Page 1

'vJ It/

3400 Counter-Ylbe

CHAINSAW

OPERATOR’S MANUAL

Carefully read and follow

Safety Rules, Precautions

and Operating Instruc

tions. Failure to do so can

result in serious personal

injury.

AwARNING:!

Beaird-Poulan Division

Emerson Electric Co.

Shreveport, Louisiana

Page 2

TABLE OF CONTENTS

Specifications ..

SPECIAL SAFETY SECTiON....

Know Your Chain Saw

Preparing Your Saw For Use

A. Getting Ready.......................................................'.____

B. Attaching The Spur

C. Attaching The Bar and Chain

D. Chain Tension....................................................................8

E. Engine Fuel Mixture

F. Bar and Chain Oil

Using Your Saw

A. Control Devices ’.

B. Starting Instructions ......................................................11

Types of Cutting

A. Basic Cutting Technique

REDUCED-KICKBACK GUIDE BAR

...............................................

.................... ЛЛ&5

...

..................................^_ __

...............................................

.................................

...........................................

.........................................................

..........................................................

................................

.....

...................................................... 10

.................................

.................................

:.. ^

...................10

.......................11

................... 7

;.............11

. 2

10

B. Tree Felling Techniques

C. Bucking.....................»....

6

7

7

7

9

D. Debranching and Pruning

Maintenance ........................................................

A. Guide Bar and Chain 16

B. Ignition and Exhaust SystemsC. Starter Rope Repair and Replacement

D. Clutch and Drum/Sprocket

E. Carburetor Adjustments

F. Air Filter .

G. Counter-Vibe® Anti-Vibration System

H. Storage .......................................................................... 21

I. Trouble Shooting Chart

J. Maintenance Chart

...

.....................................................................

.....

......................................... 12

...........

...................................

........................................14

15

......................................

........................

............................................

................................................

.........................

.................................................22

..........................................................

13

17

18.

19

20

21

21

23

Parts List..................................................................24

Parts & Service.................................................... Back Cover

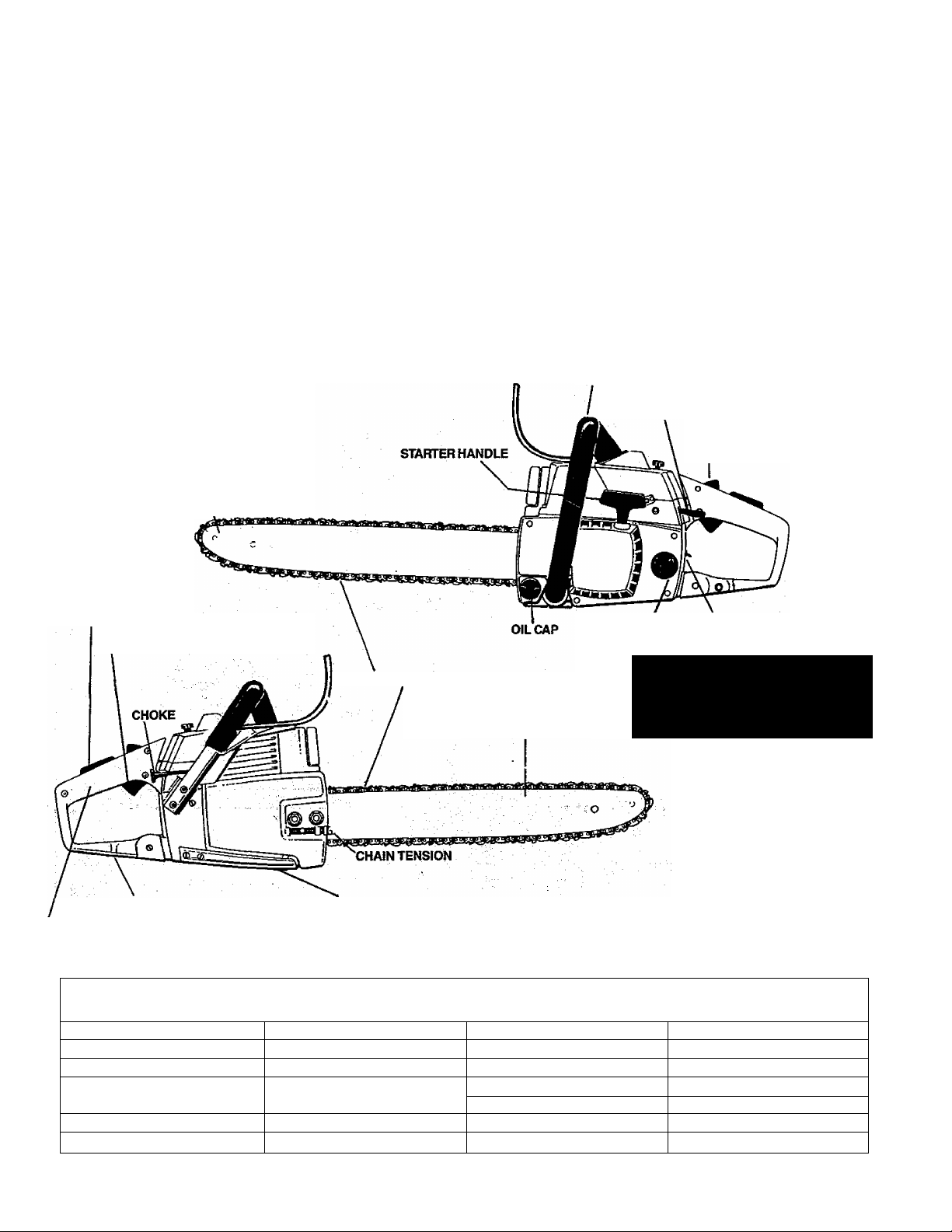

HANDLEBAR

MANUAL OILER

THROTTLE DETENT

THROTTLE LOCKOUT

THROTTLETRIGGER

LOW-KICKBACK CHAIN

REAR CHAIN GUARD

CONTROLHANDLE

FRONT CHAIN CATCHER

■■■ SPlQIFliATIONS "■

MODEL

CU.IN. DISPLACEMENT 3.4cu.in./56 cu.cm.

GUIDE BAR—SPROCKET NOSE 16M 8", 20" Control Tip ^

GUARD LINK CHAIN

SPARK PLUG

SPARK PLUG GAP

3400 Counter Vibe *' IGNITION

3/8 Pitch .050 Gauge

Chrome Cutters - P72S

Champion CJ-8Y

,023 to .027

REDUCED-KICKBACK

GUIDE BAR

MODULE AIR GAP

FUEL MIX

MUFFLER

OILER SYSTEM

FUELTANKCAPACITY

OILTANKCAPACITY

FUEL CAP START-STOP SWITCH

Read

SPECIAL SAFETY SECTION

FREQUENTLY

Solid Stale

.008 to .014

Gasoline/Oii Mixture (see p. 9)

Spark Arresting/Temperature Limiting

Automatic/Manual Override

19 oz. 562 cu.cm.

12oz. 355 cu.cm.

Page 3

SPECIAL SAFETY SECTION

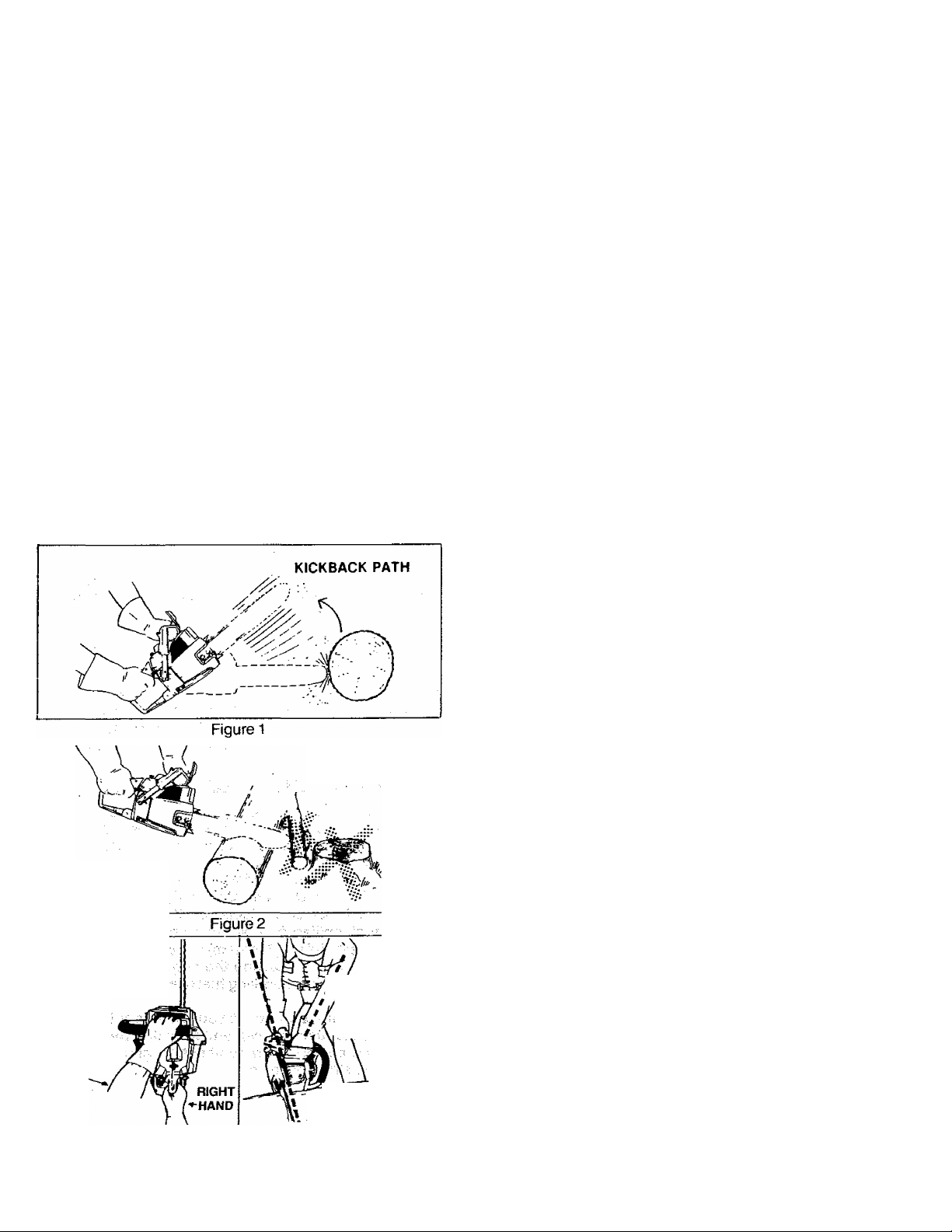

GUARD AGAINST KICKBACK

Kickback is a dangerous reaction that can lead to serious

personal injury. Do not rely only on the sdfety devices

provided with your saw. As a chain saw user, you must

take special safety precautions to help keep your cutting

Jobs free from accident or injury.

! KICKBACK WARNJNG

Kickback can occur when the moving chain contacts

an object atthe upper portion of the tip of the guide bar

or when the wood closes in and pinches the saw chain

\nthecui.Contactattheupperportionofthetipofthe

guidebarcan cause the chain to dig into the object and

stop the chain for an instant. The result is aiightning

fast, reverse reaction which kickstheguidebarupand

back toward the operator, if the saw chain is pinched

aiong the top of the guide bar, the guide bar can be

driven rapidiy back toward the operator. Either of

these reactions can cause loss of saw control which

can resuit in serious personai injury.

REDUCE THE CHANCE OF KICKBACK

Recognize that kickback.can happen. With a

1

basic understanding of kickback, you can reduce

the element of surprise which contributes to

accidents.

Never let the moving chain contact any object atthe

2.

tip of the guide bar. Figure 1.

