Pottinger SYNKRO 4003 K+T, SYNKRO 5003 K+T, SYNKRO 6003 T Operator's Manual

• Cultivator

Operator's manual

+ INSTRUCTIONS FOR PRODUCT DELIVERY . . . Page 3

Nr. 99 9765.GB.80I.1

Ihre / Your / Votre • Masch.Nr. • Fgst.Ident.Nr.

GB

SYNKRO 4003 K +T

(Type 9763 : + . . 01001)

SYNKRO 5003 K +T

(Type 9764 : + . . 01001)

SYNKRO 6003 T

(Type 9765 : + . . 01001)

ALLG./BA SEITE 2 / 0000-GB

Important information concerning Product

Liability.

According to the laws governing product liability, the manufacturer and dealer are obliged to hand the

operating manual to the customer at the time of sale, and to instruct them in the recommended operating,

safety, and maintenance regulations. Conrmation is necessary to prove that the machine and operating

manual have been handed over accordingly.

For this purpose,

-

document A is to be signed and sent to Pöttinger,

-

document B remains with the dealer supplying the machine,

-

and the customer receives document C.

In accordance with the laws of product liability, every farmer is an entrepreneur.

According to the laws of product liability, property damage is damage caused by a machine and not to

it. An excess of Euro 500 is provided for such a liabilioty.

In accordance with the laws of product liability, entrepreneurial property damages are excluded from

the liability.

Attention! Should the customer resell the machine at a later date, the operating manual must be given

to the new owner who must then be instructed in the recommended regulations referred to herein.

GB

Dear Farmer

You have just made an excellent choice. Naturally we are very happy

and wish to congratulate you for having chosen Pöttinger. As your

agricultural partner, we offer you quality and efciency combined with

reliable servicing.

In order to assess the spare-parts demand for our agricultural machines

and to take these demands into consideration when developing new

machines, we would ask you to provide us with some details.

Furthermore, we will also be able to inform you of new developments.

Dokument D

GB-0600 Dokum D Synkro

ALOIS PÖTTINGER Maschinenfabrik GmbH

A-4710 Grieskirchen

Tel. (07248) 600 -0

Telefax (07248) 600-511

GEBR. PÖTTINGER GMBH

D-86899 Landsberg/Lech, Spöttinger-Straße 24

Telefon (0 81 91) 59 0 39

Telefax (0 81 91) 59 626

GEBR. PÖTTINGER GMBH

Servicezentrum

D-86899 Landsberg/Lech, Spöttinger-Straße 24

Telefon (0 81 91) 59 0 39

Telefax (0 81 91) 59 626

- 3 -

According to the product liability please check the above mentioned items.

Please check. X

Machine checked according to delivery note. Check that the delivery is complete.

All safety equipment and operating devices at hand.

Operation and maintenance of machine and/or implement according to operating instructions explained to the

customer.

Fitting to tractor carried out.

Transporting and operating position explained.

Information given re. optional extras.

Absolute need to read the operating manual indicated.

INSTRUCTIONS FOR

PRODUCT DELIVERY

GB

In order to prove that the machine and the operating manual have been properly delivered, a conrmation is necessary.

For this purpose please do the following:

- sign the document A and send it to the company Pöttinger

(in case of Landsberg equipment: to the company Landsberg)

- document B stays with the specialist factory delivering the machine.

document C stays with the customer.

GB

CONTENTS

- 4 -

0800_GB-INHALT_9765

Attention!

Observe Safety

Points in

Supplement!

The CE sign, which is affixed

by the manufacturer, indicates

outwardly that this machine

conforms to the engineering

guideline regulations and the

other relevant EU guidelines.

Danger-flying objects; keep safe

distance from the machine as long

as the engine is running.

Never reach into the crushing

danger area as long as parts may

move.

Stay clear of swinging area of

implements

EU Declaration of Conformity

By signing the EU Declaration of Conformity, the

manufacturer declares that the machine being brought

into service complies with all relevant safety and health

requirements.

