Page 1

Freestanding Gas & Electric Cooker Slide–In Freestanding

Porter & Charles

OPERATION MANUAL

FEC 90

Page 2

1. INSTALLATION …………………………………………… PAGES 4- 6

1.1.Ventilation

1.2.Discharge of fuel gases

1.3.Positioning the cooker

1.4 Dimensions and cut-outs

1.5.Connection to the gas supply: current installation standards

1.6.Connection to the electricity supply

1.7.Converting the gas-supply to the hob burners

1.8.Regulating the minimum output of the hob burners

2. MAINTENANCE …………………………………………….. PAGES 7-8

2.1.Gas supply rubber pipe

2.2.Electricity supply cable

2.3.Access to electrical/gas components

2.4.Replacing the thermostat taps

2.5.Removing and fitting the oven door

2.6.Replacing the light bulb

2.7.Glass cover

3. USING THE COOKER ………………………………………… PAGES 9 - 14

3.1. Using the cooking hob

3.2. Ceramic Hob

3.3. Oven Performance

3.4. Using the grill

3.6. Minute timer

3.7. Electronic programmer

3.8. Cooking hob with glass-plate ( mxg 96 mfpi/v model only)

3.9. Fitting the fat filter to giant multiple-fuction oven (fig. 20).

3.10. Fitting the gas burners to the hob

3.11 Telescopic runners (only for certain models)

4. CLEANING …………………………………………………… PAGES 15 - 16

5. DIAGRAMS ………………………………………………… PAGES 17- 19

6. WARRANTY …………………………………………………. PAGE 29

2

Page 3

WARNINGS AND TIPS

⇒ Information about this model and its features is displayed on the appliance plate.

⇒ This appliance has been designed for domestic use only.

⇒ These instructions are only valid for the country indicated in the identification symbols

on the cover of the instruction handbook and on the appliance.

⇒ All installation, adjustments, gas-conversion and maintenance operations must be

carried out by qualified engineers, in accordance with the enclosed instructions and

current installation standards. The manufacturer accepts no liability for faulty

installation, setting, handling and use of the cooker.

⇒ Before carrying out any maintenance or conversion operations unplug the cooker from

the mains and shut off the gas upstream of the appliance. If any components and/or

accessories need replacing, only original Porter & Charles spare parts must be used.

Only qualified technicians may perform installation and maintenance operations.

⇒ Keep the operation manual near the cooker, so that if can be consulted at any time.

This way, the instructions and tips are close at hand for correct use and optimum

performance.

⇒ Before using the cooker remove the plastic protection from the stainless steel,

aluminium and/or painted parts in order to prevent it melting. The utmost care must be

taken when removing this protection so as to avoid damaging the protected parts.

⇒ When the cooker is in use keep children at a safe distance, as the outside of the cooker

can heat up, and they should be kept away until the cooker has completely cooled

down. Likewise children should not play with or use the cooker controls unsupervised.

⇒ Periodically check that there are no gas leaks in the pipe that connects the cooker to

the gas bottle or the supply line; replace it upon expiry

⇒ When the cooker is not in use, ensure that all the knobs are in the off position;

furthermore, if it is unused for a period of time, shut off the gas bottle valve and the

supply valve, as well as the appliance’s mains electricity supply.

⇒ Keep the burners, covers and flame diffusers clean in order to ensure optimum

operation.

⇒ Before using the oven for the first time, we recommend leaving it on for one hour at the

maximum temperature. Doing so may create smoke and unpleasant smells, which are

caused by the glue in the heat insulation or oiled plates. To get rid of these odours, air

room e.g. opening a window.

⇒ Some models are fitted with an aluminium tray, ideal for baking pastries (180-200°C).

Max. load 3 kg.

⇒ Do not discard packaging, accessories or other parts of the appliance into the

environment. If possible, take them to recycling bins or a recycling plant

3

Page 4

INSTALLATION

This appliance shall be installed in accordance with the regulations in force and only in a well

ventilated space. Read the instructions before installing or using the appliance.

1.1. VENTILATION

The room containing this cooker should have an air supply in accordance with local regulations.

- All rooms require an open window, or equivalent and some rooms will require a

permanent vent as well.

- For room areas up to 5 m

- For room areas between 5 m

- If the room is greater than 5 m

2

an air vent of 100 cm2 is required.

2

and 100 cm2 an air vent of 50 cm2 is required.

2

and has a door that opens directly to the outside, then no

air vent is required.

- If there are other fuel burning appliances in the same room local regulations should be

consulted to determine the air vent requirements.

1.2. DISCHARGE OF FUEL GASES

Cooking appliances must always discharge the flue

gases into special hoods (fig.1-C), which must be

connected to chimneys, flue pipes or have direct

access to the outside. If it is not possible to connect

a hood, an electric fan can be fitted to a window or

a wall (fig.1-E), which must be turned on when the

cooker is on, as long as ventilation standards are

strictly adhered to.

1.3. POSITIONING THE COOKER

a) Built-in cooker: Cookers in this class can be fitted

between two units, unless the side

in contact with the cooker is higher

than the hob. In this case, the unit

must stand at least 5 cm away from

the top of the hob. If the cooker has

a baseboard fitted, a 2cm vent must

be made in the front along the entire

width of the cooker.

b) Free standing cooker: After unpacking the cooker, remove the plastic protection from the

stainless steel, aluminium and/or painted parts to avoid it melting.

The utmost care must be taken when removing this protection so as

not to damage the protected parts. Now the feet can be fitted (fig.4).

