Poulan 331 Owner’s Manual

PoulanPRO

Instruction Manual

Manual de Instrucciones

Manuel d'lnstructions

331

&

For Occasional Use Only

DANGER:

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious inju_J.

PELIGRO:

Lea el manual de instruccionesy siga todas las advertencias e

instrucelones de seguridad. El no hacedo puede resultar en le-

siones graves.

DANGER: le manuel d'instructions et bien respecter tousles

avertissements et toutes les instructions de s6curit& Tout d6faut

de le faire pourrait entrafner des blessures graves.

Electrolux Home Products, Inc,

250 Bobby Jones Expressway

Augusta, GA 30907

[] Frem the _l_'trelex ateuf_ The worM's No.l choice.

Copyright ¢32002 Electrot_x Home Products, inc 530163419 1214/02

KZr¢_NC_4_NC4t_ O[Zt#OOR_t_CES _OM_Nr_

®

4==.WARNINL_: When using gardening

appliances, basic safety precautions must al-

ways befollowed to reduce therisk of fire and

serious injury.

DANGER: This power tool can be

dangerous!This unit can cause serious injury

including amputation or blindness to the op-

erator and others. The warnings and safety

instructions inthis manual must befollowed to

provide reasonable safety and efficiency in

using the unit. The operator is responsible for

following thewarnings and instructions in this

manual and on the unit. Read the entire im

struction manual before assembling and us-

ing the unit! Restrictthe use ofthis unitto per-

sons who read, understand, and follow the

warnings and instructions in this manual and

on the unit. Never allow children to operate

this unit.

iNSTRUCTiON SAFETYiNFORMATiON

MANUAL ON THE UNiT

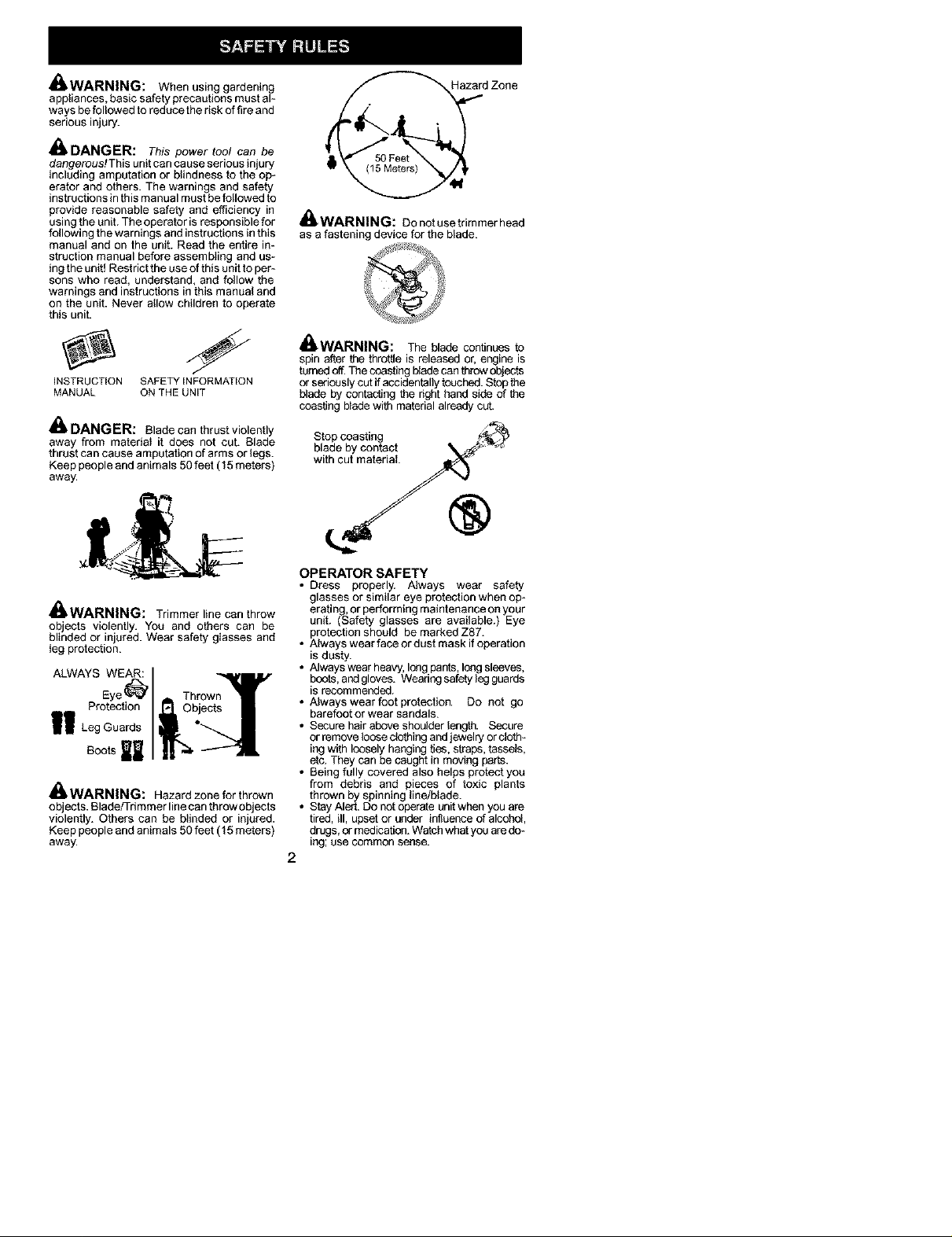

,_. DANGER: Blade can thrust violently

away from materia_ it does not cut. Blade

thrust can cause amputation of arms or legs.

Keep people andanimals 50 feet (15 meters)

away.

___td Zone

_WARNING: Do notuse trimmer heed

as afastening device for the blade.

4==.WARNINL_: The blade continues to

spin after the throttle is released or, engine is

turnedoff.Thecoasting I_adecan throwobjects

or seriouslycut if accidentallytouched.Stop the

blade by contacting the right hand side of the

coasting bladewith material already cut.

