Pottinger PRIMO 350, PRIMO 450, PRIMO 400, PRIMO 500, PRIMO 630 Operator's Manual

...

GB

/PERATOR@SMANUAL

).3425#4)/.3&/202/$5#4$%,)6%290AGE

4RANSLATIONOFTHEORIGINAL/PERATING-ANUAL

PRIMO 350 (Type 1601 : + . . 01001)

PRIMO 400 (Type 1602 : + . . 01001)

PRIMO 450 (Type 1603 : + . . 01001)

PRIMO 500 (Type 1604 : + . . 01001)

PRIMO 630 (Type 1606 : + . . 01001)

PRIMO 800 (Type 1608 : + . . 01001)

.R 99 1602.GB.80I.0

Silage wagon

Ihre / Your / Votre • Masch.Nr. • Fgst.Ident.Nr.

GB

Dear Farmer

You have just made an excellent choice. Naturally we are very happy

and wish to congratulate you for having chosen Pöttinger. As your

agricultural partner, we offer you quality and efciency combined with

reliable servicing.

In order to assess the spare-parts demand for our agricultural machines

and to take these demands into consideration when developing new

machines, we would ask you to provide us with some details.

Furthermore, we will also be able to inform you of new developments.

Important information concerning Product

Liability.

According to the laws governing product liability, the manufacturer and dealer are obliged to hand the

operating manual to the customer at the time of sale, and to instruct them in the recommended operating,

safety, and maintenance regulations. Conrmation is necessary to prove that the machine and operating

manual have been handed over accordingly.

For this purpose,

document A is to be signed and sent to Pöttinger,

-

document B remains with the dealer supplying the machine,

-

- and the customer receives

In accordance with the laws of product liability, every farmer is an entrepreneur.

According to the laws of product liability, property damage is damage caused by a machine and not to

it. An excess of Euro 500 is provided for such a liabilioty.

In accordance with the laws of product liability, entrepreneurial property damages are excluded from

the liability.

Attention! Should the customer resell the machine at a later date, the operating manual must be given

to the new owner who must then be instructed in the recommended regulations referred to herein.

document C.

ALLG./BA SEITE 2 / 0000-GB

GB

INSTRUCTIONS FOR

PRODUCT DELIVERY

Dokument D

ALOIS PÖTTINGER Maschinenfabrik GmbH

A-4710 Grieskirchen

Tel. (07248) 600 -0

Telefax (07248) 600-511

GEBR. PÖTTINGER GMBH

D-86899 Landsberg/Lech, Spöttinger-Straße 24

Telefon (0 81 91) 92 99-111 / 112

Telefax (0 81 91) 92 99-188

According to the product liability please check the above mentioned items.

Please check. X

Machine checked according to delivery note. All

attached parts removed. All safety equipment, drive

shaft and operating devices at hand.

Function of electrical installation checked and

explained.

GEBR. PÖTTINGER GMBH

Servicezentrum

D-86899 Landsberg/Lech, Spöttinger-Straße 24

Telefon (0 81 91) 92 99-130 / 231

Telefax (0 81 91) 59 656

Hydraulic connection to tractor established and

Operation and maintenance of machine and/or

implement according to operating instructions

explained to the customer.

checked re. correct supply.

Hydraulic functions (drawbar, opening of rear gate, etc.)

demonstrated and explained.

Tyres checked re. correct pressure.

Handbrake and operating brake tested re. function.

Wheel nuts checked re. tightness.

Drive shaft cut to correct lenght.

Trial run carried out and no defects found.

Correct power-take-off speed indicated.

Mechanical functions (opening of rear gate, pivoting

of cutting mechanism out/in, etc.) demonstrated and

explained.

Removing and mounting of knives explained.

Electrical connection to tractor established and

checked re. correct supply (54 g connected). Note

references in operating manual.

Fitting to tractor carried out: hight of drawbar

adjusted, brake cable installed, hand brake lever

assembled in tractor cabin.

Functions explained during trial run.

Automatic on/off switch of loading mechanism

checked.

Pivoting in transporting and operating position

explained.

Information given re. optional extras.

Absolute need to read the operating manual indicated.

In order to prove that the machine and the operating manual have been properly delivered, a conrmation is necessary.

For this purpose please do the following:

- sign the document A and send it to the company Pöttinger

(in case of Landsberg equipment: to the company Landsberg)

- document B stays with the specialist factory delivering the machine.

- document C stays with the customer.

GB-0600 Dokum D Anhänger

- 3

Table of contents

WARNING SIGNS

CE sign ......................................................................6

Meaning of warning signs.......................................... 6

PUTTING INTO OPERATION

General safety tips for using the trailer ...................... 7

Before starting work .................................................. 8

FIRST-TIME CONNECTION TO TRACTOR

Hydraulic connection ................................................. 9

Connecting hydraulic lines ........................................ 9

To make the connection to the tractor .................... 10

Adjusting the hose container ................................... 10

Adjusting the trailer coupling .................................. 11

Vibration absorption 1) ............................................. 11

Setting the pivoting drawbar ................................... 11

Locking the trailing front axle .................................. 12

SUPPORTING WHEEL

Raising the jack stand by hand ............................... 13

Garaging the trailer .................................................. 13

PICK-UP

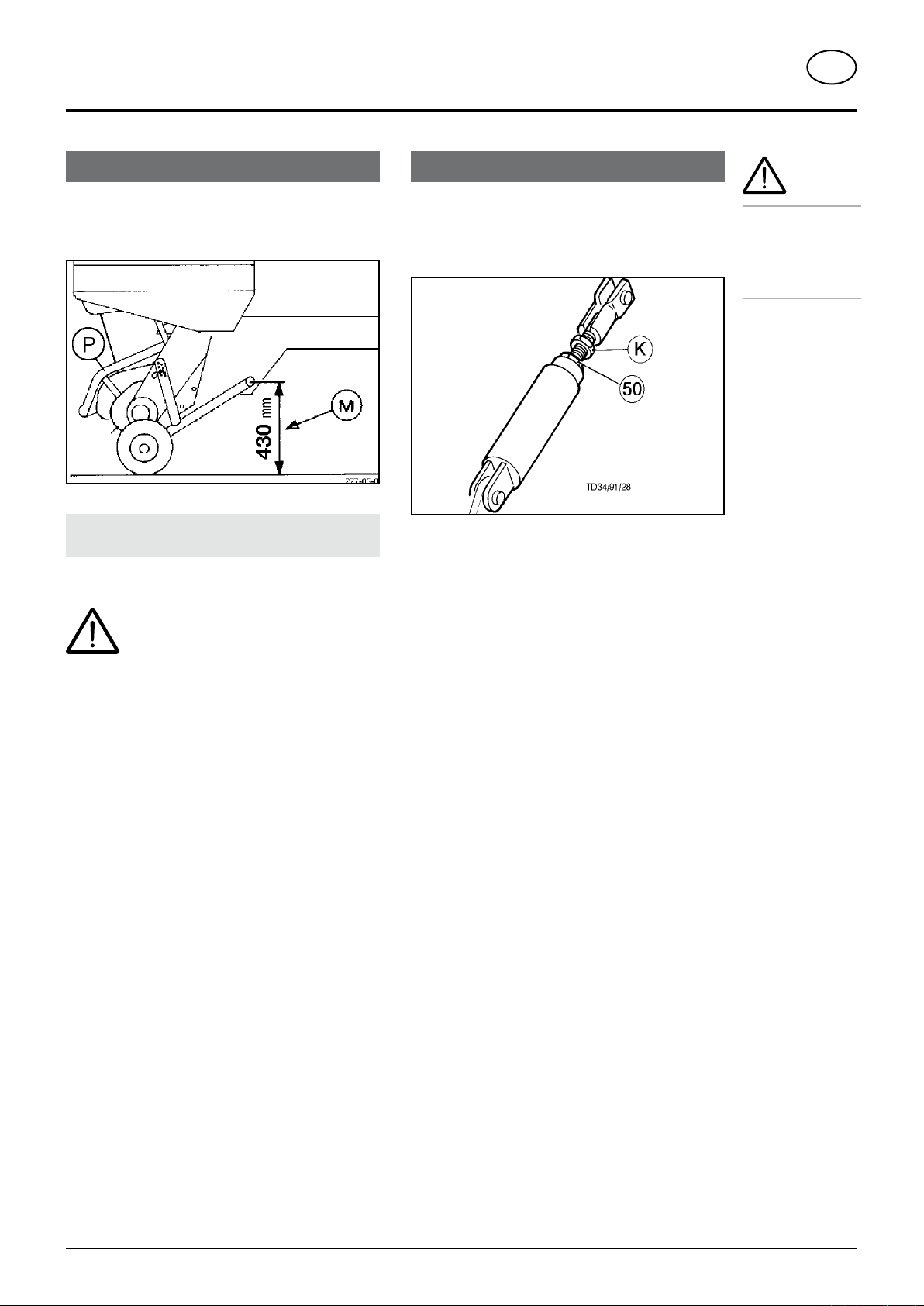

Height (M) = 430 mm ...............................................14

Setting of Pick-up pivoting area .............................. 14

CUTTER UNIT

Swivelling out upper cutter bar................................ 15

Swivelling out lower cutter bar ................................ 15

Swivelling out cutter bar hydraulically 1) .................16

Swinging cutter bar out to the side for

maintenance 1) ........................................................ 17

Removal and installation of a cutter ....................... 18

Safety points ............................................................ 18

Maintenance of cutters ............................................ 18

Disruption when swivelling out 3) ............................ 19

Alteration of gas container pressure ........................ 19

Maintenance ............................................................ 19

Adjusting the cutter beam ....................................... 20

TAILGATE

Safety mechanism .................................................. 21

Unloading using dispensing rollers.......................... 21

TAILGATE

Hydraulic opening and closing of the tail gate ........ 22

Safety device for closing of tailgate ........................ 22

Variations ................................................................. 23

Removal of regulating rollers ................................... 24

REGULATING ROLLERS

Scraper floor switch................................................. 25

Installing an oil pressure switch ............................... 25

TOP FRAME SECTION

Assembling the top frame section ........................... 26

DIRECT CONTROL - OPERATION

"DIRECT CONTROL" operating unit........................ 27

Carry out required hydraulic function ...................... 27

Loading functions .................................................... 28

Unloading functions ................................................. 29

Pivoting drawbar / Forage top frame ....................... 29

Automatic Loader- unloader 3) ................................ 30

Switching on automatic loader ................................ 30

Switching on automatic unloader ............................ 30

TABLE OF CONTENTS

POWER CONTROL - OPERATION

Configuration ........................................................... 31

Control panel ........................................................... 31

Button indication ..................................................... 31

Power control initial operation ................................. 32

WORK Menu loading functions ............................... 32

WORK menu unloading functions ........................... 34

SET functions .......................................................... 37

Diagnostic functions ................................................ 39

Cutting unit monitoring ............................................ 39

Sensor test .............................................................. 40

Adjusting machines ................................................. 40

Wireless Power Control - Control ............................ 41

Charging the AC ...................................................... 41

AC discharge ........................................................... 42

Radio contact range ................................................ 42

Pairing ...................................................................... 42

ISOBUS - TERMINAL

Operation ISO-terminal ............................................ 44

Start menu ............................................................... 45

Base setting menu ................................................... 45

Loading menu .......................................................... 45

Unloading menu ...................................................... 46

Unloading menu ...................................................... 47

Data menu ............................................................... 48

Config-menu ............................................................ 48

Set menu ................................................................. 49

TEST menu .............................................................. 51

Diagnostic menu ...................................................... 51

Joystick - Loader wagon configuration ................... 52

Setting the Joystick ................................................. 52

Uses of tractor data ................................................. 53

LOADING THE TRAILER

Loading process in general ..................................... 54

Adjusting the pick-up .............................................. 54

Starting the loading process.................................... 54

To observe during the loading process! ..................54

UNLOADING

Unloading the trailer ................................................ 55

Regulating equipment shut-off clutch (NS) ............. 55

Finishing the unloading process .............................. 55

MAINTENANCE

Safety point ............................................................. 56

General maintenance hints ...................................... 56

Cleaning of machine parts ....................................... 56

Parking in the ope .................................................... 56

Winter storage ......................................................... 56

Drive shafts .............................................................. 56

Hydraulic unit ........................................................... 56

Safety points ............................................................ 57

Gas container ..........................................................57

Overload clutch ....................................................... 57

Brake adjustment .................................................... 57

Opening the side protectors .................................... 57

Cutting unit .............................................................. 58

Transmission ............................................................ 59

Chains ...................................................................... 59

Press ........................................................................ 60

GB

Recommendations

for work safety

All points refering

to safety in this

manual are

indicated by this

sign.

0800_GB-Inhalt_1602

- 4 -

Once a year ............................................................. 60

Pick-up ....................................................................61

Adjusting measurement for end switch ................... 62

Oil pressure switch .................................................. 62

Changing the filter ...................................................62

Safeguarding the electrical unit ............................... 63

Maintaining electronic parts .................................... 63

Connecting the brake hoses ................................... 64

Service and maintenance on the air brake unit ....... 64

Release position on the brake unit .......................... 65

Parking the wagon ................................................... 65

AXLES AND AXLE UNITS

Lubrication points .................................................... 66

Maintenance work on wheels and brakes ............... 68

Maintenance work on the hydraulic running gear ...70

Maintenance work on the BOOGIE running gear .... 71

TROUBLESHOOTING

Troubleshooting ....................................................... 73

Disruptions and remedies to power failure ............. 74

TECHNICAL DATA

Technical data .......................................................... 76

Position of Vehicle Identification Plate ....................76

Optional equipment ................................................. 76

The defined use of the trailer ................................... 77

Correct loading ........................................................ 77

Air pressure ..............................................................78

SUPPLEMENT

Recommendations for work safety ......................... 81

Driveshaft ................................................................. 82

Lubrication chart ...................................................... 84

Lubricants ................................................................ 86

Emergency brake valve ........................................... 88

Internal hydraulic supply for cross conveyor belt .... 90

Oil tank..................................................................... 90

Pump ....................................................................... 90

Hydraulics plan (up to 2006 model) ......................... 91

Hydraulics plan (from 2006 model) .......................... 92

Job calculator layout plan ....................................... 93

Job calculator layout plan - PWM ........................... 94

Hydraulic plan .......................................................... 95

Connection diagram ................................................ 96

TABLE OF CONTENTS

GB

0800_GB-Inhalt_1602

- 5 -

WARNING SIGNS

495.163

CE sign

The CE sign, which is affixed by the manufacturer, indicates outwardly that this machine

conforms to the engineering guideline regulations and the other relevant EU guidelines.

