Poulan Pro 31 Instruction Manual

PoulanPR@

Instruction Manual

Manual de Instrucciones

Manuel d'lnstructions

031

For Occasional Use Only

®

&

WARNING:

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious injury.

ADVERTENCIA:

Lea el manual de instrucciones y siga todas tas advertencias e

instrucciones de seguddad. El no hacedo puede resultar en le-

siones graves.

AVERTISSEMENT:

Life le manuel d'instructions et bien respecter tousles avertisse-

ments et toutes les instructions de s6curit6. Tout d6faut de le

faire pourrait entrafner des blessures graves.

Electrolux Home Products, Inc.

250 Bobby Jones Expressway

Augusta, GA 30907

[] From the EtectroluxGroup. The world's No.l choice.

I_ITCIJF_,CLE,_N/NGAN_)OUTDOOR,_ppIJAN_ESCOM_NEIJ

Copyright/_)2002 Electrolux Home Products, Inc. 530163414 12/9/02

_,WARNING: When using gardening

appliances, basic safety precautions must al-

ways be followed to reduce the risk of fire and

serious injury. Read and follow all instruc-

tions.

This power unit can be dangerous! Operator is

responsible for following instructions and warn-

ings on unit and in manual. Read entire instruc-

tion manual before using unitTBe thoroughly fa-

miliar with the controls and the proper use of the

unit. Restrict the use of this unit to persons who

have read, understand, and will follow the

instructions and warnings on the unit and in the

manual. Never allow children to operate this

unit.

INSTRUCTION SAFETY INFORMATION

MANUAL ON THE UNIT

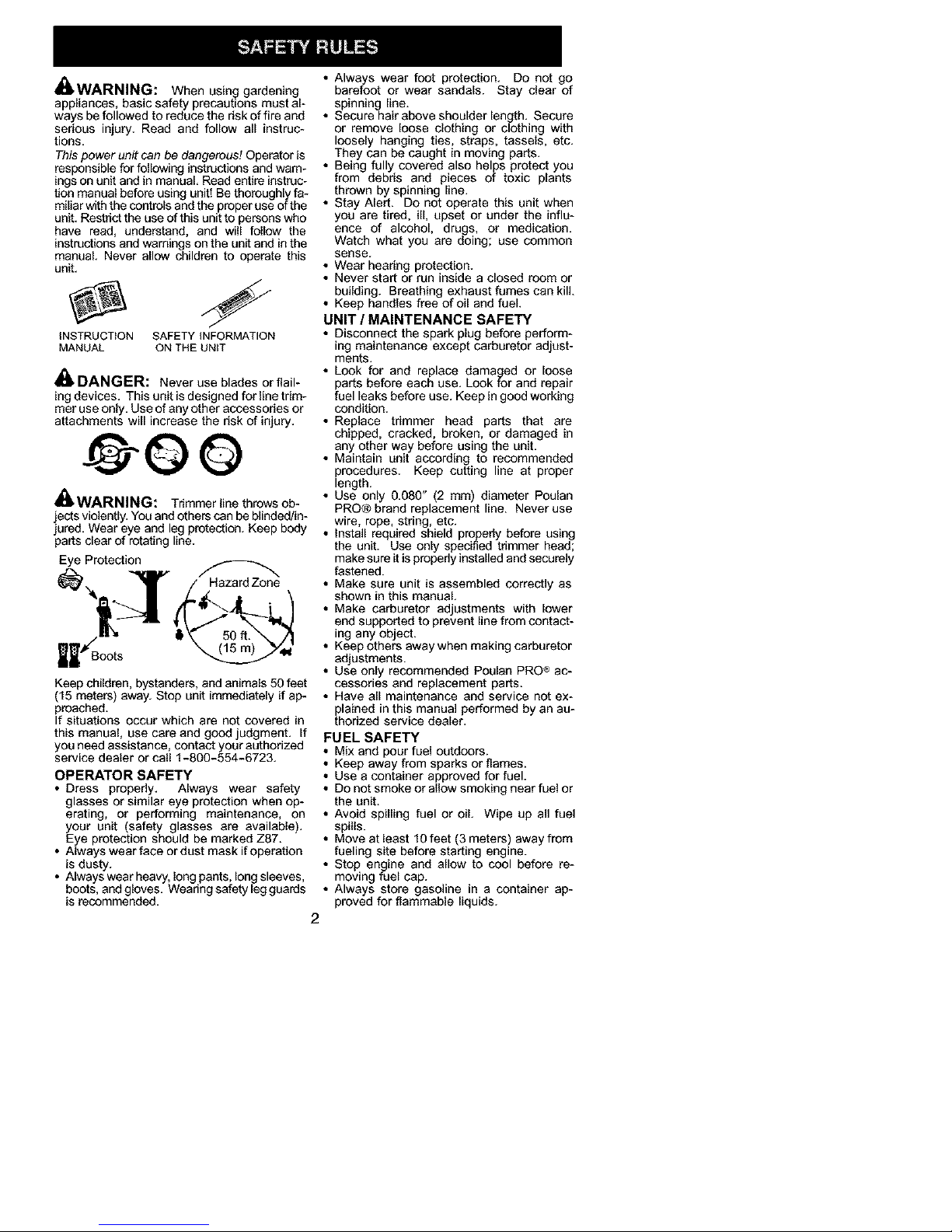

_, DANGER: Never use blades or flail-

ing devices. Thisunit isdesigned for linetrim-

mer useonly, Useof anyotheraccessories or

attachments will increase the riskof injury.

@(90

A

dllWARNING: Trimmer line throws ob-

jects violently. You and others can be blinded/in-

jured. Wear eye and leg protection. Keep body

parts clear of rotating line.

Eye Protection

/ Hazard Zone

Keep children, bystanders, and animals 50 feet

(15 meters) away. Stop unit immediately if ap-

preached.

If situations occur which are not covered in

this manual, use care and good judgment. If

you need assistance, contact your authorized

service dealer or call 1-800-554-6723.

OPERATOR SAFETY

• Dress properly. Always wear safety

glasses or similar eye protection when op-

erating, or performing maintenance, on

your unit (safety glasses are available).

