Poulan 422080, 96192002201, XT5524ES User Manual

IMPORTANT MANUAL Do Not Throw Away

OWNER'S MANUAL

MODEL NUMBER:

Read the Owner's Manual and

XT5524ES

fol low all Warnings and Safety

In struc tions. Fail ure to do so

can result in serious injury.

SNOW THROWER

Always Wear Eye Protection During Operation

WARNING:

422080 08.28.08 CL

Printed in U.S.A.

IMPORTANT

Safe Operation Practices for Walk-Behind Snow Throwers

This snow thrower is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury.

Look for this symbol to point out im por tant safety precautions. It means

CAUTION!!! BE COME ALERT!!! YOUR

SAFE TY IS IN VOLVED.

WARNING: Always disconnect spark

plug wire and place it where it can not

con tact plug in order to pre vent ac ci den tal start ing when setting up, trans port ing, ad just ing or making re pairs.

WARNING: This snow thrower is for

use on sidewalks, driveways and other

ground level surfaces. Caution should

be exercised while using on sloping surfaces. Do not use snow thrower on

surfaces above ground level such as

roofs of residences, garages, porch es

or other such structures or buildings.

Training

1. Read, understand and follow all instructions on the

machine and in the manual(s) before operating this

unit. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

2. Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

3. Keep the area of operation clear of all persons, particularly small children.

4. Exercise caution to avoid slipping or falling, especially

when operating the snow thrower in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is

to be used and remove all doormats, sleds, boards,

wires, and other foreign objects.

2. Disengage all clutches and shift into neutral before

starting the engine (motor).

3. Do not operate the equipment without wearing adequate

winter garments. Avoid loose fitting clothing that can

get caught in moving parts. Wear footwear that will

improve footing on slippery surfaces.

4. Handle fuel with care; it is highly flammable

(a) Use an approved fuel container.

(b) Never add fuel to a running engine or hot en-

gine.

(c) Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors.

(d) Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers on the ground, away from your vehicle,

before filling.

(e) When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment

on a trailer with a portable container, rather than

from a gasoline dispenser nozzle.

WARNING: Snow throwers have ex posed rotating parts, which can cause

severe injury from contact, or from material thrown from the discharge chute.

Keep the area of operation clear of all

persons, small children and pets at all

times including startup.

CAUTION: Muffler and other engine

parts become extremely hot during

operation and remain hot after engine

has stopped. To avoid severe burns on

contact, stay away from these areas.

WARNING: Engine exhaust, some of

its con stit u ents, and certain vehicle

com po nents contain or emit chem icals known to the State of Cal i for nia

to cause can cer and birth defects or

oth er re pro duc tive harm.

(f) Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times, until refueling is complete. Do not use a nozzle lock-open

device.

(g) Replace gasoline cap securely and wipe up spilled

fuel.

(h) If fuel is spilled on clothing, change clothing im-

mediately.

5. Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive motors

or electric starting motors.

6. Adjust the collector housing height to clear gravel or

crushed rock surface.

7. Never attempt to make any adjustments while the

engine (motor) is running (except when specifically

recommended by manufacturer).

8. Always wear safety glasses or eye shields during operation or while performing an adjustment or repair to

protect eyes from foreign objects that may be thrown

from the machine.

Operation

1. Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

2. Exercise extreme caution when operating on or crossing gravel drives, walks, or roads. Stay alert for hidden

hazards or traffic.

3. After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, disconnect the

cord on electric motors, thoroughly inspect the snow

thrower for any damage, and repair the damage before

restarting and operating the snow thrower.

4. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

5. Stop the engine (motor) whenever you leave the operating position, before unclogging the collector/impeller

housing or discharge chute, and when making any

2

repairs, adjustments or inspections.

6. When cleaning, repairing or inspecting the snow thrower,

stop the engine and make certain the collector/impeller and all moving parts have stopped. Disconnect

the spark plug wire and keep the wire away from the

plug to prevent someone from accidentally starting the

engine.

7. Do not run the engine indoors, except when starting

the engine and for transporting the snow thrower in or

out of the building. Open the outside doors; exhaust

fumes are dangerous.

8. Exercise extreme caution when operating on slopes.

9. Never operate the snow thrower without proper guards,

and other safety protective devices in place and working.

