POSTPROCESS DECI-SR007-02 User Manual

DECI

CE

User Manual

Automated Support Removal System

Original Instructions

PostProcess Technologies, Inc. • www.postprocess.com • REV A

Copyright

Copyright © 2018 by PostProcess Technologies Inc. “PostProcess”. All rights reserved. The information

disclosed herein is proprietary information owned by PostProcess. This information shall be used solely and

exclusively by employees and customers of PostProcess as documentation for the safe operation of

processing equipment provided by said company. The information herein shall be used by or disclosed to others

only for this purpose.

Published: September 2018

Disclaimer: The content of this guide is subject to change without prior notice. Please contact PostProcess for

the most current information. Items marked with an asterisk * have been identied as likely to be updated.

Picture on front cover is for illustrative purposes only and does not reect actual dimensions.

Conventions

WARNING

Draws attention to an operating procedure, practice, or condition, etc., that may result in injury or death if not

carefully observed or followed.

CAUTION

Draws attention to an operating procedure, practice, or condition, etc., that may result in damage to equipment if

not carefully observed or followed.

NOTE

Draws attention to an operating procedure, practice, or condition, etc., that must be emphasized or provides

information to simplify procedures tasks.

Any time a screen or button is referenced the following formatting will be used.

Screens – References to a screen on a machine will be Bold and Italicized. References to gauges on a screen will

be italicized.

Buttons – References to a button that can be pressed or activated by an operator will be BOLD AND

CAPITALIZED.

Safety Pictograms

Use Nitrile Gloves

Use Eye Protection

Power On /

Power Off

Lockout / Tagout

Consult Operator’s

Manual

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 2

Electrical Hazard

Caution Hot Surface

Grounding /

IEC Earth Symbol

Arc Flash Hazard

Table of Contents

Overview 5

Warnings, Cautions and Notes 5

Physical Description 7

1. Operation 9

1.1 Connecting Power to the DECI 9

1.2 Powering Up the DECI 10

1.3 Automatic Operation - Setup/Start 11

1.3.1 Auto Setup Controls 12

1.3.2 System Information 13

1.3.3 Features 14

1.3.4 Setting Auto-Temperature Operation 15

1.3.5 Setting Auto-Drain/Dose Operation 16

1.3.6 Recipe Management 16

1.3.7 Auto Run Mode 18

1.4 Manual Operation Screens 20

1.4.1 Manual Motion 22

1.5 Maintenance Operations 23

1.5.1 Filter Screen Maintenance 24

1.5.2 pH Sensor Maintenance 25

1.5.3 Dosatron Maintenance 26

1.6 Alarms and Warnings 28

1.6.1 Alarm Conditions 28

1.6.2 Warning Conditions 29

2. Dosatrons 30

2.1 Priming the Dosatrons 30

3. Troubleshooting 31

3.1 There is a decrease in water/detergent ow, or the ow has stopped. 31

3.2 The ALARM BUTTON is lit up and the DECI will not operate. 31

3.3 The DECI Controller touchscreen is not reacting properly. 31

3.4 Water or liquids are leaking inside of or around the DECI. 31

3.5 The internal passages of the part are not being fully cleaned. 31

3.6 The lter screen and particle lter have buildup or blockages. 32

3.7 The liquid temperatures are running too hot or too cold. 32

3.8 There is excess foam in the processing chamber. 32

3.9 The DECI is not stationary or stable 32

3.10 Where can I nd the DECI Serial Number? 32

4. Point of Contact 33

5. Revision History 33

6. Appendix A 34

Conguration Settings 34

Agitation Settings 35

Setup 38

7. Appendix B 46

Noise 46

Moving the Machine 46

Decommisioning and Disposal 47

Spare Parts List 47

CE Declaration of Conformity 48

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 3

List of Figures

Figure 1. Location of Master Power Switch 9

Figure 2. Master Power Switch “ON” 9

Figure 3. Power Connector 9

Figure 4. Controller Screen, Power Button, and Emergency Stop Button 10

Figure 5. Automatic Operation Screen - Setup/Start 11

Figure 6. Auto Setup Screen 12

Figure 7. Hardware Status 13

Figure 8. System Information Screen 14

Figure 9. Features Enabling Screen 14

Figure 10. Auto-Temperature Conguration Screen 15

Figure 11. Recipe Save As Screen 16

Figure 12. Recipe Overwrite Warning Screen 17

Figure 13. Enter Recipe Name Screen 17

Figure 14. Recipe Selection Screen 17

Figure 15. Auto Run Screen 18

Figure 16. Auto Run Warning Screen 19

Figure 17. Home Screen 20

Figure 18. Manual Operations Screen 20

Figure 19. Manual Motion Screen 22

Figure 20. Filter Screen Maintenance Screen 23

Figure 21. pH Sensor 25

Figure 22. pH Sensor Maintenance Screen 25

Figure 23. Dosatron Maintenance Screen 26

Figure 24. Dosatrons 27

Figure 25. Alarms and Warnings Screen 28

Figure 26. Dosatrons Conguration 30

Figure 27. Caster with Ratchet 32

Figure 28. Conguration Screen 35

Figure 29. Level 1 Agitation Valve Conguration Screen 35

Figure 30. Agitation Valve Conguration Screen 36

Figure 31. Segments Screen 36

Figure 32. Run Time Screen 37

Figure 33. Taper Screen 37

Figure 34. Level 0 Screen 38

Figure 35. System Conguration Screen 38

Figure 36. Auto-Temperature Conguration Screen 39

Figure 37. Heater Conguration Screen 40

Figure 38. Heater Conguration Screen 2 41

Figure 39. Over Temperature Conguration Screen 41

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 4

Overview

This User Manual is intended to explain the setup and operation of the DECI Support Removal

machine. Read this guide thoroughly before operating the DECI to ensure safe and efcient

operation. If a question is not answered in this guide, contact PostProcess for additional support.

The DECI applies patent-pending technology, including optimized energy through agitation in combination with

proprietary, eco-friendly detergents and heat to remove excess material deposited during 3D printing processes.