Eye protection should be marked Z87.

• Always wear face or dust mask if operation

is dusty.

• Always wear heavy, long pants, long sleeves,

boots, and gloves. Wearing safety leg guards

is recommended.

• Always wear foot protection. Do not go

barefoot or wear sandals. Stay clear of

spinning line.

• Secure hair above shoulder length. Secure

or remove loose clothing or clothing with

loosely hanging ties, straps, tassels, etc.

They can be caught in moving parts.

• Being fully covered also helps protect you

from debris and pieces of toxic plants

thrown by spinning line.

• Stay Alert. Do not operate this unit when

you are tired, ill, upset or under the influ-

ence of alcohol, drugs, or medication.

Watch what you are doing; use common

sense.

• Wear hearing protection.

• Never start or run inside a closed room or

building. Breathing exhaust fumes can kill.

• Keep handles free ofoil and fuel.

UNIT / MAINTENANCE SAFETY

• Disconnect the spark plug before perform-

ing maintenance except carburetor adjust-

ments.

• Look for and replace damaged or loose

parts before each use. Look for and repair

fuel leaks before use. Keep in good working

condition.

• Replace trimmer head parts that are

chipped, cracked, broken, or damaged in

any other way before using the unit.

• Maintain unit according to recommended

procedures. Keep cutting line at proper

length.

• Use only 0.080" (2 ram) diameter Poulan

PRO@ brand replacement line. Never use

wire, rope, string, etc.

• Install required shield properly before using

the unit. Use only specified trimmer head;

make sure it is properly installed and securely

fastened.

• Make sure unit is assembled correctly as

shown in this manual.

• Make carburetor adjustments with lower

end supported to prevent line from contact-

ing any object.

• Keep others away when making carburetor

adjustments.

• Use only recommended Poulan PRO® ac-

cessories and replacement parts.

• Have all maintenance and service not ex-

plained in this manual performed by an au-

thorized service dealer.

FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near fuel or

the unit.

• Avoid spilling fuel or oil. Wipe up all fuel

spills.

• Move at least 10 feet (3 meters) away from

fueling site before starting engine.

• Stop engine and allow to cool before re-

moving fuel cap.

• Always store gasoline in a container ap-

proved for flammable liquids.

2

CUTTING SAFETY

_,WARNING: Inspect the area before

each use. Remove objects (rocks, broken

glass, nails, wire, etc.) which can be thrown

by or become entangled in line. Hard objects

can damage the trimmer head and be thrown

causing serious injury.

• Use only for trimming, scalping, mowing and

sweeping. Do not use for edging, pruning or

hedge trimming.

• Keep firm footing and balance. Do not over-

reach.

• Keep all pads of yoor body away from muffler

and spinning line. Keep engine below waist

level. A hot muffler can cause serious bums.

• CL_ from your left to your right. Cutting on

right side of the shield will throw debris away

from the operator.

• Use only in daylight or good artificial light.

• Use only for jobs explained in this manual.

TRANSPORTING AND STORAGE

• Allow engine to cool before storing or trans-

porting in vehicle.

• Empty the fuel tank before storing or trans-

porting the unit. Use up fuel left in the carbu-

retor by starting the engine and letting it run

until it stops.

• Store unit and fuel in area where fuel vapors

cannot reach sparks or open flames from

water heaters, electric motors or switches,

furnaces, etc.

• Store unit so line limiter blade cannot acci-

dentally cause injury. The unit can be hung

by the tube.

• Store unit out of reach of children.

SAFETY NOTICE: Exposure to vibrations

through prolonged use of gasoline powered

hand tools could cause blood vessel or nerve

damage in the fingers, hands, and joints of

people prone to circulation disorders or abnor-

mal swellings. Prolonged use in cold weather

has been linked to blood vessel damage in

otherwise healthy people. If symptoms occur

such as numbness, pain, loss of strength,

change in skin color or texture, or loss of feeling

in the fingers, hands, or joints, discontinue the

use of this tool and seek medical attention. An

anti-vibrafioo system does not guarantee the

avoidance of these problems. Users who oper-

ate power tools on a continual and regular basis

must monitor closely their physical condition

and the condition of this tool.

SPECIAL NOTICE: This unit is equipped

with a temperature limiting muffler and spark

arresting screen which meets the require-

ments of California Codes 4442 and 4443. All

U.S. forest land and the states of California,

Idaho, Maine, Minnesota, New Jersey, Ore-

gon, and Washington require by law that

many internal combustion engines be

equipped with asparkarresting screen. Ifyoo

operate in a locale where such regulations ex-

ist, you are legally responsible for maintaining

the operating condition of these parts. Failure

to do so is a violation of the law. For normal

homeowner use, the muffler and spark arrest-

ing screen will not require any service. After

50 hours of use, we recommend that your

muffler be serviced or replaced by an autho-

rized service dealer.

4m.WARNINL_: If received assembled,

repeat all steps to ensure your unit is properly

assembled and all fasteners are secure.

Examine parts for damage. Do not use dam-

aged parts.

NOTE: If you need assistance or find parts

missing or damaged, call 1-800-554-6723.

It is normal for the fuel filter to rattle in the

empty fuel tank.

Finding fuel or oil residue on muffler is normal

due to carburetor adjustments and testing

done by the manufacturer.

ADJUSTING THE HANDLE

DWARNING: When adjusting the han-

dle, be sure it remains between the trigger

and the safety decal.

1. Loosen handle by turning T-handle/

screw counterclockwise.

2. Rotate the handle on the tube to an upright

position.

3. Adjust handle to a comfortable position

between the trigger and the safety label

on the tube.

