Page 1

Poulan—

4400/^900/5400Counter Vibe

CAUTION:

Read Rules for Safe

Operation Carefully.

Note Special

Instructions for

Bow Saw Users.

BEAIRD-POULAN/WEED EATER

Division Emerson Electric Co.

5020 Fiournoy-Lucas Road i

Shreveport, Louisiana 71109

-----------------------------------^---------

ctiainsaw

operator’s manual

Record in the space provided below the model

number and serial number of your saw.

Model No.

Retain these numbers for future reference.

.Serial No..

Page 2

TABLE OF CONTENTS

Bar and Chain Installation . , .

Chain Adjustment

Bow Installation

Operating Instructions

Cutting Tips

Bow Cutting Tips . . . .

Felling ..............................

Bucking

Pruning and Debranching

Special Safety Center Spread ,

Replacing Drum & Sprocket .

Carburetor Adjustment ....

Chain Sharpening

Trouble Shooting

.....................

........................

..............

............................

......................

.......................

SPECIFICATIONS

MODEL

CU. IN. DISPLACEMENT

4.2 in3/69 cm3

4400

4900

4.7 in3/77cm3

SPARKPLUG Champion CJ-8 Champion CJ-8

SPARK PLUG GAP

IGNITION

MODULE AIR GAP

OILER

GUIDE BAR

CHAIN

BOW GUIDE

FUEL MIX

.023 to .027"

Solid State

.008 to .014"

Adjustable Automatic

16",20",24",27",30",32", & 36" rsn

17", 21", 25" HT

3/8" Pitch - Semi Chisel Chain

13", 14"

V2 pt. (16:1) oil/1 gal. reg. gasoline V2 pt. (32:1) oil to 2 gal. reg. gas.

MUFFLER Spark Arresting

- 3,4

■ 3,4

, 7

•4, 5

. 7

5

. 6

. 6

8, 9

. 10

, 11

. 12

. 13

5400

5.2ln3/85cm3

Champion CJ-4

CHOKE

THROTTLE rear

TRIGGER CHAIN GUARD

REPLACEABLE SPROCKET NOSE BAR

CHAIN TENSION

(Located between Bar & Spur) qIL CAP

FUEL CAP

NOTICE CALIFORNIA ONLY

It is prohibited to operate this chain saw on forest brush, or grass covered land without a properly maintained SPARK ARRESTOR

(code 4442), or to operate a chain saw without a TEMPERATURE LIMITING MUFFLER (code 4443). THIS ENGINE IS NOT

EQUIPPED from the factory with such a muffler, A kit is available from your dealer.

You must maintain the approved muffler to operate this chain saw in California. Failure to do so will subject you to a liability for a

fine.

