Page 1

шш

—

Printed in U.S.А.

Page 2

ШШ

URE TO OBSE

iENERAL OPI

the manual

ily alio»

struction

machine if anyone enters the area.

Never carry passengers.

Do not mow in reverse unless absolutely necessary. Always

look down and behind before and while backing.

¡Jea'i»', I- r, ti'i : <" . n ! •, ¡i- kri ' i,i > di oinf

I di. r n iit. r.) > .,1 >0; ■ i I r, c ,v(i dt e.tN the

entire grass catcher or the guard in place.

Slow down before turning.

i Icvui Tnvc n n 11 liiing I iCu unsiiefi. kd a!wa\ s iurr, off

Diaaes, set parking brake, stop engine, and remove keys

before dismounting.

Turn off blades when not mowing.

Stop engine before removing grass catcher or unclogging

chute.

Mow only in daylight or good artificial light.

Do not operate the machine while under the influence of

alcohol or drugs.

Watch for traffic when operating near or crossing roadways.

Use extra care when loading or unloading the machine into

a trailer or truck.

SnSIDiC

J thn

9i pe

amiiiar witn tn€

by the blade.

? before mowing. Stop

'RU(

etc..

II. SLOPE OPERATION

Slopes are a major factor related to loss-of-control and

tipover accidents, which can result in severe injury or

death. All slopes require extra caution. If you cannot back

up the slope or if you feel uneasy on it, do not mow it.

DO:

• Mow up and down slopes, not across.

• Remove obstacles such as rocks, tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could

overturn the machine. Tall grass can hide obstacles.

• Use slow speed. Choose a low gear so that you will not have

to stop or shift while on the slope.

• Follow the manufacturer’s recommendations for wheel

weights or counterv/eights to improve stability.

• Use extra care with grass catchers or other attachments.

These can change the stability of the machine.

• Keep all movement on the slopes slow and gradual. Do not

make sudden changes in speed or direction.

• Avoid starting or stopping on a slope. If tires lose traction,

disengage the blades and proceed slowly straight down the

slope.

DO NOT:

• Do not turn on slopes unless necessary, and then, turn slowly

and gradually downhill, if possible.

• Do not mow near drop-offs, ditches, or embankments. The

mower could suddenly turn over if a wheel is over the edge

of a cliff or ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction could cause

sliding.

• Do not try to stabilize the machine by putting your foot on the

ground.

• Do not use grass catcher on steep slopes.

TH.

Jren OL

1'

' , s e cl h j i 5 . [ ..1 leu f

children.

.1 \ cm ,■ cr. be'. In m i ' 11 be senoii'.iy

i ii >> T ni If lb'. 1r I (I'!'

Never allow children to operate the machine.

> k L' •jxl.d V, 1C, A'.itii r.y „lino oO'nei c, ch.ubs,

t:r es, or otpi r (J.|C( c, lisi 1 \hj „.h .curr

IV. SERVICE

• Ur c .0 „СЛ1 „ [ I) I Ji. It i I

flammable and vapors are explosi

Use only an approved container.

ciiicce.

Never refuel the machine indoors.

U I f ici tb 1 I 11 I iiLc container inside where

il H i ii ,1 I II *-1/ ( о 1Л water heater.

• rea.

• (.¡.nut r j| , b lull, t b' 'e ditachment bolts, tight

jn j tbc,p B^Uifli'f-l t 1И I ;(l ( O'-dlUOn

• ■ J( v-i tanit - r if 11 < I tv dev I os Check their proper

• ''„epm hiiK . . r cb 1 lea '1 11 other debris build-up.

• Stop and inspect the equipment if you strike an object.

• Never make adjustments or repairs with the engine running.

• Grass catcher components are subject to wear, damage, and

® MoVi'er blades are i hare and can cut. Wrao the tlade(s) or

® Check brake operation freauentlv. Adjust and service as

T >r t quk |lv

sioring.

Repair, if necessary, before restarting.

deterioration, which could expose moving parts or allow

objects to be thrown. Frequently check components and

replace with manufacturer's recommended parts, when nec

essary.

wear gloves, ana use extra t.autkm wher> servicing them.

reauired.

Lo ok for tiiis .cyisiiiol to point oui important

safety prccauticns, ft means

A

A

CAUTiOW!!! BECOIWE ALERT!!! YOUR

SAFETY !S iMVOLYED.

CAUTION: Always discooriect spark plug

wire arse place .«ire whfei'e it cannot contact

spark plug in order to prevent accidental

stariirig when setting up, transporting,

adjusting cr rf.eking rspair.s.

*1

hiraren enter the area,

cl I fl 1 of h U.iVjH !ul . iUsli

otherfuels. They are

uel with the engine

re refueling. Do not

;hine to cool before

A WAKNIS'SIA A

Theengine exhaust from this product contains

chemicals known to the State of California to

cause cancer, birth defects, or other reproduc

tive harm.

Page 3

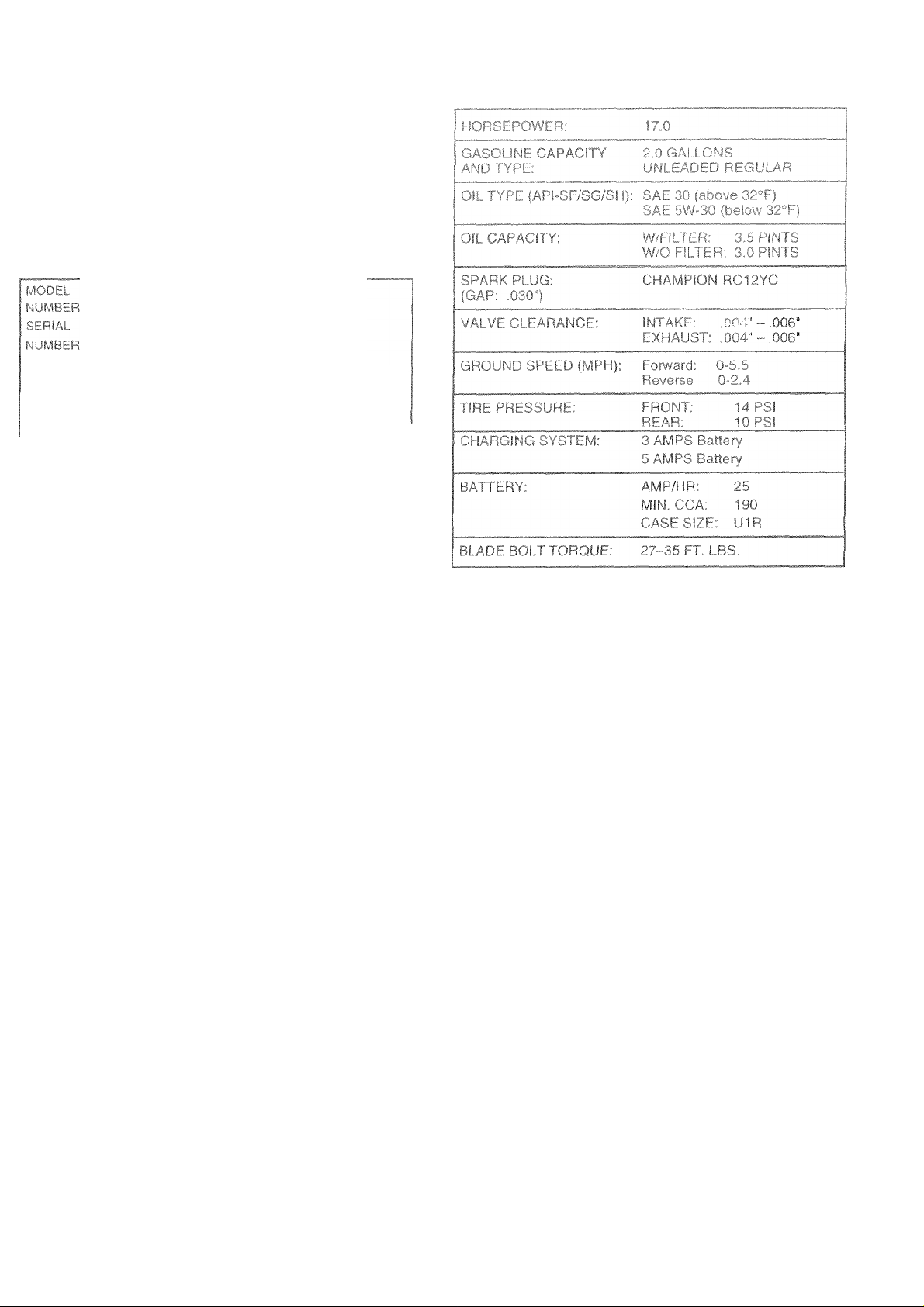

PPR17H42STB

DATE OF PURCHASE _________________________

THE MODEL AND SERIAL NUMBERS VTILL BE FOUND ON A

PLATE UNDER THE SEAT,

I YOU SHOULD RECORD BOTH SERIAL NUMBER AND DATE OF

* PURCHASE AND KEEP IN A SAFE PLACE FOR FUTURE REFER-

ENCE,

CUSTOMEP HEspori-IBliJTPES

• H-i>id ft- I ft- f'o tu'

* FullfWr lecjijlrj' rr^diiF m t int jiiiiriO caring for and

using your iracior.

« Fo!!o'A'th8 instructions underthe “Customer Responsibili

ties" and “Storage" sections of this owner's manual.

111! if

WARNING; This tractor is equipped with an internal combustion

► Pf'IPif'ATiflMÇ

engine and should not be used on or near any unimproved forestcovered, brush-covered or grass-covered land unless the engine's

exhaust system is equipped with a spark arrester meeting appli

cable local or state iavt/s (if any). If a spark arrester is used, it

should be maintained in effective working order by the operator.

In the state of California the above is required by law (Section

4442 of the California Public Resources Code). Other states may

have similar laws. Federal laws apply on federal lands.

Page 4

i mmu ^

1 he Manufac

materials and

repair or repl;

defective due

1. This wai

iraristTii;

a Uiim

2. ! ilJ!‘ I i.K ,! I t It'O ^ u r ihe ■ ij n* t f &| i 'wei cqi pni* t.i ur it ui ^ f Ti m < tl i :p nsibiiiiyci

hit u i ! t if ,y ,._r s ¡ ubn'. ed i_i r4''-. i-ri unr-^ u i ira,,tv'imja

pa, Í b i!|^ I in ti ^>Li.U-m i'jfhi tuio i: qi ' ' ted hy Fn jid oíh Hw n ni'u>t' il i'i-n,v''r--c^ E't.r,

niy uu

)il COfT

rnariuf

to the 3ngitiül cons>umer purchaser that this product as mans

eriod of two (2) years from d ate of pur T'lase by the orig

For 3 p

tion, witf îOUI CnSiQ© for parts or iabo

workma nsfiip. This /Varranty is subje ;t to the fc

It . .p..

ents, b£

rer's wa rranty on tf

y to the er gin©, other tha 1 FHP (F

ittery (exce pt as noted be

lese items.

r incurrec in replacing par tSj any p

liowing iimitation 3 and exc

1 1 / V ' _ 1

ow) or C(

jmpcnents part it C 11-

jfactured

inal cons

1 /111

is free from defects in |

umer purchaser, we will

art which we find to be

lusions.

1.1 1 1 i. a 1 '

F. W t T

d 1 :ui . VvTiiji , u i prjdi t -t. ill pi ’ "'lb - I- lit "V, .''0 *'iF u'"I- ii .uifh .vi rn .u , / t.-.tieiy

v.iiuli •' .in I 1 d ,3(f c Ti 11 I '»1 I 1« !' it j 'Pf hi b < hi ¡ y- t«*n. r^h.i Af'i ihreiv (’Xi)

.i.' V. nil I I, ibt b T'-, •‘n ' ,i 11 I n- f 1 i.f A’L atf ry im esni 0 II in .,i*h from

n ■- .fa 1. |i 'I I' t t > r ■ n 'i in+a ned m rd f r<j Ayth tF 'nsftU'‘h:,|i« luinrneu

4 f I Sb .f, fif' f (1 vl f. I I!/ p,' hj I' u -,i t~i rental oi n . uetcui ourposti is limitad to 90 Jay' Irom the

aaie or original purcriase.

5. This Warranty applies only to products which have been properly assembled, adjusted, operated, and main

tained in accordance with the instructions furnished. This Warranty does not apply to any product which has

been subjected to alteration, misuse, abuse, improper assembly or installation, delivery damage, or to normal

wear of the product.

6. Exclusions: Excluded from this Warranty are belts, blades, blade adapters, normal wear, normal adjustments,

standard hardware and normal maintenance.

7. In the event you have a claim under this Warranty, you must return the product to an authorized service

dealer.

Should you have any unanswered questions concerning this Warranty, please contact:

...... j * In Canada contact:

Fngidaire Home Products

Outdoor Products Customer Service Dept. Frigidaire Home Products

250 Bobby Jones Expressway 7075 Ordan Drive

Augusta, GA 30909 USA Mississauga,- Ontario

L5T 1K6

giving the model number, serial number and date of purchase of your product and the name and address of the authorized

dealer from whom it was purchased.

THIS WARRANTY DOES NOT APPLY TO INCIDENTAL OR CONSEQUENTIAL DAMAGES AND ANY IMPLIED WARRAN

TIES ARE LIMITED TO THE SAME TIME PERIODS STATED HEREIN FOR OUR EXPRESSED WARRANTIES. Some areas

do not allow the limitation of consequential damages or limitations of how long an implied Warranty may last, so the above

limitations or exclusions may not apply to you. This Warranty gives you specific legal rights, and you may have other rights

which vary from locale to locale.

