P/N:

1946090

1150

PD – 2600 / 2601 / 2602 / 2603 Series

FCC Notes:

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance

with the instructions manual, may cause interference to radio

communications. It has been tested and found to comply with

limits for a Class A digital device pursuant to subpart J of Part

15 of FCC Rules, which are designed to provide reasonable protection against

interference when operated in a commercial environment. Operation of this equipment

in a residential area is likely to cause interference in which case the user at his own

expense will be required to take whatever measures to correct the interference.

Warranty Limits:

Warranty terminates automatically when any person other than the authorized

technicians opens the machine. The user should consult his/her dealer for the problem

happened. Warranty voids if the user does not follow the instructions in application of

this merchandise. The manufacturer is by no means responsible for any damage or

hazard caused by improper application.

About This Manual:

Posiflex has made every effort for the accuracy of the content in this manual. However,

Posiflex will assume no liability for any technical inaccuracies or editorial or other

errors or omissions contained herein, nor for direct, indirect, incidental, consequential

or otherwise damages, including without limitation loss of data or profits, resulting

from the furnishing, performance, or use of this material.

This information is provided “as is” and Posiflex Technology, Inc. expressly disclaims

any warranties, expressed, implied or statutory, including without limitation implied

warranties of merchantability or fitness for particular purpose, good title and against

infringement.

The information in this manual contains only essential hardware concerns for general

user and is subject to change without notice. Posiflex reserves the right to alter product

designs, layouts or drivers without notification. The system integrator shall provide

applicative notices and arrangement for special options utilizing this product. The user

may find the most up to date information of the hardware from web sites:

http://www.posiflex.com or http://www.posiflex.com.tw

All data should be backed-up prior to the installation of any drive unit or storage

peripheral. Posiflex will not be responsible for any loss of data resulting from the use,

disuse or misuse of this or any other Posiflex product.

All rights are strictly reserved. No part of this documentation may be reproduced,

stored in a retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, or otherwise, without prior express written consent from

Posiflex Inc. the publisher of this documentation.

© Copyright Posiflex Technology, Inc. 2011

All brand and product names and trademarks are the property of their respective holders.

User’s Manual

Rev. D0

Part 1

BRIEF INTRODUCTION

THE PRODUCT

The PD-2600 is a stand alone pole mount customer display designed for

discrete POS applications. The PD-2601 is a pole mount customer display

option designed for Posiflex HT series POS terminals and also the PB series

discrete systems. The PD-2602 is a pole mount customer display option

designed for Posiflex KS or TP series touch POS terminals. The PD-2603 is a

pole mount customer display option designed for Posiflex FT series touch POS

terminals. It is delivered in separate carton for HT / PB / KS / TP / FT series

and shall be installed per instruction in this manual.

FEATURES

• Bright VFD (vacuum fluorescent display) with green or blue filter

• Rear mount Pole Display for Posiflex HT series hybrid terminals or

PB series discrete systems or KS or FT series fan free touch POS

terminals or TP series touch POS terminals

• Two-line display with 20 characters per line

• Adequately large characters for easy viewing (9.03 mm by 5.25

mm)

• Long life and trouble free operation

• 15°, 30° and 45° adjustable viewing angles

• Total height 410 mm (Stand alone)

• Total height 392 mm (PD-2601 on base of HT and PB series)

• Total height 325 mm (PD-2602 on base of KS and TP series)

• Total height 375 mm (PD-2603 on base of FT series)

• Display frame can rotate horizontally 270° freely

• Various command emulation modes selectable by DIP switch

• Support 12 Code Pages of 128 characters each

• Support 12 international character sets of 12 characters each

• Simple installation

• Selectable between Serial (RS232) interface model and USB

interface model

• Supports UPOS 1.8 and is WEPOS ready

• Case color choices: ivory, black for HT terminals or black for FT,

KS and TP terminals

Part 2

24 VDC

INSTALLATION GUIDES

HOST SYSTEM PREPARAION

For serial interface (RS232) PD-2601or PD-2602 or PD-2603 to be used in HT

or PB or KS or TP or FT series, you have to adjust during power off the

internal jumper of the host system to supply 5 V DC to the COM port selected

for the serial interface pole display. This adjustment has to be done by a

qualified electronic technician following guide from relevant technical manual.

