelles

pour I'utilisateur ou d'autres. II est

tres important de fire attentivement et

de bien comprendre les instructions

contenues dans ce mode d'empIoi.

AVERTISSEMENT: Ne jamais

modifier sous aucun pretexte Is ma-

chine sans rautorisation du fabricant.

N'utiliser que des accessoires et des

pieces d'origine. Des modifications

non-autorisees et I'emploi d'acces-

soires non=homologues peuvent

provoquer des accidents graves et

m6me mortels, a rutilisateur ou

d'autres personnes. Votre garantie

peut ne pas couvrir des dommages

ou la responsabilite provoques par

I'utilisation des accessoires ou des

pieces de rechange non-autorises.

3O

©©

QUELS SONT LES COMPOSANTS?

@

@

@

Quels sont les composants?

1. Lame 16.

2. Ravitaillement en lubrifiant,

renvoi d'angle

3. Renvoi d'engle

4. Protecteur pour I'equipement

de coupe

5. Axe

6. Guidon

7. G&chette de I'acc616ration

8. Bouton d'arr6t

9. Blocage de t'acc616ration

10. Bride de hernais

11. Couvercle de cylindre

12. Poignee de demarrage

13. R6servoir d'essence

14. Levier de I'etrangleur

15. Pompe a carburant

@

Couvercle du filtre & air

17.

Reglage de guidon

18. Contre-ecrou

19. Bride de support

20. Bol de garde au sol

21. Toc d'entrainement

22. T6te de coupe

23. OI6 pour 1'6crou de lame

24. Dispositif de protection pour le transport

25. OI6 hexagonale

26. Goupille d'arr6t

27. Harnais

28. Bouton de I'accel6ration au demarrage

29. R6giage du cb.ble d'accel6ration

30. Manuel d'instructions

®

31

INSTRUCTIONS GENERALES DE SECURITE

Important!

IMPORTANT? La machine est coegue uni-

quement pour le desherbage.

Les seuis accessoires pouvant utHiser le mo-

teur comme source motrise sont les equipe-

ments de coupe que nous recommandons

au chapitre Caractefistiques techniques.

Eviter d'utiliser la machine en cas de fatigue,

d'absorption d'alcool ou de prise de medica-

ments susceptibies d'affecter I'acuite visuelle.

le jugement ou la ma_trise du corps.

Ne jamais utiliser la machine darts des condi-

tions climatiques extr6mes tefles que }a froid

intense ou climat tres chaud et/ou humide.

Utiliser les equipemeets de protection per-

sonnelle. Voir au chapitre Equipement de

protection personnelle.

Ne jamais utiliser une machine qui aete mo-

difiee au point de ne pius 6tre conforme au

modele original.

Ne jamais utiliser une machine qui n'est pas

en parfait etat de marche. Suivre dans ce

manuel d'utilisation les instructions de mainte-

nance, de contr61e et d'entretien. Certaines

mesures de maintenance et d'entretien doiv-

ent 6tre contiees & un specialiste dGment for-

me et qualifie. Voir au chapitre Entretien.

Tous les carters et toutes les protections

doivent &tre montes avant le demarrage. Ve-

rifier que le chapeau de bougie et le c&ble

d'allumage ne soet pas endommages.

Risque de chocs electriques.

Uutilisateur de la machine dolt s'assurer qu'a-

ucune personne ou animal ne s'approche

moins de 15 metres (50 pieds) pendant le

travail. Lorsque plusieurs utilisateurs travail-

lent dans une m_me zone, il convient d'ob-

server une distance de securite jamais moles

de 15 metres (50 pieds).

_LAVERTISSEMENT? un equipe-

meet de coupe inad_,quat ou une

lame real affQtee peuvent augmenter

les risques d'accidents,

_IbAVERTISSEMENT? Ne jamais

laisser des enfants utiliser la

machine ou se tenir a proximite.

La machine est equipee d'un inter-

rupteur d'arr_t a detente et peut _tre

demarree par une activation a faible

vitesse et de faible puissance de la

poignee de demarrage ; dana cer-

taines circonstances, de jeunes en-

rants peuvent produire la force ne-

cessaire au demarrage de la ma-

chine. Ceci peut entrainer un risque

de blessures personnelles. Retirer

donc le chapeau de bougie Iorsque

la machine n'est pas sous surveil-

lance.

Personal protective equipment

IMPORTANT? Utilises de maniere neg_i-

gente ou erronee, les debroussailieuses et

les coupe-herbes peuvent devenir des

outiis dangereux pouvant occasionner des

blessures graves, voire mortefles pour I'u-

tilisateur ou d'autres. It est tres important

de lire attentivement et de bien com-

)rendre les instructions contenues dans

ce mode d'emploi. Un equipement de

protection personnelle homologue dolt

imperativement &tre utilise Iors de tout tra-

vail avec la machine. Uequipement de

protection personnelle n'elimine pas les

rlsques mais reduit ia gravite des bles-

sures en cas d'accident. Demander con-

sell au concessionnaire afin de choisir un

equipement adequat.

_1 AVERTISSEMENT! Soyez tou-

jours attentifs aux signaux d'alerte

ou aux appels en portant des

protege-oreilles. Enlevez-les sit6t

le moteur arr_te,

CASQUE

Utiliser un casque si ies troncs & section-

her font ptus de 2 metres (6 pieds) de haut.

PROT;:GE=OREILLES

Porter des protege-oreilles ayant un effet

attenuateur suffisant.

PROTF:GE-YEUX

Toujours porter des protege-yeux homolo-

gues. L'usage d'une visiere dolt toujours

s'accompagner du port de lunettes de

)rotection homologuees. Par lunettes de

)rotection homologuees, on entend celles

qui soet en conformite avec les normes

ANSi_ Z87.1.

GANTS

Au besoin, utiliser des gants, notamment lots

du montage de I'equipement de coupe.

32

INSTRUCTIONS GI:tNI:tRALES DE Sl:tCURITl:t

BOTTES

Utiliser des bottes antiderapantes et stables.

HABITS

Porter des v_tements fabriques darts un ma-

teriau resistant a.la dechirure, eviter les v6te-

ments excessivement amples qui risquerai-

ent de se prendre dans les broussailles et

les branches. Toujours utiliser des pantalons

longs et robustes. Ne pas porter de bijoux,

de shorts ou de sandales, et ne pas march-

er pieds-nus. Veiller & ce que les cheveux

ne tombent pas sur les epaules.

PREMIERS SEOOURS

Uee trousse de premiers secours doit tou-

jours 6tre disponibie.

Equipement de securite de la

machine

Ce section presente les equipements de seeu-

rite de la machine, leur fonction, comment les

utiIiser et les maintenir en bon etat. Voir la sec-

tion "Familiarisez-vous avec votre appareii"

sont ies composants pour trouver leur em-

placement sur ta machine.

La duree de vie de la machine risque d'etre

ecourtee et te risque d'accidents accru si la