Poulan 425 User Manual

IMPORTANT MANUAL Do Not Throw Awa

, J

.i-'t

OPERATOR’S MANUAL

MODELS; 425 & 505

GAS POWERED CHAIN SAW

Always Wear Eye Protection

lii

A WARNING:

This chain saw is capable of severe kickback that could result in seriow iqfiuy

to the user. Do not operate this saw un

less you have specialized trafiifinf and

experience for dealing with klddback;

Chain saws with signMcantly reduced

kickback potential are available*

POULAN PRO

Shreveport, Louisiana 71129 U.S.A.

TABLE OF CONTENTS

SPECIFICATIONS.......................................................... 2

WARNINGS & SAFETY INSTRUCTIONS .. . 3

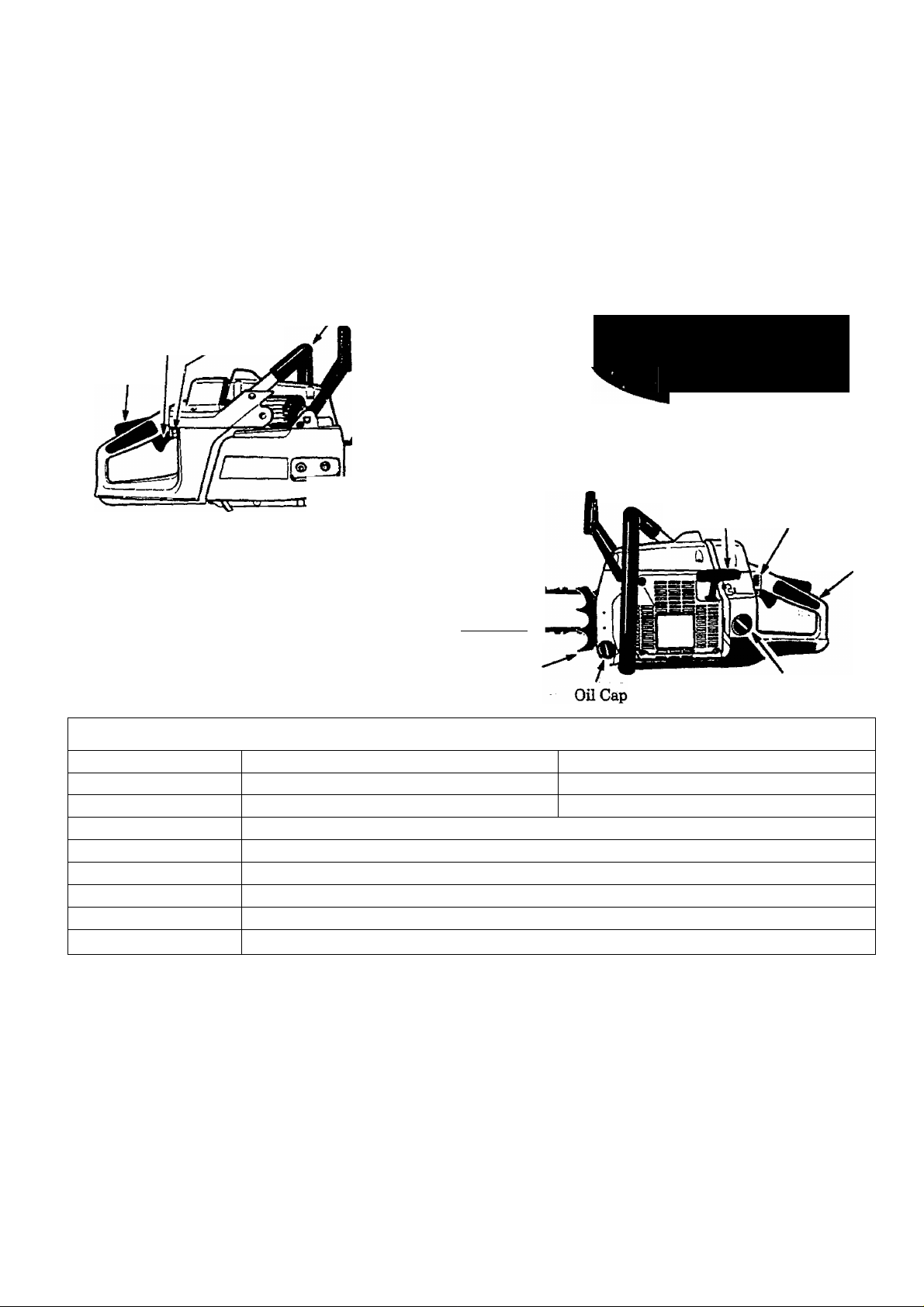

KNOW YOUR UNIT

PREPARING YOUR SAW FOR USE.............................. 7

FUELING YOUR UNIT

Throttle Choke Knob/

Trigger Throttle

Throttle

Lock-Out

........................................................

..................................................

Handlebar

Advance

6

10

STARTING YOUR UNIT ................................................11

TYPES OF CUTTING.....................................................12

GENERAL MAINTENANCE

POULAN PRO ACCESSORIES .................................... 23

PARTS & SERVICE..................................... Back Cover

.........................................

