Poulan 96194000300 User Manual

Owner’s Manual

Snow Thrower

10.5 Horsepower

Electric Start

Dual Stage

Model 96194000300

CAUTION: Before using this product,

read this manual and follow all of its

Safety Rules and Operating Instructions.

Manual del usario

Quitanieves

10.5 caballos de fuerza (hp)

Bietápico

Arranque eléctrico

Modelo 96194000300

PRECAUCIÓN: Antes de usar este producto,

lea este manual y siga todas las reglas de

seguridad e instrucciones de operación.

406888 REV2 02/21/07

Printed in U.S.A

1

2

GENERAL INFORMATION

This instruction book is written for a person with some mechanical ability.

Like most service books, not all the steps are described. Steps on how to

loosen or tighten fasteners are steps anyone can follow with some

mechanical ability. Read and follow these instructions before you use the

unit.

Know your product: If you understand the unit and how the unit

operates, you will get the best performance. As you read this manual,

compare the illustrations to the unit. Learn the location and the function of

the controls. To help prevent an accident, follow the operating instructions

and the safety rules. Keep this manual for future reference.

IMPORTANT: Many units are not assembled and are sold in cartons. It is

the responsibility of the owner to make sure the assembly instructions in

this manual are exactly followed. Other units are purchased in an

assembled condition. On assembled units, it is the responsibility of the

owner to make sure the unit is correctly assembled. The owner must

carefully check the unit according to the instructions in this manual before

it is first used.

Declared vibration emission values in accordance with Directive 98/37/EC.

Vibration Emission according to EN 1033;1996: 2,5

Values determined at the handle when the machine was operated stationary on a

concrete surface at 3700 min--1.

GB

Controls & Equipment Features (see Figure 1)

Crank Assembly (2) -- Changes the direction of the discharge chute.

Chute Deflector (3) -- Changes the distance the snow is thrown.

Discharge Chute (4) -- Changes the direction the snow is thrown.

Auger Drive Lever (5) -- Starts and stops the auger (snow gathering and

throwing) which also propels the snowthrower..

Engine Features

Stop Switch (8) -- If equipped, move to the ON position to start the

engine.

Primer Button (9) -- Injects fuel directly into the carburetor for fast starts

in cold weather.

Recoil Starter Handle (12) -- Use to manually start the engine.

Choke Control (14) -- Use to start a cold engine.

m/s2.

Declared airborne noise emissions of Lw

2000/14/EC, Annex V.

Sound Pressure Level at operator position 89 dB.

Values determined at ear according to the specifications of EN ISO 11201.

Declared airborne sound

power level of 108 dB(A) is in

accordance with Directive

2000/14/EC.

A 108 dB is in accordance with Directive

3

This manual contains safety information to make you

aware of the hazards and risks associated with snow

throwers, and how to avoid them. The snow thrower is designed and

intended for removal of snow, and should not be used for any other

purpose. It is important that you read and understand these

instructions, and anyone operating the equipment read and understand

these instructions.

GB

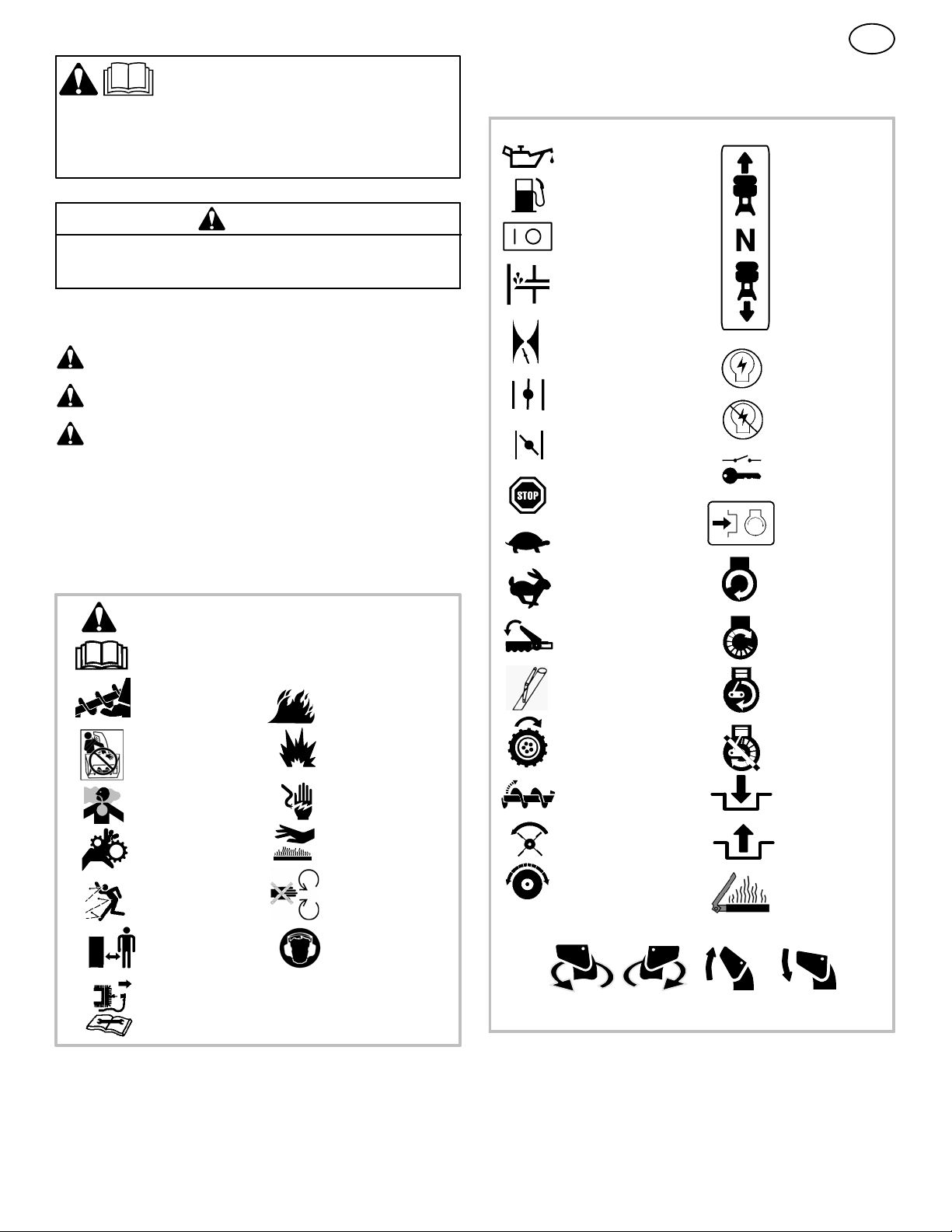

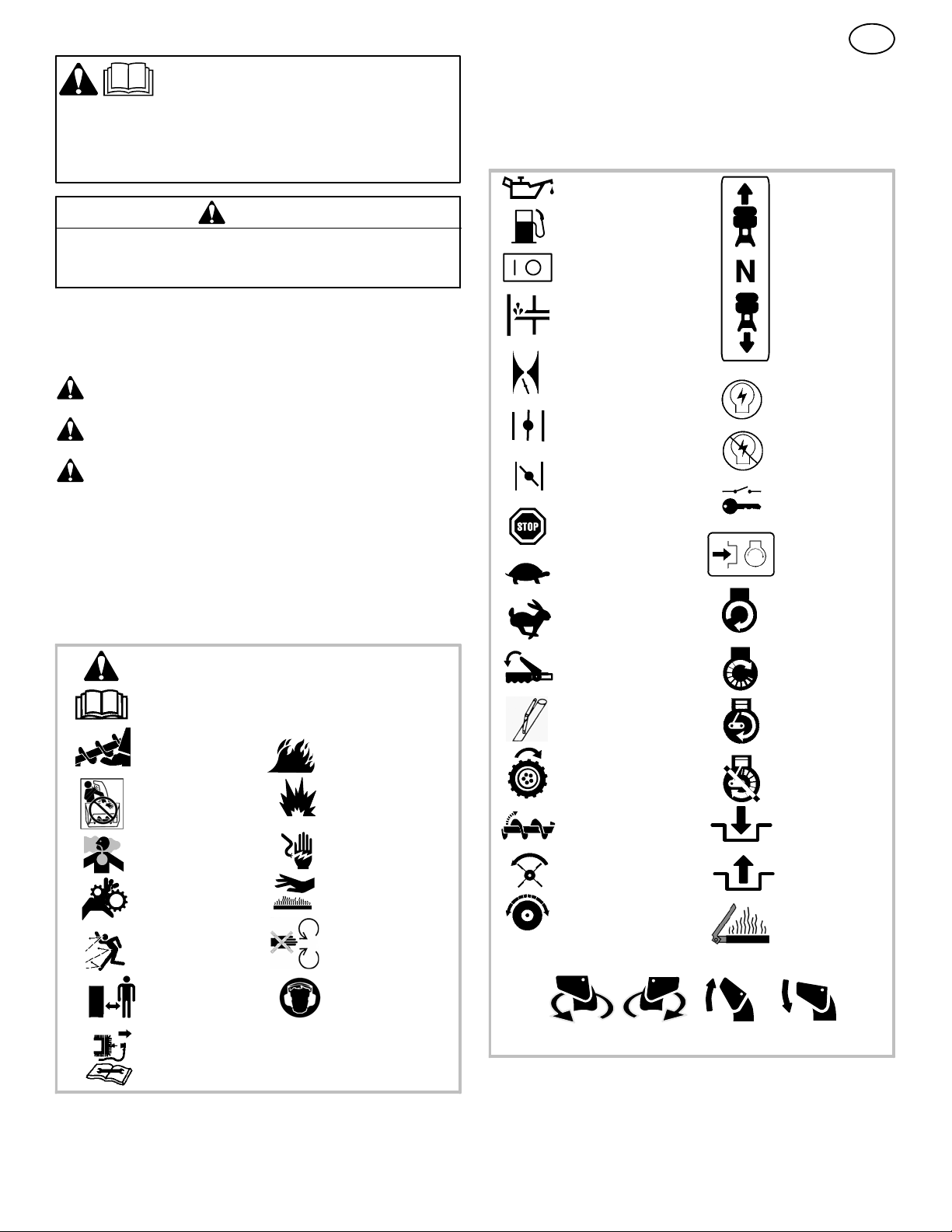

Operating Symbols and their meanings

These symbols are used on your equipment and defined in your operating

manual. It is important that you review and understand the meanings.

