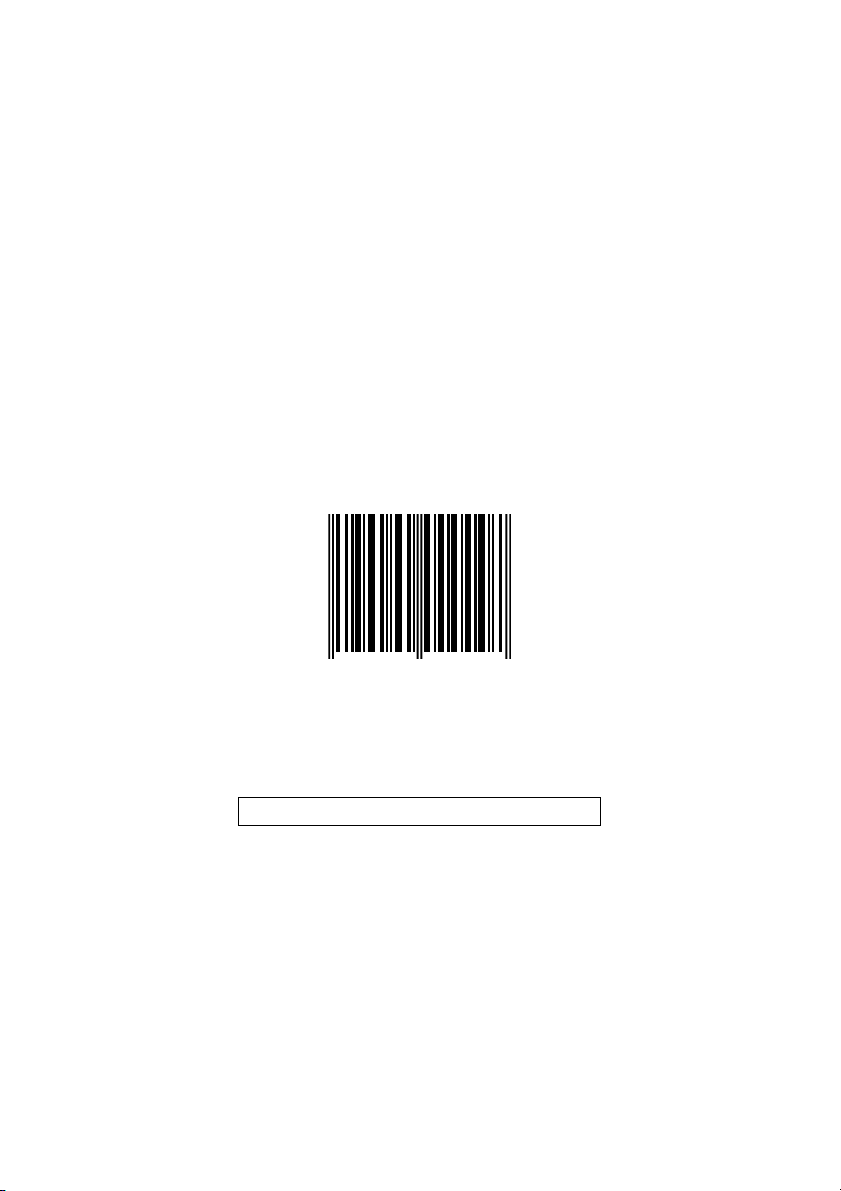

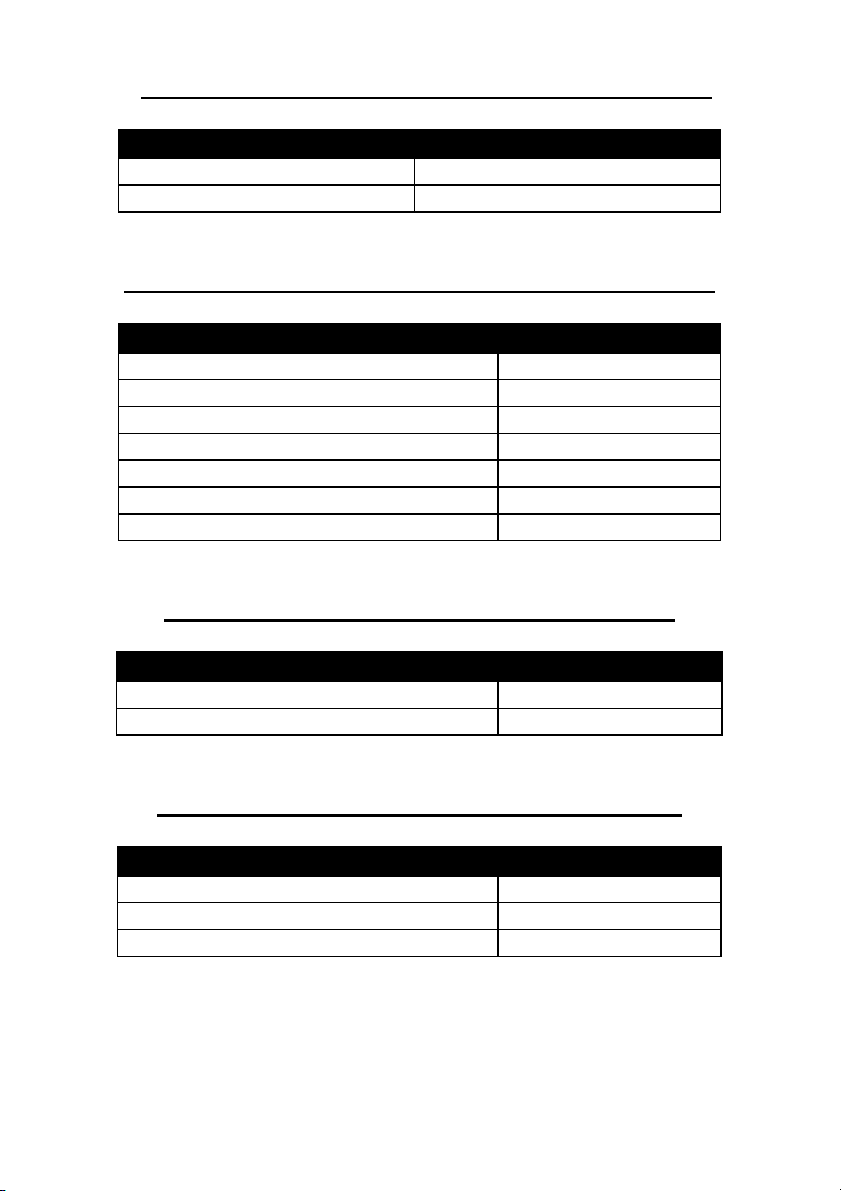

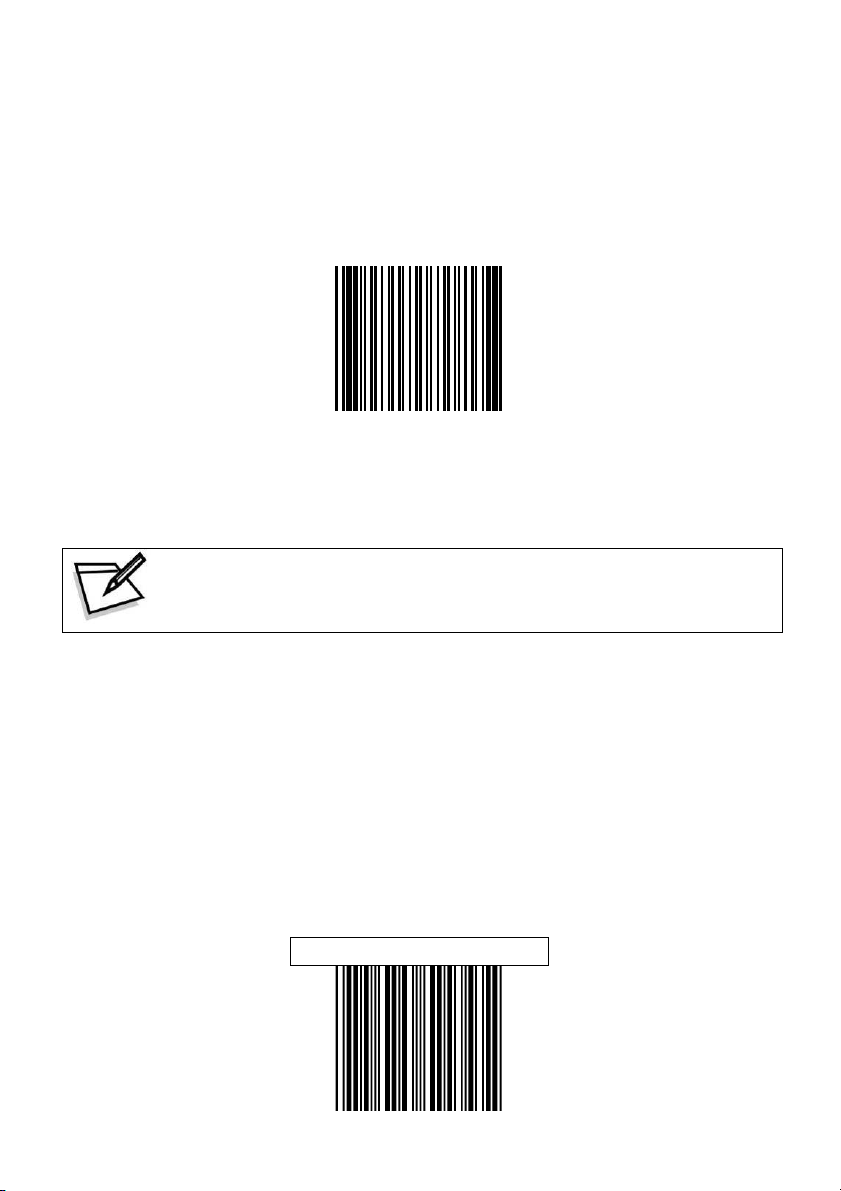

Enter/Exit Programming Mode

(This barcode can also be found at back cover page.)

Framed values are default values.

IMPORTANT NOTICE

No warranty of any kind is made in regard to this material, including, but

not limited to, implied warranties of merchantability or fitness for any

particular purpose. We are not liable for any errors contained herein nor

for incidental or consequential damages in connection with furnishing,

performance or use of this material. We shall be under no liability in

respect of any defect arising from fair wear and tear, willful damage,

negligence, abnormal working conditions, failure to follow the instructions

and warnings, or misuse or alteration or repair of the products without

written approval. No part of this document may be reproduced,

transmitted, stored in a retrieval system, transcribed, or translated into

any human or computer or other language in any form or by any means

electronic, mechanical, magnetic, optical, chemical, biological, manual or

otherwise, except for brief passages which may be quoted for purposes

of scholastic or literary review, without express written consent and

authorization. We reserve the right to make changes in product design

without reservation and without notification. The material in this guide is

for information only and is subject to change without notice. All

trademarks mentioned herein, registered or otherwise, are the properties

of their owners.

Specification or version may be subject to change without notice. The

actual specification and version are based on the product delivered.

General Handling Precautions

• Do not dispose of the scanner in fire.

• Do not put the scanner directly in the sun or by any heat source.

• Do not use or store the scanner in a very humid place.

• Do not drop the scanner or allow it to collide violently with other

objects.

• Do not take the scanner apart without authorization.

Printing Guidance

1. This programming guide is in A5 size. Please double check your

printer setting before printing it out.

2. When printing barcodes for programming, the use of a high-resolution

laser printer is strongly suggested for the best scan result.

Copyright © 2010. All rights reserved.

Latest Revision: July 30, 2010

Radio Notice

Some equipment generates uses and can radiate radio frequency energy.

If not installed and used in accordance with the instructions in this manual,

it may cause interference to radio communications. The equipment has

been tested and found to comply with the limits for a Class A computing

device pursuant to EN55022 and 47 CFR, Part 2 and Part 15 of the FCC

rules. These specifications are designed to provide reasonable

protection against interference when operated in a commercial

environment.

Radio and Television Interference

Operation of this equipment in a residential area can cause interference

to radio or television reception. This can be determined by turning the

equipment off and on.

The user is encouraged to try to correct the interference by one or more of

the following measures:

Reorient the receiving antenna.

Relocate the device with respect to the receiver.

Move the device away from the receiver.

Plug the device into a different outlet so that the device and the receiver

are on different branch circuits.

If necessary, the user may consult the manufacturer, authorized dealer, or

experienced radio/television technician for additional suggestions. The

user may find the following booklet prepared by the Federal

Communications Commission helpful: “How to Identify and Resolve

Radio-TV Interference Problems.” This booklet is available from the U.S.

Government Printing Office, Washington, DC 20402 U.S.A., Stock No.

004000003454.

For CE-countries

This scanner is in conformity with CE standards. Please note that an

approved, CE-marked power supply unit should be used in order to

maintain CE conformance.

Laser Safety

The laser scanner complies with safety standard IEC 60825-1 for a Class

I laser produce. It also complies with CDRH as applicable to a Class IIa

laser product. Avoid long term staring into direct laser light.

Radiant Energy

The laser scanner uses one low-power visible laser diodes operating at

650nm in an opto-mechanical scanner resulting in less than 3.9μW

radiated power as observed through a 7mm aperture and averaged over

10 seconds.

Do not attempt to remove the protective housing of the scanner, as

un-scanned laser light with a peak output up to 0.8mW would be

accessible inside.

Laser Light Viewing

The scan window is the only aperture through which laser light may be

observed from this product. A failure of the scanner motor, while the

laser diode continues to emit a laser beam, may cause emission levels to

exceed those for safe operation. The scanner has safeguards to prevent

this occurrence. If, however, a stationary laser beam is emitted, the

failing scanner should be disconnected from its power source

immediately.

Adjustments

Do not attempt any adjustments or alteration of this product. Do not

remove the protective housing of the scanner. There are no

user-serviceable parts inside.

Caution

Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous laser light exposure.

Optical

The use of optical instruments with this product will increase the eye

hazard. Optical instruments include binoculars, magnifying glasses, and

microscopes but do not include normal eye glasses worn by the user.

TABLE OF CONTENTS

Introduction ............................................................................................. ……1

Changing the scanner setting.......................................................................... 2

Default parameters......................................................................................... 2

Default values of operating parameters................................................. 3

Default values of keyboard emulation parameters setting….................. 4

Default values of RS-232C serial communication parameters ............... 4

Default values of USB emulation parameters........................................ 4

