Page 1

Please do not return unit to retailer.

Por favor, no devuelva el aparato al lugar de compra.

Veuillez ne pas retourner l’outil au détaillant.

1-800-554-6723

www.poulan--pro.com

Instruction Manual

Manual de Instrucciones

Manuel d’Instructions

ENGLISH

R

PP4620AVX

WARNING:

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious injury.

ADVERTENCIA:

Lea el manual de instrucciones y siga todas las a dvertencias e enstrucciones de seguridad. El no hacerlo puede resultar en lesiones

graves.

AVERTISSEMENT:

Lire le manuel d’instructions et bien respecter tous les avertissements et toutes les instructions de sécurité. Tout défaut de le faire

pourrait entraîner des blessures graves.

Poulan PRO

1030 Stevens Creek Road

Augusta, GA 30907

850 Matheson Blvd. West

Mississauga, Ontario L5V 0B4

Poulan PRO

ESPAÑOL

FRANÇAIS

545186803 Rev. 2 3/15/09 BRW

Page 2

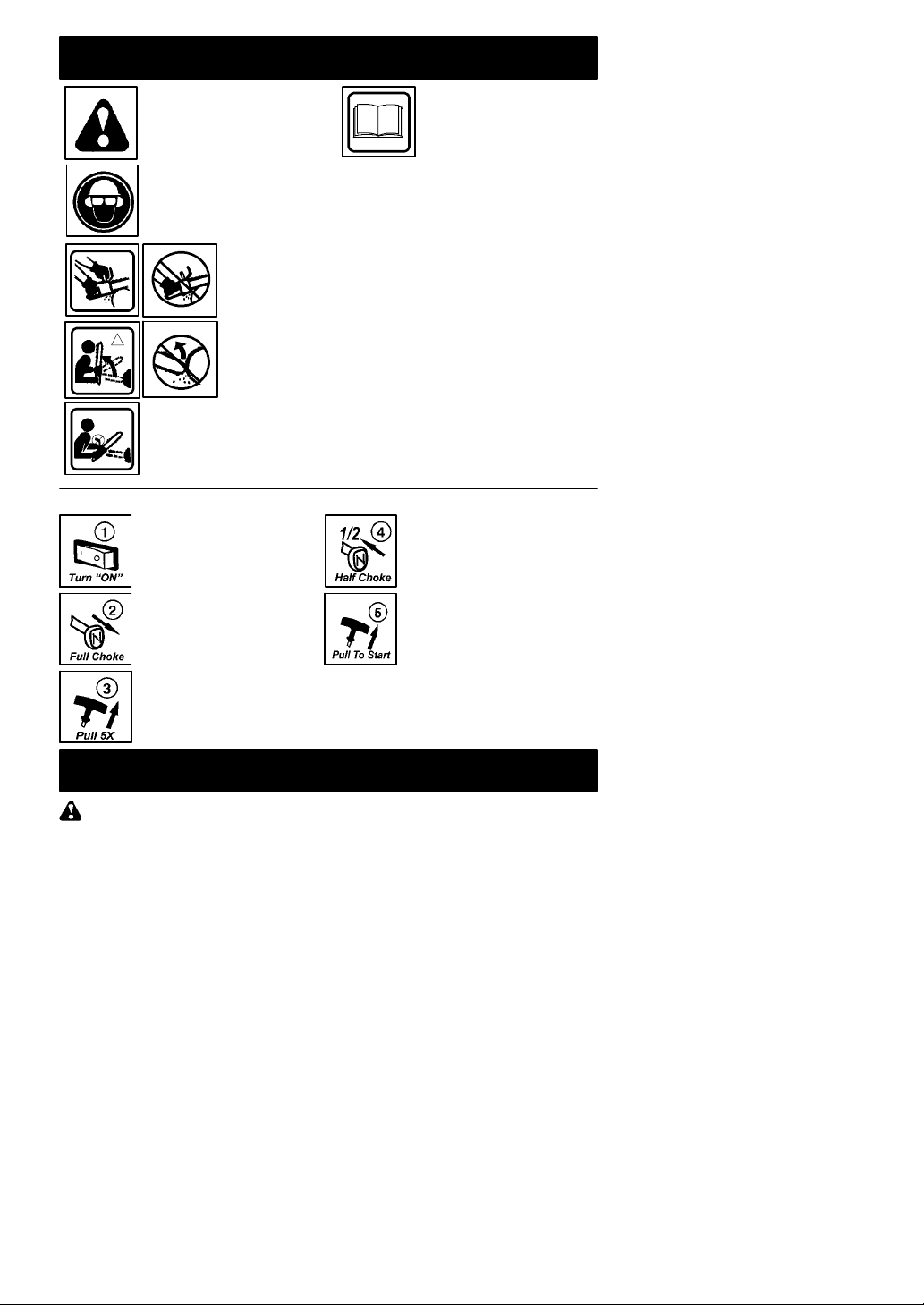

IDENTIFICATION OF SYMBOLS

WARNING! This chain

saw can be dangerous! Careless or improper use can cause

serious or even fatal injury.

Always wear appropriate earprotection, eye protection and head protection.

XX_

Measured maximum kickback value without chain brake for the bar

and chain combination on the label.

Starting Reminder

Move ON/STOP switch to

the ON position.

Pull choke/fast idle lever

out to the full extent (to

the FULL CHOKE position).

Read and understand the

instruction manual before

using the chain saw.

Always use two hands when operating the chain saw.

WARNING! Contacting the guide bar tip with any object

should be avoided; tip contact may cause the guide bar to

move suddenly upward and backward, which may cause serious injury.

Push the choke/fast idle

lever in to the HALF

CHOKE position.

Pull the starter rope sharply

with your right hand until

the engine starts.

Pull the starter rope

sharply 5 times with your

right hand.

SAFETY RULES

WARNING: Always disconnect

spark plug wire and place wire where it cannot contact spark plug to prevent accidental

starting when setting up, transporting, adjusting or making repairs except carburetor

adjustments.

Because a chain saw is a high-speed woodcutting tool, special safety precautions must

be observed to reduce the risk of accidents.

Careless or improper use of this tool can

cause serious injury .

PLAN AHEAD

S Read this manual carefully until you com-

pletely understand and can follow all safety

rules, precautions, and operating instructions before attempting to use the unit.

S Restrict the use of your saw to adult users

who understand and can follow safety

rules, precautions, and operating instructions found in this manual.

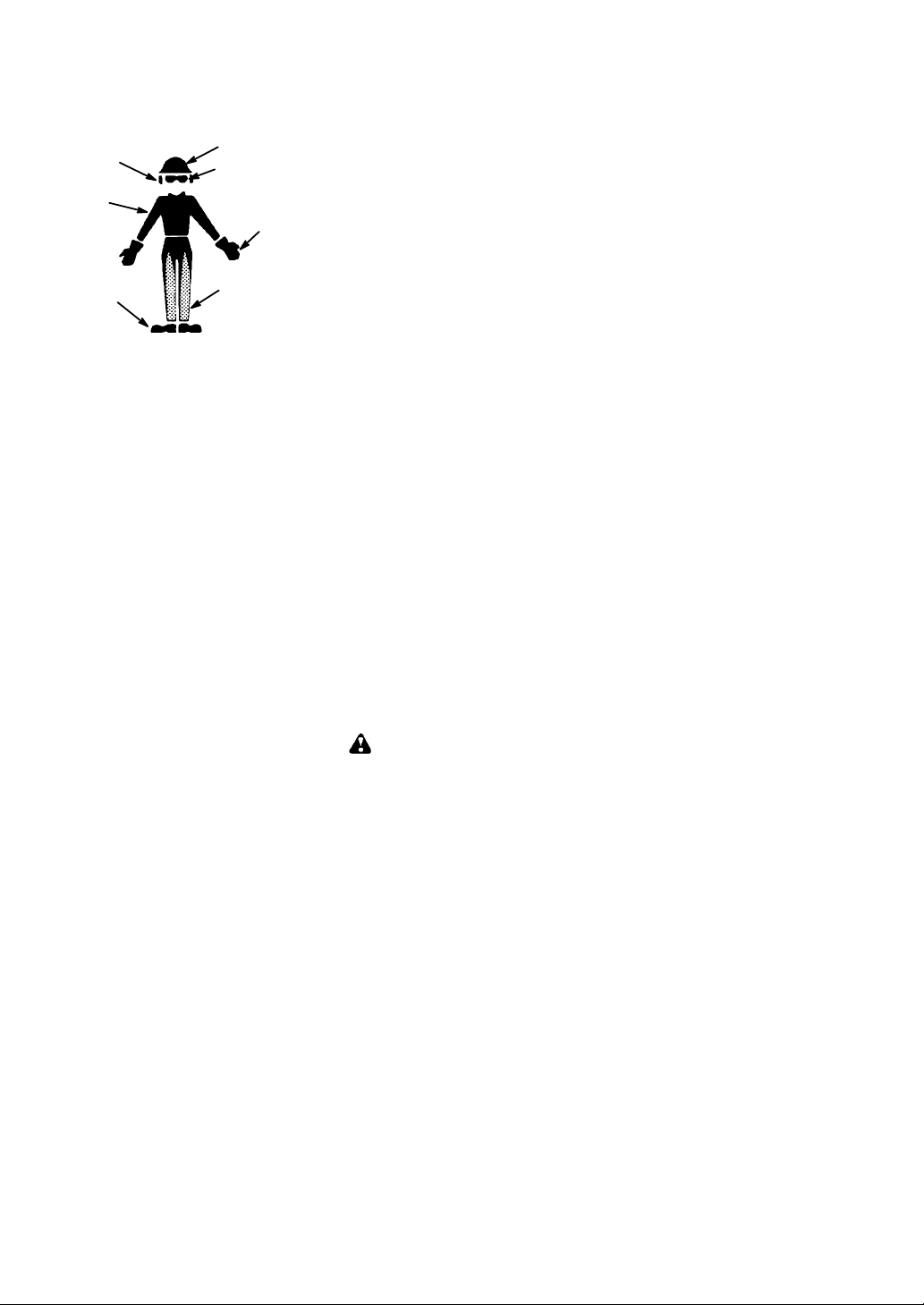

S Wear protective gear. Always use steel-toed

safety footwear with non-slip soles; snug-fitting clothing; safety chaps; heavy-duty, nonslip gloves; eye protection such as non-fog-

2

Page 3

ging, vented goggles or face screen; an

approved safety hard hat; and sound barriers (ear plugs or mufflers) to protect your

hearing. Regular users should have hearing

checked regularly as chain saw noise can

damage hearing. Secure hair above s houlder length.

