GB

/PERATOR@SMANUAL

).3425#4)/.3&/202/$5#4$%,)6%290AGE

4RANSLATIONOFTHEORIGINAL/PERATING-ANUAL

NOVAALPIN 226 (Type PSM 317 : + . . 01001)

NOVAALPIN 266 (Type PSM 318 : + . . 01001)

99 317.GB.80I.0

.R

Disc mower

Ihre / Your / Votre • Masch.Nr. • Fgst.Ident.Nr.

GB

Dear Farmer

You have just made an excellent choice. Naturally we are very happy

and wish to congratulate you for having chosen Pöttinger. As your

agricultural partner, we offer you quality and efciency combined with

reliable servicing.

In order to assess the spare-parts demand for our agricultural machines

and to take these demands into consideration when developing new

machines, we would ask you to provide us with some details.

Furthermore, we will also be able to inform you of new developments.

Important information concerning Product

Liability.

According to the laws governing product liability, the manufacturer and dealer are obliged to hand the

operating manual to the customer at the time of sale, and to instruct them in the recommended operating,

safety, and maintenance regulations. Conrmation is necessary to prove that the machine and operating

manual have been handed over accordingly.

For this purpose,

document A is to be signed and sent to Pöttinger,

-

document B remains with the dealer supplying the machine,

-

- and the customer receives

In accordance with the laws of product liability, every farmer is an entrepreneur.

According to the laws of product liability, property damage is damage caused by a machine and not to

it. An excess of Euro 500 is provided for such a liabilioty.

In accordance with the laws of product liability, entrepreneurial property damages are excluded from

the liability.

Attention! Should the customer resell the machine at a later date, the operating manual must be given

to the new owner who must then be instructed in the recommended regulations referred to herein.

document C.

ALLG./BA SEITE 2 / 0000-GB

GB

INSTRUCTIONS FOR

PRODUCT DELIVERY

Dokument D

ALOIS PÖTTINGER Maschinenfabrik GmbH

A-4710 Grieskirchen

Tel. (07248) 600 -0

Telefax (07248) 600-511

GEBR. PÖTTINGER GMBH

D-86899 Landsberg/Lech, Spöttinger-Straße 24

Telefon (0 81 91) 92 99-111 / 112

Telefax (0 81 91) 92 99-188

According to the product liability please check the above mentioned items.

Please check. X

GEBR. PÖTTINGER GMBH

Servicezentrum

D-86899 Landsberg/Lech, Spöttinger-Straße 24

Telefon (0 81 91) 92 99-130 / 231

Telefax (0 81 91) 59 656

Machine checked according to delivery note. All attached parts removed. All safety equipment, drive shaft and operating

devices at hand.

Operation and maintenance of machine and/or implement according to operating instructions explained to the customer.

Tyres checked re. correct pressure.

Wheel nuts checked re. tightness.

Drive shaft cut to correct lenght.

Correct power-take-off speed indicated.

Fitting to tractor carried out: to three-point linkage

Trial run carried out and no defects found.

Functions explained during trial run.

Pivoting in transporting and operating position explained.

Information given re. optional extras.

Absolute need to read the operating manual indicated.

In order to prove that the machine and the operating manual have been properly delivered, a confirmation is necessary.

For this purpose please do the following:

- sign the

(in case of Landsberg equipment: to the company Landsberg)

document B stays with the specialist factory delivering the machine.

-

document C stays with the customer.

-

GB-0600 Dokum D Anbaugeräte

document A and send it to the company Pöttinger

- 3 -

WARNING SIGNS

CE sign ......................................................................5

Meaning of warning signs.......................................... 5

ATTACHING TO TRACTOR

Attaching in general ................................................... 6

Driveshaft ................................................................... 6

Road Transport .......................................................... 6

Special attachment .................................................... 7

Guard plates and protective aprons .......................... 8

Transport position (< 3 m) .........................................

Working position ........................................................ 8

Quick-coupler (1) ....................................................... 9

Spring tension............................................................ 9

Attaching problems ...................................................9

STARTING WORK

Important points before starting work ..................... 11

Watch for the direction of rotation of the mowing

discs ........................................................................11

Mowing .................................................................... 11

Driving motor speed ................................................ 12

Safety hints .............................................................. 13

COLLISION SAFETY DEVICE

Collision safety device ............................................. 14

Mechanical collision safety device, ........................ 14

Function of collision safety device .......................... 14

MAINTENANCE

Safety point ............................................................. 15

General maintenance hints ...................................... 15

Cleaning of machine parts ....................................... 15

Parking in the ope .................................................... 15

Winter storage ......................................................... 15

Drive shafts .............................................................. 15

Hydraulic unit ........................................................... 15

Cutter bar oil level check ....................................... 16

Cutter bar-oil change ............................................... 16

Angular gear ............................................................17

Installing cutter blades ............................................ 17

V-belt tension ........................................................... 17

Lubrication ............................................................... 18

Checking wear on mowing blade holders ............... 19

Holder for a quick change of cutter blades ............. 20

Checking the mowing blade suspension................. 20

Changing the Cutter Blades (up to 2003 model) ..... 20

Changing the Cutter Blades (from 2004 model) ...... 21

Storing the lever ...................................................... 21

TECHNICAL DATA

Technical data .......................................................... 22

Position of Vehicle Identification Plate ....................22

The defined use of the mower unit .......................... 22

SUPPLEMENT

Recommendations for work safety ......................... 25

Driveshaft ................................................................. 26

Special attachment .................................................. 28

Maximum drive shaft angle ..................................... 28

Lubricants ................................................................ 30

Repairs on the cutter bar ......................................... 32

Combination of tractor and mounted implement .... 33

TABLE OF CONTENTS

Observe Safety

8

GB

Attention!

