• Cultivator

Operator's manual

+ INSTRUCTIONS FOR PRODUCT DELIVERY . . . Page 3

Nr. 99 9765.GB.80I.1

Ihre / Your / Votre • Masch.Nr. • Fgst.Ident.Nr.

GB

SYNKRO 4003 K +T

(Type 9763 : + . . 01001)

SYNKRO 5003 K +T

(Type 9764 : + . . 01001)

SYNKRO 6003 T

(Type 9765 : + . . 01001)

ALLG./BA SEITE 2 / 0000-GB

Important information concerning Product

Liability.

According to the laws governing product liability, the manufacturer and dealer are obliged to hand the

operating manual to the customer at the time of sale, and to instruct them in the recommended operating,

safety, and maintenance regulations. Conrmation is necessary to prove that the machine and operating

manual have been handed over accordingly.

For this purpose,

-

document A is to be signed and sent to Pöttinger,

-

document B remains with the dealer supplying the machine,

-

and the customer receives document C.

In accordance with the laws of product liability, every farmer is an entrepreneur.

According to the laws of product liability, property damage is damage caused by a machine and not to

it. An excess of Euro 500 is provided for such a liabilioty.

In accordance with the laws of product liability, entrepreneurial property damages are excluded from

the liability.

Attention! Should the customer resell the machine at a later date, the operating manual must be given

to the new owner who must then be instructed in the recommended regulations referred to herein.

GB

Dear Farmer

You have just made an excellent choice. Naturally we are very happy

and wish to congratulate you for having chosen Pöttinger. As your

agricultural partner, we offer you quality and efciency combined with

reliable servicing.

In order to assess the spare-parts demand for our agricultural machines

and to take these demands into consideration when developing new

machines, we would ask you to provide us with some details.

Furthermore, we will also be able to inform you of new developments.

Dokument D

GB-0600 Dokum D Synkro

ALOIS PÖTTINGER Maschinenfabrik GmbH

A-4710 Grieskirchen

Tel. (07248) 600 -0

Telefax (07248) 600-511

GEBR. PÖTTINGER GMBH

D-86899 Landsberg/Lech, Spöttinger-Straße 24

Telefon (0 81 91) 59 0 39

Telefax (0 81 91) 59 626

GEBR. PÖTTINGER GMBH

Servicezentrum

D-86899 Landsberg/Lech, Spöttinger-Straße 24

Telefon (0 81 91) 59 0 39

Telefax (0 81 91) 59 626

- 3 -

According to the product liability please check the above mentioned items.

Please check. X

Machine checked according to delivery note. Check that the delivery is complete.

All safety equipment and operating devices at hand.

Operation and maintenance of machine and/or implement according to operating instructions explained to the

customer.

Fitting to tractor carried out.

Transporting and operating position explained.

Information given re. optional extras.

Absolute need to read the operating manual indicated.

INSTRUCTIONS FOR

PRODUCT DELIVERY

GB

In order to prove that the machine and the operating manual have been properly delivered, a conrmation is necessary.

For this purpose please do the following:

- sign the document A and send it to the company Pöttinger

(in case of Landsberg equipment: to the company Landsberg)

- document B stays with the specialist factory delivering the machine.

document C stays with the customer.

GB

CONTENTS

- 4 -

0800_GB-INHALT_9765

Attention!

Observe Safety

Points in

Supplement!

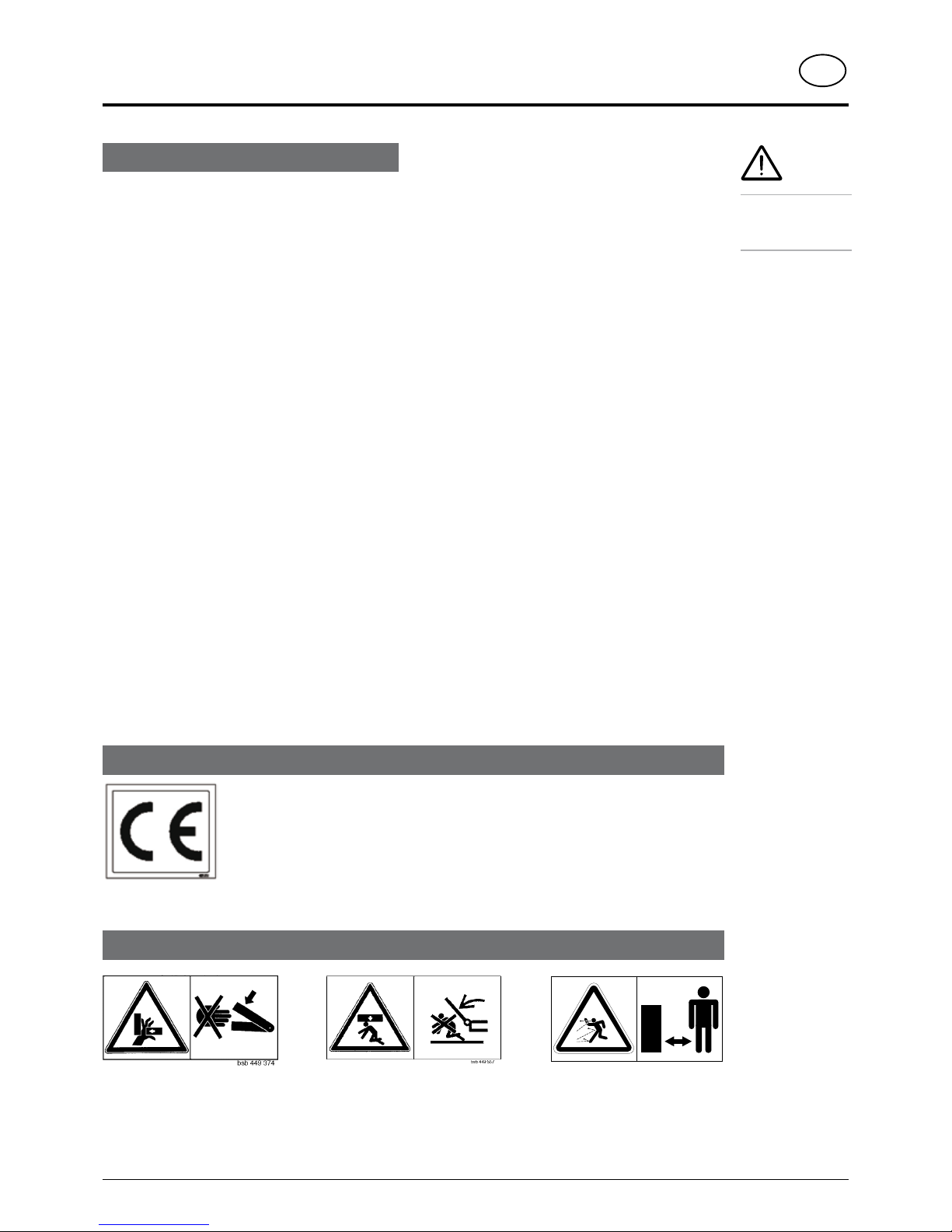

The CE sign, which is affixed

by the manufacturer, indicates

outwardly that this machine

conforms to the engineering

guideline regulations and the

other relevant EU guidelines.

Danger-flying objects; keep safe

distance from the machine as long

as the engine is running.

Never reach into the crushing

danger area as long as parts may

move.

Stay clear of swinging area of

implements

EU Declaration of Conformity

By signing the EU Declaration of Conformity, the

manufacturer declares that the machine being brought

into service complies with all relevant safety and health

requirements.

CE sign

Meaning of warning signs

Table of contents

CE sign ..........................................................................4

Meaning of warning signs .............................................4

CONNECTING TO TRACTOR

Preparing the tractor .....................................................5

Hydraulic control on the lifting gear .............................. 5

Preparing the cultivator .................................................5

Connecting to tractor .................................................... 5

C

onnecting hydraulic hoses ..........................................5

Conversion from working to transport position .............6

Driving on public roads .................................................7

Using additional implements. ........................................ 7

ADJUSTMENTS

Setting for operation ......................................................8

Equipment variants and wearing parts ..........................8

Overloading ...................................................................8

Hollow discs .................................................................. 8

Schar Schnellwechsel ................................................... 9

USE

Starting work ...............................................................10

MAINTENANCE

Safety point ................................................................. 11

General maintenance hints ..........................................11

Cleaning of machine parts ..........................................11

Parking in the ope .......................................................11

Winter storage ............................................................. 11

Drive shafts ..................................................................11

Hydraulic unit ..............................................................11

Advice for general maintence ...................................... 12

Safety points ...............................................................12

Spare parts .................................................................. 12

Hydraulic unit ..............................................................12

Cleaning of machine parts ..........................................12

Winter storage ............................................................. 12

Greasing points ...........................................................13

Description of transfers ............................................... 13

TECHNICAL DATA

Technical data .............................................................14

Position of Vehicle Identication Plate ........................14

Necessary connections ............................................... 14

Dened use of the cultivator according to the

manufacturer’s instructions. ........................................ 15

Optional equipment ..................................................... 15

DIMENSIONS

FAHRWERK

Fahrwerk 1) .................................................................. 18

Anbau ..........................................................................18

Einsatz ......................................................................... 18

SUPPLEMENT

Lubricants ....................................................................22