Page 3

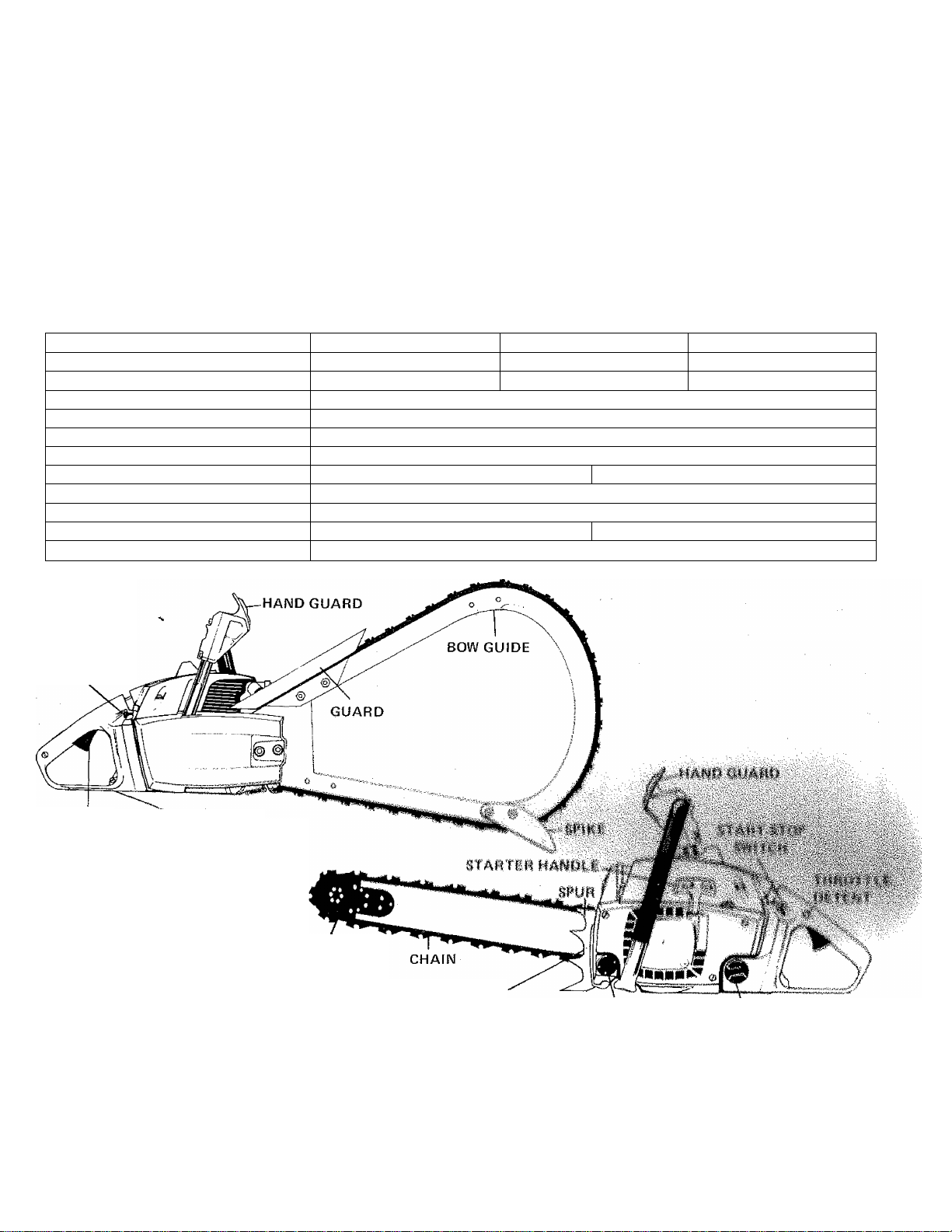

SAFETY FEATURES

Your new chain saw is equipped with guard link safety chain

to reduce kickback.

A hand guard is provided to protect your hand from coming in

contact with the cutting chain in the event your hand slips off

the front handlebar or you lose control of the saw. Hand

guards do not eliminate the possibility of injury as a result of

kickback or loss of control.

THIS SAW INTENDED FOR

PROFESSIONAL USE ONLY.

SPUR MOUNTING

HAND GUARD MOUNTING INSTRUCTIONS

1. Assemble the hand guard to the bend in the handlebar as

shown. Be sure alignment pin on guard is inserted in hole in

handlebar. Do not tighten the screws.

2. Make sure the hand guard is parallel to the handlebar.

Alternately tighten each hand guard mounting screw

maintaining an even gap between the hand guard and

mounting cap.

3. Tighten the mounting screws until the hand guard and

mounting cap are pulled together.

Caution; Screws must be tightened evenly to prevent

breakage.

Figure 1

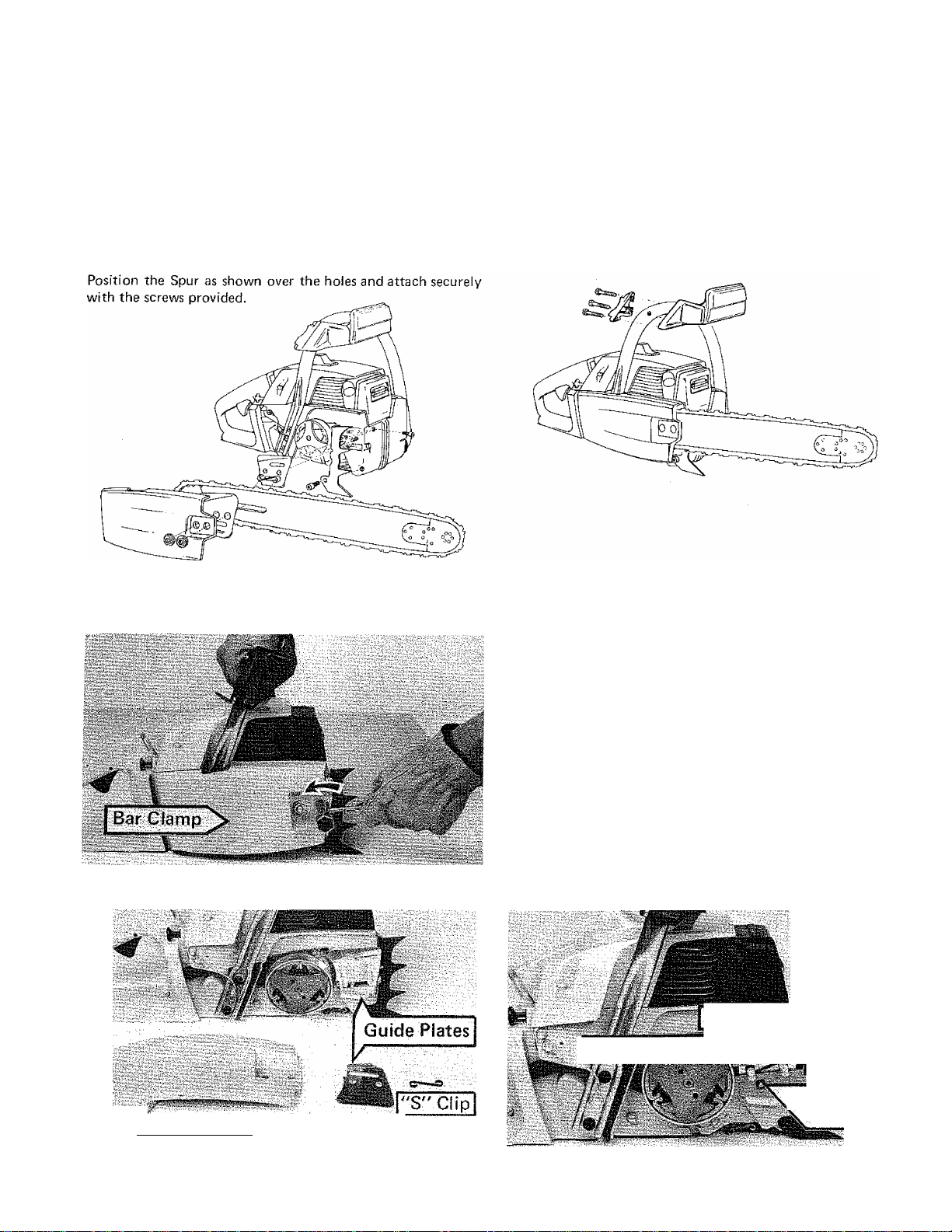

INSTALLING THE GUIDE BAR AND SAFETY CHAIN

1. Remove the bar mounting nuts. Using the scrench packed

with your saw, loosen the nuts by turning counterclock

wise. FIGURE 1.