Default values of wand emulation parameters....................................... 4

Default values of decoding parameters................................................. 5

Program procedure using barcode menus ............................................ 6

System setting................................................................................................ 7

Return to factory default ....................................................................... 8

Display firmware version ...................................................................... 8

Abort.................................................................................................... 9

Return to PC/AT default........................................................................ 9

Return to RS-232 default.................................................................... 10

Return to USB default......................................................................... 10

Return to wand emulation default ........................................................ 11

Return as customer default..................................................................11

Save as customer default ................................................................... 12

Sleep timeout selection................................................................................. 13

Same code delay time .................................................................................. 21

Beeper sound selection ................................................................................ 28

Barcode identifier code setting ...................................................................... 39

Barcode identifier code selection ........................................................ 40

Set message format with code identifier.............................................. 41

Enable identifier code table as AIM standard ...................................... 41

Barcode identifier code setting............................................................ 42

Message delay ............................................................................................. 50

Character delay ............................................................................................ 53

Interface communication setting.................................................................... 57

RS-232C interface configuration......................................................... 58

Baud rate setting........................................................................ 62

Data bit setting........................................................................... 62

Stop bit setting ........................................................................... 63

Parity bit setting ......................................................................... 64

Handshaking protocol ................................................................ 67

ACK/NAK response time setting................................................. 70

Message terminator for RS-232C............................................... 76

Keyboard wedge interface configuration............................................. 80

Message terminator for keyboard wedge .................................... 80

Keyboard language selection ..................................................... 82

Capital lock setting..................................................................... 88

Function key emulation .............................................................. 89

USB interface configuration................................................................ 90

Keyboard type............................................................................ 90

Message terminator for USB ...................................................... 91

Wand emulation configuration ............................................................ 93

Emulation speed selection ......................................................... 93

Emulation data output selection.................................................. 95

Emulation data idle state............................................................ 97

Data editing .................................................................................................. 98

Header and trailer............................................................................... 99

Truncate header / trailer character.....................................................101

Add code length ................................................................................102

Auxiliary handheld scanner setting...............................................................104

Symbology configuration..............................................................................108

Reading code selection .....................................................................109

UPC / EAN parameters setting ..........................................................120

Format......................................................................................121

Force UPC-E to UPC-A format..................................................125

Force UPC-A to EAN-13 format.................................................126

Force EAN-8 to EAN-13 format.................................................127

Transmit UPC-A check digit.......................................................129

Transmit UPC-E leading character ............................................130

Transmit UPC-E check digit ......................................................131

Transmit EAN-8 check digit.......................................................132

Transmit EAN-13 check digit .....................................................133

Transmit UPC-A leading character ............................................134

Addendum ................................................................................135

Add on format...........................................................................137

Data Redundant check..............................................................147

Code 39 parameters setting ..............................................................162