Failure to understand the symbols might result in harm to you.

Oil

WARNING

The engine exhaust from this product contains chemicals known to the

State of California to cause cancer, birth defects, or other reproductive

harm.

A signal word (DANGER, WARNING, or CAUTION) is used with the alert

symbol to indicate the likelihood and the potential severity of injury. In

addition, a hazard symbol may be used to represent the type of hazard.

DANGER indicates a hazard which, if not avoided, will result in

death or serious injury.

WARNING indicates a hazard which, if not avoided, could result

in death or serious injury.

CAUTION indicates a hazard which, if not avoided, might result

in minor or moderate injury.

CAUTION, when used without the alert symbol, indicates a

situation that could result in damage to the equipment.

Hazard Symbols and the meanings

These symbols are used on your equipment and defined in your operating

manual. Review and understand the meanings. The use of one of these

symbols combined with a signal word will alert you to potential hazards

and how to avoid them.

Safety Alert -- Identifies safety information about

hazards that can result in personal injury.

Operator’s Manual -- Read and understand before

performing any activity or running equipment.

Fuel

On Off

Primer bulb

Throttle

Choke off

Choke on

Stop

Slow

Fast

Engage

Foward

Neutral

Reverse

Ignition On

Ignition Off

Ignition Key

Push to engage

electric start

Electric

Start

Engine

Start

Rotating auger

Rotating impeller

Toxic fumes

Rotating gears

Thrown objects

Keep a safe distance

from the equipment.

Shut off engine and remove spark plug connector

before performing maintenance or repair work.

Fire

Explosion

Shock

Hot Surface

Never reach into

rotating parts.

Recommended ear

protection for extended

use.

Engage

Traction

Auger Collector

Auger Clutch

Drive Clutch

Discharge Chute

LEFT UP

RIGHT

Chute Deflector

Engine Run

Engine Off

Engage

Disengage

Heated Grips

DOWN

4

WARNING: This machine is capable ofto amputating hands and feet and throwing objects. Read these safety rules

and follow them closely. Failure to obey these rules could result in loss of control of unit, severe personal injury or

death to you, or bystanders, or damage to property or equipment. The triangle in text signifies important cautions or warnings which must be followed.

Safe Operation Practices for Snowthrowers

IMPORTANT: Safety standards require operator presence controls to

minimize the risk of injury. Your snowthrower is equipped with such controls. Do not attempt to defeat the function of the operator presence control under any circumstances.

Training

1. Read, understand, and follow all instructions on the machine and in the

manuals before operating this unit. Be thoroughly familiar with the controls and the proper use of the equipment. Know how to stop the unit

and disengage the controls quickly.

2. Never allow children to operate the equipment. Never allow adults to

operate the equipment without proper instruction.

3. Keep the area of operation clear of all persons, particularly small

children and pets.

4. Exercise caution to avoid slipping or falling especially when operating in

reverse.

Preparation

1. Thoroughly inspect the area where the equipment is to be used and

remove all doormats, sleds, boards, wires, and other foreign objects.

2. Disengage all clutches and shift into neutral before starting the engine

(motor).

3. Do not operate the equipment without wearing adequate winter outer

garments. Wear footwear that will improve footing on slippery surfaces.

Avoid loose fitting clothing that can get caught in moving parts.

4. Handle fuel with care; it is highly flammable.

a. Use an approved fuel container.

b. Never add fuel to a running engine or hot engine.

c. Fill fuel tank outdoors with extreme care. Never fill fuel tank indoors.

Replace fuel cap securely and wipe up spilled fuel.

d. Never fill containers inside a vehicle or on a truck or trailer bed with

a plastic liner. Always place containers on the ground, away from

your vehicle, before filling.

e. When practical, remove gas- -powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible, then refuel

such on a trailer with a portable container, rather than from a gasoline dispenser nozzle.

f. Keep nozzle in contact with the rim of the fuel tank or container

opening at all times, until refueling is complete. Do not use a nozzle

lock--open device.

g. Replace gasoline cap securely and wipe up spilled fuel.

h. If fuel is spilled on clothing, change clothing immediately.

5. Use extension cords and receptacles as specified by the manufacturer for all units with electric drive motors or electric starting motors.

6. Adjust the collector housing height to clear gravel or crushed rock

surfaces.

7. Never attempt to make any adjustments while the engine (motor) is

running (except when specifically recommended by manufacturer).

8. Let engine (motor) and snowthrower adjust to outdoor temperatures

before starting to clear snow.

9. Always wear safety glasses or eye shields during operation or while

performing an adjustment or repair to protect eyes from foreign objects

that may be thrown from the machine.

GB

Operation

1. Do not put hands or feet near or under rotating parts. Keep clear of the

discharge opening at all times.

2. Exercise extreme caution when operating on or crossing gravel drives,

walks or roads. Stay alert for hidden hazards or traffic.

3. After striking a foreign object, stop the engine (motor), remove the wire

from the spark plug, disconnect the cord on electric motors, thoroughly

inspect snowthrower for any damage, and repair the damage before

restarting and operating the snowthrower.

4. If the unit should start to vibrate abnormally, stop the engine (motor)

and check immediately for the cause. Vibration is generally a warning

of trouble.

5. Stop the engine (motor) whenever you leave the operating position,

before unclogging the collector/impeller housing or discharge chute and

when making any repairs, adjustments, or inspections.

6. When cleaning, repairing, or inspecting, make certain the collector/impeller and all moving parts have stopped. Disconnect the spark plug

wire and keep the wire away from the spark plug to prevent accidental

starting.

7. Do not run the engine indoors, except when starting the engine and for

transporting the snowthrower in or out of the building. Open the outside

doors; exhaust fumes are dangerous (containing CARBON MONOXIDE, an ODORLESS and DEADLY GAS).

8. Exercise extreme caution when operating on slopes. Do not attempt to

clear steep slopes.

9. Never operate the snowthrower without proper guards, plates, or other

safety protective devices in place and working.

10. Never direct the discharge toward people or areas where property

damage can occur. Keep children and others away.

11. Do not overload the machine capacity by attempting to clear snow at

too fast a rate.

12. Never operate the machine at high transport speeds on slippery surfaces. Look behind and use care when operating in reverse.

13. Disengage power to the collector/impeller when snowthrower is transported or not in use.

14. Use only attachments and accessories approved by the manufacturer

of the snowthrower (such as cabs, tire chains, etc..).

15. Never operate the snowthrower without good visibility or light. Always

be sure of your footing and keep a firm hold on the handles. W alk,

never run.

16. Never touch a hot engine or muffler.

17. Never operate the snowthrower near glass enclosures, automobiles,

window wells, drop--offs, and the like without proper adjustment of the

snow discharge angle.

18. Never direct discharge at bystanders or allow anyone in front of the

unit.

19. Never leave a running unit unattended. Always disengage the auger

and traction controls, stop engine, and remove keys.

20. Do not operate the unit while under the influence of alcohol or drugs.

21. Keep in mind the operator is responsible for accidents occurring to

other people or property.

22. Data indicates that operators, age 60 years and above, are involved

in a large percentage of power equipment--related injuries. These

operators should evaluate their ability to operate the unit safely

enough to protect themselves and others from injury.

23. DO NOT wear long scarves or loose clothing that could become

entangled in moving parts.

24. Snow can hide obstacles. Make sure to remove all obstacles from

theareatobecleared.

5

Children

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the unit and the operating activity. Never

assume that children will remain where you last saw them.

1. Keep children out of the area and under the watchful care of another

responsible adult.

2. Be alert and turn off if children enter the area.

3. Never allow children to operate the unit.

4. Use extra care when approaching blind corners, shrubs, trees, or

other objects that may obscure vision.

Clearing A Clogged Discharge Chute

Hand contact with the rotating impeller inside the discharge chute is the

most common cause of injury associated with snowthrowers. Never use

your hand to clean out the discharge chute.

To clear the chute:

1. SHUT OFF THE ENGINE.

2. Wait 10 seconds to be sure the impeller blades have stopped rotating.

3. Always use a clean out tool, not your hands.

Service, Maintenance And Storage

1. Check shear bolts and other bolts at frequent intervals for proper tightness to be sure the equipment is in safe working condition.

2. Never store the machine with fuel in the tank inside a building where

ignition sources are present such as hot water and space heaters, or

clothes dryers. Allow the engine to cool before storing in any enclosure.

3. Always refer to operator’s manual for important details if the snowthrower is to be stored for an extended period.

4. Maintain or replace safety and instruction labels as necessary.

5. Run the machine a few minutes after throwing snow to prevent freeze-up of the collector/impeller.

6. If fuel is spilled, do not attempt to start the engine but move the machine away from the area of spillage and avoid creating any source of

ignition until fuel vapors have dissipated.