Hearing

Protection

Snug

Fitting

Clothing

Safety

Shoes

S Keep all parts of your body away from the

chain when the engine is running.

S Keep children, bystanders, and animals a

minimum of 30 feet (10 meters) away from

the work area. Do not allow other people

or animals to be near the chain saw when

starting or operating the chain saw.

S Do not handle or operate a chain saw

when you are fatigued, ill, or upset, or if you

have taken alcohol, drugs, or medication.

You must be in good physical condition

and mentally alert. Chain saw work is

strenuous. If you have any condition that

might be aggravated by strenuous work,

check with your doctor before operating a

chain saw.

S Carefully plan your sawing operation in ad-

vance. Do not start cutting until you have a

clear work area, secure footing, and, if you

are felling trees, a planned retreat path.

OPERATE YOUR SAW SAFELY

S Do not operate a chain saw with o nehand.

Serious injury to the operator, helpers, bystanders or any combination of these persons may result from one-handed operation. A chain saw is intended for

two-handed use.

S Operate the chain saw only in a well-venti-

lated outdoor area.

S Do not operate saw from a ladder or in a

tree.

S Make sure the chain will not make contact

with any object while starting the engine.

Never try to start the saw when the guide

bar is in a cut.

S Do not put pressure on the saw at the end

of the cut. Applying pressure can cause

you to lose control when the cut is completed.

S Stop the engine before setting the saw

down.

S Do not operate a chain saw that is dam-

aged, improperly adjusted, or not completely and securely assembled. Always

replace bar, chain, hand guard, or chain

brake immediately if it becomes damaged,

broken or is otherwise removed.

Safety Hat

Eye

Protection

Heavy Duty

Gloves

Safety Chaps

S With the engine stopped, hand carry the

chain saw with the muffler away from your

body, and the guide bar and chain to the

rear, preferably covered with a scabbard.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

S Have all chain saw service performed by a

qualified service dealer with the exception

of the items listed in the maintenance section of this manual. For example, if improper tools are used to remove or hold the flywheel when servicing the clutch, structural

damage to the flywheel can occur and

cause the flywheel to burst.

S Make certain the saw chain stops moving

when the throttle trigger is released. For

correction, refer to CARBURETOR ADJUSTMENTS.

S Never modify your saw in any way.

S Keep the handles dry, clean, and free of oil

or fuel mixture.

S Keep fuel and oil caps, screws, and fas-

teners securely tightened.

S Use only Poulan PRO accessories and

replacement parts as recommended.

HANDLE FUEL WITH CA UT ION

S Do not smoke while handling fuel or while

operating the saw.

S Eliminate all sources of sparks or flame in

the areas where fuel is mixed or poured.

There should beno smoking, open flames,

or work that could cause sparks. Allow engine to cool before refueling.

S Always have fire extinguishing tools avail-

able if you should need them.

S Mix and pour fuel in an outdoor area on

bare ground; store fuel in a cool, dry, well

ventilated place; and use an approved,

marked container for all fuel purposes.

Wipe up all fuel spills before starting saw.

S Move at least 10 feet (3 meters) from fuel-

ing site before starting engine.

S Turn the engine off and let saw cool in a

non-combustible area, not on dry leaves,

straw, paper, etc. Slowly remove fuel cap

and refuel unit.

S Store theunit and fuelin an area where fuel

vapors cannot reach sparks or open

flames from water heaters, electric motors

or switches, furnaces, etc.

KICKBACK

WARNING: Avoid kickback which

can result in serious injury. Kickback is the

backward, upward or sudden forward motion

of the guide bar occurring when the saw

chain near the uppertip of the guide bar contacts any object such as a log or branch, or

when the wood closes in and pinches the

saw chain in thecut. Contacting a foreignobject in the wood can also result in loss of

chain saw control.