This is a limited Warranty within the meaning of that term as defined in the Magnuson-Moss Act of 1975.

5

;5

!6

«

i5

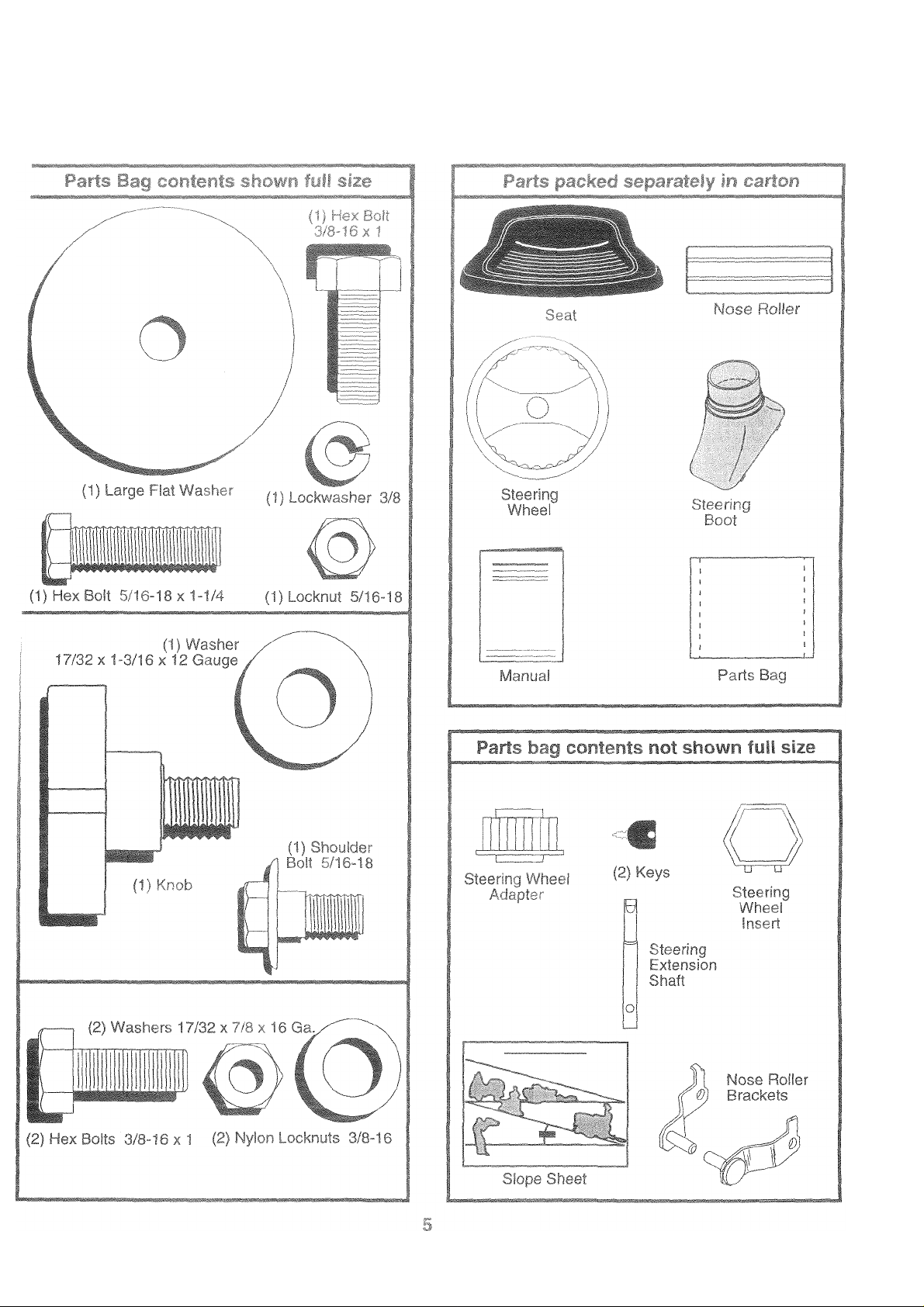

Page 5

Page 6

I V I i

IX me

ic

m f

*Un f

111 mafc

i I ! , 'tin ! r ol’el I ♦”«r' I II

(1) 9/16" wrench Tire pressure gauge

assemb

SEMBLY

isier. Standc

ith ©xcoption of the

parts and hardwai

(2) 1/2" wrenches Phillips Screwdriver

T'l, ii -j1 I f'; ft 1 i;d IS Tr-idioneo in this nianudi, u

r. wh'.'O > ' (I PC >f-erating position (seated

behind the steering wheel).

r. Vf ‘ nf N 1HB FROM CARTON

UNPACK CARTON

iVi.-ct, j le !vo..e parts and parts cartons

iro'ii cu'-Tn >' I - I :ge 6)

» 1 >Jl top to .

. 1

It irri, along lines on all fourcorners

.ji I and bv i aneis ilaf

Check for any aduilional loose parts or cartons and

remove.

BFFriRE NCLL!NO TRACTOR OFF SK!D

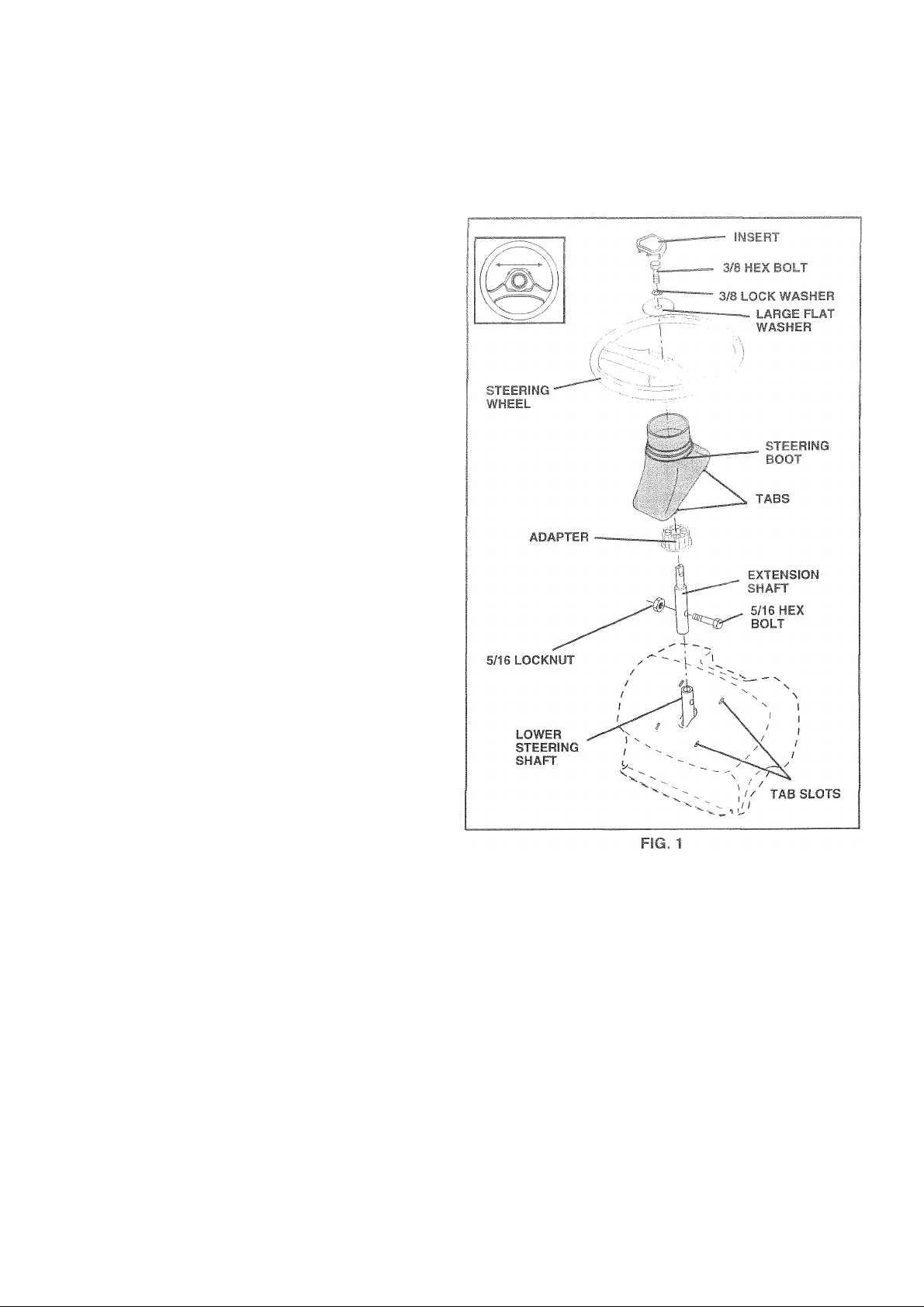

AT WHEEL (See Fig. 1)

CP .“r./i,( L , * rPN" ION SHAFT AND BOOT

nto lower steering shaft. Align

-iT >'! ( !.■ It IP extension and lower shafts and

>> t-il-'o ti‘ '■noil rd locknut. Tighten securely.

!MPOH4Wr ir^TFN BOLT AND NUT SECURELY TO

18 2 r I ! p ' I' [-fjilb

' O.'rtT ’ ♦'» iri'j boot over tab slots in dash and

o •'!! d>N/ i m uri

INWALL ^TEflilNfi WHEEL

• Posi.k pfrontwnceis of the tractor SO they are pointing

straight forward.

® Slide steering wheel adapter onto steering shaft exten

sion.

• Position steering wheel and sleeve assembly so cross

bars are horizontal (left to right) and slide onto adapter.

• Assemble large flat washer, 3/8 lock washer, 3/8 hex

bolt and tighten securely.

• Snap steering wheel insert into center of steering

wheel.

• Remove protective plastic materials from tractor hood

and grill.

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

IN SKID THAT MAY PUNCTURE TIRES WHERE TR.ACTOR

IS TO ROLL OFF SKID.

Ills left ufias jled'

OU i ITlL

tiqh

TO ROLL TRACTOR OFF SKID (See Operation

section for location and function of controls)

• Press lift lever plunger and raise aitachment lift lever to

its highest position.

• Release parking brake by depressing clutch/brake

pedal.

» Place freewheel control in freewheeling position to

disengage transmission (See “TO TRANSPORT" in

the Operation section of this manual).

• Roll tractor forward off skid.

® Remove banding holding discharge guard up against

tractor.

Page 7

^SSE^BLY

TO SET UP YOU

R TRACTOR

EClC BATTERY (Ss© F

Lift sost p3ii to rsisod posiîi

If tîiLb uau6ry IS plii II1ÏO SQpJ

in 1 or. ' ib< 1 'M■ ' ated between terminals)

oh. ,gfc bati-.’'» iOi il 1,11,.

(S-e"BATn FtC'iiT 1 ‘ ■

smtion of this matiM » c h

TERMINAL

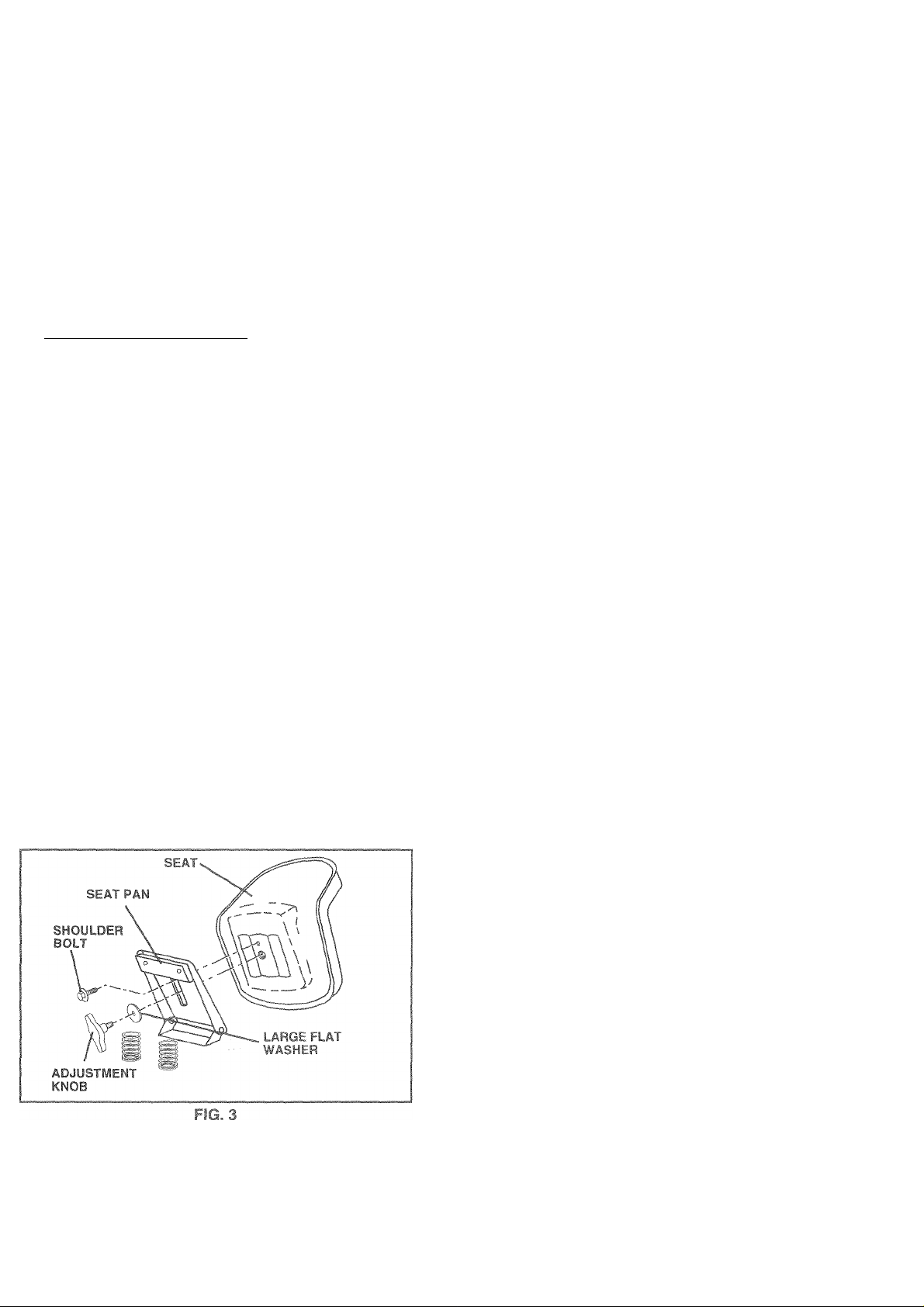

Adjust seat before tightenir.g adjustment bolt.