Hints in the

supplement!

0800_GB-Inhalt_317

- 4 -

The CE sign, which is affixed by the manufacturer, indicates outwardly that this machine

495.167

conforms to the engineering guideline regulations and the other relevant EU guidelines.

EU Declaration of Conformity (see supplement)

By signing the EU Declaration of Conformity, the manufacturer declares that the machine being

brought into service complies with all relevant safety and health requirements.

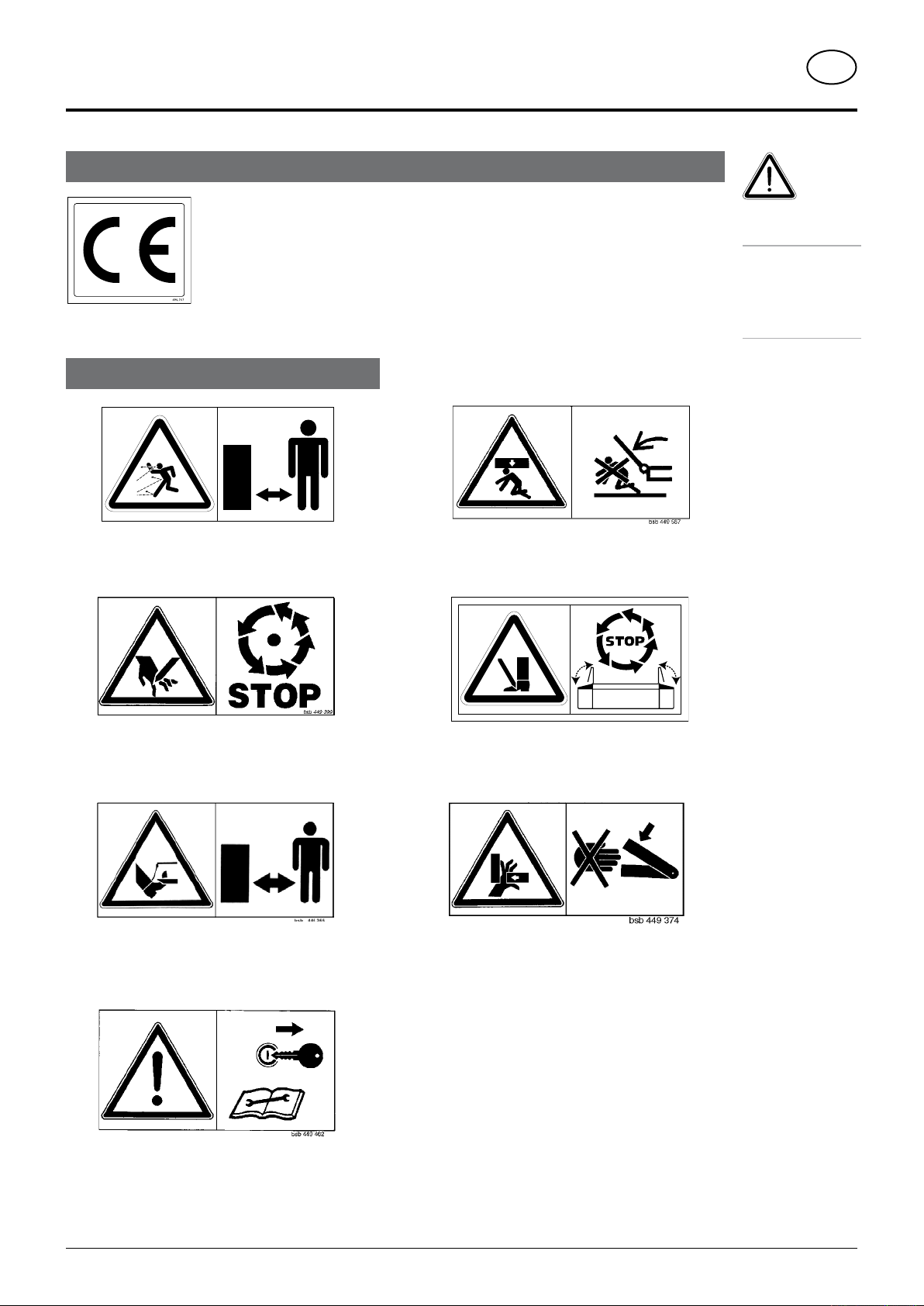

Meaning of warning signs

CE sign

WArning signs

Recommendations

for work safety

All points referring

to satety in this

indicated by this

GB

manual are

sign.

Danger - flying objects; keep safe distance from the

machine as long as the engine is running.