4. Retighten handle by turning T-handle/

screw clockwise,

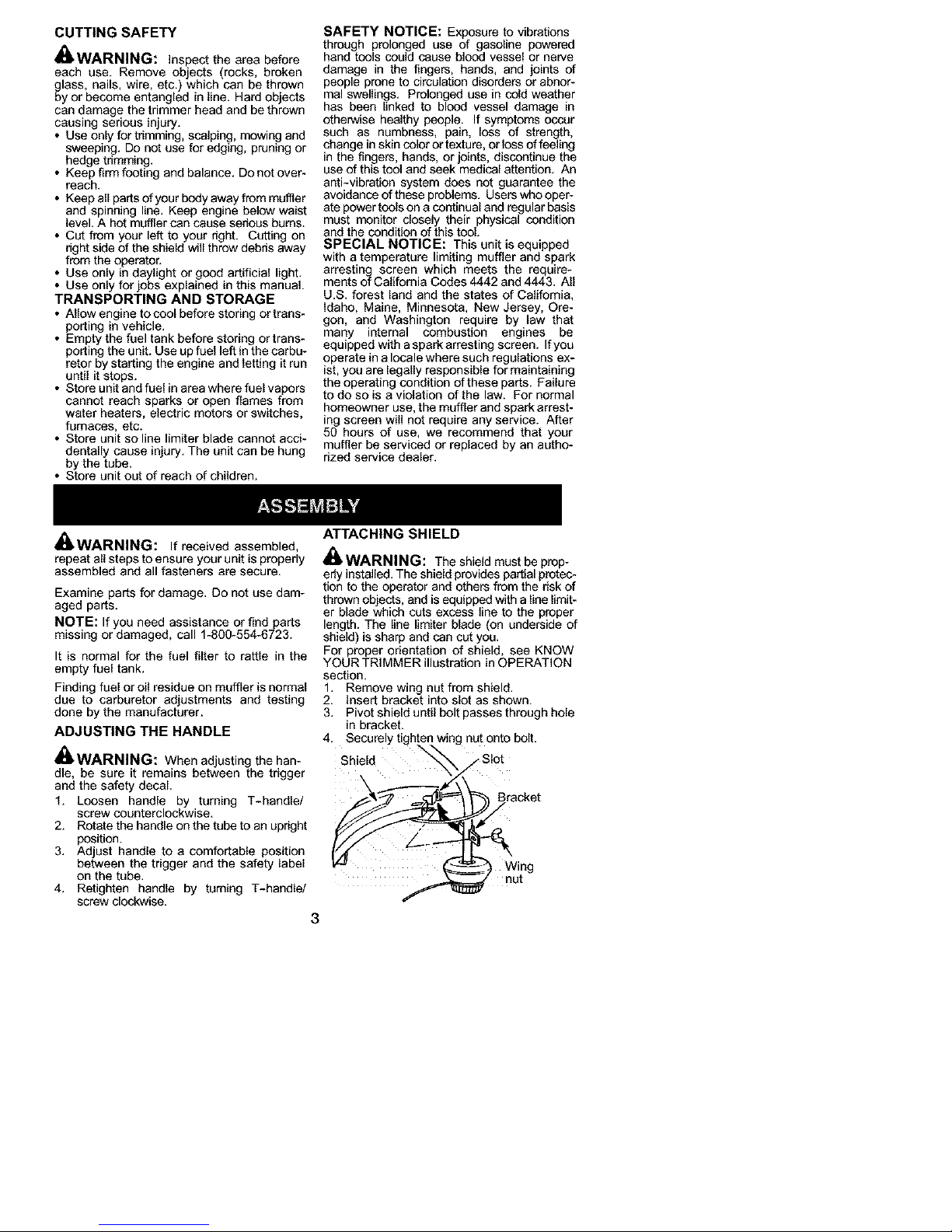

ATTACHING SHIELD

_WARNING: Theshieldmustbeprop-

erlyinstalled.The shield provides partial protec-

tion to the operator and others from the risk of

thrown objects, and is equipped with a line limit-

er blade which cuts excess line to the proper

length. The line [imiter blade (on underside of

shield) is sharp and can CL_yOU.

For proper orientation of shield, see KNOW

YOUR TRIMMER illustration in OPERATION

section.

1. Remove wing nut from shield.

2. Insert bracket into slot as shown.

3. Pivot shield until bolt passes through hole

in bracket.

