Page 1

1

; 'm

mm m

a/£î> r ,

/ ¿)

OWNER'

14.5 HP lr,v. h

Lawn Tra/:to8

Assembly

• Operation

• Customer Responsibilities

For Parts and Service, contact our authorized distributor; cal! 1-800-849-1297

For Technical Assistance: call 1-800-829-5886

i

F

• Servie» f?e<i Acfjwstments

• Storage

eshooting

• Repair Parts

\

160462 3.24.97 RH

PRINTED IN U.S.A

Page 2

IMFOi

FAILÜ

M.

SAFETY RULES

Qppfgflpll PractiCSS for RÍCÍ0“Oll PJ

A

:fc i ANU i Í

ir-IJURYOR DEATH.

arid on the machine ben

Only allow responsible

instructions, to operatij

e f itn ' i .

which could be picked i

Be sure the area is dear

machine if anyone ente

Never carry passengers

Do not mow in reverse u

look clown and behind t

L.i . i‘ /* r

s, who are familiar with ih

■( . lOLK. '• .. W').* , ,W

thrown by the blade.

srv. Alwavss'is absolutely necesi

.lire and while backing.

'r i to Of■> ¡.orI

: » “'/''I I' r"~, ‘ ' !ii .iTFiki'C h

entire grass catcher or the guard In place.

® Ekw fi r, > ,

• Fit- '-•'[< -a . I ‘ all' "liaiMuC . , T/Ltuiij if

hi. i. . I, oi 1'" nyi i-- -ii.r i tiT'vi-k- >

Is It . I jt nil'! ;

^ '! urn I fi uLC'n «iif I 1« '' iriO'V'M I

• stop f In jit.', t loic I', >i(. I.''->ji r: '.li tit' (i I'nf.loggir'u

chute.

I Mow onL 11 i'/iiylti 1 p( j milicianighi

'' Do no! cps-i t *hr-I. hiN* > .nilr, urc'u #■ induepcf .

alcohol or JfL>_..

• Watch for irptfk; w.heri ■»per. in .r- neat oi crossing loadwaj Use extra caiS w,ie ri leading or u.iiiaot'iiic ihc iriccl in« intu

a trailer or truck.

II. SLOPt OPhR/.'lO J

Slopes are a rr,a|ot ¡e* ted i.j ios. -ni control and

tipoven ryordeath.

All siopi rack up the

slope 0

DO:

• Mow up and down slopes, not across.

• Remove obstacles such as rocks, tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could

overturn the machine. Tall grass can hide obstacles.

• Use slow speed. Choose a tow gear so that you will not have

to stop or shift while on the slope.

• Follow the manufacturer’s recommendations for wheel

weights or counterweights to improve stability.

• Use extra care with grass catchers or other attachments.

These can change the stability of the machine.

• Keep all movement on the slopes slow and gradual. Do not

make sudden changes in speed or direction.

• Avoid starting or stopping on a slope. If tires lose traction,

disengage the blades and proceed slowly straight down the

slope.

DO NOT:

• Do not turn on slopes unless necessary, and then, turn slowly

and gradually downhill, if possible.

• Do not mow near drop-offs, ditches, or embankments. The

mower could suddenly turn over if a wheel is over the edge

of a cliff or ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction could cause

sliding.

• Do not try to stabilize the machine by putting your foot on the

ground.

• Do not use grass catcher on steep slopes.

ur if the operator is not alert to the

hildren are often attracted to the

machine and the mowf.

children will remain whe

• Keep children out of th<

care of another respor

• Be alert and turn mad'

• Before and when bact

children.

-I' a ■!' ’ I r ‘>n.yc 'sd md be seuously

injured or interfere with safe machine operation.

- (n *. • 1 .- r >1 =1.’ - tl «■ rf.i,nh.i U '.I 1 u t. ¡.r .V ii'i'y b‘i 11 f ornéis, shrubs,

. i I I. , I'w r. -> jrt Vi lOi.

ig activity. Never assume that

■e you last saw them.

I V mo end I (If I “nRv'atchtul

sible adult.

ii.' ! hii’cJmn enmi fii area.

M , ... ...i hi.id dri'J town lor small

I¥. SER¥iCE

‘ ii'ci '' c .( 'IÍ jr Ji.if’-n jlir fuels. They are

llr'Oiri I ,1 p'.' If -xj t-

' nC ,in . "j,. f < f r.ar.m.rio'

I . I nr. Vi iaf O' oOd foal with the engine

‘ Alio'v ( uc.oc-tc 'ool bf-iciT refueling. Do not

! I i I I’ i I .t 1. ‘-'nf i; doc.ru.

. .-I f r- ' Í ! ror-i'[f «-■ ifsids where

I’lio !i.ar:o|' 1 iki.i ‘ .w.m'i, ,j w-ff&r neater

• Never run a machine inside a closed area.

f I lit iiof I • ¡ ti<„ilvMj' tt' nmentbults,tight

M« , 1 m p >1 I >0'i c n JiiK I

operation regularly.

n,’t.t. i f 'bc r Other debris build-up.

^ ,311 I ! Ill« \ii V/ n.acnrie to cool before

storing.

Stop and inspect tl

Repair, if necessary

Never make adjustrr

Grass catcher comp«

I ■- A!ch ii.raiirif iuih's'■mmeided parts, when nec-

equipment if you strike an object,

efore restarting.

Its or repairs with the engine running,

s-nts are subject to wear, damage, and

/1. I < k r p-Et, nioving parts or allow

eck their proper

>' ick components and

f'is-.srv

I g,f,ve, and i fe fe, im caution when servicing them.

required.

Wrap the blade(s) or

djust and service as

[ f ok f r rhr yritb'^'i to point out im«

i.ií#í - fi'f pnE.,.uiwjns. It means

• >Lif rL^C-KL ALERT!!! YOUR

‘ M IHYOIvID

t spark plug

ansporting,

A

IÜTION

> > V vht iC it cannot contact

w ‘t SI Í ¥snt accidental

adjusting or making repairs.

A WARi SiNG A

8 of Califor-

[I n; tn V IÍAA cTfipt-i TíHh ¥®í«ícts, or other

2

Page 3

fi§ '5jt ; 0!' r-'i i '

It has been designed, engineered and manufactui

yive yoLi the best possible dependability and perforrn

Ik 'il' / u ' II' it' ■ > / i - /i,-\ . If. i

i ' ¡1 ,!< . I . i r ... . f- , >1 r> ' '

center/department. We have competent, well-trainee

nicians and the proper tools to service or repair this tr

Please read and retain this manual. The iristructioi

enable you to assemble and maintain your tractor pro

r •/» ’i‘ y . I “I''j' hof f i ‘i r ,li> -

MODEL

NUMBER

SERIAL

NUMBER

DATE0FPURCH4 F

THE MODEL^rJbStHiALNUMBERSWILLBE FOUND

ON A PLATE UIIDER THE SEAT.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE ArJD KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE,

HD145H42D

PRODUCT SPEC

¡GASOLINE CAPACITY

AND TYPE:

OIL TYPE |A.PI-SF/SG/cjr

IL CAPAdl

.'•PARK PLUG

(GAP: .030“)

VALVE CLEARANCE:

GROUND SPEED (MPH): FORWARD; 0.0 -5.5

TIRE PRESSURE: FRO - PSI

CHARGING SYSTEM:

;IC

ÎATIONS

NLEADED R

\E 5W-30 (b

CHAMPION R.Jt'-i M I

INTAKE: .004" - .006“

EXHAUST: .007" .003“

REVERSE: 0.0 - 2.3

REAR; 10 PSi

3 AMPS iY

5 AMPS HEADLIGHTS

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

» Foliowa regularschedule in maintaining, caringforand

using yourlractor.

» Follow the instructions under “Customer Responsibili

ties” and “Storage” sections of this owner’s manual.

BATTERY:

BLADE BOLT TORQUE: 30-35 FT. LBS.

WARNING; This tractor is equipped with an internal

combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-cov

ered land unless the engine’s exhaust system is equipped

with a spark arrester meeting applicable local or state laws

(if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

A spark arrester for the muffler is available through your

nearest authorized service center/department (See RE

PAIR PARTS section of this manual).

In the state of California the above is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands.

AMP/HR: 25

MIN. CCA: 190

CASE SIZE: U1R

Page 4

CUSTOMER RESPONSIBILITIES .................

WARRANTY ......................................................... 50

ASSEMBL

OPERATIC

INlirX

I

Adj.:o I - is.

M> » .1

Thiuitlfc ( ufiirol Cable

Air Filter, Enci ic- .......... 18

Air Screen, Engine ..............................

Assembly.............................................. 6-9

Batteiy: ■

Charging ...................................... 7

Cleaning........................................

Starting with Weak Battery

Storage ......................................

Terminals ................................... 17

Belt:

Motion Drive

Mower Belt(s)

Blade:

Sharpening.......

Replacement

Brake Adjustment

Carburetor Adjustment

Controls, Tractor

Customer Responsibilities.............. 15-19

Engine:

T factor:

Cutting Height, Mower.............

Electrical:

Interlocks and Relays..

Schematic .................................. 29

Wiring Diagram ............................ 30

... ... ......'......................22

. A- Lack......................... 21

InCjc io LitJe............................

............................25

............. 24

18

B

17

..............

26

Removal/Replacement.

Removai/Repiacement...............22

............................

......

.......................

...

............................

...

.........

16

16

22

C

...

...................... 25

.......

............................

Air Filter

Air Screen ...............................

Cooling Fins

Engine Oil ............................

Fuel Filter..................

Spark Plug(s)

Battery............

Blade......................................... 16

Lubrication Chart...................... 15

Maintenance Schedule ............ 15

Tire Care........................

Transaxle ................................

...............................

..

.............................

..............

...........................

........................

...............

11

18

18

13,17

19

19

17

7,16,23

17

E

......... 24

21

23

22

18

12

CONTENTS

MAINTEf-IAMCE SCHEDULE .................................... 15

SERVICE AND ADJUSTMENTS ............................ 20-25

REPAIR PARTS - TRACTOR ............................... 30-47

3RDERING/SERV1CE................ BACK COVER

Engine:

Air Filter........................................ 18

Air Screen

Cooling Fins...

Oil Change................................... 17

Oil Level....................................... 13

Oil Type....

Preparation .................................. 13

Starting........................................

Storage .....................................

Filter:

Air Filter.........

Fuel............................................ 19

Fuel:

Type......................................... 13

Storage .......................................

Fuse ....................................................

Hood Removal/lnstatlation .................

Leveling Mower Deck.....................

Lubrication:

Chart

Engine...

Maintenance Schedule ....................

Mower:

Adjustment, Front-to-Back........... 21

Adjustment, Side-to-Side............. 21

Blade Replacement...................... 16

Blade Sharpening .......................

Cutting Height.............................. 12

installation

Operation..................................... 13

Removal........................

Mowing Tips......................................... 14

Muffler.................................................. 19

Spark Arrester........................... 3,40

Oil:

Cold Weather Conditions........ 13,17

Engine......... 17

Storage ........................................ 26

Operation ....................................... 11-14

Operating Mower.....

.....................................

.........

.....................

....... 13,17

F

...............................

H

L

.......

.....................................

.......... 17

U

.................................... 20

...............

O

............................

.......

18

18

14

26

18

26

24

24

21

15

15

16

20

13

STORAGE ............................................................ 2i

TROUBLESHOOTING ...................................... 27-28

Options;

Spark Arrester.........................3,40

P

1 tt/.r >. r take .. .. ......................... 11-12

F.-ft Er-i_ .. 5

f rt ri tLccmenTRepair...

Produci fc'ptcificaiipns.

.................

...

......................

....30-47

3

R

Repair Parts

.................................... 30-47

S

Safety Rules

Seat.............

Service and Adjustments

Carburetor........

Fuse...........................................

Hood Removal/lnstaflation........... 24

Motion Drive Belt

Mower Belt(s)

Mower Adjustment

■ . Front-to-Back

Mower Removai/lnstallation

Tire Care............................. 7,16,23

Slope Guide Sheet

Spark Plug(s) ....................................... 19

Specifications

Starting the Engine

Steering Wheel ............................... 6,23

Stopping the Tractor

Storage...........

.........................................

.......................................

...

..............

.............................

Removal/Replacement.

Removal/Replacement

Side-to-Side ...........................

................................

...

.........................

.........................................

...

......................

....

......................... 12

....................................

..............

...............

............

13-14

3

7

20-25

25

24

22

22

21

21

20

51

2

26

T

Throttle Control Cable Adjustment

Tires............................................ 7,16,23

Troubleshooting Chart

Transaxle ....................................... 30-47

...

................

W

Warranty

Wiring Diagram

Wiring Schematic................................ 29

............................................. 3

...................................

.....

27-28

....