Combination of tractor and mounted implement ........ 24

GB

- 5 -

0700_GB-ANBAU_9765

connecting to tractor

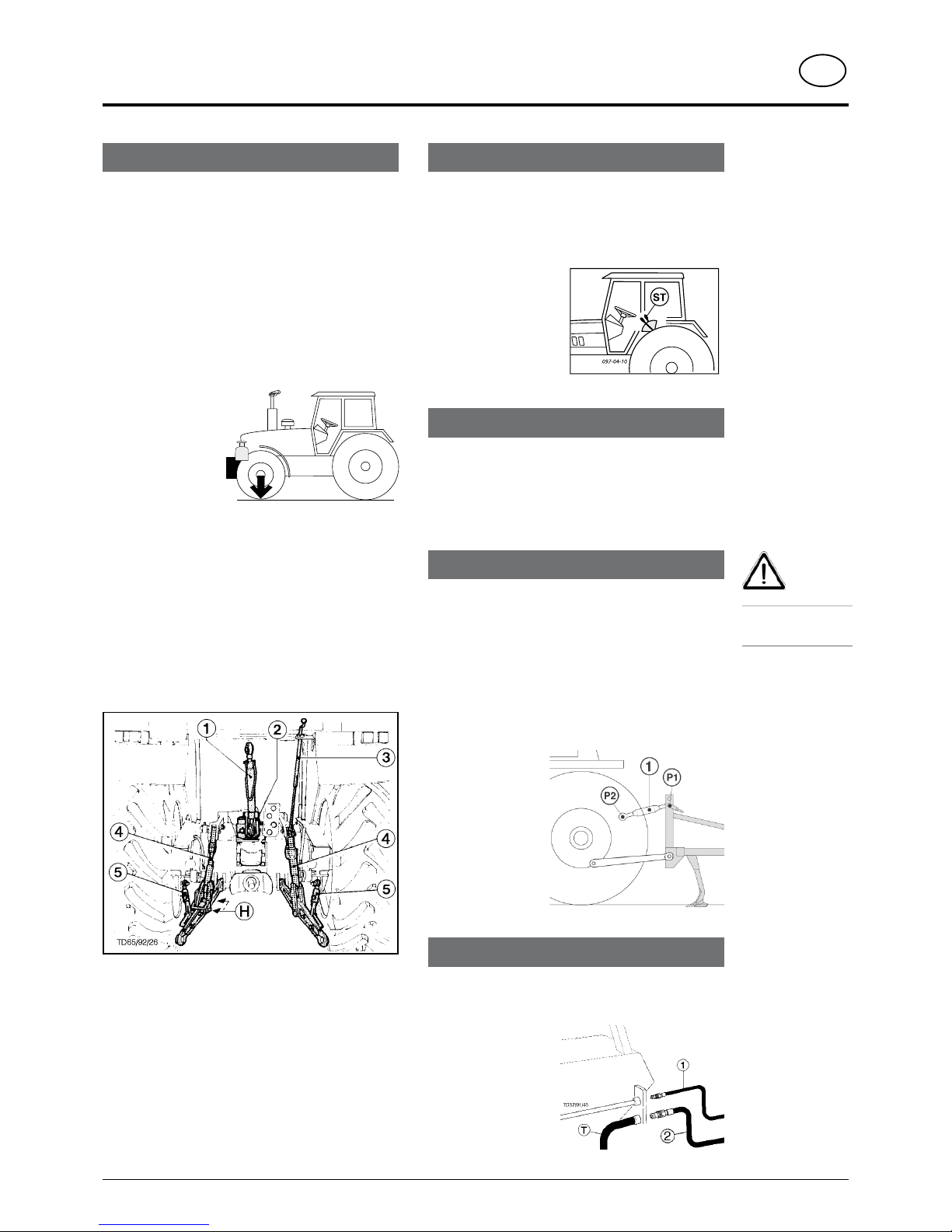

Preparing the tractor

Wheels

- Air pressure in the tractor's rear tyres should be 0.8

bar when working.

- Under heavy working conditions additional wheel

weights can be advantageos. See the tractor

manfuacturer's operating manual also.

Ballast weights

Sufficient ballast weights are to be stacked on the front

of the tractor in order to guarantee steering and braking

capabilities.

At least 20% of the

vehicle’s tare weight

on the front axle.

Lifting gear

- The left and right lifting struts (4) must be the same

length.

Adjust using adjuster (3).

-

If lifting struts (4) can be pinned at various positions

on the lower links, then select the back position (H). In

doing this, the tractor’s hydraulics will not be so greatly

overloaded.

-

Pin (2) upper link (1) in accordance with the manufacturer’s

specifications.

Setting-up for transportation

- Secure lower links with struts (5) so that attached

implement cannot swing out during transportation.

- The operating lever for the hydraulics must be secured

against lowering.

20%

Kg

Hydraulic control on the lifting gear

Control position:

For mounting and dismounting the implement and for

transportation.

The control position is the normal setting for the lifting

gear hydraulics.

T

h e m o u n t e d

implement remains at

the height (= position)

set by the servo-valve

(ST).

Preparing the cultivator

Mounting axle

Install correct mounting bar on tractor’s lifting gear

which corresponds to the connecting size (Category

II or III). See Spare Parts List also.

Connecting to tractor

- Switch tractor’s hydraulics to control position.

- Attach implement to lower link and secure with linch

pin.

Position upper link (1)

- Position upper link (1) so that the attachment point

(P1) on the implement is somewhat higher than the

attachment point (P2) on the tractor even during

operation.

C

onnecting hydraulic hoses

Double action control unit

- Connect pressure line (1) and oil-return pipe (2)

Safety

points:

see supplement-A1

Pkt. 8a. - 8h.)

GB

connecting to tractor

- 6 -

0700_GB-ANBAU_9765

- Make sure that swivel area is free and that nobody is

standing in the danger area.

- Move servo-valve (ST) to „rais“ position

The sideparts of the machine are swivelled into position

"Transport position".

-

Close hydraulic stop valve (A)

Conversion from transport to working position

- Open hydraulic stop valve (A)

- Make sure that swivel area is free and that nobody is

standing in the danger area.

-

Move servo-valve (ST) to „lower“ position

The sideparts of the machine are swivelled into position

"Working position".

Transport position SYNKRO

Safety Precaution!

Changing from

working to

transport position

is only to be

carried out on

even, firm ground.

Conversion from working to transport position

Working position SYNKRO

(A)

X = 4 m (Synkro 4003 K)

X = 5 m (Synkro 5003 K)

X = 6 m (Synkro 6003 K)

GB

connecting to tractor

- 7 -

0700_GB-ANBAU_9765

Driving on public roads

• Observe the official regulations of your country.

• Parts and attachment

- see spare parts list

• Travelling on open roads may only be carried out as

described in chapter "Transport position".

Total width of implement in the work position:

- more than 3m

Total width of implement in the transport

position:

see Technical Data

Parking, cleaning and winter storage of the

implement

• Observe the points in the chapter „Maintenance“!

Using additional implements.

Mount additional implements to the cultivator, such

as the drillbox (DB), according to the manufacturer’s

instructions.

• Do not overload the cultivator. If in doubt contact our

customer service office.

•

In addition, observe the power range limits of the tractor

in use.

- 8 -

0700_GB-EINsTELLUNGEN_9762

adjustments

DK

Setting for operation

1. The implement must be attached to the tractor in a horizontal

position, it should not hang to one side.

2. The front and rear tine rows must penetrate the ground at the

same depth (working depth).

The

frame should sit parallel to the ground surface as seen

longitudinally.

3.

Fix the lower link (4) in such a way that the machine cannot swing

out sideways.

Equipment variants and wearing parts

Rigid tines (basic equipment)

Spring-mounted tines (optional extra)

• Can be backfitted on all types

Backfitting kit (2 & 2a)

(see spare parts list)

-

Basic setting = 330 mm

Wearing parts

- are screwed to the tines and can therefore be replaced at little

cost.

Overloading

Shearing screws

Tines are secured with shearing

screws.

The shearing screw (pos. 7) breaks

when overloaded and the tine

swings upward.

-

Remove the shearing screw

remains.

-

Loosen hexagonal screw (6).

- Swing tine back to working

position.

-

Insert new shearing screw and

tighten both screws.

I

mportant!

Only use genuine shearing screws (see spare parts

list) of appropriate dimension and quality. Under no

circumstances use screws with a greater or lesser

strength.

344-05-14

7

6

Hollow discs

- serve to level out the ground surface evenly.

Setting the hollow discs

• This setting should suit the relevant operating conditions (type

of ground, speed and straw layer on the ground).

• The hollow discs are always set at the required working

depth.

