Page 1

Congratulations on the purchase of your Porter&Charles appliance.

We are sure it will provide many years of great cooking experience.

You may find that it has different features and characteristics to your last

appliance.

It is essential you read this operation manual thoroughly to fully

understand all of the various functions and operations. Experiment with

your cooking and take advantage of the features your new appliance offers.

This manual should be retained for future reference. Should ownership of

the appliance be transferred, please ensure that the manual is also passed

onto the new owner.

Contents

A - Installation check and warnings Page 3-6

B - Accessories Page 7

C - Using the appliance for the first time Page 7

D- Electronic Programmer Operation Page 8-10

E- Gas Cooktop Control Panel Page 11

F- Gas Cooktop Functions Page 12

G- Ceramic Cooktop Control Panel Page 13

H- Ceramic Cooktop Control Functions Page 14

I- Oven Functions & Control Panel Page 15-22

L- Cleaning and maintenance Page 23-26

M- Trouble shooting guide Page 26

N- Installation instructions and measurements Page 27-28

O- Electrical wiring diagrams and instructions Page 29-31

L- Warranty Page 32

2

Page 2

A - Installation check and warnings

IMPORTANT:

Please ensure that the oven cavity, venting and wiring is as specified in the relevant

section G of this manual.

A licensed electrician with relevant qualifications must perform electrical work when installing or

servicing the appliance. The supply cable and fuse rating must be suitable for the appliance. You

must never repair or replace any part of the appliance unless specifically recommended in the

operation manual.

Ventilation opening must not be covered or obstructed in any way.

DO NOT use aluminum foil on the base of ovens

The use of foil on the base of the oven to avoid spillage and improve cleaning is not

recommended. The bottom element is concealed under the base of the oven liner (not exposed).

Foil or dishes with reflective qualities must never be placed on the base of the oven during

cooking as the concentration of direct and reflected heat will damage the enamel surface.

Damage resulting from such use is not covered under the provisions of the warranty.

Initial heat up

Some smoke and smell may be noticed during the initial heat up cycle. This should quickly

dissipate.

If abnormal levels of smoke are observed (i.e.: it is not food that is burning), have the appliance

thoroughly checked.

Don’t use the appliance as a space heater

The appliance must never be used for warming or heating the surrounding room. Combustible

materials must never be placed on or near the appliance.

Do not leave children alone

Children must not be left unsupervised in the area where the appliance is in use. Children must

never be allowed to sit or stand on any part of the appliance.

Wear proper apparel when using the appliance

Loose fitting, hanging or highly flammable garments (such as synthetics) should never be worn

while using the appliance.

Use only dry pot holders

Moist or damp pot holders on hot surfaces may result in burns from steam. Do not allow pot

holder to touch hot heating elements. Do not use a towel or bulky cloth when handling hot

cooking utensils in the appliance.

Oven compartments must never be used for storage

Items, particularly flammable materials, must never be stored in an oven or near surface units.

Do not use water on grease fires

3

Page 3

Fires or flame should be smothered using flameproof material or extinguished using a dry

e

.

chemical or other suitable fire retardant.

IMPORTANT:

Please ensure that the cavity, venting and wiring is as specified in the relevant section J of

this manual.

A licensed electrician with relevant qualifications must perform electrical work when installing or

servicing the appliance. The supply cable and fuse rating must be suitable for the appliance. You

must never repair or replace any part of the appliance unless specifically recommended in the

operation manual.

Ventilation opening must not be covered or obstructed in any way.

VENTILATION

The room containing this cooker should have an air supply in accordance with local regulations.

- All rooms require an open window, or equivalent and some rooms will require a

permanent vent as well.

- For room areas up to 5 m

- For room areas between 5 m

- If the room is greater than 5 m

2

an air vent of 100 cm2 is required.

2

and 100 cm2 an air vent of 50 cm2 is required.

2

and has a door that opens directly to the outside, then no

air vent is required.

- If there are other fuel burning appliances in the same room local regulations should be

consulted to determine the air vent requirements.