The default communication protocol should be set to 9600 bps, none parity, 8

data bits, 1 stop bit with hardware handshaking on CTS. The power for the

USB interface type pole display is supported through the USB connection.

However, should these customer displays are to be connected through an USB

HUB instead of a direct USB port of the system, the HUB must be powered by

a separate power adaptor otherwise there could be the power shortage problem.

INSTALLING PD-2600

In base of stand alone models (PD-2600 models only), looking from rear side

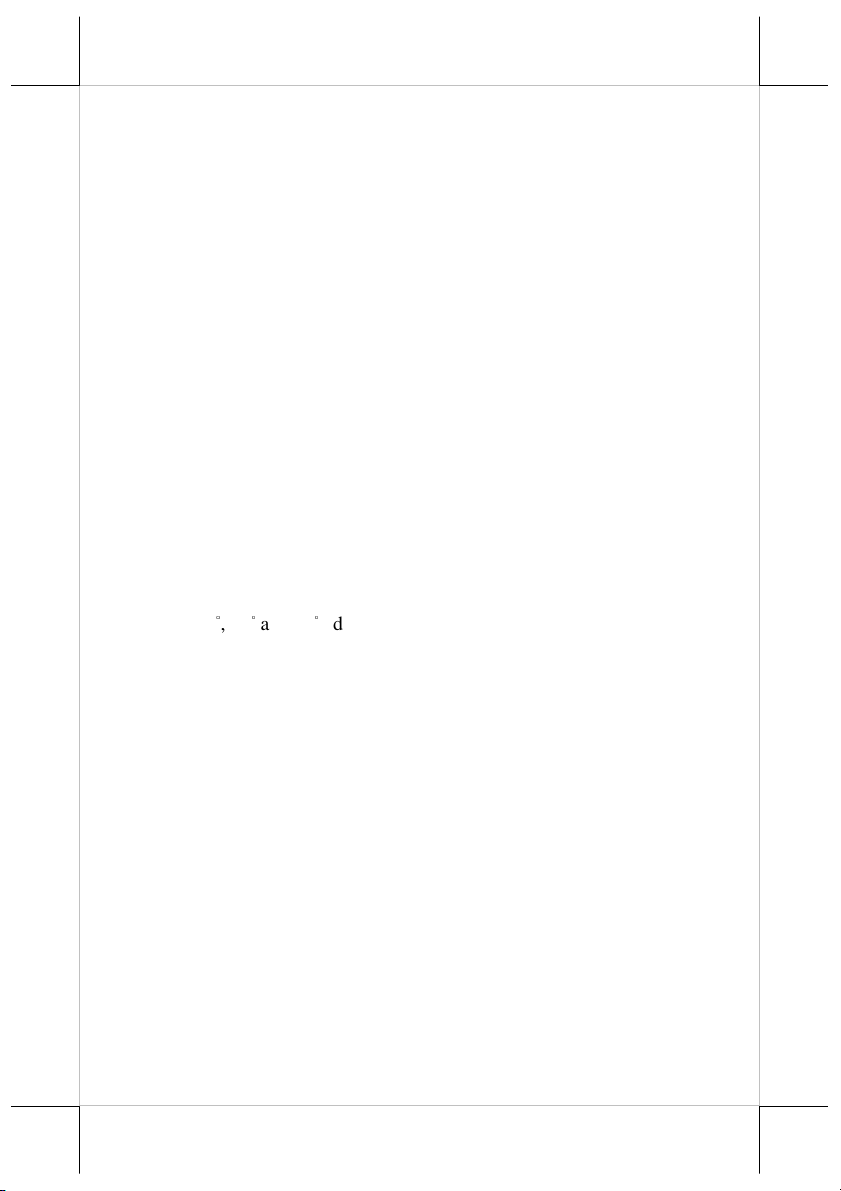

of the bottom, the connector area will look like below:

For serial (RS232) interface models:

To Display head

The RJ45 type modular connector is for internal use and is already occupied.