2. Remove the bar clamp and outer guide bar plate. (Note

position of the guide plates.) F IGURE 2.

3. Place "S" clip over the mounting studs and flush to the

inner bar plate. Now mount the slotted end of the guide bar

over the bar mounting studs and "S" clip and behind the

clutch drum. Be sure to position the bar adjusting pin into

the hole in the guide bar. FIGURE 3.

[Bar Mounting ^

Figure 2

Figure 3

Adjusting Pin

Hole

(continued}

Page 4

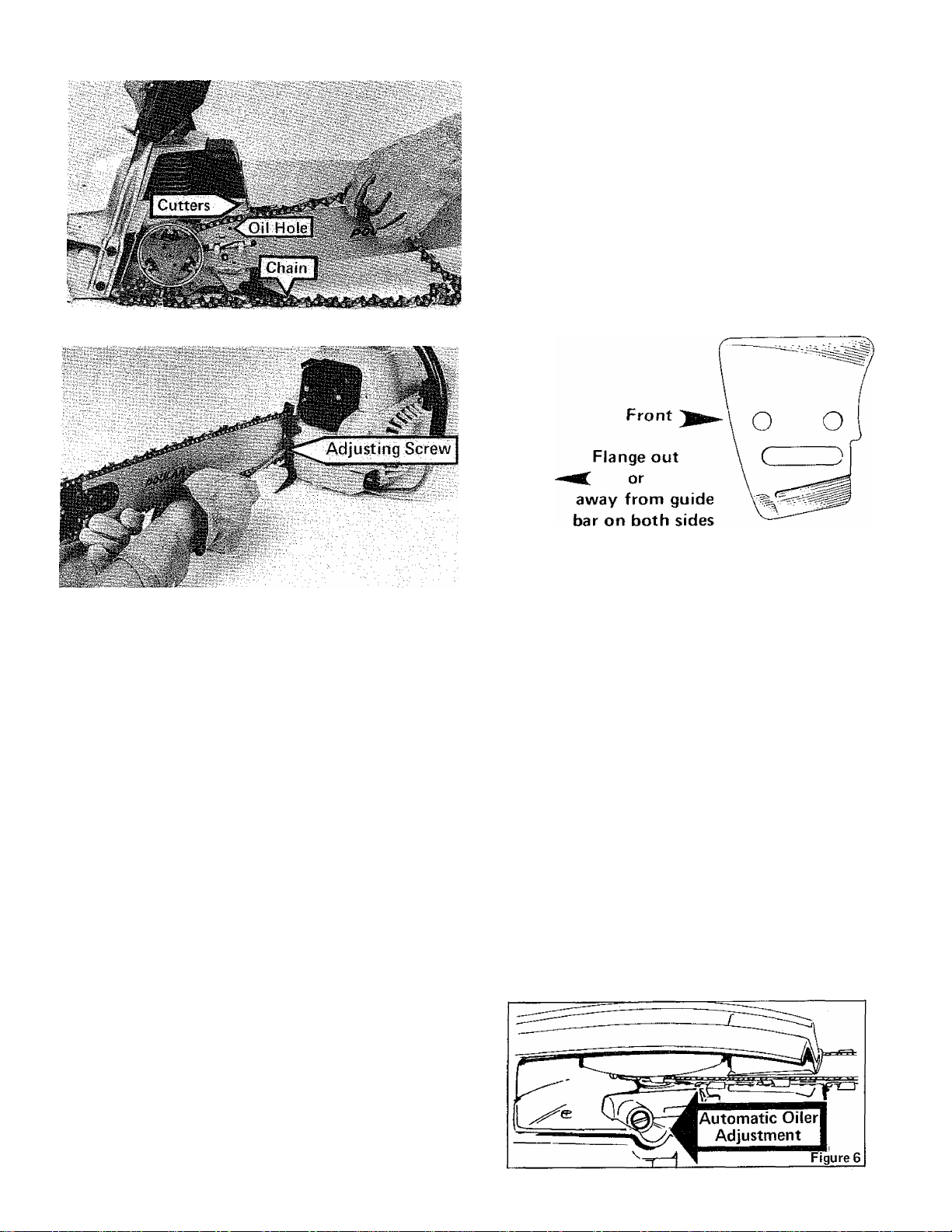

INSTALLING THE GUIDE BAR AND SAFETY CHAIN (con't)

4. Place the chain over the sprocket and engage the drive link

tangs between the sprocket teeth. (Note the direction of

the chain teeth.) Starting at the top of the bar, gradually

work the chain into the groove of the bar until all the drive

links are engaged in the bar groove. FIGURE 4.

