Page 1

, Ht f

TM

Read this Owner's Manual and follow

all Warnings and Safety Instructions.

Failure to do so can result in serious

injury.

:TRI742S|1I

LAWN TRACTOR

ALWAYS WEAR EYE PROTECTION DURING OPERATION

it WAHNIN*;

169553 4.6.99 JH

Printed in U.S.A.

Page 2

SAFFTVHIM tS

A

M, i ' .

FAILURE TO OBSER^

Read, uiidefstand, and follow all instructs

. .. re- "M * t, r iu «a'f.i ^

Tri)* ilif.i/. ,sv ,or^!oi-* s'ljffb ,v~> are

¡е;г»»л liW I r.j.»3<a№ ìj h. i-

Ol ,Ь|е^ ^ J_,* f t, f ^ * si AC.,

whrh гоиЧ t*e prKa«i if and mrcwp о/ ihe oHdr

be tne area ь dea' of otnet people betoie ng.

Jtofi tiB'hin- i‘ ati'/one i-mein tt” r^ea

fie 'er rarrv ■a'ls^ngerDo n 5f тол III -everse unless absolutely neeessarv. Ai

wa a |{,cl down and beh rd before and wh'le backing,

p- 'W4re > f the tarwe* dccharqe di't* tiop am oo net point

i» di an/'jiife Do n< jt operate the mo wet withcut either the

entire gta® ' -atrhf r r.<- ihe auard

oD* d... 0 Ь;*СГ' * wTrg

f TvW lea 0 3 machins unattended Always turn

blades sei parking Drake, stop engine, and remove keys

disniotiiuirg

Turn off blades when not mowing.

Stop engine before removing grass catcher or undogging

chute.

Mow oniy in daylight or good artificial light.

Do not operate the machine while under the influence of

alcohol or drugs.

Watch for traffic when operating near or crossing roadways.

Use extra care when loading or unloading the machine into

a trailer or truck.

II. SLOPE OPERATION

Slopes are a major factor related to loss-of-control and

tipover accidents, which can result in severe injuiY or death.

All slopes require extra caution. If you cannot back up the

slope or if you feel uneasy on it, do not mow it.

DO:

Mow up and down slopes, not across.

Remove obstacles such as rocks, tree limbs, etc.

Watch for holes, ruts, or bumps. Uneven terrain could

overturn the machine. Tail grass can hide obstacles.

Use stow speed. Choose a low gear so that you will not have

to stop or shift while on the slope.

Follow the manufacturer’s recommendations for wheel

weights or counterweights to improve stability.

Use extra care with grass catchers or other attachments.

These can change the stability of the machine.

Keep all movement on the slopes slow and gradual. Do not

make sudden changes in speed or direction.

Avoid starting or stopping on a slope. If tires lose traction,

disengage the blades and proceed slowly straight down

the slope.

DO NOT:

• Do not turn on slopes unless necessary, and then, turn

slowly and gradually downhill, if possible.

• Do not mow near drop-offs, ditches, or embankments. The

mower could suddenly turn over if a wheel is over the edge

of a cliff or ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction could cause

sliding.

• Do not try to stabilize the machine by putting your foot on

the ground.

• Do not use grass catcher on steep slopes.

'TING MACHINE li

i‘r F ,< r ■ ^ ii-

ip place

CAPABLE(

AFETY INI

IS in the manual

smiliar with the

IF AMPUTATIN

A

И If ( i. I

ih " ^tl '1'Г,

Tragic accidents can occur if the operator is not alert to the

; ' — 11» • < . j.M. 1 f r - I.>r-., .«I»- . 4'Hi j >1 { • • it'*-

.( > "r I 'Ч' ''mc.f i о u tt-t t

' He 3. -«I j.id tun, rath«'- oif if children enter the area

• Before and when backing, look behind and down for small

• Never carry children. They may fail off and be seriously

• Never aiiow children to operate the machine.

• Use extra cate wf;en approaching blind corners, shrubs,

I HANDS,

DULD RE!

Keep 'vicre’i jut ii*h'Mnov^rqai6c andi.iidb the v. | i.ij

-j - , i lOj A I p ¡,^'Llf _.iUt

chidieri

injurg'd or intedere v^ith safe machine operation.

trees, c* r=ther objects that ma/ obscure vision.

ND FEET AND THROWING <

ULT IN SERIOUS INJURY О

,i» t' .e 11H - W ri , iCt'vliy Ato. 1 r -iii 'c

i¥. SERVICE

• Use extra caro in handling gasoline and other fuels. They

are flammable and vapors are explosive.

- Use only an approved container,

• Never remove gas cap or add fuel with the engine running.

Allow engine to cooi before refueling. Do not smoke.

- Never refuel the machine indoors.

- Never store the machine or fuel container inside where

there IS an open fiame, such as a water heater.

• Never run a mactiirie inside a biosed area.

• Keep nuts and bolts, especially blade attachment bolts, tight

and keep equipment in good condition.

• Never tamper with safety devices. Check their proper

operation regularly.

• Keep machine free of grass, leaves, or other debris build-up.

Clean oil or fuel spillage. Allow machine to cool before

storing.

• Stop and inspect the equipment if you strike an object.

Repair, if necessary, before restarting.

• Never make adjustments or repairs with the engine running.

• Grass catcher components are subject to wear, damage,

and deterioration, which could expose moving parts or allow

objects to be thrown. Frequently check components and

replace with manufacturer's recommended parts, when

necessary.

® Mower blades are sharp and can cut. Wrap the blade(s) or

wear gloves, and use extra caution when servicing them.

» Check brake operation frequently. Adjust and service as

required.

Look for this symbol to point out

important safety precautions. It means

A

A

CAynON!!! BECOME ALERT!»! YOUR

SAFETY IS lN¥OL¥ED.

CAUTION: Always disconnect spark

plug wire and place wire where it

cannot contact spark plug in order to

prewent accidental starting when set

ting up, transporting, adjusting or mak

ing repairs.

A WARNING A

The engine exhaust from this product con

tains chemicals known to the State of Cali

fornia to cause cancer, birth defects, or

other reproductiwe harm.

Page 3

•J- .1*1- ^

'Jyr.ofii R

PPR1742STB

"jC r-.i/-L

MUMf.if:

.^rt i > I'Ht Hi- L

iHf ai'jI'LL 4Mi,

, ri l~r I IHi »t t nr . -I T r

OF PURCHASE AND KEEPINA SAFE PLACE FOR FUTURE |

-tr FI- rin>l£il _ _

''Rr« 1‘Fl h!-'M ..jsVbfcR. '

_MUMBERSWILL

:USTOMER RESPONSIBILiTIES

Read and observe the safety rules.

Follow a regular schedule in maintaining, caring for and

using your tractor.

Follow the instructions under "Customer Responsibilities"

and “Storage" sections of this manual.

'EARNING* Thic tractor i=- oqijipport with an internal com-

ijGtor anoint; and ahjuU net Ue jsf J on l, fit^r any

iiifTipiovu*] .'titeal ctirft-rea. brush uoieifd c»i gra^; cuy

■'6(i land unless the engine's exhaust syalem iS equipi.ed

ith a •'pa'k arrester roeetim applrable local or state !rws

any} If d impark dfir jict i'. Used, ¡t i'Odid be niaintained

effective w jrking ordet b\ the opeiator.

1 the state of California the abo ve ic- required by law (Section

442 of the California Public Resources Code). Otherstates

lay have similar laws. Fede ral laws apply on federal lands.

,4^ ' , ti I'H . I jM

__

■

SkLVE CLEARANC

GROUND

TIRE PRESSURE:

CHARGING SYSTEM:

ERY:

BLADE BOLT TORQUE:

1.2

1.5

2.4

3.5

4,8

f T|| 5.4

REVERSE: 1.5

hifcrn J r S'

Ml4H _ lOj Gi

! AMt H/' I I. H ,

AMF/MH

P/iN CFA iUO

_ i ASt^ :j7) U ■ H

.•;-3f,Fr LEi

Page 4

FABi F or eONTFNTS

SAFETY RULES ..................................................... 2

PRODUCT SPECIFICATIONS ................................. 3

CUSTOMER RESPONSIBILITIES ................... 3,14-17

WARRANTY ......................

ASSEMBLY

..............................................................

.............................................

..6-8

OPERATION ................................................................ii-13

4

REPAIR PARI T tro

PARTS ORDERING.................................. BACKPAGE

MAIMTENANCESCHEDULE ................................... 14

SERWICEA»ADJUSTMENTS ....................... 1S-24

STORAGE .........................................................25

.................................... 26-27

.......................................

3(M5

LIMITED WARRANTY

The Manufacturer warrants to the originai consumer purchaser that this product as manufactured P free from defecss in

materials end wo'krTianship. For a period of iwo (2} years from date of purchase by ttie original consumer purchaser we vril!

repair or replace, at our option, without charge for parts or labor incurred in replacing parts, any part which we find to be

defective due to materials or workmarship This Warranty T subject ¡o the following lirr.ilations and e^lusions

1. This wairariiy dues not appiy to the fiigtne. other than FHP (FouiaaTYeeci Eater) .Tianuiaciured trarisaxie/transiTHCSior.

compcneiiis. battery (except as noted below) or corripunentc Darts thereo. Please refur to the appdcabie

manufacturers warranty on these items.

2. Transportation charges for the movement of any power equipment unit or attachment are the responsibility me

purchaser. Transportation charges for any parts submitted for replacement under this warranty must be paid by the

purchaser unless such return is requested by Frigidaire Home Products (Poufan/Weed Eater).

3. Battery Warranty: On products equipped with a Battery, we will .replace, without charge to you, any battery which we find

to be defective in manufacture, during the first ninety (90) days of ownership. After ninety (90) days, we will exchange

the Battery, charging you 1/12 of the price of a new Battery for each full month from the date of the original sale. Battery

must be maintained in accordance with the instructions furnished.

4. The Warranty period for any products used for rental or commercial purposes is limited to 90 days from the date of

original purchase.

5. This Warranty applies only to products which have been properly assembled, adjusted, operated, and maintained in

accordance with the instructions furnished. This Warranty does not apply to any product which has been subjected to

alteration, misuse, abuse, improper assembly or installation, delivery damage, or to normal wear of the product.

6. Exclusions: Excluded from this Warranty are belts, blades, blade adapters, normal wear, normal adjustments, standard

hardware and normal maintenance.

7. In the event you have a claim under this Warranty, you must return the product to an authorized service dealer.

Should you have any unanswered questions concerning this Warranty, please contact:

Frigidaire Home Products

Outdoor Products Customer Service Dept.

250 Bobby Jones Expressway

Augusta, GA 30909 USA

giving the model number, serial number and date of purchase of your product and the name and address of the authorized

dealer from whom it was purchased.

THIS WARRANTY DOES NOT APPLY TO INCIDENTAL OR CONSEQUENTIAL DAMAGES AND ANY IMPLIED WARRAN

TIES ARE LIMITED TO THE SAME TIME PERIODS STATED HEREIN FOR OUR EXPRESSED WARRANTIES. Some areas

do not allow the limitation of consequential damages or limitations of how long an implied Warranty may last, so the above

limitations or exclusions may not apply to you. This Warranty gives you specific legal rights, and you may have other rights

which vary from locale to locale.

This is a limited Warranty within the meaning of that term as defined in the Magnuson-Moss Act of 1975.

In Canada contact:

Frigidaire Home Products

7075 Ordan Drive

Mississauga, Ontario

L5T 1K6

Page 5

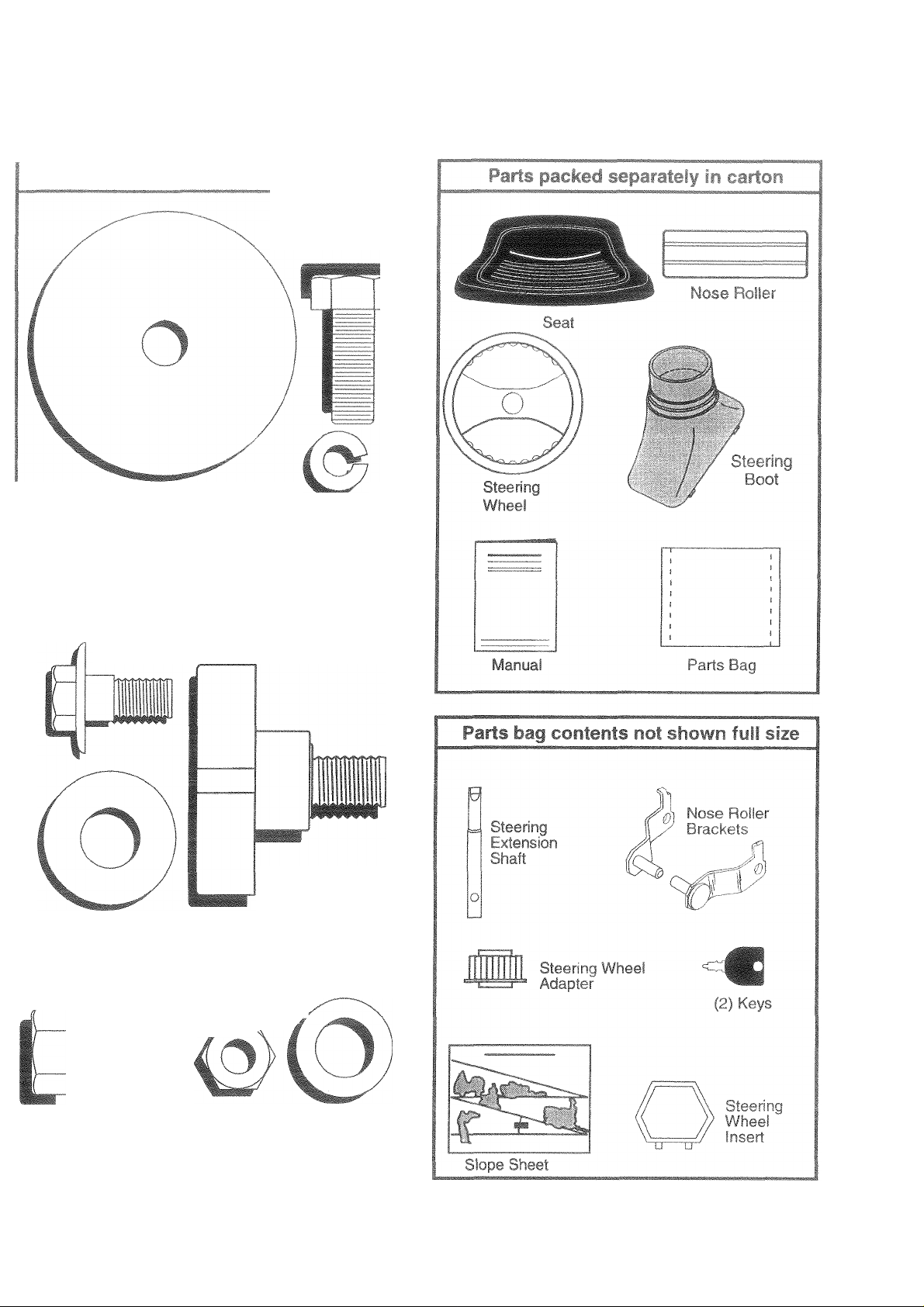

CONTEMTS OF HARDWARE PACK

Parts Bag contents showri full size

(1) Large Flat Washer Lockwasher 3/8

5X Bolt

3/8-16 X 1

§

o

(1) Hex Bolt 5/16-18 X 1-1/4 (1) Locknut 5/16-18

(1) Shoulder Bolt 5/16-18

(1)Knob

(1) Washer 17/32 x 1 -3/16 x 12 Gauge

(2) Washers 17/32 x7/8x 16 Ga.