4. Securely tighten wing nut onto bolt.

Shield "_/Slot

3

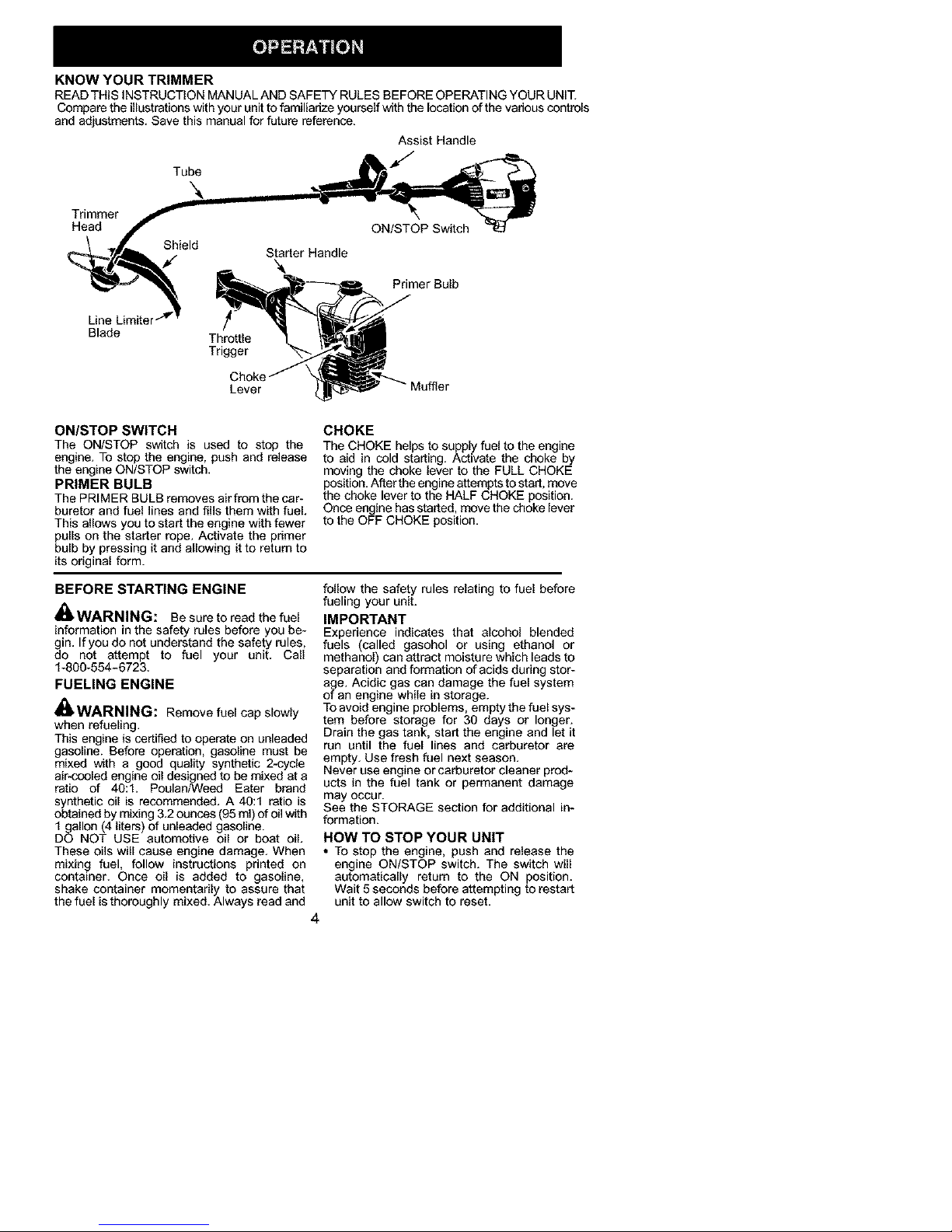

KNOW YOUR TRIMMER

READ THIS INSTRUCTION MANUAL AND SAFETY RULES BEFORE OPERATING YOUR UNIT.

Compare the illustrations with your unit to familiarize yourself with the location of the vadous controls

and adjustments, Save this manual for future reference.

Assist Handle

/

Tube

\

Trimmer

Head ON/STOP Switch

Shield

Starter Handle

Primer Bulb

Line Limiter ''_"

Blade Throttle

Trigger

Lever

ON/STOP SWITCH

The ON/STOP switch is used to stop the

engine. To stop the engine, push and release

the engine ON/STOP switch.

PRIMER BULB

The PRIMER BULB removes air from the car-

buretor and fuel lines and fills them with fuel,

This allows you to start the engine with fewer

pulls on the starter rope. Activate the primer

bulb by pressing it and allowing itto return to

its original form.

CHOKE

The CHOKE helps to supply fuel to the engine

to aid in cold starting. Activate the choke by

moving the choke lever to the FULL CHOKE

position. After the engine attempts to start, move

the choke lever to the HALF CHOKE position.

Once engine has started, move the choke lever

to the OFF CHOKE position.

BEFORE STARTING ENGINE

WARNING: Be sure to read the fuel

information in the safety rules before you be-

gin. If you do not understand the safety rules,

do not attempt to fuel your unit. Call

1-800-554-6723.

FUELING ENGINE

_ WARNING: Remove fuel cap slowly

when refueling.

This engine is certified to operate on unleaded

gasoline. Before operation, gasoline must be

mixed with a good quality synthetic 2-cycle

air-cooled engine oil designed to be mixed at a

ratio of 40:1. Poulan/Weed Eater brand

synthetic oil is recommended. A 40:1 ratio is

obtained by mixing 3.2 ounces (95 ml) of oil with

1gallon (4 liters) of unleaded gasoline.

DO NOT USE automotive oil or boat oil.

These oils will cause engine damage. When

mixing fuel, follow instructions printed on

container. Once oil is added to gasoline,

shake container momentarily to assure that

the fuel is thoroughly mixed. Always read and

follow the safety rules relating to fuel before

fueling your unit.

IMPORTANT

Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or

methanol) can attract moisture which leads to

separation and formation of acids during stor-

age. Acidic gas can damage the fuel system

of an engine while in storage.

To avoid engine problems, empty the fuel sys-

tem before storage for 30 days or longer.

Drain the gas tank, start the engine and let it

run until the fuel lines and carburetor are

empty. Use fresh fuel next season.

Never use engine or carburetor cleaner prod-

ucts in the fuel tank or permanent damage

may occur.

See the STORAGE section for additional in-

formation.

HOW TO STOP YOUR UNIT

• To stop the engine, push and release the

engine ON/STOP switch. The switch will

automatically return to the ON position.

Wait 5 seconds before attempting to restart

unit to allow switch to reset.

4

• If engine does not stop, move choke lever

to FULL CHOKE position.

,_1_,_ ON/STOP Switch

ThrottleTrig I

HOW TO START YOUR UNIT

DWARNING: The trimmer head will

turn while starting the engine. Avoid any con-

tact with the muffler. A hot muffler can cause

serious burns.

