Pottinger LADEPROFI 4 Profimatic, LADEPROFI IV, Profi Gp 1, PROFI GP 2 Operating Instructions Manual

Operating instructions

+ INSTRUCTIONS FOR PRODUCT DELIVERY . . . Page 3

Ihre / Your / Votre • Masch.Nr. • Fgst.Ident.Nr.

GB

LADEPROFI IV

(Type 105 u. 106)

LADEPROFI 4 Profimatic

(Type 105 u. 106)

Nr. 99 106.GB.80A.0

ALLG./BA SEITE 2 / 9300-GB

Important information concerning Product Liability.

According to the laws governing product liability, the manufacturer and dealer are

obliged to hand the operating manual to the customer at the time of sale, and to

instruct them in the recommended operating, safety, and maintenance regulations.

Confirmation is necessary to prove that the machine and operating

manual have been handed over accordingly.

For this purpose, document A is to be signed and sent to Pöttinger,

document B remains with the dealer supplying the machine, and the

customer receives document C.

In accordance with the laws of product liability, every farmer is an entrepreneur.

According to the laws of product liability, property damage is damage caused by a

machine and not to it. An excess of Euro 500 is provided for such a liabilioty.

In accordance with the laws of product liability, entrepreneurial property damages

are excluded from the liability.

Attention! Should the customer resell the machine at a later date, the operating

manual must be given to the new owner who must then be instructed in the

recommended regulations referred to herein.

GB

Dear Farmer

You have just made an excellent choice. Naturally we

are very happy and wish to congratulate you for

having chosen Pöttinger. As your agricultural partner,

we offer you quality and efficiency combined with

reliable servicing.

In order to assess the spare-parts demand for our

agricultural machines and to take these demands

into consideration when developing new machines,

we would ask you to provide us with some details.

Furthermore, we will also be able to inform you of new

developments.

Dokument D

GB-0100 Dokum D Anhänger

- 3

ALOIS PÖTTINGER Maschinenfabrik GmbH

A-4710 Grieskirchen

Tel. (07248) 600 -0

Telefax (07248) 600-511

GEBR. PÖTTINGER GMBH

D-86899 Landsberg/Lech, Spöttinger-Straße 24

Telefon (0 81 91) 92 99-111 / 112

Telefax (0 81 91) 92 99-188

GEBR. PÖTTINGER GMBH

Servicezentrum

D-86899 Landsberg/Lech, Spöttinger-Straße 24

Telefon (0 81 91) 92 99-130 / 231

Telefax (0 81 91) 59 656

❑ Machine checked according to delivery note. All

attached parts removed. All safety equipment, drive

shaft and operating devices at hand.

❑ Operation and maintenance of machine and/or

implement according to operating instructions

explained to the customer.

❑ Tyres checked re. correct pressure.

❑ Wheel nuts checked re. tightness.

❑ Drive shaft cut to correct lenght.

❑ Correct power-take-off speed indicated.

❑ Mechanical functions (opening of rear gate, pivoting

of cutting mechanism out/in, etc.) demonstrated and

explained.

❑ Removing and mounting of knives explained.

❑ Electrical connection to tractor established and

checked re. correct supply (54 g connected). Note

references in operating manual.

Please check. X

According to the product liability please check the above mentioned items.

INSTRUCTIONS FOR

PRODUCT DELIVERY

GB

❑ Fitting to tractor carried out: hight of drawbar adjusted,

brake cable installed, hand brake lever assembled in

tractor cabin.

❑ Function of electrical installation checked and

explained.

❑ Hydraulic connection to tractor established and checked

re. correct supply.

❑ Hydraulic functions (drawbar, opening of rear gate, etc.)

demonstrated and explained.

❑ Handbrake and operating brake tested re. function.

❑ Trial run carried out and no defects found.

❑ Functions explained during trial run.

❑ Automatic on/off switch of loading mechanism checked.

❑ Pivoting in transporting and operating position

explained.

❑ Information given re. optional extras.

❑ Absolute need to read the operating manual indicated.

In order to prove that the machine and the operating manual have been properly delivered, a confirmation is necessary.

For this purpose please do the following:

- sign the document A and send it to the company P ttinger

(in case of Landsberg equipment: to the company Landsberg)

- document B stays with the specialist factory delivering the machine.

- document C stays with the customer.

- 4 -

106.GB.80A.0 INHALT

TABLE OF CONTENTS

GB

TABLE OF CONTENTS

warning signs ........................................................................5

Recommendations for work safety ........................................ 5

General safety tips for using the trailer..................................6

Travelling on roads ................................................................6

PUTTING INTO OPERATION ............................................... 6

Before starting work ..............................................................6

Checking before operation ....................................................6

Operating the swivelling supporting wheel ............................ 7

Hitching up the implement.....................................................7

Parking the implement .......................................................... 7

Adjusting drawbar to tractor’s towing coupler ........................8

Pivoting drawbar safety device check ................................... 8

Brake adjustment ..................................................................9

Adaption to tractor ................................................................. 9

BRAKE UNIT.........................................................................9

Initial operation ...................................................................... 9

Shortening the bowden cable ...............................................9

Safety Cable (max. 25 km und max. 4 to zul. Ges Gew.) ... 12

Abreißseil (nur bei Auflaufbremsanlage) ............................ 12

Drive shaft adaption ............................................................12

Hydraulic connection ........................................................... 12

Putting into operation ..........................................................12

Uncoupling and parking the trailer ...................................... 12

Parking in the open .............................................................12

Garaging for winter..............................................................12

Hydraulic connection ........................................................... 13

Standard position: with an open hydraulic system .............. 13

Take care! with tractors with a closed hydraulic system ..... 13

Operation elements ............................................................. 14

Mounting bracket.................................................................14

Operating elements ............................................................. 14

Pick-up and hydraulic drawbar ............................................14

Dry forage extension ...........................................................14

Tail gate ...............................................................................14

Operation of hydraulic scraper floor drive ........................... 14

Dry forage extension ...........................................................15

Swivelling cutter unit ........................................................... 15

Obstructions when swivelling ..............................................15

Alteration of gas container pressure ................................... 15

Maintenance........................................................................15

Operation errors ..................................................................16

Hydraulic connection ........................................................... 17

Power supply.......................................................................17

Standard position: with an open hydraulic system .............. 17

Installation and check of the electrohydraulic operation...... 18

Pivoting drawbar.................................................................. 18

Tailgate ................................................................................18

Scraper floor reverse run (KR) ............................................18

Pick-up ................................................................................18

Dry forage extension ...........................................................19

Swivelling cutter unit ........................................................... 19

Obstructions when swivelling ..............................................19

Alteration of gas container pressure ................................... 19

Maintenance........................................................................19

Trouble shooting ..................................................................20

Maintenance........................................................................20

Emergency handling of hydraulic valves in case of power

break down..........................................................................20

Hydraulic connection ........................................................... 21

Standard position: with tractors with an open hydraulic

system ................................................................................. 21

Power supply.......................................................................21

Installation and check of comfort operation.........................22

Check switch-off functions .................................................. 22

Dry forage extension ...........................................................24

Swivelling cutter unit ........................................................... 24

Obstructions when swivelling ..............................................24

Alteration of gas container pressure ................................... 24

Maintenance........................................................................24

Trouble shooting ..................................................................25

Emergency handling of hydraulic valves in case of power

break down ( - Baujahr 1997)..............................................25

Emergency handling of hydraulic valves in case of power

break down ( + Baujahr 1998).............................................26

Trouble shooting ..................................................................26

Adjusting the pick-up ........................................................... 27

Impact deflector adjustment (52).........................................27

Loading process in general .................................................27

LOADING THE TRAILER ....................................................27

Starting the loading process ...............................................27

To observe during the loading process! ..............................27

Finishing the loading process .............................................27

Trailer fill indicator (1 ........................................................... 27

Swivelling cutter unit in and out...........................................28

Folding cutter bar down.......................................................28

Folding two cutter bars down ..............................................29

Quick-insert cutters (M) ....................................................... 29

Handling quick-insert cutters ............................................... 29

Swivelling out a quick-insert cutter ...................................... 29

Installing a quick-insert cutter .............................................30

Cutter bar ............................................................................30

Removal and installation of a cutter ....................................30

Cutter installation ................................................................ 30

Maintenance........................................................................31

Direct grinding of cutter on cutter bar .................................. 31

Grinding of removed cutters ................................................ 31

Hydraulic opening and closing of the tail gate.....................33

Unloading with raised top frame..........................................33

WHEELS AND TYRES ....................................................... 34

Troubleshooting ...................................................................35

Advice for general maintence..............................................36

Spare parts .........................................................................36

Opening the side protectors ................................................36

Closing the side protectors..................................................36

Take care when entering the loading area .......................... 36

Tyre pressure ...................................................................... 37

Scraper floor chains ............................................................38

Starting transmission ..........................................................38

Hydraulic unit ...................................................................... 38

Cleaning of machine parts .................................................. 38

Brake adjustment ................................................................38

Optional equipment .............................................................39

Technical data ..................................................................... 39

Correct loading: ................................................................... 39

Lubrication chart .................................................................40

Lubrication chart .................................................................41

Lubrication chart .................................................................42

Recommendations for work safety ...................................... 47

DRIVESHAFT ..................................................................... 48

Auflauf-Achse mit Rückfahrautomatik ................................. 49

Einstellen der Nockenbremse Typ: 30-4010 (300x60) ......... 49

Auflaufbremsanlage ............................................................50

Abstellen des Anhängers ....................................................50

Fehlerursachen und deren Beseitigung ..............................51

Important! Additional Information ........................................52

Combination of tractor and mounted implement .................52

CE sign

The CE sign, which is affixed by the manufacturer, indicates outwardly

that this machine conforms to the engineering guideline regulations and

the other relevant EU guidelines.

EU Declaration of Conformity

By signing the EU Declaration of Conformity, the manufacturer declares

that the machine being brought into service complies with all relevant

safety and health requirements.

495.151

Meaning of warning

signs

Turn engine off when

adjustment, service and

repair work is to be done.

Never reach into the pick-up

area as long as tractor

engine is running with PTO

connected.

Never reach into the crushing

danger area as long as parts

may move.

Don't step on loading

platform if PTO is connected

to tractor and Engine is

running.

Stay clear of gate swinging

area while tractor engine is

running. Access only allowed

when safety lock is applied.

Recommendations for work safety

All points referring to satety in this

manual are indicated by this sign.

Wait until all machine

components have stopped

completely before touching

them.

Stay clear of gate swinging

area while tractor engine is

running.

- 5 -

AZB 9700-GB (511)

GB

WARNING SIGNS

Before starting work

a. Before commencing work, the operator must be aware of

all operating devices and functions. The learning of these

is too late after having already commenced operation!

b. The vehicle is to be tested for traffic and operating safety

before each operation.

c. The danger of being crushed or cut exists in the Pick-up,

cutting unit, tailgate and upper extension areas. All persons

must be shown out of these areas before activating hydraulic

equipment and turning on the drive.

d. Before driving the vehicle, the driver must ensure that

nobody will be endangered and that no obstructions are

present. If the driver is unable to see and have an overall

view of the roadway directly behind the trailer, he must be

guided by somebody while reversing.

e. Observe the safety tips which are attached to the trailer. An

explanation of what the individual graphic warning symbols

mean can be found on page 4.

f. Observe also the tips in the respective chapters and in the

supplement to this operating manual.

Checking before operation

The following tips should make the trailer's operation

easier for you. Detailled information for individual

points can be found in the respective chapters in this

operating manual.

1. Check that all safety equipment (coverings, casings, etc.)

are in proper order and fitted in position on the trailer.

2. Grease the trailer in accordance with the lubrication chart.

Check the gearing for tightness and the oil level.

3. Check that tyres have the correct air pressure.

4. Check that wheel nuts are sitting firmly.

5. Ensure the correct p.t.o.-r.p.m..

6. Make the electrical connections to the tractor and check

that they are correct. Take note of the tips in the operating

manual!

7. Carry out the following adaptions:

• Drawbar height

• Laying of brake cable

• Install hand brake lever in the tractor cabin.