10. Never direct the discharge toward people or areas

where property damage can occur. Keep children and

others away.

11. Do not overload the machine capacity by attempting

to clear snow at too fast a rate.

12. Never operate the machine at high transport speeds

on slippery surfaces. Look behind and use care when

operating in reverse.

13. Disengage power to the collector/impeller when snow

thrower is transported or not in use.

14. Use only attachments and accessories approved by

the manufacturer of the snow thrower (such as wheel

weights, counterweights, or cabs).

15. Never operate the snow thrower without good visibility

or light. Always be sure of your footing, and keep a firm

hold on the handles. Walk; never run.

16. Never touch a hot engine or muffler.

Clearing a Clogged Discharge Chute

Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with

snow throwers. Never use your hand to clean out the discharge chute. To clear the chute:

1. SHUT THE ENGINE OFF!

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean-out tool, not your hands.

Maintenance and Storage

1. Check shear bolts and other bolts at frequent intervals

for proper tightness to be sure the equipment is in safe

working condition.

2. Never store the machine with fuel in the fuel tank

inside a building where ignition sources are present

such as hot water heaters, space heaters, or clothes

dryers. Allow the engine to cool before storing in any

enclosure.

3. Always refer to operator’s manual for important details

if the snow thrower is to be stored for an extended

period.

4. Maintain or replace safety and instruction labels, as

necessary.

5. Run the machine a few minutes after throwing snow

to prevent freeze-up of the collector/impeller.

CONGRATULATIONS on your purchase of a new snow

thrower. It has been designed, engineered and man u fac tured to give best possible dependability and per for mance.

Should you experience any problem you cannot easily

remedy, please contact your nearest authorized service

center. We have competent, well-trained tech ni cians and

the proper tools to service or repair this unit.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your snow thrower

prop er ly. Always observe the “SAFETY RULES”.

SERIAL NUMBER: ___________________________

DATE OF PURCHASE: _______________________

THE MODEL AND SERIAL NUMBERS WILL BE FOUND

ON A DECAL ATTACHED TO THE REAR OF THE SNOW

THROWER HOUSING.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

TABLE OF CONTENTS

PRODUCT SPECIFICATIONS

Gasoline Capacity 2.0 Quarts

and Type: Unleaded Regular only

Oil Type SAE 30 (above 40°F)

(API SG–SL): SAE 5W-30 or 10W-30 (0° to +40°F)

SAE 0W-30 (below 0°F)

Oil Capacity: 21 Ounces

Spark Plug: Champion RJ19LM (Gap: .030")

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for

and using your snow thrower.

• Follow the instructions under “Maintenance” and “Stor age” sec tions of this own er’s manual.

SAFETY RULES ........................................................ 2-3

PRODUCT SPECIFICATIONS ...................................... 3

CUSTOMER RESPONSIBILITIES ................................ 3

ASSEMBLY / PRE-OPERATION ............................... 4-7

OPERATION ............................................................ 8-12

MAINTENANCE SCHEDULE ..................................... 13

MAINTENANCE ..................................................... 13-14

SERVICE AND AD JUST MENTS ........................... 15-17

STORAGE ................................................................... 17

TROU BLE SHOOT ING ................................................ 18

REPAIR PARTS ..................................................... 20-37

WARRANTY ............................................ BACK COVER

3

PARTS PACKED SEPARATELY IN CARTON

(1) AUGER CONTROL ROD

(1) TRACTION DRIVE CONTROL ROD

(1) MULTI-

WRENCH

(180684)

(2) FLAT WASHERS

(1) POWER CORD

(1) DISCHARGE CHUTE

ROTATOR HEAD MOUNTING

(198563)

(3) RETAINER

SPRINGS

(169675)

(2) CARRIAGE BOLTS

3/8-16 x 2.25

(1) WASHER 3/8

(19131316)

(2) SHEAR BOLTS 1/4-20 x 1-3/4

(1) LOCKNUT 3/8

(73800600)

EXTRA SHEAR BOLTS AND NUTS

(2) SPACERS

(198636)

ASSEMBLY / PRE-OPERATION

Read these instructions and this manual in its entirety

before you attempt to assemble or operate your new

snow thrower. Reading the entire manual will familiarize you with the unit, which will assist you in assembly,

operation and maintenance of the product.