GB

7. Always observe safe refueling and fuel handling practices when refueling the unit after transportation or storage.

8. Always follow the engine’s manual instructions for storage preparations

before storing the unit for both short and long term periods,

9. Always follow the engine manual instructions for proper start-up procedures when returning the unit to service.

10. Maintain or replace safety and instruction labels as necessary.

11. Keep nuts and bolts tight and keep equipment in good condition.

12. Never tamper with safety devices. Check their proper operation regularly and make necessary repairs if they are not functioning properly.

13. Components are subject to wear , damage, and deterioration. Frequently check components and replace with manufacturer’s recommended

parts, when necessary.

14. Check control operation frequently. Adjust and service as required.

15. Use only factory authorized replacement parts when making repairs.

16. Always comply with factory specifications on all settings and adjustments.

17. Only authorized service locations should be utilized for major service

and repair requirements.

18. Never attempt to make major repairs on this unit unless you have been

properly trained. Improper service procedures can result in hazardous

operation, equipment damage and voiding of manufacturer’s warranty.

19. Check shear bolts (pins) and other bolts at frequent intervals for proper

tightness to be sure the equipment is in safe working condition.

Emissions

1. Engine exhaust from this product contains chemicals known, in certain

quantities, to cause cancer, birth defects, or reproductive harm.

2. If available, look for the relevant Emissions Durability Period and Air

Index information on the engine emissions label.

Ignition System

1. This spark ignition system complies with Canadian ICES-002.

6

ASSEMBLY

Read and follow the assembly and adjustment

instructions for your snow thrower. All fasteners

are in the parts bag. Do not discard any parts or

material until the unit is assembled.

WARNING: Before doing any assembly or maintenance to the snow

thrower, remove the wire from the

spark plug.

NOTE: In this instruction book, left and right

describe the location of a part from the operator’s position behind the unit.

NOTE: Torque is measured in foot pounds

(metric N.m). This measurement describes

how tight a nut or bolt must be. The torque is

measured with a torque wrench.

NOTE: Fasteners and loose parts are shown

at full size in Figure 31 on page 35.

NOTE: Illustrations are located on page 2

and on pages 29 through 34.

Tools Required

1Knife

1 Pliers

2 1/2 inch open end wrenches

2 9/16 inch open end wrenches

2 3/4 inch open end wrenches

1 Measuring tape or ruler

1 Screwdriver

How To Remove The Snow Thrower

From The Carton

1. (Figure 3) The snow thrower is shown in the

shipping position.

2. Cut and discard the plastic ties that secure

the crank assembly and the speed control

rod assembly.

3. Cut down all four corners of the carton and

lay the side panels flat.

4. Locate all parts that are packed separately

and remove from the carton.

5. Remove and discard the packing material

from around the snow thrower.

6. (Figure 1) For shipping purposes, the height

adjust skids (7) are attached to the pallet.

Remove the screw (17) that secures each

height adjust skid (7) to the pallet.

7. Hold onto the lower handle and pull the snow

thrower off the pallet.

CAUTION: DO NOT back over cables.

8. Remove the packing material from the handle assembly.

9. Cut the ties that secure the clutch control

cables (1) to the lower handle (2). Move the

cables away from the motor frame.

How To Assemble The Handle And

Crank Assembly

1. (Figure 4) Loosen, but do not remove, the

fasteners (1) in the upper holes of the lower

handle.

2. Remove the fasteners and the crank assem-

bly eyebolt (11) from the lower holes of the

lower handle.

3. (Figure 1) Put the shift lever (6) into first

forward position.

4. (Figure 4) Raise the upper handle (2) to the

operating position.

NOTE: Make sure the cables are not

caught between the upper and lower handle.

5. Install the fasteners and the crank assembly

eyebolt (11) that were removed DO NOT

tighten until all fasteners are in place.

6. (Figure 6) Attach the crank rod (15) to the

universal joint assembly (16) with the hair

pin (12).

7. (Figure 4) Tighten nut on eye bolt (11).

Make sure eye bolt (11) is properly aligned

and the crank (18) can freely rotate.

8. Tighten all handle fasteners.

How To Install The Speed Control Rod

1. (Figure 9) Attach the ball joint (6), located

on the bottom end of the speed control rod

(2), to the shift yoke assembly (7). The fasteners (8) are attached to the ball joint (6)

at the factory.

The length of the ball joint (6) and speed

control rod (2) have been pre--adjusted at

the factory. If an adjustment is required, loosen the nut (9). Remove the fasteners (8) to

disconnect the ball joint (6) from the shift

yoke assembly (7). To lengthen or shorten

the speed control rod (2), turn the adapter

(10) to obtain the correct length.

2. Attach the handle (11) onto the speed se-

lect lever (5). On some models the handle

(11) is attached. To lock in position, tighten

the hex jam nut (10) against the bottom of

the handle (11).

3. Make sure the speed select lever (5) functions correctly. Move the speed select lever

(5) through all speeds.

How To Install The Knobs

NOTE: If knobs are already installed, go to

the next selection.

Remote Chute Knob

1. Assemble remote chute knob (1) onto lever

(3) until snug against nut (2). On some mod-

els the remote chute knob (1) is attached.

2. Make sure lip (4) on the remote chute knob

(1) is pointed toward the engine.

3. Tighten the nut (2) against the bottom of the

remote chute knob (1).

How To Assemble The Chute Deflector

1. (Figure 7) Remove carriage bolt (1).

2. Raise the chute deflector (2) into operating

position (3).

3. Fasten chute deflector (2) to flange (4) with

carriage bolts (1). Make sure to install with

head of the carriage bolts (1) on the inside

of the flange (2).

4. Fasten with washers (5) and locknuts (6).

5. Tighten locknuts (6) securely.

NOTE: Make sure all carriage bolts in flange

are tight. DO NOT OVERTIGHTEN.

Check The Cables

1. (Figure 8) Check the traction drive cable

(1) and the auger drive cable (2). If the bot-

tom of the cables have become disconnected, reinstall the cables.

7

GB

2. (Figure 11) If the top of the cables (5) have

become disconnected from the drive levers

(6), attach the cables (5) to the “Z” fitting

(7).

How To Set The Skid Height (Figure 1)

The snow thrower is equipped with height adjustable skids (7) mounted on the outside of the

auger housing (4). To adjust the height of the

skids, see “How To Adjust The Height Of The

Skids” in the Maintenance section.

How To Set The Length Of The Cables

The cables were adjusted at the factory and no

adjustments should be necessary. However, after the handles are put in the operating position,

the cables can be too tight or too loose. If an

adjustment is necessary, see “How To Check

And Adjust The Cables” in the Service And Adjustment section.

How To Assemble The Drift Cutter

(if equipped)

Drift cutters are used to cut a path through snow

deeper than the auger housing.

1. Loosen the wingnuts (2) that secure the

drift cutters (1) to the auger housing.

2. Raise the drift cutters (1) to the desired

height.

3. Tighten the wingnuts (2).

How To Prepare The Engine

NOTE: The engine was shipped from the

factory filled with oil. Check the level of the

oil. Add oil as needed.

WARNING: Follow the engine

manufacturer’s instructions for the

type of fuel and oil to use. Always

use a safety fuel container. Do not smoke

when adding gasoline to the engine. When

inside an enclosure, do not fill with gasoline. Before you add fuel, stop the engine.

Let the engine cool for several minutes.

Check the oil. See the engine manufacturer’s

instructions for the type of fuel and oil to use.

Before you use the unit, read the information on

safety, operation, maintenance, and storage.

Important! Before You Start Operating

U Check the fasteners. Make sure all fas-

teners are tight.

U On electric start models, the unit was

shipped with the starter cord plugged

into the engine. Before operating, unplug the starter cord from the engine.

U If a bar code label is attached to the han-

dle, remove before operating.

OPERATION

NOTE: Illustrations are located on page 2

and on pages 29 through 34.

CAUTION: Use only attachments and accessories approved by the manufacturer of the

snow thrower (such as tire chains, electric

start kits, etc.).

Know Your Snow Thrower (Figure 1)

Read this Instruction Book and safety rules before operation the snow thrower. Compare the

illustration with your snow thrower to familiarize

yourself with the location of various controls and

adjustments.

How To Control

The Discharge Of The Snow

WARNING: Never direct the discharge of snow toward bystanders.

WARNING: Always stop the engine

before unclogging the discharge

chute or the auger housing and be-

fore leaving the snow thrower.

1. (Figure 1) Turn the crank assembly (2) to

change the discharge direction of the snow.

2. Pull the remote chute lever (20) back to

discharge the snow high and far. Push the

remote chute lever (20) forwardtodischarge the snow down.

How To Stop

The Snow Thrower (Figure 1)

1. To stop discharging snow, release the auger

drive lever (5).

2. To stop the wheels, release the traction

drive lever (1).

3. Stop the engine.

a. To stop the engine on models with a

throttle control (13), first move the

throttle control (13) to the SLOW posi-

tion and then move it to the STOP position.

b. To stop the engine on models with an

ignition switch (13), move the ignition

switch (13) to the OFF position.

c. Pull out and remove the safety key (8).

CAUTION: To stop the engine, do not move

the choke control to CHOKE position. Backfire or engine damage can occur.

How To Go Forward or Backward

(Figure 1)

1. To change the ground speed, first release the

traction drive lever (1) and then move the

speed shift lever (6) to the desired speed.