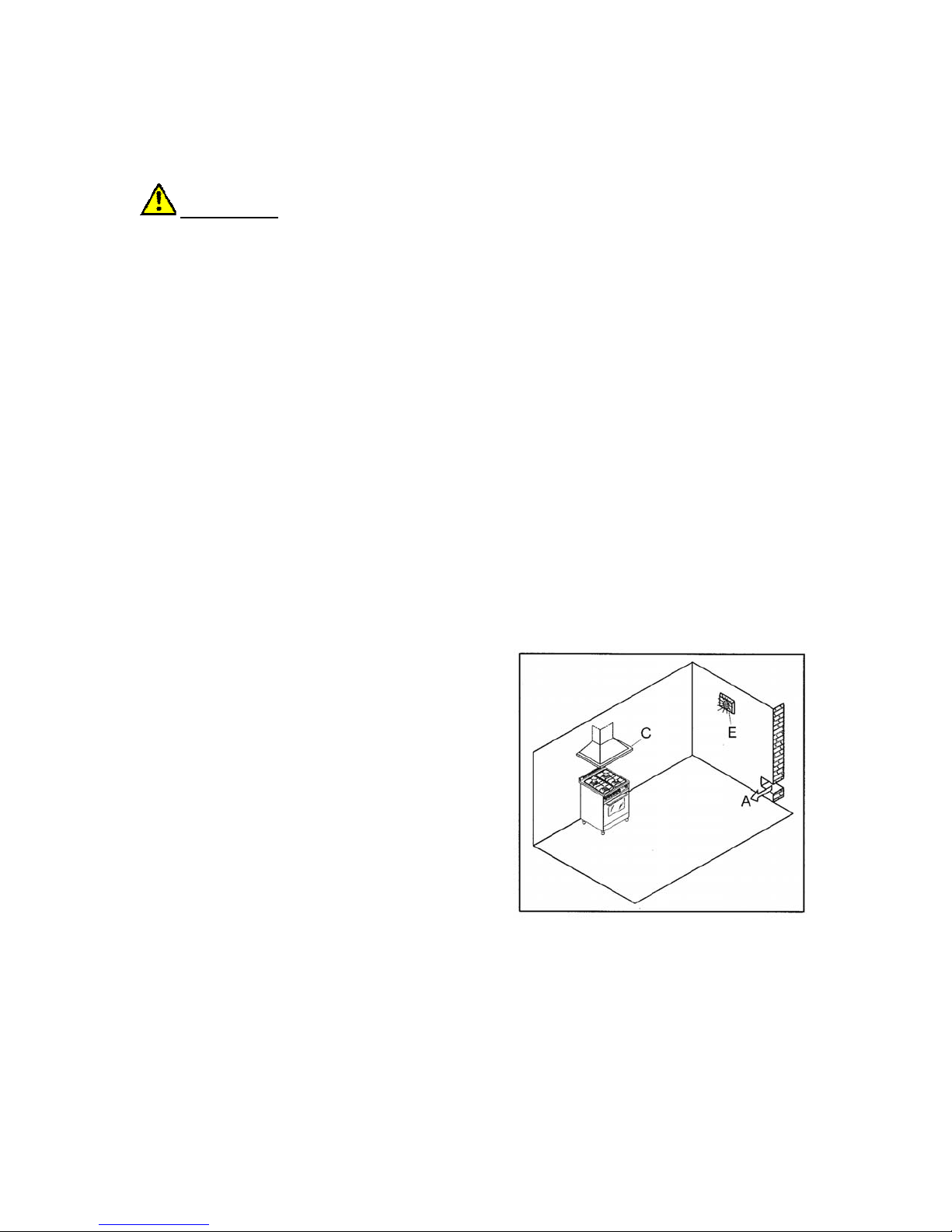

DISCHARGE OF FUEL GASE S

Cooking appliances must always discharge the flu

gases into special hoods (fig.1-C), which must be

connected to chimneys, flue pipes or have direct

access to the outside. If it is not possible to connect

a hood, an electric fan can be fitted to a window or

a wall (fig.1-E), which must be turned on when the

cooker is on, as long as ventilation standards are

strictly adhered to

Fig.1

RECOMMENDED VENTILATION HEIGHT

- for ceramic cooktop model min. 24” above range

- for gas cooktop model min. 30” above range

When ranges are installed in close proximity to vinyl finish cabinets,

those materials should be able to withstand temperature up to 75°C centigrade.