(2) Hex Bolts 3/8-16 x 1 (2) Nylon Locknuts 3/8-16

Page 6

Yoi

safi

tool

in’ 3 ,,fti sembtedatthefactorvwithexceDtionofthosepartsleftunassembiedforshippinf purposes, Toensure

. i> , 1 -1 .. onofyoii fi'.»■[ . ;■ M-ardware you assemble must befightened securely. Use the correct

t r ,-^r, .sureprci i? ...

TOC

A sc

wrefii. i»

(1) &'to'«re;«rri

(2) 1/2" wrench

When right and left hand is mentioned in this manual, it

means when you are in the operating position (seated

behind the steering wheel).

makeas'Vr-' ‘ tor is id

sted.

t-tiinv r n te

! ;re pre>i.uie gauge

TO REMO¥E TRACTOR FROIJ CAR

TON

UNPACK CARTON

• Remove all accessible loose parts and parts cartons from

carton (See page 5).

• Cut along lines on carton, from top to bottom, all fourcorners

of carton and lay panels flat.

• Check for any additional loose parts or cartons and remove.

BEFORE ROLLING TRACTOR OFF

SKID

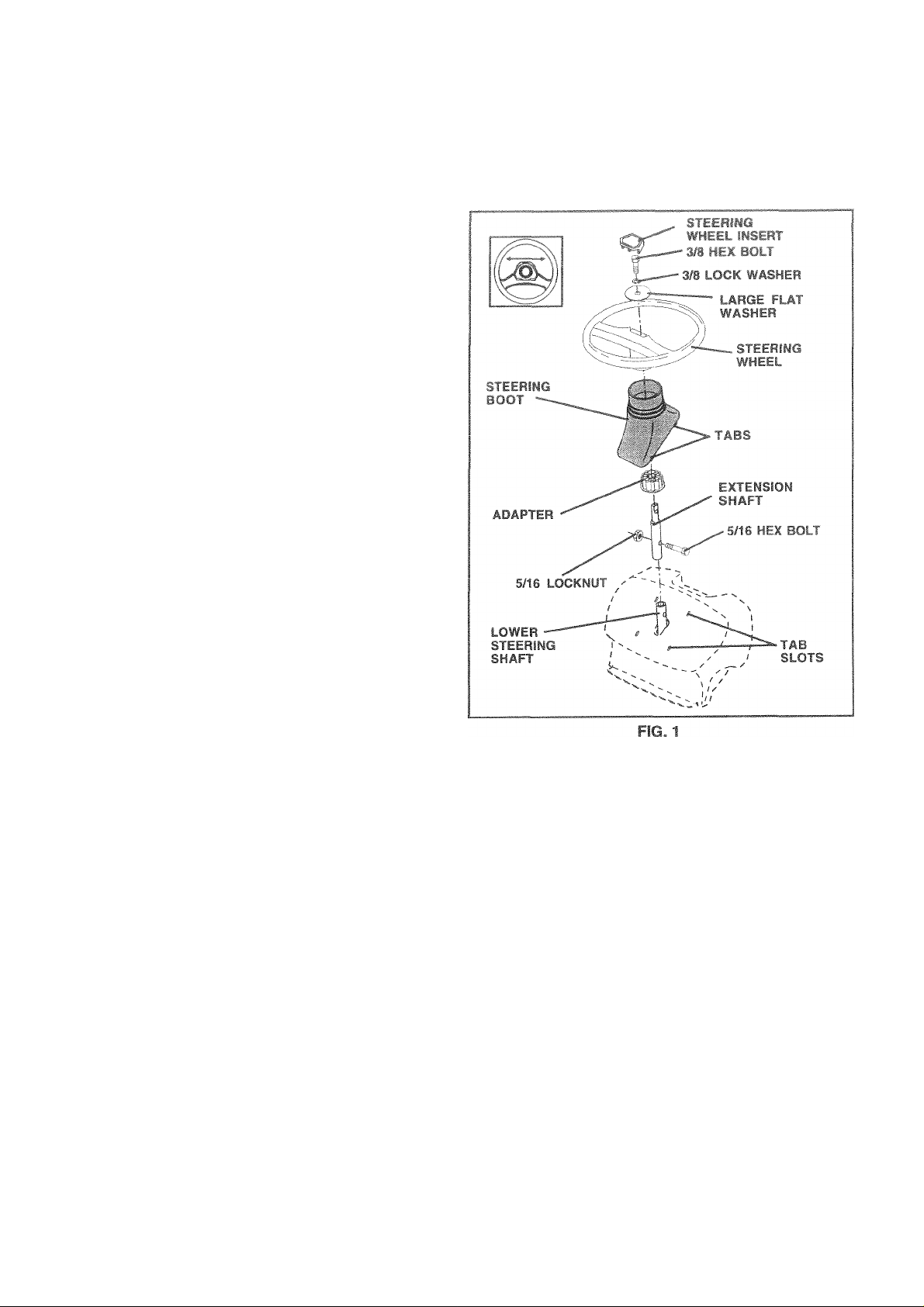

ATTACH STEERING WHEEL (See Fig. 1)

ASSEMBLE EXTENSION SHAFT AND BOOT

• Slide extension shaft onto lower steering shaft. Align

mounting holes in extension and lower shafts and install 5/

16 hex bolt and locknut. Tighten securely.

IMPORTANT: TIGHTEN BOLT AND NUT SECURELY TO

18-22 FT. LBS TORQUE.

• Place tabs of steering boot over tab slots in dash and push

down to secure.

INSTALL STEERING WHEEL

• Position front wheels of the tractor so they are pointing

straight forward.

• Slide steering wheel adapter onto steering shaft extension.

• Position steering wheel so cross bars are horizontal (left to

right) and slide inside boot and onto adapter.

• Assemble large flat washer, 3/8 lock washer, 3/8 hex bolt

and tighten securely.

• Snap steering wheel insert into center of steering wheel.

• Remove protective materials from tractor hood and grill.

IMPORTANT; CHECK FOR AND REMOVE ANY STAPLES

IN SKID THAT MAY PUNCTURE TIRES WHERE

TRACTOR IS TO ROLL OFF SKID.

TO ROLL TRACTOR OFF SK!D (See Opera

tion section for location and fynction of con

trols)

• Press lift lever plunger and raise attachment lift lever to its

highest position.

• Release parking brake by depressing clutch/brake pedal.

® Place gearshift lever in neutral (N) position.

• Roll tractor forward off skid.

• Remove banding holding discharge guard up against

tractor.

Page 7

ASSEMBLY

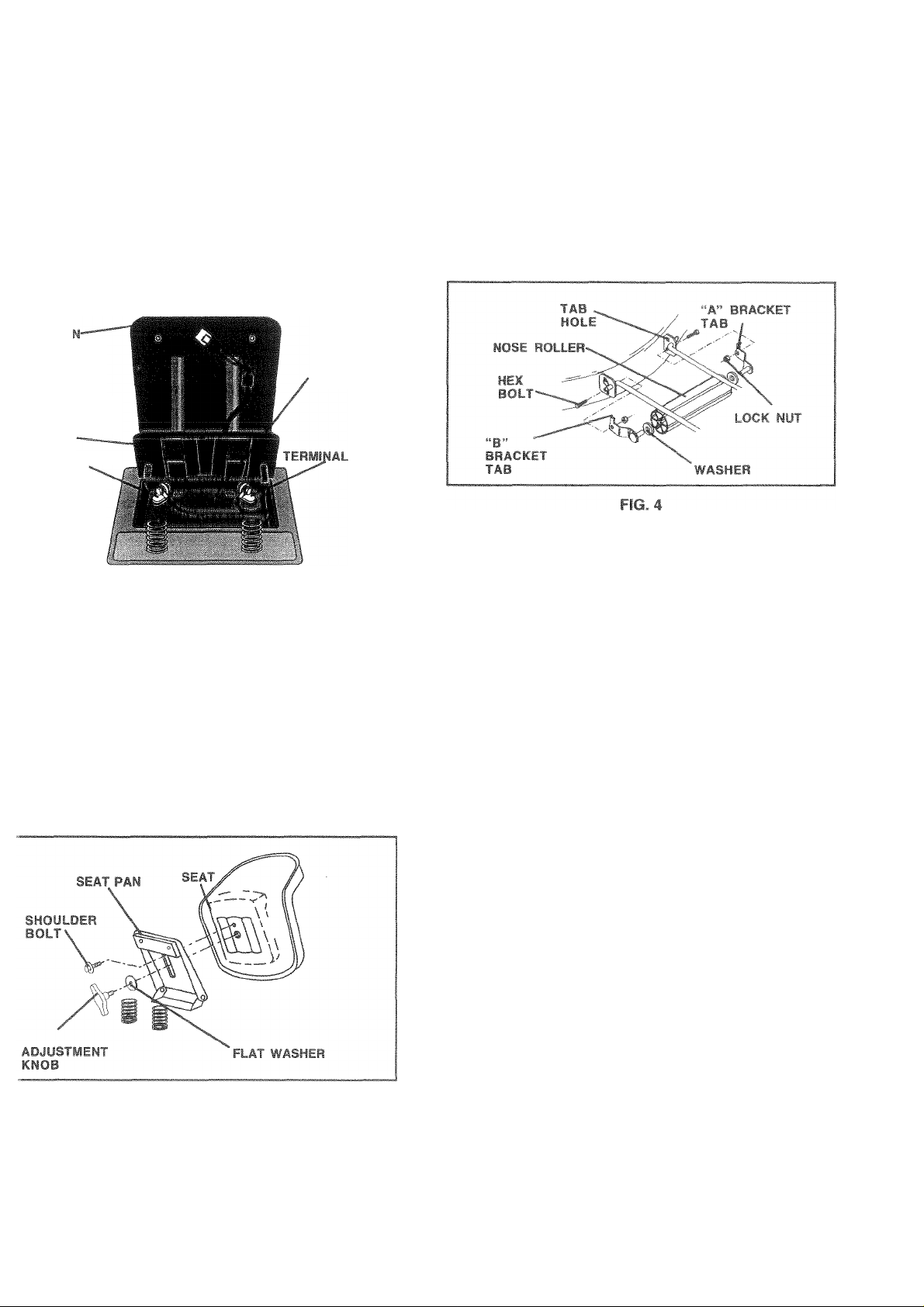

:::HECiC tY (See Fig. 2)

Lift seat pan to raised position and open batteiy box door.

If this battery is put into service after month and year

indicated on label (label located between terminals) charge

battery for minlfnum of one hour at 6-10 amps. (See "BAT

TERY^ in CUSTOMER RESPONSIBILITIES section of this

manual for charging instructions).

SEAT PAI

LABEL

BATTERY BOX

DOOR

TERMINAL-

FIG. 2

^STALL SEAT (See Fig. 3)

idjust seat before tightening adjustment knob.

Remove cardboard packing on seat pan.

Place seat on seat pan and assemble shoulder bolt. Tighten

shoulder bolt securely.

Assemble adjustment knob and flat washer loosely. Do not

tighten.

Lower seat into operating position and sit on seat.

Slide seat until a comfortable position is reached which

allows you to press clutch/brake pedal all the way down.

Get off seat without moving its adjusted position.

Raise seat and tighten adjustment knob securely.

SE ROLLER (See Fig. 4)

• Position brackets, 17/32 x 7/8 x 16 gauge washers, and

nose roller between deck mounting brackets as shown. Be

sure to position brackets on correct side, as shown.

• Install 3/8-16 X 1 hex botts and 3/8-16 lock nu iwn.

Tighten hardware securely.

NOTE; Be sure bracket tabs are positioned in tab holes in

deck brackets.

CHECK TIRE PRESSURE

The tires on your tractor were overinfiated at the factory for

shipping purposes. Correct tire pressure is important for

best cutting performance.

• Reduce tire pressure to PSI shown in “PRODUCT SPECI

FICATIONS^ section of this manual.

CHECK DECK LEYELNESS

For best cutting results, mower housing should be properly

feveied. See ‘TO LEVEL MOWER HOUSING” in the

Service and Adjustments section of this manual.

CHECK FOR PROPER POSITION OF ALL BELTS

See the figures that are shown for replacing motion and

mower blade drive belts in the Service and Adjustments

section of this manual. Verify that the belts are routed

correctly.

CHECK BRAKE SYSTEM

After you ¡earn how to operate your tractor, check to see

that the brake is properly adjusted. See ‘TO ADJUST

BRAKE” in the Service and Adjustments section of this

manuai.

FIG. 3

Page 8

'CHECKLIST

BE

DU OPERATE

AND ENJO"]

TRACTOR, WE WISH TO ASSURE THA T

RL. At. I “ ^ f ^ Vir- I |i ji I ^ ^ ^

\ tj‘t > »f i i

lU RECEIVE

' If )f! f- Ri Vi •

. " 5-JV“ ' COTLE

t LtA^i PtitEf^ to' Zll i Pf fz. Z‘‘LI :> i

, Ai< >S'“'rthi/ ¡n-ir»*! tmtii h st'f bi-i=<i i. 'rif.l< tito

f < remdinino loose 034=^ ii oer.-’f.

