Page 1

OWNER S MANUAL

MODEL NO CHD185H46A

18.5 HP46L^eh

Lawn Tractor

Assembly

« Operation

® Customer Responsibilities

• Service and Adjustments

• Storage

For Parts and Service, contact our authorized distributor: call 1-800-849-1297

For Technical Assistance: call 1-800-829-5886

• Troubleshooting

* Repair Parts

l*oul a n

159515 2.13.97TR

PRINTED IN U.S.A,

Page 2

A

PORTA

if./

F /

HLURE ”0 OBSER^ /E THE FOLLC JWIMG SAFETY INSTRUC

\i T “ T M i C' f '

UTTING MAC I

A Sau

i Operation Practice

JIME IS CAPABLE OF AMf

SAFETY RUL

3UTATIN

TIONS C

?FñU

\ND

EET AND THROWING OBJECTS

N SERIOUS INJURY OR DEATH

gene

Read, jnderstand.

Only a

instruc

Clear t le ores of c

which oLild be pick

Be sure

mac hi r e if anyone r nters the area.

Never

Do not

look do wn and behs Id loefore and w Ting,

'

Be awa

it at an

entire c

Slow cT jwn before ti

Never i

bl 1 •'

B.AL OPER

the fTic^chine

low lOBspons

ions, to Oper

the area isc ear of other peof 'e mowing. Stop

:arry passen

■now in rever

re of the rnov rer discharge di and do not point

/one. Do nc t operate the m ithOLit either the

rass catcher or the guard in place.

jvyr ^ 1 IJ 1

set parking

ATION ill CH

1 1 lOllo a al 1 1

before s^srftnn

idle adults, wh

ale the machine

bieicts such as w' toys, wire, etc..

3'd up and throv 3 blade.

le unless absoir :essary. Always

r 1 '. [ >'! i

.g machine unat

brake, stop en 111 ,iiid remove keys

IS in the manuai

amiliar with the

Always turn off

btnm dismounting.

i urn oti blades when no! mowing.

Stop engine before removing grass catcher or unclogging

chute.

Mow oniy in daylight or good artificial light.

Do not operate the machine while under the influence of

alcohol or drugs.

Watch for iratfic when operating near or crossing roadways.

Use extra care when loading or unloading the machine into

a trailer or truck.

II. SLOPE OPERATION

Slopes are a major factor related to loss-of-control and

tipoveraccidents, which can result in severe injury ordeath.

All slopes require extra caution. If you cannot back up the

slope or if you feel uneasy on it, do not mow it.

DO:

Mow up and down slopes, not across.

Remove obstacles such as rocks, tree iimbs, etc.

Watch for holes, ruts, or bumps. Uneven terrain could

overturn the machine. Tall grass can hide obstacles.

Use slow speed. Choose a low gear so that you will not have

to stop or shift while on the slope.

Follow the manufacturer's recommendations for wheel

weights or counterweights to improve stability.

Use extra care with grass catchers or other attachments.

These can change the stability of the machine.

Keep ail movement on the slopes slow and gradual. Do not

make sudden changes in speed or direction.

Avoid starting or stopping on a slope. If tires lose fraction,

disengage the blades and proceed slowly straight down the

slope.

DO NOT:

• Do not turn on slopes unless necessary, and then, turn slowly

and gradually downhill, it possible,

• Do not movr near drop-offs, ditches, or embankments. The

mower could suddenly turn over if a wheel is over the edge

of a cliff or ditch, or if an edge caves in,

• Do not mow on wet grass. Reduced traction could cause

sliding,

• Do not try to stabilize the machine by putting your toot on the

ground.

• Do not use grass catcher on steep slopes.

T raoic s

presenc

machine

cniidrGr

• Kee

U( II (■

• в 63

• Befc

мин.

M ■ ; I .1 1

• NCTC

■ w . . ( ■■

tree

IV. SEF

fcRVICE

® Lis6

lirl

there :S an op

Hi vfI luiI £ n a I

t I (>i) nm ani h )

c nri c on f gulp 11

ccur if the 0

Children a

wirtg activit

tere you iai;

the mowing i.

■onsibie

ichine off if

t£j saw them,

area and under the watchful

.lit.

hildren enter the area.

Innk

I 1 II II 1 I I iiiO 'therfueis. They are

J , <1 'aW 1 I I lo 1

only an approved container.

' I >111 iv ( i add fuel with the engine

inchine or fuel container inside where

iarne, such as a water heater,

inside a closed area.

''specially blade attachment bolts, tight

n good condition,

1 not alert to the

attracted to the

idtwer assume that

J down for small

ind be seriously

afion,

le,

corners, shrubs,

cion.

efueiing. Do not

f If I irtnpct 1/nil rttuiy tk nc-s P heck their proper

operaiion reguiany.

Keep machine free of grass, leaves, or other debris build-up.

Clean Oil or fuel spillage. Allow machine to cool before

storing.

Stop and inspect the equipment if you strike an object.

Repair, ii necessary, before restarting.

Never make adjustments or repairs with the engine running.

Grass catcher components are subject to wear, damage, and

deterioration, which could expose moving parts or allow

objects to be thrown. Frequently check components and

replace with manufacturer's recommended parts, when nec

essary.

Mower blades are sharp and can cut. Wrap the blade(s) or

wear gloves, and use extra caution when servicing them.

Check brake operation frequently. Adjust and service as

required.

1 ock for this o'/rTiboí iQ point out im-

I >oi tant .satfit'/ ,ii ecautioris. It means

( ui’línNüi i.f ' OlVUvALFRT!!! YOUR

' '• i г ' IS i!Jv> a vED.

Hi Alwf/s disconnect spark plug

■ i. are wire where it cannot contact

order to prevent accidental

. > !■ inn setting up, transporting,

!iu lit >. I making repairs.

A WARNSNQ A

The engine exhaust from this product con

tains chemicals known to the State of Califor

nia to cause cancer, birth defects, or other

reproductive harm.

Page 3

CONGRATULATIONS on your purchase of a new tractor.

It has been designed, engineered and manufacture:; ‘c

give you the best possible dependability and performance.

Should you experience any problem you cannot easily

'мая I our i ' ’j и ь

center/department. We have competent, well-trained tech-

I ‘.’1 mdiliu cop'I‘ooo r ' '1 -"'-Mm >i h* .ji io>

Please read and retain this manual. The instructions will

омэ1'' /ouKj t mi ii: anci nu i ViUn /< u' uumu- uiu.miU«

Al iiH ' ub' ^ I /' ill' " / I t I '' I iJL ^

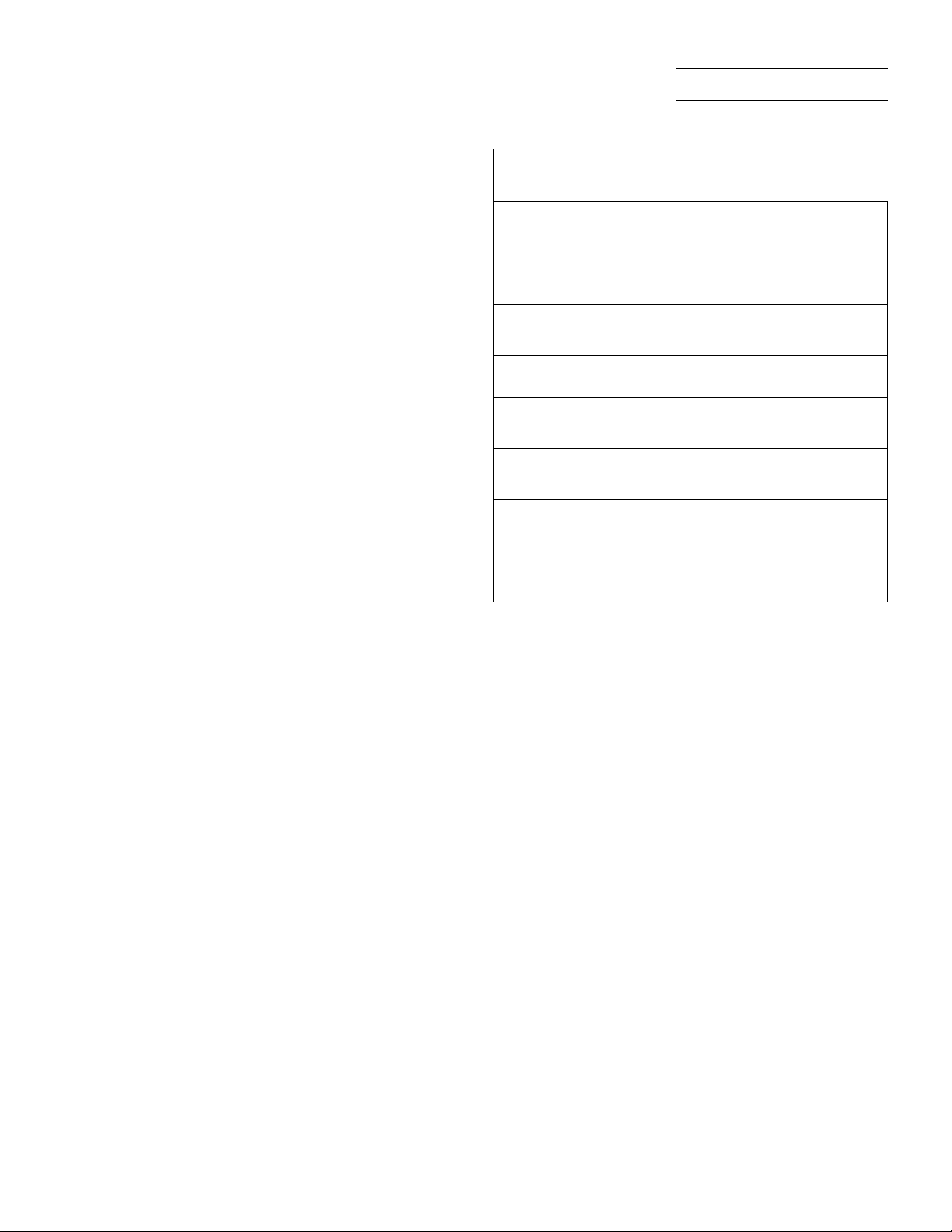

MODEL

NUMBER

CHD185H46A

SERIAL

NUMBER

DATE OF PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE FOUND

ON A PLATE UNDER THE SE.AT.

YOU SHOULD RECORD BOTH SERiAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

CUSTOMFR RESPOMf:?nioiTiES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for and

using your tractor.

• Follow the instructions under “Customer Responsibili

ties” and “Storage” sections of this owner’s manual.

PRODUCT SPECI

i riCiiwEi'RDWER;

I

‘ A/W A llJL АГАЫГ '

1 / PR d'-

OIL TYPE (API-SF/SG/SH):

OIL CAPACITY:

ÎY\fv ' CHAMPION RJ19LM

u P' ' 1 ' w 1M FI j:

TIRE PRESSURE: FRONT: 14PSI

CHARGING SYSTEM: 3 AMPS BATTERY

BATTER':":

BLADE BOLT TORQUE: 30035 FT, LBS.

FICATIONS

18,5

3.5 GALLONS

SAE 30 (above 32“F)

S7\E 5W-30 (belo'W 32°F)

3,5 PINTS

3.0 PINTS

NTAKE: ,004"-. ,006"

EEXHAUST: ,007" - ,009"

FORWARD; 0.0 -5.5

REVEFRSE: 0.0 - 2.3

REAR: 10 PSI

5 AMPS HEADLIGHTS

AMP;HR: 25

MIN. CCA: 190

CASE SIZE: U1R

\R

F

WARNING; This tractor is equipped with an internai

combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-cov

ered land unless the engine’s exhaust system is equipped

with a spark arrester meeting applicable local or state laws

(if any), if a spark arrester is used, it should be maintained

effective working order by the operator.

in

A spark arrester for the muffler is available through your

nearest authcrized service center/department (See RE

PAIR PARTS section of this manual).

In the state of California the above is required by iaw

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands.

Page 4

i nmertwmhf :r ,

The Manufacturer warrants to the

materials and workmanship. For a

repair or replace, at our option, vvi

defective due to materials or workrr

1. This warranty does not apply

(except as noted below) or co

I ( oi a i ip it I f Jicnasei tlial ihr

ii/'o Ip / ais ironi d-atc of on

nair|P !f) I .its ot lohcii incniii

n in V/r'! mry IS subjr t to ilu i

to the engine, other fhar

iiiponcnis parts thcmeoi

ATF rrianufa

Please refer t

lufactured

ginal cons

iris, any p

IS and

u nsin

inanuti

CiUE

non

c otiinoncnts, battery

‘ , waimnty on these

,ure.

items,

2. Transportation charges for the movement of any power equipment unit or attachment are the responsibility of the

purchaser. Transportation charges for any parts submitted for replacement under this warranty must be paid by the

purchaser unless such return is requested by American Yard Products,

3. Battery Warranty: On products equipped with a Battery, we will replace, without charge to you, any battery which we find

to be defective in manufacture, during the first ninety (90) days of ownership. After ninety (90) days, we will exchange the

Battery, charging you 1/12 of the price of a new Battery for each full month from the date of the original sale. Battery must

be maintained in accordance with the instructions furnished.