READ

■WARNINGS & SAFETY INSTRUI HONS

Chain

a

Chain Brake

Lever

' Handle Start/Stop

FREQUENÜA

Starter

16

Switch

Rear

Handle

wp' vf IP m

Guide Bar

Bucking

Spike

SPECIFICATIONS

MODEL:

DISPLACEMENT:

SPARKPLUG:

SPARK PLUG GAP:

IGNITION: Solid State

MODULE AIR GAP: .010” to .014”

OILER: Adjustable Automatic

FUELMDC:

MUFFLER:

Champion (CJ-7Y)

425

4.1 cu.in. (65cc)

.025” (0.7mm)

Gasoiine/Oil Mixture — 40:1 (see “Fueling Your Engine”)

Temperature Limiting/Spark Arresting—USDA Approved

Fuel Cap

505

6.0 cu.in. (83cc)

Champion (CJ—7Y)

- 2 -

WARNINGS AND SAFETY INSTRUCTIONS

(See Additional Safety Instructions throughout this Manual)

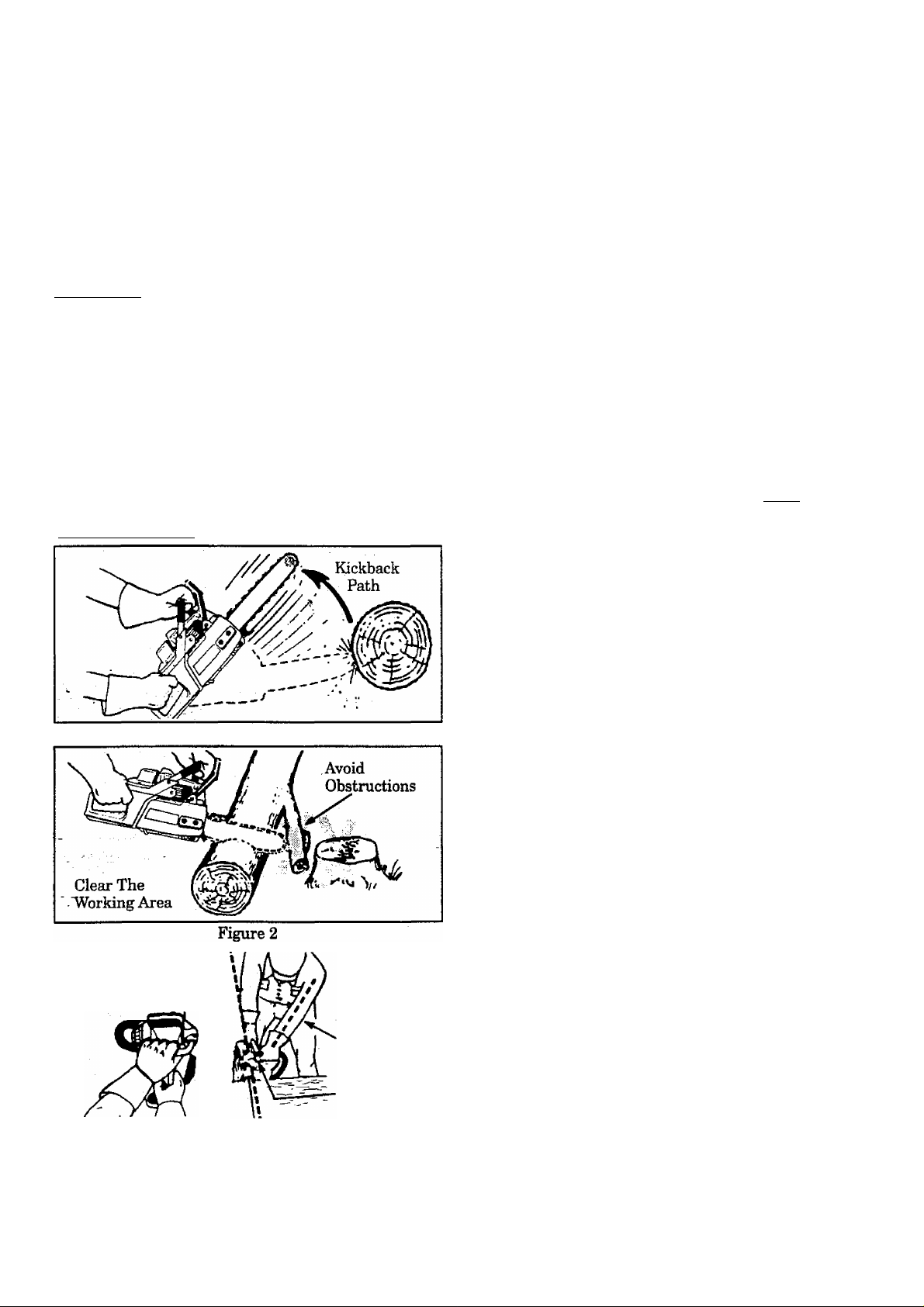

GUARD AGAINST KICKBACK

Kickback is a dangerous reaction that can lead to serious

injury. Do not rely only on the safety devices provided with

your saw. As a chain saw user, you must take special safety

precautions to help keep your cutting jobs free from accident or injury.

__________________________

_______

A KICKBACK WARNING

Kickback can occur when the moving chain con

tacts an object at the upper portion of the tip of

the guide bar or when the wood closes in and

pinches the saw chain in the cut. Contact at the

upper portion of the tip of the guide bar can

cause the chain to dig into the object, which

stops the chain for an instant. The re^t is a

lightning fast, reverse reaction which kicks the

guide bar up and back toward the operator. If

the saw chain is pinched along the top of the

guide bar, the guide bar can be driven rapidly

back toward the operator. Either of these reac

tions can cause loss of saw control which can result in serious injury.

Never Reverse

Hand Positions

Figure 1

Stand To

The Left

Of The Saw

Elbow

Locked

Thumb On

Under Side

Of Handlebar

Figure 3

___

REDUCE THE CHANCE OF KICKBACK

1. Recognize that kickback can happen, ^th a

basic understanding of kickback, you can reduce

the element of surprise which contributes to acci

dents.

2. Never let the moving chain contact any ob

ject at the tip of the guide bar. Figure 1,

3. Keep the working area free from obstruc

tions such as other trees, branches, rocks, fences,

stumps, etc. Figure 2 . Eliminate or avoid any ob

struction that your saw chain could hit while you

are cutting through a particular log or branch.

4. Keep your saw Chain sharp and properly ten

sioned. A loose or dull chain can increase the

chance of kickback to occur. Follow manufacturer’s

chain sharpening and maintenance instructions.

Check tension at regular intervals with the engine

stopped, never with the engine running. Make sure

the bar damp nuts are securely tightened after ten

sioning the chain.