Piftb^V if praoerlv piep-irw. «ird claiotr» {Minimum 1

•".Ou. it o -i< ips|

Pe 4 i adjusted i orn%rtably and tightcne'i sejrev-

pii j.r: *tt propedy hfiatfcd |Fc' shippioj^ puv ('j-rs, the

tires *ere oierinflated at >4*= fartory*

Be sura mower cieclr is properly iewfed '^sde to side/front-

io rear tor oesl rutting resuii*^ jl ires roust ue properly

iniiat&d ‘‘jS ievenf'q)

Check mower and drive belts Be sure they are routed

/

properly around pulleys and inside all belt keepers

/

Check wiring. See that al! connections are slil! secure and

wires are properly clamped.

WHILE LEARNING HOW TO USE YOUR TRACTOR, PA Y

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

/ Engine oil is at proper ievel.

✓ Fuel tank is filled with fresh, clean, regular unleaded

gasoline.

/ Become familiar with all controls - their location and func

tion. Operate them before you start the engine.

/ Be sure brake system is in safe operating condition.

8

Page 9

OPERATION

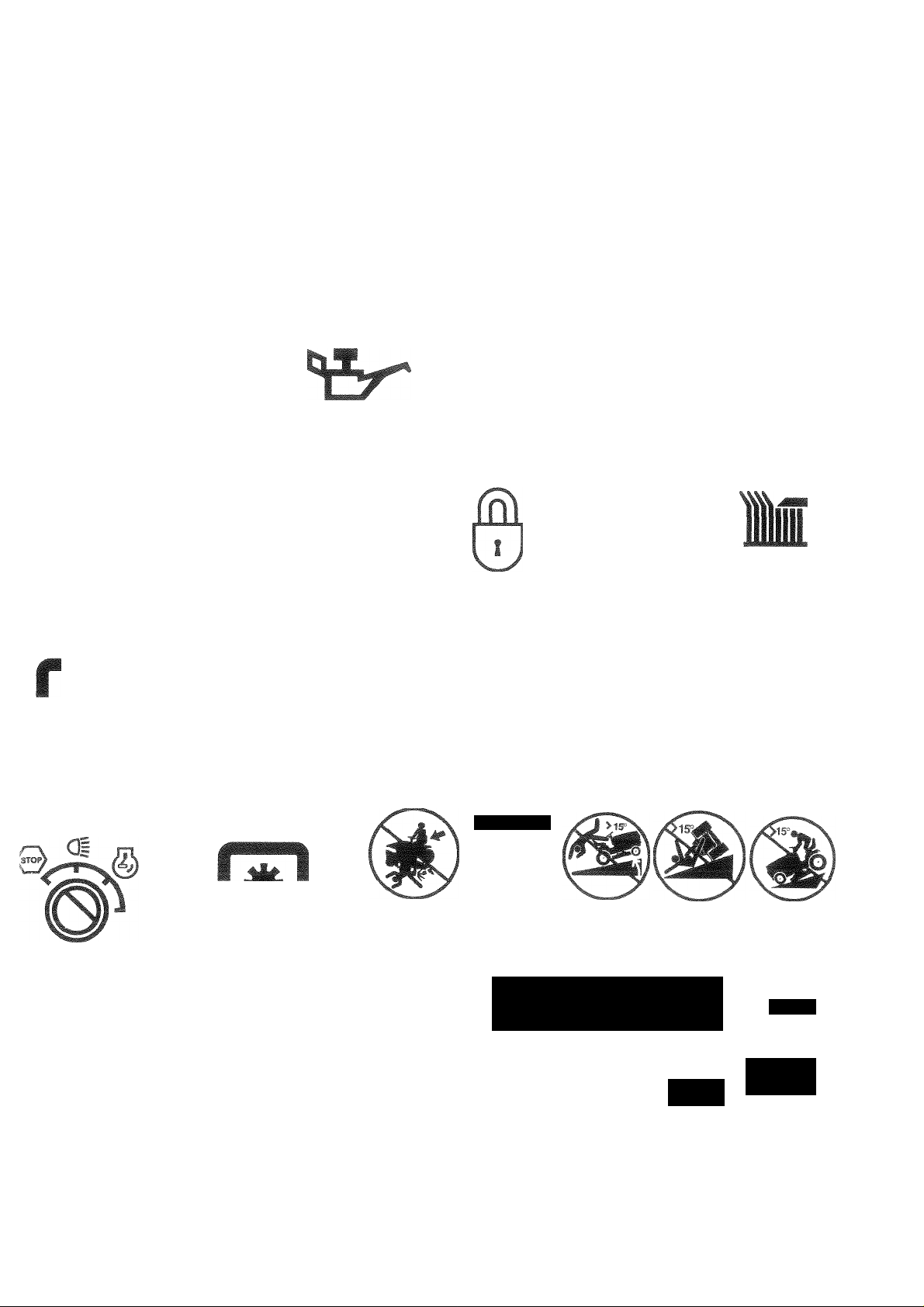

These symbols may appear on your tractor or in literature supplied with the product. Learn and understand their meaning.

Í Í

En r.

BATTERY

ENGINE ON ENGINE OFF OIL PRESSURE LIGHTS ON

CAUTION OR REVERSE

WARNING

STOP

\ X

i l\l Sk

FUEL

CHOKE MOWER HEIGHT PARKING BRAKE UNLOCKED MOWER LIFT

FORWARD

a= 0Í

OVER TEMP

LOCKED

FAST

LIGHT

d“

A

SLOW

lu

I

i* R N H L (®)|I

ATTACHMENT REVERSE NEUTRAL

TUTCH ENGAGED

«

ATTACHMENT

IGNITION

DANGER, KEEP HANDS AND FEET AWAY

CLUTCH DISENGAGED

«

KEEP AREA CLEAR SLOPE HAZARDS

HIGH LOW

(SEE SAFETY RULES SECTION)

<pH“

PARKING BRAKE

=/<#*•

FREE WHEEL

(Automatic Models only)

4 = fei

Page 10

OPERATION

KNOW YOUR TRACTOR

F' > I ‘ '*S OWNER' ^ T • UAL AND SÄFEW RULES BEFORE OPERATING YOU'* F-": T1

Compare ihe illusirat«ons with your tfaclor to familiarize yourself with the total ions of various controls and adjustrrier'iis, Sav e

this manual for future reference.

Our tractors conform to the safety standards of the American National Standards institute.

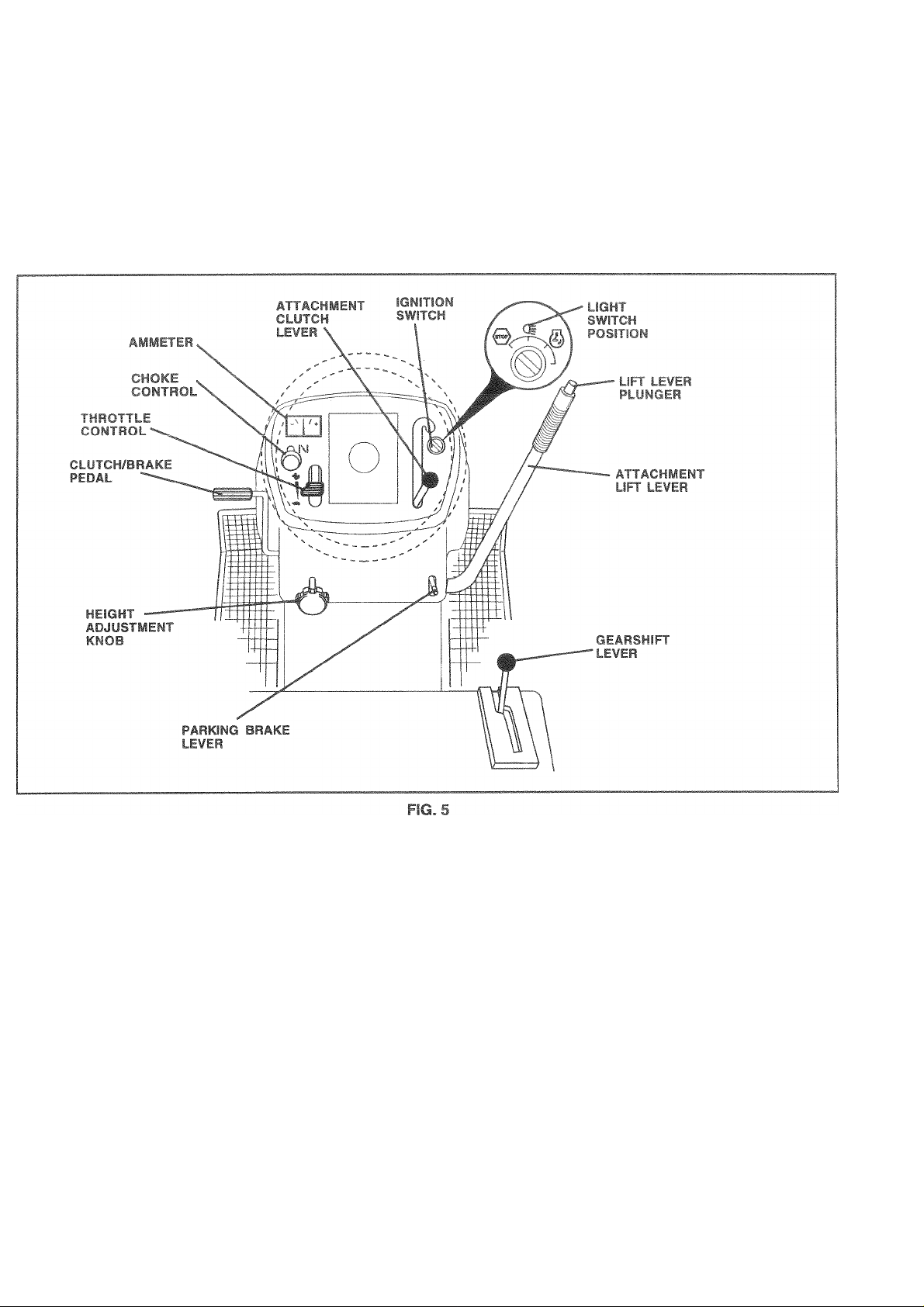

ATTACHMENT CLUTCH LEVER: Used to engage the

mower blades, ot ether attachments mounted to your

tractor.

LIGHT SWITCH POSITION - Turns the headlights on and

off.

THROTTLE CONTROL: Used to control engine speed.

CLUTCH/BRAKE PEDAL; Used for declutching and brak

ing the tractor and starting the engine.

CHOKE CONTROL - Used when starting a cold engine.

HEIGHT ADJUSTMENT KNOB - Used to adjustthe mower

cutting height.

GEARSHIFT LEVER: Selects the speed and direction of

tractor.

AMMETER - Indicates charging (+) or discharging (-) of

battery.

PARKING BRAKE LEVER: Locks ciutch/brake pedal into

the brake position.

ATTACHMENT LIFT LEVER: Used to raise, lower, and

adjust the mower deck or other attachments mounted to

your tractor.

LIFT LEVER PLUNGER: Used to release attachment lift

lever when changing its position.

IGNITION SWITCH: Used for starting and stopping the

engine.

10

Page 11

OPERATION

The operation of any tractor can result in foreign objects thrown Into the eyes, which can

f'i, I . i' ■ - ‘ wfs wear safety gla* n »Ids wliite operating four

.Ijusimentso '^^recoitiifiendawidevisionsafetfmask

¡safety glasses.

iO% h»

f!'.F*^ iL-.i fltf. h;

ISillQ

witch. When engine is running, any attempt by the

I..I >r .. ■ • f •'»pihi.ui fsrtf ‘ eii! ig hi p, rking

rake will shut off the engine.

tir.lii

Place parking brake lever in “ENGAGED” nosition and

n »i Kill. lutir'Di^rc pV" rtl Peci d shouicl

rctiiii.in ni \K j ill n i\t tr^ pelkny i rake wili

held iracl«. ii<e

CHOKE

CONTROL

HROTTLE

ONTROL

^BRAKE”

POSITION Г- \\ /

'XUTCH/BRÄKE

“DRIVE” HEIGHT

rOSITiON ADIUSÌMENT

111 ii/r<i .r.. isr Ini iiii» I iii f,«/> I-‘ poaiiori and

ATTACHMENT CtyiCH LEVER

'‘EMGAGED“ POSITION

IGNITION KEY

/ .“DISENGAGED”

POSITION

.PARKING

n W BRAKE LEVER

“ENGAGED”

POSITION

GEARSHIFT

LEVER

PARKING BRAKE

rpop

“DISENGAGED”

posmoN

FIG. 6

TOPPING (See Fig. 6)

OWEFf B!J\DES"

To stop mower blades,move attachment clutch lever to

‘'DISENGAGED” position.

ROUND DRIVE-

To Gtop^groand drive, depress clutch/brake pedal into full

“BBAKt’' position,

idove gearshift lever to neutral (N) position.

■dGSNE

Move throttle control to slow position.

JIL Failure to move th rottle control to slow position and

lowing engineto idle before stopping maycause engine to

ackfire”.

Turn ignition key to “OFF” position and remove key. Always

remove key when leaving tractor to prevent unauthorized

use.

Never use choke to stop engine.

IMPORTANT;: LEAVING

POSITION C »THER Tl-IAN "OFF" И /ILL C, 4USE THE

ÎTHEIGNITIC iN SWI"ГСН IN ANY

BATTERY TC1 BE DISCIHARGED, (DEAD).

NOTE: Unde r certain c(jnditlons wher

idle with the er

f .1! r >t gl

igine runni ng, hot engine

iss. To eiimin

1 tractoi

exhaus

ate this

Iways эр engir lina tractor on qra

G*»ttl!öil %1‘Wfa/'. sten W »r if« “Olrs

Ä

pleteif, as described above, before leav

ing llie operator's positiciir to empty

grass catcher, eie.

TO ySF HBOl 11 F G ONTROL (See Fig. 6)

Always operate engifie ai full throttle.

® Operating engine at less 'dan full throttle reduces the

battery changing rate

® Full throttle offers the best bagcjirirj and mower perform

ance

TO USE CHOKE CONTROL (See Fig. 6)

Use choke control whenever you are starting a cold engine.

Do not use to start a warm engine,

* To engage choke control, pull knob out. Slowly push knob

in to disengage

TO MO¥E FORWARD AND BACKWARD (See Fig. 6|

The direction and speed of movement is controlled by the

gearshift lever.

« Start Sfj t<«r 1 .V- -Jl fir- -.I--* re 1 ‘ Vj i G r '■ V

_h<ft tf vui n (V. utivi ii >) püjiiwri

8 ktnv«- vj-L '-nifi le.—■ i> 'Ifc'.iifc«’ r lil^fi

8 -k My 'f iSP )n* r, ff,.