Stop coasting

blade by contact

with cut material

®

13.WARNINL_: Trimmer line can throw

objects violently. You and others can be

blinded or in ured. Wear safety g_asses and

eg protect on.

ALWAYS WEAR:

Protection

I! LegGuards

Bootsl

_WARNING: Hazard zone for thrown

objects. Blade/Trimmer linecan throw objects

violently. Others can be blinded or injured.

Keep people andanimals 50 feet (15 meters)

away.

OPERATOR SAFETY

• Dress properly. Always wear safety

glasses or similar eye protection when op*

erating, or performing maintenance on your

unit. (Safety glasses are available.) Eye

protection should be marked Z87.

• Always wear face or dust mask ifoperation

is dusty.

• Always wear heavy, longpants,long sleeves,

boots,andgloves. Wearing safety ledguards

is recommended.

• A_wayswear foot protection. Do not go

barefoot or wear sandals.

• Secure hairabove shoulder length. Secure

or remove loose clothing andjewelry orcloth-

ing with loosely hanging ties, straps,tassels,

etc. Theycan becaught in moving parts.

• Being fully covered also helps protect you

from debris and pieces of toxic plants

thrown by spinning line/b_ade.

• Stay Aled. Do not operate unitwhen you are

tired, ill, upset or under influence of alcohol,

clrugs,or medication.Watchwhat youaredo*

Ing; use common sense.

2

• Wear hearing protection.

• Never start or run the engine inside a

closed room or building. Breathing exhaust

fumes can kill.

• Keep handles free of oil and foe[

• A{ways use the handlebar and a properly

adjusted shoulder strap with a b{ede (see

ASSEMBLY).

UNIT/MAINTENANCE SAFETY

_WARNING: Stop unit and disconnect

the spark plug before performing mainte-

nance (except carburetor adjustments).

• Look for and replace damaged or loose

parts before each use. Look for and repair

fuel leaks before use. Keep unit in good

working condition.

• Throw away blades that are bent, warped,

cracked, broken, ordamaged in any other

way. Replace trimmer head parts that are

cracked, chipped, broken, or damaged in

any other way before using the unit.

• Maintain unit according to recommended

procedures. Keep blade sharp. Keepcut_

ting line at the proper length.

• Use only 0.095" (2.4 mm) diameter Poulan

PRO® brand replacement line. Never use

wire, rope, string, etc.

• _nstallrequired shield properly before using

the unit. Use the metal shield for all metal

blade use. Use the plastic shield for all line

trimmer use.

• Useonly specified blade or trimmer head;

make sure it is properly inetaHed and se-

curely fastened.

• Never start engine with clutch shroud re-

moved. The clutch can fly offand cause se-

rious injury.

• Besure bledeor trimmer head stops turning

when engine idles.

• Make carburetor edjustmenta with the low-

er end supported to prevent blade or trim_

mer line from contacting any object. Hold

unit by hand;do not use the shoulder strap

for support.

• Keep others awaywhen making carburetor

adjustments.

• Use only recommended Poulan PRO®ac-

cessories and replacement parts.

• Have all maintenance and service not ex_

plainedin this manual performed byyour au-

thorized service dealer.

FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Donot smoke or allow smoking near foelor

the unit or whi_eusing the unit.

• Avoid spilling fuel or oil Wipe up all fuel

spills before starting engine.

• Move at least 10 feet (3 meters) away from

fueling site before starting engine.

• Stop engine and allow it to cool before re_

moving fuel cap.

• Empty the fueltank before storing ortrans-

porting the unit. Use upfuel left in the car-

buretor by starting the engine and letting it

run until it stops.

• Store unitand fuelin areawhere fuel vapors

cannot reach sparks or open flames from

water heaters, electric motors or switches,

furnaces, etc.

• Always store gasoline in a container ab-

proved for flammable liquids.

CUTTING SAFETY

_WARNING: Inspect the area to be

cut before each use. Remove objects (rocks,

broken glass, nails, wire, string, etc..)which

can be thrown or become entangled in the

blade or trimmer head.

• Keep others including children, animals,

bystanders, andhelpers at least 50 feet (15

meters) away. Stop engine immediately if

you are approached.

• Always keepengineontheright-handside

of your body.

• Hold the unit firmly with both hands.

• Keep firm footing and balance. Do not over-

reach.

• Keep blade or trimmer head below waist

level. Donot raise engine aboveyour waist.

• Keep all parts of your body away from

blade, trimmer head, and muffler when em

gineis running. Ahot mumercan causese-

rious burns.

• Cut from your left to your right. Cutting on

right side of the shield will throw debris

away from the operator.

: Use only in daylight orgood artificia_ light.

Use only for jobs explained in this manual.

TRANSPORTING AND STORAGE

• Stop the unit before carrying.

Keep muffler away from your body.

: Allow theengine tocoot andsecure the unit

before storing or transporting it in avehicle.

• Empty the fueltank before stedng or trans-

porting the unit. Use upfuel leftin thecarbu*

retor bystarting the engine and letting it run

until it stops.

• Store unit so the blade or line limiter blade

cannot accidentally cause injury. The unit

can be hung bythe tube.

• Store unit out of reach of children.

SAFETY NOTICE: Exposure to vibrations

through prolonged use of gasoline powered

handtools could cause blood vessel or nerve

damage in the fingers, hands, and joints of

people prone to circulation disorders or ab-

normal swellings. Prolonged use in cold

weather has been linked to blood vessel dam-

agein otherwise healthy people, ffsymptoms

occur such as numbness, pain, loss of

strength, change in skin color or texture, or

loss of feeling in the fingers, hands, or joints,

discontinue the use ofthis toot and seek med-

ical attention. An anti-vibration system does

not guarantee the avoidance of these prob-

lems. Users who operate power tools on a

continual and regular basis must monitor

closely their physical condition and the condi-

tion of this tool.