EU Declaration of Conformity (see Supplement).

By signing the EU Declaration of Conformity, the manufacturer declares that the machine

being brought into service complies with all relevant safety and health requirements.

Meaning of warning signs

GB

Recommendations

for work safety!

All points referring

to satety in this

manual are

indicated by this

sign.

Turn engine off when adjustment,

service and repair work is to be

done.

Wait until all machine components

have stopped completely before

touching them.

Don't step on loading platform if PTO

is connected to tractor and Engine

is running.

Never reach into the crushing danger

area as long as parts may move.

Stay clear of gate swinging area while

tractor engine is running. Access

only allowed when safety lock is

applied.

Never reach into the pick-up area as

long as tractor engine is running with

PTO connected.

0400_GB-Warnbilder_548

Danger - stay clear of rotating

machine parts.

- 6 -

Warning against damage

• the bolts on the left and right

hand trailer sides must always

be equally positioned otherwise

the tailgate and swivel sections

will be damaged;

therefore

- always check before opening the

tailgate hydraulically

PUTTING INTO OPERATION

20%

Kg

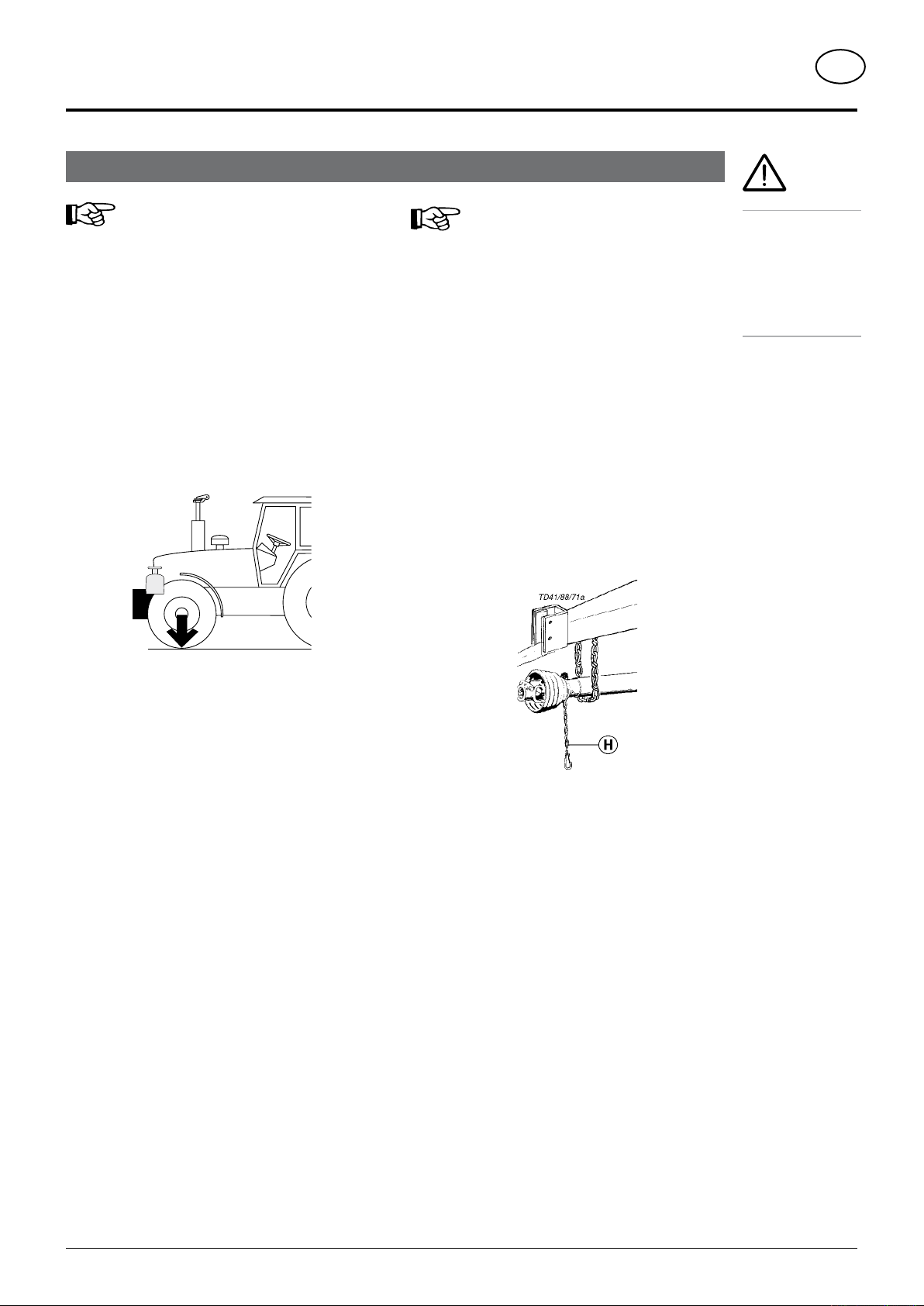

General safety tips for using the trailer

GB

Tips for travelling with the trailer

The handling of the tractor is influenced by the trailer

coupled to it.

• Danger of tipping exists when working on slopes.

• The driving must be adapted to the corresponding

terrain and ground conditions.

• Maximum speeds must be observed (depending

on implement’s equipment)

• The towing vehicle is to be sufficiently equiped

with weights at the front or at the rear in order to

guarantee the steering and braking capacity (a

minimum of 20% of the vehicle's tare weight on

the front axle).

Tips for coupling and uncoupling the

trailer

• Danger of injury exists when coupling the implement

to the tractor!

• As long as the tractor is moving backwards, do not

step between it and the trailer when coupling.

• Nobody is to stand between the tractor and trailer

without the vehicles being secured against rolling

with the parking brake and/or wheel chocks.

• Drive shaft connection or disconnection is only to

be undertaken when the motor has stopped.

• When connecting cardan shaft ensure it is properly

locked into place

Parking the implement

• When the implement ist parked, either remove the

driveshaft and store it, or secure it with a chain.

Do not use retaining chain (H) for this.

Take note!

Observe also

the tips in the

respective

chapters and in

the supplement

to this operating

manual.

• Be aware of implement’s height (especially with low

thoroughfares, bridges, overhead lines, etc.)

• The transport of persons on the machine is not

permitted.

Travelling on roads

• Observe the road rules.

• The tailgate must be closed when travelling on public

roads. Lighting devices must be fitted vertically to

the road.

Only use the trailer according to regulations!

Regulations for Use: See chapter "Technical Data".

• The trailer's load limits (permitted axle load, support

load, total weight) may not be exceeded. The relevant

details are located on the right side of the trailer.

• In addition, observe the power limits of the tractor

being used.

0700_GB-INBETRIEBNAHME_511

- 7 -

Before starting work

a. Before commencing work, the operator must be aware

of all operating devices and functions. The learning

of these is too late after having already commenced

operation!

b. The vehicle is to be tested for traffic and operating

safety before each operation.

c. The danger of being crushed or cut exists in the Pick-

up, cutting unit, tailgate and upper extension areas.

All persons must be shown out of these areas before

activating hydraulic equipment and turning on the

drive.

d. Before driving the vehicle, the driver must ensure that

nobody will be endangered and that no obstructions

are present. If the driver is unable to see and have an

overall view of the roadway directly behind the trailer,

he must be guided by somebody while reversing.

e. Observe the safety tips which are attached to the trailer.

An explanation of what the individual graphic warning

symbols mean can be found on page 5.

f. Observe also the tips in the respective chapters and

in the supplement to this operating manual.

PUTTING INTO OPERATION

Checking before operation

1. Check that all safety equipment (coverings, casings,

etc.) are in proper order and fitted in position on the

trailer.

2. Grease the trailer in accordance with the lubrication

chart. Check the gearing for tightness and the oil

level.

3. Check that tyres have the correct air pressure.

4. Check that wheel nuts are sitting firmly.

5. Ensure the correct p.t.o.-r.p.m..

6. Make the electrical connections to the tractor and

check that they are correct. Take note of the tips in

the operating manual!

7. Carry out the following adaptions:

• Drawbar height

• Laying of brake cable

• Install hand brake lever in the tractor cabin.

8. Secure trailer using only the fixtures provided.

9. Cut drive shaft to the correct length and check the

function of the overload safety (see supplement).

10. Check the electronic unit function.

11. Connect hydraulic lines to tractor.

• Check hydraulic hoses for damage and wear.

• Ensure the correct connection.

12. All swivelling parts (tailgate, adjusting lever, etc.) must

be secured against dangerous position changes.

13. Check parking brake and service brake functions.

GB

Instruction!

The following tips

should make

the trailer's

operation easier

for you. Detailled

information for

individual points

can be found in

the respective

chapters in this

operating manual.

0700_GB-INBETRIEBNAHME_511

- 8 -

7b

001-01-23

P

T

LS

7

7a

FIRST-TIME CONNECTION TO TRACTOR

GB

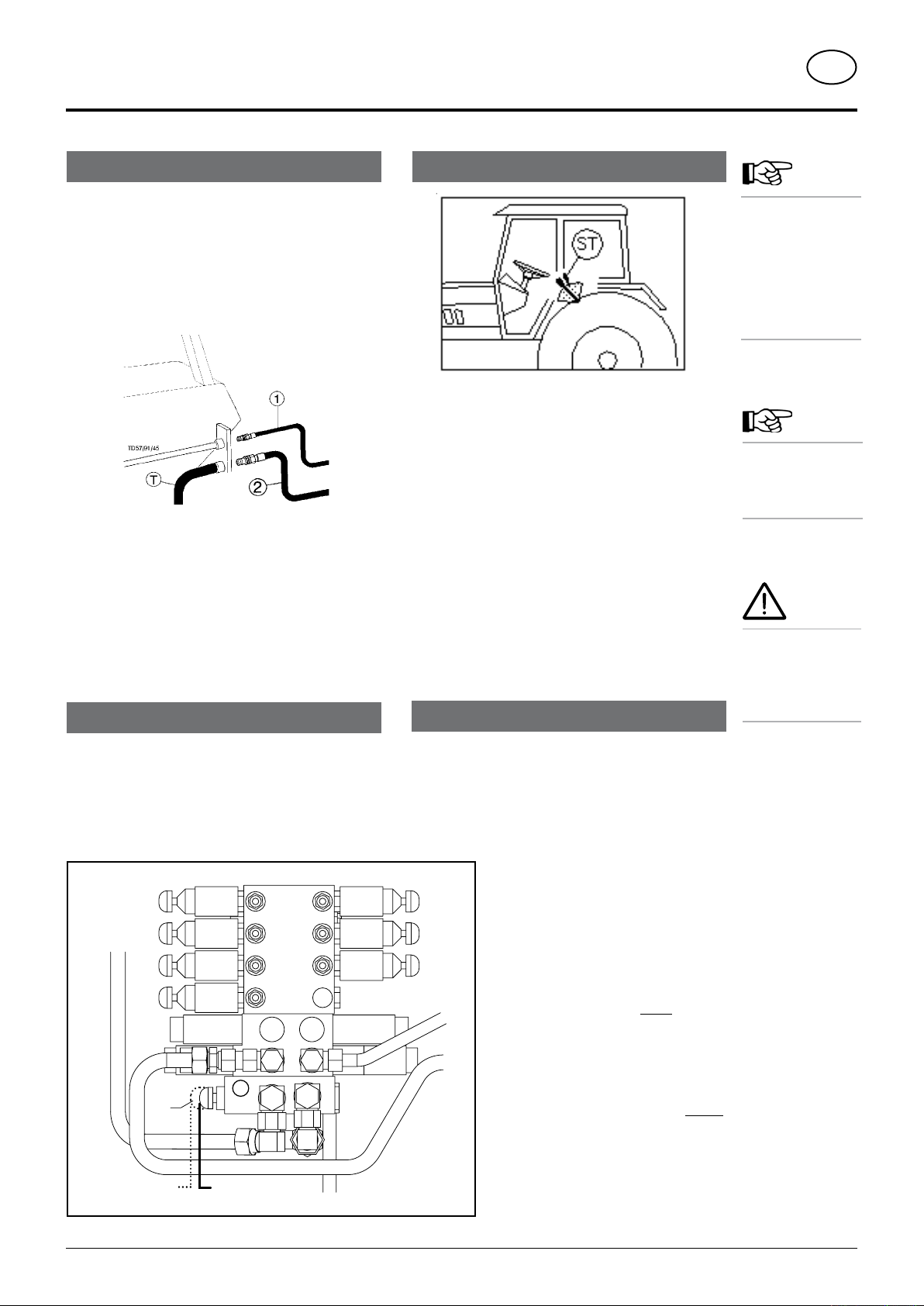

Hydraulic connection

Single-action control unit

Should the tractor only have a single-action servo-valve,

then it is absolutely necessary to have an oil-return pipe

(T) fitted by a specialist.

- Connect pressure hose (1) to the single-action control

unit. Couple the oil-return hose (2) (with the greater

diameter) to the tractor’s oil-return system.

Double-action control unit

- Connect pressure line (1) and oil-return pipe (2) (pipe

with the greater diameter is the oil-return pipe).

LS Line (Optional extra)

- Connect load sensing line to LS connection on the

tractor.

Take care with tractors with a closed

hydraulic and LS system

JOHN-DEERE, CASE - MAXXUM, CASE - MAGNUM,

FORD SERIE 40 SLE

Before coupling, the screw (7) on the hydraulic block is

to be screwed completely in (7b).

Connecting hydraulic lines

- Turn p.t.o. off before connecting

- Put lever (ST) on the control unit into the floating position

(neutral position).

- Take care that snap-lock couplers are clean.

Standard position with an open

hydraulic system

The position of the screw (7) is set in the factory

(7a).

Warning!

If this is not done then the overload valve on the tractor’s

hydraulics is continually in use and excessive warming

of the oil will occur!

Note!

If oil should

become warm

during operation

then a single-

action control

unit should be

connected (see

above).

Note!

An unpressurized

oil return must be

guaranteed on the

tractor.

Note!

The tractor’s

hydraulic

pressure must not

exceed maximum

205 bar.