IWrUPiANT r ■’Itir ’RZ ir.r A I (iMt-l L rr f( p

Litl'Jits dicnii irf.-iiniMiti jj'-l', rCitfiE

H'-LiDV ,V!LL GUUi'it-J i fit II D F* I • f'

G-l r

TO ADJUST MOV^tK CyrriilG HFiGhl (See F:g. e|

The cuh'iip Iwiuh! G llnd l.y * . ul- u the height

adjusirr.er<tl«r '!• r <T.‘I'Cff dirr'iD..;

* Turn Ktk D ' ioi L\v sr i ^! >11 <r( iitf r I h: ight.

® Turn I'iid. GviU.ik rcl'ji./ribi-(k Rt-^low i cutiing height.

The cutting iieight range Lsapproximattiyi to 4“. The

heights are nw asured from the ground to the biade tip with

the engine not running These heights are approximate and

may vary dependii ig tpor, so! conditions, height grass

and types of grass being mowed.

* The average lawn should be cut to approximately 2-1 /2

inches during the cool season and to over 3 inches

during hot months. For healthier and better looking

lawns, mow often and after moderate growth.

* For best cutting performance, grass over 6 inches in

height should be mowed twice. Make the first cut

11

relatively high; the second to desired height.

■ is standing

t y3S0S шзу

l'«)- |. .H,i

ireas

Page 12

■OPFRATSON

TO,

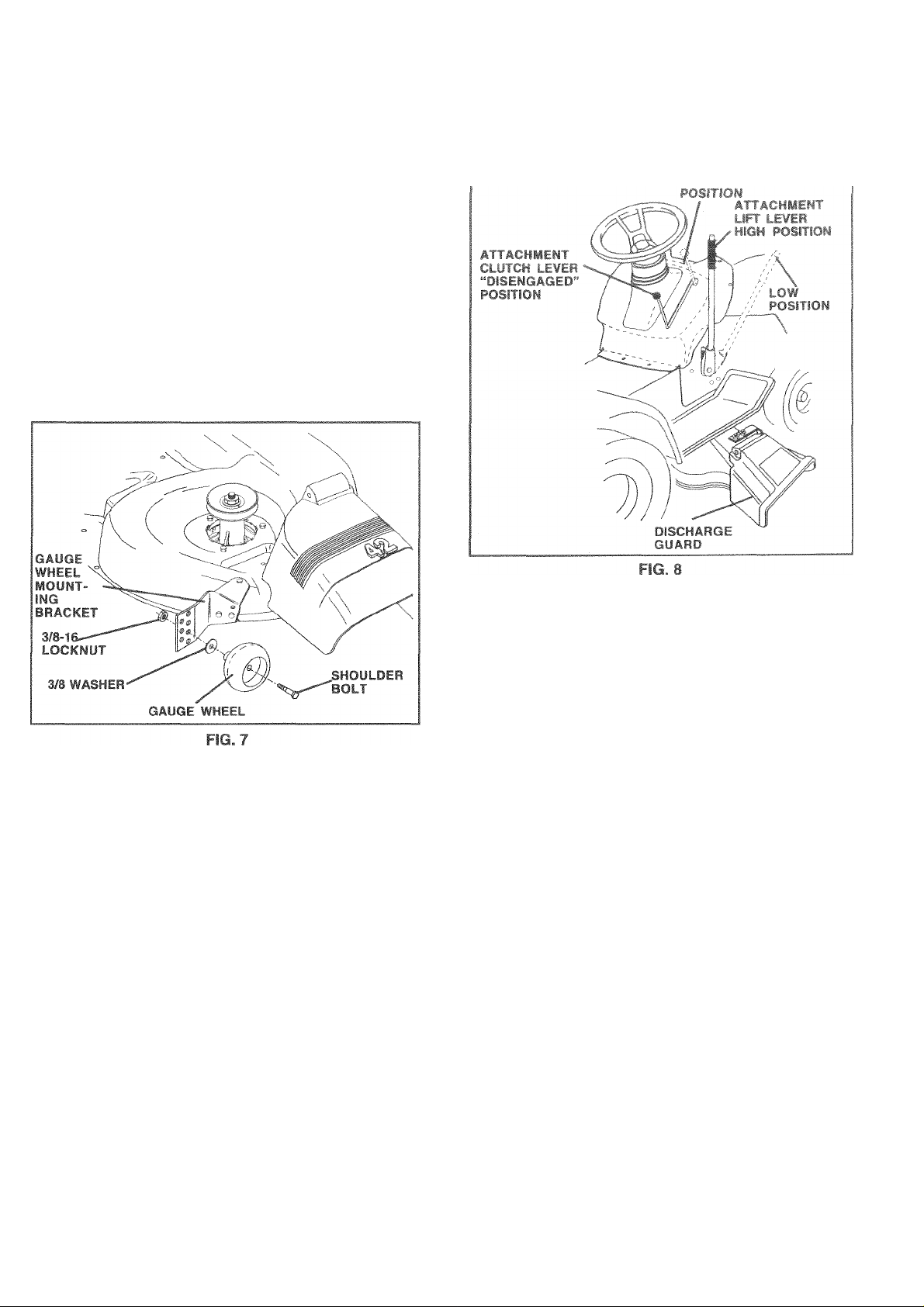

Gauge wheels are properly adjusted when they are slightly

off the ground when mower is at the desired cutting height in

' I -f-lir fs r,'.- id 'Svf (h. ,

t>i !’•» I'd (. i ( r f Ijt- -.rr • -i| •!,, , |.,** i '• i!l

conditions.

' Adjust lo dfesued c.J«i->g r(e«giii (Ste ‘T'J AfuLihi

• With mower in desired height of cut position, gauge wheels

• Repeat for opposite side installing gauge wheel in same

JUS

T GAUGE WHEEI

wh€

Adjusi gaug'-. uhte's Witt> n a il« le%el .^usface

MOWER ('U FTiNG HEKyHT -n ft*#* i5p«ra‘ior> s«=—tjon of >hi..

manual}.

should be assembled so they are slightly off the ground.

Install gauge wheel in appropriate hole with shoulder bolt, 3/

8 washer, and 3/8-16 locknut and tighten securely.

adjustment hole.

iFîa

TO OPERATE ON HILLS

TO OPERATE MOWER (See Fig. 8)

Your tractor is equipped with an operator presence sensing

switch. Any attempt by the operatorio leave the seat with

the engine running and the attachment clutch engaged will

shut off the engine.

« Select desired height of cut.

* Lower mower with attachmenr lift control.

* Start mower blades by engaging attachment clutch control.

® TO STOP MOWER BLADES - disengage attachment clutch

control.

CAUTION: Do not operate the mower

without either the entire grass catcher,

on mowers so equipped, or the dis

A

charge guard in place.

CAUTION: Do not drive up or down

hills with slopes greater than 15° and

A

• Choose the slowest speed before starting up or down hills.

• Avoid stopping or changing speed on hills.

• If slowing is necessary, move throttle control lever to slower

position.

• It stopping is absolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking brake.

• Move gearshift lever to 1st gear and be sure you have

allowed room for tractor to roll slightly as you restart move

ment.

® To restart movement, slowly release parking brake and

clutch/brake pedal.

® Make all turns slowly.

do not drive across any slope. See the

slope guide in the back of this manual.

TO TRANSPORT

• Raise attachment lift to highest position with attachment lift

control.

• When pushing or towing your tractor, be sure gearshift lever

is in neutral (N) position.

» Do not push or tow tractor at more than five (5) MPH.

NOTE: To protect hood from damage when transporting

your tractor on a truck ora trailer, be sure hood is closed and

secured to tractor. Use an appropriate means of tying hood

to tractor (rope, cord, etc.).

TOWING CARTS AND OTHER ATTACHMENTS

Tow only the adachrr.ents that are fecomrnended by ard

comply with soecifications of the manutocturer cf your

tractof. Use common sense when sowing Too heamr ct a

load, while on a slope, is dangerous. Tires car lose Ira-ction

with the ground and cause you to lose control of yourtractor.

12

Page 13

OPEFi;^

kTlOW

w

B H 8

«

iSEFORE STJ^iRTING THE EN

JHECIC ENGINE 0

The engine In y

factory, aliBady f

Check ecgiiie oil

||L LEYEL fSee Fig. 141

our tractor 'has been ship

lied iwith summer weight oi

with tractor on level groun

GINE

*pecl, 1шш the

1!

Remove oil fill c;ap/dipstick and wipe cieai 1, reinsert the

0

dipstick and sersi

T 5“ 1“ S 1 gij |.> 1

J f fn |< 9 i h

cap tight, wait for a few se<

. If nscossairy, add oil uniii '!

^ ^ HD

2onds, remove

™LILL”markon

or cold weather operation you should change oil for easier

.< li .1 jtf U'l i/iji'i II - CHr-‘rti tn ill tkisuiiBt

f I 1 'tr nr.i, i

I') I"! r.j M'4i! 11 a, r,H rfii S' HP-:|: .r>Fi')!<it‘er

l-''!« 1. il > till" (fi-S'lOf •

riii <1)^1 tjif •!'- Irt-'f< f I' «, r ci'jfr' иц|г > I ''‘.«le

v< t>i ! (fiinwiom ol P < ‘ iB.if iiLf'll 1=* ide<J yarol'iit ,vii

•I s И-14 .¡i f >i aO e-..)i Jt|'0 II i.i-iPf'UiP /Ji ь

>iIm jit i".i («Ч' Ш -'itii ' « irN ,'p iup' iti

qi.ar.tiii that i -ii h*- wifhir 'A | j S'-ч'ь *ur!

freshness.

iPoeiAilT, WHLri urEFiATirt^ IIJ ТЕМРГ r.ATURE.

Flow da'1 |ti C| FFiESl! • ,l LAi J V^lH I LP i.HAt«-

дсоппг lO MELl in ;URF (lOOn ( 01 h WFolHtH

! ARFirJO

*<IPi%iNG Ьлреич!. t’iri'iK aV- ihrt. ■'ь|„,! Ы» nd^^P

>ris ille'l i.ja^ohi f ujI ly c-lhalioi i nitihaii!ii) i, ди

-tratf moi !мгелК.(.Ь!еа^_.1с.ььркгайо!'jnfJMrmdtiofKif

itfc duiinrj sp'faq- Acidii, ga- can rfamagt th- fuel

Ociii of (П engirit! Ahiif in stoiage Тэ a¥uid eiiyii-i

иЫеть, the fuel ovsfeni dnou.a be emptied befoie stoi-

jec.f 30 days or longer Drain the gas tank эШ the engine

nd ifcf it run until the luei line>- and carburetor зге empt;.

it tiesh fue. next s<=»asofi See Sioraye instructions fur

iditional inloimatiori fJevei ust engine s>( carbureft-r

' ararproducts in thefue i tankoi pr'iiTiarieiiidarrt ige may

ilCLir.

CA'JTiON. F'di ÍC festtom u* gas tairl*

“I

filler rieck. Do not overfill. Wipe off any

A

spilled oil or iuei Do not store, soiii or

ear neat jr¡ oper fíame.

3 .Ti.ai ENGINE i t 'u -

/hen starting the engine for the first time or if the engine

as run out of fuel, it will take extra cranking time to move

e ifjii in<’ t.ini* lu hr Ku’oe-

Sit on seat in operating position, depress clutch/brake

»tirfl siw ' |: ir-iiy hif ffEf't-.. f ,, hift ftiPi II i ^ 1*1. i dJ| fosition

f i> , nil-(.r mr‘( «’< *1 Imi II t'“trAi-ED” p •* II on

Move throttle control to fast position

• iUI-w ionin!c‘i! r Cl vrit cwn an<'ri''- in a

¥ li'f tifiine stad tiilc .iipt tri ch <ke rcr.irol rrsi ti~t be

needed.

ilD Bi t t -lErhiiq rPdQ ihp # ii n r lu cold Ntanii'g

OCfctiUl ccE IjcjIUW.

|i f il i f If ifiia loiiitii r n‘'inr' rc/il iivK fi if I”

lu 111 < <‘ii 1 rey ' O.J I T' 1-1 ( I k -I 'I j 111 t

■ in t nei r^iitin in'Ey - t. f in , tibwi... id p r

nil.til. 'f!l. ^mi.r iff !. > I it r IE /ill if ,

push choke control in, wait a few minutes and try again. If

f life til* nut lai , I ill .hr whift iciita! < nd

rcirv.

WARM WE

engine I

roughly,

and tiiei

• The alia

eiiQine 1

allow it

ATHER STAF

ngirie starts, sk

jegins to run s

pull the choice <

1 continue to p

chments and g

loes not accef

to warm up fc

ITING (50* F and above)

ywly push choke control in

moothly. if the enoine stan

iorifrol out sllgiitfy for a few:

ush the control in slowly.

round drive can now be use

>t the load, restart the eiic

V one rriiriute osino the о

until the

[s to run

seconds

id. If the

iirie and

hnkfk

pc

describeid above.

COLD WE#iTHER STAR'

id «ht 1 1 n i ^oi

• When engine starts, slowly push choke control in until the

ik-g.li ,i(*tr|'i < ‘•«UMJJiC pit! tb i ii'b

fill 4 I -iMjfl E I. 1^ „ .Jlsisnsli j if 11, 41^ I 6 I rl\ 1 1 ¡ if ni I

it jriJi ill

i.. «Ííbi nyjt _ » u1 I., f,i ( Ciljnl^ рч'ЧЬ I ij'4 'nkifÁ

Ы liqlul/b/f 'д If /'„f . > |k‘ .tr<> hr П • <> I It U '.i.ntllsr-

11 1

, I ) ,J ntlO'if ilOlr is Jl/

fniini IciMiv |hs III' ! q,,-, ' CMlir>r ¥ Ц11 nr

I иЬ fi.'N < n.p l, Í . I . , ill.i.t.u it,/“! t

ImU uh ¡.life; icmpdaiUffc.

Л1о SH ( -a«' I UMi *1 p Í .iríí^jn tf« rni lip

uifli .1 lU-ifr/f 'i и IIoj Oüi

shahilv.

fJOTE: Il it - hif]ii "jit'lüdc Ht« vs, lOoy ifEEfl) 'п in cold

Í'ifipfaturc ibr-l'jw VFtideслгЬи«til»'flic!mutur -rnay

Г|.1е1ЙчЬаас||иЛсик|ГЬс teriíiin^prnoitiijn ' Sit ‘TO

ADJUST GaRB'JRF roR ’litii-St*r 1(1 itnenis

Cfc-ction ul ifii- irijiiua!