Wait until all machine components have stopped

completely before touching them.

Stay clear of mower knife area as long as tractor engine

is running with PTO connected.

Stay clear of swinging area of implements

Close both side protective coverings before engaging

p.t.o..

Never reach into the crushing danger area as long as

parts may move.

Shut off engine and remove key before performing

maintenance or repair work.

9700_GB-Warnbilder_361

- 5 -

ATTACHing TO TrACTOr

GB

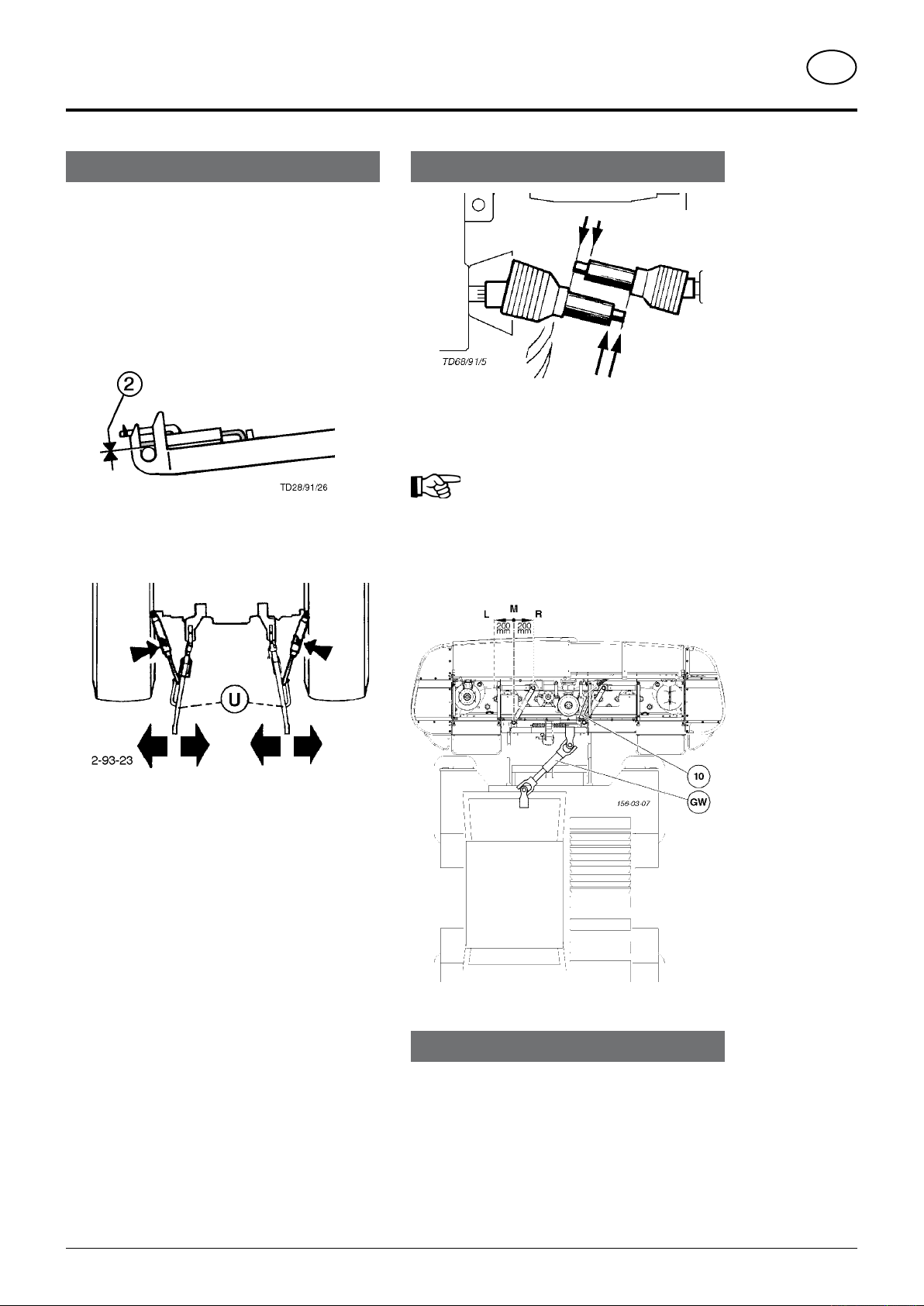

Attaching in general

1. Observe safety hints in supplement-A.

• Please also observe the hints in the chapter “Special

attachment”

2. Mark off the implement at the tractor's threepoint linkage.

• Secure locking bolts with linch pins.

• Lock lower link bolts (2) so that they are free from

play.

3. Fasten lower hydraulic link (U) so that

implement cannot swing out sideways.

Driveshaft

- Before initial operation, check drive shaft length and

adapt if necessary (see chapter “Adapting to Drive

Shaft” in Supplement B also).

Optional extra: Hydraulic cylinder

Important!

The cutter bar can be moved left (L) or right

(R) using hydraulic cylinder (10).

Take this offsetting action into account

when shortening the drive shaft.

M = central position

4. Connect hydraulic lines (Hyd) on the plug-in

connector with the double-action control

valve.

