Page 1

J)(j

OWNI =I'S MANUA

MODEL NO. HD145H42E

14.5 HP 42 Inch

Lawn Tractor

Assembly

• Operation

• Cystomer Responsibilities

• Serwice and Ad|ysiments

• Storage

• Troybieshootiiig

For Parts and Service, contact our authorized distributor: call 1-800-849-1297

For Technical Assistance: call 1-800-829-5886

• Rfepeiii’ Paits

160464 3.17.97 RH

PRINTED IN U.S.A.

Page 2

IMP'

FAIL

A

-.3 IVI Ai™.

POLL

SAFETY RULES

3per3tioii Practices for Ride-On ili

NE IS CAPABLE OF AMPUT.ATIMG HANDS A

/ING SAFETY INSTRUCTIONS COULD RES^

J4

'HROWING OBJECTS.

-RIC

G INJURY OR DEATH.

I. GEUERAL OPERATION

• Read, understand, and follow all instructions in the manual

and on the machine before starting.

• Only allow responsible adults, who are familiar with the

instructions, to operate the machine.

® Clear the area of objects such as rocks, toys, wire, etc.,

nil! 1. I . pK 1- 0 tit.u ' I L) the I lads.

I --u - f ,t I ()i if * I |sec{ ’f ' inDwing.-'loi

■ U itft- it. >1 -'ne ''It. o lOf area

• Never carry passengers.

. r<i. .< I >i> iA IS!.<1-- i’i> <: solutlv 1-.. s ry. AlWrW

I

, ,1 oo'^ fi vi‘ 1 or >iri'

! . < ir j‘ 'I. ,ce di'sciioii siifl (jo nei K-!iit

at V • - i t ? r. -t Optra.., ihe mou'-*t w<*TiOut eilhi r tr.€

. -k w j. I L ri.if lu nil Ip

• ¡it ^tL -li < I tij r.4,euiiailciKtej \lwavsiurnoff

f id.vs St; >1 i'i(j hi il-*', -lop engii.fc tivl lemov“ teys

1)' t |A o!-rc II . ng

1 an nil MaJ c'oils I >rt t v'ing.

rtop ™?,fjine ufiom temcvirni jrass ..atch^t ii unctog jing

chuie.

Mow only in daylight or good artificial light.

Do not operate the machine while under the influence of

alcohol or drugs.

VVaich for traffic when operating near or crossing roadways.

Use extra care when loading or unloading the machine into

a trailer or truck.

1!. SLOPE OPERATION

Slopes are a major factor related to loss-of-control and

tipover accidents, which can result in severe injury or death.

All slopes require extra caution. If you cannot back up the

slope or if you feel uneasy on it, do not mow it.

DO:

Mow up and down slopes, not across.

Remove obstacles such as rocks, tree limbs, etc.

Watch tor holes, ruts, or bumps. Uneven terrain could

overturn the machine. Ta// grass can hide obstacles.

Use slow speed. Choose a low gear so that you will not have

to stop or shift while on the slope.

Follow the manufacturer’s recommendations for wheel

weights or counterweights to improve stability.

Use extra care with grass catchers or other attachments.

I

hese can change the stability of the machine.

Keep all movement on the slopes slow and gradual. Do not

make sudden changes in speed or direction.

Avoid starting or stopping on a slope. If tires lose traction,

disengage the blades and proceed slowly straight down the

slope.

DO NOT:

• Do not turn on slopes unless necessary, and then, turn slowly

and gradually downhill, if possible.

• Do not mow near drop-offs, ditches, or embankments. The

mower could suddenly turn over it a wheel is over the edge

of a cliff or ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction could cause

sliding.

• Do not try to stabilize the machine by putting your foot on the

ground.

• Do not use grass catcher on steep slopes.

r *:hf- arlfi* gu rd in i.,lacc

t< j j

and whip bicki i”

III. CHILDREN

Tragie accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the

machine and the mowing activity. Never assume that

children will remain where you last saw them.

ь . t '.ivli' ' I „ I c , WÄ ni, ft.л1, ' 'f If r:ne watchful

care of another responsible adult.

Ч ii ri and lu r i o( hh f >• 11> r hiHien ~i к rthe area.

r<( !■ «' rndwh I tn ' >■ !c i <i-ii П-* iH' down for small

1 n

' I >. J ( hit- t-r 0 , . w I-‘I nff i(,d be seriously

к , i 'Г Iti* ,f - -C.U i I- ,J|M. t ji ,,<iion.

> Nr t-1 л1к ’A fiT |t. I ') iP<, life- 'Лс ■ I Ih I--.

» ,,'ti ' • r -An appi ™ T. и Ы'||г1 ( omeis. shrubs,

10 il I ( ’ 11-1 t>'. ..ir

14 SERVILF

“ rV"- It h mnlingaib iint-.andotherfuels they are

fl.'iMi'iiahA nfrd 'VI ‘ art - -p* —i i‘-

' Ise 'Ply г . I rrt 't-'d 'ontPiner

fiw.c- remr I- gas ap o. add fuel with the engine

running. Allow engine lo cool before refueling. Do not

smoke.

Never refuel the machine indoors.

Never store the machine or fuel container inside where

there is an open flame, such as a water heater.

• Never run a machine inside a closed area.

• Keep nuts and bolts, especially blade attachment bolts, tight

and keep equipment in good condition.

» Never tamper with safety devices. Check their proper

operation regularly.

• Keep machine free of grass, leaves, or other debris build-up.

Clean oil or fuel spillage. Allow machine to cool before

storing.

• Stop and inspect the equipment if you strike an object.

Repair, it necessary, before restarting.

• Never make adjustments or repairs with the engine running.

» Grass catcher components are subject to wear, damage, and

deterioration, which could expose moving parts or allow

objects to be thrown. Frequently check components and

replace with manufacturer's recommended parts, when nec

essary.

• Mower blades are sharp and can cut. Wrap the blade(s) or

wear gloves, and use extra caution when sen/icing them.

• Check biakf -,nJ.ion frexjuently. Adjust and service as

required.

i oak .a. lifis syir.boi tc point out im-

p.vftij-'it '--aieiy piiicaatiun-s. It means

A

A

u-A.UiTJM!!! BECOME ALERT!!! YOUR

EAFETY IS INYOLYED.

CAUTiuN, Aiwaya riisccnnect spark plug

wire and piece wire where it cannot contact

spark plug in order to prevent accidental

'.larJny when setting up, transporting,

aUpsiing Vf makina lepairs.

A WARNING A

The engine exhaust from this product con

tains chemicals known to the State of Califor

nia to cause cancer, birth defects, or other

reproductive harm.

Page 3

ÎONGRATIJLATIONS on

)urc

wtracfor

t has been desiqned, en(

me ufc

^OU 61

xpenence any problem you cannot easih

>e contact your nearest authorized servict

pleas

3r/d€

I' j 1 i i ‘ ‘ • ir < >-,1 f ' I 1 1.Î,i 1 ' , • ,'!l

nent. We have competent, well-trained tech

3 oroDer tools to service or repair this tractor

anc

310 QC

irmance

-, I i! •<. ■ ! I ' • - !> ( i * r HI, i ihlil i J, >1 M I |i >t > . d ;

l4o, .L . I ilv '-PE Ì h FJHF:r

ivH .In L

NUMBER

HD145H42E

SERIAL

NUMBER.

D' rtuFP'lif H-' ‘ I

THEMODEl wULWr RiAf ! !!!ML£RSW!LLBEFOUND

ON A PL

YOU SHOl! 'J hLLORb iif j fH SERIAL NUMBER AND

DATE OF i'UP.LHAi F AND h 07* IN A SAFE PLACE

FOR FUTURE Bi FthErJGl

CUSTOMER RESPONSIBILITIES . ■

• Read anri observe the eWety rules.

' Follow a regular scht-dult in maintaining, caring for and

using your tractor.

* Follow the instructions under “Customer Responsibili

ties” and “Storage” sections of this owner’s manual.

(GAP; .030")

VALVE CLEARANCE: INTAKE: .005" - ,007"

FVHAII.CT- nno"- 011“

jSPnrDf 4PH) FORWARD: 0.0 -5.5

TIRE PRESSURE:

CHARGING SYSTEM:

BATTE RY:

BLADE BOLT TORQUE: 30-:* Fi ti' .

REVERSE: 0.0 - 2.3

FRONT: 14PSI

REAR: 10PSI

G / Hi ’ f. Î1 ^ 1

^TS

Mit- c. A 1 4 )

CA.'o:,! b . ih

WARNING: This tractor is equipped with an internai

combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-cov

ered land unless the.engine’s exhaust system is equipped

with a spark arrester meeting applicable local or state laws

(if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

A spark arrester for the muffler is available through your

nearest authorized service center/depariment (See RE

PAIR PARTS section of this manual). ■

In the state of California the above is required by law

(Section 4442 of the California Public Resources Code),

Other states may have similar laws. Federal laws apply on

federal lands.

Page 4

T^riL •:=>- r

SAFETY RULES ........................................................ 3

PROOyCT SPECIFiCATIO« ..................................3

'■ f" L :p "■;r-Er;slT''^r •'

■tfwMriRAhi I ¥

.................. 3lj

..............

, ' r,Yi“i r „ ................. - ''

INDEX

A

Adjustments:

Brake

........................................

Carburetor.

.......

25

22

Mower

Front-To-Back

Side-To-Side

Throttle Control Cable

Air Filter, Engine.........

Air Screen, Engine

Assembly............

........................ 21

..........

................ 21

.................

....................

.........................

..............................

24

18

18

6-9

B

Battery:

Charging

Cleaning.

Starting with Weak Battery

Storage

Terminals

...................................

...................................

........ 23

...................................

.................................

7

17

26

17

Belt:

Motion Drive

Removal/Replacement

................

Mower Be!t(s)

Removal/Replacement

.........

22

Blade:

Sharpening

Replacement

Brake Adjustment

................................ 16

.............................

.............................

16

22

C

Carburetor Adjustment

Controls, Tractor................................. 11

Customer Responsibilities.....

Engine:

Air Filter

Air Screen .............................

Cooling Fins

Engine Oil

Fuel Filter

Spark P!ug(s)........................

T factor:

Battery...

Blade.....

Lubrication Chart........

Maintenance Schedule ...........

Tire Care .........................

Transaxle................................. 17

Cutting Height, Mower

.....................

......... 15-19

...............................

..........................

........................

..............................

..............................

................................

...........

7,16,23

......

..................12

25

18

18

18

13,17

19

19

17

16

15

15

E

Electrical:

Interlocks and Relays..

Schematic ...............................

Wiring Diagram .......................

..............

24

29

30

Enu rip

7ir '■ -ei i>. ................................. 18

( 0' ..I f i !‘r

( 41 ' hr-li'lL ...

