Page 1

”1 ^ H 4 ’ Inotractioiis." Failure to do so

.1"*^ fm. .1 i ■■ ^ ^ E-aT^j cam result in serious injury.

LAWN TEACTOFf

Always Wear Eye Pratectio . * ^rimg "Jpermtmm

^1,

Read this Owner's Maiiiial and

follow all Warnings and Safety

168737 REV.2 04.06.99 JH/VB

Printed in U.S.A.

Page 2

lAr

A

Ill

F/

)PER.

Head,

Only allow

instructions.

Clear the area of objects

"t.lu Ob C JO

Be sure the area is clear of

J /O b -- P " r p ■ -

such as rocks, toys, wire, etc.,

а-с. ■•о/-' „ Í , с

*.-i/b -dSSi 'Cb-'

IJCíirí' \fi a rC”“ '(ЮэС or 3 b ^ ‘ 5,^6333. f ^ >

(> > c' j 3 c'-r, '■ "¡■o''3 зла 'г*'‘‘е 3b~k "c

. "■ f - г - b f- -

a ='i 1.- P-' -pb'P = ‘hb ~i<-we VI,P' .’I , L ‘ lie

* 4> Q ~ T ГЕ- '-Г 1 '!,"i

t>iow uGwn before turninQ^

' e_ ' . nr r> imie undi^erideu Aiw.n/s tuiii ci'

r , c.- -II,. If,,

" j ~ir 'Í w 'I pi,! Ф >v' <"

^ ,r- - - ГРГ t-,i о r &b ''atchfci or unclogginy

kiP niv ¡n I wlltOJr Oft «.turn yr'

C j 'ГС opt I Í, i- 4100 >ле NT, - '«¡.ce, г.ь гИсь-л -

air .dl or r.

VVc.'rn c-40 1 wiit'i 4 e ai«iy'•be. ^ ..озог.^ paaviy^

Use extra 33.£ when -.adincrr p.ic'''iinr; ! ^ .т.ог.У.ге тт

a trailer or irucK.

IL SLOPE OPERATION

Slopes are a major factor reiaied to loss-of-control and

,1.1 hiai , stop enume, агО reiiiove ЧеУъ

tipover accidents, which can result in severe injury or

death. Ail slopes require extra caution. If you cannot back

up the slope or if you feel uneasy on it, do not mow it.

DO:

Mow up and do¥/n slopes, not across.

Remove obstacles such as rocks, tree limbs, etc.

Watch for holes,, ruts, or bumps. Uneven terrain could

overturn the machine. Tali grass can hide obstacles.

Use stow speed. Choose a low gear so that you will not have

to stop or shift while on the siope.

ftoilow the m<anufacturer’s recommendations for wheel

weights or counterweights to improve stability.

Use extra care with grass catchers or other attachments.

These can change the stability of the machine.

Keep ail movement on the slopes slow and gradual. Do not

make sudden changes in speed or direction.

Avoid starting or stopping on a slope. If tires lose traction,

disengage the blades and proceed slowly straight down the

slope.

DO NOT;

• Do not turn on slopes unless necessary, and then, turn slowly

and gradually downhill, if possible.

» Do not mow near drop-offs, ditches, or embankments. The

mower could suddenly turn over if a wheel is over the edge

of a cliff or ditch, or if an edge caves in.

* Do not mow on wet grass. Reduced traction could cause

sliding.

* Do not try to stabilize the machine by putting your foot on the

ground.

• Do not use grass catcher on steep slopes.

HINE

I

* С? . г -s ,/C ' “ < И WV P ¡

ar with the

3111 P ?

A

J 1 A

. 1 INiaHAMUo AND rhh 1 AMI

J c p f

'fO^

III.

)ULD RESULT iN SERIC

CHIl O'PEN

gic ac:ddents can occur if the

;..*

zhlne

1 ' 1 1 -

and the mowing activ

children'will remain where you Icist saw them.

K66p

care'

f.r.ii' , .rerricv,rp

,'C!i .3

- - , ипе 'ff ■

№

Befor- ' n W*' П , . 'Hf , ur

t г

Neva r carry children. They m.

injured Of interfere with safe ma

iSjpv/Ci

:.ii)

*

IV. SER'

S3

A

A

r allow children to operate

Use i a -n a c

tfppo

, or other objects that may obscure visiorc

VICE

' , r 1 CO- 'PC mdoih“riue!s. ¡iieware

Usee

flammable

ЭП!

nir

sm

'•s s me me E’ container inside where

ineie .s an open lar^ie, suen 53 a waier heater,

run a machine incice a c.ocod area.

Keep nuts and bolts, especially blade attachment bolts, tight

and keep equipment in good condition.

Never tamper with safety devices. Check their proper

operation regularly.

Keep machine free of grass, leaves, or other debris buiid-up.

Clean oil or fuel spillage. Allow machine to cool before

storing.

Stop and inspect the equipment if you strike an object.

Repair, if necessary, before restarting.

Never make adjustments or repairs with the engine running.

Grass catcher components are subject to wear, damage, and

deterioration, which could expose moving parts or allow

objects to be thrown. Frequently check components and

replace with manufacturers recommended parts, when nec

essary.

Mower blades are sharp and can cut. Wrap the blade(s) or

wear gloves, and use extra caution when servicing them.

Check brake operation frequently. Adjust and service as

required.

Lookforthis symbol to point out important

safety precautions. It means

CAUTION!!! BECOME ALERT!!! YOUR

SAFETY IS INVOLVED.

CAUTION: Always disconnect spark plug

wire and place wire where it cannot contact

spark plug in order to prevent accidental

starting when setting up, transporting,

adjusting or making repairs.

-iLc.. "w, explosive.

sc.r- cren ■ 1^-

.=»/=!■ r. nz |c £ cotj ' ac'

V -n-in..

' je> £t'c ,‘>aC' '-C nc 'orr.

A WARNING A

The engine exhaust from this product contains

chemicals known to the State of California to

cause cancer, birth defects, or other reproduc

tive harm.

! HHuWIHG OdJcU I b.

)US INJURY OR DEATH.

operator is not alert to the

are often attracted to the

ity. Newer assume that

a s' jr cr r-:;

( !■ 'rrn sr 1, El' -i

ij£t nd £n> down Dfsmai

, oft '>''0 oe ;er:ousl'

tchine operation.

^ 'h rner.G, stirubf:

fuel with the engine

3( i or-fore refueling. По no*

Page 3

MODEL

i'iUMBER PPR17H42STA

SERIAL,

NUMBER

IONS

UIL U-ArAO

l' I ‘r . 'I

E UNDER THi

M 1 [

L , - i

- f . " ~ i i . ' / A-

Lilow a re

sRq your

iL'l-C ’f , , '.t ..t- „ ~ f R.'‘ ' tili

ic

U' ' i I '" ■! ir, ’ I'f | •r R I

NUfV JND ON

i/'-F

! L '

I r L

•'ICI

j “

^ ' ■ r ii .,-ir' , ,^,<r I L ■ ' -t

I M J - L

".'VAHNIriC. ' >£‘ia L

-1 J.) - an ' ' 1,1 ,i f - !

covered, Icrijsn"'cov0r0cl or q

exhaust system is squippec

cable local or state laws (if

ro ulc r e '• rm ' ' - .

In the sta-

'-¿5 ! 'O

tft m

^ 0! v,-aiiior

i

. V

sctior

s mat

Page 4

*-ABÍ F Oí OONTENTS

K-~,rJ“'£.'^‘í41£ £-.r*E'J^L

■'HiJiJut#! a

SERVICE AND ADJUSTME!

CUSTOMER

I ^ * IB* r "H». *'-!*''

REPAIR PARTS - TRACTOF

^ - fí '

. i#- «

LIMITED WARRANTv

“he Mi.nuraeture: warraiiis ?o ihe o'iginai consumer purchaser rha; this orcduc: a.-> manufactured is free from defects in

materials and '.vorcnisriship, -cr a pefioci of iv-'o 0; '/ears ¡rom dare n purchase by rhe original consumer purchaser, we will

-epai: m reDiaco ar our option, without charge for parts or 'aoor incLr;ed in 'epiacir.g parts, any part which we find to be

■jste/0 hoe ro ciaieiidis cr 'wciKroansoio. Tnis 'Wairar-ty -s cut-iec; to tire foiie'wing limitatiot.s and exclusions.

1

ii'i wanahiy does not appiy to tiie eriuinfc, otiiei iftan Flip iPcuian/Yveed Eater; rnanufaotured transaxle/

t'an.sn'.isGior. components, taiiery ,'except as noted ceiow- Oi' compcntrils parts thereof. Please refer to the

appiicabie manufactureds .varranty on these irernb,

2. Transportation charges for the movement of any power equipment unit or attachment are the responsibility of

the purchaser. Transportation charges for any parts submitted for replacement under this warranty must be

paid by the purchaser unless such return is requested by Frigidaire Home Products (Pouian/Weed Eater).

3. Battery Warranty: On products equipped with a Battery, we will replace, without charge to you, any battery

which we find to be defective in manufacture, during the first ninety (90) days of ownership. After ninety (90)

days, we will exchange the Battery, charging you 1/12 of the price of a new Battery for each full month from

the date of the original sale. Battery must be maintained in accordance with the instructions furnished.

4. The Warranty period for any products used for rental or commercial purposes is limited to 90 days from the

date of original purchase.

5. This Warranty applies only to products which have been properly assembled, adjusted, operated, and main

tained in accordance with the instructions furnished. This Warranty does not apply to any product which has

been subjected to alteration, misuse, abuse, improper assembly or installation, delivery damage, or to normal

wear of the product.

6. Exclusions: Excluded from this Warranty are belts, blades, blade adapters, normal wear, normal adjustments,

standard hardware and normal maintenance.

7. in the event you have a claim under this Warranty, you must return the product to an authorized service

dealer.

Should you have any unanswered questions concerning this Warranty, please contact;

Frigidaire Home Products

Outdoor Products Customer Service Dept.

250 Bobby Jones Expressway

Augusta, GA 30909 USA

giving the model number, serial number and date of purchase of your product and the name and address of the authorized

dealer from whom it was purchased.

THIS WARRANTY DOES NOT APPLY TO INCIDENTAL OR CONSEQUENTIAL DAMAGES AND ANY IMPLIED WARRAN

TIES ARE LIMITED TO THE SAME TIME PERIODS STATED HEREIN FOR OUR EXPRESSED WARRANTIES. Some areas

do not allow the limitation of consequential damages or limitations of how long an implied Warranty may last, so the above

limitations or exclusions may not appiy to you. This Warranty gives you specific legal rights, and you may have other rights

which vary from locale to locale.

This is a limited Warranty within the meaning of that term as defined in the Magnuson-Moss Act of 1975.

In Canada contact:

Frigidaire Home Products

7075 Ordan Drive

Mississauga, Ontario

L5T 1K6

iO-41

Page 5

paratelf in carton

Close Roller

\\

(2) Washers 17/32 x 7/8 x 16 Ga,

Manual

Parts Bag

(2) Hex Boils 3/8-16x1 (2) Nylon Locknuts 3/8-16

Page 6

ß-it we I

}T vou

3roper tigfiine

•Ur

^f3.si0r Stanc

rachi

Tire Dressur

.

sn riant or

" - .no v\r

behind the

L't.7

o"" > ■ _ rp." e .0 e ports and Jri1c oarccns

n ul l

I uciiiun

r oe ts fj a yc

• C ut, from top to bottom, along lines on all four corners

of carton, and lay panels flat.

® Check for any additional loose parts or cartons and

remove.

.iJ IS iiieniiui ir >1,1., iif.r 4_j. li

>n the Dor r.a. ■ 'or ted

■■er n.