5. Replace the outer guide bar plate and bar clamp. Replace

the bar mounting nuts and tighten finger tight,

6. Holding the tip of the bar up, adjust the chain tension by

turning the bar adjusting screw clockwise. FIGURE 5.

7. When the chain is properly tensioned it will move freely but

not sag below the bar. Now tighten the bar mounting nuts

completely.

CHAIN STRETCHES WHEN USED. CHECK THE TENSION

OFTEN!

Figure 4

Figure 5

OPERATING

Before Starting

O Check the chain tension. Is the chain sharp?

O Are the handles clean of gas and oil?

O Did you fill the fuel AND oil tanks?

FUEL and OIL

Fuel Mix: 16 parts gasoline to 1 part oil {8 oz. Poulan 16:1 oil

to one gallon gasoline). (Or use Poulan 32:1 oil—2 gallons

gasoline to 8 oz. oil).

CAUTION;

When preparing fuel mixture, mix only the amount needed for

the job you are to do. Do not use fuel mixture that has been

stored longer than two (2) months. Fuel mixture stored longer

than this will cause hard starting and poor performance of

your saw. If fuel mix has been stored in your saw longer than

this time it should also be removed and filled with a fresh

mixture before using.

BAR AND CHAIN OIL: Use straight bar and chain lube above

30 Fahrenheit. If bar and chain lube is not available use a

good grade SAE 30 oil. Between 30 F and 0 F use a mixture

of 95% bar and chain lube and 5% either kerosene or# 1 diesel

fuel. For below 0 F operation increase the kerosene or diesel

fuel to 10%.

A WORD ABOUT CHAIN OILING

1. Fill the oil tank each time you fill the fuel tank. Lack of oil

on the chain will quickly ruin the bar and chain.

2. You will use at least 1/2 tank of oil for each tank of gas. If

you use less, check for a plugged oil hole in the guide bar.

Use clean oil. Do not let sawdust or dirt into the oil tank.

INSTRUCTIONS

Clean the oil cap and the area around it before removing.

Oil on the bar and chain will drip off after use. Let the saw

stand and cool off. Wipe the bottom clean before storing.

AUTOMATIC OILER: Your Poulan Chain Saw is equipped

with an automatic oiler which delivers a constant flow of oil to

the bar and chain whenever the engine is running. The

automatic oiler has an adjustment screw, to regulate the flow

of oil, located at the bottom of the bar clamp for easy access.

Turn this screw counterclockwise Jt to increase the flow,

clockwise to decrease the flow. (See Figure 6) it is

possible to run out of chain oil before running out of fuel

when operating the saw at high RPM for a long period of time,

such as when pruning and debranching. The automatic oiler

may deliver more oil than required for this type of cutting. If

there is no chain oil in the oil tank when the saw runs out of

fuel, make the following adjustment: Turn the adjustment

screw clockwise ^ X until it stops. Then turn the screw

counterclockwise %turn. REMINDER — RE-ADJUST

FLOW RATE WHEN RETURNING TO CUTTING THAT

REQUIRES MORE CHAIN LUBRICATION, SUCH AS FELL

ING AND BUCKING.

Page 5

OPERATING INSTRUCTIONS (cont'd)

STARTING

Move bystanders and obstructions well out of reach!

WARNIMG; Chain will be moving when engine starts. Make

sure chain is not touching anything before starting,

h Pull Choke Knob out.

2. Move START-STOP Switch to START position.

3. Squeeze the throttle trigger, then press the throttle detent

located on the left side of the handle.

4. Release Trigger but keep Throttle Detent depressed com

pletely. This will open throttle slightly for easier starting.

5. Set saw on ground and place right foot in lower part of

control handle.

6. Kneel on left knee, grasp Handlebar with left hand and

Starter Handle with right hand. (See Figure 7).

1. Holding saw firmly, pull briskly on Starter Rope Handle

until engine fires. (A single "pop” is sufficient).

8. After engine fires, push Choke Knob in and engine should

run on next few pulls.

9. After engine starts and runs a few seconds, give Throttle

Trigger a light squeeze and Throttle Detent will release

automatically, allowing engine to idle.

Mote: Overchoking engine will cause it to flood. Should

engine flood, repeat starting instructions with Choke

Knob pushed in until engine starts.

10. To stop engine move START-STOP Switch to STOP

position.

Check The Wind — If it is strong enough to move the top of

the tree, DON'T CUT! Come back another day!

Check The Lean — Tie a weight to a piece of string about 3

feet long. Hang the weight in your line of sight. The string

is a good vertical line to help you judge the lean of the tree.

The tree will try to fall the way it is leaning. (See Figure 8)

Check The Weight Distribution — A tree is heavier on the side

with the most limbs. It will try to fall on its heavy side.

Clear The Work Area — You need a clean area all around the

tree for good footing. Get everything out of the area where

the tree will fall. People, pets, cars, etc.

Find a Retreat Path — Know which way you are going when

the tree starts to fall. Make sure it is clear.

FELLING {Cutting down a tree)

A Small Trees -- Less than 8” across

1. If there is doubt about the direction of fall, use "notch"

method described in B.

2. Make a single felling cut on the side away from the

direction of fall. Don't cut all the way through!

3. When the tree starts to fall, stop the saw, put the saw

down and GET AWAY QUICKLY!

