Page 1

£)£) " - ^

r

y I'

OW! i-t

MODE^í'í■■ Hik>y]Fh:42„.

145 Hr y" if.^M I'

Lawn4r:v'

..............................

Assembly

• Operation

• Cystomer Responsibilities

For Parts and Service, contact our authorized distributor: call 1-800-849-1297

1 1

tf'

r

* Serwice and Adjysiinents

• jrage

• lubiesiiooting

• Repair Parts

For Technical Assistance: call 1 -800-829-5886

1fS5370 Rev. 1 7.24.98 RH/JH

PRINTED IN U.S.A.

Page 2

ULUi

UB

UTTING

THE

i A I iOri

and follow all instryc

in the manual

i before starting,

ll'y

instructions, to operate the machine.

• Clear the area of objects such as rocks, toys, wire, etc.,

, t i •'* ,ji. to

• Be sure the area is clear of other people before mowing. Stop

rrischine if anyone enters th© area.

• Never carry passengers.

• Do not mow in reverse unless absolutely necessary. Always

I f L J, \’,ii I u h'.id I • f.M wtiile t .1 k I. I

' w ,• 1 i »> > m i«,'M ig» d!ii-'lk • il Honoto'''nt

i1 , l.gCii. i ■'!« t .'p' loh ilV tUO*-i Ai,rhi)l>i ©!iht I ho

■i.i , . 1 ■ il f 'li >t>t iji. ad in i !oi.t

• Stow down before turning.

i. irl,) ryipiiMi] t!i ti’i iifiatttiidtd 4lwaws t ,in c'ff

i I i(,e m jilinghr to "1.<p enginp ji.U ¡©mov. t'^-ys

’ ti i , 1- <riiir.u

Tim .c*if>luj>s vtspn not mrv/ing.

wt.p Dr tor'- r^rr iT.g yias*- '■ t -¡ti or unci .gging

uhuie.

• Mo»' only in daylight or good artificial light.

® Dc not opt-rate »he niachido while under the influence of

alci.T'ol or 'Jrugc

® Wsf' h for traffic v^hen pp»r»i!og near or crossing roadways.

® Us V txt-'a care when loading or unloading the machine into

a trailer or truck.

sible adults, who are familiar with the

1 1

,| .1, < uirt v • n,, fi>, ulfcide.

il. SLOPE OPERATION

Slopes are a major factor related to ¡oss-of-controi and

iipover accidents, which can result in severe injury or death.

Ail slopes require extra caution, if you cannot back up the

slope or if you fee! uneasy on it, do not mow it.

DO:

Mow up and down slopes, not across.

Remove obstacles such as rocks, tree limbs, etc.

Watch for holes, ruts, or bumps. Uneven terrain could

overturn the machine. Tall grass can hide obstacles.

Use .‘lowspeed ChoosoalowgearsothaS w-uwillnothave

to c-t'ip or shift wl'ii© on ihe slope

ri II.-.« the mshulaiiiirerto lecciiTinithd‘¡ions for wheel

Vi.iijfit.

» 1

couniu. weighls to iriipro'/e '■icJtilit/.

Use t 4ra cart' vnth gra;' crttln-i r or other attachments.

Tf-es ' ar< char.ito the st >1:11!'.' o-i fh- tiw'hiti'/.

K(,e|' li movemoiii on tht sit-f :icvy oikl y idual. Do not

to- "-uddoti cnunges in speei -ji difeotion

Avoid starting or stopping on a slope. If tires lose traction,

disengage the blades and proceed slowly straight down the

slope.

DO NOT;

• Do not turn on slopes unless necessary, and then, turn slowly

and gradually downhill, if possible.

® Do not mow near drop-offs, ditches, or embankments. The

mower could suddenly turn over if a wheel is over the edge

of a cliff or ditch, or if an edge caves in.

® Do not mow on wet grass. Reduced traction could cause

sliding.

• Do not try to stabilize the ma i.ice by putting your foot on the

ground.

• Do not use grass catcher on steep slopes.

J IN SERK

INJU

BJECTS.

DEATH.

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the

machine and the mowing activity. Never assume that

children will remain where you last saw them.

•• 1 .-Dill tehoLl hih^ ,1! VHii. i(t 'indlitu.f rtiie WdirnilJcare of another responsible adult.

r. !• and tom tiiito.ii't w «t chi! in n i,v r the aiea.

B'f'i‘ ,nd //I i€ 11 b -f t ii 1(1 look behind an ! down foi small

u i! ■•« II

® Nc-ver .'vri-/ ■-'hildreri. They may fall ait and be seriously

injurcfi

0 1

interfere witti eafe machine operation.

® Never children to operate the machine.

• Use extra tHfe when approaching blind corners, shrubs,

tree-s or other obieots that may obccuro vision.

I¥. SERVICE

• Use extra care in handling gasoline and otherfuels. They are

flammabife and vapors are explosive.

Use only an approved container.

Never rcimove gas cap or add fuel with the engine

running. Allow engine to cool before refueling. Do not

smoke.

Never refuel the machine indoors.

Never store the machine or fuel container inside where

there IS an open flame, such as a water heater.

• Never run a machine inside a dosed area,

• Keep nui3 and bolts, especially blade attachment bolts, tight

and keep equipmemit in good condition.

• fJever tamper with safety devices. Check their proper

operation regularly.

• Keep machine free of grass, leaves, or other debris build-up.

Clean oil or fuel spillage. Allow machine to cool before

storing.

• Stop and inspect the equipment if you strike an object.

Repair, if necessary, before restarting.

• Never make adjustments or repairs with the engine running.

• Grass catcher components are subject to wear, damage, and

deterioration, which could expose moving parts or allow

objects to be thrown. Frequently check components and

replace with manufacturer's recommended parts, when nec

essary.

® Mower blades are sharp and can cut. Wrap the blade(s) or

wear gloves, and use extra caution when servicing them.

• Check brake operation frequently. Adjust and service as

required.

Look for this symbo! to point out im

portant safety precautions. It means

A

A

CAUTION!!! BECOME ALERT!!! YOUR

SAFETY IS INVOLVED.

CAUTION: Always disconnect spark plug

wire and place wire where it cannot contact

spark plug in order to prevent accidental

siarting when setting up, transporting,

adjusting or making repairs.

A WARNING A

The engine exhaust from this product con

tains chemicais known to the State of Califor

nia to cause cancer, birth defects, or other

reproductiwe harm.

Page 3

NGRATULATiONî

utiptii

lu ï x u n i i ' i

cai

bHouiQ you sxpeii

rsmsdy, pl63,S6 cc

C8riî0r/ctepartni6îit,

nicîansand theDfo

PI68S0 read and retain this rnanuaL l he insiructions wi!!

m M ‘ o m [rt.'jii/ I ^ ^ ' b ‘ m

Always observe the “SAFETY RULES*'.

ifiy problem you

our rieaies! Bxitt

lis

11.

NUMBER HD145H42J

SERIAL

iJtlMNH ^ ^

DATE OF PURCHASE

iSil P,/I> .(T I ,-»! iL» t-1 t|/J I ‘h'ffU ' '/•',! t t ' ! ' .h

____

______________________

_____

ON A PLATE UNDER THE SEAT. j

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

I E V M- EUH' Ha' I ' M' ■ I 11 ¡h> A '<t I I ( At t

FOR FUHTiF hi FHIf tji i J

I VALVE CLEARANCE: INTAKE: .003" - .005“

I

I

GROUND SPEED (MPH):

TIRE PRESSURE: FRONT; 14PSI

CHARGING SYSTEM:

EXHAUST: .005*'^ .007"

FORWARD: 5.7

REVERSE; 2.7

REAR; 12PSI

3 AMPS BATTERY

5 AMPS HEADLIGHTS

,

CUSTOMER m ii u ii s

• Read and km iik ‘.’.Oj n,;. j

• Followan igforand

using your tractor.

• Follow the instructions under “Customer Responsibili

ties” and “Storage” sections of this owner’s manual.

BATTERY;

BLADE B SQUE:

WARNING: This tractor is equipped with an internal

combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-cov

ered land unless the engine’s crxhaust system is equipped

with a spark arrester meeting applicable local or state laws

(if any), if a spark arrester is used, it .shoufd be maintained

in effective working order by the operator.

A spark arrester for the muffler is available through your

nearest authorized service ceriter/department (See RE

PAIR PARTS section of this manual).

In the state of California the above is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands.

AMP/HR; 25

MIN, CCA; 190

CASE SIZE; U1R

27-35 FT, LBS,

_ _ _

J

Page 4

SAFETY ROLES ......................................................... 2

PRODUCT SPECIFICATIONS .................................... 3

CUSTOMER RESPONSIBILITIES .....................3, 15-19

WARRANTY ................................................................. 4

MAINTENANCE SCHEDULE

.......................................... 15

SERVICE AND ADJUSTMENTS..........................20-25

IE ..............................................

.....................26

TROySLESHOOTING ...................................... 27-28

REPAIR PARTS - TRACTOR.................................30-45

OPERATION ......................................................... 9-14

iERING/SERVICE .............. BACK COVER

LIMITED WARRANTY

I ht M ■ ii.i Hit iv

ifi 4 ■

repair oi

defective

1.

2.

3. Battery Warranty: On products equipped with a Battery, we will replace, without charge to you, any battery which we find

4. The Warranty period tor any products used for rental or commercial purposes is limited to 90 days from the date of

5. This Warranty applies only to products which have been properly assembled, adjusted, operated, and maintained in

6. Exclusions: Excluded from this Warranty are belts, blades, blade adapters, normal wear, normal adjustments, standard

7. In the event you have a claim under this Warranty, you must return the product to an authorized service dealer.

Should you have any unanswered questions concerning this Warranty, please contact:

giving the model number, serial number and date of purchase of your product and the name and address of the authorized

dealer from whom it was purchased.

THIS WARRANTY DOES NOT APPLY TO INCIDENTAL OR CONSEQUENTIAL DAMAGES AND ANY IMPLIED WARRAN

TIES ARE LIMITED TO THE SAME TIME PERIODS STATED HEREIN FOR OUR EXPRESSED WARRANTIES. Some areas

do not allow the limitation of consequential damages or limitations of how long an implied Warranty may last, so the above

limitations or exclusions may not apply to you. This Warranty gives you specific legal rights, and you may have other rights

which vary from locale to locale.

This is a limited Warranty within the meaning of that term as defined in the Magnuson-Moss Act of 1975.

•iii'.'fft'ir 111 if|, F'l r iron’'-..ir* 1

t* |tI .< rfl i>iii i.f5|{ 1, AiJi It rtiiry-if-r ¡.riti' ill I'lKi ip'(j p <f in ft f part srijf pan tthi h i a id in ben.i I .(min'd! I W...I!'IK I lA/1/. I d,‘iy I surj It life i IlffHiii) |iiOii iiorit, niW^rlii i n-

rhi

'ffsi -I't/not apply to th( o.igin' 1 ihi r Trill 4 n'rii nui f h) ( i ira 1'idt'trcii-iiir •'’ll •,<> ll¡■<lnnlIr '.iTtori*

r.t • i>!ji£ J l-‘'hw) or comi'ontiilf p. iiL th‘lenf Pic -.«-iif 4 th pplicafilr tiieHiuton it :r rr jriO i»n ih*'r

{€

Items.

Transportation charges for the movement of any power equipment unit or attachment are the responsibility of the

purchaser. Transportation charges for any parts submitted for replacement under this warranty must be paid by the

purchaser unless such return is requested by American Yard Products.

to be defective in manufacture, during the first ninety (90) days of ownership. After ninety (90) days, we will exchange the

Battery, charging you 1/12 of the price of a new Battery for each full month from the date of the original sale. Battery must

be maintained in accordance with the instructions furnished.

original purchase.

accordance vjith the instructions furnished. This Warranty does not apply to any product which has been subjected to

alteration, misuse, abuse, improper assembly or installation, delivery damage, or to normal wear of the product.

hardware and normal maintenance.

if! U't oiiJu-i .'h-uiT I put ha:^' .hai

American Yard Products In Canada contact:

Service Department American Yard Products

P.O. Box 1687 1580 Trinity Drive, Units 5-8

Orangeburg, SC 29116 USA Mississauga, Ontario

tti M" .(ini' IftHnuf- >l.r< rt !

purchase by the original consu

L5T1L6

frp-f from dOf-'f i‘i

•IM- p-’i« n li t-r if‘ iWiI

Page 5

Seat

Manual

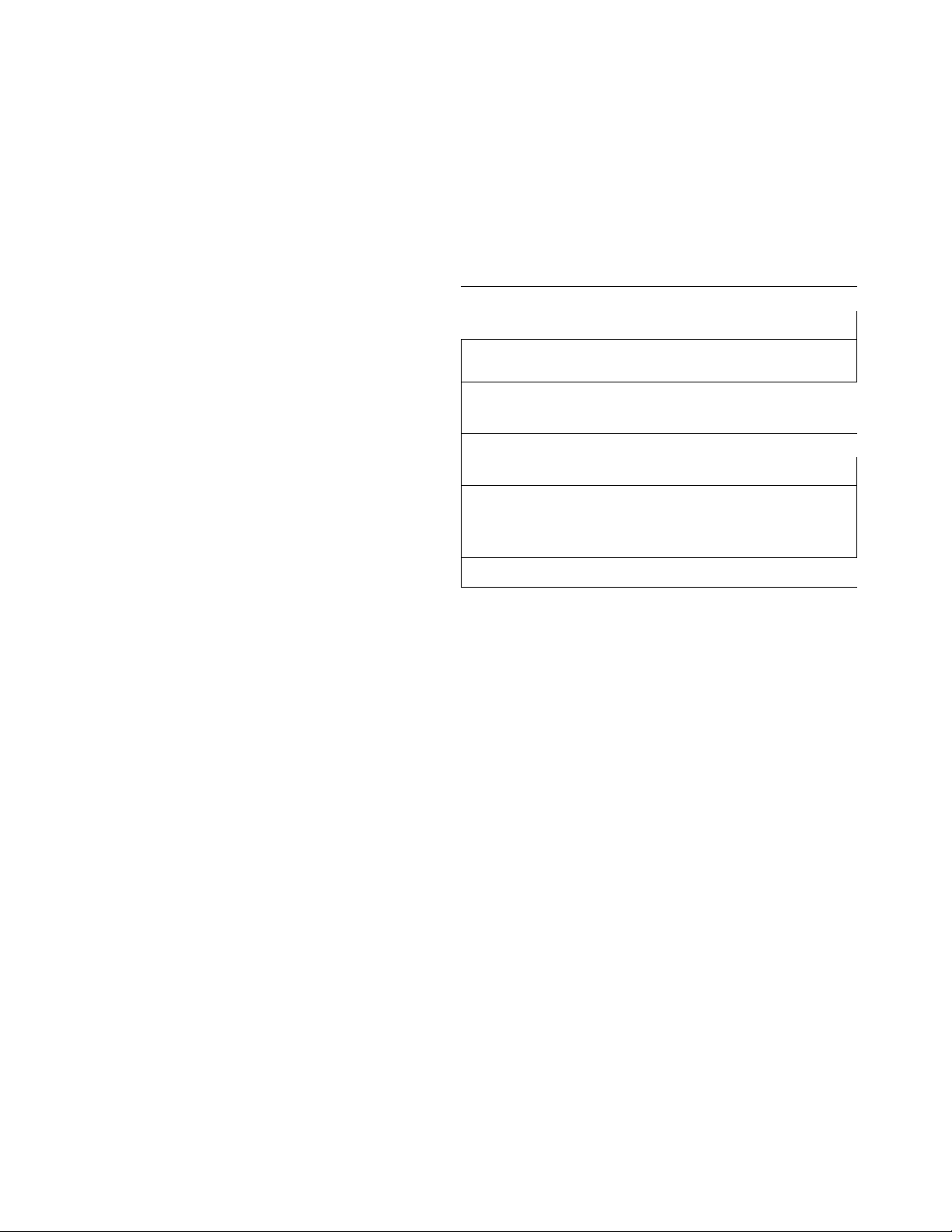

Parts bag contents not sho¥P« f'tlS size

(2) Shoulder Bolts

©

(2) Washers 17/£

X 15/16 X 12 Gaug„

Steering

Wheei

insert

Parts Bag

tj- ' ^ / //

(2) Center-

lock Nuts

k5)