8. Secure trailer using only the fixtures provided.

9. Cut drive shaft to the correct length and check the function

of the overload safety (see supplement).

10. Check the electronic unit function.

11. Connect hydraulic lines to tractor.

• Check hydraulic hoses for damage and wear.

• Ensure the correct connection.

12. All swivelling parts (tailgate, adjusting lever, etc.) must be

secured against dangerous position changes.

13. Check parking brake and service brake functions.

General safety tips for using the

trailer

Tips for travelling with the trailer

The handling of the tractor is influenced by the trailer

coupled to it.

• Danger of tipping exists when working on slopes.

• The driving must be adapted

to the corresponding terrain

and ground conditions.

• The towing vehicle is to be

sufficiently equiped with

weights at the front or at the

rear in order to guarantee the

steering and braking capacity

(a minimum of 20% of the

vehicle's tare weight on the

front axle).

• The transport of persons on the machine is not permitted.

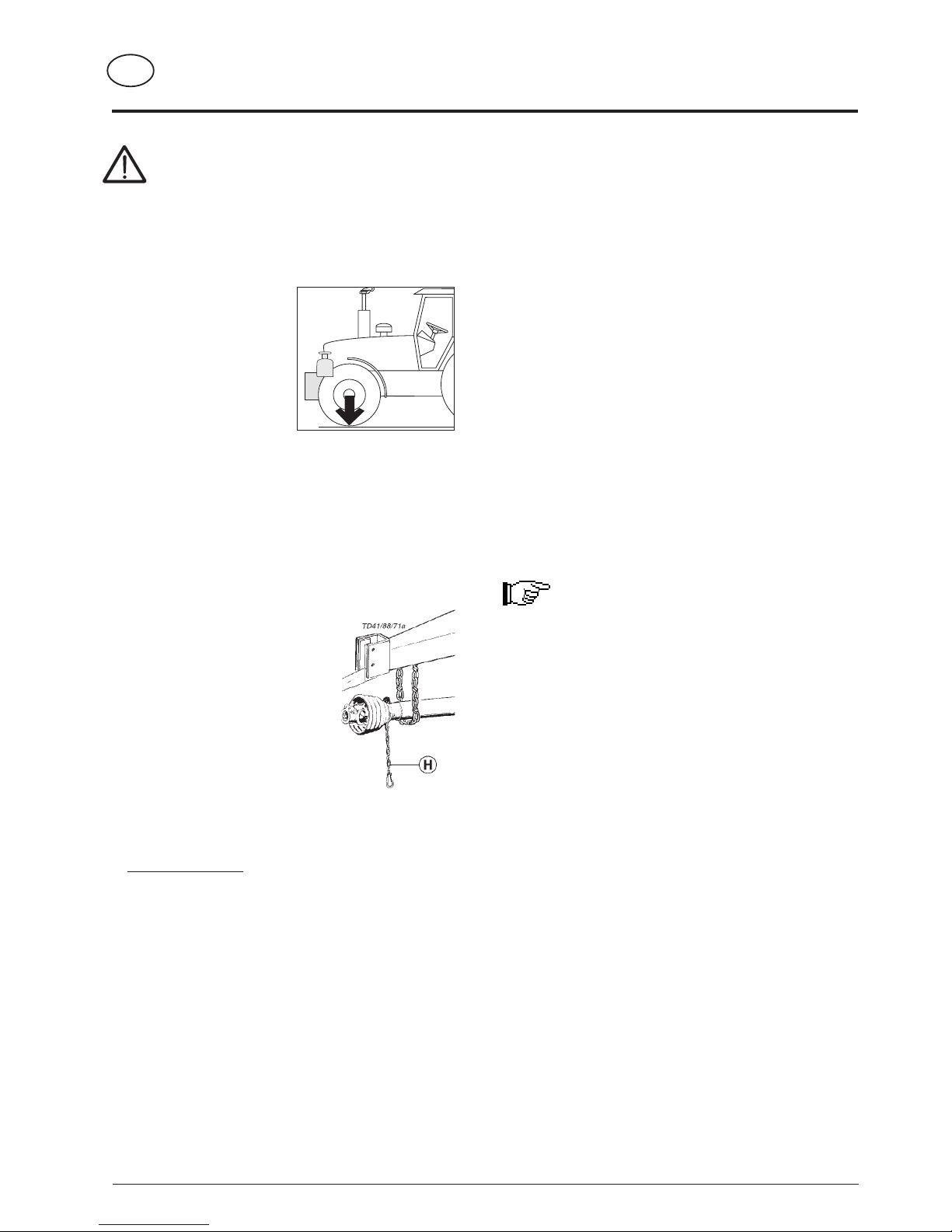

Tips for coupling and uncoupling the trailer

• Danger of injury exists when coupling the implement to the

tractor!

• As long as the tractor is moving backwards, do not step

between it and the trailer when coupling.

• Nobody is to stand between the tractor and trailer without

the vehicles being secured against

rolling with the parking brake and/or

wheel chocks.

• Drive shaft connection or

disconnection is only to be undertaken

when the motor has stopped.

Parking the implement

• When the implement ist parked, either

remove the driveshaft and store it, or

secure it with a chain.

Do not use retaining chain (H) for this.

Only use the trailer according to regulations!

Regulations for Use: See chapter "Technical Data".

• The trailer's load limits (permitted axle load, support load,

total weight) may not be exceeded. The relevant details

are located on the right side of the trailer.

• In addition, observe the power limits of the tractor being

used.

Travelling on roads

• Observe the road rules.

• The tailgate must be closed when travelling on public

roads. Lighting devices must be fitted vertically to the road.

20%

Kg

GB

- 6 -

9500 GB INBETRIEBNAHME (511)

PUTTING INTO OPERATION

- 7 -

511 / STÜTZRAD 9800-GB

GB

SUPPORTING WHEEL

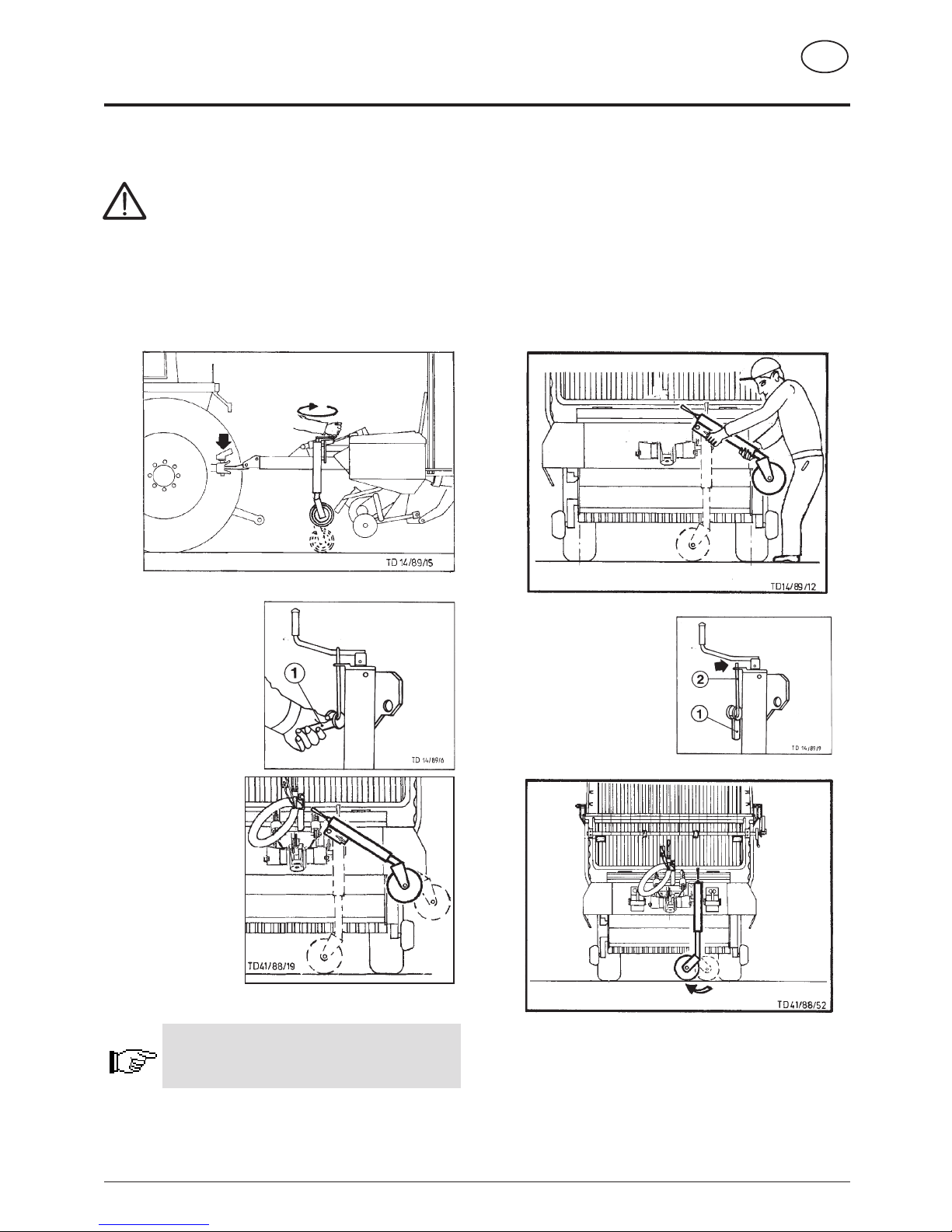

Operating the swivelling supporting wheel

Only use eccentric lever (1) when implement is hitched

to tractor (danger of an accident should the trailer tip

sideways)! Therefore keep children away from the

parked trailer.

Hitching up the implement

1. Couple implement to tractor and wind up supporting

wheel.

2. Unlock positioning bolts

with eccentric lever (1).

3. Swivel supporting

wheel up and secure.

Support wheel must not protrude beyond

external contour of tractor!

Wind supporting wheel completely up!

Parking the implement

• Park the trailer on firm, level ground.

If the ground is soft then the area where the support

wheel is to stand must be appropriately increased using

a suitable aid (e.g. wooden board).

• Park only empty implement on supporting wheel!

• When trailer is parked, apply the brake and secure

against rolling with wheel chocks.

1. Using eccentric lever (1) raise supporting wheel slightly and

unlock.

2. Swivel supporting wheel

down and lock using

eccentric lever (1).

Engaging positioning bolts

can be visually discerned

using safety rod (2).

3. Turn supporting wheel crosswise inwards.

4. Wind implement up until tow ring is clear of tractor's coupling.

Maintenance advice

Grease locking bolts occasionally!