Uj.

nass0íTib¡0f

mo

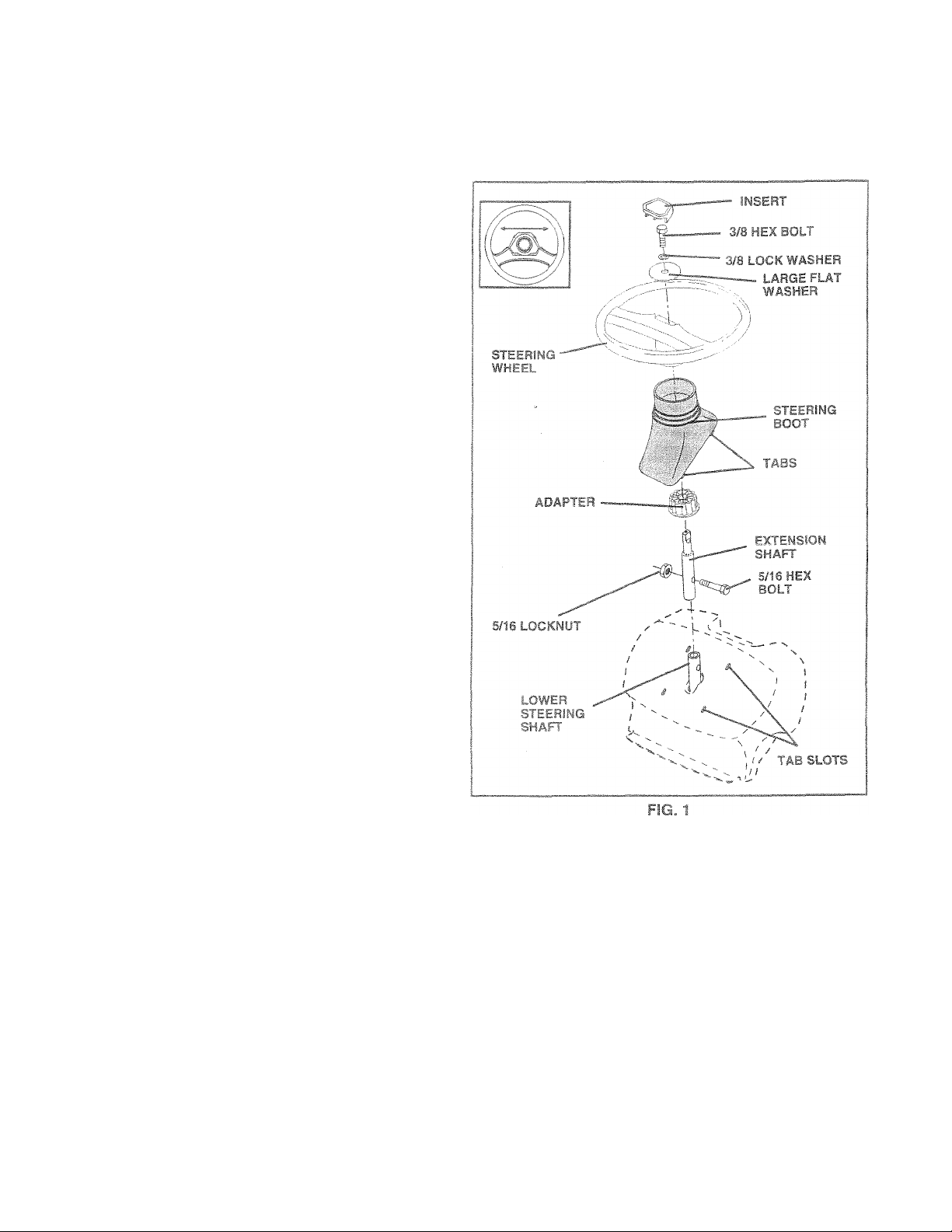

Ü PV ~ SI V/HEEl {Sef* =ec, 1

ASSEMBLE EXT

• Slide extensi

1 ,n . f,T one’ icwer cnatF and

- " h r -( r J’.mr

IM

1 s

DU

j secure.

flNG WHEE

;itfi

• c,ip^ ta~'i wheel nf'f'ifc*=iing t: I r, a;ten

sion.

I whseel;

• - ' ■ - ' , . f _i r' r-- -p a, ' 'j

bars are fiorizoritsl (left to right) and slide onto aeJaptBr.

® MS. am. - _fc 1a Wc iiH, j/8 lO'-i« Washer. 3/B he'

ooi am igri'n se ureC

• Snap steering wheel insert into center of steering

wheel.

® Remove protective plastic materials from tractor hood

and grill.

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

IN SKID THAT MAY PUNCTURE TIRES WHERE TRACTOR

iS TO ROLL OFF SKID.

M 'HA.= r AND BC4 7

‘-an at'' ( wer Sibi.r i r naff Aiff n

, C IV^

he

Cl So neve ..untiiiy

in deisn

' ^ -A 7L ', . :t. vH off SKIC tSe€ Gperatiori section for location and function of controls)

* Press lift lever plunger and raise attachment lift leverto

its highest position.

® Release parking brake by depressing clutch/brake

pedal.

* Place freewheel control in freewheeling position to

disengage transmission (See “TO TRANSPORT" in

the Operation section of this manual).

» Roll tractor forward off skid.

* Remove banding holding discharge guard up against

tractor.

Page 7

w

HOW TO Si

uuor.

if this battery is put

n ( It

r ‘ a* > r' "'■''' ~" .

(See "BATTERY" in

suidutio“.' e. r

BATTERY ,

BOX DOOR

TERMiNAL'

¥Ol

№KI

^ TRACTOR

n Bncj open bsttery box

- "i lif r 1 -

' - I' cl .

one hour at 6-10 amps.

-• -£S-'"R£E" IT"

rging instructions).

LABEL

-TERMINAL

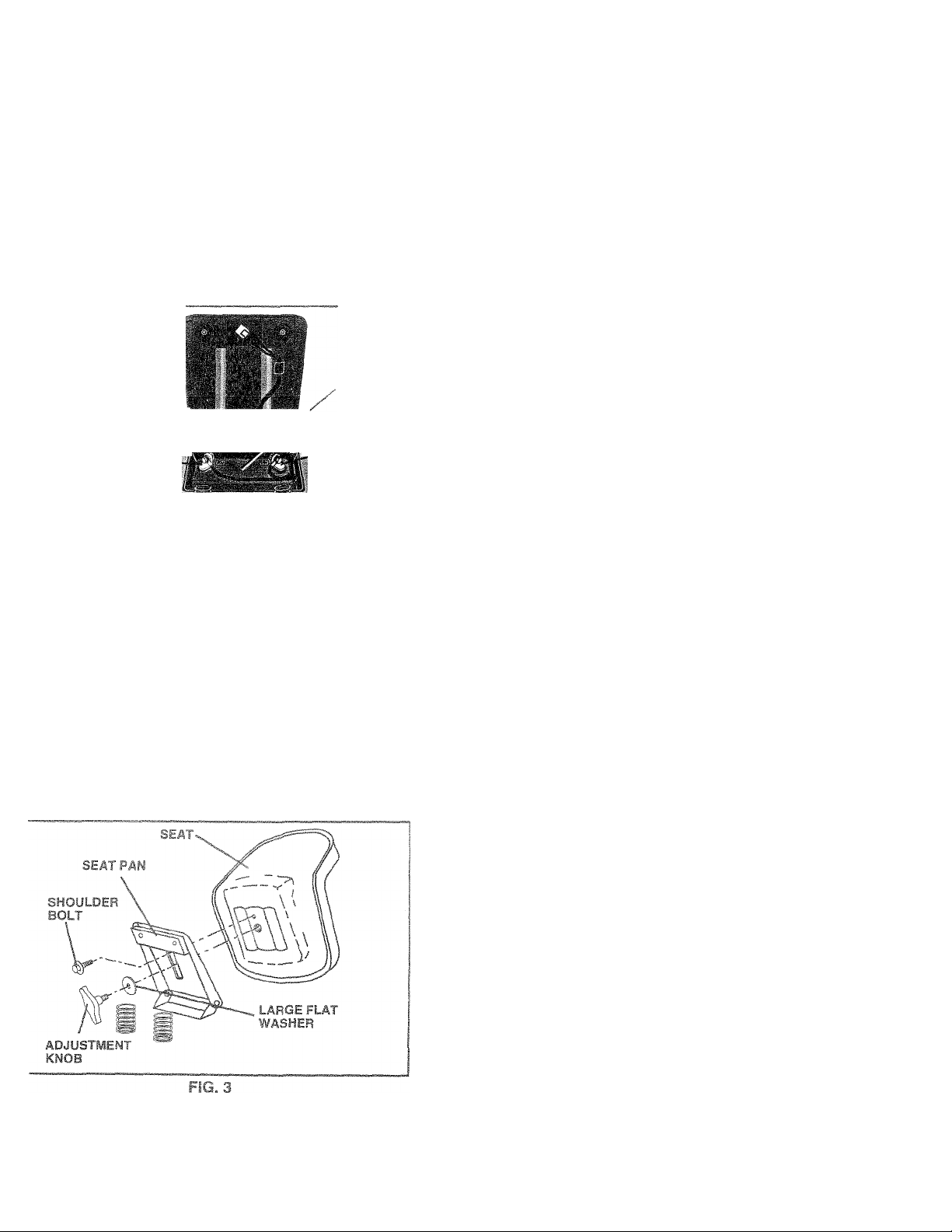

MSTALL SEAT (See Fig. 3)

idjust seat before tightening adjustment bolt.

Remove cardboard packing on seat pan.

Place seat on seat pan and assemble shoulder bolt.

Tighten shoulder bolt securely.

Assemble adjusiment bolt, lock washer and flat washer

loosely. Do not tighten.

Lower seat into operating position and sit on seat.

Slide seat until a comfortabte position is reached which

allows you to press ciutch/brake pedal all the way

do'wn.

Get off seat without moving its adjusted position.

Raise seat and tighten adjurjiment bolt securely.

,/( I

TO

>rac

® Insiail 3/t

MG c .--c .

ne" . i " r r

NO&c

HEX

BOLT

gjr

BRACKET.

TAB

F!G. 4

CHECK TIFT PRESSURE

f s£b" j .-I R V.

sbippirg c..'''~c®'cs Tl m nri*'“

bes. n TT‘rg r.6""‘'.ner. -

® Reduce tire pressure to PBf si*

SPECIFICATIONS" on page 3 o

CHECK DW"

r . f "

iev€

ce: -R ‘ ' I HiM

CHECK “Ch T

8 FLIC

Tea‘he nm r. m ,.w

r'worbGt'" or j tm'i- '

SPi.irw o; f.|S ‘rzfi'- . >/• >r 1 j

CO' -cii I

CHEr-TC“'Ar. " :t-¥

i“c'/'o't''" f )' • » o'‘fa ' ' ,v -t,. ■

.na+ Te ¡..fric r ( ? .u o T !

F^L-rE’ fo .nt Ftrv..„e enc .i' imertr sec .'or or ih

manual.

i O “ Tf

i/ere

? E

nis

Ml

^OWER

1 mot

Adii I

Page 8

ASSEMBLY

^CHECKLIST

ЧАТЕ AND ENJOY YOUR NEW

TO ASSURE THAT YOU RECEIVE

'ANCEANDSATlSFACTiO,

1L

PLEAi

- ^ i - n I 'f(- , . - _ .'1 ■ “

/ 'jc '.a 'e Dec, c

- >-io ' " 0=1- n .

/г j_c iFu „'•'¡arge-. i linimum

1 hour at 6 amps}.

"<-,'■0 ’ -a onhiy istt-Пг-п s^rjiriy.

./ ",!го -i/n>3'=_ ^0'I no.p Г'З Lf'^c'e,

^ 4- Л - ! >0 -¡ra '• !ra I,

fc'O^StCet

^ "30' Cl .^3“ juiiig GO j' “ ( 15. [>"■

.1 ' ‘5’-, г e 'e'lfir’i

' Л ' iG ar.j лае aelîs. be'Ure‘hey ¿re foutec

0 :„c ' a 0!.. c-,c'!a/ ard TSiOf .лИ s elf-eece

j r i r ,-,c £• 9 hai all ocnner-o IS Gfi-sMbecure

c r/v-^ 31 'U^mDed

Z~'< ' - 1,«. •'• ' "*i r. ^ure tme/v^eel rct-Gl is ¡fi

drive position.

V/HILE LEARNING HOWTO USE YOUR TRACTOR, PAY

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

/ Engine oil is at proper level.

/ Fuel tank is filled with fresh, dean, regular unleaded

gasoline.

/ Become familiar with all controls - their location and

function. Operate them before you start the engine.

/ Be sure brake system is in safe operating condition.

/ It is importani to purge the transmission before operat

ing your tractor for the first time. Follow proper starting

and transmission purging instructions (See “TO START

ENGINE” and “PURGE TRANSMISSION” in the Op

eration section of this manual).

8

Page 9

.-iPeeaTíO?'^

These symbols may appear on your tractor or in literature supplied with the product. Learn and understand their meaning.

I

♦

BATTERY

©

ENGINE ON

i

FUEL

CAUTION OR

WARNING

pv» -or-'

p' • vrj

to

ENGINE OFF

l\l

CHOKE

R

REVERSE FORWARD FAST

"fir

OIL PRESSURE

MOWER HEIGHT

N

LIGHTS ON OVER TEMP

to

PARKING BRAKE

LOCKED

H L

-t'ri

LIGHT

UNLOCKED

SLOW

f

if

MOWER LIFT

ATTACHMENT

JJTCH ENGAGED

IGNITION

DANGER, KEEP HANDS AND FEET AWAY

REVERSE

ATTACHMENT

CLUTCH DISENGAGED

NEUTRAL

HIGH LOW

KEEP AREA CLEAR SLOPE HAZARDS

(SEE SAFETY RULES SECTION)

PARKING BRAKE

FREEWHEEL

(Automatic Models only)

Page 10

OPF RATION

^*11'P jc.t- r» m

- £1 r ^ AMPS--;“'■f PriF'.l-i^'r.REOPfr’^-Wf.'^OUP :riR

Compare the

this manual 1

I I i With < .. ¡1- , f io familial

iture reference.