Road Transport

• Observe the regulations issued by your country's

legislative body.

• Travelling on public roads may only be undertaken as

is described in the chapter "Transporting Position".

• Fasten lower hydraulic link (U) so that implement cannot

swing out sideways.

0500-GB ANBAU_317

- 6 -

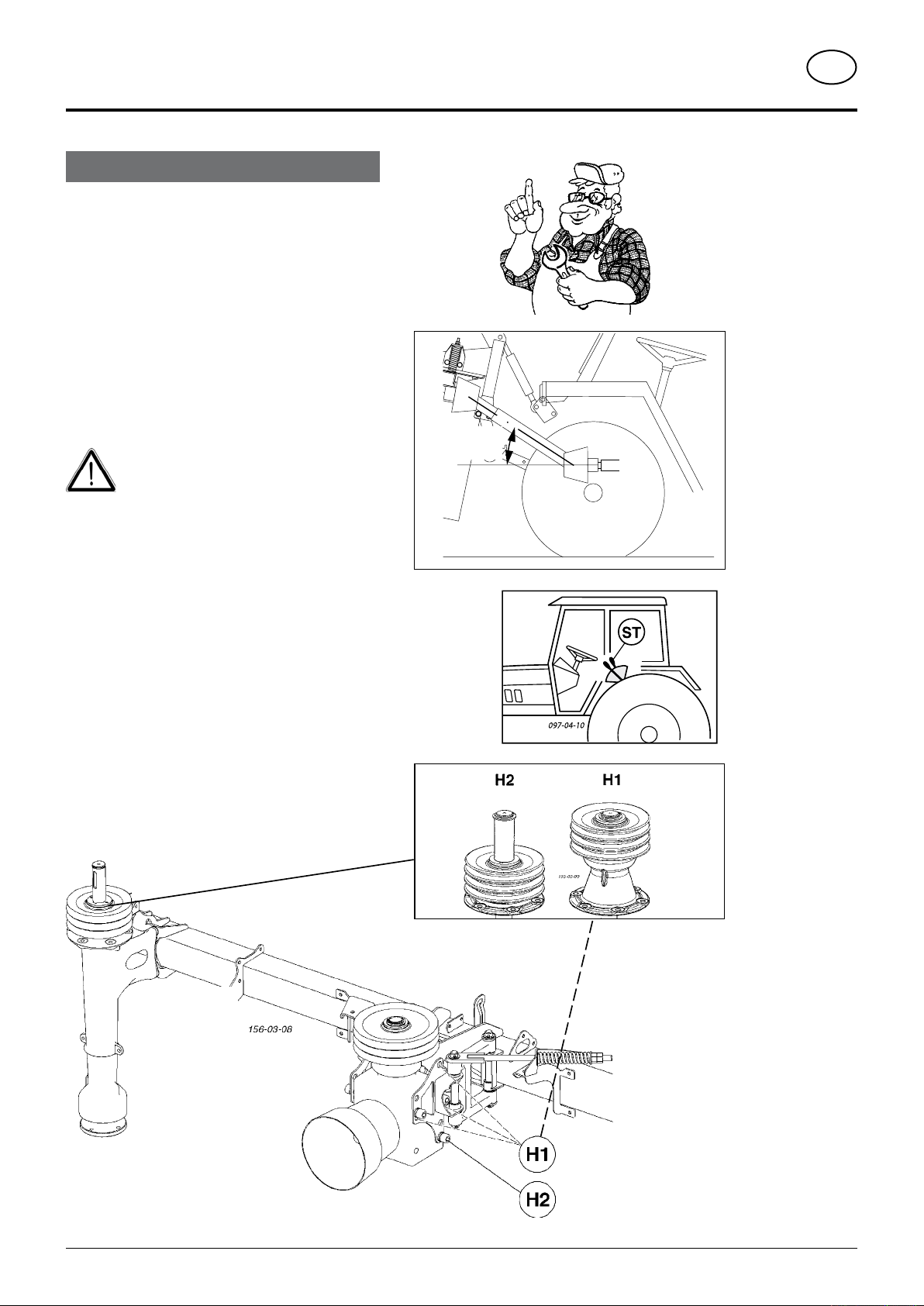

Special attachment

GW�

max.

TD 37/96/4

Because of the different lifting gears on various tractors

special attaching kits are to be used.

• see supplement-D

• see Spare Parts List also.

Maximum drive shaft angle

Most drive shafts in continuous operation may only be

angled to a maximum 25° (GW max.).

• Observe the advice in the drive shaft

manufacturer's operating manual.

Gearing positions

Gearing can be fitted in two positions (H1, H2)

For this the relevant adaptors must also be fitted.

