Page 1

Please do not return unit to retailer.

Por favor, no devuelva el aparato al lugar de compra.

Veuillez ne pas retourner l’outil au détaillant.

1-800-554-6723

www.poulan--pro.com

Instruction Manual

Manual de Instrucciones

Manuel d’Instructions

PP2822

For Occasional Use Only

WARNING:

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious injury.

ADVERTENCIA:

Lea el manual de instrucciones y siga todas las advertencias e

instrucciones de seguridad. El no hacerlo puede resultar en lesiones graves.

AVERTISSEMENT:

Lire le manueld’instructions et bien respecter tous lesavertissements et toutes les instructions de sécurité. Tout défaut de le

faire pourrait entraîner des blessures graves.

Poulan PRO Poulan PRO

9335 Harris Corners Parkway

Charlotte, NC 28269

850 Matheson Blvd. West

Mississauga, Ontario L5V 0B4

LOÑAPSEHSILGNE

FRANÇAIS

115365126

Rev. 4 01/26/11 BRW

Page 2

SAFETY RULES

WARNING: Failure to follow all

Safety Rules and Precautions can result in

serious injury.

DANGER: THIS POWER TOOL CAN

BE DANGEROUS! This unit can cause serious

injury including amputation or blindness to the

operator and others. The warnings and safety

instructions in this manual must be followed to

provide reasonable safety and efficiency in using this unit. The operator is responsible for following the warnings and instructions in this

manual and on the unit. Never allow children to

use this tool.

KNOW YOUR UNIT

S Read your instruction manual carefully until

you completely understand and can follow

all warnings and safety rules before operating the unit.

D Restrict unit to users who understand and

will follow all warnings and safety rules in

this manual and on the unit.

PLAN AHEAD

WARNING: Inspect area before start-

ing unit. Remove all debris and hard objects

such as rocks, glass, wire, etc. that can ricochet, be thrown, or otherwise cause injury or

damage during operation.

D Always wear eye protection when operating,

servicing, or performing maintenance on unit.

Wearing eye protection will help to prevent

brush or debris from being thrown or ricocheting into eyes and face which can result in

blindness and/or serious injury. Eye protection should be marked Z87.

D Wear hearing protection when using this

unit.

D Secure hair above shoulder length. Secure or

remove jewelry, loose clothing, or clothing

with loosely hanging straps, ties, tassels, etc.

They can be caught in moving parts.

D Stay alert. Do not operate unit when you are

tired, ill, upset, or if you are under the influence

of alcohol, drugs, or medication.

D Keep children, bystanders, and animals

away from work area a minimum of 30 feet

(10 meters) when starting or operating unit.

HANDLE FUEL WITH CAUTION

D Eliminate all sources of sparks or flame (in-

cluding smoking, open flames, or work that

can cause sparks) in the areas where fuelis

mixed, poured, or stored.

D Mix and pour fuel in an outdoor area; store

fuel in a cool, dry, well ventilated place; use

an approved, marked container for all fuel

purposes.

D Do not smoke while handling fuel or while

operating the unit.

D Do not fill fuel tank while engine is running.

D Make sure the unit is properly assembled

and in good operating condition.

D Avoid spilling fuel or oil. Wipe up fuel spills

before starting the engine.

D Move at least 10 feet (3 meters) away from

fuel and fueling site before starting engine.

D Always store gasoline in a container ap-

proved for flammable liquids.

OPERATE YOUR UNIT SAFELY

DANGER: RISK OF CUT; KEEP

HANDS AWAY FROM BLADE

moves momentarily after the trigger is released. Do not attempt to clear away cut material when the blade is in motion. Make sure

the switch is in the OFF position, the spark

plug wire is disconnected, and the blade has

stopped moving before removing jammed

material from the cutting blade. Do not grab or

hold the unit by the cutting blade.

D Inspect unit before each use for worn,

loose, missing, or damaged parts. Do not

use until unit is in proper working order.

D Keep outside surfaces free from oil and fuel.

D Never start or run engine inside a closed

room or building. Breathing exhaust fumes

can kill.

D Avoid dangerous environments. Do notuse

in unventilated areas or where explosive

vapors or carbon monoxide build up could

be present.

D Do not overreach or use from unstable sur-

faces such as ladders, trees, steep slopes,

rooftops, etc. Keep firmfooting and balance

at all times.

D Do not raise unit above your shoulders; the

cutting blade can come dangerously close

to your body.

D Always keep unit infront of your body.Keep

all parts of your body away from the cutting

blade.

D Keep the cutting blade and air vents free

from debris.

D Use only for jobs explained in this manual.

MAINTAIN YOUR UNIT PROPERLY

D Have all maintenance other than the rec-

ommended procedures described in the instruction manual performed by an authorized service dealer.

D Disconnect spark plug before performing

maintenance except for carburetor adjustments.

D Do not use a cutting blade that is bent,

warped, cracked, broken, or damaged in

any other way. Have worn or damaged

parts replaced by an authorized service

dealer.

D Use only recommended Poulan PRO cut-

ting blades and replacement parts; use of

any other parts may void your warranty and

cause damage to your unit.

D Empty fuel tank before storing the unit. Use

up fuel left in carburetor by starting engine and

letting it run until it stops.

D Hand carry the unit with the engine stopped

and the muffler and cutting blade away from

your body, preferably with the blade cover

installed.

-- 2 --

--Blade

Page 3

Safety

Glasses

Boots

30 ft.

(10 m)

Blades move

momentarily

after the

trigger is

released.

Allow blades to stop

before removing

them from the cut.

WARNING:

Blades can throw objects violently.

D Y ou can be blinded or injured.

D Wear safety glasses.

WARNING:

Hazard zone for thrown objects

D Blades can throw objects violently.

D Others can be blinded or injured.

D Keep people and animals 30 feet

(10 meters) away.

WARNING:

Blades move momentarily after the

trigger is released.

D The blades can seriously cut you or

others.

D Allow blades to stop before

removing them from the cut.

D Allow engine to cool, empty the fuel tank,

and secure the unit before storing or transporting it in a vehicle.

D Do not store the unit or fuel in a closed area

where fuel vapors can reach sparks or an

open flame from hot water heaters, electric

motors or switches, furnaces, etc.

D Store unit so the cutting blade cannot acci-

dentally cause injury.

D Store unit with the blade cover installed.

D Store in a dry area out of reach of children.

WARNING: The engine exhaust from

this product contains chemicals known to the

State of California to cause cancer, birth defects or other reproductive harm.

SAFETY NOTICE:Exposure to vibrations

through prolonged use of gasoline powered

hand tools could cause blood vessel or nerve

damage in the fingers, hands, and joints of

people prone to circulation disorders or abnormal swelling. Prolonged use in cold

weather has been linked to blood vessel damage in otherwise healthy people. If symptoms

occur such as numbness, pain, loss of

strength, change in skin color or texture, or

ASSEMBLY

Examine parts for damage. Do not use damaged parts.

NOTE: If you need assistance or find parts

missing or damaged, call 1-800-554-6723.

It is normal for the fuel filter to rattle in the

empty fuel tank.

loss of feeling in the fingers, hands, or joints,

discontinue the use of this tool and seek

medical attention. An anti vibration system

does not guarantee the avoidance of these

problems. Users who operate power tools on

a continual and regular basis must monitor

closely their physical condition and the condition of this tool.

SPECIAL NOTICE: This unit is equipped

with a temperature limiting muffler and spark

arresting screen which meets the requirements of California Codes 4442 and 4443. All

U.S. forest land and the states of California,

Idaho, Maine, Minnesota, New Jersey, Oregon, and Washington require by law that

many internal combustion engines be

equipped with a spark arresting screen. If you

operate in a localewhere such regulations exist, you are legallyresponsible formaintaining

the operating condition of these parts. Failure

to do so is a violation of the law. For normal

homeowner use, the muffler and spark arresting screen will not require any service. After

50 hours of use, we recommend that your

muffler be serviced or replaced by an authorized service dealer.

Finding fuel or oil residue on muffler is normal

due to carburetor adjustments and testing

done by the manufacturer.

ASSEMBLY

Yourhedge trimmer is fully assembled; no assembly is required.