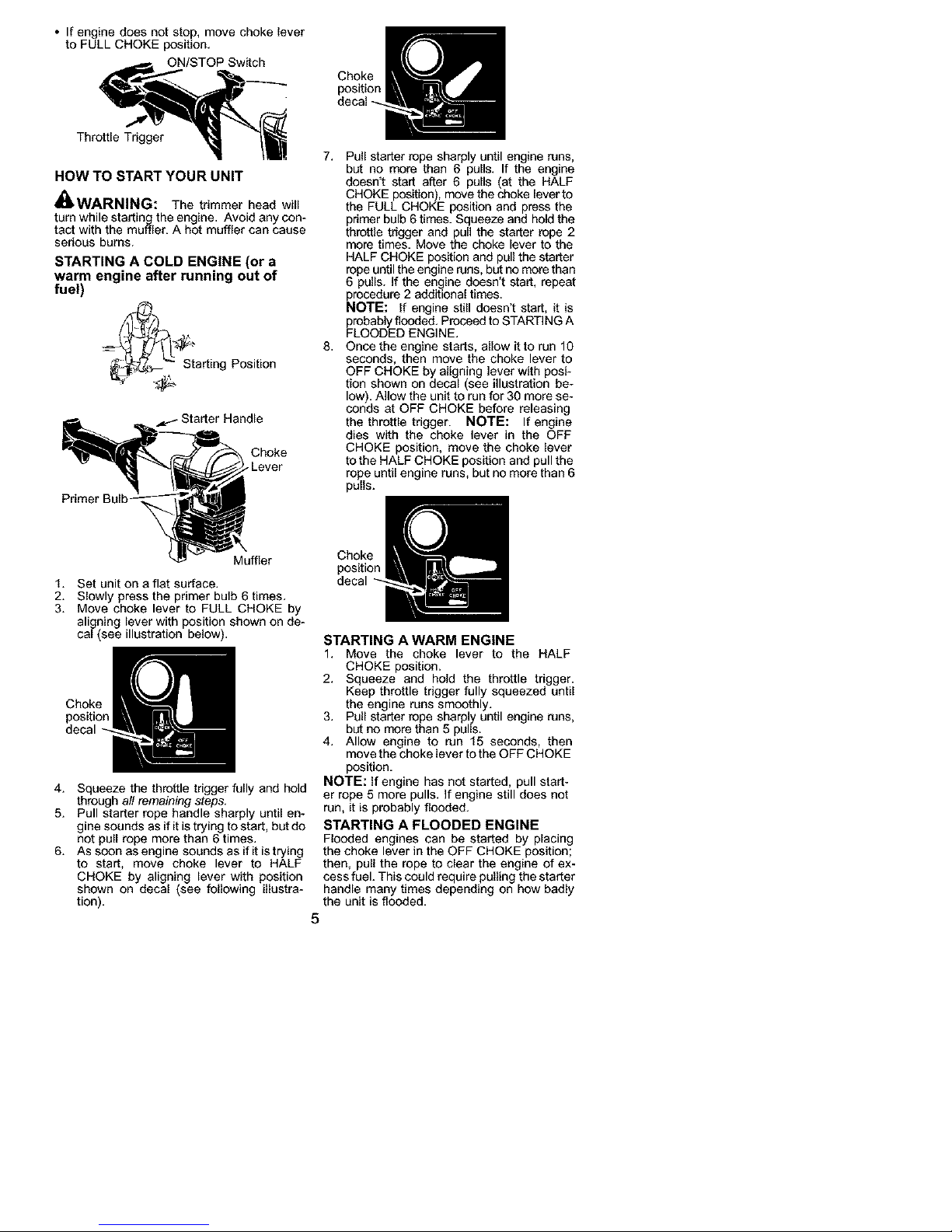

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

Starting Position

._÷

Handle

Choke

.Lever

Muffler

1. Set unit on a flat surface.

2. Slowly press the primer bulb 6 times.

3. Move choke lever to FULL CHOKE by

aligning lever with position shown on de-

cal (see illustration below).

4. Squeeze the throttle trigger fully and hold

through al! remaining steps.

5. Pull starter rope handle sharply until en-

gine sounds as if it is trying to start, but do

not pull rope more than 6 times.

6. As soon as engine sounds as if it is trying

to start, move choke lever to HALF

CHOKE by aligning lever with position

shown on decal (see following illustra-

tion).

Choke

position

7. Pull starter rope sharply until engine runs,

b_ no more than 6 pulls. If the engine

doesn't start after 6 pulls (at the HALF

CHOKE position), move the choke lever to

the FULL CHOKE position and press the

primer bulb 6 times. Squeeze and hold the

throttle trigger and pull the starter rope 2

more times. Move the choke lever to the

HALF CHOKE position and pull the starter

rope until the engine runs, but no more than

6 pulls. If the engine doesn't start, repeat

procedure 2 additional times.

NOTE: If engine still doesn't start, it is

probably flooded. Proceed to STARTING A

FLOODED ENGINE.

8. Once the engine starts, allow it to run 10

seconds, then move the choke lever to

OFF CHOKE by aligning lever with posi-

tion shown on decal (see illustration be-

low). Allow the unit to run for 30 more se-

conds at OFF CHOKE before releasing

the throttle trigger. NOTE: If engine

dies with the choke lever in the OFF

CHOKE position, move the choke lever

to the HALF CHOKE position and pull the

rope until engine runs, but no more than 6

pulls.

STARTING A WARM ENGINE

1. Move the choke lever to the HALF

CHOKE position.

2. Squeeze and hold the throttle trigger.

Keep throttle trigger fully squeezed until

the engine runs smoothly.

3. Pull starter rope sharply until engine runs,

bL_no more than 5 pulls.

4. Allow engine to run 15 seconds, then

move the choke lever to the GFF CHOKE

position.

NOTE: If engine has not started, pull start-

er rope 5 more pulls. If engine still does not

run, it is probably flooded.

STARTING A FLOODED ENGINE

Flooded engines can be started by placing

the choke lever in the OFF CHOKE position;

then, pull the rope to clear the engine of ex-

cess fuel. This could require pulling the starter

handle many times depending on how badly

the unit is flooded.

5

If the unit still doesn't start, refer to

TROUBLESHOOTING TABLE or call

1-800-554-6723.