B

Large Trees — 8” or larger across

1. The notch is very important. The tree will try to fall

"into” the notch. (See Figure 9)

2. Make the bottom notch cut first, about 1/3 to 1/2 way

into the tree.

3. Complete the notch with the slant cut. Remove the

wedge of wood before going on.

4. The felling cut is next. Make it on the side opposite the

notch.

5. It is made 2" higher than the bottom of the notch.

6. DO NOT try to cut through to the notch.

7. As the tree starts to fall, stop the saw, put the saw down

and GET AWAY QUICKLY!

CUTTING TIPS

^ Read the safety center spread frequently. Always keep

your chain sharp.

Plan Ahead

Figure 7

Direction

of Fall

l-<|\lotch1

Figure 9

Page 6

BUCKING

Bucking is the sawing of a log or fallen tree into smaller pieces.

(See Figúrelo)

□ Use Both Hands — grip the saw firmly. (See Figure 11.)

□ Stand Uphill — a log that is cut loose will roll downhill.

□ Keep The Chain Out Of The Dirt — dirt will dull the

chain. A dull chain is unsafe.

Q Stand to the left of the saw.

How To

A In area "A", come up from the bottom 1/3 of the way.

Finish by coming down from the top. Figure 10

B In area "S", come down from the top 1/3 of the way.

Finish by coming up from the bottom. Figure 10

PRUNING AND DEBRANCHING

1 Be Careful

O Use Both Hands — keep a firm grip. (See Figure 11)

O Look Out For Kickback — don't let the tip of the bar

touch anything while the engine is running.

O Don't Cut Overhead — keep the saw below chest high, The

chain is too close to your face in this position.

2 Pruning (Cutting limbs from standing tree)

O If you must cut in a tree, do not carry a running saw while

climbing.

O Keep BothL Hands On The Saw -- keep a firm grip. Figure 11

O Be Sure Of Your Support — don't cut off balance.

O Cut Up From The Bottom, Finish Down From The Top.

3 Debranching (Cutting the limbs from a fallen tree)

O Cut On The Opposite Side Of The Tree — keep the tree

between you and the chain. (See Figure 12)

O Be Sure Of Your Footing — work slowly and deliberately.

O Look Out For Springpoles — limbs bent under pressure

will snap up at you when cut.

the tree between you and the chain!

Figure 12

Page 7

BOW INSTALLATION

To install a bow guide to a standard

guide bar model it is necessary to

modify the bar clamp and saw body as

Ref.

Part No.

No.

1 4484

44126

"44127

51053

2

51132 1

*51133

3

1325

4

1326

5 1615 2

6 625567

7

1725

1709

8

9 11276 1

22162 1 Guard (14" Bow)

*NOTE:

To use 14” bow guide and chain with .404 pitch, .062 gauge,

it is necessary to install a .404 pitch sprocket which is included

with the bow kit.

BOW ASSEMBLY IMSTRUCTIONS

1, Attach 1325 and 1326 spikes to bow guide with two {2)

625567 screws and two (2} 1615 locknuts.

2. Attach guard to bow guide with open side away from

engine, using two (2) 1709 screws and two (2) 1725

locknuts.

3, Mount inner guide bar plate, bow guide, outer guide bar

plate, chain, and bar clamp on saw making sure adjusting

pin enters hole on bow guide.

4. Install mounting nuts finger tight, adjust chain tension,

and tighten nuts.

Qty,

Req. Description

1

13" Bow Guide (3/8 Pitch)

1

14" Bow Guide (3/8 Pitch)

1

14" Bow Guide (.404 Pitch)

1

P720-80 Chain (13" Bow 3/8 Pitch)

P720-87 Chain (14" Bow 3/8 Pitch)

1

P27-79 Chain (14" Bow .404 Pitch)

1 Spike - Left

1 Spike - Right

Locknut - Va - 20

2

Screw - Va-20 X 1% Hex Head

2

Locknut - 12-24

2

Screw - 12-24 x 5/8 Hex Head

Guard (13" Bow)

Always begin cutting in the correct

entry area of the bow. Figure 13

LOOK OUT FOR KICKBACK

1. When the bow contacts an object in the danger area,

(See Fig, 13) the bow is thrown upward with considera

ble force. THIS IS KICKBACK!

2. Hold the saw firmly with both hands.

3. Don't overreach.

4. Cut only at high engine speeds.

5.

DO NOT REACH ABOVE WAIST HIGH. THE BOW IS

TOO CLOSE TO YOUR FACE IN THIS POSITION.

6.

Keep your chain sharp. A dull chain kicks back harder

than a sharp chain.

BE CAREFUL

1. DO NOT OPERATE WITHOUT THE SPIKES, GUARD,

AND HAND GUARD PROPERLY ATTACHED.

2. Be sure the spikes are in place against the log before

beginning the cut. (See Fig, 13)

3. Do not cut small limbs or brush with a bow.

4. Do not under buck with a bow. y

5. Keep the chain tight and sharp.

J

Page 8

Your Planning

and Preparation

• Do not handle or op

erate a chain saw when

you are fatigued or tired, have

been drinking alcoholic bev

erages, are on medication, or

^ are upset. You must be in

good physical condition and

mentally alert.

Always wear personal protective gear. Wear

safety footwear, protective gloves, snugfitting clothing, and eye, hearing and head

protection devices.

Use caution when handling fuel. No smok

ing when fueling or operating the saw.