Your new snow thrower has been as sem bled at the factory

with the ex cep tion of those parts left unassembled for shipping purposes. All parts such as nuts, washers, bolts, etc.,

necessary to com plete the as sem bly have been placed in

the parts bag. To ensure safe and proper operation of your

snow thrower, all parts and hard ware you assemble must

be tightened se cure ly. Use the correct tools as nec es sary

to ensure proper tightness.

REMOVE SNOW THROWER FROM CAR TON

1. Remove all accessible loose parts and parts boxes

from carton.

(1) SAFTEY IGNITION KEY

(2) LOCKNUTS

(198638)

(35062)

(2) HANDLE KNOBS

1/4-20

(73800400)

2. Cut down all four corners of carton and lay panels flat.

3. Remove the two (2) screws securing the auger housing

to the pallet.

4. Remove all packing materials ex cept plastic tie holding

speed control rod to lower handle.

5. Remove the two (2) plastic ties securing the upper

handle to the pallet.

6. Remove snow thrower from carton and check carton

thor ough ly for ad di tion al loose parts.

HOW TO SET UP YOUR SNOW THROWER

TOOL BOX (See Fig. 8)

A toolbox is provided on your snow thrower. The toolbox is

located on top of the belt cover. Store the extra shear bolts,

nuts and multi-wrench provided in parts bag in the toolbox.

4

ASSEMBLY / PRE-OPERATION

NOTE: The multi-wrench may be used for assembly of the

chute rotator head to snow thrower and making ad just ments

to the skid plates.

UNFOLD UPPER HANDLE

1. Raise upper handle to the operating position and

tight en handle knobs securely. Additional carriage

bolts, washers and handle knobs are in bag of parts.

Use to secure upper handle to lower handle. Install

in lower holes in handles.