While the DECI is robust, care should be used during operation. When accessing the main chamber, gently open

and close the chamber door. Be careful when extracting nished parts to limit the amount of detergent that is

lost during the part removal process. Ensure no heavy materials are stored above the DECI that may fall and

damage it.

Warnings, Cautions and Notes

Ventilation

PostProcess Technologies detergents are specically formulated chemistry for maximized 3D printed support

removal efciency. It is recommended that the equipment be located in a well ventilated room. Specic

ventilation requirements can vary widely due to size of the install room, existing ventilation (positive or negative)

and differences in individual sensitivities to airborne scents or fragrances. For more information on the safe use

of PostProcess detergents refer to the SDS for the specic detergent used.

Warnings

Failure to adhere to any of the warnings below could result in personal injury or damage to equipment.

Improper

the machine. If the machine appears to be malfunctioning in any way, immediately PUSH the

EMERGENCY STOP button and refer to the Troubleshooting section of this guide on page 31. If the

issue is not able to be resolved, call PostProcess Support.

Caution should be used whenever working with industrial-powered equipment. If there is an emergency situation,

it is important to note that hitting the EMERGENCY STOP button does not turn off power to the DECI. It turns off

the DECI’s operating cycle only. To shut off power to the DECI, turn off the MASTER POWER SWITCH, located on

the front left panel of the DECI. (For a visual of the switch location, see Figure 1. Location of MASTER POWER

SWITCH)

use of PostProcess equipment may void the warranty. Read thoroughly before operating

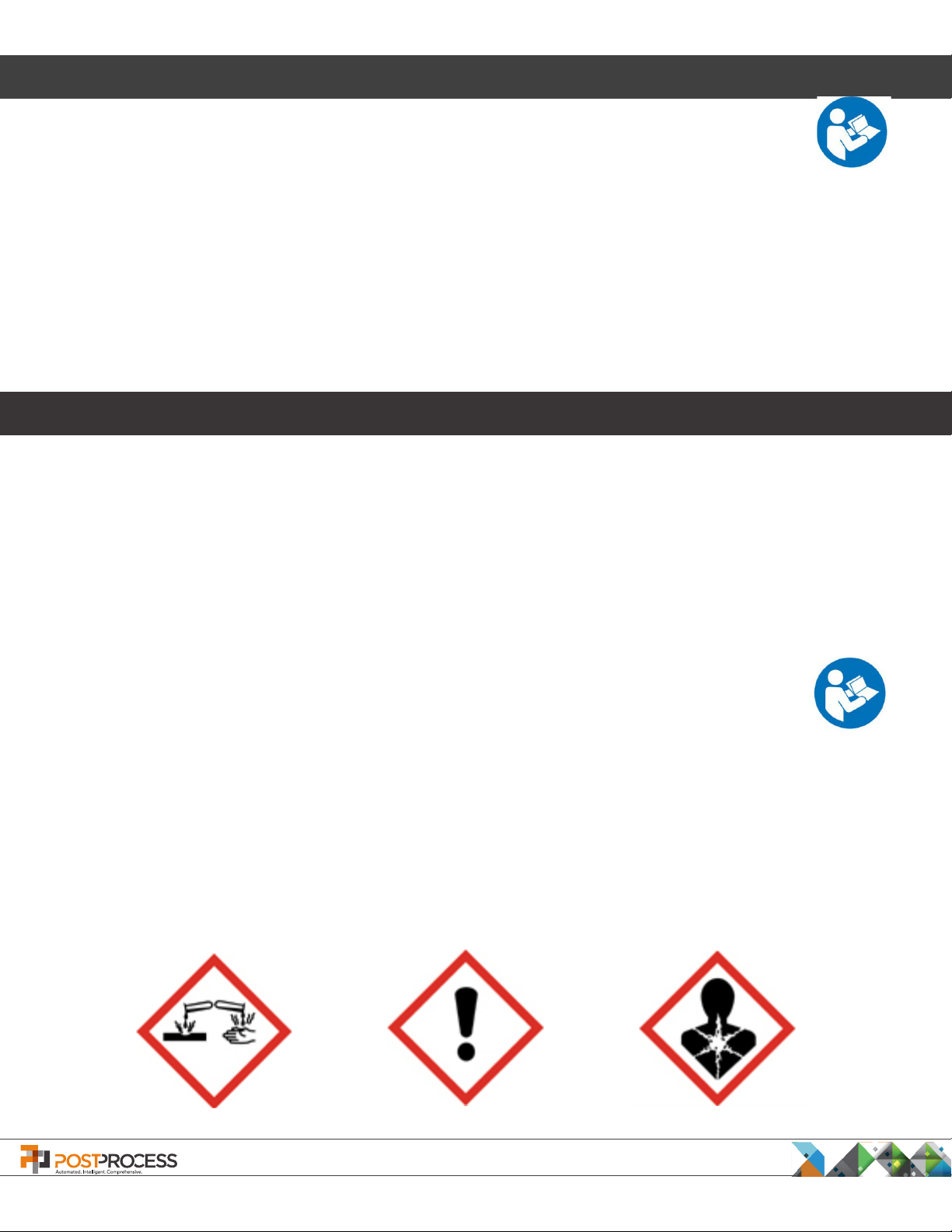

GHS Hazards

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 5

Warnings, Cautions and Notes

Environmental Temperature and Humidity

The operating environmental temperature must be between 10°C and 40°C (50°F to 104 °F), and humidity

between 20% and 80% relative humidity, non-condensing.

Foreseeable Misuse

• Do not operate the unit without proper grounding.

• Do not allow alcohol, gasoline or other ammable solutions near the machine. Doing so could

cause a re or explosion.

• Do not attempt to disassemble or repair the machine.

• Do not place the power cord in a location where it may come into contact with water or liquids.

• Connect the unit only to three-phase 400v power 50Hz.

• Use only PostProcess detergents. Do not add any other liquid solutions to the machine.

• Do not operate the machine without sufcient detergent in the tank.

Residual Risks

• Do not touch the detergent with bare skin. Use nitrile gloves, laboratory-style

eyeglasses and other necessary personal protective equipment when performing

any operations including removing parts where skin could come into contact with

the detergent.