2. Ground speed is determined by snow conditions. Select the speed by moving the speed

shift lever (6) into the appropriate notch on

the shift lever plate.

Speed 1, 2 Wet, Heavy

Speed 3 Light

Speed 4 Very Light

Speed 5, 6 Transport only

3. To go forward, engage the traction drive

lever (1). Maintain a firm hold on the handle

as the snow thrower starts to move forward.

Guide the snow thrower by moving the handle either left or right. Do not attempt to push

the snow thrower.

4. To go backward, release the tractor drive

lever (1).

5. Move the speed shift lever (6) into either

first or second reverse.

6. Engage the traction drive lever (1).

IMPORTANT: Do not move the speed shift

lever (6) while the traction drive lever (1) is

engaged.

How To Throw Snow (Figure 1)

1. Engage the auger drive lever (5).

2. To stop throwing snow, release the auger

drive lever (5).

WARNING: The operation of any

snow thrower can result in foreign

objects being thrown into the eyes,

which can result in severe eye damage.

Always wear safety glasses or eye shields

while operating the snow thrower. We recommend standard safety glasses or use a

wide vision safety mask over your glasses.

Before Starting The Engine

1. Before you service or start the engine, familiarize yourself with the snow thrower. Be

sure you understand the function and location of all controls.

2. Check the tension of the clutch cable before

starting the engine. See “How To Adjust The

Clutch Cable” in the Maintenance section of

this manual.

3. Make sure that all fasteners are tight.

4. Make sure the height adjust skids are properly adjusted. See “How To Adjust The Height

Of The Skids” in the Maintenance section of

this manual.

5. Check the air pressure in the tires. The correct air pressure is 14 PSI (1 BAR) to 17 PSI

(1.25 BAR). Do not exceed the maximum

amount of air pressure shown on the side of

the tire.

How To Stop The Engine (Figure 1)

1. To stop the engine on models with a throttle

control (13), first move the throttle control

(13) to the SLOW position and then move it

to the STOP position.

2. To stop the engine on models with an igni-

tion switch (13), move the ignition switch

(13) to the OFF position.

3. Pull out and remove the safety key (8).

CAUTION: To stop the engine, do not move

the choke control to CHOKE position. Backfire or engine damage can occur.

How To Start The Engine (Figure 1)

Models equipped with an Electric Starter

NOTE: An electric starter kit can be added to

recoil start engines. Electric starter kits are

available from your nearest authorized service center.

GB

WARNING: The starter is equipped

with a three--wire power cord and

plug and is designed to operate on

220 volt A.C. household current. The power

cord must be properly grounded at all times

to avoid the possibility of electrical shock

which can injure the operator. Carefully follow all instructions in the “How To Start The

Engine” section. Make sure that your house

wiring is a three--wire grounded system. If

you are not sure, ask a licensed electrician.

If your house wire system is not a

three--wire grounded system, do not use

this electric starter under any conditions. If

your system is grounded but a three--hole

grounded receptacle is not available to start

the engine, have a three--hole grounded receptacle installed by a licensed electrician.

To connect a 220 volt A.C. power cord, always connect the power cord to the switch

box (11) on the engine first. Then, plug the

other end into the three--hole grounded receptacle. When disconnecting the power

cord, always unplug the end from the

three--hole grounded receptacle first.

How To Start A Cold Engine (Figure 1)

1. Check the engine oil.

2. Fill the fuel tank with regular unleaded petrol.

See “How To Prepare The Engine”.

3. Make sure the traction drive lever (1) and

the auger drive lever (5) are in the disengaged (released) position.

4. To start the engine on models with a throttle

control (13), move the throttle control (13)

to the FAST position. Operate the engine

with the throttle control (13) in the FAST

position.

5. To start the engine on models with an igni-

tion switch (13), move the ignition switch

(13) to the ON position.

6. Insert the safety key (8) into the ignition slot.

Make sure the safety key (8) snaps into

place. Do not turn the safety key (8). Remove the extra safety key and keep in a safe

place.

7. Move the choke control (14) to the full

choke position.

8. (Electric Start) Connect the power cord to

the switch box (11) located on the engine.

9. (Electric Start) Plug the other end of the

power cord into a three--hole, grounded 220

VOLT, A.C. receptacle. (See the WARNING

in this section).

10.Push the primer button (9). Every time you

push the primer button (9),waittwoseconds. For the number of times required to

push the primer button (9), see the engine

manufacturer’s instructions.

11. (Electric Start) Push on the electric start

button (10) until the engine starts. Do not

crank for more than 5 seconds at a time.

Wait one minute between starts to allow the

starter to cool.

12.(Recoil Start) Slowly pull the recoil starter

handle (12) until resistance is felt and then

pull rapidly to start the engine. Do not allow

the recoil starter handle (12) to snap back.

Slowly return the recoil starter handle (12).

13.If the engine does not start in 5 or 6 tries,

See the “Trouble Shooting Chart” Instructions.

8

14.Allow the engine to warm up for several minutes. As the engine warms up, adjust the

choke control (14) toward the RUN position.

Wait until the engine runs smoothly before

each choke adjustment.

15.(Electric Start) First disconnect the power

cord from the three--hole receptacle. Then,

disconnect the power cord from the switch

box (11).

NOTE: In temperatures below 0°F, allow

the engine to warm up for several minutes

before blowing snow.

16.When throwing snow, always run the engine

with the throttle control (13), if equipped, in

the fast position.

WARNING: Never run the engine

indoors or in enclosed, poorly ven-

tilated areas. Engine exhaust contains carbon monoxide, an odorless and

deadly gas. Keep hands, feet, hair and

loose clothing away from any moving parts

located on the engine or the snow thrower.

The temperature of muffler and nearby

areas may exceed 150°F. Avoid these

areas.

How To Start A Warm Engine (Figure 1)

If an engine has been running and is still warm,

leave the choke control (14) in the off position

and do not push the primer button (9).Ifthe

engine fails to start, follow the instructions “How

To Start A Cold Engine”.

NOTE: Do not use the primer button (9) to

start a warm engine.

How To Start An Engine With A Frozen Electric

Starter (Figure 1)

If the electric starter is frozen and will not turn

the engine, follow the instructions below.

1. Pull as much starter rope as possible out of

the starter.

2. Release the starter handle and let it snap

back against the starter. Repeat until the engine starts.

Warm engines will cause condensation in cold

weather. To prevent possible freeze--up of recoil

starter and engine controls, proceed as follows

after each snow removal job.

1. Run the snow thrower a few minutes after

throwing snow to prevent freeze--up of the

auger/impeller.

2. With engine off, allow engine to cool for several minutes.

3. Pull starter rope very slowly until resistance

is felt, then stop. Allow the starter rope to recoil. Repeat three times.

4. With the engine not running, wipe all snow

and moisture from the carburetor cover in

area of controls and levers. Also, move the

choke control and starter handle several

times.

How To Remove Snow or Debris From

The Auger Housing

WARNING: Do not attempt to remove snow or debris that may be-

come lodged in auger housing with

your hands. Use the clean--out tool or a pry

bar to remove snow or debris.

(Figure 5) On some models, a clean--out tool

(1) is attached to the top of the auger housing.

Use the clean--out tool (1) to remove snow

from the auger housing.

1. Release the auger drive lever (5).

2. Stop the engine.

3. Remove the safety key (8).

GB

4. Disconnect the spark plug wire.

5. Do not place your hands in the auger hous-

ing (4) or the discharge chute (3).

6. (Figure 5) Use the clean-out tool (1) or a

pry bar to remove any snow or debris.

Snow Throwing Tips

1. For maximum snow thrower efficiency in removing snow, adjust ground speed. Go

slower in deep, freezing or wet snow. If the

wheels slips, reduce forward speed.

2. Most efficient snow throwing is accomplished

when the snow is removed immediately after

if falls.

CAUTION: Do not overload the machine

capacity by attempting to clear snow at

too fast a rate.

3. For complete snow removal, slightly overlap

each previous path.

4. Whenever possible, discharge the snow

down wind.

5. For normal usage, set the skids so that the

scraper bar is 1/8” above the skids. For extremely hard--packed snow surfaces, adjust

the skids upward so that the scraper bar

touches the ground.

6. Rocks and gravel must not be picked up and

thrown by the machine. On gravel or crushed

rock surfaces, set the skids at 1--1/4 inch below the scraper bar. See “How To Adjust The

Height Of The Skids” in the Maintenance

section.

7. After each snow throwing job, allow the engine to idle for a few minutes. The snow and

accumulated ice will melt off the engine.

8. Clean the snow thrower after each use.

9. Remove ice, snow and debris from the entire

snow thrower. Flush with water to remove all

salt or other chemicals. Wipe snow thrower

dry.