Code 39 reading length setting..................................................166

Data redundant check ...............................................................170

Codabar parameters setting ..............................................................172

Format......................................................................................172

Codabar reading length setting .................................................174

Codabar concatenation .............................................................176

Check digit................................................................................177

Data redundant check ...............................................................179

Code 128 parameters setting.............................................................181

Check digit................................................................................182

Code 128 FNC2 concatenation .................................................183

Code 128 reading length setting................................................183

EAN-128 FNC1 character .........................................................184

Data redundant check ...............................................................186

ITF 2 of 5 parameters setting.............................................................189

Check digit................................................................................189

ITF 2 of 5 reading length setting ................................................191

Data redundant check ...............................................................194

Chinese post code parameters setting...............................................196

Chinese post code reading length setting ..................................196

Data redundant check ...............................................................199

MSI/PLESSY code parameters setting...............................................201

Double check digit.....................................................................201

Single check digit......................................................................203

MSI/PLESSY code reading length setting..................................204

Data redundant check ...............................................................206

Code 93 parameters setting ..............................................................208

Check digit................................................................................208

Code 93 code reading length setting.........................................210

Data redundant check ...............................................................212

GS1 DataBar parameters setting.......................................................214

Full ASCII code table ...................................................................................226

Appendixes .................................................................................................291

Appendix A........................................................................................292

Appendix B........................................................................................294

ADVANCED PROGRAMMING GUIDE

1. INTRODUCTION

This is an advanced programming guide for varies omnidirectional laser

scanners. This guide contains a series of programming barcode labels,

and by scanning these codes, it can make configurations to the scanners.

This allows decoding options and interface protocols to be tailored to a

specific application. The configuration is stored in non-volatile memory

and will not be lost by removing power from the scanner. Other than

specified in this guide, for any special functions or specifications, please

contact your dealer for details.

The scanner must be properly powered before programming. For

RS-232C type scanners, an external power adapter must be used to

supply DC power to the scanner. If a keyboard emulation type scanner

is used with an IBM PC/XT/AT, PS/2 or any fully compatible computers,

power will be drawn from the keyboard port; therefore no external power

adapter is required. If keyboard emulation type scanner is used with any

other non IBM PC compatible computers, an external power adapter may

be required.

Under the programming mode, the laser scanner will acknowledge a good

and valid reading with a short beep. It will give long beeps for either an

invalid or bad reading.

1

PROGRAMMING GUIDE

2. CHANGE THE SCANNER SETTING

In order to change the scanner setting, please follow the steps

below:

1. Scan the

Enter/Exit Programming Mode

barcode. There will

be 2 beeps (low-high) indicating ready to make settings.

2. Scan barcodes for the desired feature (1 beep)

3. Scan the

Enter/Exit Programming Mode

barcode again to

save the configuration. There will be 2 beeps (long-short)

indicating a successful setting.

After reading a valid barcode in programming mode, the scanner

will give a high beep.