-- 3 --

Page 4

OPERATION

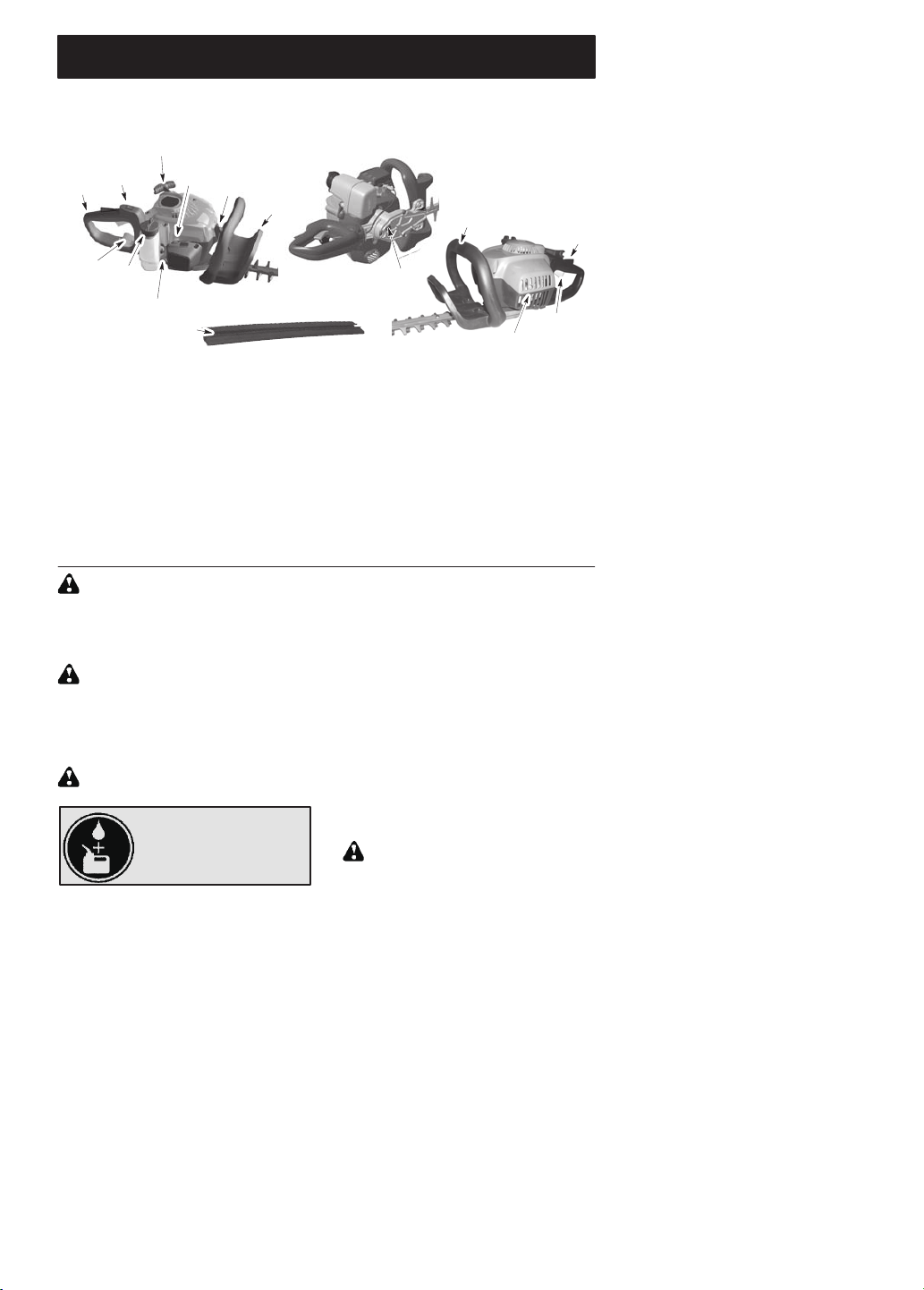

KNOW YOUR HEDGE TRIMMER

READ THIS INSTRUCTION MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

UNIT. Compare the illustrations withyour unit to familiarize yourself withthe locationof the various controls and adjustments. Save this manual for future reference.

Starter Rope

ON/OFF

Rear

Switch

Handle

Handle

Lever

Fuel Mix

Fill Cap

ON/OFF SWITCH

The ON/OFF SWITCH is used to stop the engine.To stop engine, moveswitch to OFF.

CHOKE

The CHOKE helps to supply fuel to the engine

to aid in cold starting. Activate the choke by

moving chokelever to the desiredposition.See

STARTING YOUR ENGINE for complete starting information.

FRONT HANDLE AND REAR

HANDLE

The FRONT HANDLE and REAR HANDLE

are used to maintain control of the unit.

WARNING: Muffler is very hot during

and after use. Do not touch the muffler or allow combustible materialsuch asdry grass or

fuel to do so.

BEFORE STARTING ENGINE

WARNING: Be sure to read the fuel

information in the safety rules before you begin. Ifyou do not understand the safety rules,

do not attempt to fuel your unit. Call

1-800-554-6723.

FUELING ENGINE

WARNING: Remove fuel cap slowly

when refueling.

This engine is certified to operate on unleaded

gasoline. Before operation, gasoline must be

mixed with a good quality synthetic 2-cycle aircooledengine oil designedto be mixedat a ratio

of 40:1. Poulan/WEED EATER brand synthetic

oilis recommended. A 40:1 ratiois obtained by

Primer Bulb

Spark Plug

Hand Guard

Choke Lever

Blade

Cover

HELPFUL TIP

To obtain the correct oil mix

ratio, pour 3.2 ounces of

2--cycle synthetic oil into

one gallon of fresh gas.

Front Handle

Grease Nozzle

(not serviceable)

Muffler

HANDLE LEVER

The HANDLE LEVER can be used to rotate

the rear handle to allow operation of the unit

o

at a 45

and 90o position.

PRIMER BULB

The PRIMER BULBremoves air fromthe carburetor and fuel lines and fills them with fuel.

This allows you to start the engine with fewer

pulls on the starter rope. Activate the primer

bulb by pressing it and allowing it to return to

its original position

THROTTLE TRIGGER

The THROTTLE TRIGGER controls engine

speed.Squeezethetrigger for full speed operation; release it for idle speed.

mixing3.2fluidounces(95 ml)of oil with1 gallon

(4 liters) of unleaded gasoline). DO NOT USE

automotive oil or boat oil. These oils will cause

engine damage. When mixing fuel, follow

instructions printed on oil container. Once oil is

addedto gasoline,shake containermomentari

to assure that the fuel is thoroughly mixed. Always read and follow the safety rules listed under HANDLE FUEL WITH CAUTION.

CAUTION: Never use straight gasoline in

your unit. This will cause permanent engine

damage and void the limited warranty.

FUEL REQUIREMENTS

This engine requires the use of minimum 87

octane [R+M]/2 clean gasoline.

IMPORTANT

Use of alcohol blended fuels (called gasohol or

using ethanol or methanol) cancause major engine performance and durability problems.

WARNING: Alternative fuels (not gas-

oline) such as E--15 (15% alcohol), E--20 (20%

alcohol),E--85(85%alcohol) are NOT classified

as gasoline and are NOT approved for use in

2--stroke gasoline engines. Use of alternative

fuels will cause problems such as: improper

clutch engagements, overheating, vapor lock,

power loss, lubrication deficiency, deterioration

of fuel lines, gaskets and internal carburetor

.

-- 4 --

Throttle

Lock-- out

Throttle

Trigger

ly

Page 5

components, etc. Alternative fuels cause high

moisture absorption into the fuel/oil mixture

leading to oil and fuel separation.

OPERATING INSTRUCTIONS

It is recommended that the engine not be

operatedfor longerthan 30seconds at full

throttle. Releasing the trigger and allowing

the engine to briefly return to idle speed (5 -10 seconds) will be sufficient.

IMPORTANT POINTS

• Use the minimum throttle speednecessary

to effectively cut hedges for optimal hedge

trimmer performance.

• Never attempt to use this hedge trimmer to

cut hedges that have any branches with a

diameter larger th

OPERATING POSITION

Hearing

Protection

WARNING: During operation, hold

the unit with the muffler exhaust away from

your body and clothes.

HANDLE LEVER

The HANDLE LEVER can be used to rotate

the rear handle to allow operation of the unit

o

at a 45

and 90o position.

To rotate rear handle:

1. Allow engine to return to idle speed.

2. Pull handle lever and rotate rear handle to

desired position.

3. Release handle lever.

Rear Handle

an 1″ (2.54 cm).

Eye

Protection

• Hold the unit on the ground in thestarting

position as shown. Support unit so the

blade is off of the ground and away from

trees, bushes, onlookers, etc.

HELPFUL TIP

If your engine still does not

start after following these

instructions, please call

1--800-- 554--6723.

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

WARNING: The cutting blade will be

moving once the engine starts. Wear your

protective equipment and observeall safety

instructions.

ON/OFF

Switch

1. Move the ON/OFF switch to the ON position.

2. Slowly press the primer bulb 10 times.

3. Move thechoke lever to theFULLCHOKE

position.

Throttle Lock-out

Throttle

Trigger

Primer Bulb

Handle Lever

STOPPING YOUR ENGINE

• To stop the engine, move the ON/OFF

switch to the OFF position.

• If engine does not stop, move choke lever

to the FULL CHOKE position.

STARTING YOUR ENGINE

• Fuel engine. Move at least 10 feet (3 me-

ters) away from the fueling site.

• Remove the blade cover from the blade

before starting the unit.

Choke Lever

4. Pull starter rope handle sharply until engine sounds as if it is trying to run, but do

not pull rope more than3times.

-- 5 --

Page 6

5. Move the choke lever to the HALF

CHOKE position.

6. Pull starter rope sharply until engine

starts.

If the engine doesn’t start after 6 pulls

NOTE:

(at the HALF CHOKE position), check to make sure the ON/OFF switch is in the ON position. Move the choke lever to the FULL CHOKE position andpress theprimer bulb 6 times; pull the starter rope 2 more times.

Move the choke lever to the HALF CHOKE

position and pull the starter rope until the

engine runs, but no more than 6 more pulls.

If the engine still doesn’t start, it is probably

flooded. Proceed to STARTING A FLOODED ENGINE.

7. Once the engine starts, allow engine to run

10 to 30 seconds, then pull trigger to operate. Choke lever will automatically move

to RUN position.