Oil L,f‘.'P! ..

OilTyit- .............................. 13,17

F*rrp,_r-iiiin

Stpilnu .... 14

Storagp

................................... 26

Filter:

Air Filter................................... 18

Fuel........................................... 19

Fuel;

Type

........................................ 13

Storage ........................................ 26

Fuse ........................................... 24

Hood Removal/lnstallation ...............

22

Leveling Mower Deck......................

Lubrication:

Chart..................................... 15

Engine

.................................... 17

Maintenance Schedule

Mower:

Adjustment, Front-to-Back

Adjustment, Side-to-Side

Blade Replacement...................... 16

Blade Sharpening ..................... 16

Cutting Height........................... 12

Installation

Operation

Removal................................ 20

Mowing Tips

..................................... 14

Muffler........................................ 19

Spark Arrester..................

Oil:

Cold Weather Conditions........ 13,17

Engine..................................... 17

Storage

..................................... 26

Operation .................................. 11-14

Operating Mower...........

1AINTF“*"^= ei-ucniii c

SERVICE Al»' 'I

STORJ

i-. «E, 7 «-

REPAii

PARTS ORDERiNG/SER¥ICE

.

...................... 18

.....

.............. 18

.

.......................... 17

....

........................... 13

............................

13

F

H

24

L

21

M

....................

.............................. 20

.................................. 13

O

...................

......

....21

...........

......

3,40

15

21

13

1R

...............20-25

.

.................. 26

................27-28

»0 %!

bfitl- liWEh

Options:

Spark Arrester......................

....

3,40

p

Parking Brake

Parts Bag

Parts, Replacement/Repair

Product Specifications. ....................

.....

................................... 11-12

....

............................................... 5

..........

............

30-47

3

R

Repair Parts ..............................

30-47

S

Safety Rules.....................................

Seat

.................................................

Service and .Adjustments ............... 20-25

Carburetor.

..................................

Fuse........................................

Hood Removal/lnstallation

Motion Drive Belt

Removal/Replacement

Mower Belt(s)

Removal/Replacement

Mower Adjustment

Front-to-Back........................

Side-to-Side ........................

Mower Removal/lnstallation

Tire Care.............................

Slope Guide Sheet

Spark Plug(s)

Specifications

Starting the Engine

.............................

....................................

.....................................

........................

Steering Wheel ..........................

Stopping the Tractor

Storage.........

...........................12

..................................

3

7

25

24

...........

24

...........

22

................ .

21

21

........

20

7,16,23

51

19

2

13-14

.6,23

26

T

Throttle Control Cable Adjustment

Tires

.......................................

Troubleshooting Chart

Transaxle

Warranty......

..................................... 30-47

....................................... 3

Wiring Diagram

..................

W

...................................

Wiring Schematic ...........................

.......

7,16,23

27-28

30

29

24

22

Page 5

firs'" S' ; ■: :

Parts Bag contents shown fyll size

(1) Large Flat Washer Lockwasher 3/8

(1) Locknut

5/1608

(1) Hex Bolt 5/1608 X 1-1/4

(2-'

Parts packed separately in carton

(1) Shoulder Boit 5/16-18 (1) Hex Bolt 1/2-13x1

(1) Lock Washer 1/2

(1 ) Washer 17/32 x 1 -3/16x12 Gauge

(2) Hex Bolts 1/4-20x3/4

(2) Hex Nuts 1/4-20

(2) Lock Washers 1/4

(2) Washers 9/32 x 5/8 x 16 Gauge

Parts bag contents not shown fyll sizi

e

(2) Shoulder Bolts

(2) Washers 17/32

X 15/16 X 12 Gauge

steering

Wheel

Insert

Slope Sheet

(2) Gauge

Wheels'

n

Steering

b-**- rc vm

o

(2) Center-

lock Nuts

o

(2) Washers 3/8

X 7/8 X 14 Gauge

J,- 1

i

Steering Wheel

Adapter

(2) Keys

(o

Page 6

ths fBCtory with ©Xcsp

I o 6nsu

the corn

: prop

3ur tractor all parts an

3roper tightness.

rU.iU '.t y.JtNi t- i 4 ajn./

^ so* n ' ^" F h r{/'is> e M 1 ^ ‘ im ^' I

wrench sizes are listed.

/1. y/'J" Uu» t I .r'f. r'H tK T I li.lliv h(i*o

(2) 7/ib' wionct.eo 1 ire pressute gauge

(2) 1/2" wrenches

(1) 9/16" wrench

When right or left hand is mentioned in this manual, it

means when you are in the operating position (seated

behind the steering wheel).

TO NEMOVE TRACTOR FROM CARTON

UNPACK CARTON

• Remove all accessible loose parts and parts cartons

from carton (See page 5).

• Cut, from top to bottom, along lines on all four corners

of carton, and lay panels flat.

• Check for any additional loose parts or cartons and

remove.

tion of ihose pai

j hardware you ^

jft unassembled for shipping purposei

itoble must be tightened securely. Us

BEFORE ROLLING TRACTOR OFF SKID

ATTACH STEERING WHEEL (See Fig. 1)

ASSEMBl i h 1 LWSiON SHAFT AND BOOT

• Slide extension shaft onto lower steering shaft. Align

mounting holes in extension and lower shafts and

install 5/16 hex bolt and locknut. Tighten securely.

IMPORTANT: TIGHTEN BOLT AND NUT SECURELY TO

18-22 FT. LBS TORQUE.

• Place tabs of steering boot over tab slots in dash and

push down to secure.

INSTALL STEERING WHEEL

• Position front wheels of the tractor so they are pointing

straight forward.

• Slide steering wheel adapter onto steering shaft exten

sion.

• Position steering wheel and sleeve assembly so cross

bars are horizontal (left to right) and slide onto adapter.

• Assemble large flat washer, 3/8 lock washer, 3/8 hex

bolt and tighten securely.

• Snap steering wheel insert into center of steering

wheel.

• Remove protective plastic from tractor hood and grill.

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

IN SKID THAT MAY PUNCTURE TIRES WHERE TRACTOR

IS TO ROLL OFF SKID.

TO ROLL TRACTOR OFF SKID (See Opera

tion section for location and function of con

trols)

• Press lift lever plunger and raise attachment lift lever to

its highest position.

• Release parking brake by depressing clutch/brake

pedal.

• Place freewheel control in freewheeling position to

disengage transmission (See ‘TO TRANSPORT” in

the Operation section of this manual).

• Roll tractor backwards off skid.

Page 7

^ ft li If4 I i^iis ; I Í iM

“ERY (See Fiqs. 2 an

'^isimasssmssimsi

IITION: Do not short battery teririi-

A

• D >1,1 \r I .1, - '| or ujinif pan and iiii {.at

pan to raised position.

• Open battery box door.

® Remove terminal protective caps and discard.

• i¡th¡, Pu'-f ■' i'v> Í dhci riK-ntfi arid year

iridif itd c,r <v,m| liiiwfsfj hoi'Aieen terminals)

chafpr ¡'‘.■rtf-n Í I i ,((!'oiviH.1 U»>•-hoiji at G-iO amps.

» Fir“'!t err,- fHt 1 R *' !/caMetjpfHii'/r.|-j-)|crfnina!

v>iy-h I 11 L ”'¡01 hi F «D--her and he'nut as

fhori! 1 int T( n 'rely

• C o'liifh btK jio..iifJinqcabittonegdtivei-)termi-,

rui Aiih i< rnr?tn nij pt. Puli, flat washer lock washer

and ilb liUi Ttih^ii LCufely.

» Clo-c f->3fTri/bf" door.

Open balk i-v ho' door lor

• !nspe(>'Oi fo( ¥C.utf connections (lo tighten hard

ware).

• Inspection for corrosion.

• Testing battery.

• Jumping (if required).

f u, e I. iili '1 'ui 1-. Í f't- I i/S ¥ Cl

ii i,' ¡i ,itO If.'.Í as r ifi»;;'!

> 4 j,r h-vitc<

I , L .1 ,i tit '*'0 , > ^

¥e metal bracelets, wristwatch

SEAT

PAN

BATTERY BOX DOOR

I

F!G. 3

INSTALL SE4T|.‘ fb )

Adjust seat bbk h iiol i m c ■ i-, tf .. ¡4 jili.

• Remove I iidbu jr> ■ r V *i . i i, n.

• Place iPit on £c I p 'll r no ' r il l< . houlder bolt.

• Assemble a{ijui:im»-rii h it, lo. p wash« r ind flat washer

loose!V Dor'oiii.hhn

• Tighten ‘ hould^' ’■•oit ureV

• Lower rerjl irifo olh * iti ig po: ijci, eri'J .crt on seat.

• Slide seat until a. liimiiab!« |h.- loni reachedwhich

allows vou to pp'ss dulrh/br. p. t!ai all the way

down.

» Get off seat without moving II dfliu'Jbii position.

• Raise seat and tighten adjuhm a ih ' <L ■ ecurely.

4)

FIG. 2

Page 8

.wmm'-'

' f t'TI ^ ~ 7a Hi ^,Vn r,

Dl

ECK (See Fia. 5)

Th© gauge wheels are designed to keep the mower deck ir:

If! |ii <1 I t j, jcl ii li ■ [<i .<ufe iiitiV aifci

property adjusted to ensure optimuni mower performance.

" ' i J ^ cl Wflh l( mi ='^n a flrtt iBvcf

surface.

AOji ♦ irc .-vc-r t < itf-'j CÜ ung h‘ighi (.-f-F ‘'*0 AD

JSJ‘ HD'WFh CiT"iiJm HFiGf i’in flic * )p'ranon

i> ' *it r f f ihi n 'HUJi)

rt W' n ir- fie r ae'sred noghi ut rut poviticn. yr ug^

'/'h ,i -houllm i-.i.biKj'■ ih<^i/aife-iigiit!v'ufttii

y imri is.t-nli qo’jgr. v-neel in epprnprrtc holt witfi

sh.iUldLr tr!t 17/31 washf-r 3/>i war tier r.ndGS-le

¡fCMT.t and <i>jhteii jeF'ureiv

- Rtf 6 0 fi.< ...ppuciiF cid»- II stai'mo fj-tuge ¥'hee! in

sanioddit' ur.f^nl Hülfe

CHECK TIRE PRESSURE

The tires on your tractor were overinflated at the factory for

shipping purposes. Correct tire pressure is important for

best cutting performance.

® Reduce tve pressure to PSI shown in “PRODUCT

SPECIFICATIONS’^ on page 3 of this manual.