4. The Warranty period for any products used for rental or commercial purposes is limited to 90 days from the date of

original purchase.

5. This Warranty applies only to products which have been properly assembled, adjusted, operated, and maintained in

accordance with the instructions furnished. This Warranty does not apply to any product which has been subjected to

alteration, misuse, abuse, improper assembly or installation, delivery damage, or to normal wear of the product.

6. Exclusions: Excluded from this Warranty are belts, blades, blade adapters, normal wear, normal adjustments, standard

hardware and normal maintenance,

7. In the event you have a claim under this Warranty, you must return the product to an authorized service dealer.

Should you have any unanswered questions concerning this Warranty, please contact:

American Yard Products In Canada contact:

Service Department American Yard Products

P.O, Box 1687

Orangeburg, SC 29116 USA

giving the model number, serial number and date of purchase of your product and the namie and address of the authorized

1 580 Trinity Drive, Units 5-8

Mississauga, Ontario

L5T 1 L6

dealer from whom it was purchased.

THIS WARRANTY DOES NOT APPLY TO INCIDENTAL OR CONSEQUENTIAL DAMAGES AND ANY IMPLIED WARRAN

TIES ARE LIMITED TO THE SAME TIME PERIODS STATED HEREIN FOR OUR EXPRESSED WARRANTIES. Some areas

do not allow the limitation of consequential damages or limitations of how long an implied Warranty may last, so the above

limitations or exclusions may not apply to you. This Warranty gives you specific legal rights, and you may have other rights

which vary from locale to locale.

This is a limited Warranty within the meaning of that term as defined in the Magnuson-Moss Act of 1975.

elects in

r, we will

nd to be

Page 5

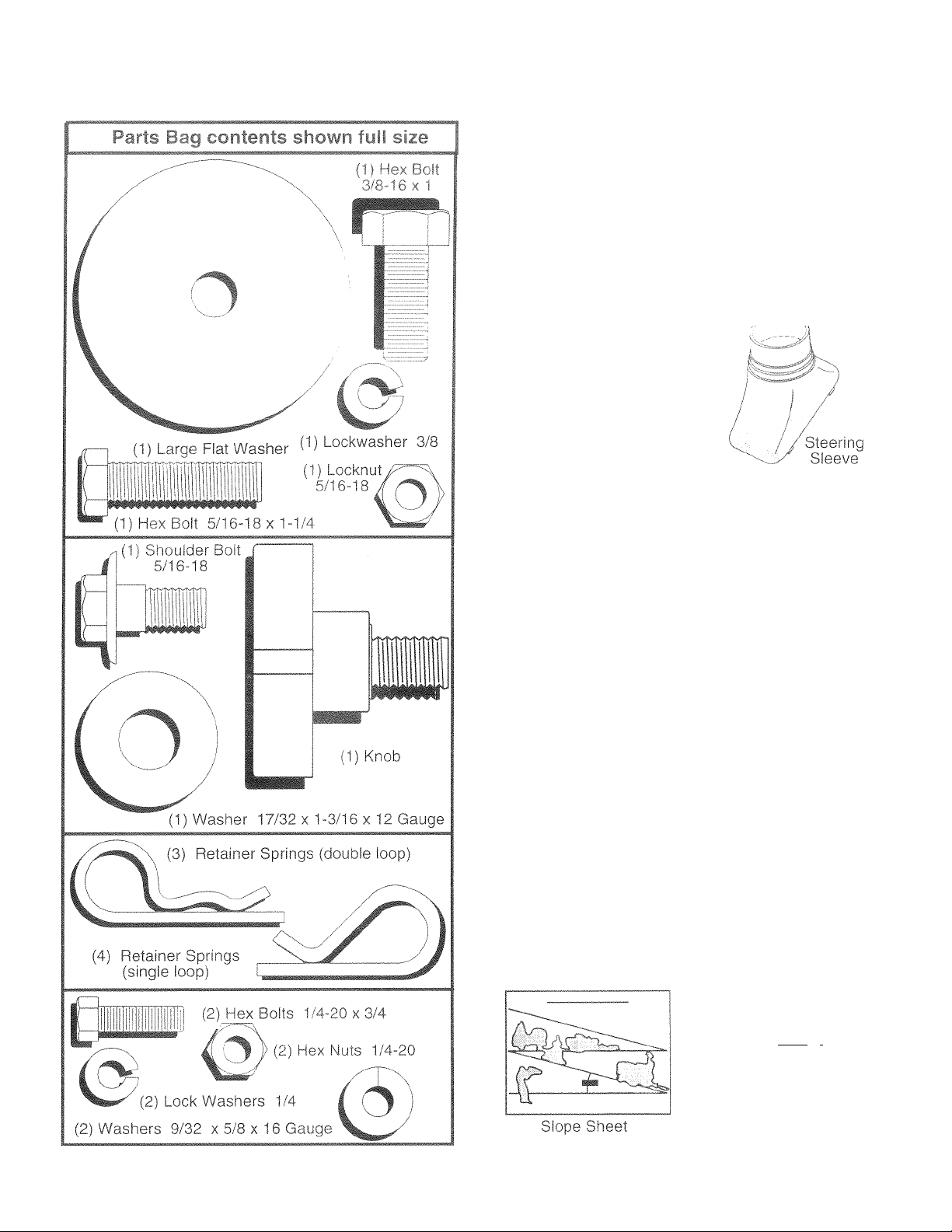

CONTENTS OF HARDWARE PACK

Steering Wheel

f in carton

Manual

Parts b ' ntenis not shown ful! size

(2) Shoulder

Bolts

(2) Center-

lock Nuts

Steering

Wheel

Insert

W (2) Washers 3/8

i i X 7/8 X 14 Gauge

Steering

Extension

Shaft

(2) Front Link Assemblies

Steering Wheel

Parts Bag

(2) Gauge

Wheels

i i! i i I j

Adapter

(2) Keys

Page 6

YOU!Ì t - / ' ' 1 i

nsure S3.f'

To e

the ccorrect toe

TOi

OLS R

A soiC)ket wreO'

I " lie I < • i nr 1^ J cti ru f icio ; \u ri

and proper operation of your tractor all part;

s as necessary to insure proper tightness.

EQUIRED FOR ASSEMBLY

h set will make assembly easier. Standard

wrench sizes c

(f) SA'" So( I ( . I it Utility knife

(2) 7/16" wrenches Tire pressure gauge

(2) 1/2" wrenches Pliers

(1} 9/16" wrench

When right or left hand is mentioned in this manual, it

means v/hen you are in the operating position (seated

behind the steering wheel).

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

• Remove all accessible loose parts and parts cartons

from carton (See page 5).

• Cut, from top to bottom, along lines on all four corners

of carton, and lay panels flat.

• Check for any additional loose parts or cartons and

remove.

copi,on ji musr cm oieltun-ccc ihlco ^ . hi| ,cnti m. <c

! and hardware you assemble must be tightened securely.

BEFORE ROLLING TRACTOR OFF SKID

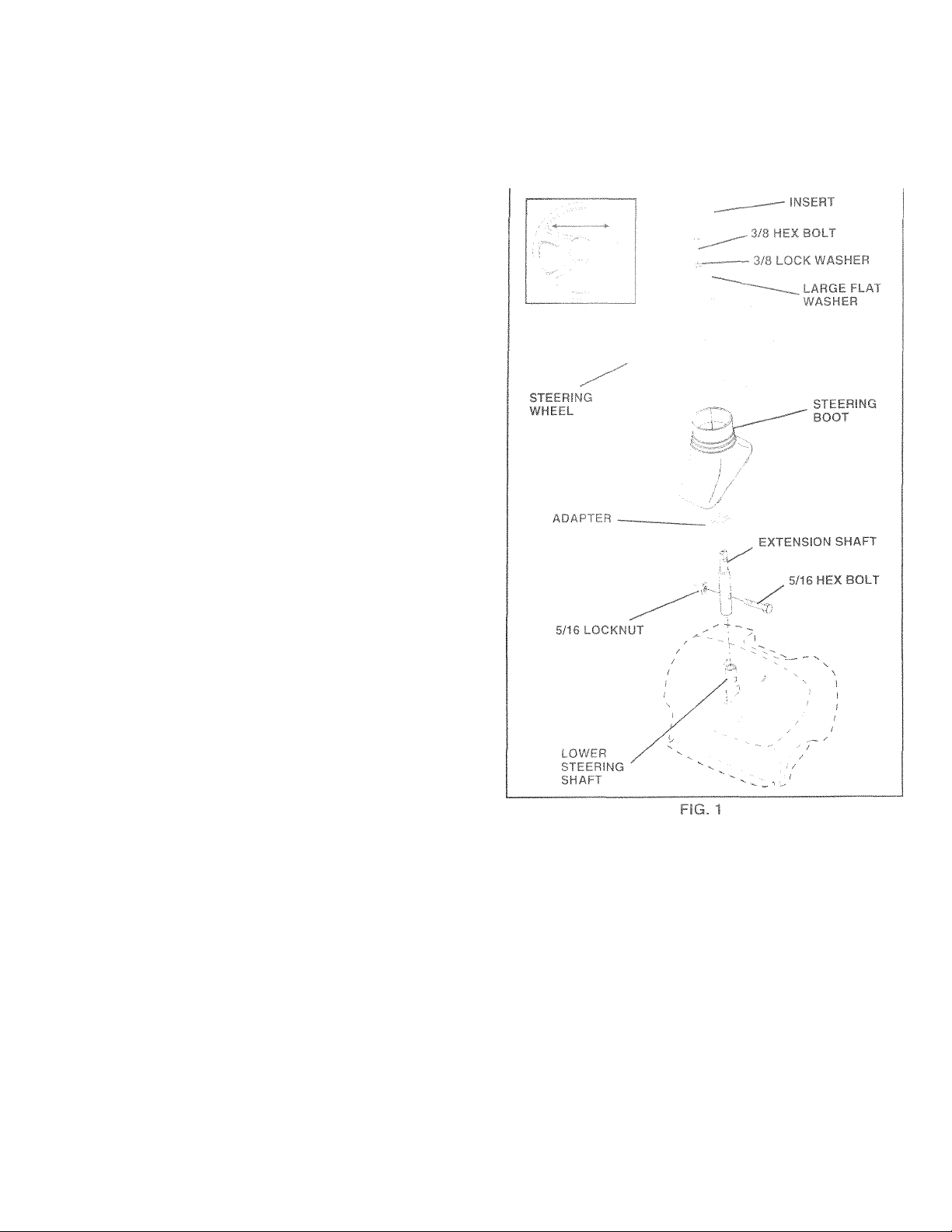

ATTACH STEERING WHEEL (See Fig. 1)

ASSEMBLE EXTENSION SHAFT AND BOOT

• Slide extension shaft onto lower steering shaft. Align

mounting holes in extension and lower shafts and

install 5/16 hex bolt and locknut. Tighten securely,

IMPORTANT: TIGHTEN BOLT AND NUT SECURELY TO

18-22 FT, LBS TORQUE,

• Place tabs of steering boot over tab slots in dash and

push down to secure.

INSTALL STEERING WHEEL

• Position front wheels of the tractor so they are pointing

straight forward.

• Slide steering wheel adapteronto steering shaft exten

sion.

• Position steering wheel and sleeve assembly so cross

bars are horizontal (left to right) and slide onto adapter.

• Assemble large fiat washer, 3/8 lock washer, 3/8 hex

bolt and tighten securely.

• Snap steering wheel insert into center of steering

wheel.

• Remove protective plastic from tractor hood and grill.

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

IN SKIDTHATMAY PUNCTURE TIRES WHERE TRACTOR

IS TO ROLL OFF SKID.

TO ROLL TRACrOR OFF SKID (See Opera

tion section for location and function of con

trols)

• Press lift lever plunger and raise attachment lift leverto

its highest position.

• Release parking brake by depressing dutch/brake

pedal.

• Place freewheel control m freewheeling position to

disengage transmission (See 'TO TRANSPORT” in

the Operation section of this manual).

• Roll tractor backwards off skid.

• Remove banding holding discharge guard up against

tractor.