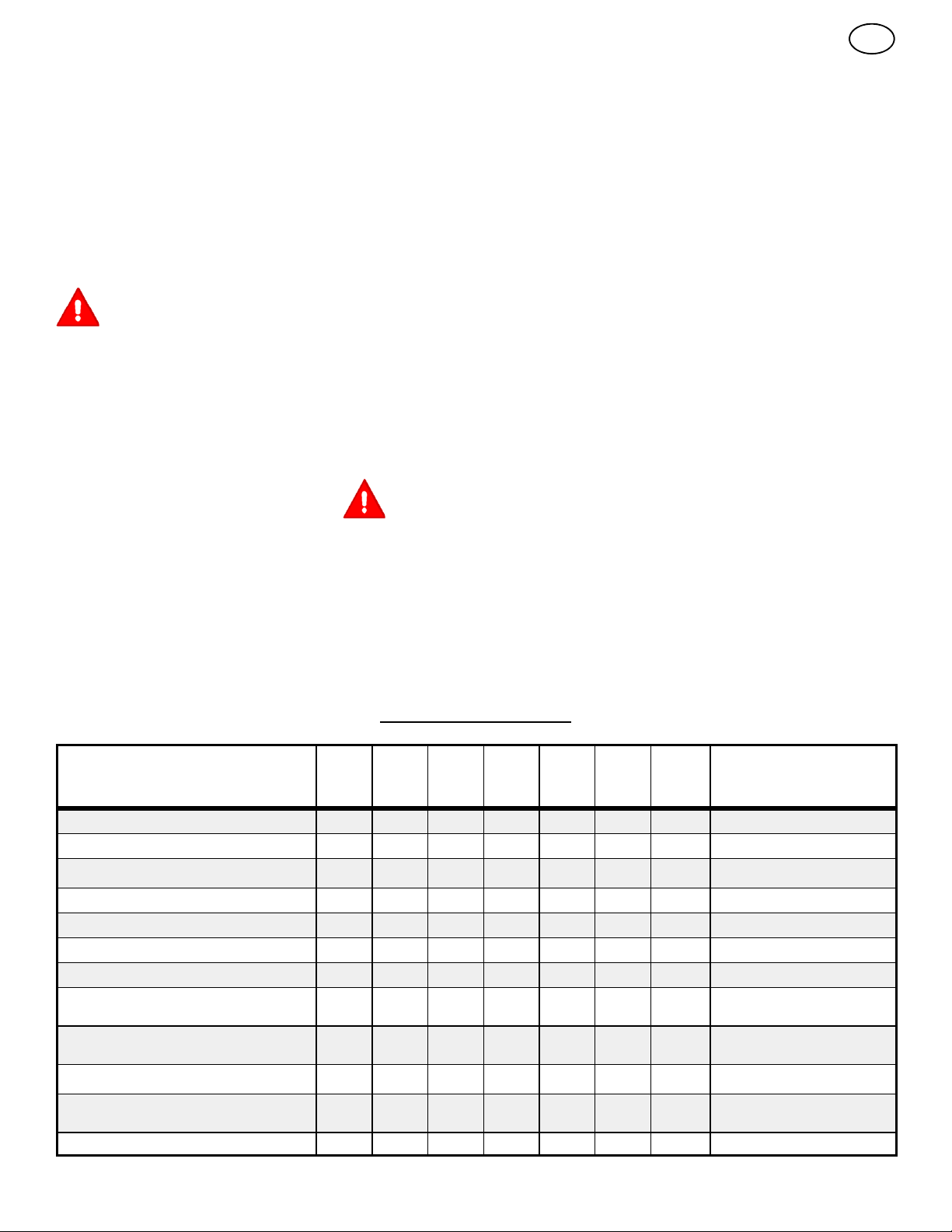

CUSTOMER RESPONSIBILITIES

SERVICE RECORDS

Fill in dates as you

complete regular

service.

Check Engine Oil Level

Change Engine Oil

Check And Tighten All Screws and Nuts

Check Spark Plug

Adjust Drive Belt

Check Fuel

Drain Fuel

Check Auger Clutch Cable Adjustment

(See Cable Adjustment)

Check Traction Clutch Cable Adjustment

(See Cable Adjustment)

Lubricate All Pivot Points

Lubricate Auger Shaft

(See Shear Bolt Replacement)

Lubricate Drive Chains and Sprockets

MAINTENANCE CHART

Before

Each

Use

First

2

Hours

Every

5

Hours

Every

10

Hours

Every

25

Hours

√ √ √

√ √

√ √

√ √

√ √ √

√

√ √

√ √

√

√ √

√ √

9

Each

Season

Before

Storage

√

√

SERVICE DATES

MAINTENANCE

NOTE: Illustrations are located on page 2

and on pages 29 through 34.

Use the following maintenance section to keep

your unit in good operating condition. All the

maintenance information for the engine is in the

engine manufacturer’s instructions. Before you

start the engine, read this book.

WARNING: Before you make an inspection, adjustment (except

carburettor), or repair, disconnect

thewirefromthesparkplug.

General Recommendations

The warranty on this snow thrower does not cover items that have been subjected to operator

abuse or negligence. To receive full value from

the warranty, the operator must maintain the

snow thrower as instructed in this manual.

Some adjustments must be made periodically to

properly maintain the snow thrower.

After Each Use

G Check for any loose or damaged parts.

G Tighten any loose fasteners.

G Check and maintain the auger.

G Check controls to make sure they are

functioning properly.

G If any parts are worn or damaged, replace

immediately.

G Check all safety and instruction decals and

labels. Replace any decals or labels that are

missing or cannot be clearly read.

All adjustments in the Maintenance section of

this manual should be checked at least once

each season.

As Required

The following adjustment should be preformed

more than once each season.

1. Adjust the auger drive belt after the first 2 to

4 hours, again at mid--season, and twice

each season thereafter. See “How To Adjust

The Auger Drive Belt” in the Maintenance

section.

Lubrication

Every10Hours(Figure 14)

1. Lubricate the Zerk fittings (1)everyten

hours with a grease gun.

2. Each time a shear bolt is replaced, the auger

shaft must also be greased.

3. Lubricate all pivot points.

Every25Hours

Chute Rotation Gear

(Figure 6) Lubricate the chute rotation gear (1)

with automotive type oil.

Chains

1. (Figure 1) Move the speed shift lever (6) to

first gear.

2. Remove the gas from the gas tank. Stand

the snow thrower up on the front end of the

auger housing (4).

WARNING: Drain the gasoline outdoors, away from fire or flame.

3. (Figure 22) Loosen the bolts (3) on each

side of the bottom panel (2).

4. Remove the bottom panel (2).

5. (Figure 15) Lubricate the chains (5) with a

chain type lubricant.

6. Wipe the hexshaft and sprockets (6) with

5W30 motor oil.

NOTE: If grease or oil come in contact

withthediscdriveplate(1)orthefriction

wheel (3), damage can result. Clean off

any oil or grease with a alcohol base solvent.

7. (Figure 22) Install the bottom panel (2).

8. Tighten the bolts (3) on each side of the bot-

tom panel (2).

Items Not To Lubricate (Figure 15)

1. Do not lubricate the hex shaft and sprockets (6). All bearings and bushings are life-

time lubricated. For storage, put a slight

amount of 5W--30 motor oil on a cloth and

wipe the hex shaft and sprockets (6) to

prevent rust.

2. If grease or oil comes in contact with the

disc drive plate (1) or the friction wheel

(3),thefriction wheel (3) can be damaged.

Make sure to thoroughly clean the disc drive

plate (1) and the friction wheel (3).

CAUTION: Any greasing or oiling of the

above components can cause contamination of the friction wheel (3). If the disc

drive plate (1) or the friction wheel (3) become contaminated with grease or oil,

damage to the friction wheel will result.

3. The auger gear case is lubricated at the factory and does not require additional lubrication. If for some reason the lubricant leaks

out, have the auger gear case checked by a

factory authorized service center.

How To Adjust The Height Of The Skids

(Figure 1)

This snow thrower is equipped with two height

adjustable skids (7). These skids elevate the

front of the snow thrower. For normal hard surfaces, such as a paved driveway or walk, adjust

the skids as follows.

1. Put the snow thrower on a level surface.

2. Make sure both tires are equally inflated.

The correct air pressure is 14 PSI (1 BAR) to

17 PSI (1.25 BAR). Do not exceed the maximum amount of air pressure shown on the

side of the tire.

3. Put the extra shear bolts (found in the parts

bag) under each end of the scraper bar (15)

next to the adjustable skids (7).

4. Loosen the mounting nuts (16) that hold the

adjustable skids (7). To bring the front of the

snow thrower down, raise each adjustable

skids (7) . Tighten the mounting nuts (16).

NOTE: For rocky or uneven surfaces, raise

the front of the snow thrower by moving the

adjustable skids (7) down.

10

GB

WARNING: Be certain to maintain

proper ground clearance for the

area to be cleared. Objects such

as gravel, rocks or other debris, if struck

by the impeller, can be thrown with sufficient force to cause personal injury, property damage or damage to the snow thrower.

How To Adjust

The Scraper Bar (Figure 1)

After considerable use, the scraper bar (15) will

become worn. The scraper bar (15),inconjunction with the skids, must be adjusted to allow

1/8 inch clearance between the scraper bar

(15) and the sidewalk or area to be cleared.

1. Put the snow thrower on a level surface.

2. Make sure both tires are equally inflated.

The correct air pressure is 14 PSI (1 BAR) to

17 PSI (1.25 BAR). Do not exceed the maximum amount of air pressure shown on the

side of the tire.

3. Loosen the carriage bolts and nuts that hold

the scraper bar (15) to the auger housing

(4).

4. Adjust the scraper bar (15) to allow 1/8 inch

clearance between the scraper bar (15) and

the sidewalk or area to be cleared.

5. Tighten the carriage bolts and nuts. Make

sure that the scraper bar (15) is parallel with

the sidewalk or area to be cleared.

6. To extended the life of the scraper bar (15),

remove and reverse the mounting of the

scraper bar (15).

How To Check And Adjust The Cables

The traction drive cable and the auger drive

cable are adjusted at the factory. During normal

use, a cable can become stretched and must be

checked and adjusted as follows.

How To Check The Cables (Figure 16)

1. To check for correct adjustment, disconnect

the “Z” fitting (1) from the drive lever (2).