SPECIAL NOTICE: This unit is equipped

with a temperature limiting muffler and spark

arresting screen which meets the require-

ments of California Codes 4442 and 4443. All

U.S. forest land and the states of California,

3

Idaho, Maine, Minnesota, New Jersey, Ore-

gon, and Washington require by law that

many internal combustion engines be

equippedwith aspark arresting screen. Ifyou

operatein a locale where such regulations ex-

ist, you are legally responsible for maintaining

the operating condition of these parts. Failure

to do so is a violation of the law. For normal

homeowner use,the mumerand spark arrest-

ing screen will not require any service. After

50 hours of use, we recommend that your

muff]erbeserviced or replaced byyour autho_

dzed service dealer.

CARTON CONTENTS

Check carton contents against the following

list:

Brushcutter

Blade shield screws (4)

Cupped washer

Large nut for installing blades

Hex wrench

Metal shield

Plastic shield

Shoulder strap with warning

4-point weed blade

Trimmer head (assembled on unit)

Handlebar (assembled on unit)

Wing nut (screwed onto shield)

Container of oil

_WARNING: Always stop unit and dis-

connect spark plugbefore performing any as-

sembly procedures.

,_.WARNING: If received assembled,

repeat allsteps to ensure your unit is propedy

assembled and atlfasteners are secure.

Examine partsfor damage. Do not usedamn

aged parts.

NOTE: NOTE: If you need assistance or

find parts missing or damaged, call

1-800-554-6723.

It is normal for the fuel filter to ratbo in the

empty fuel tank.

Finding fuel or oil residue on muffler is norm al

due to carburetor adjustments and testing

done by the manufacturer

TOOLS REQUIRED

• Hexwrench (provided)

• Adjustable w_ench

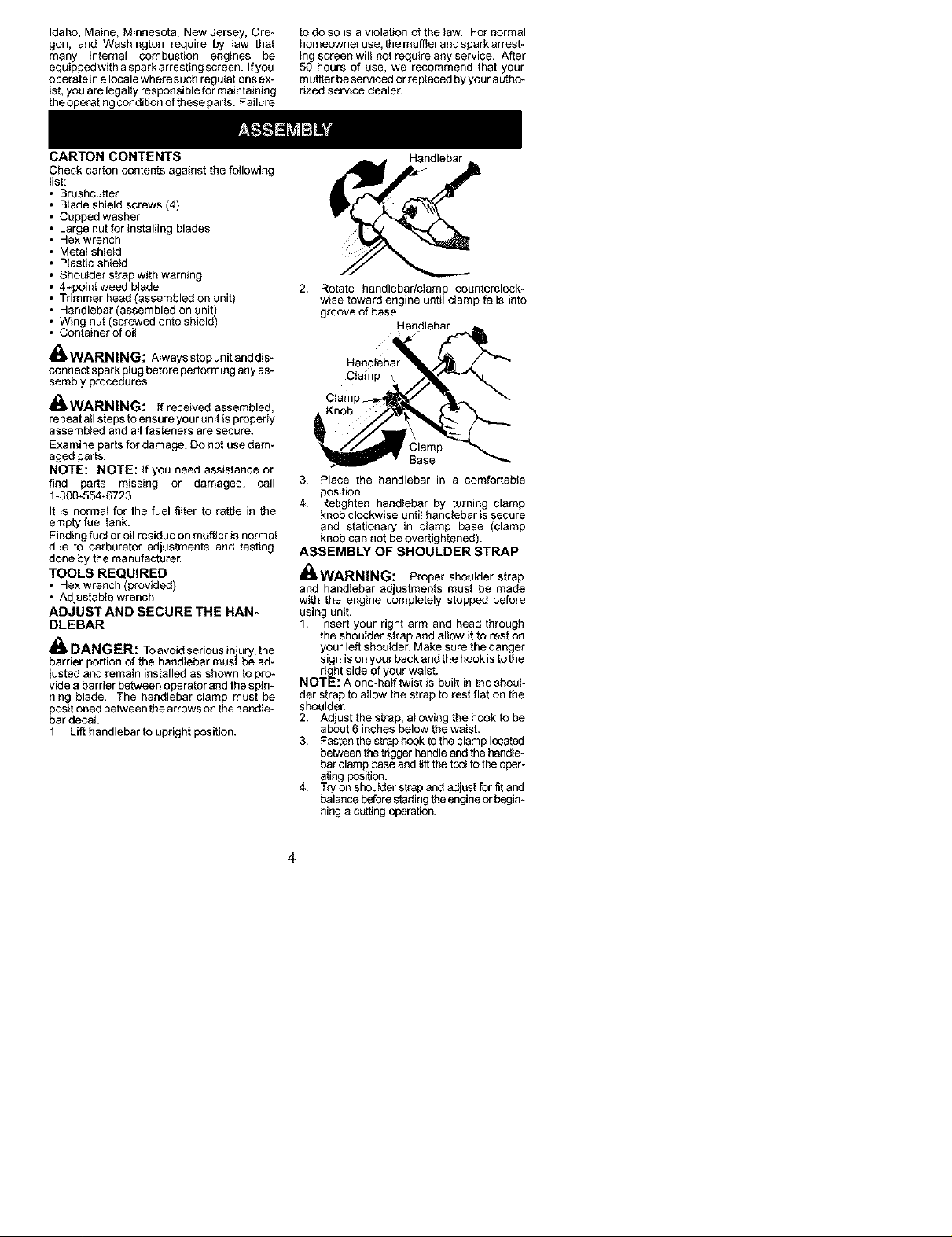

ADJUST AND SECURE THE HAN-

DLEBAR

_ DANGER: Toavoid serious inury, the

herr er port on of the hand ebar must be ad_

justedand remain installed as shown to pro-

vide a barrier between operator and the spire

ning blade. The handlebar clamp must be

positioned between the arrows on the handle-

bar decal

1. Lift handlebar to upright position.

Handlebar

2. Rotate handlebar/clamp counterclock-

wise toward engine until clamp falls into

groove of base.

Clamp

Clam

3. Place the handlebar in a comfortable

position.

4. Retighten handlebar by turning clamp

knob clockwise until handlebar is secure

and stationary in clamp base (clamp

knob can not be overtightened).

ASSEMBLY OF SHOULDER STRAP

_WARNING: Proper shoulder strap

and handlebar adjustments must be made

with the engine completely stopped before

using unit.