',w \ , .ute

Page 6

ASSEMBLY

has been assembled i

nd proper operation of

as necessary to insure

S RE

wrench

;izes arc

snc

' 'il 1 ' ■'ti.rl ( T w, Ir vt .aerici Ut.liiy brill J

(1) 9/16" wrench Tire pressure gauge

(2) 1/2“ wrenches

I (in 1» i(-fr ’land is mentioned in this manual, it

ht hitid ihi iu'-iji o ^lieel).

/ypfl n - I- — ^ u hi

rlltHlct* f? it

n the operating position (seated

it tighines!

MBLY

r. Siandar

fi'» liijvr ; HAL L jR FROM CARTON

f .^iiTON

ble ioose parts and parts cartons

iic f 11 ti . (be» p ige 5).

Ci iivOic |> Id boroiTi, along lines on all four corners

f i I il'iib .'tid lay panels flat.

» Check for any additional loose parts or cartons and

remove.

3tioii of those parts left unassembled for shipping purpose

:d hardware you assembte must be tightened securely. Us

BEH iRt HOLLING TRACTOR OFF SKID

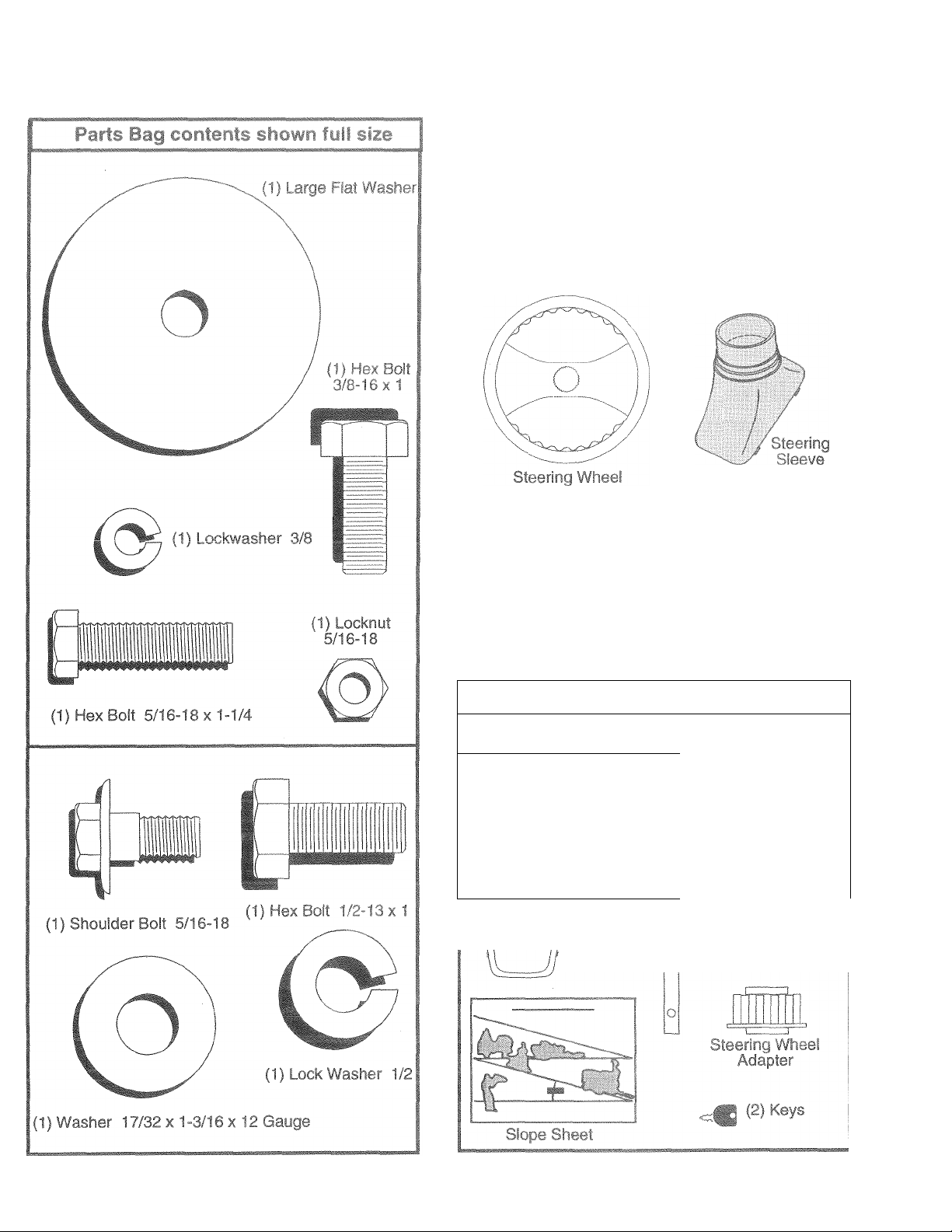

ATlAi T SiEERING WHEEL (See Fig. 1)

ASSEyOLE EXTENSION SHAFT AND BOOT

» Slide- eyfension shaft onto lower steering shaft. Align

mounting holes in extension and lower shafts and

instali S/l6 hex bolt and locknut Tighten securely.

IMPORTANT. TIGHTEN BOLT AND NUT SECURELY TO

18”22 Ff, LBS lORQUE.

• Piete tabs of steering boot over tab slots in dash and

push down to secure.

INSTAl I STFERING WHEEL

» Position Irani wheels of the tractor so they are pointing

siraijiit fonward.

» Cicc steering v/heel adapter onto steering shaft exten-

sicn,

• Frii.-itiuii stening wheel so cross bars are horizontal

(lefc to right) and slide inside boot and onto adapter.

• Assemble large flat washer, 3/8 lock washer, 3/8 hex

bolt and tighten securely.

• Snap steering wheel insert into center of steering

wheel.

• Remove protective materials from tractor hood and

grill.

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

IN SKID THAT MAY PUNCTURE TIRES WHERE TRACTOR

IS TO ROLL OFF SKID.

TO ROLL TRACTOR OFF SKID (See Opera

tion section for location and function of controis)

» Press lift lever plunger and raise attachment lift lever to

its highest position.

® Release parking brake by depressing clutch/brake

pedal.

» Place freewheel control in freewheeling position to

disengage transmission (See “TO TRANSPORT” in

the Operation section of this manual).

® Roll tractor forward off skid.

• Remove banding holding discharge guard up against

tractor.

Page 7

ASSEMBLY

HOW TO SET UP YOUR TRACTOR

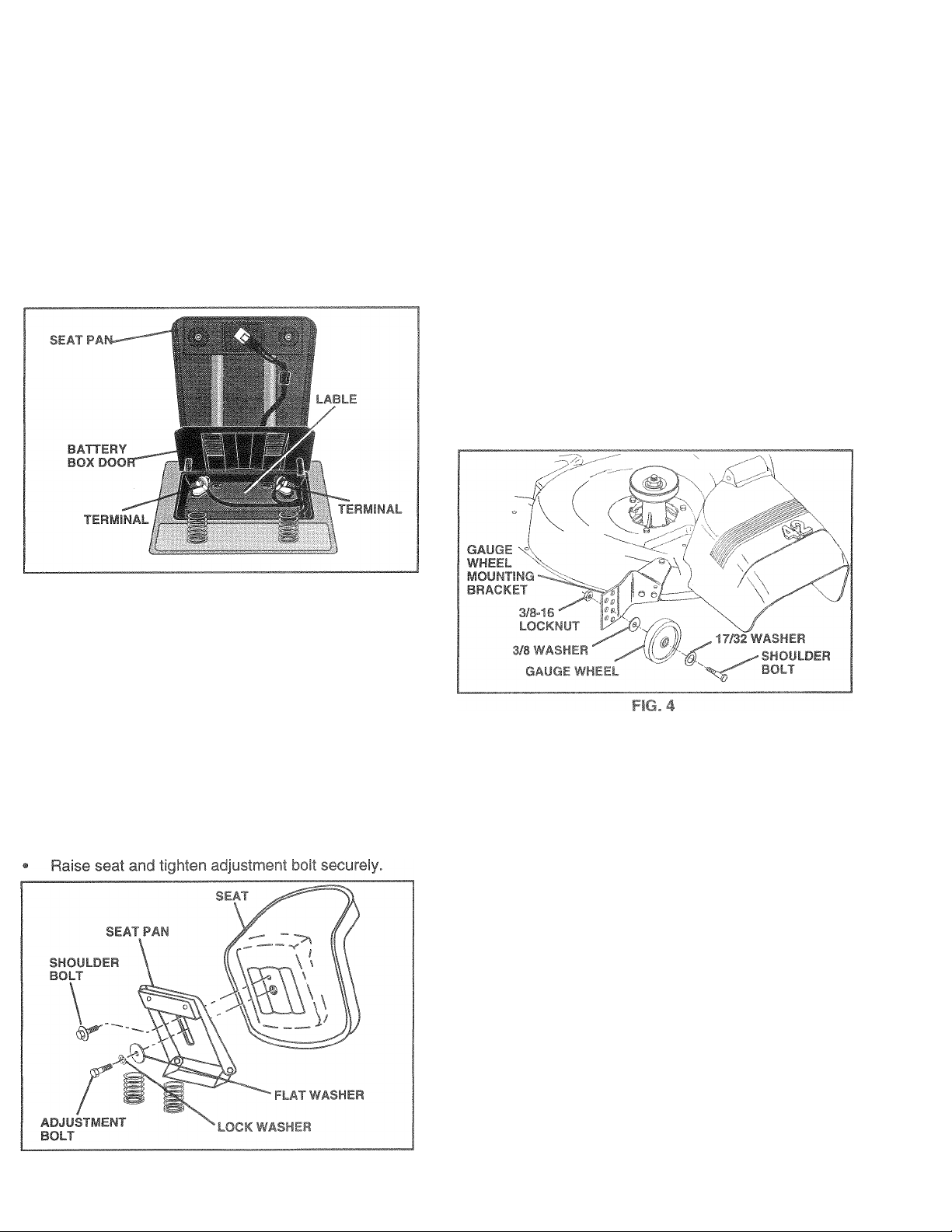

CHECK BATTERY (See Fig. 2)

'jf*- f'3i pan u* 'c ' > f ‘ 'V‘i ^'i ■ i- !■-' / h''

cioor.

“ If t!i‘ L-^tte I ¡1 .4' itii . t , .1 • .'■< I .i c'i!i-50']-/fer.i

inslii.-Ji-il or htt*-' ii ’ '-I I ■( •'-<* i.nyr I] ifrrP'riai*..

ch^o^fc batp.a ff 1 i>ii I'll < ■' ■■ *' '

{Src“BATTLi,('“.nbii 'f.F !3iLiI!F..

spction of this riHri'i-.i’f f ‘ I'ucimn'i;

FIG. 2

TO MOWER

■II

The gauge wheels ar

proper position wher

properly adjusted to c

h I ‘ A t (• , >. i.i'i h I 1 <1 . ,1 m l < t I f v e'

;-;i!('

Ad ju I rni i ;< I i ll < i i nd ■ tiir .g ‘it -H hi I f- ‘|.s A f> Jl •* i F l y J • 'JT sl iL h L in , r .!( ih i jp eic -i io n

section of this manual).

With mower in desired height of cut position, gauge

!,h .Midi ' tdh', a. ,liyhiiyfif(he

gn 'ji'd liO-id'l i. 'I' (» 1.I'll ..ppH p-mt" liuL with

shoulder bolt, 17/32 washer, 3/8 washer, and 3/8-16

k’l hull 1(1 f'(!hi-n '

Ret.f li t-,r .,u! :• >!< nil ! isr.iliih'! fj • ig in

sen If i.jjii'k.if'ik ii ;

ire optimum mower performance.

jp the mower deck in

sr. Be sure they are

INSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment bolt.

• Remove cardboard packing on seat pan.

® Place seat on seat pan and assemble shoulder

bolt.Tighten shoulder bolt securely.

• Assemble adjustment bolt, lockwasherand flat washer

loosely. Do not tighten.

• Lower seat into operating position and sit on seat.

• Slide seat until a comfortable position is reached which

allows you to press cluich/brake pedal all the way

down.

• Get off seat without moving its adjusted position.

CHECK TIRE Г

Thetire-s un y- u, if -Ur i i ‘irrl jtr-d at thefactoryfor

shipping puipu. i-s ' i<imii tire ¡»f-s; uio is important for

best CLiitirig реги s сп..! f

• Reduce tire pressure to PSI shown in “PRODUCT

SPECIFICATIONS” on page 3 of this manual.

CHECK СЕСКрГ/LlbT sF

For best! i.fiing'■esij't' т.о"-* Ik ncnimhould be properly

ievele DUSING” in the

Servic nanual.