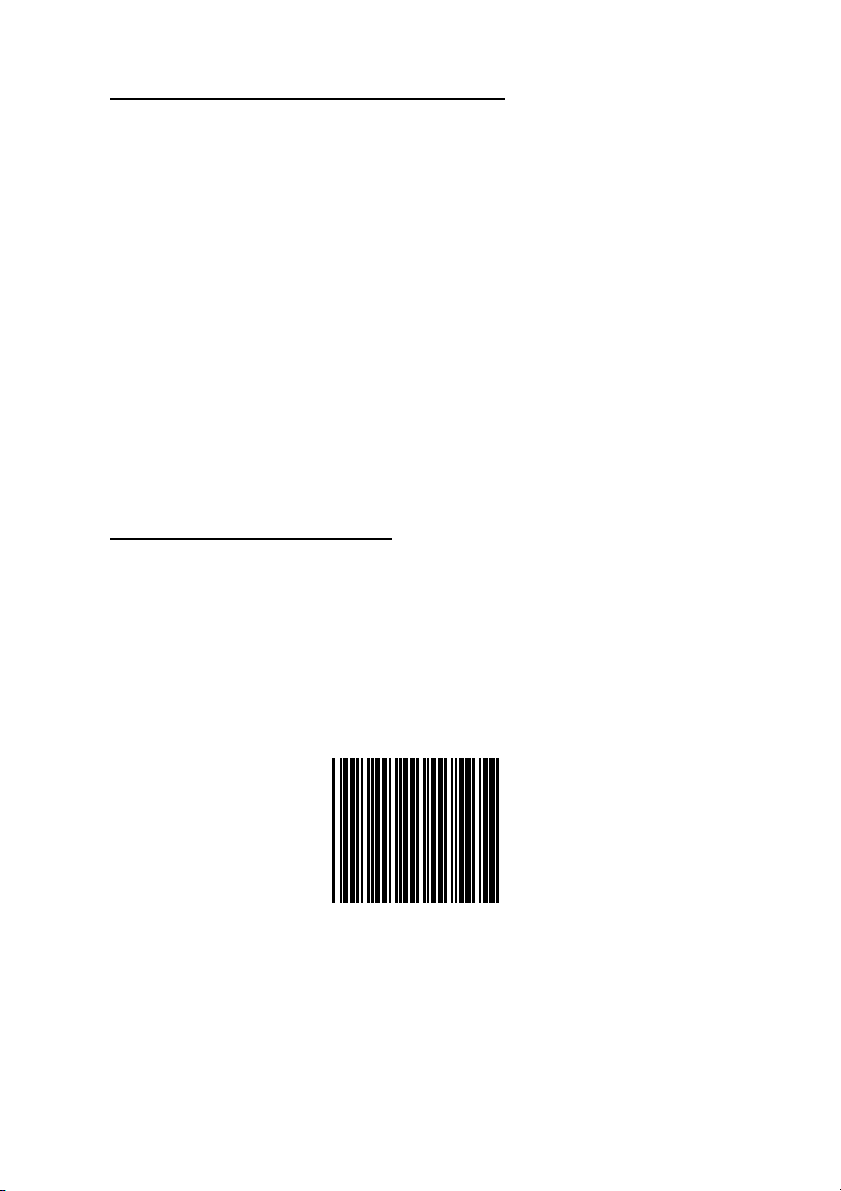

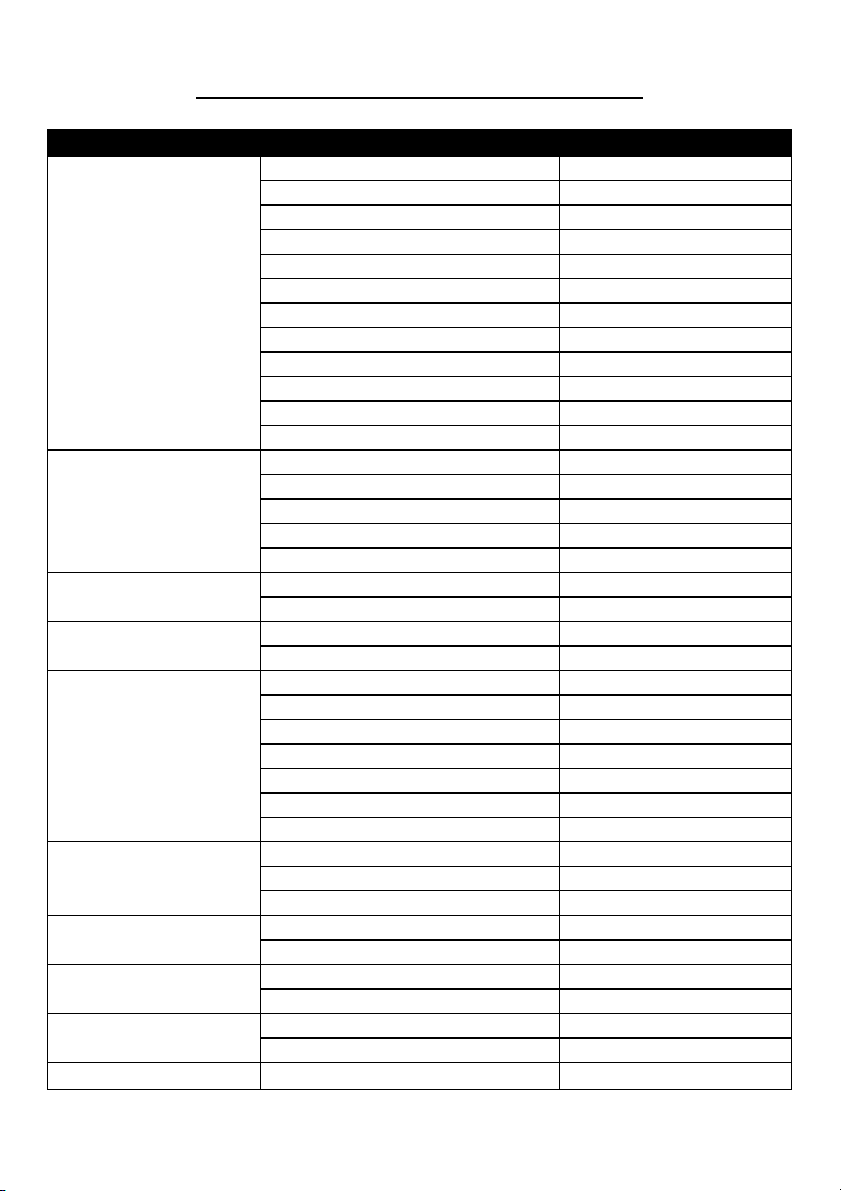

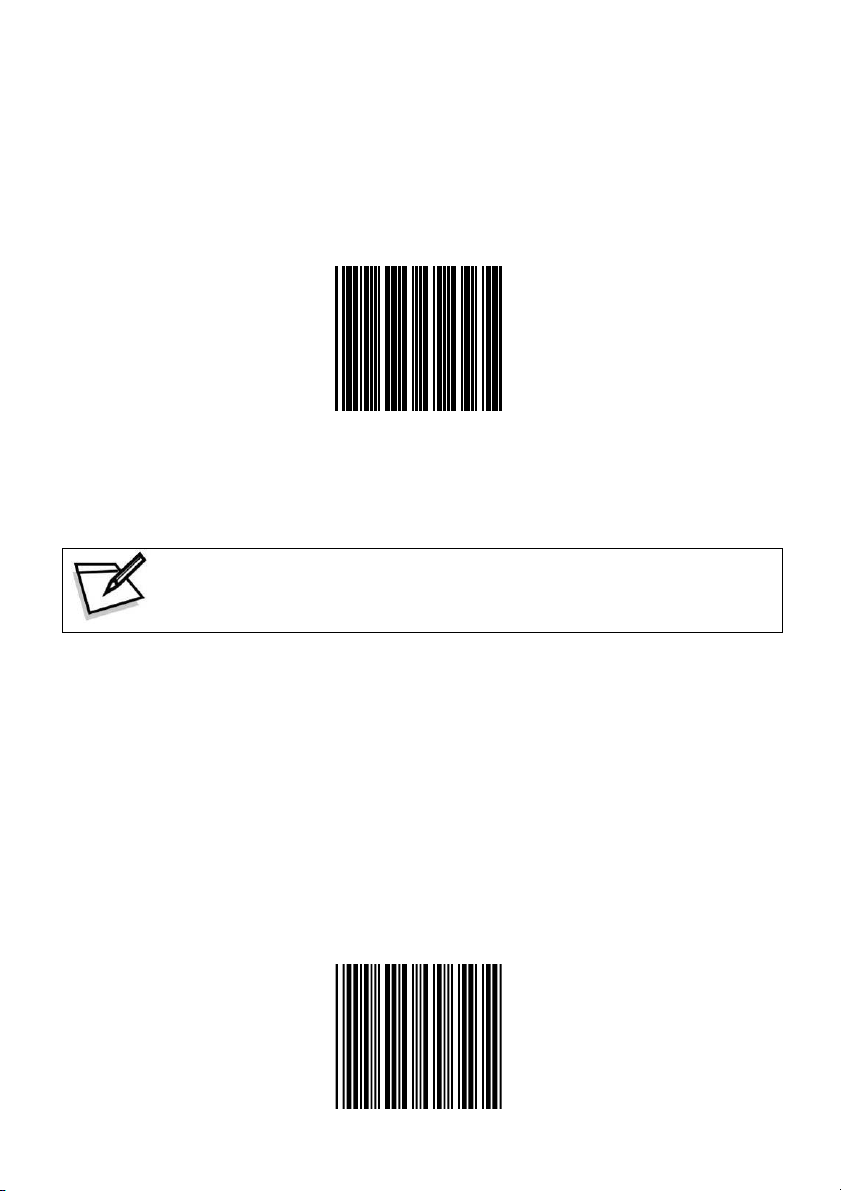

3. DEFAULT PARAMETERS

This table gives the default settings of all the programmable

parameters. The default settings will be restored whenever the

Reset programming label is scanned. (This label can also be

found on p.8.)

Reset (Return to factory default)

OMNIDIRECTIONAL SCANNER

2

PROGRAMMING GUIDE

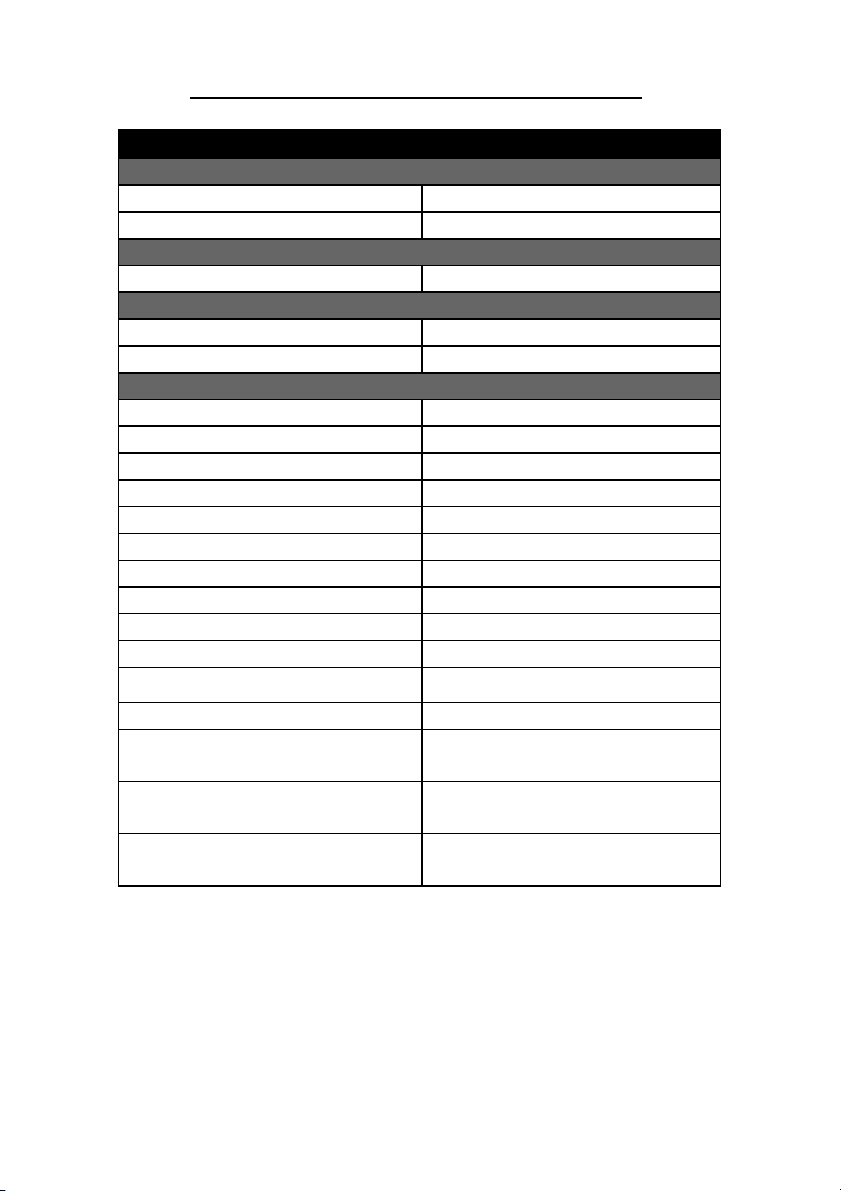

Default Values of Operating Parameters

Function Default

Sleep mode

Motor sleep mode After 30 minutes

Laser sleep mode After 10 minutes

Scanner timing

Same code delay 200msec

Beeper Tone

Frequency medium

Duration 50msec

Code Identifiers

Code ID off

Code 39 M

ITF 2 of 5

I

Chinese post code H

UPC-A A

UPC-E

E

EAN-13 F

EAN-8 FF

Codabar N

Code 128 K

Code 93 L

MSI/Plessy P

GS1 DataBar Omnidirectional

RS

(Formally RSS-14 Standard)

GS1 DataBar Limited

RL

(Formally RSS Limited)

GS1 DataBar Expanded

RX

(Formally RSS Expanded)