3.

Keep the working area free from obstructions

such as other trees, branches, rocks, fences,

stumps, etc. Figure 2. Eliminate or avoid any

obstruction that your saw chain could hit while you

are cutting through a particular log or branch.

4.

Keep your saw chain sharp and pipperly ten

sioned. Follow manufacturer’s chain sharpening and

maintenance instructions. Check tension at regular

intervals with the engine stopped, never with the engine

running. Make sure the bar clamp nuts are securely

tightened after tensioning the chain. A loose or dull

chain can increase the chance of kickback to occur.

5.

Begin and continue cutting at full throttle. If the

chain Is moving at a slower speed, there is greater

chance for kickback to occur.

6.

Cut one log at a time.

7.

Use extreme caution when re-entering a previous

cut.

8.

Do not attempt plunge cuts.

9.

Watch for shifting logs dr other forces that could

close a cut and pinch or fall into the chain.

10.

Use the Reduced-Kickback Guide Bar and LowKickback Chain specified for your saw.

CLEAR

WORKING AREA

NEVER

REVERSE

HAND

POSITIONS

LEFT HAND

Figure 3

AVOID

OBSTRUCTIONS

STAND

TO THE

f* / LEFT OF

V A THE SAW

ELBOW

LOCKED

THUMB ON

UNDER SIDE

OF HANDLEBAR

MAINTAIN CONTROL

Keep a good firm grip on the saw with both hands

1

when the engine is running and don’t let go.

Figure 3. A firm grip can neutralize kickback and

help you maintain control of the .saw. Keep the

fingers of your left hand encircling and your left

thumb under the front handlebar. Keep your right

hand completely around the rear handle whefher

you are right handed or left handed. Keep your left

arm straight with the elbow locked.

is in a straight line with your right hand on the rear

handle when making bucking cuts. Figures. Never

reverse right and left hand positions for any typei of

cutting.

3.

stand with your weight evenly balanced on

both feet.

4.

Stand slightly to the left side of thè saw, to keep

your body from being in a direct line with the

cutting chain. Figures.

5.

Do not overreach. You could be drawn or thrown

off balance and lose control of the saw.

6.

Do not cut above shoulder height. It is difficult to

maintain control of the saw above shoulder height.

Page 4

SPECIAL SAFETY SECTION (continued)

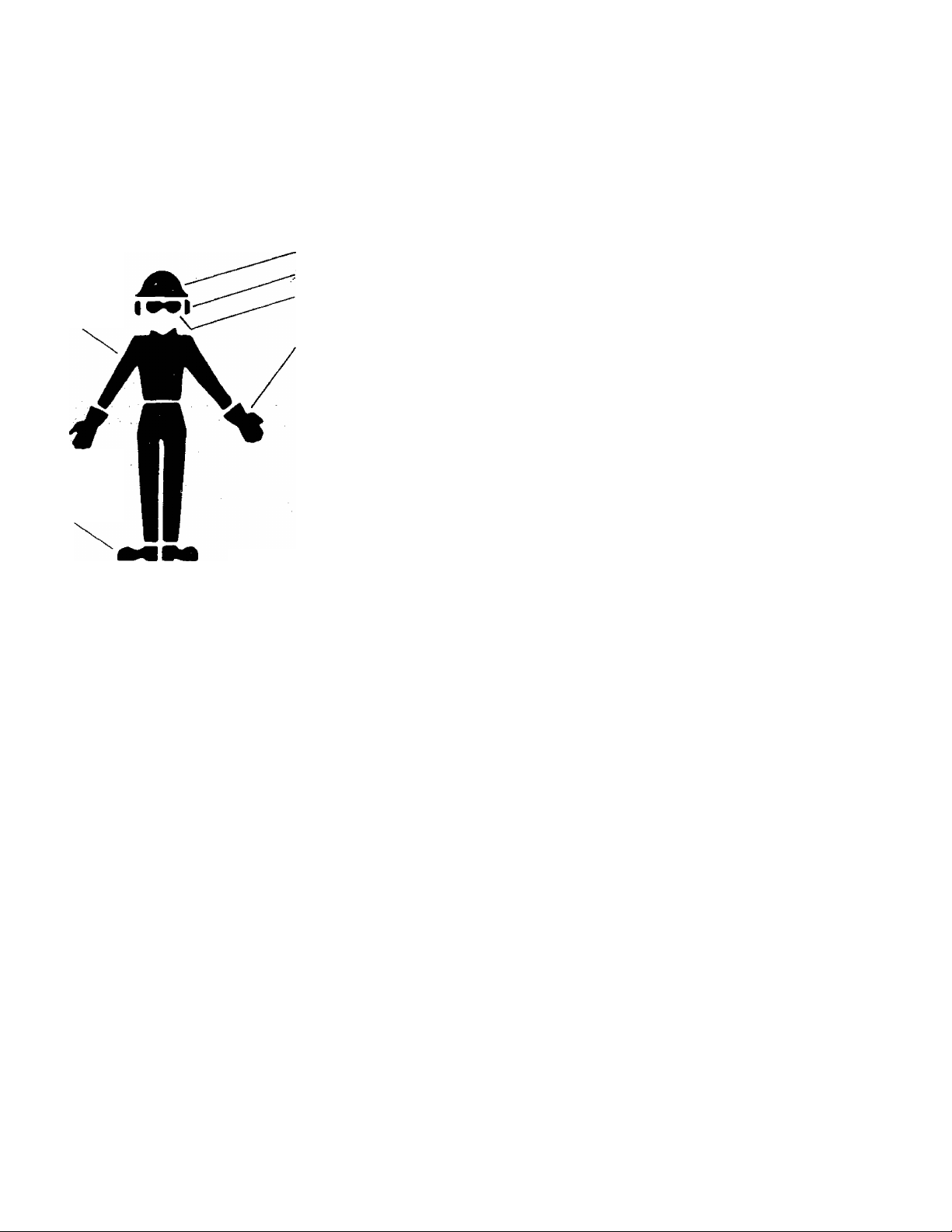

I. WARNING

Because a chain saw is a high-speed wood-cutting tooi, special safety precautions must

be observed to reduce the risK of personal accidents. Careless or improper use can

cause serious personal injury.

SAFETY HAT

SNUG

FITTING

CLOTHING

SAFETY

SHOES

HEARING PROTECTION

EYE PROTECTION

HEAVY DUTY GLOVES

Figure 4

KNOW YOUR SAW

1. Read your Operator’s Manual carefully until you com

pletely understand and can follow ail safety rules and

operating instructions before attempting to operate the

unit.

2. Restrict the use of your saw to adult users who under

stand and follow the safety rules, precautions, and

operating Instructions found In this manual.

PLAN AHEAD

1. Wear personal protective gear. Figure 4. Always use

steel-toed safety footwear with non-slip soles; snug-fitting

clothing: heavy-duty non-slip gloves; eye protection such

, non-fogging, vented goggles or face screen; an ap^ proved safety hard hat, and sound boners—ear plugs or

mufflers to protect your hearing. Regular users should

have hearing checked regularly as chain saw noise can

damage hearing.

2. Keep children, bystanders, and animals out of the

work area—a minimum of 30 feet (10 meters). Do not

allow othejr people or animals to be near the chain saw

when starting or operating the chain saw.

3. Do not handle or operate a chain saw when you are

fatigued, ill, or upset; or if you have taken alcohol,

drugs or medication. You must be in good physical

condition and mentally alert. Chain saw work is

strenuous. If you have any condition that might be

aggravated by strenuous work, check with your doctor

before operating a chain saw.

4.

Do not attempt to use your chain saw during bad

weather conditions such as strong wind, rain, snow,

etc., or at night.

5.

Plan yoursawing operation carefully in advance. Do

not start cutting until you have a clear work area, secure

footing, and if you are felling trees, a planned retreat path.

AVOID REACTIVE FORCES

Pinch-Kickback and Pull-in occur when the chain is

suddenly stopped by being pinched, caught, or by

contacting a foreign object in the wood. This results in a

reversal of the chain force used to cut wood and causes the saw

to move in the opposite direction of chain rotation. Pinch-

Kickback drives the saw straight back toward the operator.

Pufl-ln pulls the saw away from the operator. Either reactions

can result in loss of control and possible serious person^ Injury.

To avoid Pinch-Kickback:

1. Be extremely aware of situations or obstructions

that can cause material to pinch the top of or other

wise stop the chain.

2. Do not cut more than one log at a time.

3. Do not twist the saw as the bar is withdrawn from an

under-cut when bucking.

To avoid Pull-in:

1. Always begin cutting with the engine at full throttle

and the saw frame or spur against the wood.

2. Use wedges made of plastic or wood, (never of metal)

. to hold the cut open.

HANDLE FUEL WITH CAUTION

1.

Eliminate all sources of sparks or flame in the areas

where fuel is mixed, poured, or stored. There should

be no smoking, open flames, or work that could cause

sparks.

Mix and pour fuel in an outdoor area, on bare ground;

2.

store fuel in a cool, dry, well-ventilated place; and use

an approved, marked container for ail fuel purposes.

3.

Wipe up all spilled fuel before starting your saw.

4.

Move at least 10 feet (3 meters) away from fuel and

fueling site before starting the engine.

5.

Do not smol№ while handling fuel or while operating

the saw.

6.

Turn the engine off and let your saw cool before

removing the fuel tank cap and refueling the unit.

7.

Let the saw cool in a non-combustible area, not on

dry leaves, straw, paper; etc.

Page 5

OPERATE YOUR SAW SAFELY

1. Do not operate a chain saw that is damaged, im

properly adjusted, or not completely and securely

assembled.

2. Operate the chain saw only in outdoor areas.

3. Do not operate the saw from a ladder or in a tree.

4. Position all parts of your body to the left of cut and

away from the saw chain when the engine is

running.

5. Cut wood only. Do not use your saw to pry or shove

away limbs, roots or other objects.

6. Make sure the chain will not make contact with any ob

ject while starting the engine. Never try to start the saw

when the guide bar is in a cut or kerf.

7. Use extreme caution when cutting small size briish

and saplings. Slender material can catch the saw

chain and be whipped toward you or pu!| you off

balance.

8. Be alert for springback when cutting a limb that is

under tension so you will not be struck by the limb or

saw when the tension in the wood fibers Is released.

9. Do not put pressure on the saw at the end of a cut.

This can cause you to lose control when the cut is

completed.

10. Stop the engine before setting the saw down.

MAINTAIN YOUR SAW IN GOOD WORKING ORDER

1. Have all chain saw service performed by a qualified

service dealer with the exception of the items listed

in the maintenance section of this manual. For

example, if improper tools are used to remove or hold

the flywheel when servicing the clutch, structural

damage to the flywheel can occur and cause the

flywheel to burst.

2. Keep fuel and oil caps, screws and fasteners

securely tightened.

3. Keep the handles dry, clean, and free of oil or fuel

mixture.

4. Make certain the saw chain stops moving when the

throttle trigger is released. For correction, refer to

page 20 fo> carburetor idle adjustment instructions.

5. Stop the saw if the chain strikes a foreign object. In

spect the unit and repair or replace parts as necessary.

6. Disconnect the spark plug before performing any

maintenance except for carburetor adjustments.

7. Never modify your saw in any way. Use only attach

ments supplied or specifically recommended by the

manufacturer.

8. Always replace the handguard immediately if it

becomes damaged, or broken or is otherwise

removed.

CARRY AND STORE YOUR SAW SAFELY

1. Hand carry the unit with the^engine stopped, the

Muffler away from your body, and the Guide Bar and.

Chain to the rear covered preferably with a scabbard.

2. Before transporting in any vehicle or storing in any

enclosure, allow your saw to cool completely, cover

the bar and chain and properly secure to avoid

turnover, fuel spillage or damage.