® Remove cardboard packing on seat pan.

» Place seat on seat pan and assemble shoulder bolt.

Tighten shoulder bolt securely.

* Assemble adjustment bolt, lock washer and flat washer

loosely. Do not tighten.

* Lower seat into operating position and sit on seat.

• Slide seat until a comfortable position is reached which

allows you to press clutch/brake pedal aii the waydown.

• Get off seat without moving its adjusted position.

® Raise seat and tighten adjustment bolt securely.

cn Hnd opon bsttory box

<ce after month and year

)f one hour at 6-10 amps.

lER RESPONSIBILITIES

arging instructions).

rO ATTACH NOSE ROLL!

Position bfârkBts 17/32 X 7/8 Î

c Fla. 41

X I o gauge wasners,

¡nting brackets as she

n correct side, as she

hex b

lien uc

■^OTî I • U> I r (I . loi, i' -.'lU t !l. , Ii 'h ItS n

lOr'lrf"

TAB HOLE-

I'd

nd 3/8-11 li nuts

I I \ -S'F r TAB

>L\ M

>c<l

^ \

..OCK MUT

Û m ~

' WASHER

CHECK TIRE PRESSURE

The tires on your tractor were overinflated at the factory for

shipping purposes. Correct tire pressure is important for

best cutting performance.

• Reduce tire pressure to PSI shown in “PRODUCT

SPECIFICATIONS” on page 3 of this manual.

CHECK DECK LEVELNESS

For best cutting results, mower housing should be properly

leveled. See “TO LEVEL MOWER HOUSING” in the

Service and Adjustments section of this manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion and

mower blade drive belts in the Service and Adjustments

section of this manual. Verify that the belts are routed

correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see

that the brake is properly adjusted. See “TO ADJUST

BRAKE” in the Service and Adjustments section of this

manual.

Page 8

jctions have been completed.

•e parts in carton.

hOU;

IS propt

it 6 aiTif

adiustec

prepared and charged. (Minimum

omfortabiy and tightened securely.

/ All tires are properly inflated. (For shipping purposes,

the tires were overinflated at the factory).

!*,'■ c> * II •' < t i I I ' a d aiif-to =|fir/

front-to-rear for best cutting results. (Tires must be

properly inflated for feveling).

' wh. t i-m; i.. flit/, h I* tc s.j'Pilityaie louied

pr ;• I i/ '(.UM.iiu -y. nil i ide ail bed bee,lets

,, ( t*. ij. v/!iir\. r,oe ifia«..III m licri.ons ate still secure

jiic tAj.reo to propc iy f i.u «}> d

F.' f 0M\M‘J c rr1np bi’ uti tree v-hei-'Lf nti'-i It in

drive position.

Vi/Hli L _ flfv «h/m/yoi.1'70 .,7. f iUURli \CTOHjAf

LXV, / • rtk '/•/ fv ?/,T LOWINC ,.MFOhlANT

:TEM‘

/ Engine oil is at proper level.

/ Fuel tank is filled with fresh, clean, regular unleaded

gasoline.

/ Become familiar with all controls - their location and

function. Operate them before you start the engine.

/ Be sure brake system is in safe operating condition.

/ It is important to purge the transmission before operat

ing your tractor tor the first time. Follow proper starting

and transmission purging instructions (See “TO START

ENGINE” and “PURGE TRANSMISSION” in the Op

eration section of this manual).

8

Page 9

OPERATION

These symbols may appear on your tractor or in literature supplied with the product. Learn and understand their meaning.

1

f

BATTERY

CAUTION OR

WARNING

STOP

REVERSE FORWARD FAST

©

ENGINE ON ENGINE OFF OIL PRESSURE LJGHTS ON

iS l\l

FUEL

CHOKE MOWER HEIGHT PARKING BRAKE

f

SLOW

G= ©1

OVER TEMP

LIGHT

Ik

if

©

UNLOCKED MOWER LIFT

LOCKED

i

is* NHL

ATTACHMENT REVERSE

CLUTCH ENGAGED

ATTACHMENT

IGNITION

DANGER, KEEP HANDS AND FEET AWAY

CLUTCH DISENGAGED

m

NEUTRAL HIGH LOW

♦

KEEP AREA CLEAR SLOPE HAZARDS

PARKING BRAKE

(SEE SAFETY RULES SECTION)

h-'■ =/<éím

FREE WHEEL

(Automatic Models only)

Page 10

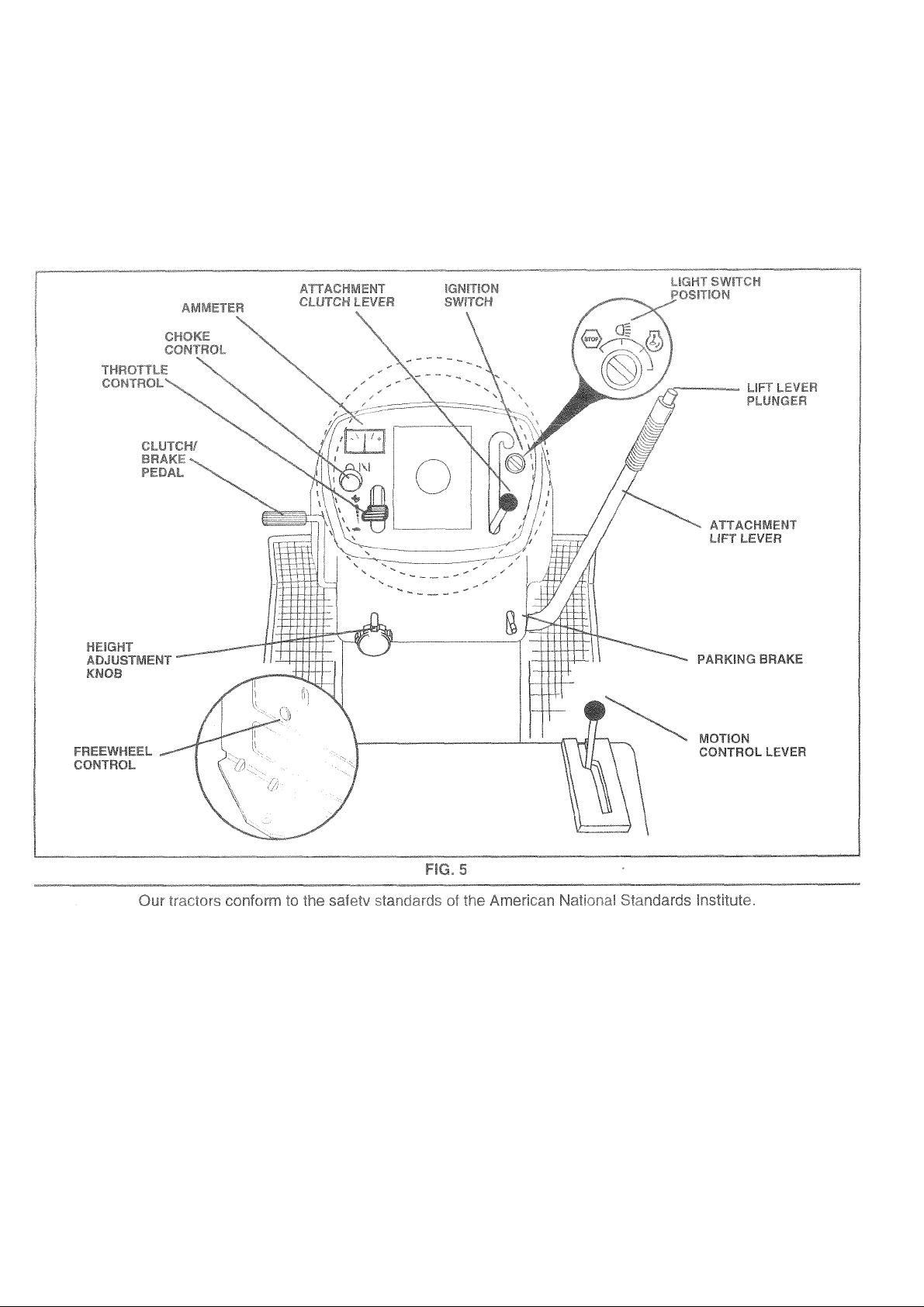

KNOW YOUR TRACTOR

CHOKE CONTROL: Used when starting a cold engine.

FREEWHEEL CONTROL: Disengages transmission for

pushng or towing the tractor with the engine off.

ATTACHMENT LIFT LEVER: Used to raise and lower the

mower deck or other attachments mounted to your tractor.

LIFT LEVER PLUNGER: Used to release attachment lift

lever when changing its position.

IGNITION SWITCH: Used for starting and stopping the

engine.

HEIGHT ADJUSTMENT KNOB: Used to adjust the mower

height.

AMMETER; indicates charging (+) or discharging (-) of

battery.

10

Page 11

^ ^ IP

3ms

L

tiom rc: ii“.t

TO •’ PâFsHMG DP‘r r I',, riQ g,

* Depress clutch/brake pedal into full “BRAKE” position

rtid hi.i( ,

» HiCi-p'fhiiqi'i ■! •' ■ i ii ‘ r'li> (»nsifiond'id

'f i-j tptfc lit' Iλ f' !»*■ d't ■' E il'd l t dri!; iiOiild

remain in “BRAKE” position. Make sure parking brake

v/!il t ;kJ ’ _ I >

fV

N< Ft Hi''' r • f t,., iivf'i'r r w-u-i . ' i'_ - I

idle with the engine running, hot engine exhaust gases may

Cv.,1' • r, f. ii _ I (■' . '.I ‘->i j (tiiliL,

always stop engine when stopping tractor c-n grass areas.

C ■ T r !> 'R AlAfnyz ‘ lt>r fri *: k, |

A

|j| Skv ,Lcf.jit 1er.-' f

Viti tht .trT-m''' r.fj'it'or tr f

gras

‘tCKtr rfr

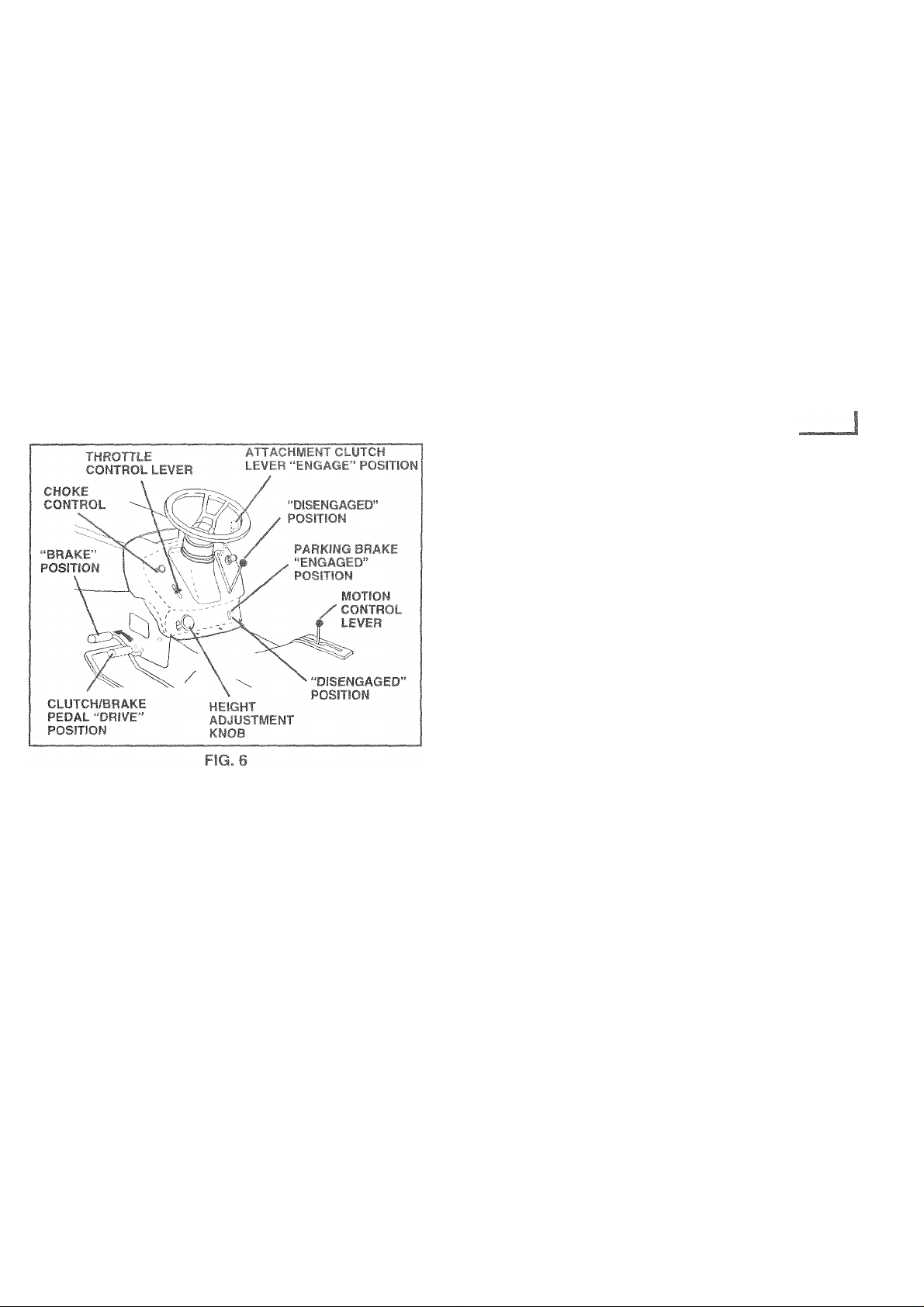

TO I/' L ' O ^ iOf^ Rii. |Oee Fig b|

Aiwav' t -.If- fci'pirr dt full V rattle

“ r -iijiiie 'si less ih.in full throttle reduces the

b t(( I y I rid..'fing rate.