2. Move the drive lever (2) forward until the

drive lever (2) is contacting the plastic

bumper (3).

3. The control cable is correctly adjusted if the

center of the “Z” fitting (1) is aligned (4)

withtheholeinthedrive lever (2) and there

in no droop in the cable.

How To Adjust The Auger Drive Cable

1. Remove the gas from the gas tank. Stand

the snow thrower up on the front end of the

auger housing.

WARNING: Drain the gasoline outdoors, away from fire or flame.

2. (Figure 16) Disconnect the “Z” fitting (1)

from the drive lever (2).

3. (Figure 17) Pull the spring cover up to expose the spring (5). Push the cable (6)

through the spring (5) to expose the square

end (7) on the cable (6).

4. Hold the square end (7) with pliers and adjust the locknut (8) in or out until the excess

slack is removed.

5. Pull the cable (6) back through the spring

(5).

6. (Figure 16) Connect the “Z” fitting (1) to the

drive lever (2).

NOTE: When the auger drive belt is adjusted

or replaced, check and adjust the cable.

How To Adjust The Traction Drive Cable

1. Remove the gas from the gas tank. Stand

the snow thrower up on the front end of the

auger housing.

WARNING: Drain the gasoline outdoors, away from fire or flame.

2. (Figure 22) Loosen the bolts (3) on each

side of the bottom panel (2).

3. Remove the bottom panel (2).

4. (Figure 16) Disconnect the “Z” fitting (1)

from the traction drive lever (2).

5. (Figure 27) Slide the cable boot (3) off the

cable adjustment bracket (4).

6. Push the bottom of the traction control

cable (5) through the cable adjustment

bracket (4) until the “Z” hook (6) canbere-

moved.

7. Remove the “Z” hook (6) from the cable

adjustment bracket (4). Move the “Z” hook

(6) down to the next adjustment hole.

8. Pull the traction control cable (5) up

through the cable adjustment bracket (4).

9. Put the cable boot (3) over the cable ad-

justment bracket (4).

10.(Figure 16) Install the “Z” fitting (1) to the

traction drive lever (2).

11. (Figure 15) To check the adjustment, depress the drive lever and check the length

“A” of the drive spring (7). In correct adjustment, the length “A” of the drive spring (7)

is as follows:

minimum 3 inches (76 mm.)

maximum 3-3/8 inches (85 mm.).

12.(Figure 22) Install the bottom panel (2).

13.Tighten the bolts (3) on each side of the bot-

tom panel (2).

How To Adjust The Belts

The belts will stretch during normal use. If you

need to adjust the belts due to wear or stretch,

proceed as follows.

How To Adjust The Auger Drive Belt

If the snow thrower will not discharge snow,

check the adjustment of the auger drive cable.

See “How To Check And Adjust The Cables” in

the Maintenance section. If the adjustment is

correct, then check the condition of the auger

drive belt. If the auger drive belt is damaged,

replace the auger drive belt. See “How To Replace The Belts” in the Maintenance section. If

the auger drive belt is loose, adjust as follows.

1. Disconnect the spark plug wire.

2. (Figure 18) Remove screw (2) from belt

cover (1). Remove the belt cover (1).

3. (Figure 19) Loosen the nut (2) on the idler

pulley (3) Move the idler pulley (3) 1/8 inch

toward the auger drive belt (4).

4. Tighten the nut (2).

5. (Figure 21) Depress the auger drive lever.

Check the tension on the auger drive belt

(4). In correct adjustment, the auger drive

belt (4) will deflect 1/2 inch (5) with moder-

ate pressure. If the adjustment is not correct,

repeat the adjustment.

6. (Figure 18) Install the belt cover (1). Tighten

screw (2).

7. Check the adjustment of the auger drive

cable. See “How To Check And Adjust The

Cables” in the Maintenance section.

8. Attach the spark plug wire.

Traction Drive Belt

The traction drive belt has constant spring pressure and does not require an adjustment. If the

traction drive belt is slipping, replace the belt.

See “How To Replace The Belts” in the Maintenance section.

How To Replace The Belts

The drive belts are of special construction and

must be replaced with original factory replacement belts available from your nearest authorized service center.

Some steps require the assistance of a second

person.

How To Remove the Auger Drive Belt

If the auger drive belt is damaged, the snow

thrower will not discharge snow. Replace the

damaged belt as follows.

1. Disconnect the spark plug wire.

2. (Figure 22) Remove the bolts (1) on each

side of the bottom panel (2).

3. Loosen the bolts (3) on each side of the bot-

tom panel (2).

4. Remove the bottom panel (2).

5. (Figure 18) Remove screw (2) from belt

cover (1). Remove the belt cover (1).

6. (Figure 19) Loosen the belt guide (9). Pull

the belt guide (9) away from the auger

drive pulley (10).

7. Pull the idler pulley (3) away from the auger

drive belt (4) and slip the auger drive belt

(4) offoftheidler pulley (3).

8. Remove the auger drive belt (4) from the

engine pulley (11). To re m ove th e auger

drive belt (4), the engine pulley (11) may

have to be partially rotated.

9. (Figure 20) Remove the top four bolts (21)

that hold together the auger housing (22)

and the motor box (23). Loosen the bottom

two bolts (24). The auger housing (22) and

the motor box (23) can now be split apart for

removal of the belt.

10.(Figure 19) Remove the old auger drive

belt (4) from the auger drive pulley (10).

Replace the auger drive belt (4) with an

original factory replacement belt available

from an authorized service center.

11.Install the new auger drive belt (4) onto the

auger drive pulley (10)

NOTE: To assemble the auger housing

(22) to the motor box (23), have someone

hold the auger clutch lever in the ENGAGED position. This will move the idler

arm and pulley (3) enough to allow the

auger drive pulley (10) to move back into

position.

12.Assemble the auger housing (22) to the

motor box (23) with the four bolts (21) that

wereremovedinstep9.Tightenthebottom

two bolts (24).

13.Install the auger drive belt (4) onto the en-

gine pulley (11).

14.Slip the auger drive belt (4) under the idler

pulley (3).

.

11

GB

15.Adjust the auger drive belt (4). See “How To

Adjust The Auger Drive Belt” in the Maintenance section.

16.Adjust the belt guide (9). See “How To Adjust The Belt Guide” in the Maintenance section.

17.(Figure 18) Install the belt cover (1). Tighten

screw (2).

18.(Figure 22) Install the bottom panel (2).

19.Install the bolts (1) on each side of the bot-

tom panel (2).

20.Tighten the bolts (1) and bolts (3) on each

side of the bottom panel (2).

21.Check the adjustment of the cables. See

“How To Check And Adjust The Cables” in

the Maintenance section.

22.Connect the spark plug wire.

How To Remove the Traction Drive Belt

If the snow thrower will not move forward, check

the traction drive belt for wear or damage. If the

traction drive belt is worn or damaged, replace

the belt as follows.

1. Disconnect the spark plug wire.

2. Remove the auger drive belt. See “How To

Remove The Auger Drive Belt” in the Maintenance section.

3. (Figure 19) Remove the e--ring (17) from

one end of the swing plate axle rod (18).

Remove the swing plate axle rod (18) to

allow the the swing plate to pivot forward.

4. Remove the traction drive spring (16).

5. Remove the old traction drive belt (13) from

the traction drive pulley (14) and from the

engine pulley (15). Replace the traction

drive belt (13) with an original factory re-

placement belt available from an authorized

service center.

6. Install the new

the traction drive pulley (14) and onto en-

gine pulley (15).

7. Make sure the traction drive idler pulley

(12) is properly aligned with the traction

drive belt (13).

8. Attach the traction drive spring (16).

9. Install the swing plate axle rod (18) and secure with the e--ring (17) removed earlier.

10.(Figure 30) The bottom of the swing plate

(20) must be positioned between the alignment tabs (19). Make sure the swing plate

(20) is properly secured.

NOTE: If the drive will not engage after

the traction drive belt has been replaced,

then check to make sure that the swing

plate is positioned between the alignment

tabs (19).

11. (Figure 19) Install and adjust the auger

drive belt (4). See “How To Remove The

Auger Drive Belt” in the Maintenance section.

12.Adjust the belt guide (9). See “How To Adjust The Belt Guide” in the Maintenance section.

13.(Figure 22) Install the bottom panel (2).

14.Tighten the bolts (3) on each side of the bot-

tom panel (2).

15.(Figure 18) Install the belt cover (1). Tighten

screw (2).

16.Check the adjustment of the cables. See

“How To Check And Adjust The Cables” in

the Maintenance section.

17.Connect the spark plug wire.

How To Adjust The Belt Guide

1. Disconnect spark plug wire.

traction drive belt (13) onto

2. (Figure 18) Remove screw (2). Remove the

belt cover (1).

3. (Figure 1) Engage the auger drive lever (5).

4. (Figure 23) Measure the distance between

the belt guide (2) and auger drive belt (3).

The correct distance (4) is 1/8 inch (3.175

mm).

5. If an adjustment is necessary, loosen the

mounting bolt for the belt guide (2).Move

the belt guide (2) to the correct position

(4). Tighten the mounting bolt for the belt

guide (2).

6. (Figure 18) Install the belt cover (1). Tighten

screw (2).

7. Connect the spark plug wire.

How To Adjust Or Replace The Friction

Wheel

How To Check The Friction Wheel

If the snow thrower will not move forward, check

thetractiondrivebelt,thetractiondrivecableor

the friction wheel. If the friction wheel is worn or

damaged, it must be replaced. See “How To

Replace the Friction Wheel” in this section. If the

friction wheel is not worn or damaged, check as

follows.