5. Begin and continue cutting at full throttle. If

the chain is moving at a slower speed, there is great

er chance for kickback to occur.

6. Cut one log at a time.

7. Use extreme caution when re-entering a

previous cut.

8. Do not attempt plunge or bore cuts.

9. Watch for shifting logs or other forces that could

close a cut and pinch or faU into cheun.

10. A reduced kickback guide bar and low kickback chain are available for your saw and are

strongly recommended to further reduce the hazard

of kickback.

MAINTAIN CONTROL

1. Keep a good, Brm grip on the saw with both

hands when the engine is running and don't

let go. Figure 3 . A ftrm grip can neutralize kick-

backandhelpyou maintain controloffhe saw. Keep

the fingers of your left hand encircling and jrou left

thumb under the front handlebar. Ke^your ri^t

hand completely around the rear handle whether

your are right handed or left handed. Keep your left

arm straight with the elbow locked.

2. Position your left hand on the &ont ЬапШе-

bar so it is in a straight line with your right

hand on the rear handle when making buck

ing cuts. Figure 3 . Never reverse right and left

hand positions for any type of cutting,

3. Stand with your weight evenly bidanced on

both feet.

4. Stand slightly to the left side of the saw to

keep your body from being in a direct line

with the cutting chain. Figure 3 .

5. Do not overreach. You could be drawn or thrown

off balance and lose control of the saw.

6. Do not cut above shoulder height. It is difficult

to maintain control of saw above shoulder height.

WARNINGS AND SAFETY INSTRUCTIONS (continued)

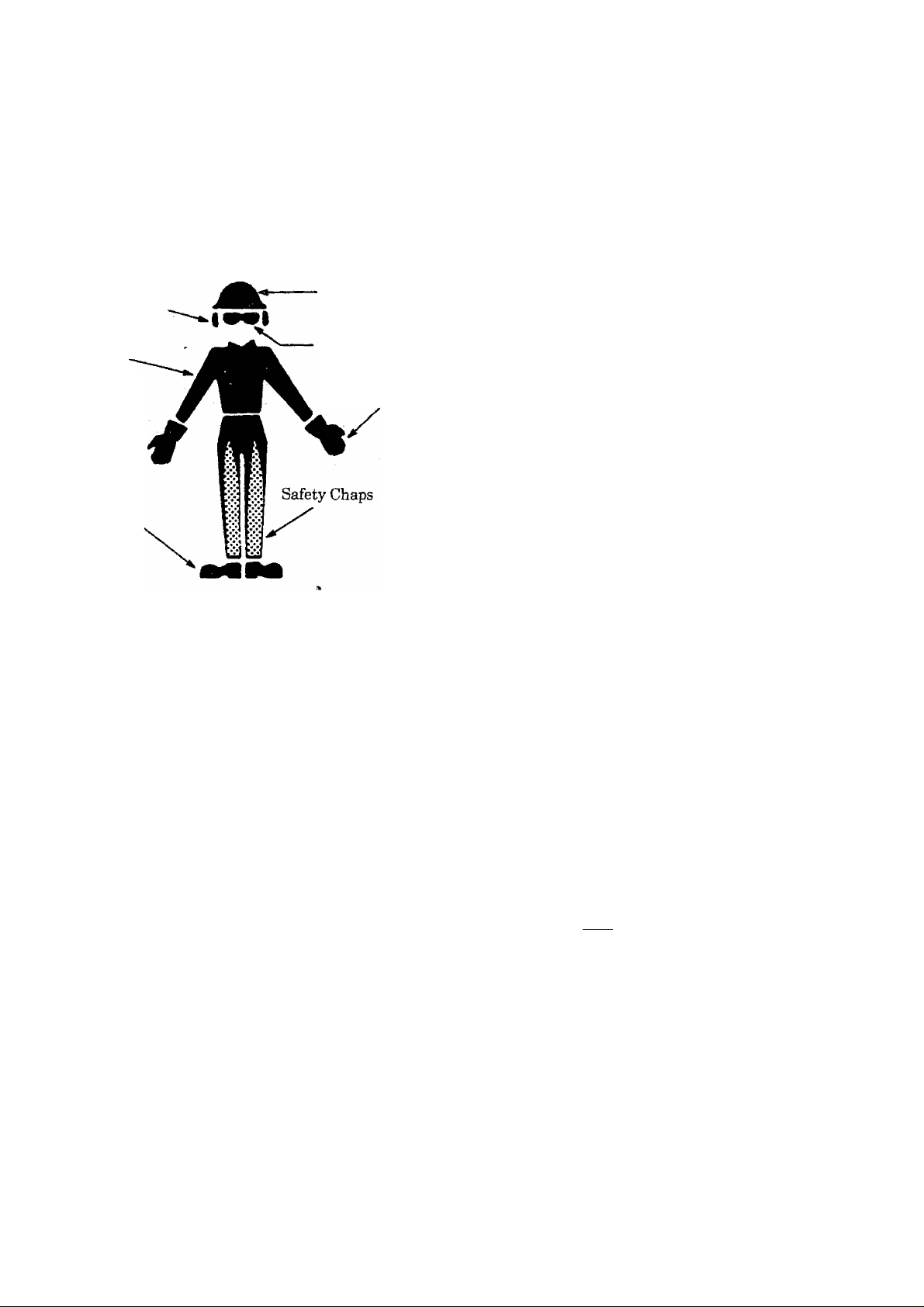

A WARNING

Because a chain saw is a high-speed wood-cutting tool» special safety precautions must be observed

to reduce the risk of accidents. Careless or improper use of this tool can cause serious injury.

Hearing

Protection

Snug

Fitting

Clothing

Safety

Shoes

Figure 4

Safety Hat

Eye Protection

Heavy Duty Gloves

KNOWYOURSAW

1. Read your operator's manual carefully until

you completely understand and can follow all safety

rules, precautions, and operating instructions be

fore attempting to operate the unit.