30

24

Page 5

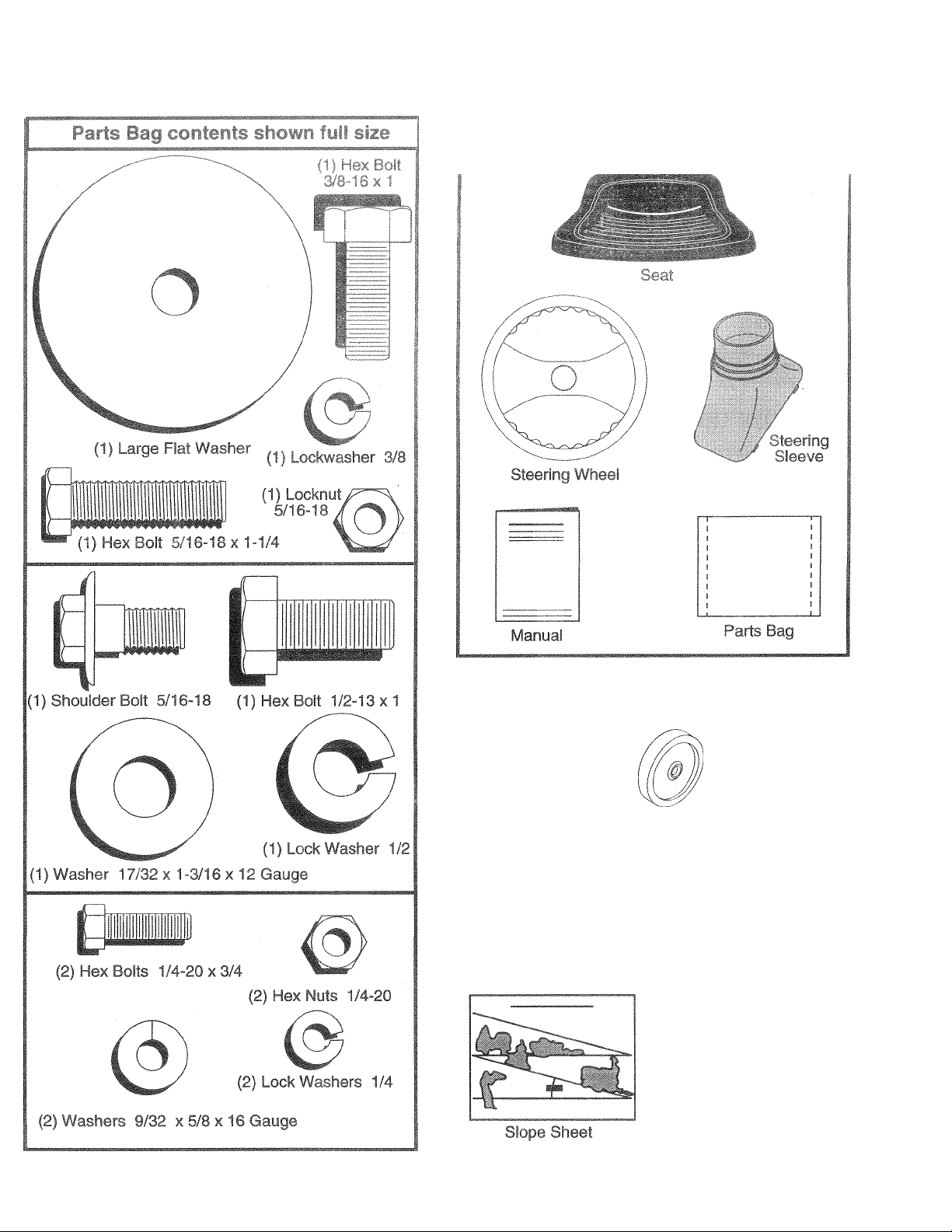

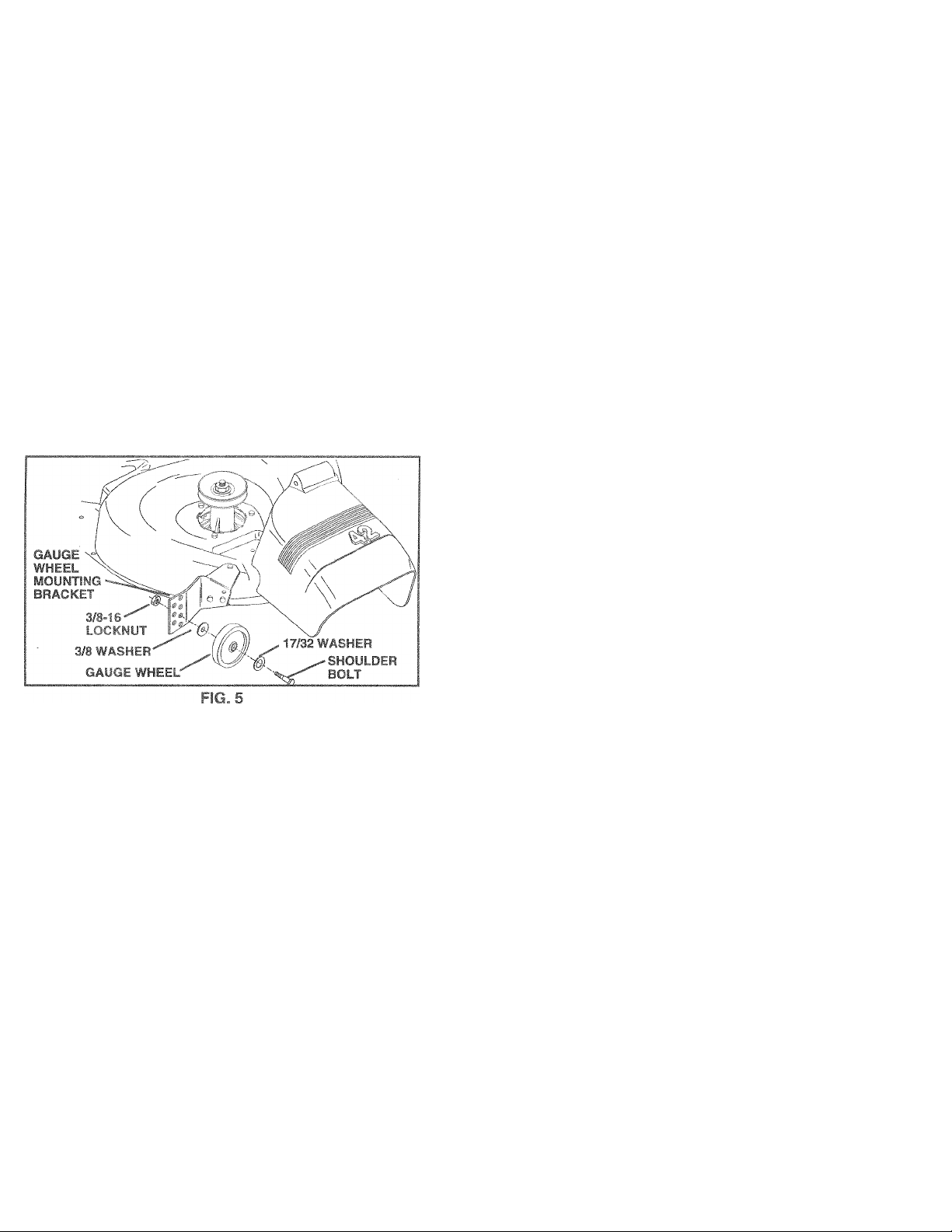

Parts bag contents not shown full size

S

(2) Shoulder Bolts

(2) Washers 17/32

X 15/16 X 12 Gauge

(2) Gauge

Wheels

(2) Center-

lock Nuts

@

(2) Washers 3/8

X 7/8 X 14 Gauge

Steering

Wheel

Insert

Steering

Extension

Shaft

o

Tznznr

steering Wheel

Adapter

(2) Keys

Page 6

'5 . t-Lait'ii

TOOLS REQUIRED FOR ASSEMBLY

/ •• P- b -1 p'i 1 , , . . , :

K‘l nch SI, L -,h *

3/d" y^Lk;! i I " I < litt till, y Hills

(2) 7/16" wrenches Tire pressure gauge

(2) 1/2" wrenches

(1) 9/16" wrench

When right or left hand is mentioned in this manual, it

means when you are in the operating position (seated

behind the steering wheel).

TO REMCj¥t 1 Hht TUR FROit CARTON

UNPACK r ASTON

• Remove al! accessible loose parts and parts cartons

from carton (See page 5).

• Cut, from top to bottom, along lines on al! four comers

of carton, and lay panels flat

® Check for any additional loose parts or cartons and

remove.

eption of th'

and hardwa

il I > f dl~ ’ ! |.l' l( i'jSO>

amble must be iiqhtened securely. Use

BEFORE ROLLING TRACTOR OFF SKID

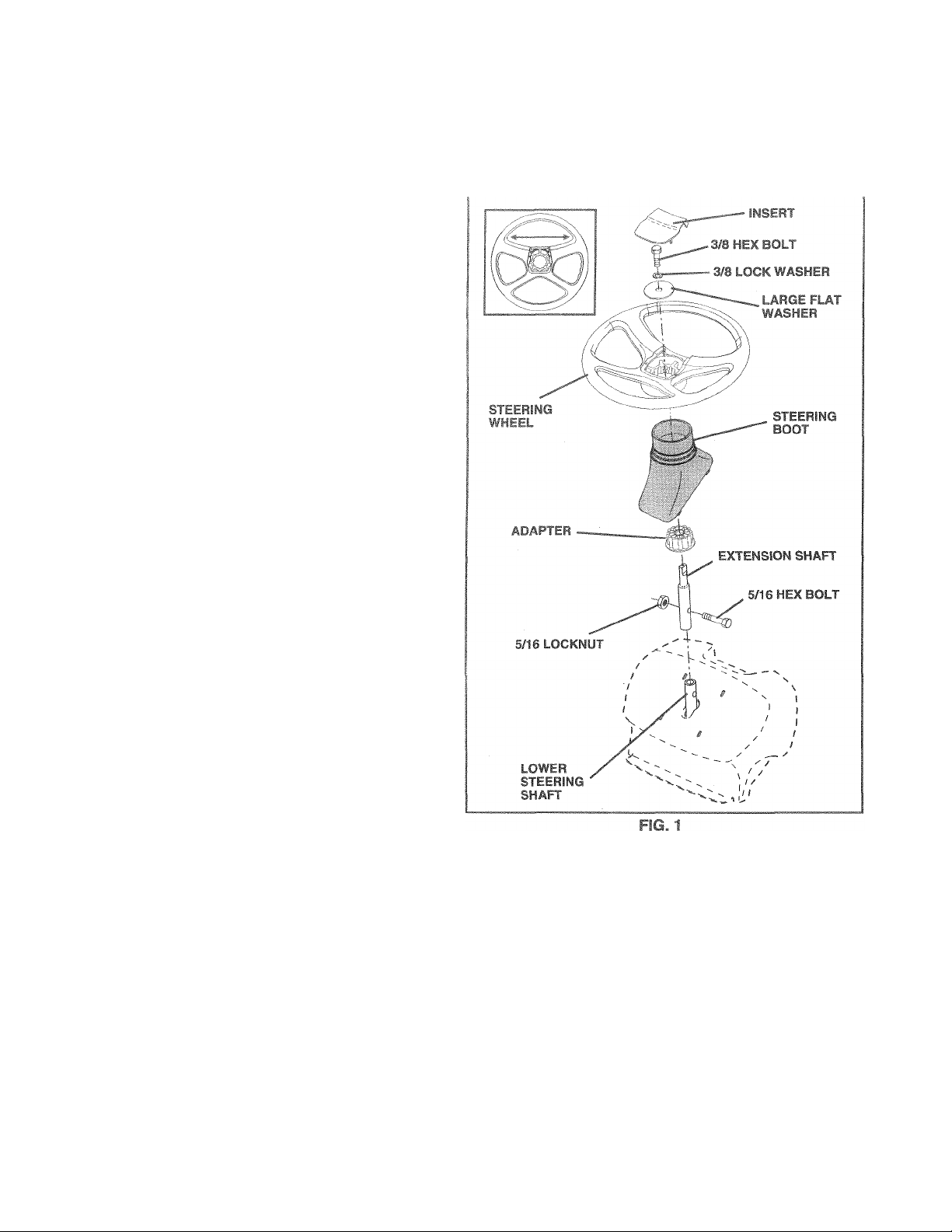

ATT*w*,H TTFF.PiPC WHFFb Fig. 1)

L it V-L N Sil/CT Ai.u L’> Hi

e ori '.hah Oi'f- Vs/V ifc iipg.>-hifl /-lign

nrmii.ro II ' shat'', t^nd

-t.shiil O, I , i I, ,',t (l t , 'T t. .’•cru II SL- Ul'ly.

IMPORIAMi TH HT. .i Bt.LT/f<r» i\iUr i hCl'Rl I - TO

16-2.. FI. Lb.1 I„RQLL.

• Place tabs of steering boot over tab slots in dash and

push down to secure.

INSTALL STEERING WHEEL

• Position front wheels of the tractor so they are pointing

straight forward.

• Slide steering wheel adapter onto steering shaft exten

sion.

• Position steering wheel so cross bars are horizontal

(left to right) and slide onto adapter.

• Assemble large fiat washer, 3/8 lock washer, 3/8 hex

bolt and tighten securely.

• Snap steering wheel insert into center of steering

wheel.

• Remove protective materials from tractor hood and

gri.L

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

IN SKID THAT MAY PUNCTURE TIRES WHERE TRACTOR

IS TO ROLL OFF SKID.

TO ROLL TRACTOR OFF SKID (See Opera

tion section fot location and function of con

trols)

• Press lift lever plunger and raise attachment lift leverto

its highest position.

® Release parking brake by depressing clutch/brake

pedal.

• Place freewheel control in freewheeling position to

disengage transmission (See ‘TO TRANSPORT” in

the Operation section of this manual).

» Roll tractor backwards off skid.

• Remove banding holding discharge guard up against

tractor.

Page 7

HO^

CONNECT BATTERY (See Figs. 2 and 3|

CAUTION: Do not short batterf termi

nals by al ¡owing a wrench or any other

object to contact both terniiiials at the

same time. Before connecting battery,

remove metal bracelets, wristwatch

A

< t > *1 I t, n

first to prevent s

tal qrounding.

TKM

SEAT

PAN

BirTERYBOX DOOR

lire

p.i.i to ; I '. I 'tt .I

® C'pf ri i»{> J< i .(h wiii i.i- f t< 1i. r I ¡riSiic.

¡it! ai• H i-c ^ 1?.' I

• R- ft Ji- : nn -,^1 f fct f fi I ' u vrt ' f •']

• l‘'ih. h-*Ter. .' |.i!: ,11 fc ^ir 'll ' I a.f.ver

irdsta!. a on l-t-> iinL«-! .uoateo r.-tu'cen i-tr,'na*s)

chaty' b. tif n- fo' ,aiiH‘r!iiim ot or<- noyrdtC-'Cj .-mps.

• First ccnnect ril-[ 10 ittcivcc.blpt( fo.itn (+) leirninal

With tiex bC’lt 1at luc> Wu. h‘o' -.nd hex nut as

sh? T rpht'> .a!/

• Co» nect BLAGF yr>un>Jrg cabi- to negative {) termi

nal with rcrmininy b-\ bait, flat vasher. iock washer

and hex nut Tight'-; i r,t< ureiy

• Close battery box door.

Open battery box door for:

• Inspection for secure connections (to tighten hard

ware).

• Inspection for corrosion.

» Testing battery.

• Jumping (if required).

• Periodic charging .