Page 7

M j-hj -^1 S - f Up itifi'iB/lC:'rOR

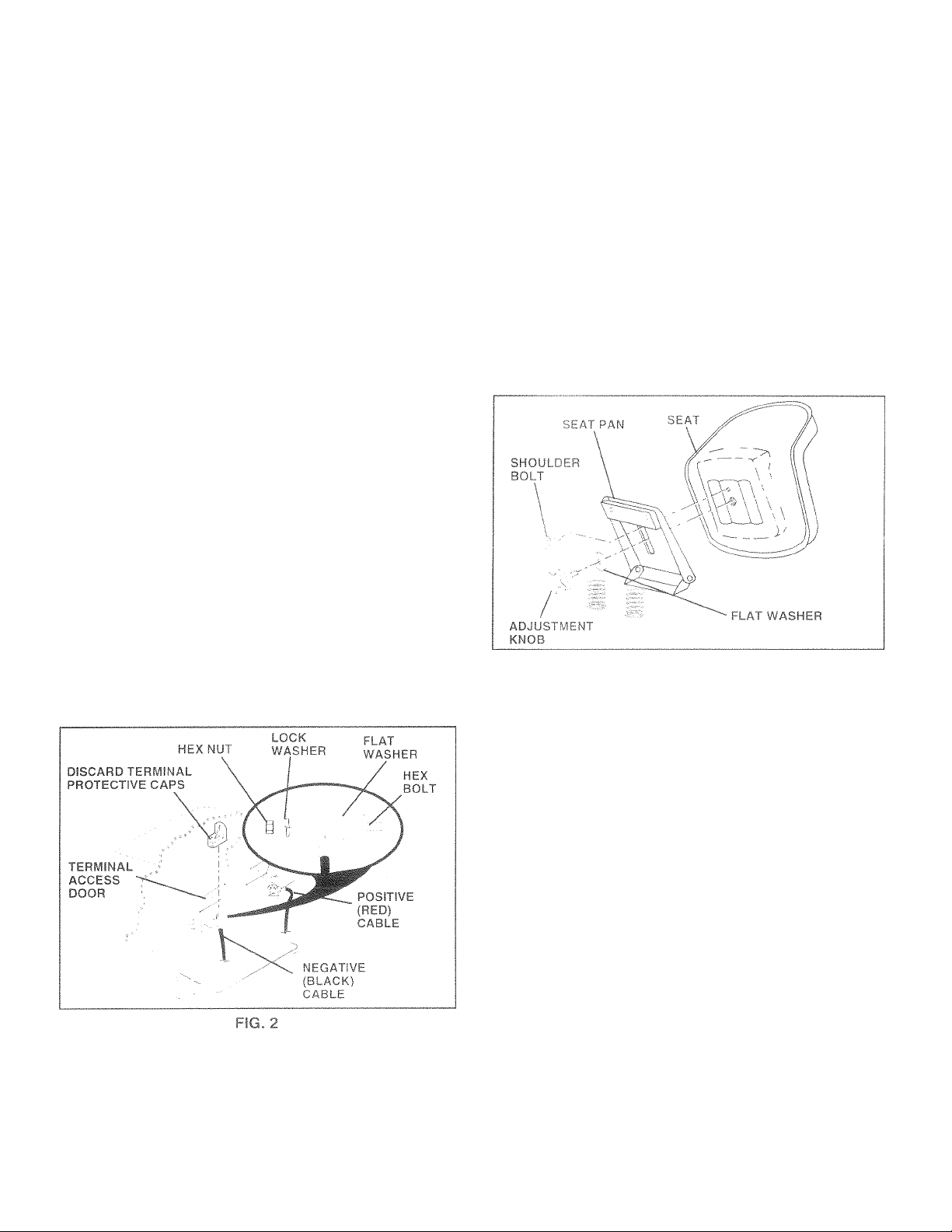

CONNECT BATTERY (See Fig. 2)

CAUTION: Do not short battery termi-

i ‘ i .r t ' , ■ ' I i

A

b. ,ic! Mi. j , eic.

Positive terminal must be connected

first to prevent sparking from acciden

tal grounding.

• Lift hood to raised position.

• Open terminal access doors, remove terminal protec

tive caps and discard.

« if this battery is put into service after month and year

indicated on label (label located between terminals)

charge battery for minimum of one hour at 6-10 amps.

• First connect RED battery cable to positive (+) battery

terminal with hex bolt, flat washer, lock washer and hex

nut as shown. Tighten securely.

• Connect BLACK grounding cable to negative (-) bat

tery terminal with remaining hex bolt, flat washer, lock

washer and hex nut.

• Close terminal access doors.

Use terminal access doors for:

• Inspection for secure connections (to tighten hard

ware).

• Inspection for corrosion.

• Testing battery.

• Jumping (if required).

• Periodic charging.

I fir.) -h I i r t. h

* •

Tighten securely.

rrdCTM f [ A‘f Fhf f,

¿ujust 'j- I IH..IO' - iyti(‘=-miiu m '-1 ■ ImiOl.

• K0rnov6 c3rdD03rci packiriQ on sG3t psn.

' d| (f V n ¡>..1'rina '-m <Ne r.hmildnr Iron

' m L - ul djnsirri'aii Oiob ano ilad A/mppi loosclv

r„/(,i noi iKiiimri.

® i t If '<1 [ POi { ~ U i F i /

• n seat.

• hed which

I the way

• lOLit moving its adjusted position.

‘ tighten adjustment knob securely.

FIG. 3

Page 8

A eoci

Imm !

ilE

H 1^ T*°l

The tires on your t

shipping purpose:s. Correct tire pressure is important for

PRESSURE

sc ii w( ii 0./'- .iirt'au 0 ui cii' i.K'Mrvioi

best cutting perroi mailU::.:

i p( 1 1 , 1 r 1

SPECIFICATIONS” on page 3 of this manual.

CHECK Itf'/Ti :,E SYSTEM

ATier you learn now to operate your iracior. cnecK to see

that the brake is

BRAKE" in the Service anci Adjustments section of this

sressure to PSI shown in “PRODUCT

properly adjusted. See "lO ADJUST

manual.

CHEi

BEI-ORE

.j..

^CTO

THlEBESTPERFORMANi.Az'ANUS/

THIS QU,ELITY PRCEIH..JC T.

PLtEASE HE F(AL

/

All as

No if

/

Battei

1 hOLJ

Seat I

/

/

All tirr

the tires were ov erinfiate;d at the

Re 11

/

in rn

pnp

( he I < mower an

/

prope

Cue ' 1< wiring, Sc

/

and wires are pn

t-ittOli

/

dii'/i ‘

WHILE LEARNING HOWTO USE YOUR TRACTOR. PA Y

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

/ Engine oil is at proper level.

/ Fue! tank is filled with fresh, clean, regular unleaded

gasoline.

/ Become familiar with all controls - their location and

function. Operate them before you start the engine.

/ Be sure brake system is in safe operating condition.

/ It is important to purge the transmission before operat

ing your tractor for the first time. Follow proper starting

andtransmission ourqing instructions (See'TO START

ENCilNE^' and "PURGE TRANSMISSION” in the Op

eration section of this manual).

YOU OP.ERA TEAND £ENJOY YOUFE NEW

fV M./W !y//C

semoiv "-m

maininq kuC

-y jC; arc CP''

r oi) o aa'jCi:

;S ai"G ore Of

re mower c

o-rear for i oest cut

riy inflated for ieve^Tig).

E propri

conefort

oriy inlin.ted, iF( Dses,

leek IS i

' n Hi

!\/ afoi c '

e onvinc] O’cactor, be

puHeys.and insr

re that aII cenne

jpetiy c lamped.

OICL/i >r

JC/ /per '

THA T YO U RECEIVE

E TIE) FA C TION FROM

1 f'^IA/lkl

> have b■een completed

red and mum

' i!,

ting res uk' (irr must be

telts. Be

? sure fr 1 e'Kneel rontif)| is in

‘-‘V I !

on.

rely.

factory).

1 r ! g ,idi to side/

II Ihf / r.ir muted

1, libfeittf ['ers.

(IK ns am [ill secure

8

Page 9

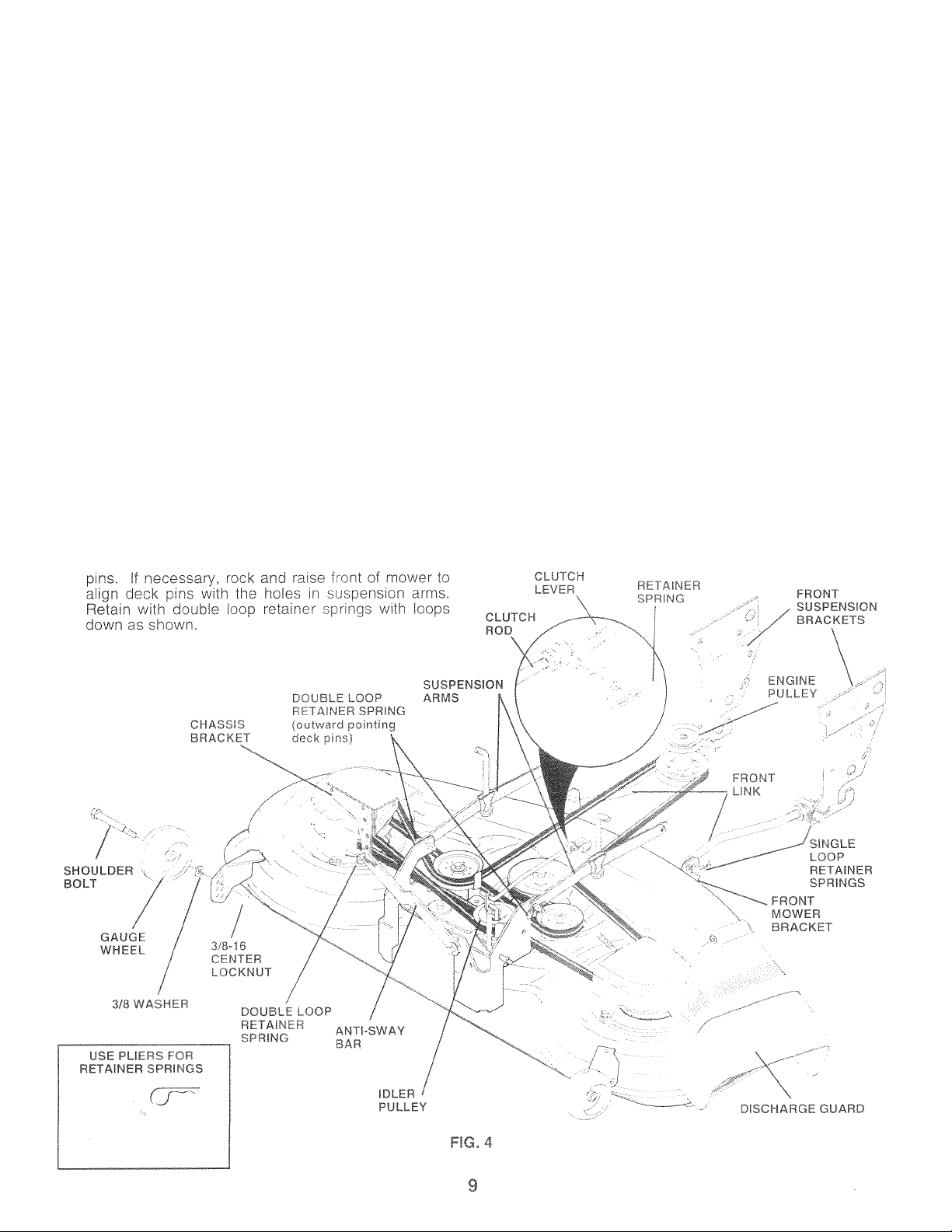

.L MOWi

Figs

• cut and remove

and 5)

factor is on

raised with

iki

Swing anti

c//ay ba

3ce a

it 'hi

fhrr

curing anth

!oit oido oi

E BELT (See

lower suspension

.cn'rol. Engage park-

i/ay bar and belts,

sower deck.

• Slide mower under tractor with discharge guard to right

side of tractor.

iMPORTANT; CHECK BELT FOR PROF'ER ROUTING ¡N

ALL MOWER PULLEY GROOVES, INSTALL BELT INTO

ENGINE PULLEY GROOVE,

» Install one front linK in top hole of the L.H. front mower

bracket and L.H, front suspension bracket. Retain with

two single loop retainer springs as shown,

• Install second front link in R.H. front suspension bracket

and retain with single loop retainer spring as shown.

• Slide right side of mower back and install link in top hole

of R.H. front m,ower bracket. Retain with single loop

retainer spring as shown,

• Turn height adjustment knob counterclockwise until it

stops.

» Lower miower linkage with attachment iift control.

Place the suspension arms on outward pointing deck

Connect anti-sway bar to chassis bracket under left

footrest and retain with double loop retainer spring.

Install clutch rod in clutch lever. Secure with retainer

spring.

Turn height clockwise to remove

slack f.rom n

Raise deck i

■as shown

СНЕС

MOWER LEVELNESS

Foidc.. I 1 iiiv I cuiis nv'Vi.r iiouki po piopc ily leveled.