Only fine adjustment is necessary

344-05-14

7

6

adjustments

- 9 -

0700_GB-EINsTELLUNGEN_9762

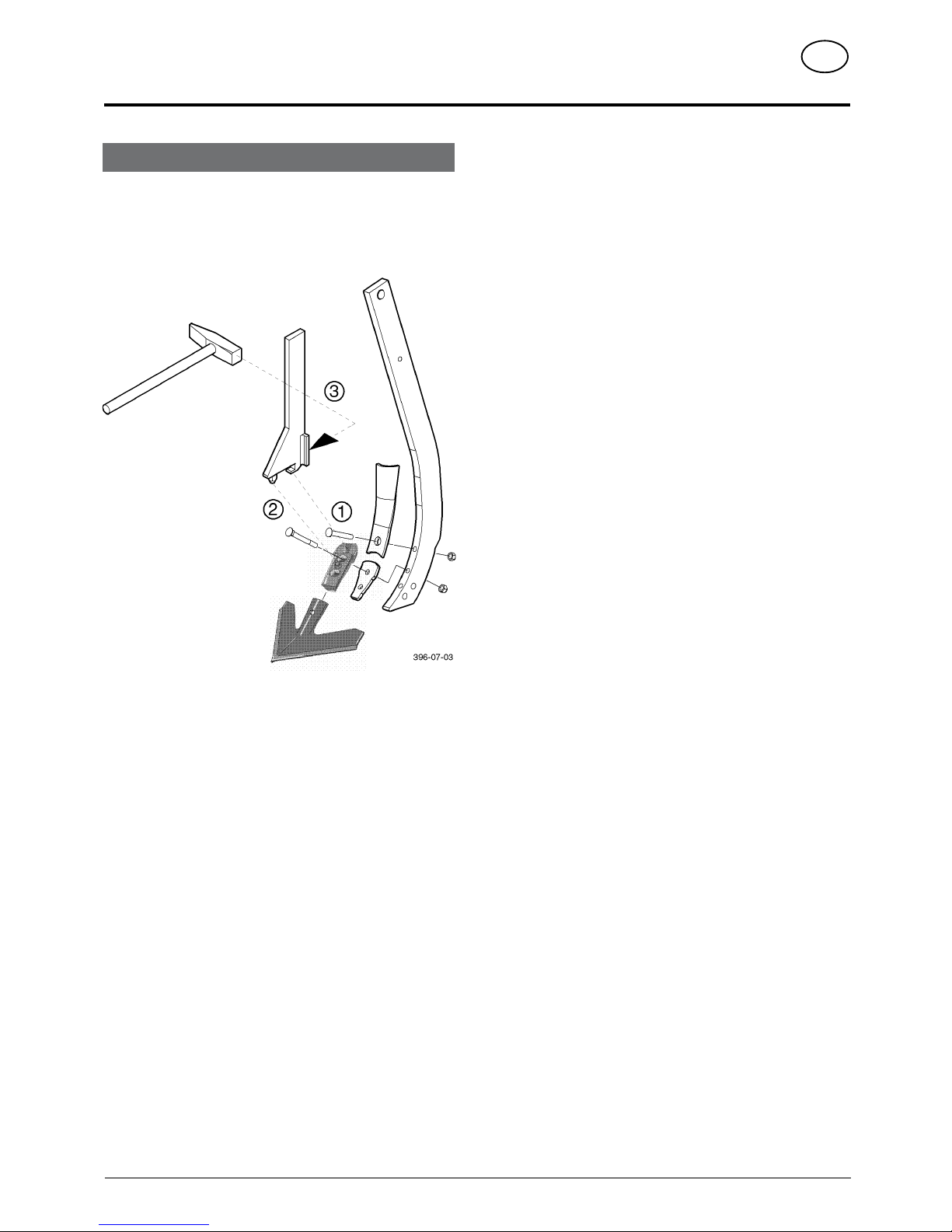

Share quick-change

1. Use change key

2. Press down on lock button

3. Release share with a hammer blow

DK

- 10 -

0700_GB-EINsATz_9762

use

GB

1. Check for proper attachment.

Before initial operation check all screws for tightness and retighten

if necessary.

2. Set required working depth.

Position both the support arms with pins (6) accordingly.

3. Swing hollow discs (left and right) into working position

(A)

Make sure pins (7) are inserted accordingly

4. Lower implement to the ground using tractor’s lifting

gear.

Drive a few metres into the working area then check the working

depth and the closing of the tine furrows.

5. If necessary, adapt tine angle to the operating conditions

(SK, EX).

Pos. B: Swivel the tines back (pos. B) if the required working

depth is not being obtained, e.g. with very heavy

ground.

Pos. N: Normal tine position.

SK

B

N

344-05-11

TD 34/95/20

5

2/3

1/3

Starting work

Basic setting for hollow discs: 1/3 of the total working depth.

O: Upper pins

To secure the trailer

U: Lower pins

For setting the working depth

Working depth difference from hole to hole of approx. 1.5 cm

Always change both pins!

- 11 -

GB

0400_GB-BA-Allg. Wartung

Parking in the ope

When parking in the open for

long periods of time, clean

piston rods and then coat

with grease.

FETT

Safety

points!

• Turn engine off

when adjustment,

service and repair

work is to be

done.

•

Do not work under the machine

without safe

support.

•

Retighten all

screws after the

first hours of

operation..

General maintenance hints

In order to keep the implement in

good condition after long periods

of operation, please observe the

following points:

-

Tighten all screws after the first

hours of operation.

In particular check:

- blade screws on the mowers

- tine screws on the swather and tedder.

Spare part

a. The original components and accessories have

been designed especially for these machines and

appliances.

b. We want to make it quite clear that components and

accesories that have not been supplied by us have

not been tested by us.

c.

The installation and/or use of such products can,

therefore, negatively change or influence the

construction characteristics of the appliance. We are

not liable for damages caused by the use of components

and accessories that have not been supplied by us.

d. Alterations and the use of auxiliary parts that are

not

permitted by the manufacturer render all liability

invalid.

Cleaning of machine parts

Attention! Do not use high-pressure washers for the

cleaning of bearing- and hydraulic parts.

- Danger of rust!

- After cleaning, grease the machine according to the

lubrication chart and carry out a short test run.

-

Cleaning with too high pressure may do damage to

varnish.

Safety point

• Turn engine off when adjustment, service and repair

work is to be done.

Hydraulic unit

Caution! Danger of injury or infection!

Under high pressure, escaping fluids can penetrate

the skin. Therefore seek immediate medical help!

After the first 10 operating hours and then every

consecutive 50 operating hours

- Check the hydraulic unit and lines for tightness and

retighten screw connections if necessary.

Before operation

- Check hydraulic hoses for wear.

Replace worn or damaged hydraulic hoses immediately.

The replacement hoses must meet the manufacturer’s

technical requirements.

Hose

lines are subject to natural ageing. The period of

use should not exceed 5 – 6 years.

Winter storage

- Thoroughly clean machine before storage.

- Put up protection against weather.

- Change or replenish gear oil.

- Protect exposed parts from rust.

- Lubricate all greasing points according to lubrication

chart.

Drive shafts

- see notes in the supplement

For maintenance please note!

The instructions in this operating manual are always

valid.

In case there are no special instructions available, then

the notes in the accompanying drive shaft manufacturer´

instructions are valid.

Repair Instructions

Please refer to

repair instructions

in supplement (if

available)

maintenance

0500-GB WArTUNG_965.p65

MAINTENANCE

GB

- 12 -

Advice for general maintence

In order to keep the machine in good condition even after

a longer period of operation, please observe the following

notes.

Safety points

• Turn engine off when adjustment, service and repair work

is to be done.

•

Do not work under the machine without safe support.

- Afterthersthoursofoperation,tightenallscrews.

Spare parts

a. The original components and accessories have been

designed especially for these machines and appliances.

b. We want to make it quite clear that components and

accesories that have not

been supplied by us have

not been tested by us.

c.

The i n s t allation a n d/

or us e o f s uch prod

uct s ca n , th e refore ,

neg ativel y ch ange or

inuencetheconstruction

characteristics of the appliance. We are not liable for damages caused by the use of

components and accessories that have not been supplied

by us.

d. Alterations and the use of auxiliary parts that are not permitted

by the

manufacturer render all liability invalid.

Hydraulic unit

Caution! Danger of injury or infection!

Under high pressure, escaping fluids

can penetrate the skin. Therefore seek

immediate medical help!

After the first 10 operating hours and

then every consecutive 50 operating

hours

- Check the hydraulic unit and lines for tightness and retighten

screw connections if necessary.

Before operation

- Check hydraulic hoses for wear.

Replace worn or damaged hydraulic hoses immediately. The

replacement hoses must meet the manufacturer’s technical

requirements.

Cleaning of machine parts

Attention!

Do n ot u se h igh -pre ssur e

washers for the cleaning of

bearing- and hydraulic parts.

- Danger of rust!

- After cleaning, grease the

machine according to the

lubrication chart and carry out a short test run.

-

Cleaning with too high pressure may do damage to varnish.

Winter storage

- Thoroughly clean the implement

- After cleaning, grease all greasing points and evenly apply

grease to the bearings (e.g. carry out a short trial run).

-

Protect exposed parts against rusting with an environmentally

safe protective agent.

-

Garage the implement where it is weather protected.

0500-GB WArTUNG_965.p65

MAINTENANCE

GB

- 13 -

Greasing points

Bearing

• Hollow discs

• „Rotopack“ tine roller

• Cage drum roller

• Spring-mounted tines

100 ha20

h

8

h

495.777

Every 100 hectares

• Check bearing bushes wear.

- Replace worn bearing brushes!

Every 20 operating hrs.

• Grease bearings

Every 8 operating hrs.