1. Insert your right arm and head through

the shoulder strap and allow itto rest on

your left shoulder. Make sure the danger

sign is on your back andthe hook is tothe

d_ht side of your waist.

NOTE: A one-haff twist is built in the shoul-

der strap to allow the strap to rest flat on the

shoulder.

2. Ad ust the strap, allowing the hook to be

about 6 nches be ow the wa st.

3. Fastenthestrap hook to the clamp located

between the triggerhandleandthe handle-

her clamp baseand lif_the tootto theoper-

ating position.

4. Try on shoulderstrap and adjustfor fit and

balance before sfedingtheengineor begim

ning a cuttingoperation.

Handlebar

Base

4

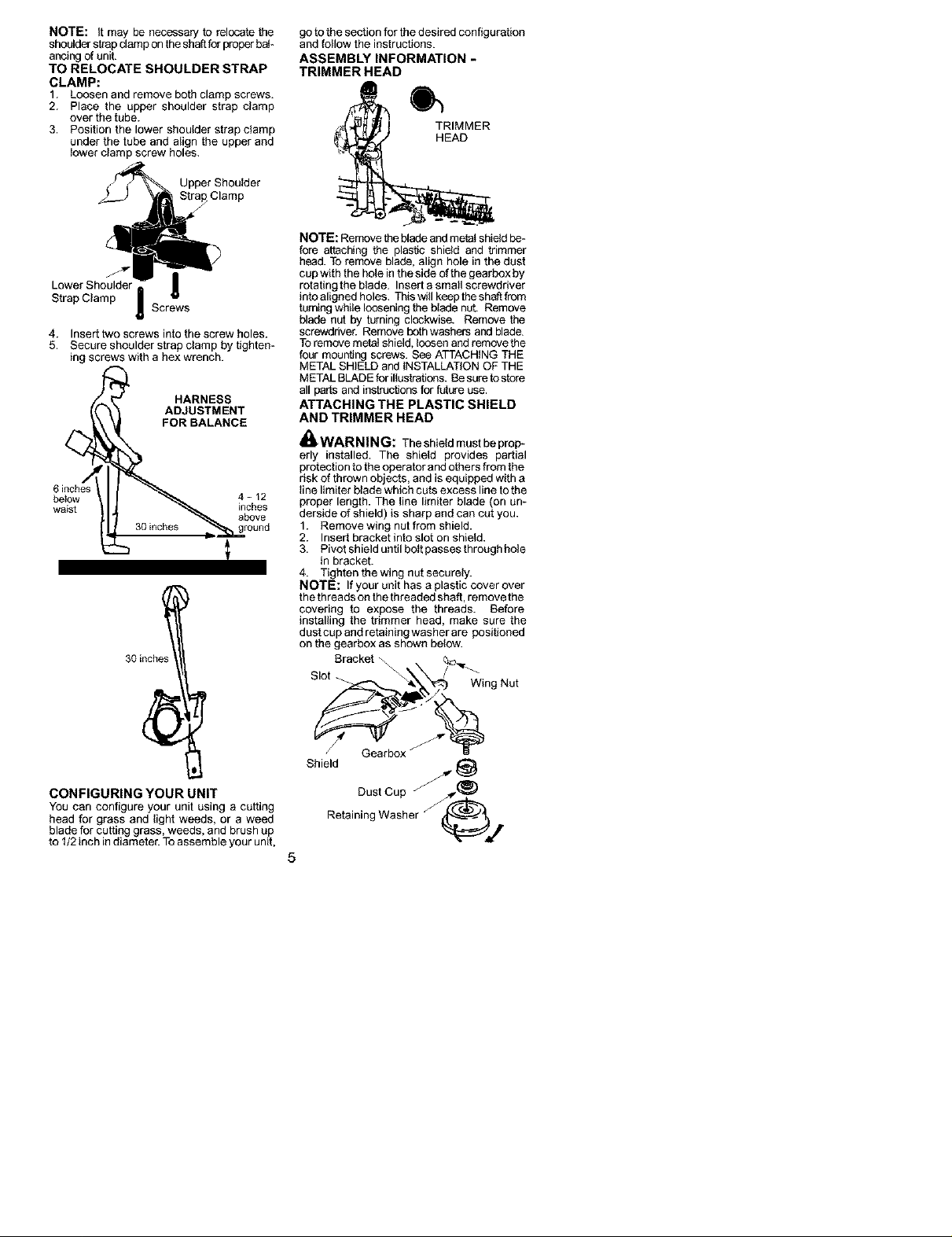

NOTE: it may be necessary to relocate the

shoulderstrapclamp onthe shaftforproperbah

ancingof unit.

TO RELOCATE SHOULDER STRAP

CLAMP:

1. Loosen and remove both clamp screws.

2. Place the upper shoulder strap clamp

over the tube.

3. Position the lower shoulder strap clamp

under the tube and a_ignthe upper and

_owerclamp screw holes.

Upper Shoulder

Clamp

Lower Shoulder J

Strap Clamp

4. Insert two screws into the screw holes.

5. Secure shoulder strap clamp by tighten-

ing screws with a hex wrench.

6 inches

betow 4 - 12

waist inches

Screws

30inches

HARNESS

ADJUSTMENT

FOR BALANCE

.'_ ground

above

goto the section for thedesired configuration

and follow the instructions.

ASSEMBLY INFORMATION -

TRIMMER HEAD

TRIMMER

HEAD

NOTE: Remove theblade andmeta_shieldbe-

fore attaching the plastic shield and trimmer

head. To remove blade, align hole inthe dust

cup with the hole in the side ofthe gearbox by

rotating the blade. Insert asmall screwdriver

into aligned holes. This will keeptheshaftfrom

turningwhile looseningtheb_adenut. Remove

blade nut by turning clockwise. Remove the

screwdriver. Remove both washers and blade.

Toremove meta_shield,loosenand remove the

four mounting screws. Bee ATTACHING THE

METAL SHIELD and INSTALLATIONOF THE

METALBLADE for illustrations.Besure tostore

all pade andinstructions for future use.