OPERATING POSITION

ALWAYS WEAR; }_1--

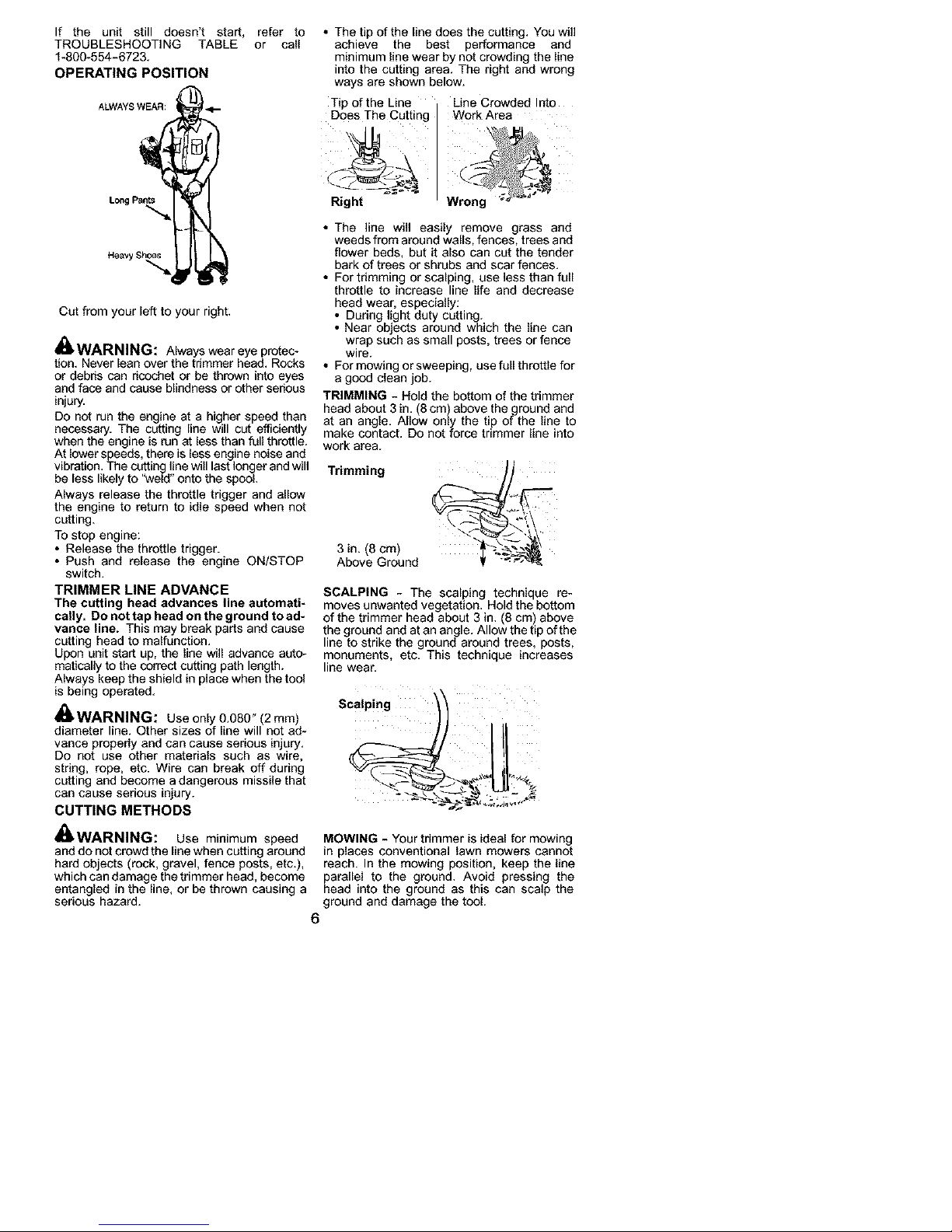

• The tip of the line does the cutting. You will

achieve the best performance and

minimum line wear by not crowding the line

into the cutting area. The right and wrong

ways are shown below.

Tip of the Line I Line Crowded Into

D0es The Cut!ing Work Area

Right _='" ' Wrong

Cut from your left to your right.

_,WARNING: Alwaysweareyeprotec-

Ion. Never lean over the trimmer head. Rocks

or debris can ricochet or be thrown into eyes

and face and cause blindness or other serious

injury.

Do not run the engine at a higher speed than

necessary. The CL_ting line will CL_ efficiently

when the engine is run at less than full throttle.

At lower speeds, there is less engine noise and

vibration. The cutting line will last longer and will

be less likely to "weld" onto the spool.

Always release the throttle trigger and allow

the engine to return to idle speed when not

cutting.

To stop engine:

• Release the throttle trigger.

• Push and release the engine ON/STOP

switch.

TRIMMER LINE ADVANCE

The cutting head advances line automati-

cally. Do not tap head on the ground to ad-

vance line. This may break parts and cause

cutting head to malfunction.

Upon unit start up, the line will advance auto-

matically to the correct CL_ting path length.

Always keep the shield in place when the tool

is being operated.

_,WARNING: Useonly0.080"(2mm)

diameter line. Other sizes of line will not ad-

vance properly and can cause serious injury.

Do not use other materials such as wire,

string, rope, etc. Wire can break off during

cutting and become a dangerous missile that

can cause serious injury.

CUTTING METHODS

_WARNING: Use minimumspeed

and do not crowd the line when cutting around

hard objects (rock, gravel, fence posts, etc.),

which can damage the trimmer head, become

entangled in the line, or be thrown causing a

sedous hazard.

• The line will easily remove grass and

weeds from around walls, fences, trees and

flower beds, but it also can cut the tender

bark of trees or shrubs and scar fences.

• For trimming or scalping, use less than full

throttle to increase line life and decrease

head wear, especially:

• During light duty cutting.

• Near objects around which the line can

wrap such as small posts, trees or fence

wire.

• For mowing or sweeping, use full throttle for

a good clean job.

TRIMMING - Hold the bottom of the tdmmer

head about 3 in. (8 cm) above the ground and

at an angle. Allow only the tip of the line to

make contact. Do not force trimmer line into

work area.

Trimming

3 in. (8 cm)

Above Ground

SCALPING - The scalping technique re-

moves unwanted vegetation. Hold the bottom

of the trimmer head about 3 in. (8 cm) above

the ground and at an angle. Allow the tip of the

line to strike the ground around trees, posts,

monuments, etc. This technique increases

line wear.

Scalping

MOWING - Your trimmer is ideal for mowing

in places conventional lawn mowers cannot

reach. In the mowing position, keep the line

parallel to the ground. Avoid pressing the

head into the ground as this can scalp the

ground and damage the tool.

6

Mo*ing '

SWEEPING - The fanning action of the rotat-

ing line can be used for a quick and easy

clean up. Keep the line parallel to and above

the surfaces being swept and move the tool

from side to side.