Handle fuel only in open, well-ventilated

areas. Wipe up spills.

All chain saw service other than the items

listed in the operator's manual maintenance

instructions, should be performed by

competent chain saw service personnel.

> Keep the handles dry, clean and free of oil

or fuel mixture.

> Do not operate a chain saw that is damaged,

is improperly adjusted, or is not completely

and securely assembled. Keep all screws

and fasteners tight.

Move the chain saw at least 10 feet (3m)

from the fueling point, before starting the

engine.

Make sure chain is sharp and at proper

tension.

Carry the chain saw with the engine

stopped, the guide bar and chain covered

and to the rear, and the muffler away from

your body.

Conditions in Your Work Area

Do not attempt to cut If the weather is bad

— strong wind, rain, snowing, or other

adverse weather conditions. You need

good visibility, so don’t cut at night.

Operate the chain saw only in well-venti

lated areas. Don’t operate it In an enclosed,

confined area because you need room to

perform the cutting and good ventilation.

Do not start cutting until you have a clear

work area, secure footing, and a planned

retreat path from the falling tree (If you are

cutting down trees).

Do not allow other persons to be near the

chain saw when starting or cutting with the

chain saw. Keep bystanders and animals

out of the work area.

Operate the chain saw on level, solid

ground.

Do not operate the chain saw in a tree

unless you have been specifically trained

to do so.

Never carry your saw while climbing. You

need both hands for safe climbing.

Page 9

OPERATING YOUR CHAIN SAW

i Wear your protective gear.

^ Before you start the engine, make sure the

saw chain is not contacting anything.

^ Keep all parts of your body away from the

saw chain when the engine is running.

► Hold the chain saw firmly with both hands

when the engine is running. Use a firm grip

with thumbs and fingers encircling the

chain saw handles.

» Do not let the nose of the guide bar contact

a log, branch, the ground, or any other ob

struction, to help prevent kickback.

> Guard against kickback. Kickback is the

upward motion of the guide bar which

occurs when the saw chain at the nose of

the guide bar contacts an object. Kickback

can lead to dangerous loss of control of the

chain saw.

'Do not overreach. You might iose your

balance.

' Do not cut above shoulder height. Don’t

cut overhead, since you would have poor

control of the saw and the saw would be

too close to your face and body.

%

Use extreme caution when cutting small

size brush and saplings because slender

material may catch the saw chain and be

whipped toward you or puil you off

balance.

When cutting a limb that is under tension

be alert for springback, so that you will not

be struck by the limb when the tension in

the wood fibers is released.

Be sure that the saw chain stops moving

when the throttle control trigger is re

leased.

After cutting, shut off the engine before

setting the saw down.

Let the saw cool in a non-combustible

area, not on dry leaves or paper.

Wipe off oil before storing the chain saw.

Do not store your chain saw in any room

with any type open flame heater or stove.

Store the saw in a locked area or in an area

away from children.

Follow manufacturer’s sharpening and

maintenance instructions for the saw

chain.

Always do your cutting at high engine

speed.

CONTROLLING KICKBACK by Lioyd Tuggle

KICKBACK may happen when the nose or tip of the moving chain touches an object while

the saw is operating. This contact may abruptly STOP the cutting action and in some cases

may cause a lightning fast reverse REACTION, kicking the saw tip up and back. KICKBACK

has caused some operators to lose control of the saw. The cutting chain can then cause

injury if it comes in contact with any part of the body.

As a chain saw user you can take several steps to keep your cutting free from accident or

injury due to kickback.

1. By simply UNDERSTANDING and knowing about kickback you take out the element of

SURPRISE. It's the SURPRISE that really contributes to accidents.

2. Make sure your HAND GUARD is securely fastened to the handlebar AT ALL TIMES.

3. Make sure the area in which you are cutting is FREE FROM OBSTRUCTIONS such as

other trees, branches, rocks, fences, stumps, etc. Eliminate or avoid any obstructions that

your saw chain could hit while you are cutting through a particular log or branch.

4. Keep a good firm grip on the saw with BOTH hands. (Left hand completely around the

front handlebar with thumb under and the right hand completely around the rear

handle.) A FIRM GRIP can neutralize kickback and help you maintain COMPLETE

CONTROL of the saw. DON'T LET GO.

Your Poulan chain saw is a reliable and powerful cutting tool. Please use it safely and

carefully so that each cutting job is SUCCESSFUL AND SAFE. Controlling kickback is

really a partnership between you and Poulan. GOOD CUTTING.

Lloyd Tuggle, Senior Vice President, Engineering, Beaird-Poulan

Avoid

Obstructions

Clear

Working

Good Firm

Grip With

Both Hands

Page 10

REPLACING DRUM AND SPROCKET

WARWING!—Do not start engine without guide bar, chain, and bar clamp completely assembled. The clutch can come off without

the guide bar and chain completely assembled and serious injury could result.

1. Remove the cylinder cover and the high tension lead from

the spark plug to prevent accidental starting of the saw.

Figure 14.

2. Remove the bar clamp and the bar and chain. Figure 15.

3. Remove the clutch by using a hammer and punch. Position

the punch as shown in Figure 16 and tap lightly with the

hammer. The threads are LEFT HAND so a clockwise

rotation is necessary to remove.

Figure 14

Remove the clutch drum and sprocket and inspect for wear.