CHE ON OF ALL

BELTS

See the figures that are shown for replacing motion and

mower blade drive belts in the Service and Adjustments

section of this manual. Verify that the belts are routed

correctly.

RG.3

СНЕСИ

After you learn ha." iu <jp“C.ua .«.jji cactor, check to see

that the bia ks i-'. - oTc-ied. oae ‘TO ADJUST

BRAKE” in fl'c Tsi ,'ге d -.djusunrrts section of this

manual.

Page 8

•' IQT

д r.fmn f

YQU Qp

Ч, tVE WIi

rPERFOf

К RATE AND ENJOY 4EW

jH to assure THA T Yi EI¥E

IMANCE AND SA TiSFAi ЧОМ

llJAi PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

/ -'li ■ f IiT!/ Ilf <-f ITipi-!-I!.

/ I in r< n-'l til'U I '1 t ¡urf‘ in '.игто'!

V Д I 1*''^ ^ c Ib pn~|4' s JiTeiini'i::;! I® iJ (гв1М|1ПиГП

1 (loui ni e ni;''.)

/ ill' iJid-li'ic'Tiii'if it-!« iri'l я|!ге1у.

/ ii; ptiriflal-ii diippinc. nurfidses,

ihf-fl-- ' .M-if i)>'d.4(iML(J li th> fnifiii/)

/ f‘-i UK iiit'Vt-, jf-i'k t pr »рнг1у iFWHi(4j b> side/

i f.'it <'i i- -i! Ini '.nF| (dittincj tp.-ul!' (Tirp rmist be

piupt ifv i fui le,/»-li!iy)

/ CI иД !TK jvp; end drive btitb. Be sure they aie routed

piopi-iij 'irt iMtJ риУеуе eti 1 iiitidc- all belt rcepers.

/ Che!! wiiii,y Гее indt dll connections are stil! secure

and'wifi-' rtie pi -pi riy'-lamped.

/ Beior- -iiiviny imctu! be нле freewheel control is in

driv. t G: : iofl

WHILE LEARNING HOWTO USE YOUR TRACTOR, PA Y

EXTRA AITENTION TO THE FOLLOWING IMPORTANT

ITEMS:

/ Engine oil is at proper level.

/ Fuel tank is filled with fresh, clean, regular unleaded

gasoline.

/ Become familiar with all controls - their location and

function. Operate them before you start the engine.

/ Be sure brake system is in safe operating condition.

/ It is important to purge the transmission before operat

ing your tractor for the first time. Follow proper starting

and transmission purging instructions {See “TO START

ENGINE” and “PURGE TRANSMISSION” in the Op

eration section of this manual).

8

Page 9

These symbols may appear on your tractor or in literature supplied with the product. Learn and understand their meaning.

- +1

BATTERY

CAUTION OR

WARNING

STOP

I

I

REVERSE FORWARD FAST

i ' It'- '"'I

©

ENGINE ON ENGINE OFF OIL PRESSURE CLUTCH LIGHTS ON

OVER TEMP

® l\l ^ # -i'

CHOKE MOWER HEIGHT DIFFERENTIAL P/

LOCK

1-

UNLOCKED

SLOW

LIGHT

I R N H te»|I

REVERSE NEUTRAL HIGH

MOWER LIFT

m

ATTACHMENT ATTACHMENT

CLUTCH ENGAGED CLUTCH DISENGAGED

DANGER, KEEP HANDS AND FEET AWAY

«

LOW

KEEP AREA CLEAR SLOPE HAZARDS

(SEE SAFETY RULES SECTION)

IGNITION

PARKING BRAKE

FREE WHEEL

(Automatic Models only)

Page 10

OPERATION

KNOW

F. r-fS OWNER'S MANUAL AK[i FifLES BEFORE OPERATINCi YOP^* U-R

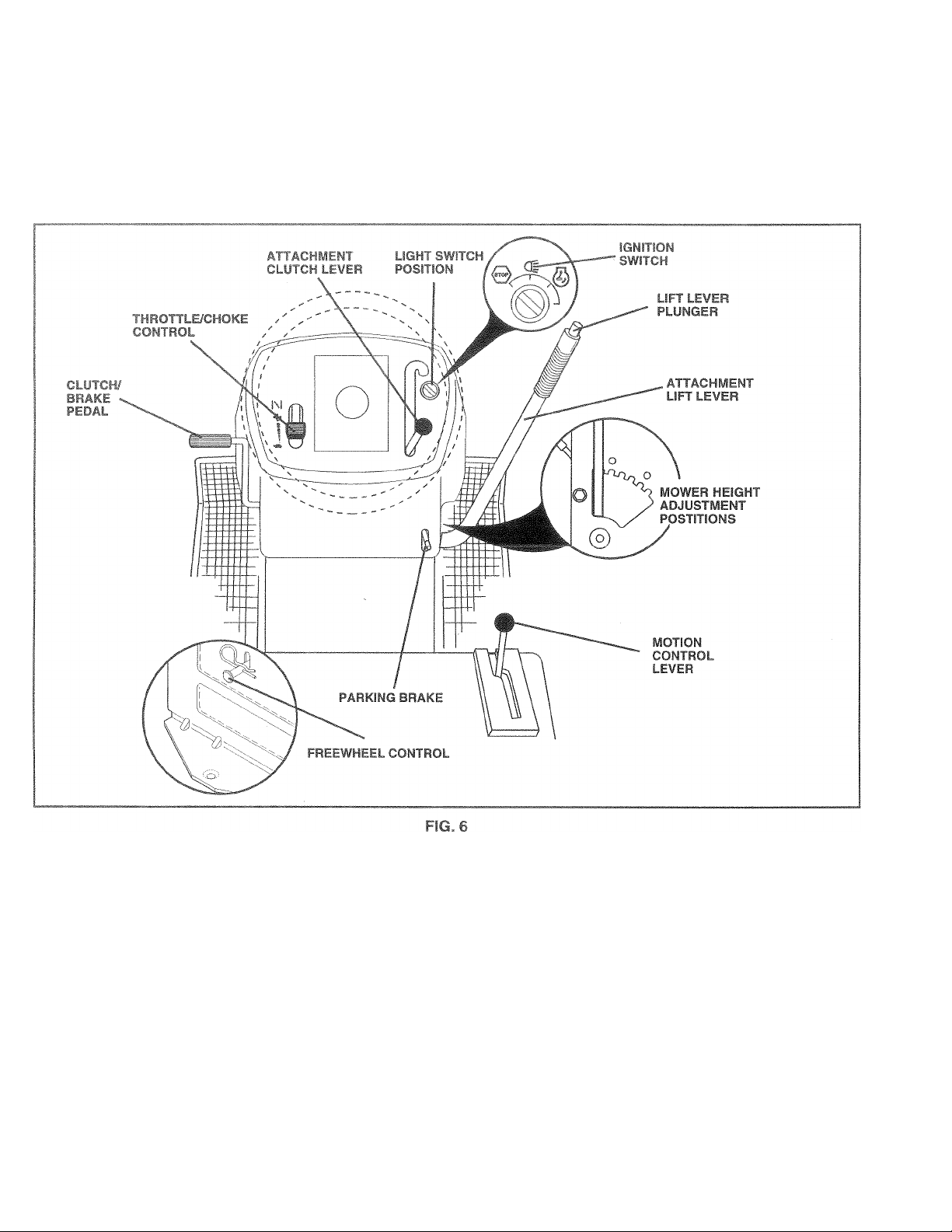

Compare the illustrations with your tractor to familiarize yourself with the locations of various controls and adjustments. Save

this manual for future reference.

Our tractors conform to the safety standards of the American National Standards Institute.

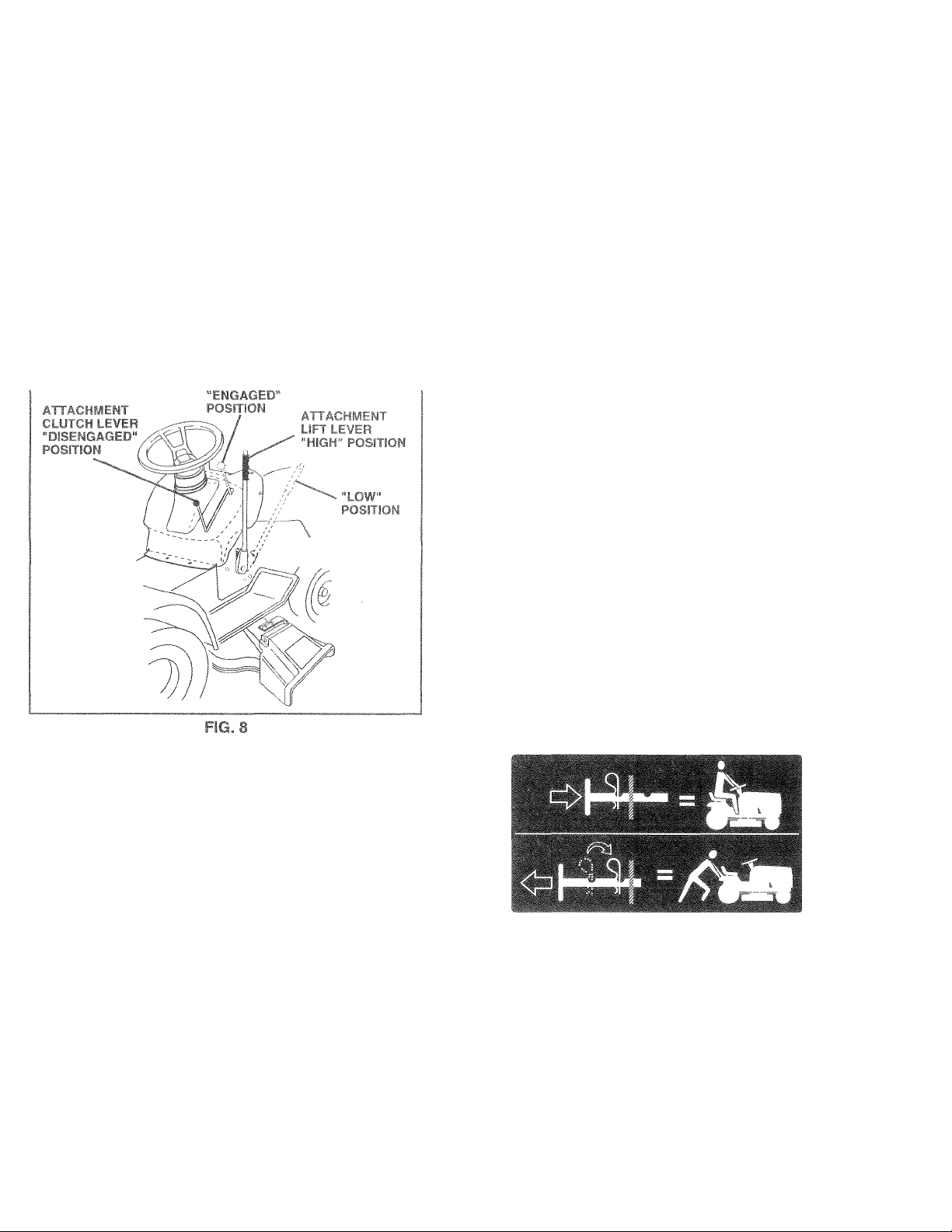

ATTACHMENT CLUTCH LEVER: Used to engage the

mower blades, or other attachments mounted to your

tractor.

LIGHT SWITCH: Turns the headlights on and off.

THROTTLBCHOKE CONTROL - Used for starting and

controlling engine speed.

CLUTCH/BRAKE f EDAL: Used for declutching and

braking the tractor and starting the engine.

P*-RKING BRAKE: Locks clutch/brake pedal into the

brake position.

MOTION CONTROL LEVER:

direction of tractor.

ATTACHMENT LIFT LEVER - Used to raise and lower the

mower deck or other attachments mounted to your tractor.

LIFT LEVER PLUNGER: Used to release attachment lift

lever when changing its position.

IGNITION SWITCH: Used for starting and stopping the

engine.

FREEWHEEL CONTROL - Disengages transmission for

pushing or slowly towing the tractor with the engine off.

Selects the speed and

10

Page 11

>■ fí'FRAI'f-

HO^T^ySfc

The open

result in í

your trac

safety ms

3k over

If tractor can r

e damage. Alw

rforming any a

»pectacies or s

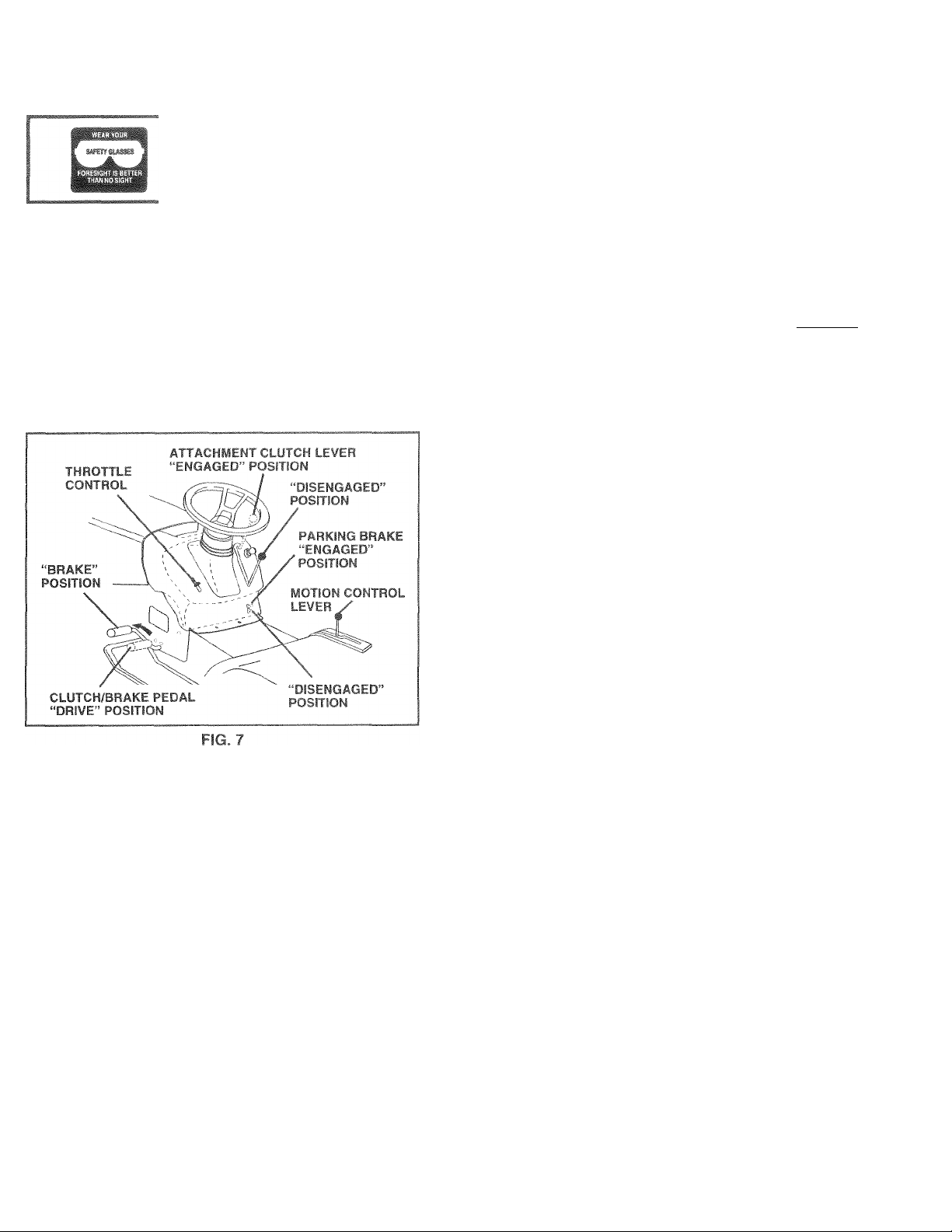

TO SET PAR^iNCi BR5PE iV'r- Fiy

'YL!UrtrariOili>=^tjUlppt (J »i-ilh . in,,( t ¡..j| - ir ■- /-I|,inc!