MúwmG 4PS

’ M(>m jh 1 ilcJ b'* ptoncilyto! *.i't t.o.virig perfur-

пчпсе See'roi EVtl MCjWEFiHOn^.lN'S' •iith/ ''¡ervice

^rd Adjusti.'’Mfr rcJ: n cf n.-n ч!

' rii .rii • aii'j ..iJi i > hiu¥ к ah.Hjiu he dreri 1()Г iiimming.

Dr vest fhatf lipp'ngt'are disthaiged onto thr-jrea that has

beer cut Have the rut aiea to the right of the tractor. This

wii| msult 1(1 a more ri‘ n lBiiihutior, rf ,-i pp.'nqc and mote

uniform cutting.

= Vt/heE( mowing large- tas, -fartDytiriiingtotheryjlitf’nth.^t

c ippig-r и .i| difirharye •‘wa^ fmiri fEhtiib^ ffnA'' Uri' wayw гуцр (I round' I •'</, ir* i! f> jopii'K)

dtiectior ,>i?l<ina ‘etf »i.cid I >rr< t rit.i ¡k' •=Ьек , >■' f >g

' it ’0'^ . - (.smel, ».JÍ! . .. -'*1 'i. *. If di¡<

load c-id [ojicible fir^ f<nzv',fd iT'>n Jiir j '.1>рр1Пч' flefri

fuel i.ut ►-Ntwelv high 1гв ж-f -.'.и tu ! e t. >tqh

' [*onottiiow0ГЛ -u'hfciiiti m' V\nit,f4, wiii./liir,пин<ч

fr. lit . ncif: irahíu f hnip.' ik'- r c i” i 7 t.

il 10 Wirtes.

• Aif ly '» »r f' a' full к I'!'. o¡ f r П iv'n I '(

h^ ut f-tkr-i! Л П {i‘ii Hi I' jt I pro| I rti Ci|i|f

l- ‘f, it 1' I Ч •! t 1 ,.,ii J -;j. ' -y I < I, , , I. .

f I. ugf. 3' si t. J - ill... 11 Ow- I e lU . t p I 1. I a \ ; ¥. '1

is- (! - f|i| litj ■! ' «<í i! ‘Pf il

® '.УЬ'‘|| i. nl‘M's ■ inimi" I ‘ .| ij, i Í. rf ,,1-i

vill U(! ihe kii-iii ii.d qiii 'f p-u.,p.i., , )f tn.-

rrtäf hrr'r~ni ti.-ir,.t I) ^

13

Page 14

H wr^tpfiNSiBU

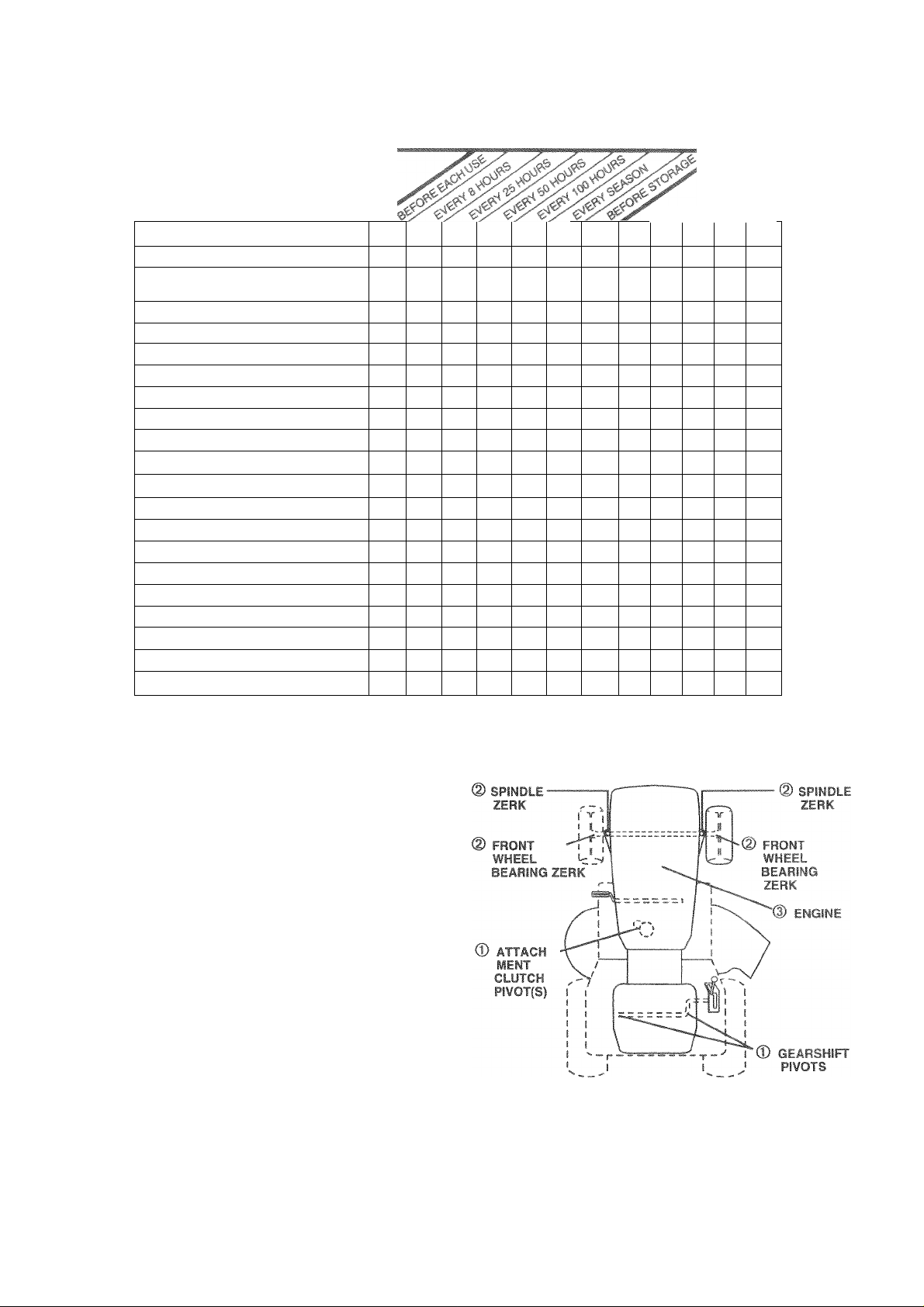

MAINTENANCE SCHEDULE

FILL IN DATES

AS YOU COMPLETE

REGULAR SERVICE

Check Brake Operation

Check Tire Pressure

ChecK Operator apn

l.icict-l

Lh^c(< for 1 or«;'» -

Mi=t M- i-Repla e BidJc

LKt'icatr.r Chart

C* fA Battery Lc^< 1

Cied'i Bate j md Te-r.

C“«? r » rsrSarlo ^

Adjust Blade B&itlsi rei<s«>

AujüS» Molrjii L>ri»e belt(Sl r^'i luii

Check Engine Oil Level

Change Engine Oil

Clean Air Filter

Clean Air Screen

Inspect Muffler/Spark Arrester

Replace Oil Filter (If equipped)

Clean Engine Cooling Fins

Replace Spark Plug

Replace Air Filter Paper Cartridge

Replace Fuel Filter

1 - Change more often when operating under a heavy load or in high ambient temperatures. 5 - if equipped with adjustable system.

2 - Service more often when operating in dirty or dusty conditions.

3 - If equipped with oil filter, change oil every 50 hours.

4 - Replace blades more often when mowing in sandy soil

✓ ✓

!✓

✓

✓

✓

✓ ✓

✓ 1

✓

^2.3

✓ a

✓ 2

✓

✓ r

✓

✓ 1

^,2

✓ 2

✓

✓

✓ 2

✓

6 - Not required if equipped with maintenance-free battery.

7 - Tighten front axle pivot bolt to 35 ft.-tbs. maximum.

Do not overtighten.

SERVICE DATES

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover items that have

been subjected to operator abuse or negligence. To receive

fuii 4/alue from the warrarity, operator must iriaintairi tractor

as instructed in this manuai.

Some adjustments will need to be made periodically to

properly maintain your tractor

All adjUGtmentG in the Ser/icc and Adjustments section of

this manual should be checked at least once each season.

• Ooce a year you should replace the spark plug, clean or

replace air filter, and check blades and belts for wear. Anew

spark plug and clean air filter assure proper air-fuel mixture

end tielp your engine run better and test longer.

BEFORE each’ USE

• Check engine oi! level

» Check brake operation.

• Check tire pressure.

• Check operator presence and

interlock systems for proper operation.

• Check for loose fasteners.

LUBRICATION CHART

© JO OP 10W1J P9T0R Mi

(7) iiPUFBAi DiipprtQP f.Bpa'iF

(3) REFER TO C'JSTOMER RESri^hOiBILiTIES 'ENGINE*

SECTION.

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS. VISCOUS LUBRI

CANTS WILL ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRICATING BEARINGS, IF YOU

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY,

POWDERED GRAPHITE TYPE LUBRICANT SPARINGLY.

14

Page 15

i I*

if

‘M RESPOMSIBILiTIE

BRAKE OPERATlOf

(6; feet stopping distance

o brake must be adjusted,

i> 4 fl',! ^

the Service and Adjust-

ssction of this iT!anu3l|.

Maintain pr<»er air pressure in all tire;

if f • Ji I' 1<»(!■“ 11 i iiw

(See “PRODUCT

niiaii.

i et n .ir- , nr oi u-i. cl> It ui' f» ..¡51 C-'cr nir&l Lhermt-rfls

which can harm rubber,

k ‘KJ i 1-1 ^ i(/i ►- (it.'- ,1 (>_,i I lip I is till! lilfil

1 = ' I i rh I»’ H <-.0 f t'o uo-r' itj*-

I . - 11 i P J'.ntL 0- ''M p o"i (I ‘ !■ '

' H If ;l - ti.r Sr uinnt t.irtv t" piivtiO'-ed k '•in p u; sr-.ai

,.ft- ,J.3ql(r| fiff. |.rrvttll rr* 04 (Fl '

urinjinn

IPERATOR PRESENCE S¥StEM

»€ •'•«j, - (pr-raioi pipsen<,p aric- (r„erbcl> systems art

sotVv.q If <ioiji liacioi dufq i 0( fi'.'attiri .»

esciriie‘1. ifpjinheprjl ierr imrrw dnffl/

! n<' tngin«’ ‘-houtc i.oi a«irt unlbSo lue .auith/bi .,rs p* ua!

i (•jlly depressed and iifactiriTier.f Ini'h > »jH m'i i|.lhe

flisengaged position

Whr!' the er gine i.- rum.ng irij dlcmpi by ihr 'pSi n a ia

„itho’jf first s-tt'og tne part inq oral r ■.he jfd

shut off the engine.

When the engine is running and the attachment clutch is

engaged, any attempt by the operator to leave the seat

should shut off the engine.

The attachment dutch should never operate unless the

operator is in the seat.

3LADE CARE

or best results mower blades must be kept sharp. Replace

ent or damaged blades.

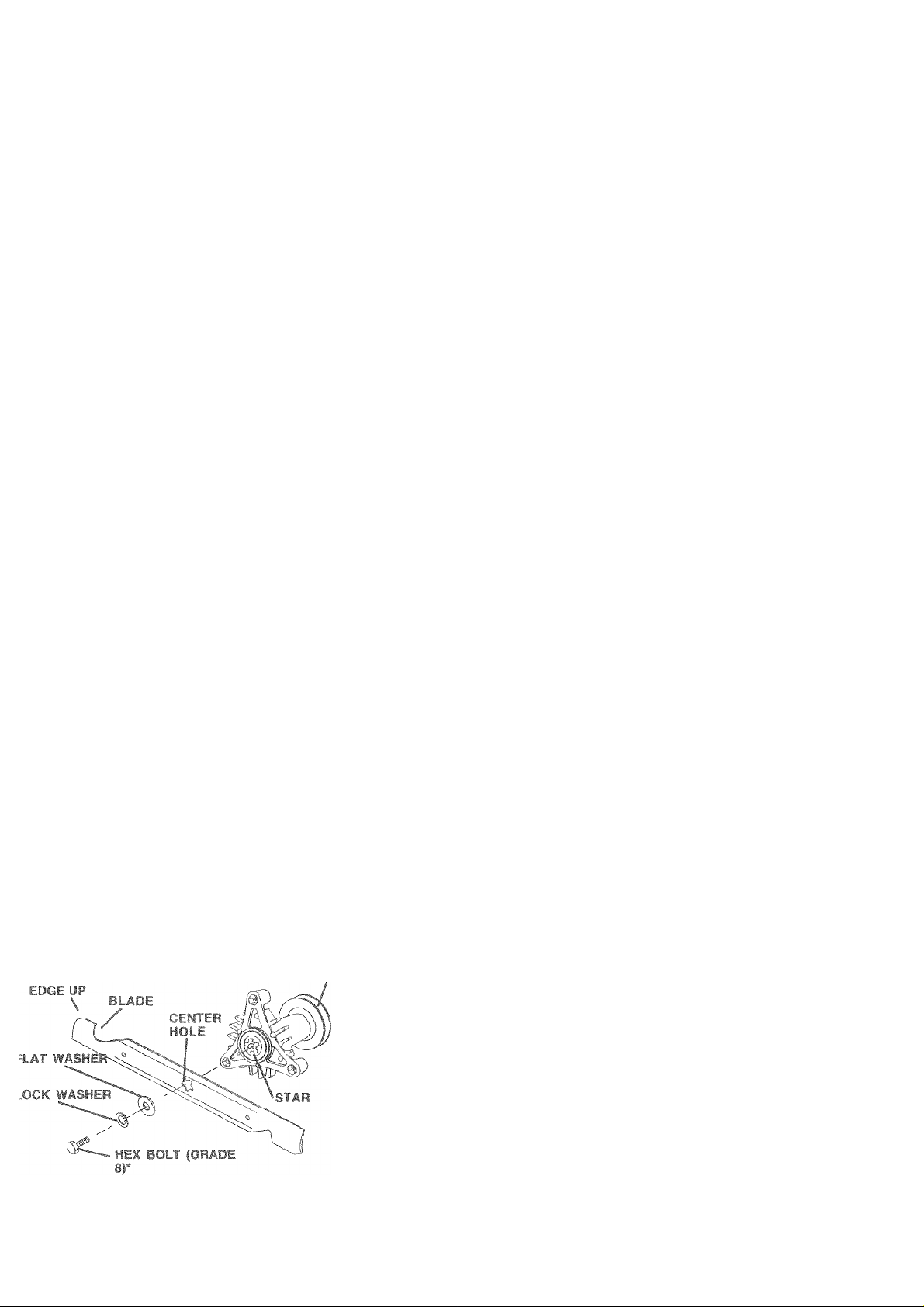

I LADE REMOVAL (See Fig 10)

Raise mower to highest position to allow access to blades.