Stt ¡0 L.L /l.l_ MOWEn HuUbIMG m [he Cervice and

Adjustmients section of this manual.

ClltfO

БГ* 0

See the figures that are s

dm I- I "f I I I If

A *Ju h < ( I i>

rn Ю

■ive

lanu

SmON OF ALL

ilacing motion, mower

5 in the Service and

Gerify that the belts are

к UP ti ( I n 1 V

culder

ighten

Page 10

OPERATiON

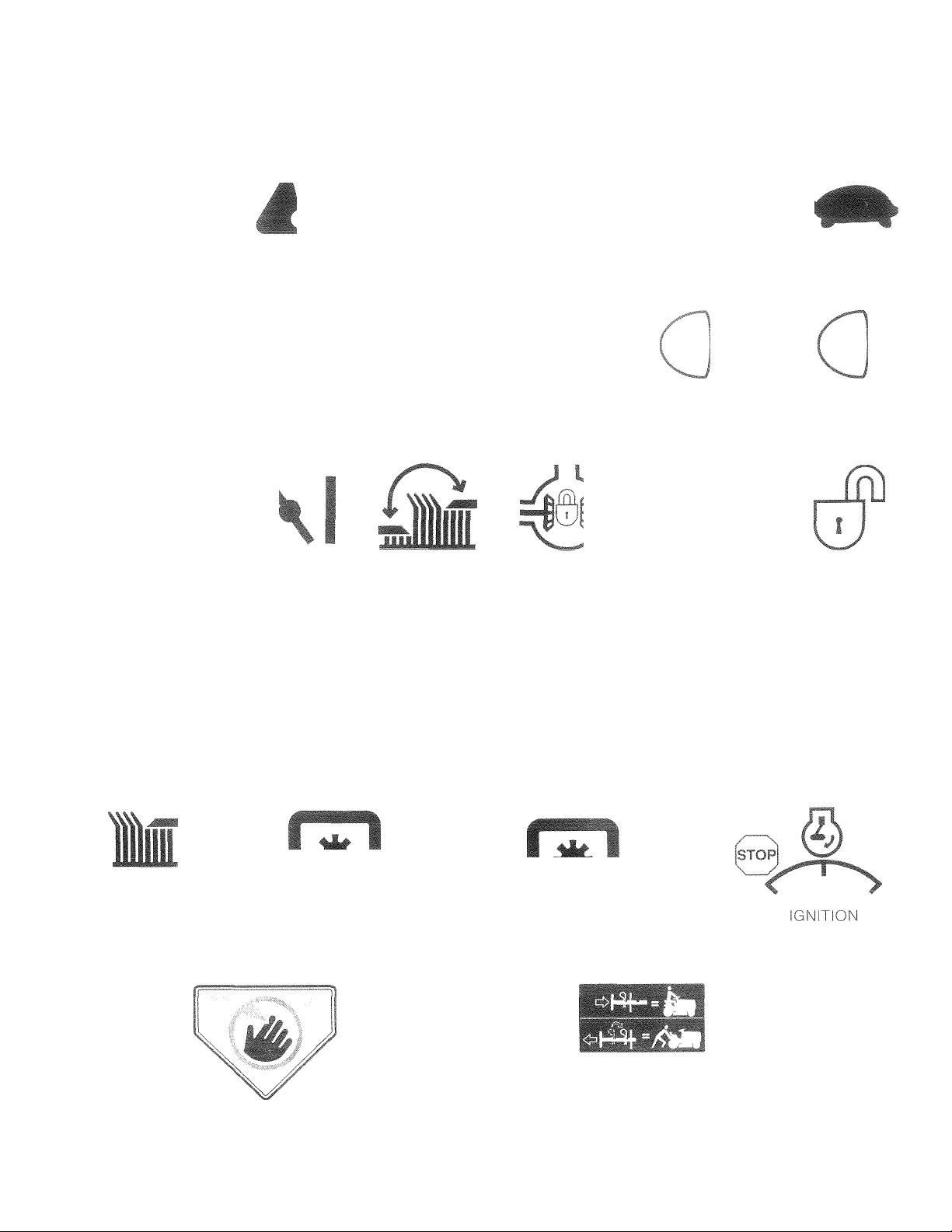

These symbols msiy appear on your tractor or in literature supplied with the product. Learn and understand their meaning.

I

BATTERY

CAUTION OR

WARNING

STOPI

REVERSE FORWARD FWST

SLOW

I

ENGINE ON ENGINE OFF OIL PRESSURE CLUTCH LIGHTS ON LIGHTS OFF

fi

FUEL CHOKE

R N H

MOWER HEIGHT DIFFERENTIAL PARKING BRAKE UNLOCKED

LOCK LOCKED

©

(®)|I

Ik

REVERSE NEUTRAL HIGH LOW

I

MOWER LIFT

DANGER, KEEP HANDS AND FEET AWAY

ATTACHMENT

CLUTCH ENGAGED

PARKING BRAKE

*

ATTACHMENT

CLUTCH DISENGAGED

HYDROSTATIC FREE WHEEL

(Hydro Models only)

10

Page 11

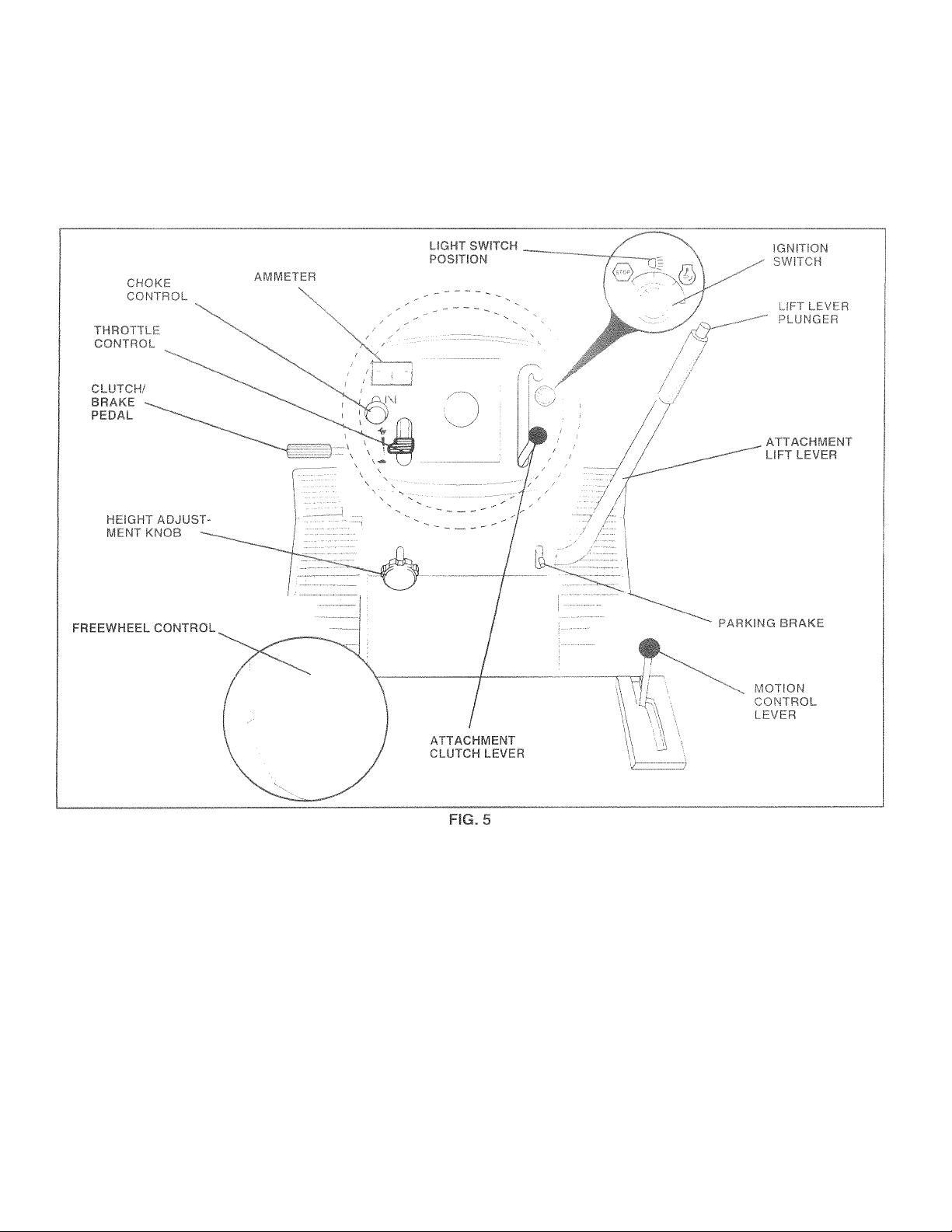

KNOW t'K

-r'l; * Aiiu ' ^ ikiif

Compare? the if fust rations with yourtractorto familiarize yourself with th

liii" nr I jal y I ! 1 ui( f r'ri

FORE OPERATINi

jtions of various control

lACTOR

jnts. Save

Our tractors conform to the safety standards of the American National Standards Institute.

ATTACHMENT CLUTCH LEVER: Used to engage the

mower blades, or other attachments mounted to your

tractor.

LIGHT SWITCH: Turns the headlights on and off.

AMMETER - Indicates charging (+) or discharging (-) of

battery.

CHOKE CONTROL - Used when starting a cold engine.

THROTTLE CONTROL - Used to control engine speed.

CLUTCH/BRAKE PEDAL - Used for declutching and

braking the tractor and starting the engine,

PARKING BRAKE - Locks clutch/brake pedal into the

brake position.

MOTION CONTROL LEVER - Selects the speed and

direction of tractor,

ATTACHMENT LIFT LEVER - Used to raise and lower the

mower deck or other attachments mounted to your tractor.

LIFT LEVER PLUNGER - Used to release attachment lift

lever when changing its position,

IGNITION SWITCH - Used for starting and stopping the

engine.

FREEWHEEL CONTROL - Disengages transmission for

pushing or slowly towing the tractor with the engine off,

HEIGHT ADJUSTMENT KNOB - Used to adjustthe mower

cutting height.

11

Page 12

ie operai

suit in Sí

îur tracte

lt6t¥ ÏTI3S

iny irdcior Cdïl resi

/e damage. Always

perform ir

'er the spe

nv adju

it in foreign objects

wear safety glass«

Affi ^ il •• i

tandard safety qla.

ye sriie

recomr

while operating

d a wide vision

_J

HOW ■ < 4- ' Hlr I'

TO lT i i '•Ohllti ^ H ■ f e ' 'fj. c|

hour cat ic'S ( (J''u* Ml. HIM i .r j (est nc e censini;

swilch \/'hi-n -fiC's iiihMTK) iv i'lPinpi hv 'tie

opcrcioiu itM' I ' . M '] ! u.i oMiiiiii ih' par'iing

brake will hui . . ' f f. 'jnu

Depia s.luu i> l l.< irn j nl' f P/M~ ’ f-i'

ana noici.

• Place parking brake lever in “ENGAGE:D”j:)Osition and

release pressure from clutch/brake pedal. Pedal should

remain in “BRAKE” position. Make sure parking brake

will hold tractor secure.

A I TAi HIUkrt r CLUTCH LEVER

FNG/,GEL POSITION

THROTTLE

CONTRO!.

CLUTCH/

BRAKE

PEDAL

“DRIVE”POSITION

.

FIG. 6

“DISENGAGED”

POSITION

PARKING

BRAKE

“ENGAGED”

POSITION

GEARSHIFT LEVER

/

\ DISENGAGED”

.'OSITION

'“'I; Always stop tractor coiri“ |

s described above, before ieavoperator's positioii; to empty

tcher, etc»

TO?- i row ■ r^Thr," of TDeeFig. 6)

Aiwa/,. , M M u ig ii i1 ili ih o ill

® Operating engine at less than full throttle reduces the

battery charging rate.

• Full throttle offers the best bagging and mower perfor

mance.

TO USE CHOKE CONTROL (See Fig. 6)

Use choke control whenever you are starting a cold engine.

Do not use to start a warm engine.

® To engage choke control, pull knob out. Slowly push

knob in to disengage.

TO MOVE r IRWaRO T f^D BACKWARD (See

Fig. 6)

The direction and speed of movement is controlled by the

motion control lever.

• Start tractor with motion control lever in neutral (N)

position.

• Release parking brake and clutch/brake pedal.

• Slowly move motion control lever to desired position.

STOPPING (See Fig. 6j

MOWER BLADES ■

• Move attachment clutch lever to “DISENGAGED” po

sition.

GROUND DRIVE -

• Depress clutch/brake pedal into full “BRAKE” position.

• Move motion control lever to neutral (N) position.

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED,

ENGINE -

• Move throttle control to slow i -^) position.

NOTE: Failure to move throttle control to slow c^)

position and allowing engine to idle before stopping may

cause engine to “backfire”

• Turn ignition key to “OFT” position and remove key.