CE sign

Meaning of warning signs

Table of contents

CE sign ..........................................................................4

Meaning of warning signs .............................................4

CONNECTING TO TRACTOR

Preparing the tractor .....................................................5

Hydraulic control on the lifting gear .............................. 5

Preparing the cultivator .................................................5

Connecting to tractor .................................................... 5

C

onnecting hydraulic hoses ..........................................5

Conversion from working to transport position .............6

Driving on public roads .................................................7

Using additional implements. ........................................ 7

ADJUSTMENTS

Setting for operation ......................................................8

Equipment variants and wearing parts ..........................8

Overloading ...................................................................8

Hollow discs .................................................................. 8

Schar Schnellwechsel ................................................... 9

USE

Starting work ...............................................................10

MAINTENANCE

Safety point ................................................................. 11

General maintenance hints ..........................................11

Cleaning of machine parts ..........................................11

Parking in the ope .......................................................11

Winter storage ............................................................. 11

Drive shafts ..................................................................11

Hydraulic unit ..............................................................11

Advice for general maintence ...................................... 12

Safety points ...............................................................12

Spare parts .................................................................. 12

Hydraulic unit ..............................................................12

Cleaning of machine parts ..........................................12

Winter storage ............................................................. 12

Greasing points ...........................................................13

Description of transfers ............................................... 13

TECHNICAL DATA

Technical data .............................................................14

Position of Vehicle Identication Plate ........................14

Necessary connections ............................................... 14

Dened use of the cultivator according to the

manufacturer’s instructions. ........................................ 15

Optional equipment ..................................................... 15

DIMENSIONS

FAHRWERK

Fahrwerk 1) .................................................................. 18

Anbau ..........................................................................18

Einsatz ......................................................................... 18

SUPPLEMENT

Lubricants ....................................................................22