The RS232 input port is a DB9 female connector. Connect the attached RS232 signal cable to this port and one of the COM port in the host system. Set

the RS-232 communication protocol for this port to 9600 bps, no parity, 8 bits,

1 stop bit with hardware handshaking. Connect the power adaptor to the

rightmost power connector. Turn on the switch in the front side of the base.

For USB interface models:

USB

The RJ45 type modular connector is for internal use and is also already

occupied. Connect the “B” type connector of the interface cable to “USB” in

connector area and the “A” type end to USB port of the host. Insert the 2 pin or

RS232 In

12 VAC In

12 VAC In +24 V DC In +24 V DC Out To Display head

Part 3

3 pin power connector from either 12 V AC or +24 V DC power adaptor to

the“12 V DC In” or “+24 V DC In” jack in the connector area. Insert either

end of the power cable to “+24 V DC Out” jack in the connector area and

insert the other end to the power connector of Posiflex POS printer if needed.

Be sure to hear a click at each connection to obtain a firm contact. You may

now place the base on a horizontal surface and prepare to power on and adjust

the direction of the display head for best viewing effect in application.

INSTALLING PD-2600

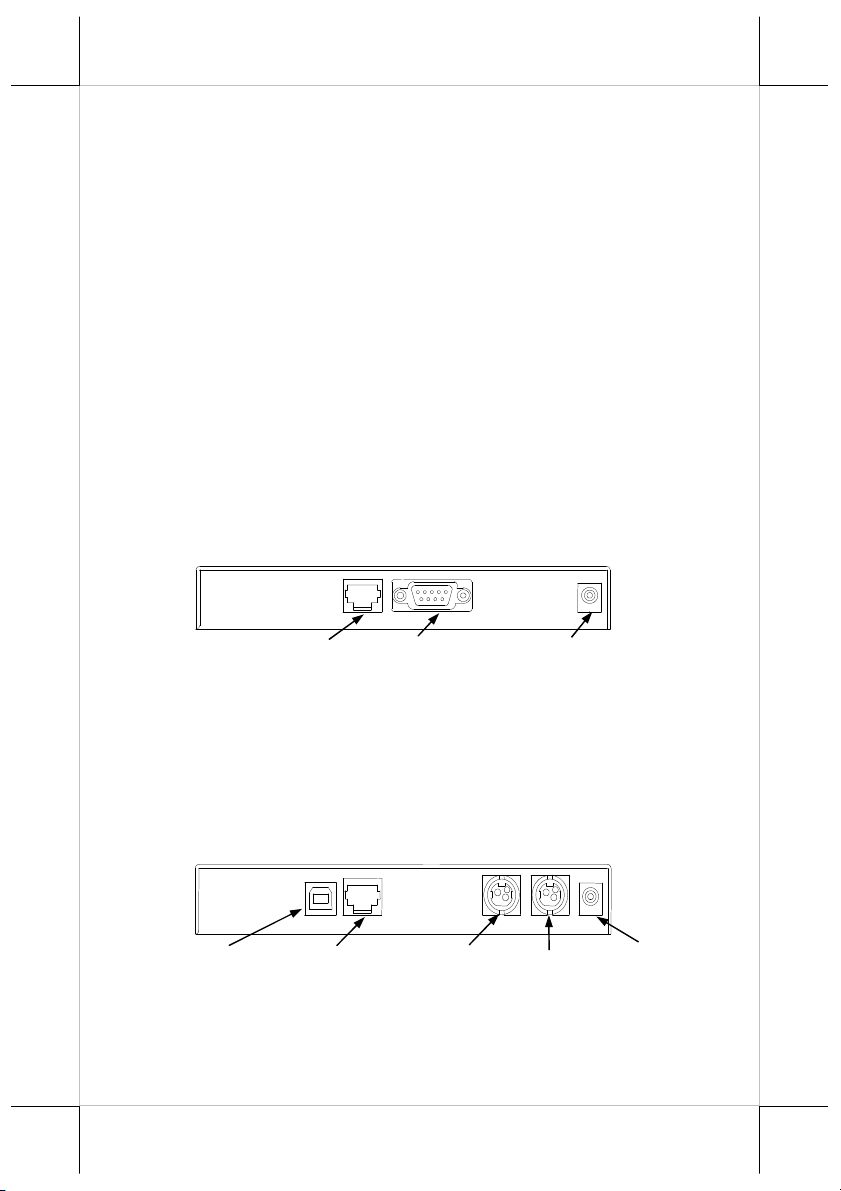

Stand Alone Model:

This instruction is for stand alone model only. Please

unpack the inner box of pole display and it easy to find

the base, display unit with tube and adaptor separately.

Please remove the PE foam and bring out the

components carefully.

Firstly, place the display head and tube on a flat surface

and find the cable which in the end of tube. Let this

cable pass through the short tube which on the base

stand and it shows in the picture at right.

Next, please assemble the display head with tube to the

base stand which shows in the right picture. Please pay

more attention during the process since there is a hole

and a compression lock which are in the two side of tube

and marked arrow signs. Aim these two arrow signs

nearby compression lock to the holes and push the tube

to the end. After hear the “click” sound, the assembly is

complete.

Once combine the display head with tube and base stand,

please place the pole display as a horizontal position

which can easily to check the bottom plate.

Please plug the cable to the connector which showing

“To Display” and route the cable as arrowed in the right

picture.

Part 4

Pix. 1

A

A

B B

C

C

Pix. 2

A’

A’

B’ B’

C’ C’

Pix. 3

INSTALLING PD-2601