0701_GB-Erstanbau_5543

7a

Standard position with an open hydraulic

system

7b

Take care with tractors with a closed

hydraulic and LS system

LS = Load sensing

- 9 -

FIRST-TIME CONNECTION TO TRACTOR

GB

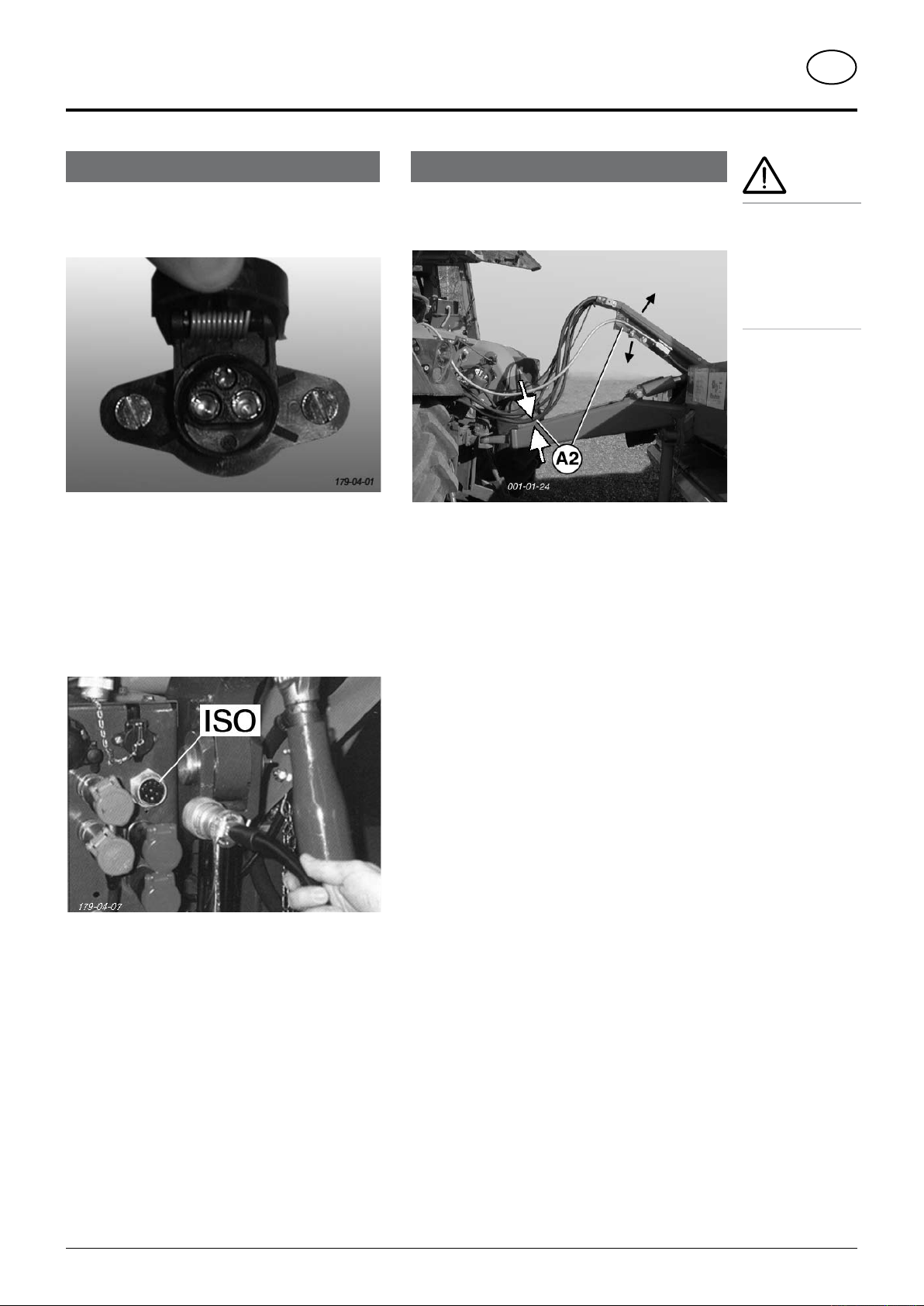

To make the connection to the tractor

Operation:

- Connect the 3-channel plug to the DIN 9680 socket

on the tractor

Lighting:

- Connect 7-channel plug to tractor

- Check that lighting is functioning on wagon

For tractors with ISO Bus control

- Connect 9-channel ISO plug to ISO Bus socket on the

tractor

Adjusting the hose container

- Adjust the hose container in such a way that there is

sufficient distance between the hydraulic lines and the

drawbar (A2).

Important!

Before putting

the tractor into

operation check

vehicle safety

(lights, brake

unit, protective

covering, .....).

0701_GB-Erstanbau_5543

- 10 -

FIRST-TIME CONNECTION TO TRACTOR

A

001-01-26

136-07-01

G

K

1 - 3 cm

A1

001-01-25

GB

Adjusting the trailer coupling

- Extend the drawbar coupling (A) so that there is sufficient

gap between drive shaft and drawbar of attached trailer,

especially in the event of pivoting (A1).

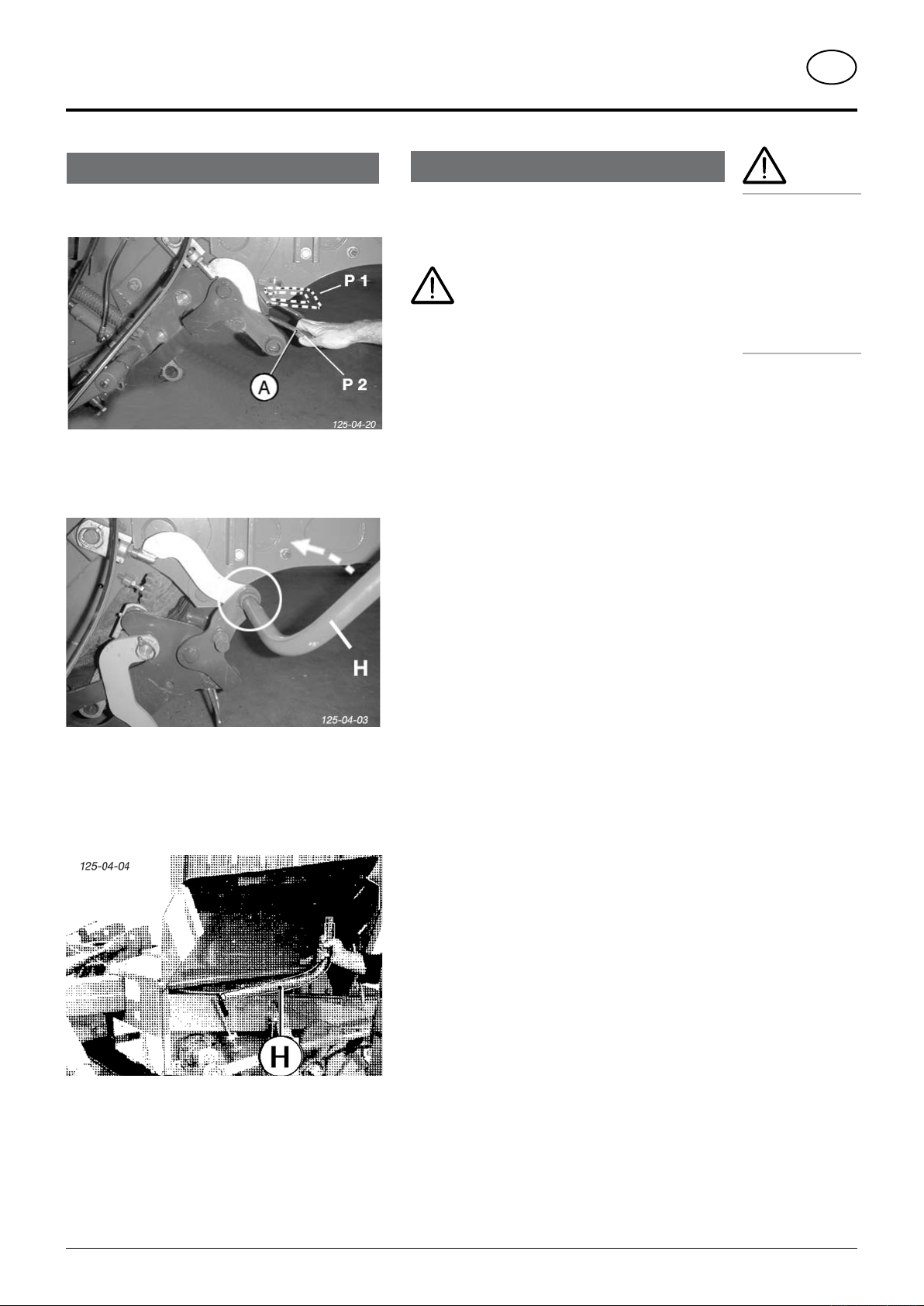

Vibration absorption 1)

Important!

To ensure that vibration absorption functions properly:

- cylinders (K) must not be completely inserted when

driving on roads

- extend cylinders (K) approx. 1 – 3 cm.

Setting the pivoting drawbar

To allow pick-up to work properly, the height (H ) of coupled

trailer must be correctly set (pick-up pivoting area).

- Setting measurement (M) see chapter “Pick-up”

Starting position:

- Couple trailer to tractor

- Both hydraulic cylinder pistons must be completely

inserted.

Adjustment process:

- Loosen lock nut (K) on the threaded spindle

- By twisting the cylinder piston (50), screw the threaded

spindle in or out until the height (M) is achieved.

Do not exceed maximum regulating limits (see table

below for L max)

- Adjustment of both hydraulic cylinders must take place

alternately

- Both hydraulic cylinders must be set at the same

length

- Retighten lock nut (K)

Note!

Damage can

occur if threaded

spindle is

unscrewed too

far. Observe

maximum

measurement

according to

table!

Pressure in the gas container (G):

Type Fill pressure

PRIMO, FARO

EUROPROFI

TORRO, JUMBO (3 to-Anhängung)

JUMBO (

2 to-mounting)

• To alter pressure – see chapter “MAINTENANCE”

1) Series factory tting for JUMBO, TORRO

Optional extra for EUROPROFI, FARO, PRIMO

0701_GB-Erstanbau_5543

50 bar

70 bar

80 bar

100 bar

Type Parts number L max

PRIMO, FARO

EUROPROFI,

TORRO, JUMBO

(2 to-mounting)

JUMBO 3t

(3 to-mountng)

- 11 -

442.240 555 mm

442.313 615 mm

FIRST-TIME CONNECTION TO TRACTOR

137-06-02

137-06-03

137-06-04

Locking the trailing front axle

GB

• The trailing front axle is operated differently depending

on tractor and wagon equipment

Variant 1

Attention!

The trailing front

axle must always

be locked during

fast road travel

with a full wagon!!!

Variant 2

- For tractors without Load sensing system:

- connect additional hydraulic line to tractor

- open or close the trailing front axle using control

(ST)

Attention!

The trailing front axle must be locked

- when travelling straight ahead quickly at 30 km/h or more

- with unpaved surfaces

- in sloped areas

- with load on the front axle through pivoting drawbar usage

- when travelling over a drive-in silo

- when lateral traction of the unguided axle is no longer sufficient

For tractors with Load sensing system:

- hydraulic line is connected to hydraulic block

- operation takes place using “POWER CONTROL”

unit or “Isobus terminal”

(see description of Control)

0700_GB-Lenkachssperre_5543

- 12 -

SUPPORTING WHEEL

GB

Raising the jack stand by hand

- Couple the trailer to tractor

- Take load off jackstand by using pivoting drawbar.

- Pull out locking bolt (1), swing jack stand up and lock

again.

- Make sure bolt is properly locked in (1).

Garaging the trailer

• Park the trailer on firm, level ground.

If the ground is soft then the area where the jack

stand is to stand must be appropriately increased

using a suitable aid (e.g. wooden board).

- Raise the trailer a little using the pivoting drawbar.

- Pull out locking bolt (1), swing jack stand down and

lock again.

- Make sure bolt (1) is properly locked in!

- Lower the trailer using the pivoting drawbar.

- Uncouple hydraulic- and electric lines and detach

trailer.

Attention!

Only garage an

empty trailer on

the jack stand

and chock the

wheels to prevent

rolling.

0500_GB-Stützfuß_1612

- 13 -

PICK-UP

GB

Height (M) = 430 mm

To allow pick-up to work properly, the height (H ) of coupled

trailer must be correctly set (pick-up pivoting area).

Note: Where the floor is uneven, reduce the measurement

by 1 cm (M = 420 mm)

The deflector (P) also serves as accident

protection and must not be removed during

operation.

Setting of Pick-up pivoting area

(Height (M) = 430 mm)

- Couple trailer to tractor

- Both hydraulic cylinder pistons must be completely

inserted.

Adjustment of both hydraulic cylinders must

take place alternately

- Loosen lock nut (K) on the threaded spindle

- By twisting the cylinder piston (50), screw the threaded

spindle in or out until the height (M) is achieved.

- Retighten lock nut (K)

Take care!

Be aware of

crushing points

when moving the

Pick-up down or

up!