Replace if necessary. Inspect the clutch shoes and springs.

Replace any that are broken or worn. Figure 17. Replace

the clutch in a counterclockwise direction. Replace high

tension lead and cylinder cover.

Inspect the chain sprocket regularly for wear; a worn

sprocket will make the chain run erratically and will

shorten the life of the bar and chain. Figure 18.

Figure 17

10

Figure 15

Figure 16

A -S

Figure 18

Page 11

CARBURETOR ADJUSTMENT

(Model 4400/4900/5400)

STOP THE ENGINE ~ Make sure you are using clean, fresh

fuel mixture at the correct gasoline/oil ratio. THE AIR

FILTER MUST BE CLEAN AND FASTENED SECURELY.

The cylinder shield should be in place and fastened securely.

1. Turn the high speed and low speed mixture screws

clockwise until they stop. DO NOT TIGHTEN OR

FORCE THE SCREWS ANY FARTHER! YOU MAY

DAMAGE THE NEEDLE SEATS. Turn the high speed and

low speed mixture screws 1 full turn counterclockwise.

Figure 19.

CAUTION! THE CHAIN WILL BE MOVING DURING

THE FOLLOWING PROCEDURE.

2. Start the engine and run for a few minutes to bring it to

operating temperature.

3. Squeeze the throttle trigger and run the engine at full RPM

for approximately 3 SECONDS, then allow it to return to

idle speed.

4. If the engine will not idle after it is warm, or it idles too

fast causing the chain to move, adjust the idle speed screw.

Turn the screw clockwise to increase idle speed,

counterclockwise to decrease idle speed. The idle

speed should be set as fast as possible, without causing the

chain to move.

5. Turn the low speed mixture screw clockwise until

the engine RPM increases and then starts to decrease. Note

this setting point. Now turn the screw counterclockwise

X. until the RPM starts to decrease again. Set the low

speed mixture screw midway between these two points.

6. Squeeze the throttle trigger quickly. If the engine dies or

hesitates, turn the low speed mixture screw 1/16 turn

counterclockwise iC . Repeat this procedure until the

engine will accelerate without hesitation.

CAUTION! THE HIGH SPEED MIXTURE SCREW MUST

NEVER BE SET AT LESS THAN 7/8 TURN OPEN. A^

LEAN MIXTURE WILL CAUSE THE ENGINE TO RUN

HOT AND DAMAGE IT.

7. With the high speed mixture screw 1 full turn open, make a

test cut with the saw. If the engine fails to have power and

run smoothly during the test cut, allow the engine to return

to idle speed, and turn the high speed mixture screw 1/16

turn clockwise Make another test cut. Continue this

procedure until the engine runs smoothly and with power

in the test cut. REMINDER-NEVER SET THE HIGH

SPEED MIXTURE SCREW LESS THAN 7/8 TURN OPEN.

8. After the low speed and high speed mixture settings are

made, it may be necessary to re-adjust the engine idle

speed. Refer to step 4.

AIR FILTER

Clean the air filter after every 10 tanks of gas or every 5

hours of operation.

TO CLEAN:

1. Close choke to prevent dirt from entering carburetor.

2. Remove the cylinder cover, then remove air filter. Fig. 20.

3. Separate the two air filter halves.

4. Using a soft bristled brush such as a small paint brush,

brush away all dust or other debris from the filter.

5. Clean by soaking in a non-oily, non-flammable solvent.

6. Allow to dry.

7. Before replacing filter clean away chips, saw dust, and

other debris on surfaces filter is to be placed on.

WARNING:

Do not operate your saw without the air filter in place.

Dirt and dust in the air can be drawn in carburetor caus

ing damage to the engine.

MOUNTS:

Your saw is equipped with a counter-vibe system which

consists of 6 isolator mounts Fig. 21, Just as the shock

absorbers on a car protect you from jolts and bumps the

isolators protect the user from engine, bar and chain

vibration. Mounts should be checked daily when saw is in

operation and should be replaced when vibration appears

excessive or when mounts develop an out of round or

swollen shape. This is usually caused from being exposed

to gasoline and oil for long periods of time. IT IS

NECESSARY TO REPLACE ALL MOUNTS WHEN A

MOUNT FAILURE OCCURS.

Page 12

STARTER ROPE

If your starter rope breaks near the pulley, it can be repaired

by the following method, otherwise replace the rope:

1. Remove the fan housing.

2. Remove screw using a 3/16 alien wrench. Figure 22.

3. Lift out pulley.

4. Tie a knot in one end of the rope. Heat and flatten the knot

end to prevent knot from slipping. Heat opposite end of

rope and form a point. Feed pointed end of rope through

the pulley and under the pulley bridge. Pull the rope

through until the knot is tight against the pulley. Figure 22.

5. Pass the pointed end of the rope through the hole in the fan

housing and then the starter handle. Tie a double knot and

insert knot end of rope back into the handle. Pull the slack

out of the rope and wrap the rope on the pulley in a

clockwise direction.

6. Apply light grade silicone lubricant to the pulley bore and

place pulley back in the fan housing. Place the pulley

washer in position and secure with the pulley screw.

7. To retension the starter spring pull a loop of rope from the

pulley approximately 12 in. long. Secure the rope in the

notch in the pulley and using the rope turn the pulley

THREE TURNS counterclockwise • Release the

rope from the notch and allow to rewind slowly on pulley.