They must be fixed to the ends of the slits on the cooker pedestal.

Their height can be adjusted in order to line the cooker up with other

units. Ensure that the cooker is perfectly stable. Fit the burners, the

flame diffusers and the grids into their seats on the hob (see

paragraph 3.9). Some models come with rubber pads that prevent

the steel hob surface from being scratched. Fit them to the central

pan grid made of chrome-plated rod.

N.B. When the burners are alight, there must not be any draughts inside the room in

that they may affect the flame or even blow it out. (PLEASE NOTE: The fixing hook is

not provided as the type will depend on the construction of the wall to w hich it will be

drilled and fitted. The installer should provide the fixing hook).

4

Page 5

1.4 Dimensions and Cut-outs

MODEL

60 cm

24 Inches

90 cm

26 Inches

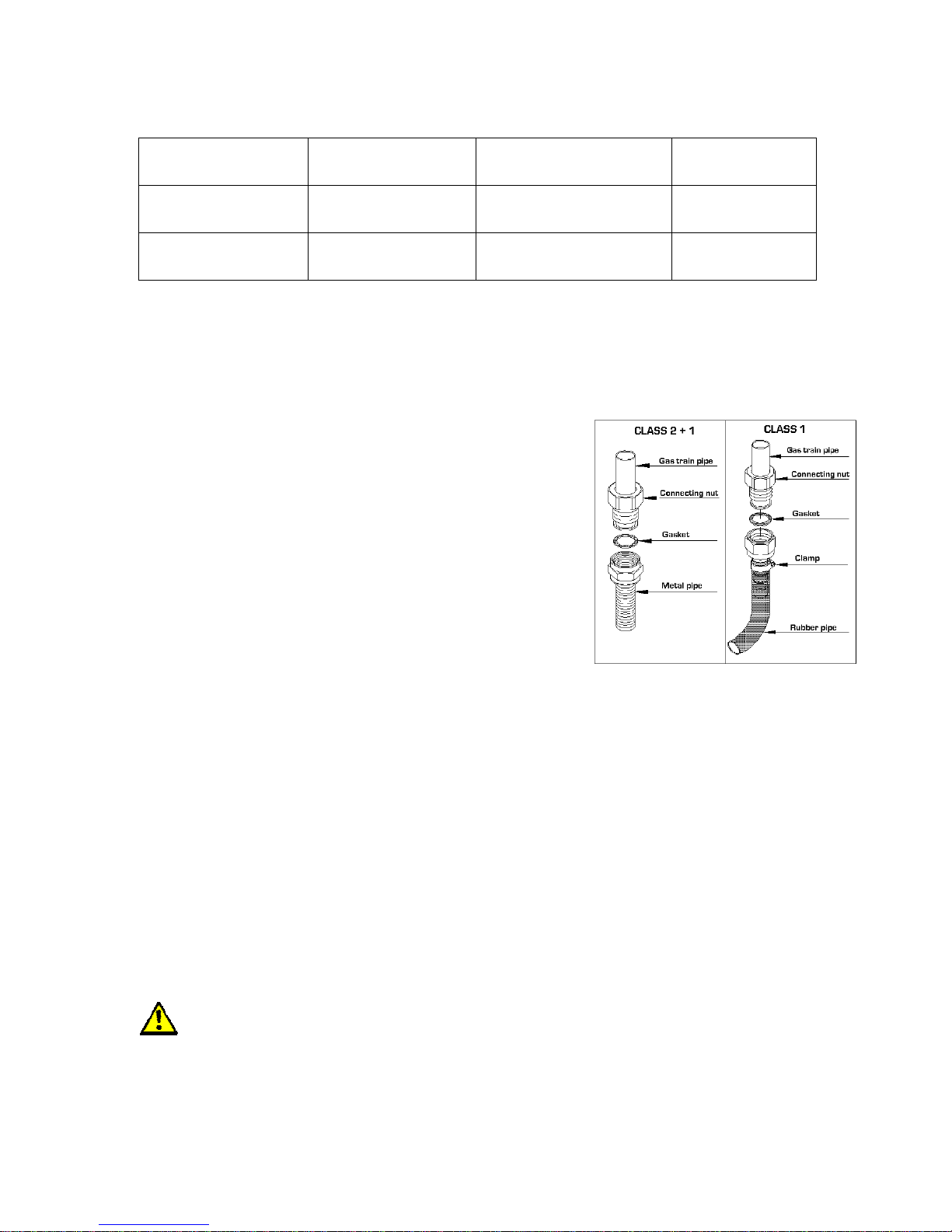

1.5. CONNECTION TO THE GAS SUPPLY: CURRENT INSTALLATION STANDARDS

The cooker should be connected according to local

regulations, using either a rigid or flexible connections.

a) For building in: Use a continuous flexible stainless steel

pipe, as per current installation standards, which can be

extended to a maximum of 2000 mm.; the ends of the pipe

must be fitted with an ISO 228/1coupling and gasket or an

ISO 7/1 threaded coupling with mechanical gasket.

b) For free standing: A non-metallic flexible pipe can be used

as long as it complies with current standards and the

following installation instructions are observed: the pipe

must be longer than 400 mm and shorter than 1500 mm; it

must not exceed 50àC in any point; it is not pulled or

twisted; it cannot be choked and the entire edges, sharp

corners or other similar hazards.