0701_GB-Pick-up_1602

- 14 -

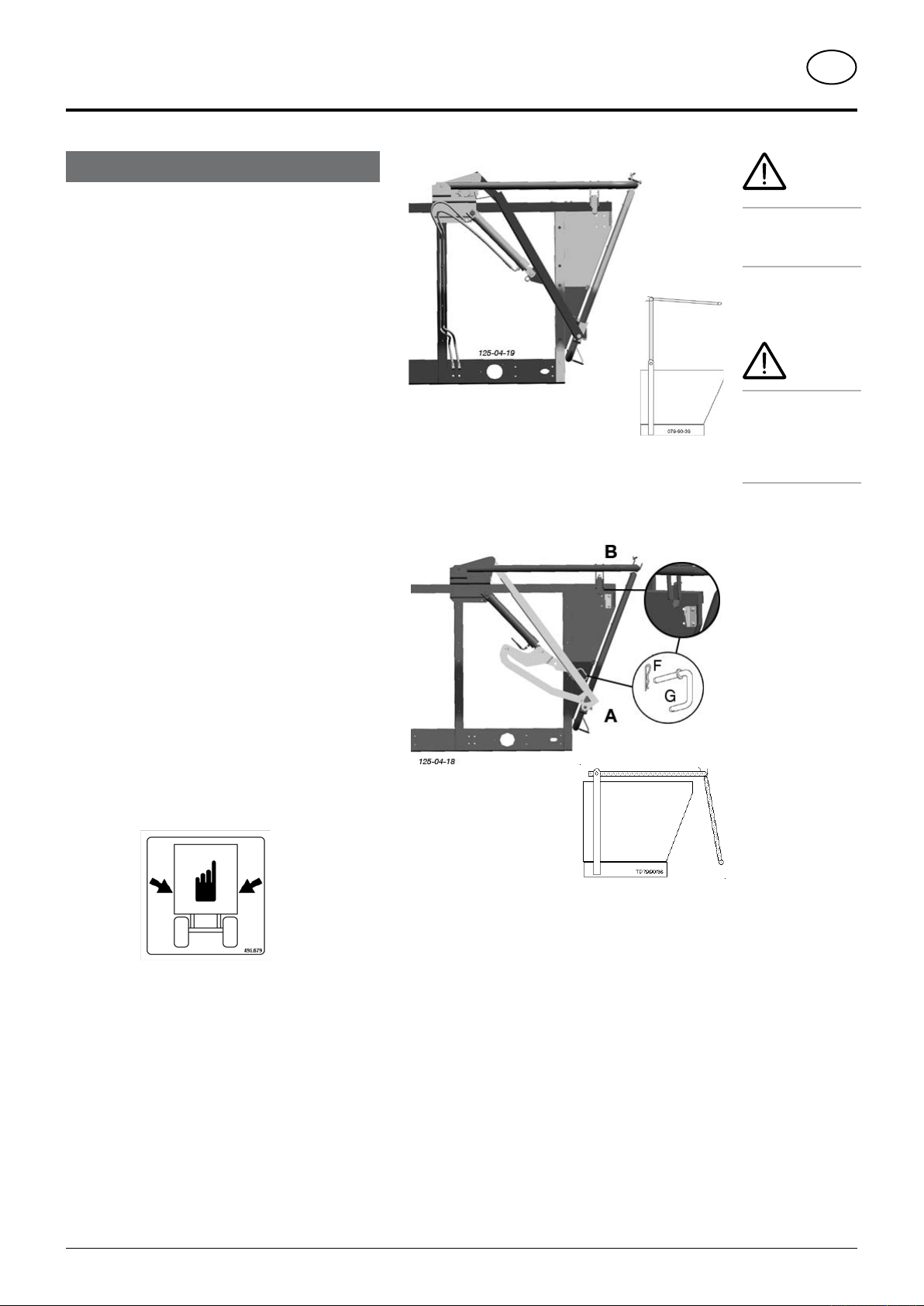

CUTTER UNIT

GB

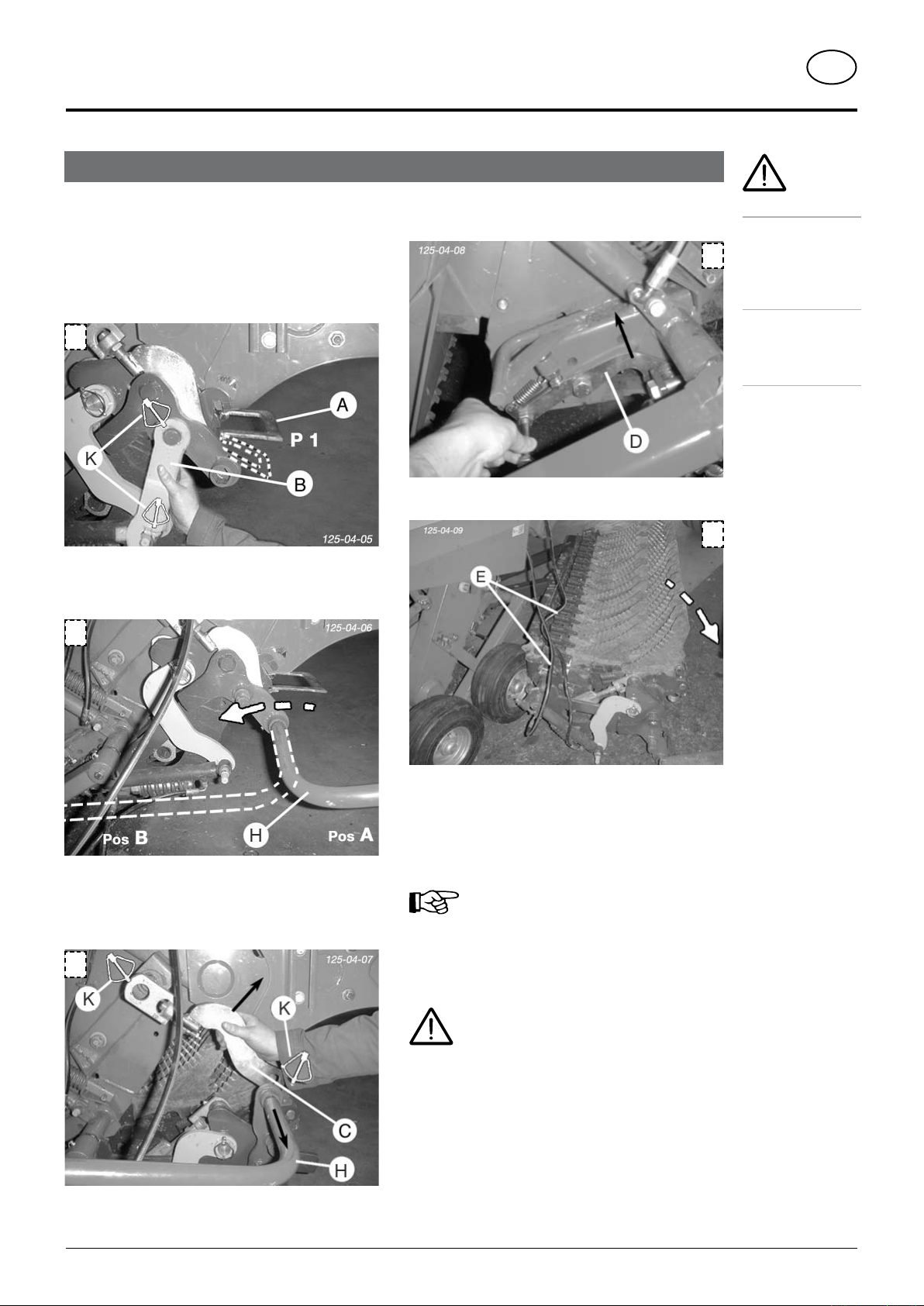

Swivelling out upper cutter bar

(Mechanically)

- Move stirrup grip (A) to position P2

- Insert lever (H) into hexagonal socket on cutter bar.

- Move lever forward.

- Cutter bar swivels out to central position.

- Lever (H) is located underneath front collapsible side

guard.

Swivelling out lower cutter bar

• When only one cutter bar is needed for mowing,

the lower cutter bar can be swivelled out using the

accoompanying lever (H).

Attention!

Do not reach into swivel range of cutter

bar when swivelling in / out.

Important checks to be carried out on the cutter

beam before each operation

- left and right hand pins locked

- for wear on the cutters

- for dirt on the cutter overload fuse

- for adequate ground clearance

* Vehicle must not be driven whilst cutter beam is in fully

extended position

General information

To facilitate maintenance work on the cutting unit, the

cutter beam can be swung on to the left-hand side of the

vehicle (Optional equipment).

All cutters are then accessible:

- for grinding the cutters

- for installing or removing the cutters

- for cleaning

Attention!

Increased chances

of injury with all

work carried out

on cutter bar,

particularly with

swinging cutter

bar in from the

side or when

swivelling it up!

0500_GB-Schneidwerk_563

- 15 -

CUTTER UNIT

GB

Swivelling out cutter bar hydraulically

- Move stirrup grip (A) to position P2

Variant with Select-Control operating unit

1)

- Swivel cutter bar out with hydraulic cylinder (Z)

- Bar locks in central position

Variant with Direct-Control operating unit

Attention!

Cutter bar is

swivelled out and

in hydraulically.

Beware of

crushing in stirrup

grip area!

3

1. Press cutting unit button (3)

- The integrated control lamp (LED) lights up

2. Activate control valve on tractor

- Cutter bar swivels out

3. Deactivate hydraulic function

- Press button, integrated control lamp (LED) goes

out

For safety reasons always deactivate the

preselected function

See chapter “Select-Control Preselection”

also

3

4

1. Swing cutting unit in

Press (3) button and hold (= touch function)

- The control lamp (LED), integrated into the key,

glows red.

- Cutting unit swivels in under pressure

2. Swing cutting unit out

Press (4) button and hold (= touch function)

- The control lamp (LED), integrated into the key,

glows red.

- cutting mechanism is swivelled out

The cutting sensor available (option) signals the LED

(constant light) of the swivelled out state.

Signal tone when Pick-up is lowered

See chapter “Direct-Control Operation” also

0500_GB-Schneidwerk_563

- 16 -

1)

Optional equipment

CUTTER UNIT

GB

Swinging cutter bar out to the side for maintenance

- Swivel cutter bar completely in

1. Lock stirrup grip (A) in position P1.

- Cutter bar is not locked in central position.

- Remove linch pin (K)

- Remove bracket (B)

1

2. Move lever (H) forward (pos B)

- Swivel cutter bar completely out

2)

2)

1)

4. Release lock (D)

- on left and right vehicle sides

5. Swing cutter bar out to side

• Turn engine off

4

when adjustment,

service and repair

machine without

5

Safety advice!

work is to be

done.

• Do not work

under the

safe support.

2

3. Remove linch pin (K) and take off left and right brackets

( C )

- Remove lever (H)

3

- Observe hydraulic lines (E) when swinging cutter bar

out to the side

Assembling the cutter bar occurs in reverse

order

Attention!

Increased chances of injury with all work

carried out on cutter bar, particularly with

swinging cutter bar in from the side or

when swivelling it up!

1)

Optional equipment - Only for variant with hydraulic cutting unit

0500_GB-Schneidwerk_563

- 17 -

CUTTER UNIT

GB

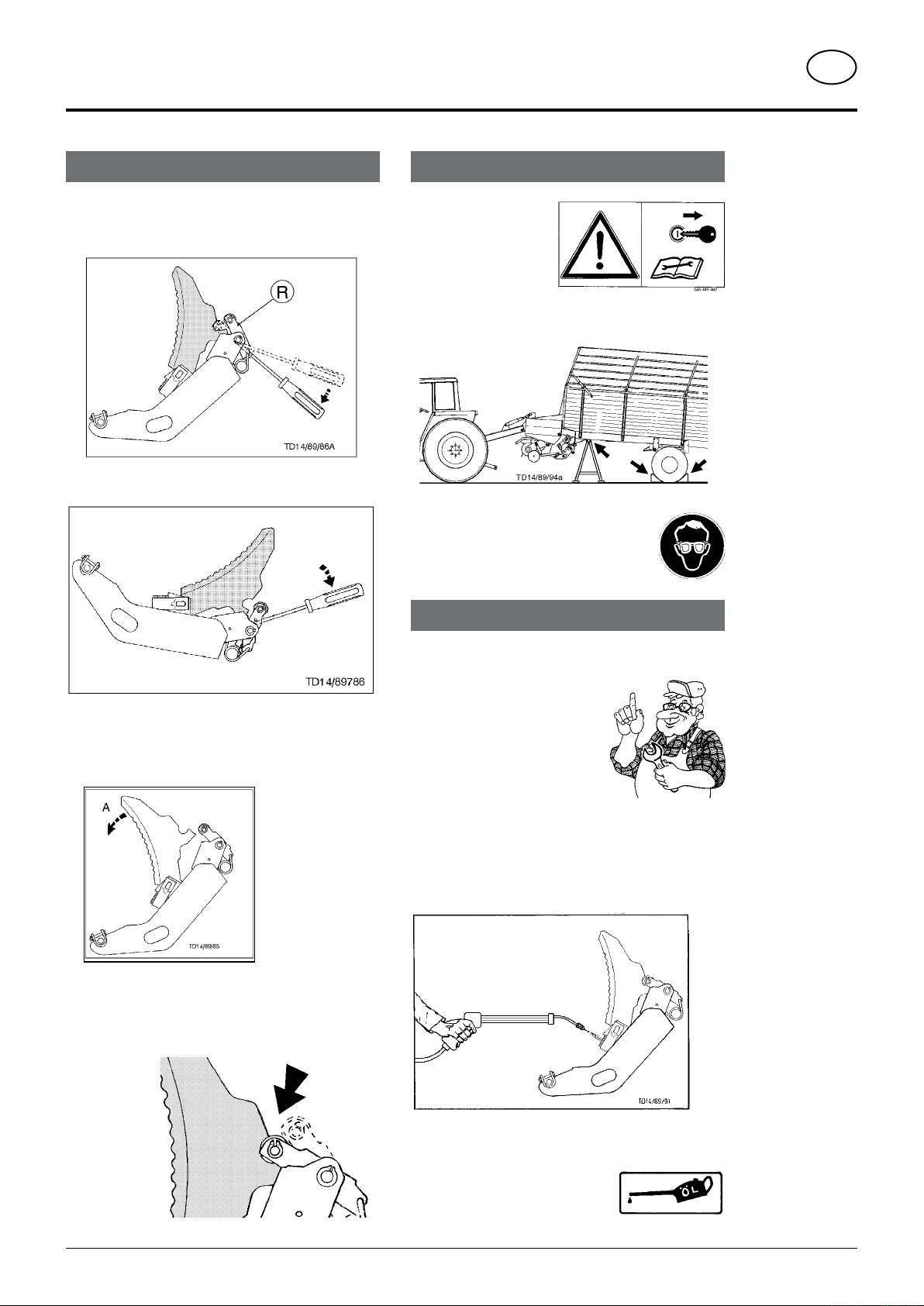

Removal and installation of a cutter

Removing a cutter from a swivelled out cutter bar.

1. Pull catch lever (R) down using screwdriver.

Removing a cutter from a swivelled up cutter bar.

Safety points

• Turn engine off when

adjustment, service

and repair work is to

be done.

• Do not work under the machine without safe

support.

• Wear protective glasses.

Maintenance of cutters

2. Swivel cutter up (position A) and remove by pulling

backwards.

Cutter installation

- Take care that catch lever caster rests properly in cutter

recess.

Well ground cutters save energy and provide good cutting

quality.

Caution!

Only grind the smooth

side of the cutter

Sensible g rinding

wi t h o ut he a ti n g

(tarnishing) the cutter

guarantees a long life.

Cutter safeguard

Regularly cleaning is recommended to guarantee the

perfect function of the cutter safeguard.

0500_GB-Schneidwerk_563

• Clean pressure springs with high pressure cleaner.

• Oil cutter and safeguard element

before winter storage!