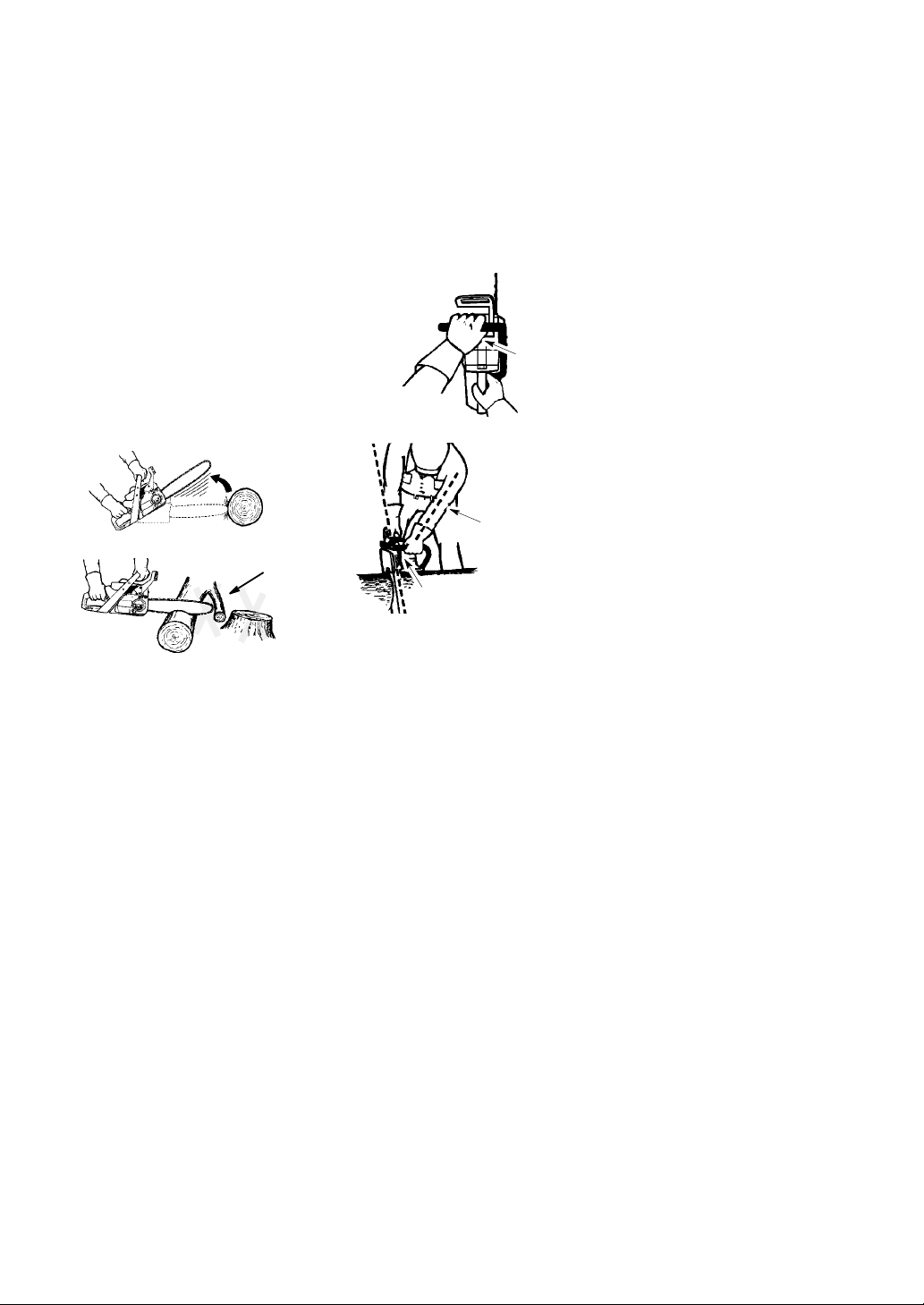

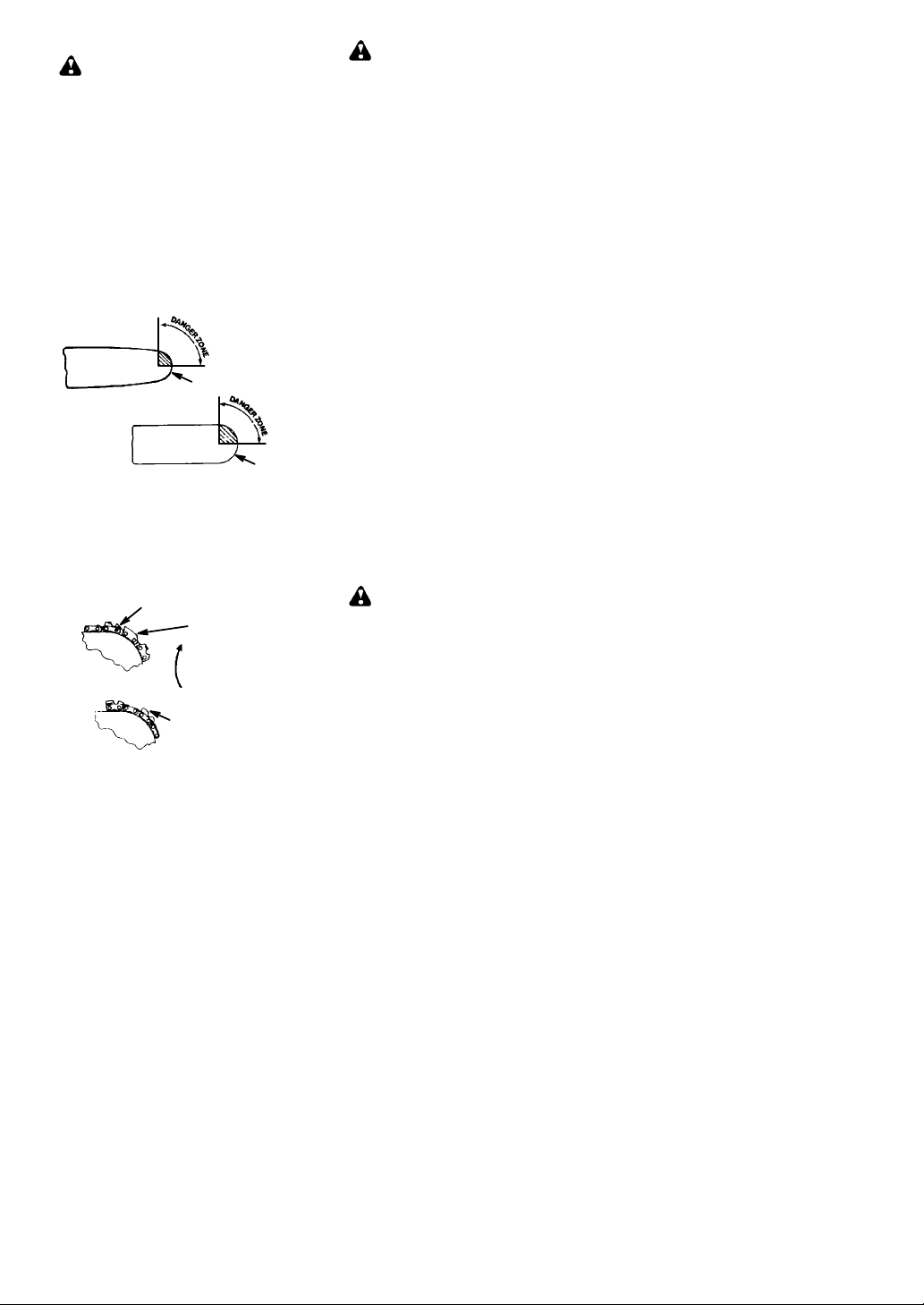

S Rotational Kickbac k can occur when the

moving chain contacts an object at the upper

tip of the guide bar. This contact can cause

the chain to dig into the object, which stops

the chain for an instant. The result is a lightning fast, reverse reaction which kicks the

guide bar up and back toward the operator.

3

Page 4

S Pinch-Kickback can occur when the the

A

wood closes in and pinches the moving

saw chain in the cut along the top of the

guide bar and the saw chain is suddenly

stopped. This sudden stopping of the

chain results in a reversal of the chain

force used to cut wood and causes the

saw to move inthe opposite direction of the

chain rotation. The saw is driven straight

back toward the operator.

S Pull-In can occur when the moving chain

contacts a foreign object in the wood in the

cut along the bottom of the guide bar and the

saw chain is suddenly stopped. This sudden

stopping pulls the s aw forward and away

from the operator and could easily cause the

operator to lose control of the saw.

Avoid Pinch--Kickback:

S Be extremely aware of situations or ob-

structions that can cause material to pinch

the top of or otherwise stop the chain.

S Do not cut more than one log at a time.

S Do not twist the saw as the bar is with-

drawn from an undercut when bucking.

Avoid Pull--In:

S Always begin cutting with the engine at full

speed and the saw housing against wood.

S Use wedges made of plastic or wood.

Never use metal to hold the cut open.

Kickback Path

void Obstructions

Clear The

Working Area

REDUCE THE CHANCE OF

KICKBACK

S Recognize that kickback can happen.

With a basic understanding of kickback,

you can reduce the element of surprise

which contributes to accidents.

S Never let the moving chain contact any ob-

ject at the tip of the guide bar.

S Keep the working area free from obstruc-

tions such as other trees, branches, rocks,

fences, stumps, etc. Eliminate or avoid

any obstruction that your saw chain could

hit while you are cutting. When cutting a

branch, do not let the guide bar contact

branch or other objects around it.

S Keep your saw chain sharp and properly

tensioned. A loose or dull chain can increase the chance of kickback occurring.

Follow manufacturer’s chain sharpening

and maintenance instructions. Check tension at regular intervals with the engine

stopped, never with the engine running.

Make sure the chain brake nuts are securely tightened after tensioning the chain.

S Begin and continue cutting at full speed. If

the chain is moving at a slower speed, there

is greater chance of kickback occurring.

S Cut one log at a time.

S Use extreme caution when re-entering a

previous cut.

S Do not attempt cuts starting with the tip of

the bar (plunge cuts).

S Watch for shifting logs or other forces that

could close a cut and pinch or fall into

chain.

S Use the Reduced--Kickback Guide Bar

and Low-- Kickback Chain specified for

your saw.

MAINTAIN CONTROL

Stand to the

left of the saw

Thumb on

underside of

handlebar

Never reverse

hand positions

Elbow locked

Thumb on underside of

handlebar

S Keep a good, firm grip on the saw with both

hands when the engine is running and don’t

let go. A firm grip will help you reduce kickback and maintain control of the saw. Keep

the fingers of your left hand encircling and

your left thumb under the front handlebar.

Keep your right hand completely around the

rear handle whether your are right handed or

left handed. Keep your left arm straight with

the elbow locked.

S Position your left hand on the front handle-

bar so it is in a straight line with your right

hand on the rear handle when making

bucking cuts. Never reverse right and left

hand positions for any type of cutting.

S Stand withyour weight evenly balanced on

both feet.

S Stand slightly to the left side of the saw to

keep your body from being in a direct line

with the cutting chain.

S Do not overreach. You could be drawn or

thrown off balance and lose control of the

saw.

S Do not cut above shoulderheight. It is diffi-

cult to maintain control of saw above

shoulder height.

4

Page 5

KICKBACK SAFETY FEATURES

K

WARNING: The following features

are included on your saw to help reduce the

hazard of kickback; however, such features

will not totally eliminate this danger. As a

chain saw user, donot rely only onsafety devices. You must follow all safety precautions, instructions, and maintenance in this

manual to help avoid kickback and other

forces which can result in serious injury.

S Reduced--Kickback Guide Bar, designed

with a small radius tip which reduces the

size of the kickback danger zone on the

bar tip. A Reduced--Kickback Guide Bar

has been demonstrated to significantly reduce the number and seriousness of kickbacks when tested in accordance with

safety requirements for gasoline powered

chain saws as set by ANSI B175.1.

ickback Symmetrical Guide Bar

Reduced

Small Radius Tip

Symmetrical Guide Bar

S Low--Kickback Chain, designed with a

contoured depth gauge and guard link

which deflect kickback force and allow

wood togradually ride into the cutter.Low-Kickback Chain has met kickback performance requirements when tested on a

representative sample of chain saws below 3.8 cubic inch displacement specified

in ANSI B175.1.

Low--- Kickback

Chain

Not a Low --- Kickback Chain

S Front Hand Guard, designed to reduce the

chance of your left hand contacting the chain

if your hand slips off the front handlebar.

S Position of front and rear handlebars, de-

signed with distance between handles and

“in-line” with each other . The spread and

“in-line” position of the hands provided by

this design work together to give balance

and resistance in controlling the pivot of

the saw back toward the operator if kickback occurs.

Contoured De pth Gauge

Large Radius Tip

Elongated Guard Link

Deflects

kickback force

and allows wood

to gradually ride

into cutter

Can Obstruct Material

CHAIN BRAKE AND CKA ANGLE

S Chain Brake, designed to stop the chain in

the event of kickback.

WARNING: WE DO NOT REP-

RESENT AND YOU SHOULD NOT ASSUME THAT THE CHAIN BRAKE WILL

PROTECT YOU IN THE EVENT OF A

KICKBACK. Kickback is a lightning fast action which throws the bar and rotating chain

back and up toward the operator. Kickback

can be caused by allowing contact of the bar

tip in the danger zone with any hard object.

Kickback can also becaused by pinching the

saw chain along thetop of theguide bar. This

action may push the guide bar rapidly back

toward the operator. Either of these events

may cause you to lose control of the saw

which could result in serious injury or even

death. DO NOT RELY UPON ANY OF THE

DEVICES BUILT INTO YOUR SAW. YOU

SHOULD USE THE SAW PROPERLY AND

CAREFULLY TO AVOID KICKBACK. Reduced-- kickback guide bars and low--kickback saw chains reduce the chance and

magnitude of k ickback and are recommended. Your saw has a low kickback chain

and bar as original equipment. Repairs on a

chain brake should be made by an authorized servicing dealer. Take your unit to the

place of purchase if purchased from a servicing dealer, or to the nearest authorized

master service dealer.

S Tip contact in some cases may cause a

lightning fast reverse REACTION, kicking

the guide bar up and back toward the operator.

S Pinching the saw chain alongthe top of the

guide bar may push the guide bar rapidly

back toward the operator.

S Either of these reactions maycause you to

lose control of the saw which could result

in serious injury.Do not rely exclusively

upon the safety devices built into your saw.

WARNING: Computed kickback

angle (CKA) listed on your saw and listed in

the CKA table below represents angle of

kickback your bar and chain combinations

will have when tested in accordance with

CSA (Canadian Standards Association) and

ANSI standards. When purchasing replacement bar and chain, considerations should

be given to the lower CKA values. Lower

CKA values represent safer angles to the

user, higher values indicate more angle and

higher kick energies. Computed angles represented in the non-activated column indicate total energy and angle associated without activation of the chain brake during

kickback. Activated angle represents chain

stopping time relative to activation angle of

chain brake and resulting kick angle of saw.

In all cases lower CKA values represent a

safer operating environment for the user.

The following guide bar and chain combinations meet kickback requirements of CSA

Z62.1, Z62.3, & ANSI B175.1 when used on

saws listed in this manual. Use of bar and

chain combinations other than those listed is

not recommended and may not meet the

CKA requirements per standard.

5

Page 6

Computed kickback angle (CKA) Table

BAR

MODEL

PP4620AVX

NOTE: If this saw isto be used for commer-

cial logging, a chain brake is required and

shall not be removed or otherwise disabled

to comply with Federal OSHA Regulations

for Commercial Logging.

WARNING: The engine exhaust

from this product contains chemicals known

to the State of California to cause cancer,

birth defects or other reproductive harm.