ATTACHING THE PLASTIC SHIELD

AND TRIMMER HEAD

_WARNING: The shield must be prop*

erly installed. The shield provides partial

protectionto the operator and others from the

risk of thrown objects, and is equipped witha

_inelimiter blade which cuts excess line to the

proper length. The line limder blade (on un-

derside of shield) is sharp and can cut you.

1. Remove wing nut from shield.

2. Insert bracket into slot on shield.

3. Pivot shield unfil bo_tpassesthrough hole

in bracket.

4. Tighten the wing nut securely.

NOTE: If your unit has a plasticcover over

thethreads onthe threaded shaft, remove the

covering to expose the threads. Before

installing the trimmer head, make sure the

dust cup and retaining washer are positioned

on the gearbox as shown below.

Bracket -_\_

Slot

Wing.or

CONFIGURING YOUR UNIT

You can configure your unit using a cutting

head for grass and light weeds, or a weed

blade for cutting grass, weeds, and brush up

to I/2 inch indiameter. Toassemble your unit,

Shield

Dust Cup @___

Retaining Washer @4€_

5

NOTE: Make sure al; parts are properly

fastaltad as shown in the illustration before

installing the trimmer head.

5. Align hole in thedust cup with the hole in

the side of the gearbox by rotating the

dust cup.

6. Insert a smal; screwdriver into aligned

holes. This wil_keep the shaftfrom turn_

fag whi;e tightening trimmer head.

of bladethrust which can causeserious injury

such as amputation to the operator or by-

standers. Failure to install the shield in the

position shown can result inserious injury to

theoperator. The length of theshield must be

aligned with the length of the tube.

1. Place the metal shield under the gearbox,

and align thescrew holes.

Screwdriver

7. While holding thescrewdriver in position,

thread trimmer head onto the shaft in the

direction shown on the decal (counter_

clockwise). Tighten until secure.

NOTE: The retaining washer must be pobl-

tioned with the raised section facing toward the

gearbox.

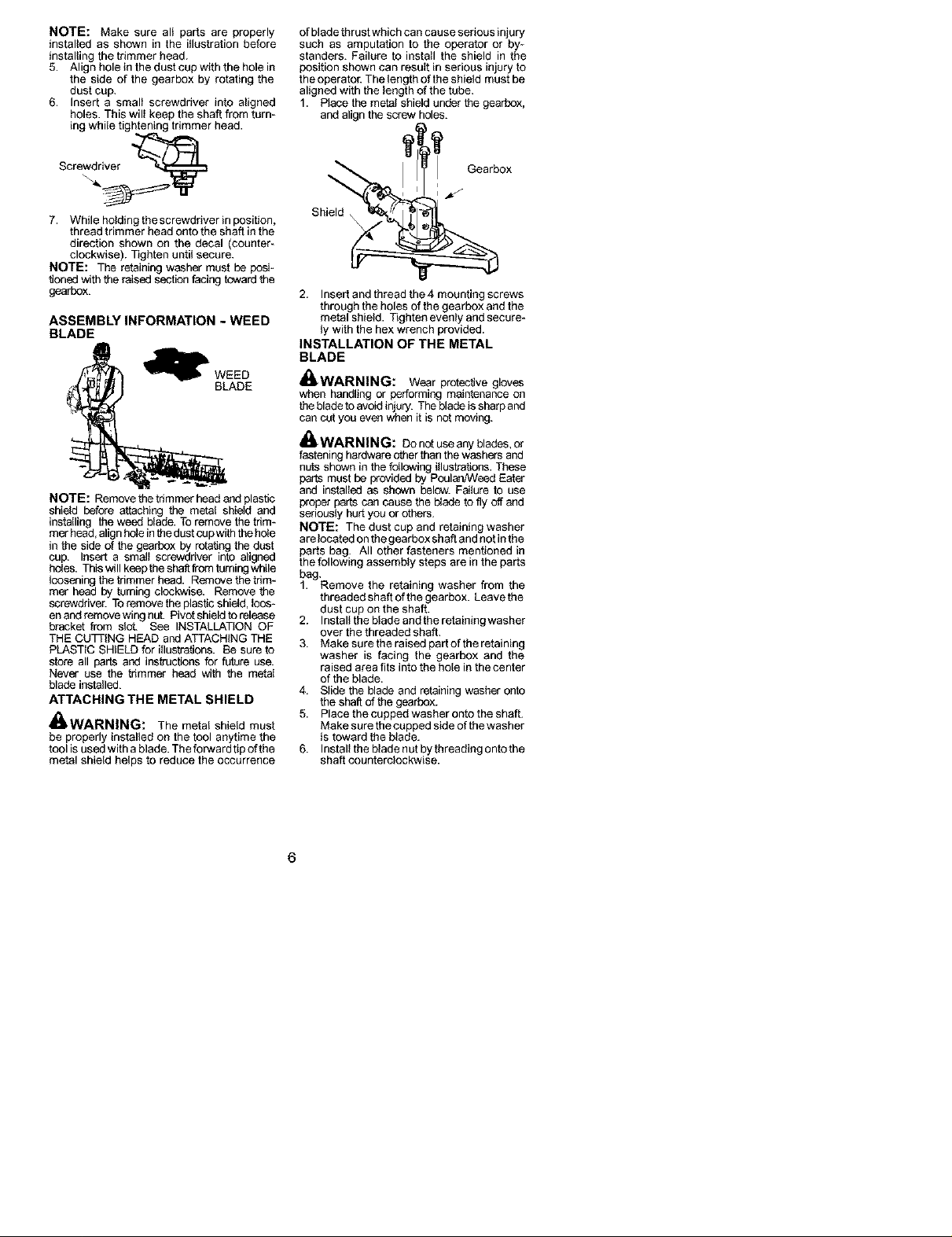

ASSEMBLY INFORMATION - WEED

BLADE

_WEED

BLADE

NOTE: Removethe trimmer headand plastic

shield before attaching the metel shield and

installing the weed blade. To remove the tdm-

methead, alignhole inthedustcupwith thehele

in the side of the gearbox by rotating the dust

cup. Insert a small screwdriver into aligned

holes. Thiswill keepthe shaft fiom turningwhile

faoseningthe thmmer head. Remove the tdm-

met heed by turning clockwise. Remove the

screwdriver. Toremove theplastic shield, loos-

enand removewing nut. Pivot shieldto release

bracket from slot. See INSTALLATION OF

THE CU3RING HEAD and ATTACHING THE

PLASTIC SHIELD for iiluelrations. 8e sure to

store all parts and instructionsfor future use.