- 18 -

CUTTER UNIT

GB

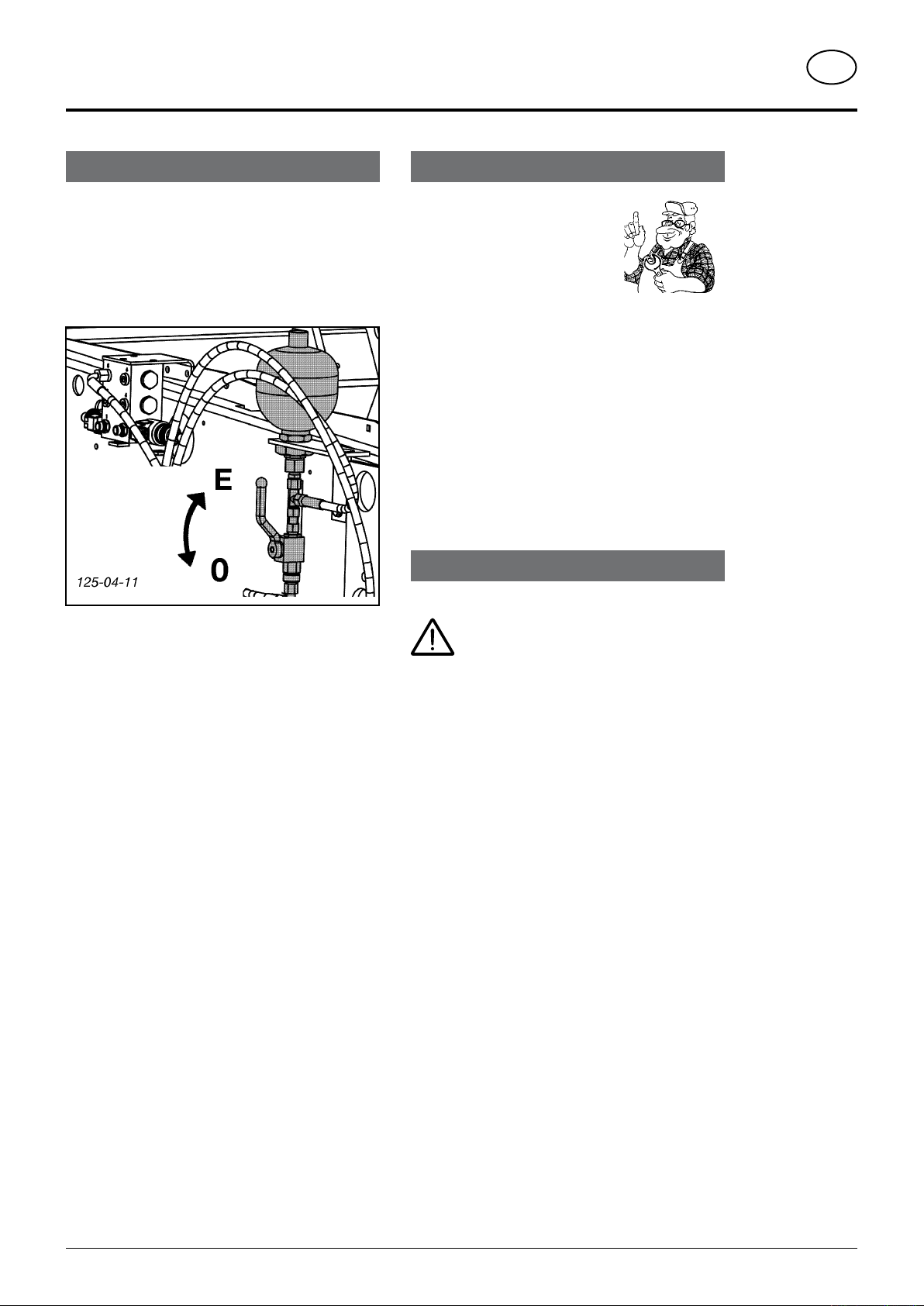

Disruption when swivelling out

- Remove foreign body from swivel range.

• When cutter bars do not swivel in properly it may be

due to pressure loss in cutting unit hydraulics.

• Remedy by hydraulically filling the reservoir

- Move lever to position "E" on 3-way valve.

- Actuate servo-valve.

3)

Alteration of gas container pressure

• This work may only be carried

out by customer service or a

specialist.

• In order to reduce or increase the

pressure in the gas container a

special filling and checking device

is necessary.

Note

• According to manufacturer's information all gas

containers have a slight pressure drop after a certain

amount of time.

• The gas loss (nitrogen) amounts to 2-3 % per year.

• After 4-5 years it is recommended that container

pressure be checked and if necessary corrected.

Maintenance

- Cutter bars are swivelled out hydraulically.

- Leave servo-valve (ST) in the press position for a few

seconds while moving the lever on the 3-way valve to

position "0".

• If obstruction cannot be removed then check gas fill

pressure (100 bar nitrogen) in hydroreservoir.

Beware!

No welding, soldering or mechanical

works of any kind may be carried out

on the container.

• Hydraulic oil change according to tractor manual.

• Before welding on trailer disconnect all plugs from

tractor and disconnect trailer.

3)

Only for variant with Select-Control operation

0500_GB-Schneidwerk_563

- 19 -

125-04-29

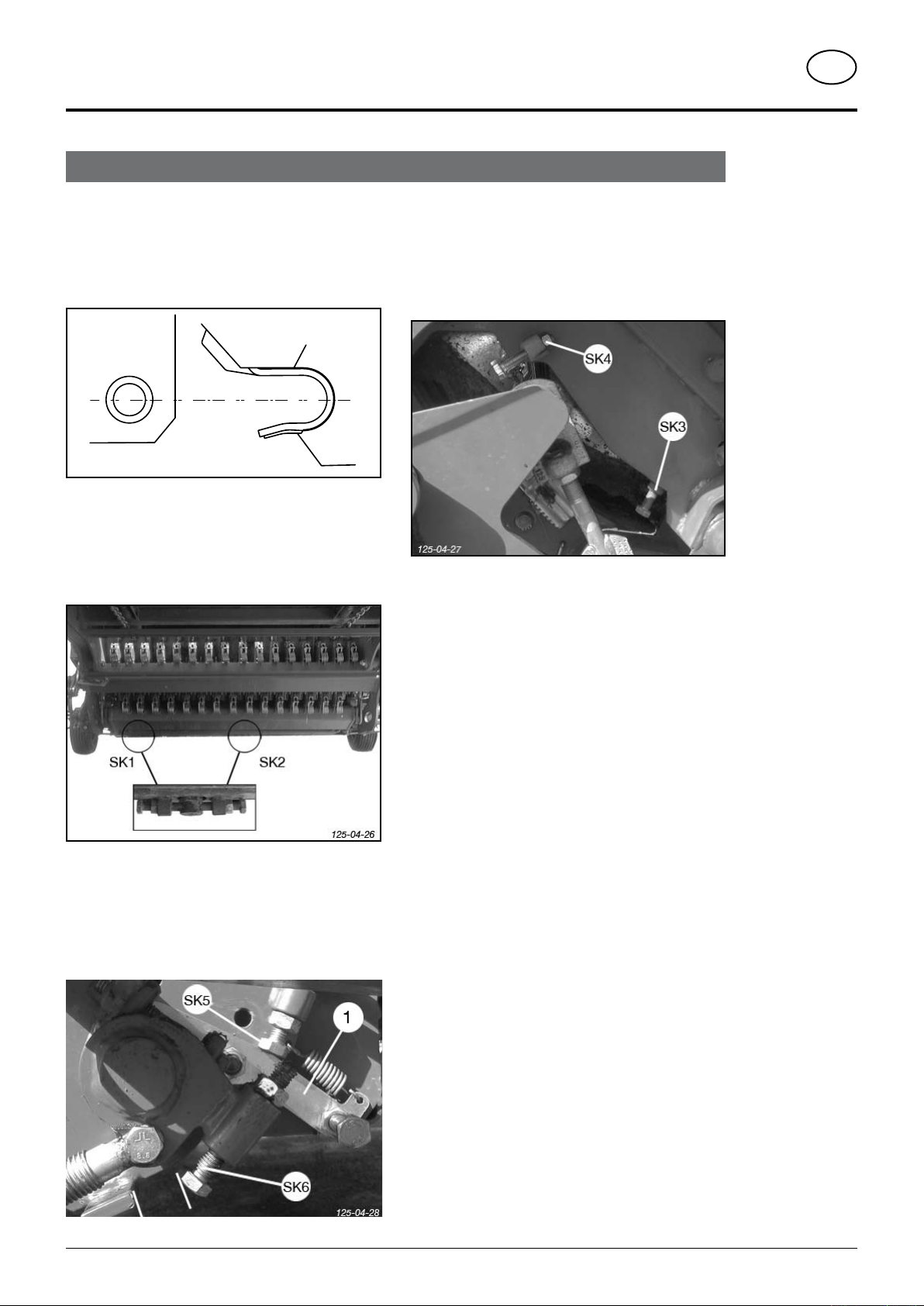

Adjusting the cutter beam

CUTTER UNIT

GB

Set cutter beam vertically

- When the cutter frame is swung back in, the setting

should be such, that it enables the frame tubing to fit

into the opening on the moulded frame without any

difficulty (see sketch).

Adjustment on the underside of the cutter beam

- Firstly, adjust the height with screws (SK1)

- Then adjust horizontally with screws (SK2)

- Repeat procedure if necessary

Secure the cutter beams against unintentional

swinging out

The screws (SK3 and SK4) prevent the cutter beams

from swinging out during operation

- Screw (SK4) for the upper cutter bar

- Screw (SK3) for the lower cutter bar

Setting

- Loosen locking nut

- Turn the screw far enough to place light pressure

on the cutter beam

- Secure screw with locking nut

Adjusting screws for lower cutter beam

- The catch hook (1) is adjusted with screws (SK5)

- The limit stop in the lower position of the cutter beam

is adjusted with (SK6)

0500_GB-Schneidwerk_563

- 20 -

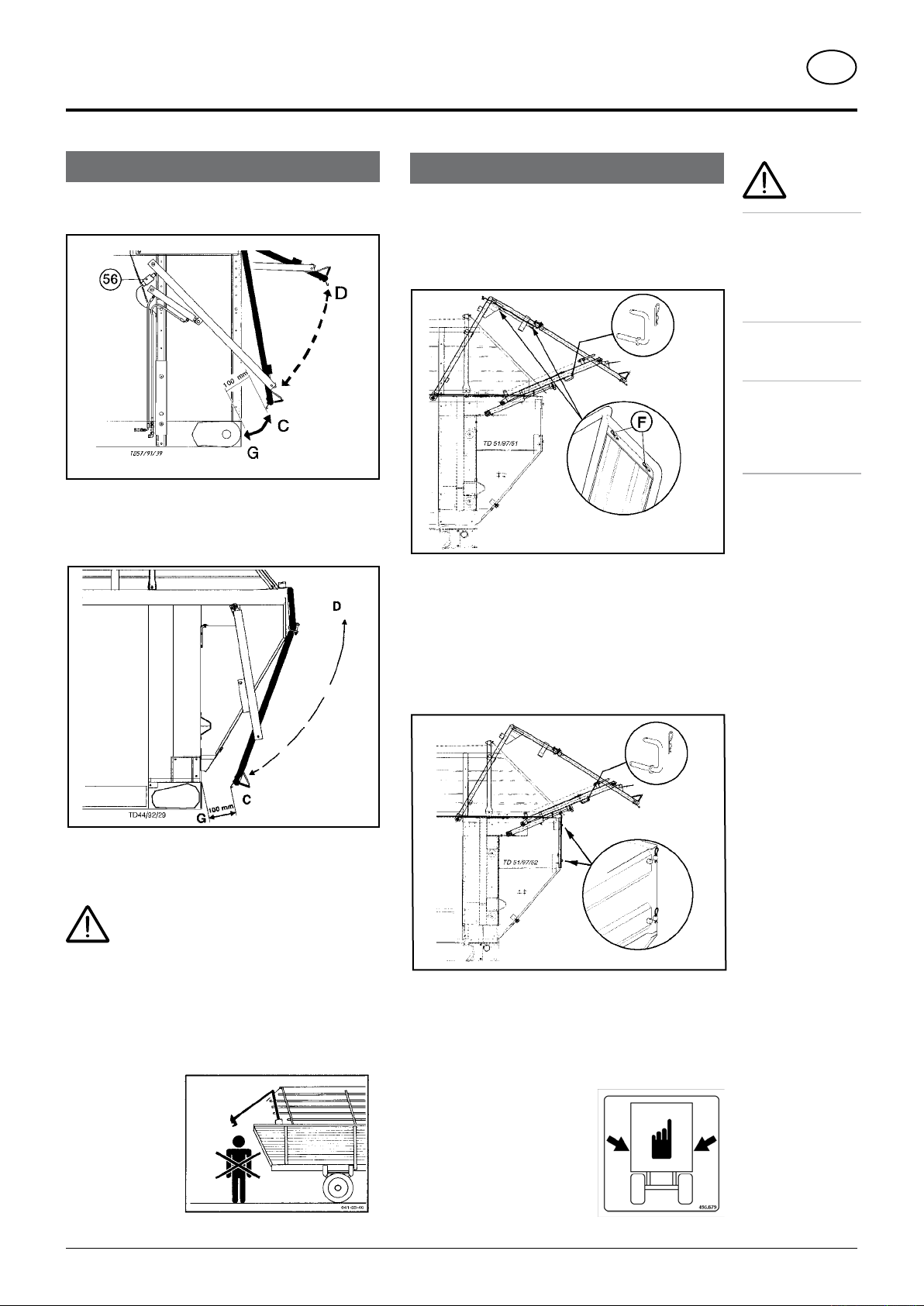

TAILGATE

GB

Safety mechanism

The tailgate’s own weight is used to lower it to position

C. No other pressure is used.

Only when in this position (C) is the hydraulic function activated through switch (56) and the tailgate is

closed under pressure.

Unloading using dispensing rollers

Variations

1. Standard dispensing

• Rear steel section fixed to swivel frame

- secure with linch pin (F) (left and right)

2. Fine dispensing

• Rear steel section fixed to side walls

- secure with spring pin (F) (left and right)

The forage falls evenly distributed to the ground as with

standard dispensing

Attention!

Nobody should

be within the

swinging range

of the tail gate

when opening and

closing!

Do not stand

underneath the

raised tail gate!

Travelling on public

roads must only

be undertaken

with the tailgate

closed!

With all of these switching procedures, be

alert to the danger distances!

An example:

Danger of injury arises if a person stands

at the rear of the trailer and somebody in

the tractor cabin activates a switching

function (opening the tailgate, switch on

the driving gear, ...).

0400_GB-Rückwand_5543

Warning against damage

• The bolts on the left and right hand trailer sides

must always be equally positioned otherwise the

tailgate and swivel sections will be damaged

therefore

- alway s check befo re

opening the t a i l g a t e

hydraulically

- 21 -

Hydraulic opening and closing of the tail gate

G

C

56

125-04-17

ca

.