1. (Figure 1) Remove the gas from the gas

tank. Stand the snow thrower up on the front

end of the auger housing (4).

WARNING: Drain the gasoline outdoors, away from fire or flame.

2. Disconnect the spark plug wire.

3. (Figure 22) Remove the bolts (1) on each

side of the bottom panel (2).

4. Loosen the bolts (3) on each side of the bot-

tom panel (2).

5. Remove the bottom panel (2).

6. (Figure 1) Position the shift speed lever (6)

in the lowest forward speed.

7. (Figure 24) Note the position of the friction

wheel (4). The correct distance “A” from the

right side of the friction wheel (4) to the outside of the motorbox is as follows:

Tire Size Distance “A”

12 and 13 inch 4-1/8” (10.5 cm.)

16 inch 4-5/16” (10.95 cm.)

If the friction wheel (4) is not in the correct

position, adjust as follows.

How To Adjust The Friction Wheel

1. (Figure 1) Position the shift speed lever (6)

in the lowest forward speed.

2. (Figure 9) Loosen hex jam nut (9) on speed

select rod (2). Remove ball joint (6) from

shifter rod (7).

3. (Figure 24) Move the friction wheel (4) to

the correct position.

4. (Figure 9) Turn the adaptor (10) until the

ball joint (6) is aligned with the mounting

hole in the shifter rod (7). When aligned,

attach the ball joint (6) to the shifter rod (7).

5. (Figure 22) Install the bottom panel (2).

6. Install the bolts (1) on each side of the bot-

tom panel (2).

7. Tighten the bolts (1) and bolts (3) on each

side of the bottom panel (2).

How To Replace The Friction Wheel

If the friction wheel is worn or damaged, the

snow thrower will not move forward. The friction

wheel must be replaced as follows.

WARNING: Do not lubricate the

disc drive plate or the friction

wheel.

1. (Figure 1) Remove the gas from the gas

tank. Stand the snow thrower up on the front

end of the auger housing (4).

WARNING: Drain the gasoline outdoors, away from fire or flame.

2. Disconnect the spark plug wire.

3. (Figure 28) Remove the bolts (1) on each

side of the bottom panel (2).

4. Loosen the bolts (3) on each side of the bot-

tom panel (2).

5. Remove the bottom panel (2).

6. Remove the rear support brace (18).

7. (Figure 29) Use a 3/16” allen wrench and

remove the fastener that secures the right

axle clamp (30) to the axle (34).

8. Remove the right wheel (35), axle (34), axle

clamp (30), and washer (31).

9. (Figure 28) Remove the left wheel (10) from

the axle (11).

10.Remove the fasterners that secure the axle

suport (32) to the motorbox. Remove the

axle suport (32) and bushing (33).

11.Loosen (do not remove) the bolts that secure

the axle bearings (19) to the motor box.

12.Remove the clutch/drive sprocket assem-

bly (20) from the axle (11).

13.(Figure 30) Remove the four bolts (16) that

hold the bearings (7) on each side of the

hex shaft (8).

14.(Figure 31) Remove the hex shaft (8) and

bearings (7).

NOTE: Take special note of the position of

the washers (13) .

15.(Figure 26) Remove the three fasteners (4)

that hold the friction wheel (5) to the hub

(6).

16.(Figure 26) Remove the friction wheel (5)

from the hub (6). Slip the friction wheel (5)

off the hex shaft (8).

17.Assemble the new friction wheel (5) onto

hub (6) with the fasteners removed earlier.

18.(Figure 31)

bearings (7) with the four bolts removed earlier.

Make sure the washers (17) are properly

installed in the original position. Also,

make sure the two washers (13) are properly aligned with the actuator arms (14).

19.Make sure the hex shaft (8) turns freely.

20.To install the remaining parts, reverse the

above steps.

21.Check the adjustment of the friction wheel.

See “How To Adjust The Friction Wheel” in

this section.

22.Make sure the friction wheel and the disc

driveplatearefreefromgreaseoroil.

23.(Figure 28) Install the bottom panel (2).

24.Install the bolts (1) on each side of the bot-

tom panel (2).

25.Tighten the bolts (1) and bolts (3) on each

side of the bottom panel (2).

26.Connect the spark plug wire.

Install the hex shaft (8) and

12

GB

How To Replace the Auger Shear Bolt

The augers are secured to the auger shaft with

special shear bolts. These shear bolts are designed to break and protect the machine if an

object becomes lodged in the auger housing.

Do not use a harder bolt as the protection provided by the shear bolt will be lost.

WARNING: For safety and to protect the machine, use only original

equipment shear bolts.

To replace a broken shear bolt, proceed as follows. Extra shear bolts were provided in the assembly parts bag.

1. Stop the engine.

2. Disconnect the spark plug wire. Make sure

all moving parts have stopped.

3. (Figure 14) Lubricate the auger shaft Zerk

fitting (1), if equipped, with a grease gun.

4. (Figure 25) Align the hole in the auger with

the hole in the auger shaft. Install the new

shear bolt (2), spacer (3), and locknut (4).

NOTE: If the model has a 33” (84cm) Au-

ger Housing, the spacer (3) is not required.

5. Connect the spark plug wire.

How To Prepare The Snow Thrower For

Storage

WARNING: Do not remove gasoline

while inside a building, near a fire,

or while you smoke. Gasoline

fumes can cause an explosion or a fire.

If the snow thrower is to be stored for an extended period, refer to the engine manufacturer’s operating manual (included with some

models) for important maintenance or storage

details.

1. Drain the fuel tank.

2. Let the engine run until it is out of gasoline.

3. Never store the snow thrower with fuel in the

tank inside a building where ignition sources

are present such as hot water and space

heaters, clothes dryers, and the like. Allow

the engine (motor) to cool before storing in

any enclosure.

4. Drain the oil from the warm engine. Fill the

engine crankcase with new oil.

5. Remove the spark plug from the cylinder.

Pour one ounce of oil into the cylinder. Slowly pull the recoil--start grip so that the oil will

protect the cylinder. Install a new spark plug

in the cylinder.

6. Thoroughly clean the snow thrower.

7. Lubricate all lubrication points. See the Maintenance section.

8. Be sure that all nuts, bolts and screws are

securely fastened. Inspect all visible moving

parts for damage, breakage and wear. Replace if necessary.

9. Cover the bare metal parts of the blower

housing, auger, and the impeller with spray

rust preventative lubricant.

10.Put the unit in a building that has good ventilation.

11.If the machine must be stored outdoors,

block up the snow thrower to be sure the entire machine is off the ground.

12.Cover the snow thrower with a suitable protective cover that does not retain moisture.

Do not use plastic.

How To Order Replacement Parts

The replacement parts are shown either on the

back pages of this Instruction Book or in a

separate Parts List Book.

Use only manufacturer’s authorized or approved

replacement parts. The letter placed on the end

of the part number denotes the type of finish for

the part, C for chrome, Z for zinc, a PA for

purchased assembly. It is important that you

include this when ordering a part. Do not use

attachments or accessories not specifically

recommended for this unit. In order to obtain

proper replacement parts you must supply the

model number (see nameplate).

To obtain replacement parts, contact:

BRIGGS AND STRATTON CANADA

Factory Customer Service

1195 Coutneypark Drive East

Mississauga, Ont. L5T--1R1

1--800--661--6662

Collect telephone calls will not be accepted.

Replacement parts for the engine, transaxle, or

transmission, are available from the

manufacturer’s authorized service centre found

in the yellow pages of the telephone directory.

Also, see the individual engine or transmission

warranties to order replacement parts.

When ordering the following information is

required:

(1) The Model Number

(2) Serial Number

(3) Part Number

(4) Quantity

TROUBLE SHOOTING CHART

TROUBLE CAUSE CORRECTION

Difficult starting Defective spark plug. Replace spark plug.

GB

Water or dirt in fuel system. Use carburetor bowl drain to flush and refill with

Engine runs erratic Blocked fuel line, empty gas tank, or stale

Engine stalls Unit running on CHOKE. Set choke lever to RUN position.

Engine runs erratic;

Loss of power

Excessive vibration Loose parts: damaged impeller Stop engine immediately and disconnect spark

Unit fails to propel itself Drive belt loose or damaged. Replace drive belt.

Unit fails to discharge snow Auger drive belt loose or damaged. Adjust auger drive belt; replace if damaged.

gasoline

Water or dirt in fuel system. Use carburetor bowl drain to flush and refill with

Incorrect adjustment of traction drive cable Adjust traction drive cable.

Worn or damaged friction wheel. Replace friction wheel.

Auger control cable not adjusted correctly. Adjust auger control cable.

Shear bolt broken Replace shear bolt

Discharge chute clogged. Stop engine immediately and disconnect spark

Foreign object lodged in auger Stop engine immediately and disconnect spark

fresh fuel.

Clean fuel line; check fuel supply; add fresh

gasoline

fresh fuel.

plug wire. Tighten all bolts and make all

necessary repairs. If vibration continues, have

the unit serviced by a competent repairman.

plug wire. Clean discharge chute and inside of

auger housing.

plug wire. Remove object from auger.