•urseif«/iihthe> - n.iisofvarioM- '-andadjustments. Save

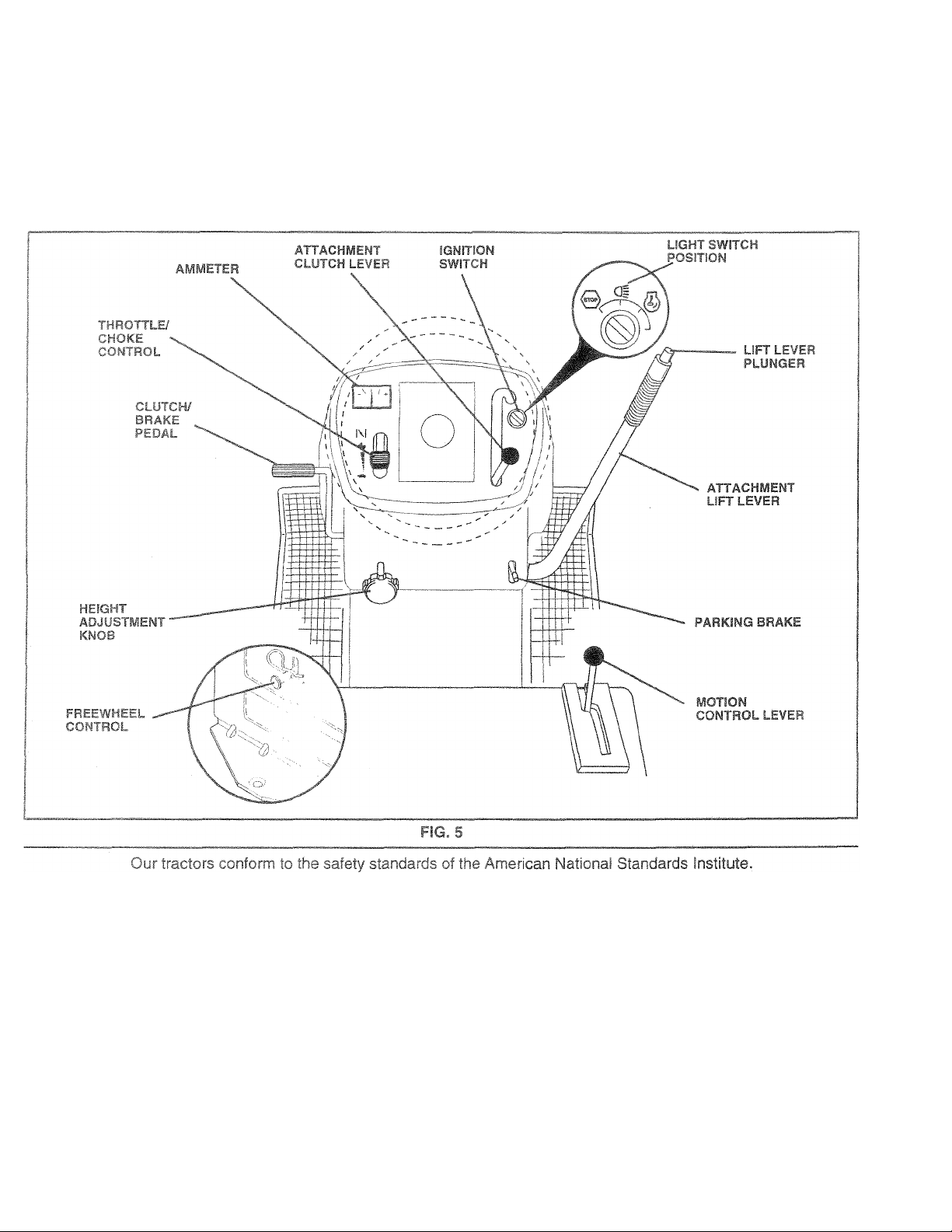

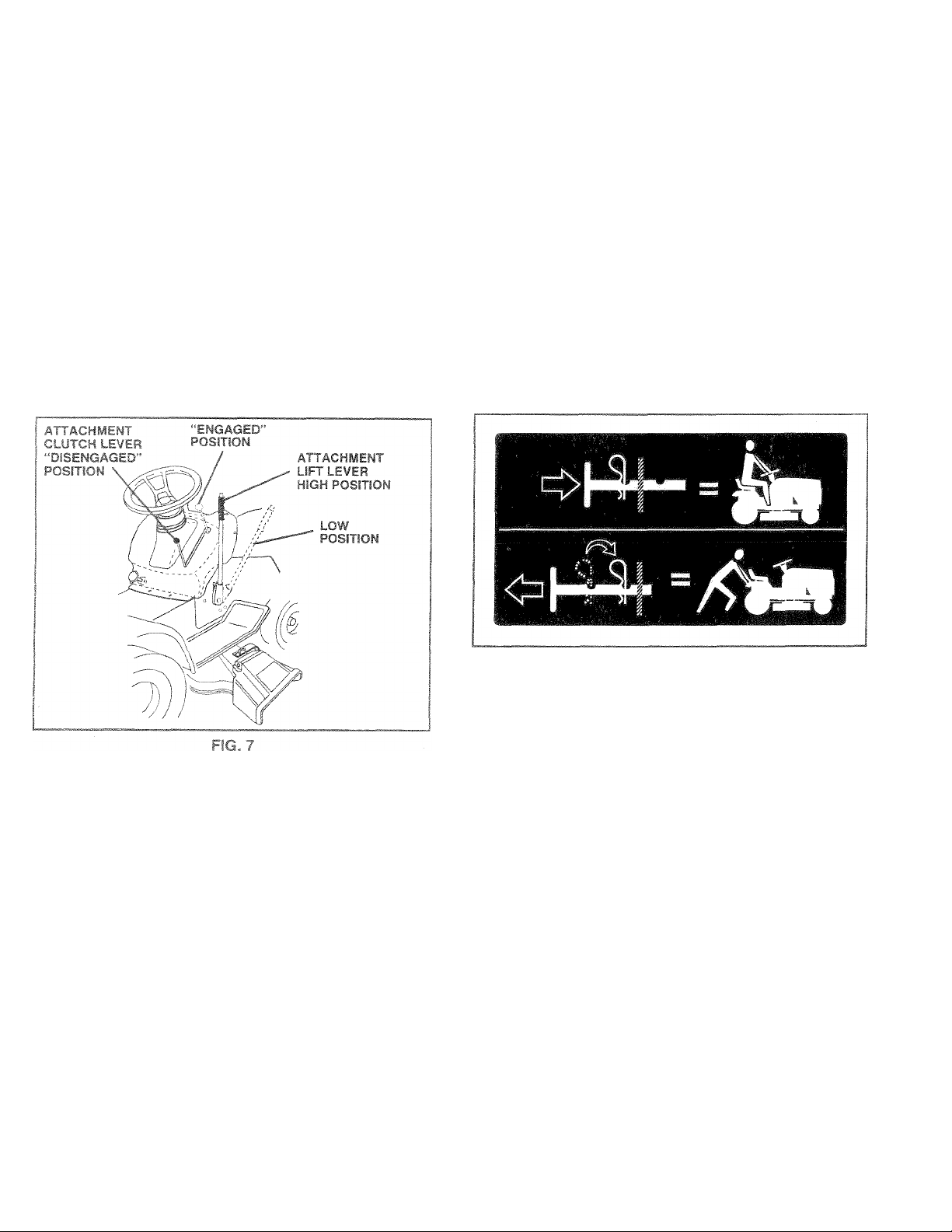

ATTACHMENT CLUTCH LE¥ER: Used to engage the

mower blades, or other attachments mounted to your

tractor.

LIGHT SWITCH: Turns the headlights on and off.

THROTTLE CONTROL: Used to control engine speed.

CLUTCH/BRAKE PEDAL: Used for declutching and brak

ing the tractor and starting the engine.

PARKING BRAKE: Locks dutch/brake pedal into the

brake position,

MOTION CONTROL LE¥ER: Selects the speed and

direction of tractor.

FREEWHEEL CONTROL: Disengages transmission for

pushng or towing the tractor with the engine off.

ATTACHMENT LIFT LEVER: Used to raise and lower the

mower deck or other attachments mounted to your tractor.

LiFT LEVER PLUNGER: Used to release attachment lift

lever when changing its position.

IGNITION SWITCH: Used for starting and stopping the

engine.

HEIGHT ADJUSTMENT KNOB: Used to adjustthe mower

height.

AMMETER: Indicates charging (+) or discharging {-) of

battery.

10

Page 11

Ciâîî1â00,* ÂlWâyS W©âf Sâf©ty §ll

- •î*-'-"rrc ,il r*.-''«"' ' '},

HC ’H* ^ " " L - î- - 'Í73P.

T SE “ — - ?.i: ” ? ^ 5 ¿C'f = g. ■

Depress

and hole

release pressure ire

r^Dsasr s / ^ S D i ^'1" /i; „ iV SSfO

Will hold tractor secure.

da! into full “BRAKE” position

'0 iH = u-'“5 Pads'ct ', "

NO I h; under i

idle with theenq

rr-U*”" C'' •.

pletelf, as described

A

grass catcher, etc.

TO USE THROTTLE CONTROL

Pi<‘i ' _- r • *

battery charging rate.

® Full throttle ofv

• >Pr. ‘ -

lers 1 lower perro

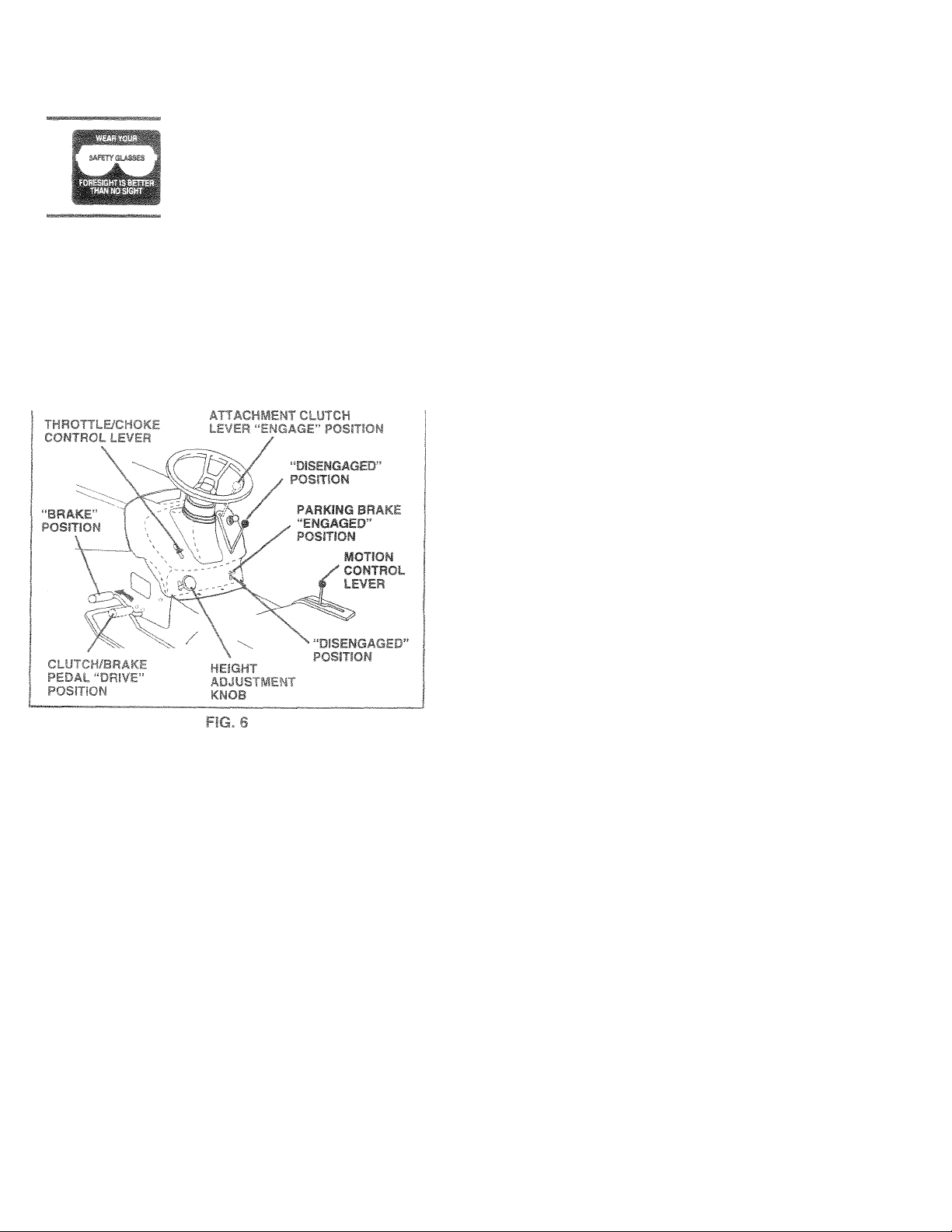

TO MOVE FORWARD AND BACKWARD

(See Fig. 6}

The direction and speed of moyement is controlled by the

motion control lever.