SAFETY NOTICE: Exposure to vibrations

through prolonged use of gasoline powered

hand tools could cause blood vessel or nerve

damage in the fingers, hands, and joints of

people prone to circulation disorders or

abnormal swellings. Prolonged use in cold

weather has been linked to blood vessel

damage in otherwise healthy people. If

symptoms occur such as numbness, pain,

loss of strength, change in skin color or texture,

or loss of feeling in the fingers, hands, or joints,

discontinue the use of this tool and seek

medical attention. An anti-vibration system

does not guarantee the avoidance of these

problems. Users who operate power tools on

a continual and regular basis must monitor

closely their physical condition and the

condition of this tool.

P/N Length CHAIN P/N

952044815 20″ 952051310 31_

CKA without chain brake

SPECIAL NOTICE: Your saw is equipped

with a temperature limiting muffler and spark

arresting screen which meets the

requirements of California Codes 4442 and

4443. All U.S. forest land and the states of

California, Idaho, Maine, Minnesota, New

Jersey, Oregon, and Washington require by

law that many internal combustion engines

to be equippedwith a spark arrestingscreen.

If y ou operatea chain saw in a state orlocale

where such regulations exist, you are legally

responsible for maintaining the operating

condition of these parts. Failure to do so is

a violation of the law . Refer to the SERVICE

section for maintenance of the spark

arresting screen.

Failure to follow all Safety Rules and Precautions can result in serious injury. If situations

occur which are not covered in this manual,

use care and good judgement. If you need

assistance, contact your authorized service

dealer or call 1-800-- 554--6723.

STAN DARDS: This saw is listed by Under-

writer’s Laboratories, Inc. in accordance with:

ANSI B175.1--2000 American National

Standards for Gasoline--Powered Chain

Saws -- Safety Requirements

CSA Z62.1--1995 Chain Saws -- Occupational Health and Safety

CSA Z62.3--1996 Chain Saw Kickback Occupational Health and Safety

ASSEMBLY

Protective gloves (not provided) should be

worn during assembly.

ATTACHING THE BUMPER

SPIKE

(If not already attached)

The bumper spike may be used as a pivot

when making a cut.

1. Loosen and remove bar knob completely

by lifting lever and turning counterclockwise.

2. Remove clutch cover.

3. Attach the bumper spike with the two

screws as illustrated.

ATTACHING THE BAR & CHAIN (If not

already attached)

WARNING: If received assembled,

repeat all steps to ensure your saw is properly assembled and all fasteners are secure.

Always wear gloves when handling the

chain. The chain is sharp and can cut you

even when it is not moving!

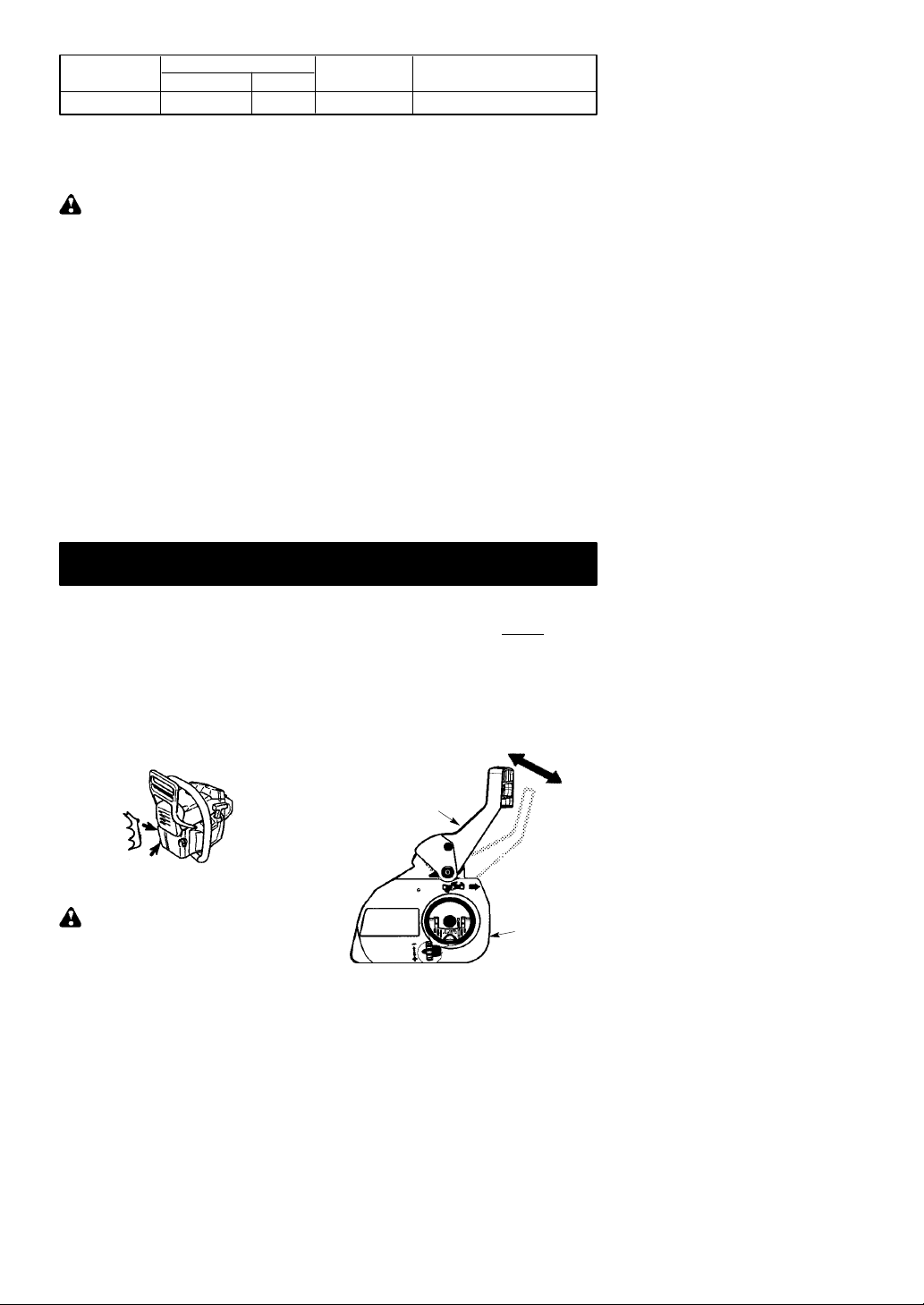

NOTE: CHAIN BRAKE MUST BE DISENGAGED BEFORE IT CAN BE REMOVED OR INSTALLED ON THE

CHAIN SAW . TO DISENGAGE CHAIN

BRAKE, PULL THE FRONT HAND

GUARD BACK TOWARD THE REAR

OF THE CHAIN BRAKE AS FAR AS

POSSIBLE (SEE ILLUSTRATION).

DISENGAGED

Front Hand Guard

ENGAGED

Chain Brake

6

Page 7

1. Loosen and remove bar knob completely

by lifting lever and turning counterclockwise.

LOOSEN

2. Remove clutch cover. Remove the plastic shipping spacer (if present).

3. Slide guide bar on bar bolts until guide

bar stops against clutch drum sprocket.

4. Carefully remove the chain from the package. Hold chain with the driv e links as

shown.

Tip of

Bar

Back

view of

clutch

cover

Adjusting pin

10. Install bar knob and finger tighten only.

Do not tighten any further at this point.

Once the chain is tensioned, you will

need to tighten the bar knob.

CHAIN TENSION (Including units with

chain already installed)

NOTE: When adjusting chain tension,

make sure the bar knob is loosened 1 ½ -- 2

turns. Attempting to tension the chain when

the bar knob is tight can cause damage.

Checking the tension:

Use a screwdriver to move chain around guide

bar. If the chain does not rotate, it is too tight. If

too loose, the chain will sag below the bar.

Guide bar

CUTTERS MUST FACE IN

DIIRECTION OF ROTATION

Cutters

5. Place chain over and behind clutch retainer, fitting the drive links in the clutch

drum sprocket.

6. Fit bottom of drive links between the

teeth in the sprocket in the nose of the

guide bar.

7. Fit chain drive links into bar groove.

8. Pull guide bar forward until chain is snug

in guide bargroove. Ensure all drive links

are in the bar groove.

9. Install clutch cover. Be sure adjusting pinis

in the adjusting pin hole in the guide bar.

CAUTION: It is very important when instal-

ling the clutch cover that the adjusting pin

aligns into the adjusting pin hole in the bar. Failure to install the clutch cover correctly may result in permanent damage to your chain saw.

Drive Links

Depth Gauge

Adjusting

wheel

Bar knob

Screwdriver

Adjusting the tension:

Chain tension is very important. Chain

stretches during use. This is especially true

during the first few times you use your saw.

Always check chain tension each time

before you start the chain saw.

1. Lift lever on bar knob and turn counter-

clockwise 1 ½ -- 2 turns to loosen clutch

cover .

LOOSEN

2. Turn adjusting wheel (downward direction) to tension chain until chain solidly

contacts bottom of guide bar rail. Lift tip

of guide bar while adjusting tension.

7

Page 8

Tighten

chain

3. Use a screwdriver to move chain around

guide bar to ensure all links are in bar

groove.

4. While lifting tip of guide bar, tighten bar

knob securely (clockwise). Hand tight-

en only!

Loosen

chain

Adjusting Wheel

TIGHTEN

5. Push lever on bar knob down to returnlever to closed/locked position.

WARNING: Failure to push lever on

bar knob down to closed/locked position

could result in serious personal injury or

damage to your chain saw.

6. Use a screwdriver to move chain around

guide bar.

7. If chain does not rotate, it is too tight.

Loosen bar knob 1 turn (counterclockwise); then, loosen chain by turning the

adjusting wheel

tion). Retighten bar knob.

8. If chain is too loose, it will sag below the

guide bar. DO NOT operate the saw if the

chain is loose.

NOTE: The chain is tensioned correctly when

the weight of the chain does not cause it to sag

below the guide bar (with the chain saw sitting

in an upright position), but the chain still moves

freely around the guide bar .

WARNING: If the saw is operated

with a loose chain, the chain could jump off the

guide bar and result in serious injury to the operator and/or damage the chain making it unusable. If the chain jumps off the guide bar , inspect each drive link for damage. Damaged

chain must be repaired or replaced.