• When working with or near detergents, always wear nitrile gloves.

• Wear laboratory-style protective glasses.

• If bare skin comes in contact with detergent, thoroughly wash the body part with

soap and warm, clean water.

• It is recommended that an eyewash station is near the DECI and any detergent

storage areas.

Electrical Safety

Caution should be used whenever working with industrial-powered equipment.

If there is an emergency situation, it is important to note that hitting the

EMERGENCY STOP button does not turn off power to the DECI. It turns off the

DECI’s operating cycle only. To shut off power to the DECI, turn off the MASTER

POWER SWITCH, located on the left-side panel of the DECI.

NOTE

The EMERGENCY STOP button should only be used in actual emergency situations. For any other

situation requiring the machine to be powered down, use the MASTER POWER SWITCH.

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 6

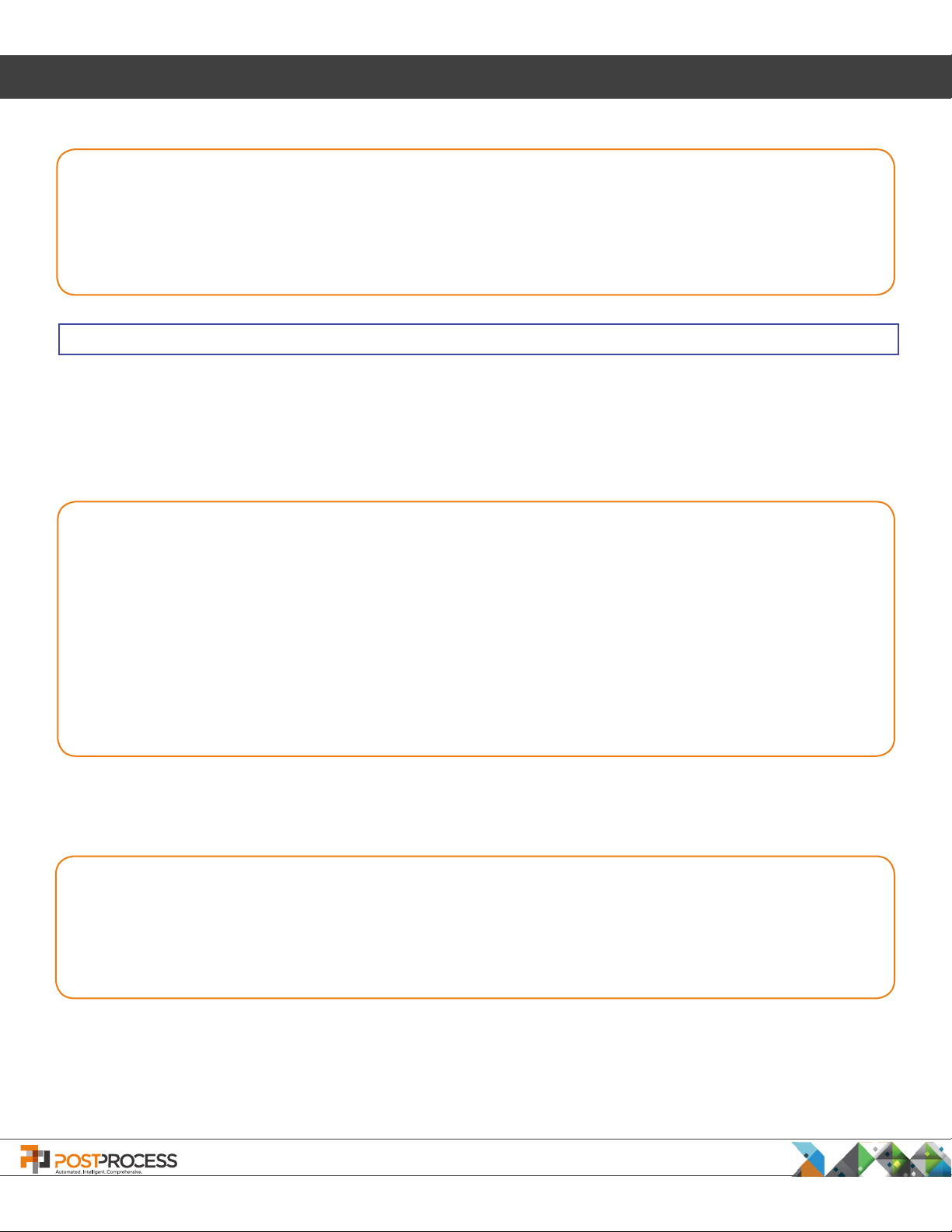

Physical Description

Power and Electrical

Phases: 3 Voltage: 400 Amperage: 30

Cord: 5 wire Lapp ÖLFLEX® Gauge: 8

Plug: Hubbell HBL516P6W (1.83 m cord)

Recommended Connector or Receptacle:Hubbell HBLS530C6W* (Female Connector) or

Hubbell HBLS530R6W* (Female Receptacle) and BB2030N* (housing)

*Not supplied with machine

NOTE

High Leakage Current - Earth connection essential before connecting supply. Incoming Primary Earth conductor

must be a minimum of 10mm2 CSA.

Size and Weight

External Dimensions (Doors Open):

Length: 1.13 m Width: 2.09 m Height: 2.54 m

External Dimensions (Doors Closed):

Length: 1.13 m Width: 1.03 m Height: 2.38 m

Note: This height is measured to a removable stack light. The maximum xed height (with stack light

removed) is 2.12 m.

Approximate Weights:

Empty: 317.5 kg Full: 453.6 kg

Envelope and Capacity

Internal Envelope Dimensions:

Length: .48 m Width: .7 m Height: .66 m

The maximum tank capacity is approximately 75.7 liters.

The maximum part weight for the xture is 22.7 kg.

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 7

Physical Description

Dimension Drawings

Closed-door dimensions Open-door dimensions

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 8

1. Operation

1.1 Connecting Power to the DECI

The DECI is delivered with an industrial power cord. Use only the power cord supplied by PostProcess with the

DECI. Connect the DECI only to 3-phase 400v power 50Hz. Do not place the power cord in a location where it

could come into contact with water or other liquid substances. It is recommended to keep the entire power cord

suspended above the oor surface.