Combination of tractor and mounted implement ........ 24

GB

- 5 -

0700_GB-ANBAU_9765

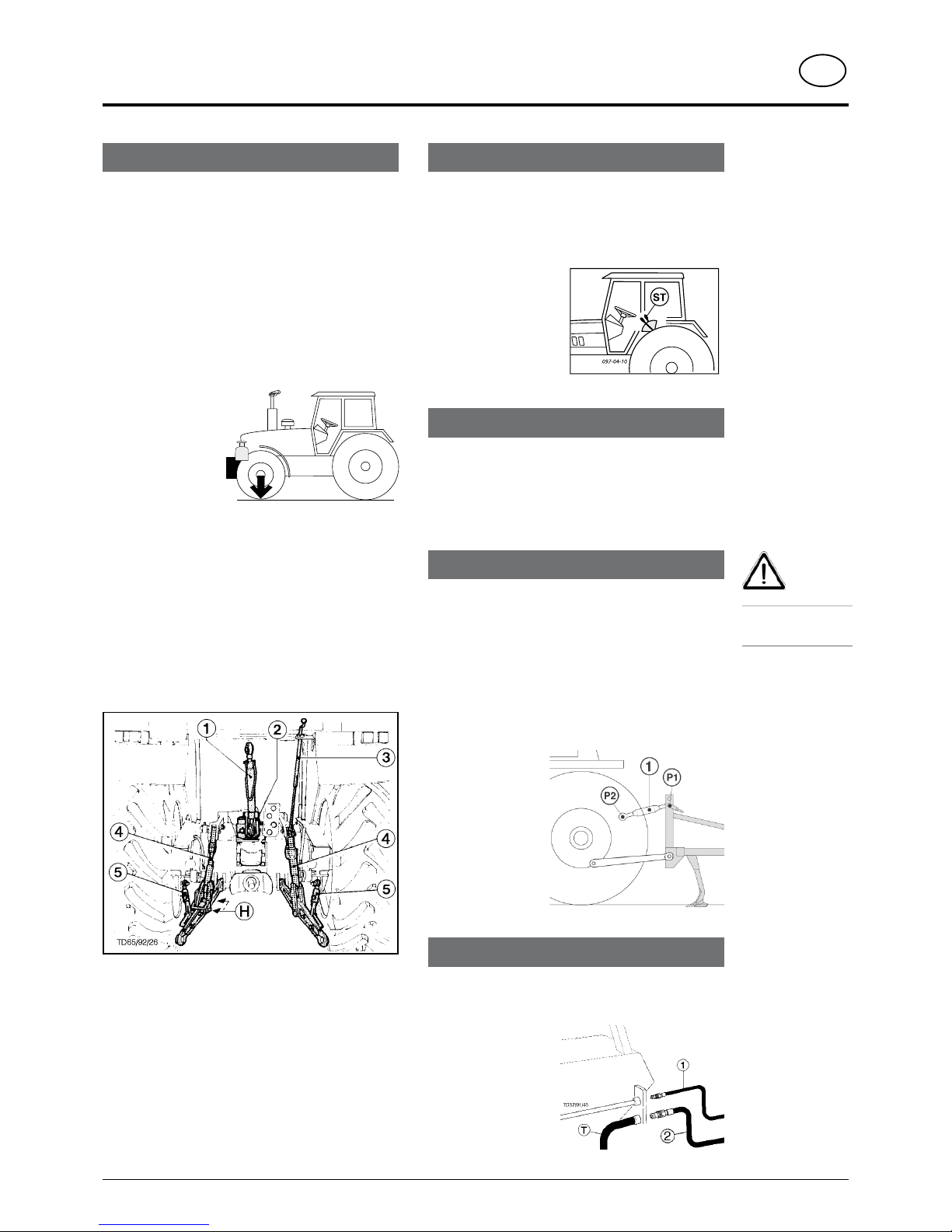

connecting to tractor

Preparing the tractor

Wheels

- Air pressure in the tractor's rear tyres should be 0.8

bar when working.

- Under heavy working conditions additional wheel

weights can be advantageos. See the tractor

manfuacturer's operating manual also.

Ballast weights

Sufficient ballast weights are to be stacked on the front

of the tractor in order to guarantee steering and braking

capabilities.

At least 20% of the

vehicle’s tare weight

on the front axle.

Lifting gear

- The left and right lifting struts (4) must be the same

length.

Adjust using adjuster (3).

-

If lifting struts (4) can be pinned at various positions

on the lower links, then select the back position (H). In

doing this, the tractor’s hydraulics will not be so greatly

overloaded.

-

Pin (2) upper link (1) in accordance with the manufacturer’s

specifications.

Setting-up for transportation

- Secure lower links with struts (5) so that attached

implement cannot swing out during transportation.

- The operating lever for the hydraulics must be secured

against lowering.

20%

Kg

Hydraulic control on the lifting gear

Control position:

For mounting and dismounting the implement and for

transportation.

The control position is the normal setting for the lifting

gear hydraulics.

T

h e m o u n t e d

implement remains at

the height (= position)

set by the servo-valve

(ST).

Preparing the cultivator

Mounting axle

Install correct mounting bar on tractor’s lifting gear

which corresponds to the connecting size (Category

II or III). See Spare Parts List also.

Connecting to tractor

- Switch tractor’s hydraulics to control position.

- Attach implement to lower link and secure with linch

pin.

Position upper link (1)

- Position upper link (1) so that the attachment point

(P1) on the implement is somewhat higher than the

attachment point (P2) on the tractor even during

operation.

C

onnecting hydraulic hoses

Double action control unit

- Connect pressure line (1) and oil-return pipe (2)

Safety

points:

see supplement-A1

Pkt. 8a. - 8h.)

GB

connecting to tractor

- 6 -

0700_GB-ANBAU_9765

- Make sure that swivel area is free and that nobody is

standing in the danger area.

- Move servo-valve (ST) to „rais“ position

The sideparts of the machine are swivelled into position

"Transport position".