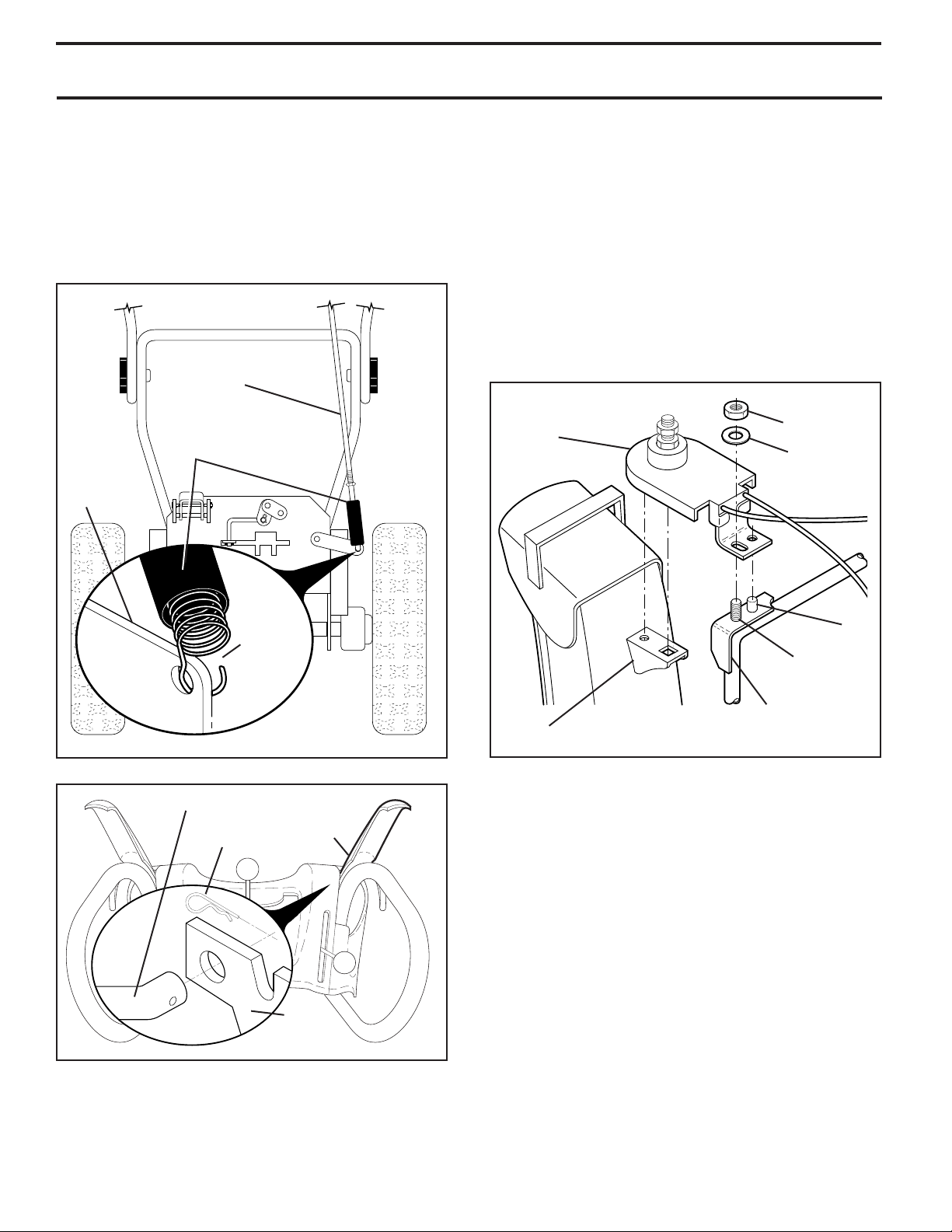

INSTALL SPEED CONTROL ROD (See Figs. 1 and 2)

1. Remove plastic tie securing rod to lower handle.

SPEED

CONTROL

ROD

PLASTIC TIE

UPPER

HANDLE

HANDLE

KNOB

2. Insert rod into speed control bracket and secure

with retainer spring.install traction DRIVE control rod

(See Figs. 3 and 4)

The traction drive control rod has the long loop on the end

of the spring as shown.

1. Slide rubber sleeve up rod and hook end of spring into

pivot bracket with loop opening down as shown.

2. With top end of rod positioned under left side of control

panel, push rod down and insert top end of rod into hole

in drive control bracket. Secure with retainer spring.

TRACTION DRIVE

CONTROL ROD

RUBBER

SLEEVE

LOWER

HANDLE

FIG. 1

SPEED CON TROL ROD

RETAINER

SPRING

PIVOT

BRACKET

TRACTION DRIVE

CON TROL LEVER

LOOP OPEN ING DOWN

FIG. 3

RETAINER

SPRING

TRACTION

DRIVE

CON TROL

ROD

SPEED

CONTROL

BRACKET

FIG. 2

SPEED

CONTROL

LEVER

DRIVE

CONTROL

BRACKET

FIG. 4

5

ASSEMBLY / PRE-OPERATION

INSTALL AUGER CONTROL ROD (See Figs. 5 and 6)

The auger control rod has the short loop on the end of the

spring as shown.

1. Slide rubber sleeve up rod and hook end of spring into

control arm with loop opening up as shown.

2. With top end of rod positioned under right side of

control panel, push down on rod and insert end of rod

into hole in auger control bracket. Secure with retainer

spring.

AUGER

CONTROL

ROD

RUBBER

SLEEVE

CONTROL

ARM

INSTALL DISCHARGE CHUTE / CHUTE ROTATER

HEAD (See Fig. 7)

NOTE: The multi-wrench provided in your parts bag may

be used to install the chute rotater head.

1. Place discharge chute assembly on top of chute base

with discharge opening toward front of snow thrower.

2. Position chute rotater head over chute bracket. If nec es sary, rotate chute assembly to align square and pin on un der side of chute rotater head with holes in chute brack et.

3. With chute rotater head and chute bracket aligned,

po si tion chute rotater head on pin and threaded stud

of mounting bracket.

4. Install 3/8 washer and locknut on threaded stud and

tighten securely.