100

m

m

TAILGATE

GB

Do not stand underneath the raised tail

gate!

- Opening and closing is effected hydraulically from the

tractor seat.

- Locking takes place automatically.

- Tailgate must be closed when driving on the road.

Safety device for closing of tailgate

Variant with DIRECT-CONTROL operation

The tailgate’s own weight is used to lower it to position

C. No other pressure is used.

Only when in this position (C) is the hydraulic function

activated through switch (56) and the tailgate is closed

under pressure.

For opera tion s ee chap ter “D IRECT-CO NTROL

operation”

Attention!

Nobody should

be within the

swinging range

of the tail gate

when opening and

closing!

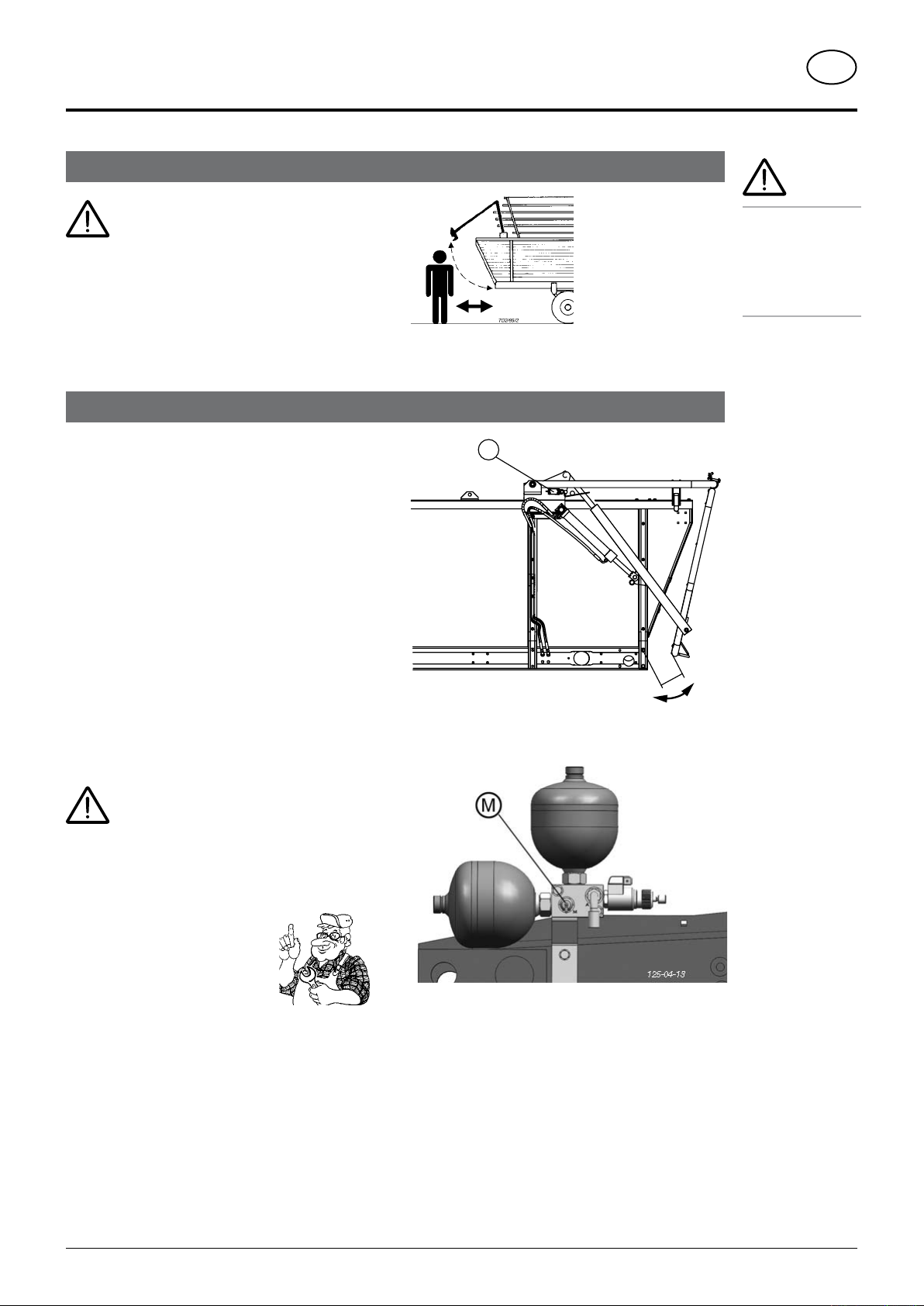

Variant with Select-Control operation

Attention!

Compressed air is used to lower and close

the tailgate

- Danger of crushing when closing

• In order to reduce or increase the

pressure in the gas container a

special filling and checking device

is necessary (M).

Pressure in the gas container: 25

bar Nitrogen (N).

• This work may only be carried out by customer service

or a specialist.

See also “Alter pressure in gas container “ in chapter

“CUTTER UNIT”

Fo r operation see chapter “ SELE CT-CONTROL

Preselection”

0500_GB-Rückwand_563

- 22 -

Variations

Rigid tailgate strut

- The tail gate and the tubular frame swing all the way

to the top when opening.

For operation see

- Select-control preselection or

- Direct-control operation

TAILGATE

underneath the

raised tail gate!

Travelling on public

roads must only

be undertaken

with the tailgate

GB

Attention!

Do not stand

Attention!

closed!

Adjustable tailgate strut

- Open or close whole tailgate as with rigid tailgate

strut.

In addition it is also possible

- Lock tubular frame against raising

- by repositioning both hooks (G)

- from position (A) to position (B)

- The tail gate swings backwards when opening.

For operation see

- Select-control preselection or

- Direct-control operation

Warning against damage

• The bolts on the left and right hand trailer sides

must always be equally positioned otherwise the

tailgate and swivel sections will be damaged

therefore

- al ways check before opening t he tailgate

hydraulically

0500_GB-Rückwand_563

- 23 -

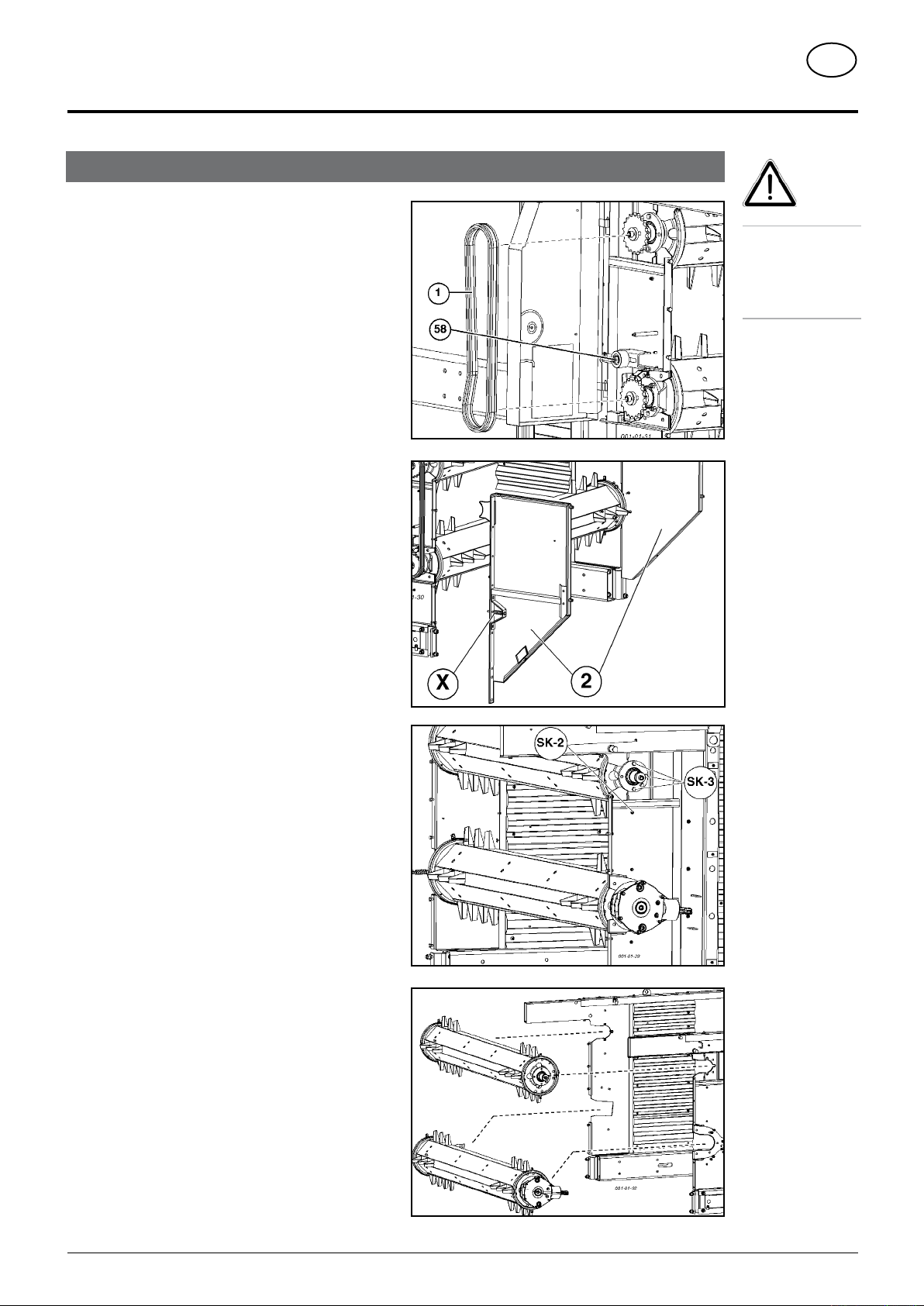

Removal of regulating rollers

REGULATING ROLLERS

GB

1. Open trailer tailgate.

2. Relax chain tension (58) and take off drive

chain (1).

3. Remove metal plates (2) left and right.

Take care! Do not after the torque pre-tensioning (X)

4. Dismantling Upper Regulating Roller

remove the following screws, left and right:

- three screws (SK-3) on the flange bearing

- two screws (SK-2) on the guard ring

5. Dismantling the Lower Regulating Roller

remove two screws (SK-2) on the guard ring, left and

right

6. Slide regulating rollers backwards.

7. Re-fit metal plates (2) left and right again.

Take care!

Do not reach into

regulating rollers

area while drive

motor is still

running.

8. Adjusting the switch

- see next page

0700_GB-DOSIERER_548

- 24 -

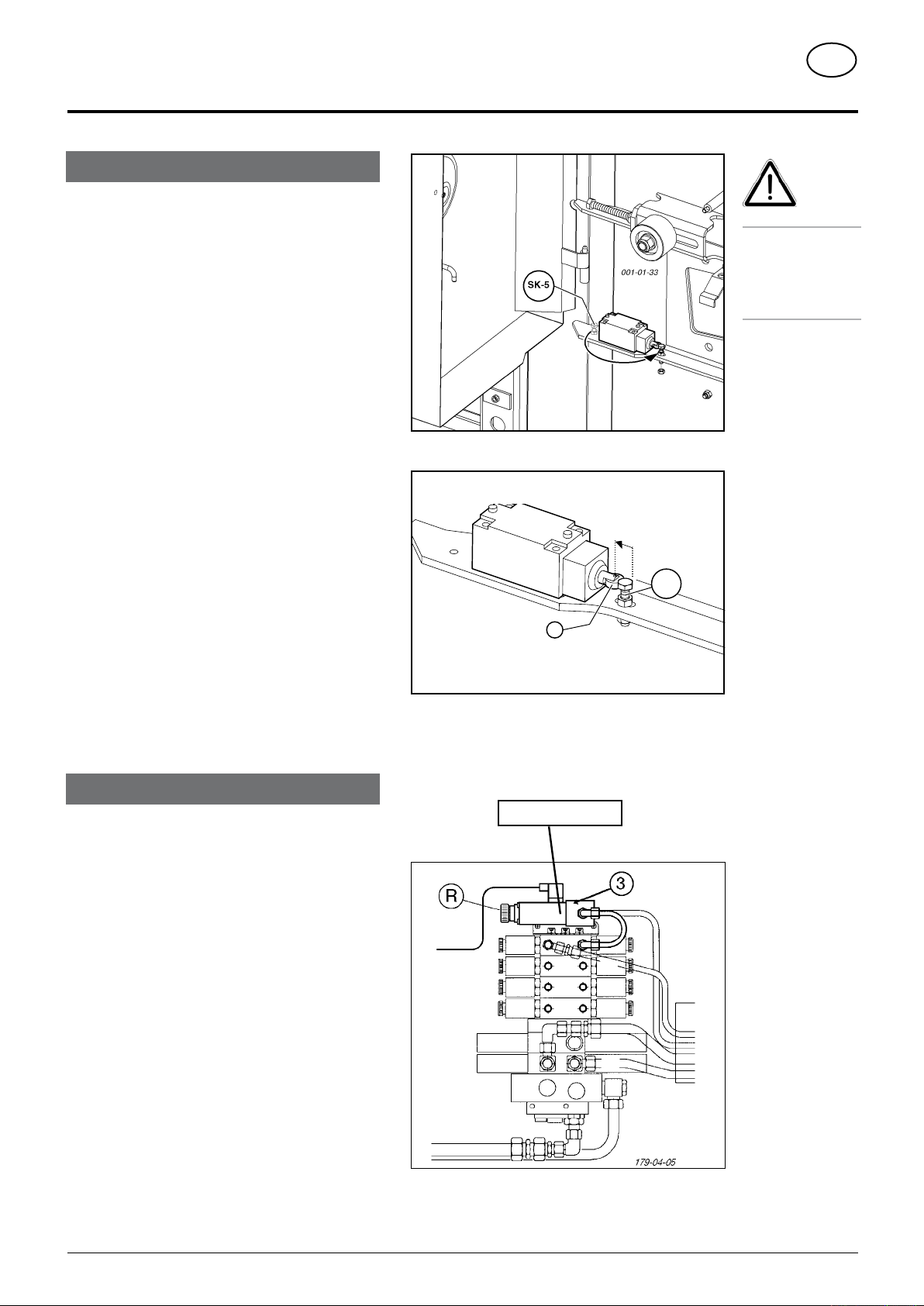

Scraper floor switch

001-01-34

A

SK-5

B

90

General

Where regulating rollers are built in, the screw (SK-5) is

situated behind the switch and has no function there.

The switch slider (90) is held in position A by means of a

component on the regulating roller.