Before connecting the non-metallic flexible pipe, the pipe holder and gasket supplied with the

cooker and/or available form the reseller must be fitted to the pipe/gas train on

the back of the cooker.

c) A certified gas plumber must complete the installation and meet with local regulation

requirements for gas connections. Where the unit has an armour cable a certified electricain

must complete the electrical connection. The white, or neutral wire will not be used and must

be capped using a marrette.

HIEGHT

(Adjustable Feet)

92 cm

36 Inches

92 cm

36 Inches

DEPTH

(Including Rear Vent)

64 cm

25 Inches

64 cm

25 Inches

WIDTH

60 cm

24 Inches

90 cm

35.5 Inches

1.6. CONNECTION TO THE ELECTRICITY SUPPLY

The flexible mains lead is supplied connected to a fused plug fitted with a fuse of 13 amp

capacity. If you need to replace the plug for any reason, it should be carried out as outlined

below:

WARNING: THIS APPLIANCE MUST BE EARTHED.

5

Page 6

BLACK

TO LINE 1

GREEN

TO EARTH

RED

TO LINE 2

FUSE

BLACK

TO LINE 1

RED

TO LINE 2

CORD

CLAMP

GREEN

TO EARTH

The wires in the mains lead are coloured in accordance with the following code:

Green & Yellow = Earth – Blue= Neutral – Brown= Live

As the colours of the wires in the mains lead of the appliance may not correspond with the

coloured markings, to identify the terminals in your plug, proceed as follows:

1. The wire which is coloured Green & Yellow must be connected to the terminal marked E

(Earth) or coloured Green.

2. The wire which is coloured Blue must be connected to the terminal marked N (Neutral) or

coloured Black.

3. The wire which is coloured Brown must be connected to the terminal marked L (Live) or

coloured Red.

The plug and socket must be accessible after installation. Should the mains lead ever need

replacing it is recommended that this operation is carried out by a qualified electrician who

will replace it with a lead of the same size and temperature rating.

1.7 CONVERTING THE GAS-SUPPLY TO THE HOB BURNERS

Burners: auxiliary, semi-rapid, rapid, triple crown, griddle burner.

These burners are all fitted with injectors designed to create a primary input of air gauged for

each type of gas. This means that the air regulator does not have to be regulated. Proceed as

follows in order to convert from one type of gas to another: remove the grids, covers, holed flame

diffuser and the burner supports (fig. 7); replace the holed injectors as indicated in 7/C according

to the type of gas used (see table 1); put the burner supports, flame diffusers, covers and grids

back in position; regulate the minimum output following the instructions in paragraph 1.7.