-

Close hydraulic stop valve (A)

Conversion from transport to working position

- Open hydraulic stop valve (A)

- Make sure that swivel area is free and that nobody is

standing in the danger area.

-

Move servo-valve (ST) to „lower“ position

The sideparts of the machine are swivelled into position

"Working position".

Transport position SYNKRO

Safety Precaution!

Changing from

working to

transport position

is only to be

carried out on

even, firm ground.

Conversion from working to transport position

Working position SYNKRO

(A)

X = 4 m (Synkro 4003 K)

X = 5 m (Synkro 5003 K)

X = 6 m (Synkro 6003 K)

GB

connecting to tractor

- 7 -

0700_GB-ANBAU_9765

Driving on public roads

• Observe the official regulations of your country.

• Parts and attachment

- see spare parts list

• Travelling on open roads may only be carried out as

described in chapter "Transport position".

Total width of implement in the work position:

- more than 3m

Total width of implement in the transport

position:

see Technical Data

Parking, cleaning and winter storage of the

implement

• Observe the points in the chapter „Maintenance“!

Using additional implements.

Mount additional implements to the cultivator, such

as the drillbox (DB), according to the manufacturer’s

instructions.

• Do not overload the cultivator. If in doubt contact our

customer service office.

•

In addition, observe the power range limits of the tractor

in use.

- 8 -

0700_GB-EINsTELLUNGEN_9762

adjustments

DK

Setting for operation

1. The implement must be attached to the tractor in a horizontal

position, it should not hang to one side.

2. The front and rear tine rows must penetrate the ground at the

same depth (working depth).

The

frame should sit parallel to the ground surface as seen

longitudinally.

3.

Fix the lower link (4) in such a way that the machine cannot swing

out sideways.

Equipment variants and wearing parts

Rigid tines (basic equipment)

Spring-mounted tines (optional extra)

• Can be backfitted on all types

Backfitting kit (2 & 2a)

(see spare parts list)

-

Basic setting = 330 mm

Wearing parts

- are screwed to the tines and can therefore be replaced at little

cost.

Overloading

Shearing screws

Tines are secured with shearing

screws.

The shearing screw (pos. 7) breaks

when overloaded and the tine

swings upward.

-

Remove the shearing screw

remains.

-

Loosen hexagonal screw (6).

- Swing tine back to working

position.

-

Insert new shearing screw and

tighten both screws.

I

mportant!

Only use genuine shearing screws (see spare parts

list) of appropriate dimension and quality. Under no

circumstances use screws with a greater or lesser

strength.

344-05-14

7

6

Hollow discs

- serve to level out the ground surface evenly.

Setting the hollow discs

• This setting should suit the relevant operating conditions (type

of ground, speed and straw layer on the ground).

• The hollow discs are always set at the required working

depth.