3. Drain oil and fuel tank before storing for more than

30 days.

4. Store in a dry area out of the reach of children and

away from where fuel vapors can reach sparks or an

open flame from hot water heaters, furnaces, etc.

NOTE: Exposure to vibrations through prolonged use of

chain saws may produce Whitefinger disease

(Raynaud’s phenomenon). This phenomenon

reduces the hand’s ability to feel and regulate

temperature, produces numbness and burning

sensations and can cause nerve and circulation

damage and tissue necrosis.

An anti-vibration system designed to reduce

engine vibration is recommended for those using

chain saws on a regular or sustained basis. An antivibration system does not guarantee the

avoidance of Whitefinger disease. Continual and

regular users must monitor closely their use of

chain saws and physical condition.

Notice: Refer to the Code of Federal Regulations, Section

1910.266(5); 2.5.1 of American National Standard

Safety Requirements for Puipwood Logging, ANSI

03.1-1978; and relevant state safety codes when

using a chain saw for logging purposes.

SAVE THESE INSTRUCTIONS

Page 6

KNOW YOUR CHAIN SAW

A. INTRODUCTION ^

• Your saw has been designed with safety in mjnd and

includes the following features as standard equipment:

-Reduced-Kickback Guide Bar (Contfol Tip®)

— Low-Kickback Chain (ElongatedGuard Link)

— Spark Arrestor

—Temperature Limiting Muffler

— Handguards

—Temperature Limiting Mufflei'

-Counter-Vibe® Anti-Vibration System

A WARNING

The following features are included on your saw to help

reduce the hazard of kickback, however, such features

will not totally eliminate this dangerous reaction. As a

chain saw user, do not rely only on safety devices. You

must follow all safety precautions, Instructions and

maintenance in this manual to help avoid kickback and

other forces which can result in serious personal injury.

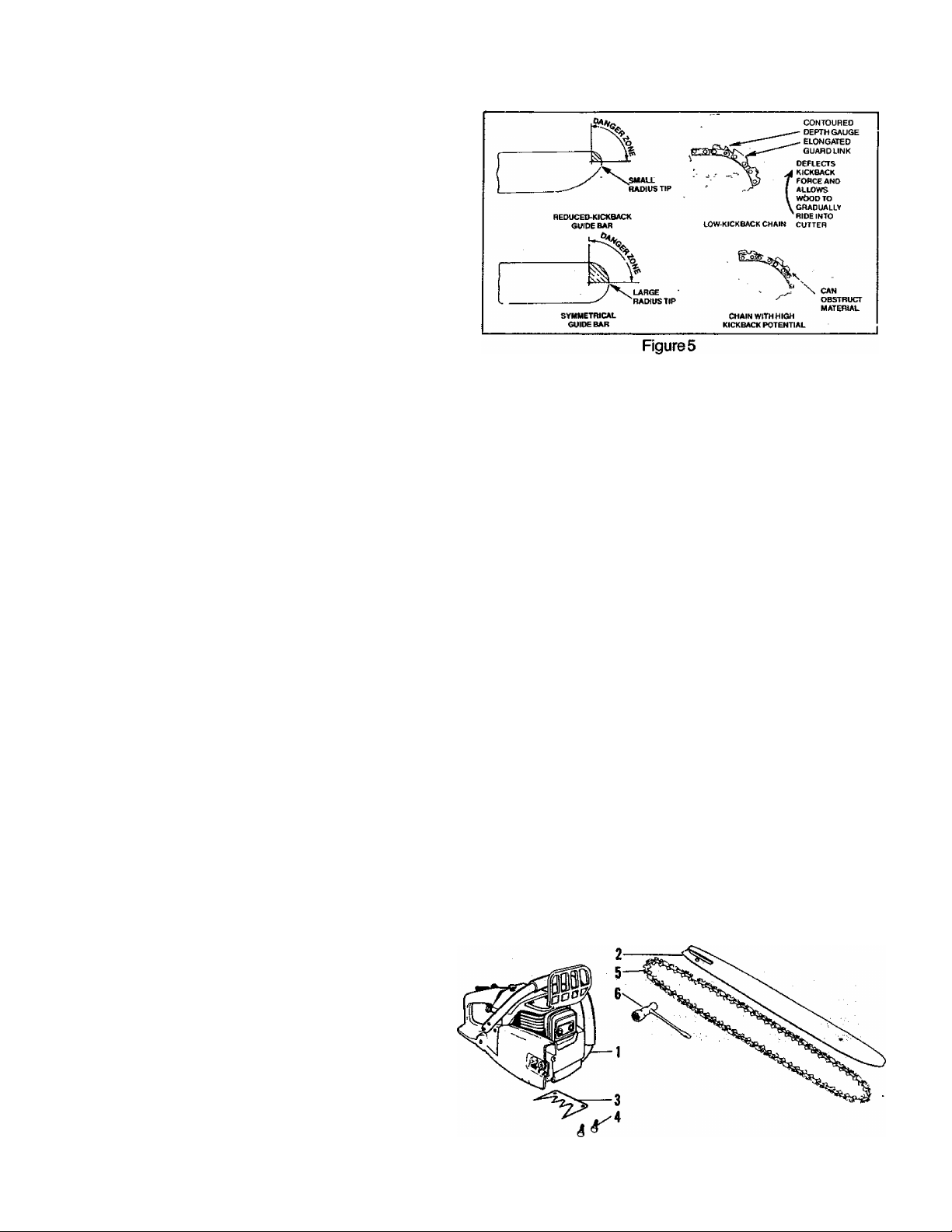

B. KICKBACK SAFETY FEATURES

— Reduced-Kickback Guide Bar, designed with a small

radius tip w^ich reduces the size of the kickback danger

zone on the bar tip. Figure 5. A Reduced Kickback

Guide Bar is one which has been demonstrated to

significantly reduce the number and seriousness of

kickbacks when tested in accordance with the safety

requirements for gasoline powered chain saws as set

by the American National Standards Institute, Inc.,

Standard B175.1 -1985.

— Low-Kickback Chain, designed with a contoured

depth gauge and guard link which deflect the kickback

force and allow wood to gradually ride into the cutter.

Figure 5. Low Kickback Saw Chain is chain which has

met the kickback performance requirements of ANSI

B175.1 (Safety Requirements for Gasoline-Powered

Chain Saws) when tested on a representative sample of

chain saws below 3B cubic inch displacement speci

fied in ANSI B175.1. (American National Standards

. Institute, Inc., Standard B175.1-1985).

-^Handguard, designed to reduce the chance of your left

hand contacting the chain if your hand slips off the front

handlebar.

— Position of front and rear handlebars, designed

with distance between handles and “in line” with each

other The spread and “in line” position of the hands

provided by this design work together to give balance

and resistance in controlling the pivot of the saw back

toward the operator if kickback occurs.

STATE AND LOCAL REQUIREMENTS.

Your saw is equipped with a temperature limiting

muffler and spark arresting screen which meets the

requirements of California Codes 4442 and 4443.

All U.S. forest land and the states of California, Maine,

Washington and Oregon require many internal com

bustion engines to be equipped with a spark arrestor

screen by law.

If you operate a chain saw in a state or locale where

such regulations exist, you are legally responsible

for maintaining the operating condition of these

parts. Failure to do so could subject you to liability

or to a fine. Muffler and spark arrestor maintenance

is found on page 17 & 18.

D.

CARTON CONTENTS

After you unpack the carton:

1. Check the contents against the list below.

2. Examine the items for damage.

3. Notify your dealer immediately if a part is missing

or damaged.

NOTE: A rattle like noise in a powerhead with an

empty fuel or oil tank is a normal condition, caused

by afilter moving against the wal I of an em pty tank.

KEY NO. CARTON CONTENTS:

Power Head

Guide Bar

‘Spur

‘Screw - Spur

Chain

Scrench

Loose Parts Bag (not shown)

Operator’s Manual (not shown)

QTY.

1

1

1

2

1

1

1

^WARNING

Do not operate the chain saw unless the safety devices

or their specified replacements are properly installed

and maintained according to the instructions in this

manual. Do not use any other guide bar and chain com

bination that is not equivalent to the original equipment

or not certified to comply with ANSI B175.1. Failure

to follow these instructions can result in serious per

sonal injury.

Page 7

PREPARING YOUR SAW FOR USE

A. GETTING READY

1. READ YOUR OPERATOR’S MANUAL

Your Operator’s Manual has been developed to

help you prepare your saw for use and to under

stand its safe operation. It is important that you

read your manual completely to become familiar

with the unit before you begin assembly or attempt

operation. Your Poulan® dealer is available to show

you how to operate your saw. Be sure to ask for his

assistance.

2. HAVE THE FOLLOWING AVAILABLE:

a. Protective gloves

b. Approved, marked, fuel container.

c. One gallon leaded or unleaded, regular

gasoline

d. 8 oz. (1/2 pt.), 2>cycle, air-cooled engine oil

(See page 9).

e. Bar and Chain Oil (See page 10.)

f. Scrench — provided with your unit. No other

tool is necessary for assembly. Use the long

end of the tool as a slotted screwdriver, the

small pipe end as a socket wrench, and the

larger pipe end to remove the spark plug.

B, ATTACHING THE SPUR (Standard Equipment on Some Units)

The spur is a special piece of equipment designed

to assist the cutting operation. When assembled to

the saw, the spur will dig into the tree or log and:

- relieve contact pressure adding ease to the saw

ing operation.

-allow the saw to be more easily rotated or pivoted

into the cut.

To Install:

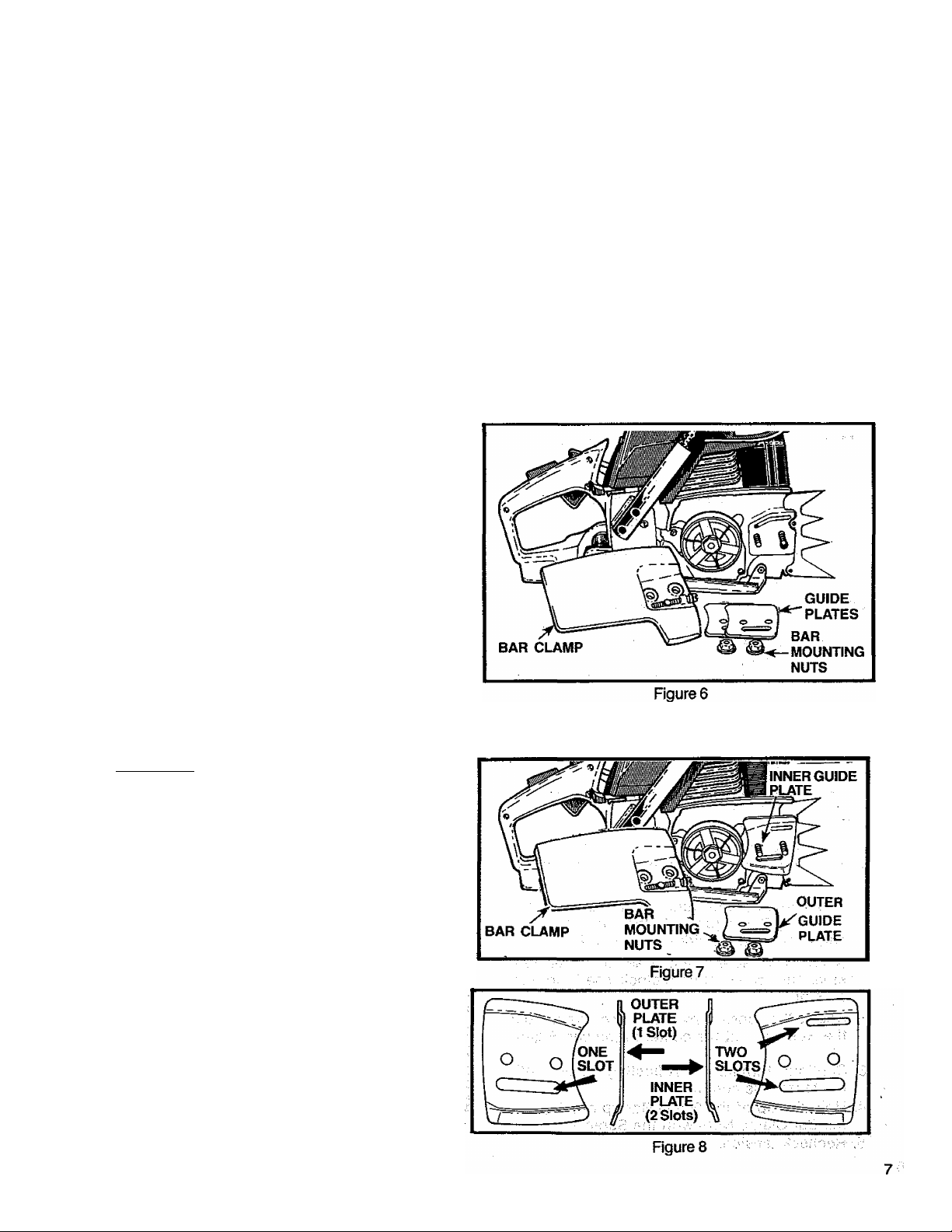

1. Remove Bar Clamp Nuts, Bar Clamp and Guide Bar

Plates.