13

GB

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC EQUIPMENT OWNER WARRANTY POLICY

Effective March 1, 2005 replaces all undated Warranties and all Warranties dated before March 1, 2005

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the equipment that is defective in material or

workmanship or both. Transportation charges on parts submitted for repair or replacement under this warranty must be borne by purchaser. This

warranty is effective for the time periods and subject tothe conditions stated below.For warranty service, find the nearest Authorized Service Dealer

in our dealer locator map at www.briggspowerproducts.com.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TOTHE EXTENT PERMITTED BY LAW ANY AND ALL IMPLIED

WARRANTIES ARE EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE EXTENT

EXCLUSION IS PERMITTED BY LAW.Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or

countries do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state or country to country.

OUR EQUIPMENT*

LAWN & GARDEN

PRODUCTS

SNOWTHROWER

WARRANTY PERIOD**

Consumer Use

2 year

Commercial Use

30 days

OUTBOARD

MOTOR

2 years

none

PRESSURE WASHER

Elite

Seriest

2 years

90 days

All other

Models

1 year

90 days

WATER

PUMP

1 year

90 days

PORTABLE

GENERATOR

WELDER

2 years

1 year

HOME STANDBY GENERATOR SYSTEM

Less than

10 KW

2 years

none

10 KW

or greater

3 years or

1500 hours

none

TRANSFER

SWITCH

3 years

none

* The engine and starting batteries are warranted solely by the manufacturers of those products.

** 2 years for all consumer products in the European Union. Parts only on 2nd year for consumer use of Portable Generator and

Home Standby Generator System -- Less than 10 KW, outside of European Union.

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time stated in the

table above. “Consumer use” means personal residential household use by a retail consumer.“Commercial use” means all other uses, including use for

commercial, income producing or rental purposes. Once equipment has experienced commercial use, it shall thereafter be considered as commercial

usefor purposes ofthis warranty.Equipment usedfor prime power in place of utilityare not applicable to this warranty. Electric poweredpressure

washers used for commercial purposes are not warranted.

NO WARRANTYREGISTRATIONIS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE YOUR PROOF OF PURCHASERECEIPT.IF YOUDO NOTPROVIDE PROOFOF THEINITIAL PURCHASEDATEAT THE TIME WARRANTY SERVICEIS REQUESTED,THE

MANUFACTURING DATE OF THE PRODUCT WILL BE USED TO DETERMINE THE WARRANTY PERIOD.

IMPORTANT:Many units are sold unassembled and cartoned. It is the responsibility of the owner to ensure assembly is performed per the exact instuctions as outlined in the Operating & Maintenance Instruction. Other units are purchased pre--assembled. It is theresponsibility of theowner to ensure the

unit is correctly assembled. The owner must carefully check the unit according to the instructions in the Operating & Maintenance Instructionsbeforeitis

first used.

ABOUT YOUR EQUIPMENT WARRANTY

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty repairs. Most warranty

repairs are handled routinely,but sometimes requests for warranty service may not be appropriate. For example, warranty service would not apply if equipment

damageoccurred becauseof misuse, lack of routinemaintenance, shipping, handling, warehousing or improper installation.Similarly,the warrantyis void if the

manufacturing date or the serial number on the equipment has been removed or the equipment has been altered or modified. During the warranty period, the

Authorized Service Dealer, at its option, will repair or replace any part that, upon examination, is found to be defective under normal use and service.This

warranty will not cover the following repairs and equipment:

S Normal Wear: Outdoor Power Equipment, like all mechanical devices, needs periodic parts and service to perform well. This warranty does not cover

repair when normal use has exhausted the life of a part or the equipment.

S Installationand Maintenance: This warranty does not apply to equipment or parts that have been subjected to improper or unauthorized installation or

alteration and modification, misuse, negligence, accident, overloading, overspeeding, improper maintenance, repair or storage so as, in our judgment, to

adversely affect its performance and reliability. This warranty also does not cover normal maintenance such as adjustments, fuel system cleaning and

obstruction (due to chemical, dirt, carbon, lime, etc.).

S Other Exclusions: This warranty excludes wear items such as quick couplers, oil gauges, belts, o-rings, filters, pump packing, etc., pumps that have

been run without water supplied or damage or malfunctions resulting from accidents, abuse, modifications, alterations, or improper servicing or freezing

or chemical deterioration. Accessory parts such as guns, hoses, wands and nozzles are excluded from the product warranty. This warranty excludes failures due to acts of God and other force majeure events beyond the manufacturers control. Al so excluded is used, reconditioned, and

demonstration equipment; equipment used for prime power in place of utility power and equipment used in life support applications.

14

INFORMACIÓN GENERAL

Este manual de instrucciones está destinado para una persona con

cierta habilidad mecánica. Como en la mayoría de los manuales de

servicio, no se describen todos los pasos. Pasos como aflojar o apretar

los sujetadores son pasos que la persona, con cierta habilidad

mecánica, puede seguir. Lea y siga estas instrucciones antes de usar la

unidad.

Conozca su producto: Si usted entiende el funcionamiento de la

unidad, obtendrá de ésta el mejor rendimiento. A medida que vaya

leyendo este manual, compare las ilustraciones con la unidad. Aprenda

la ubicación y la función de los controles. Para prevenir accidentes, siga

las instrucciones de funcionamiento y las reglas de seguridad. Guarde

este manual para referencias futuras.

IMPORTANTE: Muchas unidades no están ensambladas y se venden

en cajas de cartón. Es la responsabilidad del propietario asegurarse que

las instrucciones de ensamblaje se sigan exactamente. Otras unidades

se compran ya ensambladas. En las unidades ensambladas, es la

responsabilidad del propietario asegurarse que la unidad esté

correctamente ensamblada. Antes de usar la unidad por primera vez, el

propietario, debe revisarla cuidadosamente según las instrucciones de

este manual.

Características de los controles y del equipo (ver figura 1)

E

Manivela de ajuste (2) - Cambia la dirección del ducto de descarga.

Deflector de descarga (3) - Cambia la distancia a la que la nieve es

lanzada.

Ducto de descarga (4) - Cambia la dirección a la que la nieve es

lanzada.

Palanca del propulsor de la barrena (5) - Arranca y para la barrena

(junta y arroja la nieve) que también impulsa el quitanieves.

Características del motor

Interruptor para parar (8) - DebemoversealaposicióndeON

(encendido) para arrancar el motor.

Botón cebador (9) - Inyecta combustible directamente en el carburador

para producir arranques rápidos cuando hace frío.

Manija del arranque a reacción (12) - Se usa para arrancar el motor

en forma manual.

Control de cebado (14) - Se usa para arrancar el motor cuando está

frío.

Declarado valores de emisión de vibración en conformidad con la Directiva

98/37/EC.

En conformidad a la emisión de vibración EN 1033;1996: 2,5

Los valores determinados en el mango cuando la máquina estaba funcionando

sobre una superficie de hormigón a 3700 min--1.

Declarado emisión de ruido transportado por el aire de Lw

conformidad a la Directiva 2000/14/EC, Anexo V.

Nivel de presión del sonido en la posición del operador 89

Los valores determinados en el oído en conformidad a las especificaciones de

EN ISO 11201.

Declarado nivel del potencia

del sonido transportado por

el aire de 108 dB(A) es en

conformidad a la Directiva

2000/14/EC.

m/s2.

A 108 dB es en

dB.

15

Estemanualcontiene información de seguridad para

avisarle de los peligros y riesgos asociados a las

lanzadoras de nieve y cómo evitarlos. La lanzadora

de nieve fue diseñada para la finalidad de eliminar nieve, y no debe

usarse para ningún otro fin. Es importante que usted lea y comprenda

estas instrucciones y que cualquiera que opere el equipo lea y

comprenda estas instrucciones.

ADVERTENCIA

El escape del motor de este producto contiene sustancias químicas que el

estado de California sabe que causan cáncer, defectos de nacimiento u

otros daños reproductivos.

Se usa una palabra de señal (PELIGRO, ADVERTENCIA o PRECAUCIÓN)

con el símbolo de alerta para identificar la probabilidad y potencial gravedad de

lesiones. Además, se puede usar un símbolo de peligro para representar el

tipo de peligro.

PELIGRO indica un peligro que, si no se lo evita, resultará en

muerte o lesión grave.

ADVERTENCIA indica un peligro que, si no se lo evita, podría

resultar en muerte o lesión grave.

PRECAUCIÓN indica un peligro que, si no se lo evita, podría

resultar en lesión menor o moderada.

PRECAUCIÓN, cuando utilizado sin el símbolo de alerta, indica

una situación que podría resultar en daños al equipo.

Símbolos de peligro y significados

Estos símbolos se utilizan en su equipo. Su definición se encuentra en su

manual de operación. Revise y comprenda los significados. El uso de uno de

estos símbolos combinado con una palabra de señal le alertará sobre peligros

potenciales y cómo evitarlos.

Símbolos de operación y significados

Estos símbolos se utilizan en su equipo. Su definición se encuentra en su

manual de operación. Es importante que usted revise y comprenda los

significados. Si no comprende los símbolos, usted puede resultar herido.

Aceite

Combustible

Prender

Apagar

Bulbo de

cebador

Acelerador

Estrangulador

apagado

Estrangulador

prendido

Parar

Lento

Rápido

Adelante

Neutro

Marcha

atrás

Ignición

prendida

Ignición

apagada

Llave de

ignición

Oprimir para

activar arranque

eléctrico

Arranque

eléctrico

E

Alerta de seguridad - identifica información de seguridad

sobre peligros que pueden resultar en lesión personal.

Manual del operador - léalo y compréndalo antes de

realizar cualquier actividad u operar el equipo.

Barrena rotatoria

Impulsor rotatorio

Vapores

tóxicos

Engranajes

rotatorios

Objetos

arrojados

Mantenga una

distancia segura

del equipo.