2. Restrict the use of your saw to adult users who

understand and can follow safety rules, precau

tions, and operating instructions found in this

manual.

PLAN AHEAD

Wear protective gear. Figi^ 4. Always use

1.

steel-toed safety footwear with-non-slip soles;

snug-fitting clothing; heavy-;-duty, non-slip

gloves; eye protection such as non—fogging, vented

goggles or face screen; an approved sal^ hard hat;

and sound barriers--ear plu^ or mufflers to pro

tect your hearing. Regular users should have hear

ing checked regularly as chain saw noise can dam

age hearing.

Keep children, bystanders, and animals a

2.

minimum of 30 feet (10 Meters) away from the

work area. Do not allow other people or animals

to be neeu: the chain saw when starting or operating

the chain saw.

Do not handle or operate a chain saw when

3.

you are fatigued, ill, or upset, or if you have

taken alcohol, drugs, or medication. You must

be in good physical condition and mentally alert.

Chain saw work is strenuous. Ifyou have any condi

tion that might be aggravated by strenuous work,

check with your doctor before operating a chain

saw.

4. Do not attempt to use your chain saw during

bad weather conditions such as strong wind, rain,

snow, ice, etc., or at night.

5. Carefully plan your sawing operation in ad

vance, Do not start cutting until you have a clear

work area, secme footing, and, if you are felling

trees, a planned retreat path.

AVOID REACTIVE FORCES

Pinch-Kickback and Pull-In occur when the

chain is suddenly stopped by being pinched,

caught, or by contacting a foreign object in the

wood. This sudden stopping of the chain results in a re

versal of the chain force used to cut wood and causes the

saw to move in the opposite direction of the chain rotation.

Pinch-Kickback drives the saw straight back toward

the operator. Pull-In pulls the saw away from the opera

tor. Either reaction can result in loss of control and possi

bly serious injury.

To avoid Pinch-Kickback:

1. Be extremely aware of situations or obstruc

tions that can cause material to pinch the top of or

otherwise stop the chain.

2. Do not cut more than one log at a time.

3. Do not twist the saw as the bar is withdrawn from

an under-cut when bucking.

To avoid Pull-Ih:

1. Always begin cutting with the engine at full

throttle and the saw housing agai^t wood.

2. Use wedges made of plastic or wood, (never of

metal) to hold the cut open.

HANDLE FUEL WITH CAUTION

1. Eliminate all sources of sparks or flame in the

areas where fuel is mixed, poured, or stored.

There should be no smoking, open flames, or work

that could cause sparks.

2. Mix nnH pour fuel in an outdoor area on bare

ground; store fuel in a cool, dry, well ventilated

place; and use an approved, marked container for

all fuel purposes.

3. Wipe up all fuel spills before starting saw.

4. Move at least 10 feet (3 meters) from the fuel

ing site before starting the engine.

5. Do not smoke while handling fuel or while

operating the saw.

6. Turn the engine off and let your saw cool in a

non-combustible area, not on dry leaves, straw,

paper, etc. Slowly remove fuel cap and refuel unit.

7. Store the unit and fuel in an area where fuel vapors

cannot reach sparks or open flames from water

heaters, electric motors or switches, furnaces, etc.

if situations occur which are not covered in this manual, use care and good judgment.

Contact your Service Dealer ifyou need assistance.

WARNINGS AND SAFETY INSTRUCTIONS (continued)

OPERATE YOUK SAW SAFELY

1. Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and.

securely assembled.

2. Operate the chain saw only in outdoor areas.

3. Do not operate saw from a ladder or in a tree.

4. Position all parts of your body to the left of

the cut and away from the saw chain when

the engine is running.

5. Cut wood only, Do not cut metai, plastics, mason

ry, non—wood building materials, etc. Do not use

the saw to pry or shove away limbs, roots, or other

objects.

6. Make sure the chain will not make contact

with any object while starting the engine. Never

try to start the saw when guide bar is in a cut or kerf.

7. Use extreme caution when cutting small size

brush and saplings. Slender material can catch

the saw chain and be whipped toward you or pull

you off balance.

8. Be alert for springbuck when cutting a limb that

is under tension so you will not be struck by the

limb or saw when tension in the wood fibers is re

leased.

9. Do not put pressure on the saw at the end of a

cut. Applying pressure can cause you to lose con

trol when the cut is completed.

10. Stop the engine before setting the saw down.

11. Engage the chain brake when engine is run

ning but not involved in a cutting procedure.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

1. Have all chain saw service performed by a qu-

. alified service dealer with the exception of the

items listed in the maintenance section of this man

ual. For example, if improper tools are used to re

move or hold the flywheel when servicing the

clutch, structural damage to the fl5rwheel can occur

and cause the flywheel to burst.

2. Keep fuel and oil caps, screws, and fasteners

securely tightened.

3. Keep the handles dry, clean, and free of oil or

fuel mixture.

4. Make certain the saw chain stops moving

when the throttle trigger is released. For cor

rection, refer to the "Trouble Shooting Chart,”

' 5. Stop the saw if chain strikes a foreign object.

Inspect unit and repair or replace parts as neces

sary,

6. Disconnect spark plug before performing

any maintenance except for carburetor adjust

ments.

7. Never modify your saw in any way. Use only at

tachments supplied or specifically recommended by

the manufacturer.

8. Always replace the chain brake immediately

if it becomes damaged, broken, or is other

wise removed.

9. Keep the vibration isolators in good condi

tion. Periodically inspect isolators for tears, rips,

or separation of the mbber portion from the metal

mountings. Have a qualified service de^er replace

the isolators if worn or damaged, if vibration in

creases, or if mounts develop an out of round or

swollen shape from exposure to gasoline and/or oil.

CARRY AND STORE YOUR SAW SAFELY

1. Hand carry your saw with the engine

stopped, the muffler away from your body,

and the guide bar and chain to the rear cov

ered preferably with a scabbard.

2. Before transporting in any vehicle or storing

in any enclosure, ¿low your saw to cool com

pletely, cover the bar and chain, and properly secure

to avoid turnover, fuel spillage, or damage.