CHUTE

ROTATER

HEAD

3/8 LOCKNUT

3/8 WASHER

LOOP

OPENING

FIG. 5

AUGER CONTROL ROD

RETAINER

SPRING

FIG. 6

UP

AUGER

CONTROL

LEVER

AUGER

CONTROL

BRACKET

PIN

THREADED

STUD

CHUTE

BRACKET

ALIGN BEFORE

TIGHTENING LOCKNUT

FIG. 7

ROTATER HEAD

MOUNT ING

BRACKET

CHECK TIRE PRESSURE

The tires on your snow thrower were overinflated at the factory for shipping purposes. Correct and equal tire pres sure

is important for best snow throwing performance.

• Reduce tire pressure to 14-17 PSI (19-24.5 N-m).

6

OPERATION

FORWARD

PRIMER

IGNITION KEY.

INSERT TO START

AND RUN,

PULL OUT TO STOP.

READ AND FOLLOW ALL SAFETY INFORMATION

AND INSTRUCTIONS BEFORE USE OF THIS PRODUCT.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

DANGER

OR WARNING

REVERSE

SNOW

DISCHARGE

TRACTION

DRIVE CONTROL

DISENGAGED

ENGAGED

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUAL AND ALL SAFETY RULES BEFORE OPERATING YOUR SNOW THROWER. Compare

the illustrations with your snow thrower to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

These symbols may appear on your snow thrower or in literature supplied with the product. Learn and understand

their meaning.

7

OPERATION

SPARK

SAFETY

IGNITION

KEY

CHOKE

CON TROL

THROTTLE

/ ENGINE

CONTROL

NOTE: ITEMS ABOVE

LOCATION ON THE

ENGINE. ACTUAL

LOCATION MAY VARY

WITH THE ENGINE

PLUG

RECOIL

STARTER

HANDLE

PRIM ER

ARE SHOWN IN

THEIR TYPICAL

ON YOUR UNIT.

POWER

CORD

PLUG

ELECTRIC

START

BUTTON

ENGINE OIL CAP

WITH DIPSTICK

FUEL

SHUT-OFF

VALVE

DISCHARGE

CHUTE

OIL DRAIN PLUG

CLEAN-OUT TOOL

GAS O LINE

FILLER

CAP

AUGER

CONTROL

LEVER

CHUTE

DE FLEC TOR

DISCHARGE CHUTE CONTROL LEVER

DRIVE SPEED

CON TROL LEVER

TRACTION

DRIVE

CONTROL

LEVER

LIGHT

HANDLE

KNOB

MUF FLER

TOOLBOX

AU GERS

FIG. 8

MEETS A.N.S.I. SAFETY REQUIREMENTS

Our snow throwers conform to the standards of the American National Standards Institute.

Toolbox - used to store spare shear bolts, locknuts and

wrench.

Safety ignition key - must be inserted for the engine to

start and run. Remove when snow thrower is not in use.

Electric start button – used for starting the engine.

Recoil (auxiliary) starter handle – used for start ing the

en gine.

Primer - pumps additional fuel from the carburetor to the

cylinder for use when starting a cold engine.

Throttle/engine control - used to se lect either FAST or

SLOW engine speed and to STOP the engine.

Choke control - used for starting a cold engine.

Drive speed control lever - used to select forward or

reverse motion and speed of snow thrower.

Traction drive control lever - used to engage power-pro pelled for ward or reverse motion of snow thrower.

Auger control lever - used to engage auger motion (throw

snow).

Discharge chute control lever - used to change the di rec tion the snow is thrown.

Skid plate - used to adjust height of scraper bar from the

ground.

8

SKID PLATE

OPERATION

The operation of any snow thrower can result

in foreign objects thrown into the eyes, which

can result in severe eye damage. Always wear

safety glasses or eye shields while operating

your snow thrower or performing any ad just ments or repairs. We recommend standard safe ty glasses

or a wide vision safety mask worn over spectacles.

HOW TO USE YOUR SNOW THROWER

Know how to operate all controls before adding fuel or

attempting to start the engine.

STOPPING

TRACTION DRIVE

• Release traction drive control lever to stop the forward

or reverse movement of the snow thrower.

AUGER

• Release the auger control lever to stop throwing snow.

ENGINE

1. Move throttle control to “STOP” position.

2. Remove (do not turn) safety ignition key to prevent

unauthorized use.

NOTE: Never use choke to stop engine.