2. Align the spur over thé two holes on the bar clamp

side of the saw. Figure 6.

3. Insert the two screws and tighten evenly and sec

urely.

C. ATTACHING THE BAR AND CHAIN

CAUTION:! Wear protective gloves when han

dling or operating your saw. The chain is sharp

and can cut you even when it Is not moving!

• Your saw is equipped with a Reduced-Kickback

Guide Bar and a Low-Kickback Chain.

• Always use the Reduced-Kickback Guide Bar

and the Low-Kickback Chain specified for your

chain saw model, when replacing these parts.

Do not start engine without guide bar and chain

completely assembled. Otherwise, the ciutch can

come off and serious personal injury can result

Zi\ WARNING

1. Install the Inner Guide Plate overttie bar mounting

studs. Figure 7.

NOTE: Be sure the Inner Guide Plate curves or

flanges toward the saw frame away from the

Guide Bar. Figure 8.

Page 8

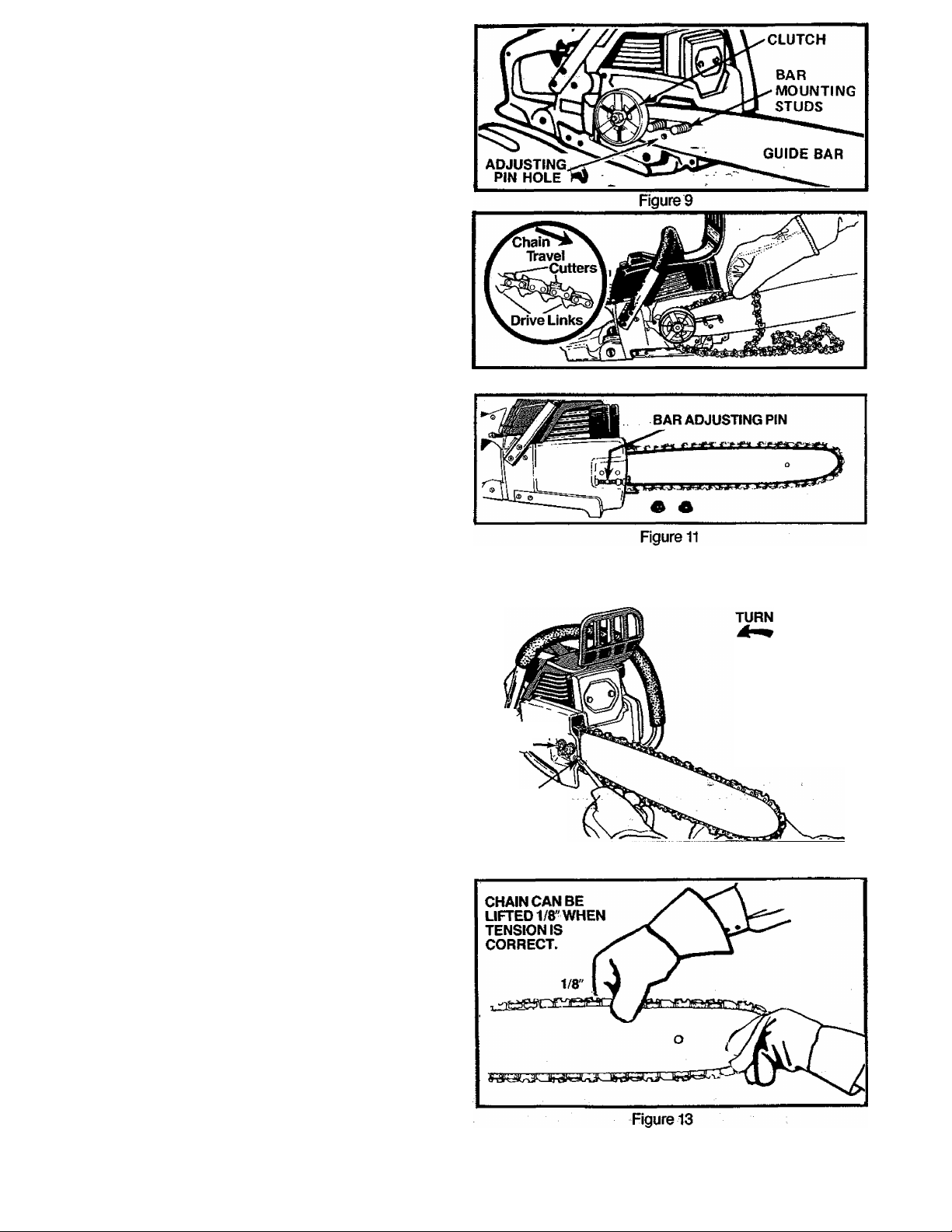

2. Mount the Guide Bar with the slotted end

over the bar mounting studs. Figure 9 .

NOTE: Be sure the Guide Bar is positioned

with the round hole below the large slot.

3. Hold chain with cutlers facing as shown in

Figure 10.

4. Place chain over and behind the clutch

drum onto the sprocket.

5. Slide Guide Bar to the rear of the saw as far

as possible.

6. Fit the bottom of the drive links between

the teeth in the sprocket.

7. start at the top of the bar and fit the chain

drive links into the groove around the Guide

Bar. Figure 10.

8. Pull the Guide Bar forward until the chain is

snug in the guide bar groove. Figure 11.

9. Install the outer guide plate. Figure? .

10. Slide the Bar Clamp over the mounting studs and fit

the bar adjusting pin (Rgure 11) into the adjusting pin

hole in the Guide Bar. Figure 9.

11. Replace the Bar Mounting Nuts and tighten

finger tight only.

NOTE: The Bar Clamp nuts must be slightly

loose to tension the chain correctly.

12. Follow “Chain Tension” instructions below.

Figure 10

D. CHAIN TENSION

• Correct chain tension Is very important:

—a loose chain will wear the bar and itself,

—a loose chain can jump off the bar while

you are cutting.

—a tight chain can damage the saw and/or

break.

• Chain tension is correct when the chain:

—can be lifted about 1/8” from the Guide Bar

at a point near the middle of the bar, and

—will move freely around the bar.

• The chain stretches during use, especialiy

when new; Check tension:

— each time thè saw is used

— more frequently when the chain is new

— as the chain warms up to normal operating tem

perature

1. Hold the tip of the Guide Bar up and turn the

Adjusting Screw just until the chain does not

sag beneath the Guide Bar. Rgure 12.

NOTE: Turn screw clockwise to tighten ten

sion. Turn screw counterclockwise to loosen

tension.

2. Check the tension by lifting the chain from

the Guide Bar at the center of the bar. Figure

13.

3. Continue turning the Adjusting Screw until

the tension is correct.

4. Hold the tip of the Guide Bar up and tighten

the Bar Clamp Nuts with the Scrench.

5. Recheck tension.

BAR

MOUNTING

STUDS

ADJUSTING

SCREW

TO LOOSEN

TENSION

TURN

TO TIGHTEN

TENSION

Figure 12

Page 9

E. ENGINE FUEL MIXTURE

• Your chain saw is powered by a two-cycle engine

which requires a fuel mixture of regular^asoline

(leaded or unleaded) and a high quality engine oii

specially made for 2-cycie air-cooled engines. The

internal design of the 2-cycie engine reqy ires lubrica

tion of moving parts. Lubrication is provided when you

use the recommended mixture of gasoline and oil.

• Gasoline must be clean and not over two months

old. After a short peiiod of time, gasoline begins to

chemically break down and will form compounds that

can cause hard starting and damage in 2-cycle en

gines.

• The correct measure of gasoline to oil is very im

portant.

—Too much oil in the mixture will foul the spark plug.

—Too little oil will cause the engine to overheat re

sulting in damage.

• Mix the fuel thoroughly in a container since

gasoline and oil do not readily combine. Do not

try to mix fuel directly in the fuel tank.

1. DONOTUSE:

• BIA Oii (Boating Institute of America)—

— Does not have proper additives for air-cooled,

2-cycIe engines and could cause damage.

• AUTOMOTIVE OIL—

— Does not have proper additives for 2-cycle

engines and could cause damage.

• GASOUNE CONTAINING ALCOHOL—

(High Test, Premium or Gasohoi)

—Stiffens critical carburetor fuel metering ele

ments and causes engine damage from over

heating.

— Increases vaporlock(causes hard starting).

— Attracts water causing corrosion damage.

Figure 14

2. USE THE FOLLOWING:

Two types of PoulanAA/eed Eater Engine Oil are

available — one blended to be mixed at a 16:1

ratio and the other ata 32:1 ratio.

'*OULaN/wE60 eXTEt'

tGAUO«

REGULAR

GASOÜHE

[leaded or

unleaded)

2 TWO

GALLCmS

regular

GASOLINE

(leaded or

unleaded)

+

(U2 PT}

0.1

16:1 Ratio

gNGINE OIL ^

^ —OR— ^

Awr GOOD

16:1

COOLED 2-CYCLt

.— Engine oil —

EOULAN/WEED

32:t Ratio

_ engine oil

jCAUTION:! If you use a 32:1 fuel mix, you must

use genuine PouianA/Veed Eater 32:1 Engine Oil

or engine damage can occur. Do not use a fuel

mix leaner than 32:1.

3. HOW TO MIX FUEL

Pour one-half of the gasoline into an approved,

a.

marked container. Do not try to mix oil and

gasoline directly in the fuel tank.

Add entire measure of 2-cycle Engine Oil.

b.

Mix.

c.

Add remainder of gasoline.

d.

Mix thoroughly for one minute.

e.

4. IMPORTANT POINTS

a. Use only recommended fuel mixtures.

b. Eliminate ail sources of sparks or flames in

the areas where fuel is mixed, poured, or

stored. There should be no smoking, open

flames or work that could cause sparks.

c. Use an approved, marked containerfor all

fuel purposes.

d. Mix and pour fuel in an outdoor area on bare

ground. Store fuel in a. cool, dry, well-

ventilated place. Gasoline vapors are harmful to

your health and can cause serious hazards

such as explosion and fire. Use a funnel or spout

when pouring fuel.