3. Empty the fuel tank before storing the tool.

Use up the fuel left in the carburetor by starting the

engine and letting the engine run until it stops.

4. Store unit and fuel in a dry area out of the

reach of children. Do not store where fuel vapors

can: reach sparks or an open flame from hot water

heaters, electric motors or switches, furnaces, etc.

NOTICE: Refer to the Code of Federal Regulations,

Section 1910.266(5); 2.5.1 of American National

Standard Safety Requirements for Pulpwood Log

ging, ANSI 03.1-1978; and relevant state safety

codes when using a chain saw for logging purposes.

A WARNING

The following features are available for your saw

(in models equipped with 16”, 20”, and 24” 0.050

gauge bars) to help reduce the hazard of kickback; however, such features will not totally elim

inate this dangerous reaction. As a cham saw

user, do not rely only on safety devices. You most

follow all safety precautions, instructions, and

maintenance in this manual to help avoid kickback and other forces which can result in serious

injury.

_________________________

KICKBACK SAFETY FEATURES

• Position of front and rear handlebars, de

signed with distance between handles and "in line”

with each other. The spread and *ni Une” position

of the hands provided by this design work together

to give balance and resistance in oontroUmg the

pivot of the saw back toward the operator if kickback occurs.

• Chain Brake, if activated during kickback, is a de

vice to stop the chain. Do not rely on the chain

brake to protect you against injujy from kickback.

Although it may appear the chain is stopping quick

ly, it stdl may not be fast enough to provide protec

tion in the event of kickback.

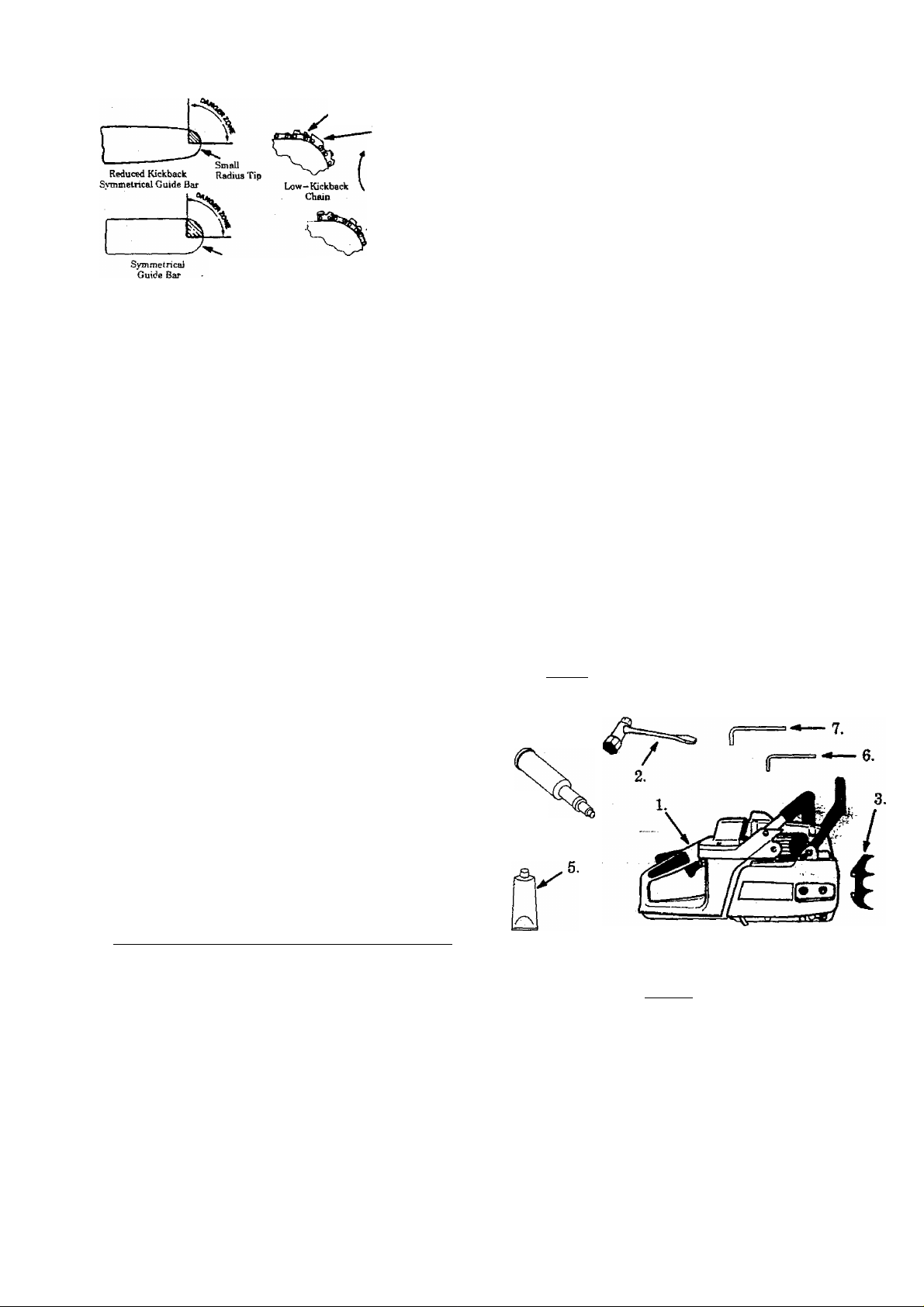

• Optional Reduced—Kickback Guide Bar, de

signed with a small radius tip which reduces the size

of the kickback danger zone on the bar tip. Fig

ure 5 . A reduced—kickback guide bar has been

demonstrated to reduce the hazard of kickback.

• Optional Low-Kickback Chain, designed vrith

a contoured depth gauge and elongated guard Unk

which allows wood to gradually ride into the cutter.

Figures. Low-Kickback Chain has been demon

strated to reduce kickback significantly.