Opening the back cover on system

For ease of PD-2601 installation operation, the HT main unit

or PB system has to be opened with sufficient precautions.

First push in the circled knobs on both sides as in Pix. 1 to

remove the back cover. Take out the arrow pointed pole

cover from it.

Opening the top cover of system

Prepare a piece of clean soft clothe of appropriate size in

front of the HT system to prevent damage. Turn the display

panel to straight up position. For both HT and PB system, push in the

rectangular marked spring button in Pix. 1 on both sides of chassis and raise

the rear edge of the top cover. The COM port DC support can be set at this

moment.

Find joining points on system

Refer to Pix. 2 that is a picture of the HT or PB chassis near the right bottom

corner (as you are facing the HT or PB system from its back) with several

portions enlarged around, please find 2 rectangular PD installation holes A on

the bottom chassis; 2 circular locating holes B on I/O plate; and 2 circular

screw holes C on metal sidewall.

Find joining points on pole display base

Part 5

A

Pix. 4

A’

Take PD-2601 out of its box and refer to Pix. 3 that is a picture of the pole

display base unit (lowest part of the PD) with 2 enlarged portions to the right

and a slightly enlarged side view picture to the left to find 2 bottom locking

lugs A’; 2 short cylindrical locating bosses B’ to fit into I/O plate; and 2 plastic

screw bosses C’ on side. Please note that the PD cable comes out of the bottom

end of the base tube yet in the illustration pictures the cable is eliminated for

sake of minimum visual confusion.

Insert bottom locking lugs

Turn the pole display base unit opposite to have the bottom locking lugs A’ in

Pix. 3 facing left and now insert the 2 bottom locking lugs A’ on base unit into

the 2 rectangular installation holes A on bottom of HT or PB chassis from the

right corner with the pole display slightly inclined to the left as in Pix. 4.

Please note that both bottom locking lugs A’ should be completely inserted

and come out of the bottom plate of HT or PB system as emphasized by an

arrow in the enlarged portion.

Fit in locating bosses

Please always keep a gentle pressure at the bottom end of pole base (bottom

locking lugs A’) to the left (away from the sidewall of system chassis) when

moving the upper part of pole toward sidewall and matching the 2 short

cylindrical locating bosses B’ into 2 round holes B in the I/O plate. Please refer

to Pix. 5 to see the 2 locating bosses B’ from inside of HT or PB system.