® Full throttle offers the best bagging and mower perfor

mance.

TO ‘ Hi AF CONTROL (See Fig, 6|

Usec'K i- conlnilwhi nfv‘-rvou ire starting a cold engine.

Do n('t I r TO tarf. warn, ''noine

• T' ct>'W coniro! pull knob out. Slowly push

knob m lo disengage.

STOPPING (See Fig. 6)

MOWER BLADES -

• To stop mower blades, move attachment clutch lever to

“DISENGAGED" position.

GROUND DRIVE-

• To stop ground drive, depress clutch/brake pedal into

full “BRAKE" position.

• Move motion control lever to neutral (N) position.

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

ENGINE -

• Move throttle control to slow position.

NOTE: Failure to move throttle control to slow position and

allowing engine to idle before stopping may cause engine

to “bacWire”.

• Turn ignition key to “OFF" position and remove key.

Always remove key when leaving tractor to prevent

unauthorized use.

• Never use choke to stop engine,

IMPORTANT; LEAVING THE IGNITION SWITCH IN ANY

POSITION OTHER THAN "OFF" WILL CAUSE THE

BATTERY TO BE DISCHARGED, (DEAD).

TO MOVE FORWARD AND BACKWARD

(See Fig. 6)

The direction and speed of movement is controlled by the

motion control lever.

• Start tractor with motion control lever in neutral (N)

position.

• Release parking brake and clutch/brake pedal.

• Slowly move motion control level to desired position.

TO ADJUST MOWER CUTTING HEIGHT

(See Fig. 6|

Tne cutiirig ne.qtit is eonirelied by turning the height

aojustnient knob iii desired direction.

• Turn knob clockwise ( AK) to raise cutting height.

• Turn knob counterclockwise (Km) to lower cutting

height

The cutting height range is approximately 1 -1/2" to 4“. The

heights are measured from the ground to the blade tip with

the engine not running. These heights are approximate

and may vary depending upon soil conditions, height of

grass and types of grass being mowed.

• The average lawn should be cut to approximately 2-1/2

inches during the cool season and to over 3 inches

during hot months. For healthier and better looking

lawns, mow often and after moderate growth.

® For best cutting performance, grass over 6 inches in

height should be mowed twice. Make the first cut

relatively high; the second to desired height.

11

Page 12

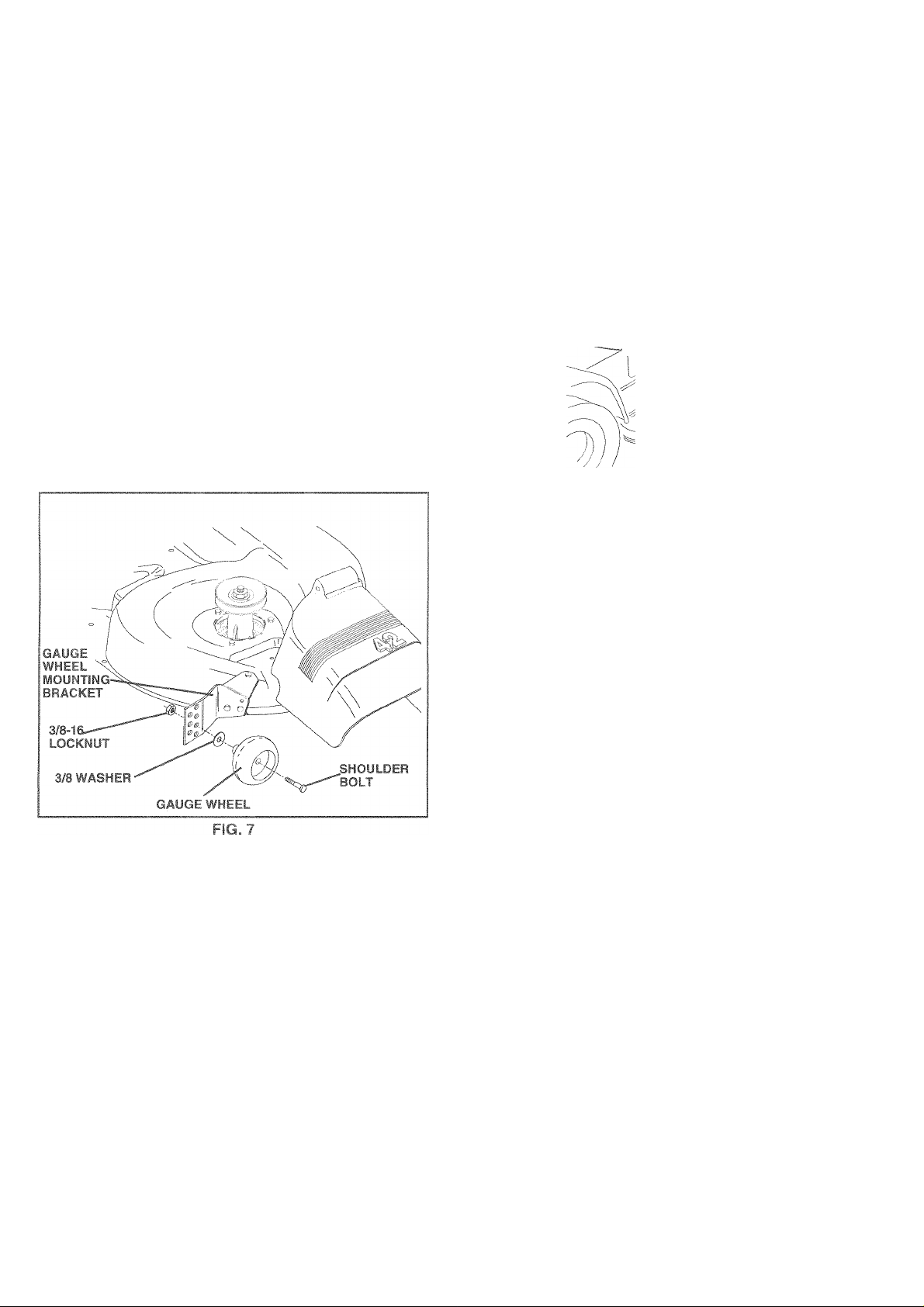

Adjust gauge wheels with tractor on a flat level surface.

Adjust mower to desired cutting height (See “TO AD

JUST MOWER CUTTING HEIGHT’ in the Operation

section of this manual).

With mower in desired height of cut position, gauge

wheels should be assembled so they are slightly off the

ground, install gauge wheel in appropriate hole with

shoulder bolt, 3/8 washer, and 3/8-16 locknut and

tighten securely.

Repeat for opposite side installing gauge wheel in

same adjustment hole.

T

TO OPERA! fc ON HiLLO

CAUl ICjii |J.< itoidriv'* «Jp oroown hills

'viir? y »id do not

a

dli.U M lOsb 'iMi, cluf-

LOW

POSITION

/ ;

\ /

r ii »

TT OPLG J r. (y Frfi 51

Yourtractor is equipped with an operator presence sensing

switch. Any attempt by the operator to leave the seat with

iht i.yvii ru.ii ii'i ana iti tm h centciuGh engt y-d «ill

shut off the engine.

• f-'' c das V c t c igtr >t cut.

• L IV-/hiGvv_i rfitn ditf'Jimeni lift control.

r-nn1

A,

■««fr blades engaging attachment clutchbiar

ES - disengage attachment

CTUTitTi Dr riot operate the mower

wiihc-m pi'iier "he entire grass catcher,

on mowers so equipped, or fire dis

charge guard in place.

C l.cor

hll£

» Avoid stopping or changing speed on hills.

• if slowing is necessary, move throttle control lever to

slower position.

• if stopping is absolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking

brake.

® Move motion control lever to neutral (N) position.

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED,

• To restart movement, slowly release parking brake and

clutch/brake pedal.

® Slowly move motion control lever to slowest setting.

• Make all turns slowly.

til .nwesi spe. d bt to: darting up or down

TO TRANSPORT (See Fiqs. 5 and 9)

When pushing or towing yourtractor, be sure to disengage

transmission by placing freewheel control in freewheeling

position. Free wheel control is located at the rear drawbar

of tractor.

® Raise attachment lift to highest position with attach

ment lift control.

® Puli freewheel control out and down into the slot and

release so it is held in the disengaged position.

• Do not push or tow tractor at more than two (2) MPH.

• To reengage transmission, reverse above procedure.

NOTE; To protect hood from damage when transporting

your tractor on a truck or a trailer, be sure hood is closed

and secured to tractor. Use an appropriate means of tying

hood to tractor (rope, cord, etc.).

12

Page 13

OPERATION

TC dPr' W'f,,

‘ ' V ,ui4 'i' r f ■ 1

CO !lf 1/ Viitfi p • ill , 1,1 . f the

tidCtct U.t, • hi-,’>ii >- f/nsn I owing. Too heavy of a

load v.hilc jIi -'op, '1 <srous.

with the fjiou !.:.>■

tra tor BEt ‘jfi A ' ‘ " i‘ THE E

• The engine in your tractor

factory, already filled with■ sumrner weight oil.

• v,ntT * igi 1, 1 ■■ fli i

• f-.j 1 lO't, 4 111 , '•> , * !

dipJic !■ in 1 1- ft/ 4 '1

“FiitJ ..»fi 1. w

t ,j i( >11 -1 Ri- r ,'i H H -

* 1 0 rill IU<- I'jl' H ' 1

1

CHECK miyjyi • ’ nE¥El

tem^cw err r 1 [ v.

• t O' cold : -ih 1 HI } 11 y O L

esiit' H-n'ti' ('■ ' IL VISD

THE! 3 attachments

it are

you tc

recommended by and

manufacturer of your

Ilf 1 r l> n,t cn

) lose control of your

ENGINE

. (See Fig. 14)

)een shipped, from the

has t

)!or or 1 level grourrd.

c and ^vipe clean, reinsert the

□ntf w

L if n I - m - J 1 111 til

s reac

3 S0

^ the Ctostomer Responsibili-

ait for a few seconds,

1 - (1 ') r/ 1 j nil.

" !l|t 11

1

tj ' 1 4 *Or

! ! ' ‘ Ì toPl in ¡ne

Ction of this mariuai).

ADD GfcbWt :r-F

» r ill 'Ut' > 1 i 1 t

'Id-' III i ' 'll . >f. Jf,

gasoline will increase carl

and reduce valve life). C

Purchase fuel in quantitie

(’ . . ) .TO - II 1 ‘ ’ >

IMP T.t .|i t . i r ^

tj F ' W A f 4 1 [ 1 ’ 1 ÌH, CL.EAN WINTER GRADE

CA-i 1 INF TCi 1 E 1 F W >'■ E GO OD COLD WEATHER

STARTING.

WARNING: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which leads to separation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before stor

age of 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See Storage Instruc

tions for additional information. Never use engine or

carburetor cleaner products in the fuel tank or permanent

damage may occur.

h, eie an, regular unleaded

fi7 f)

Don ar

to not mix oil with gasoline.

less.

WING .1 11 v4 rf r RiPLS

i iip. I'i' ‘ i.i 1« Fed

id lead oxide deposits

rpo ,II . ,j / ||ri|,| 30

p A UTION* Fill tc

filter fiscic» Do not

ik

"A

When starting the engine for the fi

has run out of fuel, it will take extra

fuel from the tank to the engine.

• Be sure freewheel control is in the transmission en-

uOa^J uuoluo.,.

i -It - , ^ d ‘ *p'-i p •; h I I* I < Imi ììI,h i <

I <• I , j, i 1,1 ( h r <-

® P!ac0 motion control lovor in neutral (N) position»

• Move attachment clutch to “DISENGAGED” position.