Sweeping

DWARNING: Disconnect the spark

plug before performing maintenance except

for carburetor adjustments.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Spark Plug Boot

• Air Filter

• Housing Screws

• Assist Handle Screw

• Debris Shield

CHECK FOR DAMAGED OR

WORN PARTS

Contact an authorized service dealer for re-

placement of damaged or worn parts.

• ON/STOP Switch - Ensure ON/STOP

switch functions properly by pushing and

releasing the switch. Make sure engine

stops. Wait 5 seconds before attempting to

restart unit to allow switch to reset. Restart

engine and continue.

• Fuel Tank - Discontinue use of unit if fuel

tank shows signs of damage or leaks.

• Debris Shield - Discontinue use of unit if

debris shield is damaged.

INSPECT AND CLEAN UNIT AND DE-

CALS

• After each use, inspect complete unit for

loose or damaged parts. Clean the unit and

decals using a damp cloth with a mild deter-

gent.

• Wipe off unit with a clean dry cloth.

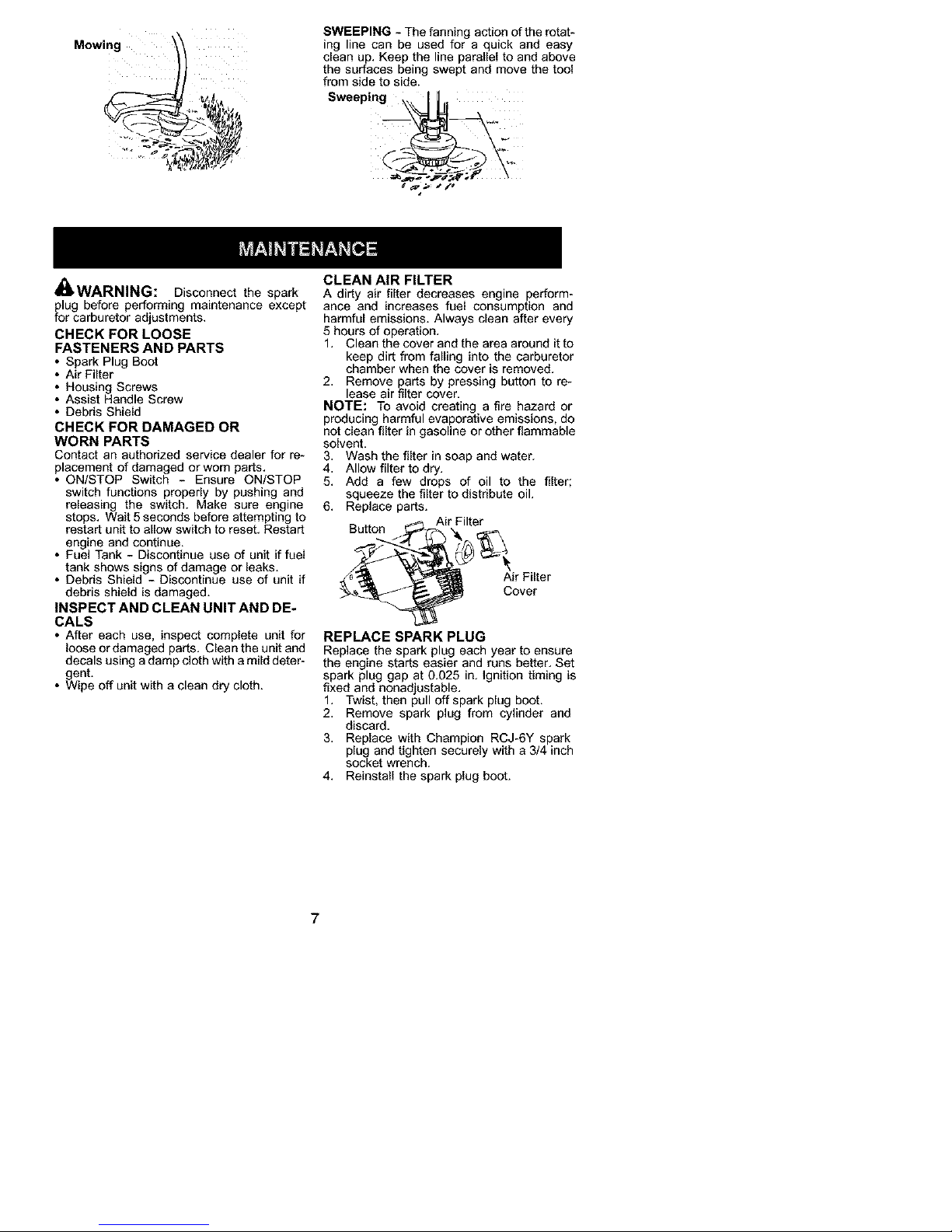

CLEAN AIR FILTER

A dirty air filter decreases engine perform-

ance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

1. Clean the cover and the area around it to

keep dirt from falling into the carburetor

chamber when the cover is removed.

2. Remove parts by pressing button to re-

lease air filter cover.

NOTE: To avoid creating a fire hazard or

producing harmful evaporative emissions, do

not clean filter in gasoline or other flammable

solvent.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Add a few drops of oil to the filter;

squeeze the filter to distribute oil.

6. Replace parts.

A_v_lrter

REPLACE SPARK PLUG

Replace the spark plug each year to ensure

the engine starts easier and runs better. Set

spark plug gap at 0.025 in. Ignition timing is

fixed and nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder and

discard.

3. Replace with Champion RCJ-6Y spark

plug and tighten securely with a 3/4 inch

socket wrench.