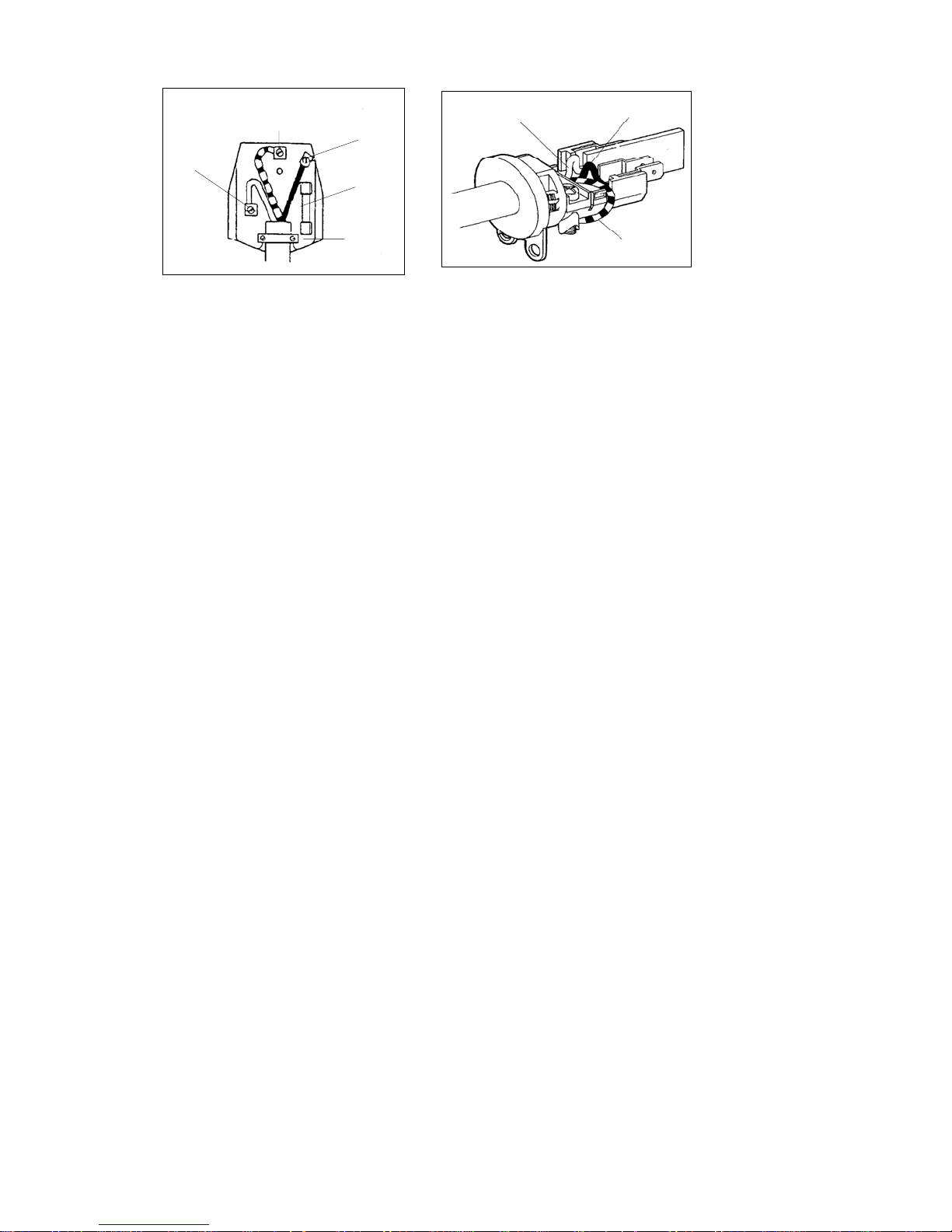

1.8 REGULATING THE MINIMUM OUTPUT OF THE HOB BURNERS

Normal/valve taps:

Ignite the burners and turn the knob to the maximum position. Remove the knob and insert a

small flat-head screwdriver into the rod or through the holes on the side of the control panel, in

accordance with the type (fig. 8 A/B). Loosen the by-pass screw by two turns in an anti-clockwise

direction and rotate the rod to the minimum position. Adjust the previously loosened screws until

the flame is lowered but stable, even when rapid changes are made from the maximum to the

minimum position with the burner cold. If safety taps are fitted, let the burner run on minimum for

a few minutes to ensure that the device does not cut in. If it does, increase the minimum.

N.B. For liquid gas settings, the burner minimum must be set by fully tightening the tap

by-passes.

Replace the knob and turn it to the minimum position, remove the knob and adjust the previously

loosened screw until the flame is lowered but stable, even when rapid changes from maximum to

minimum are made and the oven door is opened or closer quickly.

N.B. For liquid gas setting, the oven burner minimum is set by fully tightening the

thermostat by-passes.

6

Page 7

2. MAINTENANCE

WARNINGS:

Before carrying out any maintenance or conversion operations turn off the electricity

supply and close the gas upstream of the appliance. If components and/or

accessories need replacing, use only Porter & Charles spare parts only. All the

operations hereunder must be carried out by qualified technicians in accordance with

the enclosed instructions and current installation standards.

2.1. GAS SUPPLY RUBBER PIPE

The condition of the gas supply pipe should be checked periodically (once a year) and replaced

by the date printed on the outside of the pipe and if there are signs of cracking, cuts, scratches or

burns, or if it is no longer flexible but hard and plastic. The pipe must be suitable for use with

liquid gas and comply with the applicable standards.

2.2. ELECTRICITY SUPPLY CABLE

If the electricity supply cable needs replacing, please remember that this is an X type of

connection; therefore only authorised Porter & Charles technicians may replace it. Use

HO5FRR-F cables only. The earth wire (yellow/green) must be at least 2 cm longer than the other

two phase wires (fig. 5 B). This ensures that the electrics are safe should the wire be pulled

accidentally.

For the cookers with a gas oven and an electric grill, use a 3x1 mm² HO5RR-F cable, for cookers

with electric oven and grill, use a 3x1.5 mm² HO5RR-F cable with a maximum external diameter

of 9 mm.

2.3. ACCESS TO ELECTRICAL/GAS COMPONENTS

To carry out maintenance and/or to replace the electrical components fitted in the back of the

cooker (e.g. light bulb older, rotisserie, supply cable, electric ignition generator, resistors) the rear

protection panel must be removed by unfastening the screws that secure it to the sides.

To carry out maintenance and/or replace the electrical components fitted to the front panel (e.g.

control panel, taps, thermostat, timer, etc), you have to remove the rear panel and also proceed

as follows:

- remove the flue pipe, if fitted;

- remove the hob grids and burners;

- unfasten the screws that secure the cups to the hob and, for models with safety device, also

remove the nuts that secure the thermocouples;

- unscrew the 2 top front or side front screws (fig. 9) that fasten the hob and then lift it;

- remove the knobs and remove the screws that fasten the gas train to the front control panel,

remove the gas train taking care not to damage any pipes or thermocouples.

- to reassemble follow these instructions in reverse order.

2.4. REPLACING THE THERMOSTAT TAPS

If a tap or a thermostat needs replacing, first follow the instructions given in paragraph 2.3.

(access to electrical/gas components), then remove the nut fastens the supply pipe to the burner,

the thermocouple nut and the screws that fasten the tap or the thermostat to the gas train.

Besides the tap or the thermostat, it is also important that the gasket is replaced in order to

prevent any gas leaks. After maintenance, ensure that there are no leaks by using a specific

instrument or soapy water.

7

Page 8

2.5. REMOVING AND FITTING THE OVEN DOOR

Open the oven door fully; insert the rotation-blocking device (A) in the hook on the hinge rods as

illustrated in Fig. 10. Grasp the door on both sides and slowly close until you feel a certain

resistance at this point simultaneously push and lift the door upwards to free it from the cooker

hinge locks and then remove it.

To fit the door, follow these instructions in reverse, taking care that the hinge lock is properly fitted

into the seat.

2.6. REPLACING THE LIGHT BULB

Turn the cooker off at the mains before replacing the bulb.

Open the oven door, remove the protective glass cover, and replace the light bulb (CAUTION: it

must be resistant up to 300°C) and replace the glass protection.

8

Page 9

4. USING THE COOKER

WARNINGS:

- If the burner flames accidentally go out, turn off the KNOB and wait for at least one minute

before igniting.