CHECK DECK LE¥ELNESS

For best cutting results, mower housing should be properly

leveled. See “TO LEVEL MOWER HOUSING” in the

Service and Adjustments section of this manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion and

mower blade drive belts in the Service and Adjustments

section of this manual. Verify that the belts are routed

correctly.

r'HFO RRLFF C, : n_U

t V ') ir >f 1 ii' I ■ <1i /t <11 t! i.oDi i’htik to see

ill ' .hr r-ml.

[TNT ,r, Ü.

s t la! fuoj.

;>■ rl HdiMcifed

I 'I' u. Adi J'i<

-ff- ro ADJUST

I* ./..ttiui of this

'WC^LISl

RtHfeWi :>U 0^ht~Aih ANi> kN.'uf fLfUR NEW

rH4t T, >H vVt I'Vi ‘.H / U.AF SURE TH4 i yQU RECEIVE

mt tFAi ,-f-RH Ri\,iAN( F -\NL> FAT ISh ACTION FROM

THISfRIALiTY PRODUCI

PLEASE REVIEW THE FOLLOWING CHECKLIST:

/ Ali assembly instructions have been completed.

/ No remaining loose parts in carton.

/ Battery is properly prepared and charged. (Minimum

1 hour at 6 amps).

/ Seat is adjusted comfortably and tightened securely.

/ All tires are properly inflated. (For shipping purposes,

the tires were overinflated at the factoly).

/ Be sure mower deck is properly leveled side-to-side/

front-to-rear for best cutting results, (Tires must be

properly inflated for leveling).

/ Check mower and drive belts. Be sure they are routed

properly around pulleys and inside all belt keepers.

/ Check wiring. See that all connections are still secure

and wires are properly clamped.

/ Before driving tractor, be sure freewheel control is in

drive position.

WHILELEARNING HOWTO USE YOUR TRACTOR, PAY

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

/ Engine oil is at proper level.

/ Fuel tank is filled with fresh, clean, regular unleaded

gasoline.

/ Become familiar with all controls - their location and

function. Operate them before you start the engine.

/ Be sure brake system is in safe operating condition.

✓ It is important to purge the transmission before operat

ing your tractor for the first time. Follow proper starting

and transmission purging instructions (See‘TO START

ENGINE” and “PURGE TRANSMISSION” in the Op

eration section of this manual).

8

Page 9

OPERATION

These symbols may appear on your tractor or in literature supplied with the product. Learn and understand their meaning.

X *

Q

BATTERY

ENGINE ON

fl

FUEL

♦

CAUTION OR

WARNING

f'" N

STOF

ENGINE OFF

REVERSE FORWARD FAST

OIL PRESSURE CLUTCH LIGHTS ON

l\l

CHOKE MOWER HEIGHT

( a

fn\

W

DIFFERENTIAL PARKING BRAKE

LOCK

LOCKED

SLOW

LIGHTS OFF

UNLOCKED

R N

IL

REVERSE NEUTRAL

t

if

rr

MOWER LIFT

DANGER, KEEP HANDS AND FEET AWAY

ATTACHMENT

CLUTCH ENGAGED

1

H L (d

HIGH LOW PARKING BRAKE

HP

ATTACHMENT

CLUTCH DISENGAGED

-/¿I

HYDROSTATIC FREE WHEEL

(Hydro Models only)

»11

IGNITION

- i»

Page 10

OPERATION

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the illustrations with your tractor to familiarize yourseif with the locations of various controls and adjustments. Save

this manual for futures reference.

ATTACHMENT CLUTCH LEVER: Used to engage the

mower blades, or other attachments mounted to your

tractor.

LIGHT SWITCH: Turns the headlights on and off.

THROTTLeCriOhE control ^ Used for starting and

controlling engine speed

CLUTCH/BRAKE PEDAL: Used for declutching and

braking the tractor and starting the engine.

PARKING BRAKE: Locks dutch/brake pedal into the

brake position.

MOTION CONTROL LEVER: Selects the speed and

direction of tractor.

ATTACHMENT LIFT LEVER - Used to raise and lower the

mower deck or other attachments mounted to your tractor.

LIFT LEVER PLUNGER: Used to release attachment lift

lever when changing its position.

IGNITION SWITCH; Used for starting and stopping the

engine.

FREEWHEEL CONTROL - Disengages transmission for

pushing or slowly towing the tractor with the engine off.

10

Page 11

OPS ration

The operation of any tractor can result in foreign objects thrown into the eyes, which can

result in severe eye damage. Always wear safety glasses or eye shields while operating

your tractor or performing any adjustments or repairs. We recomme Me vision

safety mask over the spectacles or standard safety glasses.

aSti\CTOR

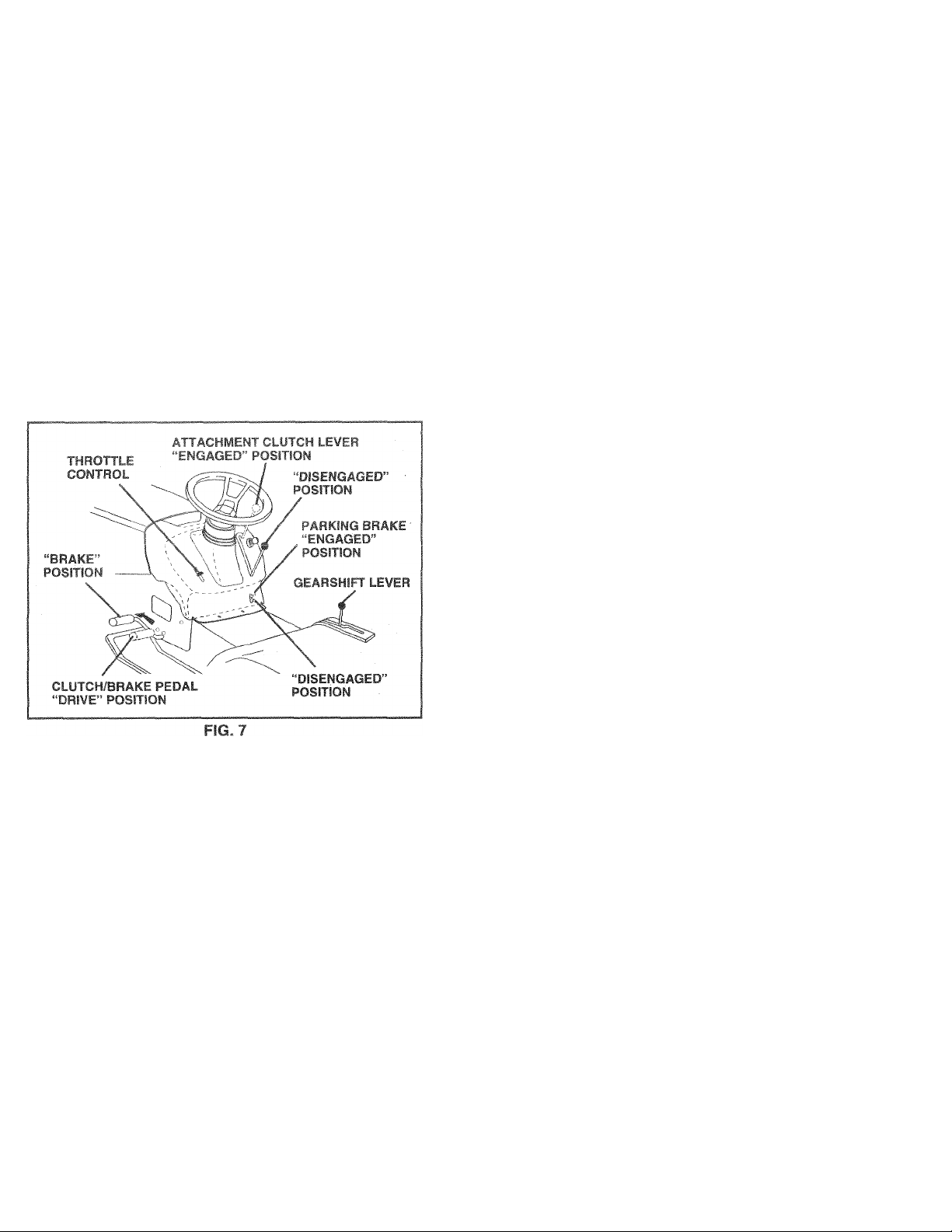

TO SET FT KKING BRAKE (See Fig. 7)

Yourtracior is equipped with an operator presence sensing

switch. When engine is running, any attempt by the

operator to leave the seat without first setting the parking

brake will shut off the engine.

® Depress clutch/brake pedal into full “BRAKE”, position

and hold.

• Place parking brake lever in “ENGAGED” position and

release pressure from clutch/brake pedal. Pedal should

remain in “BRAKE” position. Make sure parking brake

will hold tractor secure.

STOPPING (See Fig. 7)

MOWER BLADES -

• Move attachment clutch lever to “DISENGAGED” po

sition.

GROUND DRIVE -

• Depress clutch/brake pedal into full “BRAKE” position.

• Move motion control lever to neutral (N) position.

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

ENGINE -

• Move throttle control to slow (*•) position.

NOTE: Failure to move throttle control to slow (««A)

position and allowing engine to idle before stopping may

cause engine to “backfire”.

• Turn ignition key to “OFF” position and remove key.

Always remove key when leaving tractor to prevent

unauthorized use.

• Never use choke to stop engine.

NOTE: Under certain conditions when tractor is standing

idle with the engine running, hot engine exhaust gases may

cause “browning” of grass. To eliminate this possibility,

always stop engine when stopping tractor on grass areas.

CAUTION: Always stop tractor com

plete ave, before leav

„

ing the operator's position; to empty

grass catcher, etc.

TO USE THR' QNTROL (See Fig. 7)

Always operate engine at full throttle.

• Operating engine at less than full throttle reduces the

battery charging rate.

• Full ffircftY- .offers the best bagging and mower perfor

mance

TO MOVE FORWARD AND BACKWARD (See Fig. 7)

The direction and speed of movement is controlled by the

motion control lever.

• Start tractor with motion control lever in neutral (N)

position.

• Release parking brake and clutch/brake pedal.

• Slowly move motion control lever to desired position.

TO ADJUST MOWER CUTTING HEIGHT (See Fig. 6)

The position of the attachment lift lever determines the

cutting height.

• Grasp lift lever.

• Fress plunger with thumb and move lever to desired

position.

The cutting height range is approximately 1 -1/2 to 4". The

heights are measured from the ground to the blade tip with

the engine not running. These heights are approximate

and may vary depending upon soil conditions, height of

grass and types of grass being mowed.

• The average lawn should be cut to approximately 2-1 /2

inches during the cool season and to over 3 inches

during hot months. For healthier and better looking

lawns, mow often and after moderate growth.

• For best cutting performance, grass over 6 inches in

height should be mowed twice. Make the first cut

relatively high; the second to desired height.