TO USE FUEL SHUT-OFF VALVE (See Fig. 9)

The fuel shut-off valve is located beneath the fuel tank on

the engine. Always op er ate the snow thrower with the fuel

shut-off valve in the OPEN position.

TO USE CHOKE CON TROL (See Fig. 11)

The choke con trol is located on the en gine. Use the choke

control when ev er you are starting a cold en gine. Do not

use to start a warm en gine.

• To engage choke, turn knob clockwise. Slowly turn

knob counterclockwise to disengage.

FULLOFF

FIG. 11

TO CONTROL SNOW DISCHARGE (See Figs. 12 & 13)

WARNING: Snow throwers have ex posed rotating parts, which can cause

severe injury from contact, or from material thrown from the discharge chute.

Keep the area of operation clear of all

persons, small children and pets at all

times including startup.

WARNING: If the discharge chute or

au ger become clogged, shut-off en gine

and wait for all moving parts to stop. Use

the clean-out tool, NOT YOUR HANDS,

to un clog the chute and/or auger.

OFF

OPEN

FIG. 9

TO USE THROTTLE CONTROL (See Fig. 10)

The throttle control is located on the engine. Always op er ate

the snow thrower with the engine at full throttle. Full throttle

offers the best snow thrower performance.

FAST

SLOW

FIG. 10

The DIRECTION in which snow is to be thrown is controlled

by the discharge chute control lever.

• To change the discharge chute position, press down ward

on discharge chute control lever and move lever left

or right until chute is in desired position. Be sure lever

springs back and locks into desired position.

DISCHARGE CHUTE

CONTROL LEVER

FIG. 12

The DISTANCE that snow is thrown is controlled by the

position of the chute deflector. Set the deflector low to

throw snow a short distance; set the deflector higher to

throw snow farther.

• To change the deflector position, loosen knob, move de-

9

flector to desired position and tighten knob securely.

OPERATION

• Restart the engine, then squeeze the auger control

HIGH

POSITION

lever to the handle to clear snow from the auger housing and the discharge chute.

DISCHARGE CHUTE

KNOB

CHUTE

DEFLECTOR

LOW POSITION

FIG. 13

TO THROW SNOW (See Fig. 14)

The auger rotation is controlled by the auger control lever

located on the right side handle.

• Squeeze auger control lever to handle to engage the

auger and throw snow.

• Release the auger control lever to stop throwing snow.

AUGER

CONTROL

LEVER

CLEAN-OUT

TOOL

MOUNTING

CLIP

FIG. 15

TO MOVE FORWARD AND BACKWARD (See Fig. 16)

SELF-PROPELLING, forward and reverse movement of

the snow thrower, is controlled by the traction drive control

lever located on the left side handle.

• Squeeze traction drive control lever to handle to en gage

the drive system.

• Release traction drive control lever to stop the forward

or reverse movement of the snow thrower.

SPEED and DIRECTION are controlled by the drive speed

control lever.

• Press downward on the speed control lever and move

lever to de sired po si tion BE FORE engaging the trac tion drive control lever. Be sure lever springs back and

locks into desired position.

FIG. 14

USING THE CLEAN-OUT TOOL (See Fig. 15)

In certain snow conditions, the discharge chute may become clogged with ice and snow. Use the clean-out tool

to dislodge this blockage.

When cleaning, repairing, or in spect ing, make

certain all controls are disengaged and the auger/impeller and all moving parts have stopped.

Disconnect the spark plug wire and keep the

wire away from the spark plug to prevent accidental starting.

• Release the auger control lever and shut off the engine.

• Remove the clean-out tool from it's mounting clip. Grasp

the tool firmly by the handle and push and twist the tool

into the discharge chute to dislodge the blockage.

After the packed snow has been dislodged, return the cleanout tool to it's mounting clip by pushing it into the clip.

• Make sure the discharge chute is pointed in a safe direction (no vehicles, buildings, people, or other objects are

in the direction of discharge) before restarting engine.

CAUTION: Do not move speed con trol le ver

when traction drive control lever is en gaged.

Damage to the snow thrower can result.

• Slower speeds are for heavier snow and faster speeds

are for light snow and transporting the snow thrower. It

is recommended that you use a slower speed until you

are familiar with the operation of the snow thrower.