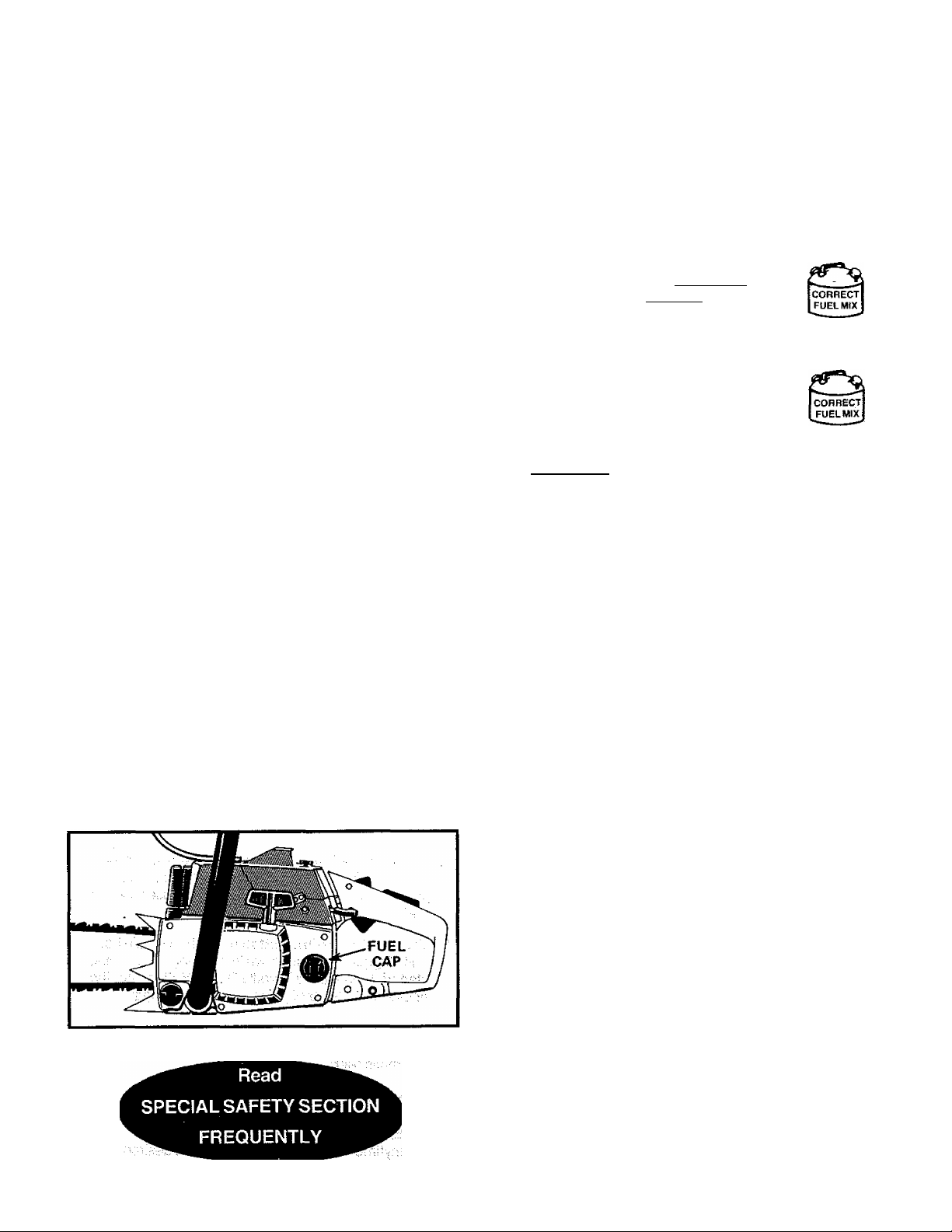

e. Avoid over filling the fuel tank. Allow % inch

V for expansion. Tighten Fuel Cap securely. Ftg-

ure 14.

f. Wipe up ail fuel spills. Wipe off any fuel spilled

on the saw. Completely dry the saw before

using.

g. Move at least 10 feet (3 meters) away from'

fuel and fueling site before starting the engine.

Page 10

F. BAR AND CHAIN OIL

• The Guide Bar and Cutting Chain require

continuous lubrication In order to remain in

operating condition. Lubrication is provided

by the automatic oiler system when the oil tank

is kept filled.

— Lack of oil will quickly ruin the Bar and

Chain.

—Too little oil will cause overheating shown

by smoke coming from the chain and/or dis

coloration of the Guide Bar Rails.

• Genuine Poulan® bar and chain oil is re

commended to protect your: unit against

excessive wear due to heat and friction.

Poulan® lubricant resists high temperature

thinning. If Poulan® bar and chain lube is not

available, use a good grade SAE 30 oil. Never

use wasteoil for this purpose.

• In freezing weather oil will thicken, making

it necessary to thin bar and chain oil with a

small amount of Diesel Fuel #1 or

Kerosene. Bar and chain oil must be free flow

ing for the oil system to pump enough oil for ad

equate lubrication.

1. USE THE FOLLOWING;

2. HOWTO FILL THE OIL TANK

a. Stop the engine.

b. Turn saw on its side with oil cap up. Figure 15.

c. Loosen cap slowly and wait for pressure in the

tank to be released before temoving the cap.

d. Fill the oil tank,

e. Replace the oil cap securely.

3. IMPORTANT POINTS TO REMEMBER

a. Prime the oil pump on a new saw or a saw that

has been unused for an extended period of

time. Pump the manual oiler slowly several times.

Start the engine and allow the chain to run. Stop the

engine and check for an even flow of oil on the

chain. Repeat this procedure until oil is visible on

the chain.

b. Fill the oil tank each time you refill the fuel

tank to ensure there will be sufficient oil for the

chain whenever you start and run the saw.

c. Thesawwiiluseabout1/2tankofchainoiifor

each tank of fuel mixture. If less oil is used,

check for a plugged oil hole in the guide bar.

d. It is normal for a small amount of oil to appear

under the saw after the engine stops. This is

due to oil draining from the bar and chain when

not in use.

30"F or above—Lubricant—undiluted.

SO'^-O^F—95% lubricant to 5% Diesel Fuel

#1 or Kerosene.

Below 0°F—90% lubricant to 10% Diesel

Fuel #1 or Kerosene.

USING YOUR SAW

A. CONTROL DEVICES

Understanding the control devices on your saw

is an important part of learning how to properly

and safely operate the unit. Figure 16.

THROTTLE

DETENT

BUTTON

CHOKE

THROTTLE

LOCKOUT

MANUAL

OILER

START/STOP^

SWITCH

TRIGGER

START

STOP

START/STOP

SWITCH

HALF

FULL-i i;:

CHOKE

2. The two-position Choke helps to start the saw by

■ controlling the air flow to the fuel system.

3. The Trigger accelerates and controls the speed of

the engine and is designed; to be used: with the

Throttle Lock.

i

OFF

4. The Throttle Lock is a control feature which pre

vents the Trigger from becoming accidentally en

gaged. The Throttle Lock must be pressed before

the Trigger can be activated.

5. The Throttle Detent Button holds the Throttle Lock

and Trigger in position while the engine is being

started. Release tiie Throttle Detent Button after the

engine is started by lightly squeezing the trigger.

6. The Manual Oiler is placed to be operated by your

right thumb. Use the manual oiler to supplement the

automatic oiler;

Figuréis

1. The ignition Switch is a toggle switch which is

moved up for the "Start" position and moved down

for the “Stop” position.

10

—during a long felling cut

—when cutting into a log or tree which is greater in

■ anytime an additional supply of oil is desired.

Page 11

STARTING INSTRUCTIONS

1.BASIC PROCEDURE

a. Set the saw on flat ground making certain the

saw chain is free tatum without contacting any

object. Figure 17.

b. Move ignition switch to the “Start” position.

c. Push down on the throttle lockout, squeeze the

trigger, press and hold down the throttle detent

button, then slowly release the trigger.

d. Adjust choke according to “Starting Pro

cedure for Varying Conditions” below.

e. Hold front handlebar with left hand & place right

foot through rear handid to stablize saw.

f. Pull starter rope quickly, using no more than

15-18 inches of rope per pull. Using the full length

of the starter rope may cause it to break. Do not let

the starter rope snap back. Hold the handle and let

the rope rewind slowly.

g. Release the throttle detent button after engine

starts, allowing the engine to idle. The chain must

not move when the engine runs at idle speed. If cor

rection is required, refer to “Carburetor Adjust

ments,” page 20.

h. Stop engine by moving the Ignition switch to the

“STOP” position (Figure 16).

^WARNING

Always wear gloves; safety footwear; snug-fitting

clothing; and eye, hearing, and head protection

devices when operating a-ehain saw.

vii^RNING

Avoid bodily contact with the muffler when start

ing or using a warm engine to avoid serious burns.

2. STARTING PROCEDURE FOR VARYING CONDITIONS

Squeeze trigger

X X

X

X X

X

CONDITIONS

a. Cold Engine

b. Warm Engine

c. Refueled Engine after

X

X

X

Puit choke knob

X X

chtAeoff

X X

Move ignition

switch to start ; tofuilchoke

Press llinttte Press throttie Puli starter rope Pushchoke knob: Puif Starter rope

lockottlsnd detent button untli engine tires in until engine runs to release

squeeze triggerrelease trigger throttle detent

X 3-5 times X

X X

X 3-5 times X

running out of gas

d. Flooded Engine

e. Cold Weather Starting

X

X X

choke off

X X

X X 3-5 times

half choke'

(out of cut)

X X

X

X

*Allow engine to warm-up (1-2 min.) on half-choke, then move choke to the “Off" position. Do not cut with the choke at the

“On” or “Half” position. Figure 15.

TYPES OF CUTTING

BASIC CUTTING TECHNIQUE

A.

1. IMPORTANT POINTS.

Cut wood only. D6 not cut metal, plastics,

a.

masonry, non-wood, building materials; etc.

Stop the saw if the chain strikes a foreign

b.

object. Inspect the unit and repair or replace

parts as necessary.

c. Keep the chain out of dirt and sarid. Even a

thus, increase the possibility of kickback.

2. UNDERSTAND REACTIVE FORCES

Pinch-Kickbackand Pull-In occur when the chain

is suddenly stopped by being pinched, caught, or

by contacting a foreign object in the wood. This

results in a reversal of the chain force u^d to cut wood

and causes the saw to move in the opposite direction of

chain rotation. Either reaction can result in loss of con

trol and possible serious personal injury.

Kickback can occur when the moving chain contacts an

object at the upper portion of the tip of the g ulde bar or

when the wood closes in and pinchesthe saw chain in

the cut. Contact at the upper portion of the tip of the

stop the chain for an instant. The result ts a iightning

fast, reverse reaction which kicks the guide bar up and

back towaid the operator. If the saw chain is pinched

along the top of the guide bar, the guide har can be

drivenrapidiybacktowardtheoperatqr.BWheroHhese

reactions can cause loss of saw control wb/cb can

resuit in serious personai injury.

A KICKBACK WARNING

• Pinch-Kickback

—bccu rs when the chain, on top of the bar is suddenly

stopped when the top of the bar is used for cutting.

— rapidly drives the saw straight back toward the

operator

11

Page 12

• Pull-In —

— can occur when fhe chain on the bottom of the

bar is suddenly stopped.

—pulls the saw rapidly forward.

3. PROCEDURE

Practice cutting a few small logs using the following techni

que to get the “feel” of using your saw before you begin a

major sawing operation.

a. Accelerate the engine to full throttle just before

entering the cut by squeezing the throttle trigger.

b. Begin cutting with the saw frame or spur against

the wood. Figure 18.

c. Keep the engine at full throttle the entire time you

are cutting.

d. Allow the chain to cut for you; exert only light

downward pressure. If you force the cut, damage to

the bar, chain, or engine can result.

e. Release the throttle trigger as soon as the cut is

completed} allowing the engine to idle. If you run the

saw at full throttle without a cutting load, unnecessary

r

wear can occur to the chain, bar, and engine.

f. Do not put pressure on the saw at the end of the cut

to avoid losing control wherrthe cut is complete.

g ■ Stop the engine before setting the saw down after

cutting.