- Using a gas cooker produces heat and humidity in the room where it is installed. Ensure the

room is well ventilated by keeping all the natural air vents open or by installing an extraction

hood with flue pipe.

- Intensive or extensive use of the cooker may require supplementary ventilation e.g. opening

a window, or more efficient ventilation e.g. increasing the capacity of the mechanic

ventilation, if installed.

If the cooker has an electric oven, there is a green light and also a yellow light, which turns on

and off when the THERMOSTAT cuts in to regulate the oven temperature.

3.1. USING THE GAS COOKING HOB

Automatic electronic ignition built into the knob: turn the knob to the maximum position

push it in and the burner lights up automatically.

• No gas supply (knob turned off)

Maximum gas supply Minimum gas supply

To obtain minimum supply, turn the knob in an anti-clockwise direction until the indicator points to

the small flame

Safety device: once the burner is on, keep the knob pressed for at least 5 seconds and then

release it. The burner remains alight due to the thermocouple (Fig. 7 point A) that keeps the gas

flow by means of a safety valve, which shuts off the gas flow should the burner go out

accidentally.

Burner performance: a variety of pans with a minimum diameter of 120 mm can be used on the

“medium and small” burners. The pans must not have concave or convex bottoms, but be

perfectly flat as shows in Fig. 14. For optimum performance, use the saucepans shown in fig. 13,

i.e. the flames must not go beyond the bottom of the pan. When a liquid starts boiling, lower the

flame as much as possible, but keep it on the boil. For safety reasons, we recommend using pans

with the following diameters on the various burners:

Auxiliary (1000W) 120÷180 mm.

Semi-rapid (1750W) 120÷220 mm.

Rapid (3000W) 180÷280 mm.

Triple Crown (3900W) 240÷330 mm.

Griddle Burner (3000W) 120÷280 mm. (indicated minimum measurements)

Electric plates

The first time the plate is turned on or if it has not been used for a long time, it should be turned

on and left on for 30 minutes in position 1 on the selector switch in order to dry out any humidity

absorbed by the insulating cover. To avoid heat dispersion and damage to the plate, use flat

bottomed pans that have the same diameter as the plate, no more no less (fig. 14). Dry the

bottom of the pan before putting it on the plate. When the plate is on, never stand an empty pan

on it, or leave the plate on without a pan. Turning the plates on – centre the pan on the plate and

turn the corresponding knob to the required position (see Table 2). The increasing numbers

indicate greater power.

.

9

Page 10

3.2 GLASS CERAMIC HOB

60cm HOB

1.2

kW

HL

2.2/0.75

Kw

1.7

kW

90cm Hob

HL

2.4/1.5

kW

2.4/1.5

kW

2.0/1.1

kW

1.7

kW

HL

2.2/0.75

kW

The hi-lite elements make it possible to reach maximum power in a few seconds. Further the

thick fibreglass insulation around the elements prevents heat dispersion and concentrates the

effect.

The energy regulator is a device which regulates power gradually according to the position set

on the knob (% of maximum power). Control of the heating zones is automatic, by activating or

disabling the heating elements at regular intervals, thus ensuring precise, uniform heating ie:

short heating periods and long pauses indicate low temperature; long heating periods and brief

pauses indicate a higher temperature. With the energy regulator, you can totally or partially heat

a particularly zone of the glass ceramic top.

Plate lay-out (see tables)

1.2

kW

10

Page 11

Characteristics of the heating zones in 4 heating plate kitchen ranges.

Position

Front left

Rear left Switch

Front right Switch

Rear right

Type of

command

Energy

regulator

Energy

regulator

Effective heated

zone

All Clockwise 2200W

Central

All

All

All Clockwise 2400W

Circular

Knob

rotation

anticlockwise

anticlockwise

anticlockwise

anticlockwise

max

power

750W

1200W 150 W 200 W 350 W 500 W 850 W 1200 W

1700W 180 W 300 W 450 W 750 W 1200 W 1700 W

1500W

Knob position and relevant power

1 2 3 4 5 6

10 % 25 % 50 % 65 % 90 % 100 %

10 % 25 % 50 % 65 % 90 % 100 %

Characteristics of the heating zones in 5 heating plate ceramic hob.

Position

Front left

Front right Switch

Rear right Switch

Rear left

Type of

command

Energy

regulator

Energy

regulator

Effective heated

zone

All

Central

All

All

All Clockwise 2400W

Circular

Knob

rotation

Clockwise 2200W

anti-

clockwise

anti-

clockwise

anti-

clockwise

anticlockwise

Max

power

7500W

1200W 150 W 200 W 350 W 500 W 850 W 1200 W

1700W 180 W 300 W 450 W 750 W 1200 W 1700 W

1500W

Knob position and relevant power

1 2 3 4 5 6

10 % 25 % 50 % 65 % 90 % 100 %

10 % 25 % 50 % 65 % 90 % 100 %

Central

All Clockwise 2000W

Energy

regulator

Circular

anticlockwise

1100W

10 % 25 % 50 % 65 % 90 % 100 %

Residual heat

The glass ceramic top is divided into 5 heating zones. To ensure extra safety, it has indicator

lights (residual heat indicators), which light up when a zone is hot.

The indicators stay lighted for as long as the heated zone remains hot, even with the plates OFF.

How to use the glass ceramic top

When using the top for the first time, we advise you to turn ON the heating zones one at a time

for a few minutes, in order to eliminate any humidity accumulated in the insulation.