The MASTER POWER SWITCH is located on the left side of the DECI in the upper right corner (Figure 1.

Location of Master Power Switch). Before connecting or disconnecting the DECI to a power outlet, or inserting

or removing the power cord, ensure the MASTER POWER SWITCH is in the horizontal “O” or OFF position (Figure

2. Master Power Switch “ON”).

When the power cord is connected to the DECI and plugged into a 3-phase 400v 50Hz power outlet, turn the

POWER switch 90 degrees clockwise to the vertical “I” or ON position. The DECI is now ready to be powered up.

Figure 1. Location of Master Power Switch

The Master Power Switch is located

on the left side in the upper right corner.

The DECI utilizes 400v 50Hz power

provided through an industrial power

cable/connector located on the upper

rear of the unit as shown in Figure 3.

Power Connector.

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 9

Figure 2. Master Power Switch “ON”

To turn off the Master Power Switch grab

the handle and rotate counter clockwise

90° to the OFF position.

Figure 3. Power Connector

1. Operation

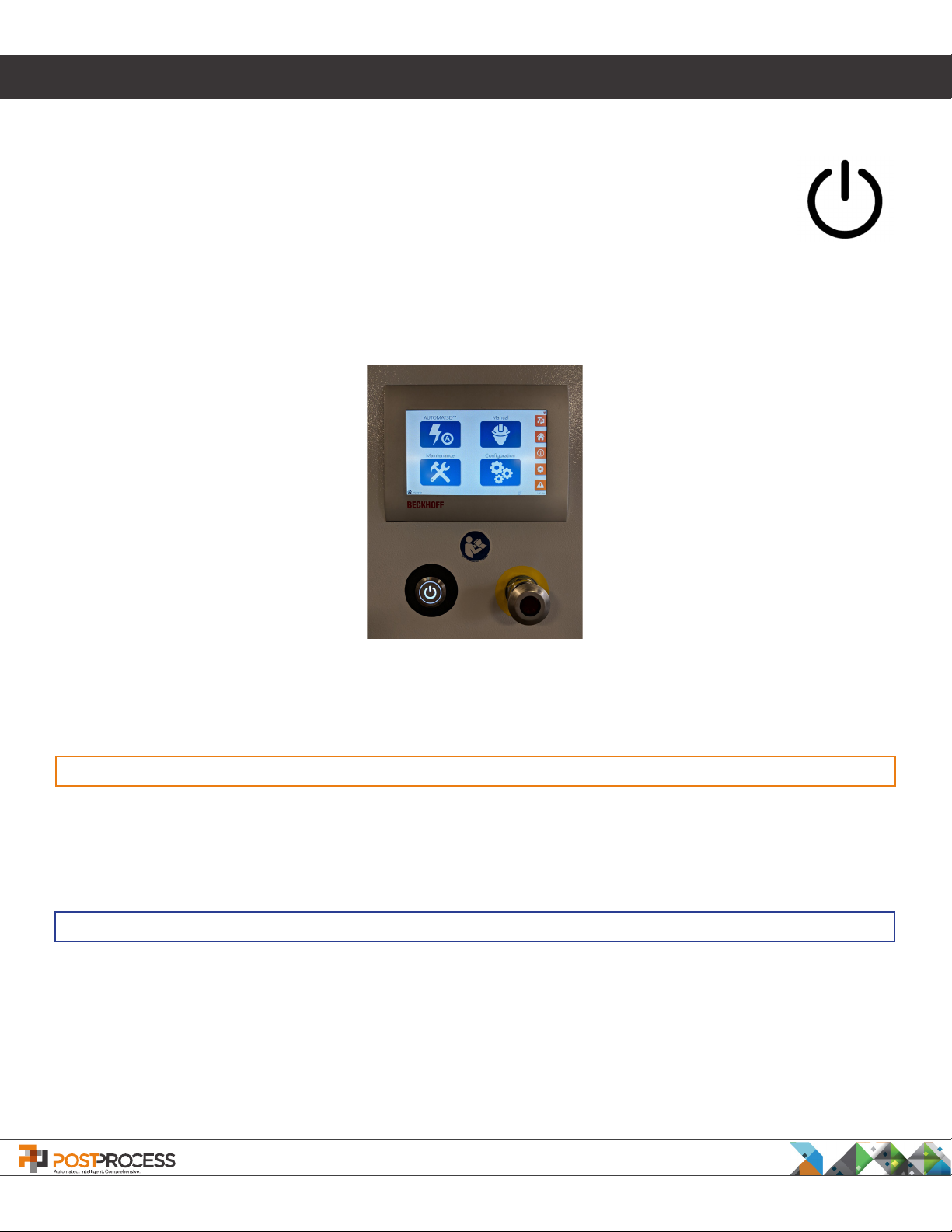

1.2 Powering Up the DECI

The POWER button for the DECI is located to the lower left of the Controller Touchscreen (Figure

4. Controller Screen, Power Button, and Emergency Stop Button). To power up (or down) the

DECI, press the POWER button. If the POWER button is illuminated, the DECI is on.

Below the Controller Touchscreen on the right is the Emergency Stop button (shown below, right)

Figure 4. Controller Screen, Power Button, and Emergency Stop Button

CAUTION

If the DECI appears to be malfunctioning in any way, immediately PUSH the EMERGENCY STOP button and

refer to the Troubleshooting section of the Manual. If the issue is not able to be resolved, contact PostProcess

Support.