Figure 18

B. TREE FELLING TECHNIQUES

1. PLAN YOUR SAWING OPERATION CARE

FULLY IN ADVANCE

a. Clear the work area. You need a clear area all

around the tree where you can have secure

footing.

b. Study the natural conditions that can cause

the tree to fall in a particular direction:

1. ) The WIND direction and speed

2. ) The LEAN of the tree

3. ) WEIGHTED with BRANCHES on one side

4. ) Surrounding TREES and OBSTACLES

c. Look for decay and rot. If the trunk is rotted,

it could snap and fall toward the operator.

d. Check for broken or dead branches which

could fall on you while cutting.

e. Make sure there Is enough room for the tree

.....

to fail. J\/laintaining a distance - of . 2V2 tree

- “lengths from the nearest person or other ob

jects. Engine noise may drown out warning

call-

f. Remove dirt, stones, loose bark, nails,

staples, and wire from the tree where cuts

are to be made.

DON’T PUT YOURSELF IN THESE POSITIONS

g. Plan to stand on the up-hill side when cut

ting on a slope.

h. Plan a clear retreat path to the rear and

diagonal to the line of fail. Figure 20.

2. FELLING SMALL TREES —LESS THAN 6"

IN DIAMETER

a. If you know the direction of fall:

1. ) Make a single felling cut on the side away

from the direction of fall.

2. ) Cut all the way through.

3. ) Stop the saw, put it down, and get away

quickly on your planned retreat path.

b. If you are not sure which way the tree will fall,

use the notch method described for felling large

trees.

Awarning

DO NOT CUT: / ^ '

— near electricai wires or buildings.

— if you do not know the direction of tree fall.

—at night since you will not be able to see well.

— during bad weather — strong wind, snow, rain,

etc.

12

Page 13

3. FELLING LARGE TREES

6' DIAMETER

OR MORE

The notch method is used to cut large trees. A

notch is cut on the side of the tree in ^e desired

direction of fall. After a felling cut is made on the

opposite side of the tree, the tree will tend to fall

into the notch.

NOTE: if the tree has large buttress roots, remove

before making the notch. Cut into the buttresses

vertically, then horizontally. Figure 19

a. Make the notch cut. Figure 21 .

1. ) Cut the bottom of thè notch first, through 1 /3

of the diameter of the tree.

2. ) Complete the notch by making frie slant cut.

3. ) Remove the notch of wood.

b. Make the felling cut on the opposite side of the

notch about 2" higher than the bottom of the

notch.

c. Leave enough uncut wood between the felling

cut and the notch to form a hinge. Rgure 22.

NOTE: The hinge helps to keep the tree from

twisting and falling in the wrong direction.

d. Use a wedge if there is any chance that the tree

will not fall In the desired direction.

Figure 21

Figure 22

/U WARNING

Stay on the uphill side of the terrain to avoid the

tree rolling or sliding downhill after it is felled.

NOTE: Before the felling cut is complete, drive

wedges to open upthe cut when necessary to con

trol the direction of fall. Use wood or plastic wedges

but never metal, to avoid kickback and chain

damage.

e. Be alert for signs that the tree is ready to fall:

1. ) cracking sounds

2. ) widening of the felling cut

3. ) movement in the upper branches.

C. BUCKING

Bucking is the term used for cutting a fallen tree

to the desired log size.

1. IMPORTANT POINTS

a. Cut only one log at a time.

b. Cut shattered wood very carefully. Sharp

pieces of wood could be flung toward the

operator.

c. Use a sawhorse to cut small logs. Never

allow another person to hold the log while cut

ting and never hold the log with your leg or foot.

d. Give special attention to logs under strain to

prevent the saw from pinching. Make the first

cut on the pressu re side to retieye the stress

on the log. Figure 23 -

e. Do not cut in an area ^ere logs, limbs and

roots are tangled such as in a blown down

area: Drag the logs intp a clear area before cut

ting bypulling put expose!^ and cleared logs

first.

f. As the tree starts to fall, stop the saw,' put it

down, and get away quickly on your planned retreatpath.

g. Be extremely cautious with partially fallen trees

that may be poorly supported. When a tree

doesn’t fall completely, set the saw aside and

pull down the tree with a cable winch, block and

tackle or tractor. Do not cut it down with your

sawto avoid injury.

Make the first bucking cut 1/3 of the way

through the log and finish with a 2/3 cut on

the opposite side. As the log is being cut, it will

tend to bend. The saw can become pinched or

hung in the log if you make the first cut deeper

than 1 /3 of ttie diameter of the log.

13

Page 14

A WARNING

Never turn the saw upside down to undercut. The

saw cannot be controlled in this position.

2. TYPES OF CUTTING USED Figure 24:

—Overcutting - begin on the top side of the log

with spur or saw frame against the log; exert

light pressure downward. ''

— Undercutting - begin on the under side of the

log with the top of Uie saw against the tog; exert

light pressure upward. During undercutting, the

saw will tend to push backiat you. Be prepared

for this reaction and hold the saw firmly to main

tain control.

/JaWARNING

If saw becomes pinched or hung in a log, don’t try to

force it out. You can lose control of the saw resulting In

personal injuryand/ordamageto the saw. Stop the saw,

drive a wedge of plastic or wood into the cut untli the

saw can be removed easiiy. Figure 25. Restart the saw

and carefully reenter the cut. Do not use a metal wedge

to avoid kicl^ackand chain damage.

3. BUCKING—WITHOUT A SUPPORT

a. Overcutwith a 1/3 diameter cut

b. Roll log over and finish with an overcut.

4. BUCKING — USING ANOTHER LOG AS A SUPPORT Figure 26.

AWARNING

Do not stand on the log being cut. The cut portion

will roll down hill.

In area A:

a.

1. ) Undercut 1 /3 of the way through the log.

2. ) Finish with an overcut

In area B;

b.

1.) Overcut, 1/3 of the way through the log.

2j Finish with an undercut '

5. BUCKING —USING A STAND Figure 27.

a. In area A:

1. ) Undercut 1 /3 of the way through the log.

2. ) Finish with an overcut

b. In area B:

1. ) Over cut 1 /3 of the way through the log.

2. ) Finish with an undercut

D. DEBRANCHING AND PRUNING

• Work slowly, keeping both hands on the saw

with a firm grip. Maintain secure fppting and bal

ance.

• Watch out for springpoles. Use extreme caution

when cutting small size iimbs. Slender material may

catch the saw chain and be whipped toward you or

pull off balance.

14

Be alert for sprlngback. Watch out for branches

that are bent or under pressure as you are cutting to

avoid being struck by the branch or the saw when the

tension in the wood fibers is released.

Keep a clear work area. Frequently clear branches

Page 15

¿V. WARNING

Never climb into a tree to debranch or prune. Do not

stand on ladders, platforms, a log or in any position

which can cause you to lose your balance or control of

the saw.

1. PEBRANCHING

a. Always debranch a tree after it^is cut down.

Only then can debranching be done safely

and properly.

b. Leave the larger lower limbs to support the

tree as you work.

c. Start at the base of the felled tree and work

towards the top, cutting branches and

limbs. Remove small limbs with one cut. Fig

ure 28.

d. Keep the tree between you and the chain.

Cut from the side of the tree opposite the

branch you are cutting.

e. Remove larger, supporting branches with

the 1 /3,2/3 cutting techniques described in

the bucking section.

¿ ; 1.) Start with an overcut

2.) Finish with an overcut

f. Always use an overcut to cut small and

freely hanging limbs. Undercutting could

cause limbs to fall and pinch the saw.

Zi^WARNING

Be alert for and guard against kickback. Do not allow

the moving chain to contact any other branches or

objects at the nose of the guide bar when debranching

or pruning. Allowing such contact can result in serious

personal injury.

2. PRUNING

a. Limit pruning to limbs shoulder height or

below. Do not cut if branches are higher than

your shoulder. Get a professional to do the

job.

b. Refer to Figure 29 for the pruning tech

nique.

1. ) Undercut 1 /3 of the way through the limb

near the trunk of the tree.

2. ) Finish with an overcut farther out from the

trunk.

3. ) Keep out of the way of the falling limb.

4. ) Cut the stump flush near the trunk of the

tree.

MAINTENANCE

A good maintenance program of regular inspection

and care will increase the service life and help to main

tain the safety and perforrhanceofyoursaw.

• Make ail adjustments or repairs (except car

buretor adjustments) with:

^ spark plug wire disconnected

—engi ne cool as bppo^d to a unit that has just

been run.

• Check the saw for loose bolts, screws, nuts and

fittings regularly. Loose fasteners can cause an

unsafe condition as well as damage to your saw.

•

^WARNING

Have all chain saw service (other than the items listed

in the maintenance section of this manual) performed

by a qualified service dealer.

Read

SPECIAL SAFETY SECTION

FREQUENTLY

15

Page 16

A. GUIDE BAR AND CHAIN

Increase the service life of your Guide Bar and

Chain by:

—Using the saw properly and as recommended

in this manual.

—Maintaining correct Chain Tension, paged.

—Proper lubrication, page 10.

—Regular maintenance as described in this sec

tion.

1. CHAIN MAINTENANCE

• Sharpen the chain when:

— Wood chips are smdil and powdery. Wood

chips made by the saw chain should be

about the size of the teeth of the chain.

— Saw has to be forced through the cut.

— Saw cuts to one side.

r ■

4.) Sharpen cutters.

a. ) Support the square rod on the file holder

(with 7/32" round file) on cutter top plate.

Figure 30.

b. ) Hold the file holder level with the 30° guide

mark paraiieUo the center of the chain

and lower file handje 10°. Figure 30.

c. y File from inside toward outside of cutter,

straight across, on forward stroke only. Use

2 or 3 strokes per cutting edge. Figure 31.

d. ) Keep all cutters the same length. Figure

32.

e. ) File enough to remove any damage to cut

ting edge(side &top plate) of cutter. Figure

32.

f. ) Fite P72S chain to meet specifications

shown in Figure 33.

ICAUTION: I Always wear gloves when hand

ling the chain. The chain can be sharp enough to

cut you even though it may be too dull to cut

wood.

a. CLEAN TREE SAP FROM THE CHAIN

BEFORE IT IS SHARPENED:

1. ) Soak chain in a petroleum based solvent

or a detergent and water solution

2. ) Dry chain thoroughly.

3. ) Immerse the clean chain In light oil until oil

seeps into the rivet holes.

NOTE: Do not run a chain which has been

cleaned without lubricating it first.

b. SHARPENING INSTRUCTIONS

Items required:

Gloves

7/32” dia. file

6” file holder

Depth Gauge Tool

Flat file

Vise

Maintain the proper hook angle according to the

manufacturer’s specification for the chain you are

using. Too much hook angle will increase the chance

of kickback which can result in serious personal

injury. Figure 33 & 35.

ZL WARNING

5.) Correct Depth Gauges

a. ) Place depth gauge tool over each cutter

depth gauge. Figure 34.

b. ) File level with the flat file If depth gauge is

higher than the depth gauge tool.

c. ) Maintain rounded front corner of depth

gauge with a flat file. Figure 34& 35.

NOTE: The very top of the depth gauge

should be flat with the front half rounded

off with a flat file.

WARNING

Depth gauge tool is required to insure proper depth

gauge. Filing the depth gauge too deep will increase

the chance of kickback which can result in serious

personal injury.