OMNIDIRECTIONAL SCANNER

3

PROGRAMMING GUIDE

Default Values of Keyboard Emulation Parameters

Function Default Values

Keyboard type selection IBM PC/AT USA

Message terminator Enter/ carriage return

Default Values of Serial Communication Parameters

Function Default Values

Handshaking protocol None

ACK/NAK response time setting 300 msec

Baud rate 9600

Data bit 8

Stop bit 1

Parity None

Message terminator selection CR/LF

Default Values of USB Emulation Parameters

Function Default Values

Keyboard Type US Keyboard

Message Terminator Enter

Default Values of Wand Emulation Parameters

Function Default Values

Wand emulation speed Normal

Wand emulation output Black = High

Data output format Transmit as scan

OMNIDIRECTIONAL SCANNER

4

PROGRAMMING GUIDE

Default Values of Decoding Parameters

Function Code Default Value

Code 39 Enable

ITF 2 of 5 Disable

Chinese Post Code Disable

UPC/EAN/JAN Enable

Codabar Disable

Reading codes

selection

Code 39

Interleaved 2 of 5

Chinese Post Code

UPC/EAN/JAN

Code 128

Code 93

MSI

Italian Pharmacy

MSI/PLESSY

Code 128 Disable

Code 93 Disable

EAN-128 Disable

Italian Pharmacy Disable

ISSN/ ISBN Disable

GS1 DataBar (RSS) Disable

Codes Standard

Start/stop characters Not transmitting

Check digit Disabled

Concatenation Off

Length 3~32

Length 6-32

Check digit Disable

Length 10~32

Check digit Disable

Format All

Addendum Disable

UPC-E=UPC-A Disabled

UPC-A leading digit Transmit

UPC-A check digit Transmit

UPC-E leading digit Transmit

UPC-E check digit Transmit

Type Standard

Start/stop characters A, B, C, D Codabar

Length 6~32 digits

FNC 2 append Disable

Check digit Disable

Length 3~32

Check digit Not transmit

Length 6~32

Check digit Transmit

Transmit "A" Character

Not transmitting

Disable

OMNIDIRECTIONAL SCANNER

5

PROGRAMMING GUIDE

Default Values of Decoding Parameters (continued)

Yes No

Function Code

GS1 DataBar Omnidirectional

GS1 DataBar Limited Disable

GS1 DataBar

(formally RSS)

GS1 DataBar Expanded Disable

Transmit GS1 DataBar Omnidirectional check digit Enable

Transmit GS1 DataBar Omnidirectional

application ID (01)

Transmit GS1 DataBar Limited check digit

GS1 DataBar Omnidirectional/EAN-128 emulation Disable

Transmit GS1 DataBar Limited application ID (01)

Transmit GS1 DataBar Expanded check digit

Transmit AI(01) of Expanded

GS1 DataBar Expanded /EAN-128 emulation Disable

Default

Value

Disable

Enable

Enable

Enable

Enable

Enable

NOTE:

Contact your distributor to make sure if your model and firmware

version support GS1 DataBar.

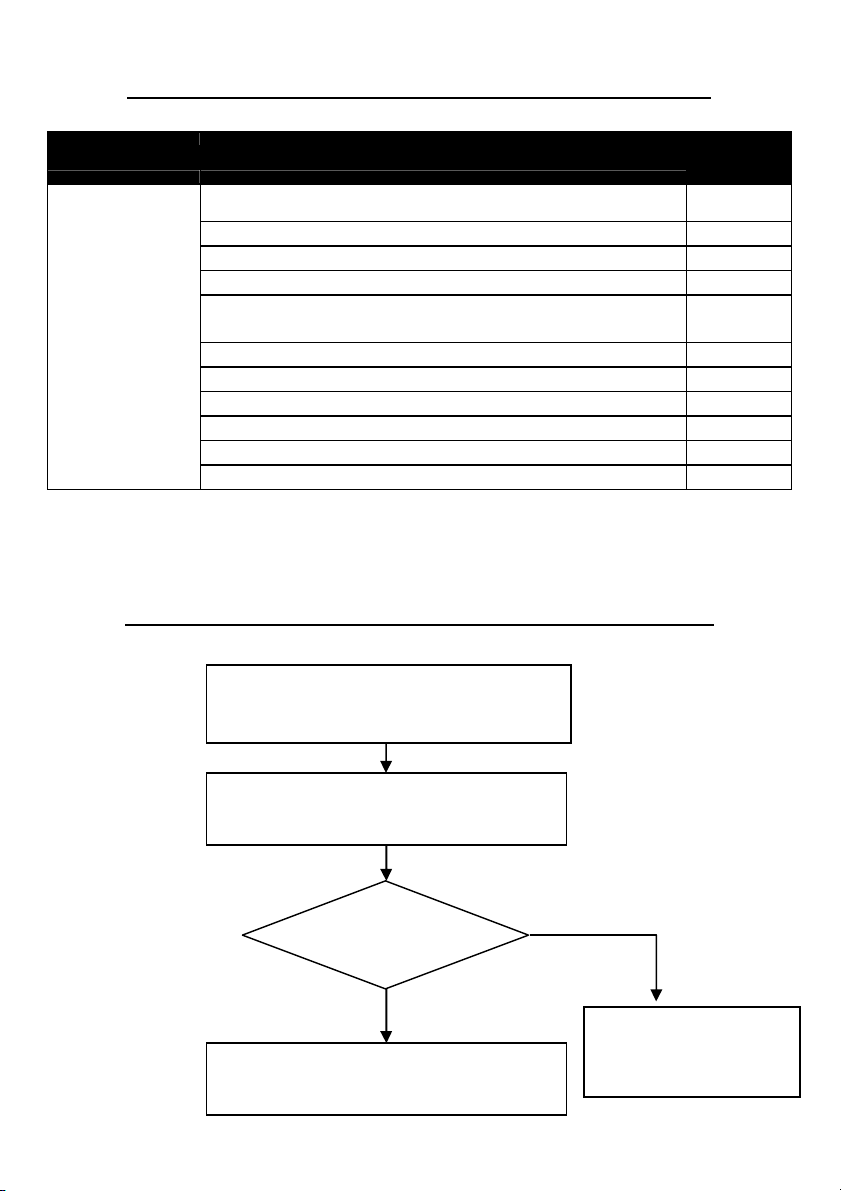

PROGRAM PROCEDURE USING BARCODE MENUS

OMNIDIRECTIONAL SCANNER

Read Enter/Exit programming mode

barcode to start configuration

Change scanner setting by scanning the

barcodes of the desired function

Select code 39 full

ASCII table?

Read Enter/Exit programming mode

barcode to save and exit

Read Save setting to

confirm barcode to

end the configuration

6

PROGRAMMING GUIDE

System Setting

The series scanner is a multi-interface communication scanner. If

you had ordered only one type of interface, the device is configured

in the interface requested, i.e. RS-232C, keyboard wedge, wand

emulation or USB. If not requested, the default interface is set in

keyboard wedge interface (PC/AT). Use this section to change

interfaces.

OMNIDIRECTIONAL SCANNER

7

PROGRAMMING GUIDE

Reset (Return to Factory Default)

Reading of “Reset” barcode label turns all parameters back to

default values, and the scanner remains in the last interface set

when it is reset.

Reset (Return to Factory Default)