If engine dies with the choke lever

NOTE:

in the RUN position, move the

choke lever to the HALF CHOKE position

and pull the rope until the engine runs, but

no more than 6 pulls.

SERVICE

WARNING: Ensure ON/OFF switch

is in the OFF position and disconnect the

spark plug before performing maintenance

except for carburetor adjustments.

HELPFUL TIP

IMPORTANT: Have all

repairs other than the recommended maintenance

described in the instruction

manual performed by an

If any dealer other than an authorized

service dealer performs work on the

product, Poulan PRO may not pay for

repairs under warranty. It is your responsibility to maintain and perform

general maintenance.

GENERAL RECOMMENDATIONS

Thewarranty onthis unitdoes notcover items

that have been subjected to operator abuse

or negligence. To receive full value from the

warranty, the operator must maintain unit as

instructed in this manual. Various adjustments will need to be made periodically to

properly maintain your unit.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Spark Plug Boot

• Air Filter

• Housing Screws

CHECK FOR DAMAGED OR

WORN PARTS

Contact an authorized service dealer for replacement of damaged or worn parts.

authorized service dealer.

STARTING A WARM ENGINE

1. Move the ON/OFF switch to the ON position.

2. Slowly press the primer bulb 10 times.

3. Move the choke lever to the HALF

CHOKE position.

4. Pull starter rope sharply until engine runs,

but no more than 5 pulls.

5.

Once the engine starts, allow engine to

run 10 seconds, then pull trigger to

operate. Choke lever will automatically

move to RUN position

If engine has not started, pull start-

NOTE:

er rope 5 more pulls. If engine still does not

run, it is probably flooded. Proceed to STARTING A FLOODED ENGINE.

STARTING A FLOODED ENGINE

Flooded engines can be started by placing

the ON/OFF switch inthe ON positionand the

choke lever in the RUN position;

then, pull the rope to clear the engine of excess

fuel. Starting could require pulling the starter

rope many times depending on how badly the

unit is flooded. If the unit still doesn’t start, refer

to the TROUBLESHOOTING TABLE or call

1-800-554-6723.

• ON/OFF Switch -- Ensure ON/OFF switch

functionsproperly by movingtheswitchto the

OFF position. Make sure engine stops; then

restart engine and continue.

• Fuel Tank -- Do notuse unitif fuel tank shows

signs of damage or leaks.

• Gearbox -- Do notuse ifthe gearboxshows

signs ofdamage orleaks. After 50 hours of

use, we recommend that your gearbox be

serviced by an authorized service dealer.

INSPECT AND CLEAN UNIT AND

LABELS

• Before and after each use, inspect com-

plete unitfor loose or damaged parts. After

each use, clean th

damp cloth with a mild detergent.

• Wipe off unit with a clean dry cloth.

e unit and labels using a

CLEAN AIR FILTER

Air Filter

-- 6 --

Air Filter

Cover

Page 7

Cleaning the air filter:

A dirty air filter decreases engine performance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

1. Clean the cover and the area around it to

keep debris from falling into the carburetor

chamber when the cover is removed.

2. Remove parts as illustrated.

NOTE: Do notclean filter ingasoline orother

flammable solvent. Doing so can createafire

hazard or produce harmful evaporative emissions.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Addafew drops of oil to the filter; squeeze

filter to distribute oil.

6. Replace parts.

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

WARNING: The muffler on this prod-

uct contains chemicals known to the State of

California to cause cancer.

As your unit is used, carbondeposits buildup

on the muffler and spark arresting screen.

For normal homeowner use, however, the

muffler and spark arrestingscreen will notrequire any service. After 50 hours of use, we

recommend that your muffler be serviced or

replaced by your authorized service dealer.

CARBURETOR IDLE SPEED

ADJUSTMENT

WARNING: Keep others away when

making idle speed adjustments. The blade

will be moving during most of this procedure.

Wear your protective equipment andobserve

all safety precautions. When making adjustments, use a screwdriver short enough to

keep your hands behind the handguard and

away from the blade. After making adjustments, the blade must not move atidle speed.

The carburetor has been carefully set at the

factory.Adjustments may benecessary ifyou

notice any of the following conditions:

• Engine will not idle when the throttle is re-

leased.

• The blade moves at idle.

Keep others away when making idle speed adjustments. Mak

ing on a level surface free of debris that can be

caughtinthehedgetrimmerblade. Serious injury to the operator and others can occur if the

carburetor is not properly adjusted. Keep all

parts of your body away from the blade and

muffler.

To adjust idle speed:

Allow engine to idle.Adjust speed until engine

runs without blademoving (idletoo fast) orengine stalling (idle speed too slow).

• Turn idle speed screw clockwise to in-

crease engine speedif enginestalls ordies.

• Turn idle speed screw counterclockwise to

decrease engine speed if the blade moves

idle.

at

e adjustments with the unit rest-

WARNING: Recheck the idle speed

after each adjustment. The blade must not

move at idle speed to avoid serious injury to

the operator or others.

If you require furtherassistance orareunsure

about performing this procedure, contact an

authorized service dealer or call

1--800--554--6723.

BLADE ADJUSTMENT

The clearance between the cutting blades

must be adjusted periodically to maintainoptimal performance and sharp cutting.

Blade guide

Flat

Washer

Blade

guide

1. Usingawrench, loosen each bolt and nut

on the blade.

Wrench

2. While holding each bolt in place with a

wrench, retighten the nuts.

Idle Speed Screw

Nut

Cupped

Bolt

Nut

Washer

Nuts

TOP SIDE OF BLADE

Blades

-- 7 --

Page 8

TOP SIDE

OF BLADE

CAUTION: If the clearance between the

cutting blades is set too wide, the blades will

not cut correctly. If theblades are adjustedtoo

tight, overheating may occur.

REPLACE SPARK PLUG

Replace spark plug each year to ensure the

engine starts easier and runs better. Set

spark plug gap at 0.025 inch (0.6 mm). Ignition timing is fixed, nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder and discard.

3. Replace with Champion RCJ-6Y spark

plug and tighten securely witha3/4 inch

(19 mm) socket wrench.

4. Reinstall the spark plug boot.

STORAGE

WARNING: Perform the following

steps after each use:

• Allow engine to cool, and secure the unit

before storing or transporting.

• Store unit and fuel in a well ventilated area

where fuel vapors cannot reach sparks or

open flames from water heaters, electric

motors or switches, furnaces, etc.

• Store unit with the blade cover installed.

Position unit so that any sharp object cannot accidentally cause injury.

• Store unit and fuel well out of the reach of

children.

SEASONAL STORAGE

Prepare unitfor storage at end of season or if

it will not be used for 30 days or more.

If your unitis to be stored for aperiod of time:

• Clean the entire unit.

• Store in a clean dry area.

• Clean all parts and check for damage.

Have damaged parts repaired or replaced

by an authorized service dealer.

• Keep all nuts, bolts, and screws tight.

• Lightly oil external metal surfaces, includ-

ing the blade.

• Install the blade cover.

• Empty fuel tank before storage.

To oil the blade, do the following:

• Stop theengine and allow blade to come to

a complete stop.

• Ensure ON/OFF switch is in the OFF posi-

tion.

• Disconnect the spark plug wire.

• Apply a light machine oil along the edge of

the top strap as shown.

REPLACE FUEL FILTER

Toreplace fuelfilter,drain unit byrunning itdry

of fuel, thenremove fuel cap/retainer assembly fromtank. Pull filter from tank and remove

it from thefuel line.Install new fuelfilter onfuel

line; reinstall parts.

Fuel

Filter

Fuel Line

OIL

Top Strap

FUEL SYSTEM

Under FUELING ENGINE in the OPERATION sectionof this manual,see messagelabeled IMPORTANT regarding the use of gasohol in your engine. Fuel stabilizer is an acceptable alternative in minimizing the formation

of fuel gum deposits during storage. Add stabilizer to gasoline in fuel tank or fuel storagecontainer. Follow the mix instructions found onstabilizer container. Run engine at least 5 minutes

after adding stabilizer.

HELPFUL TIP

During storage of your gas/

oil mixture, the oil will separate from the gas.

We recommend that you

shake the gas can weekly

to insure proper blending of

the gas and oil.

ENGINE

• Remove spark plugand pour1 teaspoonof

40:1, 2-cycle engine oil (air cooled) through

the spark plug opening. Slowly pull the

starter rope 8 to 10 times to distribute oil.

-- 8 --

Page 9

• Replac e spark plug with new one of recom-

mended type and heat range (see REPLACE SPARK PLUG section).

• Clean air filter.

• Check entire unit for loose screws, nuts,

and bolts. Replace any damaged, broken,

or worn parts.

• At the beginning of the next season, use

only fresh fuel having the proper gasoline to

oil ratio.

OTHER

• Do not store gasoline from one s eason to

another.

• Replac e your gasoline can if it starts to rust.

NEED ASSISTANCE?

NEED ASSISTANCE?

Call 1-800-554-6723 for assistance.

NEED SERVICE PARTS?

Contact your dealer.

TROUBLESHOOTING TABLE

WARNING: Alwaysstop unit and disconnectspark plug beforeperforming all of the

recommended remedies below except remedies that require operation of the unit.