- 8 -

511 / KNICKDEICHSEL 9600-GB

PIVOTING DRAWBAR

GB

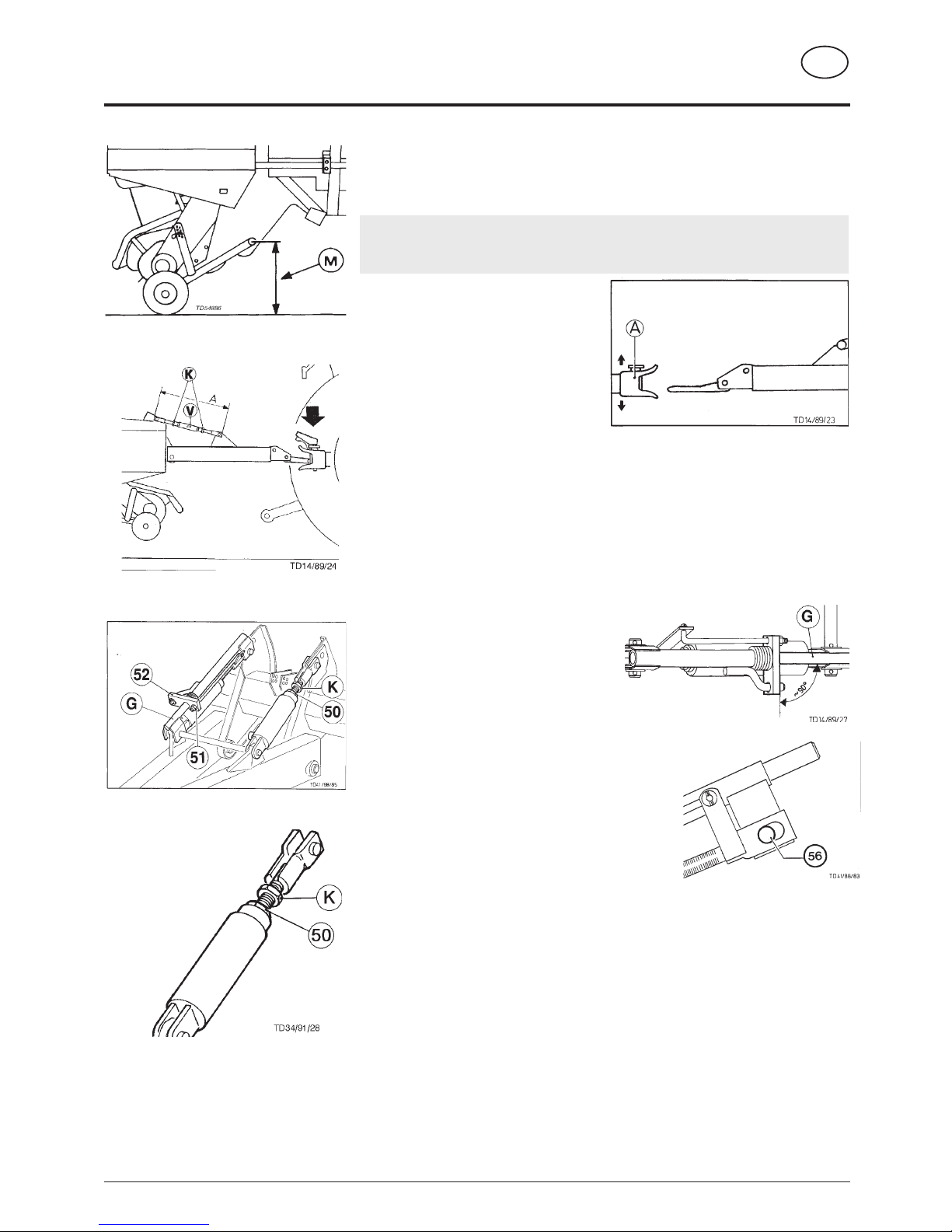

Adjusting drawbar to tractor’s towing coupler

To allow pick-up to work perfectly, the height (M) of coupled trailer must be correctly set

(pick-up pivoting area).

Height (M) = 43 cm

Note: Where the floor is uneven, reduce the measurement by 1 cm (M = 42 cm).

- Park unloaded trailer on even ground

and on jockey wheel.

- Attach trailer coupler (A) to tractor so that

on towed vehicle adequate distance exists

between drive shaft and drawbar.

- Set height (M) from ground to centre of

feeler coupling point by adjusting jockey

wheel.

Drawbar adjustment when equipped with adjusting spindle:

- Loosen lock-nuts (K).

- Twist turnbuckle barrel (V) correspondingly.

- Check height (M) of trailer coupled to tractor.

Observe following when equipped with

hydraulic cylinder:

- Couple trailer to tractor.

- The hydraulic cylinder piston must be

completely inserted.

- Twist nut (51) until clamp frame (52) is at

rightangles (about 90°) to slip rod (G). The

clamp can then be raised.

A slot is located in the fork of the regulating spindle.

- The fastening bolt (56) must make contact with the

inside of the slot.

- Loosen lock-nut (K) on the threaded spindle.

- By twisting the cylinder piston (50), screw the threaded

spindle in or out until the height (M) is achieved.

Slip rod (G) must be able to move in the casing during

the adjustment process (adjust with nut 51).

- Retighten lock-nut (K).

- Twist nut (51) until clamp frame (52) is at rightangles (90°) to slip rod (G).

Pivoting drawbar safety device check

Function of the automatic clamping device:

It prevents the trailer from tipping up during the return trip.

- Adjust by twisting the nut (51) until the clamp frame (52) prevents the trailer from

tipping up through a slight inclination of the slip rod (G).

Maintenance:

Grease pivoting drawbar safety device frequently!

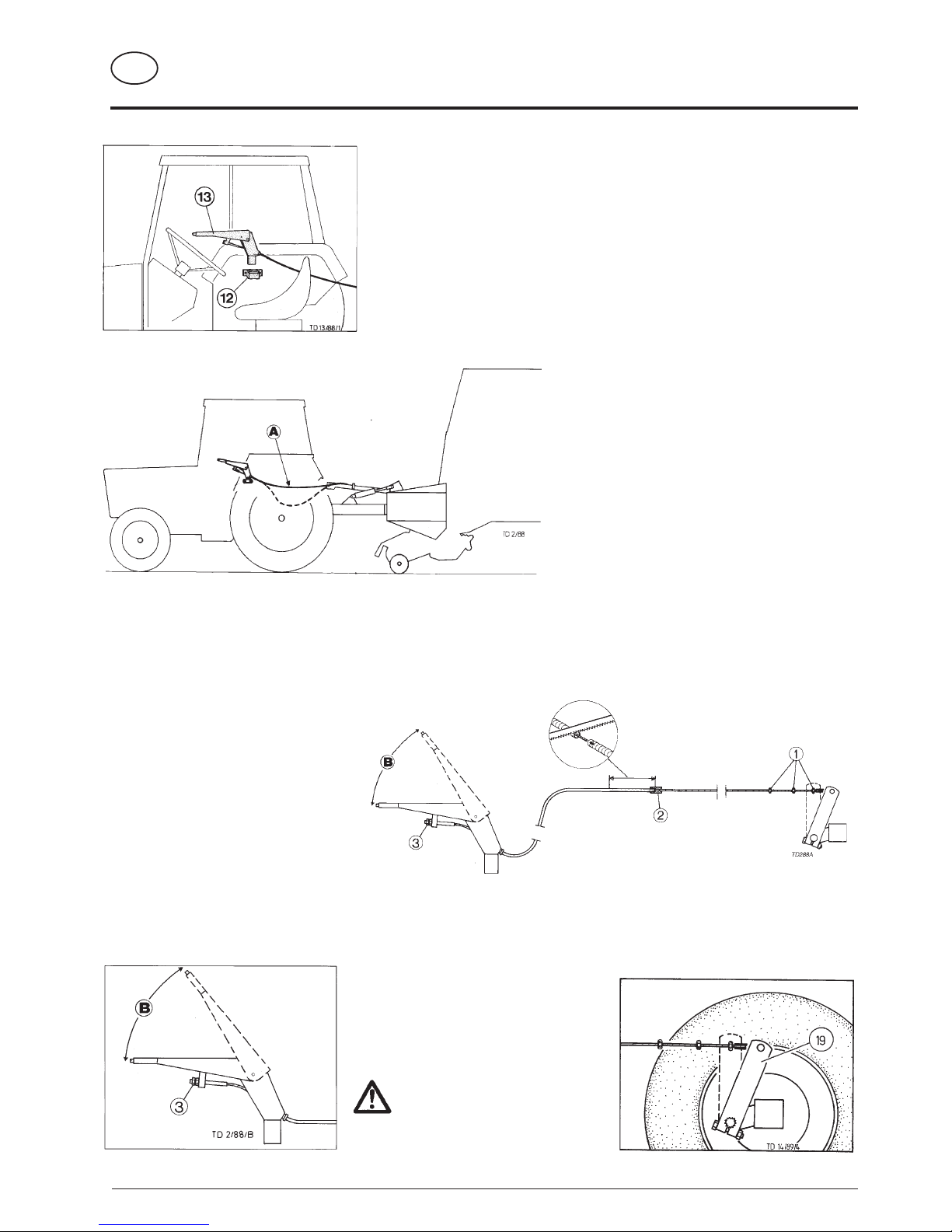

Initial operation

With initial operation install accompanying catch bracket (12) onto mudguard so that

it is within reach and can be seen.

Insert moveable hand break lever (13) onto tractor for every run.

- Carry out brake test.

Attention!

If brake fault occurs, immediately stop tractor and clear fault.

Should the adjustment action on the hand

brake lever no longer be adequate, then with

the help of the notches on the brake cam axle

lever, alter the position of the lever (19)

correspondingly.

The lever adjustment (19) must be

carried out on both sides

simultaneously.

Adaption to tractor

- Loosen cable clamps (1) and unthread the cable through the support (2).

- Shorten bowden cable covering (see diagram) to a point where trouble-free cornering is still is possible.

- Rethread cable and secure with cable clamps.

- Check lever action (B) and adjust with

hexagonal nut (3) if necessary.

Shortening the bowden cable

The extra long brake cable is manufactured to suit

the various designs of different tractor types.

In order to guarantee optimal function of brake

unit, the cable (A) should run in a straight line if

possible.

Brake adjustment

- If brake linings are worn out then brake shoes must be adjusted. This is carried out by turning adjusting nut (3) on hand brake lever.

511 / BREMSANLAGE 9300 GB

- 9 -

GB

BRAKE UNIT

(moveable handbrake)

DRUCKLUFTBREMSE MIT ALB 9400 D (540)

- 10 -

1)

Wunschausrüstung

DRUCKLUFTBREMSANLAGE

D

Ankuppeln der Bremsschläuche

- Beim Ankuppeln der Bremsschläuche ist zu beachten, daß

die Dichtringe der Kupplungsköpfe sauber sind, richtig dichten

und gemäß der

Bezeichnungen “Vorrat”

(Farbe rot) zu “Vorrat”

und “Bremse” (Farbe

gelb) zu “Bremse”

gekuppelt werden.

- Beschädigte Dichtringe

sind zu ersetzen.

Stromversorgung des ABS (Antiblockiersystem)

1)

Das ABS funktioniert ohne elektrischer Versorgung

nicht.

Vor Beginn der

Fahrt den

Stecker (1) beim

Schlepper

ankuppeln.

• Zum Abstellen des

Wagens den

Stecker an die

Steckdose der

Konsole kuppeln.

Mit dem Schwenkbügel (1a) wird der

Stecker gegen

Lösen gesichert.

- Vor der ersten täglichen Fahrt ist der Luftbehälter zu

entwässern.

- Erst dann abfahren wenn der Luftdruck im Bremssystem 5,0

bar beträgt.

Achtung!

Um ein ordnungsgemäßes Funktionieren der Bremsanlage

zu gewährleisten, sind die Wartungsintervalle sowie die

Bremseinstellung (Hub max. 30 mm) gewissenhaft

einzuhalten.

Pflege und Wartung der Druckluftbremsanlage

Luftbehälterentwässerung

Der Luftbehälter ist täglich zu entwässern. Hierzu ist der

Bolzen am Entwässerungsventil mit Hilfe eines Drahtes in

seitlicher Richtung zu ziehen. Das Entwässerungsventil ist

bei Verschmutzung aus dem Behälter zu schrauben und zu

reinigen.

Leitungsfilterreinigung

Die beiden Leitungsfilter sind je nach Betriebsbedingungen, im

Normalfall etwa alle 3-4 Monate zu reinigen. Zur Reinigung

sind die Sinterfilterpatronen herauszunehmen.

Arbeitsschritte:

a) Verschlußstück (21) an den beiden Laschen hineindrücken

und Schieber (22) herausziehen.

b)Verschlußstück mit O-Ring (23), Druckfeder und

Sinterfilterpatrone herausnehmen.

c) Die Sinterfilterpatrone ist mit Nitro-Reinigungsmittel

auszuwaschen und mit Druckluft auszublasen. Beschädigte

Filterpatronen sind zu erneuern.

d) Beim Zusammenbau in umgekehrter Reihenfolge ist darauf

zu achten, daß der O-Ring (23) nicht in den Führungsschlitz

für den Schieber am Gehäuse verkantet!

Bremseinstellung

Der Kolbenhub an den Bremszylindern darf keinesfalls mehr

als 30 mm aufweisen. Er ist daher von Zeit zu Zeit zu

überprüfen und ggf. nachzustellen.

Achtung!

Lassen Sie allfällige Wartungs- und Reparaturarbeiten

an der Bremsanlage von einer Fachwerkstätte oder

von unserem Kundendienst durchführen.