® £ . < i t t ra o K' i w ih ( o

prciiirn.

® ¡.ark,n._

SIcwlv rrin

miroi lever in neutral

iicn/DraKe pedal,

re! to desired positii

STOPPIN* g. 6)

MOWER BLADES -

® To stop mower blades,move attachment cluicfi leverto

“DISENGAGED” position.

GROUND DRIVE -

» To stop ground drive, depress ciutch/brake pedal into

full “BRAKE” position.

® Move motion control lever to neut.raf (N) position.

iMPORTANT: THE MOTiON CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (Ni POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

ENGINE-

* Move throttle control to slow position.

NOTE: Failure to move throttle control to slow position and

allowing engine to idle before stopping may cause engine

to “backfire”.

• Turn ignition key to “OFF” position and remove key.

Always remove key when leaving tractor to prevent

unauthorized use.

® Never use choke to stop engine.

IMPORTANT: LEAVING THE IGNITION SWITCH IN ANY

POSITION OTHER THAN "OFF" WILL CAUSE THE

BATTERY TO BE DISCHARGED, (DEAD).

imum

The cutting heigh

so U . , .

® Turn knob cloc

rf=igni.~ r • - y

the -rgne ‘i". .m r_ - *

and T!c vcT uevs'J. L . j >r , (-jO

grass dOJ t.-pfs

® ’ he 'awr -r" „.sc oe' , mr p t * c-m _

inches during the cool season and to over 3 inci

"•unre he m'">ih c:,-r rc-^it-icr't, ; ■

lawns mo/ s.te'^ ard rrs -ro.j~h.

■* i^'-f oe=' r sting per orr anc <:v.;r t~ .>ic '»*heiont c'’cl'o'^€ TIG''od twice r'

re'ativi^.', r 'On he se r> d Cc. • n- cm

11

id to th

-1 i =

annroxirr

her

”S

5

» in

cut

Page 12

OPERATlOí

1

IPD It

MOW

' < • I ! h , ' ' > i i' t 0>‘-^. ~i l I <1,

switch. Any atternpt by th© operator to leave the seat with

i ll . ' ■ ■ O' . I l f ) I - i W l • ■ I C ' .J i ' ' rj 'i

^ _s,- rc v='/i.th artsc'."¡e 0 .ifT, .nti-''!

* hi-’ c / = c aOes 0/ e loarny ariPfin-e^i -

-cr« s

, ' C Ç r _ - y' .py puga: „ joytafu f. : .

jiC'

wAuTtOfl. Do r»oc jperaie he nower |

w't^out aithei the entire grass caichei* I

A

cn rtiowers S3 equioped cr the dls- s

charge guarc in place, 1

If

U ' ‘ Ji . iy I I I V' l i ' J

!■' 'i i r ' V r| i ,, , fi, i . /•“V -<

position. Free wheel control is

•in«s

ol lU O

c. - c'om/.t. j!

of tractor.

' - -“r

merit iift control.

H,' 'c= vL-e' . 'I * r ro ->id i :iL‘i, L/

.'-."‘rig >eEar-rsowiC .i: fc'-v-i'c noto :> sc" red.

® ^ ■ ■.3.z,z~ - ms 5 fdr .c'C.iVH.

• ' r ^ ‘rs . i'.''-aL'' - cr'os'rom*.

TCTc "v O'^oa iCiTi damagfe wi.fc''’"ansDorripp

ycurractor a ruck"'» a '•'a.le- oe sure hood ;s closed ana

jC..,..red'c tmc.‘ r UAear.apprcpr.atciriBar'o .^fry,r,g““ci^u

m trac.o .repe, d eic ■

TO OPE-'A" r Dhl HILLS

C-AÜT'C”: Gcncî drr^eupordowRÍisíío

With î'cpes greater than 15° and do net

A

» Choose the slowest speed before starting up or down

hills.

® Avoid stopping or changing speed on hills.

* If slowing is necessary, move throttle control lever to

slower position.

• if stopping is absolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking

brake.

» Move motion control lever to neutral (N) position.

IMPORTANT; THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

® To restart movement, slowly release parking brake and

clutch/brake pedal.

® Slowly move motion control lever to slowest setting.

® Make ail turns slowly.

hr*ve across any sfooe.

FiG. 8

BEFORE STARTiNG THE ENGINE

CHECK EUGME OIL LE¥Ei_ (See Fig. 13)

* T he engine in your tractor has been shipped, from the

factcn/ralready tilled with summer weight oil.

® Check engine oH with tractor on level ground.

* Remove oil fii' cap/dipstsck and v/ipe clean, reinsert the

cicstiCK and screw cap tight, wait for a few seconds,

temere OiC read oii ievek if necessary, add oil until

‘■RuLl’ inarK on dipsticK is reached. Do not overfill,

® h sr sci-J weather operation you should change oil for

easie,'- starting 'See “OIL VISCOSITY CHART” in the

Cusiorner Responsibilities section of this manual).

* To change engine oil, see the Customer Responsibili

ties section in this manual.

ADD GASOLINE

» Fill fuel tank. Use fresh, clean, regular unleaded

gasoline with a minimum of 87 octane. (Use of leaded

gasoline will increase carbon and lead oxide deposits

and reduce valve life). Do not mix oil with gasoline.

Purchase fuel in quantities that can be used within 30

days to assure fuel freshness.

iMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW 32°F(0'’C), USE FRESH, CLEAN WINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING.

12

Page 13

np pnrf fpf

Ci,

-r

fuel

bier

^age. To avoid engine

be erriDtied before stor-

uld Í

■'ain

J0f li " ~c i <„arcu. s.c " a

asor1. See Storage Instruc-

)n.

Never use engine or

-'-A t ” r-nt

® Allow one minute for transmission to warm up. This

can be done during the engine warm up period.

The attachments can also be used during the engine

warm-up period after the tran.smission has been waimea

up.

MOTHi If 3Í E hiyli sitituds (sbovs 30^

JO fG0[i C

h ilJ6( fTilX

.S 9 £10SfC'0 " 00

JSIITI

ssGiion Of lilis msnusí.

PORGI

T°0 MOI

3 3.nd AdH

¿r* f

WAtJ

filler

ed oil or

A

IME

w i r- w~ I i 2' = A M r ' -O' me

ue!

neg

see r-i

5cr*c t; ci ¿Jz. .yfl

ir iftp's :rra'

~'C^ AO'B. spif’

. I ! " 'M 'K^c AK Tc " t /e

fuel from the

be sure

aaaed oc

-driK

see! com

)n

'

s in the transmission en-

’ tt< tr -1!, mc'cji t - i.iCi aepress clutch/Diake

ptjai C..-.U set park..ng'c,c;ke.

• Place motion control lever in neutral (N) position.

® yove attachment dutch to “DISENGAGED” position.

•• Move throttle control to choke position.

NOTE: Before starting, read the warm and cold starting

procedures below.

» Insert key into ignition and turn key ctockv/ise to “START"

position and release key as soon as engine starts. Do

not run starter coniinuously for .more than fifteen sec

onds per minute. If the engine does not start after

several attempts, move throttle control to fast position,

wait a few minutes and try again, if engine still does not

start, move the throttle control back to the choke

position and retry.

WARM WEATHER STARTING (50° F and above)

• When engine starts, move the throttle control to the fast

position.

® The attachments and ground drive can now be used. If

the engine does not accept the load, restart the engine

and allow it to warm up for one minute using the choke

as described above.

COLD WEATHER STARTING ( 50° F and below)

• When engine starts, allow engine to run with the throttle

controi in the choke position until the engine runs

roughly, then move throttle control to fast position. This

may require an engine warm-up period from several

seconds !o several minutes, depending on the tem

perature.

AUTOMATIC TRANSMISSION WARM UP

® Before driving the unit in cold weather, the transmis

sion should be warmed up as follows;

® Be sure the tractor is on level ground.

® Place the motion control lever in neutral.

Release the parking brake and lei the ciutch/brake

slowly return to operating position.

Ti, r

nino.

10 ensure proper«

T b'lupo '(¡a To '

tractor for the first time. This proc 6GUr€

1 , C,r - ‘>-r

■ mr:*’ Mm.I J ' " i "

i.uiPOF’^rt m ^ >

lission De pi.

r

---------

i

•-

3 Will rGrnove a

Ì

ÍÜW

WhlCr

ISSION REOUT

.NSMi

REMOVAL FOR SERVICE OR

SHOULD BE PURGED .AFTEF

= E- 'P-E E-F IV 1 E -/ U

® F ace , £,'< / q-. tov«i

pc

fc '

a* fr t

® Disengage transmission by pic

in freewheelinq position (See

I ! '

Sittinq in thi

INSTALLATSC

TOR.

face V

!/iih engine otfai

freewhesi conti

icing

ííT‘f\

'

TRANSPORT”

ir i

.( '■•■'p- • n

3n c

ai (N) position, sic

» ■,

»dure thre^

NOTE: During this procedure there will be no movement of

drive wheels. The air is being removed from hydraulic drive

system.

® Move motion control leverio neutral (N) position. Shut

off engine and set parking brake.

» Engage transmission by placing freewheel control in

driving position (See “TO TRANSPORT” in this section

of manual).

® Sitting in the tractor seat, start engine. After the engine

is running, move throttle control to half (1/2) speed.

With motion control lever in neutral (N) position, slowly

disengage ciutch/brake pedal.

® Slowly move motion control lever forward, after the

tractor moves approximately five (5) feet, slowly move

motion control lever to reverse position. After the

tractor moves approximately five (5) feet return the

motion control levertothe neutral (N) position. Repeat

this procedure with the motion control lever three (3)

times.

® Your tractor is now purged and now ready for normal

operation.

13

have dov'

Page 14

MOWI

• Tire chains cannot be used when the mower housing

is attached to tractor.

® Mower should be properly leveled for best mowing

performance. See “TO LEVEL MOWER HOUSING” in

the Sendee and Adjustments section of this manual.

• The left hand side of mower should be used for trim

ming.

• Drive so that clippings are discharged onto the area

that has beer*, cut. Have the cut area to the right of the

machine. This will result in a more even disiribuiion of

clippings and more uniform cutting.

• When mowing large areas, start by turning to the right

so that clippings will discharge away from shrubs,

fences, driveways, etc. After one or two rounds, mow

in the opposite direction iTiaking left hand turns until

finished (See Fig. 9).

» if grass is extremely tail, it should be mowed twice to

reduce load and possible fire hazard from dried clip

pings. Make first cut relatively high; the second to the

desired height.

)le clurrtc

wng.

} engine at

TlOWinO p€

w,- m f I ,< Hc'it'jte gr :i i c-ce- •'

. ly . '.n.,ug, yta* m c'% j.t m v-r"

tnroitfe when mowing to

> -mvr -7 . _ t..' Jc

re-,, -aif y as h- 1. £:■' , c m -c-.-*

Dfci c ^ -p—-

mm , he a, d i e '-i" '-i. . .n < a

14

Page 15

Iv I %»#IWitri nt Vi VIÖ11—I I lt-'*J

3IVIP

I W

I i/

■v^

__L

ir

I

'^6

^ - J

_____

r

I

-J-.

V^Ci'-^.O irr-

GENERÄL

T H

D— '• S i

DilMI

yriÄ"

LI#4

i not C0\

r Items tnai i

3"!i

receive ful! value from the warn

tractor as instructed in this rng

Sc ,k dd|is rci- vm •. v--

jai.

Is -nao“ penodi uiiw hi

properly maintain your iracior,

Ai! adjustments in the Service and Adjuirtments seciion of

this manual should be checked at least once each season.

* Once a year you should replace the spark plug, clean

or replace air filter, and check blades and belts for

wear. A new spark plug and clean air filter assure

proper air-fuel mixture and help your engine run better

and last longer.

BEFORE EACH A'LE

* Check engine oil levei.

® Check brake operation.

> Check tire pressure.

• Check operator presence and interlock systems for

proper operation.

• Check for loose fasteners.