NOTE

If the DECI is not used for a period of time it may be necessary to run the heater in Manual Mode to bring

detergent in the tank up to the appropriate operating temperature. Please see Section 1.4 Manual Operations

more information on how to increase operating temperatures. For more information on how temperature impacts

post-processing, see Appendix A.

the

for

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 10

1. Operation

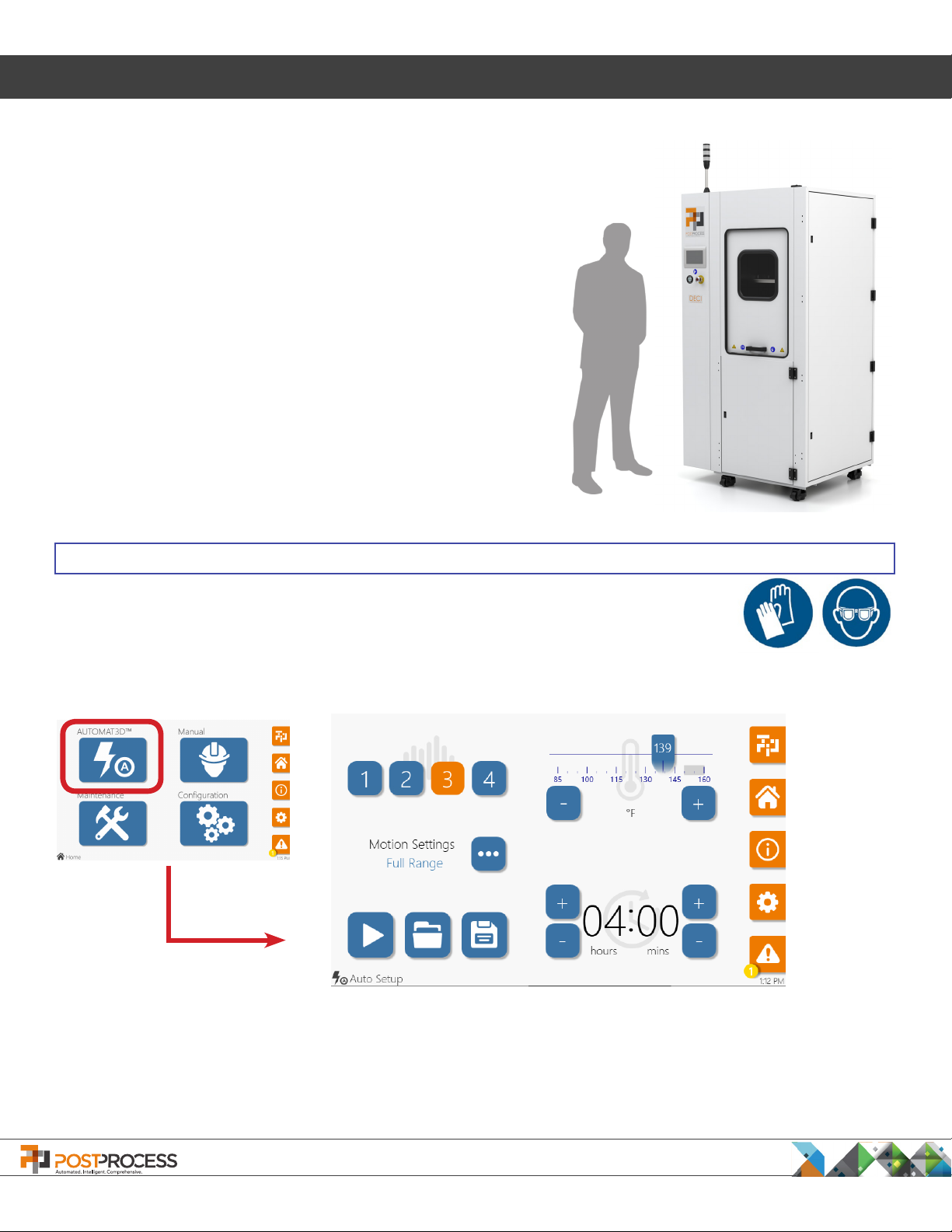

1.3 Automatic Operation - Setup/Start

The DECI is designed to be fully automatic and congured to

remove supports from the following 3D print technologies:

FDM, SLA, CLIP, Polyjet, and others. The DECI is engineered to

utilize an automated Volume Velocity Dispersion system that

is congurable based on a specic operational need. To learn

more please refer to DECI Conguration Settings.

The top side of the DECI houses the envelope (or chamber).

The envelope is roughly 47cm x 65cm x 74 cm (18” x 25 1/2” x

29”). The door utilizes a counterweight system to keep it open

once opened, yet caution should be used when reaching into the

chamber.

NOTE

Whenever an operator is handling detergents, nitrile gloves and eye glasses should be worn.

To begin the support removal cycle, press the POWER button to ON and wait for the Main Menu screen to display.

Figure 5. Automatic Operation Screen - Setup/Start

To access the Automatic Operation screen (Figure 5. Automatic Operation Screen - Setup/Start), from the

Home screen press the AUTOMAT3D™ button. The cycle settings are selected on the Auto Setup screen. The

DECI will retain the settings from the previous cycle. If no changes need to be made, press the START icon to

begin the cycle. If new settings are required, see Section 1.3.1 Auto Setup Controls.