TROUBLE CAUSE REMEDY

Engine will not

start.

Engine will

not idle

properly.

Engine will not

accelerate,

lacks power,

or dies under

a load.

Engine

smokes

excessively.

Engine runs

hot.

1. ON/OFF switch in the

OFF position.

2. Engine flooded.

3. Fuel tank empty.

4. Spark plug not firing.

5. Fuel not reaching

carburetor.

6. Compression low.

1. Carburetor requires

adjustment.

2. Crankshaft seals worn.

3. Compression low.

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

5. Compression low.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires

adjustment.

1. Fuel mixture incorrect.

2. Spark plug incorrect.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

1. Move ON/OFF switch to the ON

position.

2. See “Starting a Flooded Engine”

in Operation Section.

3. Fill tank with correct fuel mixture.

4. Install new spark plug.

5. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

6. Contact an authorized service dealer.

1. See “Carburetor Idle Speed Adjustment”

in Service and Adjustments Section.

2. Contact an authorized service dealer.

3. Contact an authorized service dealer.

1. Clean or replace air filter.

2. Clean or replace plug

and regap.

3. Contact an authorized service dealer.

4. Contact an authorized service

5. Contact an authorized service dealer.

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. Contact an authorized service dealer.

1. See “Fueling E ngine” in Operation

section.

2. Replace with correct spark plug.

3. Contact an authorized service dealer.

4. Contact an authorized service dealer.

dealer.

-- 9 --

Page 10

LIMITED WARRANTY

Poulan PRO, a division of Husqvarna Con-

sumer Outdoor Products N.A., Inc., warrants

to the original consumer purchaser that each

new Poulan PRO brand gasoline tool or attachment is free from defects in material and

workmanship and agrees to repair or replace

under this warranty any defective gasoline

product or attachment as follows from the

original date of purchase.

2 YEARS -- Parts and Labor, when used for

household purposes.

90 DAYS -- Parts and Labor, when used for

commercial, professional, or income producing

purposes.

30 DAYS -- Parts and Labor, if used for ren

purposes.

This warranty is not transferable and does not

cover damage or liability caused by improper

handling, improper maintenanceor alteration, or

the use of accessories and/or attachments not

specifically recommended by Poulan PRO for

this tool. This warrantydoes notcover tune- up,

spark plugs, filters, starter ropes, or cutting

blades that will wear and require replacement

with reasonable use duringthe warranty period.

This warranty does not cover pre--delivery setup or normal adjustments explained in the instruction manual. Th

transportation costs.

Intheevent youhavea claimunder this warranty, you must returnthe product to anauthorized

service dealer.

Should you have any unanswered questions

concerning this warranty, please contact:

Poulan PRO, a division of Husqvarna

Consumer Outdoor Products N.A., Inc.

9335 Harris Corners Parkway

Charlotte, NC 28269

1--800--554--6723

is warranty does not cover

In Canada, contact:

Poulan PRO

850 Matheson Blvd. West

Mississauga, Ontario L5V 0B4

Giving the model number, serial number and

date of purchase of your product and the nam

and address of the authorized dealer from

whom it was purchased.

THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS,AND YOU MAY HAVEOTHER RIGHTS WHICH VARY FROM STATE TO

STATE.

NO CLAIMS FOR CONSEQUENTIAL OR

OTHER DAMAGES WILL BE ALLOWED,

tal

AND THERE ARE NO OTHER EXPRESS

WARRANTIES EXCEPT THOSE EXPRESSLY STIPULATED HEREIN.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS OR THE EXCLUSION OR

LIMITATIONS OF INCIDENTAL OR CONSEQUENTIALDAMAGES,SO THE ABOVELIMITATIONS OR EXCLUSION MAY N

TO YOU.

This is a limited warranty within the meaning of

that termas defined in the Magnuson--MossAct

of 1975.

The policy of Poulan PRO is to continuously

improve its products. Therefore, Poulan

PRO reserves the right to change, modify, or

discontinue models, designs, specifications,

and accessories of all products at any time

without notice or obligation to any purchaser.

U.S. EPA / CALIFORNIA / ENVIRONMENT CANADA

EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS: The U.S. Environmental

Protection Agency, California Air Resources

Board, Environment Canada and Poulan

PRO are pleased to explaintheemissions control systemwarranty on your year 2011and later small off--road engine. In California, all small

off--road engines must be designed, built, and

equipped to meet the State’s stringent anti-smog standards. Poulan PRO must warrant

the emission control system on your small

off--road engine for

below providedthere has been no abuse, neglect, or improper maintenance of your small

off--road engine. Your emission controlsystem

includes parts such as the carburetor, the ignitionsystemand thefuel tank.Where awarrantable condition exists, Poulan PRO will repair

your small off--road engine at no cost to you.

Expenses covered under warranty include

diagnosis, parts and labor. MANUFACTUR-

ER’S WARRANTY COVERAGE: If any

emissions related part on your engine (as

the periods of time listed

listed under Emissions Control WarrantyParts

List) is defective or a defect in the materials or

workmanship of

suchan emissionrelatedpart,the part willberepaired or replaced by Poulan PRO.OWNER’S

WARRANTY RESPONSIBILITIES: As the

small off--road engineowner,you areresponsible for the performance of the required

maintenance listed in your instruction manual. Poulan PRO recommends that you retain

all receipts covering maintenance on your

small off--road engine, but Poulan PRO cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance. As the

small off--road engine owner, you should be

aware that Poulan PRO may deny you war-

ty coverage if your small off--road engine

ran

or a part of it has failed due to abuse, neglect,

improper maintenance, unapproved modifications, or the use of parts not made orapproved

by the originalequipmentmanufacturer.You are

responsible for presenting your small off--road

theenginecauses the failure of

-- 10 --

e

OT APPLY

Page 11

engineto an PoulanPROauthorized repaircenter as soon as a problem exists. Warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days. If you

have any questions regarding your warranty

rights and responsibilities, you should contact

your nearest authorized service center, call

Poulan PRO at 1--800--554--6723, or send

e-mail correspondence to

@HCOP--emission.com

MENCEMENTDATE: The warranty periodbegins on the date the small off--road engine is

purchased. LENGTH OF COVERAGE: This

warranty shall be for a period of twoyears from

theinitialdate of purchase, or untiltheendof the

product warranty (whichever is longer). WHAT

IS COVERED: REPAIR OR REPLACEMENT

OF PARTS. Repairor replacement of any war-

rantedpart willbe performedat no charge to the

owner at an approved Poulan PRO servicing

center. If youhaveanyquestions regardingyour

warranty rights and responsib

contact your nearest authorized service center,

call Poulan PRO at 1--800--554--6723, or send

e-mail correspondence to emission.warrant

@HCOP--emission.com

RIOD: Any warranted part which is not scheduled for replacement as required maintenance,

or whichis scheduledonlyfor regular inspection

to the effect of “repair or replace as necessary”

shall be warranted for 2 years. Any warranted

part which is scheduled for replacement as required maintenance shall be warranted for the

period of time up to the first scheduled replacementpointforthatpart. DIAGNOSIS: Theowner shall not be charged for diagnostic labor

which leads to the determination that a warranted part is defect

performed at an approved Poulan PRO servicing center.

The information on

Example: (Year) EPA and/or CALIFORNIA.

emission.warranty

. WARRANTYCOM-

ilities, you should

. WARRANTY PE-

ive if the diagnostic work is

the product label indicates which standard your engine is certified.

CONSEQUENTIAL DAMAGES: PoulanPRO

maybe liablefordamages toother engine components caused by the failure of a warranted

part still underwarranty. WHAT IS NOT COV-

ERED: Allfailures caused by abuse, neglect,

or improper maintenance are not covered.

ADD--ON OR MODIFIED PARTS: The use

of add--on or modified parts can be grounds

for disallowinga warrantyclaim. PoulanPRO

is not liable to cover failures of warranted

parts caused by the use of add--on or modified parts. HOW TO FILE A CLAIM: If you

have an

y questions regarding your warranty

rights and responsibilities,you shouldcontact

your nearest authorized service center, call

Poulan PRO at 1--800--554--6723, or send

e-mail correspondence to

@HCOP--emission.com

WARRANTY SERVICE: Warranty services

or repairs shall be providedat allPoulan PRO

service centers. Call: 1-- 800--554--6723 or

send e-mail correspondence to

@HCOP--emission.com. MAINTE-

warranty

NANCE, REPLACEMENT AND REPAIR

y

OF EMISSION RELATED PARTS:Any Poulan PRO approved replacement part used in

the performance of any warranty maintenance or repair on emission related parts will

be provided withoutcharge tothe owner ifthe

part is under warranty. EMISSION CON-

TROL WARRANTY PARTS LIST: Carburetor, air filter (covered up to maintenance

schedule), ignition system: spark plug (covered up to maintenance schedule), ignition

module, muffler including catalyst (if equipped), fuel tank and cap. MAINTENANCE

STATEMENT: The owner is responsible for

the performance of all required maintenance

as defined in the instruction manual.

emission.warranty

. WHERE TO GET

emission.