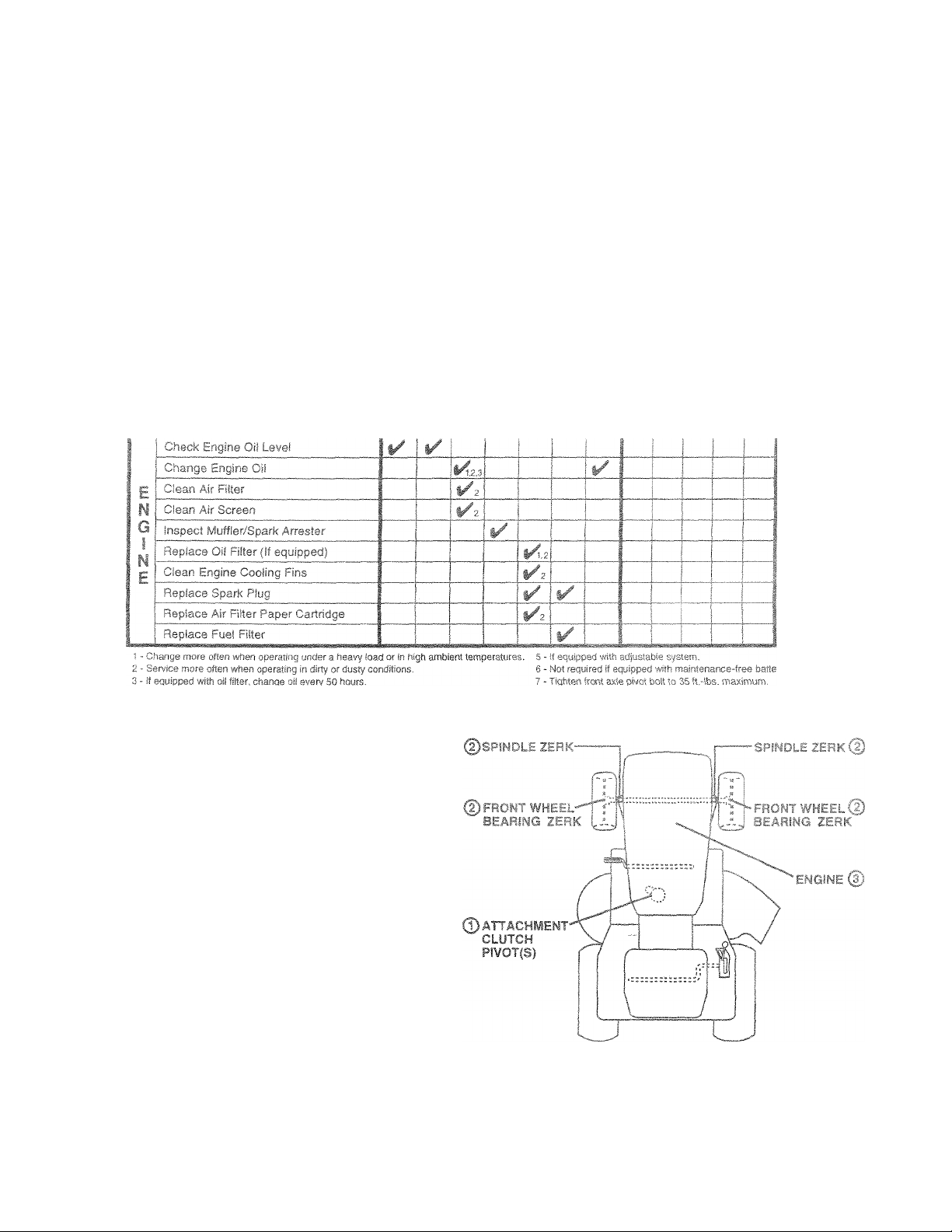

LUBRICATION CHART

CDSAE 30 OR 10W30 MOTOR OIL

©GENERAL PURPOSE GREASE

©REFER TO CUSTOMER RESPONSiBILITiES “ENGINE” SECTION

MPORTANT; DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS. VISCOUS LUBRI

CANTS WILL ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRICATING BEARINGS. IF YOU

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW

DERED GRAPHITE TYPE LUBRICANT SPARLNGLY,

1.^

Page 16

, PESí^OMS!B!línE=

TE

OH

nainte-

BRAKE OPI

. ir

at high speed ir

(See “TO ADJ

n it fib seciK 1

- .

hest gear,

; [■ /1 * h

Jai

1 ec t'p) 1 j I. j .-

:> Tr^e TitsTce aojusTsc.

ir. h-_ ^iip anc -^djLsi-

TIRES

® ivlaintain proper air pressure in all tires (See “PROD

UCT SPtCIFICATIONS” section of this manual).

• Keep tires free of gasoline, oil, or insect control chemi

cals which can harm rubber.

® Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

NOTE: To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion.

OPERATOR PRESENCE SYSTEM

Be sure operator presence and interlock systems are

working properly, if your tractor does not function as

described, repair the problem immediately.

• The engine should not start unless the clutch/brake

pedal is fully depressed and attachement clutch control

is in the disengaged position.

• When the engine is running, any attempt by the opera

tor to leave the seat without first setting the parking

brake should shut off the engine.

• When the engine is running and the attachment clutch

is engaged, any attempt by the operator to leave the

seat should shut off the engine.

® The attachmentclutch should neveroperate unless the

operator is in the seat.

¡AILING

MANDREL

ASSEMBLY

t

FLAT tf isHF.'-i

LOCK AfA-Sdfc'

HEX BOLT (GRADE 8)*

*k GRADE 8 HEAT TREATED BOLT CAN BE

IDENTIFIED BY SIX LINES ON THE BOLT HEAD.

FIG. 10

TO SHARPEN BLADE (See Fig. 11)

NOTE: We do not recommend sharpening blade - but if you

do, be sure the blade is balanced.

Care should be taken to keep the blade balanced. An

unbalanced blade will cause excessive vibration and even

tual damage to mower and engine.

• The blade can be sharpened with a file or on a grinding

wheel. Do not attempt to sharpen while on the mower.

• To check blade balance, you will need a 5/8" diameter

steel bolt, pin, or a cone balancer. (When using a cone

baiancer, follow the instructions supplied with bal

ancer.)

NOTE: Do not use a nail for balancing blade. The lobes of

the center hole may appear to be centered, but are not.

» Slide blade on to an unthreaded portion of the steel bolt

or pin and hold the bolt or pin parallel with the ground.

If blade is balanced, it should remain in a horizontal

position. If either end of the blade moves downward,

sharpen the heavy end until the blade is balanced.

B.w‘:cwRE

For best results mower blades must be kept sharp. Re

place bent or damaged blades.

BLADE REMOVAL (See Fig. 10)

» Raise mower to highest position to allow access to

blades.

• Remove hex bolt, lock washer and flat washer securing

blade.

» Install new or resharpened blade with trailing edge up

towards deck as shown.

IMPORTANT: TO ENSURE PROPER ASSEMBLY,

CENTER HOLE IN BLADE MUST ALIGN WITH STAR ON

MANDREL ASSEMBLY.

• Reassemble hex bolt, lock washer and flat washer in

exact order as shown.

» Tighten bolt securely (27-35 Ft. Lbs. torque).

IMPORTANT: BLADE BOLT IS GRADE 8 HEATTREATED.

16

Page 17

BATTERY

Your tractor he

cisnt for norm.

battery with ar

® Keen bat'^c

IS a batteiy charging system which is suffial use. However, periodic charging of the

I automotive charosr will extend its life.

ip/ and terminals dean.

® K.eep Dattc

30

II vsnt liolss op@n.

® HBcharge at 6-10 amperes for 1 hour.

I I'D 1 ’ 1 _

maintenance fi

or covers. Adc

; 1 = 1 1. tU' ic. ‘ .1 -• V m- , ;

-r-y r ^ z.’itr!i‘ > e;i' ' rr .

’ ' > ' 1 , - - ' _ . ot

n L

iTTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to “teak” Dower.

)nriec

r r' - Cl- r I - ^with plsi

0

' 'e-nc-rT .

r,, '' cm

9

&

- -'nGt. ‘ Lai f.. /

SERVICE .AND

msnuai).

t>7 J' '>ei í r oaí-

;re' í n ‘a j .

A, ‘ ^r,

nd baiter

th nrpBSi

^ r-p toíY

ADJUS

/ :br <= -I d' .ííif wire brush

r-^; d-^.Y" iníhe

>.u>CY~ sef-tnr* oí this

1

---

^—

Lf ^ V

1 op 3QO

NOTE:

improvi

»V ■. r-

jr enqin

p - r 1

CbSflQC

ones 3 ^

Cr

arc a -i if_

cap/""; c 1., 1 ^ ^ -

TO CHANGE ENGINE OIL (See

CeV- £ ir.e e, 'e a.i ,e c, - j.

A,l o‘i 'll n' -■ '

® Be sure tractor is on level suf

> Cl! fjll r r 6 /< I'5

® fei ^ ' t

* Remove oil fill cap/OipsticK. B

to enter the engine when cha

Chfí/< V-bei'í*c.

operation and ref

aojj": cr-ltí. ^ -D’t'

r» ^ /. I £. . 5,j,

The transmissior

“a '/earaiter OOhüutsof

oelís not

r _i 3iiD'rom wear.

■Id be Kepi dean

K' . ir- '

Df >•’1 'I - I . I-' - [ i:.: n r mr r>

lU 1 . .C <•' i' U ‘ . ' M>£ • t h( , T- ¡ even f L

sitie damatjO :o seáis, de not uct. bagt! pressure water ur

steam to clean transaxle.

• Inspect cooling fan to be sure fan biades are intact and

clean.

» Inspect cooling fins for dirt, grass clippings and other

materials. To prevent damage to seals, do not use

compressed air or high pressure sprayer to clean

cooling fins.

TRANSAXLE PUMP FLUID

The transaxie was seated at the factory and fluid mainte

nance is not required forthe iife of the transaxie. Should the

transaxie ever leak or require servicing, contact your near

est authorized sen/ice center/department.

ENGINE

® Aftsr 01! fiHS drainocl compiotr

-ir ■<,<,•/ r -

“PRODUCT SPECiFiCATION

» Use gauge on oil fill cap/dipsti;

reading. Keep oa at

LUBRICATION

Only use high quality detergent oi! rated with API service

classification SF, SG, or SH. Select the oil’s SAE viscosity

grade according to your expected operating temperature.

Page 18

CJJSTOWEP PESPONSiBJLmES

a. 141

j ( IH

in the foam

^leaner after

no

Hemov6

^ .0 • over

— ^I-

■’ : oeirfef A, ”000:'=-

, j V j-o vat-

'■ ' r r. 5 ‘i-,1 coth

• ^ 1 ~ >jìf.- .1 ri >t. t r, a-n I" r 1

m Lo-zc ' c

si ^ ^ J -J t 1 (. a WS i 1 1^ ^5 j ^ I I ( C" 4^ i i i »

>» -• ■ ’'-i ,v " ■ c 6, ..anooga.

® Reinstall cover and secure with knob(s).

TO SERVICE CARTRIDGE

• Remove cartridge nut.

• Carefully remove cartridge to prevent debris from en

tering carburetor. Clean base carefully to prevent

debris from entering carburetor.

• Cleancariridgebytappinggentlyonflatsurface. Ifveny

dirty or damaged, replace cartridge.

• Reinstall cartridge, nut, precleaner, cover and secure

with knob(s).

IMPORTANT: PETROLEUM SOLVENTS, SUCH AS

KEROSENE, ARE NOT TO BE USED TO CLEAN THE

CARTRIDGE. THEY MAY CAUSE DETERIORATION OF

THE CARTRIDGE. DO NOT OIL CARTRIDGE. DO NOT

USE PRESSURIZED AIR TO CLEAN OR DRY

a a dirty air filter.

i5 hours of operairtridge every 100

Tever occurs first.

CLEAN REEN iSee Fìq. 15

V ^ L f

Air scr

engine

or com

;e keot

move

, ' I < ■ VI .< ^ ,

r 4- -.1 mitt j , I. hi 1, *

r

<i'V

I 'III- ' I

'.I

ENG7-JE =:NS .See rfg ’5.

Rpnlr^^ -n./ V|, 4 -jl, Q -^1 ,Vo~ -ng.-c -Z' l,r|f un io

pro entonyirb lamags imRi jié rsahiiu

* re y= imrr’ hjnvver noi'F-pg arri D •'nti .h„

arpo c’lps'mfr Jbe issemDK idengir»

» ( - r 0 ' I'i -pe'ii' j '0 c'-^vert eoir^ ZfZil

- St, ccnar=^eed a.i'or 3iT Lrib'le trus*^ *c

■’Tan =i^g>pe "''riing ¡¡ns

® 'c 1-c‘^sentic e’<erce above crocs "ure

FiG. 14

FIG. 15

18

Page 19

CUSTOMER RESPONSIBamES

repic

ijippeaj

H Anl£?r-i

jeasori -r PTier >T ! gl»-' ofaftrat.cn «niche^/t'

"Fr'CCPt " src. - 'e'.C >S sec'ijr jf*h's .""a. ual.

s itc

5Uld crc

.115pct>-k Giup '\pe a.'d yao selling are snow" .n

n r ,,•) I

h, >i . r./

rresteriif

'in

IN-LINE FUEL FILTER (See Fig. 16)

The fuel filter should be replaced once each season. If fuel

filter becomes clogged, obstructing fuel flow to carburetor,

replacement is required.

* With engine cool, remove filter and plug fuel tine

sections.

» Place new fuel filter in position in fuel line with arrow

pointing towards carburetor.

» Be sure there are no fuel line leaks and clamps are

properly positioned.

* Immediately wipe up any spilled gasoline.

CLEANING

® Clean engine, battery, seat, finish, etc. of all foreign

matter.

• Keep finished surfaces and wheels free of all gasoline,

oil, etc.

• Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to dean your

tractor unless the electrical system, muffler, air filter and

carburetor are covered to keep water out. Water in engifie

can result in a shortened engine life.