11

Page 12

iPERATIOf

tart mower blades b

)ntroL,

clutch control.

i *f*' b»»' i}-'f ri>

on mowers so equipped, or the dis-

harge juarb ir

ita

BL

itor io le

qinq att

lent dutch

RI

m

IE ENGINE

L (See Fig. 12)

»• i i '< i .Hoc

mer weight oil.

A level ground,

^ka

wipe clean, reinsert the

Hnh-

reme

li

hor C

03SÌ€

DnsngG engine oil, S9i

section in this manu«

insti

1>J W li until

• I avertili

f f! 'cof je O'i for

.'Of óH/,pT .iiihe

1 'ill mnuul)

VI i TK r r1t-SpOnSÌDÌ;Ì-

tCi i '•* TnrJ F ,1

I-|,ii ft'» 1 ' v'r i itA •!-?-di'engage

t'or f >r I, f‘ '■ n f; :5i/hee!ing

pork 'id- i! - I ( r, i ji i ¡T-I.itrs r-'crarawbar

of tractor.

® ','.1^ i 111 t.h ..•!,! ,t _t MOi-itioii With attach-

liiciT !|ii C Jilt ji

» Pull freewheel control knob out and hold in position by

inserting retainer spring into fonward hole of control

rod.

* Do not push or tow tractor at more than two (2) MPH.

• To reengage transmission, reverse above procedure.

NOTE: To protect hood from damage when transporting

your tractor on a truck or a trailer, be sure hood is closed

and secured to tractor. Use an appropriate means of tying

hood to tractor (rope, cord, etc.).

TO OPERATE ON HILLS

CAUTION; Do not drive yp or down

A

» Choose trie rrtowesi speed beic-'e startinq up or down

hills,

» A.vcid stopping oi chsngir'ig speed on hills.

• if CGwmg is necessaiy, move tnrottle control lever to

Slower position.

® If sfopping is .-ibsolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking

brake.

• Move rnotion control lever to neutral (N) position.

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH-'BPAKE PEDAL IS DEPRESSED.

• To restart movement, slowly release parking brake and

dutch/brake pedal.

® Slowly move motion control lever to slowest setting.

• Make all turns slowly.

hills with slopes greater than 15' and

do not drive across any slope.

AH

FIG. 9

12

Page 13

operation

ADD GASOLINE

® Fill fuel tank. Use fresh,

gasofine with a minimum of ^

QBSolinG will incressB CHibC

and reduce valve iife). Do

Purchase fuel in quantifies i

)T mix 0!i

it can be

days to assure fuel freshne

IMF FPU r tlbi*

BEI ' L „ I ¡ ■

- UL I V 1 I'l (

^T/r^ni-ir

1 ^ ^ ' W “ w t L /s oF mL d [

F'F Ì1 L'"ANi/Wfir£HGP-,DE

' ‘1^1 .'/T' . C'i t

WARHINC UquM.. ~ U hisiirlrd

■‘■jeh., ( a'U i t • uu* g <^.t ai '• o. pie'.'r‘fioli ran

strm't 'u I ' ,i|- I?;, nUiinationof

di-'dC -*UrO'. -t^r It VCldl' jO. <- 1 Qcli'Ugf- ihf it'J

syG'.'-n <f .r r.g.ft p rrci: ri-Uvay^ Tc ^/C'd e'~g‘'O

prub*'n.‘ 11.' iiw-f /Uu I t.uui U'^e emprieO b°tore ;io« •

age U _c u,/_ w ’ongas Diain f.ie gas tank seri the

er.gn,- an'i Ut >i un 'Ji.kl tha fue! ines and carburetor are

empty Udfc hi-¿h fuel nryi season Fee Storage Instfuctions for additional information. Never use engine or

carburetor cleaner producís in the fuel tank or permanent

damage may occur.

CAUTION: Fill to bottom of gas tank

filler neck. Do not overfill. Wipe off any

spilled oil or fuel. Do not store, spill or

A

use gasoline near an open flame.

TO START ENGINE (See Fig. 7)

When starting the engine for the first time or if the engine

has run out of fuel, it will take extra cranking time to move

fuel from the tank to the engine.

• Be sure freewheel control is in the transmission en

gaged position.

• Sit on seat in operating position, depress dutch/brake

pedal and set parking brake.

• Place motion control lever in neutral (N) position.

• Move attachment dutch to “DISENGAGED” position.

• Move throttle control to choke (|\() position.

Note; Before starting, read the warm and cold starting

procedures below.

• Insert key into ignition and turn key clockwise to “START’

position and release key as soon as engine starts. Do

not run starter continuously for more than fifteen sec

onds per minute. If the engine does not start after

several attempts, move throttle control to fast (%)

position, wait afew minutes and try again. If engine still

does not start, move the throttle control back to the

choke (i\l) position and retry.

jlsr unl©3cl©cl

Lise of leaded

)xide deposits

with gasoline.

K ■' V"' r. !•

-' h

.V. ' ' f ) U U t.U I ( f

* When engine starts, move the throt

Ì tn0 Issi

(•#) position.

• The attachments and ground drive

the engine does not accept the loac

' ft to warm up fc

)fi

:th€

using i

•sen

V ULu Vi'r ' - I ‘UifIJU m ‘ . .1 1 '

‘V'fici I il Jif - i ,ii .11 X I ,!1<- t 'll I ' .

ft '

> I O,

G.run*! n !'• - *'h. t >1« I) flurr, .*4¡ til- mill, n '

I ji I I >!,-■ i V - ■htrtile .uruUi ,'j L I

rhi_ >1 ^ , t»g>r- <H’>p t'■-II' " ’-I’l

50 - . '■ ( LO't K iP-r-1 O' tí I If - ’ -j I r II ill

temperature.

If i ,/v pfi »

• E'ct^ite in ii'M

111

'- 111

it

1'' I f Ip wt If. I ii 11 .n I nr

Í '('ri bfouL. b* v.a‘iTk-a up fcinw;

* Be :jib me tractor is on level orm-i-d

* Place th.. fTsotion coritioi levct in ney:r,,l

Release the parking brake and let the dutch/brake

slowly return to operating position.

* Allow one minute for transmission to warm up.

This can be done during the engine warm up

period,

• The attachments can also be used during the engine

warm-up period afterthe transmission has been warmed

up.

NOTE: If at a high altitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetor fuel mixture may

need to be adjusted for best engine performance. See “TO

ADJUST CARBURETOR” in the Service and Adjustments

section of this manual.

13

Page 14

PURG

iNSMISSIO^

IJTlOf^: Newer

ingage or di!

tile the sfioiti srun

A

d that the transmis

tractor for

trapped ai

I Of-( I .

{, M< • *-' f ' h . f ' / r L i/!l , I i

Hd'i i > M - r. , f L" T 'Ll If M

t EF' r.AJ . I rfl- rr ,v K.-r

“• f I ;< > M' rr , ipl |, I I- I iinccc i-lfil ' Ox,I I- ifl.'lid

f ,l • «0 0 ' t '

•> L'l'! hgagt, Uc•i-:r..:c!cr oy gbtii.a ffteAheci c 'ntml

in rit. whtPÍTig Djiioori TO Tl-^fJ~F*Cib f” in

thi.'. of iTidiiual)

• Sitting in the tractor seat, start engine. Atterthe engine

With motion control lever in neutral (N) position, slowly

disengage clutch/brake pedal.

• Move motion control lever to full forward position and

hold for five (5) seconds. Move lever to full reverse

position and hold for five (5) seconds. Repeat this

procedure three (3) times.

NOTE: During this procedure there will be no movement of

drive wheels. The air is being removed from hydraulic drive

system.

• Move motion control ieverto neutral (N) position. Shut

off engine and set parking brake.

• Engage transmission by placing freewheel control in

driving position (See “TO TRANSPORT” in this section

of manual).

• Sitting in the tractor seat, start engine. Afterthe engine

is running, move throttle control to half (1/2) speed.

With motion control lever in neutral (N) position, slowly

disengage clutch/brake pedal.

® Slew'/ rrcvt, rnoi'on {onh(-l bver io'watd, after the

liaJti m- ve* ap|.rox!ii aTi / fi't (5) *cet, ¿lowly move

mc'icf. c-mt'f.! ir ei m n-.- r c povticn. After the

írdí r.i fTicvf appKximat'iv ti''*-- (5i ffft return the

moiic iiccntrui level ic tne i s-uttal (,N) os don. Repeat

this procedure with th^ control lever three (3)

times.

® Your tractor is now purged and now ready for normal

operation.

0 > r prr '-f ‘ ,r ’raciot

is running, move throttle control to slow (<^) position.

tim

I •! Jf '--ii'li t U'*t r*l l1 <

■ ■ ;h mav have

- . u

-ff %p!-li.'-ipp 1 t it ‘fr f,,i f-t.ir,

} IS

1 for best

MFpj HOU

3f thi:

ft he jld b d to tnm-

mir

o d V ' i,| I ,n s >, ill « pemro me the-area

dWi itaC tw-ii.Dr f aitar'-jv ihf righto! if.fc

I r. 'f. i i<- ill i _ i‘.j> -Jo iboiion f

'I'or I'j '"c '• V min.ioit . .■iti-nQ

V.’r^r. rr< i irig 1' .V li'--'- "i I'l r p V! ning to tight

.. lUnt (iipp.rg 'iiil ijicof’v'ge iway from shrubs,

i'( > 'irivtw..V' h*i Atte! "•rir- Cl Twe rounds mmv

I! ih. ¡pp., dif. ‘"Ill mchno Icfi hano tu no until

fi<ii-(vd F'p, Id)

IT d! i. is A4'ctni-ly tall II shoiilc be mowed twice to

reduce ¡Add uiiJ pc mibifc fire hazard from dried clip

pings Make firci cut reldiiveiw high: the second to the

de^”iied heiaft

Do not rriow gra'*- when it is wet A/et grass will plug

rn&’ver and loom unde^iratte clumps Allow grass to

drv before tn..wir>g

AivVayS operate engr.c d* full ihroTle when mov/ing to

d'^sure betier mowing peiformance and proper dis(ha’'qo of TirtHial. Regulate ground speed by selectinc 3 low p-noug'' gear to give t^e mower cutting

p-rfer'” :n'fr a>- welfas the qualitv of cut desired

When operating attachments, select a ground speed

that will suit the terrain and give best performance of

the attachment being used.

lowing

IS!NG”in

manual.

14

Page 15

^’Wf/*^fOEni «H i ^c p><

* FILL IN DATES

AS YOU COMPLETE

!

FfilJI AR SFRVICF

I

—

> ^ L hi I 'H

Check Tire Pressure

ill- ‘ r I, ' - i-e rri

p

p

-I-- '-r-i-s't ■ I-1' .