4. Reinstall the spark plug boot.

7

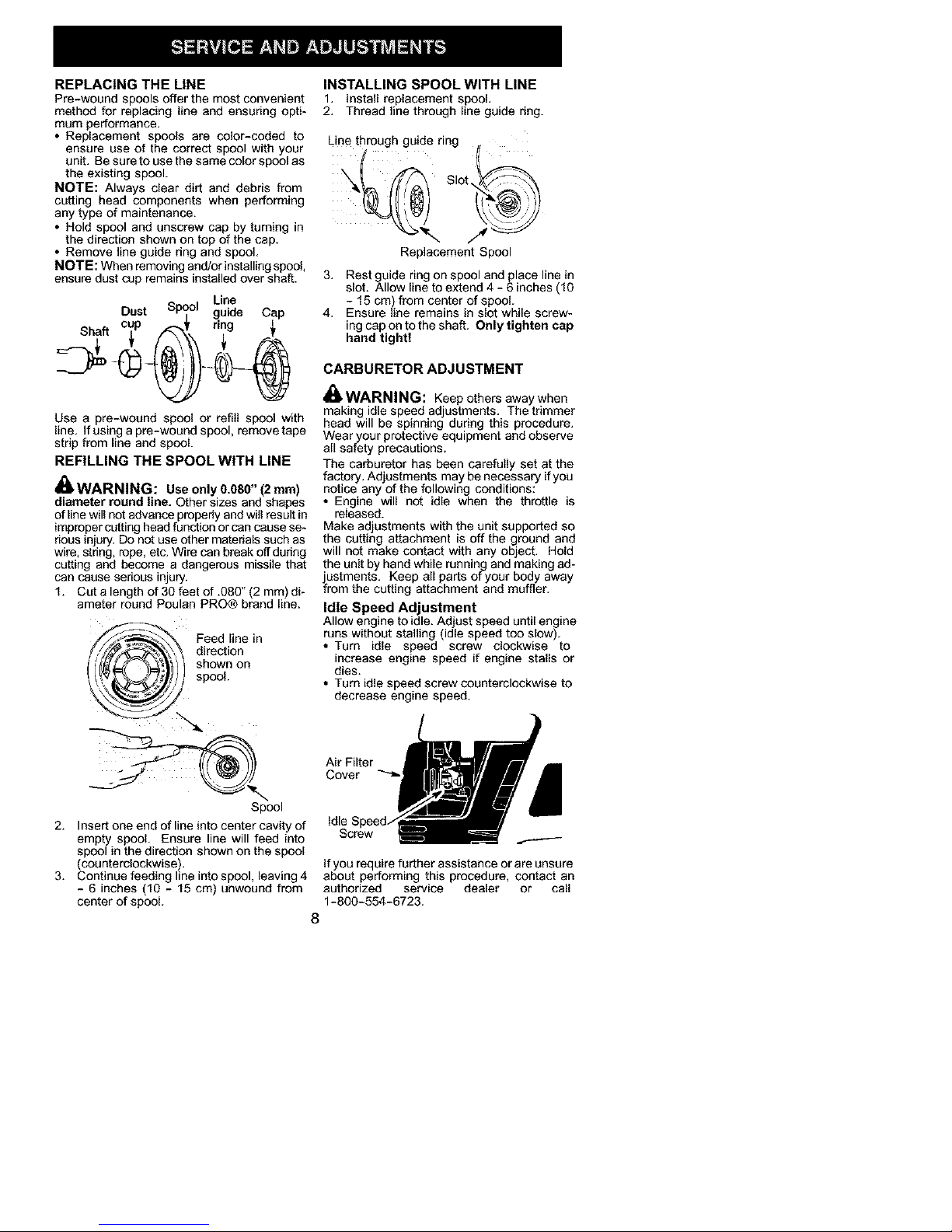

REPLACING THE LINE

Pre-wouod spools offer the most convenient

method for replacing line and ensuring opti-

mum performance.

• Replacement spools are color-coded to

ensure use of the correct spool with your

unit. Be sure to use the same color spool as

the existing spool.

NOTE: Always clear dirt and debris from

cutting head components when performing

any type of maintenance.

• Hold spool and unscrew cap by turning in

the direction shown on top of the cap.

• Remove line guide ring and spool.

NOTE: When removing and/or installing spool,

ensure dust cup remains installed over shaft.

. Line

Dust _pooi guide Cap

Shoftce,P ri.g

Use a pre-wouod spool or refill spool with

line. if using a pre-wound spool, removetape

strip from line and spool

REFILLING THE SPOOL WITH LINE

A

411WARNING: Use only 0.O8O" (2 ram)

diameter round line. Other sizes and shapes

of line will not advance properly and will result in

improper CL_tinghead function or can cause se-

rious injury. DO not use other materials such as

wire, string, rope, etc. Wire can break off during

cutting and become a dangerous missile that

can cause sedous injury.

1. Cut a length of 30 feet of .080" (2 mm) di-

ameter round Poulan PRO@ brand line.

__) eed linein

sdit_oewCtit°nn

spool

Spool

2. Insert one end of line into center cavity of

empty spool Ensure line will feed into

spool in the direction shown on the spool

(counterclockwise).

3. Continue feeding line into spool, leaving 4

- 6 inches (10 - 15 cm) unwound from

center of spool

INSTALLING SPOOL WITH LINE

1. install replacement spool.

2. Thread line through line guide ring.

Line through guide ring [

s

Replacement Spool

3. Rest guide ring on spool and place line in

slot. Allow line to extend 4 - 6 inches (10

- 15 cm) from center of spool.

4. Ensure line remains in slot while screw-

ing cap on to the shaft. Only tighten cap

hand tight!

CARBURETOR ADJUSTMENT

_, WARNING: Keep others away when

making idle speed adjustments. The trimmer

head will be spinning during this procedure.

Wear your protective equipment and observe

all safety precautions.

The carburetor has been carefully set at the

factory. Adjustments may be necessary if you

notice any of the following conditions:

• Engine will not idle when the throttle is

released.

Make adjustments with the unit supported so

the cutting attachment is off the ground and

will not make contact with any object. Hold

the unit by hand while running and making ad-

iustments. Keep all parts of your body away

rom the cutting attachment and muffler.

Idle Speed Adjustment

Allow engine to idle. Ad ust speed until engine

runs without stalling (idle speed too slow).

• Turn idle speed screw clockwise to

increase engine speed if engine stalls or

dies.

• Turn idle speed screw counterclockwise to

decrease engine speed.

Air Filter

Cover

'd' Se"wee

Ifyou require further assistance orare unsure

about performing this procedure, contact an

authorized service dealer or call

1-800-554-6723.

8

Loading...

Loading...