DISCARD

TERMINAL

PROTECTIVE

CAPS

LOCK

WASHER

FIG. 3

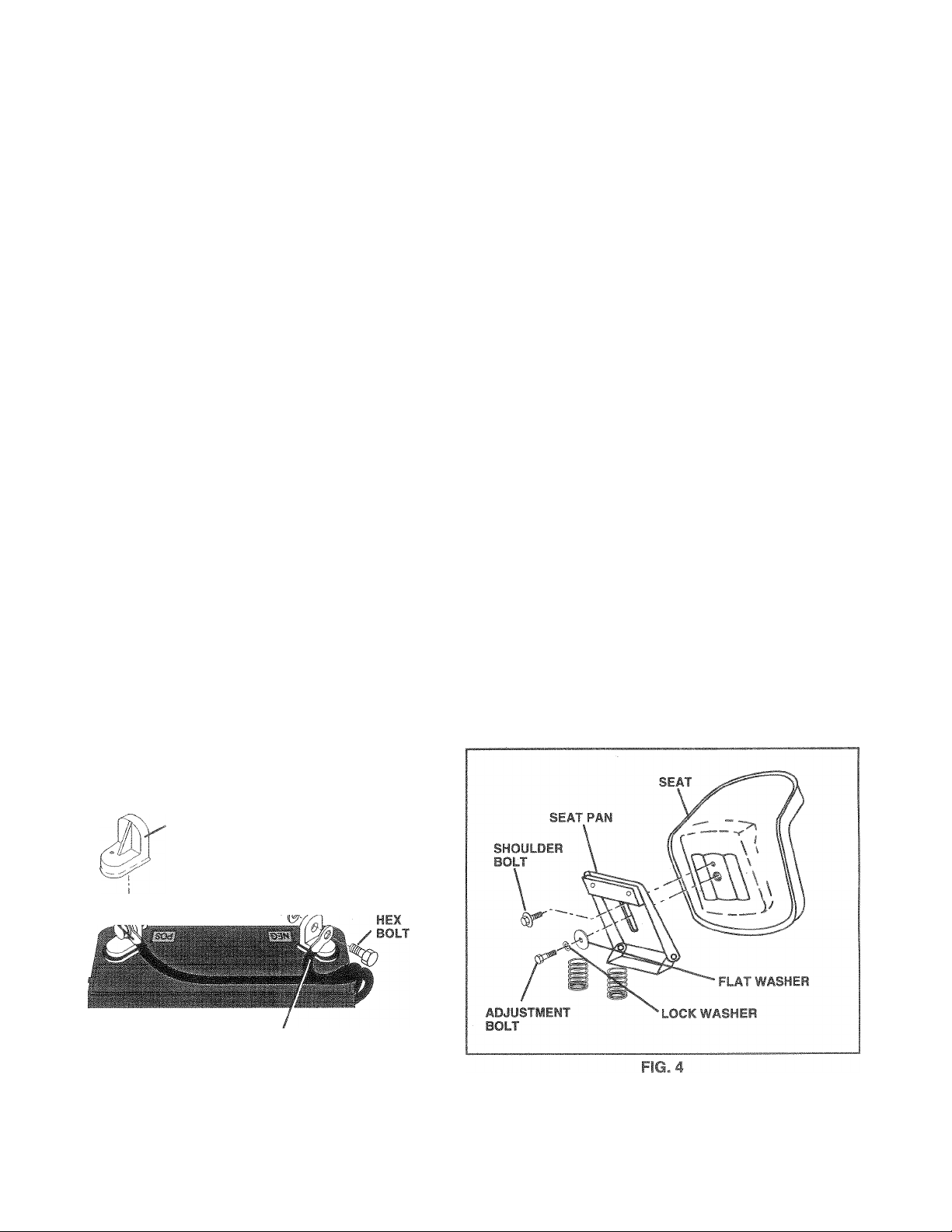

INSTALL SEAT (See Fig. 4|

Adjust seat before tightening adjustment bolt.

• Remove cardboard packing on seat pan.

• Place seat on seat pan and assemble shoulder bolt.

• Assemble adjustment bolt, lock washer and flat washer

loosely. Do not tighten.

• Tighten shoulder bolt securely.

• Lower seat into operating position and sit on seat.

• Slide seat until a comfortable position is reached which

allows you to press clutch/brake pedal all the way

down.

• Get off seat without moving its adjusted position.

• Raise seat and tighten adjustment bolt securely.

POSITIVE

(RED) N

CABLE

HEX

NEGATIVE

(BLACK) CABLE

FIG. 2

/ FLAT

/ / WASHER

Page 8

t

ASSEMBLE

S TO MOWER

DECK (See F

Th6 gauge wheels are designed to keep the mower deck in

proper position when oporHiing mower. Be sure they ar©

properly adjusted to ensure optimum mower performance.

“ eriir'k icMr* v^n<-m i.i!!'- i,,jf i:- on a Tk-.i le^ei

surface.

^ Adju r wei n i uni'*' f''ight iGte B ’ AD

JU ! vDiAf--- o‘J'r.-'ID td k s f”iiiih< Di^diic.H

seciior uf ihb rriariuai'

Wit i i.w-r ii. 'i.-j , ,1) .s dipt .itiori, ('myp

wifm A'hf.uidL^. Lit Ju ait/di' lignPyoff tiie

uio ml ¡0 *f! {^ai ,w I -pprrpfi ie hfk with

TiuiLcriiJi 1 f.f / * *i,i ,aod3/.i it?

lorKiiiit ! J tipi. < *. t. • i -ly

® Repeat i(.i ,,M .t -iJf inslalliiip gauqe wheel ¡n

same adjustment nose

CHECK TIRE PRESSURE

The tires on your tractor were overinflated at the factory for

shipping purposes. Correct tire pressure is important for

best cutting performance.

• Reduce tire pressure to PSI shown in “PRODUCT

SPECIFiCATiONS” on page 3 of this manual.

CHECK DECK LEVEL NEC >

Forbesk uiiing itít-uIR mnwe. luu'icj í.-jüiíJ be properly

leveled. Fee "Tf < 11 to L MC W. . ■ ICfSiNG” in the

Service and *diuctmr h seciic i r i ’hss manua!.

;he "EM

After you learn how to operate your tfHCtor, check to

that the brake is properly adjusted. See “TO ADJI

BRAK

manui

BEFORE 'Ai wJR and EMJO) yOUR NEVV

.. ^ o , i W A D.f -. >A1 SL'ftt I HAT YOU RECEIVE

ih!t Of - I f LhK: TViu./AV INlfYAilEFAC NON FROM

TN! m.-i /iCcTilif I

Fit - ’ ^UOyi‘h • / . •!' s 4T/Mw C hb\ hi li F

/ Mu r*-fii 'i'll,II. parl.T in rartoo

A lirtif ri 1 iirupcit, pippoff-j ahu charged (yinimum

/ dealt 3djiictea-'Oinforiably and tightened securely.

/ tiie* are properly inflated (For shipping purposes,

/ be ,-ui6 rnowet deck is properly leveled side-to-side/

/ Cheer mower and drive belts Be sure they are routed

✓ Check wiring. See that all connections are still secure

✓ Before driving tractor, be sure freewheel control is in

WHILE LEARNING HOWTO USE YOUR TRACTOR, PA Y

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

/ Engine oil is at proper level.

/ Fuel tank is filled with fresh, clean, regular unleaded

/ Become familiar with all controls - their location and

/ Be sure brake system is in safe operating condition.

/ It is important to purge the transmission before operat

n the Sen/ice and Adjustments sectiori of

,.i< ' ,r t ly tii 1“ bi-F", f ruripleiMj

the fires wer-“ overinflated at the factoiy).

ftor.Ho-et-ar tor Do't CiJtdng results. (Tires must be

nrrpArly inflated tr.- ievniing)

piopfciiy a>our.d pulleyo :itiu in^kje ail belt keepers.

and wires are properly damped.

drive position.

gasoline.

function. Operate them before you start the engine.

ing your tractor for the first time. Follow proper starting

and transmission purging instructions (See‘TO START

ENGINE” and “PURGE TRANSMISSION” in the Op

eration section of this manual).

CHECK FOR PROPER POsITS TN OF ALL BELTS

See the figures that are shown for replacing motion and

mower blade drive belts in the Service and Adjustments

section of this manual. Verify that the belts are routed

correctly.

8

Page 9

These symbols may appear on your tractor or in literature supplied with the product. Learn and understand their meaning.

1.

BATTERY CAUTION OR

WARNING

REVERSE

FORWARD FAST

Tt (J-

r-;

ENGINE ON

fi

FUEL CHOKE MOWER HEIGHT DIFFERENTIAL PARKING BRAKE

ENGINE OFF

.^l

R

OIL PRESSURE

N

CLUTCH LIGHTS ON LIGHTS OFF

^ ©

LOCK LOCKED

H L (®)|I

la

REVERSE

NEUTRAL

HIGH LOW PARKING BRAKE

SLOW

a

UNLOCKED

t

if

MOWER LIFT ATTACHMENT

CLUTCH ENGAGED

*

m

■

r

DANGER, KEEP HANDS AND FEET AWAY

ATTACHMENT

CLUTCH DISENGAGED

I—

— =/<»*

HYDROSTATIC FREE WHEEL

(Hydro Models only)

IGNITION

= im

Page 10

KNOW YOL

OPERATION

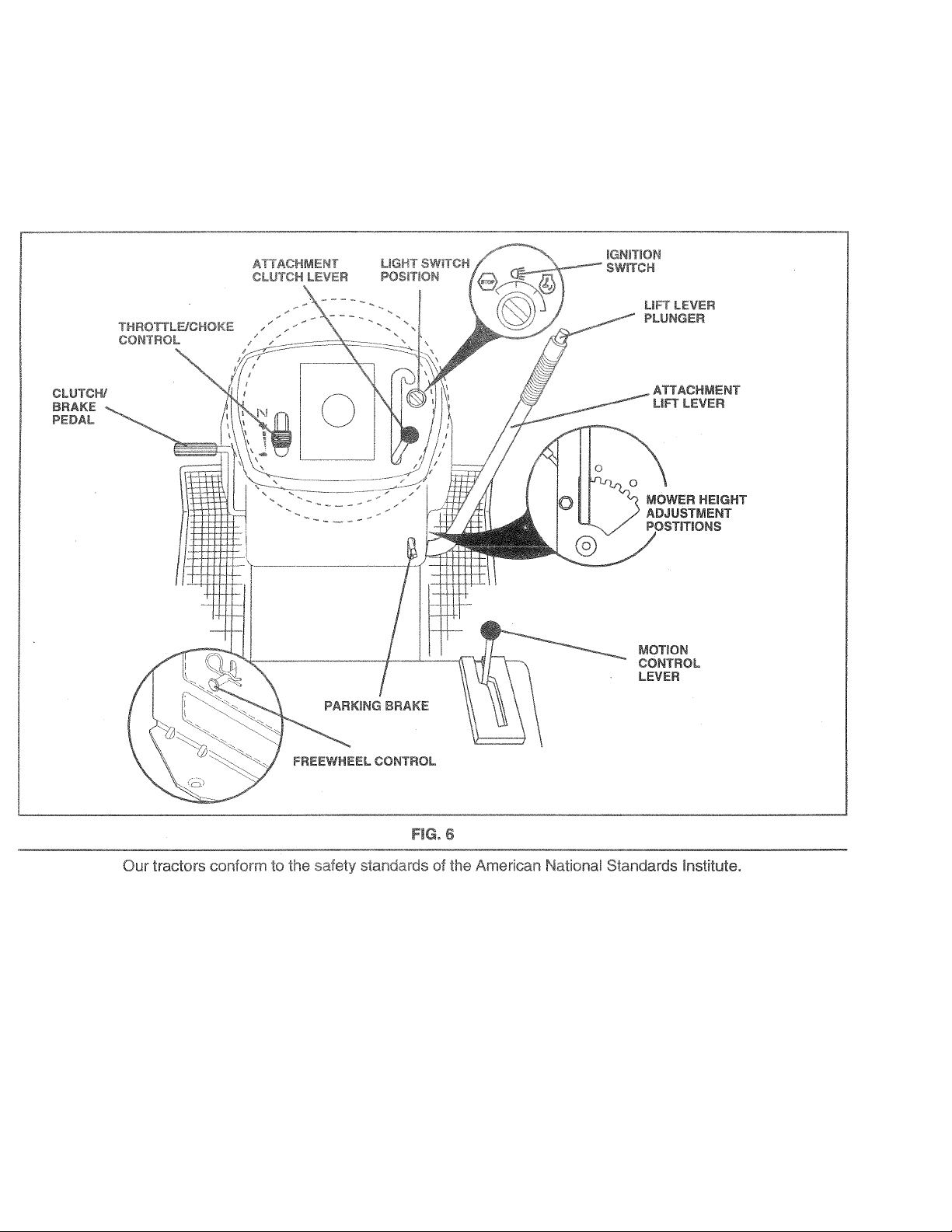

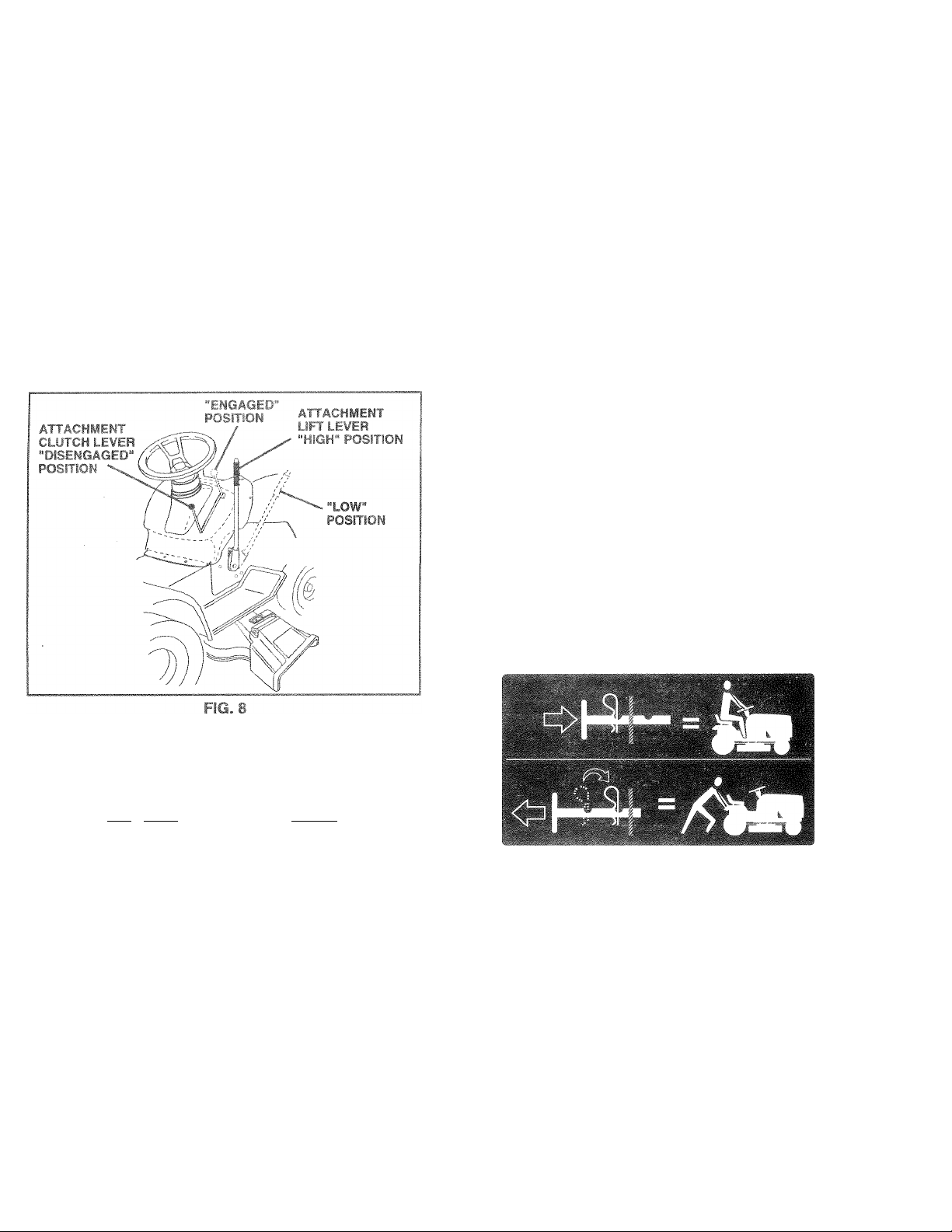

ATTACHMENT CLUTCH LE¥ER: Used to engage the

mower blades, or other attachments mounted to your

tractor.