Lubrication Chart

lie i-^i I -I F -'Me

. feC'l F.'l ' V! r • I'

y

B

Ch-_k 1 j'l 1 ' jlin'j

—

VT<-r

ik'

r

-

----

—

1

—

---------

'Ik-

,

1

V^7

....

y 1

.....

______

> 1

^ j

I.....

iS

j

✓ 1

1 J

diu.tp. 1-H hf') 7an='!iri

Ai |L=( Ma cri Crive Peit(3> Tensif f>

'-Lc k ErtJic- 1!' /0

Change Engine Oil

Clean Air Filter

C.

Clean Air Screen

N

inspect Muffier/Spark Arrester

G

✓

I Replace Oil Filter (If equipped)

N

Clean Engine Cooling Fins

t

Replace Spark Plug

Replace Air Filter Paper Cartridge

Replace Fuel Filter

1 - Change more often when operating under a heavy load or in high ambient temperatures. 5 - If equipped with adjustable system.

2 - Service more often when operating in dirty or dusty conditions.

3 - If equipped with oil filter, change oil every 50 hours.

4 - Replace blades more often when mowing in sandy soil.

✓

✓

^2,3

✓

^2

✓ 2

✓

^,2

✓ 2

✓

✓

✓ 2

✓

6 - Not required if equipped with maintenance-free battery.

7 - Tighten front axle pivot bolt to 35 ft.-lbs. maximum.

Do not overtighten.

if-RvICt-

——

1

p

ZI

___

p_——-

______

,

1 1

r 11

......

n

__ J

1 1

H

1

1

1

I

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover items that have

been subjected to operator abuse or negligence. To

receive full value from the warranty, operator must maintain

tractor as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your tractor.

All adjustments in the Service and Adjustments section of

this manual should be checked at least once each season.

• Once a year you should replace the spark plug, clean

or replace air filter, and check blades and belts for

wear. A new spark plug and clean air filter assure

proper air-fuel mixture and help your engine run better

and last longer.

BEFORE EACH USE

• Check engine oil level.

» Check brake operation.

® Check tire pressure.

• Check for loose fasteners.

LUBRICATION CHART

@ SPINDLE ZERK

@ FRONT WHEEL'

BEARING ZERK

©ATTACHMENT-

CLUTCH

PIVOT(S)

® SAE 30 OR 10W30 Mu I OR OIL

©GENERAL PURPOSE CREASE

©REFER TO CUSTOMER RESPONSIBILITIES “ENGINE” SECTION

IMPORTANT; DO NOT Oil OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS, VISCOUS LUBRI

CANTS WILL ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRICATING BEARINGS. IF YOU

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW

DERED GRAPHITE TYPE LUBRICANT SPARINGLY.

SPINDLE ZERK@

FRONT WHEEL®

■ BEARING ZERK

15

ENGINE®

Page 16

TRACTC

Always obsí5R3rve safety rules when performing a

nv rr

BRAKECJPERATION

It tractor rec

at high spee

(See “TO A

ments sectilon of this manual).

juires more than six (6) feet stoppir

j 1 •!(I'ji 1 -.1 4« ii i i 11 1 ‘1 i ,.i ) ' b

iDJUST BRAKE” in the Service a

ance

TIRES

> S/'.n ii I p’i’i 1-r II fr u' ' r _il t:r - (''-t ‘PP 'L‘-

UCT SPECIFICATIONS” on page 3 of this manual).

» i*«'fi II ‘ <q '^lií! '<i' a in£t f"! •'mtrtj chrmi-

Cdl' Í ( I ‘li'hi fillT -

• fii-jih <'r'<T !• P'h-, !>-e; ruts -h^io ooi-rts and

■dri* I h-/srr|' ihjT n >v ' 5‘i;'F [,r- daf'iape

NOTE, T i sea! tire punctures and prevent flat tires due to

slow is-sks. Tire sealant 'Way oe purchased from your local

parts rieaiei Tire se-aiant also prevents tire dry rot and

corrosion

)SHARPEN

,re should be f

balanced blade

The blade car1 be she!

wheel. Do no

To check blacle balan.

steel bolt, pin,

li ( '• 1 f( Ч

ar A.

>• ‘ 1 ! j .'f .,11' -3, uil'Cr.</1 the steel bolt

t,' (.1,1I. .If t ill I |j|! pSi-ilv I viltti the gruind.

if ! I d( I h.l • d I? h'luid lomain in e hfiisontal

. u, 'iuii I.. " I end 'j fht t latJe mo/es downward,

n -rp.-r, F." t,i M I iTtii th<- blade I- bcthriitd

IJCJIF iJf.ii.d'W- iviinji bjileoi my blade ihtloDesof

ihe . e.ite hul' tf bv centered but are not.

1 BLAC

! vvill CSÜ'

! attemp

or a cor

ow the

CENTER HOLE

12)

'3-

le blade balanced. An

iSive vibration and even-

u engii

•pened

iiith a file or on a grinding

narpen while on the mower.

v ou Will Hoed 0 5/8 diameter

ancer. (When using a cone

i isu Ljctions supplied with bal-

/

\

BLADE CARE

For test msults mcwer blades must be kept sharp. Re

place bent or damaged blades.

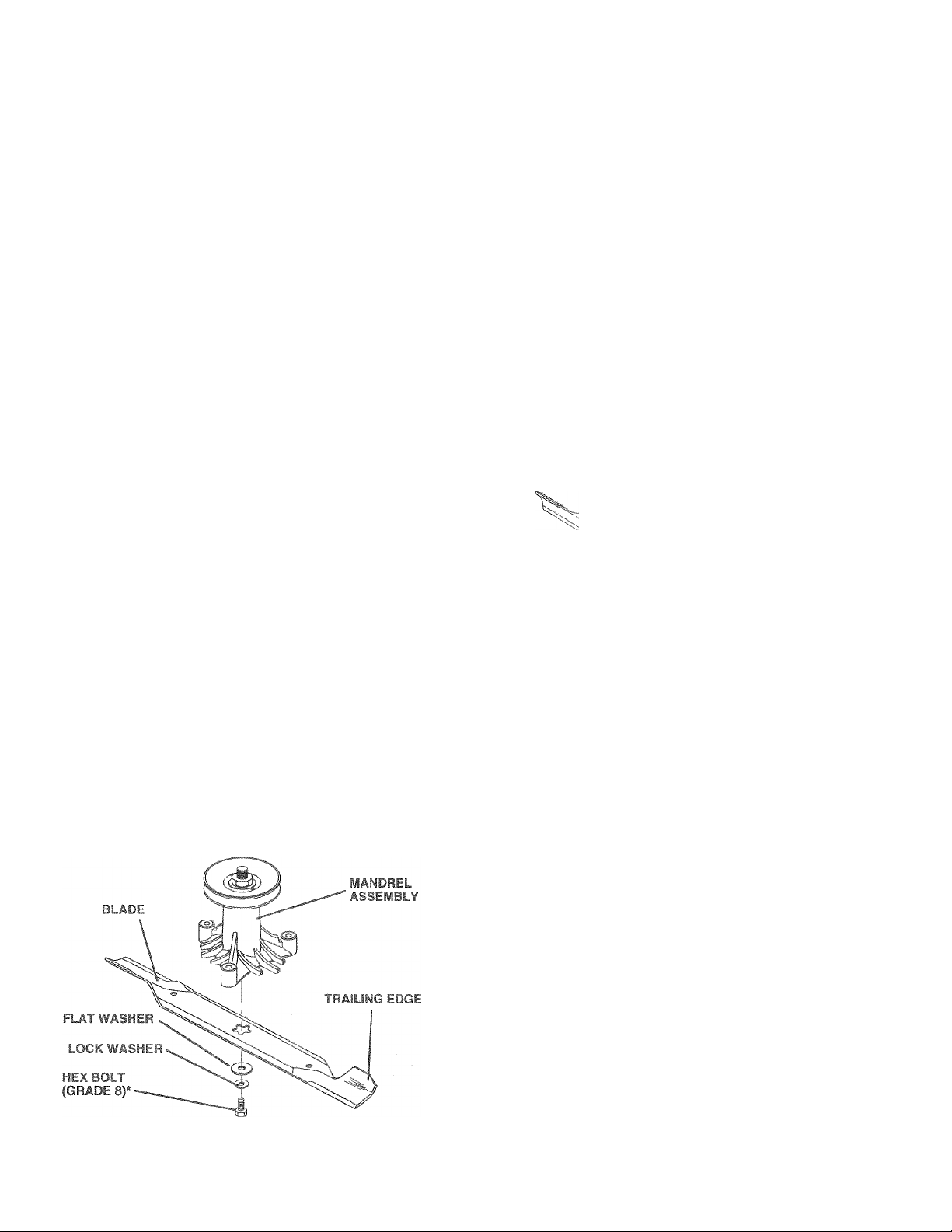

BLADE REMOVAL (See Fig. 11)

• Raise mower to highest position to allow access to

^ blades,

• Remove hex bolt, lock washer and flat washer securing

blade.

® Install new or re harpti i. d blade with trailing edge up

towards der I* a- -hown

• Reassemble hex belt lock we->her and flat washer in

exact order a- ,-howii

• Tighten boft sef urel/ (30 35 Ft, Lbs. torque).

IMPORTANT: HI Aü¡- B"'L T IS GRADE 8 HEAT TREATED.

NOTE: Wedonc-i -mmend sharpening blade - but if you

do, be sure the biant, is baianceu

*A GRADE 8 HEAT TREATED BOLT CAN BE

IDENTIFIED BY SIX LINES ON THE BOLT HEAD.

~ ^ RGm

\

5/8" BOLT

OR PIN

FIG. 12

BLADE

BATTERY

Your tractor has a battery charging system which is suffi

cient for normal use. However, periodic charging of the

battery with an automotive charger will extend its life.

• Keep battery and terminals clean.

• Keep battery bolts tight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for 1 hour.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to “leak” power.

• Open battery box door.

• Disconnect BLACK battery cable first then RED bat

tery cable and remove battery from tractor.

• Rinse the battery with plain water and dry.

• Clean terminals and battery cable ends with wire brush

until bright.

• Coat terminals with grease or petroleum jelly.

• Reinstall battery (See “CONNECT BATTERY” in the

Assembly section of this manual).

16

Page 17

RESPONSiBiLiTies

V-BELTS

Check V-belts for deterioration and wear after 100 hours of

operation and replace if necessary. The belts are not

adjustable. Replace belts if they bOQin to slip from wear.