1

/4turn (upward direc-

OPERATION

KNOW YOUR SAW

READ THIS INSTRUCTION MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

CHAIN SAW . Compare the illustrations with your unit to familiarize yourself with the location of the

various controls and adjustments. Save this manual for future reference.

8

Front Handle

Starter Rope

Fuel Mix Fill Cap

ON/STOP

Switch

Chain

Bar Sprocket

Hole

Front Hand Guard

Muffler

Bar Oil

Fill Cap

Starter Housing

Page 9

Cylinder Cover

Clutch

Cover

Adjusting

Wheel

Rear

Handle

Throttle

Trigger

Throttle

Lock--out

Choke/Fast

Idle Lever

ON/STOP SWITCH

The ON/STOP SWITCH is used to stop the

engine.

THROTTLE TRIGGER

The THROTTLE TRIGGER controls engine

speed.

T HR O T TL E L O C K --- OU T

The THROTTLE LOCK--OUT must be

pressed before you can squeeze the throttle

trigger. This feature prevents you from accidentally squeezing the trigger.

CHOKE/FAST IDLE LEVER

The choke and fast idle speed areset by pulling the CHOKE/FAST IDLE LEVER outfully

for cold or for refueled starting. The choke

provides additional fuel to the engine during

cold starting.

Chain Brake

Guide Bar

Bar

Knob

Chain

Catcher

CHAIN BRAKE

The CHAIN BRAKE is a device designed to

stop the chain if kickback occurs. The chain

brake activates automatically in the event of

kickback. The chain brake activates manually ifthe front hand guardis pushed forward.

The chain brake is disengaged by pulling the

front hand guard back toward the front handle as far as possible.

CHAIN TENSION

It is normal for a new chain to stretch during

first 15 minutes of operation. Y ou should check

your chain tension each time before you start

thechainsaw.SeeCHAINTENSIONinthe

ASSEMBLY section.

WARNING: If the saw is operated

with a loose chain, the chain could jump off

the guide bar and result in serious injury to

the operator and/or damage the chain making it unusable.

Direction

of Chain

Travel

FUELING & LUBRICATION

BEFORE STARTING ENGINE

WARNING: Muffler is very hot dur-

ing and after use. Do not touch the muffler or

allow combustible material such as dry

grass or fuel to do so.

WARNING: Be sure to read the fuel

handling information in the safety rules section of this manual beforeyou begin.If you do

not understand the fuel handling information

do not attempt to fuel your unit. Seek help

from someone that does understand the information or call the customer assistance

help line at 1-800-554-6723.

FUELING ENGINE

WARNING: Remove fuel cap slow-

ly when refueling.

HELPFUL TIP

Toobtain thecorrect oil mix

ratio, pour 3.2 ounces of

2--cycle synthetic oil into

one gallon of fresh gas.

This engine is certified to operate on unleaded

gasoline. Before operation, gasoline must be

mixed with a good quality synthetic 2-cycle

air-cooled engine oil designed to be mixed at a

ratio of 40:1. Poulan/WEED EA TER brand

synthetic oil is recommended. Mix gasoline

and oil at a ratio of 40:1. A 40:1 ratio is obtained

by mixing 3.2 fluid ounces of oil with 1 gallon of

unleaded gasoline. Included with this saw is a

3.2 ounce container of oil. Pour the entire

contents of this container into 1 gallon of

gasoline to achieve the proper fuel mixture. DO

NOT USE automotive oil or boat oil. These oils

will cause engine damage. When mixing fuel,

follow instructions printed on container. Once

oil is added to gasoline, shake container

momentarily to assure that the fuel is

thoroughly mixed. Always read and follow the

safety rules relating to fuel before fueling your

unit.

CAUTION: Never use straight gasoline in

your unit. This will cause permanent engine

damage and void the limited warranty.

FUEL REQUIREMENTS

This engine requires the use of minimum 87

octane [R+M]/2 clean gasoline.

9

Page 10

IMPORTANT

f

Use of alcohol blended fuels (called gasohol or

using ethanol or methanol) can cause major

engine performance and durability problems.

WARNING: Alternative fuels (not

gasoline) such as E-- 15 (15% alcohol), E--20

(20% alcohol), E-- 85 (85% alcohol) are NOT

classified as gasoline and are NOT approved

for use in 2- -stroke gasoline engines. Use of alternative fuels will cause problems such as: improper clutch engagements, overheating, vapor lock, power loss, lubrication deficiency,

deterioration of fuel lines, gaskets and internal

carburetor components, etc. Alternative fuels

cause high moisture absorption into the fuel/oil

mixture leading to oil and fuel s eparat ion.

BAR AND CHAIN LUBRICATION

The bar and chain require continuous lubrication. Lubrication is provided by the automatic oiler system when the oil tank is kept

STARTING

filled. Lack of oil will quickly ruin the bar and

chain. Too little oil will cause overheating

shown by smoke coming from the chain and/

or discoloration of the bar.

In freezing weather oil will thicken, making it

necessary to thin bar and chain oil with a

small amount (5 to 10%) of #1 Diesel Fuel or

kerosene. Bar and chain oil must be free

flowing for theoil system to pump enough oil

for adequate lubrication.

Genuine Poulan or Poulan PRO bar and

chain oilis recommended to protect your unit

against excessive wear from heat and

friction. Poulan or Poulan PRO oil resists

high temperature thinning. If Poulan or

Poulan PRO bar and chain oil is not

available, use a good grade SAE 30 oil.

S Never use waste oilfor bar and chainlubri-

cation.

S Always stop the engine before removing

the oil cap.

WARNING: The chain must not

move when the engine runs at idle speed. If

the chain moves at idle speed refer to CARBURETOR ADJUSTMENT within this

manual. Avoid contact with the muffler. A hot

muffler can cause serious burns.

To stop the engine move the ON/STOP

switch to the STOP position.

To start the engine hold the saw firmly on

the ground as illustrated. Make sure the

chain is free to turn without contacting any

object.

Use only 15″ --- 18 ″ ( 4 0 --- 4 5 c m ) o

per pull.

Hold saw firmly while pulling starter rope.

Starter rope handle

Right foot through rear handle

WARNING: Do not attempt to throw

or drop--start the chain saw. Doing so will put

the operator at risk of serious injury due to

loss of control of the chain saw.

rope

Left hand

on front

handle

IMPORT ANT POINTS TO REMEMBER

When pulling the starter rope, do not use the

full extent of the rope as this can cause the

rope to break. Do not let starter rope snap

back. Holdthe handle and let the rope rewind

slowly.

For cold weather starting, start the unit at

FULL CHOKE; allow the engine to warm up

before squeezing the throttle trigger.

NOTE: Do not cut material with the choke/

fast idle lever at the FULL CHOKE position.

HELPFUL TIP

If your engine still does not

start after following these

instructions, please call

1--800-- 554--6723.

STARTING A COLD ENGINE (or

warm engine after running out of

fuel)

NOTE:

choke/fast idle lever is pulled out to the full

extent, the correct throttle setting forstarting

is set automatically.

1. Move ON/STOP switch to the ON posi-

2. Pull the choke/fast idlelever outto the full

3. Pull starter rope quickly with your right

NOTE: If the engine sounds as if it is trying

to start before the 5th pull, stop pulling and

immediately proceed to the next step.

4. Push the choke/fast idle lever in to the

5. Pull the starter rope quickly with your

6. Allow the engine torun for approximately

In the following steps, when the

tion.

extent (to the FULL CHOKE position).

hand a maximum of 5 times. Then, proceed to the next step.

HALF CHOKE position.

right hand until the engine starts.

30 seconds. Then, squeeze and release

throttle trigger to allow engine to return to

idle speed.

ON/STOP SWITCH

10

Page 11

CHOKE/FAST IDLE LEVER

FULL HALF OFF

STARTING A WARM ENGINE

1. Move ON/STOP swi t chto the ONpositio n .

2. Pull the choke/fast idle lever out to the

HALF CHOKE position.

3. Pull the starter rope quickly with your right

hand until the engine starts.

4. Squeeze and release the throttle trigger

to allow engine to return to idle speed.

DIFFICULT STARTING (or starting a

flooded engine)

The engine may be flooded if it has not started

after 10 pulls.

Flooded engines can be cleared of excess fuel

by following the warm engine starting procedure listed above. Ensure the ON/STOP

switch is in the ON position.

Starting could require many pulls depending on

how badly unit is flooded. If engine still fails to

start, refer to TROUBLESHOOTING TABLE

or call 1-800-554-6723.

CHAIN BRAKE

WARNING: If the brake band is worn

too thin it may break when the chain brake is

triggered. With a broken brake band, the chain

brake will not stop the chain. The chain brake

should be replaced by an authorized service

dealer if any part is worn to less than 0.020″

(0.5 mm) thick. Repairs on a chain brake

should be made by an authorized service dealer. Take your unit to the place of purchase if

purchased from a servicing dealer, or to the

nearest authorized master service dealer.

S This saw is equipped with a chain brake.

The brake is designed to stop the chain if

kickback occurs.

S The inertia-- activated chain brake is

activated if the front hand guard is pushed

forward, either manually (by hand) or

automatically (by sudden movement).

S If the brake is already activated, it is

disengaged by pulling thefront hand guard

back toward the front handle as far as

possible.

S When cutting with the saw,the chainbrake

must be disengaged.

Disengaged

Engaged

Braking function control

CAUTION:

checked several times daily. The engine must

be running when performing this procedure.

This is the only instance when the saw should

be placed on the ground with the engine running.

Place the saw on firm ground. Grip the rear

handle with your right hand and the fronthandle with your left hand. Apply full throttle by

fully depressing the throttle trigger. Activate

the chain brake by turning your left wrist

against the hand guard without releasing

your grip around the front handle. The chain

should stop immediately.

Inertia activating function control

WARNING: When performing the

following procedure, the engine must be

turned off.

Grip the rear handle with y our right hand and

the front handle with your left hand. Hold the

chain saw approximately 14″ (35 cm) above a

stump or other wooden surface. Release your

grip on the front handle and use the weight of

the saw to let the tip ofthe guide bar fall forward

and contact the stump. When the tip of the bar

hits the stump, the brake should activate.