Con touted

Depth Gauge

Elongated

Guard Link

Dedecta

Kickbadc Force

And Allows Wood

To Gradually

Ride Into Cutter

Can Obstruct

Large

Radius Tip

Chain With High

Kickback Potential

Material

Figure 5

A WARNING

Do not operate the saw unless the safety devices

or their specified replacements are properly in

stalled and maintained according to the instruc

tions in this manual. Do not use any guide bar and

chain combination that is not equivalent to the

original or optional equipment. Failure to follow

these instructions can result in serious injury.

KNOW YOUR UNIT

SAVE THESE INSTRUCTIONS

STATE AND LOCAL REQUIREMENTS

For users on U.S. Forest Land and in some states, in

cluding Califomia(Public Resources Codes 4442

and 4443), Idaho, Maine, Minnesota, New Jersey,

Oregon, and Washington: Certain internal combus

tion engines operated on forest, brush, and/or grass—cov

ered lands, in the above areas, must be equipped with a

spark arrestor, maintained in effective working order, or

the engine must be constructed, equipped, and main

tained for the prevention of fire. Check with your state or

local authorities for regulations pertaining to these re

quirements. Failure to follow these requirements is a vio

lation of the law. This unit is factory-equipped with

a spark arrestor. If a spark arrestor is required in your

area, you are legally responsible for maintaining the oper

ating condition of these parts.

A. INTRODUCTION

Your saw has been designed with safety in mind and

includes the following safety features as standard

equipment: >

• Chain Brake

• Spark Arrestor

• Temperature Limiting Muffler

B.

UNPACKING INSTRUCTIONS

1. After removing the contents from the carton,

check parts against the Carton Contents Ust.

2.

Examine the parts for damage. Do not use dam

aged parts.

Notify your POULAN PRO^ dealer immedi

3.

ately if a part is missing or damaged.

• Throttle Lock-Out

• Anti- vibration System

• Chain Catcher Pin

NOTE: It is normal to hear the fuel filter rattle in

an empty fuel tank.

C. CARTON CONTENTS

KEY

NO.

1.

Powerhead

Bar Wrench

2.

3. Bucking Spike 1

4. Grease Gun

5.

Grease

Hex Wrench (4 mm)

6.

Hex Wrench (5 mm)

7.

•

Tool Bag

•

Operator's Manual (not shown)

QTY

1

1

/

4.

1

1

1

1

1

1

A WARNING

The effectiveness of a chain brake in reducing operator injuries has not yet been fully determined. We

cannot represent that a chain brake is an effective safety device to prevent or reduce the hazard of inju

ries resulting from kickback, DO NOT AS SUME THAT THE CHAIN BRAKE WILL PROTECT YOU IN THE

EVENT OF A KICKBACK. Instead use the saw properly and carefully to avoid kickback. Reduced—Kick-

back bars and Low—Kickback chains reduce the hazard of kickback and are recommended. Repairs on a

chain brake should be made by an Authorized POULAN PRO Service Dealer, Take your unit to the place of

purchase if purchased from a Servicing Dealer, or to the nearest Authorized Master Service Dealer.

SAFETY NOTICE

Exposure to vibrations through prolonged use of gasoline powered hand tools could cause blood vessel or

nerve damage in the fingers, hands, and wrists of people prone to circulation disorders or abnormal swel

lings. Prolonged use in cold weather has been linked to blood vessel damage in otherwise healthy pemiie.

If symptoms occur such as numbness, pain, loss of strength, change in skin color or texture, or loss of feel

ing in the fingers, hands, or wrists, discontinue the use of this tool and seek medical attention- An anti—vi

bration system does not guarantee the avoidance of these problems. Users who operate power tools on a

continual and regular basis must monitor closely their physical condition and the condition of this tool.

PREPARING YOUR SAW FOR USE

A. GETTING READY

1. READ YOUR OPERATOR’S MANUAL CAREFULLY

Your Operator’s Manued has been developed to help you prepare your saw for use and to understand its safe oper

ation. It is important that you read your manual completely to become familiar with the unit before you begin

assembly or attempt operation. Your POULAN PRO dealer is available to show you how to operate your saw. Be

sure to ask for his assistance.

2. HAVE THE FOLLOWING AVAILABLE:

a. Protective gloves

b. Approved, marked fuel container

c. One gallon regular unleaded gasoline

d. 3.2 oz. 2 cycle, air-cooled engine oil (See the

“Fueling Your Engine” section.)