Für die Schnellläuferachse "300 x 200" gibt es ein

spezielles Wartungshandbuch welches beim

Kundendienst angefordert werden kann.

Einstellung

- Die Einstellung erfolgt durch die Stellschraube (7).

- Der Kolbenhub soll bei Neueinstellung 12 - 15 mm betragen.

TD70/91/4

max. 30 mm Hub

7

DRUCKLUFTBREMSE MIT ALB 9400 D (540)

- 11 -

1)

Wunschausrüstung

DRUCKLUFTBREMSANLAGE

D

TD13/92/12

Lösestellung am Bremsventil

Die Lösestellung ermöglicht ein Bewegen des Wagens wenn die

Bremschläuche nicht am Schlepper angekuppelt sind.

- Betätigungsknopf (M) bis zum Anschlag hineindrücken. Die Bremse wird

dabei gelöst.

- Betätigungsknopf (M) bis zum Anschlag herausziehen. Der Wagen wird

durch den vom Luftbehälter kommenden Vorratsdruck wieder eingebremst.

- Beim Angekuppeln der Bremsschläuche wird der Betätigungsknopf (M)

durch den vom Zugfahrzeug kommenden Vorratsdruck automatisch

wieder herausgedrückt.

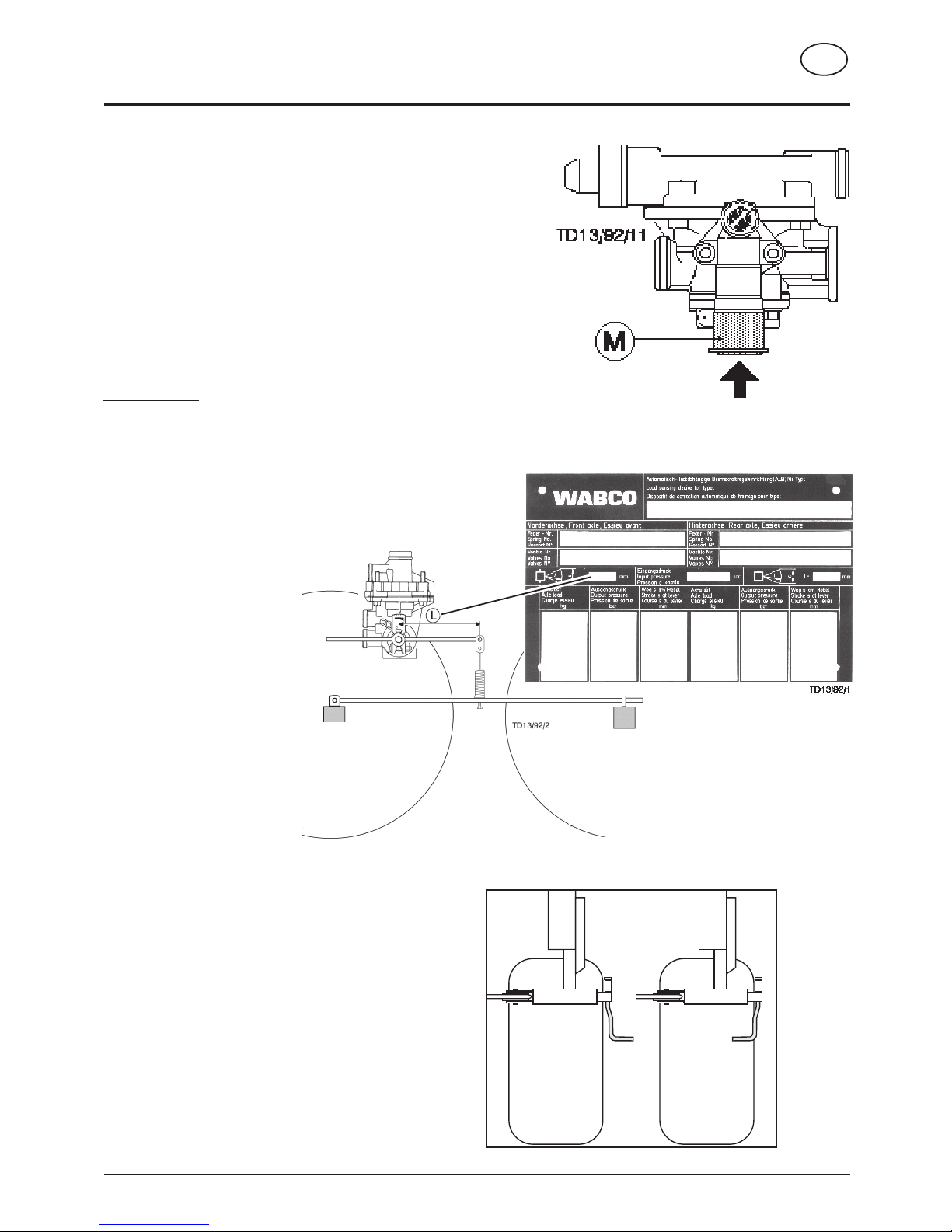

ALB-Regler (Bei Austattung mit automatischem Bremskraftregler)

1)

Mit dem ALB-Regler wird die benötigte Bremskraft, je nach

Beladungszustand des Wagens, automatisch geregelt.

Einstellung

Das Einstellmaß (L) darf nicht verändert werden. Es muß dem Wert

welcher am WABCO Leistungschild angegeben ist entsprechen.

- Vor Antritt der Fahrt ist die Feststellbremse zu lösen und die

Kurbel nach innen zu schwenken.

Abstellen des Wagens

Zum Abstellen wird der Wagen mittels Feststellbremse

eingebremst.

- Bremskraftregler auf “Lösen” stellen und Bremsschläuche

abkuppeln.

COUPLING AND UNCOUPLING THE TRAILER

GB

- 12 -

537 / AN- U. ABKUPPELN 9500 GB

Safety Cable (max. 25 km und max. 4 to zul. Ges Gew.)

- Safety cable (6) to be fitted

correctly to tractor's towing

coupler. (Safeguard against

breakage of trailer coupling

ring or detachment from

tractor.)

Abreißseil (nur bei

Auflaufbremsanlage)

- Bei Anhänger mit

Auflaufvorrichtung das

Abreißseil (1) vom

Handbremshebel am

Traktor verknoten.

(Safeguard against

breakage of trailer

coupling ring or

detachment from

tractor.)

Drive shaft adaption

To shorten the drive shaft see supplement-B!

Hydraulic connection

- Connect hydraulic lines to tractor.

• See also chapter

"HYDRAULIC OPERATION",

"ELECTROHYDRAULIC OPERATION".

Putting into operation

• Before putting the tractor or implement into operation check

vehicle safety (lights, brake unit, protective covering …)!

• Pay attention to correct load distribution during operation!

Uncoupling and parking the trailer

• See also chapter

"SUPPORTING WHEEL", "BRAKE

UNIT", "DRAWBAR".

Important!

Before uncoupling the snap-lock coupler

1. Raise the pick-up.

2. Close shut-off valve on snap-lock coupler (position A).

3. Release pressure on tractor's control unit (ST) and uncouple.

Attention!

• Always park implement so that it is standing safety.

• Secure trailer against rolling away (locking brake, wedges).

Parking in the open

When parking for longer

periods in the open, clean

plunger rods and then coat

with grease.

Garaging for winter

- Thoroughly clean the machine before garaging for winter.

- Apply weather protection.

- Change or top-up gear oil.

- Protect uncoated parts against rusting.

- Grease all lubricating points according to lubrication chart.

FETT

TD49/93/2

A

E

TD31/90/21

ST

- 13 -

HYDRAULIC OPERATION

537 / HYDR.KAB.BED. 9501 GB

GB

Standard position: with an open hydraulic

system

• e.g. a standard tractor with a gear pump.

- The standard basic setting for the shut-off valve (position A)

applies to this type. In this position the shut-off valve is open.

Tip! If the tractor has a closed hydraulic system and the unit

is operating in this position, then the hydraulic oil will heat up

(particularly due to the constant pumping of the maximum

amount of oil).

Remedy: Modify the system on the trailer or decrease the

amount of oil being pumped at the tractor as written below.

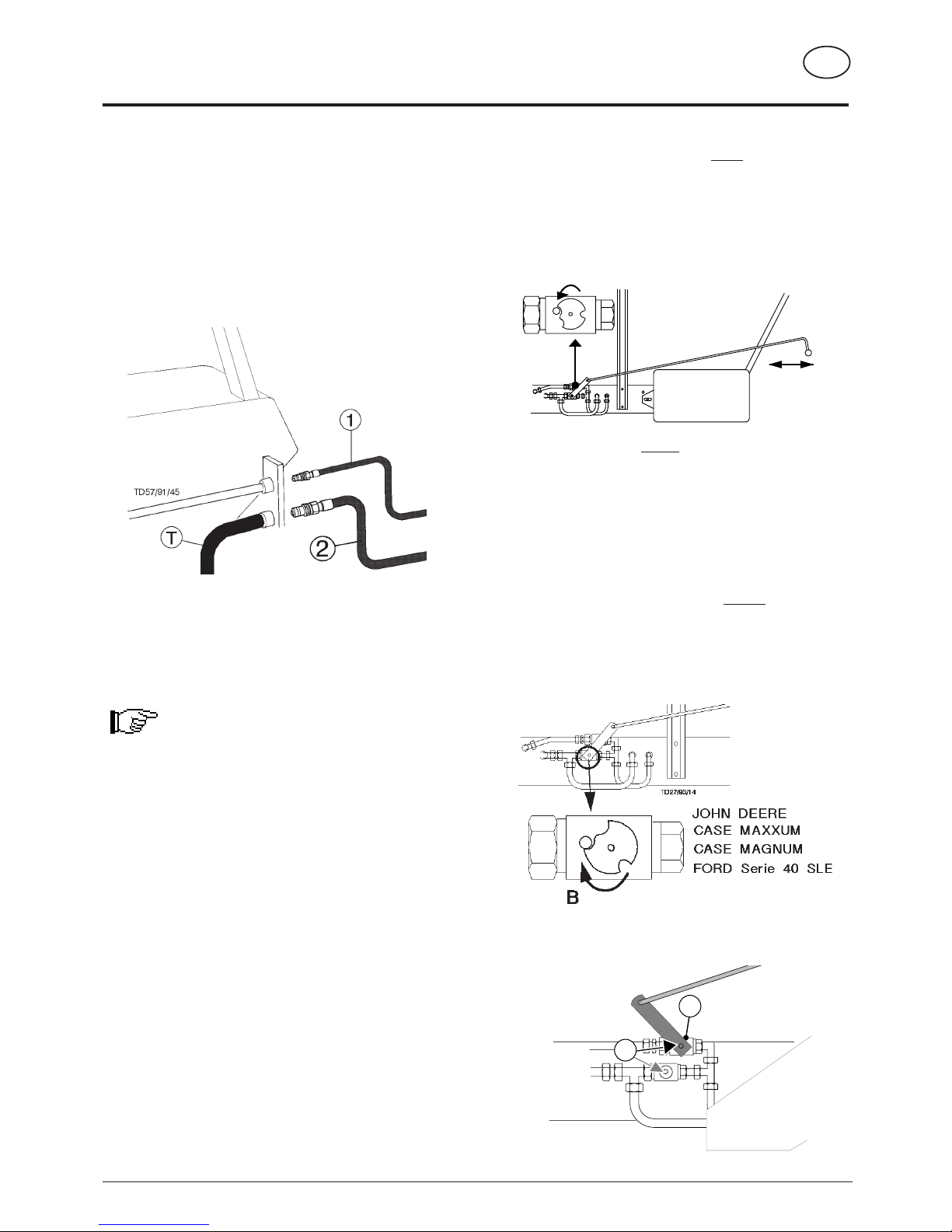

Take care! with tractors with a closed hydraulic

system

• JOHN-DEERE, FORD Serie 40 SLE

CASE-MAGNUM, CASE-MAXXUM,

1. Close the shut-off valve (position B).

2. Dismount lever (7) and fit onto the shut-off valve (11).

Hydraulic connection

Single-action control unit

Should the tractor only have a single-action servo-valve,

then it is absolutely necessary to have an oil-return pipe (T)

fitted by a specialist.