Part 6

A’

Pix. 5

B+B’

B+B’

Pix. 6

C+C

’

Pix. 8

Pix. 7

Please note the importance of keeping the leftward pressure on bottom end of

pole display during the process of turning the pole upright and inserting the

locating bosses B’ or even when you want to release the locating bosses B’

away from I/O plate B and turn the upper end of pole display to left to remove

the locking lugs A’ from bottom chassis A. Ignorance of this point may

damage or even break off the locking lugs A’ due to improper torque applied.

Apply sidewall screw

The screw bosses of PD-2601 base should

now align with the screw holes on sidewall

of system chassis. Only 1 screw needs to be

applied. Use the self-tapping screw that

comes with PD-2601 to fix from external

side of sidewall as demonstrated in Pix. 6.

PD-2601 Base

Outside of sidewall

Connect interface cable

Carefully close back the top cover of HT or PB system and connect the

interface cable of PD-2601 to appropriate port in system connector area. Then

close the back cover of the system.

INSTALLING PD-2602

Opening the rear connect cover on system

To install PD-2602 to the base of KS or TP systems, the rear connect cover on

its base has to be removed as described in the user’s

manual. The plastic hook

plate to remove the rear

connect cover in slim base is

indicated in Pix. 7 and that for

universal base is indicated in

Pix. 8.

Part 7

Pix. 9

Pix. 10

Pix. 14

Pix. 12

Pix. 11

Pix. 13

Fixing pole display base to system

To fix the PD-2602 to base of KS or TP systems, please connect the interface

cable of PD-2602 through the cable exit in base as

in Pix. 9 a peeping view

of pole display joint base

bottom to the appropriate

port in main unit passing

the inside of system base

as indicated in the top-view picture Pix. 10. Match the

pole base (joint mechanism) to the system rear connect

area Fit 2 screws through washers at arrowed points

to hold the joint tight.

INSTALLING PD-2603

Open back cover on system

First push in the circled knobs on

both sides as in Pix. 11 to

remove the back cover.

Remove pole cover

Remove the pole cover on rear edge of the base top

cover of FT system by first removing the 2 arrowed

screws in Pix. 12 and then pushing the wedge shaped

pole cover up.

Install PD and connect interface cable

Insert the base of PD-2603 / PD-2603U from top of

FT system base with the flat side of the pole base

facing the back cover direction and screw back the 2

screws as in Pix. 13. Connect the interface cable to

appropriate port.

COMMAND EMULATION MODE SETUP

DIP switch

window

Part 8

Now please check the back of PD-260X display head as in the left picture in

Pix. 14. There is a small piece of plastic cover for the “DIP switch window”.

Slide the cover downward but don’t pull it off otherwise you may have to

practice for inserting it back. You can find 6 positions of DIP switches in this

window. Adjust for the appropriate command mode used by the application

program according to below table. Switch position counts from left to right and

“ON” means pushed up as indicated in the right part in Pix. 14.

Switch Position

1 2 3 4 5 6

ON OFF OFF ON OFF OFF

ON OFF ON ON OFF OFF

ON OFF ON OFF OFF OFF

ON OFF OFF ON ON OFF

ON OFF ON OFF ON OFF

ON OFF ON ON ON OFF

The factory default command mode is set to Noritake mode for normal

delivery. Please change it to Epson mode if OPOS or UPOS driver is used for

the application program.

Command Mode

ADM

Aedex

Epson

Futaba

Noritake

UTC

POWER ON SIGN

With interface cable connection well installed (and with COM port power set

for serial models), turn on the HT or KS or TP Posiflex POS system, a

firmware identifier as power on sign will appear on the pole display screen for

a while to indicate that pole display is self-tested O.K. and ready to work.

USING THE CUSTOMER DISPLAY

INTERRFACE SELECTION

This series of customer display is designed to serve in HT / KS / TP / FT series

Posiflex POS systems with RS232 interface models and with USB interface

models. It is advisable to well study the I/O port availability of the host system

before determining which interface model to be used.