The chain brake must be

CUTTING METHODS

IMPORTANT POINTS

S Check chain tension before first use, after

1 minute of operation, and each time before you start the chain saw. See CHAIN

TENSION in the ASSEMBLY section.

S Cut wood only. Do not cut metal, plastics,

masonry, non-wood building mat erials, etc.

S Stop the saw if the chain strikes a foreign

object. Inspect the saw and repair or replace parts as necessary. If the chain

jumps off the guide bar, inspect the chain

for damaged drive links before reinstalling.

Burrs on drive links, which prevent them

from entering the groove of the guide bar,

can be removed with a flat file.

S Keep the chain out of dirt and sand. Even a

small amount of dirt will dull a chain, increase

the possibility of kickback, and require chain

sharpening or replacement.

S Practice cutting a few small logs using the

following techniques to get the “feel” of using your saw before you begin a major

sawing operation.

S Squeeze the throttle trigger and allow the

engine to reach full speed before cutting.

S Begin cutting with the saw frame

against the log.

S Keep the engine at full speed the entire

time you are cutting.

S Allow the chain to cutfor you. Exert only

light downward pressure. If you force

the cut, damageto the bar,chain, orengine can result.

11

Page 12

S Release the throttle trigger as soon as

the cut is completed, allowing the engine to idle. If you run the saw at full

throttle without a cutting load, unnecessary wear can occur to the chain, bar,

and engine.

S To avoid losing control whencut iscom-

plete, do notput pressure on saw at end

of cut.

S Stop the engine before setting the saw

down after cutting.

TREE FELLING TECHNIQUES

WARNING: Check for broken or

dead branches which can fall while cutting

causing serious injury. Do not cut near buildings or electrical wires if you do not know the

direction of tree fall, nor cut at night since you

will not be ale to see well, nor during bad

weather such as rain, snow,or strong winds,

etc. If the tree makes contact with any utility

line, the utility company should be notified

immediately.

S Carefully plan your sawing operation in ad-

vance.

S Clear thework area. You needa clear area

all around the tree so you can have secure

footing.

S Study the natural conditions that can

cause the tree to fall in a particular direction.

Natural conditions that can cause a tree to

fall in a particular direction include:

S The wind direction and speed.

S The lean of the tree. The lean of a tree

might not be apparent due to uneven or

sloping terrain. Use a plumb or level to determine the direction of tree lean.

S Weight and branches on one side.

S Surrounding trees and obstacles.

Look for decay and rot. If the trunk is rotted,

it can snap and fall toward the operator.

Check for broken or dead branches which

can fall on you while cutting.

Make sure there is enough room for the tree to

fall. Maintain a distance of

from the nearest person or other objects. Engine noise can drown out a warning call.

Remove dirt, stones, loose bark, nails, staples, andwire from the tree where cuts are to

be made.

Plan a clear retreat pathto the rear and diagonal to the line of fall.

Plan a clear retreat path

45_

2-1/2 tree lengths

Direction of Fall

FELLING LARGE TREES (6 inches

(15 cm) in diameter or larger)

The notch method is used to fell large trees.

A notch is cut on the side of the tree in the desired direction of fall. After a felling cut is

made on the opposite side of tree, the tree

will tend to fall into the notch.

NOTE: If the tree has large buttress roots,

remove thembefore making the notch. If using saw to remove buttress roots, keep saw

chain from contacting ground to prevent dulling of the chain.

NOTCH CUT AND FELLING THE

TREE

S Make notch cut by cutting the top of the

notch first. Cut through

of the tree. Next complete the notch by cutting the bottom of the notch. See illustration. Once the notch is cut, remove the

notch of wood from the tree.

Final cut here. 2 inches above

center of notch.

First cut

Notch

Second cut

S After removing the wood from the notch,

make thefelling cut on the opposite side of

the notch. This is done by making a cut

about two inches higher than the center of

the notch. This will leave enough uncut

wood betweenthe fellingcut and the notch

to form ahinge. This hinge will help prevent

the tree from falling in the wrong direction.

Hinge holds tree on stump and helps

control fall

Closing of

notch

NOTE: Before felling cut is complete, use

wedges to open the cut when necessary to

control the direction offall. To avoid kickback

and chain damage, use wood or plastic

wedges, but never steel or iron wedges.

S Bealerttosignsthatthetreeisreadytofall:

cracking sounds, widening of the felling cut,

or movement in the upper branches.

S As tree starts to fall, stop saw, put it down,

and get away quickly on your planned retreat path.

S DO NOT cut down a partially fallen tree

with your saw. Be extremely cautious with

partially fallen trees that may be poorly

supported. When a tree doesn’t fall completely, set thesaw aside and pulldown the

tree with a cable winch, block and tackle,

or tractor.

1/3 of the diameter

Opening

of felling

cut

12

Page 13

CUTTING A FALLEN TREE

(BUCKING)

Bucking is the term used for cutting a fallen

tree to the desired log size.

WARNING: Do not stand on the log

being cut. Any portion can roll causing loss

of footing and control. Do not stand downhill

of the log being cut.

IMPORTANT POINTS

S Cut only one log at a time.

S Cut shattered wood very carefully; sharp

pieces ofwood could beflung towardoperator.

S Use a sawhorse to cut small logs. Never

allow another person to hold the log while

cutting andnever hold the log with your leg

or foot.

S Do not cut in an area where logs, limbs,

and roots are tangled such as in a blown

down area. Drag the logs into a clear area

before cutting by pulling out exposed and

cleared logs first.

TYPES OF CUTTING USED FOR

BUCKING

WARNING: If saw becomes

pinched or hung in a log, don’t try to force it

out. You can lose control of the saw resulting

in injury and/or damage to the saw. Stop the

saw, drive a wedge of plastic or wood into the

cut until the saw can be removed easily. Restart thesaw and carefully reenter thecut. To

avoid kickback and chain damage, do not

use ametal wedge. Do not attempt to restart

your saw when it is pinched or hung in a log.

Useawedgetoremovepinchedsaw

Always make your first cut on the compression side of the log. Thecompression side of

the log is where the pressure of the log’s

weight is concentrated.

First cut on compression side of log

Second cut

Second cut

First cut on compression side of log

BUCKING WITHOUT A SUPPORT

S Overcut through 1/3 of the diameter of the

log.

S Roll the log over and finish with a second

overcut.

S Watch for logs with a compression side to

prevent the saw from pinc hing. See illustrations for cutting logs with a compression side.

BUCKING USING A LOG OR

SUPPORT STAND

S Remember your first cut is always on the

compression side of the log. (Refer to the

illustrations belowfor yourfirst andsecond

cut)

S Your first cut should extend

diameter of the log.

S Finish with your second cut.

Usingalogforsupport

nd

2

1/3 of the

Cut

Turn sa w

wooden wedge to force cut open.

Overcutting begins on thetop sideof the log

with the bottom of the saw against the log.

When overcutting use light downward pressure.

Overcutting Undercutting

Undercutting involves cutting on the underside ofthe logwith topof saw against the log.

When undercutting use light upward pressure. Hold saw firmly and maintain control.

The saw will tend to push back toward you.

WARNING: Never turn saw upside

down to undercut. The saw cannot be controlled in this position.

OFF and use a plastic or

2ndCut

Using a support stand

13

1stCut

st

1

Cut

nd

2

Cut

1stCut

Page 14

1stCut

nd

Cut

2

LIMBING AND PRUNING

WARNING: Be alert for and guard

against kickback. Do not allow the moving

chain to contact any other branches or objects at the nose of the guide bar when limbing or pruning. Allowing such contact canresult in serious injury.

WARNING: Never climb into a tree

to limb or prune. Do not stand on ladders,

platforms, a log, or in any position which can

cause you to lose your balance or control of

the saw.

IMPORTANT POINTS

S Work slowly, keeping both hands firmly

gripped on the saw. Maintain secure footing and balance.

S Watch out for springpoles. Use extreme

caution when cutting small size limbs.

Slender material may catch the saw chain

and be whipped toward you or pull you off

balance.

S Be alert for springback. Watch out for

branches that are bent or und er pressure.

Avoid being struck by the branch or the

saw when the tension in the wood fibers is

released.

S Keep a clear work area. Frequently clear

branches out of the way to avoid tripping

over them.

LIMBING

S Always limb atree after it is cut down. Only

then can limbing be done safely and properly.

S Leave the larger limbs underneath the

felled tree to support the tree as you work.

S Start at the base of the felled tree and work

toward the top, cutting branches and

limbs. Remove small limbs with one cut.

S Keep the tree between you and the chain.

Cut from the side of the tree opposite the

branch you are cutting.

S Remove larger, supporting branches with

the cutting techniques described inBUCKING WITHOUT A SUPPORT.

S Always use an overcut to cut small and

freely hanging limbs. Undercutting could

cause limbs to fall and pinch the saw.

PRUNING

WARNING: Limit pruning to limbs

shoulder height or below. Do not cut if

branches are higher than your shoulder. Get

a professional to do the job.

S Make your fist cut

the bottom of the limb.

S Next makea 2nd cut all the way through

the limb. Then cut a third overcut leaving

a 1 to2 inch collar fromthe truck of the tree.

Third cut

Collar

1/3 of the way through

Second cut

First cut

Pruning technique

SERVICE

WARNING: Disconnect the spark

plug before performing maintenance except

for carburetor adjustments.

We recommend all service and adjustments

not listed in this manual be performed by an

authorized service dealer.

HELPFUL TIP

IMPORTANT: Have all

repairs other than the recommended maintenance

described in the instruction

manual performed by an

If any dealer other than an authorized

service dealer performs work on the

product, Poulan PRO may not pay for

repairs under warranty. It is your responsibility to maintain and perform

general maintenance.

authorized service dealer.

MAINTENANCE SCHEDULE

Check:

Fuel mixture level Before each use....

Bar lubrication Before each use.......

Chain tension Before each use.......

Chain sharpness Before each use....

For damaged parts Before each use..

For loose caps Before each use......

For loose fasteners Before each use...