EMISSION CONTROL INFORMATION

THIS ENGINE MEETS EXH AND EVP EMISSION REGULATIONS

FOR 2011 US EPA/CALIFORNIA SMALL OFF ROAD ENGINES

POULAN/WEED EATER

FAMILY/DISP BPWES. 0284HA/28cc: EM

MODEL# PP2822 SKU# 966513101

EMISSION COMPLIANCE PERIOD 50 HOURS

SN: 11069S100001

THE AIR INDEX OF THIS ENGINE IS 8

THE LOWER THE AIR INDEX, THE LESS

POLLUTION REFER TO OWNER’S MANUAL FOR

MAINTENANCE SPECIFICATIONS AND ADJUSTMENTS.

This engine is certified to be emissions compliant for the following use:

Moderate (50 hours)

Intermediate (125 hours)

Extended (300 hours)

-- 11 --

Page 12

REGLAS DE SEGURIDAD

ADVERTENCIA: El no seguir todas

las advertencias e instrucciones de seguridad podrá ser el resultado de accidentes de

suma gravedad.

PELIGRO: ¡ESTE HERRAMIENTA

DE FUERZA PUEDE SER PELIGROSA!

Este aparato puede causar accidentes de

gravedad, icluyendo amputación o ceguera al

usuario o a otras personas. Se deberán seguir todas las advertencias e instrucciones

de seguridad en este manual para proporcionar seguridad y eficiencia razonables al usar

este aparato. El usuario será responsable de

seguir las advertencias e instrucciones de

uso en este manual y en el aparato. Nunca

permita que los niños usen esta herramienta.

CONOZCA SU APARATO

S Lea cuidadosamente el manual de

instrucciones hasta que usted entienda

completamente y pueda cumplir todas las

advertencias y reglas de seguridad antes

de comenzar con el uso de este aparato.

S Limite el uso de este aparato a aquel-- las

personas que entiendan y vayan a cumplir

con todas las advertencias y reglas de

seguridad en este manual y en el aparato.

PIENSE ANTES DE PROCEDER

ADVERTENCIA: Inspeccione el

área de trabajo antes de poner en marcha el

aparato. Retire todos los escombros y objetos

sólidos tales como piedras, vidrio, alambre, etc.,

que el aparato pueda arrojar al aire o hacer rebotar causando heridas de este o cualquier otro

modo durante el uso del aparato.

D Use siempre protección para los ojos al

hacer uso, servicio o mantenimiento del

aparato. El usar protección para los ojos le

ayudará a prevenir que brozas o desechos

sean arrojados al aire rebotando en sus

ojos y en su cara loque podría resultar en la

pérdida de la vista o en accidentes de alta

gravedad. La protección para los ojos debe

ser marcado Z87.

D Use protección de oídos cuando operar

este aparato.

D Mantenga el cabello por encima de los hom-

bros, atándolo para tal efecto si es necesario.

No use joyas, ropa suelta, ni ropa con tiras,

corbatas, borlas, etc. que cuelguen libremente, porque pueden quedar enredadas en

las piezas en movimiento del aparato.

D Manténgase alerta. No use el aparato es-

tando cansado, enfermo, ansioso, ni bajo la

influencia del alcohol, las drogas u otros

medicamentos.

D Mantenga a niños, especadores y ani-

males a una distancia mínima de 10 metros

(30 pies) al poner en marcha o al usar el

aparato.

MANEJE EL COMB USTIBLE C ON

EXTREMO CUIDADO

D Elimine todas las posibles fuentes de chis-

pas o llamas (inclusive loscigarrillos, las llamas abiertas y cualquier trabajo que cause

chispas) en las areas donde se mezcla,

vierte o guarda el combustible.

D Mezcle y vierta el combustible al aire libre,

guarde el combustible en un espacio fresco, seco y bien ventilado; use un recipiente

aprobado para combustibles y marcada

como tal, para todo manejo de combustible.

D No fume mientras trabaja con el combustible

ni cuando esté haciendo uso del aparato.

D No llene el traque de combustible mientras

el motor se encuentre en marcha.

D Asegúrese que el aparato esté cor--

rectamente armado y en buena condición

de funcionamiento.

D Evita derramar el combustible o el aceite.

Limpie todos los derrames de combustible

antes de poner el aparato en marcha.

D Aléjese por lo menos 3 metros (10 pies) del

combustible y del lugar de abastecimineto

antes de poner el motor en marcha.

D Almacéne siempre combustible en un

recipiente aprobado para los líquidos

inflamables.

SEGURIDAD EN EL MANEJO DEL

APARATO

PELIGRO: RIESGO DE CORTA-

DURAS; MANTENGA LAS MANOS

ALEJADAS DE LA CUCHILLA

chilla continuará girando momentáneamente

al soltar el gatillo acelerador. No intente limpiar material ya cortado mientras la cuchilla

se encuentre girando. Asegúrese de que el

interruptor se encuentre en la posición OFF,

el cable de la bujía desconectado, y la cuchilla detenida antes de remover el material que

se haya atascado en la cuchilla. No sostenga

o agarre el aparato por la cuchilla.

D Inspeccione el aparato antes de cada uso

para verificar piezas dañadas, gastadas o

perdidas. No use el aparato hasta que este

no se encuentre en perfecto estado de

funcionamiento.

D Mantenga las superficies externas libres

de aceite y combustible.

D Nunca ponga el motor en marcha ni lo deje

en marcha dentro de un recinto cerrado.

Respirar los vapores del combustible le

podría causar la muerte.

D Evite ambientes peligrosos. No ponga el

aparato en marcha en lugares con poca

ventilación o donde se encuentren presentes

vapores explosivos o alta concentración de

monóxido de carbono.

-Lacu-

-- 1 2 --

Page 13

Gafas de

seguridad

Botas

ZONA DE PELIGRO

30 pies

(10 m)

ADVERTENCIA:

Las cuchillas pueden arrojar objetos al aire

violentamente.

D Usted puede perder la vista o tener un

accidente.

D Use protección para los ojos.

ADVERTENCIA:

Zona del peligro para los objetos arrojados.

D Las cuchillas pueden arrojar objetos al aire violentamente.

D Terceras personas podrían perder la vista o tener acci-

dentes.

D Mantenga a personas y animales alejados 10 metros (30

pies).

Las cuchillas se

moverán mo-

mentáneamente

después que el mo-

tor se haya

apagado.

D No se extienda demasiado o use el aparato

desde superficies inestables como

escaleras m anuales, árboles, cuestas

empinadas, techos, etc. Mantenga el

balance y en pie firme todo el tiempo.

D No levante el aparato más arriba de sus

hombros; la cuchilla podría acercarse a su

cuerpo de manera muy peligrosa.

D Siempre mantenga el aparato en frente

suyo. Mantenga todas las partes del

cuerpo alejadas de la cuchilla.

D Mantenga la cuchilla y los respiraderos de

aire libres de desechos.

D Use exclusivamente para trabajos descri-

tos en este manual.

Permita que las

cuchillas se detengan antes de

remover las del

área de corte.

MANTENIMIENTO APROPIADO DE

SU APARATO

D Permito que todo mantenimiento que no haya

sido recomendado en este manual de

instrucciones, sea efectuado por su distribuidor autorizado del servicio.

D Desconecte la bujía antes de efect- - uar

mantenimiento, con la excepción de los

ajustes al carburador.

D No use el aparato si la cuchilla se encuentra

doblada, torcida, astillada, rota o dañada de

cualquier manera. Entre en contacto con su

distribuidor autorizado del servicio para el

reemplazo de piezas dañadas o

desgastadas.

D Use únicamente cuchillas y piezas de

repuesto recomendadas de la marca Poulan

PRO; el uso de cualquier otro tipo de piezas

puede cancelar su garantía y causar daños a

su aparato.

D Vacie el tanque de combustible antes de

almacenar su aparato. Use todo el

combustible que quede en el carburador

poniendo el motor en marcha y dejándolo en

marcha hasta que se detenga.

D Cargue el aparato manualmente con el motor

detenido, y con el silenciador y la cuchilla

ADVERTENCIA:

Las cuchillas se moverán momentáneamente después que el motor se haya

apagado.

D Las cuchillas pueden causar serias

cortaduras a usted y a terceras

personas.

D Permita que las cuchillas se detengan

antes de remover las del área de corte.

alejados de su cuerpo, y de preferencia la

cubierta de la cuchilla instalado.

D Permita que el motor se enfríe, vacíe el

tanque de combustible, y asegure el aparato

antes de guardar o transportar en un

vehículo.

D No almacene el aparato ni el combustible

dentro de un área cerrada donde los vapores

del combustibles entren en contacto con

chispas y llamas abiertas procedentes de

calentadores de agua, motores e

interruptores eléctricos, calefactores

centrales, etc.

D Alm acene el aparato de manera que la

cuchilla no pueda causar heridas

accidentales.

D Almacene el aparato con la cubierta de la cu-

chilla instalada.

D Almacene en un lugar seco fuera del

alcance de los niños.

ADVERTENCIA: Los gases de es-

cape del motor de este producto contienen sustancias químicas conocidas en el Estado de

California como causantes de cáncer, defectos

congénitos y otros daños reproductivos.