TRANSAXLE COOLING

mo 'fi i „ .‘H .j ft ..i‘i ji ' i> 'iiO rkept

cle It u, - '.n ¡. iu ^ > niin-j

Dr I'ul r*ne c f I*" '1 -ri .t r< I .sionwhi’e spqine IS

rurininq Oi vvli le tf - iirr.^ntc-ioii C' het

• in-fjt- li'noDi I i- f.'-Vi. pf'«je.s jfeirfe^iand

clean.

® lr.£p=ci lOC'iifo liv fo liti ■ j'S'i-ri.ppings and Other

fiì-ir T" j. . ,1 tViriopt le itròls do not use

'-.rip, fj ai" " hijh \ rrr iir' opnyer tr rlf'jn

cooling fins.

TRANSAXLE PUMP FLUID

The transaxle was sealed at the factory and fluid rhaintenance is not required forthe life of the transaxle. Should the

transaxle ever leak or require servicing, contact your near

est authorized service center/department.

ENGINE

TO CHAN

Determine temp«

All oil must meet

# p

sure tractor is on level surface.

Oil will drain more freely when warm.

Catch oil in a suitabte container.

H„nr.’ I C I till -P tvi £T' ‘ 3 't' I ti >1 f , Jlo ‘■ rirs

ti Ciitor Itic mcir-' cfie tli"r mijui!

RfetTiove hr j r ' luc

AtifruJI Itari— a.iplrt.rly. iliin. • plug

and tighten securely.

Ht,ill»-rc V with s'th.fl'yti • 'I -idi|Sf' " ' ‘ ' <r

slomly L ) '„I 0v6dii F nr 3p| r nimyi- <" if r'

‘PROD AT -c:FCiF'-“AV' fV th . » ir.>

manual.

Use gauge on oii fill cap/dipstick for checking level. Be

sure dipstick cap is tightened securely for accurate

reading. Keep oil at “FULL” line on dipstick.

NGINE OIL (f

»erature ranae

LUBRiCATION

Only use high quality detergent oil rated with API service

classification SF, SG or SH. Select the oil’s SAE viscosity

grade according to your expected operating temperature.

SAE ViSCOSITY GRADES

0° 30° 32° 40° 80“ 100“

»C -30” 20° -10° 0° 10° 20° 30° 40°

TEMPERATURE RÄNGE ANTICIPATED BEFORE NEXT OIL CHANGE

NOTE: Although multi-viscosity oils (5W30, 10W30 etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F. Check your engine oil level more frequently to avoid

possible engine damage from running low on oil.

Change the oil after the first two hours of operation and

every 50 hours thereafter or at least once a year if the

tractor is not used for 50 hours in one year.

Check the crankcase oil level before starting the engine

and after each eight (8) hours of operation. Tighten oil fill

cap/dipstick securely each time you check the oil level.

'"eo“-20°

17

Page 18

r I r* iCif K, , '- ¡'I. V

AIR FILTER (See Fig. 14A)

Your engine will not run properly using a dirty air filter.

Clean the foam pre-cleaner after every 25 hours of opera

tion or every season. Service paper cartridge every 100

hours of operation or every season, whichever occurs first.

Service air cleaner more often under dusty conditions.

• Remove knob(s) and cover.

TO: LF .-I t “'HL-.O ! / M' h

• Slide foam pre-cleaner off cartridge.

® Vv'rti ii i.i inoiid Orr iQf-n! si. p'f.i' I.

/ly'(-. > H Ji" 'll - ' Ojh c 111

‘ . a;ui /1 T i>i > nu" L il .'V 4 !■ <n , i :i, -ih ,0 beiif

< luih rd - f' ■ * tit. ( ii

^ P "t Jliy U On *1- ISpL-Li- t“"Ci-c-FI.

® HeinOai! iirt-^l'-ona o/c-r cattiidyr

• ric.Fisr.gi 1..0/0 and cm urc with knob(^).

TO SERVICE CARTRIDGE

• Remove cartridge nut.

• Carefully remove cartridge to prevent debris from en

tering carburetor. Clean base carefully to prevent

debris from entering carburetor.

• Clean cartridge by tapping gently on flat surface. If very

dirty or damaged, replace cartridge.

• Reinstall cartridge, nut, precleaner, cover and secure

with knob(s).

IMPORTANT: PETROLEUM SOLVENTS, SUCH AS

KEROSENE, ARE NOT TO BE USED TO CLEAN THE

CARTRIDGE. THEY MAY CAUSE DETERIORATION OF

THE CARTRIDGE. DO NOT OIL CARTRIDGE. DO NOT

ENGINE OIL FILTER (See Fig. 14B)

Replace the engine oil filter every season or every other oil

‘ ‘ I t I ' ■ ‘ I . . , ( f I , ( WJ

} counterclockwise. Use a

ibl

!;S

»ii I ■ 'libber pdol-etApply a thin coating of r

on replacement oil filtei

In rtrif ^Fr-.ti 1.1 Til -• ‘ ; n.iiiii g do( kwise until

r.jbl V'or-C I " iii i ; (ii-tivj ".ii'-Gre then tighten

filter an additional 1/2 to 3/4 turn.

i ill i! - r>i i • 'I ,—V. 1.1 lO (-RANGE EN1 i«i[ JIL .1, ir . .1., • rt. .i.jiiLwi) Forapprovimar- (ir.i t, , i'H 1.1. i SPECIF If. ATIONS’ on

f) O' i i f d, I i

iw'' . h ‘ I. r . Cjtrecionvleaks

bt futt p!r U t<j(r I I'.T • t'j'l "OOMlnri

OIL FILTER

FIG. 14B

ENGINE COOLING FINS (See Fig. 15)

Remove any dust, dirt or oil from engine cooling fins to

prevent engine dan.age from overheating.

• Remove sroews fiom bcwet housing and lift housing

and dipstick tube assembly off engine.

• Cover oil fill opening to prevent entry of dirt.

• Use compresseo air or stiff bristle brush to thoroughly

clean engine cooling tins

• To reassemble, reverse above procedure.

FIG. 14A

CLEAN AIR SCREEN (See Fig. 14A)

Air screen must be kept tree of dirt and chaff to prevent

engine damage from overheating. Clean with a wire brush

or compressed air to remove dirt and stubborn dried gum

fibers.

18

Page 19

CUSTOMER RESPONSIBILiTIES

MUFFLER

Inspect and replace corroded muffler and spark arrester (if

. >t'i i|f* ' ate . tire ha li mi1;»1 Jiimo'

f “pL - |j i i.)U f't'- l"cyii'"rg ut'^^-'1 >~i'. oing

I f r-t. i- K,l h" „ s, pernt>'/i

yruur- iimt '^pdrk D.uq type dii«f gap seiting ai6 sho*ii ii i

f-RCC'Uh ! tsPEh'FlOfJa on i)dqe2 >ii if(K fnaiiuril

IN-LINE FUEL FILTER (See Fig. 16)

The fuel filter should be replaced once each season. If fuel

filter becomes clogged, obstructing fuel flow to carburetor,

replacement is required.

• With engine cool, remove filter and plug fuel line

sections.

• Place new fuel filter in position in fuel line with arrow

pointing towards carburetor.

• Be sure there are no fuel line leaks and clamps are

properly positioned.

• Immediately wipe up any spilled gasoline.

FIG. 16

CLEANING

• Clean engine, battery, seat, finish, etc. of all foreign

matter.

• Keep finished surfaces and wheels free of all gasoline,

oil, etc.

• Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to clean your

tractor unless the electrical system, muffler, air filter and

carburetor are covered to keep water out. Water in engine

can result in a shortened engine life.

19

Page 20

CAUTION: BEFORE PERFORMIMG ANY SERYiCE OR ADJUSTMENTS:

• Depress clutch/brate pedai fylif Sis'm sm. parking brake.

• Place motion control lever in neutral (N) position.

A

• Place attachment clutch in “DISENC3AC3ED” position.

• Turn ignition key “OFF” and remove key.

® Make sure the blades and all moving parts have completely stopped.

• Disconnect spark plug wire from spark plug and place wire where it cannot come in contact

with plug.

TRM -CiP

*^0 hEPGVr I (Om Piif. 1TI

MCWi v'dili ) - i I. .i-fi nil'. r..”ilector.

ittactimc ilute

“DiSENG. L‘ u _iiion.

^ Ml c t4idcl-.n< i.tict I' .^,ilMVv''mu lowei ('lowerto its

• Roll belt off engine pulley.

• Disconnect clutch rod from clutch lever by removing

retainer spring.

• Disconnect anti-sway bar from chassis bracket by

removing retainer spring.

® Disconnect suspension arms from rear deck brackets

by removing retainer springs.

• Disconnect front links from deck by removing retainer

springs.

• Raise lift lever to raise suspension arms. Slide mower

' out from under tractor.

IMPORTANT: IF AN ATTACHMENT OTHER THAN THE

MOWER IS TO BE MOUNTED TO THE TRACTOR, THE

R.H. AND L.H. SUSPENSION ARMS MUST BE REMOVED

FROM TRACTOR.

TO INSTALL MOWER (See Fig. 17)

• Raise attachment lift lever to its highest position.

• Slide mower undertractorwith discharge guard to right

side of tractor.

• Lower lift lever to its lowest position.

• Install mower in reverse order of removal instructions.

CLUTCH ROD

SUSPENSION

ARMS ^

RETAINER

SPRING

ANTI-SWAY BAR

CLUTCH LEVER

RETAINER

SPRING

ENGINE

PULLEY

RETAINER

SPRINGS

(BOTH SIDES)

RETAINER

SPRINGS

(BOTH SIDES)

FIG. 17

20

Page 21

SERVICE AND AD.IiiSTi»4EfS'r-^

Adjust tli6 mowsr whif0 trsctor is psrkscf on l©¥s! QrouncJ or

toi,r*ivr ' di"" r ' ' I u I I ^f-

"PRODUCT SPECIFICATIONS” on page 2 of this manual).

If tires are over or underinflated, you will not properly adjust

yuui 11 luvvei.

Sir- ‘ i'T -[Ml ' ^ -id 19)

• P'-ji se mow L-. li- h.u htst t- j-ition

• At the nidpu nl uJ -oth side.- o- mower measure height

from bottom edge of mo /srto ground Distance “A” on

uurti side-. "I

fj each _thcr

• IT ad uotnent i- no- or, rn-te :djii*^iRtrnt on one

side

of

rruwe.

• To raise one side of mower, tighten lift link adjustment

nut on that side.

• To lower one side of mower, loosen lift link adjustment

nut on that side.

NOTE: Three full turns of adjustment nut will change

mower height about 1/8".

•' Recheck measurements after adjusting.

ifiowt.

only

:ujid

be

ihe c.ame tr within 1/4"

IT i

IMPORTANT: I

THE FOLLOWl

NECESSARY, E

EQUALLY

U IRP TO .

iTH F

) MC ¡VVER WILL STA' Y LEVEL

SIDE

SIDE.