NOTE: When both traction drive and auger control levers

are engaged, the traction drive control lever will lock the

auger control lever in the engaged position. This will allow

you to release your right hand from the handle and adjust

the discharge chute direction without interrupting the snow

throwing process.

TRACTION DRIVE

CONTROL LEVER

DRIVE SPEED

CONTROL LEVER

10

FIG. 16

OPERATION

TO ADJUST SKID PLATES (See Fig. 17)

NOTE: The wrench provided in your parts bag may be

used to adjust the skid plates.

Skid plates are located on each side of the auger housing

and adjust the clearance between the scraper bar and the

ground surface. Adjust skid plates evenly to proper height

for current surface conditions. For removal of snow in

normal con di tions, such as a paved driveway or side walk,

place skid plates in the highest position (lowest scraper

clear ance) to give a 1/8" clearance between the scraper

bar and the ground. Use a middle position if the surface

to be cleared is uneven.

NOTE: It is not recommended to operate the snow thrower

over gravel or rocky surfaces. Objects such as gravel, rocks

or other debris, can easily be picked up and thrown by the

impeller, which can cause serious personal injury, property

dam age or damage to the snow thrower.

• If snow thrower must be operated over gravel surface,

use extra caution and be sure skid plates are adjusted

to lowest (highest scraper clear ance) position.

1. Shut off engine and wait for all moving parts to stop.

2. Adjust skid plates by loosening the hex nuts, then moving skid plate to desired position. Be sure both plates

are adjusted evenly. Tighten securely.

HIGH POSITION

(LOW GROUND

CLEARANCE)

WARNING: Wipe off any spilled oil or

fuel. Do not store, spill or use gasoline

near an open flame.

CAUTION: Alcohol blended fuels (called gas o hol or using ethanol or methanol) can attract

moisture which leads to separation and for ma tion of acids dur ing storage. Acidic gas can

damage the fuel system of an engine while in

storage. To avoid engine problems, the fuel

system should be emptied be fore stor age of

30 days or longer. Empty the gas tank, start

the engine and let it run until the fuel lines

and carburetor are empty. Use fresh fuel next

season. See Storage In struc tions for ad di tion al

information. Never use engine or car bu re tor

cleaner products in the fuel tank or per ma nent

damage may occur.

ENGINE OIL

FILL CAP /

DIPSTICK

SAFETY

IG NI TION

KEY

THROT TLECHOKE CONTROL

PRIM ER

AUGER

HOUSING

SCRAPER BAR

HEX

NUTS

LOW POSITION (HIGH GROUND CLEAR ANCE)

FIG. 17

SKID PLATE

SCRAPER BAR (See Fig. 17)

The scraper bar is not adjustable, but is reversible. After

con sid er able use it may become worn. When it has worn

almost to the edge of the housing, it can be reversed,

providing additional service before requiring replacement.

Replace a dam aged or worn scrap er bar.

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. 18)

The engine on your snow thrower has been shipped, from

the factory, already filled with oil.

1. Check engine oil with snow thrower on level ground.

2. Remove oil fill cap/dipstick and wipe clean, reinsert

the dipstick and screw tight, wait for a few seconds,

remove and read oil level. If necessary, add oil until

“FULL” mark on dipstick is reached. Do not overfill.

• To change engine oil, see “TO CHANGE ENGINE OIL”

in the Main te nance sec tion of this manual.

ADD GASOLINE (See Fig. 18)

• Fill fuel tank to bottom of tank filler neck. Do not overfill. Use fresh, clean, regular unleaded gasoline with

a minimum of 87 octane. Do not mix oil with gasoline.

Purchase fuel in quan ti ties that can be used within 30

days to assure fuel freshness.

GAS O LINE

FILLER CAP

FUEL SHUT-

OFF VALVE

RECOIL

STARTER

HANDLE

NOTE: ALL ITEMS ARE SHOWN IN THEIR TYPICAL LOCATION.

ACTUAL LOCATION MAY VARY WITH ENGINE ON YOUR UNIT.

FIG. 18

STARTER BUTTON

POWER CORD PLUG

TO START ENGINE

• Be sure fuel shut-off valve is in the OPEN position.