19

Page 20

SERVICE AMO ADJUSTMENTS

CAUTION: BEFORE PEaFORMING ANY SERVICE OR ADJUSTMENTS:

Depress clutch/brake pedal fully and set parking brake.

Place motion control lever in neutral (N) position.

A

“Ea'.c- tc. I MEf SfecT rig. !

iv,z \ - A !-'TiD'-i- ,-t •"!-Hhc't iav_r

' -'a^5 r, ‘_/IFch-GAAFr J.OS- '~n

"< vr li't e/.f' /'-rrf' c'//errro'ver‘o is

• Roll belt off engine pulley.

• Disconnect clutch rod from clutch lever by removing

retainer spring.

® Disconnect anti-sway bar from chassis bracket by

removing retainer spring.

• Disconnect suspension arms from rear deck brackets

by removing retainer springs.

•• Disconnect front links from deck by removing retainer

springs.

• Raise lift lever to raise suspension arms. Slide mower

out from under tractor.

IMPORTANT: IF AN ATTACHMENT OTHER THAN THE

MOWER iS TO BE MOUNTED TO THE TRACTOR,

REMOVE THE FRONT LINKS.

Place attachment clutch in “DISENGAGED” position.

Turn ignition key “OFF” and remove key.

Make sure the blades and all moving parts have completely stopped.

Disconnect spark plug wire from spark plug and place wire where it cannot come in contact with

plug.

tier

TO PSTALL MOWER (See Fig. 17)

® Raise attachment lift lever to its highest position.

» Slide mower under tractor with discharge guard to right

side of tractor.

® Lower lift lever to its lowest position.

• install mower in reverse order of removal instructions.

20

Page 21

àun 40 - -

HOUSING

level QrOUnQ О

5УГЕ

3W€

Ba „e 'r 1 ii 'га

'MtlU .

^ -nf_ -- rip3 xnz^-fz , Г'.~ heio'-t

ticr 1‘ *"'>■ - * je-/ T c'ver''*'L'i.=*anc-“A" л

tfihr c«- L~ I ► ' fTi". rwiif.in

0 -^ac,

’ i, _GI ^ ,n

C|r^ T r't a

e T: - f' 'Г - :

I ь .e - jufirneni on one

irite

nU 01. OC

^ T

nut on that Sid

^■}ГЕ Тоаъ

I -.01 i ^ er nut wili change

¡Ti.v/ci hpioh, “ГО

cf h-.~’ m6&E_rei'r=-ntc arte' aGiiist>rc,

■ inflsied (Sei

of this гт1зпий1)

properly adjus

■: 3 and S Э)

' ■* usimem

adjustment

IE Fi

To obtain the best cutiing

ll 'oh-- ^ I i,"

—,

ы'~

po'^'fcr

Che:r чС’о . n oi i

kr. - ‘ 1 ‘I-' if r

edc- (rt r ъ II I! •

‘ Гг^о •J.r'o'' f'c

=004. , r, -t-. |f •/ -

^ V 5 P " О -i

ijust one link to ?

i Ì i^-'i i<

•zii'-' ’ ' 4c . lì -ui "E” - 'Л

links an equal number of turns.

■'v'f'si ■'fsT' ' m t ■/_" ' \ (

i=ai 10.' >‘z.i m ’ i n 1 .1 .

1 i n k" »di'

I’- Гш-с lOii :i O'j’vfc' icra.<in. i,' . m

^ Ри''” Гt СГ '■ г- 'Г

ecuai пипсе ; iLrn..-.

Wnen cis.arn ‘3 /S‘ > ' i .hor..

reoqiigriie. л„. . ronaoiol

Recbeck'ПО Ч rc г m -pt.

FiG. 19

S \ JZ

/Л

I cm

0O

til

i Veai^

ч-

MANDREL

NUT "E"

Page 22

SFF.vif f mD an.insTf-.iFfjT'^

lOWER BLADE DRIVE BELT

(See Fig. 22)

The mower blade drive belt may be replaced without tools.

Park the tractor on level surface. Engage parking brake.

BELT REMOV.AL -

® Remove mower from tractor (See “TO REMOVE

MOWER” in this section of this manual).

® Work belt off both mandrel pulleys and idler pulleys.

• Pul! belt away from mower.

BELT INSTALLATION ^

® instal! new belt in reverse order of removal.

* Make sure belt is in all pulley grooves and inside all belt

guides.

® install mower in reverse order of removal instructions.

PANDREL

PULLEY

\,

IDLER

PULLEYS

4

PULLEY

FIG, 22

WITH PARKING BRAKE “ENGAGED”

NUT“A”

JAM NUT

L u »JW- r-*IS -YJ . ;r

S,lEhl :s .YECESSAR/

.'-'iR »EASES’" ibiMOPilD

~=o/DE=A'= 'mu.r

FiG. 23

1 T ^EFLTCc DRIVE BELT

(VFG ~SG- 2A,

F^ir\ Ilf itac l; . i rfEngage parking brake.

F^r atsirtan:: ,r.c e y r dry .nstailation guide decai on

0( non tn- Mr . cat

- Rerrm - mo REMOVE MOWER” in this

sertic" ' ni' 'a. loa*'

Fe.mr =- celt jorr siat'Ciwr / idler and clutching idler.

‘ I I jI&i" ! ‘'■'JQ ■‘-ci. I tractor. Carefully remove

UflM CY i"srf‘’'' imrsm s'rion input pulley and over

' ■! no ,n ,..cl C

)r and remove downward

lie c ' Ui I I 1.

above procedure.

Your

whicf

with ar

iide of the transaxte.

If trac

a t I

De.ve ‘■m

Measure distc

nut “a”

THnCfe Ufc

' on bra-^e rod

It, "< 5, e idjusted.

- a ^eccrking brake.

4aei CO jperating arm and

If distance is other than 1-9/16", loosen jam nut and

turn nut “A” until distance becomes 1-9/16“. Reiighten

jam nut against nut “A”.

Road test tractor for proper stopping distance as stated

above. Readjust if necessary. If stopping distance is

still greater than six (6) feet in highest gear, further

maintenance is necessary. Contact your nearest au

thorized service center/depariment.

I system

distance

22

Page 23

-Iflì. -

TRANSAXLE MOTION CONTROL LE¥ER

i JSTMENT (See Fig. 25)

The motion control lever has been preset at the factory and

adjustment should not be necessary.

• Loosen adjustment bolt in front of the right rear wheel,

and lightly tighten.

® Start engine and move motion control lever until tractor

does not move forward or backward.

* Hoid motion control lever in that position and turn

engine off.

•» While holding motion control lever in place, loosen the

adjustment bolt.

Move motion control lever to the neutral (N) (lock gate)

position.

NOTE; If

ment bolt,

liter above adjustment is made,

U. C i _ _C i * - i V . t r -' l i r

osition, follow these steps:

Loosen the adjustment boil.

Mr ve . - r,i . '' , , - j ,

(j! <r r I t O/ re ^ ' "rc-

' I.,it- I f .r i~ '( '

V O h

i l i ’' a ct O ’' ‘ “ f ec t , C' 3

:VEF

1»

id to get to adj usi

le lowest position.

b . ..imr , seo«

1/2 inc

/5 Ul !ilf bet

I „for

dA i r

TO REMOVE WHEEL FOR REPAIRS

(See Fig. 2S)

» Block up axle securely.

* Remove axle cover, retaining ring and washers to allow

wheel removal (rear wheel contains a square key - Do

not lose).

« Repair tire and reassemble,

® On rear wheels only: align grooves in rear wheel hub

and axie. Insert square key.

s Repiace washers and snap retaining ring securely in

axle groove.

* Replace axle cover.

NOTE: To seal tire punctures and prevent flat tires due to

.slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry roi and

corrosion.

WASHERS

RETAINING

aiNG

AXLE COVER

TO HTTP

5^*^ "j -

SQUARE KEY

(REAR WHEEL ONLY)

IF

'm

■■■■ ..V ./ 5

¿Cu r:vc.-*T

BOLT

T. — T :

Ljhouid your [isnsmission r©c|U{r8 rGmovsf for sorvic© or

Sc't -n I r h„ • j«: -'m re i"'wt!Piini> ^r-r

opem if j I See ‘'-jRDc:TRA''jSMIL-

LCN'-n ih£on -«„tor.., n,= ncfuai.

TO ADJUST STEERING WHEEL ALIGNMENT

if steering wheel crossbars are not horizontal (left to right)

when wheels are positioned straightforward, remove steer

ing wheel and reassemble per instructions in the Assembly

section of this manual.

iONT WHEEL TOE-IN/CAMBER

ie front wheel toe-in and camber are not adjustable on

,our tractor, if damage has occurred to affect the front

.aeei toe-in or camber, contact your nearest authorized

ervics center/departmeni.

&

^ „ J U' „

' Æ

If i ■ I - .

recharged. (See “BATTERY" inthe CUSTOMER RESPON-

'-'iE* _i~ - -jt - -

f ‘ ' l~C" r" - ,

T.is ¡.mc“-’jre

MFCR^AYT F

'Ol" nEGm I • c qPC'! 'DC ~ z' ^ - r „ Li

VE-'iCl.E A,_3G B£ ¡ED‘~~

CROUNDEC SrO”5Y l ... v: , 13- ^V.FTRqCOF

EATTEF ' T3 3 . AR~" C S~T^_E£.

TO ATTACH JUMPER CABLES » Connect each end of the RED cable to the POSITIVE

(+) terminal of each battery, taking care not to short

against chassis.

® Connect one end of the BLACK cable to the NEGA

TIVE (-) terminal of fully charged battery.

• Connect the other end of the BLACK cable to good

CHASSIS GROUND, away from fuel tank and battery.

TO REMOVE CABLES, REVERSE ORDER ® BLACK cable first from chassis and then from the fully

charged battery.

• RED cable last from both batteries.

23

Page 24

• ^ Ail:* A'jjU*:ÌA<£iirA

POSITIVE TEHII!NA.L MEGATiVE TERMINAL

z

_

—

Cl-

POSITIVE TERMINAL

FIG. 27

zo ana £x

- ,‘T''osOer* xeiTi.

,rr ~ : 'C

'smove !

I eo: . O' ài': TiF.t.

T to .e-T’iosIs ai «1«

i .. iO OCÌÌi“'^

'acelets, wristwatch

><AL

KEPS

foSrTUL;

C/ Ff ?

___

,

FIG. 29

NEGATIVE

(BLACK) CABl

TO REPLACE HEADLIGH

® Raise hood.

® Pull bulb holder out of the hole in the backside of the

grill.

® Replace bulb in holder and push bulb holder securely

back into the hole in the backside of the grill.

® Close hood.

G -'EiAf3

:

Loose or

DOC if, - op running,

ffl Chec

H©pi3C© with tJU 3.r

fuse holder is iocati

A F

ir Parts sec;tion of this man

Reoa

or prevent it fro

See electrical m

til

!'* h r <- in use. The

i"d c''".

to run

UTÌ in the

securely.

Close baker m

must b© connected

fi baite

aDie to oosiih/e (+) terminal

3 shown= Tighten securely.

iSuOr/icr' - A-mr»

TO REMOVEH

^f%\

Jnsnap neadiight wii

: . i • .0 , r ..

inqine and lift off of i

ID Mil

ionnector.

Ur1lL.l

oodr!. s fic? iT oward

lEMBLY

FIG. 28

24

Page 25

I HUji,

ie Fig.

^ infOtiiS

C - f

I'i' I" 'n:^s. : .(III," »u

from slow to choke oosit

choke to fast position.

■ ' in-. ' i—' ■-

. r.if c . 7

!u

I'- i' -) iiu

/vernor control ieve

je

L I

■ c'-ii I

ro ADJUST CARBURETOR

"he carburetor has been preset at the factory and adjustneni should not be necessary. Hov/sver, minor adiusinent may be required to compensate for differences in fuel,

emperature, altitude or load. If the carburetor does need

idiustmeni, see engine manual.

iigh speed stop is factor/ adjusted. Do not adjust iamage may result.

MPORTANT: NEVER TAMPER WITH THE ENGINE

GOVERNOR, WHICH IS FACTORY SET FOR PROPER

iNGINE SPEED. OVERSPEEDING THE ENGINE ABOVE

"HE FACTORY HIGH SPEED SETTING CAN BE

)ANGEROUS. IF YOU THINK THE ENGINE-GOVERNED

IIGH SPEED NEEDS ADJUSTING, CONTACT

I BAREST AUTHORIZED SERVICE CENTER/

»EPARTMENT, WHICH HAS PROPER EQUIPMENT AND

iXPERIENCE TO MAKE AMY NECESSARY

.DJUSTMENTS.

YOUR

25

Page 26

ST

for store

)r will

CAIJ I ION' N©¥Sr StOf© til© trBCtor Witll

ef = ^ " = - " - • ' _ 3 ' C if.