- Connect pressure hose (1) to the single-action control unit.

Couple the oil-return hose (2) (with the greater diameter) to

the tractor’s oil-return system.

Double-action control unit

- Connect pressure line (1) and oil-return pipe (2) (pipe with

the greater diameter is the oil-return pipe).

Note:

If oil should become warm during operation then a

single-action control unit should be connected (see

above).

TD113/91/5

JOHN DEERE

CASE MAXXUM

CASE MAGNUM

FORD Serie 40 SLE

11

7

A

TD7/91/22

EIN

MARCHE

ON

AAN

AUS

ARRET

OFF

UIT

- 14 -

HYDRAULIC OPERATION

537 / HYDR.KAB.BED. 9501 GB

GB

Operation elements Pick-up and hydraulic drawbar

1. Put lever switch "6" into position "I".

2. Put lever switch "7" into position "A".

3. Select desired funktion with lever (9 resp. 10).

4. Engage control valve (ST).

Dry forage extension

1. Put lever switch "6" into position "I".

2. Put lever switch "7" into position "E1".

3. Engage control valve (ST).

Tail gate

1. Put lever switch "6" into position "I".

2. Put lever switch "7" into position "E2".

3. Engage control valve (ST).

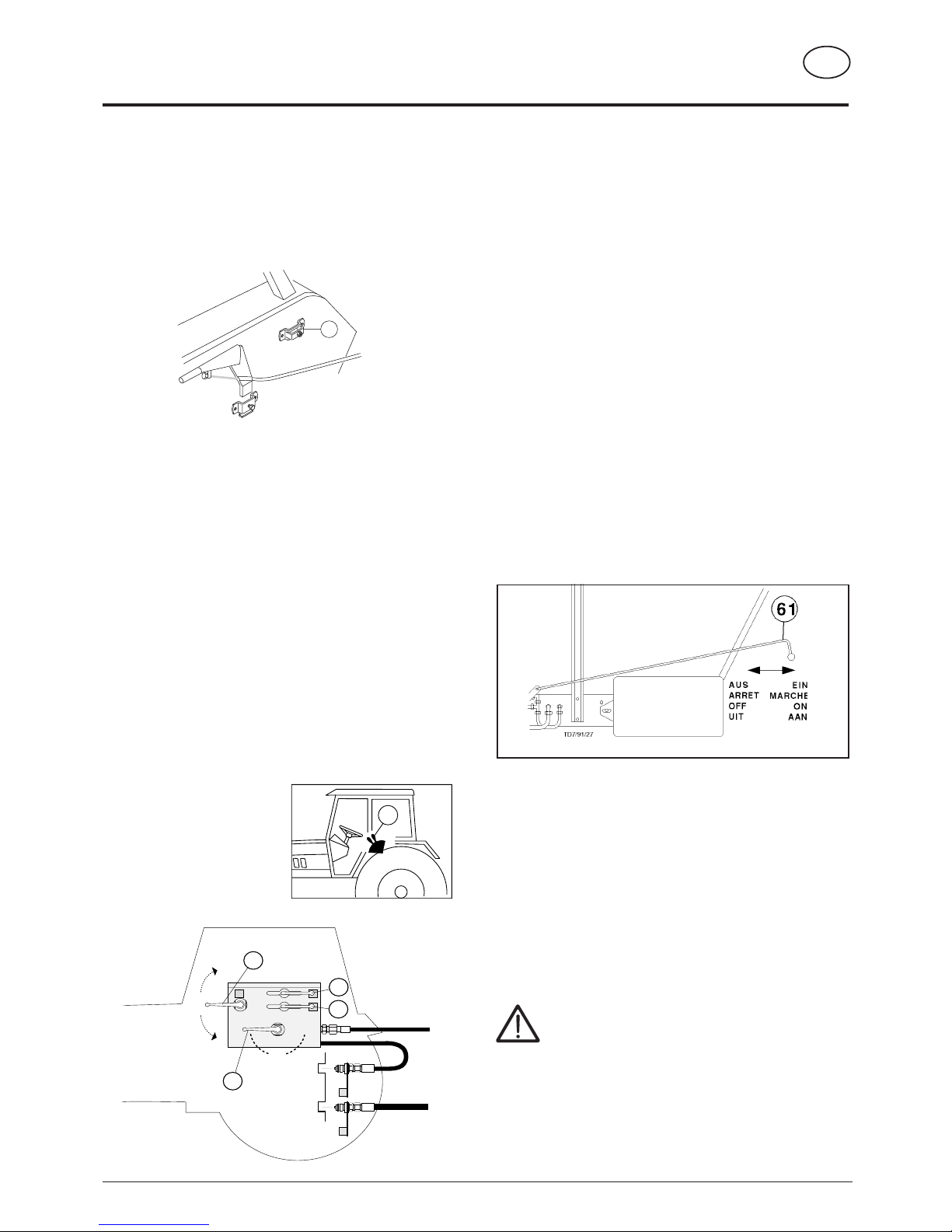

Operation of hydraulic scraper floor drive

Front operation (from the tractor cabin)

1. Shift lever (61) to the "ON" position.

2. Put lever switch (6) into position II (scraper floor drive).

3. Engage or disengage the scraper floor drive with the control

valve (ST).

Rear operation

1. First shift the lever (61) into the "OFF" position.

2. Put lever switch (6) into position II (scraper floor drive).

3. Engage control valve (ST).

4. Switch scraper floor drive "on" or "off" with lever (61).

Safety tips

Please take particular care when the operating

elements on the trailer and the tractor are to be used

simultaneously by more than one person. A

conscientious arrangement should be made by those

concerned before operation.

An example:

Danger of injury arises if a person stands at the rear of the

trailer and somebody in the tractor cabin activates a switching

function (opening the tailgate, switch on the driving gear, ...).

Mounting bracket

• The accompanying bracket (L) is for mounting the hydraulic

switching element in the cabin and is to be installed on the

tractor's mud guard.

Operating elements

• Depending on the trailer's fittings, the order of the operating

elements can differ slightly to the representation shown. For

example, the lever with positions "E1-A-E2" can only be

used on trailers with all extras (e.g. hydraulic drawbar,

hydraulic dry forage extension, tailgate).

The following operating instructions refer to trailers

with all extras

• Shift lever "6" serves to reverse the hydraulic flow between

the the oil cycle of the hydraulic scraper floor drive and the

oil cycle of the preselection levers for the Pick-up lift,

drawbar, etc..

ST = Control valve

0 = 0-position

I + A = Pick-up (9), hydraulic drawbar (10)

II = Hydraulic scraper floor drive

I + E2 = Tail gate

I + E1 = Dry forage extension

P = Pressure hose

T = Runback hose

TD27/93/25

L

A

E1 E2

TD27/93/24

II

0

7

10

P

T

I

6

9

ST

- 15 -

HYDRAULIC OPERATION

537 / HYDR.KAB.BED. 9501 GB

GB

SW DA

TD 18/93/13

W

A

E1 E2

TD27/93/24

II

0

7

10

P

T

I

6

9

Obstructions when swivelling

- Remove foreign body from swivel range.

• If the cutter bars do not swivel in properly, then a pressure

loss in the cutter unit hydraulic could be the cause.

Remedy by hydraulically filling the reservoir

1. Move lever to position "E" on 3-way valve.

2. Actuate servo-valve. The cutter bar is swivelled out

hydraulically.

3. Leave servo-valve (ST) in the press position for a few

seconds while moving the lever on the 3-way valve to

position "0".

• If obstruction cannot be removed then check gas fill pressure

(100 bar nitrogen) in hydroreservoir.

Alteration of gas container pressure

• This work may only be carried out by customer service or a

specialist.

• In order to reduce or increase the pressure in the gas

container a special filling and checking device is necessary.

Note

• According to manufacturer's information all gas containers

have a slight pressure drop after a certain amount of time.

• The gas loss (nitrogen) amounts to 2-3 % per year.

• After 4-5 years it is recommended that container pressure be

checked and if necessary corrected.

Maintenance

Beware!

No welding, soldering or mechanical works of any

kind may be carried out on the container.

• Hydraulic oil change according to tractor manual.

Dry forage extension

1. Lever (W) in position "DA".

2. Lever on control panel in position "E1".

3. Engage servo-control (ST) on tractor.

Folding extension up or back gradually.

Swivelling cutter unit

Caution!

Do not reach into swivel range of cutter bar

when swivelling in / out.

1. Lever (W) in position "SW".

2. Lever on control panel in position "E1".

3. Engage servo-control (ST) on tractor.

Both cutter bars swivel in resp. out.

• When only one cutter bar is needed for mowing, the lower

cutter bar can be swivelled out using the accompanying

lever (H).

- 16 -

HYDRAULIC OPERATION

537 / HYDR.KAB.BED. 9501 GB

GB

60

A

E1 E2

TD27/93/24

II

0

7

10

P

T

I

6

9

A

E1 E2

TD27/93/24

II

0

7

10

P

T

I

6

9

Operation errors

In the operation errors which follow, a problem can arise with the coupling and/

or uncoupling of the hydraulic hoses.

Operation error no. 1

- Pressure hose (P) and runback hose (T) coupled. CORRECT !

- Selector valve (9) open for pick-up operation. CORRECT !

- Lever switch (6) into position I. CORRECT !

- Pick-up in raised condition. WRONG !!!

Result:

Due to the dead weight of the pick-up, pressure builds up in the hydraulic hose

(P). To uncouple the pressure hose is only possible with great effort.

Solution:

Put lever switch (6) into the "0"-position for reoperation. The pressure in the

hydraulic hose can be eased by opening a screw connection.

Caution!

Close the selector valve (9) for pick-up operation before uncoupling and

bring the control valve (S) into "lower" or "float" position.

Operation error no. 2

The wagon with hydraulic drawbar is coupled to the tractor and the jockey

wheel is cranked up.

- Pressure hose (P) and runback hose (T) coupled. CORRECT !

- Selector valve (10) opened for hydraulic drawbar operation. CORRECT !

- Lever switch (6) to pick-up operation (position I). CORRECT !

- The hydraulic drawbar cylinder is not quite retracted

before garaging the wagon. WRONG !!!

Result:

Because of the load resting on the cylinders, excess pressure builds up in the

hydraulic hose (P). Uncoupling of the hose is not possible.

Solution:

Completely retract the hydraulic drawbar cylinder or garage the wagon on the

jockey wheel so that the load on the cylinder is eased.

Caution!

Do not operate the hydraulic drawbar while the wagon is supported on the

jockey wheel.