B. ATTACHING THE SPUR

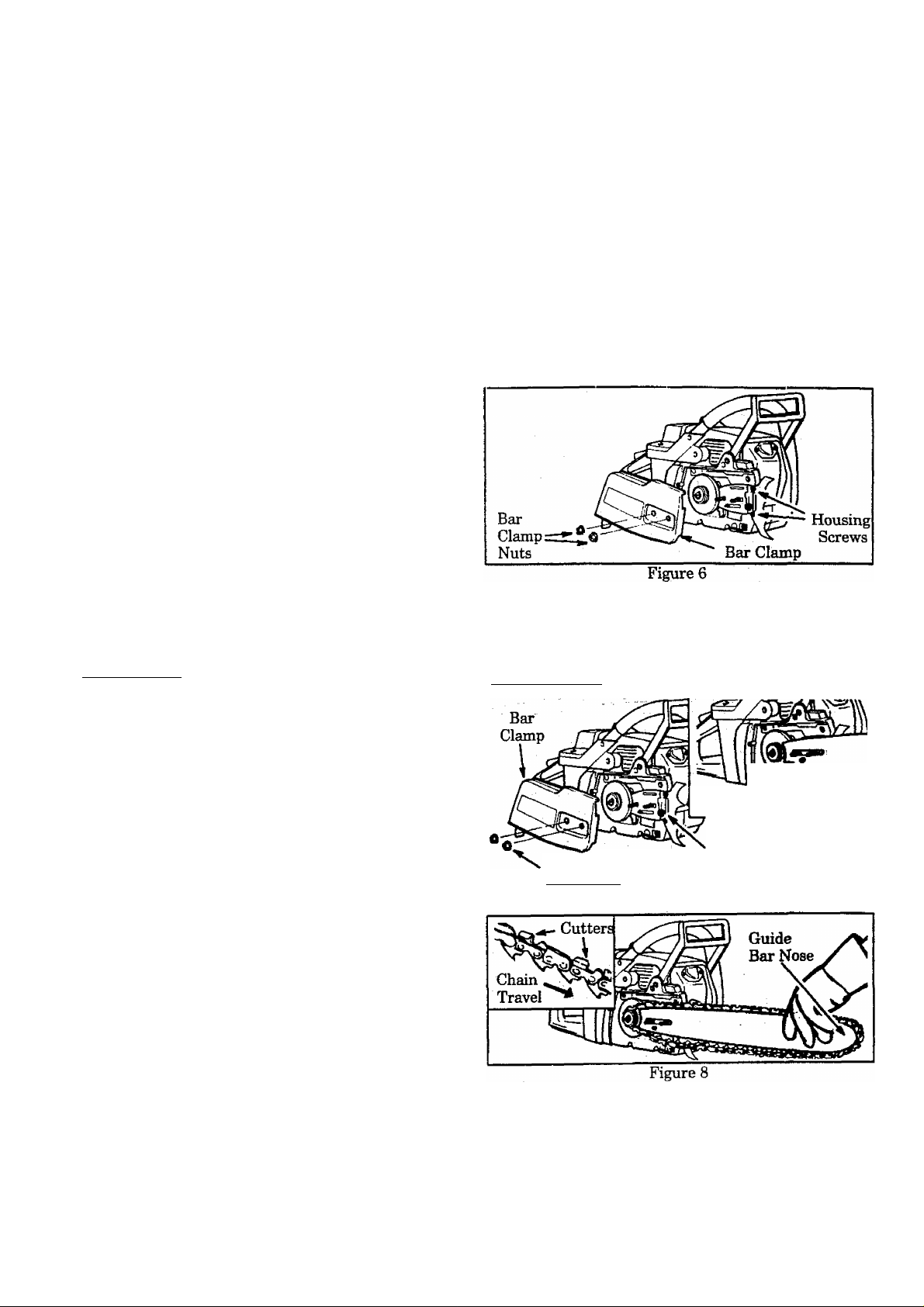

1. Set saw upright on a flat surface. Figure 6 .

2. Remove bar damp nuts and bar clamp using the

bar wrench provided with the unit. Figure 6 .

3. Remove the two housing screws shown in Fig

ure 6.

4. Align screw holes in the spur with the screw holes

on the crankcase. Figure 6 .

5. Install the housing screws removed in step 3.

Tighten evenly and securely.

C. ATTACHING THE BAÈ AND CHAIN

• See your POULAN PRO Dealer for the vari

ous bars and chains available for your tmit.

I CAUTION: I Wear protective gloves when

handling or operating your saw. The chain is

sharp and can cut you even when it is not movingl

1. Set the saw upright on a flat surface. Figure 7 .

2. Turn the adjustini^ screw counterclockwise with a

standard screwdriver to move the adjusting pin

almost as far as it will go to the rear. Figure 7 .

3. Mount the guide bar with the slotted end over the

mounting bolts and the small adjusting pin

through the small hole in the bar. Figure 7 (inset).

4. Slide the guide bar toward the rear of the saw as

far as possible.

5. Hold tne chain with the cutters facing as shown in

Figure 8 (inset).

V 6. Place the chain on the sprocket. Fit the bottom of

the drive links in the slots in the sprocket.

7. Fit the bottom of the chain drive links into the

groove on top of the guide bar, then around the

guide bar nose. Figure 8 .

8. Turn the adjusting screw clockwise with a stan

dard screw(h*iver until the chain is snug in the

guide bar groove.

9. Hold the guide bar against the saw frame and

install the bar clamp.

10. Replace the bar mounting nuts. Tighten finger

tight only.

11. Follow “Chain Tension” instructions.

Bar and Chain Oil (See the “Bar and Chain

e.

Oil” section.)

Bar Wrench

Standard Screwdriver

g-

Allen Wrench (hex)

h.