• Retighten screws

Description of transfers

FETT

GB

- 14 -

0900_GB-SCHAR-VARi Anten_0965

SHARE VARIANTS

1. Pointed share with winged shares

(Standard)

• Working depth, ploughing depth: 5 – 15 cm

• Hoeing: very good

• Mixing: very good

• Levelling: very good

• Without winged shares: deeper cultivation

With winged shares: total area cultivation

Share variants

3. Double-diamond share with wings

(Optional extra)

• Working depth, ploughing depth: 5 - 15 cm

• Hoeing: very good

• Mixing: very good

• Levelling: very good

• Without winged shares: deeper cultivation

With winged shares: total area cultivation

• Double-diamond is rotatable, therefore usable twice

• No guiding plate

2. Solo pointed share

(Lower price)

• Working depth, ploughing depth: 10 - 30 cm

• Hoeing: very good

• Mixing: from 10 cm good mixing

• Levelling: very good

• Without winged shares: deeper cultivation

GB

SHARE VARIANTS

- 15 -

0900_GB-SCHAR-VARi Anten_0965

4. Solo double-diamond

(Optional extra)

• Working depth, ploughing depth: 10 - 30 cm

• Hoeing: very good

• Mixing: from 10 cm good mixing

• Levelling: very good

• Without winged shares: deeper cultivation

• Double-diamond is rotatable, therefore usable twice

• No guiding plate

6. Quick changer with narrow share

(Optional extra)

• Working depth, ploughing depth: 10 - 30 cm

• Hoeing: very good

• Mixing: from 10 cm good mixing

• Levelling: very good

• Without winged shares: deeper cultivation

5. Quick changer with flat share

(Optional extra)

• Working depth, ploughing depth: 5 - 10

• Hoeing: very good

• Mixing: from 10 cm good mixing

• Levelling: very good

• Winged shares: total area cultivation

GB

SHARE VARIANTS

- 16 -

0900_GB-SCHAR-VARi Anten_0965

Overview of share variants

1.

Poin t e d share

w i th w in ge d

shares

2.

So l o po i nte d

share

3.

Double-diamond

with wings

4.

So l o do u bl e-

diamond

5.

Quick ch anger

with flat share

6.

Quick ch anger

w i t h n a r r o w

share

Working

depth,

Ploughing depth

5 – 15 cm 10 – 30 cm 5 – 15 cm 10 – 30 cm 5 – 15 cm 10 – 30 cm

Hoeing Very

good Very good Very good Very good Very good Very good

Mixing Very

good

From 10 cm

good mixing

Very good

From 10 cm

good mixing

Very good

From 10 cm

good mixing

Levelling Very

good Very good Very good Very good Very good Very good

Difference:

Wit

h or without

winged share

Total area

cultivation

Deeper

cultivation

T

otal area

cultivation

Deeper

cultivation

Total area

cultivation

Deeper

cultivation

- 17 -

0800-GB TechDat _9765

GB

Position of Vehicle Identification Plate

The factory number (Masch.-Nr.) is imprinted on the accompanying Vehicle

Identification Plate (as shown) and on the frame. Guarantee issues and further

inquiries cannot be processed without the factory number being stated.

Please enter the number onto the front page of the operating manual immediately

after taking delivery of the vehicle/implement.

Technical data

All data subject to alteration.

Necessary connections

• 1 double-action hydraulic plug-in connection

Operating pressure min.: 150 bar

Operating pressure max.: 200 bar

TECHNICAL DATA

Description

SYNKRO 4003 K +T

Type 9763

SYNKRO 5003 K +T

Type 9764

SYNKRO 6003 T

Type 9765

Working width [m] 4 5 6

Transport width [m] 3 3 3

Working depth

No. of tools 14 14 22

Row gap

[mm] 750 750 750

Line gap

[mm] 280 280 270

Frame height

[mm] 800 800 800

Attachment

Cat II, Cat III Cat II, Cat III Cat II, Cat III

Power r

equirement from [kw/hp] 110/150 110/150 160/220

W

eight – basic implement [kg]

with spring elements [kg]

2000

2430

2000

2430

2730

3456

W

eight - Tubular cage drum roller Ø 540 [kg]

Double roller [kg]

Oscillating rotor pack [kg]

Cutting ring roller [kg]

Cutting packer roller [kg]

440

580

-740

820

1200

440

580

-740

820

1200

--

680

-1060

1100

1200

Noise pollution level <70 dB (A) <70 dB (A) <70 dB (A)

- 18 -

0800-GB TechDat _9765

TECHNICAL DATA

GB

Defined use of the cultivator according to the manufacturer’s instructions.

The „SYNKRO 4003 K+T, SYNKRO 5003 K+T, SYNKRO 6003 T“ cultivator is intended solely for normal use in agricultural work.

• To prepare the upper layer of arable land for sowing which is to follow.

Any other uses outside of this are regarded as not in accordance with the defined use.

The manufacturer will not be held liable for any damages resulting from misuse. The risk is carried by the user alone.

• The keeping of operating, servicing and maintenance requirements as specified by the manufacturer also come under the heading of „defined

use“.

Optional equipment

1 Edge disc - left

Edge disc - right

2 Automatic stump-jump device

Can be backfitted to all SYNKRO types

3 Lighting

Trailing implements

5 Tubular cage drum roller 540 mm

7 Double roller

8 Cutting ring roller

9 Cutting packer roller

433-05-13

2

- 19 -

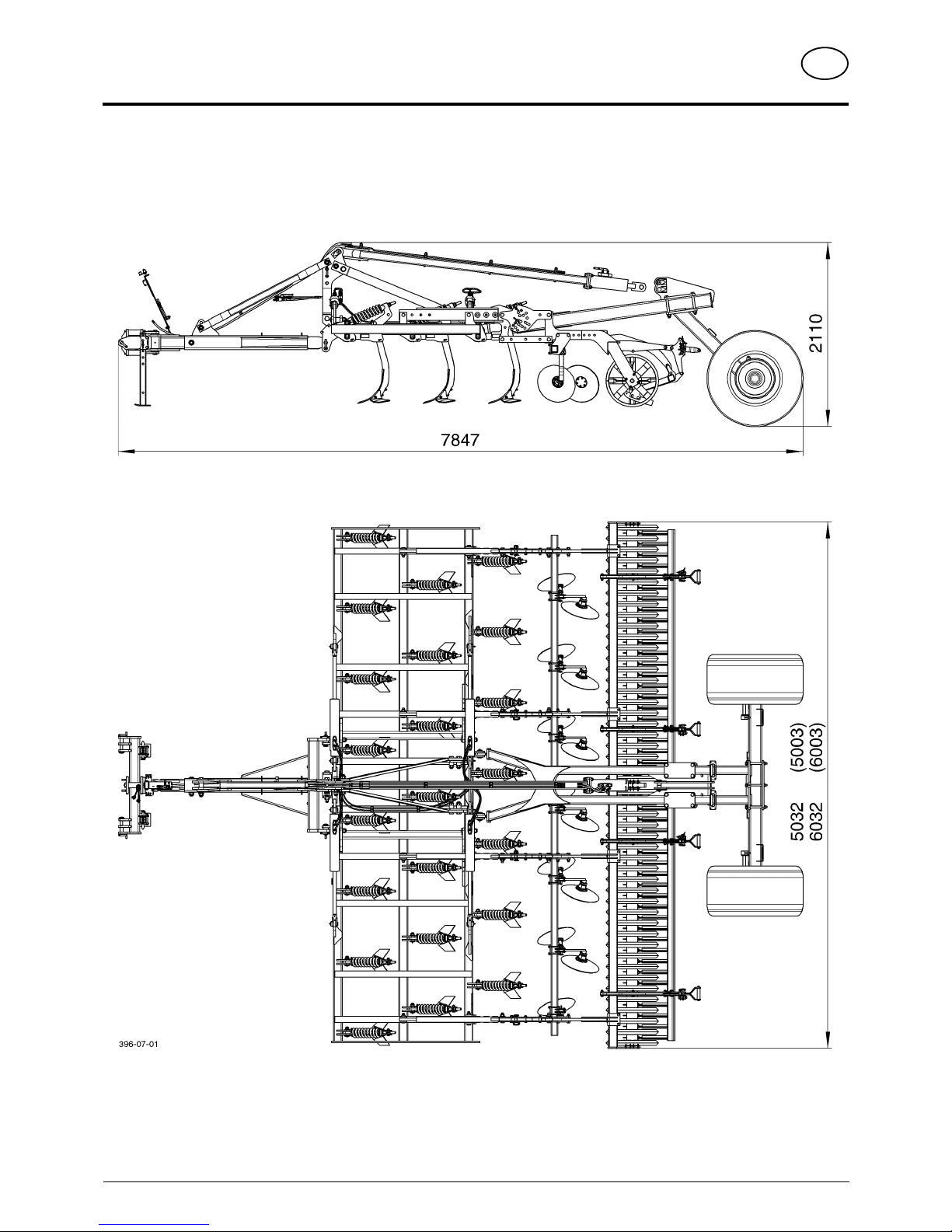

0700_GB-MassBlatt_9765

GB

All data subject to alteration without notice

dimensions

SYNKRO 4003 K

SYNKRO 5003 K

SYNKRO 6003 K

- 20 -

0700_GB-MassBlatt_9765

GB

dimensions

All data subject to alteration without notice

SYNKRO 5003 +T

SYNKRO 6003 +T

- 21 -

0700-GB CArGO_9765

GB

running gear

Running gear 1)

Safety advice:

See supplement A1

(Pt. 8a – h)

1) Optional extra

P

A = Working position

V = Pre-turning position

T = Transport position

Safety advice!

Changing from

working to

transport position

and vice-versa

is to be carried

out on even, firm

ground.

Ensure the swivel

range is free and

no-one is in the

danger area.

Attaching

- Set tractor lower link in centre

- Fix hydraulic lower link (U) so that device cannot swing

out sideways

-

against erratic, unstable machine trailing

- Couple pendulum axle (P) to lower link

- Properly secure the coupling bolts (1)

- Raise both parking supports (2) into the transport

position

-

Secure with linch pin (3)

Operation

The tractor hydraulic and lifting gear is relieved when

transporting through the running gear.