'■-vrifch Wher p>nnini ■' ru• i-.t'i.ft tj iIh

operatot to leave the _« J vaUir.iii tit a .vitni.j fti- p-irMrig

brake will t>huf ofi thn «nuii.i.

• DepresM iutt pr-j i i v|E po'-muii

and hold.

• Place-path n>i hickc k /»a in Lfj>-AFt F*'p" it'ori and

teleasepre3&ijrefrorn'‘lutch/t.re*'f pf dil PedaRhould

remain in‘BRAKF pOim .n l-N-f ii't p-irFinn brake

wil! hold iratior cecuro

suit

ays we!

qn

ill

№hi

opi rating

djustments or

tandard safety

!MPOR

POSIT!

BATTE RYTC) BE DISl 3HARC3ED

HOTF '

>i< i/'ltf

cause ‘

-il Wrjf sto

TA NT: LEAVIt JG THE

j f

lot

)THER ■

; Il

;r certain

id€

ith

> ‘Usl b Í 1 If *fling, h

& 0

hr.

....

ingine wh

■P€

i Ciifet f i( irfoi turn

A

U M 'ÍK )> I ' ¡.<4 ll‘ I W ‘ * 'Pty

'¡I Ì. ► t I

“ 1 o

N11

1CiN SWITCH f IN ANY

™ .

FHAN '*OF

ions wt ler1 tractor is 't snding

conditi

otei

jrass. '

len stoi

....

pptr

/ILL. CAU.

AO).

Í C)E,

rigii

le - hrt I'iiqdses mj'/

11». 5 r . f iGf

ig ti

Tor on gras

TOOSETHKO.fl ( er. rig. 7)

Afwavj Oil«-*' vfiio'-« I in I ihn .Lli

• Optrs'iiiy' Qiiif i F !, «I. I!i|i throttle reduces ihe

bjti-ry vgínt

• Full rhfuff.f oifci'if. L ,L ' . o and I ¡rower perfor

mance,

TO Mt'VK FiL' ..i ,.t\WARD

(See Fifj 0

The direction and . pei i of movement is controlled by the

motion contrc

• Start tractor with motion control lever in neutra! (N)

position.

• Release parking brake and ciutch/brake pedal.

® Slowly move mritrol lever to desired position.

iision

SE THE

ir.llltv

STOPPING (See Fig. 7)

MOWER BLADES -

• T0 stop mower blades,move attachment clutch lever to

“DISENGAGED” position.

GROUND DRIVE -

• To stop ground drive, depress ciutch/brake pedal into

full “BRAKE” position.

• Move motion control lever to neutral (N) position.

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

ENGINE "

• Move throttle control to slow position.

NOTE: Failure to move throttle control to slow position and

allowing engine to idle before stopping may cause engine

to “bacWire”.

• Turn ignition key to “OFF” position and remove key.

Always remove key when leaving tractor to prevent

unauthorized use.

• Never use choke to stop engine.

TO ADJUST MfV.iihF CUTTING HEIGHT

(See Fig. 6)

The position of the attachment lift lever determines the

cutting height.

• Grasp lift lever.

• Press plunger with thumb and move lever to desired

position.

The cutting height range is approximately 1-1/2 to 4". The

heights are measured from the ground to the blade tip with

the engine not running. These heights are approximate

and may vary depending upon soil conditions, height of

grass and types of grass being mowed.

• The average lawn should be cut tc

inches during the cool season e ver 3 inches

during hot months. For healthie etter looking

lawns, mow often and after mode

• For best cutting performance, grass over 6 inches in

height should be mowed twice. Make the first cut

relatively high; the second to desired height.

.....

imately2-1/2

____

^.owth.

11

Page 12

1

ЭРЕ1ЧАТЕ 110 WEI Ч (See Fi

г is eouippec

Iractoi

/ attempt by

IQin© i

running and the attachriiGni c

"%ff fhp

J with

' the c

jht of

mower with"

OWGr i

lower blade

attaci

!S by

ontrol.

1 В1Д,DES ™ dise

luich c ') It C 1

«.'bilifOH |if> o;»t><< к j

hitPjiJ|e-bi|.^'-.ht _ fit|,v .jr . -i r -, I

i^rs .4 «qiiiir.p- I <‘E !i -, .¡p |

A

y’JéE S к |.|а'.Г f

anoperatoi r prese

9- 8)

dutch f

cu!\

hmeni iif! о

engsging

ontrol,

attach

ngage nment

HILL

IN: Do not drive up or d

:h_slopes greater than 15°

A ГпоТ!

Ifive across sny slope.

est speed before starting up

Avoid stopping 0

f changing speed on hills.

If slowing is nec<sssary, move throttle control

If stopping is abs

lOt.-k' .<- - - ' / L )M> |-|'ll'

pedal quickly to brake position and engage

brake,

I>'|‘ •- , ' f «V ii ",il I / >k n-rl-t!-I |i 1| p Ilr<r>

• u ( '-t! I •! i*'i, > t ,t I, t ‘ 'I I i Fit ), L f V bh I ' a

f'f r r ' I ■ I ! ' > PM 11 (I - I ' K li 'PHi 11 rpE

ill!' ,l f MM- i/>i ! m ! Ht ,M •

(. 't a., „vp',,. \ I'>wv!y ¡'Jp^ ep'iMnq'-t-i. H, j.d

ciutch/brake pedai.

I .'pi > i • ,■ ill-,'r-fi "G, frr I !. vr I M-It >p( sf M d.iig

H;| .(< t ' Ill'll I' tJ'l'/

r F:qs. 9 ahrl F, I

j « ir-y vf-Hi il Mil ba-me tiiiHi'-ng ine

hai! nil I ,iM>/t'i'-('II i b'Oi.iK.i ir. iipf'Wbt t iiiig

POMi Ti r >«' r ' • f ontiu! I Mi.f iM'i at the (^a' dravi/har

, T irm It

• Raise attachment lift to highest position with attach

ment lift control.

• Pull freewheel control knob out and hold in position by

inserting retainer spring into forward hole of control

rod.

• Do not push or tow tractor at more than two (2) MPH.

® To reengage transmission, reverse above procedure.

NOTE: To protect hood from damage when transporting

your tractor on a truck or a trailer, be sure hood is closed

and secured to tractor. Use an appropriate means of tying

hood to tractor (rope, cord, etc.)!

FT

FIG. 9

Page 13

OPERATIO^

i m t"' ?! H’H í'frH' >* ’jf. I t - " f

• Th6 Giipins in yourtrsctor ll3S b<

fáctory, slrssdy fif©d with sumiT

.1 i |.(- i jifi, , j| > -f.1 , ,,

*' (',» lll>j\V, f.(< f H (' h n I • .

rÍ!pollf I cu lu lïrüü ^ i! li s’ I U I t' \ %'h!* J

rcFioc- w-d r‘-'lí f-,* I /' ! il i!i ' ■ ' 'I ' iMir.íii

f Uü rnaw ,r .>1^ :ii i w' r,- ^ ,ir:

® For luid wGoth«"'(f.‘rjiiiiM mo i L> o • <y> hií . .f

easf-i ùïartinq (de- 'w!l VL/ • i i / i-l HÎ ’ ii. Ihe

oU'Jorpe'Rp"pf>noiDÍiii‘. f"f|,,r, m; í| I rn-nurl)

* Ce cfidiigo » fi©,ny olí "f- tíir-' ii 4i.»i,ibili-

íieo secfon in (hi* aunU'’!

ADD GASOLINE

• Fill fuël tank. Use ire.-h, i'lf.oíi iegula' ui .leaded

gasoline with o mininujin uf 8 / octane (Use of leade J

gasoline will increase caibori and lead oxide deposits

and reduce valve life). Do not r t‘k oii w ith gasoline.

Purchase fuel in quani’ties that can be used within 20

days to assure fuel freshness

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW 32“F(0°C), USE FRESH, CLEAN WINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING.

WARNING: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which leads to separation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before storage of 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See Storage instruc

tions for additional information. Never use engine or

carburetor cleaner products in the fuel tank or permanent

damage may occur.

CAUTION: Fill to bottom of ças tank;

filier neck. Do notoverflil. Wipe off any

spilled oil or fyel. Do not store spill or

A

use gasoline near an open fieme.

F

J ff 1©

I qrounci.

:tean, rsinsertíhe

•iq.

qin

TU€

Oil on seat in c

51TIC

pedal and set

Place motion c

N1ov0 êittHchiTï

® Move throttle c

NOIE r

Ü I ' ‘ ,1 (, I ■ .1 fi’h 1,1 .iti'j>I

ns tliV Í, h O >r ! I I . > .rU (J-'OtlOr,.

)ntro! to choke position.

ii.‘ .< .• 11 f I fiI i!I Î ' ( !■ ! ' i,'fiiriy

procedures oeiow.

• Insert key into ignition and turn key clockwise to “START”

pi" iti> !|(! i‘ !■ 1 i ' . iti < ► fiU’ii ! Do

m it r-j!' t, li I I i! ill! II' D A f III. I! if ’I fii-Lor f

f»hO p( t iiifKf K i.qn. di ' ivA ; I »rt .^itsrt

fevei j' ittf-Pii.! fi ' ifir..;t!i .«.»'Lit j''> ipo‘^itifiii,

U3P •*> V r. It.m Mill/ <i i I'MMiiit MillfSi O'not

at irt mi'Vt «>•( ih.Mil ■ f tilr I r ■ k fi fh^ choke

pt nHl ii-il

WAnMyCArUff "MUik,/ iac.i'»

• Wfitta ii.jfii .1.1 • I ( ifCr .'icifteiriSt

p,j itl. 11

e I!l'--'ii l t-.ill 1" ( , I r|f<vvn(- IKi-.j If

(ht ‘ iiyr- df*i-‘ Ml, -[/! h -id r«-=f rrftnr t-ngine

.irdd’i' I'lit,,! i li iiiKi. f-U'iiiiitti»-chokf

a 1 dl Mt r| ,

COLD Vvf/-' hi n I/ fl'T .'ri ,-iidbeloWj

• WTf noinir.e d.'ih ji! M/! i«vio foiun With the thfottie

(orii.ul in !fi( >' |¡'^г• rntii ftt engine runs

r jiiuh'' tl' ri c.i. r,i >ii|t rli tij.Mitiun Thi-,

h'. / r quir« it. iv it I I p DOfiod fi cm several

txMid If i* hi. MM • |ii-ii>1irig <1. flit teni-

J<-t it'itl

AUTUMA ¡1 U /■ h V, k ■' I i <P

• Bi foil i.rf.rqi! Kill 111 '.j iii,M ih( ironsmis-

' oil 1 . I up I ill- »

• Be sure the tractor is on level ground.

* Place the motion control lever in neutral.

r, i< , t| f ,M« ,1, - I ' i(U< h[.' h'Fp/hrake

.( f'A c m ft ■ U r> n

s OIL. J f, 1 .IIUH ' <I . tr ii I It, tc Aatt.. up.

This can be done during the engine warm up

period.

• Tlie atk'chrrienU c / n arso be bsed during the engine

«3iT-.f osrri’ I ii- -an 'ii.r'V'I bar been wormed

up.

NOTE: If at a high altitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetor fuel mixture may

need to be adjusted for best engine performance. See ‘TO

ADJUST CARBURETOR'' ii'i the Service and Adjustments

section of this manoai.

utch/brske

13

Page 14

р'Г.Т'АГИ. tr;

PURGE IMI

li: 111

»nsun8 pri

menided1:hat the tr

:or to

trad

trapj

ped s

j dur

opei

IMP)OñT JWT

REMOV/

SHC)ULC

open

зрета!юп arid

ansmission bie purged befc

r thi

5 first time. This procedure wiill

lir in 4^ 1 li ill ii.,- i

ing Í

shippiing of your traicior.

4 ' "iiLli f TF. • OYL .. ICЛ- ВЫ.4 IR'

\L I

FOR SERVICE C

) 'b

JRGED AFT ER REINS

BEFORE OP:ERA! ING THE TR,

Placestraidor S;afely on level í

h Trki

ng t

set.

Lrf'i'j ;r II, iHtiii'.-, 4M>^ |4i. inq iiF-f /ftiH-l ubtroi

ill fifелЬс-rii'iQ |:r,vit'on q'> ^ Tf' ТР«'П~Р'~'Н * ’ :n

t^llf P''tr.n 1 iT(iflU?''ll

® I sedt ^trtengiiit Afiertht fjngine

, luntiilH 'П tde rhr'itlP <,>r.tri.i to alow pO>ltijn Wilh

•»»tier, I iii.iol '“v'tr и I cUiral (M) pfritsor, -Lwly

‘ Ihic h'hral-p

f~iL . riris'snn '"rrifrnl If i-crfr, rnh i rnH

i I Id fo! iwi- (Ы 'Ы Of ids Move к vh to full !е\-^'?е

pi i-it.s.ti fii.id for ffi- iPt und- R'-pf-as this

proo5»dur. throf (di tini-'»

MOTP' t<ut!! g'hit piocoouff ttm ¥i|iDenortiOd meiitof

dri/i *ht fl" ' he iiri; beirifj'*,ni -^d rcm hydnulic drive

system.