AVISO DE SEGURIDAD: El estar expuesto

a las vibraciones a través del uso prolongado de

herramientas de fuerza a gasolina puede causar daños a los vasos sanguíneous o a los nervios de los dedos, las manos y las coyunturas

en aquellas personas que tienen protensidad a

los trastormos de la circulación o a las hinchazones anormales. El uso prolongado en tiempo

frío ha sido asociado con daños a los vasos

sanguíneos de personas que por otra parte se

encuentran en perfecto estado de salud. Si

ocurrieran síntomas tales como el entumecimiento, el dolor la falta de fuerza, los combios

en el tido en los dedos, las manos o las coyunturas pare de usar esta máquina inmediatamente y procure atención médica. Los usuarios

-- 1 3 --

Page 14

que hacen uso continuo y prolongado de las

herramientas de fuerza deben fiscalizar atentamente su estado físico y el estado del aparato.

AVISO ESPECIAL: Su aparato viene

equipada con silenciador limitador de

temperature y con rejilla antichispa que

cumple los requisitos de los Códigos de

California 4442 y 4443. Todas las tierras

forestadas federales, más los estados de

California, Idaho, Maine, Minnesota, Nueva

Jersey, Washington, y Oregón,requieren por

ley que muchos motores de combustión

interna estén equipados con rejilla

antichispa. Si usted usa una podadora de

setos en un estado y otra localidad donde

existen tales reglamentos, usted tiene la

responsabilidad

piezas en correcto estado de

funcionamiento. De lo contrario, estará en

infracción de la ley. Para el uso normal del

dueño de la casa, el silenciador y la rejilla

antichispa no requerirán ningún servicio.

Después de 50horas deuso, recomendamos

que al silenciador se le de servicio o sea

substituido por su distribuidor autorizado del

servicio.

jurídica de mantener estas

MONTAJE

Examine las piezas para verificar que no

haya daños. No use piezas dañadas.

AVISO:Si necesita ayuda, si faltanpiezas o

si hay piezas dañadas, llame al número

1-800-554-6723.

Es normalescuchar que el filtro decombustible

golpetee en el tanque vacío.

Esnormalencontrar residuosde aceiteo degasolina en el silenciador, debido a los ajustes al

carburador y a las pruebas efectuadas por el

fabricante.

MONTAJE

El aparato viene completamente armado; no

hay necesidad de montaje.

USO

CONOZCA SU RECORTADORA DE SETOS

LEA ESTE MANUAL DE INSTRUCCIONES Y LAS REGLAS DE SEGURIDAD ANTES DE

COMENZAR A USAR ESTE APARATO. Compare las ilustraciones con su aparato para

familiarizarse con la ubícación de los varios controles y ajustes. Guarde este manual para uso

futuro.

Mango

traserodle

Cuerda de arranque

Interruptor

ON/OFF

Bombeador

Bujía

Protector

de mano

Mango delantero

Bloque del

Acelerador

Palanca

del mango

Tapa del tanque

de combustible

Cebador

Cubierta para

la cuchilla

INTERRUPTOR ON/OFF

El INTERRUPTOR ON/OFF permite detener

el motor. Para detener el motor, mueva el

interruptor a la posición OFF.

CEBADOR

El CEBADOR ayudaasuministrarcombustible

al motor para facilitar el arranque cuando el

motorestáfrio. Accioneelcebadormoviendola

palanca a la posición deseada. Vea la sección

ARRANQUE DEL MOTOR para obtener la

información completa sobre el arranque

motor.

del

MANGO DELANTERO Y MANGO

TRASERO

El MANGO DELANTERO y MANGO TRASERO

permiten mantener el control de la unidad.

Boquilla de engrase

(No es reparable)

Silenciador

PALANCA DEL MANGO

La PALANCA DEL MANGO pueden ser usados para girar la mango trasera para permitir

a las operacion de la unidad en una posición

de 45° y 90°.

BOMBEADOR

El BOMBEADOR esusadopara remover aire

de el carburador y de las líneas de

combustible y las llena de mezcla de

combustible. Esto le permite poner el motor

en marcha conmenos tironesde la cuerdade

arranque. Active elbombeador apretándoloy

huego dejándo que retome su forma original.

GATILLO ACELERADOR

El GATILLO ACCELERADOR controla la

velocidad del motor. Apriete el gatillo para

máxima velocidad;suelteel gatillo paravolver a

la marcha lenta.

-- 14 --

Gatillo

Acelerador

Page 15

ADVERTENCIA: El silenciador es

extremadamente caliente durante el uso y

después de usar el aparato. No toque el silenciador ni permita que el material combustible tal como gasolina o hierba seca hagan

contacto.

ANTES DE PONER EN MARCHA EL

MOTOR

ADVERTENCIA: Lea atentamente

la información sobre el combustible en las

reglas de seguridad antes de comenzar. Si no

comprende las reglas de seguridad, no intente

abastecer el aparato de combustible. Llame al

número 1-800-554-6723.

ABASTECIMIENTO DEL MOTOR

ADVERTENCIA: Remueva la tapa

del tanque decombustible lentamente al reabastecer combustible.

INFORMACION UTIL

Para obtener la proporción

correcta de mezcla de

aceite vierta 3,2 onzas de

aceite sintético de 2 ciclos

dentro de gasolina fresca.

Este motor estáhabilitado parafuncionar con

gasolina sin plomo. Antes decomenzar con el

uso, se deberá mezclar la gasolina con un

aceite de sintético de buenacalidad paramotores de 2 tiempos enfriadosaaire. Recomendamos el aceite de sintético de la marca

Poulan/WEED EATER. Mezcle la gasolina

con el aceite en la proporción 40:1. (Se

obtiene una proporción de 40:1 mezclando

3,2 onzas de aceite con cada galón de

gasolina sin plomo). NO USE aceite para

automóviles ni para barcas. Estos aceites

dañarán el motor. Al mezclar elcombustible,

siga las instrucciones impresas en el

recipiente de aceite. Una vez añadido el

aceiteala gasolina, agite el rec

brevemente para asegurarse que el

combustible esté completamente mezclado.

Lea siempre y siga las reglas de seguridad

que se encuentran bajo MANEJE EL COMBUSTIBLE CON EXTREMOCUIDADO enla

sección reglas de seguridad.

PRECAUCION: Nunca utilizar gasoline

pura en el aparato. Esto provocará daños permanents al motor y alulará la garantía limitada.

REQUERIMIENTOS DELA COMBUSTIBLE

Este motorrequiere el uso de gasoline limpia

con un mínimo de 87 octanos [R+M]/2.

IMPORTANTE

Elusodelos combustiblesmezclados conalcohol (los llamados gasohol o los que contienen

etanol o metanol) pueden causar proble

serios en el rendimiento y la durabilidad del

motor.

ADVERTENCIA: Los combustibles

alternativos (no gasolina), tales como E--15

(15% alcohol), E--20 (20% alcohol), E--85

ipiente

mas

(85% alcohol) NO están clasificados como

gasolina y NO están aprobados para el uso

en motores de gasolina de 2 tiempos. El uso

de combustibles alternativos ocasionaráproblemas como: enganche incorrecto del embrague, sobrecalentamiento, obstrucción de

vapores, perdida de potencia, deficiencia en

la lubricación, deterioración de las líneas de

combustible, de los componentes del carburador internos y las juntas, etc. Combustibles

alternativos ocasionan que se absorba humedaden gran cantidaden lamezcla decombustible/aceite haciendo que el aceite y e

combustible se separen.

INSTRUCCIONES DE USO

Se recomienda que no opere el motor por

masde 30 segundos ala velocidadmáxima.

Suelte el gatillo del acelerador y permita que el

motorregresemoderadamente a la marchalenta (5 -- 10 segundos) serán suficientes.

PUNTOS IMPORTANTES

• Use la mínima velocidad necesaria para

cortar con eficacia y para el funcionamiento

óptimo de la recortadora de setos.

• Nunca intente utilizar esta recortadora para

cortarsetos quetengan ramascondiámetros

superiores a 2,54 cm (1 de pulgada).

POSICION DE USO

Protección

de oídos

ADVERTENCIA: Sostenga el equi-

po de modo que el escape del silenciador

quede alejado de su propio cuerpo y sus

prendas durante el uso.

PALANCA DEL MANGO

La palanca del mango pueden ser usados para

girar la mango trasera para permitir a las operacion de la unidad en una posición de 45°

y 90°.

Para girar el mango trasero:

1. Permita que el motor regrese a la velocidad

de ralentí (idle).

2. Tire la palanca del mango y gire el mango

trasero a la posición deseada.

3. Suelte la palanca del mango.

Mango trasero

Palanca del

mango

-- 15 --

Protección

para los ojos

l

Page 16

COMO DETENER EL MOTOR

• Para detener el motor, mueva el interruptor

ON/OFF a la posición OFF.

COMO ARRANCAR EL MOTOR

• Abastezca el motor con combustible. Alé-

jese por lo menos 3 metros (10 pies) de la

zona de abastecimiento.

• Remueva lacubierta dela cuchilla antes de

arrancar el motor.

• Sostenga el aparato en el suelo en la posi-

ción de arranque como se ilustra. Apoye el

aparato de manera que la cuchilla se encuentre a distancia del suelo y alejada de

rboles, arbustos, espectadores, etc.

á

INFORMACION UTIL

Si el motor de su aparato

no se pusiera en marcha

después de haber seguido

estas instrucciones, llame

al 1-- 800--554--6723.

PARA ARRANCAR CON MOTOR

FRIO (o motor caliente después de

quedar sin combustible)

ADVERTENCIA:

se moverá una vez que el motor arranque.