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

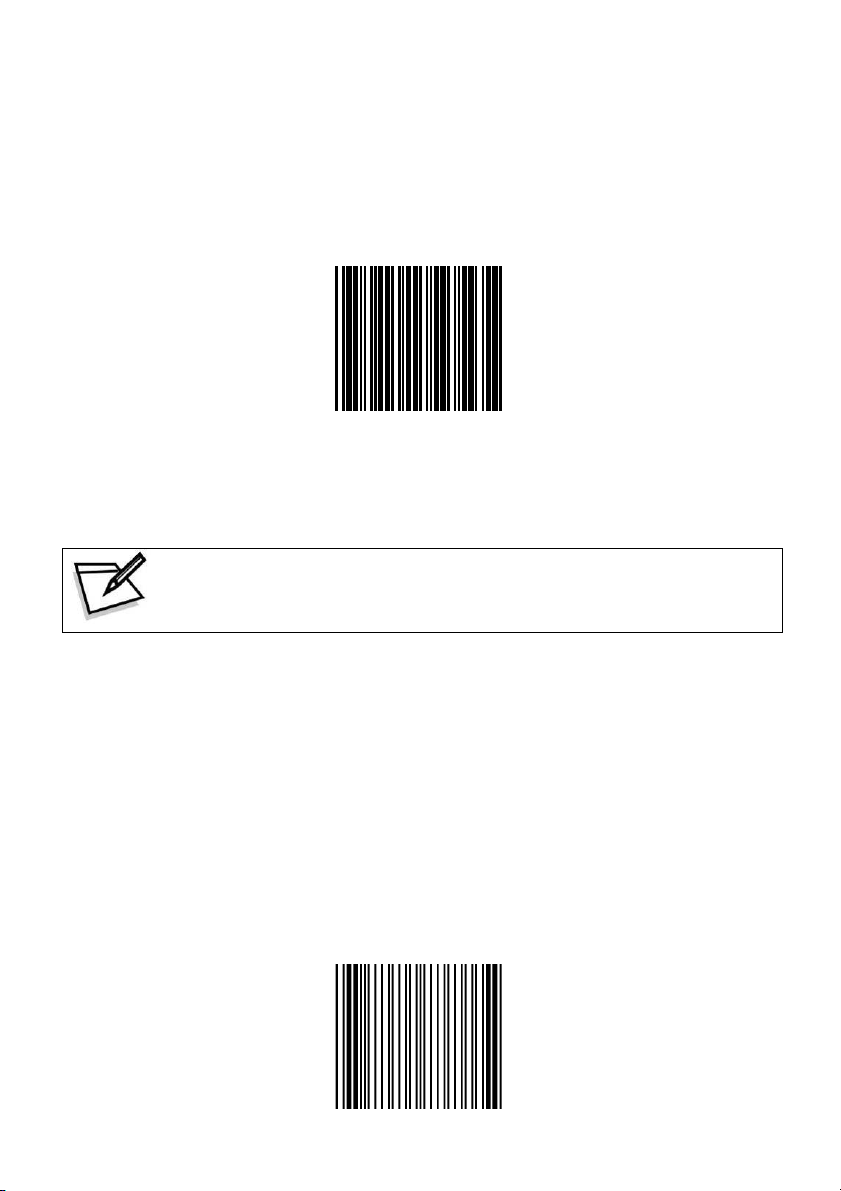

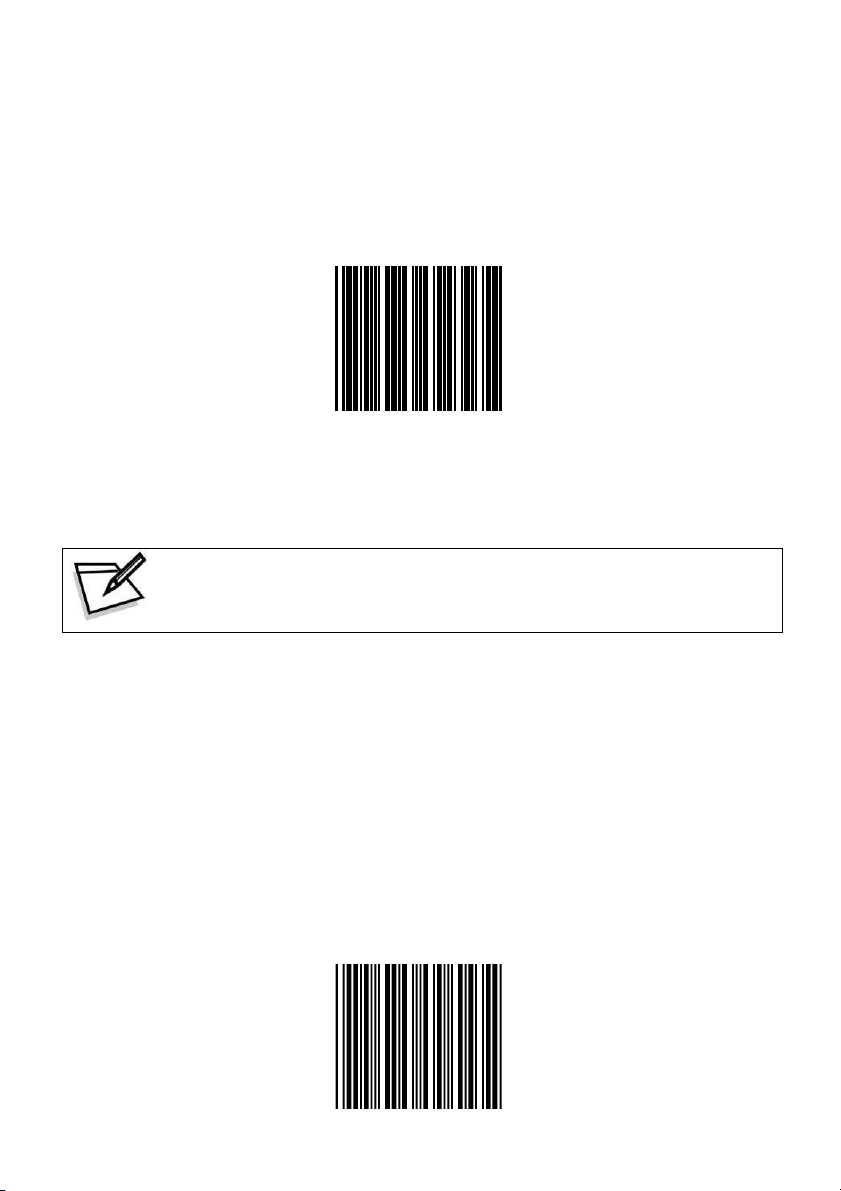

Display Firmware Version

Reading of the “Display Firmware Version” will show the current

firmware version on host.

Display Firmware Version

OMNIDIRECTIONAL SCANNER

8

PROGRAMMING GUIDE

Abort (Exit Programming Mode)

Reading of the “Abort” barcode label discards all the parameters

read prior to scan the “Enter/Exit of Programming Mode”.

Abort (Exit Programming Mode)

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Return to PC/AT Default

This barcode allows setting in keyboard wedge interface for IBM PC

AT/PS/2 and compatibles.

Return to PC/AT Default

OMNIDIRECTIONAL SCANNER

9

PROGRAMMING GUIDE

Return to RS-232 Default

The RS-232C interface scanner is often used when connecting to

the serial port of a PC or terminal. Read the barcode to set the

scanner into RS-232 interface.

Return to RS-232 Default

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Return to USB Default

Reading of “Return to USB default” sets the device into USB

interface support.

Return to USB Default

OMNIDIRECTIONAL SCANNER

10

PROGRAMMING GUIDE

Return to Wand Emulation Default

The Wand emulation is achieved by decoding a scanned barcode

and then encoding it again, so that the output is readily decoded by

an external decoder designed for processing of wand data.

Return to Wand Emulation Default

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Return as Customer Default

Reading of the label sets the device back to customer saved

parameter settings.

Return as Customer Default

OMNIDIRECTIONAL SCANNER

11

PROGRAMMING GUIDE

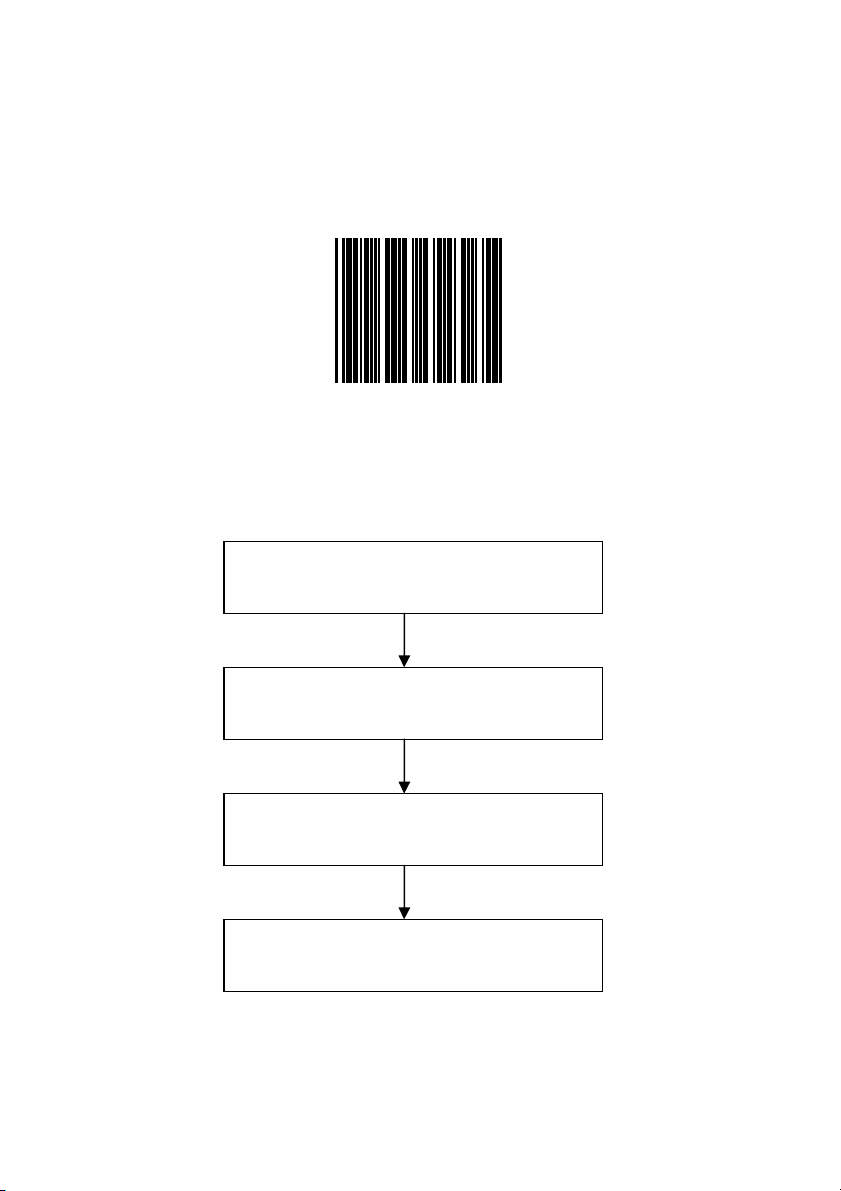

Save as Customer Default

barcode

Reading of this label to save the desired parameters set into

customer’s own default setting.