To obtain

should bee

|)0 lit! ■!

Checl" ooju i/t'e a ih I 'U - ‘i‘.

tapceii fly .. s r 1

best cutting results, t he rfiowe r hoL

steels,o that the front is approximat

1 the

rear when the mo wer is in f is hia

eiy 1/

iure dist bottom

edge n ^ - ■ r h.i m' .g ;■ r

• Before making any necessary adji

botl 1 ti If! i' JU y' . I - i ‘.

lents, check that

h links should be

cippiC V‘t ia'( I' f (H

» It link ■ -<Y ii a -r i'Mf ill,. ^ ,1! 11 r!<-ill.i-i ; r^'

lenuth .»hi ti'f''

» To inwei f.oiit t)‘ .I'lwu li>j'l I't.i “E" cu both irurl

links a' -quel i»oTiber cf lurtis

• When Oiatarice D la ' A »o b_" L'Wer ui fiont thcii

real, tighten nuts F ag-nnm trjr.r i,-»n on both from

links.

• To raise front of mower, loosen nut “F” from trunnion on

both front links. Tighten nut “E” on both front links an

equal number of turns.

• When distance “D” is 1/8" to 1/2“ lower at front than

rear, tighten nut “F” against trunnion on both front links.

• Recheck side-to-side adjustment.

SUSPENSION ARM

FIG. 19

LIFT LINK

ADJUSTMENT NUT

21

FIG. 21

Page 22

REPLACE MOWER BLADE DRI¥E BELT

(See Fig. 22)

The mower blade drive belt may be replaced without tools.

Park the tractor on level surface. Engage parking brake,

BELT REMOVAL -

• Memove mower irom iractor (aee "ou htiviuvE

ifV'.iM' ’■ >f' i' H, !'‘< ( I .-iiid 0l> I f' dl.-y .

• Puii bei! away from mo¥#er,

bELi IM-TV I TP N

'f, L1 I ' V' I f It II or ' I I. ’ Cl , jl

VrT - . t-r'i i ,ri-<0. jH., .• ' iiOiu-rill belt

guides.

' ir t„<i .,]f (,/< >1 . ^-1 ‘ r '.t rof-v

Road test iractorfor proper stopping distance as stated

above. Readjust if necessary. If stopping distance is

still greater than six (6) feet in highest gear, further

mainteriance is necessary. Contact your nearest au

thorized service center/department.

I •, < T t I L

Iv-e«* ^ fi. ‘-Aj

f rii h- ii r'f.i .

II W .rtofii'f- ilFr' ■

, O' HELT

R wl !!• ” f , ngage parking brake.

ition guide decal on

NA < tn ■id- - .f ipfr r: ft =

Remove mower

section of this n

inual.)

VE MOWER" in this

• hi 'i I . [ 0 f II I F. ij ‘

• Rtnit >• Чч .И11 > ii'cv ■ hr and clutching idler.

» Hi|!| bf ii bC f- L vva (i IP-. oi if-Uor. Carefully remove

1 e!t uf WrVub fmrii i чп vni'.'-ifin input pulley and over

ГО ,l!tq fan

• Full belt toward ft '1 ч tf traf tci- and remove downward

from aro' nd encinp pulley

• Ih'.tall пел bc-l! t / ifcvrrbing above procedure.

IMPOnrANT MAkF SURE UPPER BELT KEEPER IS

POSiriONEf. PRr.ppfl. / BFTWEEri LOCATOR TABS.

TO ADJUST BRAKE (See Fig. 23)

Your Ldctor I r luipoed ^ sd(> st'Die brake system

which !■ - rroi'ntteJ <“'n s'd- f. the tra'sa'Ic.

Iftrarif' '■^gu-'ei: ¡0're that -i/iLi feet =t(pping distance

athighrf.fci-u iL i ,= ibicke‘nustbeadjusted.

• DeprF-':f lijt''hTbr.'sFepP09i ind-'nfj^gp perking brake.

• MeasLtt distance between b"ikn cperaiing arm and

nut on brake rod

• If di'ienct IS othe tnan i 'O' L-ormn jam nut and turn

nut’ u.vii c. b-eomf t c/gg Retighten jam

nUl dO'TlIWt t ‘t

22

Page 23

SERVICE AND ADJUSTMEN'f

ro ADJUi

Fig, 25)

The motion control

adjustment should

If for any reason tf

position while at as

friction pack locate

« y j \ Ticii tOI >

ignition Key to

Li aKc.

• Adjust motion control lever by tightening adjustment

locknut one half (1/2) turn.

NOTE: If for any reason the effort to move the motion

control lever becomes too excessive, reverse the above

adjustment procedure by loosening locknut 1/4 to 1/2 turn.

Road test tractor after adjustment and repeat procedure if

necessary.

Miijif.ri aiiThui iStt

lever has been preset at the factory and

not be necessary.

10 .motion control lever will r lot hold its

elected speed, it may be adju i ,

' r h- ’ '1 , O'- '1 ti". ission.

1- ' i>r.' -0 rrp tr-cir>r

r r 1 i dii S'"" - pf rf-incj

turn ng

TRANSMISSION REMOVAUREPLACEMENT

Should your transmission require removal for service or

replacement, it should be purged after reinstallation and

before operating the tractor. See “PURGE TRANSMIS*

SION” in the Operation section of this manual.

"O REteo^^t MH ft i s i K itt f

(See Fig. 26)

« R innï t f in Ovis tf

* DIUL>t\ up ciAlt? tsfeiOui

* Fismov© 3x1© cov©r,

Af'-'inU 1 1

not lose).

• t iji |IK

a 'j,> 1 1 1 t-c-»., ,1

anc Cxi- 1 r f 1 qi

NOTE: To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion.

WASHERS

RETAINING

RING

- 1

H r -

eiv.

retaining ring

■ wheel conta

»semble.

r. align groo:

in rt

writ

TO ADJUST STEERING WHEEL ALIGNMENT

If steering wheel crossbars are not horizontal (left to right)

when wheels are positioned straightforward, remove steer

ing wheel and reassemble per instructions in the Assembly

section of this manual.

FRONT WHEEL TOE-IN/CAMBER

The front wheel toe-in and camber are not adjustable on

your tractor. If damage has occurred to affect the front

wheel toe-in or camber, contact your nearest authorized

service center/department.

AXLE COVER

SQUARE KEY

(REAR WHEEL ONLY)

FIG. 26

Page 24

r- ijjr. ilIMPPrJTS

whe

timail

WEAK BATTERY

iri€

srotectic

fr I If! be

ro START

A

If your battery is too weak to s' lari the snginei

ifl.tl-t' J- 'i k ’ lt( ' 1.1 Bra Lissd for

rr.sfiinj -v, if 1. < .r

IV!»-* -p fU'J 1 ■ H ' 1 !/ 1 '

VOLT NEGATIVE GROUNDE D SYSTEM. T

fl IS EQUIPPEC

•L eiHti

.'FHICI L ,il t ' G M A 12 VOLT i

.RvlUH . [ jTI

BATTERY TO STARTO

:R VEHICLE

II . 4'r 1 Pn ' f-lf

TO ATTACH JlJyPER C

* Connect each end o

Irli t'lidlos Ol I

..1 I f • the i-Ri.l iIjE“

jI i i<i . le not 10 shore

LI I n

* It-nnecicne -no i ih- * t r-LI-to the NEGA-

TI\/[ o, terriiK m <jt fuHi/ H ]f ! L' ti >/

® ('onneri tne >-ih I rf !i I Lo(i cable to good

( H'Si: IS ' 1 *r r ti,. . lU^J tiiik and battery.

TO REMOTE C«H1 t ‘ r->0 ^ V OHtTR ■■

* BL T c Ì .'nr • 1 'jiid to n from the fully

CrifTJ ribc:tt-

* RLn<abOi'i- II i.,| ,th b iVine:

Si ¿*:i yrAi-t\ ijui

Pul! bulb holdof 1

out of th.e hoi

iid@ of th6

oriiL .

1 uuiu III 1 IU8UGG at

back into the hot

0 In the !

iU pL

» ■■ T

Close hood.

INTEai CCKS AMP REl AYS

• z-LZ- zi y.-nia'>d ‘iiriro rrec uauEC vutr trocOr t.j run

p' r.rlv ' lor. •'onn-nq Of I r-o r-nf jt ffom starting

® { oFi I jvirin.j '~ffc FiHftrrai 'Ainna diagram in the

Fiepan Barts ci* zi on of ihi- menual ’

TO REPLACE FUSE

hepOc- witii A' at-ip autjniotiv'F lype plug-.n fuse The

fuse holder L lorair-d behind the dash

TO REMOVE HOOD AND GRILL ASSEMBLY

(See Fig. 28)

• Raise hood.

• Unsnap headlight wire connector.

• Stand in front of tractor. Grasp hood at sides, 1

engine and lift off of tractor.

» To replace, reverse above procedure.

PCSIIR'E "FPStiilf I.

'x

ULi-WJL TERMINAL

CHARGED

Page 25

9.; :Srs-

ENGIf

T*0 &

1 he fhrc

MUST THRC

ittle control has

adjusirntjnt should not be

describe

d below before

necessa ry, proceed as fi

• With engine not run

from

level

® ChOi

in gc

Ij f 1 ‘ ^ f

;k that holes “A”

ivernor plate line

- fO 1

loos^an clamp screw £

iligned. Tighter

are c

ITTLE CONTROL CABLE

been preset at the factory and

■ necessary. Check adjustment as

1 , 1 !,i I* 1 •' 1 .

Dliows:

1 ■( 1 t L-i JO- t" * 1 />-r

i.y

-

i| 1/ poyi

1 t 'it,' M

i< J',.. > 'hmh!'. ^-1 ir i!rir!l holt s

, ' ,, f :■ -w •

I ,

' Jf wly u " '

, , t

fi hid Ir I ; -,i ’ 1 (Is

j. I'd- ",c w rrl aliqrt'i,

. If .

h<

Final

Ifni

line

3K

holdl

I urn luie bpeeo surev

8 /Ur

11 1 ,

. ,1,

<|v . 'lii >

turn idle mixture valvi

gins to die and then tur

girie runs rough. Turr

bei

ri those two positions

throttle le

!

• Ft

i ', ti; h ^ r.- ',11 1 I r

poi

, il >11... > «'•I. r-.i' 1 m L'l

rorn slow

coiK'h'j' _ii,v i it *<■ c-_ m( ' .

cites b! HuOil ily.

tr

n idle

speatl

igirie c

iier-

High speed stop is factory adjusted. Do not adjust -

damage may result.