Working position (A)

• Lift the running gear with the hydraulic servo-valve

- the machine rests on the ground

Pre-turning position (V)

• Lower the running gear with the hydraulic servovalve

- the wheels run on the ground

Transport position (T)

• Fold the machine in the transport position

• Lower the running gear with the hydraulic servovalve

-

the wheels run on the ground

GB-Anhang Titelblatt _BA-Allgemein

GB

supplement

GB-Anhang Titelblatt _BA-Allgemein

GB

The decision must be made, ”original” or ”imitation”? The decision is often governed

by price and a ”cheap buy” can sometimes be very expensive.

Be sure you purchase the ”Original” with the cloverleaf symbol!

• Quality and precise fitting

- Operating safety.

• Reliable operation

• Longer lasting

- Economy

•

Guaranteed availability through your

Pöttinger Sales Service.

Things will run better with

genuine Pöttinger parts

The original cannot be copied ...

9400_GB-Anhang A_Sicherheit

supplement - a

Recommendations for work safety

- A 1 -

20%

Kg

Recommendations for work safety

All points refering to safety in this manual are indicated

by this sign.

1.) Defined use

a. See "Technical Data".

b. The keeping of operating, service and maintenance requirements

layed down by the manufacturer also come under the heading of

"defined use".

2.) Spare parts

a. The original components and accessories have been designed

especially for these machines and appliances.

b. We want to make it quite clear that components and accesories

that have not been supplied by us have not been tested by us.

c.

The installation and/or use of such products can, therefore,

negatively change or influence the construction characteristics

of the appliance. We are not liable for damages caused by the

use of components and accessories that have not been supplied

by us.

d. Alterations and the use of auxiliary parts that are not permitted

by the

manufacturer render all liability invalid.

3.) Protection devices

All protection devices must remain on the machine and be

maintained in proper condition. Punctual replacement of worn

and damaged covers is essential.

4.) Before starting work

a. Before commencing work, the operator must be aware of all

operating devices and functions. The learning of these is too late

after having already commenced operation!

b. The vehicle is to be tested for traffic and operating safety before

each operation.

5.) Asbestos

- Certain sub-supplied components of the

vehicle may contain asbestos due to technical

reasons. Observe the warning on spare

parts.

6.) Transport of persons prohibited

a. The transport of persons on the machine is not permitted.

b. The machine may only be driven on public roads when in the

position stipulated for road transport.

7.) Driving ability with auxiliary equipment

a. The towing vehicle is to be sufficiently equiped with weights at the

front or at the rear in order to guarantee the steering and braking

capacity (a minimum of 20% of the vehicle’s tare weight on the

front axle).

b

. The driving ability is

influenced by ground

conditions and by the

auxiliary

equipment. The

driving must be adapted

to the corresponding

t

errain a nd ground

conditions.

c. When driving through

curves with a connected

a

ppliance, observe the

ra dius and swi ngin g

mass of the appliance.

d. When travelling in a curve with attached or semimounted

implements, take into account the working range and swing mass

of the implement!

8.) General

a. Before attaching implement to three-point linkage, move system

lever into a position whereby unintentional raising or lowering is

ruled out!

b. Danger of injury exists when coupling implement to tractor!

c. Danger of injury through crushing and cutting exists in the three-

point linkage area!

d.

Do not stand between tractor and implement when using three-

point linkage external operation!

e.

Attach and detach drive shaft only when motor has stopped.

f. When transporting with raised implement, secure operating lever

against lowering!

g.

Before leaving tractor, lower attached implement to the ground

and remove ignition key!

h.

Nobody is to stand between tractor and implement without tractor

being secured against rolling using parking brake and/or wheel

chocks!

i.

For all maintenance, service and modification work, turn driving

motor off and remove universal drive.

9.) Cleaning the machine

Do not use high-pressure washers for the cleaning of bearing- and

hydraulic parts.

Leistung und Lebensdauer der Maschine sind

von sorgfältiger Wartung und der Verwendung

gu t e r B e t ri e bs s t of f e a b h än g i g. Un s e r e

Betriebsstoffauflistung erleichtert die richtige Auswahl

geeigneter Betriebsstoffe.

Im Schmierplan ist der jeweils einzusetzende

Betriebsstoff durch die Betriebsstoffkennzahl (z.B.

“III”) symbolisiert. Anhand von “Betriebsstoffkennzahl”

kann das geforderte Qualitätsmerkmal und das

en tspre che nde Produkt der Mi ner alö lfi rmen

festgestellt werden. Die Liste der Mineralölfirmen

erhebt keinen Anspruch auf Vollständigkeit.

Getriebeöl gemäß Betriebsanleitung - jedoch

mindestens 1 x jährlich wechseln.

- Ölablaßschraube herausnehmen, das Altöl

ausl a u f e n lasse n u n d ord n u n g sgemäß

entsorgen.

Vor Stillegung (Winterperiode) Ölwechsel durchführen

und alle Fettschmierstellen abschmieren. Blanke

Metallteile außen (Gelenke, usw.) mit einem Produkt

gemäß “IV” in der umseitigen Tabelle vor Rost

schützen.

I II III IV V VI VII

(II)

Ö

L

(IV)

FE T T

- D 1 -

Betriebsstoff-Kennzahl

Lubricant indicator

Code du lubriant

Numero caratteristico del

lubricante

Smeermiddelen code

gefordertes Qualitätsmerkmal

required quality level niveau

de performance demandé

caratteristica richiesta di

qualità

verlangte kwaliteitskenmerken

Getriebeöl SAE 90 bzw. 85

W-140 gemäß API-GL 5

gear oil SAE 90 resp. SAE 85

W-140 according to API-GL 5

huile transmission SA 90 ou

SAE 85 W-140, niveau API

GL 5

oilio per cambi e differenziali

SAE 90 o SAE 85 W-140 se-

condo

specicheAPI-GL5

Komplexfett (DIN 51 502: KP 1R)

complex grease

graisse complexe

grasso a base di saponi comp-

lessi

Getriebeießfett

(DIN 51 502:GOH

transmission grease

graisse transmission

grasso

uidoperriduttorie

motoroduttori

Li-Fett (DIN 51 502, KP 2K)

lithium grease

graisse au lithium

grasso al litio

Getriebeöl SAE 90 bzw. SAE 85 W-140

gemäß API-GL 4 oder API-GL 5

gear oil, SAE 90 resp. SAE 85 W-140

according to API-GL 4 or API-GL 5

huile transmission SAE 90 ou

SAE 85 W-140, niveau API-GL 4 ou

API-GL 5

olio per cambi e differenziali SAE 90

o

SAE85W-140secondospeciche

API-GL 4 o API-GL 5

Motorenöl SAE 30 gemäß

API CD/SF

motor oil SAE 30

according to API CD/SF

huile moteur SAE 30 niveau

API CD/SF

oilo motore SAE 30 secondo

speciche

APICD/SF

HYDRAULIKöL HLP

DIN 51524 Teil 2

Siehe Anmerkungen

*

**

***

The performance and the lifetime of the farm

machines are highly depending on a careful

main tenance and appl icati on of cor re ct

lubricants. our schedule enables an easy

selection of selected products.

The applicable lubricants are symbolized (eg.

“III”). According to this lubricant product code

number the specification, quality and brandname

of oil companies may easily be determined.

The listing of the oil companies is not said to

be complete.

Gear oils according to operating instructions

- however at least once a year.

-

Take out oil drain plug, let run out and duly

dispose waste oil.

Before garaging (winter season) an oil change and

greasing of all lubricating points has to be done.

Unprotected, blanc metal parts outside (joints,

etc.) have to be protected against corrosion with

a group "Iv" product as indicated on the reverse

of this page.

Le bon fonctionnement et la longévité

des machines dépendent d’un entre-tien

soigneux et de l’utilisation de bons lubrifiants.

Notre liste facilite le choix correct des

lubrifiants.

Sur le tableau de graissage, on trouve un code

(p.ex."III") se référant à un lubrifiant donné.

En consultant ce code on peut facilement

déterminer la spécification demandée du

lubrifiant. La liste des sociétés pétrolières

ne prétend pas d’être complète.

Pour l’huile transmission consulter le cahier

d’entretien - au moins une fois par an.

- retirer le bouchon de vidange, laisser

l'huile s'écouler et l'éliminer correcte-

ment.

Avant l’arrêt et hiver: vidanger et grais-ser.

métaux nus à l' extérieur protéger avec un

produit type “Iv” contre la rouille (consulter

tableau au verso).

L'efficienza e la durata della macchina dipendono

dall'accuratezza della sua manutenzione e dall'impiego

dei lubrificanti adatti. Il nostro elenco dei lubrificanti Vi

agevola nella scelta del lubrificante giusto.Il lubrificante

da utilizzarsi di volta in volta è simbolizzato nello schema

di lubrificazione da un numero caratter-istico (per es.

"III"). In base al "numero caratteristico del lubrificante"

si possono stabilire sia la caratteristica di qualità che il

progetto corrispondente delle compagnie petrolifere.

L'elenco delle compagnie petrolifere non ha pretese di

completezza.

Motori a quattro tempi: bisogna effettuare il cambio

dell'olio ogni 100 ore di funzionamento e quello dell'olio

per cambi come stabilito nel manuale delle istruzioni per

l'uso (tuttavia, almeno 1 volta all'anno).

-

Togliere il tappo di scarico a vite dell’olio; far scolare

l’olio e eliminare l’olio come previsto dalla legge anti-

inquinamento ambientale.