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 11

1. Operation

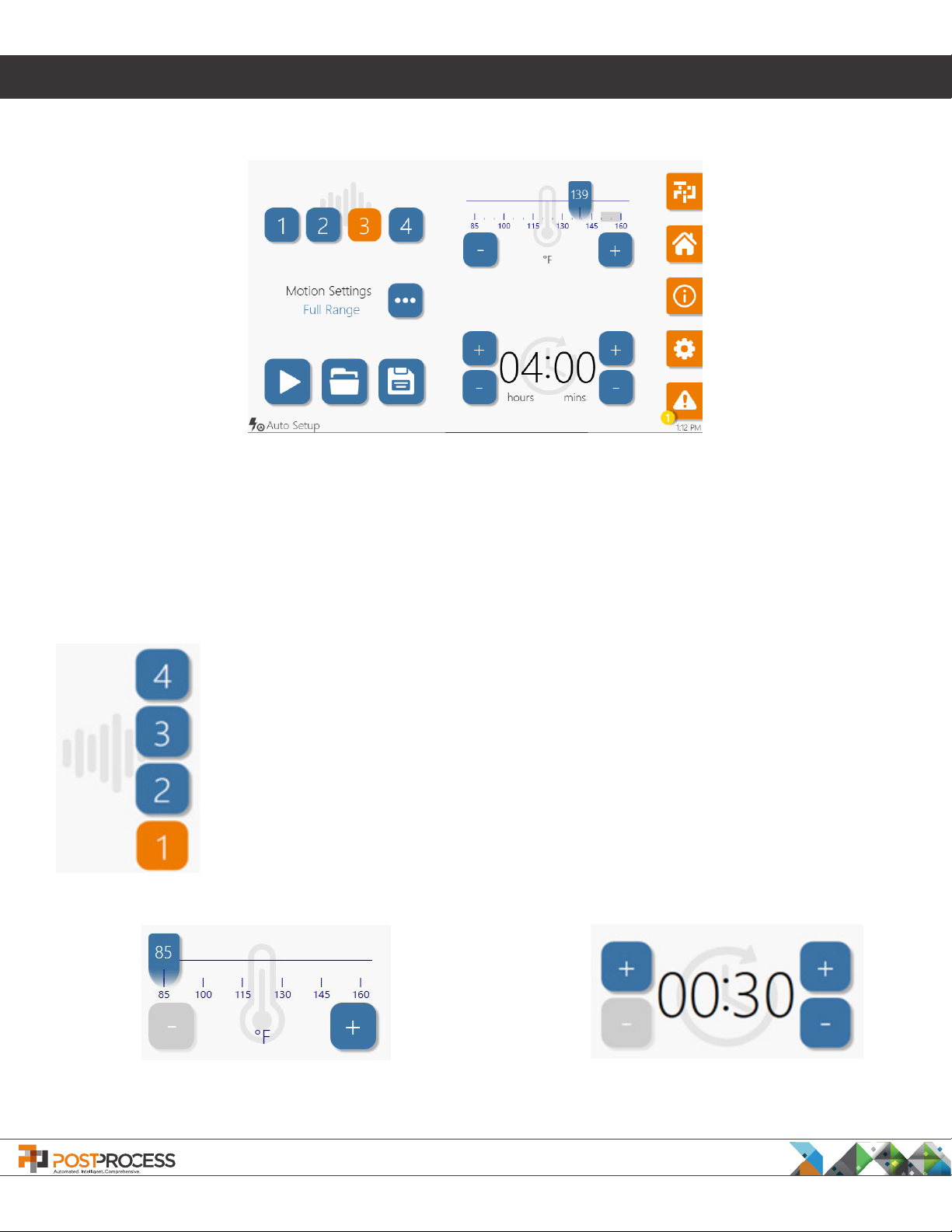

1.3.1 Auto Setup Controls

Figure 6. Auto Setup Screen

Three settings can be congured on the Auto Setup screen (Figure 6. Auto Setup Screen). The settings must be

properly congured based on the unique properties of the parts to be processed by the DECI and are discussed

in greater detail below.

At the upper, left are four buttons that control the Agitation (Energy) Level by conguring the spray nozzles

to operate in a predetermined sequence. These settings are congured by PostProcess personnel during the

installation process. For detailed information about conguring the settings, see the DECI Appendix A.

Press (4) for High Agitation – bottom spray nozzles and the upper narrow-angle nozzles all

operate for the highest agitation.

Press (3) for Medium Agitation– bottom spray nozzles, one upper narrow-angle nozzles and

the upper wide angle nozzles operate for higher agitation.

Press (2) for Low Agitation – spray nozzle conguration for low level combination of bottom

nozzles and upper nozzles.

Press (1) for Ultra-Low Agitation –bottom spray nozzles only.

The selected Agitation Level turns ORANGE while non-selected levels remain BLUE.

Temperature Control – Use the slider to set the desired

temperature of the detergent in the tank. The operator can

also use the + / - to adjust the temperature.

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 12

Run Time - To set the desired run time for

the automatic cycle use the + / - to adjust

the Hours (Left) and Minutes (Right).

1. Operation

The icons on the right of the screen control access to basic functions.

LIGHT - Turns the chamber light on/off

HOME - Returns to the Home Screen.

INFO - For machine data.

CONFIGURATION - For basic system settings.

ALERTS - Displays Alarm conditions.

(See Section 1.6 Alarms and Warnings).

After adjusting the settings to their appropriate levels for the part to be cleaned press the START button

on the left side of the screen (as shown above).

To select a Recipe having the desired settings (See Section 1.3.6 Recipe Management) press the

SELECT RECIPE button.

To save newly created Automatic Cycle settings as a Recipe for future use (See Section 1.3.6 Recipe

Management) press the SAVE RECIPE icon.