Never use the trimmer head with the metal

blade installed.

ATTACHING THE METAL SHIELD

_WARNING: The metal shield must

be properly installed on the tool anytime the

tool is used with a blade. Theforward tip of the

metal shield helps to reduce the occurrence

Gearbox

Shield

2. Insert and thread the 4 mounting screws

through the holes ofthe gearbox and the

metal shield. Tighten evenly and secure-

ly with the hex wrench provided.

INSTALLATION OF THE METAL

BLADE

_WARNING: Wear protective gloves

when handling or performing maintenance on

thebladetoavoid injury. The bladeissharpand

can cut you even when it is not moving.

_WARNING: Do notuse any blades,or

fasteninghardware other than thewashers and

nuts shown inthe fc_lowingillustrations. These

parts must be providedby PoulanNVeedEater

and installed as shown below. Faiture to use

proper partscan cause the bladeto fly off and

seriously hurt you or others.

NOTE: The dust cup and retaining washer

arelocated on thegearbox shaft andnot inthe

parts bag. All other fasteners mentioned in

thefollowing assembly steps are in the parts

bag.

1. Remove the retaining washer from the

threaded shaftof the gearbox. Leave the

dust cup on the shaft.

2. Install the blade and the retaining washer

over the threaded shaft.

3. Make sure theraised part of theretafafag

washer is facing the gearbox and the

raised area fits into the hole in the center

of the blade.

4. Slide the blade and retainingwasher onto

the shaft of the gearbox.

5. Place the cupped washer onto the shaft.

Make surethe cupped side of the washer

is toward the blade.

6. Install the blade not by threadfag ontothe

shaft counterblockwise.

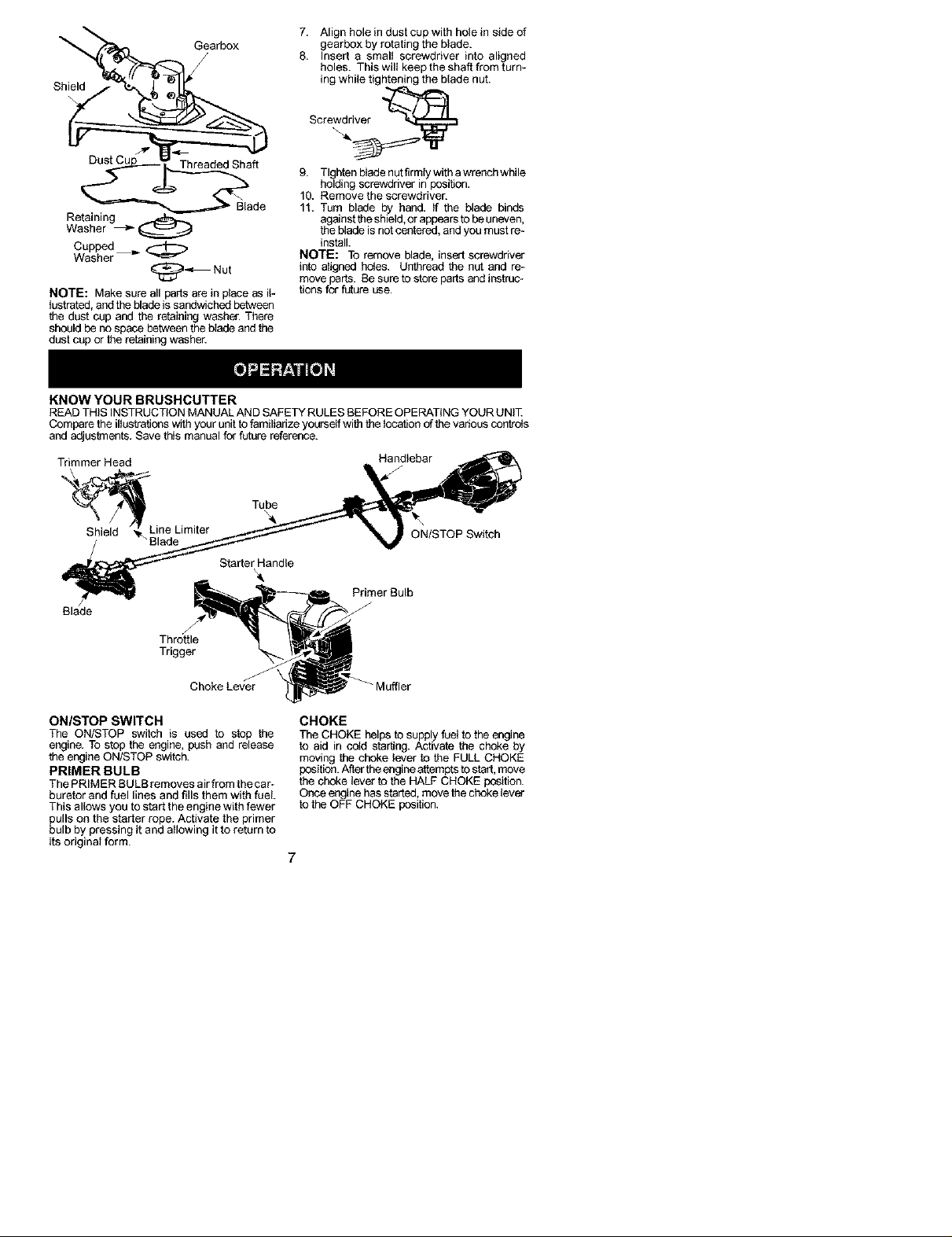

6

Shield

Gearbox

7. Align hole in dust cup with hole in side of

gearbox by rotating the blade.