Alternatively, heat insulating barriers should be installed to avoid any

deterioration to the finish.

The equipment must not be installed near inflammable materials, such as curtains, cloths etc.

4

Page 4

Pay particular attention to the position of the electric cable and gas pipe: they must

not touch any hot parts of the oven

The manufacturer will not accept responsability for damages to cabinetry where

manufacturer installation guidelines were not adhered to.

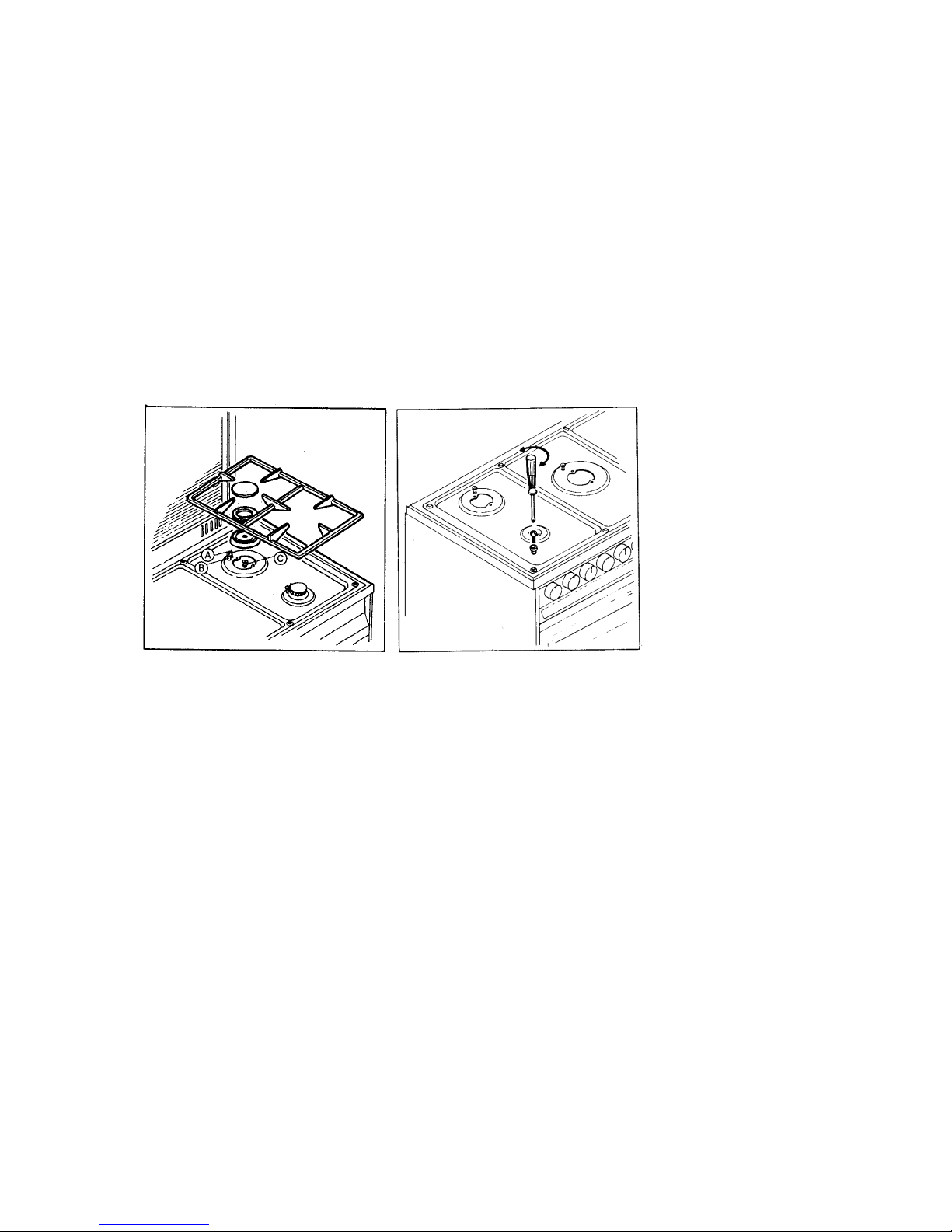

CONVERTING THE GAS-SUPPLY TO THE HOB BURNERS

Burners: auxiliary, semi-rapid, rapid, triple crown, griddle burner.

These burners are all fitted with injectors designed to create a primary input of air gauged for

each type of gas. This means that the air regulator does not have to be regulated. Proceed as

follows in order to convert from one type of gas to another: remove the grids, covers, holed flame

diffuser and the burner supports (fig. 7); replace the holed injectors as indicated in 7/C according

to the type of gas used (see table 1); put the burner supports, flame diffusers, covers and grids

back in position; regulate the minimum output following the instructions in paragraph

Fig.7 7/C

REGULATING THE MINIMUM OUTPUT OF THE HOB BURNERS

Normal/valve taps:

Ignite the burners and turn the knob to the maximum position. Remove the knob and insert a

small flat-head screwdriver into the rod or through the holes on the side of the control panel, in

accordance with the type (fig. 8 A/B). Loosen the by-pass screw by two turns in an anti-clockwise

direction and rotate the rod to the minimum position. Adjust the previously loosened screws until

the flame is lowered but stable, even when rapid changes are made from the maximum to the

minimum position with the burner cold. If safety taps are fitted, let the burner run on minimum for

a few minutes to ensure that the device does not cut in. If it does, increase the minimum.

N.B. For liquid gas settings, the burner minimum must be set by fully tightening the tap

by-passes.

5

Page 5

Fig.8

WARNINGS:

- If the burner flames accidentally go out, turn off the KNOB and wait for at least one minute

before igniting.