Save as Customer Default

How to Save as Customer Default

Read Enter/Exit Programming Mode

barcode to start configuration

OMNIDIRECTIONAL SCANNER

Change scanner setting by scanning

selected mode

Read Save as Customer Default

Read Enter/Exit Programming Mode

barcode to save and exit

12

PROGRAMMING GUIDE

Sleep Timeouts Selection

In this section, user can set both laser and/or motor to enter into

sleep mode. The timeout programming labels will allow users to

set the different time frame before entering into laser and/or motor

sleep mode. The feature reduces power consumption and

prolongs scanner life time.

NOTE:

1. Laser always enters sleep mode before motor.

2. If the motor timeout is set shorter than the motor timeout,

then laser would enter sleep mode as motor enters sleep

mode.

OMNIDIRECTIONAL SCANNER

13

PROGRAMMING GUIDE

Motor sleep mode off

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Motor sleep time 5 min.

OMNIDIRECTIONAL SCANNER

14

PROGRAMMING GUIDE

Motor sleep time 10 min.

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Motor sleep time 20 min.

OMNIDIRECTIONAL SCANNER

15

PROGRAMMING GUIDE

Motor sleep time 30 min.

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Motor sleep time 60 min.

OMNIDIRECTIONAL SCANNER

16

PROGRAMMING GUIDE

Laser sleep mode off

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Laser sleep time 5 min.

OMNIDIRECTIONAL SCANNER

17

PROGRAMMING GUIDE

Laser sleep time 10 min.

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Laser sleep time 15 min.

OMNIDIRECTIONAL SCANNER

18

PROGRAMMING GUIDE

Laser sleep time 20 min.

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Laser sleep time 25 min.

OMNIDIRECTIONAL SCANNER

19

PROGRAMMING GUIDE

Laser sleep time 30 min.

OMNIDIRECTIONAL SCANNER

20

PROGRAMMING GUIDE

Same Code Delay Time

This parameter sets the minimum time allowed between decodes of

the same label.

OMNIDIRECTIONAL SCANNER

21

PROGRAMMING GUIDE

Same code delay time 50 msec.

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Same code delay time 100 msec.

OMNIDIRECTIONAL SCANNER

22

PROGRAMMING GUIDE

Same code delay time 200 msec.

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Same code delay time 300 msec.

OMNIDIRECTIONAL SCANNER

23

PROGRAMMING GUIDE

Same code delay time 400 msec.

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Same code delay time 500 msec.

OMNIDIRECTIONAL SCANNER

24

PROGRAMMING GUIDE

Same code delay time 600 msec.

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Same code delay time 700 msec.

OMNIDIRECTIONAL SCANNER

25

PROGRAMMING GUIDE

Same code delay time 800 msec.

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Same code delay time 900 msec.

OMNIDIRECTIONAL SCANNER

26

PROGRAMMING GUIDE

Same code delay time 1000 msec.

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Same code delay time infinite

OMNIDIRECTIONAL SCANNER

27

PROGRAMMING GUIDE

Beeper Sound Selection

This section includes all setting labels for beeper sound settings,

including tone frequency, volume, duration time, power on beep

enable/disable, and enable/disable sound when the scanner enters

sleep mode.

.

OMNIDIRECTIONAL SCANNER

28

PROGRAMMING GUIDE

LED/Beep after transmission

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

LED/Beep before transmission

OMNIDIRECTIONAL SCANNER

29

PROGRAMMING GUIDE

Power-up tone enable

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Power-up tone disable

OMNIDIRECTIONAL SCANNER

30

PROGRAMMING GUIDE

Sleep sound

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Sleep silent

OMNIDIRECTIONAL SCANNER

31

PROGRAMMING GUIDE

Medium beeper tone

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Low beeper tone

OMNIDIRECTIONAL SCANNER

32

PROGRAMMING GUIDE

High beeper tone

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Speaker disable

OMNIDIRECTIONAL SCANNER

33

PROGRAMMING GUIDE

Beeper sound duration (100msec)

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Beeper sound duration (50msec)

OMNIDIRECTIONAL SCANNER

34

PROGRAMMING GUIDE

Beeper sound duration (20msec)

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Beeper sound duration (5msec)

OMNIDIRECTIONAL SCANNER

35

PROGRAMMING GUIDE

Beeper sound duration 200msec

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Beeper sound duration 500msec

OMNIDIRECTIONAL SCANNER

36

PROGRAMMING GUIDE

Loud beeper volume

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Medium beeper volume

OMNIDIRECTIONAL SCANNER

37

PROGRAMMING GUIDE

Low beeper volume

OMNIDIRECTIONAL SCANNER

38

PROGRAMMING GUIDE

Barcode Identifier Code

Setting

The scanner can transmit maximum 2 digits barcode identifier code

for different types of barcodes. Use Enable or Disable identifier

setting barcode to determine the transmission of barcode ID.

The procedure is as follows:

1.) Scan

2.) Scan

3.) Scan the new code mark from ASCII table (maximum 2 digits).

For example, if AB is the code mark, then scan A and B.

4.) Scan

5.) Scan

Enter/Exit Programming Mode

Barcode Identifier Setting Code

Save Setting to Confirm

Enter/Exit Programming Mode

label

label

label

label

OMNIDIRECTIONAL SCANNER

39

PROGRAMMING GUIDE

Barcode Identifier Code Selection

Disable identifier code

Scan “Enable identifier code” label to transmit the label ID as shown

in the table below.

Code 39 M

ITF 2 of 5 I

Chinese post code H

UPC-A A

UPC-E E

EAN-13 F

EAN-8 FF

Codabar N

Code 128 K

Code 93 L

MSI/Plessy P

GS1 DataBar Omnidirectional

(RSS-14 Standard)

GS1 DataBar Limited

(RSS Limited)

GS1 DataBar Expanded

(RSS Expanded)

RS

RL

RX

Enable identifier code

OMNIDIRECTIONAL SCANNER

40

PROGRAMMING GUIDE

Set Message Format with Code Identifier

I S 0 2

Code Code identifier

UPC-A A

UPC-E E

EAN-8 FF

EAN-13 F

CODE 39 *

CODBAR %

ITF 2 OF 5 i

CODE 93 &

CODE 128 #

MSI/PLESSY @

EAN-128 P

Enable Identifier Code Table as AIM Standard

OMNIDIRECTIONAL SCANNER

41

PROGRAMMING GUIDE

Barcode Identifier Code Setting

Code 39 identifier code setting

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

ITF 2 of 5 identifier code setting

OMNIDIRECTIONAL SCANNER

42

PROGRAMMING GUIDE

Chinese Post code identifier code setting

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

UPC-E identifier code setting

OMNIDIRECTIONAL SCANNER

43

PROGRAMMING GUIDE

UPC-A identifier code setting

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

EAN-13 identifier code setting

OMNIDIRECTIONAL SCANNER

44

PROGRAMMING GUIDE

EAN-8 identifier code setting

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Codabar identifier code setting

OMNIDIRECTIONAL SCANNER

45

PROGRAMMING GUIDE

Code 128 identifier code setting

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Code 93 identifier code setting

OMNIDIRECTIONAL SCANNER

46

PROGRAMMING GUIDE

MSI identifier code setting

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Save setting to confirm

OMNIDIRECTIONAL SCANNER

47

PROGRAMMING GUIDE

GS1 DataBar Omnidirectional identifier code setting

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

GS1 DataBar Limited identifier code setting

OMNIDIRECTIONAL SCANNER

48

PROGRAMMING GUIDE

GS1 DataBar Expanded identifier code setting

OMNIDIRECTIONAL SCANNER

49

PROGRAMMING GUIDE

Message delay

This section contains different delay time frames between two

consecutive messages. This delay will be added before each data

transmission.