Remove hex bolt, lock washer and flat washer securing

install new or resharpened blade with trailing edge up

towards deck as shown.

iPORTANT: TO ENSURE PROPER ASSEMBLY,

ENTER HOLE IN BLADE MUST ALIGN WITH STAR ON

'Me h'

W3S

n©r in *

IMPORTANT: BLADE BOLT IS GRADE 8 HEAT TREATED.

I 1 s 5>s jd f . , p<L iif, Kf! r V , f ,1 I j ;

NOTE: We do not recommend shaipening blade - but if you

uO, D© sur© ttiB bl3.d6 is bslEiicsd.

Care should be taken to keep the blade balanced. An

ur-l il,-t>i -d.4 «if- tviii, .1 . ' (>( IV ribrat '• r-

Kil‘Jar■ >f{f {ill' 1 -n j!.1.

'll t.i Hiv I (' i{ -G, I. !■; d t.tti , ’i* o* ■! irfi l>(H|

a Ur v-l s', ^firfrtp ■ > . fi?tp rii"irl (V tr.'

'• i hi« rill Llvl-K ‘Vli viP til '-i ; .Pj!l *• f I.’ i

i sCjil pif I !, J « t! sr L -.! ^1 |V«/t(r 1 I M 111. V i 6 s h .1 {( s« «

(f llul 'I ' Ifl -|l!l (,‘)l Ijj4*|!(-s» h (it . 1 ,<1 4>r 6 1

fltiiL Ici'-y t 1 boif.-ii .iiflnff: II

ih 6«Ii"'Em 1 6( -sy s|-,,sC|i:r| i,«j|

’ ids Ci !(,- vH ‘ J.-. vr.rr.r" vdf! i P !ltiv I m r. f , i U j', r-i

¡.r and hW. ii.F Loll oi p n pdrrfli«-i siith il (ji • nm i bi-.diiv bahneed it efu'uld rf-main s i i ! on outai po tti>)n li

tithfr tnd if tiw blodt- liiov-fc •ioAimair! -h.upr-i. the

he -'V <^f>d ur til ttv tTiay i • Cai.in.

t LMTi^P KOI r

5/8" BOLi

OR PIN

FIG 1 i

YfU' . -'mf b3 ! f /0 m ■<4't h 1

SLitfk tomforuofiiH'i S-' 'cr Oi-nctiic haiginguffh'

batter/w |«S ,iSi lUf-iir'Tim haOjei v-i'l ^xt no ¡tr life

'■ . p fi itt( I, jiia tH,i ill I (1 i

" i Of |i r .*(« ry '>..!( tirt-t

' M’i p , r I ,li vcdi i| ' h

’ i-'v ti.jfvI' ai r-(0 I ii'-u "(i

NOTE: The original equipment battery on your tractor is

nr:.imi-!i frm L c .toWtt-rrij.,-ip. ,1 u- riic.cfvp.

fjr ( 6,'M i «idiii! >ii Uir^iHiK-i€/i! " i f li Wi »'vr 1 11«4

necessary.

U H III

|CL

Ids con caura

!(<•. A AtWt (I iLO , Tijil II

Corrosion and dirt on the batten

ihf iMimiy I |i -it 1». .v'-i

r't V l 'ill ry I .1

firfuiri- 1 BLi' f f ..tsoiv , itl' f>i t

f h'f!. n.J r msvf- h tt «V fr>'m *■ (in«

ifien F'cD »raitcry

Itiii''' >hi'batte.i with dI m «at i -«nd tty.

' /1 -.r isfrficai‘ i!c'^ sier/cab!. Uidc vifh’.vrcbfi.cn.>rtil

bright.

• Coat terminals with grease or petroleum jelly.

• Reinstall battery (See “REPLACING BATTERY” in the

SERVICE AND ADJUSTMENTS section of this manual).

Page 16

m ^4por4*iiB!UiiF5;

¥-B^

Check V-belts for deterioration and wear after 100 hours of

OP8rStlOO End f6DlSC6 if n6C@SS3,f¥» Tll6 b©itS 8f6 OOt

adjustable. Replace belts if they begin to slip from wear.

O (jbitjuiiu I P Ji Uli I'l. ill .i< ( 1 '„n

re.'ufi * nol.iig

ENGINE

LUBRICATiON

Only use high quality detergent oil rated with API service

classification SF, SG, or SH. Select the oil's SAE

viscosity grade according to your expected operating

temperature.

SAE VISCOSITY GRADES

^ f-

S' S

Op

-20" 0" 30“ 32“ 40“

°C -30* 20“ -10“ 0“ 10“ 20“ 30“ 40°

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

NOTE: Although multi-viscosity oils (5W30,10W30 etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F. Check your engine oil level more frequently to avoid

possible engine damage from running low on oil.

Change the oil after every 50 hou rs of operation or at least

once a year if the tractor is not used for 50 hours in one year.

Check the crankcase oil level before starting the engine

and after each eight (8) hours of operation. Tighten oil fill

cap/dipstick securely each time you check the oil level.

TO CHANGE ENGINE OIL (See Fig. 12)

Determine temperature range expected before oil change.

All oil must meet API service classification SF, SG or SH.

• Be sure tractor is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

• Remove oil fill cap/dipstick. Be careful not to allow dirt

to enter the engine when changing oil.

• Remove drain plug.

• After oil has drained completely, replace oil drain plug

and tighten securely.

• Refill engine with oil through oil fill dipstick tube. Pour

slowly. Do not overfill. For approximate capacity see

“PRODUCT SPECIFICATIONS” section of this manual.

• Use gauge on oil fill cap/dipstick for checking level. Be

sure dipstick cap is tightened securely for accurate

reading. Keep oil at “FULL” line on dipstick.

60“

80“ 100“

AIR ;hrrN

OIL

DR AIM

PLUG

4

OIL FILL

CAP/DIPSTSICK ■

FIG. 12

AIR FILTER (See Fig. 13)

Your engine will not run properly using a dirty a r filter. Ckai,

the foam pre cleaner after every 25 hours of operation rr

every season. Service paper cartridge every 100 hctrs nl

operation or every season, whichever occurs fifst.

Service air cleaner more often under dusty conditions

• Remove knobs and cover.

TO SERVICE PRE-CLEANER

• Wash it in liquid detergent and water.

• Squeeze it dry in a clean cloth.

• Saturate it in engine oil. Wrap it in clean, absorbent cloth

and squeeze to remove excess oil.

• If very dirty or damaged, replace pre-cleaner.

TO SERVICE CARTRIDGE

• Clean cartridge by tapping gently on flat surface. If very

dirty or damaged, replace cartridge.

• Reinstall precleaner cartridge, cover and secure with

knobs.

IMPORTANT: PETROLEUM SOLVENTS, SUCH AS

KEROSENE, ARE NOT TO BE USED TO CLEAN THE

CARTRIDGE. THEY MAY CAUSE DETERIORATION

OFTHE CARTRIDGE. DO NOTOIL CARTRIDGE. DO

NOT USE PRESSURIZED AIR TO CLEAN OR DRY

CARTRIDGE.

KNOBS

COVE

FOAM

PRE-CLEANER

CAR

TRIDGE

16

FIG. 13

Page 17

^N AIR INTAK

ING area:

jre the arass

111 tin

:: v©ry 100 flours of op©r3tÌon fiTioro oft©n undsf ©xtrsniBlv

Jijsty, dirty conditions), remove the blower housing and

II > < «V }). I'; ; I- , 1. lii' : i.-ff" *' i -h ' ,K '

iurfaces as necessary. Make sure the cooling shrouds are

eiristalied.

*’ir. < r .hknist.jG j ;t-

tr; >.i ,uc iii-.fj fin, n.O!«f.‘| 'h''4!il; >a

1«. f-,ill f Mj.- dU. rii'rUIh>

ItA|^ Mli i&e.£ ftij. Id!

ii- «.rcivni TiO 1 hi ‘ i'f-l trtrt- lit ‘|lH iud CiiHii *<"> .'U 'f

“jineKjt iioiiiuiCftf 4ii»sy ^ y.ari wiih nrf!'--ufu

. funyi- ail so njiiiuvo ctiri taajDboi.i aiko yum

.jcr j.

i3Ei'l(epl4t e irro.M irnufhei ->’fi yvjr mi=sler(if

^iiropii-i) If «uki creatt,. fir- tia'ard snd/'.r ,j-mage.

PARk PLUGS

( pi ,e pi>>g> rt lA Leq<nn;.iij i/ --tii h tnuwirig

‘jOiei- fil-t '^p lA j1u«j tvpc and ga>i setting ■’te hown .n

■'ROUUL 1 i.prf IFIC/* ^lUiNlS' .section of this ma'iuai.

'Kcnii __>r 'ftor PI (.'¡Y ifi'l hi-|iic 'it rpprJtiPi, .'il'irl-ou'jr

ENGINE OIL FILTEF

rIC

ft til

IN-LINE FUEL FILTEF

I

iieiiieiiiiter :

" ' • juldberepli

tilter Decomes cloggea, oBstructiPig fuel tlovr to carburetor,

replacement is required.

J *‘yit „ ,i ' ( ir. (-ill hO|.U " Oh .fiMti

* dL' HrU i'!“f >*!•''• fi I ■< i 'Lfl I ‘'¡I* 'ilr. >> Ilif

[»I*: fiS tj . <1 i»^! { /ti Jli-itiS

* Be sure there are no fuel line leaks and clamps are properly

® Irnmedlately wipe up any spiffed gasoline.

® Clean engine, betteiy, seat, firsish, etc. of all foreign

matter.

• Keep finished surfaces and whec Ir, free of all gasoline,

oil. etc.

® Protect painted suifaceri witfi mi!' ¡motive type wax.

We do not recommend using a garderi hose to clean your

tractor unless the electrical systerr.. muffler, air filter and

carburetor are covered to keep wafer out. Water in engine

can result in a shoftened engine life

! 100 hours in one ye

Fig. 14)

® each season. If fu

Page 18

and

CAUTION: BEFORE PERFORMING ANY SERVICE OR ADJUSTMENTS:

» ijeoress ciutch/brake pedal fully and set parking brake.

A

• Place gearshift lever in neutral (N) position.

• Place attachment clutch in “DISENGAGED" position.

• Turn igmtion key ' OFF*' and remove key

• Make sure the blades and all moving parts have completely stopped.

• Disconnect spark plug wire from spark plug and place wire where >♦ car-not come in i ontact «itn

plug.

TRACTOR

TO REMOVE MOWER (See Fly. 15)

Mowerwill be easierto remove from the right side of tractor.

Place attachment clutch in “DISENGAGED” position.

Move attachment lift leverforward to lower mower to its

lowest position.

Roll belt off engine pulley.

Disconnect clutch rod from clutch lever by removing

retainer spring.

Disconnect anti-sway bar from chassis bracket by

removing retainerspring.

Disconnect suspension arms from rear deck brackets

by removing retainer springs.

Disconnect front links from deck by removing retainer

springs.

Raise lift lever to raise suspension arms. Slide mower

out from under tractor.

IMPORTANT: IF AN ATTACHMENT OTHER THAN

THE MOWER IS TO BE MOUNTED TO THE

TRACTOR, REMOVE THE FRONT LINKS.

TO INSTALL MOWER (See Fig. 15)

• Raise attachment lift lever to its highest position.

• Slide mower under tractor with discharge guard to right

side of tractor.

• Lower lift lever to its lowest position.

• Install mower in reverse order of removal instructions.

18

Page 19

SERWICE ÄND ADJUSTMENTS

ilOWEfl

/i£

иге tires НГ0 properly inffsteo (Se^

’PRODUCTSPECIhlCAriONS^*sectionoflhisrnaiiuEl). i

ves are over or iinderinflated, you will not properiy adius

'Otir mower.

ilDE-TO-SIDE ADJUSTMENT ({

Flaise fTiow0r to its hicjliest position.

Aiip* f ifb lUi i fo-, . . h-io'b

*1'-тРснГоо *^dr’i.^r* «.pil IHnn. ьА я

buPi Ufi V* I О У, 4i(,i !.i дппт 1/r

: f ar i 1 -th* (

If adjustment is necessary, make adjustment on one

side of mower only.

' I lai s un. 'l-lf, ut Pii.wn t'.Jii» !• Illfird uit .! bcnJ

Htd .0 iPrtl :id(-

i .j -f • fiPowei loosen lift iii!kad|ustrpefIt

.14! i.n tint =Klf

fiTP тьгв“ 1и1| turr-.s of adiuciment nut will chancie

owt^r tieiuhl atiiiw 1/fi".

Hecl've к mir‘a-uft rnentsaftef adiu- i<nu

елгэм EDOt

eel on level ошипо о

^ Fiqs. 16 and 17)

dO i rOM fc06E i

it

Full WIMG FRC

UJ II

position,

’.BE SURE

О ^OWE

adjusted s

erthan the

WIL

1 life th

> that the

when the ГГ

SiDE-TO^SID

ÄDJUSTMEN

¡ТВ

)TH FRONT LI

LEVEL SIDE

: IS approximately 1/8

|hes

t't.ml siif! trio>>n Ичс: v»t< . ! 'm ff», ш

distil. О dir'-'Dji I' 't(.f f hd ■ „hi'nJ lf|>- Г’^пН>-Г.1 “■

h*'til,»П . d,-.i fit ,(i'wrr (>'■< i h IK M

1 . tijif' Oint-l ( j <льу ,iC‘.b < у -И(ч (И rtiO hi'V i*- iihiNi

,’i 111 hilf . 4lL сГ((|«| Im Ir ,).j 11 l*u(fi li-.i 'll I'l'i h

Trf.''imaVV Id 3/p‘

Fill .1« fiC'.Mf.j Jifiii-ii'<.1 liS; t iOiieiitiHobaib' Ltn.il-i

as other link.

¡.,1,/jv V, Ht• illj^11 lu ■ 'I,! I’E"’jLboihit'jrifl.ul' ..ts

к -jlSai tlUri.L-f r ‘)l tUVi'

Wb^-n di ionci- L> !• '>B' b 'I i о imril hi n lear,

iKlhttn mit, ‘F against trnnnio«i 'Vi r. Fh irint In О

' idr<ir.i iif fiiufinow r кч1.‘“еппи i fi jriitiiiiii.icn xibofh

iionl lirifi fighteri iiui ‘F on hnfh погУ hnHr an aqui!

riumr.e, rf опт

“ Whf 0 di-tiiv' fi Hj' ь i/T !'.л<м кого v,an resi,

tght n '.!t ‘Г ' * j -,-in r, both ' or ¡¡ni,::.