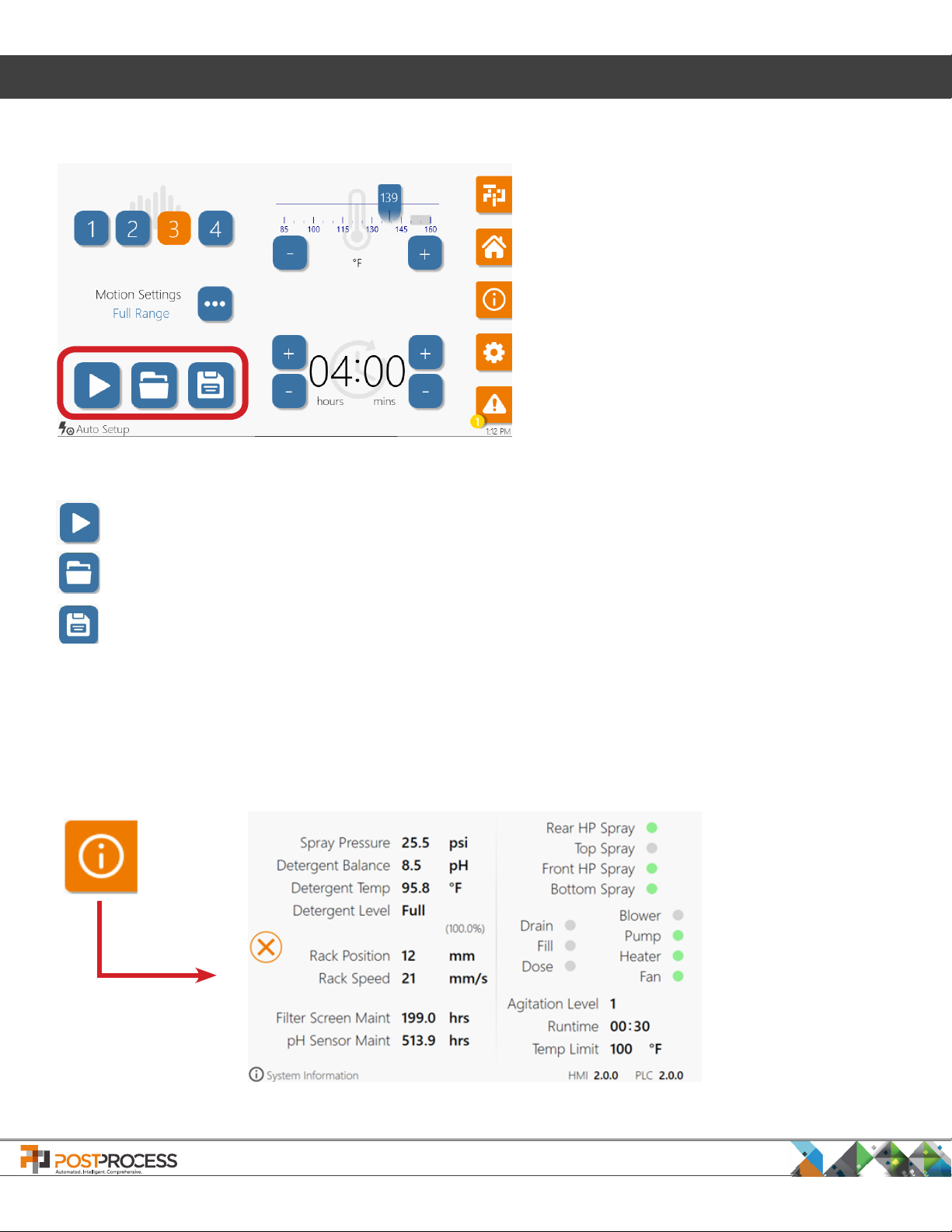

1.3.2 System Information

The operator can access basic system information by pressing the INFORMATION button from any screen.

Figure 7. Hardware Status

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 13

1. Operation

When multiple pages are available, the screen will have a right/left arrow to allow navigation between the screens

(Figure 8. System Information Screen). To close the Information screens, press the X.

Figure 8. System Information Screen

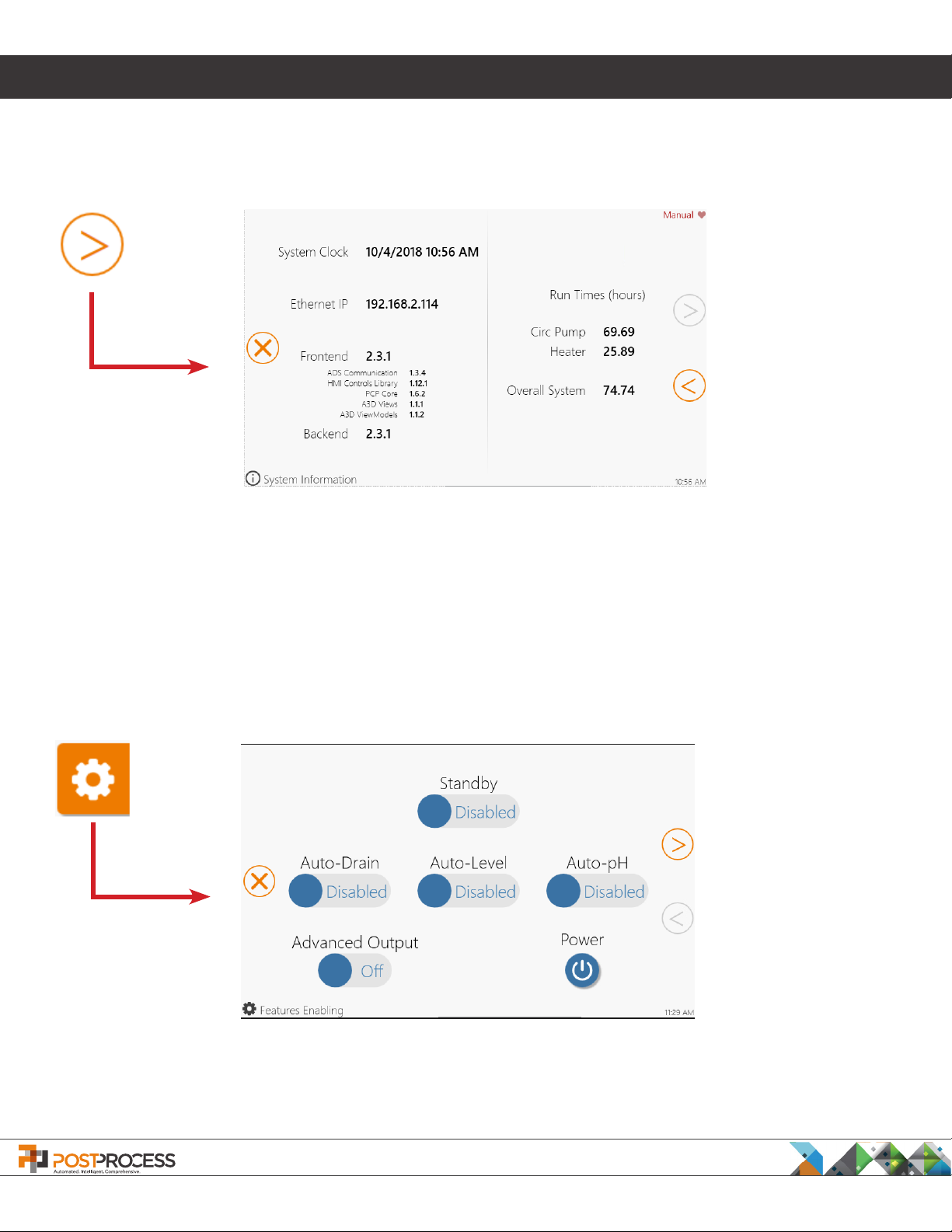

1.3.3 Features

When the FEATURES button is pressed, the operator has access to basic operational functions

9. Features Enabling Screen the Features menu has three areas that can be adjusted.

Press the X button

to exit the Features

screen. A conrmation

will display.