16

Figure 32

Figure 34

ROUNDED

CORNER

Figure 35

TOO MUCH SQUARED

HOOK ANGLE qfF CORNER

\

WRONG WAY

Page 17

b. CHAIN REPLACEMENT

1. ) Replace the chain when cutters or links

break.

2. ) See a qualified service dealer to replace

and sharpen individual cutters for^atching your chain.

3. ) Always replace the worn sprocket when

installing a new chain to avoid excessive

wear to the chain.

2. GUIDE BAR MAINTENANCE

• Conditions which can jcequire guide bar

maintenance:

—saw cuts to one side

—saw has to be forced through a cut

—inadequate supply of oil to bar and

chain.

Check the condition of the guide bar each

time the chain is sharpened. A worn guide

bar win damage the chain and make cut

ting more difficult.

Replace the guide bar when:

—the inside groove of the guide bar rails is

worn.

—the guide bar is bentorcracked.

a. Remove the guide bar to service.

b. Clean oil holes at least once for each

five hours of operation.

c. Remove sawdust from the guide bar

groove periodically with a putty knife or

a wire. Figure 36.

d. Remove burrs by filing the side edges

of the guide bar grooves square with a

flat file.Figures/.

e. Restore square edges to an uneven rail

top by filing with a flat file. RgureSZ.

M ilfl lU

B, IGNITION AND EXHAUST SYSTEMS

• Carbon deposits will build up on exhaust ports,

spark arrestor, muffler, and spark plug as the saw

is used. All of these parts should be cleaned at the

same time to prevent engine damage, overheating,

loss of power, and hard starting.

• Clean parts:

—as required

^at least once for each 25-30 hours of opera

tion

1. COOLING AND EXHAUSTSYSTEM

• Carbon build-up on the cooling and exhaust

system can cause the engine to lose power

in a cut.

• Keep the spark arrestor clean at all times.

• Replace the spark arrestor when breaks in

the screen are found.

Items required:

—wire brush

— 3/8"wrench

— hardwood stick

CORRECT

GUIDE BAR

GROOVE

a. Disconnect the spark plug.

b. Remove the muffler, baffles, and screen. Fig-

c.

d.

WORN GROOVES

Figure 37

ure38.

Puli the starter rope until the piston moves far

enough to close the exhaust ports.

Scrape the carbon deposits from the exhaust

ports and surrounding exhaust chamber using a

hardwood stick. Figure 39.

FILE EDGES

SQUARE

[CAUTION: iDo not use a metallic scraping tool

to avoid damage to the piston.

e. Blow out loosened carbon with compressed air.

f. Glean the spark arrestor screen with a wire

brush or replace if breaks in the screen afe

found.

g. Reassemble muffler parts.

17

Page 18

2. SPARKPLUG

• Maintenance is indicated when the engine is

hard to start.

• Keep the spark plug: ^

—clean

— properly gapped (.025")

SPARKPLUG

CHAMPION ed-8Y

Items Required: Small brush, such asa tooth brush,

or a pocket knife.

a. Remove the carburetor cover.

b. Pull the rubber connector from the spark plug

and remove the spark plug from the cylinder.

c. Clean deposits from the electrodes of the spark

plug with a small brush oír a pocket knife.

NOTE: Be careful when removing, cleaning,

gapping and replacing the spark plug. If it is

damaged, it will not work properly and must be

replaced.

C. STARTER ROPE REPAIR AND REPLACEMENT

• A starter rope that breaks next to the pulley

can be repaired.

• Replace the starter rope if the rope breaks more

than 2-3 Inches away from the pulley as the rope

will be too short to repair properly.____________

A WARNING

Always wear eye protection when servicing the

starter rope. The recoil spring beneath the pulley

is under tension. If the spring pops out, serious

personal injury can result.

NOTE: The recoil spring, located beneath the

pulley, is under tension. If spring pops out, it

will require considerable time and effort to

reinstall. For this reason, you may want to let a

qualified service dealer handle this repair. If you

do try to repair the starter rope and the recoil

spring pops out take the unit to your dealer.

1. Remove the four screws on the side of the fan

housing. Figure 41.

GAP .025"

Figure 40

d. Set the gap between the electrodes to .025

using a wire or flat gauge. Figure 40.

e. Replace the spark plug in the cylinder and attach

the rubber connector.

f. Replace carburetor cover and knob.

NOTE: The tension on the starter spring will be

released if the rope has broken.

4. Turn the pulley counterclockwise until the spring

tension is released.

5. Remove the pulley screw in the center of the pul

ley. Figure 43.

6. Lift the pulley carefully while gently twisting it

counterclockwise , and remove the old

rope.

7.. Move away from the fuel tank and melt the end of the

new rope to go into the pulley.

8. Allow the melted end to drip once,* then while the

rope is still hot, pull the melted end through a rag

to obtain a smooth, pointed end.

9. Feed the rope through the round starter hole in the

the fan housing. Figure 43.

10. Snake rope inside pulley, then through topside pulley

hole by pushing the rope from the underside hole

with a small round ob|ect, such as a Phillips

screwdriver. See insert. Figure 43.

18

"- NOTE: Notice the different iengths bf the screws

and their proper locations while removing the

screws.

2. Remove the fan housing.

3. If the starter rope is not broken, release the spring

tension by pulling about 12 inches of rope from

the pulley and catch the rope in the notch as

shown. Figure 42.

Page 19

11.

Wrap rope counterclockwise around

pulley ratchet and tuck loose end back under rope

leaving a 3/8-1/2 inch tail. Pull tightly around ratchet.

Figure 43.

12.

Pull the rope tightly around ratchet and wrap around

the pulley clockwise ^

13.

Set the pulley into the housing; push it down and

engage the spring.

14.

Replace and tighten the pulley-screw.

15.

Pull out 12 inches of rope and catch the rope

in the notch in the pulley. Figure 43 ,

16.

Turn the pulley 3 complete turns clockwise

winding up the spring.

17.

Hold the pulley, pull the starter rope to the full

extent of length then letThe rope rewind slowly.

18.

Replace fan housing with the four screws in their

proper location.

D. CLUTCH AND DRUM/SPROCKET

Awarning

Do not Start engine without Guide Bar, Chain, and Bar

Clamp Housing completely assembled. The clutch can

come off without the guide bar and chain completely

assembled and serious injury can result. Do not loosen

and spin the clutch off the crankshaft with a power tool.

The clutch shoes and drum can separate causing the

clutch to violently fly apart and serious personal injury

can result.

• Take the saw to a qualified service

dealer for full clutch inspection and service after

each 100 hours of operation, /t is recommended

that you do not try to service the clutch or

drum/sprocket yourself unless you are a competent

small engine mechanic and have the proper clutch

service tools. Proper disassembly and repair of the

clutch is extremely important to the life of the engine

and the safety of the operator.

» Clutch maintenance is required when:

—the chain continues to turn while engine idles

after the idle speed screw has been adjusted

to its capacity,

— slippage occurs during a cut.

—a chattering noise occurs during cutting.

• Clean the clutch, drum/sprocket and surround-

. ing area daily during heavy use of the saw.

^ Check to see that the clutch drum turns freely and

smoothly.

i Inspect the drum/sprocket regularly for wear. A

worn sprocket will make the chain run erratically

and will shorten the life of the bar and chain. Figure

45.

» Replace the drum/sprocket whenever a new

chain is installed in order to gain the full life expec

tance of the chain. Use the following procedure:

9/16" Socket Wrench

3/4" Socket Wrench

2. Remove the bar clamp, outer guide plate, guide

bar, and chain. Figure 46.

3. Remove the fan housing.

4. Use a 9/16" socket wrench on the flywheel nut to

keep the crankshaft from moving. Figure 47.

NOTE: Place the socket handle forward as shown

in Figure 47.

Figure 46

1. Remove the carburetor cover and pull the spark

plug away from the rubber connector.

Figure 47

KEEP

CRANKSHAFT

FROM MOVING

19

Page 20

CLOCKWISE

REMOVE CLUTCH

INSTALL CLUTCH

COUNTERCLOCKWISE

Figure 48

E. CARBURETOR ADJUSTMENTS

5. Remove the clutch with a 3/4" socket or end wrench

maclockwise direction. Figure 48.

ICAUTIO^ Do not remove the clutch with a

punch or a powerful tool to avoid damage or

breakage to the clutch; •

6. Remove worn drum/sprockejt-and replace.

7. Install clutch in a counterclockwise direction. Rg-

ure48.

8. Hold flywheel by hand and tighten clutch with 3/4

socket wrench.

NOTE: Do not hold a wrench on the flywheel nut

when replacing the clutch. This could loosen the

flywheel nut.

9. Reinstall fan housing, bar chain and bar clamp.

• The carburetor has been adjusted at the factory for

sea level conditions. Adjustment may become nec

essary if the unit is used at significantly higher al

titudes or if you notice any of the following conditions:

—Chain moves with the engine at idle speed.

— Loss of cutting power which is not corrected

by air filter or muffler screen cleaning.

— Engine dies or hesitates when it should accel

erate.

• Permanent damage will occur to the engine if in

correct carburetor adjustments are made. It Is

best to let a qualified service dealer make carburetor

adjustments. If you choose to make the adjustments

yourself, follow the procedu re below very carefu lly.

TVIIARNING

The chain may be moving during this procedure.

Wear your protective gear and observe all of the

safety precautions.

1. PREPARATION

- a. Stop engine.

b.

Use a fresh fuel mixture wifii proper gasoline/oil

ratio. '■■■■

c.

Place the saw on a solid, flat surface and nriake

sure the chain will not contact any object,

d. Locate the three (3) Carburetor adjusting screws

located on the fan housing side of the saw. Figure

49.

Turn the Low Speed Mixture Screw and the

e.

------

High Speed Mixture Screw Clockwise

just until they stop. Do not turn Vie screws until

they qre tight as you m^ damage the needle

seats.

f. Turn the Low Speed Mixture Screw and the

High Speed Mixture Screw one full turn coun-

tercloclwise

2. IDLE SPEED ADJUSTMENT— I

a. Start the engine and allow to idle.

b. Adjust if the engine dies or stops by turning the

ldleSpeedScrew1/2turncioclwise

NOTE: To increase idle

Speed Screw clockwise

idle speed, turn the Idle

terclockwise

c. Run the engine for a few minutes to bring it up

to operating temperature.

speed,

Speed Screw coun-

turn the idle

. To decrease

NOTE: The engine must be at operating temper

ature for proper adjustments to be made.

3. LOW SPEED MIXTURE ADJUSTMENT

a. Turn the Low Speed Mixture Screw slowly

clockwise until the RPM starts to

drop. Note the position.

b. Turn the Low Speed Mixture Screw coun

terclockwise until the RPM speeds up

, . and startsto drop again. Note the position.

c. Set the Low Speed MIxture Screw at the mid

point between the two positions.

4. IDLE SPEED ADJUSTMENT—II

a. Allow engine to idle.

b. Adjust if the chain is turning by turning the Idle

Speed Screw counterclockwise

c. Squeeze the throttle trigger: the saw should ac

celerate without hesitafing.

NOTE: It may be necessary to recheck the low

speed mixture setting after the idle speed has

been reduced by repeating “Low Speed Mixture

Adjustment” as in step 3 above.

20

Figure49

5. HIGH SPEED MIXTURE ADJUSTMENT

a. Make a test cut.

b. Adjust if the saw smokes or seems to have low

power in the test cut by turning the High Speed

Mixture Screw 1/16th of a turn clockwise^^.

c. Repeat test cut.

d. Repeat adjustrnerit until the saw runs smoothly.

Page 21

CAUTION:I Never set the High Speed Mixture

Screw less than 7/8 turn open. This is too lean

a setting and will damage your engine.