I- Rechst к cidi if jidp iJ'nstmfrf

Page 20

SFRVÍGf ANO ADJUSTiVIENTS

Tfl FIFii A:-| M ir M r l. Pi iiPF pP'3i*r Pf I

(See Fig. 20)

The mower blade drive belt may be replaced without tools.

Park the tractor on level surface. PnpaQe parklnp brake.

BELT REMOVAL -

• Remove mower from tractor (See *TO REMOVE MOWER”

r thti ssct'on a thi_ ETianuali

'• Wuit ^li bcil< jjUI 'y A iiiu nils ( pula

" Pull bp(t lWr<y U'jtC, ftlUAGi

BELTIN^TAI I A nr-N

■* Install ne\ Lett «n rout-,*. - '-rda» .f

'1irt ^u.f 1 If. vl pi'Py f. n iiKi'le dii c,eit

y

mr ,«=i rn (e 'ef''- arder i=rr''v.il lOirrjrtioni

fC&r.\l J F-PLk T iv_*. r.,v

Your tractor is equipped with

which is mounted on the riqti

T» j rqji*. ’ z . tdj .i. (r' ''re. 'f f,.i y ipi , .

a| im*" ^ »" ~(lhi- ti] rr>;''Sf.aS'.' Cl«’ ?t - ' '

* Depress clytcti/'brake pedal and engage parking brake,

e d“'4dn ^ I r«i .lit I

n U!1 OlHRt! II.ÍU.

If aislante IS otneriricjii I U' Í»'an i:»n nu'an l .n.i nui

jniil distante k.-'-orre, I 1Y BcSiahtcr ,jtit i ul

laainst nut A

• Road test tia''tri I t prop-i 'lopf ing distance .-¡ntri

above HtidajuY if peces .a t / If utoppirig dNlancs '. < 1'

greater than ip byhect gear t'lrthermainieranct

r nsc' 3 ai, Ciiiidct /oMt f.. arcs! atth< -r^

cerner.

1 adjus

ide of'

iblefc

insaxk

FIG. 20

20

Page 21

SERVICE AND ADJUSTMENTS

ÌEPLACE MOTION DRIVE BELT

зпогт

Remov© mower (See i O REMOVE MOWER m this;

iioo of this manual,,)

Remove belt from stationary idler and clutching idler.

,' (¡i b-l'* I- 1 ,«<i,i > H

'■> •in tijicex'“ t j.* ,'it t!^ b « U' pji

Pull belt toward front of tractor and remove downwards f

* < lui ii 1 »IL,

Install new belt by reversing above procedure.

ifds

rom

TRANSAXLE GEAR Sl-

TRAL ADJUSTMENT !*■

The transaxle should be in neu

is in neutral (N) (lock gate) p

preset at the factory; howeve

proceed as follows:

flOE v'di'cr h.f tinrj'.

tras,- U'- 1 .,i_.

. ÍJttj f.,rt 4 ‘ us ID i

¡ ( .|M > H ) 'i| (..ft h

" Tiqh, - Í it' r-, >: -1-,

fc If iijdifii iir'. k r

ment bolt, move mower deck h

IIFT LEVE

»ee Fig. 23

rai wlien thè c

osition. The

r, if adjustrne

ir wheels mo

3ot of thè right ÎBâf Ш

SI thè neutra!,

urely.

■I ijt '• t<

eight to thè lowest Position

R NE

:u-

lift f^ve

adjust

Tieni ÍS

nt is г

leeded

ve fr©ely, the

ffieeL

N) pos

Шоп»

Of í

adjust

——

utili HAI

Í Ш H

GATE

-----

1

'“V-.T'

d

FIG. 23

NEUTRAL

LOCK GATE

21

Page 22

Sr=?VICF-

fO ADJUST STEERING WHEEL ALIGNMENT

If steering wheel crossbars are not horizontal (left to right)

when wheels are positioned straight forward, remove steer

ing wheel and reassemble per instructions in the Assembly

section of this manual.

FRONl WHEfcl ryE4N/CAMBER

Thp front wheel toe-ir« and camber are not ddjustable on

your irdclor If damage has otcuned to affect ilie lioni

wheel toe-in or camber, contact your nearest authonzed

serves center/departmerii,

TO REMO¥E WHEEL FOR REPAIRS (See Fig. 24)

Block up axle securely.

Remove axle cover, retaining hog .a-id washers to alow

wheel removal hear wheel contains a square key - Do not

lose,!.

Repair tire and reassemble.

On rear wheels only: align grooves in rear wheel hub and

axle, insert square key.

Replace washers and snap retaining ring securely in axle

groove.

Replace axle cover.

NOTE: To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire diy rot and

corrosion.

FMGINEWITHAWEAr I

g. 25)

CAUTiOH » foil s,.Jd batw 'c- qfe-ierateexplosivegases. Keep sparks,lame

and smoking materials away from bat

A

If your battery is too weak to start the engine, it should be

recharged (See BATTERY" in the CUSTOMER RE

SPONSIBILITIES section of this manual).

If “jumper cables” are used for emergency starting, follow

this procedure:

IMPORTANT YOUR tractor IS EQUIPPED WITH A

VOLT NEGATIVE GROUNDED SYSTEM. THE OTHER

VEHICLE MUST ALSO BE A i2 VOLT MEGA'IVE

GROUNDED SYSTEM. DO NOT USE YOUR TRACTOR

BATTERY TO START OTHER VEHICLES.

TO ATTACH JUMPER CABLES -

• Connect each end of the RED cable to the POSITIVE (+)

terminal of each battery, taking care not to short against

chassis.

• Connect one end of the BLACK cable to the NEGATIVE () terminal of fully charged battery.

• Connect the other end of the BLACK cable to good CHAS

SIS GROUND, away from fuel tank and battery.

TO REMOVE CABLES, REVERSE ORDER -

• BLACK cable first from chassis and then from the fully

charged battery.

• RED cable last from both batteries.

teries. Always wear eye protection

when around batteries.

AXLE COVER

SQUARE KEY (REAR

WHEEL ONLY)

FIG. 24

POSmVE TERMINAL

CHASSIS-

POSITIVE

TERMINAL

NEGATIVE TERMINAL

CABLES

CHARGED

BATTERY

NEGATIVE

TERMINAL

FIG. 25

22

Page 23

SERVICE AND

.. '.K • - , r^- . 26 an . ,1

CAUTIOI ot short battery terininalsbyal lowing a wren« y other

object to contact both terminais at the

A

Lift seat pan to raised position and open battery box door.

Disconnect BLACK battery cable first then RED battery

cable and carefully remove battery from tractor.

Install new battery with terminals in same position as old

battery.

First connect RED battery cable to positive (+) terminal with

hex bolt and keps nut as shown. Tighten securely.

Connect BLACK grounding cable to negative (-) terminal

with remaining hex bolt and keps nut. Tighten securely.

Close battery box door.

SEAT PAN

same time. Before connecting battery,

remove metal bracelets, wrlstwatch

bands,rings,etc.

Positive terminal must be connected

first to prevent sparking from acciden

tal grounding.

rtfcrl lat

31' IS locate

t* I

he

• Pull bulb holder out of the hole in the backside of the grill,

r ir-p:}' c i (jiti 11 ;,i'l I > po I' 1/ '‘O ,, i <t 1 -I > f • N

1, <> h'•!. ! ) >t !■,' ' a 't i „ 1 II1

• Close hood.

itdTERlANLi RtlAA-

Loo f), ‘mni-j ■, uu.).' ;t.'I / ..h * !oi i • no

poorly, stop running or prevent it from starting.

’ i'c t Alili! i < L r ,11, «,ii‘ ,•( i'.gi .f»l ■ f III'

I *."¡'•.1 P «L , i 'll

iOLmi

TO NEMOVe HGi iD AmO . LL |Sgc

^ MciiSo tswCy.

• U.i_.[k4 htdcjpiyh* i«/i. kiio.

• Maridiniofitoilr ru<, f ,msplir<>d >i n'l i ¡wer! and

lift jfi uf t»a:tof

• To replace iLevp pi

BATTERY

BOX DOOR

FIG. 26

KEPS NUT—

POSITIVE (RED) CABLE NEGATIVE (BLACK) CABLE

FIG. 27

2P

23

Page 24

SERVICE AND ADJUSTMENTS

ewuswr

I AD

TC

^ t,4t M -el IS again t a^op l! it f no! Iccser* cable

1 OADJySI CHOKE CONTROUSee Fig 30|

adiP atment should noi be necessary Gheclc adjustment as

describsi bsLvv befoie looser mg static !i idiusimi-' i r

« engr-«‘ not rimrang, moie cnoke cjntrr.i ('.icatcd m

• Loosen knob and remove cover assembly from air cleaner.

• Choke should be closed. If it is not, loosen casing clamp

• Replace air cleaner cover assembly and tighten knob.

TO ADJUST CARByRETOR

Your carburetor is not adjustable. !f your engine does not

operate properly due to suspected carburetor problems,

take your tractor to an authorized service center for repair

and/or adjustment.

High speed stop is factory adjusted. Do not adjust damage may result.

IMPORTANT: NEVER TAMPER WITH THE ENGINE

GOVERNOR, WHICH IS FACTORY SET FOR PROPER

ENGINE SPEED. OVERSPEEDING THE ENGINE ABOVE

THE FACTORY HIGH SPEED SETTING CAN BE

DANGEROUS. IF YOU THINKTHE ENGINE-GOVERNED

HIGH SPEED NEEDS ADJUSTING, CONTACT YOUR

NEAREST AUTHORIZED SERVICE CENTER/

DEPARTMENT, WHICH HAS PROPER EQUIPMENT AND

EXPERIENCE TO MAKE ANY NECESSARY

ADJUSTMENTS.

JUS

e th

111stmeni

iscribf

HROTTLE CONTROL CABLE (See Fig. 29)

shoui

d beic

y, pro

not be nec

r before loo

as folic

ry.

ig«

idju!

idju:

sni

ant

vVitn enpioo I,Cl luonotj i>i .w- ir. • »chirol M ‘i7> oposition.

■lamp arid puli '•able back i 'ntil swivel i>„ aqainst stop

Tighten -'amp ■'''rew se-'orsl,

1 oe choke contioi has been preset at the factory and

r.ec6SSa7 proceed ssfc'loW'

dash panel) to full choke position

screw and move choke cable until choke is completely

closed. Tighten casing clamp screw securely.

SWIVEL

CLAMP.

SCREW

FIG. 29

24

Page 25

: tfie en

A

ìW DfeD

CAUTION: Nswef store tti© tractor with

gasoline in the tank inside a building

whfife fuiii©s rosy r@3ch sfi open f Ifliii©

.»t W- . M

, ir ,6£«if k <H‘i rS £ 3

J

RACTOR

lemove mower from tractor for winter storage. When

lower is to be stored for a period of time, clean it

ioroughly, remove all dirt, grease, leaves, etc. Store in a

lean, dry area.

r r ' ri|il5 ¡1.-1 t'K ! -i ‘ ( _l_ ' f'.'IU' rii i[>.' ! |( lOrdSi

h’f -.f irt,1,1 I dfl.dil , 1 tf-r- Jl’l

In |) £ I iH'\ !i^ptc>ci- b-lt- it -..T.o'v t J*-"i »‘ipia ,errif n1 incitiuntioris in th Pciiii p and Arijb*-!'nenK rccrioiioi

this manual).

I nL.i< 3it- js bbùwn 'll fli- C lotpiiipi Hr il'he S'-c-

( ijfi '«I ihis riiinuil

R£ IKP ih It £<ll hUt , hr.if ariu rc«£ f <P'Urnl/ flS"

tp'ie-t inspect n oviwj DdttF .ur dnt'ujt l«r at i-]«- and

hr H* pid c 4 'SI/.

I ouch up 111 iiiFted or c lippeu piiftt uriotf-r sitid iiytiiiy

hefjre iiaititing

lATTERY

Fully charge the battery for storage.

After a period of time in storage, battery may require

recharging.

To help pfeveiit coirosion and powet leakage duiir.g long

periods of storage, battery cables should be disconnected

and battery rJeaned thoroughly (see 'TO CLEAN BAT

TERS AUD TERyiNALS" if. the Customes Responsibilities

section of ih!& manual).

After cleaning, leave cables diGcorinectod and place cables

where triey «Miiiiot come in contact wiih baiter/ tfimrei:..

If battery ic temoved from tractof for storage, do not store

b.atteiy directlv en concrete or damp surfaces

E N 1 ^ E

FUEL S¥'

IIIPORTAN'

DEPOSITS

FUEL

FUELS (CAL

METHANOL;

TO SEPARA

STORAGE.

SYSTEM OF

• Drain the fuel tank.

itiit hif 1 q!!i- „-'i i, t .1 nii, II,i! jbe s.jti ,ii,en ti.u

carburetor are empty.

' L I'l" ‘ J >1 i fj udULti h t’Hi;

tank or permanent damage may occur.

•" U- f fu ' ll t.r i r.» vl 'C , .>>

fniiwfiteino tfiir ioiiiteiiri tu<* (¡iii-f ,« ¡¡. ir. lii’MPc»

hiorai.te Old-IdbsOvr !o yi'-olitH 111 flit f {iiif el «.torwih

f Aiw lys foilr-/.' th^'» rriy f «Tin ,ou /! uH T T.iIi ,>•■

FROM FOhMIMG in ESSENTIAL FUEL

ITS SUCH AS CARBURETOR, FUEL FILTER.

, OR TANK DURING STORAGE. .ALSO,

-■fg

E INDICATES THAT ALCOHOL BLENDED

LED GASOHOL OR USING ETHANOL OR

CAN ATTRACT MOISTURE WHICH LEADS

riON AND FORMATION OF ACIDS DURING

ACIDIC GAS CAN DAMAGE THE FUEL

AN ENGINE WHILE IN STORAGE.

‘'‘e> 'iüilte. ■ all 'b. .¡iil'e ,T'i.< ii ' i'

COiilaint Hl'ii eriginu o Oa:-t lu I'l.HLUt- ifte' -rldlbp

itahilcpi to all..wiheTrtüiiCfcftore„chth^c nhuieiur. Du

n'4>Jriii*tiit-'M tjfil aruif er .-jk tc., m'jattifHijf kWbil'zer

ENGiNE Oil

Di'ttnr liiwiti.pnqi.te ./«rif.) ift'J leplci f'with dean enpine

oil. (e>ee ENGINE in the customer Responsibilities

section of this manual).