Figure 9. Features Enabling Screen

Press the RIGHT

ARROW to access

the Auto-Drain/Dose

Conguration Screen.

. As shown in Figure

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 14

1. Operation

Standby –

allow the detergent

TEMPERATURE button should be enabled if the tank needs to be kept at a constant temperature between

cycles. If AUTO-TEMPERATURE is not enabled, the DECI tank heater will need to be run manually to bring the

temperature up to the desired level before starting the cycle.

Auto-Drain – When enabled, the tank will automatically drain after the completion of a user dened amount of

auto cycles.

Auto-Level - When enabled, the tank level will be monitored at a user dened interval. If the tank level drops

below a predened level the tank will be automatically dosed back to 100%. A message will appear to inform the

operator.’

Auto-pH - When enabled, the tank’s pH will be monitored. If the pH falls below the Minimum Operational pH Level

a warning will become active and the tank will be automatically drained and re-dosed to correct the pH level. A

message will appear to inform the operator.

Advanced Output – If enabled, system data is collected for PostProcess Support.

Light Stack Test – When pressed the light stack will illuminate so the operator can verify that the lights are

operational. The light stack should be tested at the beginning of each shift.

Because heat is an important component of post-processing, the DECI has functionality built-in to

to be maintained at a certain temperature when the machine is not in use. The AUTO-

Power – When pressed a menu will appear for restarting the PC, shutting down the PC, or exiting the application.

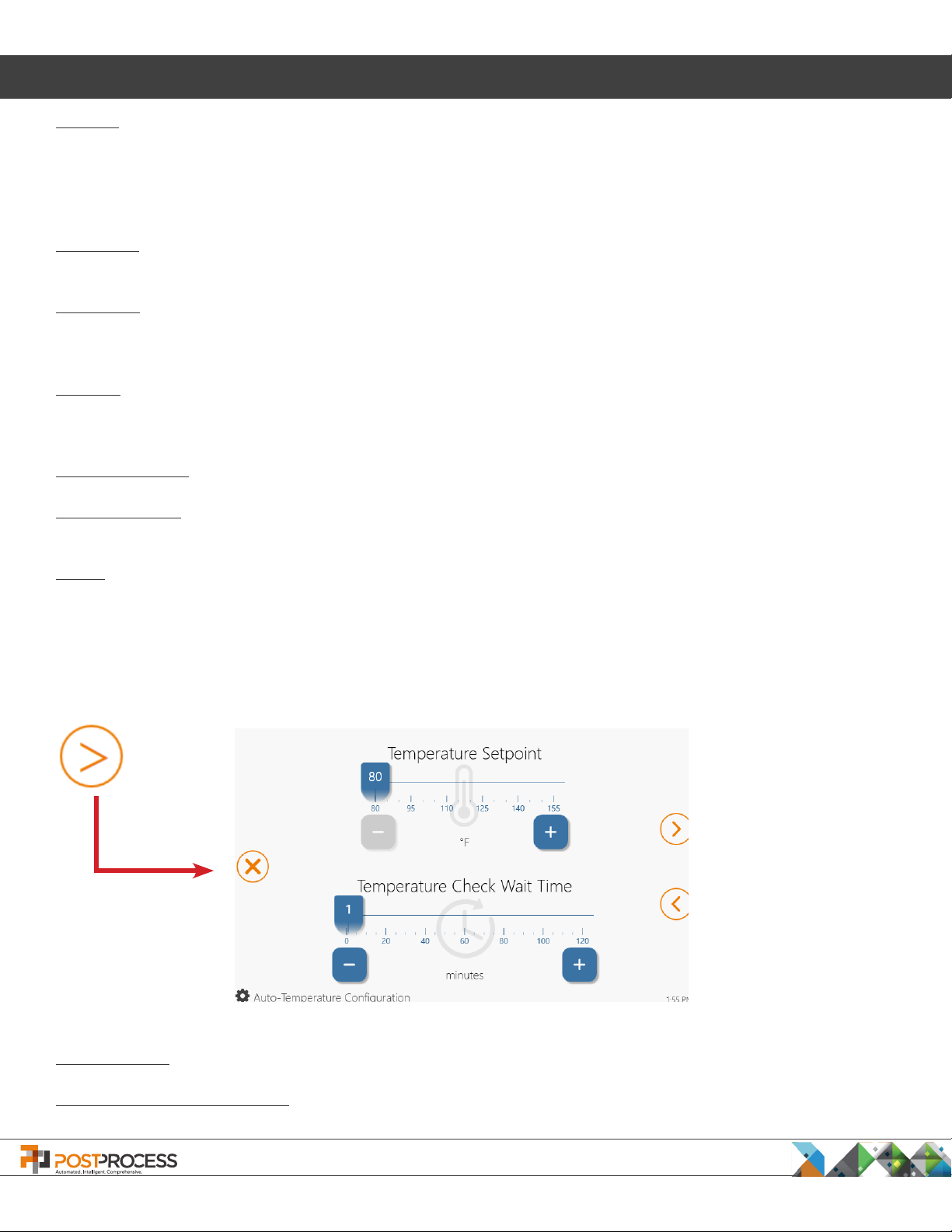

1.3.4 Setting Standby Operation

Once the

To access the settings, press the “right arrow” from the Features Enabling Screen.

Press the X button

to exit the Auto-

Temperature screen.

A conrmation will

display.

AUTO-TEMPERATURE

Figure 10. Auto-Temperature Conguration Screen

is enabled, the operator can adjust the Auto-Temperature Conguration settings.

Press the LEFT ARROW

to return to the

Features screen.

Temp Setpoint – Use the slider bar to set the desired tank temperature for Auto-Temperature mode.

Temperature Check Wait Time – Sets the time between temperature checks while in Auto-Temperature mode.

PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 15

Loading...

Loading...