To avoid heat dispersion and for excellent performance, we advise you to use pots/pans with a

flat, thick bottom. Further, whenever possible, the pots should be of the size as the heating zone

being used.

The heated zone stays hot for a certain period of time. You should therefore exploit this by

switching the plate off a few minutes before end of cooking, so that you finish cooking by

exploiting the residual heat accumulated by the glass, and save on energy.

11

Page 12

We advise you to clean when the glass has cooled. Wash the glass with the type of liquid

detergent as per supplied sample, or with soapy water. For stubborn dirt, use the supplied

scraper. Do not use abrasive material such as Scotch brite, metal sponges or the like. Take

care not to spill sugar while cooking, because impossible to remove deposits could be formed.

Any cast-iron pots or with a rough bottom tend to leave light coloured traces, which can be

removed with a cloth dampened with vinegar.

WARNING:

When the top is in operation or the residual heat indicator is ON, take great care,

and keep children away.

WARNING:

If the glass ceramic breaks, disconnect electric power and call in the Lofra

Authorised Service Centre.

3.3. OVEN PERFORMANCE

Electric ovens

STATIC OVENS: heat produced inside the oven by electric elements fitted in the top and bottom

of the oven; these elements can work together or independently. This gives more even cooking,

for example when the cooking time is almost up, the food may need more heat at the top or the

bottom. The temperature is kept constant by the thermostat, which can be set between 50°C and

250°C. During cooking, only open the oven door when strictly necessary. During this cooking

method, humidity loss from the food is slow and uniform.

FAN OVENS; heat is produced by the forced circulation of hot air inside the oven. A circular

element next to a motorised fan heats the air, which this fan circulates evenly and rapidly. This

type of oven cooks faster than traditional ovens; hence you should set your cooking temperatures

10-20°C lower than normal. Once again the thermostat maintains the oven at the pre-selected

temperature, which range from 50°C and 250°C. The oven can take several dishes together

without altering the flavours in any way.

Switching on the multiple-function oven: turn the oven knob marked by the

symbol to the right and set the required temperature, in accordance with the cooking method.

12

or the

Page 13

3.3. OVEN PERFORMANCE

Electric ovens

STATIC OVENS: heat produced inside the oven by electric elements fitted in the top and bottom

of the oven; these elements can work together or independently. This gives more even cooking,

for example when the cooking time is almost up, the food may need more heat at the top or the

bottom. The temperature is kept constant by the thermostat, which can be set between 50°C and

250°C. During cooking, only open the oven door when strictly necessary. During this cooking

method, humidity loss from the food is slow and uniform.

FAN OVENS; heat is produced by the forced circulation of hot air inside the oven. A circular

element next to a motorised fan heats the air, which this fan circulates evenly and rapidly. This

type of oven cooks faster than traditional ovens; hence you should set your cooking temperatures

10-20°C lower than normal. Once again the thermostat maintains the oven at the pre-selected

temperature, which range from 50°C and 250°C. The oven can take several dishes together

without altering the flavours in any way.

Switching on the multiple-function oven: turn the oven knob marked by the

symbol to the right and set the required temperature, in accordance with the cooking method.

3.4. USING THE GRILL

The food is laid on the oven grill, which should then be placed inside the oven. The grill’s position

depends on the type of food, e.g. flat or thin meat should be placed on the level closest to the

grill, while a roll of meat, or poultry, etc. should placed on the middle level. The drip tray should be

fitted on the guides below the grill.

.

Using the electric grill:

a) MODELS WITH MULTIPLE-FUNCTION OVENS: switch on the grill by turning the

functions knob to right (F Fig. 19) and set it to the required grill position

the oven thermostat knob (T Fig.19) and set the temperature to 200°C. The oven door

must stay closed.

b) MODELS WITH MULTIPLE FUNCTION OVEN AND RADIATING GRILL: the grill cooks

by radiating heat, which is produced by a special element that reaches a temperature of

approx. 800°C in a few seconds. It produces infrared rays which a transparent pyroceram

plate use to ensure ultra-quick cooking times. The layout of the heating filament and the

high insulation level mean that heat distribution is concentrated on the surface of the

pyroceram plate, thus ensuring even cooking and energy savings.

The plate should be cleaned once the oven has cooled down. The plate can be cleaned

more thoroughly and more easily, and it protects the heating element from splashes and

fat.

or the

. Then turn

c) MODELS WITH CHANGEABLE GRILL

regulated by the knob put on the position MIN. – MED. – MAX. According to the

utilization.

Grill operation: switch on the grill by turning the function knob to the right (F Fig. 19) and

set it to required grill position. Then turn the oven thermostat knob (T Fig.19) and set

temperature to 200°C. The oven door must stay closed.

WARNING: The accessible parts get very hot when the grill is in use. Keep children

at a safe distance.

ON THIS SET: the grill action can be

13

Page 14

3.6. MINUTE TIMER

This mechanical minute timer goes from 0 to 60 minutes and sounds a bell when the preset time

is up. To start the timer, turn the knob to the right and set it to the required time. The knob

automatically returns to zero, and the bell rings at the end of the preset time.

WARNING: the knob must not be turned in anti-clockwise towards the hand symbol,

otherwise you can break the timer.

3.7. ELECTRONIC PROGRAMMER

Porter & Charles electronic programmer is an easy to operate one hand operation.

Illustrated below is the functions explained.

TURN THE KNOB

PRESS THE KNOB

LED

Cooking Time

At the moment of the first ignition the display blinks.

Cooking Programming

Function

ON

LED

LED

Timer

Function

OFF

14

Page 15

How to program time at initial set up.