*

e !- jr «!,"/> ar«gfne >

RA

Wr

I — fc-

rUCL

IMPOR

OSITS FROM FORMING IN ESSENTIAL FUEL

EF.iE np iur -A. A_S CL E' FNCEl

II

iT: IT IS IMPORTANT TO PREVENT GUM

or*^tank during* storage, also’

“p "'OnC „ n jz I,-- £T"'i -

3R

r o r

i‘C

mowsr ii

oughi'/, !

dean, dr

jibiir

h-

" 0 _ 0 *0i O'"inage, bro eOe -

and wear. Replace if necessary.

* Toijch jp di .'US's or cPippeo pairu _uiiac'o& oi.d

ligntiy before painiing.

red for a period of time, dean it thor-

■ nis

' - . d - wusiomer Rpsoonsibilmef

r' •( S\ ! r '1 'T . Oi .W A i«Hi

' ^ . e- I 0

I > C.L !'' ’■¡nir'f-,Ci,SiO'''ie.

r Cf ■ I , ’,, n.

- ' uo, 'r cry (L-_ belt ro

id L 'H . r G I .dmentp

, 0 cr -wc are so i r ■/

BATTERY

® Fully charge the battery for storage.

® After a period of time in storage, battery may require

^ recharging.

o To help prevent corrosion and power leakage during

long periods of storage, battery cables should be

disconnected and battery cleaned thoroughly (see “TO

CLEAN BATTERY AND TERyiMALS” in the Cus

tomer Responsibilities section of this manual).

* After cleaning, leave cables disconnected and place

cables where they cannot come in contact with batten/

terminals.

® If battery is removed from tractor for storage, dc not

store battery directly on concrete or damp surfaces.

ORAGE.

STEM O

,C 1 r,- Z, • ir -r

carburetor are empty.

' mat- G t -= , iu c ithe

fuel tank or permanent dama^

® Use fresh fuel next season.

n ‘T T/^ "LI G' " . -vs'e ,1'em'rij- ,i

- ‘ , ',1 -10 ‘ e 'GiraTr' us cgi~~ denes cumg s'O'"

,ae atd -i-r I It: lO e !'■ t< <~s ,of‘ zv^rac-

rntr-in-i - <V3 /' "''ilcv' I - ,r . a.i o c s ^ afciiize''

'irs i-icr?- '-m m,r. C- arm- ancirg

,-^3 u aife:;(3c u ¡G " he .libLiotCi e-r

i _.r , Tmgi.: snJ c curb's'i Oirc . ..c'sfaoi.Cf r.

El^CT't c[i

Drain oil (with engine warm) and replace with clean engine

oil. (See “ENGINE” in the Customer Responsibilities

section of this manual).

Ä I n I

4M fmG

mv I . ’

i i

ii

^R!NG

FUEL

and

CYLINDER(S)

® Remove spark plug(s).

® Pour one ounce of oil through spark plug hoie(s) into

cy'linder(s).

® Turn ignition key to “START” position for a few seconds

to distribute oil.

® Replace with new spark plug(s).

OTHER

• Do not store gasoline from one season to another.

® Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

• If possible, store your tractor indoors and cover it to

give protection from dust and dirt.

• Cover your tractor with a suitable protective cover that

does not retain moisture. Do not use plastic. Plastic

cannot breathe which allows condensation to form and

will cause your tractor to rust.

IMPORTANT: NEVER COVER TRACTOR WHILE ENGINE

AND EXHAUST AREAS ARE STILL WARM.

26

Page 27

aOBLEM CAUSE

CORRECTION

ill not start

ird îo start

gine will not turn over

Chut of fuel.

Engine not “CHOKED” properly.

2.

Engine flooded.

3.

4. Bad spark plug.

Dirty air filter.

5.

Dirty fuel filter.

6,

7. Water in fuel.

Loose or damaged wiring.

8.

9. Carburetor out of adjustrniint.

Engine vaives out of adjustment.

10.

1. Dirty air filter.

2. Bad spark plug.

.3. Weak or dead battery.

4. Dirty fuel filter.

5. Stale or dirty fuel.

6. Loo.se or damaged wiring.

7. Carburetor out of adjustment.

8. Engine valves out of adjustment.

Clutch/brake pedal not depressed.

Attachment dutch Is engaged.

Weak or dead battery.

Blown fuse.

Corroded battery terminals.

Loose or damaged wiring.

Faulty ignition switc,h.

Faulty solenoid or starter.

Faulty operator presence switch(es).

1. Fill fuel tank.

See “TO START ENGINE” in Operation section.

2.

3. Wait several minutes before attempting to start.

4.

Replace spark plug.

5, Clean/repiace air filter.

6, Replace fuel filter.

7.

Drain fuel tank and carburetor, refill tank with fresh

gasoline and replace fuel filter.

8, Check all wiring.

9. See “To Adjust Carburetor” in Service Adjustments

section.

I

10. Contact an authorized service center/department.

Ciean/replace air filter.

Replace spark plug.

Recharge or replace battery.

Replace fuel filter.

Drain fuel tank and refill with fre,sii gasoline,

Check all wiring.

See "To Adjust CarburetoC in Service Adjustments

section.

Contact an authorized service center/department.

1. Depress clutch/brake pedal.

2. Disengage attachment dutch.

3. Recharge or replace battery.

4. Replace fuse,

5. Clean battery terminals.

6. Check all wiring.

7. Check/replace ignition switch,

8. Check/reptace solenoid or starter.

9. Contact an authorized service cenier/department.

gine eiicks but wiii not

rt

9S of power

«ssive vibration

1. Weak or dead battery.

2. Corroded battery terminais.

3. Loose or damaged wiring.

4. Faulty solenoid or starter.

1. Cutting too much grass/too fast.

2. Throttle in "CHOKE” position.

3. Buiid-up of grass, leaves and trash under mower,

4. Dirty air filter,

5. Low oil levef/dirty oil.

6. Faulty spark plug.

7. Dirty fuel filter.

8. Stale or dirty fuel.

9. Water in fuel.

10. Spark plug wire loose.

11. Dirty engine air screen/fins.

12. Dirty/ciogged muffler.

13. Loose or damaged wiring.

14. Carburetor out of adjustment.

15. Engine valves out of adjustment.

1. Worn, bent or loose blade.

2. Bent blade mandrel.

3. Loose/damaged partfs).

Recharge or replace battery.

Clean battery terminals.

Check all wiring.

Checfc'repiace solenoid or starter.

Set in “Higher Cuf position/reduce speed,

.Adju-st throttle control.

Clean underside of mower housing.

Clean/repiace air filter.

Check oil ievei/change oil.

Clean and regap or change spark plug.

Replace fuel filter.

Drain fuel tank and refill with fresh gasoline.

Drain fuel tank and carburetor, refill tank with fresh

gasoline and replace fuel filter.

Connect and tighten spark plug wire.

Clean engine air screen/fins.

Clean/repiace muffler.

Check all wiring.

See “To Adjust Carburetor’ in Service Adjustments

section.

15.

Contact an authorized service cenier/department.

1. Replace blade. Tighten blade bolt,

2. Replace blade mandrel.

3. Tighten loose partis). Replace damaged parts.

27

Page 28

PROBLEM

CAUSE

CORRECTION

Engine continues to run

when operator leaves seat

with attachment clutch

engaged

Poor cut - uneven

Mower blades will not

rotate

Poor grass discharge

1. Faulty operator-safety presence control system.

1. Worn, bent or loose blade.

2. yower deck not level.

3. Buildup of grass, leaves, and trash under mower.

4. Bent blade mandrel.

5. Clogged mower deck vent holes from buildup of

I grass, leaves, and trash around mandrels.

1. Obstpjction in clutch mechanism.

I 2. Worn/damaged mower drive belt.

3. Frozen idler pulley.

4. Frozen blade mandrel.

1. Engine speed too slow.

2. Travel speed too fast.

3. Wet grass.

4. Mower deck not level.

5. Low/uneven tire air pressure.

6. Worn, bent or loose blade.

7. Buildup of grass, leaves and trash under mower.

8. Mower drive belt worn.

9. Blades improperly installed.

10. Improper blades used.

11. Clogged mower deck vent holes from buildup of

grass, leaves, and trash around mandrels.

1. Check wiring, switches and connections. If not

corrected, contact an authorized .service center/

department.

1. Replace blade. Tighten blade bolt.

2. Level mower deck.

3. Clean underside of mower housing.

4. Replace blade mandrel.

5. Glean around mandrels to open vent holes.

1. Remove obstruction.

2. Replace mower drive belt.

• 3. Replace idler pulley.

; 4. Replace blade mandrel.

1. Place throttle control in “FAST” position.

2. Shift to slower speed.

3. Allow grass to dry before mowing.

4. Level mower deck.

5. Check tires for proper air pressure.

6. Replace/sharpen blade. Tighten blade bolt.

7. Ciean underside of mower housing.

8. Replace mower drive belt.

9. Reinstall blades sharp edge down.

TO. Replace with blades listed in this manual.

11. Clean around mandrels to open vent holes.

Headiight(s) not working :

(if so equipped) 1

Batten/ will not charge

Loss of drive

Engine “backfires”

when turning engine

“OFF”

1. Switch is “OFF”.

2. Bu(b(s) burned out.

3. Faulty light switch.

4. Loose or damaged vriring.

5. Blown fuse.

1. Bad battery cell(s).

2. Poor cable connections.

3. Faulty regulator {if so equipped).

1

4. Faulty aiternator.

1. Freewheel control in “disengaged” position.

2. Motion drive belt worn, damaged, or broken.

3. Air trapped in transmission during shipment

or servicing.

1. Engine throttle control not set at “SLOW"

position for 30 seconds before stopping engine.

1. Turn switch "ON”,

2. Replace buib(s).

3. Check/replace light switch.

4. Check wiring and connections.

5. Replace fuse.

1. Replace batteiy.

2. Check/clean all connections.

3. Replace regulator.

4. Replace alternator.

1. Place freewheel control in “engaged” position.

2. Replace motion drive belt.

3. Purge transmission.

1. Move throttle control to “SLOW” position and allow

to idle for 30 seconds before stopping engine.

28

Page 29

SCHEMATIC

TRACTOR - - MODEL NUMBER PPR17H42STA

IGNITION SWITCH

POSITION

OFF

RUN/LIGHT

RUN . B + L

START

CIRCUIT

G + M + L

3 + L + S

B + L

“MAKE”

NONE

A +Y

NONE

NONE

NOTE

YOUR TRACTOR

EQUIPPED WITH A SPECIAL

ALTERNATOR SYSTEy.

THE LIGHTS ARE NOT

CONNECTED TO THE

BATTERY, BUT HAVE THEIR

OWN ELECTRICAL SOURCE.

BECAUSE OF THIS, THE

BRIGHTNESS OF THE LIGHTS

WILL CHANGE WITH ENGINE

SPEED. AT IDLE THE LIGHTS

WILL DIM. AS THE ENGINE IS

SPEEDED UP, THE LIGHTS

WILL BECOME THEIR BRIGHTEST.

NON-REMOVABLE

CONNECTIONS

WIRING INSULATED CLIPS

NOTE: IF WIRING INSULATED CLIPS WERE REMOVED FOR

SERVICING OF UNIT, THEY SHOULD BE REPLACED TO

PROPERLY SECURE YOUR WIRING.

29

REMOVABLE

CONNECTIONS

Page 30

REPAIR PART

ELECTRICAL

MODEL NUl . , -hL TA

Page 31

REPAIR PARTS

f MOD* s F’’

•LECTRiCAL

KEY PART

NO.

NO.

1

144925 Battery 12 Volt 25 Amp

74-760^-12 Bolt Hex Hd 1/4-20unc X 3/4

1564', 7

3

153664 Switch Interlock Push-In

16

19 1GC90400

20 7-3350400

166181

21

DESCRIPTION

Case Battery Mech Hinge

Washer Lock 1/4

Nut Jam Hex 1 /4-20 Line

Harness Socket Light

22 4152J Bulb, Light# 1156-

24

4799J

146147

25

166160 Fuse 15 Amp

26

27

73510400

4207J Cable Ground 6ga 12 black

28

29 121305X Switch Plunger Nc Gray

140301 Switch Ign 4 Pos W/L P/L

30

12421IX Nut Ignition

31

32 141226

33 122147X Key Ign Molded Generic

40 166145 Harness Ign

41

71110408 Bolt Fin Hex 1/4-20uncx 1/2

42 131563

43 145673

44

73640400

45 121433X Ammeter Rectangular

52 141940 Protection Loop

70 166659

Cable Battery

Cable Battery 6 Ga Red w/16 wire

Nut Keps Hex 1/4-20 Line

Cover Sw Key

Cover Terminal Red

Solenoid

Nut Keps BIk 1/4-20 Unc

Harness Engine

NOTE; All component dimensions given in U.S. inches

1 inch =: 25.4 mm

31

Page 32

ì',‘ “ L , !' Ш 3 - ^21: ■ ,

CHASSIS ÄND ENCLOSURES

32

Page 33

1EPAIR PARTS

TRACTOR - - MOOTL l'IUMBER PPR17H42CTÄ

«ASSIS ÄND ENCLOSURES

KEY PART

NO. NO.