LIGHT SWITCH; Turns the headlights on and off.

THROTTLE/CHOKE CONTROL • iJsed fcr staling and

controlling engine speed.

CLyTCH/BRAKE PEDAL; Used toi -JteiLtching and

braking the tractoi and starting trie engine.

PARKING BRAKE: Locks dutch/brake peda! into the

brake position.

MOTION CONTROL LE¥ER: Selects the speed and

direction of tractor.

ATTACHMENT I ¡FT LE¥ER ■■ Used to raise and lower the

mower deck or other attachments mounted to your tractor.

LIFT LEYER PLUNGER; Used to release attachment lift

lever when changing its position.

iGNiTlON SWITCH: Used for starting and stopping the

engine.

FREEWHEEL CONTROL - Disengages transmission for

pushing or slowly towing the tractor with the engine off.

10

Page 11

^3

i riATrr^-f-!.

The operation of any tractor can result in foreign objects thrown into the eyes, which can

result In sewere eye damage. Alwe fety glasses or eye shields while operating

your tractor or performing any adjustments or repairs. We recomme ide ¥lsion

safety mask ower the spectacles or standard safety glasses.

... H. y

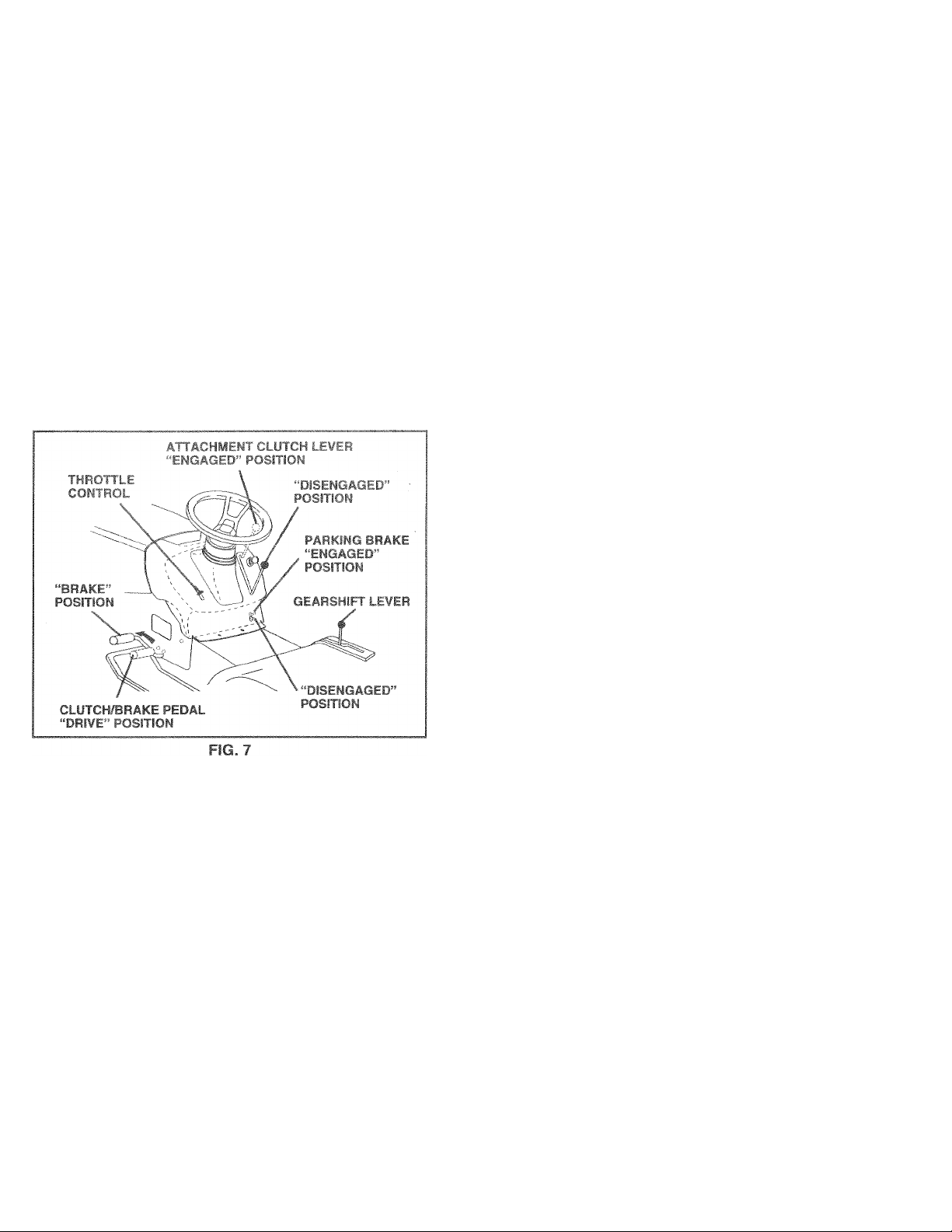

w-mif ^ J caking . :K , ‘ g. 7|

Yourtractor is equipped with an operator presence sensing

switch. When engine is running, any attempt by the

operator to leave the seat without first setting the parking

brake will shut off the engine.

* Depress clutch/brake pedal into full “BRAKE”, position

and hold.

• Place parking brake lever in “ENGAGED” position and

release pressure from clutch/brake pedal. Pedal should

remain in “BRAKE” position. Make sure parking brake

will hold tractor secure.

STOPPING (See Fig. 7)

MOWER BLADES -

• Move attachment clutch lever to “DISENGAGED” po

sition.

GROUND DRIVE -

• Depress clutch/brake pedal into full “BRAKE” position.

• Move motion control lever to neutral (N) position.

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

ENGINE-

• Move throttle control to slow {«^) position.

NOTE: Failure to move throttle control to slow

position and allowing engine to idle before stopping may

cause engine to “backfire”.

• Turn ignition key to “OFF” position and remove key.

Always remove key when leaving tractor to prevent

unauthorized use.

• Never use choke to stop engine.

NOTE: Under certain conditions when tractor is standing

idle with the engine running, hot engine exhaust gases may

cause “browning” of grass. To eliminate this possibility,

always stop engine when stopping tractor on grass areas.

CAUTION: Always stop tractor com

plete 3ve, before leav

A

ing the operator's position; to empty

grass catcher, etc.

Gi USE , Ki Y • ,1.1 wKd iTROL (See Fig. 7)

Always operate engine at full throttle.

• Operating cingine at less than full throttle reduces the

battery charging rate.

• Full throttle offers the best bagging and mower perfor

mance.

” PmVI Fi SRWARD AND BACKWARD

(O« Flq. 'I

The direction and speed of movement is controlled by the

motion control lever,

• Start tractor with motion control lever in neutral (N)

position.

• Release parking brake and clutch/brake pedal.

• Slowly move motion control lever to desired position.

TO ADJUST MOWER CUTTING HEIGHT (See Fig. 6)

The position of the attachment lift lever determines the

cutting height.

• Grasp lift lever.

• Fress plunger with thumb and move lever to desired

position.

The cutting height range is approximately 1 -1/2 to 4". The

heights are measured from the ground to the blade tip with

the engine not running. These heights are approximate

and may vary depending upon soil conditions, height of

grass and types ot grass being mowed.

• The average lawn should be cut to approximately 2-1/2

inches during the cool season and to over 3 inches

during hot months. For healthier and better looking

lawns, mow often and after moderate growth.

• For best cutting performance, grass over 6 inches in

height should be mowed twice. Make the first cut

relatively high; the second to desired height.

11

Page 12

»ERATE MOWEP

'.ЭХХ rnower

то STOP MOWER E

лОм f-4i '

'„•i'O* L.r

)'<,R i.iíf"-( -Г,- ‘ ! Л» - cjfrhe-

\Á

L- ‘‘Q-1'^Зтт ^ '■A

] ne

witf

. . . >'ll< 1^ * * llCf!

• , « , ' Ч- Esti ni

_

1É«‘

¡ "Л T«'-

^GINL

*1

)if with tractor on level ground.

-' <R > ( , . >11 i i^r

removí

i

To

tie

ь ^ 'F: E i 44 h .rja. R dl«, w |

WMЧ.'jM-Tih. , > I i,. ,. nil liw-4.twt.ur t •dteongage

triiii..i, . I 1 i.io -M 4 ¡,4-1 4JI 411 .-1 ireewneeling

|{i£i. .. n--I i. r>'> и,'-. 1И'J - lii'6 iw i drawbar

Ui tini

‘ i : ' I ‘ I s Л,. Ii I t 4 . F 1 position w'lth attach-

• ‘ . 1* к - ill I

■' I :r'dhi!(l ih position by

r-. ii44 t 1 и ' i.-n I ,n f'-ijA-rd h'^le of control

i d

'• i 1 . Jl t ,44 . , i W, , d ¡.|>'> - th'»n two ( \ЛРН.

> ■ i (/-' i ; f •! . ' ..ds opl until

J, t./ _*•

> i. V . V'.. ■ a . s T ilnr monua!).

I . r , i> ' •■w .rrtf f R--p'nsibili-

his manual.

' nSjll I z )( \ .^kLOIld..,

4 .1! 0 u Ji ,1. uvjnge oil fc"'

” i ^ ' -E-RT in thfc

e Fig. 12)

31J

shipped, from the

! J.i .¡i

W

1 [ -it . I i- h, v'f picK edure.

NOlr. , ( '< ' s , i, ‘,'iijOF worn transporting

your!-" ^ I * n-' ' 4 i .'f , W 'J4 os .d IS closed

n>J ' 1 ' " . 1 --it lop.1-4 • I-.n-uf tying

iiOoJ . I ■ , I ,

ТО OPERATE ON HILLS

caution 00 11, drivF up or down

Á

» • hoij ' tri! w I I. !’ i fift! tir f down

hills,,

• / ti J Id, f il'< 't > ' < • 'is h!'l

» 1 itrf'inp !► ' s, 1/ * ' n i f' •' erto

Id %r r I O'ilr '

• f "-to^piiiq ic D< i|, d|^ii , f If’!,! itdn/hrake

pedfcl qu'ckl) h hr e pc iiiii ano » < laCft- parking

brake.

» flit v'l r'*tir.i3 t.ji.i f i lo'< I I Ik ./ifS!'R* j caiiu >.

IMPORT i". IHr MOliO WOMiTiOL WVL, i OES

NOT HEIU! (J Tr) .JEU7-V L 'K- : «,'* > i ,> it'' wribR THE

CLUTOH/F RAI- F i H'^i- RT ht Fu

» fn fM ihmoveifirn siovi <'leds-p kiiigbiakeand

clutch/brake pedal.

« iaiowiy move rrioiion coniroi lever lo siowesi selling.

» Make all turns slowly.

hills with slopes ^iieoifei than 15° and

_Jo rtL.t driVL £ ? tope.

12

Page 13

fet'âî

•D G

m

SOLINE

Fill

fU6

oasc

and

Pure ise fuel in i

days5 IC

ORT

ow

BE

ï. "J i-ii

SOLINE. TO HELF^ INSURE C

STARTiNG.

tU' ■■' -f t 4 •' L-i I<1 <n:.f' ■ I r<-K. «I“'' ' rJi

1. k . vk/ gas t J'- 'î' >r. ><jî s» i

il tank. 1

llir lewitham

le wi!l inerì

rpi

due© vslvc

ì assuro ft le! freshnes

IT* WHE^

32''^F(0°C), U

' ' t ' (If - >tij. -1' - ilj, i - ' >h , *■ K f d

' !'>lt r vil I' ;'i t'< 'i ,r^íh~, r. <‘ ¡1'.!. I

Jse fresh, clean, regular unleaded

inifiium of 8 7 octane. (Use of ieaded

1 and lead oxide deposits

ì fife). Do ì

QuantitiBS II

4 OPERATING IN TEMPERATURES

SE FRESH,

not mix oil with gasoline.

lat can be used within 30

■ t 'l-.il ‘IS . 1 /'. i

300D COLD WEATHER

oyStCn li -.n r» '51 .s Vk'lç in 'J-raÇ; 1_. •_!<'- jMf

pi'Urn,' a t,. „,-cl=!<i vt Oui-) btCI ■ I.Jun i i

acjt J f if.aqei. l/talr'ff^^ îjc.. t ni' i tie

trifji« ^ ~rii 1' If iTi untii [lif* in'-f Hif V .«lu .-'rtt.'.' ' . e

urfip{> Ij^u re^f inai 1,^/1 iea&i'p kac Ctar.«.3 !ri î'uc

tioria tor :oiitiGii3Î Ttforrnaiior. Kfcva: uto r-iior! or

carbnrer.i dtarier p'u'jsiots iri tne îue! kn» oi s «erri i aient

damagt- la, occ'Jt

CÄÜTIOH- FÜI to bottoi« of gas tank

filier r»ecl< DonoiowerfilL Wipeoffany

A

spiiieo oii Ol fsjei, Co not ¿tore, spiii or

use gasoiine near an open Harne.