Use su equipo de protección y observe todas

las instrucciones de seguridad.

Interruptor

ON/OFF

1. Asegúrese de que el interruptor ON/OFF

se encuentre en la posición ON.

2. Oprima lentamente el bombeador 10 veces.

3. Mueva la palanca del cebador a la posición FULL CHOKE.

Cebador

La cuchilla de corte

Botón para cierre

del acelerador

Gatillo

Acelerador

Bombeador

4. Tire firmemente delmango de lacuerda de

arranque hasta que el motor suene como

si esté intentandoarrancar,pero notire de

la cuerda más de 3 veces.

5. Mueva la palanca del cebador a la posición HALF CHOKE.

6. Tire firmemente del mango de la cuerda

de arranque hasta que el motor arranque.

AVISO: Si el motor no arranca después del

sexto tirón de la cuerda de arranque (con la

palanca del cebador en la posición HALF

CHOKE), verifique que el interruptor ON/

OFF está en laposición ON. Mueva lapalanca del cebador a la posi

oprima el bombeador 6 veces; tire firmemente del mango de la cuerda de arranque

otras 2 veces. Mueva la palanca del cebador

a la posiciónHALF CHOKEy tirede la cuerda

de arranque hasta que el motor se ponga en

marcha, perono más de6veces. Si el motor

no arranca, probablemente se encuentre

ahogado. Proceda con la sección ARRANQUE DE MOTOR AHOGADO.

7. Una vez que el motor arranca, permita que

el motor marche por 10 a 30 segundos, luego presione el gatillo para funcionarlo. La

palanca del cebador se moverá automáticamente a la posición RUN.

AVISO:Si eI motor se cala con lapalanca del

cebador en laposición RUN, mueva la

palancaala posición HALF CHOKEy tire de la

cuerdade arranque hasta que el motor se ponga en marcha, pero no más de6tirones.

ción FULL CHOKE y

PARA ARRANCAR CON EL MOTOR

CALIENTE

1. Asegúrese de que el interruptor ON/OFF

se encuentre en la posición ON.

2. Oprima lentamente el bombeador 10 veces.

3. Mueva la palanca del cebador a la posición HALF CHOKE.

4. Tire firmemente de la cuerda de arranque

hasta que el motor se ponga en marcha,

pero no más de5veces.

5. Una vez que el motor arranca, permite que

el motor marche por 10 segundos, luego

presione el gatillo para funcionarlo. La palanca del cebador se moverá automáticamente a la posición RUN.

AVISO: Si el motor no se ha puesto en mar-

cha, tire de la cuerda de arranque otras 5

veces. Si el motor persiste sin arrancar, probablemente se encuentre ahogado. Proceda

con la sección ARRANQUE DE MOTOR

AHOGADO.

ARRANQUE DE MOTOR AHOGADO

Un motor que se encuentra ahogado se podrá

poner en marcha m

ON/OFF a la posición ON y la palanca del

cebador a la posición RUN accione ;

luego, tire de la cuerda de arranque para aclarar el motor del exceso de combustible.

Que el motor se ponga en marcha podrá significar que se tire de la cuerda de arranque

muchas veces, dependiendo cuán ahogado

se encuentre el motor. Si el motor no arranca

después de este procedimiento, vea la TABLA

DIAGNÓSTICA o llame al 1-800-554-6723.

oviendo el interruptor

-- 16 --

Page 17

SERVICIO

ADVERTENCIA: Asegúrese de

que el interruptor ON/OFF está en posición

OFF y desconecte la bujía antes dehacer cualquier mantenimiento, con la excepción de

los ajustes al carburador.

INFORMACION UTIL

IMPORTANTE: Permita

que toda reparación queno

sea el mantenimiento recomendado en el manual

de instrucciones sea efectuada por un distribuidor

Si un distribuidor NO autorizado efectuara cualquier trabajo en el producto,

Poulan PRO no pagará reparaciones

bajo la garantía. Es su responsabilidad el

mantener y efectuar el mantenimiento

general del producto.

RECOMENDACIONES GENERALES

La garantía de este aparato no cubre piezas

que hayan sido sometidas a la negligencia ni

al maltrato del usuario. Para recibir el valor

completo de la garantia, el usuario deberá

mantener el aparato como se instrye en este

manual. Será necesario hacer varios ajustes

periódicos para mantener el aparato

apropiadamente.

VERIFICAR QUE NO HAYA PIEZAS

NI FIJADORES SUELTOS

• Cubierta de la bujía

• Filtro de aire

• Tornillos de la caja

VERIFICAR QUE NO HAYA

PIEZAS DANADAS O GASTADAS

Entre en contacto con el distribuidor

autorizado del servicio para el reemplazo de

piezas dañadas o gastadas.

• Interruptor ON/OFF -- Asegúrese de que el

interruptor ON/OFF funcione correctamente

colocándolo en la posición OFF. Asegúrese

de que el motor se detenga; luego, vuelva a

arrancar el motor y continue.

• Tanque de Combustible -- Deje de usar el

aparato si hay señales de daños o pérdidas

en el tanque de combustible.

• Cajade engranajes -- Deje deusarel aparato

si hay señ

de engranajes. Después de 50 horas de uso,

recomendamos que al caja de engranajes se

le de servicio o sea substituido por un distribuidor autorizado del servicio.

INSPECCIONE Y LIMPIE EL

APARATO Y LAS PLACAS

• Antes de que cada uso y después de que

cada uso, inspeccione el aparato completa

para saber si hay piezas flojas o dañados.

Después de quecada uso,limpie el aparato

y sus placas usando u trapo húmedo con

detergente suave.

• Seque el aparato con un trapo limpio y seco.

autorizado del servicio.

ales dedaños o pérdidas en elcaja

LIMPIE EL FILTRO DE AIRE

Tapa del

Filtro de Aire

Filtro de aire

Limpie el filtro de aire:

Los filtros de aire sucios disminuyen l

útil y el rendimiento del motor e incrementan

el consumo de combustible y de emiciones

nocivas. Limpie siempre el filtro de aire

después de cada 5 horas de uso.

1. Limpie la tapa y la superficie alrededor de

la tapa para evitar que caiga suciedad o

desechos en el carburador cuando se saque la tapa.

2. Retire las piezas como se ilustra.

AVISO: Para evitar peligro de incendio y de

emiciones evaporativas nocivas, nolimpie elfiltro de aire con gasolina ni cualquier otro solvente inflammable.

3. Limpie el filtro con agua y jabón.

4. Permita que el filtro se seque.

5. Aplique varias gotas de aceite al filtro; exprima el filtro para

6. Reponga las piezas.

distribuir el aceite.

INSPECCIONE LA REJILLA ANTICHISPA Y EL SILENCIADOR

ADVERTENCIA: El silenciador en

este producto contiene las substancias

químicas que el estado de California reconoce como causantes de cáncer.

A medida quese use el aparato, el silenciador

y la rejilla antichispas se van carbonizando.

Para el uso normal del dueño de la casa, sin

embargo, el silenciador y la rejilla antichispano

requerirán ningún servicio. Después de 50

horas de uso, recomendamos que al

silenciador se le de servicio o sea substituido

por un distribuidor autorizado del servicio.

AJUSTE DE LA MARCHA LENTA

DEL CARBURADOR

ADVERTENCIA: Mantenga a otras

personas alejadas de la zona en donde se encuentre haciendoajustes de marcha lenta. La

cuchilla se moverá durante la mayor parte de

este procedimiento. Use su equipo protector y

observe todas las precauciones de seguridad.

Al hacer ajustes, utilice un destornillador corto

para mantener sus manos detrás del protector

demano y lejos de la cuchilla.Después de finalizar con el procedimiento de ajuste, la cuchilla

-- 17 --

a vida

Page 18

deberánparar de moverse mientras el motor se

encuentra a la velocidad de marcha lenta.

El carburador ha sido ajustado cuidadosamente en la fábrica. Posiblemente sea necesario hacer ajustes si se nota cualquiera de

las siguientes condiciones:

• El motorno funciona enmarcha lenta cuan-

do se suelta el acelerador.

• La cuchilla se mueve en marcha lenta.

Mantenga a otras personas alejadas de la zona

en donde se encuentre haciendo ajustes de

marcha lenta. Haga los ajustes mientras el

aparato descansa en una superficie planalibre

de escombros quepuedan enredarse en la c

chilla de larecortadora desetos. Si elcarburadornose ajustade formaapropiadapuedecausar graves heridas al usuario u otras personas.

Mantenga todas las partes de su cuerpo alejadas de la cuchilla y del silenciador.

Para ajuste de la marcha lenta:

Deje elmotor en marcha lenta. Ajuste las revoluciones hasta que el motor se mantenga en

marcha sin que el cuchilla se muevan (la marchalentaes demasiado) o que el motor se ahogue (la marcha lenta es demasiado lenta).

• Gire el tornillo de marcha lenta hacia la dere-

chaparaa

tor se ahoga o se para.

• Gire el tornillo de marcha lenta hacia la iz-

quierda para reducir las revoluciones si la

cuchilla permanecieran moviéndosemientras el motorse encuentraen marcha lenta.

la marcha lenta después de cada ajuste. La

cuchilla no deberánmoverse cuando elmotor

se encuentra en marcha lenta para así evitar

graves heridas al usuario o a otras personas.