Always remove key when leaving tractor to prevent

unauthorized use.

• Never use choke to stop engine.

NOTE: Under certain conditions when tractor is standing

idle with the engine running, hot engine exhaust gases may

cause “browning” of grass. To eliminate this possibility,

always stop engine when stopping tractor on grass areas.

TO ADJUST MOWER CUTTING HEIGHT (See

Fig. 6)

The cutting height is controlled by turning the height

adjustment knob in desired direction.

• Turn knob clockwise (“ t) to raise cutting height.

• Turn knob counterclockwise (AT) to lower cutting

height.

The cutting height range is approximately 1-1/2" to 4". The

heights are measured from the ground to the blade tip with

the engine not running. These heights are approximate

and may vary depending upon soil conditions, height of

grass and types of grass being mowed.

• The average lawn should be cut to approximately 2-

1/2 inches during the cool season and to over 3 inches

during hot months. For healthier and better looking

lawns, mow often and after moderate growth.

• For best cutting performance, grass over 6 inches m

height should be mowed twice. Make the first cut

relatively high; the second to desired height.

12

Page 13

MT

I f-ayc5fc i<P£ FSij. %

f-tj\\\ j- ,J J vh I A/'tll liruU I I,n |?,|if>'i i.M !■

• Adjust mower to desired cutting height (See ‘TO AD

JUST MOWER CUTTING HEilGUr” in the Operation

section of this manual).

® With mower in desired height of cut position, gauge

wheels shouid be assembled so they are slightly off the

ground, install gauge wheel in appropriate hole with

shoulder bolt, 3/8 washer, and 3/8-16 locknut and

tighten securely.

• Repeat for opposite side installing gauge wheel in

same adjustment hole.

GUAGE

WHEEL

MOUNTING

BRACKET"

3/8-16-^

LOCKNUT

3/8 WASHER

GAUGE WHEEL

TA

SHOULDER BOLT

/

FIG. 7

TO OPERATE MOWER (See Fig. 8)

Your tractor is equipped with an operator presence sensing

switch. Any attempt by the operator to leave the seat with

the engine running and the attachment clutch engaged will

shut off the engine.

• Select desired height of cut.

• Lower mower with attachment lift control.

• Start mower blades by engaging attachment clutch

control.

• TO STOP MOWER BLADES - disengage attachment

clutch control.

ATTACHMENl

"ENGAGED'

CLUTCH LEVE

USED

riON

"LUW ■

POSITION

ATT.ACHIV1ENT

LIFT LEVER

"HIGH"

POSITION

FIG. 8

TO orí HILLY

A

l4 '

Ink

Avoid

If slowing i‘ nm r r / h J till k- Í

G not;

n -lc»Mr '

/e acros

eirawwocL

I' ’ I Í j ' Í

slowei oca i ell

• If stopping IS absolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking

brake.

• Move motion control lever to neutral (N) position.

IMPORTANT; THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

• To restart movement, slowly release parking brake and

clutch/brake pedal.

• Slowly move motion control lever to slowest setting.

• Make all turns slowly.

I ir. ft'-U di

; greater 1

ive up ore

than IS'"a

■s any sic

cnfopri Kr "Jr^rci etwrti

mpptd'J uL

iangtng s|

i( d )i 1

nd d( not

' down

CAUTION: Do not operate the mower

without either the entire grass catcher,

on mowers so equipped, or the dis

charge guard in place.

13

Page 14

то TRANSPORT (See Figs. 9 and 5)

When pushing or towing your tractor, be sure to disengage

transmission by placing freewheel control in freewheeling

position. Free wheel control is located at the rear drawbar

nf traritii-

• Raise attachment lift to highest position with attach

ment lift control,

' Pull lipovdii ( I cm hoi I mh о i , no ■ * in mo uo i bv

inbeiiiiig ii c.iof-f |j I I I If, о m' ti fo u тлоп'

roa,

I'C uui I |Чт>,тго,/| , in ro iMoio ,haii ICO i i'/,P4

" 1 о reel o. 1 i mno ^, n lO/er* < Lcn/e r row dutc

mil о ,.i I' R "p

voui ii ■( : I ii I

and i i I ( 111 ' ' I I I

hood lo I . t ,i (П I ( ' ' ii

damaeje when transporting

liter, be sure hood is dosed

o oroj u t( meai'S of l,/>nn

P... i

IMPORTANT: WHE

BELOW 32 F(0”C),l

GASOLINE TO HEL

STARTING.

WARNING: Experi

fuels (called gasohe

'll 111 > ^ 1 im III'

acids durino sioragi

S m , ' m

p,i,0' I I

age of 30 days or l(

er fiir'e f n • II

eti'p / 11

[iCi I h I I I

t.ainurc-. I I

On I, I ill (

CAUTION: Fill to bottom of gas tank

; :t W m , ( .f [(/. , ii Wipe c If any

.1 i' 'I' <1 li'- Í c it , tere, rpill Oi

A

'■Cl- 1 le 'if r ‘.fi I ¡i' П "lame.

OPERATING

FRESH, CL

MSURE GO(

torage.

id be em;

in the c|£IS tank, start the

a lines ar

>on, See

Ì, N S' V er use engine or

ne luel ta:Пк or clerrnanent

EMPERATURES

VINTER GRADE

OLD WEATHER

alcohol blended

r m.ethanol) can

and formation of

, e Fwl

i Oiigitie

hi

afore stor-

j (

mretor are

je Instruc-

Storac

FIG. 9

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. 16)

• The engine in yourtractor has been shipped, from the

factory,' already filled with summer weight oil.

• Check engine oil with tractor on level ground.

• Unthread and remove oil fill cap/dipstick; wipe oil off.

Reinsert the dipstick into the tube and rest oil fill cap on

the tube. Do not thread the cap onto the tube. Remove

and read oil level. If necessary, add oil until “FULL”

mark on dipstick is reached. Do not overfill.

• For cold weather operation you should change oil for

easier starting (See “OIL VISCOSITY CHART” in the

Customer Responsibilities section of this manual).

• To change engine oii, see the Customer Responsibili

ties section in this manual.

ADD GASOLINE

• Fill fuel tank. Use fresh, clean, regular unleaded

gasoline with a minimum of 87 octane. (Use of leaded

gasoline will increase carbon and lead oxide deposits

and reduce valve life). Do not mix oil

Purchase fuel in quantities that can be used within 30

days to assure fuel freshness.

with gasoline.

TU . ] I Mí {ML

When I III inr> I 1 m

has I un on I he ' I

fuel froi n [' ' I I 1 to II I t

• He sill*., iccotteci c

/С

Pw Fig. 6)

first time or if the engine

a cranking time to move

gine.

... .in the transmission en

gaged position.

• Sit on seat in operating position, depress clutch/brake

pedal and set parking brake.

• Place motion control lever in neutral (N) position.

• Move attachment dutch to “DISENGAGED” position.

• Move throttle control to fast («%) position

• Pull choke controi out for a cold engine start attempt.

For a warm engine start attempt the choke control may

not be needed.

Note: EBefore starting, read the warm and cold starting

procedures below,

» Insert key into ignition and turn key clockv/ise to “START”

position and release key as soon as engine starts. Do

run starter continuously for more than fifteen sec

not

onds per minute. If the engine does not start after

several attempts, push choke control in, wait a few

minutes and try again. If engine still does not start, pull

the choke control out and retry.

WARM WEATHER STARTING (50° F and above)

• When engine starts, slowly push choke control in until

the engine begins to run smoothly. If the engine starts

to run roughly, puli the choke control out slightly for a

few seconds and then continue to push the control in

slowly,

• The attachments and ground drive can now be used. If

the engine does not accept the load, restart the engine

and allow it to warm up for one minute using the choke

as described above,

COLD WEATHER STARTING (50° F and below)

• When engine starts, slowly push choke control in until

the engine begins to run smoothly. Continue to push

the choke control in small steps allowing the engine to

accept small changes in speed and load, until the

choke control is fully in. If the engine starts to run

roughly, pull the choke control out slightly for a few

seconds and then continue to push the control in

slowly. This may require an engine warm-up period

from several seconds to several minutes, depending

14

on the temperature.

Page 15

RANSMISSION WARM UP

the unit in cold weatt

Jon should

r warmed up as follow

le tractor is on level gr 'ound.

motion control lever ir

ie parking brake and le

• Allow one minute for transmission to warm up.

This can be done during the engine warm up

period.

• The attachments can be used during the engine warm

up period after the transmission has been warmed up

and may require the choke control be pulled out sligntly,

NOTE: If at a high altitude (above 3000 feet) or in coid

temperatures (below 32 F) the carburetor fuel mixture may

need to be adjusted for best engine performance. See "TO

ADJUST CAREJURETOR” in the Service and Adjustments

1er, the transmis-

i neutral.

ihr 1 Íilr li/oi' ke

section of this manual.

PURGE TRANSMISSION

CAUTION. Never engage or dicengage

trenwheei ¡ever while the engine is run

A

To ensure proper operation and performance, it is recom

mended that the transmission be purged before operating

tractor for the first time. This procedure will remove any

trapped air inside the transmission which may have devel

oped during shipping of your tractor.

IMPORTANT: SHOULD YOUR TRANSMISSION REQUIRE

REMOVAL FOR SERVICE OR REPLACEMENT, IT

SHOULD BE PURGED AFTER R E i N ST ALL ATI ON

BEFORE OPERATING THE TRACTOR.

• Place tractor safely on level surface with engine off and

parking brake set,

• Disengage transmission by placing freewheel control

in freewheeiing position (See 'Tb TRANSPORT” in

this section of manual).

• Sitting in the tractor seat, start engine. Afterthe engine

is running, move throttle control to slow {•0A) position.

With motion control lever in neutral (N) position, slowly

disengage clutch/brake pedal.

• Move motion control lever to full forward position and

hold for five (5) seconds. Move lever to full reverse

position and hold for five (5) seconds. Repeat this

procedure three (3) times.

NOTE: During this procedure there will be no movement of

drive wheels. The airis being removed from hydraulic drive

system.

• Move motion control ieverto neutral (N) position. Shut

off engine and set parking brake.

• Engage transmission by placing freewheel control in

driving position (See 'TO TRANSPORT” in this section

of manual),

• Sitting in the tractor seat, start engine. Afterthe engine

is running, move throttle control to half (1/2) speed.

With motion control lever in neutral (N) position, slowly

disengage clutch/brake pedal.

ning.

Slowly move motion c(

tractor moveos apiproxirri

motion control lever tc ) reverse pc

tractor moves approxir

motion control Ieverto it le neutral (N ) position. Repeat

this procedure with the ITiOtlOn СОГТtrol lever three (3)

Your tractor IS now purged and now ready tor normal

operation.

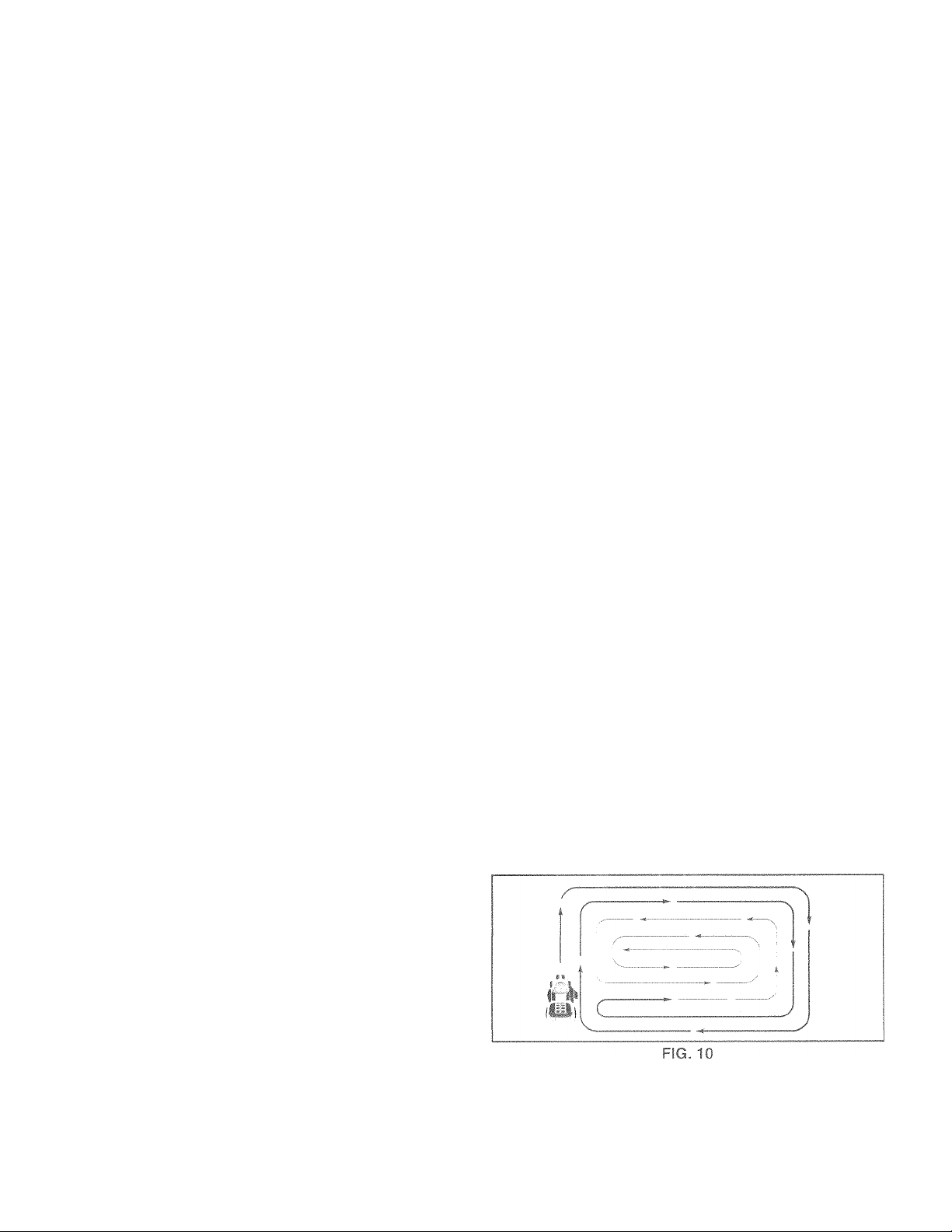

WOVr:'-

peiii

the ;

Ih

m i

t

tl I 11 i I • r>n cut. Have the cut area, to the right of the

ti, I 01 I IS Will result in a more even distribution of

clii 1 I 'I "ud more uniform cutting.