The scraper floor drive can only be switched on as

follows:

- by means of the automatic loader

or

- by activating the scraper floor switch on the switch

console

Where regulating rollers have been dismantled, the switch

slider (90) would be in position B. In this position, the

scraper floor drive is constantly switched off. However this

is not required in the loading and unloading procedures.

Thus, where the regulating rollers have been dismantled,

the switch must be fixed in position A. This is achieved

by means of the bolt supplied (SK-5).

REGULATING ROLLERS

A greater injury

behind opened

protective covers.

GB

Note!

danger exists

when working

Setting when regulating rollers have been

dismantled

1. Push the switch slider (90) into position A

2. Screw the bolt (SK-5) down in the elongated hole, so

that the switch slider (90) remains fixed in position A.

Installing an oil pressure switch

It is recommended that an oil pressure switch (3) be installed

when operating without regulating rollers.

When the load presses against the tailgate, the scraper

floor drive is automatically switched off by means of the

oil pressure switch.

The oil pressure switch has no function when regulating

rollers are installed.

- Electro-connection see spare parts list, circuit diagram

see supplement.

- For setting see chapter “MAINTENANCE”

220 - 230 bar

0700_GB-DOSIERER_548

- 25 -

TD 57

/

91/5

6

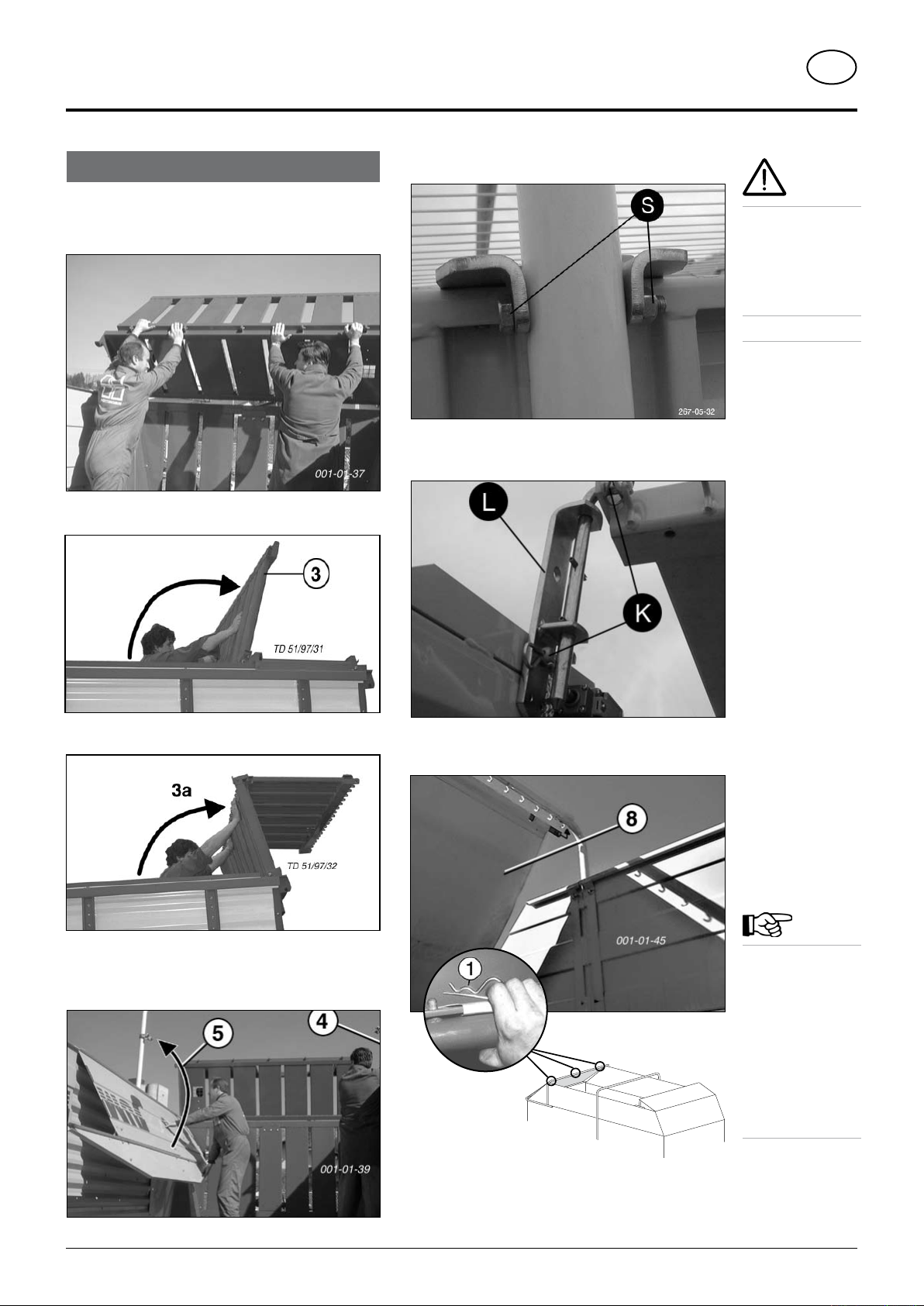

TOP FRAME SECTION

GB

Assembling the top frame section

• It is imperative that the machine stand horizontally and

that two people carry out this modification.

• Danger of injury!

1. Swing upper railing (3) up

4. Screw side panel with holder (S)

Attention!

• It is imperative

that the machine

stand horizontally

and that two

people carry out

this modification.

• Danger of injury!

5. Mount the guide plate (L)

- fix with linch pin (K)

2. Swing lower railing (3a) up

3. Swing front side wall up

- left and right

6. Install tarpaulin (8) with linch pin (1).

Note!

When the dry

forage extension

is up, the rear

tarpaulin (8)

must be removed

when using

the regulating

rollers otherwise

damage could

occur to the

tarpaulin.

7. Connect top ropes

0600_GB-Aufbauoberteil_5543

- 26 -

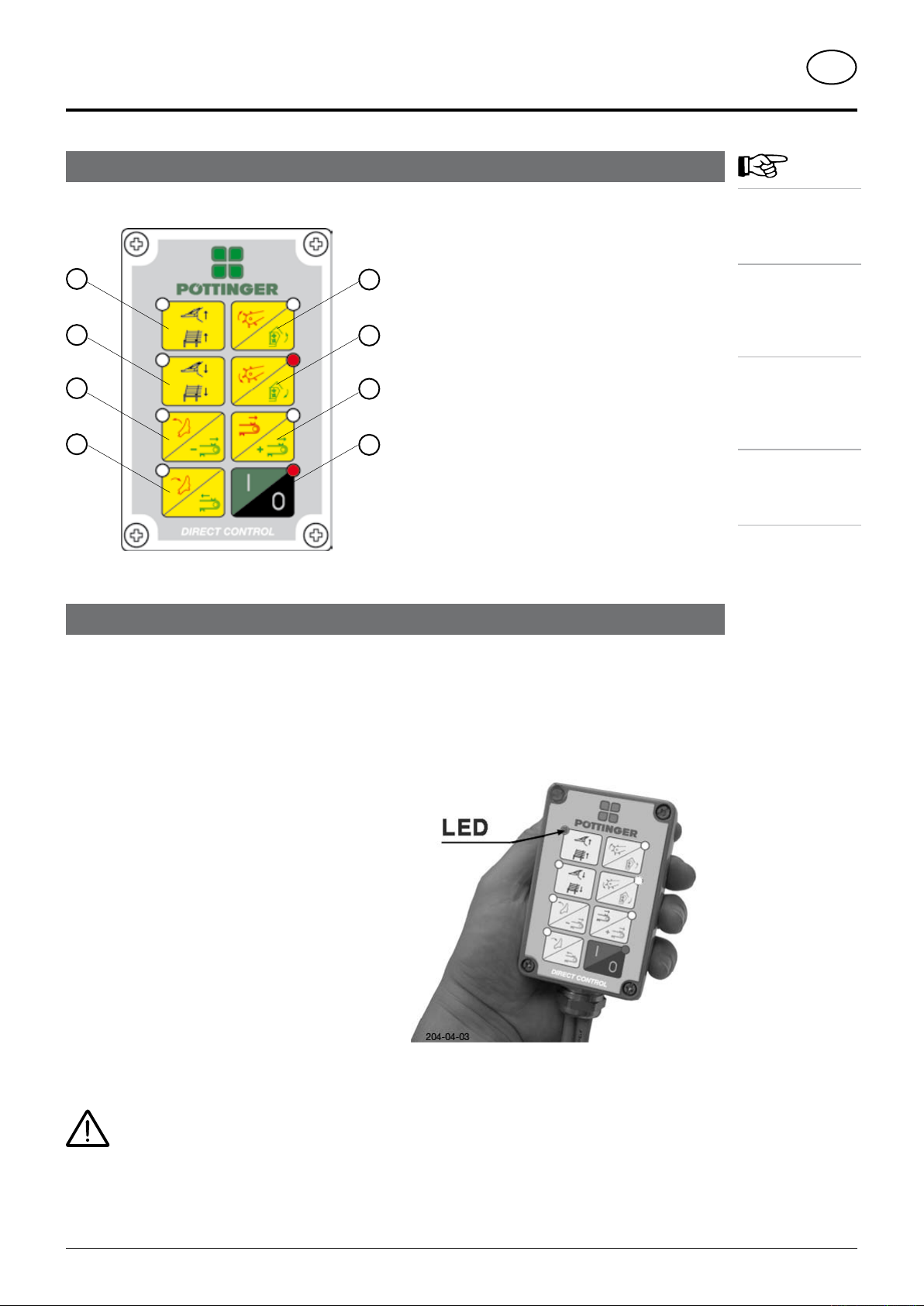

DIRECT CONTROL - OPERATION

GB

"DIRECT CONTROL" operating unit

Meaning of control panel buttons

1 Raising pivoting drawbar

Raise forage top frame

1

2

3

4

5

2 Lower pivoting drawbar

Lower forage top frame

3 Swing cutting unit in

6

Reduce scraper oor unloading speed

4 Swing cutting unit out

Scraper oor forward run

7

5 Raising pick-up

Open tailgate (with dosing roller on)

8

6 Lower pick-up

Close tailgate (with dosing roller off)

7 Scraper oor back run (= touch function)

Increase scraper oor unloading speed

8 ON/OFF button

- Change to other operation mode (red/green)

- STOP button

Operation is divided

and unloading

The red symbols

with the red LED

to the loading

The green symbols

with the green

LED are allocated

to the unloading

The black symbols

are available for

both operation

Note:

into loading

functions.

are allocated

functions.

functions.

modes

Carry out required hydraulic function

Switching on operating device

Press the I/O key for a few seconds

- the integrated control lamp glows red

Loading functions (= red symbols)

- Loading functions are always activated after switching

on

- The LED in the I/O key glows red

- Only the red symbol functions are active

- The required hydraulic function is carried by pressing

the appropriate key

- the (LED) in the selected key glows red

Unloading functions (= green symbols)

- The LED in the I/O key glows green

- Only the green symbol functions are active

- The required hydraulic function is carried by pressing

the appropriate key

- the (LED) in the selected key glows green

The pivoting drawbar (= black symbols) can

be actuated in both levels

Should the forage top frame be adjusted, the

operating device must be changed also

(see key description “Pivoting drawbar /

Forage top frame”)

Change to other operation mode

Briefly press button I/O

- the (LED) changes to green

Control light (LED)

If one of the control lights (LEDs) lights up, it means that

that particular function has been activated.

The example on the illustration above shows

- The top left integrated control light (LED) is on

- The function “raise pivoting drawbar” is carried

out.

0601-GB-DIRECT-CONTROL_563

- 27 -

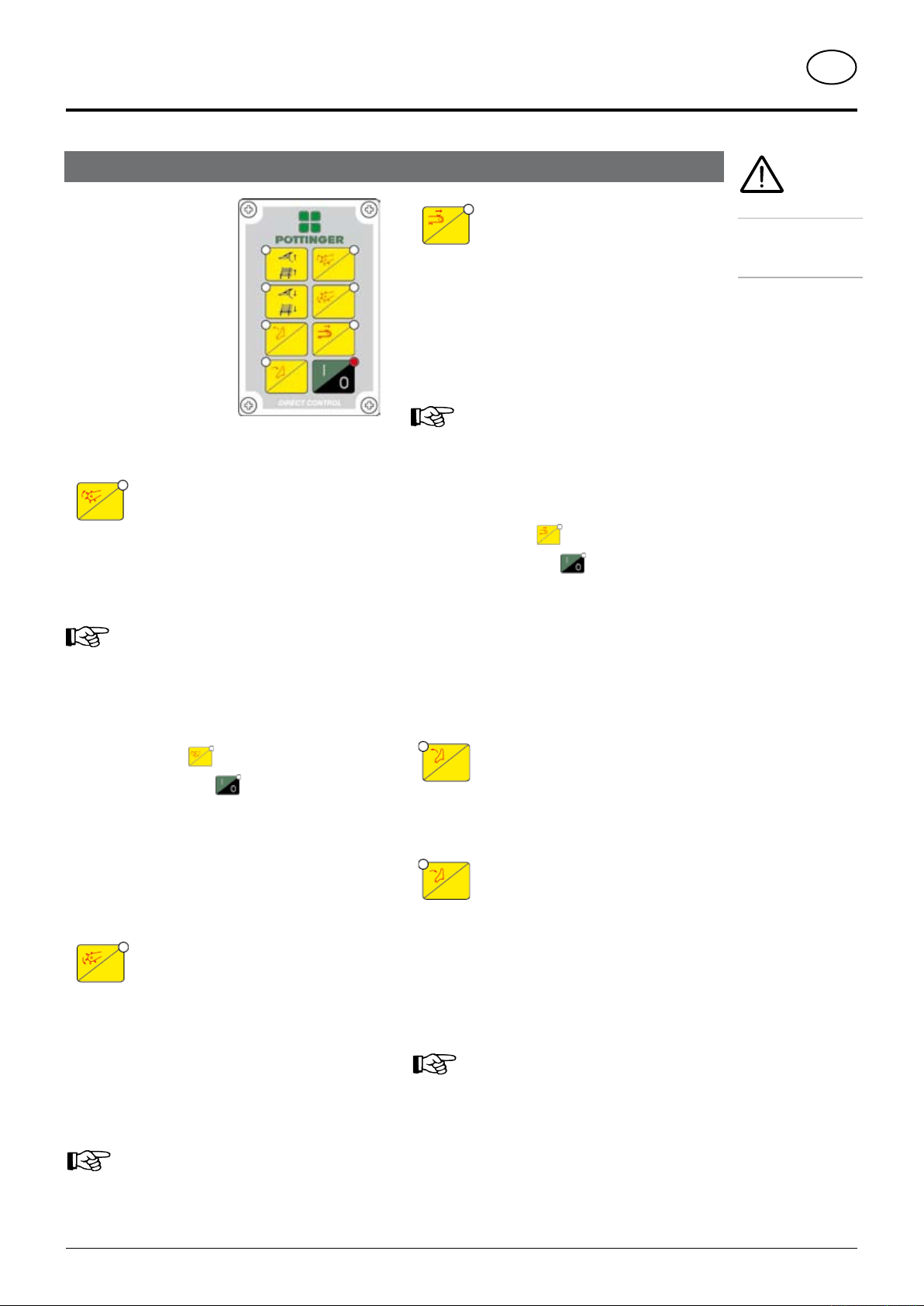

DIRECT CONTROL - OPERATION

Loading functions

GB

- Loading f unct ions are

always activated after

switching on

- The LED in the I/O key

glows red

- Onl y t he red s y m bol

functions are active

- Se l e c t t he r e qu i red

hydraulic function

- The (LED) in the selected

key glows red

Press button and hold (= touch function)

- pick-up is raised

- the integrated LED lights up

Adjustment process:

- The operating device is switched off in the starting

Raising pick-up

Note!