- see Spare Parts List

ATTACHing TO TrACTOr

GB

In order to prevent damage

- Limit the lifting gear’s lifting height

Limit the lifting height with lever (ST)

0500-GB ANBAU_317

- 7 -

ATTACHing TO TrACTOr

495.167

GB

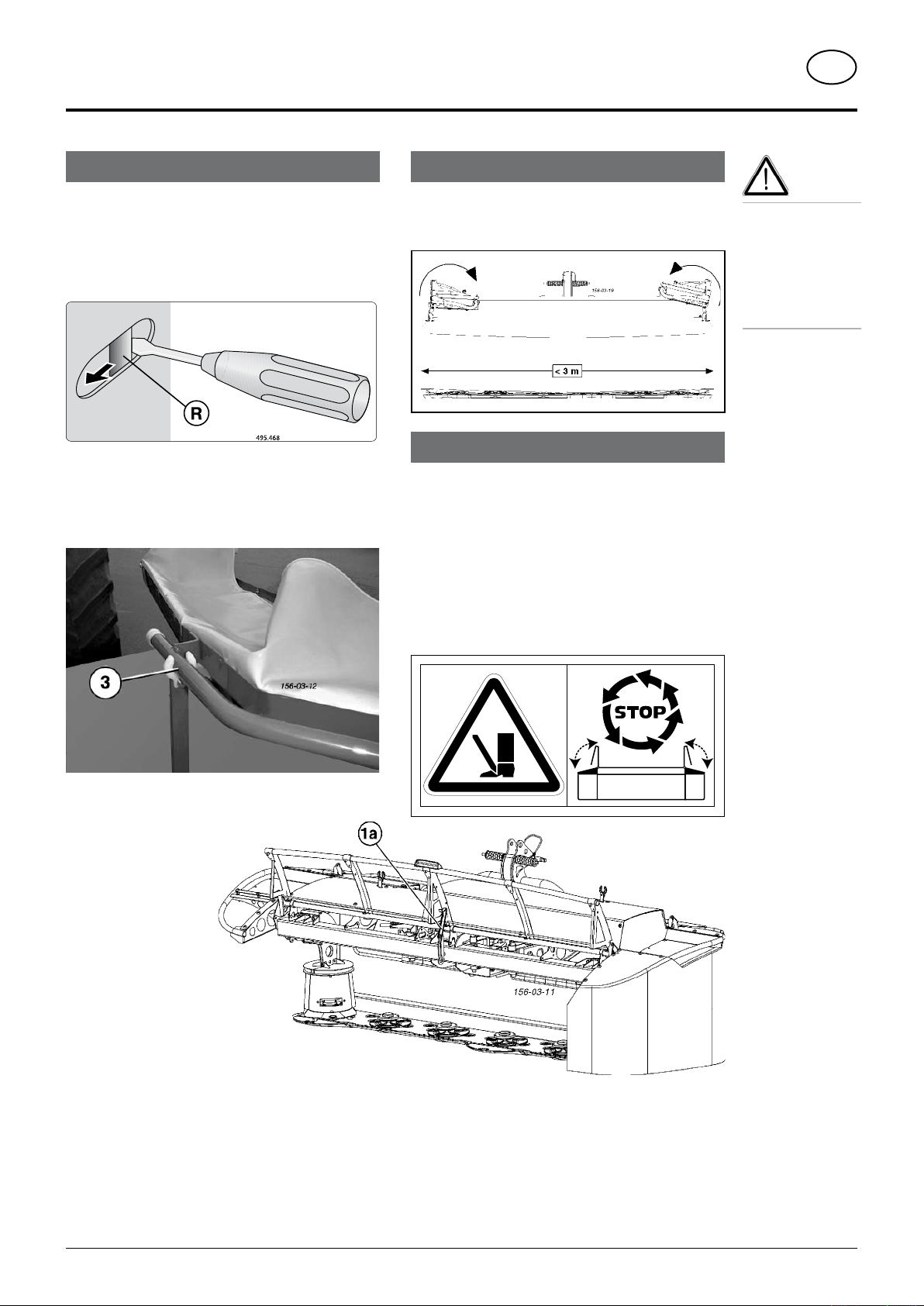

Guard plates and protective aprons

Guard plates and protective aprons can be raised when

maintenance work is to be done.

Open the locking bar „R“ with a suitable aid (e.g. screw

driver) and simultaneously swing the protector up.

Opening the side protector

- Unlock the catch (R) and swing protector up

- engage protective frame in holder (3)

- left and right

Transport position (< 3 m)

When both protective elements have been raised and

are engaged in the holder (3), the total width of the unit

is less than 3m.

Working position

Before commencing work

Turn the p.t.o. on only when all safety devices

(coverings, protective aprons, casings,

etc.) are in proper condition and attached

to the implement in the correct protective

positions.

For safety reasons mowing may only be

conducted in this position.

Attention!

For safety reasons

it is necessary to

wait for mowing

disks to stop

completely before

raising and securing guard plates.

Open front protector

- Unlock the catch (R) and

swing protector up

- lock holder in place

(1a)

Close front protector

- Disengage holder and

swing protector down

The catch will engage

automatically

Closing the side protectors

Swing the protector down, the locking bar engages

automatically and locks the protector against

unintentional opening.