\ ig large areas, start by turning to the right

S( J ' ippings wiii discharge away from shrubs,

fcuccs oiiveways, etc. After one or two rounds, mow

in I he opposite direction making left hand turns until

finished (t,ee Fig. 10).

If grass IS extrerneiy tall, it should be mowed twice to

reduce lead and possible fire hazard from dried clip

pings. Make first cut reiaiively high; the second to the

desired neight.

Do no» mow grass when it is wet. Wet grass will plug

mowca and leave undesirable clumps. Allow grass to

dry before mowing.

Always operate engine at full throttle when mowing to

assure better mowing performance and proper dis

charge of material. Regulate ground speed by select

DC

to tractor,

V -lu /'djustments section of this manual.

d side of mower should be used for trim-

t clippings are discharged onto the area

Dntro! iever

ately five (5'

nateiy five (

9 used when the mower housing is

dCDeriv leveled for best mowinq

"O LEVEL. MOWER HOUSING” in

kv/v,,io r.ii.-i ih-

1 feet, slowly move

S'Sition. After the

me, n-V)t 1 mr

ing a low enough gear to give the mower cutting

performance as weli as the quality of cut desired.

When operating attachments, select a ground speed

that will suit the terrain and give best performance of

the attachment being used.

15

Page 16

CUSTOMER RESPONSIBILITSES

3 - It equipped with

4 - Replace blades

y 50 hours,

g in sandy soil

GENERAL HLCi.mm

The warranty on this tractor does not cover items that have

been subjected to operator abuse or neqliqr nee. To

receive full value from the warranty, operator,, ., .aintain

tractor as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your tractor.

All adjustments in the Service and Adjustments section of

this manual should be checked at least once each season.

• Once a year you should replace the spark plug, clean

or replace air filter, and check blades and belts for

wear. A new spark plug and clean air filter assure

proper air-fuel mixture and help your engine run better

and last longer.

BEFORE LAi fd t toL

• Check engine oil level.

• Check brake operation.

• Check tire pressure.

• Check for loose fasteners.

-lbs. m£ixirnum.

nON CHART

(DsPINDLE ZERK—

(D FRONT WHEEL

BEARING ZERK

©ATTACHMENT

CLUTCH

PIVOT(S) C

©SAE 30 OR 10W30 MOTOR OIL

©GENERAL PURPOSE GREASE

©REFER TO CUSTOMER RESPONSIBILITIES “ENGINE” SECTION

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS. VISCOUS LUBRI

CANTS WILL ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRICATING BEARINGS.

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW

DERED GRAPHITE TYPE LUBRICANT SPARINGLY.

-----

------) ____________

p—SPINDLE ZERK(2)

FRONT WHEEL©

BEARING ZERK

GEARSHIFT ©

PIVOTS

16

ENGINE @

IF YOU

Page 17

OJ:

I I llfl

U

11

ITiCC

■RACTOF

Iways obsen. ules when performing any mair

BRAKE OPERATION

It tractor requires mor

at high speed in hiahe:

(See “TO ADJUST E

ments section of this i

® Maintain omoer air pressure in all tires (See "PROD^^

UCT SPECIFiCATIONS” on page 3 of this manual),

» Keep tires tree of gasoline, oil, or insect control chemi

cals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

NOTE: To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion.

BLADE CARE

For best results mower blades must be kept sharp. Re

place bent or damaged blades.

BLADE CARE

For best results mower blades must be kept sharp. Re

place bent or damaged blades,

m &u iO; icei iiuoui m liSianor

jear, tnen brake must

>^1- In heivKi i|ii Adju^

tnuau.

J|i 'seed

TO SHARPEN BLADE (See Fig. 12)

Care should be taken to keep: the blade balanced. An

.1(1, Ik Ih n i Wf- ' Pt null ai, - (Pii

tual dam.a ye to mower and engine.

• The blade can be sharpened with

wheel. Do not attempt to sharper

• To check blade balance, you will need a 5./8" diameter

steel boil. pin. ora cone balancer. iTA'ien using a cone

balancer, follow the mstruciions supplied with bal

anced,

• n ^ 'll , n -1 I >1 I -el bolt

or pm and hold trie bolt or pm oamllel with the ground.

If blade IS balanced, i! should remain in a horizontal

; '{,11,1,- I i[,( I [ '( 11 I ' ufc D, iward,

1 I I- I I / m I I ' n m IIK . u lb I im • ed

NOTE: Do not use a nail for balancing blade. The lobes of

the center hole may appear to be centered, but are not.

CENTER HOLE

5./8" BOLT

OR PIN -—

"Oil' I inm, ig

on the mower.

BLADE

BLADE REMOVAL (See Fig. 11)

.• Raise mower to highest position to allow access to

blades.

• Remove hex bolt, lock washer and fiat washer securing

blade.

• Install new or resharpened blade with trailing edge up

towards deck as shown,

• Reassemble hex bolt, lock washer and flat washer in

exact order as shown.

• Tighten bolt securely (30-35 Ft. Lbs. torque).

IMPORTANT: BLADE BOLT ISGRADE 8 HEATTREATED,

NOTE: We do not recommend sharpening blade - but if you

do, be sure the blade is balanced.

.it:; MANDREL

' ASSEMBLY

BLADE

á

TRAILING EDGE

HEX BOLT

(GRADE 8)*

FIG. 12

BATTERY

Your tractor has a battery charging system which is suffi

cient for normal use. Flowever, periodic charging of the

battery with an automotive charger will extend its life.

• Keep battery and terminals clean,

• Keep battery bolts tight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for 1 hour.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to “leak” power.

• Remove terminal guard.

• Disconnect BLACK battery cable first then RED bat

tery cable and remove battery from tractor.

• Rinse the battery with plain water and dry,

• Clean terminals and battery cable ends with wire brush

until bright.

• Coat terminals with grease or petroleum jelly.

• Reinstall battery (See “CONNECT BATTERY” in the

Assembly section of this manual).

*A GRADE 8 HEAT TREATED BOLT CAN BE

IDENTIFIED BY SIX LINES ON THE BOLT HEAD.

FIG. 11

17

Page 18

V-BELTS

Check V^belts for deterioration and wear after 100 hours of

operation and replace if necessary,. The belts are not

adjustabiw Ffeplace belts if they begin to slip from ¥,'ear.

' iNSAXLE COOLING

The fan and cooling fins of transmission should be kept

clean to assure proper cooling.

Do not attempt to clean fan or transmission while engine is

running or while the transmission is hot,

• Inspect cooling tan to be sure fan blades are intact and

clean.

• Inspect cooling fins for dirt, grass clippings and other

materials. To prevent damage to seals, do not use

compressed air or high pressure sprayer to clean

cooling fins.

TRANSAXLE PUMP FLUID

The transaxle was sealed at the factory and fluid maintenance is not required for the life of the transaxle. Should the

transaxle ever leak or require servicing, contact your near

est authorized service center/department.

ENGINE

TC CHANGE ENGINE OIL (See Fig. 13)

Determine temperature range expected before oil change.

All oil must meet API service classification SF, SG or SH.

Be sure tractor is (3n levei surface.

Oil will drain more freely when warm.

careful not to allow dirt

ging oil.

/. replace oil drain plug

' N I I 1 ' M [i|i fli 1 (X ‘ul Pour

H ly 'll' 1 I 1 iioxin -do ( ip city see

Ml (' r L M' 1 >N k )| I I ■ 01 pm of this

manual.

Use gauge on oil fill cap/dipstick tor checkin i wel. Be

sure dipstick cap is tightened secuiely toi accurate

reading. Keep oil at “FULL” line on dipstid

LUBRICATION

Only use high quality detergent oil rated with API service

classification SF, SG or SH. Select the oil’s SAE viscosity

grade according to your expected operating temperature.

SAE VISCOSITY GRADES

TLV.'ERATURE RAK^

■ 20

NOTE: Although multi-viscosity oils (5W30, 10W30 etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F. Check your engine oil level more frequently to avoid

possible engine damage from running low on oil.

Change the oil after the first two hours of operation and

every 50 hours thereafter or at least once a year if the

tractor is not used for 50 hours in one year.

Check the crankcase oil level before starting the engine

and after each eight (8) hours of operation. Tighten oil fill

cap/dipstick securely each time you check the oil level.

TED ! ' T-IF. M[ • r t IL C- ' NOE

18

Page 19

CUSTOMEF

air

,'t .1 i-MOIti- ' I n M f I'l M ( .h M III- iilM - ir .1,1!

f ' t U ,, . 1 f if - . . I ( I / If . ('f-i-

fuh I r V I , 1-1 > rf I ! I ! . itii > 1^*0

hi)Ui; fil 11| f If , c I, ( ■■ r v' I / ‘ lb .1 Vi/liif I t '/> . ( I .1 ; iir* i.

Service air cleaner more often under dusty conditions.

» Remove knob(s) and cover.

TO SERVICE PRE^CLEANER

Slide foam pre-cleaner off cartridge.

Wash it in liquid detergent and water.

Squeeze it dry in a dean cloth.

Saturate it in engine oil. Wrap it in dean, absorbent

cloth and squeeze to remove excess oil.

If very dirty or damaged, replace pre-cleaner.

Reinstall pre-cleaner over cartridge.

c ; t' iq

CLEAN AIR SCREEN (See Fiq. 141

Air screen must be

engine damage fror

or compressed air t

fiht I ,

ENGir

[n .Vi

na r

Mi"

and A

Reinstall cover and secure with knob(s),

TO SERVICE CARTRIDGE

Remove wing nuts and cartridge plate.

Carefully remove cartridge to prevent debris from

entering carburetor.

Clean cartridge by tapping gently on flat surface. If very

dirty or damaged, replace cartridge.

Reinstall cartridge plate, wing nuts, precleaner, cover

and secure with knob(s).

IMPORTANT: PETROLEUM SOLVENTS. SUCH AS

KEROSENE. ARE NOT TO BE USED TO CLEAN THE

CARTRIDGE. THEY MAY CAUSE DETERIORATION OF

THE CARTRIDGE. DO NOT OIL CARTRIDGE. DO NOT

USE PRESSURIZED AIR TO CLEAN OR DRY

CARTRIDGE.

I free of dirt and chaff to prevent

I I ^ i ' / 1 . a /vh 1 mdi

riove dirt and stubborn dried qum

)OLING FINS (S

Just, din or oil fror'Tl

. damage from overn

ed. Remove side pa.

t)D AND GRILL ASo

ns section of this nn

to

’ " overs

a H i e ‘TO

I li I otvice

19

Page 20

CUSTC

n r

....

¡Oil

ENGINE OIL FILTER (See Fiq. 16)

Replace the engine oil filter i

change if the tractor is usee

year.