/1

' ' ihr 'riU -f ' ti jl ( cti 4 f

NOTr* Pel ,r» »iliii'p i--'d ih_ V.» "0 =r ^ Ir i'nrtmg

pro- ( dt>t. L : lA/

e 111'cdl-i-y ifif r r|oc,i >'r'eti 'FARF'

,/i ti II rcj*tl( ISC ‘-'m soon -‘.f in tort' nri

h .1 ri. . t n-r t Oil* r Jl U''! • f( i iiioro lh,.n lifiP ri tc-

, , V ^ - 01,If F .-r.ijni; 1 "Ijp »ftt-r

f, fi if 'ttf-ifìfis muM th cttleconir j| to toM po-itrr,

V'-It ^ wminutf " anf’iry ?qc-in itemjin»- itiildot noi

•ton move rhe throttle coi.troi sack >o th ■ kc

position and retry.

WARM WEATHER STARTING (50“ F and above)

• When engine starts, move the throttle control to the fast

position.

• The attachments and ground drive can now be used, if

the engine does not accept the load, restart the engine

and allow it to warm up for one minute using the choke

as described above.

COLD WEATHER STARTING ( 50° F and below)

• When engine starts, allow engineto run with the throttle

control in the choke position until the engine runs

roughly, then move throttle control to fast position. This

may require an engine warm-up period from several

seconds to several minutes, depending on the tem-

• Before driving the unit in cold weather, the transmis

sion should be warmed up as follows:

• Be sure the tractor is on level ground.

• Place the motion control lever in neutral.

Release the parking brake and let the clutch/brake

slowly return to operating position.

• Allow one minute for transmission to warm up. This

can be done during the engine warm up period.

• The attachments can also be used during the engine

warm-up period after the transmission has been warmed

up.

NOTE: If at a high altitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetor fuel mixture may

need to be adjusted for best engine performance. See “TO

ADJUST CARBURETOR” in the Service and Adjustments

section of this manual.

>line near an open flame

JGINE Fit

3iTi of oas tank

Hfl

me or if the engine

nkinci time to move

Page 14

OPERA

Ш

Il ¡I

“'PAài^

ài

insure proper of

ided that the trai

tor for the first t

ipBU dJi líldlüí

d duririq shit

ope

IMP

DRTAN1

REf

MOVAL FOR SERVICE OR REPLACEMENT, IT

OULD BE PURGED AFTER REINS FALLATION

FORE OPERATING THE TRACTOR,

ng of your tractor.

)ULD YOURTRANSMISSION REQUIRE

-I 16 \ !trV " ‘' r i* ' ^ iV'if’ ' f I" .c if snri

parking brake set,

L'i - I'O - %>i h'i'iL-n by I k( ing iir‘HidMiOi

.1. n V, ,! ||D pj. iti-.n (Sf€ TO t“F vT- .F f in

this section of rrianuaS).

I'‘ , III'. ii'H .!• i ,,i iichn ‘ !c//j iti,,i 'Vith

n i' F,t,' II i •' !(' itrai (Hi pc ifi i „'owlv

Hm

Nk ' - irbhoi" coii*i.)l • a I to full tor^/ard (. CA.tian and

fi'dii for b/- d • '.iH.T Mova if/ei to full reverse

C dior . r. ‘ hoiR ‘f,i fivt (5) recimds heor О this

¡‘•r c-edure tf.iee (3) ¡rnes.

NOTE;: During this procedure there will be no rnovement of

drive wheels. The air is being removed from hydraulic drive

Move motion control lever to neutral (N) position. Shut-

ir ih.Oi i )i ,-rdt. ddilt igine /Ttrf ht f-ngine

¡I .r.

-fir

lance, It is recom-

d before operating

ili remove any

ay have devel-

iNi

cha

MOWGif sfiouiu be pre

nprfnr

pci iKJiтпапсе. See TC

The IiÍÍÍ hand side of mower should be

>periy leveled tor

) LEVEL MOV/ER

itfT^ents section of

Dest rnowino

HOUSING'" In

this ШЕП1Ш1.

used for trirn-

minq.

Drive

< Ti't . Hpf IIifi

that hi as been cut. Ha’

machi rie . hf ' "I

1 --lie ' 1 , '

clippir

Whon mowing large a

so thi 1 iifpit 0 V1.;

fence:

til L i Ve *■ ig •< ,

It grn-, r e/Tit-rnt Iv I-i| i „hr i

H a V if' T *

fadu. t- •' ili ..,d t 'VibC I'l' r.

p.iiy“- M-ik T|1 J J I I la. v-.lv r, qfi ih

s 3.re discfierQed

if- ^ Ut ’ T -• t' db Ц i

uli in a more even и Qi

1

liform cutting.

’1- • • *-[f, 41.liiMj t(. thr f rhr

i ' : 1И| _ n ^li /

¡f- r.i ^ ij 1 ^ j

LIT Î ! Оси Í 11 i (< i Ji 11ч Uííul

be îTüWfcd twicr to

il I irr n Tp-

|i Mi' CiUb ,

Il'ij'i'J, (now

¿w'iiu olht

df 'irej h''IOr.t

[>'. ru‘t iiicw 'jt-w 'vrv I i_ wuf t'/ i grj V will plug

nuUi I I id It .V.'jiidfcur.TlB j'lipi. ‘illcw Cjia,-s rc

n n f r>. "T rW H.n CV

l.,i) ii k.„/ i; \./' i 'i

.............

I(

..........

'■ ii '/ k :■ ;■ \..a ,■

Alw&V' opeiu’'-tngim ,i‘>J! itiH-ttlB wtien mo/tiing to

as:ijti betiei »n^wiry ptriC'iriaicfc ano propei disc!idiye c! ir=tferici F.egu.aie gtoLri j ipted by adeciing a I-w 'tivujgh ge^r L tjiva iL.t mower cutting

performance as well as the quality of cut desired.

When operating attachments, select a ground speed

that will suit the terrain and give best performance of

the attachment being used.

Engage transmission by placing freewheel control in

driving position (See “TO TRANSPORT” in this section

of manual).

Sitting in the tractor seat, start engine. After the engine

is running, move throttle control to halt (1/2) speed.

With motion control lever in neutral (N) position, slowly

disengage ciutch/brake pedal.

Slowly move motion control lever forward, after the

tractor moves approximately five (5) feet, slowly move

motion control lever to reverse position. After the

tractor moves approximately five (5) feet return the

motion control lever to the neutral (N) position. Repeat

this procedure with the motion control lever three (3)

Your tractor is now purged and now ready for normal

operation.

Page 15

MER RESPONSIBILITIES

; F j i i <• I 1 ! I 4 i 1 fi \ "-li

GENERAL RECOMMENDATIONS

The warranty'.n ihi-1'^rif.( d ) .•'»;_f iit; t itnrhwe

been subjected k opttJ > c.b‘' c u. n'^g'sjcnc > To

receive full vai'.cfrr* di* • pcr-'^t s'■us <in

tractor as instru- ted h it e in. riu !

Some adjustm^ nts will nt od tü be made peroucdl v lo

properly maintain youi ir. i lOi

All adjustment in th^ ' j ■ -.nu'id, i trr n.'s( ( ih n cf

this manual sh-tnl'i t, i r,^. » .imi t-'-f h - , on.

« Once a yeai /ou ^ h ik pk ' he ''■ean

or replace a.i filter, i ' i nei.K teon-. and bs i’ for

wear. A nev* spah ^ hn iitj ulea.i ai filie» . ' uie

proper air-fum mix Cc ci j i elp your engine run better

and last longer.

BEFORE EACH USE

• Check engine oi! level.

• Check brake operation.

» Check tire pressure.

• Check operator presence and interlock systems for

proper operation.

• Check for loose fasteners.

Do not overtighten,

LUBRiCATION CHART

©SAE 30 OR 10W30 MOTOR OIL

©GENERAL PURPOSE GREASE

©REFER TO CUSTOMER RESPONSIBILlTiES “ENGINE” SECTION

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS. VISCOUS LUBRI

CANTS WILL ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRiCATING BEARINGS. IF YOU

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW

DERED GRAPHITE TYPE LUBRICANT SPARINGLY.

15

Page 16

IQ úiSíSnCB

e adjusted,

ind Adjust-

j FLAT WASHER

¡LOCKWASHEf

in all tire

36 “PROD-

anual).

lime, oil, or insi

itrol chemi-

ubber.

Avoid stufTips stor ibjects and

other hazards that i may CBUS6 tire damage.

fE; To sea! tiTG purl' [ires due to

1? leaks, tire sealant 1 your local

Q d0£||0f T

pBil

corr

osion.

ERATORI PRES¡ENCE SYSTEM

OP

Be sure operalior pres

wo riking propelriy. if y

cribed, repciir the pr oblern immediately.

desi

Ire seaJc try rot and

'Stems are

unction as

The engineÌ should utch/brake

pedal is fu!i'

ydepres itch control

is in the die?enQaQG^3 position.

When the e

ingine is

tor to 1©3VC3 the se«

iiir hTkj iiiv t eriipi by the opera-

1 ,'ih' .r 'II..Í ‘•ctfing the parking

brskG shoulid shut c)ff the engine.

When the emoine IS m, lililí, nr. iii8 .Uachment clutch

is ©riQHQSd 3 leave the

seat shoulc

©

Qftor''Hr

J shut oil

nentclut 1 cl muid ne '-or operate unless the

f the engine.

operator ¡s in the se;at.

(C

*A GRADE 8 Hi

IDENTiFiED BÌ

line

3 BOLT CAN BE

D.

FIG. 11

ft I ' pr I-

in 11 /'■ f 111» I Mil.'

Jo, be sure the blade is b

dare should be taken to

Ul Ot

d blade will caus

The blade can b

wheel. Do not a'

alanced.

I - [ ip hi ,> ‘a Ian ,ed. An

a: fi.:, hi/■■mr;

h i'

lUt if you

id even-

grinding

mower.

• Pm bpf.t lio’lf h limn I >A u 'o!hi‘-^d 15/8" diameter

. ell'Mii, pill '>■ lm.i i ,il 111 pJii. n using acone

h .laric> . (OiPw th' m trui .n .ivpiied with bal

ancer,]

NOTE: Do not use a nail for balancing blade. The lobes of

the center hole may appear to be centered, but are not.

» Slide blade on to an unthreaded portion of the steel bolt

or pin and hold the bolt or pin parallel with the ground,

if blade is balanced, it should remain in a horizontal

position. If either end of the blade moves downward,

sharpen the heavy end until the blade is balanced.

ADE CAF

BL

For best result:

piac e bent or damageci

3 mower iharp. Re-

<.... „..,S......

UlciUGo,

BLADE REMOVAL (See Fig. 11)

DiSu6.

install D6

towards

iViANDREL ASSEMBLY.

> , ^ (nn Ik> L -vash'-i ^ lO t!.a* vvasher in

exact order as shown.

• Tighten boit securely (27-35 Ft. Lbs. torque).

access to

srsecuring

ig edge up

SEMBLY,

STAR OR

TREATED.

Page 17

BATTERY

iractc

■ ha

for П'

'H

riTic

jrger will

s clean.

narging

" I ( r II ‘ill '' lit t> I I

“ h ► ( r -.tyc t I •; h 1» r f I i li t>'.

N‘'^Tf fiO . Iiir, h .1 ■ _ .iprr.r, I 1 .it u(i< li ,r'^t t(.' ¡e

m.-mii^tiani - t'. - f' >ii i i' i i| :■ i.g.-iini* ri. i'*. i-¡o

or covers. Adding or checking level of electrolyte is not

he«'

rO • I Fah hai ir R 111 - fRRMINALif

Orrru-.cti if", j.i'uiioioo aerv and tenniodis uan cause

The >u ‘f j puvrei.

( ipfll i) 4ti-iV L,Ui JuCk.

Di*^(onrifc Kfi )l)ie first then RtD bat-

ti. r, I able all. iLt*i i~ itti ,y ii> rri 1ra< tc-i.

Rin-'6 tfic bitlef' vhi. tJdiii w 4c r and dcy

Clediitrrr|-.f,jj._,-[', f, . IjIj ends #ith wire brush

until bright.

Coat terminals with grease or petroleum jelly.

Reinstall battery (See “REPLACING BATTERY" in the

SERVICE AND ADJUSTMENTS section of this

manual).

V-BELTS

Check V-belts for deterioration and wear after 100 hours of

operation and replace if necessary. The belts are not

adjustable. Replace belts if they begin to slip from wear.

TRANSAXLE COOLING

The transmission fan and cooling fins should be kept clean

to assure proper cooling.

Do not attempt to clean fan or transmission while engine is

running or while the transmission is hot. To prevent pos

sible damage to seals, do not use high pressure water or

steam to clean transaxle.

® Inspect cooling fan to be sure fan blades are intact and

clean.

• inspect cooling fins for dirt, grass dippings and other

materials. To prevent damage to seals, do not use

compressed air or high pressure sprayer to clean

cooling fins.

rriCIP ED BEFORE

All- irjh T.iiii. v'l^. ' И, I

improve starting in cold weather, thes

wm iW/’i'etc.j

I.D-i' . >t/Ol'S

40'

II]

Vi/P r.»' ■! i>> iri'I : wi ,ih tb'¡tif 11't. wf.-n i =-.'1 nho''e

a, ' f fli T (I r^'igint n , bvO‘ lr>-|UM>iL't{- -/Old

pc- .bit 'I J .1 - Jr 1

1

l-i- ll ! I U ‘ !и|И. I jIi III

Cr. ncy 'he ml -,ць • eiyCdfiouv <! • f Jiic.h гч-i f-dSi

ипс' -j if ihr 1, , “-mu - !. 1 ,4 h ' i£ 'ч or ^ r.

Ch..,'.' the ■ r i-pi are nil R.tl of- or- doning 4ic •riigine

ar. f .лПы ' rtf riyfii (f! fiLbm t 'p 5 aucr Г jhmii ill fill

cap/'ip tiof fecuiely ЗЭ' you ■‘ht-tHhe oil Itvel.