0500-GB ANBAU_317

- 8 -

ATTACHing TO TrACTOr

TD28/91/28

1

TD29/93/2�

20�

GB

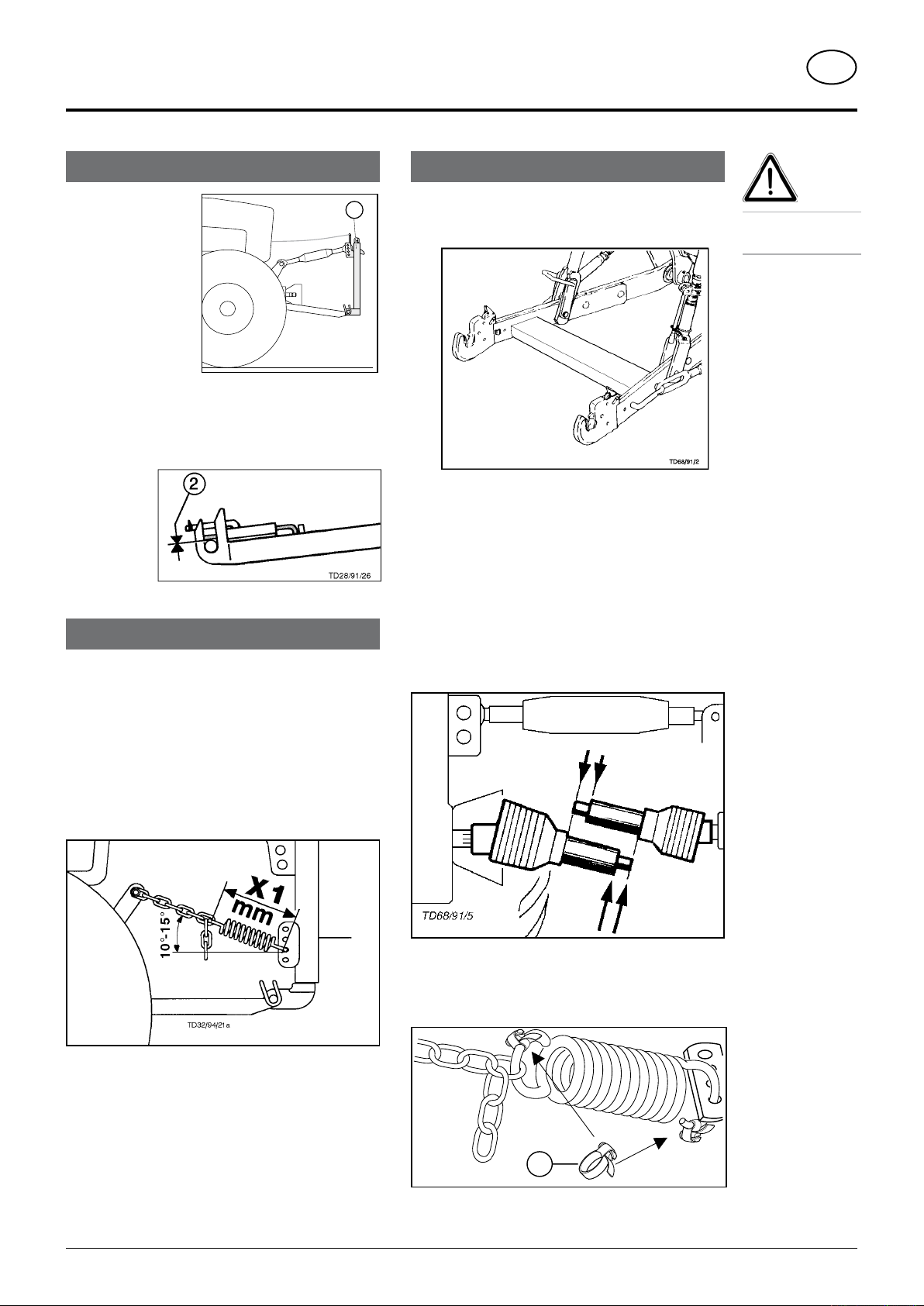

Quick-coupler (1)

- M o u n t s n a p

connector (Weiste

triangle) onto the

front lifting gear in

a vertical position

or inclined slightly

forward.

- Lock lower link bolts (2) so that they are free from

play.

Spring tension

Mounting kit (Optional extras)

The mower drum’s ground pressure is controlled through

spring tension

• The mowing bar should weigh 150kg resting on the

ground (75kg left and right).

- Raise the unit hydraulically

- Secure both chains

- Lower implement to ground.

Check angle 10° - 15°

Attaching problems

• For lifting gear with a crossbar between the lower links

damage to the cardan shaft could occur when lowering

the attached implement.

To prevent damage fit an uplift device between lifting

gear and Weiste triangle

In a case such as this please contact our Customer

Service Dept.

• For tractors where the cardan shaft end is located quite

far forward, the length must be extremely shortened.

When the implement is engaged then there is insufficient

casing to over the drive shaft.

In this case the mounting frames (K1, K2) are to be

fitted in the relevant positions (see Supplement-D)

Safety

hints:

see supplement-A1

Pkt. 8a. - h.)

Setting measurement "X1"

- Slip the hose clamp (20) onto the tension spring.

Doing this means that spring tension does not have to

be checked every time unit is attached to tractor.

Only when changing tractors is the setting (X1) to be

checked and if necessary reset.