IMPORTANT: NEVER TAMPER WITH THE ENGINE

GOVERNOR, WHICH IS FACTORY SET FOR PROPER

ENGINE SPEED. OVERSPEEDING THE ENGINE ABOVE

THE FACTORY HIGH SPEED SETTING CAN BE

DANGEROUS. IF YOU THINK THE ENGINE-GOVERNED

HIGH SPEED NEEDS ADJUSTING. CONTACT YOUR

NEAREST AUTHORIZED SERVICE CENTER/

DEPARTMENT, WHICH HAS PROPER EQUIPMENT AND

EXPERIENCE TO MAKE ANY NECESSARY

ADJUSTMENTS.

TO ADJUST CARBURETOR (See Fig. 30j

The carburetor has been preset at the factory and adjust

ment should not be necessary. However, minor adjust

ment may be required to compensate fordifferences in fuel,

temperature, altitude or load. If the carburetor does need

adjustment, proceed as follows;

In general, turning idle mixture valve In (clockwise) de

creases the supply of fuel to the engine giving a leaner fuel/

air mixture. Turning the idle mixture valve out (counter

clockwise) increases the supply of fuel to the engine giving

a richer fuel/air mixture.

IMPORTANT: DAMAGE TO THE NEEDLE VALVE AND

THE SEAT IN CARBURETOR MAY RESULT IF SCREW IS

TURNED IN TOO TIGHT.

PRELIMINARY SETTING -

• Air cleaner assembly must be assembled to the carbu

retor when making carburetor adjustments.

• Be sure the throttle control cable is adjusted properly

(see above).

• With engine off turn idle mixture valve in (clockwise)

closing it finger tight and then turn out (counterclock

wise) 1 full turn.

25

Page 26

¡rnmediately

the season o

)ur trac

:ior will

■for

‘NOINE

CAUTION’ Never store the tractor with

gasoline in the tank inside a building

wr -'"'p if *f7-Ax / »' a'"h • V I*'*», *

'► -pii-rti ihiow the er»iJ«nr tu -a.

,Htrriii>s ifi -in»' em

!HAI rc^H

pA.jit , (|,r,s rr i jtr. i'j t It i'v! iiA when

«riiv.ii f'l i> ,tx I !• ■ px II.'J . t (irit>x (.Car. !i ¡nor

>iiL|li!. i-rru aÌ iJitf ijr iw [ ' tf«-. 'Z’jic ina

clean, dry area.

Cif^aiiAii r Vifidu'iC ' > ‘L/fJ||iC i.iii c C Link rner

ill ‘ |hx . C.|,i|t;0 Wii n . I òii_ iKdhJtjf}

« liiApect tnrl replce b'^lts n riecesser/ (oee belt ri -

placement in Tructiotw iti *ni oc. nee and AdiustmeiAts

section of this manual)

• Lutroste db "-hotfin ,n the Customer Responsibilities

iictiou (if (hit riii-iruai

• Be sure that all nuts, bolts and screws are securely

fastened. Inspect moving parts for damage, breakage

and wear. Replace if necessary.

• Touch up all rusted or chipped paint surfaces; sand

lightly before painting.

BATTERY

• Fully charge the battery for storage.

• After a period of time in storage, battery may require

recharging.

• To help prevent corrosion and power leakage during

long periods of storage, battery cables should be

disconnected and battery cleaned thoroughly (see “TO

CLEAN BATTERY AND TERMINALS”

tomer Responsibilities section of this manual).

• After cleaning, leave cables disconnected and place

cables where they cannot come in contact with battery

terminals.

• Be sure battery drain tube is securely attached.

• It battery is removed from tractor tor storage, do not

store battery directly on concrete or damp surfaces.

in the Cus

ilv1t

DEPOSITS

SYSTEM PA

FUEL HOSE

EXPERIENCE IN

FUELS (CALLED

I'V T r '-f.fii 1 „I

'-t F .‘Oil dD', I hrMdlCli OF AUDS DURING

< '/• M i"!C ' f TJ D' M' Gb fuel

>' r 11r ' 11 Ids’ vH ' I lij - '"orame

I :

-OB

■ • I ' ILi f . Mi Ml! r I TF>,

I* ( 1!, I .IJ'U», Ll.R^-r-b iloO

IT,

a 11 - |i-*r “lCOHuL BLENDEü

-H 'L ■ )- iMIfir -PHAilOi. OR

FRa.m i/Hr-TijHF A'l-nCh LEADS

lEVENl

S > I. ■ i , I limi 'UL'

51

iVi

» Drain the fuel tank.

' I t ii.‘_ tup' T, I Lj I ui uiif'l lie tuci lineo and

Ot III* ( r *rt Mil M

“ I ijx b . ,1 jr)ijiL*..r* leaner ptuducts mthe

)ij'. 'if |.uirii 4i» .it cMiTHge may occur

® IJ i.- h iutLi iH /f Ar MWiri

NOTE Fuel 'Mbili/ef .& an acceptable alternative in

rr.inirriiz.ing ttie fcrmatior 1 fuei aum deposits during stor

d'3f lij anbilMM to gasoline m fuel tank or storage

container A|wa,= tjiiew tic mir ratio found on stabilizer

container. Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the carburetor. Do

not drain the gas tank and carburetor if using fuel stabilizer.

ENGINE OIL

Drain oii (with engine warm) and replace with clean engine

oil. (See “ENGINE” in the Customer Responsibilities

section of this manual).

CYLINDERS

• Remove spark plug(s).

» Pour one ounce of oil through spark plug hole(s) into

cylinder(s).

• Turn ignition key to “START” position for a few seconds

to distribute oil.

• Replace with new spark plug(s).

OTHER

• L I ■ t -(')> < osnlin T(... cn eason to another.

• r { h,- /r,m ( ^ uiiriF f ai. it sour can starts to rust.

Re i it>r or i>111 yv.ni qd'jcline will cause problems,

® h f I ■ibk t ,r^ /oi't l. r k f indoors and cover it to

yi I, pi. ic cix-n fmr ’ duM in 1 Jirt.

• ■ ( > * yruilM'iLi vilh A uitable protective cover that

d( .X not rt iihfiioiiur . Du n't use plastic. Plastic

tMiiutbn o' if whirlialk w^toiidensationtoformand

'\r*''r'U”- oi'M'jtt.'t t '•'jxt

IMPGFTLi'r neVED COVER TRACTOR WHILE ENGINE

AN VARM.

'26

Page 27

FSHOOTING POINTS

PROBLEM

Will not start

Hard to start

Engine will not turn over

LISE

1, Out of fuel.

Engine not “CHOKED” property. 2. See “TO START ENGINE” in Operation section.

2,

3. Engine flooded.

4, Bad spark plug.

Dirty air filter. 5. Clean/replace air filter.

5.

6. Dirty fuel filter. 6.

7. Water in fuel.

Loose or damaged wiring.

8.

Carburetor out of adjustment. 9.

9.

Engine valves out of adjustment. 10.

10.

1. Dirty air filter.

Bad spark plug.

2.

Weak or dead battery. 3.

3.

4. Dirty fuel filter.

5. Stale or dirty fuel.

6. Loose or damaged wiring.

7. Carburetor out of adjustment.

Engine valves out of adjustment.

8.

Clutch/brake pedal not depressed.

1,

2. Attachment clutch is engaged.

Weak or dead battery.

3.

Blown fuse.

4.

5. Corroded battery terminals.

Loose or damaged wiring.

6.

7. Faulty ignition switch.

8. Faulty solenoid or starter.

9. Faulty operator presence switch(es).

CORRECTION

1. Fill fuel tank.

3, Wait several minutes before attempting to start.

4,

Replace spark plug.

Replace fuel filter.

7.

Drain fuel tank and carburetor, refill tank with fresh

gasoline and replace fuel filter.

8. Check all wiring.

See To Adjust Carburetor” in Service Adjustments

section.

Contact an authorized service center/department.

1. Clean/replace air filter.

2. Replace spark plug.

Recharge or replace battery.

4. Replace fuel filter.

Drain fuel tank and refill with fresh gasoline.

5.

6. Check all wiring.

7. See To Adjust Carburetor" in Service Adjustments

section.

8. Contact an authorized service center/department.

1. Depress clutch/brake pedal.

2, Disengage attachment clutch.

3. Recharge or replace battery.

4, Replace fuse.

Clean battery terminals.

5.

6. Check all wiring.

Check/replace ignition switch.

7,

8. Check/replace solenoid or starter.

Contact án authorized service center/department.

9.

Engine clicks but will not

start

Loss of power

1. Weak or dead battery.

2. Corroded battery terminals.

Loose or damaged wiring. 3.

3,

4. Faulty solenoid or starter.

1. Cutting too much grass/too fast. 1.

1. Recharge or replace battery.

2. Clean battery terminals.

Check all wiring.

4. Check/replace solenoid or starter.

Set in “Higher Cut” positlon/reduce speed.

2. Throttle in “CHOKE” position. 2. Adjust throttle control.

3. Build-up of grass, leaves and trash under mower. 3.

4. Dirty air filter.

Clean underside of mower housing.

4.

Clean/replace air filter.

5. Low oil level/dirty oil. 5. Check oil level/change oil.

6, Faulty spark plug. 6.

Dirty fuel filter. 7.

7.

Stale or dirty fuel. 8.

8.

Water in fuel. 9.

9.

10. Spark plug wire loose.

11. Dirty engine air screen/fins.

12. Dirty/clogged muffler. 12. Clean/replace muffler.

13. Loose or damaged wiring. 13.

14. Carburetor out of adjustment. 14.

Engine valves out of adjustment. 15. Contact an authorized service center/department.

15.

Clean and regap or change spark plug.

Replace fuel filter.

Drain fuel tank and refill with fresh gasoline.

Drain fuel tank and carburetor, refill tank with fresh

gasoline and replace fuel filter.

10, Connect and tighten spark plug wire.

11. Clean engine air screen/fins.

Check all wiring.

See “To Adjust Carburetor” in Service Adjustments

Section.

Excessive vibration 1. Worn, bent or loose blade. 1. Replace blade. Tighten blade bolt.

2. Bent blade mandrel. 2. Replace blade mandrel.

3. Loose/damaged part(s). 3. Tighten loose part(s).. Replace damaged parts.

27

Page 28

TROUBi FííHOOTfNG RnsHTS

PROBLEM CAUSE

Engine continues to run

when operator leaves seat

with attachment clutch

engaged

Poor cut - uneven

Mower blades will not

rotate

Poor grass discharge

1. Faulty operator-safety presence control system.

1. Worn, bent or loose blade.

2. Mower deck not level.

3. Buildup of grass, leaves, and trash under mower.

'4. Bent blade mandrel.

5. Clogged mower deck vent holes from buildup of

grass, leaves, and trash around mandrels.

1. Obstruction in clutch mechanism.