Your snow thrower engine is equipped with both a 120 Volt

A.C. electric starter and a recoil starter. The electric starter

is equipped with a three-wire power cord and plug and is

designed to operate on 120 Volt A.C. household current.

• Be sure your house is a 120 Volt A.C. three-wire

ground ed system. If you are uncertain, consult a

li censed electrician.

WARNING: Do not use the electric

start er if your house is not a 120 Volt

A.C. three-wire grounded system. Se ri ous per son al injury or damage to your

snow thrower could result.

11

OPERATION

COLD START - ELECTRIC STARTER

1. Insert safety ignition key (packed separately in parts

bag) into ignition slot until it clicks. DO NOT turn the key.

Keep the extra safety ignition key in a safe place.

2. Place throttle control in FAST position.

3. Rotate choke control to FULL position.

4. Connect the power cord to the engine.

5. Plug the other end of the power cord into a three-hole

grounded 120 Volt A.C. receptacle.

6. Push the primer three (3) times.

7. Push starter button until engine starts.

IMPORTANT: Do not crank engine more than five con tin u ous seconds between each time you try to start. Wait 5 to

10 seconds between each attempt.

8. When the engine starts, release the starter button and

slowly move the choke control to the “OFF” position.

9. Disconnect the power cord from the receptacle first,

then from the engine.

Allow the engine to warm up for a few minutes. Engine will

not develop full power until it has reached normal operating temperature.

WARM START - ELECTRIC STARTER

Follow the steps above, keeping the choke control in the

OFF position.

COLD START - RECOIL STARTER

1. Insert safety ignition key (packed separately in parts

bag) into ignition slot until it clicks. DO NOT turn the key.

Keep the extra safety ignition key in a safe place.

2. Place throttle control in FAST position.

3. Rotate choke control to FULL position.

4. Push the primer four (4) times if the temperature is

below 15°F/–10°C, or two (2) times if temperature is

between 15° and 50°F/–10°C and 10°C. If temperature

is above 50°F/10°C, priming is not nec es sary.

NOTE: Over priming may cause flooding, preventing the

engine from starting. If you do flood the engine, wait a few

minutes be fore at tempt ing to start and DO NOT push the

primer.

5. Pull recoil starter handle quickly. Do not allow starter

rope to snap back.

6. When the engine starts, release the recoil starter

han dle and slowly move the choke control to the OFF

position.

Allow the engine to warm up for a few minutes. Engine will

not develop full power until it has reached normal operating temperature.

WARM START - RECOIL STARTER

Follow the steps above, keeping the choke in the OFF

position. DO NOT push the primer.

BEFORE STOPPING

Run the engine for a few minutes to help dry off any moisture on the engine.

IF RECOIL STARTER HAS FROZEN

If the recoil starter has frozen and will not turn the engine,

proceed as follows:

1. Grasp the recoil starter handle and slowly pull as much

rope out of the starter as possible.

2. Release the recoil starter handle and let it snap back

against the starter.

If the engine still fails to start, repeat the above steps or

use the electric starter.

SNOW THROWING TIPS

• Always operate the snow thrower with the engine at

full throttle. Full throttle offers the best performance.

• Go slower in deep, freezing or heavy wet snow. Use the

drive speed control, NOT the throttle, to adjust speed.

• It is easier and more efficient to remove snow im me di ate ly after it falls.

• The best time to remove snow is the early morning. At

this time the snow is usually dry and has not been exposed to the direct sun and warming tem per a tures.

• Slightly overlap each successive path to ensure all

snow will be removed.

• Throw snow downwind whenever possible.

• Ad just the skid plates to proper height for current snow

con di tions. See “TO ADJUST SKID PLATES” in this

section of this manual.

• For extremely heavy snow, re duce the width of snow

removal by over lap ping previous path and moving

slowly.

• Keep engine clean and clear of snow during use. This

will help air flow and extend engine life.

• After snow-throwing is completed, allow engine to run for

a few minutes to melt snow and ice off the engine.

• Clean the entire snow thrower thoroughly after each

use and wipe dry so it is ready for next use.

WARNING: Do not operate snow

thrower if weather conditions im pair visibility. Throwing snow dur ing a heavy,

windy snowstorm can blind you and be

hazardous to the safe operation of the

snow thrower.

12

Loading...

Loading...