• Move motion control lever to neutral (N) position. Shut-

ihite

performanc Í, It IS n

0СОГП“

)ге opecrating

remos any

» S hi III-!

t haved©¥0l"

)R REPLA C L Í ' !T, IT

» - Ì. /Р

Г ALLA

surface with ngine c

TION

if <nd

ilOWINI

• Tirecha

I f (M lU..

i' It' ’ '/ n< t I'ppiritjS i .j=* hoKjeo a dr th,.

iti'tl'i, l-'-fMiii Hav-^fhe t I’i nieatothe riqt.tof ihn

Y ,< I .• , r,i will

IP

)UlC

jrC

a Adjustments

side of mower

. 1 1 1

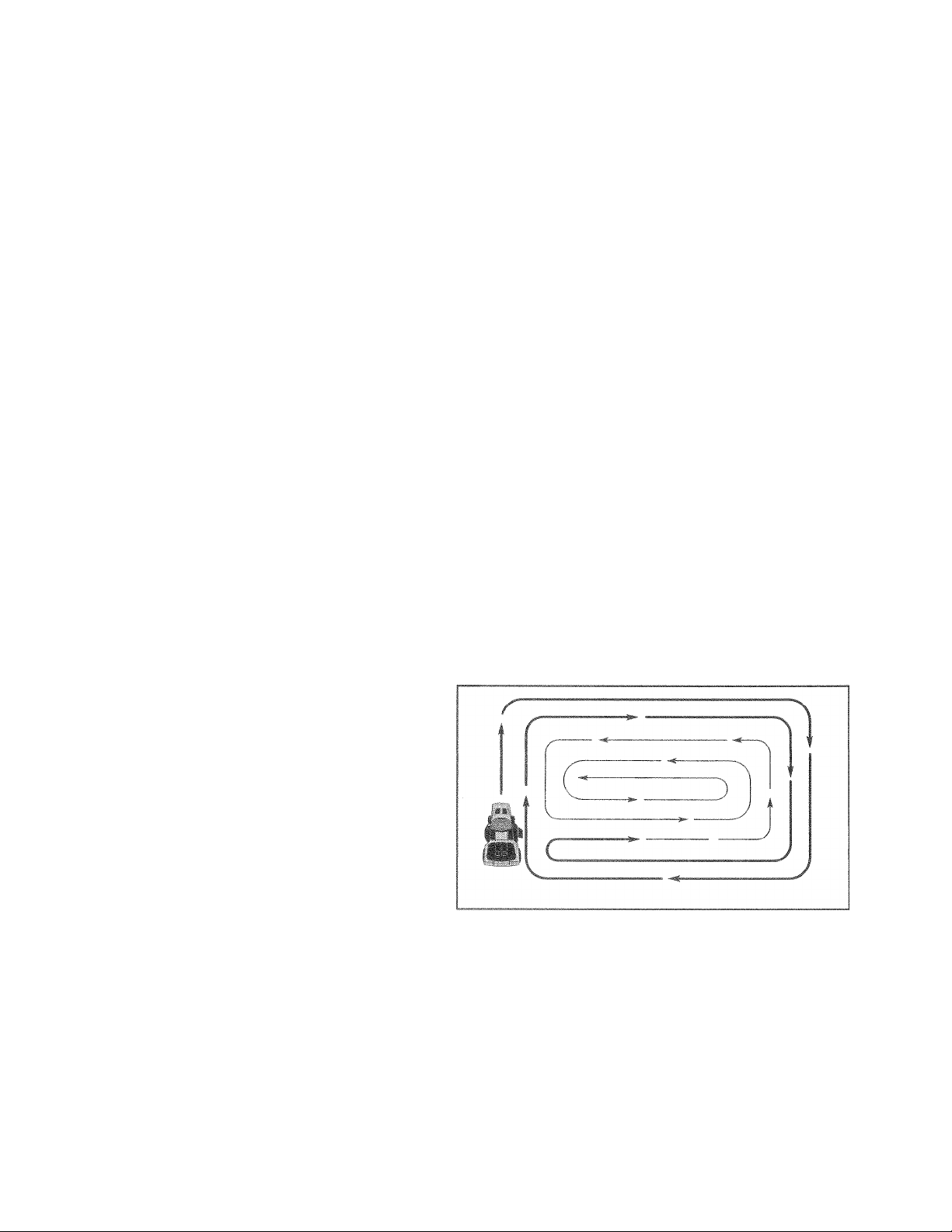

r-ote Fi/en di^ttib'fEinn el

-E'

' ho

eled for bes

^OWER HOI

action of this

)uld b¡ Us

t mowing

JSING’dn

J t'ji IM II-

lipf. fi I mil) ins»- l•rllfOfГ^^ r Httihd

'/.It II r.I x'i"i' II(j( ir m Tan b/ luir, ng s' (h*- nght

• di 4 will irchaifie from «-hrubi

, dnv< 'f »y- lit t'lR'-or'p ut Iwo irurido mow

i<i 4i ' ppj‘i|t_ diieaiOh inatiii.j left hano lunm until

e I iL! 10)

It q'i' ' i: L 4i' «iiely tall 4 "hr uk< bt fnow"- a twice to

red jce I rad and possible fre hazaid frem dntd clippii.ijj Make firG f'jt relatively nigh the second to the

deciteri heighi

U' ■ not inow grd'S when it is wet Wei glass will plug

rnower and Itavs- undesirable clumps Allow grass to

dr/ befijie mowing

Aiwa/c opeijfs fiigine ai lull jinoaie wnen mowing lo

oire bettei mowing performanrt and proper dis

(riciye of ifHteiHl Reguldto giound ipetd by seleu

iny 1 low enough gear to give the rnewer cutting

ptuumiarv e is well as the quality of cut desiied

VVhti* operating attachments select a gtound apeed

that will cut the teiiain and give best performance of

the attachment being used.

manual.

Engage transmission by placing freewheel control in

Sitting in lh< tri! to: seat, •'t i/»ngir,t. Aftc ■ tr.. ngine

S lU irinr ri I It ihrrr'jp r.inirof+o half (ISj ^peed.

Witli riv t!L,i! ■ ,r tru! .e/t * n neutral (I i> ¡Xn (ii n slowly

fJi. cngaoe > !UP e/liiakt p» ti-i

•lowly nio'-f r-K itf- . i oriti .1 k li I forv/.i ij niter the

t>'.‘f,r r ic--,, X pi-vo-xir „iol, five Ri poi, 'tv.iymove

ro'.fii f i-'» r t( |. tpit I the

•t V f MtiVf; ppro. iifwtriy ‘i/c (5) ft

is'>ii'>ipo>.iiuoilsvci to 1 t Hr Mii I ij ij po; iiLh Rt peat

thi. pr- ttilu:i v/ith ths niotirn siitrtroi k vr i ,hree (3)

' - 1

eturn the

times.

Your tractor is now purged and now ready for normal

operation.

Page 15

i" í; F'íf-''NPrU:J

IF

4 Repía^e blade; incre often ' fTi >/'snj in andy *il

GENERAL RECOMMENDAI IONS

The warranty on this tractor does not to^/er items that have

been subjected to operator abuse or negligence. To

receive fuli value from the wo rraniy, operator must maintain

tractor as instructed iri this rnanual.

Some adjustments will need to be made periodically to

properly maintain your tractor.

All adjustments in the Service and Adjustments section of

this manual should be checked at least once each season.

• Once a year you should replace the spark plug, clean

or replace air filter, and check blades and belts for

wear. A new spark plug and clean air filter assure

proper air-fuel mixture and help your engine run better

and last longer.

BEFORE EACH USE

• Check engine oil level.

• Check brake operation.

• Check tire pressure.

• Check operator presence and

interlock systems tor proper operation.

• Check tor loose fasteners.

Do hit <■ .’jh ..

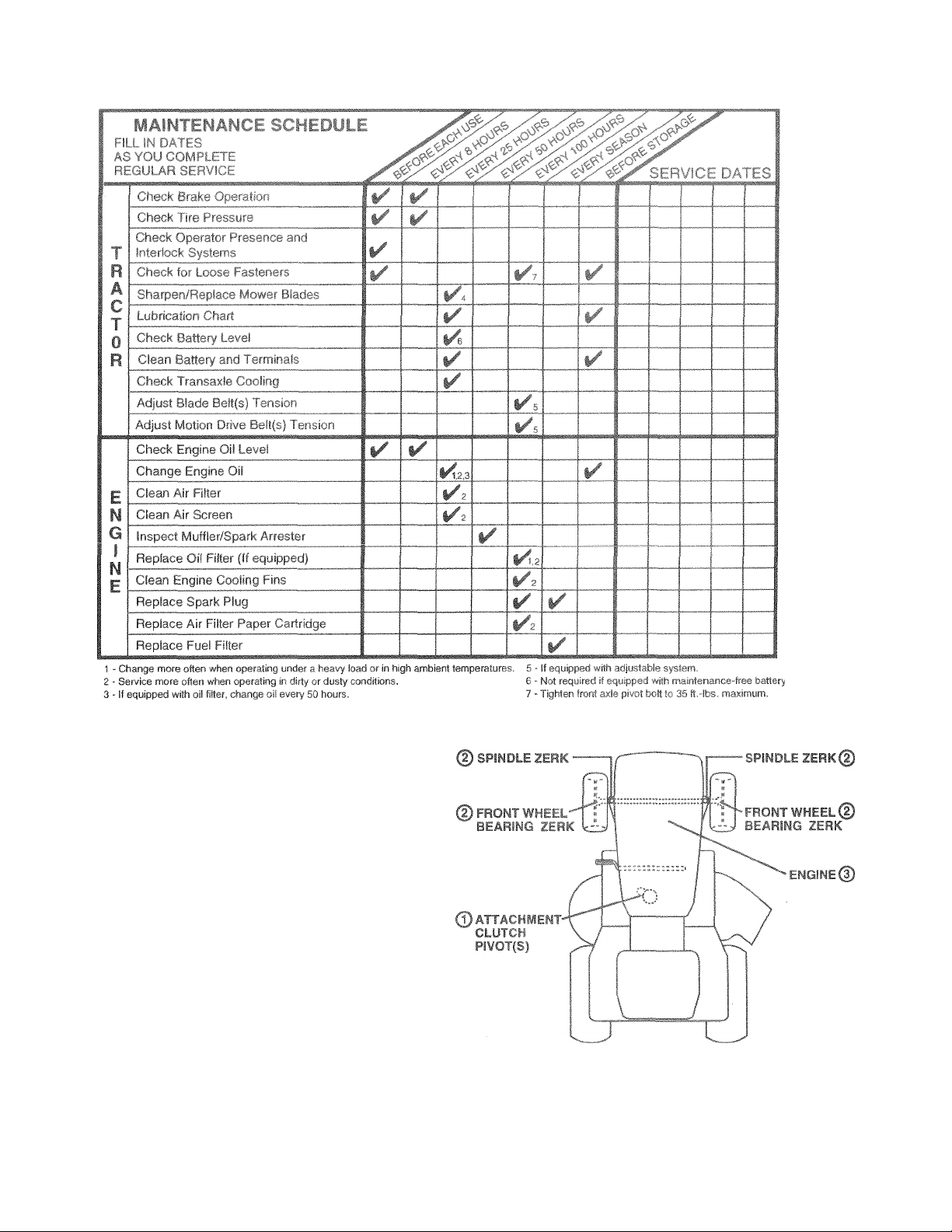

LUBRICATION CHART

0SAE- r. i ‘

djREFERlO W-fi

iMPCRT*..‘i- f . I I . •< . F fHL r -m,! POINTS

WH Cri H WF or ito i> ' b 3E -vi H k f . \ IF C ,.US LUBRI

CANTS WILL n ll ; ■ m , Dll-l HST All L SHORTEN

THE UFF r-f iH- • r ■ ' '‘'F°!W KNC. BFARINfiS. IF YOU

DERED GRAPHITE TYPE LUBRICANT SPARINGLY.

OIL

‘ SNl-iNt" SECTION

15

RY, POW

Page 16

TRACTOR

AIvtfays observe safety rules when performing any mainte-

ir'hsri.vi:;,.

If tract

or rc

iquires more than si)< (6) f(3et StopF

ispe ed in hi'/* 1 t (j- 1

at high

(See ‘ ADJUS 1 • i

ments

TIRE

tion of 1P 1.

o

• M.âintclin propler air presisure in c

3J £SPECIFICATIONS

U(

® Kc

septir©s frete of gasolirle, oil, or insec

ti

hidi ca n harm rut )ber.

ils W

» A\/Old stumps stones, tdec

otiher f

lazards5 that may

fJÎMΓf. 1 0seal tir <turi:ium ind pi

si ni'*

peri' 1

, tire se

jaks

•alant may be

dealtsr. Tire fcdidhi isc, pieL tire

, th¡en bréikem lUSt be"a

!'■

n the Sorv

ll).

•1 t|r

in pag0 3 0f this manual).

!” C

3, shsrp

sp rut!

(lî

e darusep.

e.'eni

n iff kdmv

corrosion.

OPr.R/' K?F] REiJC r

ni ‘ ux-* .. r H>' ;i,(! lilt itui ! sJituii' are

w< <hnq piftjt'lv if yt>ui does not mnctn-n as

•Jesunr-i !i j. 1 >f.t pri t'i-II. .t.untdMifiy

" Fnf rrniri- h-jij!Jiut tan unie- ihe nlutrhRrake

poci'iisfi liui*i.prv''‘^“d tlbitmcnem-Oillutchcontrol

IS in ifio d -Mid iqed [Mwiiioii.

' ’.i'lhr, d>< t-nginr I funniiio ..nvattf^miiibytheopera-

toi ir IfriVfc ihc Xf'ai Without iirst ‘ettiru the orrking

brak : houl.. hot off ihe or-yine

' Whf nttif r^npiriF k runni !<j sndtnr Litiarhmentdutch

IS en .o |i-d If i tempt by the oper.-io 1o leave the

■^eai h ail i 'hue off the < nqne

* The att3chm(=n!cl<Jich should never operate unless the

oper tor is ir, the "^eat.