8. Insert a small screwdriver into aligned

holes. This will keep the shaft from turn-

ing while tightening the blade nut.

Screwdriver

Threaded Shaft

Retaining

Washer _ _

Cupped

Washer

_Nut

NOTE: Make sure all parts are in piece as iF

lustrated, and the blade is sandwiched between

the dust cup and the retaining washer. There

should he no space between the blade and the

dust cup or the retaining washer.

KNOW YOUR BRUSHCUTTER

READ THIS INSTRUCTIONMANUAL AND SAFETYRULES BEFOREOPERATING YOUR UNR_

Comparethe illustrations with your unit tofamiliarize yourself with thelocation ofthe vaheus controls

and adjustments. Save this manual for future reference.

Blade

Trimmer Head

_ N_k_Liln_Limite r

Starter Handle

9. Tllgrhtenbledenutfirmlywithawrenchwhile

holding screwdriver in _ition.

10. Remove the screwdriver.

]t. Turn blade by hand. If the blade binds

againstthe shield, or appears to be uneven,

the blade is not centered, and you must re_

install.

NOTE: To remove blade, insert screwdriver

into aligned holes. Unthread the nut and re*

move parts. Be sure to store parts and instruc-

tions for future use.

Handlebar

ON/STOP Switch

Primer Bulb

Throttle

Trigger

Choke Lever

ON/STOP SWITCH

The ON/STOP switch is used to stop the

engine. To stop the engine, push and release

the engine ON/STOP switch.

PRIMER BULB

The PRIMER BULB removes air from thecar*

buretor and fuel lines and fills them with fuel.

This allows you to start the engine with fewer

pulls on the starter rope. Activate the primer

bulb by pressing it and allowing it to return to

its original form.

CHOKE

The CHOKE helps to supply fuetto the engine

to aid in cold starting. Activate the choke by

moving the choke lever to the FULL CHOKE

position.Aftertheengineattemptsto start,move

thechoke lever to the HALF CHOKE position.

Onceengine has started,movethe choke lever

to the OFF CHOKE position.

7

BEFORE STARTING ENGINE

_WARNING: Besure to read the fuel

information in the safety rules before you be-

gin. Ifyou do not understand the safety rules,

do not attempt to fuel your unit. Call

1-800_554-6723.

FUELING ENGINE

_WARNING: Remove fuel cap slowly

when refueling.

This engine is certified to operate on um

leaded gasoline. Befc_e operation, gasoline

must be mixed with a good quality synthetic

2*cycle air-cooled engine oil designed to be

mixed at a ratio of 40:1. PoulanANeedEater

brandsyntheticoil is recommended. Mixgasc_

line and oil ata ratio of 40:1.A 40:1ratio is ob_

tained by mixing 3.2ounces (95 ml) of oil with

1 gallon (4 liters) of unleaded gasoline.

DO NOT USE automotive oil or boat oil.

These oils will cause engine damage. When

mixing fuel, follow instructionsprintedon con_

tainer. Once oil is added to gasoline, shake

container momentarily to assure that the fuel

is thoroughly mixed. Always read andfollow

the safety rules relating to fuel before fueting

your unit.

IMPORTANT

Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or

methanol) can attract moisture which leadsto

separation and formation of acids during stor-

age.Acidic gas can damage the fuel system

of an engine while in storage.

Toavoid engine problems, empty thefuel sys*

tern before storage for 30 days or longer.

Drain the gas tank, start the engine and let it

run until the fuel lines and carburetor are

empty. Use fresh fuel next season.

Never use engine or carburetor cleaner prod-

ucts in the fuel tank or permanent damage

may occur.

See the STORAGE section for additional im

formation.

HOW TO STOP YOUR UNIT

• To stop the engine, push and release the

engine ON/STOP switch. The switch will

automatically return to the ON position.

Wait 5seconds before attempting torestart

unit to allow switch to reset.

• Ifengine does not stop, move choke lever

to FULL CHOKE position.

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

rting Position

J Starter Handle

Choke

-Lever

Primer Bulb

Muffler

1. Set unit on a flat surface.

2. Slowly press the primer bulb 6 times.

3. Move choke lever to FULL CHOKE by

ali ning lever with position shown on de_

ca_(see illustration below).

Choke

position

decal

4. Squeeze the throffle tnggorfully and hold

throughall remaining stega.

5. Pull starter rope handle sharply until en-

gine sounds as if itis trying to start, butdo

not pull rope more than 6 times.

6. As soon as engine sounds as ifit is trying

to start, move choke lever to HALF

CHOKE by aligning lever with position

shown on decal (see illustration below).

Thrott'oT"0 11

HOW TO START YOUR UNIT

_WARNING: The trimmer head will

turn while starfin_gthe engine. Avoid any con-

tact with the muffler. A hot muffler can cause

serious burns.

Pull startar rope sharply until engine runs,

but no more than 6 pulls. If the engline

dcesn't start after 6 pulls (at the HALF

CHOKE position), move thechoke leverto

the FULL CHOKE position and press the

pdmer bulb 6times.Squeeze and hold the

throttle tdggor and pull the starter rope 2

more times. Move the choke lever to the

HALF CHOKE positionand pullthe starter

rope untilthe engine runs,butno morethan

6 pulls. If the engine doesn't start, repeat

prccedure 2 additionaltimes.

8

NOTE: If engine still doesn't star{, it is

probablyflooded.ProceedtoSTARTINGA

FLOODED ENGINE.

8. Once tbeenginestaffs, al;owit torun 10se-

coeds,then move the choke lever to OFF

CHOKE by a_igning lever with position

shown ondecal (see illustration below).A_-

low the unit to runfor 30 more seconds at

OFF CHOKE before releasingthe throttle

trigger. NOTE: If engine dies with the

choke lever in the OFF CHOKE position,

move thechoke lever to the HALFCHOKE

position andpull therope untilengineruns,

but no morethan 6 pulls.

STARTING A WARM ENGINE

1. Move the choke lever to the HALF

CHOKE position.

2. Squeeze and hold the throttle trigger.

Keep throttle trigger fully squeezed until

the engine runs smoothly.