TCfH-NGF FrJGINEfJiL i^ee^g 14)

[•emriT nt leirij-ii-iciiurumno-r t/pe JoJ before oil change

All Oil nibSi mefci Ar i .jcrvioe Lir-bDiiication SF, LG or SH

• Be sure tractor is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

• Remove oil fill cap/dipstick. Be careful not to allow dirt

to enter the engine when changing oil.

• Remove drain plug.

« After oil has drained completely, replace oil drain plug

and tighten securely.

• Refill engine with oil through oil fill dipstick tube. Pour

slowly. Do not overfill. For approximate capacity see

“PRODUCTSPECIFICATIONS” section of this manual.

• Use gauge on oil fill cap/dipstick for checking level. Be

sure dipstick cap is tightened securely for accurate

reading. Keep oil at “FULL” line on dipstick.

TRANSAXLE PUMP FLUID

The transaxle was sealed at the factory and fluid mainte

nance is not required forthe life of the transaxle. Should the

transaxle ever leak or require servicing, contact your near

est authorized service center/department.

ENGINE

LUBRiCATiON

Only use high quality detergent oil rated with AP! service

classification SF, SG, or SH. Select the oil’s SAE viscosity

grade according to your expected operating temperature.

17

Page 18

^leaner aft

MCD OETOOi

n dried qum

dush

iflO

"R\/l

DcIlUidie II II

doth and so'

® Clean cartridge by tapping gentiy on flat surface. If very

IE4dLEANER

UicI dotergen! and water.

ry in a clean cloth.

engine on. Wrap it in Ci0c

jeeze to remove excess oii

r damaged, replace pre-cle

iRT'RIDGE

abeoiLefii

tnr r.

iirn- i t mill ig d r I. • , [ rings

® Reinstall precleaner cartridge, cover and secure with

M lUUS.

IMPORTANT; PETROLEUM SOLVENTS, SUCH AS

KEROSENE. ARE NOT TO BE USED TO CLEAN THE

CARTRIDGE. THEY MAY CAUSE DETERIORATION OF

THE CARTRIDGE. DO NOT OIL CARTRIDGE. DO NOT

USE PRESSURIZED AIR TO CLEAN OR DRY

CARTRIDGE.

ENGINi

Ftemove any dust, dirt or oi! from engine cooling fins to

0 1

m iioinii' 1 -I , ' I

. 5

! I

/ 1

■! eE 1 . £ i ! 11.' ' ( I i( I r - ' . I • I . 1 [I ' ■ I ,H,i J I it , i ‘

REMOVE HOOD AND GRILL ASSEMBLY” in the Service

and Adiustments section of this manual).

T' PAIR

GUIDE rOVFR .

1

ENGINE

COOLING FINS

r;J ^

, '•« I

ri

"8

FIG. 16

Page 19

c? i '■ mtH m i

3r and spark arrester (if

lazard and/or damage.

SPARK PLUGS

Replace spark plugs at the beginning of each mowing

season or after every 100 hours of operation, whichever

occurs first. Spark plug type and gap setting are shown in

“PRODUCT SPECIFICATIONS” section of this manual.

IN-LINE FUEL FILTER (See Fig. 17)

The fuel filter should be replaced once each season. If fuel

filter becomes clogged, obstructing fuel flow to carburetor,

replacement is required.

• With engine cool, remove filter and plug fuel line

sections.

• Place new fuel filter in position in fuel line with arrow

pointing towards carburetor.

• Be sure there are no fuel line leaks and clamps are

properly positioned.

• Immediately wipe up any spilled gasoline.

FIG. 17

CLEANING

• Clean engine, battery, seat, finish, etc. of all foreign

matter.

• Keep finished surfaces and wheels free of all gasoline,

oil, etc.

• Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to clean your

tractor unless the electrical system, muffler, air filter and

carburetor are covered to keep water out. Water in engine

can result in a shortened engine life.

19

Page 20

Mm

II I^TiiFM

ME

10 liisciss Slid nil iTiovinQ psrts li3¥B corfipi&id^ stoppsd»

»park plijci wire from spark plug and place wire where it cannot con

,1 IFl .'ivr .ftiii.'.p

TRACTOR

TO REiJQ¥E MOWER (See Fig. 18)

Mower will bo easier to remoyefronrlhe ri*^ht side of tractor.

• Place attaenment clutch in “DiSEMGAGED” position.

I ' .lii [ «3 "E r ‘li / eF 'y eTeO rr» ' O eO

Roll belt off engine pulley.

■ .E ,EH, w > I I I i-.... dEjicIi W/ei t'i/ lamo'/irq

retainer spring.

removing retainer spring.

i:vw! i’-u '.licpersioi, .000? irt«rn rti.it dwh bfa>'’kri3

by removing retainer springs.

uisGonnect front Iihks from deck by removing retainer

springs.

Raise lift lever to raise suspension arms. Slide mower

out from under tractor.

IM

MC

RE

TO

-EititA-E Lwr ‘.nn, i,bas.sic b‘3i^ket ov

- AN ATTACHMENT OTHER THAN THE

BE MOUNTED TO THE TRACTOR,

ONT LINKS.

iOWER (See Fig. 18)

lent lift lever to its highest position,

nder tractor with discharge guard to right

' ; mn,h hOD

CLUTCH LEVER

' ;r I o.-. <:

,FILIN'

FIG. 18

r to its lowest position,

n reverse order of removal instructions.

20

Page 21

<s I . fi/j) ijifM, ' ■;|li

Adjust the mower while tractor is parked on le¥el ground or

driveway. Make sure tires are properly inflated (See

“PRODUCT SPECIFICATIONS" on page 3 of this manual).

If tires are over or underinflated, you will not properly adjust

mwer.

)U

j|i4 “IO-biL'^ Ji M. II ipo. i3c;ru30j

• Raise mow/er to its highest position.

^ Atihemidpoi.Huf buiii aiutaoi mo.ver, measure height

from bottom edge of mowerto ground. Distance “A” on

both sides of mower should be the same or within 1 /4"

of each other.

• if adjustment is necessary, make adjustment on one

side of mower only.

• To raise one side of mower, tighten lift link adjustment

nut on that side.

• To lower one side of mower, loosen lift link adjustment

nut on that side.

NOTE; Three full turns of adjustment nut will change

mower height about 1/8“.

• Recheck measurements after adjusting.

FRON

IMPORTANT: DECK

THE FOLLOWING F

NECESSARY. BESU

J-BA

To obtain the best cutting results, the n

should be adjusted so that trie front is appro

OJUS

rO ADJl

IK ADJUSTMENT if

'BOTH FRONT LJNKi

er he

3inq

I,, -

1A io-xf. t-efi u! m.r rtfi-n •.! I w wr-i i m >(- higiiesl

position.

Check adjustment on right side of tfdcior. Measure dis

tance “D” directly in front and behind the mandre! at bottom

edge of mower housing as shown.

® Before making any necessary adjustments, check that

both front links are equal in length. Both links should be

approximately 10-3/8".

• if links are not equal in length, adjust one link to same

length as other link.

• To lower front of mower loosen nut “E” on both front

links an equal number of turns.

• When distance “D” is 1/8" to 1/2" lower at front than

rear, tighten nuts “F” against trunnion on both front

links.

• To raise front of mower, loosen nut “F” from trunnion on

both front links. Tighten nut “E” on both front links an

equal number of turns.

• When distance “D” is 1/8” to 1/2“ lower at front than

rear, tighten nut “F” against trunnion on both front links.

FIG. 19

FIG. 20

FIG. 21

BOTH FRONT LINKS MUST BE EQUAL IN LENGTH

21

FIG. 22

Page 22

BE

yuiut;&.

•• Instail mo'wer in reverse order of remova! instructions.

t PULLEY

MAI IÍA F'

PULLEY

FIG. 23

riNG

DO NOT TOUCH THIS NUT. IF FURTHER

I HaKL . . HOT'u. ' I istct ST

< '''ivfi-i ■ , > iti f'f i ',i r At Vi' >!-; ri)

< t-RVIi t Ijl fiVR-' L '

FIG. 24

TC RFfli a; I pr rdifr ORIuf n

f.-- Fk: '^*^1

r'.4 tfi i! •'< ! -r . ud lo i «'igr j, p irFii'j brake.

Fur 5v 1-1 ir\' 'nn I ■ ioli icf.u..latK r. qii dt tiecal on

bottom irie c> lidt in.i.-r -'.t.

» Hi nt(-/f rrio-r ■ f ■' e “T'H REMOVE MOWER’ in this

sertir n of thr tr- ni. i| ]

Remi.ve beM n iOionuoy i her and iutching idler.

“ Pull bOi'iacl. uWi.f i tea oftr-vtur, i irefully remove

bell upwmds in»n tiansmissic r. input pulley and over

cooling fan blades.

» Pul! belt toward front of tractor and remove downward

from around engine pulley.

• Install new belt by reversing above procedure.

TO ADJUST BRAKE (See Fig. 24)

Your tfsctor is 6QUiCsped \A

which is mounted or1 the siide of the tran.saxle.

If tractor requires me

Jl© Inc in six (6) feet stopping distance

at high speed in highest ge ed.

• Depress c!uich/t

)r3.ke f)edal and engage parking brake.

® Measure distan<ce between brake operating arm and

nut “A” on brake! rod.

• If distance is ot!

ler thi and

turn nut “A” until distan

jam nut against nut “A

• Road test tractor for pn ted

above. Readjusil IT 08' 8 is

still greater than six ( f- f-i 1 riiahesf ijeci> fudher

maintenance is riGCBS:

sary. Contact your nearest au-

thorized service cente r/department.

em

ten

22

Page 23

H ‘‘.NSAILE IIOTIOr ' «TOOL LE¥ER

NEUTRAL ADJUSTME Fig. 26)

The motion control lever has been preset at the factory and

adjustment should not be necessary.

Loosen adjustment bolt in front of the right rear wheel,

and lightly tighten.

Start engine and move motion control lever until tractor

does not move forward or backward.

Hold motion control lever in that position and turn

engine off.

While holding motion control lever in place, loosen the

adjustment bolt.

Move motion control lever to the neutral (N) (lock gate)

position.

Tighten adjustment bolt securely.

NOTE: If additional clearance is needed to get to adjust

ment bolt, move mower deck height to the lowest position.

After above adjustment is made, if the tractor still creeps

forward or backward while motion control lever is in neutral

position, follow these steps;

• Loosen the adjustment bolt.

• Move the motion control lever 1/4 to 1/2 inch in the

direction it is trying to creep.

• Tighten adjustment bolt securely.

• Start engine and test.

• If tractor still crtpps rtpr if yc^ttpr unhl --dtLfied.

MOTION i'ONTRuL

LE/FR — A

NEÜÎRAL

LOCK GATE

REMOVE WHEEL FOR REPAIRS

(See Fig. 27)

Block up axle securely.

Remove axle cover, retaining ring and washers to allow

wheel removal (rear Vi/heel contains a square key - Do

not lose).

Repair tire and reassemble.

On rear wheels only; align grooves in rear wheel hub

and axle. Insert square key.

Replace washers and snap retaining lim securely in

axle groove.

Replace axle cover.

NOTE: To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion.

WASHERS

RETAINING

RING-

AXLE COVER

TO

SQUARE KEY

(REAR WHEEL ONLY)

FIG. 27

TO START ENGINE WITH A WEAT EAHERY

(See Fig. 28

ADJUSTMENT

BOlT

nc 2i

TRAMSMiS¥l£>f4 RbTjIüVÂUP? I'^kLEMENT

LfijUid /jUi (Im: c r gu > nx al v ivic* n

rf-pir {tiTif-fii,'i ~h< ul t ' f.bX * ifit t ieir H llaiion -I'i'i

brfurt opi ratitiu the ti ut Tm ‘f UhC L t RANSMI. SlOh’ in the Upnaiun o-iction o ihis ma.iuai.

TO ADJUST STEERING WHEEL ALIGNMENT

If steering wheel crossbars are not horizontal (left to right)

when wheels are positioned straight forward, remove steer

ing wheel and reassemble per instructions in the Assembly

section of this manual.

FRONT WHEEL E-IN/CAMBER

The front wheel toe-in and camber are not adjustable on

your tractor. If damage has occurred to affect the front

wheel toe-in or camber, contact your nearest authorized

service center/department.

CAUTION; Lead-acid batteries gener

ate explosive gases. Keep sparks, flame

and smoking materials away from bat

A

If your battery is too weak to start the enqine, it should be

recharged. (See “BATTERY" in the CUSTOMER RESPON

SIBILITIES section of this manual).

If “jumper cables" are used for emergency starting, follow

this procedure;

IMPORTANT: YOUR TRACTOR IS EQUIPPED WITH A 12

VOLT NEGATIVE GROUNDED SYSTEM. THE OTHER

VEHICLE MUST ALSO BE A 12 VOLT NEGATIVE

GROUNDED SYSTEM. DO NOT USE YOUR TRACTOR

BATTERY TO START OTHER VEHICLES.

TO ATTACH JUMPER CABLES -

• Connect each end of the RED cable to the POSITIVE

(+) terminal of each battery, taking care not to short

against chassis.

• Connect one end of the BLACK cable to the NEGA

TIVE (-) terminal of fully charged battery.

• Connect the other end of the BLACK cable to good

CHASSIS GROUND, away from fuel tank and battery.