Turn the knob and program hour and minutes.

Confirm pressing the knob completely.

How to regulate the hour.

To modify the hour after the first time, keep pressed the knob for 3 seconds, and

carry out the previous operation.

Minute counter function.

Turn the knob to program the time of the “minute counter”.

The display shows the remaining time and the led

display shows “END” and an alarm is heard.

The alarm is repeated for 10 minutes.

It is intermittent in the first 30 seconds, and then every 15 seconds. To stop press

the knob.

Turning the knob in clockwise direction a new minute counter begins and you have

the ability to modify the time.

To stop the function you have to turn the knob to 0 or press the knob.

Cooking time function.

Turning the knob when the oven is on activates the cooking time function.

the led

When on the display “ END” appears, the oven switches off and an alarm is heard.

To come back to the hour press the knob or switch to off position.

Turn the knob to the right and a new count will begin again, the oven switches on

and it is possible to program a new time.

To stop the function turn the knob to 0 or press the knob.

blinks, at the end the

blinks and the remaining time is showed.

To start the “minute counter” function during a cooking cycle and the “cooking time

function” is not on without switching off of the oven, press the knob twice and the

minute counter will be activated pre-programmed to signal every minute for 5

15

Page 16

minutes, however the limit can be adjusted via the knob.

It is possible to modify the time operating on the knob.

N.B. If the knob is pressed twice consecutively it is possible to regulate the timer at intervals of 5

minutes. Push once more to fix the desired time.

Function “ cooking programming” with delayed starting.

Pressing the knob with the oven switched off, the function “cooking programming”

is on, the blinking led

switches on, you program the start time of automatic

programming with the knob and you confirm it by pressing the knob.

Turn the knob to program the cooking time, the two leds

blink.

Press the knob to come back to the hour, the programming has been completed.

The programming led

blinks to indicate that the function is on. After you

can program the desired function and temperature of the oven operating on the

knob.

At the programmed hour, the oven switches on, the led displays the remaining

cooking time and the led

At the end it switches off and “End” is seen, followed by an alarm.

blinks.

16

Page 17

If you want to continue the cooking, turn the knob to program the new hour.

N.B. With a programmed start, the function remains memorized, even if the light has been turned off.

LIST OF FUNCTIONS

1 Oven light.

2 Conventional oven.

The heat distributes evenly from the top and the bottom. Ideal for baking pastries, cakes & biscuits

and roasts. Recommended for cooking individual items.

3 Cooking using bottom element

The heat distributes from the bottom to give cooked food a finishing touch.

4 Cooking using top element

The heat comes from the top element. Ideal for cooking the top of dishes without grilling.

5 Grilling or rotisserie.

The heat is radiated in the oven. Ideal for grilling, browning, and au gratin dishes.

6 Maxi-grill and rotisserie.

Like function 5, but with higher power and a larger radiating surface.

7 Maxi-grill with fan-assisted oven and rotisserie.

The heat is radiated in the oven and is evenly distributed by the fan. Ideal for browning food without

drying them out.

8 Even cooking.

The heat emitted by the top and bottom heating elements is distributed by the fan for quick, even

cooking inside and out. Recommended for cooking individual items.

9 Fan-assisted cooking

The heat is distributed by forced ventilation. Ideal for food that has to be well-cooked in the middle and

not well-done on the outside. This function enables you to cook three different dishes at the

same time.

Super fast defrosting

Set the switch to “fan-assisted cooking” and the thermostat to 50°C in order to defrost food in no

time at all.

17

Page 18

10 Defrosting

Set the oven thermostat to “0” position. Food can be defrosted by using the fan without any heat.

4. CLEANING

Cleaning and tips

The glass plate should only be cleaned when it has cooled down. Use a liquid detergent to wash

the glass, or alternatively use soapy water. For more stubborn dirt, use a scraper supplied with

the cooker. Do not use abrasive pads, such as Scotch Brite, wire wool or similar.

For cooking in pans, we recommend using only smooth flat-bottomed pans. Take care when

using cast-iron or rough bottom pans as they may leave marks, but a cloth soaked in vinegar will

remove these.

When cooking is finished, the heated area remains hot for a certain period of time. Take

care not to place your hands on it. Keep children at a safe distance.

Working:

- Touch the symbol

Electronic Module on and off.

- If the Module is on but no +/- sensors are activated, it automatically turns off after 10

seconds.

- If the heat selector is turned to "0", it automatically turns off

after 10 seconds.

- Touch the +/- sensors to select a heat level between 1 and 9.

- If a heat level is selected for just one area, the other area automatically turns off after 10

seconds if no level is selected for it.

- If just one heating area is activated, the other can be activated at any moment by

touching the +/- sensors.

- When a heating area is activated, pressing the +/- keys together can deactivate it.

to turn the

18

Page 19

- For additional safety, if a sensor is touched for more than 10 seconds all the heating

areas are automatically turned off.

- If a heating area is turned off and "H", appears on the display, it means that there is

residual heat in the area and you must be careful to avoid burns. The "H" symbols goes

out automatically when the residual heat has reduced sufficiently.

- Automatic heat push: At the beginning of the cooking cycle, the heating areas can be set

to the maximum level for a period of time calculated automatically by the Module in order

to reach the set cooking temperature as quickly as possible. The automatic heat push is

activated by touching the "+" sensor immediately after turning the Module on, and then

selecting the required output. A dot (•) appears alongside the set value. When the heat

push time is up, the dot disappears and the heating areas continue to work at the set

level at even temperatures.