Effettuare il cambio dell'olio ed ingrassare tutte le parti

che richiedono una lubrificazione a grasso prima del fermo

invernale della macchina. proteggere dalla ruggine tutte le

parti metalliche esterne scoperte con un prodotto a norma

di "Iv" della tabella riportata sul retro della pagina.

prestaties en levensduur van de

ma chi nes zijn a fhankel ijk va n

een zorgvuldig onderhoud en het

gebruik van goede smeermiddelen.

Dit schema vergemakkeli jkt de

goede keuze van de juiste smeer-

middelen.

Olie in aandrijvingen volgens de ge-

bruiksaanwijzing verwisselen - echter

tenminste 1 x jaarlijks.

- Aftapplug er uit nemen, de olie

aftappen en milieuvriendelijk

verwerken.

Voor het buiten gebruik stellen (win-

terperiode) de olie-wissel uitvoeren

en all e vetnipp el smeerpunte n

doorsmeren. Blanke metaaldelen

(koppelingen enz.) met een product

uit groep "Iv" van de navolgende tabel

tegen corrosie beschermen.

D

Betriebsstoffe

Ausgabe 1997

GB

Lubricants

Edition 1997

F

Lubrifiants

Édition 1997

I

Lubrificanti

Edizione 1997

NL

Smeermiddelen

Uitgave 1997

-

OSO 32/46/68

ARNICA 22/46

MOTOROIL HD 30

SIGMA MULTI 15W-40

SUPER TRACTOROIL UNIVERS.

15W-30

ROTRA HY 80W-90/85W-140

ROTRA MP 80W-90/85W-140

GR MU 2 GR SLL

GR LFO

ROTRA MP 80W-90

ROTRA MP 85W-140

VITAM GF 32/46/68

VITAM HF 32/46

SUPER KOWAL 30 MULTI TURBO-

RAL SUPER TRAKTORAL 15W-30

GETRIEBEÖL EP 90 GETRIEBEÖL

HYP 85W-90

ARALUB HL 2 ARALUB FDP 00

ARALUB FK 2

GETRIEBEÖL HYP 90

AGIP

ARAL

IV

ANMERKUNGEN

III VIV VIIII I

Firma

(IV)

FE TT

(II)

ÖL

HYDRAULIKÖL HLP 32/46/68

SUPER 2000 CD-MC *

HYDRA HYDR. FLUID * HYDRAU-

LIKÖL MC 530 ** PLANTOHYD

40N ***

SUPER 2000 CD-MC

SUPER 2000 CD

HD SUPERIOR 20 W-30

HD SUPERIOR SAE 30

SUPER 8090 MC

HYPOID 80W-90

HYPOID 85W-140

MULTI FETT 2

SPEZIALFETT FLM

PLANTOGEL 2 N

GETRIEBEFLIESSFETT NLGI 0

RENOLIT DURAPLEX EP 00

PLANTOGEL 00N

RENOPLEX EP 1 HYPOID 85W-140

BAYWA

AVILUB RL 32/46

AVILUB VG 32/46

MOTOROIL HD 30

MULTIGRADE HDC 15W-40 TRAC-

TAVIA HF SUPER 10 W-30

GETRIEBEÖL MZ 90 M MULTIHYP

85W-140

AVIA MEHRZWECKFETT

AVIA ABSCHMIERFETT

AVIA GETRIEBEFLIESSFETT

AVIALUB SPEZIALFETT LD GETRIEBEÖL HYP 90 EP MULTIHYP

85W-140 EP

AVIA

ENERGOL SHF 32/46/68 VISCO 2000

ENERGOL HD 30

VANELLUS M 30

GEAR OIL 90 EP

HYPOGEAR 90 EP

ENERGREASE LS-EP 2 FLIESSFETT NO

ENERGREASE HTO

OLEX PR 9142 HYPOGEAR 90 EP

HYPOGEAR 85W-140 EP

BP

HYSPIN AWS 32/46/68 HYSPIN

AWH 32/46

RX SUPER DIESEL 15W-40

POWERTRANS

EPX 80W-90

HYPOY C 80W-140

IMPERVIA MMO CASTROLGREASE LMX EPX 80W-90

HYPOY C 80W-140

CASTROL

WIOLAN HS (HG) 32/46/68

WIOLAN HVG 46 **

WIOLAN HR 32/46 ***

HYDROLFLUID *

MULTI-REKORD 15W-40

PRIMANOL

REKORD 30

HYPOID-GETRIEBEÖL

80W-90, 85W-140

MEHRZWECKGETRIEBEÖL

80W-90

WIOLUB LFP 2 WIOLUB GFW

WIOLUB AFK 2 HYPOID-GETRIEBEÖL

80W-90, 85W-140

ENAK HLP 32/46/68

ENAK MULTI 46/68

SUPER EVVAROL HD/B SAE 30

UNIVERSAL TRACTOROIL SUPER

HYPOID GA 90

HYPOID GB 90

HOCHDRUCKFETT LT/SC 280 GETRIEBEFETT MO 370

EVVA CA 300 HYPOID GB 90

HLP 32/46/68

HLP-M M32/M46

MOTORÖL 100 MS SAE 30

MOTORÖL 104 CM 15W-40 AUS-

TROTRAC 15W-30

GETRIEBEÖL MP 85W-90 GETRIE-

BEÖL B 85W-90 GETRIEBEÖL C

85W-90

LORENA 46

LITORA 27

RHENOX 34

-

GETRIEBEÖL B 85W-90 GETRIEBE-

ÖL C 85W-140

OLNA 32/46/68

HYDRELF 46/68

PERFORMANCE 2 B SAE 30 8000

TOURS 20W-30 TRACTORELF ST

15W-30

TRANSELF TYP B 90 85W-140

TRANSELF EP 90 85W-140

EPEXA 2

ROLEXA 2

MULTI 2

GA O EP

POLY G O

MULTIMOTIVE 1 TRANSELF TYP B 90 85W-140

TRANSELF TYP BLS 80 W-90

NUTO H 32/46/68

NUTO HP 32/46/68

PLUS MOTORÖL 20W-30 UNIFARM

15W-30

GEAROIL GP 80W-90 GEAROIL

GP 85W-140

MULTI PURPOSE GREASE H FIBRAX EP 370

NEBULA EP 1

GP GREASE

GEAR OIL GX 80W-90

GEAR OIL GX 85W-140

ULTRAMAX HLP 32/46/68 SUPER

TRAC FE 10W-30* ULTRAMAX

HVLP 32 **

ULTRAPLANT 40 ***

SUPER HPO 30

STOU 15W-30

SUPER TRAC FE 10W-30

ALL FLEET PLUS 15W-40

HP GEAR OIL 90

oder 85W-140

TRANS GEAR OIL 80W-90

MULTILUBE EP 2

VAL-PLEX EP 2

PLANTOGEL 2 N

RENOLIT LZR 000

DEGRALUB ZSA 000

DURAPLEX EP 1

TELLUS S32/S 46/S68 TELLUS

T 32/T46

AGROMA 15W-30

ROTELLA X 30

RIMULA X 15W-40

SPIRAX 90 EP

SPIRAX HD 90

SPIRAX HD 85/140

RETINAX A

ALVANIA EP 2

SPEZ. GETRIEBEFETT H SIMMNIA

GREASE O

AEROSHELL GREASE 22 DOLIUM

GREASE R

SPIRAX HD 90

SPIRAX HD 85W-140

AZOLLA ZS 32, 46, 68 EQUIVIS ZS

32, 46, 68

RUBIA H 30

MULTAGRI TM 15W-20

TOTAL EP 85W-90

TOTAL EP B 85W-90

MULTIS EP 2 MULTIS EP 200

MULTIS HT 1

TOTAL EP B 85W-90

DTE 22/24/25

DTE 13/15

HD 20W-20

DELVAC 1230

SUPER UNIVERSAL 15W-30

MOBILUBE GX 90

MOBILUBE HD 90

MOBILUBE HD 85W-140

MOBILGREASE MP

MOBILUX EP 004 MOBILPLEX 47

MOBILUBE HD 90

MOBILUBE HD 85W-140

RENOPLEX EP 1

HYPOID EW 90

HYPOID 85W-140

HYDRAULIKÖL HLP/32/46/68

HYDRAMOT 1030 MC * HYDRAU-

LIKÖL 520 **

PLANTOHYD 40N ***

MULTI 2030

2000 TC

HYDRAMOT 15W-30 HYDRAMOT

1030 MC

GETRIEBEÖL MP 90

HYPOID EW 90

HYPOID 85W-140

MEHRZWECKFETT

SPEZIALFETT GLM

PLANTOGEL 2 N

GETRIEBEFLIESSFETT

PLANTOGEL 00N

HYDRAN 32/46/68 DELTA PLUS SAE 30

SUPER UNIVERSAL OIL

PONTONIC N 85W-90 PONTONIC

MP 85W-90 85W-140

SUPER UNIVERSAL OIL

MARSON EP L 2

NATRAN 00

MARSON AX 2 PONTONIC MP 85W-140

RENOPLEX EP 1 RENOGEAR SUPER 8090 MC

RENOGEAR HYPOID 85W-140

RENOGEAR HYPOID 90

TITAN HYDRAMOT 1O3O MC

TITAN UNIVERSAL HD

RENOGEAR SUPER 8090 MC

RENOGEAR HYPOID 85 W-140

RENOGEAR HYPOID 90

RENOSOD GFO 35

DURAPLEX EP 00

PLANTOGEL 00N

ELAN

FUCHS

GENOL

MOBIL

RHG

SHELL

TOTAL

ELF

ESSO

EVVA

FINA

VALVOLINE

VEEDOL

RENOLIN B 10/15/20 RENOLIN B

32 HVI/46HVI

EXTRA HD 30

SUPER HD 20 W-30

MEHRZWECKGETRIEBEÖlSAE90

HYPOID EW 90

MEHRZWECKFETT

RENOLIT MP

DURAPLEX EP

RENOSOD GFO 35

RENOPLEX EP 1 HYPOID EW 90

-

-

ANDARIN 32/46/68 HD PLUS SAE 30

MULTIGRADE SAE 80/90 MULTI-

GEAR B 90

MULTIGEAR C SAE 85W-140

MULTIPURPOSE

MULTIGEAR B 90

MULTI C SAE 85W-140

WINTERSHALL

HP GEAR OIL 90

oder 85W-140

RENOLIN 1025 MC ***

TITAN HYDRAMOT 1030 MC **

RENOGEAR HYDRA *

PLANTOHYD 40N ***

RENOLIT MP

RENOLIT FLM 2

RENOLIT ADHESIV 2

PLANTOGEL 2 N

CASTROLGREASE LM

- D 2 -

* Bei Verbundarbeit mit

Naßbremsen-schlep-

pern ist die internatio-

naleSpezikationJ20

A erforderlich

** Hydrauliköle

HLP-(D) + HV

***HydrauliköleaufPan-

zenölbasis HLP + HV

Biologisch abbaubar,

deshalb besonders

umweltfreundlich

0000-GB ZUSINFO / BA-EL ALLG.