® 'o n|f [S ( t i 'ill III 1.. .Miii'r-i^lockwise. Use a

^ 1 1 I ' , I. II i I I I'

* 'g r>i ' Uri 1 I ( 1 I yy i iDiie o,| .0 rubber gasket

I ) I I I ( ;' 1 I I 1 ' ! I 1

» In I >|i nil' ii i‘ I I I iJM inmir-n clockwise until

I'll.h r 1 t ■ 1-K I ,1'i, > r Uiii.ee, then tighten

fll. I ,rl 1 1 I

• filli liif.'i- /illi I 'iiiiw.pf fiCHANGE EENtii.t ',¡1 I I - HUw I "RFC IFICATIONS” on

pp ' . 1 ,11 I I

® Start engine and check for oil leaks. Correct any leaks

before placing engine into full operation.

' - ‘ or f ■ ^ o

)re than 100 hours in one

il). Forapproxi-

MUFFLER

Inspect and replace corroded muffler and spark arrester (if

equipped) as it could create a fire hazard and/or damage,

IN-LINE FUEL FILTER (See Fiq.

The fue

filter be

vvitn engine coon remove niter and plug fuel line

sections.

Place new fuel filter in position in fuel line with arrow

pointing towards carburetor.

Be sure there are no fuel line leaks and clamps are

properly positioned.

Immediately wipe up any spilled gasoline.

uctinq fuel flow 1

on. If fuel

jrburetor,

CLEANING

• Clean engine, battery, seat, finish, etc. of all foreign

matter.

• Keep finished surfaces and wheels free of all gasoline,

oil, etc.

• Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to clean your

tractor uniess the eiectricai system, muffler, air filter and

carburetor are covered to keep water out. Water in engine

can result in a shortened engine life.

SPARk P’ Unc

Replace spark plugs at the beginning of each mowing

season or after every 100 hours of operation, whichever

occurs first. Spark plug type and gap setting are shown in

“PRODUCT SPECIFICATIONS" on page 2 of this manual.

20

Page 21

TO BEHOVE MOWf- i. ee Fig. 18)

• Place alirchment clutch in "‘DISENGAGED” position.

• Turn height adjustment knob to lowest setting.

» Lower mower to its lowest position.

• Disconnect clutch rod from clutch lever by removing

retainer spring.

• Remove retainer spring holding anti-swaybar to chas

sis bracket and disengage anti-swaybar from bracket.

® Remove retainer springs from suspension arms at

deck and disengage arms from deck.

• Raise attachment lift to its highest position.

• Remove two retainer springs from each front link and

remove links.

CLUTCH SPRING

punev

trvvard and reme Dell from engine

• Slide :

¡MeOI , /

Ml v/r^

REMrWi

r out from under right side of tractor.

F an attachment other than the

iS TO BE MOUNTED ON THE TRACTOR,

^RONT LINKS,

TO iMStTL^ MOWER

Follow procedure described in ‘‘INSTALL MOWER AND

DRIVE BELT” in the Assembly section of this manual.

RETAINER

ENGINE

PULLEY

FRONT

SUSPENSION

BRACKET

FIG. 18

21

Page 22

3ERVK

/iCMTQ

IV!

LEVEL MOWER HOUSING

Adjust the mower wniie tractor is parkea or

driveway. Make sure tires are properly inflate

“PRODUCT SPECIFICATIONS” on page 2 of this manual),

li tires ^iieuvei V Jii'i-i o'ra o ^ lU a |i n f i lopcily dugj t

your mower.

SIDE-TO-SIDE ADJUSTMENT (See Figs. 19 and 20)

• Raise mower to its highest position.

• At the midpoint of both sides of mower, measure height

from bottom edge of mower to ground. Distance “A” on

both sides of mower shouid be the same or within 1/4"

of each other.

• If adjustmient is necessary, make adjustment on one

side of mower only.

• To raise one side of mower, tighten lift link a.djustment

nut on that side.

• To lower one side of mower, loosen lift link adjustment

nut on that side.

NOTE: Three full turns of adjustment nut will change

mower height about 1/8".

• Recheck measurements after adjusting.

{bee

approxirric -3/8"

not equal

other link.

'/n- ' k t - ' - ' , , ■ lo vet at front than

' - t Ji : Í . to,¡'VI on both front

length,.

or infiwp

adjust one lin

n nut “E” on

k to san

both fro

Hrv

To raise front ot mower, loosen nut “F” from trunnion on

both front links. Tighten nut “E" on both front links an

equal numiber of turns.

When distance "D" is TC" to 1/2" lower at front than

rear, tighten nut against trunnion on both front links.

Recheck side-to-side adiustment.

MANDREL

"b" '‘D"|

FIG. 21

BOTH FRONT LINKS MUST BE EQUAL IN LENGTH

I:

FIG. 20

FRONT-TO-BACK ADJUSTMENT (See Figs. 21 and 22)

IMPORTANT: DECK MUST BE LEVEL SIDE-TC3-SIDE. IF

THE FOLLOWING FRONT-TO-BACK ADJUSTMENT IS

NECESSARY, BE SURE TO ADJUST BOTH FRONT LINKS

EQUALLY SO

SIDE.

MOWER WILL STAY LEVEL SIDE-TO-

To obtain the best cutting results, the mower housing

should be adjusted so that the front is approximately 1 /8" to

1/2" lower than the rear when the mower is in its highest

position.

Check adjustment on right side of tractor. Measure dis

tance “D” directly in front and behind the mandrel at bottom

edge of mower housing as shown.

» Before making any necessary adjustments, check that

both front links are equal in length. Both links should be

22

/

j

.....

.

NUT "E"

NUT “F

FRONT LINKS TRUNNION

FIG. 22

TO REPLACb MOWER DRIVE BELT

MOWER DRIVE BELT REMOVAL (See Fig. 23) -

• Park tractor on a level surface. Engage parking brake.

Disengage attachment clutch control,

• Remove four screws from L.H, mandrel cover and

remove cover,

• Roll belt over the top of L.H. mandrel pulley.

• Remove belt from engine pulley.

• Remove belt from idler pulleys.

• Remove any dirt or grass clippings which may have

accumulated around mandrels and entire upper deck

surface.

Page 23

» » i

1 « 4 i

!■% Ill

rs

.ee

rotate

MOWER DHE

k6€3De

Idle

INÌ

WLATION

v1ake sure

)wn.

Fig, 23) -

; in both belt

Install new belt onto engine pulley.

Hoii Pelt into upper groove ot l,h. manarei pulley.

Carefully check belt routing making sure belt Is in the

grooves correctly and inside belt keepers.

Ih st

Ihcy

• Reinst.

AND C

all mower to t

)RIVE BELT”

rnanua

® Beasse

MOW E

L.H. MANDREL DRtVEt BELT

amble mower

tR DRIVE BEL

MOWER

/Si “[. -M,".

ractor

in the

Assembly sec

drive belt (See “TO

lis section of tl"

ivf ^ L..Ì 1 L.

SCREW

FIG. 24

1 Mf'WFi'

lion

jI

iIms

REPLACE

us manual).

SEECONDARY

IDLER ARM

SPRING

.H.

ANDREL

OVER

FIG. 23

TO REPLACE MOWER BLADE DRiVE BELT

(See Fig. 24)

Park the tractor on level surface. Engage parking brake.

• Remove mowerdrive belt (See “TO REPLACE MOWER

DRIVE BELT" in this section of this manual).

• Remove mower (See “TO REMOVE MOWER” in this

section of this manual).

• Remove four screws from R.H. mandrel cover and

remove cover.

• Carefully roll belt off R.H. mandrel pulley.

• Remove belt from center mandrel pulley, idler pulley,

and L.H. mandrel pulley.

• Remove any dirt or grass which may have accumu

lated around mandrels and entire upper deck surface.

• Check secondary idler arm and idler to see that they

rotate freely.

• Be sure spring is hooked in secondary idler arm and

sway-bar bracket.

• Install new belt in lower groove of L.H. mandrel pulley,

idler pulley, and center mandrel pulley as shown.

• Roll belt over R.H, mandrel pulley. Make sure belt is in

all grooves properly.

• Reconnect secondary clutch rod to pivot rod with

retainer spring.

• Reinstall R.H. mandrel cover.

TO ADJUST BRAKE (See Fig. 25)

Your tractor is equipped with an adjustable brake system

which is mounted on the side of the transaxle.

If tractor requires more than six (6) feet stopping distance

at high speed in highest gear, then braKe must be adjusted.

• Depress clutch/brake pedal and engage parking brake.

» Measure distance between brake operating arm and

nut "A" on brake rod.

• If distance is other than 1 -3/4“. loosen jam nut and turn

nut "A" until distance becomes 1-3/4". Retighten jam

nut against nut “A".

• Road test tractorfor proper stopping distance as stated

above. Readjust if necessary, if stopping distance is

still greater than six (6) feet in highest gear, further

maintenance is necessary. Contact your nearest au

thorized service center/department.

WITH PARKING BRAKE “ENGAGED"

/

NUT “A”

-JAM NUT

\

OPERATING

ARM

DO NOT TOUCH THIS NUT, IF FURTHER

BRAKE ADJUSTMENT IS NECESSARY

CONTACT YOUR NEAREST AUTHORIZED

SERVICE CENTER/DEPARTMENT

FIG. 25

23

Page 24

m mi

KIT

!■. i ‘ ^ fiK rf'! c.Ei T

(Sse Fig. 26)

P li i . ' ( '. 'I ' ( j|! > II , ' ' , I - I'l . b be

For assistance, there is a belt installation guide decal on

bottom side of left footrest,

- I in 0 r - ' ' m REMOVE MOWER” in this

I n '( r,/r belt 'Or.

• i clutching idler.

e tarefully remove

pulley and over

• Ttove downward

• ocedure.

IMPORTANT: MAKE SURE UPPER BELT KEEPER IS

POSITIONED PROPERLY BETWEEN LOCATOR TABS,

TO ADJUST MOTION CONTROL LEVER (See

Fig. 27)

The motion control lever has been preset at the factory and

adjustment should not be necessary.

If for any reason the motion control lever will not hold its

position while at a selected speed, it may be adjusted at the

friction pack located on the right side of transmission.

• Park tractor on level surface. Stop tractor by turning

ignition key to “OFF” position, and engage parking

brake.

• Adjust motion control lever by tightening adjustment

locknut one half (1/2) turn.

NOTE: If for any reason the effort to move the motion

control lever becomes too excessive, reverse the above

adjustment procedure by loosening locknut 1 /4 to 1 /2 turn.

Road test tractor after adjustment and repeat procedure if

necessary.

1 MT11 i .'J i , ;? m . y M L ’M W f f h't

Should your transmission

replacement, it should be i

before ooeratina the fracto

; If

ÌP4 ill If

TO ADJUS'

If steering whr

ÌTE

eros

when wheels c

ing wheel and

ire removal tor service or

ed after reinstallation and

M I ,W I f’M Wl‘/l t,

dC

ADJUSTMENT

LOCKNUT

hfu. 2i

¡m(-.Wììti'L ALIGNMENT

I i.if ii' is I I iddi (left to right)

I ti ' ^ t' I vdid, remove steer-

le Assemibly

section of this rnariLi

FRONT ‘vvHEEL TOEJN/CArv1BER

The front wheel toe-in and camber are not adjustable on

your tractor. If damage has occurred to affect the front

wheel toe-in or camber, contact your nearest authorized

service center/department.

TO REMOVE WHEEL FOR REPAIRS (See Fig. 28)

• Block up axle securely.

• Remove axle cover, refaming ring and washers to allow

wheel removal (rear wheel contains a square key - Do

not lose).

• Repair tire and reassemble.

• On rear wheels only: align grooves in rear wheel hub

and axle. Insert square key.

• Replace washers and snap retaining ring securely in

axle groove.

• Replace axle cover.

NOTE: To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion.

WASHERS

RETAINING

RING

AXLE COVER

SQUARE KEY

(REAR WHEEL ONLY)

24

FIG. 28

Page 25

‘ I 5 J

MENTS

TO STA

iSpe Fit

SIGINE WITH A WEAK BATTERY

(1 , » R ,

away from bai

-tion I

und batteri

If /uur b I In >c w I

ti ' \i g- ( I I 'I 't' '

ii (Ik Pill pp ¡1 ' hould be

' ' pf 1')i M i( iqenr '

■-itjfi'iI I ' J ' II (

iMPPHI r . M

)R kS Ei

\'U 1 !H 0 _

N FBI'' I , P I I '

I BiOUi p m ' -1 11

LA rTLh f I u ) an f W I 11 cl, L,, 1 !IcL v„,

DUIPPED T/ITH A 12

D S Y S1 '1 1 1 n CHIP

ii . '

VOLT NEGATIVE

1 r ” 'CrOR

TO ATTACH JUMPER CABLES ^

• Connect each end of the RED cable to the POSITIVE

(+) terminal of each battery, taking care not to short

against chassis,

• Connect one end of o the NEGA

TIVE (R terminal of fully cfi mgr: bm ly.

• Connect the other end oi ihe ^ J A cable to good

CHASSIvS GROUND awaviioi due' nikand battery.

TO REMOVE CABLES, REVERSE ORDER -

« BLACK cable first from chassis and then from the fully

charged battery.