OMNIDIRECTIONAL SCANNER

50

PROGRAMMING GUIDE

Inter message delay 0 ms

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Inter message delay 100 ms

OMNIDIRECTIONAL SCANNER

51

PROGRAMMING GUIDE

Inter message delay 500 ms

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Inter message delay 1000 ms

OMNIDIRECTIONAL SCANNER

52

PROGRAMMING GUIDE

Character Delay

This option governs delay time between two consecutive characters;

the delay time can be altered by scanning the following labels.

OMNIDIRECTIONAL SCANNER

53

PROGRAMMING GUIDE

Character delay 5 ms

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Inter character delay 0 ms

OMNIDIRECTIONAL SCANNER

54

PROGRAMMING GUIDE

Inter character delay 10 ms

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Inter character delay 20 ms

OMNIDIRECTIONAL SCANNER

55

PROGRAMMING GUIDE

Inter character delay 50 ms

OMNIDIRECTIONAL SCANNER

56

PROGRAMMING GUIDE

Interface Communication

Setting

This section contains labels to configure the scanner to user’s host

terminal. The following interfaces are supported:

*RS-232C interface

*Keyboard wedge

*USB interface

*Wand emulation

OMNIDIRECTIONAL SCANNER

57

PROGRAMMING GUIDE

RS-232C Interface Configuration

1. Baud Rate Setting

Baud Rate 38400

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Baud Rate 19200

OMNIDIRECTIONAL SCANNER

58

PROGRAMMING GUIDE

Baud Rate 9600

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Baud Rate 4800

OMNIDIRECTIONAL SCANNER

59

PROGRAMMING GUIDE

Baud Rate 2400

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Baud Rate 1200

OMNIDIRECTIONAL SCANNER

60

PROGRAMMING GUIDE

Baud Rate 57600

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Baud Rate 115200

OMNIDIRECTIONAL SCANNER

61

PROGRAMMING GUIDE

2. Date Bit Setting

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

7 data bit

8 data bit

OMNIDIRECTIONAL SCANNER

62

PROGRAMMING GUIDE

3. Stop Bit Setting

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

1 Stop bit

2 Stop bit

OMNIDIRECTIONAL SCANNER

63

PROGRAMMING GUIDE

4. Parity Bit Setting

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Even Parity

Odd Parity

OMNIDIRECTIONAL SCANNER

64

PROGRAMMING GUIDE

Mark Parity

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Space Parity

OMNIDIRECTIONAL SCANNER

65

PROGRAMMING GUIDE

None Parity

OMNIDIRECTIONAL SCANNER

66

PROGRAMMING GUIDE

5. Handshaking Protocol

The RS-232C type scanner supports four handshaking protocols.

With these options of communication protocol, users can tailor the

scanner to meet the requirement of most systems. These

handshaking protocols are:

*None

The scanner will transmit any read data unconditionally. The

scanner will not check the receiving device or the transmitted

message.

*RTS/CTS

Under this handshaking protocol, the scanner use the RTS pin to

instruct the connected device to transmit data and test the CTS pin

for readiness of the connected device to receive data.

*ACK/NAK

The scanner waits for an ACK or NAK signal from the host

computer after each data transmission. Normally, the scanner will

temporarily stored the scanned data in the memory buffer before

receiving the ACK or NAK signal. If the ACK signal is received, it

will clear the transmitted data and continue to send the next data.

In case the NAK signal is received, it will repeat to transmit the

same data until receiving the ACK signal.

*Xon/Xoff

During the data communication, if a scanner receives an Xoff

(ASCII 013H), it will stop the transmission at once. The scanner

waits for a Xon (ASCII 01H) to start the transmission again.

OMNIDIRECTIONAL SCANNER

67

PROGRAMMING GUIDE

None handshaking

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

ACK/NAK

OMNIDIRECTIONAL SCANNER

68

PROGRAMMING GUIDE

Xon/Xoff

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

RTS/CTS

OMNIDIRECTIONAL SCANNER

69

PROGRAMMING GUIDE

6. ACK/NAK Response Time Setting

ACK/NAK response time 300ms

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

ACK/NAK response time 500ms

OMNIDIRECTIONAL SCANNER

70

PROGRAMMING GUIDE

ACK/NAK response time 1s

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

ACK/NAK response time 2s

OMNIDIRECTIONAL SCANNER

71

PROGRAMMING GUIDE

ACK/NAK response time 3s

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

ACK/NAK response time 5s

OMNIDIRECTIONAL SCANNER

72

PROGRAMMING GUIDE

ACK/NAK response time Infinity

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Disable ACK/NAK timeout beeper

OMNIDIRECTIONAL SCANNER

73

PROGRAMMING GUIDE

Enable ACK/NAK timeout beeper

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Enable beeper on<BEL> character

OMNIDIRECTIONAL SCANNER

74

PROGRAMMING GUIDE

Ignore beep on <BEL>character

OMNIDIRECTIONAL SCANNER

75

PROGRAMMING GUIDE

7. Message terminator for RS-232C

The series RS-232C type scanner can be programmed to append a

terminator to every message sent via the serial port. Different

terminator will be appended at the end of message sent from the

serial port.

RS-232 message terminator-none

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

RS-232 message terminator-CR/LF

OMNIDIRECTIONAL SCANNER

76

PROGRAMMING GUIDE

RS-232 message terminator-CR

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

RS-232 message terminator-LF

OMNIDIRECTIONAL SCANNER

77

PROGRAMMING GUIDE

RS-232 message terminator-H tab

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

RS-232 message terminator-STX/ETX

OMNIDIRECTIONAL SCANNER

78

PROGRAMMING GUIDE

RS-232 message terminator-EOT

OMNIDIRECTIONAL SCANNER

79

PROGRAMMING GUIDE

Keyboard Wedge Interface Configuration

1. Message Terminator for Keyboard Wedge

Keyboard terminator---none

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Keyboard terminator---Enter

OMNIDIRECTIONAL SCANNER

80

PROGRAMMING GUIDE

Keyboard terminator---H-TAB

OMNIDIRECTIONAL SCANNER

81

PROGRAMMING GUIDE

2. Keyboard Language Selection

Enable International keyboard type

(Alt method)

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Keyboard language support---USA

OMNIDIRECTIONAL SCANNER

82

PROGRAMMING GUIDE

Keyboard language support---Germany

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Keyboard language support---UK

OMNIDIRECTIONAL SCANNER

83

PROGRAMMING GUIDE

Keyboard language support---French

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Keyboard language support---Spanish

OMNIDIRECTIONAL SCANNER

84

PROGRAMMING GUIDE

Keyboard language support--- Italian

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Keyboard language support--- Swiss

OMNIDIRECTIONAL SCANNER

85

PROGRAMMING GUIDE

Keyboard language support---Swedish

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Keyboard language support---Japanese

OMNIDIRECTIONAL SCANNER

86

PROGRAMMING GUIDE

Keyboard language support---Belgium

OMNIDIRECTIONAL SCANNER

87

PROGRAMMING GUIDE

3. Capital Lock

Select the suitable code to match your keyboard caps lock status.

Capital lock on

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Capital lock off

OMNIDIRECTIONAL SCANNER

88

PROGRAMMING GUIDE

4. Function Key Emulation

In this section, users can emulate Function keys, Arrow keys, and

many other extended keys. An IBM compatible keyboard does not

translate to ASCII characters; it can be concatenated with input

data as header and/or trailer. (See Appendix B)

Function key emulation enable

Function key emulation disable

OMNIDIRECTIONAL SCANNER

89

PROGRAMMING GUIDE

USB Interface Configuration

The USB mode is effectively a keyboard emulator that works with

hosts, such as USB-compatible operating system and USB ports.

USB compatible operating systems are Windows 98, Windows NT

5.0 and later. No additional software is needed since the USB

driver supports its built-in operating system

1. Keyboard Type

Keyboard type---USA

(Scan method)

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Keyboard type.

(ALT code method)

OMNIDIRECTIONAL SCANNER

90

PROGRAMMING GUIDE

2. Message terminator for USB

None

To prevent confusion in code scanning, cover the

unwanted label and present the desired barcodes one by

one to the scanner.

Enter

OMNIDIRECTIONAL SCANNER

91

PROGRAMMING GUIDE

H tab

OMNIDIRECTIONAL SCANNER

92

Loading...

Loading...