0200-GB ELEK-HYD_537

- 17 -

GB

ELECTROHYDRAULIC OPERATION

12V=

+

-

8

11

9

7-POL

"54g"

"31"

10

12

TD 18/93/11

86 86a 87

85 30

A

TD7/91/22

EIN

MARCHE

ON

AAN

AUS

ARRET

OFF

UIT

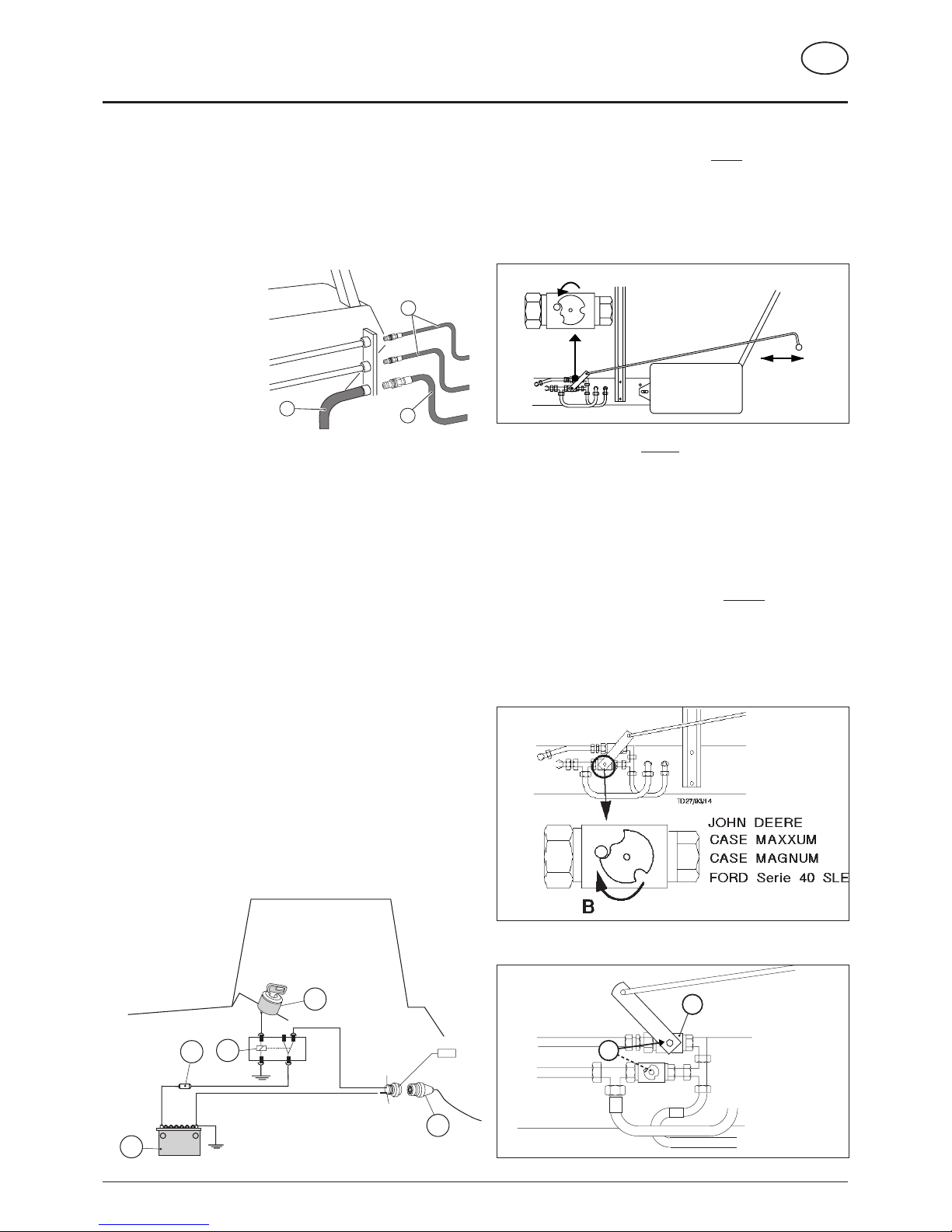

Hydraulic connection

Single-action control unit

Should the tractor only have a single-action servo-valve,

then it is absolutely necessary to have an oil-return pipe (T)

fitted by a specialist.

- Connect pressure hose (1)

to the single-action control

unit.

- Couple the oil-return hose

(2) (with the greater

diameter) to the tractor’s

oil-return system.

Double-action control unit

- Connect pressure line (1) and oil-return pipe (2) (pipe with

the greater diameter is the oil-return pipe).

Note:

If oil should become warm during operation then a singleaction control unit should be connected (see above).

Power supply

• Power (8) 12V is supplied via relay (9) connected to the

ignition (10).

• Lead diameter 2,5 mm2, fuse 16A (11).

• Power for the trailer is supplied via socket "54g" (+pole) and

"31" (-pole).

This modification is to be carried out only by

specialized workshops.

• Don’t connect directly to ignition (danger of fire and/or

damage of electrical equipment).

Establishing electric connection

- After completing above mentionnned work connect 7-pole

plug from trailer with socket.

- Check lights.

Standard position: with an open hydraulic

system

• e.g. a standard tractor with a gear pump.

- The standard basic setting for the shut-off valve (position A)

applies to this type. In this position the shut-off valve is open.

Tip! If the tractor has a closed hydraulic system and the unit

is operating in this position, then the hydraulic oil will heat up

(particularly due to the constant pumping of the maximum

amount of oil).

Remedy: Modify the system on the trailer or decrease the

amount of oil being pumped at the tractor as written below.

Take care! with tractors with a closed hydraulic

system

• JOHN-DEERE, FORD Serie 40 SLE

CASE-MAGNUM, CASE-MAXXUM,

- Close the shut-off valve (position B).

- Dismount lever (7) and fit onto the shut-off valve (11).

2

T

TD 18/93/10

1

11

TD27/93/16

JOHN DEERE

CASE MAXXUM

CASE MAGNUM

FORD Serie 40 SLE

7

0200-GB ELEK-HYD_537

- 18 -

GB

ELECTROHYDRAULIC OPERATION

Installation and check of the

electrohydraulic operation

- Mount supplied

bracket (13) for the

electrohydraulic

operating with two

hexagon screws

within driver’s vision

and reach in tractor

cabin.

- Insert front control

panel (14) in bracket (13).

Operation

- Preselect desired function on control panel. Switch engages.

- Preselected function is

engaged using servocontrol (ST) on tractor.

Note:

- If tractor is to be parked with implement

attached, electro-hydraulic operation

lever is to be shifted into neutral

position "C".

This prevents battery discharge.

Safety tips

Please take particular care when the operating

elements on the trailer and the tractor are to be used

simultaneously by more than one person. A

conscientious arrangement should be made by those

concerned before operation.

An example:

Danger of injury arises if a person stands at the rear of the

trailer and somebody in the tractor cabin activates a switching

function (opening the tailgate, switch on the driving gear, ...).

Pivoting drawbar

1. Lever on control panel in position "A".

2. Engage servo-control (ST) on tractor.

Attention!

Do not engage pivoting drawbar when

implement is standing on supporting wheel.

Tailgate

1. Lever on control panel in position "D".

2. Engage servo-control (ST) on tractor.

Automatic unlocking, raising/lowering and

shutting of tailgate.

Scraper floor reverse run (KR)

Front operation

1. Shift lever (61) to the "ON" position.

2. Lever on control panel in neutral position "C".

3. Engage servo-control (ST) on tractor.

Rear operation

1. First shift the lever (61) into the "OFF"

position.

2. Lever on control panel in neutral position

"C".

3. Engage servo-control (ST) on tractor.

4. Switch scraper floor drive "on" or "off" with lever (61).

Pick-up

1. Lever in position "E".

2. Engage servo-control (ST) on tractor.

Raising or lowering pick-up.

I n doing so loading unit operation and pick-

up are automatically switched on or off.

Dry forage extension

1. Lever on control panel in position "B".

2. Engage servo-control (ST) on tractor.

Folding extension up or back gradually.

TD 18/93/9

A

BC

D

E

KB - KR

KR

ST

0200-GB ELEK-HYD_537

- 19 -

GB

ELECTROHYDRAULIC OPERATION

SW DA

TD 18/93/13

W

TD 18/93/9

A

BC

D

E

Dry forage extension

- Lever (W) in position "DA".

- Lever on control panel in position "B".

- Engage servo-control (ST) on tractor.

Folding extension up or back gradually.

Swivelling cutter unit

Caution!

Do not reach into swivel range of cutter bar

when swivelling in / out.

- Lever (W) in position "SW".

- Lever on control panel in position "B".

- Engage servo-control (ST) on tractor.

Both cutter bars swivel in resp. out.

• When only one cutter bar

is needed for mowing, the

lower cutter bar can be

swivelled out using the

accoompanying lever (H).

Obstructions when swivelling

- Remove foreign body from swivel range.

• If the cutter bars do not swivel in properly, then a pressure

loss in the cutter unit hydraulic could be the cause.

Remedy by hydraulically filling the reservoir

- Move lever to position "E" on 3-way valve.

- Actuate servo-valve. The cutter bar is swivelled out

hydraulically.

- Leave servo-valve (ST) in the press position for a few

seconds while moving the lever on the 3-way valve to

position "0".

• If obstruction cannot be removed then check gas fill pressure

(100 bar nitrogen) in hydroreservoir.

Alteration of gas container pressure

• This work may only be carried out by customer service or a

specialist.

• In order to reduce or increase the pressure in

the gas container a special filling and checking

device is necessary.

Note

• According to manufacturer's information all

gas containers have a slight pressure drop

after a certain amount of time.

• The gas loss (nitrogen) amounts to 2-3 % per year.

• After 4-5 years it is recommended that container pressure be

checked and if necessary corrected.

Maintenance

Beware!

No welding, soldering or mechanical works of

any kind may be carried out on the container.

• Hydraulic oil change according to tractor manual.

• Before welding on trailer disconnect all plugs from tractor

and disconnect trailer.

0200-GB ELEK-HYD_537

- 20 -

GB

ELECTROHYDRAULIC OPERATION

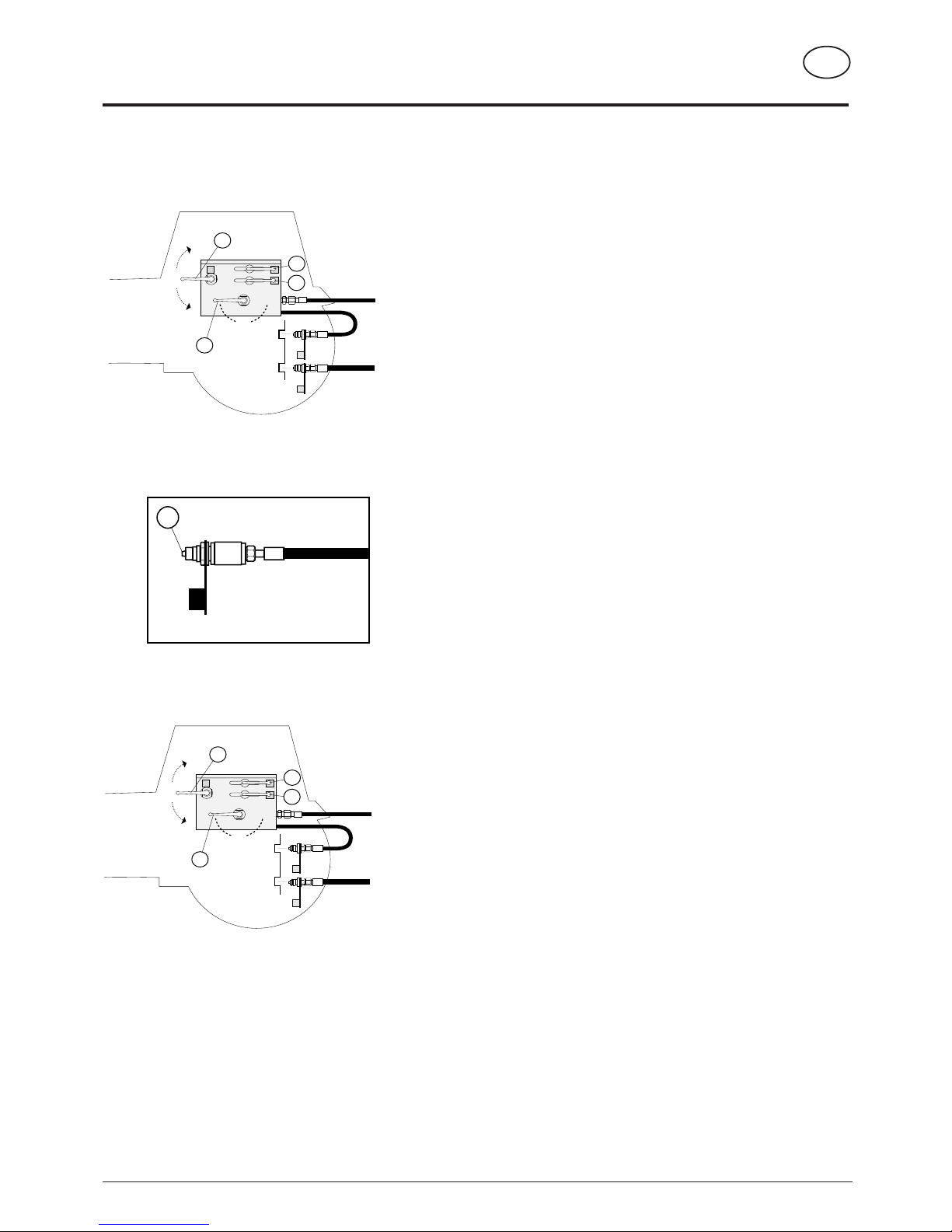

Trouble shooting

Beware!