CYUNDERfS)

• Remove spark plug(s).

• Pour one ounce of oil through spark plug hole(s) into

cyiinder(s).

• Turn ignition key to “START’ position for a few seconds to

distribute oil.

» Replace with new spark plug(s).

OTHER

• D . In I Tort jc'cln>' frm nre ‘cr-.m U rnuthi i

Pepi=re - .i: nH-'c-i'.., ..-m ir V I I m gf ritt r, t. Rust

f.iit III ,,iiur qrili.-ih «iP ' p|. Dii n.

If I ' ._ibi It'' /01'. ti. I • ..(Jr ;rs end rove, it to give

|.f .r-i f| ir, 1- , H nrf , ot V.,tjt tiui.r I rviifi -i)iiT*! |■rnкcf^•/eco\ 'ithatdoes

M)t -'tiin M, I tfj.6 H r< t "’t 'testic. PI. ir cannot

(".if, PL .'Ll fi Ü - ■H.t r.-tt . I to-m 3r ; .wil cause

your tractor to rust.

iMPORlÄNT iil-Vi r! (te/ER ¡RAO'iOR WHILE

FN. :|NE AliU F <HAUL /.htA.t ART FT Ii V'/ARM.

25

Page 26

TROUBLESHOOTING POINTS

PROBLEM CAUSE'

Will not start 1. Out of fuel. 1

2. Engine not “CHOKED” properly. 2. See “TC START ENGINE” in Operation

3. Engine flooded.

á RaH ftnark nil in

Dirt# m Íilifeí

h billy tuei filrei 6. Replace fuel filter.

; Wate* ill ftei

L-jOst nr ft5 iiag<=d wiring.

9. Garoureio: nut ot adjustment.

10, Engine valves out of adjustment.

Hard to start

1. Dirty air filter.

2. Bad spark plug.

3. Weak or dead battery.

4. Dirty fuel filter.

5. Stale or dirty fuel.

6. Loose or damaged wiring.

7. Carburetor out of adjustment.

8. Engine valves out of adjustment.

CORRECTION

Lie! tank.

section.

3. Wait several minutes before attempting to

start.

4. Replace spark plug.

5. Clean/replace air filter.

7. Drain fuel tank and carburetor, refill tank with

fresh gasoline and replace fuel filter.

8. Check all wiring.

9. See “To Adjust Carburetor” in Service Adjust

ments section.

10. Contact an authorized service center/depart

ment.

1. Clean/replace atr Piter

2. Replace spark plug.

3. Recharge or replace battery.

4. Replace fuel filter.

5. Drain fuel tank and refill with fresh gasoline.

6. Check all wiring.

7. See ‘To Adjust Carburetor” in Service Adjust

ments section.

8. Contact an authorized service center/depart

ment.

Engine will not

tyrn over 2. Attachment clutch is engaged.

Engine dicks but

will not start

Loss of power

1. Clutch/brake pedal not depressed.

3. Weak or dead battery.

4. Blown fuse.

5. Corroded battery terminals.

6. Loose or damaged wiring.

7. Faulty ignition switch.

8. Faulty solenoid or starter.

9, Faulty operator presence switch(es).

1. Weak or dead battery.

2. Corroded battery terminals.

3. Loose or damaged wiring.

4. Faulty solenoid or starter.

1. Cutting too much grass/too fast.

2. Throttle in “CHCKE” position.

3. Build-up of grass, leaves and trash under

mower.

4. Dirty air filter.

5. Low oil level/dirty oil.

6. Faulty spark plug.

7. Dirty fuel filter.

8. Stale or dirty fuel.

9. Water in fuel.

10. Spark plug wire loose.

11. Dirty engine air screen/tins.

12. Dirty/clogged muffler.

13. Loose or damaged wiring.

14. Carburetor out of adjustment.

15 Engine valves out of adjustment.

1. Depress clutch/brake pedal.

2. Disengage attachment clutch.

3. Recharge or replace battery.

4. Replace fuse.

5. Clean battery terminals.

6. Check all wiring.

7. Check/replace ignition switch.

8. Check/replace solenoid or starter.

9. Contact an authorized service center/depart

ment.

1. Recharge or replace battery.

2. Clean battery terminals.

3. Check ail wiring.

4. Check/replace solenoid or starter.

1. Set in “Higher Cuf position/reduce speed.

2. Adjust throttle control.

3. Clean underside of mower housing.

4. Clean/replace air filter.

5. Check oil level/change oil.

6. Clean and regap or change spark plug.

7. Replace fuel filter.

8. Drain tuei tank and refill with fresh gasoline.

9. Drain fuel tank and carburetor, refill tank with

fresh gasoline and replace fuel filter.

10. Connect and tighten spark plug wire.

11. Clean engine air screen/tins.

12. Clean/replace muffler.

13. Check all wiring.

14. See “To Adjust Carburetor” in Service Adjust

ments section.

15. Contact an authorized service center/depart

ment.

26

Page 27

KKOtJI.Cii

UAUSt

-M1 ION

Excessi¥e¥ibrat»ii torn, bent or loose blade.

2. Bent blade mandrel.

3. Loose/damaged part(s).

Engine continues to

■|jn when operator

saves seat

1. Faulty operator-safety presence control

systems.

with attachment

:lutch engaged

^oor cut -ynewen

1. Worn, bent or loose blade.

2. Mower deck not level.

3. Buildup of grass, leaves, and trash under

mower.

ent blade mandrel.

5. Clogged mower deck vent holes from

i.uildtip iffi/as.-o leaves, and trash around

mandtelb

lower blades will

lot rotate

; •JLc4ruct»ui: M ^.iuf:h mechanism.

Worn/dani«gei mower drive belt.

E Ftozeii idloi pulley

4 f ¡nec-n blade mandrel.

*oor grass discharge ., E.iyiOi- 'petfii k o ¿low.

2 Travel speed too fast.

3. Wet grass.

4. Mower deck not level.

5. Low/uneven tire air pressure.

6. Worn, bent or loose blade.

7. Buildup of grass, leaves and trash under

mower.

0 MoW( r dri' P holt worn.

9 iniprnp_,iy installed.

10 Imptopt. hi ed.

11 t 'cp'Kdm wf' d> ck vent holes from

bijiitJi Ip A jt le xves, and trash around

rfH'idrei

Replace blade. Tightei

2. Replace blade mandrel.

3. Tighten loose part(s

1. Check wiring, swii

flections. If not cc

authorized service m nt .tofepaffrr-.r-rii

1 i' 1 lace blade. Tighten blade boh

2. Level mower deck.

3. Clean underside of mower housing.

Replace blade mandrel.

5. Clean around mandrels to open vent

holes.

1. Ri'movfr -.bsttuf lirn

2. Replrv e rroWf:r duv.i belt.

3. Replace iJIh p.Jiey

4. Repin- ft blade rnandrcT

1. i la T ’•ott.i- rent,' I ir, “FAST’ position.

2. Shift to i lower speed.

3. Allow press to dry' before mowing.

4. Level mower decK.

5. Check tires for proper air pressure.

6. Replace/sharpen blade. Tighten blade bolt.

7. Clean underside of mower housing.

8. Replace mower drive belt.

9. Reinstall blades sharp edge down.

10. Replace with blades listed in this manual.

11. Clean around mandrels to open vent holes.

lead!ight{s)not

iorkingfif so

quipped)

attery wiii not

targe

ngine “backfires”

'hen tyrning engine

DFF”

i C wiH 111 ‘{j F

: I 1 I f ) Siu:iii-d jU'

J. f ttilrj IkjIi /l|IC1l I

' I M* igon wiring.

^ . 1 <l tL

1 ftnd b, tu-iy reiiis).

2. Poor cable connections.

3. Faulty regulator (if so equipped).

4. Faulty alternator.

; Engine throttle control not set at “SLO’

position for 30 seconds before stopping

engine.

27

1. Turn switch “ON”.

2. Rtpiace bu!lj(:r).

3. Diec-S'replacfcf light switch.

4. Chftck wifiny and connections.

5. Replace fuse

1 f.r oiace battery.

2. Check/clean all connections.

3. Replace regulator.

4. Replace alternator.

1. Move throttle control to “SLOW” position and

allow to idle for 30 seconds before stopping

engine.

Page 28

Hnîfh

Page 29

SCHEMATIC

^ iiODEL NUiC-.-rC MPIsi C

IGNITION SWITCH

POSiTION

OFF

RUN/LIGHT

RUN

START

CIRCUIT “MAKE"

G + M + L NONE

B + L + S NONE

B + L A +Y

B + L NONE

NOTE

YOUR TRACTOR

EQUIPPED WITH A SPECIAL

ALTERNArOH SYSTEM.

THE LIGHTS ARE NOT

CONNECTED TO THE

BATTERY. BUT HAVE THEIR

OV#J ELECTRICAL SOURCE.

BECAUSE OF THIS, THE

BRIGHTNESS OF THE LIGHTS

WILL CHANGE WITH ENGINE

SPEED. AT IDLE THE LIGHTS

WILL DIM. AS THE ENGINE IS

SPEEDED UP, THE LIGHTS

WILL BECOME THEIR BRIGHTEST.

NON-REMOVABLE

CONNECTIONS

WIRING INSULATED CLIPS

NOTE: IF WIRING INSULATED CLIPS WERE REMOVED FOR

SERVICING OF UNIT, THEY SHOULD BE REPLACED TO

PROPERLY SECURE YOUR WIRING.

2i

REMOVABLE

CONNECTIONS

Page 30

REPAIR PARTS

r'PA^f, - MODEL NU'*«Nr-“ ’ “r-

:al ' ■ ' '

21 22

Page 31

I ~r ji. - - mou:: 1► :h' [%

KEY PART

NO,

NO.

!440£,-1

1

? ^4/00412

b ;5o4l/

10

153664 3wit{ n liilerlfiCh Fusn-ln

19

10090400

20 /3350400

¡6618( Harness Socket Ligiit

21

nsr^j

9 ’’

,?A

4799J

S *"

14614,-

26 166180 ruse 15 Amp

27 73510400 Nut Keps Hex 1/4-20 Unc

4207J

28

29 121305X

30 140301

12421IX Nut Ignition

31

32 141226

122147X Key Ign Molded Generic

33

40 166145 Harness Ign

41

71110408

42 131563

145673 Solenoid

43

44 73640400 Nut Keps BIk 1/4-20 Unc

45 121433X

52 141940 Protection Loop

70 166659 Harness Engine

OESt RIPTlOfI

Rdtte^ 17oit - 'i Amp

Bnlt Hex Hd 1/4-,‘Oi nc X 3/4

Battery Merh Hinge

vVjSrier Leek f''4

Hut Jam riet 1/4 20 Unc

RtilP ! nht #115/.

C able Ba№tv

('able Babe> 6 fja Red w/16 wire

Cable Ground 6ga 12 black

Switch Plunger Nc Gray

Switch Ign 4 Pos W/L P/L

Cover Sw Key

Bolt Fin Hex 1/4-20uncx 1/2

Cover Terminal Red

Ammeter Rectangular

NOTE: All component dimensions given in U.S. inches

1 inch = 25.4 mm

31

Page 32

REPAIR PARTS

p ;N - - MODEL NUMBER PPPi

CHASS ID ENCLOSURES ' '

Page 33

REPAIR PARTS

C-'K - MODEL NUMlir’'’ '■ ! , i r

JHASSIS AND ENCLOSURES

KEY

NO.

1

2

3 1706C«12

4 19131216 Washer 13/32 x 3/4 x 16 Ga.

5

9

10 72140606 Boll Carnage 3/8-16 x 1

11 155927

12 145660 Diip 1 innerman

13

14 17490608

17

18

20

23

24 74780616 Bolt Fin Hex 3/8-16x1 Gr5

25

26

28

29 146654X599 Lens LT/PL

3G 168749X428 Fender Footrest STLT Pnt

31 139976 Bracket Support Fender

33 145244X428

34

35 72110606 Bolt Rdhd Sht Sqnk 3/8-16 x 3/4

37 17490508 Screw Thdrol 6/16-18 X1/2 TYT

38

39 139887 Bracket, Asm. Pivot, R.H., Mower Rear

51 73800400

52 19091416

53 144697 Bracjet Grukke Lh

54

55

57 74780412 Bolt Hex 1/4-20x3/4

58

64

74 73680600

114 158112

115 17060620 Screw 3/8-16x1-1/4

116 19131614

140 158418 Bracket Suspension Front

142 165867

145

...........

PART

NO.

166819

140356 DrawPar, Stretch

155272

151917X012 Dash P/L

169118

159639X428 HoodLT/PL

126938X

156437

124028X Bushing

19131312

738CX3600 Nut Lock Hex W/lns 3/8-16 Unc

157428

145243X428 Footrest Pnt Rh

139886

161464

144696 Bracket Grille Rh

162266

154798

156524

Washer 13/32 X 13/16 X 12 Ga

Grille LT/PL

Footrest Pnt Lh

Bracket, Asm. Pivot, L.H., Mower Rear

Nut Lock Hex W/lns 1/4-20

Washer 9/32 x 7/8 x 16 Ga.

Screw Hex Wshd 8-18 x 7/8

Duct Air

Dash Lower STLT

Nut Crownlock 3/8-16unc

Keeper Belt Rear Lh

Washer 13/32 x 1 x 14 Ga

Plate Reinforcement STLT

Rod Pivot Chassis/Hood

' " '

DESCRIPTION

Chiissis

Screw 3/3-16X.75

Bumper HoocJ/Dash

Panel Dash Lh

Panel Dash Rh

Screw Thdrol 3/8-16x1/2 Ty-tt

Bumper Hood

Plate Mtg Battery Fuel Tank Fr

NOTE: All component dimensions given in U.S. inches

1 inch = 25.4 mm

33

Page 34

REPAIR PARTS

DRI¥E

f -- MODEL NUMEl ' ^ I -

34

Page 35

MODEL NU

^ PART

1.

1 I5C)

146682

2

123666X Pulley T ransaxle 18" tires

3

12000028

4

121520X Strap Torque 30 Degrees

5

6 17060512

8

Ir'X 7

10 76020416

11 105,01X

74550412

13

fir4010ii

14

18 4780616

“1900000

19

?1 140845

i 30801.

22

“lOhiXlOO

24

:06B88< Spiiity rtfd bi .h l(i/me OR r t7o2<

25

1 03.156

26

27 /60^6412

28 545201

716/ t i hp brah PiT-ntj

29