Si requiriera ayuda adicional o no se sintiera

seguro al desempeñar este procedimiento,

entre encontacto conel distribuidorautorizado del servicioollame al 1--800--554--6723.

AJUSTE DE LA CUCHILLA

La separaciónentre las cuchillas delcorte se

debe ajustar periódicamente para mantener

funcionamiento óptimo y el corte agudo.

umentar lasrevoluciones siel mo-

ADVERTENCIA: Vuelva a verificar

Tornillo de Ajuste

de la Marcha Lenta

Guía de

Cuchilla

Arandela

plana

Guía de

u-

Cuchilla

1. Afloje cada tornillo y en tuerca la superior

de la cuchilla con la llave.

Llave

2. Mientras quesostienecada perno en su lugar conla llave, vuelvaa apretarlastuercas.

PRECAUCION: Si laseparación entre las

cuchillas de corte están demasiado separadas, las cuchillas nocortarán correctamente.

Si lascuchillas se ajustan demasiado apretadas, el recalentamiento puede ocurrir.

CAMBIE LA BUJIA

Deberá cambiarse la bujía anualmente para

asegurarse que elmotor arranquefácilmente

y tenga un mejor rendimiento. Ajuste la

separación de los electrodos a0,6 mm(0,025

depulgada).El encendidoes fijoe inalterable.

1. Gire y saque la cubierta de la bujía.

2. Retire la bujía del cilindro y deséchela.

3. Cámbielapor unabujía ChampionRCJ-6Yy

ajuste firmemente la bujía nueva con una

llave de cubo de 19 mm (3/4 de pulgada).

4. Instale nuevamentela cubierta de la bujía.

Tuerca

Arandela

Perno

SUPERFICIE SUPERIOR

Tuerca

abombada

Tuercas

DE LA CUCHILLA

SUPERFICIE SUPERIOR

DE LA CUCHILLA

CAMBIE EL FILTRO DE

COMBUSTIBLE

Para cambiar el filtro de combustible, vacíe por

completo el tanque de combustible, entonces,

remueva la tapa Y retentor del tanque. Tire del

filtro en el tanque y remuévalo de la línea de

combustible.

nuevo en la línea de combustible y vuelva a

instalar las piezas.

Instale un filtro de combustible

-- 18 --

Cuchillas

Page 19

Filtro de Combustible

Línea de

Combustible

ALMACENAJE

ADVERTENCIA: Realice los

siguientes pasos después de cada uso:

• Permita que el motor se enfríe y fije bien el

aparato antes de guardarlootransportarlo.

• Guarde el aparato y el combustible en un

lugar bien ventilado donde los vapores del

combustible no puedan entrar en contacto

con chispas ni llamas abiertas

provenientes de calentadores de agua,

motores o interruptores eléctricos,

calefactores centrales, etc.

• Guarde el aparato con todos los

protectores en su lugar y colóquelo de

modo que las piezas filosas no puedan

causar heridas por accidente.

• Guarde el aparato y el combustible enun

lugar seguro y completamente fuera del

alcance de los niños.

ESTACIONAL ALMACENAJE

Prepare el aparato para almacenarlo al final

de la temporada o si no lo va a usar por más

de 30 dias.

Si va a almacenar el aparato durante un

periodo largo de tiempo:

• Limpie el aparato por completo.

• Almacene en un área limpia y seco.

• Limpie todas las piezas y verifique que no

haya dañadas sean reparadas o reemplazadas por su distribuidor autorizado del

servicio.

• Mantenga todas las tuercas, pernos y tor-

nillos firmemente apretados.

• Aplique una pequeñacantidadde aceite alas

superficies externas metálicas, inclusive la

cuchilla.

• Instale la cubierta de la cuchilla.

• Vacíe el tanque de combustible antes de

almacenar la herramienta.

Para aplicaraceite a la cuchilla, ha

guiente:

• Detenga el motor y permita que la cuchilla

se detenga por completo.

• Asegúrese de que el interruptor ON/OFF

está en posición OFF.

• Desconecte el cable de la bujía.

• Aplique una pequeña cantidad de aceite de

máquina alrededor del borde de la banda

superior como se ilustra.

ga lo si-

ACEITE

Banda Superior

SISTEMA DE COMBUSTIBLE

Vea el mensajemarcado comoIMPORTANTE,

que se refiere al uso de combustibles con

mezcla de alcohol en suaparato, en la sección

de USO, bajo ABASTECIMIENTO DEL

MOTOR en este manual.

Los estabilizadores decombustible son una alternativaaceptable para minimizar la formación

de depósitos de gorna durante el almacenaje.

Añada estabilizador a la gasolina en el tanque

de combustibleoen el recipiente para

almacenar el mismo. Siga las instrucciones de

mezcla que se encuentran impresas en el

envase. P

marchapor unos 5minutosdespuésdehaberle

puesto estabilizador.

onga el motor en marcha y déjelo en

INFORMACION UTIL

Si almacenara su mezcla de

gasolina y aceite, con el

tiempo,elaceitese separará

de la gasolina.

Recomendamos agite el recipiente cada semana para

asegurarse de que la mezcla de gasolina y aceite sea

la apropiada.

MOTOR

• Retire la bujía y vierta una cucharadita de

aceite 40:1 para motores a 2 tiempos

(enfriados aaire)por la aberturaparala bujía.

Lentamente, tirede la cuerda de arranque de

8 a 10 veces para distribuir el aceite.

-- 19 --

Page 20

S Cambie la bujía por una nueva del tipo y de la

gama de calor recomendados (vea la sección

CAMBIE LA BUJIA).

S Limpie el filtro de aire.

S Examine toda el aparato para verificar que no

haya tornillos, tuercas ni pernos sueltos.

Cambie todas las piezas dañadas,

quebradas o gastadas.

S Al principio de la próxima temporada, use

exclusivamente combustible fresno con la

proporción correcta de gasolina a aceite.

OTROS

S No guarde la gasolina de una temporada a

la próxima.

S Cambie el recipiente de gasolina si éste se

empieza a oxidar.

¿NECESITA AYUDA?

¿NECESITA AYUDA?

Llame al 1--800--554--6723.

¿NECESITA REPUESTO?

Entre en contacto con su distribuidor autorizado del servicio.

TABL A DIAG N OSTICA

ADVERTENCIA: Siempre apague el aparato y desconecte la bujía antes de hac-

er cualquiera de las reparaciones recomendadas a continuación que no requieran que

la unidad esté en operación.

SINTOMA CAUSA SOLUCION

El motor no

arranca.

El motor no

anda en

marcha lenta

como debe.

El motor no

acelera, le

falta

potencia o

se para bajo

carga.

El motor

humea excesivamente

El motor

marcha con

temperatura

elevada.

1. Interruptor ON/OFF está

en la posición OFF.

2. El motor está ahogado.

3. El tanque de combustible

está vacío.

4. La bujía no está haciendo

chispa.

5. El combustible no está

llegando al carburador.

6. El carburador requier

ajuste.

1. El carburador requier

ajuste.

2. Las lunas del cigueñal

están gastadas.

3. La compresión está baja.

1. El filtro de aire está sucio.

2. La bujía está carbonizada.

3. El carburador requiere

ajuste.

4. Acumulación de Carbón.

5. La compresión está baja.

1. El cebador está parcial--

mente accionado.

2. La mezcla de combustible

se ha hecho incorrecta-mente.

3. El filtro de aire está sucio.

4. El carburador requiere

ajuste.

1. La mezcla de combustible

está se he hecho

incorrectamente.

2. Se ha instalado la bujía

incorrecta.

3. El carburador requiere

ajuste.

4. Acumulación de Carbón.

1. Mueva el interruptor ON/OFF en la

posición ON.

2. Vea “Arranque de Motor Ahogado”

en la sección Uso.

3. Llene el tanque con la mezcla

correcta de combustible.

4. Instale una bujía nueva.

5. Verifique si el filtro de combustible no

esté sucio; cámbielo. Verifique si hay

dobleces en la línea de combustible

o si está partida; repárela o cámbiela.

6. Entre en contacto con el distribuidor

autorizado del servicio.

1. Vea “Ajuste de la Marcha Lenta del Carburador” en la sección Servicio y Ajustes.

2. Entre en contacto con el distribuidor

autorizado del servicio.

3. Entre en contacto con el distribuidor

autorizado del servicio.

1. Limpie o cambie el filtro de aire.

2. Limpie o cambie la bujía y calibre

la separación.

3. Entre en contacto con el distribuidor

autorizado del servicio.

4. Entre en contacto con el distribuidor

autorizado del servicio.

5. Entre en contacto con el distribuidor

autorizado del servicio.

1. Ajuste el cebador.

2. Vacié el tanque de combustible y

llénelo de combustible con la mezcla

correcta.

3. Limpie o cambie el filtro de aire.

4. Entre en contacto con el distribuidor

autorizado del servicio.

1. Vea “Abastecimiento del Motor” en la

sección Uso.

2. Cambie por la bujía correcta.

3. Entre en contacto con el distribuidor

autorizado del servicio.

4. Entre en contacto con el distribuidor

autorizado del servicio.

-- 2 0 --

Page 21

GARANTIA LIMITADA

Poulan PRO, una división de Husqvarna