A WARNING

Do not start engine without the guide bar, chain,

and bar clamp completely assembled. Other

wise, the chain and clutch can come off resulting

in serious injury-

Bar

Clamp Nuts

________

Figure 7

_____________________

Adjusting Pin

Turn Adjusting

Screw Counterclockwise

________

-7-

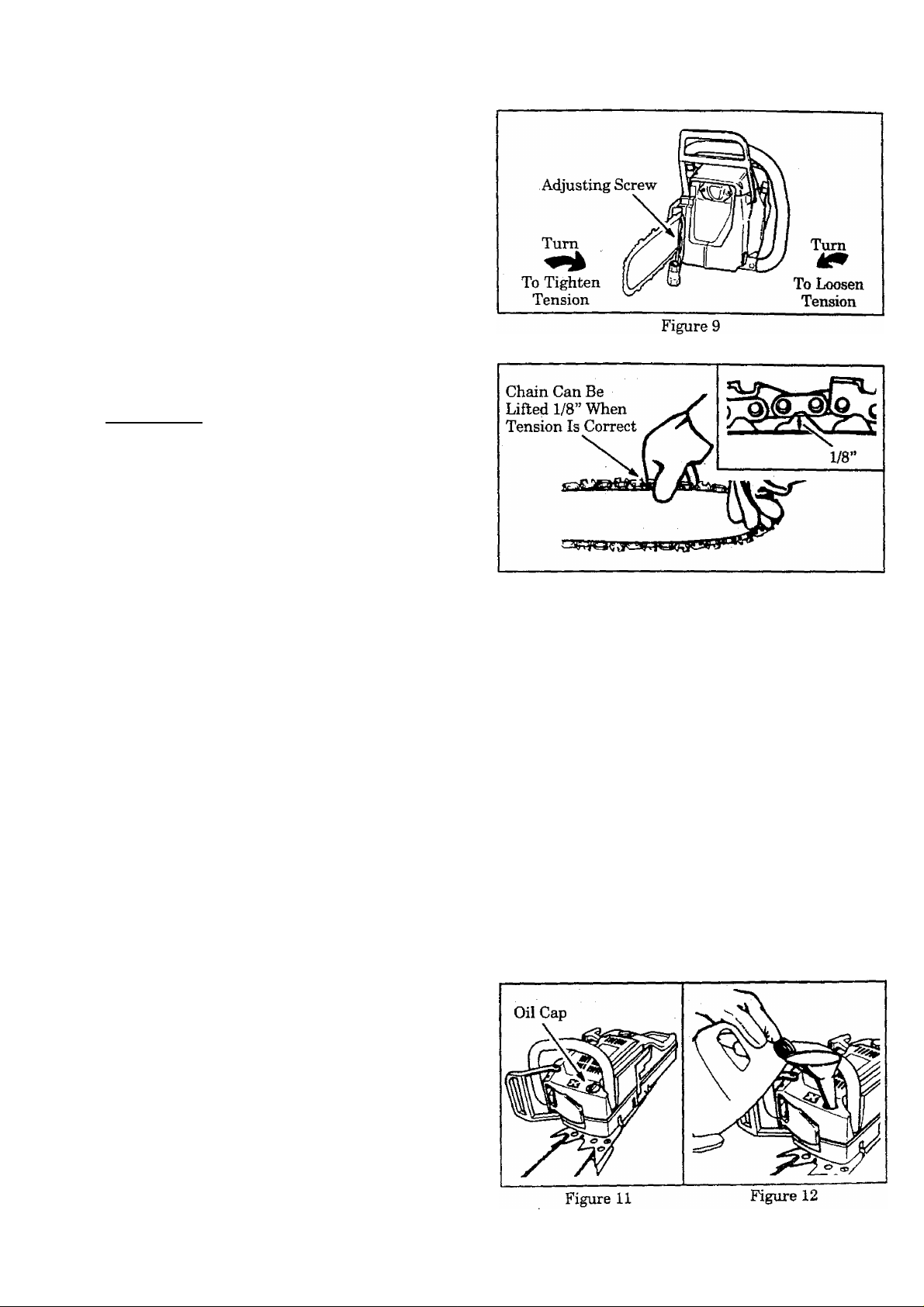

D. CHAIN TENSION

• Chain Tension is very important—

— A loose chain will wear the bar and itself.

— A loose chain can jump off bar during cutting.

~ A tight chain can break or damage the saw and/

or bar.

• The chain stretches during use, especially

when new. Check tension periodically as follows;

— each time the saw is used;

— more frequently when the chain is new;

— as the chain warms up to normal operating

temperature.

• Chain tension is correct when the chain can

be lifted about 1/8” from the Guide Bar at a point

near the middle of the bar and will move freely

around the bar.

Chain tensioning procedure:

CAUTION; I Always wear gloves when handl

ing the chain. The chain is sharp and can

cut you even when it is not moving!

1.

Lift up the tip of the guide bar and turn the adjust

ing screw clockwise until the chain does not sag

beneath the guide bar. Figure 9 .

Check the tension by lifting the chain from the

guide bar at the center of the bar. Figure 10 .

Continue adjusting the adjusting screw until the

tension is correct.

Tighten the bar clamp nuts ydth the bar wrench.

Recheck chain tension.

Figure 10

E. BAR AND CHAIN OIL

• The guide bar and cutting chain require

continuous lubrication to remain in operat

ing condition. Lubrication is provided by the

automatic oiler system when oil tank is kept filled.

- Lack of oil will quickly ruin bar and chain.

- Too little oil will cause overheating, result

ing in smoke coming from the chain and/or dis

coloration of the guide bar rails.

• Genuine POUIAN/POULAN PRO Bar and

Chain Oil is recommended to protect your

unit against excessive wear from heat and

friction, POULAN/POUIAN PRO oil resists

high temperature thinning. If POULAN/

POULAN PRO Bar and Chain Oil is not available,

use a good grade SAE 30 oil. Never use waste oil

for bar and chain lubrication.

• In freezing weather oil will thicken, making

it necessary to thin bar and chain oil with a

small amount of Diesel Fuel #1 or kerosene.

Bar ^d chain oil must be fi-ee flowing for oil sys

tem to pump enough oil for adequate lubrication.

USE THE FOLLOWING:

1.

30° or above — 100% lubricant - undiluted.

30°-0°F - 95% lubricant to 5% Diesel Fuel #1 or

kerosene

Below 0°F — 90% lubricant to 10% Diesel Fuel #1

or kerosene.

HOW TO FILL THE OIL TANK

2.

a. Stop the engine.

b. Turn saw on its side, oil cap up. Figure 11.

c. Loosen cap slowly and wait for pressure in the

tank to be released before removing the cap.

d. Fill the oil tank. Figure 12 .

e. Replace the oil cap securely.

-8-

3. IMPORTANT POINTS TO REMEMBER

Fill oil tank each time you fill fuel tank to

a.

ensure that there will be sufficient o0 for the

chain whenever you start and run the saw.

The saw will normally use about one tank

b.

of chain oil for each tank of fuel mixture.

If less oil is used, check for a plugged oil hole in

the guide bar.

Keep sawdust and debris cleaned from

c.

the oil holes in the guide bar to allow an ad

equate oil flow to the bar and chain.

Keep spilled and spattered oil wiped

d.

from the unit to avoid sawdust and de

bris build-up. Pay particular attention to

oil on the fan housing and starter assembly to

avoid overheating the en^e.

It is normal for a small amount of oil to

e.

appear under the saw ^ier the engine

stops. This is excess oil drainingfrom the bar

and chain when the saw is not in use.

Loading...

Loading...