3. Pul; starter rope sharply until engine runs,

but no morethan 5 pulls.

4. Allow engine to run 15 seconds, then

move thechoke lever to theOFF CHOKE

position.

NOTE: NOTE: ff engine has not started,

pull starter rope 5 more pulls. If engine still

does not run, it is probably flooded.

STARTING A FLOODED ENGINE

Flooded engines can be started by placing

the choke lever in the OFF CHOKE position;

then, pull the rope to clear the engine of ex-

cess fuel. This could require pulling the starter

handle many times depending on how badly

the unit is flooded.

If the unit still doesn't start, refer to

TROUBLESHOOTING TABLE or call

1-800-554-6723.

OPERATING POSITION

ALWAYS WEAR:

Long Pants

e Protection

Boots

Cut from your left to your right.

When operating unit, clip shoulder straponto

clamp, stand as shown and check for the fol_

lowing:

• Wear eye protection and heavy clothing.

• Extend your left arm and hold handlebar

grip with your left hand.

• Hold throttle grip with your right hand with

finger on throttle trigger.

• Keep unit below waist level

• Keep shoulder strap pad centered on your

left shoulder and danger sign centered on

your back.

• Maintain full weight of tool on your left

shoulder.

• Without bending over, keep the blade or

trimmer head near and parallel to the

ground and not crowded into material being

cut.

OPERATING INSTRUCTIONS FOR

USE WITH TRIMMER HEAD

_WARNING: Always wear eye protec_

t_on.Never lean over the trimmer head. Rocks

or debris can ncochetor be thrown into eyes

andface and cause blindnessor o_er serious

injury.

Beforetrimming, bring engineto aspeed suffi-

cient to cutmaterial to betrimmed.

Do not run the engine at a higher speed than

necessary. The cutting line will cut efficiently

when the engine is run at less than ful_throttle.

At_owerspeeds,thereis lessenginenoise and

vibration.The cuttinglinewil_lastlonger andwill

be less likely to 'weld" ontothe spocL

Always release the throttle trigger and allow

the engine to return to idle speed when not

cutting.

TOstop engine:

Release the throttle trigger.

Push and release the engine ON/STOP

switch.

TRIMMER LINE ADVANCE

Thetrimmer line will advance approximately 2

in. (5 cm) each time the bottom ofthe trimmer

head is tapped on the ground with the engine

running at full throttle.

Themost efficient linelen,._thisthemaximum,

_engthallowed by the line hm,ter.Always keep

theshield in p_acewhen thetoef is being oper-

ated.

To advance line:

• Operate the engine at full throffie.

• Hold the trimmer head poraHelto andabove

the grassy area.

• Tap the bottom of the trimmer head lightly

on the ground onetime. Approximately 2 in.

(5 cm) of line will be advanced with each

tap.

Always tap the trimmer head on a grassy

area. Tapping on surfaces such asconcrete

or asphalt can cause excessive wear tothe

trimmer head.If the line is worn down to 2

inches (5 cm) or less, more than one tap will

be required to obtain the most efficient line

_ength.

_WARNING: Use only 0.095" (2.4

mm) diameter line. Other sizes of line will not

advance properly and can cause serious

9

injury.DOnotuseothermaterialssuchas

wire,atdng,rope,etc.Wirecanbreakoffdur*

ingcuttingandbecomeadangerousmissile

thatcancauseseriousinjury.

CUTTING METHODS

_WARNINL_: Use minimum speed

anddo notcrowd the linewhen cutting around

hard objects (rock, gravel, fence posts, etc.),

which candamage the trimmer head, become

entangled in the line, or bethrown causing a

serious hazard.

• The tip of the line does the cutting. You will

achieve the best performance and minim

mum line wear by not crowding the line into

the cutting area. The right andwrong ways

are shown below.

• The line will easily remove grass and

weeds fromaround wails, fences, trees and

flower beds, but it also can cut the tender

bark of trees or shrubs and scar fences.

• Fortrimming or scalping, use less thanfull

throttle to increase line life and decrease

head wear, especially:

• During light duty cutting.

Near objects around which the line can

wrap such as small posts, trees or fence

wire.

• Formowing or sweeping, usefull throtfle for

a good clean job.

TRIMMING - Hold the bottomof the trimmer

headabout 3 in. (8 cm) above theground and

at an angle. Allow only the tip of the line to

make contact. Do notforce trimmer line into

work area.

Trimming

3in. (8 cm)

AboveGround

SCALPING - The scalpingtechnique removes

unwanted vesgetationdown tothegrcound.Hold

the bottom o_the trimmer head about3 in. 8

cm abovethegroundand atanang e. Ai owthe

tjp of the line to strike the ground aroundtrees,

posts, monuments, etc. This technique in-

creases line wear.

Scalping

MOWING - Your trimmer is ideat for mowing

in places conventional lawn mowers cannot

reach. In the mowing position, keep the line

parallel to the ground. Avoid pressing the

head into the ground as this can scalp the

ground and damage the tool.

Mowing

SWEEPING - The fanning action ofthe rotat-

ing line ca n be usedto blow away loosedebris

from an area. Keep the line parallel to and

above the area surface and swing the toat

from side to side.

Sweeping

OPERATING INSTRUCTIONS FOR

USE WITH WEED BLADE

• Blade Thrust is a reactionthatonly occurs

when using a bladed unit. This reaction can

cause serious injury such as amputation.

Carefullystudy this section.Itis importantthat

you understand what causes blade thrust,

hew you can reduce the chance of its

occurring,and howyou can remain incontrol

of unit if blade thrustoccurs.

• WHAT CAUSES BLADE THRUST - Blade

Thrust can occur when the spinning blade

contacts an object that it does not cut. This

contactcauses the bladetostopforan instant

and then suddenly move or "thrust" away

from the object that was hit. The "thrusting"

reaction can be violent enough to cause the

operator to be propelled in any directionand

losecontrol of the unit.The uncontrolledunit

can cause serious injury ifthe bladecontacts

the operatoror others.

10

Loading...

Loading...