TO START ENGINE (See Fig. 7)

When starting the engine for the first time or if the engine

has run out of fuel, it will take extra cranking time to move

fuel from the tank to the engine.

• Be sure freewheel control is in the transmission en

gaged position.

• Sit on seat in operating position, depress ciutch/brake

pedal and set parking brake.

• Place motion control lever in neutral (N) position.

• Move attachment clutch to “DISENGAGED” position.

• Move throttle control to choke (|\|) position.

Note: B

procedur

• inser

tion an

posit

not fl

onds

sev8

in -

.i .. ....

t ?P it--.

diok

VVA' > f ’

i/f. m f(

I ‘ pi ti-

The attachments and ground drive can now be used. If

:'K ,I.;I i ‘3 ' t U. . f.TF‘< ' , t_ ! t , t- G. ,!i't

in'i '¡A '*'.11 r'r* up i( rc t. --iiiM I F, tfii'- hth

*1 ADH !l IN { ',o f ,a

e Whi-rn I'Uir .stall -Jl ruit '«!i' Ti fhmttle

icftfoh- I = chok.. f|.« i) p'/iAu-uoti tti'-uig'ot mi s

rougfily. illon I.' evn ffir tilt iTc'tiol t« I -a i%) pocition.

Thio reguiff an tugin«. Act.ii up pp«tio>J from

i-e/pial teccrios h -tvomTniir tnes depending nr, the

tempeiaiijr*-

HYDROS’^* ' '*d ' I *F

• Before drivinq the unit ir cold weather the transmis

sion 5rn.-uicf Of j.orm.id jp roilov^i

• Be sure the tractor c on level ground.

- PldCb the motion conliol lever ii« rieutral.

Release the parking brake and let the ciutch/brake

slowly return to operating position.

• Allow one minute for transmission to warm up.

This can be done during the engine warm up

period.

• The attachments can also be used during the engine

warm-up period afterthe transmission has been warmed

up.

NOTE: If at a high altitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetor fuel mixture may

need to be adjusted for best engine performance. See “TO

ADJUST CARBURETOR” in the Service and Adjustments

section of this manual.

starting, read the ws starting

)r© îriân îfîi©©n

joes noî start

tnroltic

I Try aga

I i t ‘t 1 ji di I s 1.1 i. ' I

rts, move the throttle control to the fast

/ •' € • 31 / II •'

alf

#)

{^)

Û etili

Page 14

PIJRCsE

lUTIOD

I "

To ensure profзег ope!

mended that ttle transi

tractor for the

trapped air inside the I

> f.ec d JH,.G .

itel'DI-1 i in rO ,

RLc/<

SHR ‘ r L ^ PURG

EEH.toA fH- i THE TRACTOR.

• Place tract

[JuRlhp r.i rU ( 1

D[ etnn. lission

in rt-t

ir<i: sfcc.»i j 11 f man m¡i

wstt'li s in ifciClli tBái OcU’

ifiurriin^ «Tio-e ihraill- , ■• it j’i-j •,! л pjsiiinii.

\N>*h moti')..f r,iitrol i. '0 ni> ii= >/t 'li !| pi-sii'o i biowiy

diben>*!iyr . I Ich't A <i .

» Move nofiLP cj’^i 'J !•_ 00, ‘ 1 ■ Mr /-ic p sri in and

hu.d lu. i . ^ p-, M • 1 ■ 1 « mo I' V) uli •' /erse

posilicn 3iid • f.lo f',r ii\i. Г'} ' -/■ r. *0 Reporf this

proM -Ui' idi. I m ft -* ■

NOTE:') rifipR! p'O"«-c< i-m n irio/ementof

drivew'-m-ls •'■’o mi' >' ii-:-ulicdnve

system.

® i 1; ' v'i.ri,vii. •- ;i i'r rR|H)i.i. ton .Rnul

afleriiiii- r.m г-1 p'! !' ’M :

• t ,<y jf ii-II.Ml к ' ' pi 'dlfcCb,fjnirt!| ii'

dri-'-ru-JOS Ouf \ •_ S "R ei titCA: ir. ch - section

Ol П tea! ilidl

• Sitting i.dhtJu'c-ic. .o-mit ; s • pi.i'-. A-tu Iheengine

is running, ills.“ mfOiilr t' i' tc hall speed.

W'lth not ((I f 'n'lrn^^vtf » I'cuiibl (П) posit.on, siowiy

discriU'uie cJumh/bi k~''Ю J

• Snwiy iTOiV'-t tTioiion m iif i к /ei fom ... i after the

tractormovi' apf.riKi.nalii, л- (i. leei &,owiyrnove

motion foniro! к лег to r< >■ r*. i' i юг. After the

traUi I rrioves apfroximai ,S n-e f i feei return the

rr*o ion control R'/f I to ii le Ч 'Fmj (1'!лЮы1'оп. Repeat

this procedure with the motion control lever three (3)

times.

• Your tractor is now purged and now ready for normal

operation.

riQ*

first tirni

lipping c>f yOUi

DR SE RVICI

or safe!)

«ling p<

1“

'0r 0ilQ3Q© or diS€

I ievei“While tile engine

’âîlOn «

snd porforrnsncB

rfiissìOn be purged befor-e operating

В, Thi is procedure will n emove any

ransmission which msy t lave devel-

D YOURTRANSMISSIOt

lED / ATER REINSTr fLLATION

/on le^/ei surface with eni

3sîtîon

tfrirtor

E OR REPLACE WENT, IT

' i J U '

' H ‘ n

.

....

' p

it is recfjm-

•J REQUIRE

line off and

-t-R ,1 Trol

D! f . r ii,

ií., m,, '^iig ne

ШШШ

Tire d when 1 nq IS

B

min

Огл

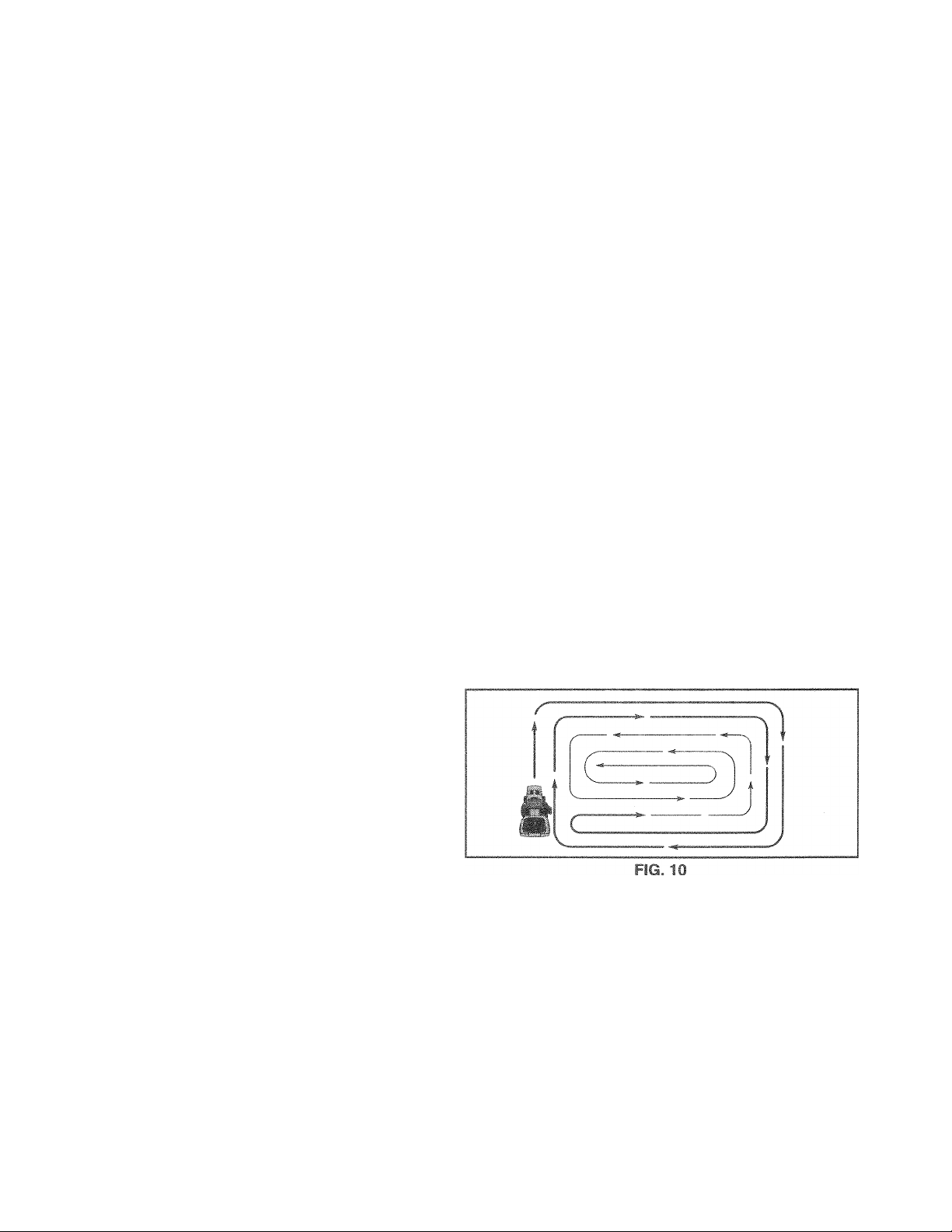

.. ,i I , p- f n ,|. 1-1 ihf-, L’' -ir-d '0 thp right of the

'J 111 1 ill u'l T. . I! o ' evrii P.stnbution rf

ii r m, »1 mo o (1* r'm, r ihr-g

I ij| . kpproi Will di?rh'-tgs away from shrubs,

,»ro- r-/- Hfti or e cr two riiUiids, mow

-1 tm pp">„te direc tiun mak'ng Iftt hand turns until

W h> d f ‘ I j 10)

|] grass i oi-ht i. w.v tali, it shi iiid be rriowtd iwicp to

r&ciK *'■ lo,.d .-..i f cssible tire ha...ard fron. dried clip

pirg. Maro f r-t mj- ■'elath'ely high, the second to the

desired height.

Do not mow grass when it is wet. Wet grass will plug

mower and leave undesirable clumps. Allow grass to

dry before mowing.

Always operate engine at full throttle when mowing to

assure better mowing performance and proper dis

charge of material. Regulate ground speed by select

ing a low enough gear to give the mower cutting

performance as well as the quality of cut desired.

When operating attachments, select a ground speed

that will suit the terrain and give best performance of

the attachment being used.

)ulci b

left hand

Id >1 I !if' inq j J. • i<-r.jpd i,nm the ima

p

4

r ‘ »vfi /iF.iHR.'- T!f. in

Adjustments

Í- , -íH'i'i'lbt Ifif intri-

lici- .ir-M- o.-art lyming tuifie nghi

*► I f ■ Iji il.uV'ltiCj

ition of this manual.

14

Page 15

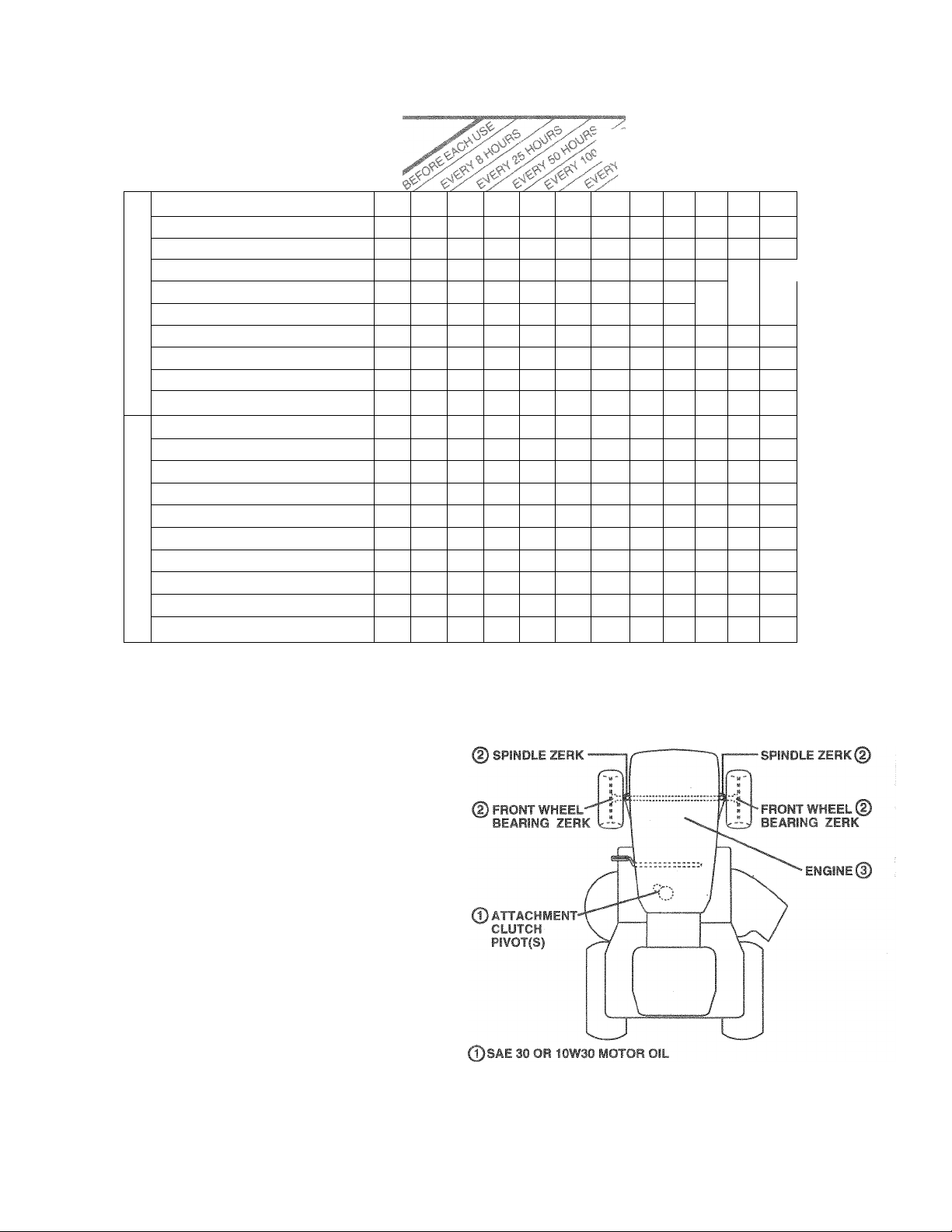

IIAINTENAWCE SCHEDULE

FILL IN DATES

AS YOU COMPLETE

REGUi^n SERVICE

Check Brake Operation

Check Tire Pressure

T

Check for Loose Fasteners

R

Sharpen/Replace Mower Blades

A

Lubrication Chart

C

Check Battery Level/Recharge

T

Clean Battery and Terminals

0

R

Check Transaxle Cooling

Adju.st Blade Belt(s) Tension

Adjust Motion Drive Belt(s) Tension

Check Engine Oil Level

Change Engine Oil

Clean Air Filter

E

Clean Air Screen

N

Inspect Muffler/Spark Arrester

G

1

Replace Oil Filter (If equipped)

N

Clean Engine Cooling Fins

E

Replace Spark Plug

Replace Air Filter Paper Cartridge

Replace Fuel Filter

1 - Change more often when operating under a heavy load or in high ambient temperatures. 5 2 - Service more often when operating in dirty or dusty conditions. 6 3 - if equipped with oil filter, change oil every 50 hours. 7 4 - Replace blades more often when mowing in sandy soil.