0500-GB ANBAU_317

- 9 -

- 10 -

0500-GB ANBAU_317

ATTACHing TO TrACTOr

GB

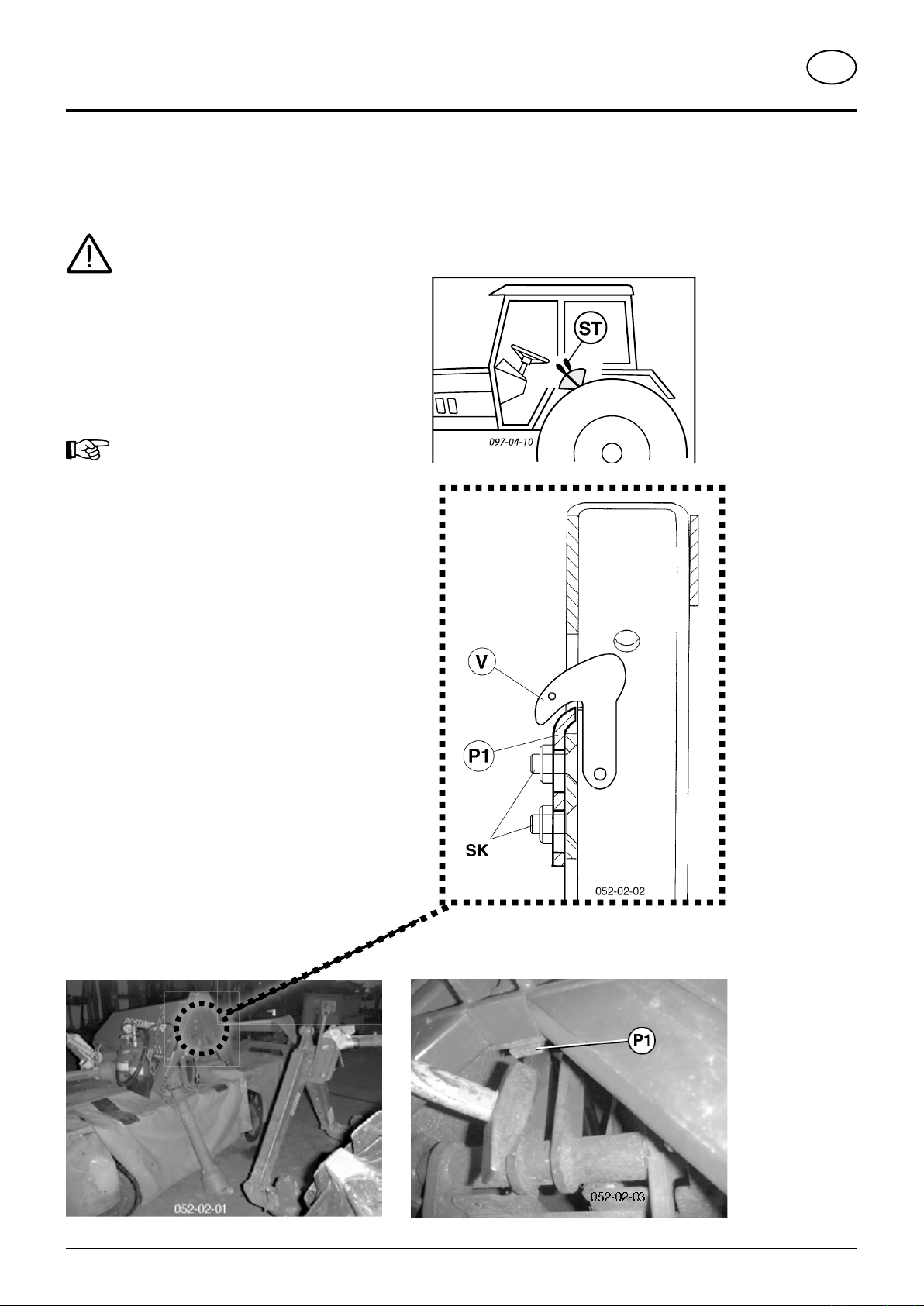

Snap connector (Weiste triangle)

Pay particul arattention before initial attachment

to Tractor!

Attention!

For front lifting gear with double-action

hydraulic cycle (danger of damage)!

Remedy:

- Switch control valve to single-action

- Convert front lifting gear to single-action function

(bypass line) through a specialist work shop.

• When the mower is attached to the tractor,

the the hydraulic control (ST) must not be

set at „Lower“.

• Immediately after such an operating error,

reset the adjustable plate (P1).. Replace

damaged parts beforehand.

The following could happen after an operating error:

- the position of the plate (P1) has changed in the slot;

the gap to the locking hook (V) is therefore too great,

- the locking hook (V) breaks,

Reset the adjustable plate (P1)

1. Loosen screws (SK) slightly

- do not loosen too much; the plate (P1) should be

able to move in the slot when tapped lightly with a

hammer.

2. Couple the mower to the tractor´s lifting gear

3. Position the adjustable plate (P1) so that the locking

hook (V) can still be unlatched. The gap to the hook

should be as narrow as possible.

4. Uncouple the mower from the tractor´s lifting gear.

5. Tighten screws (SK) to 65 Nm.

TD40/94/16

156-03-05

NOVAALPIN 226

NOVAALPIN 266

sTArTing WOrk

GB

Important points before starting work

After the first hours of operation

• Retighten all knife screw fittings.