GB

- Z.27 -

important! additional information

see instruction handbook of the tractor

see price list and/or instruction handbook of the implement

to be measured

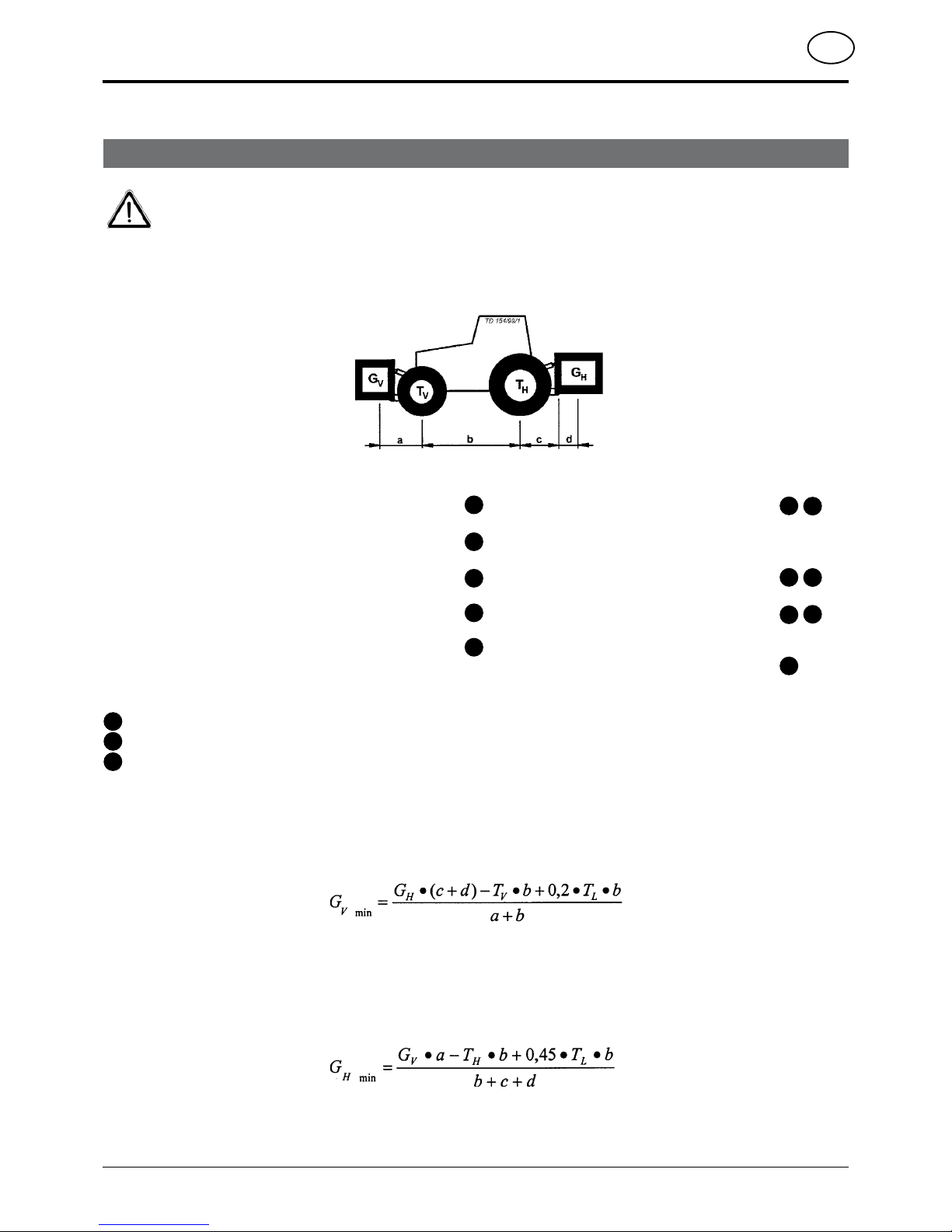

Consideration of rear mounted implement and front/rear combinations

1. CALCULATION OF MINIMUM BALLASTING AT THE FRONT G

V min

Record the calculated minimum ballasting which is needed at the front of the tractor into the table.

Front mounted implement

2. CALCULATION OF THE MINIMUM G

H min

Record the calculated minimum ballasting which is needed at the rear of the tractor into the table.

For the calculation you need the following data:

TL [kg]

T

V

[kg]

T

H

[kg]

G

H

[kg]

G

V

[kg]

unladen weight of tractor

front axle load of unladen tractor

rear axle load of unladen tractor

combined weight of rear mounted implement/rear

ballast

combined weight of front mounted implement/front

ballast

distance from centre of gravity for

combined front mounted implement/front

ballast to front axle centre

Tractor wheelbase

distance from rear axle centre to centre

of lower link balls

distance from centre of lower link balls

to centre of gravity for combined rear

mounted implement/rear ballast

a [m]

b [m]

c [m]

d [m]

2

3

1

1

1

1

1

2

2

2

3

3

1

3

2

Combination of tractor and mounted implement

The mounting of implements on the front or rear three point linkage shall not result in exceeding the maximum permissible weight,

the permissible axle loads and the tyre load carrying capacities ot the tractor. The front axle of the tractor must always to be loaded

with at least 20 % of the unladen weight of the tractor.

Make sure before buying an implement that these conditions are fulfilled by carrying out the following calculations or by weighing the

tractor/implement combination.

Determination of the total weight, the axle loads, the tyre load carrying capacity and the necessary

minimum ballasting

0000-GB ZUSINFO / BA-EL ALLG.

GB

- Z.28 -

important! additional information

3. CALCULATION OF THE REAL FRONT AXLE LOAD T

V tat

(If with the front mounted implement (GV) the required minimum front ballasting (G

V min

) cannot be reached, the weight of the front mounted

implement has to be increased to the weight of the minimum ballasting at the front!)

Record the calculated real front axle load and the permissible front axle load of the tractor into the table.

4. CALCULATION OF THE REAL TOTAL WEIGHT G

tat

(If with the rear mounted implement (GH) the required minimum rear ballasting (G

H min

) cannot be reached, the weight of the rear mounted

implements has to be increased to at least the weight of the minimum ballasting at the rear!)

Record the calculated real and the permissible total weight given in the instruction handbook for the tractor into the table.

5. CALCULATION OF THE REAL REAR AXLE LOAD T

H tat

Record the calculated real and the permissible rear axle load given in the instruction handbook for the tractor into the table.

6. TYRE LOAD CARRYING CAPACITY

Record double the value (two tyres) of the permissible load carrying capacity into the table (see for instance documentation provided by the

tyre manufacturer).

Minimum ballasting

front/rear

Total weight

Front axle load

Rear axle load

Real value according to

calculation

Permissible value

according to

instruction handbook

D

ouble permissible tyre

load carrying capacity (two

tyres)

The minimum ballasting has to be attached to the tractor either in form of a mounted implement or

ballasting weight!

T

he calculated values must be less or equal (<) the permissible values!

Table

ALOIS PÖTTINGER Maschinenfabrik Gesellschaft m.b.H.

A-4710 Grieskirchen; Industriegelände 1

0600 GB-EG Konformitätserklärung

EC Certicate of Conformity

conforming to EEC Directions 98/37/EG

We ______________________________________________________________________

(name of supplier)

__________________________________________________________________________________

(full address of company - where this concerns authorized agents within the Common Market, also state the company

name and manufacturer)

declare in sole responsibility, that the product

__________________________________________________________________________

(make, model)

to which this certicate applies, conforms to the basic safety and health requirements of

EEC Directions 98/37,

(if applicable)

and to the other relevant EEC Directions.

__________________________________________________________________________

(title and/or number and date of issue of the other EEC Directions)

(if applicable)

To effect correct application of the safety and health requirements stated in the EEC Directions,

the following standards and/or technical specications were consulted:

__________________________________________________________________________

(title and/or number and date of issue of standards and/or specifications)

Appendix 1

____________________________ ____________________________________

(Place and date of issue) (Name and job function of authorized person)

GB

Cultivator

SYNKRO 4003 K +T, Type 9763

SYNKRO 5003 K +T, Type 9764

SYNKRO 6003 T, Type 9765

Grieskirchen, 07.11.2007

pa. Ing. W. Schremmer

Entwicklungsleitung

A emp re sa PÖT TIN GER Ge s.m .b. H

esforçase continuamente por melhorar os

seus produtos, adaptando-os à evolução

técnica.