DESCRiPTiON

1 166819

2 140356 Drawbar, Stretch

3 17490612 Screw Thdrol 3/8-16x3/4 Ty-tt

4 19131216 Washer 13/32 x 3/4 x 16 Ga.

5 155272

9 161917X012 Dash P/L

10 72140608 Bolt Carriage 3/8-16 x 1

11 155927 Panel Dash Lh

12 145660 Clip Tinnerman

155936

13

14 17490608 Screw I hdrol 3/8-16x1/2 Ty-tt

17 159639X428 Hood LT/PL

126938X Bumper Hood

18

156437

20

124028X

23

24

74780616 Bolt Fin Hex 3/8-16 x 1 Gr 5

25 19131312 Washer 13/32 X 13/16 X 12 Ga

26 73800600 Nut Lock Hex W/lns 3/8-16 Unc

28 157428 Grille LT/PL

29

146654X599 Lens LT/PL

30 168749X428

31

139976

33 145244X428 Footrest Pnt Lh

34 145243X428 Footrest Pnt Rh

35 72110606

37 17490508 Screw Thdrol 6/16-18 x 1/2 TYT

38 139886 Bracket, Asm. Pivot, L.H., Mower Rear

39 139887

51 73800400 Nut Lock Hex W/lns 1 /4-20

52 19091416 Washer 9/32 x 7/8 x 16 Ga.

144697

53

161464

54

144696

55

57 74780412 Bolt Hex 1/4-20 x 3/4

150127

58

64 154798

158418

140

165867

142

156524

145

5479J Plug Btn BIk

Chassis

Bumper Hood/Dash

Panel Dash Rh

Plate Mtg Battery Fuel Tank Fr

Bushing

Fender Footrest STLT Pnt

Bracket Support Fender

Bolt Rdhd Sht Sqnk 3/8-16 x 3/4

Bracket, Asm. Pivot, R.H., Mower Rear

Bracjet Grukke Lh

Screw Hex Wshd 8-18 x 7/8

Bracket Grille Rh

Duct Air

Dash Lower STLT

Bracket Suspension Front

Plate Reinforcement STLT

Rod Pivot Chassis/Hood

NOTE: All component dimensions given in U.S. inches

1 inch = 25.4 mm

Page 34

DRIVE

:ML ' i

147'

34

Page 35

lEPAIR PARTS

}RIVE

■ r:: r ' .i42STA

E¥ PART

O. NO.

1

DESCRIPTION

Transaxle Hydro Gear 319-0650

Order Parts From Transaxle

Manufacturer

2 142431 Spring, Return, Brake

3 143995

3 165619

76020416 Pin Cotter 1/8 X 1 CAD

0

4

10040400 Washer Lock Hvy Helical

73800500

3

Pulley. Transaxle

Rod Shift Hydro LT

Nut Lock Hex W/lns 5/16-18 Unc P

3 74780616 Bolt Fin Hex 3/8-16 Unc x 1 Gr. 5

3

73800600 Nut Lock Hex W/V/sh 3/8-16 Unc

1

140845

?

145627 Rod, Brake Hydro

4

73350600 Nut

106888X

3

19131316

7

76020412 Pin Cotter 1/8 X .3/4 CAD.

i

145204 Rod, Parking Brake

?

71673 Cap. Parking Brake

)

130807 Bracket, Transaxle

:>

74760512

1

155071

>

120183X Bearing, Nylon

)

19211616 Washer

1572H

i

131494 Pulley, Idler. Fiat

j

74760644 Bolt

)

4470J Spacer, Split

Knob, Round 1/2-13

Spring, Brake Rod

Washer

Bolt Hex Hd 5/16-18 Unc x 3/4

Shaft, Foot Pedal

Pin, Roll

165838 Keeper. Belt Idler

19131312 'Washer 13/32 x 13/16 x 12 Gauoe

127783 Pulley, Idler, V-G.roove

154407 Bellcrank Clutch Grnd Drv STL 151

i

123205X Retainer, Belt

i

74760624

73680600

73680500

10571 OX

105709X

74760620

140294

140312

17490612

8883R

140186

71170764

10040700

Bolt

Nut Crownlock 3/8-16 UNC

Nut Crownlock 5/16-18 UMC

Link, Clutch

Spring, Return, Clutch

Bolt Fin Hex 3/8-16 UNC x 1-1/4

V'-Beit, Ground Drive

Keeper, Center Span

Screw Thdrol. 3/8-16 x 3/4 Ty. TT

Cover, Pedal

Pulley, Engine

Bolt, Hex

Washer

154778

66

69

142432

70

134683

140158

71

72 19132012

156347

73

74 121199X

121749X

75

76 12000001

77 123583X

78 121748X

165591

81

123782X

82

83 19171216

84 165815

89 164893X428

142564

93

94 140462

95 144643

4497H

96

97 140469

98 73510600

102 141322

103 73940800

104

140156

105 71070516

72110610

116

145 74490540

146 74490536

147 74490524

165850

150

19133210

156 166002

157 153236

158 165589

165494

159

160 19292016

72140406

161

162 73680400

163 74780416

164

19091010

165 165623

166 166880

168 165492

169 165580

NOTE: All compon

1 inch = 25

DESCRiPTION

Keeper Belt Engine

Screw

Guide Belt

Strap Torque Lh Hydro

V\/asher 13/32 x 1-1/4 x 12 Gauge

Strap Torque Rh Hydro

Spacer, Split

Washer 25/32 x 1-1/4 x 16 Gauge

t-Ring

Key, Square

Washer 25/32 x 1 -5/8 x 16 Gauge

Shaft Asm. Cross Hydro

Spring Torsion T/A

Washer 17/32 x 3/4 x 16 Ga.

Link T ransaxle

Console, Hydro

Line Fuel Hydro 4"

Fan, Hydro 1"

Control Asm Bypass Hydro

Retainer Spring 1 “ Zinc/Cad

Keeper Belt Rh Hydro 0750. 18/20“

Nut Keps Hex 3/8-16 Unc

Washer Beliviile .501D x 1.50D

Nut, Hex, Jam Toplock 1/2-20 UNF

Arm, Control Hydro

Screw Cap Hex 5/16x18x1

Bolt Rdhd Sq Neck 3/8-16 x 1.25

Bolt. Hex FLGHD 5/16-18 Gr. 5

Botl Hex FIghd 5/16-18 x 2-1/4

Bolt Hex Fighd 5/16-18 x 1-1/2

Bushing Bellcrank Grd Drive

Washer 13/32 x 2 x 10 Ga.

Washer Srrted 5/16 ID x 1,125

Bolt Shoulder 5/16-18 Unc - 2A

Bracket Shift Mount

Hub Tapered Flange Shift Lt

Washer 29/32 x 1-1/4 x 16 Ga

Bolt Rdhd Sqnk 1/4-20 x 3/4 Gr 5

Nut Crown lock 1/4-20 Unc

Bolt Hex Fin 1/4-20 Unc x 1 Gr 5

Washer 5/8 x .281 x 10 Ga

Bracket Pivot Lever

Screw 5/16-18 X 5/8

Bolt Shoulder 5/16-18 x.561

Plate Fastening Lt

oc

Page 36

STEERING ASSEMBLY

37-

]■ pf .p)« I i. ,|i|.t

38

“S3

-11

-39

-i

-42

37

36

Page 37

iTEERING ASSEMBLY

KEY PART

NO. NO.

DESCRIPTION

1

2

3

4

121472X

154427

156483

157473

Wheel Steering

Axle Asm Stmp Dropped STLT

Spindle Asm LH

Spindle Asm RH

5 6266H Bearing Race Thrust Harden

6 121748X

7

19272016

8

12000029

9 3366R Bearing Col Strg BIk

10

156438

Washer 25/32 X 1-5/8 X 16 Ga

Washer 27/32 X 1-1/4 X 16 Ga

Ring Klip #15304-75

Link Drag Extended Stamped

11 10040600 Washer Lock Hvy Hid Spf 3/8

13

154779

15 73901000

17

156546

18

57079

19

160395

22

165857

23 165851

25 154406

26 126847X

27

136874

28

19131416

29

17490612

30

76020412 Pin Cotter 1/8 x 3/4 Cad.

32

130465 Rod 1 ie

36

155099 Bushing Strg

Bearing Axle STLT/GT

Nut Lock Flange 5/8-11 Unc

Shaft Asm Strg

Washer Thrust 515x 750x 033

Support Shaft

Screw Hex Wsh Hd Torx

Shaft Asm Pittman

Bracket Steering

Bushing Link Drag

Gear Sector

Washer 13/32 x7/8x 16 Ga.

Screw Thdrol 3/8-16x3/4 Ty-tt

37 152927 Screw

38

126805X insert Cap Strg Wh Au

39

19133808

40

7810H Lock nut

41

100711L

42 145054

43

121749X Washer 25/32 X 1 1/4 X 16 Ga

44

153720 Extension Steering Shaft LR/LT

Washer 13/32 X 2-3/8 X 8 Ga

Adaptor Wheel Strg

Boot Steerina Dash

46 121232X Cap Spindle Fr Top BIk

47 6855M

51

73800500 Nut Lock Hex w/lns 5/16-18

54

74780520 Bolt Fin Hex 5/16-18 Unc x 1-1/4

62 167902

63

74780616

Fitting Grease

Kit, Steering Assembly Svc

Bolt Fin Hex 3/8-16unc x 1 Gr. 5

65 154780 Spacer Axle

66

154404 Bearing Arm Pittman

67

74781044 Bolt, Fin Hex 5/8-11 UNC x 2-3/4

68 154429 Axle, Brace

79

19132012 Washer 13/32 x 1-1/4 x 12 Ga.

80

74950612

Bolt Hex Nylon 3/8-16 x 3/4

NOTE: All component dimensions given in U.S. inches

1 inch = 25.4 mm

37

Page 38

SEAT ASSEMBLY

liv, ■ V - - nor L . t ■: -rTl'i. 7; 4: ? 1 ‘

KEY PART

NO.

1011155925

NO.

1

140117 Seat

2 140551

3

74760616

4

19131610 Washer 13/32 X 1 X 10 Ga

5

145006

6 73800600

7

124181

8

17490616

9

19131614

166369

DESCRIPTION

Bracket Pivot Seat 8 720

Bolt Fin Hex 3/8-16unc X 1 14

Clip Push-in

Nut Hex w/lns. 3/8-16 Unc

Spring Seat Cprsn 2 250 BIk Zi

Screw Thdrol 3/8-16 X 1 Ty-ti

Washer 13/32 X 1 X 14Ga.

Pan Seat

Knob Seat

KEY PART

NO.

12

13 121248X Bushing Snap Blk Ny! 50 Id

15

16

17

21

22

24

25

NOTE: All component dimensions given in U.S. inches

NO. DESCRIPTION

121246X. Bracket Mounting Switch

72050412

134300 Spacer Split 28x 88

121250X Spring Cprsn

123976X Nut Lock 1/4 Lge Fig Gr 5 Zinc

153236

73800500

19171912 Washer 17/32 X 1-3/16 X 12 Ga.

127018X

1 inch = 25.4 mm

Bolt Rdhd Sqnk 1/4-20x1-1/2

Bolt Shoulder 5/16-18 Unc

Nut Hex LockW/ins 5/16-18

Bolt Shoulder 5/16-18X62

38

Page 39

ECALS

I TOR - - MODEL NUMBER PPR17H42ST ^

PART

NO. DESCRIPTION

156993 Decal Oper

168651 Decal Fender Auto

168705 Decal Hood LH

165402

142341 Decal Drawbar Cntrl MVT Hyd LT

137259 Decal Warning Mult-Language

168649 Decal Fender Logo

157140 Decal Fender Danger E/F

168639

168703

Decal HP Engine

Decal Ins Strg Wh!

Decal Grille

1EELS AND TIRES

KEY

NO.

14

15

16

17

20

KEY PART

NO. NO.

10 7152J

11 104757X

.. 144334

PART

NO.

160396

168650 Decal Fender Auto Rh

168704 Decal Hood Rh

101892X

145005

133671 Pad Footrest

138311 Decal Handle Lft Height Adjust

168737 Manual Owner's (English)

- ,

168738

1 59192

2 65139

3 106222X

4 59904

5 106732X427

6 278H

7 9040H

8 106108X427

9 122082X

DESCRIPTION

Decal V-Belt Schematic’

Decal Clutch/Brake

Decal Bat Dan/Psn

Manual Owner’s (French)

DESCRIPTION

Cap Valve Tire

Stem Valve

Tire F Ts 15 X 6 0 " 6 Service

Tube Front (Service Item Only)

Rim Asm 6"front Silver Service

Fitting Grease (Front Wheel Only)

Bearing Flange (Front Wheel Only)

Rim Asm 8"rear Silver Service

Tire R Ts 20x10-8 C Service

Tube Rear (Service Item Only)