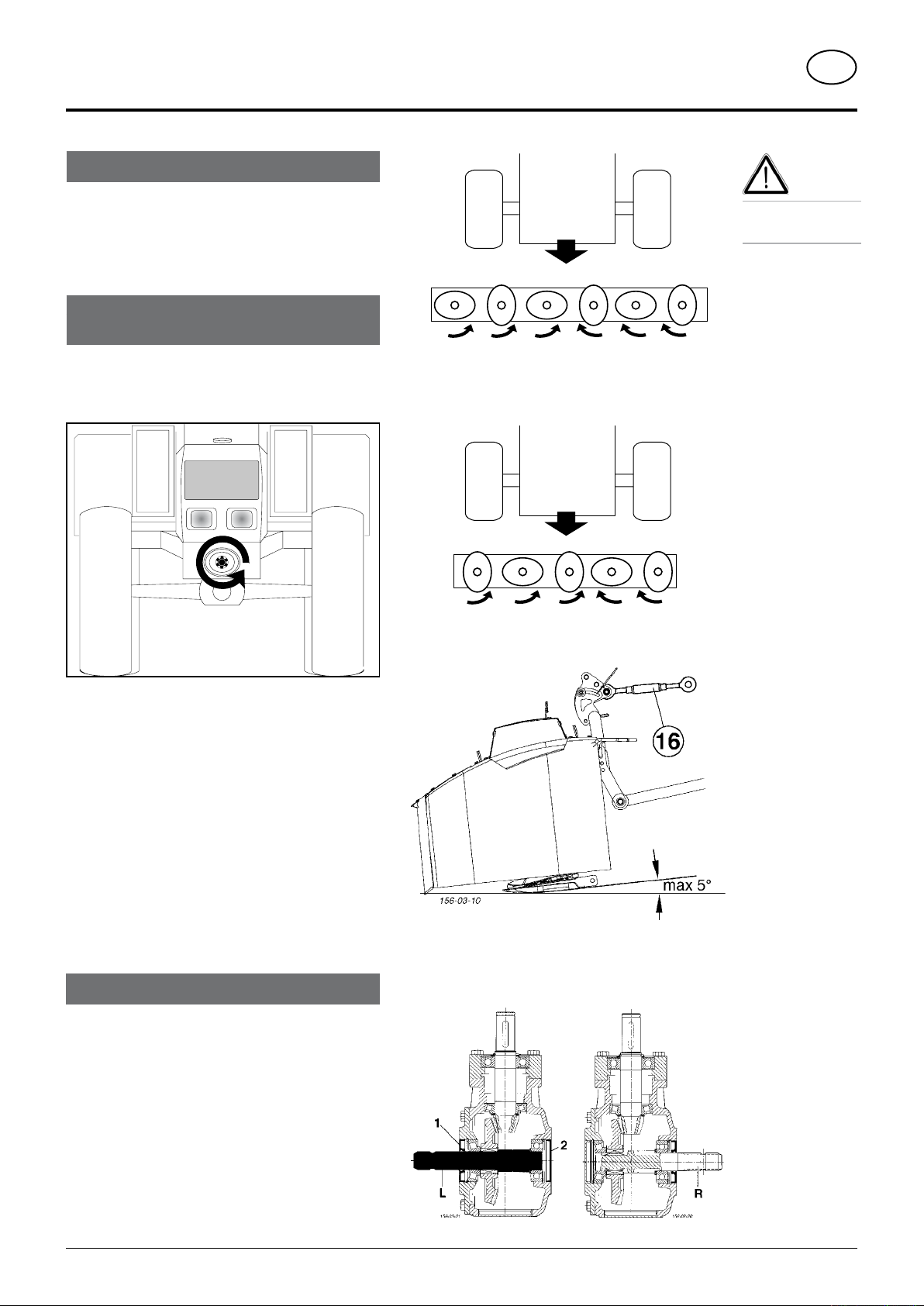

Watch for the direction of rotation of the

mowing discs

General

For mowing, the power take-off shaft drive should be

switched to turn to the left.

Safety

hints:

see supplement-A

Pkt. 1. - 7.)

Remedy, if the tractor’s power take-off shaft drive

cannot be switched to turn to the left:

Mount the drive shaft in the gearing in position L

Note: With this change replace the rotary shaft seal (1)

and the sealing cover (2) with new ones (see Spare

Parts List)

Mowing

1. Adjust cutting height by turning upper link

spindle (16) (cutter disc inclination: max. 5°)

2. Before mowing, throw-in p.t.o. slowly outside

crop and bring mower drums up to full

speed.

Noises conditional to p.t.o. free-wheel system can

be prevented through an even continious increase in

r.p.m.

- Travelling speed is set according to ground conditions

and crop.

0300-GB EINSATZ_317

- 11 -

Driving motor speed

The machine can be adapted to the r.p.m. (540 rpm, 1000

rpm) being used.

Fit both V-belt pulleys (Ø212 mm and Ø160 mm) in the

relevant position (see diagram).

sTArTing WOrk

GB

0300-GB EINSATZ_317

- 12 -

Loading...

Loading...