)ino *distance

idjusted.

ice and Adjust-

is(:

See “PROD-

)t CiDntrcll chemi-

Obj€;cts and

! tim

ifla

- due n

'fr„im ycijf itKal

dry

rut and

FIG. 11

TO SHARPEN BLADE (See Fig. 12)

NOTE: We do not recommend sharpening blade - but if you

do, be sure the blade is balanced.

Care should be taken to keep the blade balanced. An

unbalanced blade will cause excessive vibration and even

tual damage to mower and engine.

• The blade can be sharpened with a file or on a grinding

wheel. Do not attempt to sharpen while on the mower.

• To check blade balance, you will need a 5/8" diameter

steel bolt, pin, or a cone balancer. (When using a cone

balancer, follow the instructions supplied with bal

ancer).

• Slide blade on to an unthreaded portion of the steel bolt

or pin and hold the bolt or pin parallel with the ground.

If blade is balanced, it should remain in a horizontal

position. If either end of the blade moves downward,

sharpen the heavy end until the blade is balanced.

NOTE: Do not use a nail for balancing blade. The lobes of

the center hole may appear to be centered, but are not.

BLiiDE LAn t

Foi h t . V ijit ioifwer bladr's must be kept sharp. Re-

piar < hr*:f nr dam; g.- (, blades.

PLdEr ftEMCVAL (See Fig. 11)

Raise rriuvrer 'o higliesi position to allow access to

blades.

* Remove hex bolt, lockwasherand flatwashersecuring

blade.

• install new or resharpened blade with trailing edge up

towards deck as shown.

IMPORTANT: TO ENSURE PROPER ASSEMBLY,

CENTER HOLE IN BLADE MUST ALIGN WITH STAR ON

MANDREL ASSEMBLY.

® Reassemble hex bolt, lock washer and flat washer in

exact order as shown.

• Tighten bolt securely (27-35 Ft. Lbs. torque).

IMPORTANT: BLADE BOLT IS GRADE 8 HEATTREATED.

16

Page 17

^1

BATTERY

Your tractor has a battery charging system which is suffi

cient for normal use. However, periodic charging of the

1 th ' • V (! I .

.

............

I • !.;■ I<! > u' Ml

• Keep battery and terminals clean.

• Keep battery bolts tight.

» hr«-f m I’l 'f n( 'if.Ml

o >-,f ''har^t >i - ■>'» r ' . ' hi ' i

iru iPAfJ B.<-l iTi-i erJM fi HMlw n

Cornsior. and din r.|i tht -01^1111111:1 ts cause

tfie bdPery to liah p*

® Open li ittew i j> 'I'lOr

• [*Fc onnect bLKO I. bYtuy r;jrj|-t,r i iht n HI hi bai

ter/ cable -arid r-=tTi'*Vi-" batten» frort» lii«ctor

• Hinsn the buimfy wtm v.. O, an* dry

• ClferfOteriiiiiwI^ arifihitic.yr jpOi i,d with witebrush

until bright,

• Goat teriTiiridL with gnast ui | ermleuni jelly

• Reinstall battery (Sefe‘hEf Lot IfJ.-i BATTERY" in the

SERVICE and'ADJlIMMLilTS ection of this

manual).

V-BELTS

Checf* V-be!is for deterioration and afierfOO hours oi

operation and replace it nerc'^barv The belts are not

adjustable. Replace belts if tnr^y begin to slip from wear

TRANSAXLE COOLING

The fan and cooling fins 01 transmission should be kept

clean to assure proper cooling.

Do not attempt to clean fan or transmission while engine is

running or while the transmission is hot.

• Inspect cooling fan to be sure fan blades are intact and

clean.

• inspect cooling fins for dirt, grass clippings and other

materials. To prevent damage to seals, do not use

compressed air or high pressure sprayer to clean

cooling fins.

i ¥ UHAUcis

I TEMPERATUHEI

—...........................................................................

'll S I I f -f !•' n_ I E I i|tn -L,

.............

NOTE: Although fTiulti-viscosity oils (5W30, 10W30 etc.)

IÍT|¡.' t - ..l ‘i.l f, ul‘j -“„.iil Í J ITiiJfl I iH

will r • >!' iU , I (' Í t H.ilf.J -M

*>, I h-Í t ii,| • I, fill, .1,11, /» i i.ji... f. (j ( hiiK to 'ii'uld

[" 1 li ' liuilif 1 I. V- II I'll to. nil.., I il 11 r.il

fhi'.f.-ih hI . Í 1 .. . ■ 'liptljt'Mi .laíK<0

J

ii ■’! li i ! O' Vi*

once a year if the tractor is not used for 25 hours in one year.

i he i VI»- liM'i' r ill. ‘ill *(t»e woiii'j 111*-^i.qirii"

f.nu ifiM t( i<|h* L I h'>. .}>< 1 n.oFi h jhtpfi ul fil;

cap/dii'-irl ■' Hi'I » ihhrti . !• . hwr ti.c »¡IKnel.

TOrHAHiT L!jr ;ri»_ ■ Í 1 ..-f 1-. , ' j

Detc-iininH Ktiip.' All . i'£v . «pi-iíoíiti*:í!oiti*i'eriaiige.

AllciIrTii! i-fiMi/r u. I] lik atioii :L Tm h 5H.

• Be " iirr It i> t. ' 1 '/i. Sf. ~i 1! »

» III >AÍíl 'Jf 1111 it,' li it* -I ' 1' I , III

® r.jt* Í' (>li ÜI ' ' i'lMhl. ff lit !l!

» H' r'M Ih|f! ‘ ti [' p, • f*jl n o ÍO 1IL. vdirt

to enh r fht. I ii'iiní wneii c t ;ii ling oil

• Remove drain plug.

• efin r.*i has droiii-(f»•'■oipli 1'iy rofl-meoli i rein plug

Olid I'qhtr-ii sM ctriv

• R'd.ll-riLi'iL w:t'-f II th! uo'i ,I I'll dipstick tube. Pour

* lo'Aly Oo iiot .Mf ifill I . ■ f ».(oximate capacity see

■PriüüLlCT ■ f f. IFiCAfiC-tv‘'r on. page 3 of this

m. !iu I

® Usf fi'i! 1« <■ •oi> filie If viiii Í Mor checking level. Be

surt^Mf 1, t , rf, ,s [il hf. . I ecurely for accurate

rerdinq h» -p t ¡1 I ‘HJl 1 lifv on dipstick.

TRANSAXLE PUWP FLUID

The transaxie was sealed at the factory and fluid mainte

nance is not required for the life of the transaxie. Should the

transaxle ever leak or require servicing, contact your near

est authorized service center/department.

ENGINE

LUBRiCATION

Only use high quality detergent oi! rated with API service

classification SF, SG, or SH. Select the oil’s SAE viscosity

grade according to your expected operating temperature.

17

Page 18

é\

jpe

ifinage

nours 01 operaiion or every s<

Service air cleaner more often under dus

)fi

llene

jition

* Remove knob(s) sno cover.

TO SERVICE PRE-CLEANER

‘ 1 r- 1'' i pi 1“ -I, , . Il .

* ‘V t E il II KjlJli' f.( If-.PF >,1 r>f-1 -‘I t. f

® Squeeze it dry in a clean doth.

" ' niiraf .1 || ■!' I ■» I!-,

ít ih orbenl

'"T "i I ¡1* ' t k p t / e -I I 0

** '■> y «>t I J 'ill IJi I ¡1 pi ' I pi

aner.

> f s ir< .i A ! ^ ' I* I-! f'»« ' i

lit if t til <>i'- > sneJ secure with knob(s).

TO ,IO’v‘i' ^ ( "MniOi t

*> Brria'r 'Kridyf I lilt

® < Mull/kit''f . aniidy-k, ,)r-M II, tirbris from en-

f. r.r*j • rhiii,_tfir I Ifc.-in Lj:--' cartfuiiy to prevent

d Ipi . i(k fi'iq ‘.aiPbirti i

« ( luai), _ri!i‘<ie rwi^ppiri jQHitiyuniOi. urface. Ifvery

• iihy o' dauirtOi (I rep!; i o «' kTiidijt

» Ri t < 1! ( uitfirffj- nui preiiiatier o'lvr r and secure

will! ill luoisj.

IWrOPiAN* F>i~rPOLri.M ''Ol VPrn - SUCH AS

KEPO^'LUL ARE HOT TO [^F USED Tu CLEAN THE

C/T iRiC'iiL. i t MAY LA J: L DE’“FRICRATION OF

THF I HTR’DCE. Do. H H jIl MEIRIDCE. DO NOT

US'" PME , liROFFl Air. 1 k riEAU OR DRY

CAF THiiOF

■i . Ad I I F-*!; F fi F o ‘ s 5

n must be

imaqe frorr

dirt i tubborn dried gun

fiberi

iMt ' t i'^d iilii I' "O- Fttj f 0}

Reno., miy >1i't .'iit or >>!l fr'-r. -noinr rooSin tinsio

prevent engir

|. ÍI .^fpI I tr^r-z^dt’ i.>

I Pi< rri'"'-- « fcw- 'tom blotvet rou^sing ¿rii! 'ift hou; irig

a 1 ! *i|0 ti Í I'J.'fc .-iveinfilv .Jit ■ I'uii'ie

<,i.ivr of! ilii (.yt-ninq ic tjntr/ of «dti

11 rnum'ro ) 01! i t *tiff bri tío bfu Ji t dhurouLihl/

I L-1!« eri'j'! fc 'Gdini| tin*

• ti ffc..' cOifM n-'f rsfe ato prncedijtt-

naff to prf

MÍ '

CARTRIDGE

Page 19

REspow^^Bii

MUFFLER

Inspect and raplace corroded muffler and spark arrester (if

equipped) as it could create a fire hazard and/or damage.

f Ikji -

rie|. io - '»I lit p.jq J *hi '•(-<) iiiiiifj L't ‘ i( h III

iPa.Ci, I '•fmi .if-r/ is u , :.|.r i.i ¡. r tu-. rr

scouts tii3t Spa4 pliiq t/pt ind q p''fttinq are 'h{>w.-ii,

TFODUlT dFLC-ii^Sf Ik ,'Jd dth. .n r . |.

IN-LINE FUEL FILTER {See Fig. 16)

The fuel filter should be replaced once each season. If fuel

filter becomes clogged, obstructing fuel flow to carburetor,

replacement is required.

• With engine cool, remove filter and plug fuel line

sections.

• Place new fuel filter in position in fuel line with arrow

pointing towards carburetor.

• Be sure there are no fuel line leaks and clamps are

properly positioned.

» Immediately wipe up any spilled gasoline.

FIG. 16

CLEANING

• Clean engine, battery, seat, finish, etc. of all foreign

matter.

• Keep finished surfaces and wheels free of all gasoline,

oil, etc.

• Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to clean your

tractor unless the electrical system, muffler, air filter and

carburetor are covered to keep water out. Water in engine

can result in a shortened engine life.

19

Page 20

* yepress ctuicn/rjraice «<e.

* Place motion eontrel lower in neutral (N| position.

® Place attachment c

* Turn ignition key “OFF“ and remoce Icey^

* Halre mir» tN<» btsdee ' . .

® Disconnect spark plug m?ire from spark plug and place %

It

~4i

I! to.:: O,

lent lift leverforv/

!owi

Roll belt off engine pulicn

Disconnect clutch rod frc

retainer spnn<

tt"

removing retainer spring.

Disconnect siist^ension arrn

by removing retainer spring;

Page 21

BFiRv'ir r mit Mhiti'.imi fíí^

Hi M»>#rH mT5U«.»hi

Adjust the mower ftrhile tractor is parked on

Jlíi^w^j f/ih f.» - Ijr^ I,'“ .. j '< 1^ O

el ground or

flated (See

“PRODUCT SPECIFiCATIONS” on page 2 of this manual).

if il|t- 1 '•Í ' “ Í ill I t ik I li ijl. 1 -s J-. i! ‘ill 11' .1 pil 1^ I- !Í If,, 'i¡Li .

your mower.

oiDt !U .-i!iL Ali jU I r.'lt Co c,t^ i-igs. iy and ldj

® Rai .e liiotftei il - ti uh<-- nr*'itni<

« •^tihe (riidpoiiito both jid-cu1 Olí.wi t, measure height

from Dottoin edge of mowef íea'’*' I'to' E fei ¡nee “A” on

boih sides of mowe .should he fhr 'nme oi wiihin 1M'

c4 each other

• If adjustment is necessary, make adjustment on one

side of mower only.

• To raise one side of mower, tighten lift link adjustment

nut on that side.

• To lower one side of mower, loosen lift link adjustment

nut on that side.

NOTE: Three full turns of adjustment nut will change

mower height about 1/8".

• Recheck measurements after adjusting.

F

IÍ

ilMtNI (i

TBE LEVE

Í-TO-BAC

3 Piqs.

20 and 2

SIDE-TO-SiDE.

ADJUSiTMENT

ITH FRONT LINI

LEVEL. SIDE-T

FRONT

-BA

IMPORTANT: i

THE FOLLOWI

NECESSARY, BE SURE TO A[

EQUALLY SO MOWER WI

S!DE=

1' h‘-ii *1 i ‘ f Ll'it .1 - all -<-1 r i ami

shonldo^ < 1 -fhr titr ti' I hi r.; .T.aely 1/8' to

1' r II a at cha!, ih uar Alcfiii-- r i ¡i i ,i», i i u i I it^. .t

position.

Che ' hr C .1 •ichl I i ■ f !' a lui ‘tosur- d'S-

tanrr- i) flnr> iy intr'Kii iint! -'tiin ' 'Ik ma-il * ' dtbnf[om

edge of nin./h(,<, r g

• Before making any necessary adjustments, check that

both front links are equal in length. Both links should be

approximately 10-3/8".

• If links are not equal in length, adjust one link to same

length as other link.

• To lower front of mower loosen nut “E” on both front

links an equal number of turns.

• When distance “D” is 1/8" to 1/2" lower at front than

rear, tighten nuts “F” against trunnion on both front

links.

• To raise front of mower, loosen nut “F”from trunnion on

both front links. I ighten nut “E” on both front links an

equal number of turns.

• When distance “D” is 1/8" to 1/2" lower at front than

rear, tighten nut “F” against trunnion on both front links.

Ft-.. 2b

Page 22

SERVICE

REPLACE MOWER BLADE DRIVE BELT

: rtiav De

_T REMOVA!

R6iTiov0 me

MOWER” in this section of this manua!),

• Work belt off both mandrel pulleys and idler pulleys.

s Y It .,r> T, .T. j " ,

BELT INSTALLATION -

mower from tractor (See ‘TO REMOVE

WItflOUt tc

irkina br?