For loose parts Before each use......

Inspect and Clean:

Bar Before each use................

Complete saw After each use.......

Air filter Every 5 hours*.............

Chain brake Every 5 hours*........

Spark arresting screen

and muffler Every 25 hours*.........

Replace spark plug Yearl y.

Replace fuel filter Yea r ly...

*HoursofOperation

14

Page 15

AIR FILTER

ACK

CAUTION

or other flammable solvent to avoid creating

a fire hazard or producing harmful evaporative emissions.

: Do not clean filter in gasoline

Cleaning the air filter:

A dirty air filter decreases engine performance and increases fuel consumption and

harmful emissions. Always clean after 15

tanks of fuel or 5 hours of operation, whichever comes first. Clean more frequently in

dusty conditions. A used aire filter can never

be completely cleaned. It is advisable to replace your air filter with anew one after every

50 hours ofoperation, or annually,whichever

comes first.

1. Loosen 3 screws on cylinder cover.

2. Remove cylinder cover.

3. Remove air filter.

4. Clean the air filter using hot soapy water.

Rinse with clean cool water. Air dry completely before reinstalling.

5. Reinstall air filter.

6. Reinstall cylinder cover and 3 screws.

TIghten securely.

Air Filter

4. Loosen and remove the 2 muffler bolts.

Remove themuffler and backplates. Notice the orientation of these parts for reassembling.

5. Locate the 2 outlet cover screws on the

muffler. Loosen and remove both

screws. Remove the outlet cover and

spark arresting screen.

B

VIEW OF MUFFLER

Outlet Cover

Screws

Spark Arresting

Screen

6. Clean the spark arresting screen with a

wire brush. Replace screen if any wires

are broken or screen is blocked after

cleaning.

7. Reinstall spark arresting screen.

8. Reinstall outlet cover and 2 screws. Ensure outlet cover and both screws arereinstalled correctly to prevent damage to

the saw (see illustrations). The exhaust

outlets must face the chain brake (bar

side) of the saw.

Outlet Cover

Muffler

Air Filter

Screws

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

As the unit is used, carbon deposits build up

on the muffler and spark arresting screen,

and must be removed to avoid creating a fire

hazard or affecting engine performance.

Replace the spark arresting screen if breaks

occur.

CLEANING THE SPARK

ARRESTING SCREEN

Clean every 25 hours of operation or annually,

whichever comes first.

Steel

Backplate

Muffler

Muffler

Bolts

Aluminum

Backplate

1. Loosen and remove the 3 cylinder cover

screws. Remove the cylinder cover.

2. Pull off the spark plug boot.

3. Loosen and remove the locknut from the

bolt cover. Remove the bolt cover.

Muffler

Gasket

Bolt Cover

Locknut

Exhaust Outlets

Exhaust Outlets must face

chain brake (bar side) of chain saw

9. Inspect the muffler gasket and replace if

damaged.

10. Reinstall backplates, muffler gasket and

muffler using muf fler bolts. TIghten until

secure.

11. Reinstall bolt cover and locknut.

12. Reinstall the spark plug boot.

13. Reinstall the cylinder cover and 3

screws. Tighten securely.

CARBURETOR ADJUSTMENTS

WARNING: The chain will be mov-

ing during most of this procedure. Wear your

protective equipment and observe all safety

precautions. The chain must notmove at idle

speed.

The carburetor has been carefully set at the

factory. Adjustments may be necessary if

you notice any of the following conditions:

S Chain moves at idle. See IDLE SPEED--T

adjusting procedure.

S Saw will not idle. See IDLE SPEED-- T ad-

justing procedure.

Idle Speed --T

Allow engine to idle. If the chain moves, idle

is too fast. If the engine stalls, idle is too slow.

Adjust speed until engine runs without chain

movement (idle too fast) or stalling (idle too

slow).

S Turn idle speed screw (T) clockwise to in-

crease engine speed.

15

Page 16

S Turn idle speed screw (T) counterclock-

A

v

wise to decrease engine speed.

If you require further assistance or are unsure

about performing this procedure, contact your

authorized s ervice dealer or call

1-- 800--554- -6723.

BAR MAINTENANCE

If your saw cuts to one side, has to be forced

through thecut, or been run with animproper

amount of bar lubrication it may be necessary toservice your bar. A worn bar willdamage your chain and make cutting difficult.

After each use, ensure ON/STOP switch is

in the STOP position, then clean all sawdust

from the guide bar and sprocket hole.

To maintain guide bar:

S Move ON/STOP switch to the STOP posi-

tion.

S Loosen and remove chain brake nuts and

chain brake. Remove bar and chain from

saw.

S Clean the oil holes and bar groove after each

5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S Burring of guide bar rails is a normal

process of rail wear. Remove these burrs

with a flat file.

S When rail top is uneven, use aflat fileto re-

store square edges and sides.

Replace guide bar when the groove is worn,

the guide bar is bent or cracked, or when

excess heating or burring of the rails occurs.

If replacement is necessary, use only the guide

bar specified for your saw in the repair parts list

or on the decal located on the chain saw.

File Rail Edges

and Sides

Square

Correct GrooveWorn Groove

CHAIN SHARPENING

WARNING: Improper chain sharp-

ening techniques and/or depth gauge maintenance will increase the chance of kickback

which can result in serious injury.

WARNING: Wear protective gloves

when handling chain. The chain is sharp and

can cut you even when it is not moving.

Conditions which indicate the need for chain

sharpening:

S Reduction in size of wood chips. The size

of the wood chip will decrease as the chain

gets duller until it becomes more like a

powder than a chip. Note that dead or

rotted wood will not produce a good chip.

S Saw cuts to one side or at an angle.

S Saw has to be forced through the cut.

Tools required:

S 5/32 inch (4 mm) diameter round file and

file holder

S Flat file

S Depth gauge tool

TO SHARPEN CHAIN:

1. MoveON/STOPswitchtotheSTOP

position.

2. Check chain for proper tension. Adjust

chain tension if necessary. See CHAIN

TENSION section.

3. Sharpen cutters.

S To sharpen the cutters, position the

file holder level (90˚) so that it rests

on the top edges of the cutter and

depth gauge.

NOTE: The chain has both left and

right hand cutters.

File Holder

Cutter

S Align the 30˚ file holder marks paral-

30˚

File Holder Line

S Sharpen cutters on one side of the

S File onthe forward stroke only. Use 2

S Keep all cutters the same length

S File enough to remove any damage

Same Length

S File chain to meet the specifications

30˚

File

90˚

Depth Gauge

lel with the bar andto the center of the

chain.

Cutter

Cutter

chain first. File from the inside of each

cutter to the outside. Then, turn the

chain saw around and repeat the process for the other side of the chain.

or 3 strokes per cutting edge.

when filing.

to cutting edges (side plate and top

plate of cutter).

Remo

ll Cutters

as shown.

e Damage

Top Plate

Side Plate

85˚

16

60

Page 17

Hook Angle

f

f

0.025 inch

(0.65 mm)

Rounded

Right

Too Much HookAngle

Wrong

WARNING: Maintain the proper

hook angle according to the manufacturer’s

specifications for the chain you are using. Improper hook angle will increase the chance of

kickback which can result in serious injury.

4. Check and lower depth gauges.

Depth Gauge To ol

S Place gauge tool on cutter.

S If the depth gauge is higher than the

depth gaugetool, file it level to the topof

the depth gauge tool.

S Maintain rounded front corner of

depth gauge with a flat file.

NOTE: The very top of the depth

gauge should be flat with the front

half rounded off with a flat file.

If you require further assistance or are unsure

about performing this procedure, contact your

authorized service dealer or call our customer

assistance help line at 1-- 800--554-- 6723.

IGNITION TIMING

Ignition timing is fixed and nonadjustable.

Corner

Squared O

Corner

File

Depth Gauge

SPARK PLUG

The spark plug should be replaced each

year to ensure the engine starts easier and

runs better.

1. Loosen 3 screws on cylinder cover.

2. Remove the cylinder cover.

3. Pull off the spark plug boot.

4. Remove spark plug from cylinder and

discard.

5. Replace with Champion RCJ--7Y spark

plug and tighten with a 3/4 inch (19 mm)

socket wrench. Tighten securely. Spark

plug gap should be 0.025 inch (0.6 mm).

6. Reinstall the spark plug boot.

7. Reinstall thecylinder c over and3 screws

Tighten securely.

Spark Plug Boot

COOLING SYSTEM

To keep the working temperature as low as

possible the machine is equipped with a

cooling system.

The cooling system consists of:

S Air intake on the starter

S Air guide plate

S Fins on the flywheel

S Cooling fins on the cylinder

S Cylinder cover (directs cold air over the

cylinder)

Clean the cooling system with a brush after

each use, more often in demanding conditions. A dirty or blocked cooling system results in the machine overheating which

causes damage to the piston and cylinder.

STORAGE

WARNING: Perform the following

steps after each use:

S Allow the engine to cool, and secure the

unit before storing or transporting.

S Store chain saw and fuel in a well venti-

lated area where fuel vapors cannot reach

sparks or open flames from water heaters,

electric motors or switches, furnaces, etc.

S Store chain saw with all guards in place

and position chain saw so that any sharp

object cannot accidentally cause injury.

S Store chain saw well out of the reach of

children.

SEASONAL STORAGE

Prepare your unit for storage at the end of the

season or if it will not be used for 30 days or

more.

If your chain saw is to be stored for a period

of time:

S Clean saw thoroughly before storage.

S Store in a clean dry area.

S Lightly oil external metal surfaces and

guide bar.

S Oil the chain and wrap it in heavy paper or

cloth.

FUEL SYSTEM

Under FUELING ENGINE in the OPERATION section of this manual, see message

labeled IMPORTANT regarding the use of

gasohol in your chain saw.

Fuel stabilizer is an acceptable alternative in

minimizing the formation of fuel gum deposits during storage. Add stabilizer to the gasoline in the fuel tank or fuel storage container.

17

Page 18

Follow the mix instructions found on stabilizer containers. Run engine at least 5 minutes

after adding stabilizer.