• RED cable last from both batteries.

INTERLOCKS AND RELAYS

Loose or dam;

poorly, stop ru

ta ir F=

Tc f i. - I /"

Ri-iJc I f

fu ,o I

df I H I'lp .

(7-c ^ . ■

» Raise

® Unsna e conne

To replace, reverse above procedure.

. 30)

c neadhght wir

oiana in ironionracior, wrasp nooa aisiaes, tnttowara

engine and lift off of tractor.

] Wiring may cause your tractor to rt

g, or prevent it from starting.

section

Cl ICE

lineal wiring diagram in the

ns manual.

< B >' • od' 1 ' f . '¡f ! O.bEMBlO'

HOOD

HEADLIGHT

WIRE

CONNECTOR

se. The

“POSITIVE” (+ •NEGATIVE” H

FIG. 29

TO REPLACE HEADLIGHT BULB

• Raise hood.

• Pull bulb holder out of the hole in the backside of the

grill.

• Replace bulb in holder and push bulb holder securely

back into the hole in the backside of the grill.

• Close hood. 25

'7. 'c

\

FIG. 30

ENGINE

TO ADJUST THROTTLE CONTROL CABLE

(See Fig. 31)

The throttle control has been preset at the factory and

adjustment should not be necessary. Check adjustment as

described below before loosening cable, if adjustment is

necessary, proceed as follows:

• With engine not running, move throttle control lever to

fast (^) position.

• Check that swivel is against side of quarter circle. If it

is not, loosen cable clamp screw and pull cable back

until swivel is against quarter circle. Tighten cable

clamp screw securely.

Page 26

Hi ti

—

TC

Th

adj

dei

1 lOi

(/■:>

9

)ADJUSTC HOKE COfi

3 choke contre3i has been p reset at tt

ustrneni should not be necess

pcnbed below t

refore loosenir g cable, i adju

pessary, procef

With engine n

on dad (jw 1'

Re nose m

CudtoM ( d . •

Choi . M 1

ck rn 1 "Cl '/

Dt running, rno

t to full choke

eaner cover, fi

retor choke (s

e ' d' ij

rponsibilities s

be closed. If

and move choke cable until

cuinMlet"' !' ' ! ' ii, 4( n

cureiy.

«

Reassemble air cleaner.

CLAiVIP SCREW —

QUARTER

CIRCLE \

FIG. 31

CHOKE CLOSED

PI ' " 't'1

h , r >- h

CASING

CLAMP

SCREW

.

.........................'

- M

VICE

^ 1 W

———

t HOl '

ary. Check adjus

5b0 1

6 fac

”ig. 32)

tory and

trnent as

stment is

/e choke c

ontrom.(located

( \i) positic

ter and ca

1ndat i\ ' e lu

ee "AIR F ILTEt1" in the

iretion of this rnai lUcJ 1,

it iS not. loosen casing

choke is

casing da

' m

-——■ SWIVEL

CHOKE

LEVER

...........

^ ^ O

\r- 'J\f < C

! •

.........

V—■ i

.DJU

ac

® With G

H"

( II ringer

i-1/4 to 1

wise)

FINAL se:

® Start e

final ac

, Win

th rotiif:

u a

• While

screw.

engintj

w )

midwa

,aic* ack i I H 'x

i tPlVi ( . -le. ' “ 11 I nk /r I

ACCELEH/,i I 'll ll_ .

fd( ' )! 1 .

position. If er igine her

screw out (C(

ml.'. 1 i 1

orale 1 Ì 1

High speed stop is factory adjusted. Do not adjust -

damage may result.

IMPORTANT: NEVER TAMPER WITH THE ENGINE

GOVERNOR, WHICH IS FACTORY SET FOR PROPER

ENGINE SPEED, OVERSPEEDING THE ENGINE ABOVE

THE FACTORY HIGH SPEED SETTING CAN BE

DANGEROUS. IF YOU THINKTHE ENGINE-GOVERNED

HIGH SPEED NEEDS ADJUSTING, CONTACT YOUR

NEAREST AUTHORIZED SERVICE CENTER/

DEPARTMENT. WHICH HAS PROPER EQUIPMENT AND

EXPERIENCE TO MAKE ANY NECESSARY

ADJUSTMENTS.

f turn idle mixture screw in (clockwise)

r tiaht and then turn out fcounterdock-

' minutes. Make

bnri phi'll/ fTinfion

n slow i*^) Dosition, hold

speed screw and adjust idle

00 to 1400 RPM,

e Y>ver against idle speed

' ' ■* I mu -1 'i| 111

then turn out (counterdock-

xjqh

3 hold i

die speed sere"-'

' lew lO cTsain 900 to 1200

conirol b

' i horn l> w i '5^) 0 fa .1 (%)

! ! T'.i turn idle mixture

junterciG rn. Repeat test

0 adjust.

itil engine accel-

1 V .

FiG

TO ADJliST C./inBURL I OP. .Bfce Figs. 33 &

34)

The carburetor has been preset at the factory and adjust

ment should not be necessary. However, minor adjust

ment may be required to compensate for differences mfuel,

temperature, altitude or load. If the carburetor does need

adjustment, proceed as follows;

In general, turning the mixture screw in (dockyrise) de

creases the supply of fuel to the engine giving a leanertuel/

air mixture. Turning the mixture screw out (counterclock

wise) increases the supply of tue! to the engine giving a

richer fuel/air mixture.

IMPORTANT: DAMAGEt TQ THE NEEDLES AND THE

SEATS IN CARBURETOR MAY RESULT IF SCREW IS

TURNED IN TOO TIGHT.

PRELIMINARY SETTING -

• Be sure you have a dean air filter, and the throttle

control cable and choke are adjusted properly (see

above).

FIG. 34

26

Page 27

Immediately prepare your tractor for storage at the end of

the season or if the tractor will not be used for 30 days or

rnc

........

__

i re,

I ' >, ( I‘ . i ‘ ,1 , ts i “ i, •

gasoline in the tank inside a building

where fumes may reach an open flame

or spark. Allow the engine to cool

storing in any enclosure.

before

TP4CP A.

Bern ¡VP nio ' I Imrn uactor for winter storage. When

mo'/', f lb i bioif (< for a period of time, clean it ihor-

ougl'l/, 'eiMt ' dll (I I grease, leaves, etc. Store in a

CIPc.i 1, di y ' 11 I

• CIc'c.n (mtirf ir if (01 (See “CLEANING” in the Customer

Fiesfonsii ilitip<i stcrion of this manual).

® In-dO I and n f I » belts, if necessary (See belt re-

• Lubricate as shown in the Customer Responsibilities

• Be sure that all nuts, bolts and screws are securely

• Touch up ail rusted or chipped paint surfaces; sand

BATTERY

• Fully charge the battery for storage.

® After a period of time in storage, battery may require

• To help prevent corrosion and power leakage during

• After cleaning, leave cables disconnected and place

• Be sure battery drain tube is securely attached.

• If battery is removed from tractor for storage, do not

me 4 irsfi u( m ms in the Service and Adjustments

:f-ui{;iici his nidriual).

section of this manual.

fastened, inspect moving parts for damage, breakage

and wear. Replace if necessary.

lightly before painting.

recharging.

long periods of storage, battery cables should be

disconnected and battery cleaned thoroughly (see “TO

CLEAN BATTERY AND TERMINALS” in the Cus

tomer Responsibilities section of this manual).

cables where they cannot come in contact with battery

terminals.

store battery directly on concrete or damp surfaces.

ENG ìlNE

fuel SYSTEP

IMPOF 1T Ä M T ' ^iS 1MPOBT -NT GUM

DEPO SITS FRO

EM PARTS E

SYS'i E

MF 1 ' N C..,' L-.. L-/ i\

gif,

LY.

turn

F> t 1

FUi 1

10 1

HOSE, OF'

CENGE iN

P? /\ I-.'. (J !\j

. ill

• St;

rbu'eicr

<

fuel tank or pe

fi,

М FiORMI N (

5UCH

AS CAP L FILTER,

1 ТАГ

pk' DUF

iùiCA

ÍES 1 H

GAS■OHOL ( ANOL OR

! ATT PACT У

FORM/

AND

G A S C, HE FUEL

ENGi!PE WHI!W IN STORAGE,

tsink.

ne ar

/d let it 1

> pmr

prie 0г carburetor cleaner products in the

trmar

...in until the fuel lines and

age may occur.

AL FUEL

. ALSO,

3LENDED

;H LEADS

5 DURING

* Us e fresh fuelnext season

NOTE: Fuel sta bilizeг is ап acceptable alternative in

mittimzino the ionTiatiOn of fuelgum deposits during stor-

age

Acci stab'liz

1 G r , AA ’ V'J c t y P; follo X ratio found on stabilizer

cemf lit

corn 11

ler, P ,;n enqine■ at ,eas10 minutes after adding

stai er :C aTow i

in the gaspink and carbLi

not di '

ter tc

gasoil г5 in fuel tank or storage

he st;TbPzer tiI reach the carburetor. Do

etor if using fuel stabilizer.

ENGINE OIL

Drain oil (with engine warm) and replace with clean engine

oil. (See “ENGINE” in the Customer Responsibilities

section of this manual).

CYLINf/t C“-

• Remove spark plug(s).

Pour orre ounce of oil through spark plug hole(s) into

cyiinder(s)

Turn ignition key to "START” position for a few seconds

Turn ignitic

to distribuí

to distnbuie oil.

Replace with new spark plug(s).

OTHER

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

• If possible, store your tractor indoors and cover it to

give protection from dust and dirt.

• Cover your tractor with a suitable protective cover that

does not retain moisture. Do not use plastic. Plastic

cannot breathe which allows condensation to form and

will cause your tractor to rust.

IMPORTANT: NEVER COVERTRACTOR WHILE ENGINE

AND EXHAUST AREAS ARE STILL WARM.

27

Page 28

PR

Will

ore aiteiTipiing lo siari.

7,

Loose or (iamaged wiring.

1

Carburetor out of ad)ustment.

1 10. Engine valves out of adjustment. 11

Hard to start 1, Dirty air filter.

Engine wiii not turn over 1,

2

Bad spark plug. :

Weak or dead battery. 3ry.

3.

4

Dirty fuel filter.

5,

Stale or dirty fuel.

6, Loose or damaged wiring.

7, Carburetor out of adjustment.

Engine valves out of adjustment. 7

8.

Clutch/brake pedal not depressed.

2. Attachment clutch is engaged.

3. Weak or dead battery.

Blown fuse. r

5, Corroded battery terminals.

Loose or damaged wiring. 6,

6,

7. Faulty ignition switch. 7.

8, Faulty solenoid or starter.

Faulty operator presence swifch(es). 9,

9,

Engine clicks but will not

start

1, '/‘Leak or dead battery.

Corroded battery terminals. 2,

2,

Loose or damaged wiring. 3.

3,

4

Faulty solenoid or starter.

ireior. refill tank with fresh

filter.

ir” in Service Adjustments

rvice center/department.

:

f

-

DiSei i III u, ( hment clutch.

;

Rtchan 1 Cl ir ¡lince battery.

;

Replar - Ui‘ •

Clean battery terminals.

5.

Check ail wiring.

ChecICrepiace ignition switch.

Check/replace solenoid or starter.

8,

Contact an authorized service center/department.

1, Recharge or replace battery.

Clean battery termináis.

Check all wiring.

4. Check/replace solenoid or starter.

vith fresh gasoline.

)r” In Service Adjustments

irJ service center/department.

5 pedal.

Loss of power

Excessive vibration

Cutting too much grass/too fast. 1,

1

2, Throttle in “CHOKE” position.

Build-up of grass, leaves and trash under mower. 3.

3.

4. Dirty air filter. 4.

5/. Low oil level/dirty oil. 5,

6, Faulty spark plug. 6,

7. Dirty fuel filter.

8 Stale or dirty fuel.

9 Water in fuel.

10, Spark plug wire loose.

11, Dirty engine air screen/fins.

12, Dirfy/ciogged muffler.

Loose or damaged wiring. 13.

13.

14.

Carburetor out of adjustment.

15. Engine valves out of adjustment.

1 _

Worn, bent or loose blade. 1,

Bent blade mandrel.

2.

Loose/damaqed part(s).

3.

28

Set in “Higher Cut" position/reduce speed.

2. Adjust throttle control.

Clean underside of mower housing.

Clean/replace air filter.

Check oil levet'change oil.

Clean and regap or change spark plug.

7. Replace fuel filter.

Drain fuel tank and refill with fresh gasoline.

8,

Dram fuel tank and carburetor, refill tank with fresh

9,

gasoline and replace fuel filter.

Connect and tighten spark plug wire.

10.

Clean engine air screen/fins.

11.

Clean/replace muffler.

12,

Check all wiring.

See “To /kd|ust Carburetor” in Service Adjustments

14,

section.