✓

✓

✓

✓

✓ 4

✓

✓

✓

✓ 5

✓ s

✓

✓

1^2,3

✓ 2

✓

✓ 2

✓

SERVICE DATES

✓

1

✓

✓

—

—

—

✓

✓

✓

If equipped with adjustable system.

Not required if equipped with maintenance-free battery.

Tighten front axle pivot bolt to 35 ft.-lbs. maximum.

Do not overtighten.

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover items that have

been subjected to operator abuse or negligence. To

receive full value from the warranty, operator must maintain

tractor as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your tractor.

All adjustments in the Service and Adjustments section of

this manual should be checked at least once each season.

• Once a year you should replace the spark plug, clean

or replace air filter, and check blades and belts for

wear. A new spark plug and clean air filter assure

proper air-fuel mixture and help your engine run better

and last longer.

BEFORE EACH USE

• Check engine oil level.

• Check brake operation.

• Check tire pressure.

• Check for loose fasteners.

LUBRICATION CHART

©GENERAL PURPOSE GREASE

©REFER TO CUSTOMER RESPONSIBILITIES “ENGINE” SECTION

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS. VISCOUS LUBRI

CANTS WILL ATTRACT DUST AMD DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRICATING BEARINGS. IF YOU

FEEL THEY MUST BE LUBRICATED. USE ONLY A DRY, POW

DERED GRAPHITE TYPE LUBRICANT SPARINGLY.

15

Page 16

TRACTOR

Always obsep/e safety rules wh

BRAKE OPERATION

if tractor requires more than six

at high speed in highest gear, th<

(See “TO ADJUST BRAKE* ir

f!if UÍS .xe>4ip ti .-i! i.i.MiUa/

11NE,;

*' Mi • i n qf lO'- S ; Í. . 1

UCT SPECIFICATIONS” oi

Keep tires free of ¡

cals which can hs

soline, c

■ih

A\c-d ..iiiip'^ tnrr I

OÍhí-r If'.. . id (f r It.r

NOTE To .fcO'iiL pijivju CL li. TC .iJfl OiL du^ to

slowleeO .n'-; if„;v O ru» h iron, v )ur local

parts dfc.3!er. iim '^-clí£<nt ¡. t t/eiib lift u.y rot and

corrosion.

BLADE CARE

For best ir.juiif. rnowffer Uhqhs bf kept sharp. Re

place ben: i T 'nibj ;d .Ld> i

зепс

t ri IÍ -< 1Д'- 'fc

Service and Adjus'

I 0!, lit. TO J Р''|‘Л(

•L ■

I I. ... hi .1Ü. I/

'Ч 11 , f . ' '»llpid 4ii-

ruts, sharp objects and

^ > - .-ihioqt

TO SHARPEN BLADE (See Fig. 12)

Care should be taken to keep the blade balanced. An

, i , ■ t . ‘ hr -h, I J ¡1 ' 11-

tual damage to mower and engine.

i . ‘ ' h _i*- ‘0 .-.i I ) III. • " I' I u ;ri‘J'rif|

Vi ( ! ', I .<it .. I If h.<i[ '-III' h.i( or. (1 if mcf.vM

I ' i is to' ■ L ’,.f u-xr) .„'--d 3 t'e" diamstor

^ Th ■' ri - !toj.*toii.tr 'yvhenucngaco'ie

■ I i<,lk « ir,' iii.tmi tiLfi supplied with bal«1 ‘ i

> / -u. f i ..ti.ii *j sL.c.,tapG.iiuiuj!ilifetoeeibolt

M,> . ", h i, pin parallei v*ith the ground,

ii u ' ! L'i "‘<0, >1 J . !J teinain in .toioViaopta!

I>i Ht /’ I oiirioi one f'l ttie bedt moveTi rl.oAinward,

1, 'h' I, in 'y oiio unif the oladt is balanced.

Nc 'h i .1 Ì-* 'ciifm boCriringb'ode Fhelobesof

th', f -i.-j t‘.i h I, ' .ciitoj lO ht f tntcred but are not.

BLADF BEIiO'/AL fSet • I- lu 111

• Rai '(■ mower fc- hiybesc fics 'lion to How access to

. bldf '-if..

® Remm''Tie? ro!t. led war hi s riodct washersecuring

blade,

» Ir'd’ HU (':■ -^ri. f ned hit I r with trailing edge up

tOv> Vrm fW, „ I, n

• 'bTiblf l( hr It ¡ori w U tr tind flat washer in

ex..,a Jidi^r uj she ah.

• Tiqh f 1 boll -- Ji-i'f' ly t30- i m I bs. torque).

IMPORTANT Blrtf.t PCLTL ( i • U T 8 HEATTREATED.

NOTE. VVi-do nt.rv commend sht rp*- ning blade-but if you

do, be sure rhe tfk'dc is baldireu

BATTERY

Your tractor has a battery charging system which is suffi

cient for normai use. However, periodic charging of the

battery with an automotive charger will extend its life.

• Keep battery and terminals clean.

• Keep battery bolts tight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for 1 hour.

TO CLEAN BATTERY AND TERMINALS

Corrosion arid dirt on the battery and terminals can cause

the battery to “leak” power.

• Open battery box door.

» Disconnect BLACK battery cable first then RED bat

tery cable and remove battery from tractor.

» Rinse the battery with plain water and dry.

• Clean terminals and battery cable ends with wire brush

until bright.

• Coat terminals with grease or petroleum jelly.

• Reinstall battery (See “CONNECT BATTERY” in the

Assembly section of this manual).

16

Page 17

V-BELT

operation and repiace if necessary, i ne

adjustable. Replace belts if they begin to sii

TO CHAI

Determin

All oil mu

ENGINE

iperatur

rane

jrvici

)!i Change

siifcatic

TRAiSAXLE COOLING

The fan and cooling fins of transmission sr

clean to assure proper cooling.

Do not attempt to clean fan or transmission w

n ni . ,f' 4 1 ‘,|h 0,r I. . f'<|.f • f >

® Inspect cooling fan to be sure fan blades

9 1 Cf-* I . . 4 I' _).>'• ' fE 'T' . . ‘j Í

if " Í h -iM'.f.f“ I !.

< r ) ' Í, I *ii Í I n gh pici iff.

Cci iiiiU iiii

als, do not use

)rayer to clean

;t ana

other

TRAN;:/i>xr PUMt FLUiLi

Tne trdi'SfL.r't wjc fcs- *ed at »he fact: iv me f|i i'' mainte

nance isi oTn:quir:fdtortnfclite.'ft!ittran': txle * houidthc-

trancadec/“ leer ,, “-ou..< >fr/.ciiig. c» nlact jout near

est cUthr,t:c‘-d sei"Viio ente-/departm* ni

ENGINE

LUBRiCATiON

Only use high quality detergent oil rated with API service

classification SF, SG, or SH. Select the oil’s SAE viscosity

grade according to your expected operating temperature.

SAE VISCOSITY GRADES

Oil will drain more freely when

Catch oi! in a suitable containei

I' ¡»-.r' I Oi il ‘ /( -Jl' к Ft

f>! r • V dirt

to enter the engine when chanc

I ':ii ( V- dO)i. oO '

/>\^.rui '! Ji&'i-ec* ojri.pL't-(

f ^ ..r I

h-lili ■ I qifi ,'iTf Oil tfiroijyb ( il ?,ii d'f Ai'.r OL< Pc>ur

' !ov/h sK* :* errill F ir otpi.')o'.p-.riiy ree

h' r rii-' iF ,f AT'Of I .>1 CO JO » -f this

r -tnoal

io'~ C''(;j.„G»..*iifii!r-;f/dipAirr:icrthi-tHncH 'oL Be

sure dtpsrAl- rap i'- lightened securely tc>i a.'xurate

r-adiri(j Kaci: s)<| at 'Fi ILL liiv cn dipstick

◄

■ ■ -h

=F -20“ 0“

°C -30°

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

20” -10“ 0” 10“ 20° 30° 40°

30° 32° 40°

60° 80° 100°

NOTE: Although multi-viscosity oils (5W30, 10W30 etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F. Check your engine oil level more frequently to avoid

possible engine damage from running low on oil.

Change the oil after every 50 hours of operation or at least

once a year if the tractor is not used for 50 hours in one year.

Check the crankcase oil level before starting the engine

and after each eight (8) hours of operation. Tighten oil fill

cap/dipstick securely each time you check the oi! level.

Page 18

11

■ r.' !;nrs

1 FIO

AIF

ir onoif

1 OL

3,n tho 1 m preHcleaner a 25 hours of opera-

Clef

tion

hours of op

vice aif

Ser

®

TO

•

a

•

• Heii'isiaii pre-cieaner over eaririage.

• Reinstall cover and secure with knob(s).

TO SERVICE CARTRIDGE

• Remove cartridge nut.

• Carefully remove cartridge to prevent debris from en

• Clean cartridge by tapping gently on fiat surface. If very

• Reinstall cartridge, nut, precleaner, cover and secure

IMPORTANT: PETROLEUM SOLVENTS, SUCH AS

KEROSENE, ARE NOT TO BE USED TO CLEAN THE

CARTRIDGE. THEY MAY CAUSE DETERIORATION OF

THE CARTRIDGE. DO NOT OIL CARTRIDGE. DO NOT

rCj

or 0V€ify seasi3fL Son/fc

ieriation !

’ eli

Remo'/e :knob(

SERVI

tering carburetor. Clean base carefully to prevent

debris from entering carburetor.

dirty or damaged, replace cartridge.

with knob(s).

CE

Slide f' TI pre

it ir

Squee it dry

kth -

no

.14/ -1 ‘

It vf,r>

00 'Pim t

will n

ot run oro perly usirig a dirtv air fillet

or 0V0fV S0

saner more otte!n under d usty conditions.

s) snd cov er.

: PRE

TCLEAMEI

-cleaner of

4)

& paper c

;arti1dge every 100

chever occurs first.

1 liqui li and wal

in a clean cloth.

it in eìngine oil.

i ^ 0 t. o mi

sque

Wrap it il . ck- i> I dbcorbenc

iove exce

replace p

,‘C 4i

-t~ fifaner

c LEAN AIR S( CREENI

r screen must b le kept fre<e of di

0fiigine damage fre)m overheiating.

or compressed aii ' to remove

fibers.

El

NGINE COOi iS (S

iiTiovo any dust dirt or oi

prievent engine da

*

Sir in ,.T ,ftW; fiiuii Liuwer L GUring and lift

ariQ dipstick !ijbe assem cl Oit ''(¡gino

• Tovoi jiipiii., CC-r.iriQ ft. .lEC /60it entP) id ijirt

&

h f f ipr c: ^0 aii Oi iiT bii

J^:ri ertpirie ,-ir|inn »'•'

^ i casjft. r, it I If iCm. jtlO /t ' p iCtdur*.-

. T J- .. .

1

iSC6

irt and chaff to previ

Clean with a wiire brt

3i (iirt g

ind stubborn di led gi jm

-//C 1C|

• KOin

bnoirc tOcl'ri 4 ir.-

1 over!

-fie L rush 10 thor<j jghly

w

It /

to

housing

FIG. 14

18

Page 19

cyS'TOMEff RfeSPONSIBSimES

MUFFLER

Inspect and replace corroded muffler and spark arrester (if

equipped) as it could create a fire hazard and/or damage.

SPARK PLUGS

Replace

S0SSOn 0

: n

ut urs di~- ~jz^.4 pluci tvoe a> <i g-^p sfiiing lu -h^*zr. n

FR'JU i.'T 'Ff "Prtc uTis" Ni rripayc/ minimi.

iN-LiNE FUEL FILTER |3ee Fig. 16| ■

The fuel filter should be replaced once each season. If fuel

filter becomes clogged, obstructing fuel flow to carburetor,

replacement is required.

• With engine coo!, remove filter and plug fuel line

sections.

• Place new fuel filter in position in fuel line with arrow

pointing towards carburetor.

• Be sure there are no fuel line leaks and clamps are

properly positioned.

» Immediately wipe up any spilled gasoline.

if I I, rl« -j! iPlf .r > f i i w fig

it.i ' , (U‘j ii jUiu ot jperoi on, whichever

CLAMP

FUEL

FILTER

FIG. 1§

WP

CLEANING

• Clean engine, battery, seat, finish, etc. of all foreign

matter.

• Keep finished surfaces and wheels free of all gasoline,

oil, etc.

• Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to clean your

tractor unless the electrical system, muffler, air filter and

carburetor are covered to keep water out. Water in engine

can result in a shortened engine life.

19

Page 20

'.nr 'h-'i atil. ¿.rs.niSTMrNTP.

CAUTION: BEFORE PERFORMING ANY SERYICE OR ADJUSTMENTS:

• Depress cluich/brake pedal fully and set parking brake.

• Place motion control lever in neutral (N) position.

A

• Place attachment clutch in “DISENGAGED” position.