» fn'f.'i'l f.'-*! *‘i <e ti-i- rdrr (if -i' I

«• tlii-r I 1^ hr *1 lof! nlip'iiii'* ■ 'jtuO'.'c -i>.) ifi.iJe'-J1 belt

guides.

« IcAj'I .n r« venf r.-dp. of tfr-rnc’ ai Msrr.M.tions

TO ADJUST BRAKE fSee Fig. 23)

Your tractor is equipped with an adjustable brake system

which is mounted on the side of the transaxle.

If tractor ri-o"irc more W-m <6) feet stopping distance

at high p^'Ki mh ghtOg-ai tfienbiaki- n us» be adjusted.

« Depo ; ' iut! ri/biaKc Pi d_-tMn(ienfidat parking brake.

* MeriSUif fii:OriC>- brtwepii broke rating arm and

nut “A f r. hiai r tc d.

* If difaian* f i'. (-iher 1 '</io" loi^fen jam nut and

turnnut‘( ijn'i!<frtjm frrornes I b/16“. Retighten

jam ■’lit >, Oil i sa't ‘A

* Roadierd*'! tor otpn i -i 'tupoinijdisfenceas stated

above. F:> jJju'i if n* i.r- ¡f topping distance is

stii! qrf itf r 1h ti SC' Ml feW in hiyh’est gear, further

mainiei.piice i-I'lH c Cuntrit your'nearest au-

ihorizeci. .GP/iff c" ntrrtdf'paitment.

>,1-4k'fc

.

NUT “A”

u.

DO HOI TOUCH THIS NUl. iT FURTHER

BRAKE ADJUSTMENT IS NECESSARY

CONTACT YOUR NEAREST AUTHORIZED

SERVICE CENTER/DEPARTMENT

FIG. 23

TO REPLACE MOTION DRIVE BELT

(See Fig. 24)

Park the tractor on level surface. Engage parking brake.

For assistance, there is a belt installation guide decal on

bottom side of left footrest.

• Remove mower (See “TO REMOVE MOWER” in this

section of this manual.)

• Remove belt from stationary idler and clutching idler.

• Pull belt slack toward rear of tractor. Carefully remove

belt upwards from transmission input pulley and over

cooling fan blades.

• Puli belt toward front of tractor and remove downward

from around engine pulley.

22

FIG. 24

Page 23

St :( 4MR hU-iil‘. E r.fit f I|!;

rf) AÍJ iSST MFFHirl. ^

•j Í- » > i H‘ A t i - I I Í . . •' « i i" I / (I E ) h l< (■ 11 1 ,

when wheels are positioned straight forward, remove steer,i j w1wa| j.’iU m 1 ’ll ~ ii I ■ • I, I ‘1 r.i. !

- 'ritOl ,,t +M« 1

FRONT #HEEL TOE iN/CAMBFh

The ftunf A hem ir: i»i ^<<d ^nr-tr r- iii»r vijU.i-icfe iryour tractor It dr-n)3rifc trm >•* iirn a n> ad' c* tht trohi

wheel toe-in or «^amber. ''ontan a ur ui i. t cutht„ri7'.j

ser</ice f encer/dep: nment

Hi r*r oh' < / 'Si { ' I

IR REPAIR

Block up axis securelv.

Remove axle cover, retainin

wheel removal (rear wheel <

ishers to allow

luare kev - Do

® Repair tire and rBassembfo-

„a I I o ai V* * '3d „ s E ^ i \|h aj siV ,/t, eO - ' / hi el fiUl

Wif* ^ 1'- il, ri i ,

e f e A >'Ol I, ¡irt I ¡1 1-1 iliiln I i|,(, ■■ ( 'll fly in

fllUtiVi.-;.

* Replace axle cover.

NOTE; To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion.

WASHERS

RETAINING

RING

AXLE COVER

SQUARE KEY

(REAR WHEEL ONLY)

FIG. 25

23

Page 24

;■ /h L fijximmm'f S

■■ I '^GINE ■' ‘ Î-’ t; 'Gl?/ -

(See Fig. 26)

CAUTiON: Lead-acid batteries gener- I

ate explosive gsses. Keep sparks, flame I

' 1. . I I. > 1 ts. i M ' ' ill !(| >‘r, i'

A

i‘ I L'. ■ I I i'*i <1. <u i.Jii fLn r iHjH'i ii lijld t>e

‘-I Hfiiyi-1 I P-'' 'Lh ' iTht-'/U~ rr <fi‘> Nr^Pol'JSIBILiTIES section of this manual).

,i ' ,'jUij., “I I I' i' II <-j I . ( I ftji sif / I >’■ ifi’Kj I'i<oft'

tills plOGtsdUle.

irtn* >i-;| <sfi , M[' , j i . I -o I L> ‘UIP - i '» W' I M 0 • 0

'f,' I IJ <. I I 'P ' lu uni Tu t m Fhi iHE OTHi- P

. L iii ! I P. i « f, i i , I 'OL^ nC' mivr

oni-UdriLLi ir/| •.(.rJPi'i L .C>Jh rhtClOP

BATTERY TO START OTHER VEHICLES.

TO ATTACH JUMPER CABLES -

roain^il '■ii-

•* ( tiiitifci 1 Jifti md . i iht Li A« I l. bio Lj the NEGA' p/E ( ) ti roiir 'I • I fi*IU ' h^roed L'iceiy

r .0’CtT me '..’ho sfid o ¡h' ¡.oT' ¥ cabie lo good

ro Hf Ml '• t-m- rif R , Tr ORDE h ~

' TI AfK'.iPii f!i .tiioi oridi‘:i' ?nathr r, from the fully

» f’.i !)• It' IfOfO fcciih baitert;S

' f I r.tfl f *V ft I

when around batteries. I

“ iiiitc 1 e ti* fi I f oi d.- Ill O' - <bo to lilt F'OSiTP/E

<' f tfcimir>-^i ui h u tt>( % 05 inn ! net to short

I'ti'Ri »bfiO iu-'itant and battery.

RE ING Fiœ and ¿81

CAUTION: Do not short battery termi

nals by allowing a wrench or any other

.oirr-i t . jiiitas I L M tetniin lis .4 tbs

artir thi beiute ? jn^i't^cting cattary

№rPOtf<^ metal bi^ceietp. wiistwatch

l>iiriO«i Kfiüf. Hi

Pc»s.ltivfc îLrmi.iai Le tonnecteo

fi: r* to f rc' ent spar!* ing fre-n atcider

tel grounding

I lit ,t ,, n f'o n ed no itiiif, «r r! ..¡mr> b, tt«!; bu<

cioor.

Disconnect BLACK battery cable first then RED battery

cable and carefully remove battery from tractor.

Install new battery with terminals in same position as

old battery.

First connect RED battery cable to positive {+) terminal

with hex bolt and keps nut as shown. Tighten securely.

Connect BLACK grounding cable to negative (-) termi

nal with remaining hex bolt and keps nut. Tighten

securely.

Close batter/ box door.

SEAT PAN

BATTERY

BOX DOOR

I r-JOTL/r tCRiASo!

Ch

I POSrn/E

FIG. 26

IIECATiVF fERMirJAL

CABLES

CHARGED

BATTERY

NEGATIVE TERMINAL

POSITIVE (RED)

CABLE

FIG. 27

KEPS

'NUT

HEX

BOLT

NEGATIVE

(BLACK) CABLE

F!G. 28

24

Page 25

>EF

^0

Ji

:E AND ADJUSTME

iiCi

Puif b

qrili.

»LACI

hood

uib hoi

E HE ADI

I ifSH

f • Í ii-'i «• h. llíí t' '< 4i 1' I .■! I I 11 i 'I '!■ 11' <l 1 r ■ ii [•

f - • I- ÍÍII ■ *?.( I I (Í' J M. I Í' • . ' ' .

Close hood.

NTERLOCK^^ AND REl Afb

Ii-r t .1 (J-itn Iljtd If j ill i '>U. liJtt i' ■! i(. I'lh

nil fiy, . iup ■» Sn'» »/“(>1 it ■'< j!T- t' li'il.j

C.rit > I- 'Viri u -L.' '-i- ail -i! V*! iiK. U! trji .Cl III Ihe

'!l! f‘,l!¡ ■ Si. ... Í .¡'ll' lilfJlH -J

ÜI

INI

TO ADJUST Tf

^Se0 Fig.. 30)

The throttle control

adjustment should n

described below before loosening cable

1 r‘ c* ■ I f‘ pH I i' Ii V..'

• iViiri . itfiiFi- ta liiMHHty ■(../. iiif..tti < nii I li(

fi .ii -.1 iJ i' ( III И f.. I ifi »1 ■ 1 .'!' II) ' l. . i I a,i

tJl' I f to 1 ' ) p ■> -I.'! (

■ Check that holes “A” in governor control ¡ever and hole

ill fjiW. rinx pLile IlfiH up !l huh i\ Iii'£ tiliCjii и

).■ .о;'f f Iji/f-ai.-# jiiif 'k Vk ihrolfii i ibC.iiiti' <н.ti

if' Jifjiio»! Iiijhh*1' !.-i! f и ...p

so BERLAtE Flisr

i«pNc'f with ti' 11 Of. jiiion'otivf- type pliiij in ill-- Th<^

ilKe h'dfjf^r ii If./ f.t-ij hf-hind th. .'Jjsi.

ÍO REMOVE HOOD AND OBILL ASSEMBLY

See Fig 29)

• Raise hood.

• Unsnap headlight wire connector.

‘ Stand in front of tractor. Grasp hood at sides, tilt toward

engine and lift off of tractor.

TO ADJUST f ARBlIHCTfjS

ihc ( •tfjitifKv ii2i; i)fc-mipr *r >1 irv fcitoiy ind .-.fJiu ,i

merit should гю! or ct-m.irv l-iuwf ver, minor -nljiG

merit may be requited toe orri|-ifcii'.atc- f< ¡r riifirff-nce^- in fuel

tempeiatuic c,ltihido m loaif iftlir- iT-tiretoi Пб‘*‘!

bfijii-truHii eee ►-ngirik uidiiliei

IMPORrANl fttvH. TAMI tFi VdiH THE ENGItlF

GOVFHNOR WHICH lb FACK4W Off F()H PRCPth

ENGINE 4FEFD 0\/EHf.FEbDHM{, THE E rjGItlE AFTiVc

1НГ FACTORY HIGH TPEEU SETTING САП BE

L'ANGl HO-Jl 'F YOU THINK iHK tNGINb-Gt*VhP.f!fcC)

.^FEFI» IMLEDC AC<JU>!!NCS CONTAtT .'"'lilt

HIGH

r'EAFiFb: AU rnOFi'ZEf) SERVK.F CFNTFFI/

СЕРАВГМГН! WHICH HAS f RuPEFT FQlliPMEriT AND

EXPERIENCE TO MAKE ANY idtCFSSAFiY

ADJUSTMENTS.

BL

rt

m

'k

adjustment c

idjUw.tra iiT

25

Page 26

STORAGE

Imrnediatelv Drenare your tractor for storage at the end of

the season or if the tractor will not be used for 30 days or

more.

nON: Never store the tractor with

line in the tank inside a building

e fumes may reach an open flame

A

TRACTOR

Rei'Tiove mower

mower is to be

oijgWy, remove

clean, dry area.

Responsibilities section of this manual).

pl-iLt rn( fitiirtfiKtiur." irah‘ rv!t t end Adiimirnf nts

settK'h of t,.r minujl)

i ub •' Hi V I,'

section of this manual.

imrrfvd lo'[, < r iiM. ini) p iit lot (hmaqi hroakige

mill V .r \ if . >p- h IK ‘ (f; o,y

luU'i iip all ru‘uii or . Iiioni ij paint nrijcm .ind

liqhtiv ffrluro paiiitii.y

BATTERY

® Fulb riiifj. the L.itl> I r f'H Pir

® M'( > ptiifiii H iiriii ,.i Jot^ai battf Iy may require

trcholfjio'i

* " ■ i.elp pi< .if It ut I • . ,h . nd I irf/f r ’t.e‘ '^gr during

i ina pHiiL j of loijc I itn 7 cdbl tfiould be

nF'lfhofTfr., /'»' P Hitllftol . in the Cus”

tomer Responsibilities section of this manual).

® lace

^. hi v-.< < ¡'|M- no itni >1 in ■ oi,f H i with batten

terminals.

• !i b tp- 7 I • 0 <. I .i‘.si t. 1 foi * j«' I'le, (JO not

store batte7 directly on concrete or damp surfaces.

or spark. Allow the engine to cool

before storing in any enclosure.

from tn 3ctor for w

to red fc)T a period

all dirt,

factor (Í

i ft ..rid r. ploi s 1» It t >ii -f'; iry (See uelt *e-

> 1

i> hi ' '■ tf.hioi Pm poii dnliTit s

< ur* litidliiiiJi i oim n id L'.rowj .ti„ ..tt uiuv

i, ti i/> to ,rio Itho ouqlily(~ee“TO

grease, tec

toe“CLEAI>JING”intheCi j'-iunibr

inter storage. When

of time, clear 1 if thor-

ives, etc. St< ore in a

=UEL i

IMPORTANT: IT IS IMPORTANT TO PrtEVENT GUM

DEPOSITS FROM FORMING IN ESSENTIAL FUEL

1 ijt I H-c i >H lAfit [ I,hin ' f()H«(-p .I'M

EXPERIENCE INDICATES THAT ALCOHOL BLENDED

luK I i.rr O- 'tL-. R diC -"’rhOlOt ,Fl

MriH/'i! *1; Af. T 1 IhAi ! iViui ,Tt'RL WHI*'H 11 aD :

. <•. 7J afto R< TI ''Ur- FOpMi ! K»n • to ^« IDS riUBirir’

mUHAGb. A( ID'i GLS i /-fJ LtoMALL IMF F'IEL

•, UN ih f .Jtoitiv ■OHii F Ifi 1

• Drain the fuel tank.

• Start the engine and let it run until the fuel lines and

- Ni-vf' iicv. 1 H

® U =<• frt'li fuel q£/.i „1-3 on

flOTE ruel inbilrei w. Ti a».-vptHDto DltornjjtW''^ in

niininiv ing ih(- f'liin 4i(>n o! fiw I cjiiin deposK-. during stor

tge t-dd ctybilivei t. qa' olin< iti tuel nnk oi storage

1 ont-ii’ Alw. ys iollf'W ilv mi^ r iliu f-vind on stdbilizei

icmfuifi'« mifJiMir it- Mf lo idiiiijit - -trter adding

SI jüi I I'j-ill> iiti iht lubiil as I* < 1 tat h the •* aTuuiei'ji Do

riutdrin thf-uastonk _ndrait)!iretor if uungtijf^totabiiizer

w‘ m I j ' it , ‘ i i T I fit I f I ■[ R

carburetor are empty.