TO REMOVE CABLES, REVERSE ORDER -

• BLACK cable first from chassis and then from the fully

charged battery.

23

RED cable last from both batteries.

teries. Always wear eye protection

when around batteries.

Page 24

X X

X

'LT

№

u

■ CHARGED

BATTERY

i

I

POSITIVE TERMIN

rICa.

A <i5‘ i

I f!Äi ITI

' 1 s* ‘ . fil) , . It I, vr S|\> hf r

i.itf t- >'T3«ti ht-i.'miosis cr.e

M" 1 », f . t f ' ithi- » ling l)eiti»^rv

A

LIU i

UO'Oi".

[.I ' .n.itc ' 4. 't/fcbl' '¡rf ic..cn BLl *L ttery

L.IT a.id. i. I ,, '• r«.H IV hf.rn tr.Ttor

In- tN. ri' « ucTt I . ‘Ill* V .iii.'cls III me [ c)‘ition as

eh *c-^

r " 1> I Ml, , 1 J ■! . [. 0 J . ^ 1+) f< Ir ludl

V'lf'I! ■ l| < t‘. ‘ (1 ■ II !| t _ ift.I) ‘-I <;f-I/

C/OH. I, ! / ) • . •* . c ifi r>-rariVL (yj. m<i:irtl ' 1 II ■ r* if 1 i- • >!i .ili Kt|i' nUi f,gi!l?n

Sfci u Iv,

do: " I ^t'l- < f w I

.fi ii i:l »•-■nstwaccli

bands,rings,etc.

.tr ‘ '*1 t Ms . Lfc cOITIOCffeu

, . < I I" .My ff'nil iSs-IQCri-

1 sl 'J >>[, if,

it pan lised

......

I ill nd I |ien b-i'iPf) box

iTiVE TERMINAL

.. 30)

termi-Do not short batte _

POSITIVE (RED)

CABLE

FIG. 30

»EGÄTIVE

(BLACK) CABLE

TO RFK tr E LE HI MIL B

• F'ci f • '‘U* 1

• Je of the

aim,

e R p|p - I iif inhoki'mnBi h ' I hoi j.^r securely

o-cf Ii t ih.- h le T lit- h f' I h o' .1)0 (jnii

» Close hood.

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause your tractor to run

poorly, stop running, or prevent it from starting.

» Check wiring. See electrical wiring diagram in the

Repair Parts section of this manual.

TO REPLACE FUSE

Replace with 30 amp automotive-type plug-in fuse. The

fuse holder is located behind the dash.

TO REMOVE HOOD AND GRILL ASSEMBLY

(See Fig. 31)

• Raise hood.

• Unsnap headlight wire connector.

• Stand in front of tractor. Grasp hood at sides, tilt toward

engine and lift off of tractor.

• To replace, reverse above procedure.

SEAT PAN

ijATTERY

BOX DOOR

24

Page 25

ÜC

IE

JUS

SERVICE AND ADJUSTMENTS

STOP

)NTROL CABLE

/

tlo ,

described below t

necessary, proce«

' V' lib -I, ji- 1

fast position.

« ( h-' I- Oi •

■ -li I ,1. in

t U II I

jij ^ n cp OT f r.^jTcr: I 33J

Th- no - ' .it j 1 n pti f ttu I ,1 I >/ and

aoiLOt' c. !, h:ul>‘,iaiL> i i* / ' b ' dji-'t.'i itac

dts>íl'L^^J halo.'/ h«^ -a -en ng <' bT If .idi J ir.,>- nt is

nececrir/ o!oc'~'• li.ll-jw

® ’r/iih rrigine not ujn.iirtj n f./-d'...K Lontii ■! h'' ated

"n hash r sntl| t> f Jil Ch'4 r tiOa

• Luoseii ^1 cl li'J Tmn ^ afSotnt<lv Tc m air

cL.n r

• Chore choula be doifcd it it .s n< t Icn.e'i ing

cb.,irip '_rrw jii d hio/e I ti(4 - ccfile until ^het^ >s

conpletelv cloEod T ghtei • ?sir,g riarnp screw se

curely.

• Replace air cleaner cover assembly and tighten knob.

TOilO'Wt

ninq, n

w'ivel is against stop

screw ana puli

Tighten cable c

3t 3t ths fsctorv 3nd

ib!e. If adjusiment is

irottle control lever to

ibi€

■ew securely.

)sen

el is

/1 Pi.'

; . ,,--r ll ^iT

'L|y< (, "5'. ¡1 '"y.

-;T-

SWIVEL

FIG. 32

CLAMP

SCREW

iMrii

TO ADJUST CARBURETOR

Your carburetor is not adjustable, if your engine does not

operate properly due to suspected carburetor problems,

take your tractor to an authorized service center for repair

and/or adjustment.

High speed stop is factory adjusted. Do not adjust -

damage may result.

IMPORTANT: NEVER TAMPER WITH THE ENGINE

GOVERNOR, WHICH IS FACTORY SET FOR PROPER

ENGINE SPEED. OVERSPEEDING THE ENGINE ABOVE

THE FACTORY HIGH SPEED SETTING CAN BE

DANGEROUS. IF YOU THINK THE ENGINE-GOVERNED

HIGH SPEED NEEDS ADJUSTING, CONTACT YOUR

NEAREST AUTHORIZED SERVICE CENTER/

25

Page 26

ImfTiedíately prepare your tractor for storage at the end of

ther selason or if the tractor will not be used for 30 clays or

:r:r o:

CAUTION: Never store the tractor with

gasoline in the tank inside a building

where fumes may reach an open flame

A

or spark. Allow the engine to cool

before storing in any enclosure.

TRACTOR

Remove mower from tractor for winter storage. When

movs'er is to be stored for a period of time, clean it thor

oughly, remove all dirt, grease, leaves, etc. Store in a

clean, dry area.

• Clean entire tractor (See “CLEANING" in the Customer

Responsibilities section of this manuai).

• Inspect and replace belts, if necessary (See belt re

placement instructions in the Service and Adjustments

section of this manual).

» Lubricate as shown in the Customer Responsibilities

section of this manual.

• Be sure that all nuts, bolts and screws are securely

fastened. Inspect moving parts for damage, breakage

and wear. Replace if necessary.

• Touch up all rusted or chipped paint surfaces; sand

lightly before painting.

BATTERY

• Fully charge the battery for storage.

• After a period of time in storage, battery may require

recharging.

• To help prevent corrosion and power leakage during

long periods of storage, battery cables should be

disconnected and battery cleaned thoroughly (see “TO

CLEAN BA 1 TERY AND TERMINALS” in the Cus-

..¡(.II- I ( V IK. I • 1 hv iii'i d ■)

• it' I-' le ' if.-q 0 •■to'" Q. c i mccL i and p'act

cables where they cannot come in contact with battery

terminals.

» ff battery is removed from tractor for storage, do not

store battery directly on concrete or damp surfaces.

DEPOSITS FRC

SYSTEM PARTS

FUEL HOSE,

EXPERIENCE Ik

FUELS (CALLEC

METHANOL) CAI

TO SEPARATiOr4 ANID FORMATIOi

STORAGE, AC

SYSTEM OF AN

• urain me rue

• Start the enc

carburetor arB erripty.

• Never use ennine

fuel tank or p

® Use fresh fu€d ne>

NOTE: Fuel st:

imtiii • ir g dll r .rmati

ig*- /'Idtoabiiizer 1 ;o gasoline in

ullM’ii^l /.H« u.

container. Run <

to' ^ ito to i! ‘

ri -! di'-i.h th 1 i

3IVI f■'to'RMiNG !N

H AS CARBUF

0

IDICj ATES THAT ,

1

GA SOHOL OR L

TRACT MOIS’ TURE 'WHICH LEADS

N AT

IDIC

ENG INE WHILE IL

I tsnl

line c snd let it run L

eriric irient damage

abiliz er is an acci

'S foil

angir

th

l| ir

GAS CAN f 3AMAGE THE FUEL

or carburetor c

(t season.

'ji t ji 1 y a.

ow the mix ra

■tabilizerto rea

,'iO 1 DIJK Ir

t: S S E N T i A L F' U E L

STORAGE, also'

ALCOHOL "blended

ISiNG ETHANOL OR

• ' ‘ ,! ■ ,

1 STORAGE.

intil the fuel lines and

may occur.

[H T ■ 'lit rn iti /1 n

ti'- '"Un i on L't.lil..*3l

. f 1. ,10

tii.i lit 'fit . rvJdif'j

< fi 'no ■ lit-ur ton fro

>f i 1 >'ri(j ft -1 -1 bilirer.

1

i •hum

i, .!.■ 111 the

1 i p ‘ II' tor

iiici taiT or .lot v|e

i tic-mh oil

DtnMi r ii (ijiili triginc w vrin. nri r plact wiih ( k m enyino

oil c- (I it.f i U'-tomef Respunsibilitifs

section of ihis rnanuaij.

CYLiNDEF

• .Re,r!iove spark plug(s).

® Pour one ounce of oil through spark plug hole(s) into

cylinder(s).

« Turn ignition key to “START” position for a few seconds

to distribute oil.

® Replace with new spark plugis).

CMhiii

Do not storr

® Replace your gasoline can if your can starts to rust.

Bu t, i dAv Oj I in ;o,j. ij soline v./i!i r.ause problems.

irom 0ii6

® If possible, store your tractor indoors and cover it to

give protection from dust and dirt.

• Cover your tractor with a suitable protective cover that

does not retain moisiure. Do not use plastic. Plastic

cannot breathe which allows condensation to form and

will cause your tractor to rust.

IMPORTANT: NEVER COVER TRACTOR WHILE ENGINE

AND EXHAUST AREAS ARE STILL WARM.

u ..I. .-noth I

26

Page 27

PROBLEM

Will not start

‘ r-" r

1 :=.

Engine itooded,.

|i: ,

Bad spark pluq.

i:'

Dirty air filter.

i; ii::.

Dirty fuel filter.

Li '7

Water in fuel.

1 u . u tv/'rir 0 8. r ( 3 1 V i,ru

' f

l o

I “'

10.

Hard to start I 1. Dirty air filter.

ii "■■"

i ;j'.

K' Z:i

1 C

I 6.

I

Engine will not turn over 1. Clutch/brake pedal not depressed.

i.ii f . tt (lusiiiir m 9.

L i> li ' ' “ J* .r i>j »inent

J <1 ,l'al<

.it'i ^ . 1 ti'jitee/

, V [■ ‘ 1

'iDf .jl rjiiiJ fufi

1

iJl

1 ci.t'i ,1 ri= nectd uirino

t _ii I't i ( '•nt uf cdjirtriitnt

Engine valves out of adjustment.

8.

Attachment clutch is engaged. 2. Disengage attachment clutch.

2.

3. Weak or dead battery.

4. Blown fuse.

5. Corroded battery terminals.

6. Loose or damaged wiring.

7. Faulty ignition switch.

8. Faulty solenoid or starter. 8, Check/replace solenoid or starter.

9. Faulty operator presence switch(es).

—1

Wait several minutes before attempting to start.

1 4. Replace spark plug.

1 5

Ciean/replace air filter.

1 6.

I

1

a !, i-.b 1 r p d(.' air lit-

h-

1 4.

1 6.

L.I'T' i 1 i

1 1. 1 ft 1

j ' .1 " 10 ,n pL< > I ■'

u

tit-7 I'm. , ' . 'CP rentet/depar+meni

f fci- msi- p iiK r J ,

fiC,' '! iut i L>r 1 "/

' '-pm jei ,iim

‘ir'j

n iU'^l tsiit ,n>* r'fill ,viih fresh gasoline

5

Cht-ch bil * irinij

„ -e 10 A'Jj jct 1 a burc *< r m Ser/ice Adjustments

section.

8.

Contact an authorized service center/department.

1, Depress clutch/brake pedal.

'■ ,ir.'

|i 1 i< i'll, rpfili i,a,iK W'lb fresh

- - !'■ 1 'bu.i fm ’ .1.36 bus/>d;Lisirnerts

3. Recharge or replace battery.

4. Replace fuse.

5. Clean battery terminals.

6. Check ail wiring.

7. Check/replace ignition switch.

9, Contact an authorized service center/department.

Engine clicks but w ill not 1. Weak or dead battery.

start 2. Corroded battery terminals. 2. Clean battery terminals.

1. Recharge or replace battery.

3. Loose or damaged wiring. 3, Check all wiring.

Loss of power 1.

4.

Faulty solenoid or starter.

Cutting too much grass/too fast.

2. Throttle in “CHOKE” position. 2, Adjust throttle control.

4. Check/replace solenoid or starter.

1.

Set in “Higher Cuf position/reduce speed.

3, Build-up of grass, leaves and trash under mower. 3. Clean underside of mower housing.

4. Dirty air filter. 4,

Clean/replace air filter.

5. Low oil level/dirty oil. 5. Check oil level/change oil.

6, Faulty spark plug.

7.

Dirty fuel filter. 7. Replace fuel filter.

8.

Stale or dirty fuel. 8.

9. Water in fuel.

10. Spark plug wire loose. 10.

Clean and regap or change spark plug.

6.

Drain fuel tank and refill with fresh gasoline.

Drain fuel tank and carburetor, refill tank with fresh

9.

gasoline and replace fuel filter.

Connect and tighten spark plug wire.

11. Dirty engine air screen/fins. 11. Clean engine air screen/fins.

12. Dirty/clogged muffler. 12. Clean/replace muffler.

13. Loose or damaged wiring. 13.

14.

Carburetor out of adjustment. 14. See “To Adjust Carburetor” in Service Adjustments

Check all wiring.

section.