• Turn ignition key “OFF” and remove key.

• Make sure the blades and all moving parts have completely stopped.

• Disconnect spark plug wire from spark plug and place wire where it cannot come in contact

with plug.

TR/%f T"r

TO I iiOiiT T : 'rr,

Mo#'i r tun iti f,oinTheri'iriiid*-ctiir t.<r.

Pi I'f dfir • I nt( ri ‘1)1'-1 ,fh' Cm ' ition.

f.i'Dtia'h. t iii'ii /1 i> r/art i l jl> ' H./k« rtoits

|fi4<- ^ t j. *tSi '•!

Roll belt off engine pulley.

Disconnect clutch rod from clutch lever by removing

retainer spring.

DiSLOiineci ami-swrty bar from chassis bracket by

leit’uvihg leteinei spring.

Disconnect suspension arms from rear deck brackets

by removing retainer springs.

Disconnect front links from deck by removing retainer

springs.

Raise lift lever to raise suspension arms. Slide mower

^ out from under tractor.

IMPORTANT: iF AN ATTACHMENT OTHER THAN THE

MOWER IS TO BE MOUNTED TO THE TRACTOR, THE

R.H. AND L.H. SUSPENSION ARMS MUST BE REMOVED

FROM TRACTOR.

TO INSTALL MOWER (See Fig. 17)

• Raise attachment lift lever to its highest position.

• Slide mower undertractor with discharge guard to right

side of tractor.

® Lower lift lever to its lowest position.

• install mower in reverse order of removal instructions.

FIG. 17

20

Page 21

го LEVEL MOWER HOUSÌNC

er while tractor is deAdjust the r

driveway.

“PRODUC

if tires are c

' • U' >

I) '

ik

)NS” on page 2 of this manual).

derinflatec

SIDE-TO-SIDE ADJUSTMENT (See Figs. If

F 1 It , .^t< E ' h.ijf«" ;i po-iti'.'i

« A'idt- lOldpOii P f Wild ' dc'- I ',r tvV i 1 i el .IV«“- ' f !■ hi

irMObttfont-fn-'-'.f rnuAW-> it ir,( r3ii;mhce‘'/' ,,n

hoih '■d'-: .'»f inc'.v^a • hfiiln r- thi' t'wiw • -»Thiri Pd"

of fcao!- < -her

• 1, II ^.wr/ ITi" !-'> i 1 li Itll' On one

‘-№ o* rnnwer «trili

“ T'lO "-'or,»- :k ifn.ovi-n fghti r< liii ii yj; tmeni

Ilia n f'Ct ..idt

• To vjWfci one sifiL f rnowt!. bosctt iii' lir I- rdjastment

f'ut on that side

NOTE !hffe9 tu*l iiirnc of adjustment nut will change

mower height about 1/8".

• Recheck measurements after adjusting.

Ked on level ground or

iS are properly infiated (See

..II * iroperly adjust

Arili I

d 19)

FRONT-T O-BA

IMPORTANT: I

WIN

iTMEN"^

Fic

ilDI

JECE

tow

To IobiBill theЭ 1

sho!uid beadji

1/2“ iO'■/1 ihrtri

DOS!ilO

C'tLck s-gij-h

0 0

и d'"'-

1 tr > \

tane

edoi

Before making a,ny necessary acJjustmenis, check that

Pithfri rcliiib -'c-ya'CII I ii’ii , k I Oi.iikJhe

BppfoxiffistBly 10'"3/8".

SiiTF,<3-t»- S' 11.'ngtii, ad|iict.jn l if t< n’me

li.rvjth io > *i '-I P -

Tr Is.wii • '‘I’l rr->to-‘ ! ' (. i tp T'' nn both fr mt

linb -- co'j; ‘ fifirritBi (’I i ■ u

When distance "D" is i/8“ lo i/z" tower at iron! than

rear, tighten nuts “F” against trunnion on both front

links.

To raise front of mower, loosen nut “F” from trunnion on

both front links. Tighten nut “E” on both front links an

equal number of turns.

When distance “D” is 1/8" to 1/2“ lower at front than

rear, tighten nut “F” against trunnion on both front links.

Recheck side4o-side adjustment.

30st cutting 1

:ed so that the

the rear whei

jnt on right s

"ПС

у in front and i

3tl’

housing as sf

3W8f housing

iTiately 1/8'‘ to

in its highest

• p.-_t i - its-

. bit it.lT)

ENT li

21

FIG. 21

Page 22

CCI

‘О REPLACE Mi

Clrt

MOWER” in this seetior. of this manual),

• Work belt off both mandrel pulleys and idler pulleys.

' t L.i- I 'I № I 111 'll I >

BELilMol iLWfb

Insccaii b ^il 1 tf 1 1 i ' 1 mi I ^

- Sinfcl '„’i*' 1» 1 a :sif bOit

guides.

1DÌI#P ЙР1 1

!,lSi i’i ' »‘IV-> I' 1 I'I I> 'f r,' '•!, 'i, .rtons.

nee IS other than

’ until distance b€

ainst nut A .

^03.d t©st It3ctorforp

above. Read just if 111

still greater if lan six

naintensnee IS nece 'il '..bt'.t ‘ ,ul 1 flCdlt :jI all-

:horized servi

ce center/eJepartment.

■ 1II ' > 1 1 . f ¡1 у i ' I (' f -fl

il , 1 -f''Ji‘-(ai't fe is

V , ' Г! Ii! higl- S St C, f-inrei

I. '■ '-Г im.'l .4> Hlitl'L'in

s 1-1/2". Retiqhten jam

TO htPl.AiL ulUliOrl DRl^E BELT

('Sec l-ig. 24S

Poik ill., li..'to or ¡c.'U iiitjoe E ngaqe parking brake,

for tr..:r<' IS belt .rut.ilfijtion guide decal on

btib 'll _iA, ol i I f' iTi .ti

j W rr-r, , \r-fco 1 A' ROdOcT MOWE»^’ in this

SBCtiofi of this rnanual.)

’ li^,t . Y'tWspfcr

• Ron > 'O bell tfcm stationaiv idler and clutching idler.

• i Liil btiisleck reward rear of tractor Carefully remove

toll upwards frern transmission input pulley and over

cooling fan blades.

• Pull belt toward front of tractor and remove downward

from around engine pulley.

• Insrali f-t A 1. k cv rf-iit'-.iny above ptocedure.

iMPOR'.AN/' P./g a sUHf UPPER BELT KEEPER IS

PO. Ih >. n - f ^ l-urei / Bi-TWEEN i.OCATOR TABS.

TO ADJUST BRAKfc Pi» ГЗ-

Yout frtoi I'"' epi rmd o.h. r- acji. v4-i biake system

which li i4.i it-'I ’П и ,u ‘ I ,1. tvt-.

If trarto'teouirf" n>'r-ill , ь m ^ _t ,tt nf,ing distance

athighijpeed .nh! j!.< a.j j '■-r b> - t .nurfbeadjusted.

• [tepressclutm f'lJ'ir r>d i.gag parking brake.

• Measure disiaimt betwe iiO,<ki opt rating arm and

nui “A” on br^ki toil

Wtlh .Y> ' Ilio ■'h , I ACAuED”

/" ^ \ NUT “A”

MENT IS NECESSAH ' • оЛ . Ut as'.EST AUTHO

RIZED SERVICE

_____ t[-Cp ___

FiG. 24

22

Page 23

Ann £.n-ni'i■« mru t''

TRANSMISSION REMOVAUREPLACEMENT

Should your transmission require removal for service or

replacement, it should be purged after reinstaliaiion and

before operating the tractor. See “PURGE TRANSIvlISSION” in the Operation section of this manual.

ru ADJUST STEERING WHEEL AUGNiiEKT

If steenng vvhevJ t.tossbars are not fsoriioritai (ieA to ngrrt)

when wnsets are positioned straightfcrwara remove steer

ing wheel and reassemble per instructions ¡n the Assemb'y

section of this manual.

FRONT WHEEL TOE-IN/CAMBER

The frt.iii wf’fce! ioeari and oamb<=r ii» • ad '>-rtabl8 n

yoi I ttvioi |r ' rtiagf has o'Cii-rei to t'nt front

wheel to«' ir- or ( amhoi < rmao /uur near^-s' -..nth >ii/Ki

service tfcniar/depdrtfner.t.

TO REMOVE WHEEL FOR REPAIRS

g. 25)

» Block up axle securely.

* Remove axle cover, retaining ring and washers to allow

wheel removal (rear wheel contains a square key - Do

not lose).

RefOi' (itf- i'i' 'fn“^

(,It, <hev( Tp[y diior. :¡-

and «•»I*- !n-s-it -fiiHi '

Repiat - w '«li“-.,' lu '-.-D • .

aUe ci-J

- Rr-pio t e (. e t. t,

NOTE* 1Sr c*l fift; per,dun,,- urid | a i» at ‘ • Im di> *.)

blow um *0'Wf'ta ' pur h' pH-ter , .n k,f,.!

parts nt-aler. Tire sc-r^h'-t il-'^ t, < .a / m.¡ nrid

corrosion.

RETAINING

RING

wheel hub

ecurelv in

AXLE COVER

SQUARE KEY

(REAR WHEEL ONLY)

FIG. 25

23

Page 24

miMEm

from

REPLACE HEADLIGHT BULB

• Raise hood.

of the

ariit,

curely

f , < > . ■ >-i i 'I. >T I h if tm 01' I

If ,'i‘i). I, .,1

recharged. I

i^ri. ,• i .>

Mfrf riC, ,• . . I

\, l i , ¡> -C i L i , i

7tH.f L[ •: j i. ' '■

g.'t( L I I",.'. I •

F - ' ¡7 F . T' i g ■ t rC , ‘

I .i i I i ;. • . -t .c-'i-f '

•!> C‘‘fi .f' '• e v‘i ;i I , '

( 1 ; It- I il fiei <i li 11. i I •

audi-itt I l''C.-.r.

“ Gc.nne>t.;ne tnocdthi I l ■

TiVE H ieri! >ia< • ' !' *!\ '

^ ( onfiSCi'h-. ■ ih£i .. !..

CHGSS'E E ■ M tf ■ c - (

TO REMOVE C^-bi Ed ■ f ..E' i

e E L.b^ E t..' M 'I. ' i . I. I,

CEErC 1 brdC.r.,

e RE U •'•-»Lie *' iiE / li.

POf fWi r. FEF'E.

\

engine, it should be

sed for emergency

■' I r T| if

' 1 Ì ! ftr

' ' Ei lOl

i d tT'-'R

.. : , hi ' 'E ‘E

‘ >m . !i fu n

. ■ ' die riEfiA=

' at '

• ' I 'able fo good

' - k and batter/

E-

.( t 1. II fern iheiuliy

■ ,■ ,uc tr.F'iwiNAi ~1

I

'-rrEfiOf^li^ AMD RELAYS

i ii’ ^ '“II .. .iiriI Ihuy ..si yuui tlaCiOs tO fUn

cor.li, ’ I •' I'l-r J ■!. pie eni li horn starting

* ! -cr r iHif, uct- t-le vi'irinq diay'^m in the

H‘p;i f rm iLi,rio., of ihis rrianudl

“10 RtbLACE FUSE

H-piot • with ao dnijj irutornotiveyvDG plug-sn fuse. The

fu u h(J:. rL lu.ateu bt hind the da^f'

TO REMOVE HOOD AND GRILL ASSEMBLY

(See Fig. 27)

* Raise hood.

* Unsnap headlight wire connector.

® Stand in front of tractor. Grasp hood at sides, tilt toward

engine and lift off of tractor.

* To replace, reverse above procedure.

I

CH...

POSITIVE TERMINAL

V

NEGATIVE TERMINAL

FIG. 26

24

Page 25

ENGINE

FINAL SETTING -

The throttle control nas been preset at the factory ana

adjustment should not be necessary. Check adjustment as

described below before loosening cable. If adjustment is

necessary, proceed as follows:

Alii , i i 1 !i, !• i I i ni • ‘e’/nr

¡1 ,!ii t ' ( ' li«iS 'i |, p ■ iti -n ii > w iiiDve

! I ; I, r '•'»'1 i d l|'f. 1, i ( m, , > if I

* Check that holes “A” in governor control lever and hole

in governor plate line-up. If holes “A" are not'aligned,

!'■ ii r.i!.f ' I'.1-j'Mr.i •' Ihi .pi: ' ' ok-‘tuil h-!'7

Hr ''i.ig, f' '' ih,.- . kmp ri ■ Hint.

® Move '

SCf0^¥.

•

AC

* |\Л li/h

1 S III 1

Higf. • p. ,4 stop is

dai

throttle COntrol iever

finger,

rotate anc

Turn idle

J hold thro

■ to slow {• positic

tîle lever.

f0wr 10 aîicîin 17S0 П

still holdi ng ihrottif 3 iever a<

' i. ~ '

turn idle mixture Vialve in (cil

joins to dil

gi.'U,

until etigine runsi rough. T

betwet

. !l . 1

sand then turn OUt((

urn valve to a point i

wo positic

ms. Relec

ATIOM Tl

ihrotfie CO

n. Ifengii

If il * s

ne hesitat

from slow / to fé

es or dies , turn"idle

valve €ml (countierclockwii ( 1 i'.< •

lA-'Hh

ates SI

je to adju

K hi,'

st, if nece

factory c

SSârv uni gIOO

.dit r . > ■

jIt.

0Ck¥i/1SG) l

TQA

1.^ Ftepeati

Do not с

in. 'With

speed

inW enskwise)

nidway

. {

mixture

:es! and

id just “

IMFCRTANf NL-H? *.-fC i*ih FNf.ilil

GO'/ERfJuFi WhIcH id F;GiuP. , O! i PChYTT

ENCIHF f.f'F. f!. ■ c/ypcf i.L^! I i"Hf LflTINn \B Gb

THE FACTORY HIGH SPEED SETTING CAN BE

DANGEHijUS If /01 ih"Jb N1“. Lib'.lfiE /I hNW»

HIGH SprFD NEED i ALHIj;-iiNG .ijjlT/. i f vj['

NEAREST /Uifir-MliE«' f_Ei''iLR/

DErAfi I MHi I '#r!l( H 4A„ F'H'. iF Lk r< ».‘li Ml Ik AND

EXPERIENCE TO MA!F \NV IIF C Ef CART

ADJUSTMENTS.