Por este motivo, reservamonos o direito de modificar

as figuras e as descrições constantes no presente

manual, sem incorrer na obrigação de modificar

máquinas já fornecidas.

As características técnicas, as dimensões e os pesos

não são vinculativos.

A reprodução ou a tradução do presente manual de

instruções, seja ela total ou parcial, requer a autorização

por escrito da

ALoIS PÖTTINGER

Maschinenfabrik Gesellschaft m.b.H.

A-4710 Grieskirchen

Todos os direitos estão protegidos pela lei da prop-

riedade intelectual.

Im Zuge der technischen Weiterentwicklung

arbeitet die PÖTTINGER Ges.m.b.H ständig

an der Verbesserung ihrer Produkte.

Änderungen gegenüber den Abbildungen und

Beschreibungen dieser Betriebsanleitung müssen wir

uns darum vorbehalten, ein Anspruch auf Änderungen

an bereits ausgelieferten Maschinen kann daraus nicht

abgeleitet werden.

Technische Angaben, Maße und Gewichte sind

unverbindlich. Irrtümer vorbehalten.

Nachdruck oder Übersetzung, auch auszugsweise,

nur mit schriftlicher Genehmigung der

ALOIS PÖTTINGER

Maschinenfabrik Gesellschaft m.b.H.

A-4710 Grieskirchen.

Alle Rechte nach dem Gesetz des Urheberrecht

vorbehalten.

D

Beroende på den tekniska utvecklingen

arbe-tar PÖTTINGER Ges.m.b.H. på att

förbättra sina produkter.Vi måste därför

förbehålla oss förändringar gentemot avbildningarna

och beskrivningarna i denna bruksanvis-ning. Däremot

består det inget anspråk på förändringar av produkter

beroende av denna bruksanvisning.

Tekniska uppgifter, mått och vikter är oförbindliga.

Fel förbehållna.

Ett eftertryck och översättningar, även utdrag, får

endast genomföras med skriftlig tillåtelse av

ALoIS PÖTTINGER

Maschinenfabrik Gesellschaft m.b.H.

A – 4710 Grieskirchen

Alla rättigheter enligt lagen om upphovsmannarätten

förbehålls.

La société PÖTTINGER Ges.m.b.H améliore

constamment ses produits grâce au progrès

technique.

C'est pourquoi nous nous réser-vons le droit de

modifier descriptions et illustrations de cette notice

d'utilisation, sans qu'on en puisse faire découler un

droit à modifications sur des machines déjà livrées.

Caractéristiques techniques, dimensions et poids sont

sans engagement. Des erreurs sont possibles.

Copie ou traduction, même d'extraits, seulement avec

la permission écrite de

ALoIS PÖTTINGER

Maschinenfabrik Gesellschaft m.b.H.

A-4710 Grieskirchen.

Tous droits réservés selon la réglementation des

droits d'auteurs.

Following the policy of the PÖTTINGER Ges.

m.b.H to improve their products as technical

developments continue, PÖTTINGER

reserve the right to make alterations which must not

necessarily correspond to text and illustrations contained in this publication, and without incurring obligation

to alter any machines previously delivered.

Technical data, dimensions and weights are given as an

indication only. Responsibility for errors or omissions

not accepted.

Reproduction or translation of this publication, in

whole or part, is not permitted without the written

consent of the

ALoIS PÖTTINGER

Maschinenfabrik Gesellschaft m.b.H.

A-4710 Grieskirchen.

All rights under the provision of the copyright Act

are reserved.

PÖTTINGER Ges.m.b.H werkt permanent

aan de verbetering van hun producten

in he t k a der van hu n t e c hnis c he

ontwikkelingen. Daarom moeten wij ons veranderingen

van de afbeeldingen en beschrijvingen van deze

gebruiksaanwijzing voorbehouden, zonder dat daaruit

een aanspraak op veranderingen van reeds geieverde

machines kan worden afgeleid.

Technische gegevens, maten en gewichten zijn niet

bindend. Vergissingen voorbehouden.

Nadruk of vertaling, ook gedeeltelijk, slechts met

schriftelijke toestemming van

ALoIS PÖTTINGER

Maschinenfabrik Gesellschaft m.b.H.

A-4710 Grieskirchen.

Alle rechten naar de wet over het auteursrecht voor-

behouden.

La empresa PÖTTINGER Ges.m.b.H se

esfuerza contínuamente en la mejora

constante de sus productos, adaptándolos

a la evolución técnica. Por ello nos vemos obligados

a reservarnos todos los derechos de cualquier

modificación de los productos con relación a las

ilustraciones y a los textos del presente manual, sin

que por ello pueda ser deducido derecho alguno a la

modificación de máquinas ya suministradas.

Los datos técnicos, las medidas y los pesos se

entienden sin compromiso alguno.

La reproducción o la traducción del presente manual

de instrucciones, aunque sea tan solo parcial, requiere

de la autorización por escrito de

ALoIS PÖTTINGER

Maschinenfabrik Gesellschaft m.b.H.

A-4710 Grieskirchen.

Todos los derechos están protegidos por la ley de la

propiedad industrial.

La PÖTTINGER Ges.m.b.H è costantemente

al lavoro per migliorare i suoi prodotti

mantenendoli aggiornati rispetto allo

sviluppo della tecnica.

Per questo motivo siamo costretti a riservarci la facoltà

di apportare eventuali modifiche alle illustrazioni e alle

descrizioni di queste istruzioni per l’uso. Allo stesso

tempo ciò non comporta il diritto di fare apportare

modifiche a macchine già fornite.

I dati tecnici, le misure e i pesi non sono impegnativi.

Non rispondiamo di eventuali errori. Ristampa o

traduzione, anche solo parziale, solo dietro consenso

scritto della

ALoIS PÖTTINGER

Maschinenfabrik Gesellschaft m.b.H.

A-4710 Grieskirchen.

Ci riserviamo tutti i diritti previsti dalla legge sul diritto

d’autore.

Som led i den tekniske videreudvikling

arbejder PÖTTINGER Ges.m.b.H hele tiden

på at forbedre firmaets produkter.

Ret til ændringer i forhold til figurerne og beskrivelserne

i denne driftsvejledning forbeholdes, krav om

ændringer på allerede leverede maskinen kan ikke

udledes deraf.

Tekniske angivelser, mål og vægtangivelser er

uforpligtende.

Der tages forbehold for fejl.

Kopiering eller oversættelse, også delvis, kun med

skriftlig tilladelse fra

ALoIS PÖTTINGER

Maschinenfabrik Gesellschaft m.b.H.

A-4710 Grieskirchen.

Alle rettigheder forbeholdes iht. loven om ophavsret.

Som et ledd i den tekniske videreutviklingen

arbeider PÖTTINGER Ges.m.b.H. stadig

med forbedring av firmaets produkter.

Derfor tar vi forbehold om endringer i forhold til bildene

og beskrivelsene i denne bruksanvisningen, krav

om endringer på allerede leverte maskiner kan ikke

utledes fra dette.

Tekniske angivelser, mål og vekt er veiledende. Med

forbehold om feil.

Kopiering eller oversetting, også i utdrag, utelukkende

med skriftlig tillatelse fra

ALoIS PÖTTINGER

Maschinenfabrik Gesellschaft m.b.H.

A-4710 Grieskirchen.

Med forbehold om alle rettigheter iht. loven om

opphavsrett.

Beroende på den tekniska utvecklingen

arbetar PÖTTINGER Ges.m.b.H. på att

förbättra sina produkter.

Vi måste därför förbehålla oss förändringar gentemot

av bildning arna o ch be skr ivn ingar n a i d enn a

bruksanvisning.

Däremot består det inget anspråk på förändringar av

produkter beroende av denna bruksanvisning.Tekniska

uppgifter, mått och vikter är oförbindliga.

Fel förbehållna.Ett eftertryck och översättningar,

även utdrag, får endast genomföras med skriftlig

tillåtelse av

ALoIS PÖTTINGER

Maschinenfabrik Gesellschaft m.b.H.

A – 4710 Grieskirchen

Alla rättigheter enligt lagen om upphovsmannarätten

förbehålls.

F

NL

E

FIN N

I

S P

DK

GB

GEBR. PÖTTINGER GMBH

Servicezentrum

Spöttinger-Straße 24

Postfach 1561

D-86 899 LANDSBERG / LECH

Telefon:

Ersatzteildienst: 0 81 91 / 92 99 - 166 od. 169

Kundendienst: 0 81 91 / 92 99 - 130 od. 231

Telefax: 0 81 91 / 59 656

ALOIS PÖTTINGER

Maschinenfabrik Gesellschaft m.b.H

A-4710 Grieskirchen

Telefon: 0043 (0) 72 48 600-0

Telefax: 0043 (0) 72 48 600-511

e-Mail: landtechnik@poettinger.co.at

Internet: http://www.poettinger.co.at

GEBR. PÖTTINGER GMBH

Stützpunkt Nord

Steinbecker Strasse 15

D-49509 Recke

Telefon: (0 54 53) 91 14 - 0

Telefax: (0 54 53) 91 14 - 14

PÖTTINGER France

129 b, la Chapelle

F-68650 Le Bonhomme

Tél.: 03.89.47.28.30

Fax: 03.89.47.28.39

Loading...

Loading...