- To avoid activating the automatic heat push, touch the "-" key after turning the Module

on. The selector will go to 4 automatically and the require output can then set. The

selected functions can be topped by touching the

sounds and a light illuminates each time you attempt to change the set levels. At this

point, the Electronic Module can be turned off, but the function stop is still enable. To

disable the function stop, touch the

3.8. FITTING THE FAT FILTER TO MULTIPLE-FUNCTION OVEN (fig. 20).

key again for a few seconds.

key for a few seconds. A buzzer

- Place tabs A-B in line with the holes in the fan cover A1-B1 at back of the oven.

- Press rod C so that the tabs fit perfectly into the holes A1-B1.

3.9. FITTING THE GAS BURNERS TO THE HOB

Burners: auxiliary, semi-rapid, rapid, super rapid:

To fit the burners, flame diffusers and the enamel burner caps correctly in the hob cups, follow

the sequence illustrated in fig. 21. Ensure that the cup burner guides and the burner flame

diffuser guides are matched perfectly.

Triple crown burner: fit the flame diffuser to the burner support so that it cannot rotate (fig. 22).

ATTENTION: the triple crown burner caps must alw ays sit perfectly in their seats. If they

are not, the flame may return inside and deform the burner by progressive overheating.

Griddle burner: fit the flame diffuser by placing the hole in the bottom part over the electronic

ignition candle in the hob cup (fig. 23).

3.10 TELESCOPIC RUNNERS (only for certain models)

The telescopic runners guarantee greater stability to the oven accessories. Placing the food on

the shelves or on the tray is easier and safer. The shelves and trays must be securely fitted into

their housing on the runners. We recommend using oven gloves during cooking or while the

oven is still hot.

Before cleaning turn off at the mains and leave the oven and burners to cool.

Clean the hob and oven after each use in order to prevent build-up of stubborn dirt that is difficult

to remove and may damage the surfaces.

To clean the stainless steel, enamelled, and glass parts and the control panel, we recommend

using a sponge or damp cloth with a non-abrasive cleaner. Do not use steel wool, abrasive

powders and corrosive substances that could scratch.

19

Page 20

To keep the internal enamelled parts shiny for a long time, they should be cleaned frequently with

warm soapy water. The grid guides and drip pan can be removed by unscrewing the

nuts/washers G (fig. 24) for more thorough cleaning. Refit the parts by placing the 2 P extensions

of the side guides in the holes F on the bottom of the oven; line up the 2 front eyelets of the

guides with the screws fitted to the sides, and then secure the guides with nuts/washers G. Do

not wash the oven when it is still hot and do not use abrasive substances or products.

Ensure that the enamelled surface does not come into prolonged contact with acid and alkaline

substances, such as: VINEGAR, COFFEE, MILK, SALT WATER, LEMON JUICE, TOMATO

JUICE, ETC.

To clean the inside of the oven door (according to the model):

a) open the oven door unfasten the two screws that secure the internal glass; then

remove the glass, paying attention to the sealing gasket.

b) for models with triple-glazed oven door, remove the top frame using a

screwdriver, as illustrated in fig.10A, and slide the glass out of the guides. Take

the utmost care when completing this action.

The burners, caps, and flame diffusers should be cleaned periodically with soapy water. Before

replacing them in their housing they should be dried carefully and check that the holes in the

flame diffusers are clear.

FIG. 1

FIG. 2

FIG. 3

20

Page 21

FIG. 4

FIG. 8

FIG. 5

FIG.6

FIG. 7

FIG. 9

21

Page 22

FIG. 10

FIG. 12

FIG. 10 A

FIG. 13 FIG. 14

FIG. 15

FIG..18

FIG..19

FIG. 20

22

Page 23

FIG. 21 FIG. 22

FIG. 23 FIG. 24

23

Page 24

I - Warranty

Porter&Charles products are designed and built to the highest standards.

We expect your appliances to provide many years of trouble free enjoyment.

In the event of an appliance requiring attention, each appliance is covered by a 2

year warranty from the date of purchase.

Refer to warranty policy for complete terms and conditions.

Coverage is for costs of parts and labor for appliances in capital cities &

metropolitan areas. We reserve the right to charge directly for handling

expenses outside the metropolitan region.

Porter&Charles products are supported by a national service support system.

Call our customer service department for attention.

Please retain your Porter&Charles invoice to quote should you require

service assistance. This will identify your product for our priority service

back-up. Please attach your invoice to this manual for easy future

reference.

PORTER & CHARLES INCORPORATION

2278 Speers Road

Oakville, Ontario, Canada, L6L 2X8

Telephone 1-800-421-6332

Telephone 905-829.3980

Facsimile 905-829.3985

For Service & Spares:

EURO-PARTS

1-800.678-8352

Important: Please record details of your purchase below and mail or fax to Porter & Charles as above :

--------------------------------------------------------------------------------------------cut along line ---------------------------------------------------------------------------------

Name: ________________________________ TEL No __________________________

Address:

______________________________________________________________________________

City : __________________________ State:_____________ Zip Code:_________________

Where purchased: _____________________________ Purchase date: ___________________

Items purchased:________________________________________________________________

Serial No. (s): _________________________________________________________________

Porter&Charles

24

Page 25

Porter & Charles

Porter & Charles Incorporated

Telephone – 800-421-6332

Telephone- 905-829-3980

Facsimile – 905-829-3985

25

Loading...

Loading...