Figure 23.

8. Replace the fan housing.

GUIDE BAR MAINTENANCE

Check the condition of the guide bar often. A worn bar will

damage the chain and make cutting harder.

1. Figure 24 shows a cross-section of the guide bar. Keep the

edges square as in (1) with a flat file.

2. Rollover is shown in (2). This will cause you to press extra

hard when cutting.

3. Worn rails are shown in {3}. This occurs most often at the

guide bar nos^.

4. Uneven rails are shown in (4). This will cause the saw to cut

on an angle.

5. Keep the rails flat and square as shown in (1).

6. Grease S/N Bar before use and at least 3 times per day for

heavy use.

CHAIN SHARPENING Keep Your Chain Sharp

Dirt will dull a chain instantly. Keep the chain out of the dirt.

If the chain cuts to one side, it is dull.

Extra rough cutting is a sign of a dull chain.

Powder-like wood chips mean a dull chain.

Cutting is much easier and safer with a sharp chain.

To Sharpen

1. Set the chain tension tight. You must still be able to move

the chain around the bar.

2. Clamp the guide bar in a vise. Don't clamp the chain!

Clamp in the center of the bar.

3. Use only a 7/32" round file.

4. Sharpen all the cutters away from you first. Then turn the

saw around and sharpen the cutters on the other side.

5. Position file holder at 10° angle (Figure 25) and align the

30 file holder marks with the bar as shown in Figure 26,

6. File in ONE direction only! Figure 27.

7. Press hard! Two or three strokes should do it.

8. Always check the depth gauge with the depth gauge filing

guide after filing. If the depth gauge sticks out, file it off

with a flat file. Figure 28.

3

Worn

Rails

Align The File Holder

Figure 26

Depth Gauge

File In One Direction Only

Figure 27

12

Always Check Depth Gauges

Figure 28

Page 13

TROUBLE SHOOTING

TROUBLE

ElMGilME WONT START

ENGINE DIES

ENGINE SMOKES EXCESSIVELY

ENGINE WONT IDLE PROPERLY

CAUSE

1. Switch off,

2. Empty fuel tank.

3. Spark plug not firing.

4. Fuel not getting to carburetor.

5. Flooded engine.

6. Low compression.

1. Out of gas.

2. Dirty air filter,

3. Fouled spark plug.

4. improper carburetor adjustment.

5. Inlet needle stuck or worn.

1. Hi speed needle needs adjustment.

2. Dirty air filter,

3. Oil rich fuel mixture.

4. Inlet needle stuck or worn.

5. Crankcase sealant leaking.

1. Engine idling speed set too low.

2. Lo speed needle out of adjustment.

3. Engine idles too fast.

4. Crankshaft seal defective.

REMEDY

1. Move switch to "START" position.

2. Fill tank with correct mixture

3. Replace with new plug.

4. Remove air filter and be sure choke

lever is working. Check for dirty fuel

filter in tank. Check for kinked or

split fuel line.

5. Push choke knob in completely.

Remove and dry spark plug. Pull

starter until engine starts and clears

itself.

6. Return saw to dealer for internal

problems.

1. Fill with correct mixture.

2. Clean air filter,

3. Clean plug.

4. See carburetor adjustment page 11.

5. Replace or return to dealer for service.

1. Adjust Hi speed mixture. See page 11.

2. Clean air filter.

3. Refill with correct mixture.

4. Replace or return to dealer for service.

5. Return to dealer for service.

1. Adjust idle speed screw clockwise to

increase speed.

2. Adjust Lo speed needle - page 11.

3. Adjust idle speed screw counterclock

wise to reduce speed.

4. Return to dealer for service.

ENGINE RUNS HOT

SAW CUTS POORLY

OILER NOT WORKING OR NOT

ENOUGH OIL TO CHAIN.

CHAIN CLATTERS OR

CUTS ROUGH

CHAIN CUTS AT ANGLE

1. Wrong fuel mixture.

2. Wrong type plug.

3. Clogged air cooling passages.

4. Saw runs lean.

5. Spark arrestor or exhaust ports

plugged with carbon.

1. Dull chain.

2. Chain not sharpened properly.

3. Chain improperly adjusted.

4. Worn or damaged guide bar.

5. Chain on backwards.

6. Engine low on power.

1. Out of oil,

2. Dirty oil filter.

3. Guide bar oil hole blocked.

1. Chain too loose.

2. Depth gauges too low.

3. Worn sprocket.

4. Incorrect filing angles.

1. Damaged cutters on one side or

chain dull one side.

2. Bar rails worn.

1. Mix fuel thoroughly using recommend

ed oil and gas.

2. Replace with correct plug.

3. Clean out dirt and trash from around

flywheel and cylinder.

4. Check for air leaks, return to dealer.

5. Clean and replace.

1. Sharpen chain. See Page 12.

2. See correct procedure for filing chain -

page 12.

3. See adjustment of chain - page 3 & 4.

4. Replace with new bar.

5. See installation of chain - page 3 & 4.

6. Return to dealer for service.

1. Fill tank.

2. Clean and replace.

3. Remove bar and clean.

1. See instructions - page 3 & 4.

2. See instructions - page 12.

3. Replace with new one.

4. See instructions - page 12.

1. Resharpen making sure all cutters are

filed alike.

2. Reshape or replace. See page 12.

13

Loading...

Loading...