6. IDLE SPEED ADJUSTMENT—III

Recheck for proper idle mixture setting. ^

NOTE: It may be necessary to repeat Idle Speed

Adjustment — I and Low Speed Mixture Adjust

ment.

7. CHECK ACCELERATION

Adjust if there is a slight hesitation, by turning the

Low Speed Mixture Screw 1 /16 of a turn at a time

ojunterclockwise until you have smooth

acceleration.

NOTE: Check to be sure the chain is not turning

when engine is idling.Jf chain moves at idle speed,

repeat Idle Speed Adjustment—II.

AIR FILTER

• A dirty air filter:

— reduces cutting power

— increases fuel consumption

• Clean the Air Filter:

—frequently, especially under very dusty condi

tions.

—always after 10 tanks of fuel mixture or 5 hours

of operation, whichever is less.

G. COUNTER-VIBE® ANTI-VIBRATION SYSTEM

This saw is equipped with a counter vibration

system consisting of 5 isolator mounts. Figure 51.

The Isolator Mounts reduce engine and chain vibration

similar to the way shock absorbers on a car reduce jolts

and bumps in the road.

1 CAUTION^ Never operate the unit without the

air filter in place to avoid damage to the engine.

Items Required: soft bristled brush, such as a paint

brush.

1. Clean off the carburetor cover and the area around

it.

2. Close choke to prevent dirt from entering the car

buretor.

3. Remove the carburetor cover. Figure 50.

4. Removetheairfiltercarefully.

5. Soak the filter in soap and water.

CAUTION:! Do not use gasoline or other flam

mable liquid to clean the filter to avoid creating

afire hazard.

6. Brush away all dust and debris from the filter.

7. Allow filter to dry.

8. Brush away all debris from surfaces which were

covered by the carburetor cover.

9. Replace filter and carburetor cover.

1. Check isolators each time the saw is used.

2. Replace isolators when:

—vibration increases

—mounts develop an out of round or swollen

shape usually caused from exposure to gasoline

and oil for long periods of time.

3. Replace ail five isolators when a failure to one

occurs.

H. STORAGE

When your saw is to be stored for over 30 days al

ways:

1- Drain fuel tank in a safe manner (see “Impor

tant Points,” page 9).

2. Start engine and allow to run at idle speed

until the engine stops.

NOTE: This will remove most of the fuel from the

fuel system.

CAUTION:I Wear protective gloves when han

dling the chain. The chain is sharp and can cut

you even when it is not moving.

3. Drain oil tank.

4. Remove,, clean, and dry the bar and chain.

5. Store the chain in a container filled with oil to pre

vent rust.

6. Apply a coating of oil to the entire surface of the bar

and wrap it in heavy paper, cloth or plastic.

7. Clean the outside surfaces of the engine.

8. Store frie saw in a dry place out of the reach of chil-.

dren and away from where fuel vapors can reach

open flames from hot water heaters, furnaces, etc.

21

Page 22

I. TROUBLE SHOOTING CHART

TROUBLE

ENGINE WILL NOT START

ENGINE WILL NOT IDLE

PROPERLY

ENGINE WILL NOT

ACCELERATE, LACKS

POWER OR DIES

IN THE CUT

ENGINE SMOKES

EXCESSIVELY

ENGINE RUNS HOT

OIL INADEQUATE FOR

BAR AND CHAIN

LUBRICATION

CHAIN MOVES AT

IDLESPEED

CHAIN DOES NOT MOVE

WHEN ENGINE IS

ACCELERATED

CAUSE

1. ignition Switch off.

2. Fuel tank empty.

3. Spark Plug not firing.

4. Fuel not reachirjg carburetor.

5. Engine flooded.

6. Compression low.

1. Idling speed set too tow.

2. Idle speed set too high.

3. Low speed screw requires adjustment.

4. Crankshaft seals worn.

5. Compression tow.

1. Carburetor requires adjustment.

2. Air filter dirty.

3. Spark Plug fouled.

4. Carbon build-up.

5. Low Compression.

1. Choke partially on.

2. High speed needle requires adjustment.

3. Airfitterdirty.

4. Oil rich fuel mixture.

5. Crankcase leak.

1. Fuel Mixture Incorrect.

2. Spark Plug Incorrect.

3. Carbon build-up.

4. High Speed Mixtu re set too low.

1. Oil tank empty,

2. Oilpumporoilfitterclogged.

3. Guide bar oil hole blocked.

1. Carburetor requires adjustment.

2. Clutch requires repair.

1. Chain tension too tight.

2. Carburetor requires adjustment.

3. Guide bar rails pinched.

4. Clutch slipping.

REMEDY

1. Move switch to “Start.”

2. Fill tank with correct fuel mixture, page 9.

3. Install new plug, page 18.

4. Check for dirty fuel fitter; clean. Check for

kinked or split fuql line; repair or replace.

5. See Starting Instructions, page 11,

6. Contact a qualified senrice dealer.

1. Adjust idle speed screw clockwise to

increase speed, page 20,

2. Adjust idle speed screw counterclockwise

to reduce speed, page 20.

3. See Carburetor Adjustments, page 20.

4. Replace seals or contact a qualified service

dealer.

5. Contact a qualified service dealer.

1. See Carburetor Adjustments, page 20.

2. Clean or replace air filter, page 21.

3. Clean or replace Spark Plug and regap,

page 18.

4. Clean exhaust system including spark

arrestor, page 17.*

5. Contact a qualified service dealer.

1. Push Choke in.

2. See Carburetor Adjustments, page 20.

3. Cleanorreplaceairfilter.page 21.

4. Empty fuel tank and refill with correct fuel

mixture, 'page 9.

5. Contact a qualified service dealer.

1. See Engine Fuel Mixture, page 9.

2. Replace with correct plug, page 18.

3. Clean exhaust systems including spark

arrestor, page 17.

4. See Carburetor Adjustments, page 20.

1. Fill oil tank, page 10.

2. Contact a qualified service dealer.

3. Removebarandctean, page7&17.

1. See Carburetor Adjustments, page 20.

2. Contact a qualified service dealer.

1. See Chain Tension, pages.

2. See Carburetor Adjustments, page 20.

3. Repair or replace, page 7 & 17,

4. Contact a service dealer.

CHAIN CLATTERS OR

^ CUTS ROUGHLY ^ > ; ^ ^ ^ ^ ’

CHAIN STOPS WITHIN

THECUT

CHAIN CUTS AT

AN ANGLE

22

1, Chain tension incorrect

'2.V Gutters dulii improperly sharpened; depth' ' , ; i a

gauges too high.

3. Sprodietwom.

4. Chain wear due to contact with dirt, sand

or frozen wood.

5. Cutters damaged after striking foreign

material.

t. Chain cutter tops not filed flat.

2. Guide bar burred or bent: rails uneven.

3. Clutch slipping.

1. Cutters damaged on one side.

2. Chain dull on one side.

^3 Guide bar bent, or worn.

1. See ChainTension, pages.

2. t ; See.Ghain Sharpening Instructions^

pageie.

3. Replace, page 17.

4. Resharpen or replace Chain, page 7 & 16.

5. Contact a qualified service dealer.

Sharpen all cutters evenly and uniformly

or replace Chain. See Chain Sharpening

Instructions, page 16.

1. See Chain Sharpening Instructions,

page 16.

2. Repairer replace Guide Bar, page 7 & 17.

3. Contact a qualified service dealer.

■ 1. Resharpen until all cutters have equal

angles and lengths, page 16.

2. Resharpen until all cutters have equal

angles and lengths, page 16.

3. Replace guide bar, page 7.

Page 23

J. MAINTENANCE CHART

r

-C w

« c

Z <D

0) 3

O 0>

Q.

o

>v

c

o

5

E

TJ

CD

1

O)

CD

-S’

£

(0

■B -

TJ

CD

O)

*3

CD

cr

O-

2

CD

CO

CD

CO

c -S'

o

ic OJ

5

sà

^ CO

^ o

^ i

<

Complete machine

Throttle trigger, safety throttle lock, stop switch

Riterin fuel tank

Fuel tank

Chain oil tank

Chain lubrication

Saw chain

Guide bar

Visual inspection {condition, leaks)

Clean

Check operation

Clean Felt

Replace felt

Clean

Clean

Check X

Inspect, also check sharpness

Check chain tension

Sharpen

Inspect (wear, damage)

Clean

Lubricate sprocket nose

Deburr

X X

X

X X

X X

X X

X

X

X

X

X

X X

X

10

X

10

8

X

16

17

17

17

Chain sprocket

Air filter

Exhaust ports

Cylinder fins

Carburetor

Spark plug

All accessible screws and nuts

{not adjusting screws)

\^bration mounts

Spark arrestor screen

Replace

Check

Clean X

Replace

Clean

Clean

Check idle adjustment -

chain must not turn

Readjust idle

Readjust electrode gap

Retighten

Inspect

To be replaced by a qualified Service Dealer

Inspect

Clean or replace

X

X X

X

X

X

X

X

X

X

7

19

21 ‘

21

17

X

17

20

X

20

X

X

X

18

21

17-

X

17

23

Page 24

PARTS LIST

A. ILLUSTRATION and DESCRIPTION 1

PART

KEV

NO. NO.

1 39095

2

3

4 15123

6

7

42051

B

9 42053

10

11 15365

12

.13

16

16

17 42056

18

19

JO

21

22

23

24

*lndïcates contents ofQasket Kit ^69190 tfom pags2£x

Key Numbers ^26,3BGi€5

162G

23S17

1726

28487

24329

15364

1722

15036

24232

42054 :

42052

12034

15366

24476

15434

10696

QTV.

1

1

2

1

6

1

1

1

1

1

1 ScrBW-lO-24)(1-3/3-Fan

1

1 Screw-10-.24 4 1/2

1

1

1 Rope Starter (Bulk 6128)

1

2

2

1

PART

KEY

NO.

DESCRIPTION

Flywheel Ass'y-t'ncL #3) 24 30039

Washer Flywheel

Spring-StarlBrOog

Washer- Starter Pulley

Screw-8*32 - v/iip-HeK

Hd.-Disc. Mounting

also Air Baffle eruf Clamp Lead

Puliev Starter

Bustling Recoil Spring 31

Spri ng-Sta rter Recoil

Disc^ Recoil Spring-Outer

Screw-10-24 • 1-ÒvalHd,

Fan HouMng-fTop Frontf

Housing {Lowet Front)

Flywheel Nut %■ 24

Starter Pultey .

Air Baffle "

Oisc.RacotlSpring Inner

HendteStarterRope

Fan Housing Assembly

Screw-10*24 ■ 3-%i-

Fan Housing IResrl

Spur* Optional

Screw-'10-24 - Vift-HoJtHtl.

Spur

Crankcase Assy (incl. *24.

25 & 33 this page: from page 26

includes 417.30.47 and one of 34.)

NO.

76444

25

27

32051

28 15354

29 24492

30

15425

39093

32 24334

33 19097*

35 23661

36

15238

37

10331

19122* 1

35

10286

40

di

23576

24858

42

.23732 Switch-toggle...'

43

44

39115

■ 45 ■

2596 ■ Key-Flywheel

10314

45

4743- 24332

15368

DESCRIPTION

QTY.

Kit‘Stud Bar Replacement

2

Oil Cap Assembly

1

6ea ri ng-Crankshaft

2

Thru St Washer-Cra nksha ft

2

1

Crankshaft Ass'v- f'hcl.

Connecting Rod and Bearing)

Screw** 10-24 * 'V-MûduleMnt.

2

IgnitionModule(inc). #44&53]

1

Clamp- H igh Tension Lead ■

1

Crankcase

Seal-Crankshaft

2

2 Clamp-Module Lead

Screw 10-24* filHd,

3

Crankcase

Fuel Cap Assembly

1

FuefTankAssemblv

1