15. Engine valves out of adjustment. 15. Contact an authorized service center/department.

Excessive vibration

1. Worn, bent or loose blade. 1,

2. Bent blade mandrel. 2.

3. Loose/damaged part(s). 3.

Replace blade. Tighten blade bolt.

Replace blade mandrel.

Tighten loose part(s). Replace damaged parts.

27

Page 28

Worn, bent or loose biacie.

Mower deck not level.

iH‘, |i ,1 j ■ , o ita«'n If (if r .flower

!' 1 ( H II .I'l. I

'in I- I ,|'v I k 1 . Ill nr Ifl-n tuildljp ' I

(J- I ii I 11 li i ""1 lendieK

a

i

I 1, Replac

h;

I 4. Repfac

1 5, Cloan 1

«blade. Tights n blade bolt.

power deck,

ondersicie of mo wer housing.

:e blade mandre

around mandre!:s to open vent holes.

rotate

Poor grass discharge

3. Frozen idler pulley.

rsu£.«H yicluc mcinutcsi.

1. Engine speed too slow.

2. Travel speed too fast.

3. Wet grass.

4. Mower deck not level.

5. Low/uneven tire air pressure.

6. Worn, bent or loose blade.

7. Buildup of grass, leaves and trash under mower.

8. Mower drive belt worn.

9. Blades improperly in-stalled.

10. Improper blades used.

11. Clogged mower deck vent holes from buildup of

grass, leaves, and trash around mandrels.

Headiight(s) not working

(if so equipped)

Battery will not charge 1. Bad battery cell(s).

1. Switch is “OFF”.

2. Bulb(s) burned out.

3. Faulty light switch.

4. Loose or damaged wiring.

5. Blown fuse.

2. Poor cable connections.

3. Faulty regulator (if so equipped).

4. Faulty alternator.

i 2. Replace mower drive belt.

• f' f |(’l 1 (. (Ik '

a. Rc|jtacfe bsaÜK iftctriUiel.

1. Place throttle control In “FAST” position.

2. Shift to slower speed.

3. Allow grass to dry before mowing.

4. Level mower deck,

5. Check tires tor proper air pressure.

6. Replace/sharpen blade. Tighten blade bolt.

7. Clean underside of mower housing.

8. Replace mower drive belt.

9. Reinstall blades sharp edge down.

10. Replace with blades listed in this manual.

11. Clean around mandrels to open vent holes.

1. Turn switch “ON".

2. Replace bu!b(s).

3. Check/replace light switch.

4. Check wiring and connections.

5. Replace fuse.

1. Replace battery.

2. Check/clean all connections.

3. Replace regulator.

4. Replace alternator.

Loss of drive

Engine “backfires”

when turning engine

“OFF”

1. Freewheel control in “disengagecf position,

2. Motion drive belt worn, damaged, or broken.

3. Air trapped in transmission during shipment

or servicing.

1. Engine throttle control not set at "SLOW”

position for 30 seconds before stopping engine.

1. Place freewheel control in “engaged” position.

2. Replace motion drive belt.

3. Purge transmission.

1. Move throttle control to “SLOW” position and allow

to idle for 30 seconds before stopping engine.

Page 29

SCHEMATIC

I-./' ^ - MODEL NUMBER PPR17H42STI?

BLACK

IGNITION SWITCH

POSITION

OFF

RUN/LIGHT

RUN B + L NONE

START B + L + S

CIRCUIT “MAKE”

G + M + L

B + L A +Y

NONE

NONE

NOTE

YOUR TRACTOR IS

EQUIPPED WITH A SPECIAL

ALTERNATOR SYSTEM.

THE LIGHTS ARE NOT

CONNECTED TO THE

BATTERY, BUT HAVE THEIR

OWN ELECTRICAL SOURCE.

BECAUSE OF THIS, THE

BRIGHTNESS OF THE LIGHTS

WILL CHANGE WITH ENGINE

SPEED. AT IDLE THE LIGHTS

WILL DIM. AS THE ENGINE IS

SPEEDED UP, THE LIGHTS

WILL BECOME THEIR BRIGHTEST.

NON-REMOVABLE

CONNECTIONS

CONNECTIONS

WIRING INSULATED CLIPS

NOTE: IF WIRING INSULATED CLIPS WERE REMOVED FOR

SERVICING OF UNIT, THEY SHOULD BE REPLACED TO

PROPERLY SECURE YOUR WIRING.

29

REMOVABLE

Page 30

REPAIR PARTS

TRACTOR - - MODEL NUMBER PPR17H42STB

ÎAL

Page 31

PL.ECTRICAL

TRACTOR -

MODEL NUMBER PPR17H42STB

KEY PART

NO. MG.

14-62-:

1

7d760-412

153417

B

153664

16

10090400 Washer Lock 1/4

19

2G 73350400 Nut Jam Hex 1/4-20 Unc

21 166181

02

4152 j

24 4799J

146147

¿5

26 166180

73510400

2/

26 4207J Cable Ground 6ga 12 black

29 121305X

30 140301

12421IX Nut Ignition

31

32 141226

33 122147X

40

166145

41 71110408

42 131563

43 145673

44 73640400

121433X

45

52 141940

70

166659

DESCRIPTION

Baiterv 12 Volt 25 Amp

Bolt Hex Hd 1/4-20unc X 3/4

Case Battery Mech Hinge

Switch Interlock Push-In

Harness Socket Light

Bulb, Light# 1156

Cable Battery

Cable Battery 6 Ga Red w/16 wire

Fuse 15 Amp

Nut Keps Hex 1/4-20 Unc

Switch Plunger Nc Gray

Switch Ign 4 Pos W/L P/L

Cover Sw Key

Key Ign Molded Generic

Harness (gn

Bolt Fin Hex 1/4-20uncx 1/2

Cover Terminal Red

Solenoid

Nut Keps BIk 1/4-20 Unc

Ammeter Rectangular

Protection Loop

Harness Engine

NOTE: All component dimensions given in U.S. inches

1 inch = 25.4 mm

31

Page 32

REPAIR PARTS

t . 1 --MOt -cL, : r r

CHASS DENCLOSURES

Page 33

ARTS

ENCLOSURES

,-.iilODELNUi4^L=i. r,

KEY

NO.

1 156619 Chassis

p

5

"0

^ 1 155527

id 14-566ij

13

14 17490608

17 15963&X428

18

20

23

24

25 19131312

26

2fc 157426

29

30 168749X428

31 139576

33 145244X428 Footrest Pnt Lh

34 145243X428 Footrest Pnt Rh

35 72110606

37

38 139886

39 139887

51

52

53

54 161464

55 144696

57

58

64 154798 Dash Lower STLT

140

142

145

r ,p-

MO.

-mO.556

17060612

4

19l3l216

155275

9 '51iC7X012

72140603

169118

126938X

156437

124028X Bushing

74780616

73800600

146654X599

17490508

73800400 Nut Lock Hex W/lns 1 /4-20

19051416 Washer 9/32 x 7/8 x 16 Ga.

144697 Bracjet Grukke Lh

74780412

162266 Duct Air

158418

165867 Plate Reinforcement STLT

156524 Rod Pivot Chassis/Hood

DESCRIPTION

Drawbar, Stretch

Screw 3/8-16 X .75

Washer 13/32 x 3/4 x 16 Ga.

Bumper Hood/Dash

Dash P/L

Bolt Carriage 3/8-16 x 1

Panel Dash Lh

Clip Tinnerrnan

Panel Dash Rh

Screw Thdrol 3/8-16x1/2 Ty-tt

Hood LT/PL

Bumper Hood

Plate Mtg Battery Fuel Tank Fr

Bolt Fin Hex 3/8-16 X 1 Gr5

Washer 13/32 X 13/16 X 12 Ga

Nut Lock Hex W/!ns 3/8-16 Unc

Grille LT/PL

Lens LT/PL

Fender Footrest STLT Pnt

Bracket Support Fender

Bolt Rdhd Sht Sqnk 3/8-16 x 3/4

Screw Thdrol 6/16-18 x 1/2 TYT

Bracket, Asm. Pivot, L.H., Mower Rear

Bracket, Asm. Pivot, R.H., Mower Rear

Screw Hex Wshd 8-18x7/8

Bracket Grille Rh

Bolt Hex 1/4-20x3/4

Bracket Suspension Front

NOTE: All component dimensions given in U.S. inches

1 inch = 25,4 mm

33

Page 34

REPAIR PARTS

M. - ■ i ^ : ': I ' ;*/ /. z

DRi¥E

147'

34

Page 35

DRIVE

.^442STB

KEY

NO.

10 76020416

14

16

18

19

21 140845 Knob, Round 1/2-13

22 145G27 Rod, Brake Hydro

24 73350600 Nut

25

26

27 76020412 Pin Cotter 1/8 X 3/4 CAD.

28

29

30 130807 Bracket, Transaxle

32

34 155071 Shaft, Foot Pedal

35

36 19211616

37 1572H Pin, Roll

38

39

40 4470J Spacer, Split 145

41

42 19131312 Washer 13/32 x 13/16x12 Gauge 147

47 127783 Pulley, Idler, V-Groove

48 154407 Bellcrank Clutch Grnd Drv STL 15i

49 123205X Retainer, Belt 15b

50 74760624

51

52 73680500

53 10571 OX

55 105709X Spring, Return, Clutch It'' 72HU~^06

56 74760620 Bolt Fin Hex 3/8-16 UNC x 1-1/4

57 140294 V-Belt, Ground Drive 16j 74780416

59 140312 Keeper, Center Span

61

62

63 140186

64 71170764

65

PART

NO.

1

142431

2

143595 Pulley, Transaxie

3

165619 Rod Shift Hydro LT

8

10040'i.00

73500500

741^^60616

73800600 Nut Lock Hex W/Wsh 3/8-16 Unc

10B888X Spring, Brake Rod

19131316 Washer

145204 Rod, Parking Brake

71673

74760512 Bolt Hex Hd 5/16-18 Unc x 3/4

120183X Bearing, Nylon

131494 Pulley, Idler, Flat

74760644

165838 Keeper, Belt Idler I4t

73680600 Nut Crownlock 3/8-16 UNC 158 1F55P9

17060612

8883R Cover, Pedal

10040700

DESCRIPTION

Transaxle Hydro Gear 319-0650

(Order Parts From Transaxle

Manufacturer)

Spring, Return, Brake

Pin Cotter 1/8 X 1 CAD

Washer Lock Hvy Helical

Nut Lock Hex W/lns 5/16-18 Unc P 76

Bolt Fin Hex 3/8-16 Unc x 1 Gr. 5

Cap, Parking Brake 95

Washer

Bolt

Bolt

Nut Crownlock 5/16-18 UNC 159

Link, Clutch 160

Screw Thdrol. 3/8-16 x .75 165 1656.22

Pulley, Engine 168

Bolt, Hex 169

Washer

KEY

NO.

66

70

~J 1 . b12 Washer 13/32 x 1-1/4 x 12 Gauge

73

74 1211ysX

75

77

7o

81

82

o«3

8-*

dS

93

94

yb

97

HP

102 1-032"

lUo

10- 140156

105

1 16

150 16--0

157

if-

164

10b

NOTE: All component dimensions given in U.S. inches

PART

NO.

154778

14P432

134683

140158

156347

1 P1 “740 Y

12000001 E-Ring

123583X

7 i "‘-L

0 5591 Shaft Asm, Cross Hydro

r ObLX

1j 1,1216

■ »/ M Link Transaxie

1 6

-'£9 3X428 Console, Hydro

1

140462

-'6755!.

1-0-169

l-'^IObOO Nut Keps Hex 3/8-16 Unc

73940800

71 (-70516

7211C610

744SU540

74490536

74490524 Bolt Hex FIghd 5/16-18 x 1-1/2

1?1 .210 Washer 13/32 x 2 x 10 Ga.

166002

15-^23*- Bolt Shoulder 5/16-18 Unc - 2A

192^^016

73680400

19091010

166880 Screw 5/16-18 X 5/8

165452 Bolt Shoulder 5/16-18 x .561

165580 Plate Fastening Lt

1 inch = 25.4 mm

DESCRIPTION

Keeper Belt Engine

Screw

Guide Belt

Strap Torque Lh Hydro

Strap Torque Rh Hydro

Spacer. Split

Washer 25/32 x 1-1/4x16 Gauge

Key, Square

Washer 25/32 x 1-5/8 x 16 Gauge

Spring Torsion T/A

Washer 17/32 x 3/4 x 16 Ga.

Line Fuel Hydro 4"

Fan, Hydro 7"

Control Asm Bypass Hydro

Retainer Spring 1“ Zinc/Cad

Keeper Belt Rh Hydro 0750. 18/20'

Washer Beliville .501D x 1.50D

Nut, Hex, Jam Toplock 1/2-20 UNF

Arm, Control Hydro

Screw Cap Hex 5/16x18x1

Bolt Rdhd Sq Neck 3/8-16 x 1.25

Bolt, Hex FLGHD 5/16-18 Gr. 5

Botl Hex FIghd 5/16-18 x 2-1/4

Bushing Bellcrank Grd Drive

Washer Srrted 5/16 ID x 1.125

Bracket Shift Mount

Hub Tapered Flange Shift Lt

Washer 29/32 X 1-1/4 X 16 Ga

Bolt Rdhd Sqnk 1/4-20 x 3/4 Gr 5

Nut Crownlock 1/4-20 Unc

Bolt Hex Fin 1/4-20 Unc x 1 Gr 5

Washer 5/8 x .281 x 10 Ga