¡ 1 1

to

, 1

<toM I jiiei pK.dii, t'. iri itie

L H ! I "I l' p "I p“" IN Idhf nf d, 01 mui" 1 iiA I u'. Up

ENGINE OIL

Drain oil (with engine warm) and replace with clean engine

oil. {See “ENGINE” in the Customer Responsibilities

section of this manual).

CYLINDERfS)

• Remove spark plug(s).

9 Pour one ounce of oil through spark plug hole(s) into

cylinder(s).

» Turn ignition key to “START” position for a few seconds

to distribute oil.

• Replace with new spark plug(s).

01 HEB

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

® If possible, store your tractor indoors and cover it to

give protection from dust and dirt.

• Cover your tractor with a suitable protective cover that

does not retain moisture. Do not use plastic. Plastic

cannot breathe which allows condensation to form and

will cause your tractor to rust.

IMPORTANT: NEVER COVER TRACTOR WHILE ENGINE

AND EXHAUST AREAS ARE STILL WARM.

26

Page 27

-'‘RouBi ESHooTiN»:,

PROBLEM

Will not start

Hard to start

Engine will not turn over 1.

cuysb

10.

O'j-' '■/ k'-r!

Ffi-iin*; r<oi ■ •';H0KED” property.

?

Engine flooried.

'3

Bad sparK plug.

4

b. Difiy aif filter.

Dirty fuel filter.

6.

Water in fuel.

7.

Loose or damaged wiring.

8.

Carburetor out of adjustment.

9.

Engine valves out of adjustment.

1. Dirty air filter.

2. Bad spark plug.

Weak or dead battery. 3.

3.

4. Dirty fuel filter.

5. Stale or dirty fuel.

Loose or damaged wiring. 6.

6.

7. Carburetor out of adjustment.

8. Engine valves out of adjustment.

Clutch/brake pedal not depressed.

Attachment clutch is engaged.

2.

Weak or dead battery.

3,

4. Blown fuse.

Corroded battery terminals.

5.

Loose or damaged wiring.

6.

Faulty ignition switch.

7.

8. Faulty solenoid or starter.

Faulty operator presence switch(es).

9.

RRECTION

1. Fill fuel tank.

See ‘TO START ENGINE” in Operation section.

2.

Wait several minutes before attempting to start.

3.

Replace spark plug.

4.

Clean/replace air filter.

5.

Replace fuel filter.

6.

Drain fuel tank and carburetor, refill tank with fresh

7.

gasoline and replace fuel filter.

8. Check all wiring.

See ‘To Adjust Carburetor” in Service Adjustments

9.

section.

Contact an authorized service center/department.

10.

1. Clean/replace air filter.

2, Replace spark plug.

Recharge or replace battery.

4. Replace fuel filter.

5. Drain fuel tank and refill with fresh gasoline.

Check all wiring.

See “To Adjust Carburetor” in Service Adjustments

7.

section.

8. Contact an authorized service center/department.

1. Depress ciutch/brake pedal.

2. Disengage attachment clutch.

3. Recharge or replace battery.

4. Replace fuse.

Clean battery terminals.

5.

6. Check all wiring.

7, Check/replace ignition switch.

Check/replace solenoid or starter.

8.

Contact an authorized service center/department.

9.

Engine clicks but will not 1.

start 2. Corroded battery terminals.

Lose of power

Excessive vibration

Weak or dead battery.

Loose or damaged wiring.

3-

4. Faulty solenoid or starter.

1. Cutting too much grass/too fast. 1.

Throttle in “CHOKE” position.

2.

Build-up of grass, leaves and trash under mower. 3.

3.

4. Dirty air filter. 4. Clean/replace air filter.

5. Low oil level/dirty oil.

Faulty spark plug. 6.

6.

7. Dirty fuel filter.

Stale or dirty fuel. 8. Drain fuel tank and refill with fresh gasoline.

8.

9. Water in fuel.

10. Spark plug wire loose.

Dirty engine air screen/fins. 11. Clean engine air screen/tins.

11.

Dirty/clogged muffler. 12. Clean/replace muffler.

12.

13. Loose or damaged wiring.

Carburetor out of adjustment. 14. See “To Adjust Carburetor” in Service Adjustments

14.

Engine valves out of adjustment. 15. Contact an authorized service center/department.

15.

1. Worn, bent or loose blade. 1. Replace blade. Tighten blade bolt.

2. Bent blade mandrel. 2.

3. Loose/damaged part(s). 3.

1. Recharge or replace battery.

2. Clean battery terminals.

3. Check all wiring.

4. Check/replace solenoid or starter.

Set in “Higher Cut” position/reduce speed.

2. Adjust throttle control.

Clean underside of mower housing.

5. Check oil level/change oil.

Clean and regap or change spark plug.

7.

Replace fuel filter.

Drain fuel tank and carburetor, refill tank with fresh

9.

gasoline and replace fuel filter.

10. Connect and tighten spark plug wire.

13. Check all wiring.

section.

Replace blade mandrel.

Tighten loose part{s). Replace damaged parts.

27

Page 28

problem 1 CAUSE RRECTION

Engine continues to run

when operator leaves seat

1. Faulty operator-safety presence controi system.

with attachfiient clutch

engaged

i'L.Of cut Ul'i'S'jfcfi 1 P/orri. bent or loose blade,

r,'io лег decK rot level

I ijuildui'i of glass ifc&ves, and bash under mower.

У Ber.t Ltade rnandrei,

I C iocjgej "ПОА'бг deck vent holes frorr; buildup of

ytas-', leaves, and irash around mandrels.

Mower siades wiii not

I 1 Obstruction in ciulch mecnariisrn. 1, Remove obstruction.

rotate 1 2 Worrddamaged mower drive belt,

i 3 Гюгеп idler pulley,

1 4, Frozen blade mandrel.

Poor grass discharge 1. Engine speed too slow.

[ Travel .speed too fast,

3. Wet grass.

4. Mower deck not level.

5. Low/uneven tire air pressure.

6. Worn, bent or loose blade.

7. Buildup of grass, leaves and trash under mower.

8. Mower drive belt worn.

9. Blades improperly installed.

10. Improper blades used.

11. Clogged mower deck vent holes from buildup of

grass, leaves, and trash around mandrels.

1, Check wiring, switches and connections. If not

corrected, contact an authorized service center/

department.

1. Replace blade. Tighten blade bolt.

2. Level mower deck.

3. Clean underside of mower housing.

4. Replace blade mandrel.

5. Clean around mandrels to open vent holes.

2. Replace mower drive belt,

3. Replace idler pulley.

4. Replace blade mandrel.

1. Place throttle control in “FAST” position.

2. Shift to slower speed.

3. Allow grass to dry before mowing.

4. Level mower deck.

5. Check tires for proper air pressure.

6. Replace/sharpen blade. Tighten blade bolt.

7. Clean underside of mower housing.

8. Replace mower drive belt.

9. Reinstall blades sharp edge down.

10. Replace with blades listed in this manual.

11. Clean around mandrels to open vent holes.

Headlight(s) not working 1. Switch is “OFF”.

{if so equipped) 2. Bulb(s) burned out.

3. Faulty light switch.

4. Loose or damaged wiring.

5. Blown fuse.

Battery will not charge

1. Bad battery cell(s).

2. Poor cable connections.

3. Faulty regulator (if so equipped).

4. Faulty alternator.

Loss of drive 1. Freewheel control in “disengaged” position.

2. Motion drive belt worn, damaged, or broken.

3. Air trapped in transmission during shipment

or servicing.

Engine “backfires”

when turning engine

“OFF”

1. Engine throttle control not set at “SLOW”

position for 30 seconds before stopping engine.

1. Turn switch “ON”.

2. Replace bulb(s),

3. Check/replace light switch.

4. Check wiring and connections.

5. Replace fuse.

1, Replace battery.

2. Check/clean all connections.

3, Replace regulator,

4. Replace alternator.

1. Place freewheel control in “engaged" position.

2. Replace motion drive belt,

3. Purge transmission.

1, Move throttle control to “SLOW” position and allow

to idle for 30 seconds before stopping engine.

28

Page 29

ICHEIIATIC

RED

-MODL ''

♦

o

BATTERY

FUSE 30 AMP.

CLUTCH/BRAKE

(PEDAL UP)

O a

SOLENOID

ATT'MENT CLUTCH

(CLUTCH OFF)

IGNITION

UNIT

CHARGING SYSTEM OUTPUT

3 AMP DC e 3600 RPM

<XY •— o

STARTER

BLACK

SEAT SWITCH

(NOT OCCUPIED)

GROUNDING

CONNECTOR

SPARK

PLUG ^

U gap w

(2 PLUGS ON

TWIN CYL. ENGINES)

28 VOLTS AC MIN. « 3600 RPM

(CHARGING SYSTEM DISCONNECTED)

IGNiTION SWITCH

PO' '! N ( R( U 7

G + M + L NOL L,

RUN Lit HT r i L M

“MAI*E •

NONE

NONE

FUEL SHUT-OFF

SOLENOID

ORANGE

NOTE

YOUH TFri Fvjh

E (Al'l TLC y/MH A fL( lAL

ALTERrJMluR c-'.'SrFM

THE LICri^T AtiE rJCf

( i •rifJPtTFr TC TdL

FA TTERt EUr HA)/t iHFIP

OWII ELEPTRIOAI Sf'HBi'F.

PECAL.-E C'F FHIF 1 HE

EF.I'.-HìrjLSSCr INE LFHFS

W'LLCH.AHCE WifH I rJGiriE

FPEEC. AT ìdlF fHF i IGHTS

Wil„DIF1 AbTHE Li'GirJE !S

F RLE DFDUF (HFllGm«^

W<l L btCufViF 1 HtlH tìhiC HTEST

NON-REMOVABLE

CONNECTIONS

WIRING INSULATED CUPS

NOTE: IF WIRING INSULATED CLIPS WERE REMOVED FOR

SERVICING OF UNIT, THEY SHOULD BE REPLACED TO

PROPERLY SECURE YOUR WIRING.

29

REMOVABLE

COHMECTiONS

Page 30

. ;/'V. '-Ч -MCi h« I., Hi

Page 31

REPAIR PARTS

.iX . l:4:rr. v iVk..

LECTRICAL

KEY PART

NO. DESCRIPTION

NO.

1 144925 Battery 12 Volt 25 Amp

74760412 Bolt Hex Hd 1/4-20unc X 3/4

2

156417 Case Battery Mech Hinge

8

153664 Switch Interlock Push-In

16

19 10090400 Washer Lock 1/4

73350400 Nut Jam Hex 1/4 20 Unc

20

21 136850

22 4152J

4799J

24

146147 Cable Battery 6 Ga Red w/16 wire

25

108824X

26

73510400 Nut Keps Hex 1/4-20 Unc

27

4207J

28

121305X Switch Plunger Nc Gray

29

140301

30

12421IX Nut Ignition

31

Harness Socket Light

Bulb, Light# 1156

Cable Starter 6ga 11 “ Red

Fuse 30 Amp Auto Green

Cable Ground 6ga 12“black

Switch Ign 4 Pos W/L P/L

32 141226 Cover Sw Key

122147X Key ign Molded Generic

33

40 156442

41 71110408

131563

42

145673 Solenoid

43

44 73640400

140844 Adapter Ammeter Rectangular

48

Harness Ign

Bolt Fin Hex 1/4-20uncx 1/2

Cover Terminal Red

Nut Keps BIk Fin Hex 1/4-20 Unc x 1/2

52 141940 Protection Loop

140422 Harness Eng B&S 14 OHV Dual

70

NOTE: All component dimensions given in U.S. inches

1 inch = 25.4 mm

31

Page 32

REPAIR PARTS

CHASS D ENCLOSURES

32

Page 33

REPAIR PARTS

::hass!S and enclosures

TRACTOR

KEY PART

NO.

1

160393

140C 5f

5

i,490G12

4 191 3T-16

5 155272

e

155923 Saddle Fender Shift Hat

8 155135

9 1fcl93.'<011

10 “2140603

1 1 155923

ir 145660

13 155934X010

1749060S

14

15 74180512

16 73510500

17 159639X428

18 126938X

20 156437

23 124028X

24 74780616

25 19131312

26 73800600

28 157373

29 140273

30 157583X428

31 136619 Bracket Fender

33 105476X428

34 105475X428 Footrest Pnt. Rh Ms-428

35 72110606

37

17490508

38 139886

39 139887

51 73800400

52 19091416

53 144697

54 161464 Screw hex Wshd 8-18 x 7/8

144696 Bracket, Grille RH

55

57 74780412

58 150127 Air Duct Private Labe!

140 158418

156524 Rod Pivot Chassis/Hood

145

5479J

NOTE: All component dimensions given in U.S. inches

1 inch = 25.4 mm

MODELNU

Drawbar Streicn 94

Screw ThdroL 3/SDG > 3/4 Ty-Tt

Washer 13/32 x 3/4 x 16 Ga.

Bumper Hood/Dash

Clip Retainer Siide-On

Dash Private Label

Eoii RdHd Sqnk, 3/8-16 Unc x 1

Panel Asm. Dash Lh

Clip Tinnerman Grile P/L

Panel Dash Rh

Screw Thdro! 3/8-16 x 1 <2 Ty-Tt

Screw Mach Trhd 5/16-18 Unc x 3/

NutKeps 5/16-18 Unc

Hood Pnt Steel Private Label

Bumper Hood

Plate Mtg Battery/Fuel Tank

Bushing Snap Nyl. BIk Fuel Line

Bolt Fin Hex 3/8-16 Unc x 1 Gr. 5

Washer 13/32 x 13/16 x 12 Ga.

Nut Lock Hex w/lnsert 3/8-16 UNC

Grill Private Lable BIk

Lens Grille Private label

Fender Asm LT w/Shift MS-428

Footrest Pnt. Lh Ms-428

Bolt RdHd Sht. Sqnk, 3/8-16 x 3/4

Screw ThdroL 5/16-18 x 1/2 Tyt

Bracket Asm. Pvt. Lh Mwr. Rear

Bracket Asm. Pvt. Rh Mwr. Rear