Whenever eliminating trouble it is

essential to turn off power take-off.

During all these raising and/or lowering,

turning on and off processes mind

safety distances!

Maintenance

• Hydraulic oil change according to tractor manual.

• Before welding on trailer disconnect all plugs from tractor and disconnect trailer.

Lowering the pick-up

• Loosen lock nut(* (G).

• Screw in screw (H) on valve "Y1".

• Shift servo-control (ST) on tractor to lowering or "floating" position.

Pick-up is then lowered.

• Screw out screw (H) and lock with nut

(*

(G).

Raising the pick-up

• If valve (Y5) is installed, upper control cock at rear of implement must

be shifted to position "B".

• Loosen lock nut(* (G).

• Screw in screw (H) on valve "Y1".

• Shift servo-control (ST) on tractor to raising position. Pick-up is then

raised.

• Screw out screw (H) and lock with nut

(*

(G).

Lowering the pivoting drawbar

• Loosen lock nut(* (G).

• Screw in screw (H) on valve "Y2".

• Shift servo-control (ST) on tractor to lowering or "floating" position.

Pivoting drawbar is then lowered.

• Screw out screw (H) and lock with nut

(*

(G).

Raising the pivoting drawbar

• If valve (Y5) is installed, upper control cock at rear of implement must

be shifted to position "B".

• Loosen lock nut

(*

(G).

• Screw in screw (H) on valve "Y2".

• Shift servo-control (ST) on tractor to raising position. Pivoting drawbar

is then raised.

• Screw out screw (H) and lock with nut

(*

(G).

Emergency handling of hydraulic valves

in case of power break down

Lowering the dry forage extension

• Loosen lock nut(* (G).

• Screw in screw (H) on valve "Y3".

• Shift servo-control (ST) on tractor to lowering or "floating"

position. Dry forage extension is then lowered.

• Screw out screw (H) and lock with nut

(*

(G).

Raising the dry forage extension

• If valve (Y5) is installed, upper control cock at rear of implement

must be shifted to position "B".

• Loosen lock nut(* (G).

• Screw in screw (H) on valve "Y3".

• Shift servo-control (ST) on tractor to raising position. Dry forage

extension is then raised.

• Screw out screw (H) and lock with nut

(*

(G).

Opening the tailgate

• If valve (Y5) is installed, upper control cock at rear of implement

must be shifted to position "B".

• Loosen lock nut

(*

(G).

• Screw in screw (H) on valve "Y4".

• Shift servo-control (ST) on tractor to raising position. Tailgate

then opens.

• Screw out screw (H) and lock with nut

(*

(G).

Closing the tailgate

• Loosen lock nut(* (G).

• Screw in screw (H) on valve "Y4".

• Shift servo-control (ST) on tractor to lowering or "floating"

position. Tailgate then closes.

• Screw out screw (H) and lock with nut

(*

(G).

Y2

Y4

Y1

Y3

TD 18/93/14

Y5

ST

G

H

024-02-04

H

Variation 1

(* only for variation 1

GB

ELECTROHYDRAULIC COMFORT OPERATION

- 21 -

9500-GB ELEK.HYD.KOMF. (511)

Hydraulic connection

Single-action control unit

Should the tractor only have a single-action servo-valve,

then it is absolutely necessary to have an oil-return pipe

(T) fitted by a specialist.

- Connect pressure hose (1) to the single-action control

unit.

- Couple the oil-return hose (2) (with the greater diameter)

to the tractor’s oil-return system.

Double-action control unit

- Connect pressure line (1) and oil-return pipe (2) (pipe with

the greater diameter is the oil-return pipe).

Note:

If oil should become warm during operation then a singleaction control unit should be connected (see above).

Standard position: with tractors with an open

hydraulic system

• e.g. a standard tractor with a gear pump.

- The position of the slotted screw (7) is set in the factory. The

slotted screw (7) must be screwed out to the point where the

screw head is level with the

surface (6) of the hydraulic

block.

Tip! If the tractor has a closed hydraulic system and the unit

is operating in this position, then the hydraulic oil will heat up

(particularly due to the constant pumping of the maximum

amount of oil).

Remedy: Modify the system on the trailer or decrease the

amount of oil being pumped at the tractor as written below.

Take care! with tractors with a closed hydraulic

system

• JOHN-DEERE, FORD Serie 40 SLE

CASE-MAGNUM, CASE-MAXXUM

Before coupling, the slotted screw (7) on

the hydraulic block is to be screwed

completely in.

Power supply

• Power (8) 12V is supplied via relay (9) connected to the ignition

(10).

• Lead diameter 2,5 mm2, fuse 16A (11).

• Power for the trailer is supplied via socket "54g" (+pole) and

"31" (-pole).

This modification is to be carried out only by specialized

workshops.

• Don’t connect directly to ignition.

• Don’t connect directly to battery (danger of fire and/or

damage of electrical equipment).

Establishing electric connection

- After completing above mentionnned work connect 7-pole

plug from trailer with socket.

- Check lights.

TD 20/94/5

7

JOHN DEERE

CASE MAXXUM

CASE MAGNUM

FORD Serie 40 SLE

Standard-

position

TD20/94/6

JOHN DEERE

CASE MAXXUM

CASE MAGNUM

FORD Serie 40 SLE

GB

ELECTROHYDRAULIC COMFORT OPERATION

- 22 -

9500-GB ELEK.HYD.KOMF. (511)

Installation and check of comfort operation

Installation

- Mount supplied bracket

(13) for comfort operating

with two hexagon screws

within driver’s vision and

reach in tractor cabin.

- Insert front control panel

(14) in bracket.

Check switch-off functions

1. The scraper floor drive must be switched off.

• The press-button (16) on the control panel must not be depressed

(OFF- position).

• Likewise, the press-

button (32) in the switch

box located rear left of

the trailer must not be

depressed (OFFposition).

Control lamp:

The control lamp which is intergrated in the press-button

(16) lights up when either of the press-buttons (16, 32) is depressed

(scraper floor drive is switched on).

Safety tips

Please take particular care when the operating elements on the

trailer and the tractor are to be used simultaneously by more than

one person. A conscientious arrangement should be made by

those concerned before operation.

An example:

Danger of injury arises if a person stands at the rear of the trailer and

somebody in the tractor cabin activates a switching function (opening

the tailgate, switch on the driving gear, ...).

2. Operating switch

- All switches, except switch (19)

which is for the Pick-up lift, are

to be briefly switched down (B)

(switch off or lower position).

Pick-up lift

• Moving the switch (19) down (B) lowers the

Pick-up.

Caution!

If the lever (43) is in the "ON"

position then the loading unit and

Pick-up drive will automatically

switch on when lowering.

Therefore always stay at a safe

distance if the drive shaft is

coupled to the tractor and the p.t.o.

drive is switched on.

3. Engage control valve.

- Move lever (ST) to "ON" position and secure.

In so doing the trailer’s control block is supplied

with oil.

- By using a switch (15, 20, …) on the control panel

the relative hydraulic function takes place.

ST

GB

ELECTROHYDRAULIC COMFORT OPERATION

- 23 -

9500-GB ELEK.HYD.KOMF. (511)

Functions

Pick-up switch (19)

- Pushed down (B) - pick-up drops and

remains in floating position.

- Pushed up (A) - pick-up rises (feed

and pick-up drive stop automatically).

Caution!

If the lever (43) is in the "ON" position then the

loading unit and Pick-up drive will

automatically switch on when lowering.

Therefore always stay at a safe distance if the

drive shaft is coupled to the tractor and the

p.t.o. drive is switched on.

Hydraulic drawbar switch (26)

- Pushed up (A) - drawbar rises.

- Pushed down (B) - drawbar drops.

On the road hydraulic drawbar cylinder must be

completely retracted.

Rear gate lifting switch (15)

- Switch (15) pushed up (A) - rear gate

is released and opened.

- Switch (27) pushed down (B) - rear

gate is lowered.

Persons to leave pivoting area!

Attention!

While lowering switch stays turned on. After locking

rear gate switch has to be brought to position "0".

Scraper floor drive push-button front (16) and rear

(32)

- When pressing pushbutton (32/16) it

remains in position (C)

and moving floor drive

is turned on.

Integrated control

lamp (16) at front

control panel lights up.

- Pressing the push-button again turns off the moving floor

drive (D).

• The control lamp in push-button (16) must go out.

If the control lamp remains lit up nevertheless, then the

second push-button (32) is still depressed and the scraper

floor is still operating!

General hints

Selecting another function in addition to the moving

floor feed will automatically interrupt the moving

floor feed.

103 / SPEICHER 9400 GB

ELECTROHYDRAULIC COMFORT OPERATION

- 24 -

GB

Dry forage extension

- Lever (W) in position "DA".

- Move switch (20) to position "A".

Dry forage extension folds up.

- Move switch (20) to position "B".

Dry forage extension folds down.

Swivelling cutter unit

Caution!

Do not reach into swivel range of cutter bar

when swivelling in / out.

- Lever (W) in position "SW".

- Move switch (20) to position "B".

Both cutter bars swivel out.

- Move switch (20) to position "A".

Both cutter bars swivel in.

• When only one cutter bar

is needed for mowing, the

lower cutter bar can be

swivelled out using the

accompanying lever (H).

Obstructions when swivelling

- Remove foreign body from swivel range.

• If the cutter bars do not swivel in properly, then a pressure

loss in the cutter unit hydraulic could be the cause.

Remedy by hydraulically filling the reservoir.

- Move lever to position "E" on 3-way valve.

- Actuate servo-valve (ST).

- Move switch (20) on control panel to position "B".

The cutter bar is swivelled out hydraulically.

- Leave switch (20) and servo-valve (ST) in the press position

for a few seconds while moving the lever on the 3-way valve

to position "0".

• If obstruction cannot be removed then check gas fill pressure

(100 bar nitrogen) in hydroreservoir.

Alteration of gas container pressure

• This work may only be carried out by customer service or a

specialist.

• In order to reduce or increase the pressure in

the gas container a special filling and checking

device is necessary.

Note

• According to manufacturer's information all

gas containers have a slight pressure drop

after a certain amount of time.

• The gas loss (nitrogen) amounts to 2-3 % per year.

• After 4-5 years it is recommended that container pressure be

checked and if necessary corrected.

Maintenance

Beware!

No welding, soldering or mechanical works of

any kind may be carried out on the container.

• Hydraulic oil change according to tractor manual.

• Before welding on trailer disconnect all plugs from tractor

and disconnect trailer.

DASW

W

TD20/94/11

103 / ELEK-STÖRUNG 9400 GB

GB

ELECTROHYDRAULIC OPERATION

- 25 -

Trouble shooting

Beware!

Whenever eliminating trouble it is essential to

turn off power take-off.

No welding, soldering or mechanical works of

any kind may be carried out on the gas

container.

During all these raising and/or lowering,

turning on and off processes mind safety

distances!

Emergency handling of hydraulic valves in

case of power break down ( - Baujahr 1997)

TD 20/94/10

Y6 Y5

Y3

Y2

Y4

Y1

G

H

DASW

W

TD20/94/11

Lowering the pick-up

• Loosen lock nut (G).

• Screw in screw (H) on valve "Y1".

• Shift servo-control (ST) on tractor to lowering or "floating"

position. Pick-up is then lowered.

• Screw out screw (H) and lock with nut (G).

Raising the pick-up

• Loosen lock nut (G).

• Screw in screw (H) on valve "Y1".

• Shift servo-control (ST) on tractor to raising position. Pick-up

is then raised.

• Screw out screw (H) and lock with nut (G).

Lowering the pivoting drawbar

• Loosen lock nut (G).

• Screw in screw (H) on valve "Y2".

• Shift servo-control (ST) on tractor to lowering or "floating"

position. Pivoting drawbar is then lowered.

• Screw out screw (H) and lock with nut (G).

Raising the pivoting drawbar

• Loosen lock nut (G).