Only fine adjustment is necessary

344-05-14

7

6

adjustments

- 9 -

0700_GB-EINsTELLUNGEN_9762

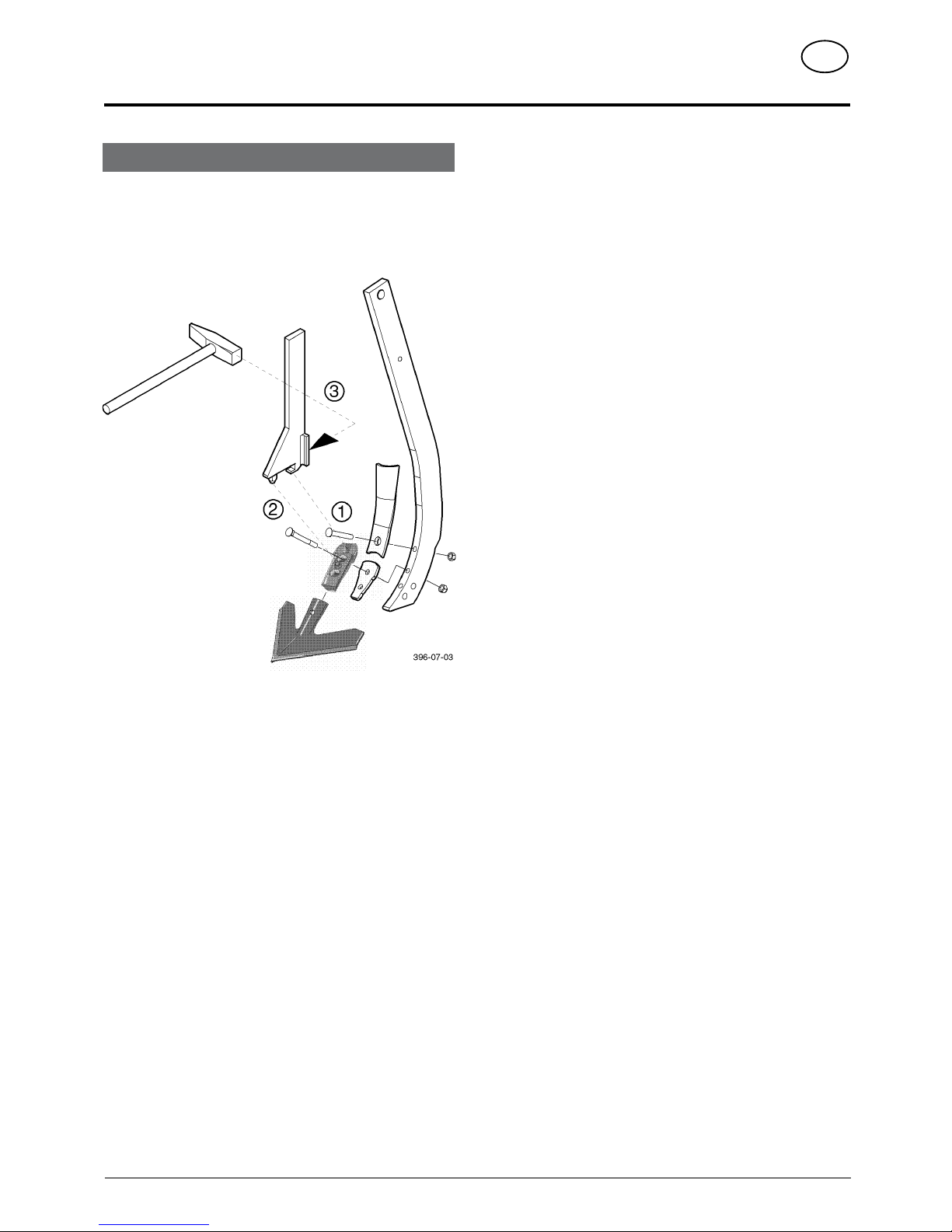

Share quick-change

1. Use change key

2. Press down on lock button

3. Release share with a hammer blow

DK

- 10 -

0700_GB-EINsATz_9762

use

GB

1. Check for proper attachment.

Before initial operation check all screws for tightness and retighten

if necessary.

2. Set required working depth.

Position both the support arms with pins (6) accordingly.

3. Swing hollow discs (left and right) into working position

(A)

Make sure pins (7) are inserted accordingly

4. Lower implement to the ground using tractor’s lifting

gear.

Drive a few metres into the working area then check the working

depth and the closing of the tine furrows.

5. If necessary, adapt tine angle to the operating conditions

(SK, EX).

Pos. B: Swivel the tines back (pos. B) if the required working

depth is not being obtained, e.g. with very heavy

ground.

Pos. N: Normal tine position.

SK

B

N

344-05-11

TD 34/95/20

5

2/3

1/3

Starting work

Basic setting for hollow discs: 1/3 of the total working depth.

O: Upper pins

To secure the trailer

U: Lower pins

For setting the working depth

Working depth difference from hole to hole of approx. 1.5 cm

Always change both pins!

Loading...

Loading...