Poulan/WEED EATER 40:1, 2-cycle engine

oil (air cooled) is blended with fuel stabilizer.

If you do not use this oil, you can add a fuel

stabilizer to your fuel tank.

HELPFUL TIP

During storage of your gas/

oil mixture, the oil will separate from the gas.

We recommend that you

shake the gas can weekly

to insure proper blending of

the gas and oil.

ENGINE

S Remove spark plug and pour 1 teaspoon

of 40:1, 2-cycle engine oil (air cooled)

through the spark plug opening. Slowly

pull the starter rope 8to 10times to distribute oil.

S Replace spark plug with new one of rec-

ommended type and heat range.

S Clean air filter.

S Check entire unit for loose screws, nuts,

and bolts. Replace any damaged, broken,

or worn parts.

S At the beginning of the next season, use

only fresh fuel having the proper gasoline

to oil ratio.

OTHER

S Do not store gasoline from one season to

another.

S Replace your gasoline can if it starts to

rust.

TROUBLESHOOTING T A BLE

WARNING: Always stop unit and disconnect spark plug before performing all of

the rec ommended remedies below except remedies that require operation of the unit.

TROUBLE CAUSE REMEDY

Engine will not

start or will run

only a few

seconds after

starting.

Engine will

not idle

properly.

Engine will not

accelerate,

lacks power,

or dies under

a load.

Engine

smokes

excessively.

Chain moves

at idle speed.

1. Ignition switch off.

2. Engine flooded.

3. Fuel tank empty.

4. Spark plug not firing.

5. Fuel not reaching

carburetor.

1. Carburetor requires

adjustment.

2. Crankshaft seals worn.

1. Air filter dirty.

2. Spark plug fouled.

3. Chain brake engaged.

4. Carburetor requires

adjustment.

1. Too much oil mixed with

gasoline.

1. Idle speed requires

adjustment.

2. Clutch requires repair.

1. Move ignition switch to ON.

2. See “Difficult Starting” in

Operation Section.

3. Fill tank with correct fuel mixture.

4. Install new spark plug.

5. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

1. See “Carburetor Adjustment” in the

Service and Adjustments Section.

2. Contact an authorized service dealer.

1. Clean or replace air filter.

2. Clean or replace plug and regap.

3. Disengage chain brake.

4. Contact an authorized service dealer.

1. Empty fuel tank and refill with

correct fuel mixture.

1. See “Carburetor Adjustment” in the

Service and Adjustments Section.

2. Contact an authorized service dealer.

18

Page 19

LIMITED WARRANTY

Poulan PRO, a division of Husqvarna Con-

sumer Outdoor Products N.A., Inc., warrants to the originalconsumer purchaser that

each new Poulan PRO brand gasoline chain

saw is free from defects in material and

workmanship andagrees torepair o rreplace

under this warranty any defective gasoline

chain saw as follows fromthe original date of

purchase.

2 YEARS -- Parts and Labor, when used for

household purposes.

60 DAYS -- Parts and Labor, when used for

commercial, professional, or income producing purposes.

30 DAYS -- Parts andLabor, if used for rental

purposes.

This warranty is not transferable and does not

cover damage or liability caused by improper

handling, improper maintenance or alteration,

or the use of accessories and/or attachments

not specifically recommended by PoulanPRO

for this chain saw. This warranty does not cover tune--up, spark plugs, filters, starter ropes,

chain sharpening, bars, chains, and other parts

which wear and require replacement with reasonable use during the warranty period. This

warranty does not cover predelivery setup,

installation of guide bar and chain, and normal

adjustments explained in the instruction manual such as chai n te n si o n adj u stments. This

warranty does not cover transportation costs.

In the event you have a claim under this warranty, you must return the product to an authorized service dealer.

Should you have any unanswered questions

concerning this warranty, please contact:

U.S. EPA / ENVIRONMENT CANADA

EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS: The U.S. Environmental

Protection Agency, California Air Resources

Board, Environment Canada and Poulan

PRO are pleased to explain the emissions

control system warranty on your year 2009 and

later small off- -road engine. In California, all

small off--road engines must be designed, built,

and equipped to meet the Sta te’ s stringent

anti--smog standards. Poulan PRO must

warrant the emission control system on your

small off--road engine for the periods of time

listed below provided there has been no

abuse, neglect, or improper maintenance of

your small off--road engine. Yo ur emission

control system includes parts such as the carburetor, the ignition system and the fuel tank .

Where a warrantable condition exists, Poulan PRO will repair your small off-- road engine at nocost to you. Expenses covered under warranty include diagnosis, parts and

labor. MANUFACTURER’S WARRANTY

COVERAGE: If any emissions related part

on your engine (as listed under Emissions

Poulan PRO, a division of Husqvarna

Consumer Outdoor Products N.A., Inc.

1030 Stevens Creek Road

Augusta, GA 30907

1--800-- 554-- 6723

In Canada, contact:

Poulan PRO

850 Matheson Blvd. West

Mississauga, Ontario L5V 0B4

Giving the model number, serial numberand

date of purchase of your product and the

name and address of the authorized dealer

from whom it was purchased.

THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY HAVE

OTHER RIGHTS WHICH VARY FROM

STATE TO STATE.

NO CLAIMS FOR CONSEQUENTIAL OR

OTHER DAMAGES WILL BE ALLOWED,

AND THERE ARE NO OTHER EXPRESS

WARRANTIES EXCEPT THOSE EXPRESSLY STIPULATED HEREIN.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS OR THE EXCLUSION OR

LIMI TATI ONS OF IN C ID E NTAL OR CO NSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATIONS OR EXCLUSION

MAY NOT APPLY TO YOU.

This is a limited warranty within the meaning

of that term as defined in the Magnuson-Moss Act of 1975.

The policy of Poulan PROis to continuously

improve its products. Therefore, Poulan

PRO reserves the right to change, modify ,or

discontinue models, designs, specifications,

and accessories of all products at any time

without notice or obligation to any purchaser.

Control Warranty Parts List) is defective or a

defect in the materials or workmanship of the

engine causes the failure of such an emission

related part, the part will be repaired or replaced by Poulan PRO. OWNER’S WAR-

RANTY RESPONSIBILITIES: As the small

off--road engine owner, you are responsible

for the performance of the required maintenance listed in your instruction manual. Poulan PRO recommends that you retain all receipts covering maintenance on your small

off--road engine, but Poulan PRO cannot

deny warranty solely for the lack of receipts

or for your failure to ensure the performance

of all scheduled maintenance. As the small

off--road engine owner, you should be aware

that Poulan PRO may deny you warranty

coverage if your small off--road engine or a

part of it has failed due toabuse, neglect, improper maintenance, unapproved modifications, or the use of parts not made or approved by the original equipment

manufacturer. You are re s ponsible for presenting your small off-- road engine to an Poulan

19

Page 20

PRO authorized repair center as soon as a

problem exists. Warranty repairs should be

completed in a reasonable amount of time, not

to exceed 30 d ays. If you have any questions

regarding your warranty rights andresponsibilities, you should contact your nearest authorized service center, call Poulan PRO at

1--800-- 554-- 6723, or send e-mail correspondence to

emission.com

MENT DATE: The warranty period begins

on the date the small off-- road engine is purchased. LENGTH OF COVERAGE: This

warranty shall be for a period of two years

from the initial date of purchase. WHAT IS

COVERED: REPAIR OR REPLACEMENT

OF PARTS. Repair or replacement of any

warranted part will be performed at no

charge to the owner at an approved Poulan

PRO servicing center. If you have any questions regarding your warranty rights and responsibilities, you should contact your nearest authorized service center, call Poulan

PRO at 1--800--554--6723, or send e-mail

correspondence to

HCOP--emission.com

RIOD: Any warranted part which is not

scheduled for replacement as required

maintenance, or which is scheduled only for

regular inspection to the effect of “repair or

replace as necessary” shall be warranted for

2 years. Any warranted part which is scheduled for replacement as required maintenance shall be warranted for the period of

time up to the first scheduled replacement

point for that part. DIAGNOSIS: The owner

shall not be charged for diagnostic labor

which leads to the determination that a warranted partis defective ifthe diagnostic work

is performed at an approved Poulan PRO

servicing center.

emission.warranty@HCOP--

. WARRANTY COMMENCE-

emission.warranty@

. WARRANTY PE-

CONSEQUENTIAL DAMAGES: Poulan

PRO may be liable for damages to other engine components caused by the failure of a

warranted partstill underwarranty. WHAT IS

NOT COVERED: All failures caused by

abuse, neglect, or improper maintenance

are not covered. ADD --ON OR MODIFIED

PAR TS: The use of add -- on or modified parts

can be grounds for disallowing a warranty

claim. Poulan PRO is not liable to cover failures

of warranted parts caused by the use of add-on or modified parts. HOW TO FI LEA CLAIM:

If you have any questions regarding your

warranty rights and responsibilities, you

should contact your nearest authorized service center, call Poulan PRO at

1--800-- 554-- 6723, or send e-mail correspondence to

emission.com

RANTY SERVICE: Warranty services or

repairs shall be provided at all Poulan PRO

service centers. Call: 1--800--554--6723 or

send e-mail correspondence to

sion.warranty@HCOP--emission.com

MAINTENANCE, REPLACEMENT AND

REPAIROF EMISSION RELATED PARTS:

Any Poulan PRO approved replacement

part used in the performance of any warranty

maintenance or repair on emission related

parts will be provided without charge to the

owner if the part is under warranty. EMIS-

SION CONTROL WARRANTY PARTS

LIST: Carburetor, air filter (covered up to main-

tenance schedule), ignition system: spark plug

(covered up to maintenance schedule), ignition

module, muffler including catalyst (if equipped),

fuel tank. MAINTENANCE STATEMENT:

The owner is responsible for the performance of all required maintenance as defined in the instruction manual.

emission.warranty@HCOP--

. WHERE TO GET WAR-

emis.

The information on the product label indicates which standard your engine is certified.

Example: (Year) EPA and/or CALIFORNIA.

This engine is certified to be emissions compliant for the following use:

Moderate (50 hours)

Intermediate (125 hours)

Extended (300 hours)

20

Loading...

Loading...