Key is also used to select the automatic

unloader

position

Press button and hold (= touch function)

- thescraperoormovesatmaximumspeedtowards

- the integrated LED lights up

- the scraper oor remains still after releasing the

Adjustment process:

- The operating device is switched off in the starting

- Press and hold

Briefly press button

- The LED blinks and an acoustic sound signals the

Status is shown each time the operating device is

- LED blinks briefly = switched on

- LED does not blink = switched off

Scraper floor back run

the tailgate

key

Note!

Key is also used to select the automatic

1)

loader

position

key, then

(2 secs.)

status change.

switched on.

Safety hints!

See the relevant

chapters in this

operating manual!

- Press and hold

Briefly press button

- The LED blinks and an acoustic sound signals the

status change.

Status is shown each time the operating device is

switched on.

- LED blinks briefly = switched on

- LED does not blink = switched off

Press button (= rest function)

- pick-up is lowered

- Pick-upremainsintheoatingposition

- the integrated LED lights up

The function can only be cancelled out using the “Raise

Pick-up” key

Lower pick-up

Note!

If actuating another function, the Pick-up function

is locked for this time period

key, then

(2 secs.)

Press button and hold (= touch function)

- Cutting unit is swung in under pressure

Press button and hold (= touch function)

- cutting mechanism is swivelled out

With the cutting unit sensor available (as option) the

LED signals the swung out status

- Signal tone when Pick-up is lowered

Swing cutting unit in

Swing cutting unit out

Note!

For automatic loader and unloader see chapter

“Automatic Loading and Loading”.

0601-GB-DIRECT-CONTROL_563

- 28 -

1)

Only if loading gates are available

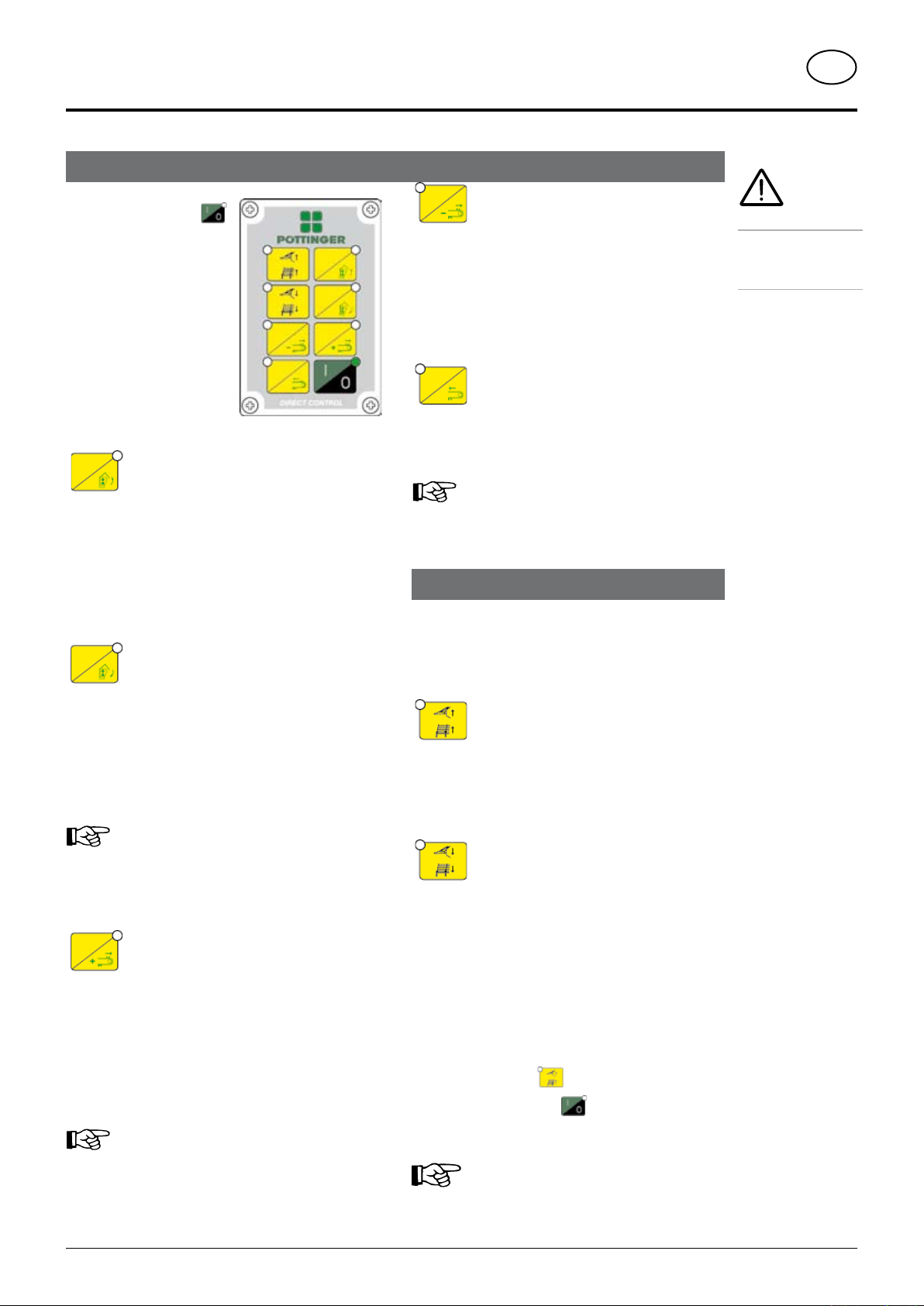

Unloading functions

- Briefly press button

- The mode is changed

- The LED in the I/O key

glows green

- Only the green symbol

functions are active

- Se l e c t t he r e qu i red

hydraulic function

- The (LED) in the selected

key glows green

Open tailgate

Press button (= rest function)

- the tailgate is raised

- the dosing rollers are switched on (if provided)

- the integrated LED lights up

DIRECT CONTROL - OPERATION

Decrease scraper floor speed

Briey press button (= touch function)

- decrease scraper floor back run speed

- the integrated LED lights up

- the speed is reduced further each time the key is

pressed

Scraper floor forward run

Press button and hold (= touch function)

- Scraper floor moves toward the Pick-up

- the integrated LED lights up

Note!

Use this key to stop scraper floor back run

also

Pivoting drawbar / Forage top frame

GB

Safety hints!

See the relevant

chapters in this

operating manual!

Close tailgate

Press button (= rest function)

- the tailgate is lowered

- the scraper floor is stopped

- the dosing rollers are switched off (if provided)

- the integrated LED lights up

Note!

If the tailgate automatic is interrupted by

another function (e.g. pivoting drawbar), the

tailgate remains on hold until the other function

is finished.

Unload scraper floor and

increase scraper floor speed

Press button (= rest function)

- the scraper floor runs backwards (when tailgate is

opened)

- the integrated LED lights up

The speed can be increased through further

pressing

Note!

After 5 seconds the up-to-date value is stored

and used as the start value for the next unloading

procedure (only with automatic unloading)

These functions can be carried out with the red as well

as the green LEDs

- The “pivoting drawbar” function is the standard

setting.

Raising pivoting drawbar /

Raise forage top frame

Press button and hold (= touch function)

- wagon is raised at the front or

- forage top frame is raised (switch over)

Lower pivoting drawbar /

Lower forage top frame

Press button and hold (= touch function)

- wagon is lowered at the front or

- forage top frame is lowered (switch over)

- If the “Forage top frame” function is required, switch

to another mode

Adjustment process:

- Switch operating device off

Press and hold

-

Briefly press button

- Both LEDs “Forage top frame raise” and “Forage

top frame” lower blink alternatively

Each time the operating device is switched

off the setting reverts to the pivoting drawbar

function.

key, then

(2 secs.)

0601-GB-DIRECT-CONTROL_563

- 29 -

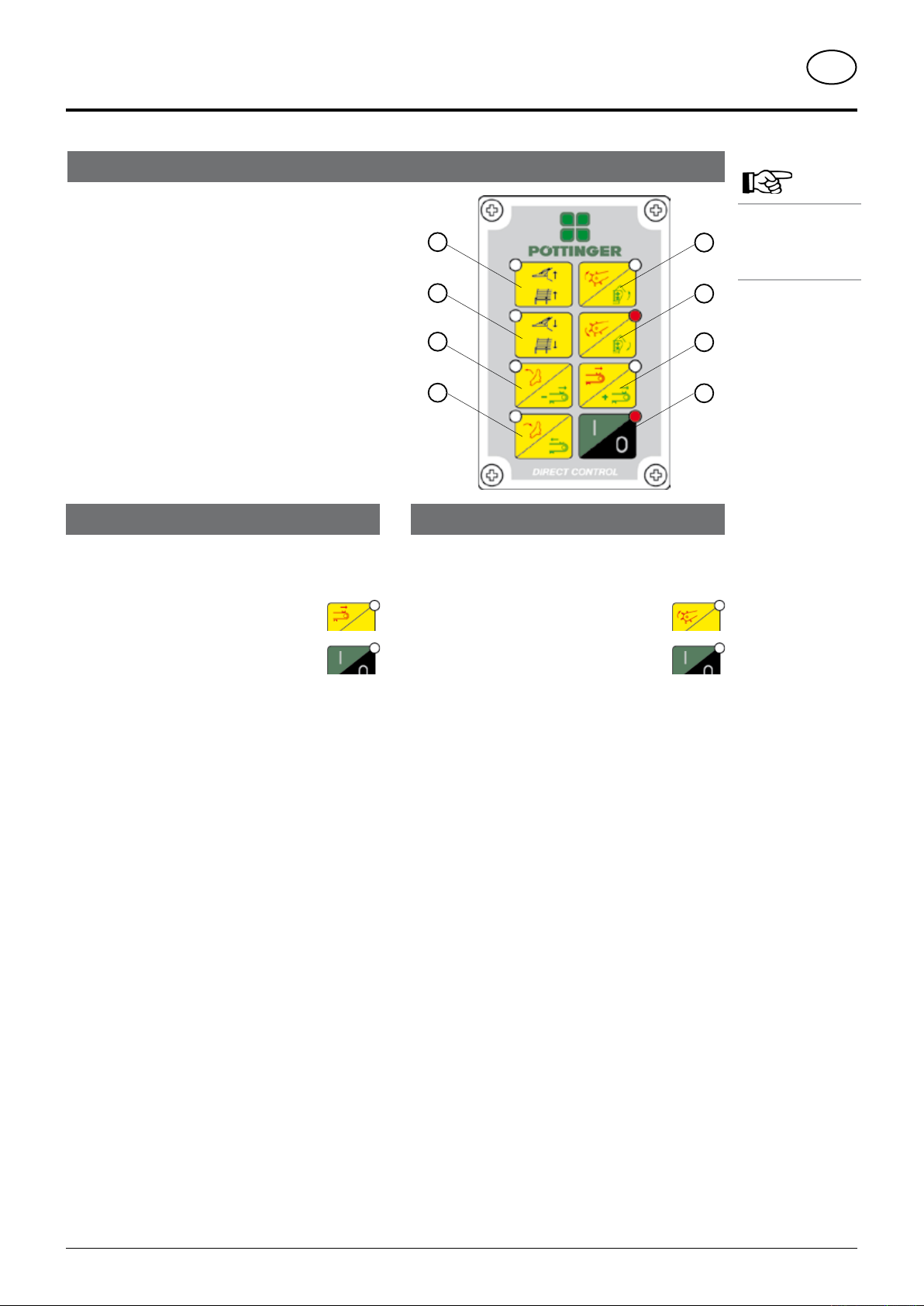

Automatic Loader- unloader 3)

Check status:

1. Switch operating device off using button 8

(LED 8 does not light up)

2. Switch operating device on using

LED 7 lights up briefly:

Automatic loader is activated

LED 7 remains dull:

Automatic loader is deactivated

LED 5 lights up briefly:

Automatic unloader is activated

LED 5 remains dull:

Automatic unloader is deactivated

Status is shown each time the operating device is

switched on.

button 8

DIRECT CONTROL - OPERATION

1

2

3

4

5

6

7

8

loader needs to be

GB

Take note!

The automatic

switched on only

once.

Switching on automatic loader

Adjustment process:

The operating device is switched off in the starting

position

- Press

and then

- Briefly press

until LED 7 lights up briefly and an acoustic

signal sounds

Advantages of the automatic loader

- very compacted load

- minimum blockages in the feeder channel

- prevents overloading the entire drive

- forage protection

- relieves the driver

- increase in load capacity

Control of the automatic loader through

- level sensor below

- level sensor (flap above)

- oil pressure switch

button 7 and hold

button 8 (2 seconds)

3)

3)

3)

Switching on automatic unloader

Adjustment process:

The operating device is switched off in the starting

position

- Press

and then

- Briefly press

until LED 5 lights up briefly and an acoustic

signal sounds

Advantages of the automatic unloader

- fast, efficient and even unloading

- forage protection when unloading

- One press of the button opens the tailgate and starts

Functional procedure

- open the tailgate

- Scraper floor starts at the given speed

button 5 and hold

button 8 (2 seconds)

unloading

Functional procedure

- A level sensor reacts

- scraper floor switches on automatically

- forage conveyed to the rear

- procedure repeats until loading space is full

WAGON FULL indicator

• when the oil pressure switch registers excessive

pressure

- double horn tone sounds on control panel

0601-GB-DIRECT-CONTROL_563

- 30 -

3)

Only if level sensors are available

Loading...

Loading...