TO AfylJJ? i (Sc. nq

1 ho I rtiL.i tv! fiv >f t tht *a m / ^ !> f nJjustnitiit ■'hou(I fioi I’l ii '' riov^ .{I iiii.Li d|iist(nenim i/!i* ri-g'Jii iioi oh'fi. t,w jiniuel,

i( mpi r tiFf 1 I'fC. '• 'on! 'ftho'aruu ‘o: loc: need

(,f I I K -t I , ‘ i< I i'W

!n ij > iiw y idl (ii> i Ji V «! If ly -I [«w'l t) de

creases the supply of fuel to the engine giving a leaner fuel/

an m ijji' > .iftii ,.j *ht idl rci-tiitf cl - oyi y ouiiier-

kiLi w> I 11 1!. - tti- uj. ph r-i ii'* 11 kr riijine giving

a richer fuel/air mixture.

'i iw loMhwh i iHt..'LG«i! '/'¡YE AND

Till l!M H FiA.'He U> li CRE/V iS

TUMlItl. III 1 ■ I HI

PRi LhkiiiH , I iri

o WKP irirr Li iiiH> Vi'S i X , r-!.U i i( the CaiDU-

rptc;f < fi fi nakir-' "rt I'll tf I <fli ''TtiII pt~

• Be sure the throttle control cable is adjusted properly

(see above).

* With engine off turn idle mixture valve in (clockwise)

closing it finger tight and then turn out (counterclock

wise) 1 full turn.

25

Page 26

iilON: Ы

w: inside a

тасЬ ari^ op^

tli0 enQioe

un

A

wiiere fui

or spark

before St

TRACTOR

Remove mower from tr:

I/1< W^ ' I i' |i 'i 1

oughly, remove all dirt,

^ l{ ""h ’ V / t ‘

sP III I|

bi I 'VI t , >,

Í. |r,cpf(_i jí.'liepií'ii hC li Í.-,' Í ,.iy( f l-til lO

piaOt-l!li •difivli« i-> ) Wi ifiL 't,i‘ - M,' - <i|irf ; 'onls

' Ctrl'0 of All (ii.piiiHL

Í iibnvtiK thowi I Pit- • ' P’lii'i h- рои if.,!dCb

T< ti' Ii ;hi ill all' i!

• pi ^ ' L; r J' i't: ' _ e ' ^ ‘ ' Limi'/

MW Jill.d, ¡..да f I fi p.iiui. d ifi-.v| Lrt okaoc

and wear. Replace if necessan/.

® И‘И L ii(i d!i I V It a Ml i.t.ipp 'i 1 ;,,t up satiJ

■И h I. L íoPt f. ..¡'i. P' .

BATTERY

• Fully charge the battery for storage.

• After a period of time in storage, battery may require

recharging.

• To help prevent corrosion and power leakage during

long periods of .storage, battery cables should be

disconnected and battery cleaned thoroughly (see “TО

CLEAN BATTERY AND TERMINALS” in the Cus

tomer Responsibilities section of this manual).

• After cleaning, leave cables disconnected and place

cables where they cannot come in contact with battery

terminals.

• Be sure battery drain tube is securely attached.

• If battery is removed from tractor for storage, do not

store battery directly on concrete or damp surfaces.

ЗГ for w! Pite г

period of tir

ase leaves

' (See “CLEANING” in the Customer

iction of this manuai).

ciQe„ When

rlean it thor-

Store in a

DSITS FROM FORMING IN ESSENTIAL FUEL

FUE

iTof ’ll T'bli -I I' n -"fpoLk .Jernative in

h!.i (iiiiLihp tip It Htirjlii« i 'ft til.' fjiim 'WpT !ir during storr p- /.Li I iuiii (. I !i. gdioliii- If t3tiK or storage

.fill ill . Nil' iiui ii it if-dit Tj iiiii.ijttc after adding

...IcL llO I P. .1 :г t.il, Г. to macL th mrbureior. Do

iofcL i i T. !_• .iji'it -ji<Jc<.rDiir( lor it lining fuel stabilizer.

. f 'W. 1' JUII , , _,r ALSO,

. ■ i ' ' ii [ it • 11 Mi ,1 f f ,t(.i BLENDED

I ' I t . Ill < 'miw' ;|.FA AHICH LEADS

i ' i!-m FwhMF i!‘TJ OF 'D DURING

r / Ui i ‘ ,L , II < t/ ! HE FUEL

I ! 4

...............................

Jrafn the fuel tank.

Jtart the enqine and lei it

irbureior

ever usei

se fresh f

i ... i.i L ih,-. ttif rrii/ idtio It'tniil un stabilizer

' d <t .f ' 14. ^ I H \NOL OR

, N'f.l • ;lf r t .

impt\

etor cleaner products in the

nage may occur.

j| next season.

'ENT GUM

ELFILTER,

lines and

ENGINE OIL

jii fit •!. ./V frn)and i( pia; ewithdeanengine

'»il * •‘UiJf ' in the i u..iomer Responsibilities

section of this manual).

ЭС

CYi G

f 1 !■ ' ‘-j. "k |)l

Pour one 01jnee (

cylinder(s).

1 M ryi.ili

to distribute oil.

ii' pf >- Will new ..Mil |. iu(i(, I

OTHER

® f- I.' I . fja 'll ii I- .Inont m Wiin t-1'another.

11' j'l.v . ... ‘I 1‘liriA .11 -I y 'Ll! c'li marts to rust.

“ I '.•• ii > I , It I hci t'i indofi;) inri rover it to

iI I 1 fi< If i.'im J‘i I )P(J .firt

• 1 . ir,,i to. fjith j I >fi-itilr príitííti/c rover that

• i.f III !' 1,.» m li. tiiii Iti' not L-cs plastic. Plastic

...... I f A i£ ■1. ivhid. all..n jndfc,nfctiontoformand

will cause your tractor to rust.

ANij E j Ai! I “f . Í !t ' ri! ! '/VAfiM.

1 key t'

/ I I'sG , ;j 1 j r.lifr Will > Ml ' problems.

ii A vFf -FA. TOPWHILEENGINE

;TART” position fora few seconds

26

Page 27

f ?i

Will not start

1 Cj

VUSE

i—

Out of fuel.

1.

Engine not “CHOKED” properly.

1 2,

«II

Engine flooded.

Bad spark ptua.

1 ^

.Jin < ill till -1

If Í ^ tc' Í' f

1 6.

7.

Water in fuel.

L'lO f '1 1 I'l

I ^

toll '111 >11 if 'll r.e.ii

1 y

ORRECTION

I,;

T~

>■ M:!

See “TO START ENGINE" in Operation section.

1

Wait several minutes before attempting to start.

1 4,

Replace spark plug.

1 5

1 c

Replace fuel filter.

1 7.

‘ 1 ( , *1 ' 1 aetji rriii'tatil ri,i ii &h

fi

gasoHr-is and replace fuel filter.

1 g_

'• '1

1 . , ‘ ■ rt 1 lO 1.1..1VI.!. iidiuttitients

10. Engine valves out of adjustment.

Hard to start 1, Dirty air filter.

Engine will not turn over

2

Bad spark plug.

3. Weak or dead battery.

4.

Dirty fuel filter.

5. Stale or dirty fuel.

6.

Loose or damaged wiring. 6.

7.

Carburetor out of adjustment. 7.

8. Engine valves out of adjustment.

1. Clutch/brake pedal not depressed.

2.

Attachment clutch is engaged.

3. Weak or dead battery.

4,

Blown fuse.

5. Corroded battery terminals.

6.

Loo.se or damaged wiring.

7.

Faulty ignition switch. 7.

8. Faulty solenoid or starter.

9.

Faulty operator presence switch(es).

Engine clicks but will not 1. Weak or dead battery.

start 2.

Corroded battery terminals.

3. Loose or damaged wiring.

4. Faulty solenoid or starter.

1.1 >11,1 , ;|t, 11,r ) I iilf nt

il

Cfean/replacB sir fitter.

1.

1 o

I

I 4-

r

1 2.

O'* ' 1 ' •

Recharge or replace battery.

it ri II

5. D 1, . 1 11.« 1 i( ill' t 1 h g . line

N f* ii' 111 <

8.

1 irit.i, ..ill. luio r. ic . Gtmer/depariment

L p. ^ ' 1 f( i 1 T t ki I dal

, ‘ r j 1! hiTi 1 * luich

Ht- h Kia II mi ia> e L mtei >

4, Replace ruse.

5. Clean battery terminals.

6, Check ail wiring.

Check/repiace ignition switch.

8.

Check/replace solenoid or starter.

9. Contact an authorized service center/department.

1.

Recharge or replace battery.

2, Clean battery terminals.

3.

Check all wiring.

4.

Check/replace solenoid or starter.

t 'o, 1 . ( t . lu, ’ 1, t -rviL Adjuccrr.enfs

Loss of power 1.

10. Spark plug wire loose.

11.

12.

13.

14. Carburetor out of adjustment.

15. Engine valves out of adjustment.

Excessive vibration 1.

Cutting too much grass/too fast.

2.

Throttle in “CHOKE” position.

3.

Build-up of grass, leaves and trash under mower. 3.

4.

Dirty air filter. 4,

5. Low oil level/dirty oil.

6.

Faulty spark plug.

7.

Dirty fuel filter.

8.

Stale or dirty fuel.

9. Water in fuel.

Dirty engine air screen/fins.

Dirty/clogged muffler.

Loose or damaged wiring.

Worn, bent or loose blade.

2. Bent blade mandrel.

3. Loose/damaged part(s).

27

1.

Set in “Higher Cut” position/reduce speed.

2.

Adjust throttle control.

Clean underside of mower housing.

Ciean/replace air filter.

5.

Check oil level/change oil.

6. Clean and regap or change spark plug.

7. Replace fuel filter.

8. Drain fuel tank and refill with fresh gasoline.

9. Drain fuel tank and carburetor, refill tank with fresh

gasoline and replace fuel filter.

10. Connect and tighten spark plug wire.

11.

Clean engine air screen/fins.

12.

Ciean/replace muffler.

13.

Check all wiring.

14.

See “To Adjust Carburetor” in Service Adjustments

section.

15. Contact an authorized service center/department.

1.

Replace blade. Tighten blade bolt.

2.

Replace blade mandrel.

3. Tighten loose part(s).. Replace damaged parts.

Page 28

PROBLEM

CAUSE CORRECTION

Engine continues to run

when operator leaves seat

with attachment clutch

engaged

Poor cyt - uneven

1. Faulty operator-safety presence control system. 1, Check wiring, switches and connections. If not

1. Worn, bent or loose blade.

2. Mower deck not level,

3. Buildup of grass, leaves, and trash under mower.

' 4. Bent blade mandrel.

5. Clogged mower deck vent holes from buildup of

grass, leaves, and trash around mandrels.

Mower blades will not

rotate

1. Obstruction in dutch mechanism.

2. Worn/damaged mower drive belt.

3. Frozen idler pulley.

4. Frozen blade mandrel.

Poor grass discharge 1. Engine speed too slow.

2. Travel speed too fast.

3. Wet grass.

4. Mower deck not level.

5. Low/uneven tire air pressure.

6. Worn, bent or loose blade.

7. Buildup of grass, leaves and trash under mower.

8. Mower drive belt worn.

9. Blades improperly installed.

10, Improper blades used.

11, Clogged mower deck vent holes from buildup of

grass, leaves, and trash around mandrels.

corrected, contact an authorized service center/

department.

1. Replace blade. Tighten blade bolt,

i 2. Level mower deck.

' 3. Clean underside of mower housing.

: 4. Replace blade mandrel.

' 5. Clean around mandrels to open vent holes.

1. Remove obstruction.

2. Replace mower drive belt.

3. Replace idler pulley.

4. Replace blade mandrel.

1. Place throttle control in “FAST” position.

2. Shift to slower speed.

3. Allow grass to dry before mowing.

4. Level mower deck.

5. Check tires for proper air pressure.

6. Replace/sharpen blade. Tighten blade bolt.

7. Clean underside of mower housing.

8. Replace mower drive belt.

9. Reinstall blades sharp edge down.

10. Replace with blades listed in this manual.

11. Clean around mandrels to open vent holes.

Headlight(s) not working

(if so equipped)

Battery will not charge 1. Bad battery cell(s).

1. Switch is “OFF”.

2. Bulb(s) burned out.

3. Faulty light switch.

4. Loose or damaged wiring.

5. Blown fuse.

2. Poor cable connections.

3. Faulty regulator (if so equipped).

4. Faulty alternator.

Engine “backfires”

when turning engine

“OFF”

1. Engine throttle control not set at “SLOW”

position for 30 seconds before stopping engine.

1. Turn switch “ON”.

2. Replace bulb(s),

3. Check/replace light switch,

4. Check wiring and connections.

5. Replace fuse.

1. Replace battery.

2. Check/clean all connections.

3. Replace regulator.

4. Replace alternator.

1. Move throttle control to “SLOW” position and allow

to idle for 30 seconds before stopping engine.

28

Page 29

SCHEMATIC

ni; 1"' — MODEL 42D

IGNITION SWITCH

POSITION CIRCUIT “MAKE”

OFF G + M + L

RUN/LIGHT B + L

RUN B + L

START

B + L + S

NONE

A +Y

NONE

NONE

YOUR TRACTOR

EQUIPPED With A SPECIAL

alternaior System.

THE LIGHTS ABE fJOT

CONNECTED TC-’ THE

BATTERY. BUT HAVE THEIR

OWN ELECTRICAI SOURCE.

BECAUSE OF THIS, THF

BRIGHTNESS OF THE [YWTS

WILL CHANGE WITH L NG!t ‘L

SPEED. AT IDLE THL I .CHTS

WILL DIM. ASTHE Er'(',ir:F |P

SPEEDED UP, THE LiGrITt

WILL BECOME THEIR BRIGHTEST.

NON^REMOVABLE

CONNECTIONS

WIRING INSULATED CLIPS

NOTE: !F WIRING INSULATED CUPS WERE REMOVED FOR

SERVICING OF UNIT, THEY SHOULD BE REPLACED TO

PROPERLY SECURE YOUR WIRING.

29

REMOVABLE

CONNECTIONS

Page 30

REPAIR PARTS

ELECTRICAL

. t r''> - MODEL ' . mCL'l L:i45H42D

22

X /

/

Page 31

REPAIR pmi H

E :al

‘ ’'»‘ODEL rc L 5H42D

KEY PART

NO. NO. r-1^ h.rnm

1 144925

n

74760412

4