When a RS232 (serial) interface model of PD-2601 / 2602 / 2603 is used, the

jumper on main board of HT / KS / TP / FT system must be modified to supply

power to the COM port designated for PD-2601 / 2602 / 2603. Whenever the

RS232 interface PD-2601 / 2602 / 2603 is to be removed from the HT / KS /

TP / FT system, consequently the jumper has to be changed back to neutralize

the COM port, otherwise damage could occur!

Part 9

The USB interface model of PD-2601 / 2602 / 2603 should be connected

directly to an USB port and must not be through any non-self-powered USB

HUB to get power through the USB port itself and there is no need for other

special arrangement.

COMMAND MODE SELECTION GUIDE

The below table provides some comparison for selection on command mode to

be used in the application program if it is not yet determined.

Mode ADM Aedex Epson Futaba Noritake UTC

Cursor N.A. N.A. Invisible

Default mode N.A. N.A. Over/W V. scroll Over/W PT

User defined font N.A. N.A. 2 chars N.A. 2 chars

Brightness control NO NO YES YES YES YES (DP)

Leading code change NO YES NO YES YES YES (PT)

Code page select NO NO YES YES YES YES

Auto scroll message NO NO NO YES YES YES (PT)

Timer clock NO NO YES NO NO YES (PT)

Blinking

Block

Blinking

Block

Blinking

Block

(DP)

2 chars

(PT)

DRIVER INSTALLATION

For application software to use RS232 interfaced PD-260X, there is no direct

need for any driver. The OPOS (OLE POS) driver or the JPOS (Java POS)

driver would be required for OPOS or JPOS programs and the PD-260X would

have to be set to “Epson” command mode. These drivers are available from

our web page:

http://www.posiflex.com.tw/Download%20list.asp?Status=1&Series_Name=U

POS&Model_Name=OPOS and execute the file “SETUP.EXE” to install the

OPOS Control Manager. To add the customer display under OPOS control

please set in OPOS Control Manager device name “PD2x-Line Display” in the

top row. For RS-232 models, select the COM port in the 3rd row and set baud

rate to “9600” in 4th row as in the left sample screen below. Select “USB” in

3rd row for USB interface models as in the right sample picture below.

For USB interfaced PD-260X, please visit our web site and find the driver

from the class “PD23_26U”. The guidance for each function call in the library

“USBPD.dll” is covered in the “ReadMe” file in that class.

Part 10

T31454

SPECIFICATION

OPTICAL

Number of digits 20 digits/row, 2 rows

Dot matrix 5 X 7 dots

Digit height 9.03 mm

Digit width 5.25 mm

Display color Blue or Green (505 nm)

MECHANICAL

Total Height (PD-2600) 410 mm

Total Width (PD-2600) 220 mm

Total Depth (PD-2600) 110 mm

Total Height (PD-2601) 392 mm

Total Height (PD-2602) 325 mm

Total Height (PD-2603) 375 mm

Display Head Height 57.5 mm

Display Head Width 196.6 mm

Display Head Depth 39.5 mm

Case color Black or Ivory

ELECTRICAL

Power from interface port of FT / HT / KS / TP system:

+ 5VDC 1A

ENVIRONMENTAL

Operating temperature 0° to + 40°C

Storage temperature -20° to + 70°C

Operating humidity 20% to 85%, non-condensing

Storage humidity 5% to 90%, non-condensing

WARNING: If the user opens the pole display housing to make any

modification, all the product warranty will be voided.

NOTE: Please refer to Posiflex Product Information CD or DVD or

visit our web http://www/posiflex.com.tw for further information

when needed.

警告使用者

警告使用者

警告使用者警告使用者

這是甲 類的資訊 產品,在 居住的 環

境中 使 用時 ,可 能 會造 成射 頻 干

擾,在 這種情況 下,使用 者會被 要

求採取某些適當的對策。

Part 11

Loading...

Loading...