• Screw in screw (H) on valve "Y2".

• Shift servo-control (ST) on tractor to raising position. Pivoting

drawbar is then raised.

• Screw out screw (H) and lock with nut (G).

Lowering the dry forage extension

• Lever (W) in position "DA".

• Loosen lock nut (G).

• Screw in screw (H) on valve "Y3".

• Shift servo-control (ST) on tractor to lowering or "floating"

position. Dry forage extension is then lowered.

• Screw out screw (H) and lock with nut (G).

Raising the dry forage extension

• Lever (W) in position "DA".

• Loosen lock nut (G).

• Screw in screw (H) on valve "Y3".

• Shift servo-control (ST) on tractor to raising position. Dry

forage extension is then raised.

• Screw out screw (H) and lock with nut (G).

Swivelling the cutter unit out

• Shift servo-control (ST) on tractor to locking position.

• Lever (W) in position "SW".

• Loosen lock nut (G).

• Screw in screw (H) on valve "Y3".

• Shift servo-control (ST) on tractor to raising position. Cutter

unit then swivels out.

• Screw out screw (H) and lock with nut (G).

Swivelling the cutter unit in

• Lever (W) in position "SW".

• Loosen lock nut (G).

• Screw in screw (H) on valve "Y3".

• Shift servo-control (ST) on tractor to lowering or "floating"

position. Cutter unit then swivels in.

• Screw out screw (H) and lock with nut (G).

Opening the tailgate

• Loosen lock nut (G).

• Screw in screw (H) on valve "Y4".

• Shift servo-control (ST) on tractor to raising position. Tailgate

then opens.

• Screw out screw (H) and lock with nut (G).

Closing the tailgate

• Loosen lock nut (G).

• Screw in screw (H) on valve "Y4".

• Shift servo-control (ST) on tractor to lowering or "floating"

position. Tailgate then closes.

• Screw out screw (H) and lock with nut (G).

Switching on scraper floor drive

• Set the button in position „Y6“.

9800-GB ELEK-STÖRUNG (103)

GB

ELECTROHYDRAULIC OPERATION

- 26 -

Trouble shooting

Beware!

Whenever eliminating trouble it is

essential to turn off power take-off.

No welding, soldering or mechanical

works of any kind may be carried out on

the gas container.

During all these raising and/or lowering,

turning on and off processes mind safety

distances!

Emergency handling of hydraulic valves in case of

power break down ( + Baujahr 1998)

DASW

W

TD20/94/11

Lowering the dry forage extension

• Lever (W) in position "DA".

• Shift servo-control (ST) on tractor to lowering or "floating"

position. Dry forage extension is then lowered.

Raising the dry forage extension

• Lever (W) in position "DA".

• Shift servo-control (ST) on tractor to raising position. Dry

forage extension is then raised.

Swivelling the cutter unit out

• Lever (W) in position "SW".

• Shift servo-control (ST) on tractor to raising position.

Cutter unit then swivels out.

Swivelling the cutter unit in

• Lever (W) in position "SW".

• Shift servo-control (ST) on tractor to lowering or "floating"

position. Cutter unit then swivels in.

Y4 Y3

Y2 Y1

Y6 Y5

Y5 Y2 Y2

AB

PT

Standard

Y3Y5 Y3

Y4

Y6

Y4Y5

Y1Y1Y5

495.690

(John Deere

Case Maxum

Case Magnum

Ford-Serie 40 LS

. . . . . )

Starting the loading process

1. Move control lever (43) for pick-up and conveyor drive

to "ON" position.

2. Switch on tractor’s

p.t.o..

3. Lower pick-up.

Take care! Doing this

automatically switches on

the Pick-up and press

drive.

When switch lever „43“ is

in the „OFF“ position then

the Pick-up and press will

not be activated.

4. When loading, switch control unit (ST)

to "lower" or "float" and in doing so

the pick-up regulates itself to the

uneven ground.

5. Observe p.t.o.-r.p.m.

• Load using average p.t.o.-r.p.m. (400-450 rpm).

To observe during the loading process!

• Only raise pick-up when loading channel is empty.

• When driving

through curves

reduce motor

r.p.m.

• When driving

through sharp

curves switch off

p.t.o. and raise

pick-up.

• Avoid uneven

loads! Important

because of

possible drawbar

overloading (see

details on the

drawbar

concerning permitted support load).

• To optimumly fill the loading space, switch the scraper floor on

briefly (do not let it run continually).

• Watch the trailer fill indicator

(1

.

• Observe the permitted axle load and total weight!

Finishing the loading process

1. Raise Pick-up.

Doing this automatically switches off the Pick-up and conveyor

drive.

2. Move the switch lever „43“ to the „OFF“ position.

This position is for your safety. Doing this prevents the Pick-up

and press from being unintentionally activated, e.g. when lowering

the Pick-up while the p.t.o. is running.

Trailer fill indicator

(1

A = not full; B = full

Switch off scraper floor drive when

indicator is in the „B“ position.

Safety tips:

• Turn off the drive motor and take off the drive shaft

when carrying out all adjustment work.

• Faults in the Pick-up area are to be eliminated

only when the drive motor has been stopped.

Adjusting the pick-up

1. Raise pick-up slightly and secure with adjusting struts (51),

left and right sides in same position.

2. Secure with linch pin.

High adjustment:

with tall stubble and

extremely uneven

ground.

Low Adjustment:

with short green

fodder and even

ground.

Impact deflector adjustment (52)

- In low position (T) for small swaths and short fodder.

- In high position (H)

for high swaths.

Loading process in general

Important tips:

• A transfer, which is located on the drawbar, tells which

p.t.o.-r.p.m. (540 rpm/1000 rpm) your trailer is equipped

for.

• Therefore take care that a drive shaft with the correct

overload safety is used (see spare parts list), so that no

unnecessary damage is caused to the trailer through

overloading.

• Always adapt driving speed to the surroundings.

• Avoid making sudden curves when driving through hills and

valleys, and when transversing slopes (danger of tipping).

Loading green fodder

- As a rule green fodder is collected in swaths.

- Cut swaths collected are always stalk heads.

- Set deflector (52) low position (T).

Loading dry fodder

- Correct dry fodder collection is in swaths.

- Don’t make swaths too small in order to save loading time.

- Set deflector (52) in the position (H).

A

B

TD75/90/18

(1 = only when available

ST

9700-GB BELADEN (107)

LOADING THE TRAILER

- 27 -

GB

- 28 -

CUTTER UNIT

GB

103 / SCHNEIDWERK 9500 GB

Swivelling cutter unit in and out

Lever (H) is located underneath front collapsible

side guard.

- Insert lever (H) into hexagonal socket on cutter

bar.

- Push lever forward (position A) and in so doing

cutter unit swivels out.

- Push lever backward (position B) and in so doing

cutter unit swivels in.

Safety points

• Turn engine off when adjustment, service and repair work is to

be done.

• Do not work under the machine without safe support.

Folding cutter bar down

• Only necessary for maintenance and conversion work!

1. Swivel cutter bar out using lever (H)

lever should be in

position A.

2. Remove lever (H) from

socket and secure it in

position B.

3. Loosen linch pin (K)

on right side of trailer

first, then remove

securing bracket (L).

- 29 -

CUTTER UNIT

GB

103 / SCHNEIDWERK 9500 GB

Quick-insert cutters (M)

Handling quick-insert cutters

- With a low loading trailer, quick-insert cutters (M) are

accessible from loading area after folding cover plate (A) up.

- With a high loading trailer, quick-insert cutters (if existing)

are accessible from underneath.

Swivelling out a quick-insert cutter

1. Push leaf spring (F) away to the side.

2. Pull cutter (M) down gently and remove.

4. Lift cutter unit using lever (H) to relieve load.

5. Pull out linch pin and remove securing bracket (L).

Caution!

Cutter unit folds down automatically under its

own weight.

Take care that your hand is not crushed between

lever and floor!

Folding two cutter bars down

- As described previously, swivel upper cutter bar down first

then lower cutter bar.

- 30 -

CUTTER UNIT

GB

103 / SCHNEIDWERK 9500 GB

Cutter bar

Removal and installation of a cutter

Removing a cutter

from a swivelled out

cutter bar.

1. Pull catch lever (R)

down using

screwdriver.

2. Swivel cutter up

(position A) and remove

by pulling backwards.

Removing a cutter from

a swivelled up cutter bar.

Cutter installation

- Take care that catch lever

caster rests properly in cutter

recess.

Removing a quick-insert cutter

1. Push leaf spring (F) away to the side and swivel

cutter out.

2. Push lower leaf spring (U) away to the side and

remove complete individual cutter by sliding down.

Installing a quick-insert cutter

- When installing complete individual cutter ensure

that both leaf springs (F/U) catch.

- 31 -

CUTTER UNIT

GB

103 / SCHNEIDWERK 9500 GB

Maintenance

Well ground cutters save energy and

provide good cutting quality.

Safety points

• Turn engine off when

adjustment, service and

repair work is to be done.

• Do not work under the machine without safe support.

• Wear protective glasses.

Caution!

Only grind the smooth side of the cutter

Sensible grinding without heating (tarnishing) the cutter

guarantees a long life.

Cutter safeguard

Regularly cleaning is recommended to guarantee the perfect

function of the cutter safeguard.

• Clean pressure springs with high pressure cleaner.

• Oil cutter and safeguard element

before winter storage!

Direct grinding of cutter on cutter bar

1. Swivel cutter bar down to the ground.

2. Grind cutter in installed position with hand grinder.

Grinding of removed cutters

- Remove individual cutter and grind with hand grinder.

- 32 -

GB

DRY FORAGE EXTENSION

511 / DÜRRFUTTERAUFBAU 9500 GB

Mechanical adjustment

• Instead of the mechanical adjusting unit the trailer

can also be fitted with a hydraulic one (see the

relevant chapter in this operating manual).

Folding dry forage extension up/down

1. Unlock right support strut (RS).

2. Attach tailgate raising lever (A) to dry forage extension.

3. Unlock left support strut (LS) while holding lever (A)

firmly.

Take care!

The dry forage extension can fold together

itself a little under its own weight. Be aware

of lever's (A) and support strut's jib range.

4. Always hold lever (A) firmly when adjusting and

manoeuvre extension slowly!

5. Secure left support strut (LS) first, then right support

strut (RS).

6. Detach lever (A).

D = Dry forage position

G = Dried silage and green forage position

Sliding plates (56)

- With low entrances it may be necessary to remove both sliding

plates (56).

Top ropes

- When loading chaff, remove top ropes.

Safety tip

Adjusting the relieving spring

The operating force on lever (A) should not exceed 25 kp

(245 N).

From there adjust the relieving spring tension (Z) accordingly.

D

G

TD34/91/12

56

TD14/89/35a

TD56/94/7

Z

LS

max.

25 kp

A

GB

TAIL GATE

- 33 -

103 / RÜCKWAND 9500 GB

Hydraulic opening and closing of the tail gate

Nobody should be within the swinging

range of the tail gate when opening

and closing!

Do not stand underneath the raised tail

gate!

- Opening and closing is effected

hydraulically from the tractor seat.

In doing so, the locking hooks (58) are

unlocked and locked automatically.

Unloading with lowered top frame

- Lock tubular frame against raising (clip left and right into position B).

- The tail gate swings backwards when

opening.

Unloading with raised top frame

- Unlock tubular frame to raise (clip left and right

into position A).

- The tail gate and the tubular frame swing all

the way to the top when opening.

Adjustments

• So that the opening and closing of the tail gate

functions properly, set the adjusting screws

left and right according to the following

sequence.

- Turn the hexagonal screw (57) until the lower

pipe of the tail gate fits into the slotted plate (K).

- Set a gap (1-3 mm) by means of the hexagonal

screw (56).

- Slip the yoke end of the frame (G) from the pin

and turn it until the hooks (58) rest, without

play, on the pipe.

- Check that all lock nuts are firmly fixed.

TD79/90/38

B

TD7/91/11a

A

TD79/90/39

General

Check regularly that wheel nuts are firmly tightened ( see table for screw starting torque)!

Attention!

After the first 10 hours of operation retighten wheel nuts.