- Using a gas cooker produces heat and humidity in the room where it is installed. Ensure the

room is well ventilated by keeping all the natural air vents open or by installing an extraction

hood with flue pipe.

- Intensive or extensive use of the cooker may require supplementary ventilation e.g. opening

a window, or more efficient ventilation e.g. increasing the capacity of the mechanic

ventilation, if installed.

N.B. When the burners are alight, there must not be any draughts inside the room in

that they may affect the flame or even blow it out. (PLEASE NOTE: The fixing hook is

not provided as the type will depend on the construction of the wall to which it will be

drilled and fitted. The installer should provide the fixing hook per customer request).

DO NOT use aluminum foil on the base of ovens

The use of foil on the base of the oven to avoid spillage and improve cleaning is not

recommended. The bottom element is concealed under the base of the oven liner (not exposed).

Foil or dishes with reflective qualities must never be placed on the base of the oven during

cooking as the concentration of direct and reflected heat will damage the enamel surface.

NOTE

Damage resulting from such use is not covered under the provisions of the warranty.

6

Page 6

B - Accessories

Your appliance should come equipped with the following items.

1 x pair of Retractable Slide Runners fitted to upper position and capable of being moved

to any selected position as required

1 x Deep Enameled Roasting Pan with dual height reversible Grill Rack insert – ready for

sliding into side rack positions or fitting onto Retractable Slide Runners

2 x Wire Oven Shelves that can be fitted into Retractable Slide Runners or for sliding into

side rack positions

Note: Additional Retractable Slide Runners are available as an optional extra and can be

fitted at any time

Note: Additional oven shelves and pans are available as optional extras.

C - Using the appliance for the first time

After installation remove all notification labels (not identification or warning labels) and packaging

materials. After cleaning make sure cleaned surfaces are thoroughly rinsed a nd wiped dry using a

clean, soft cloth.

Power on

NOTE: oven will not operate unless time clock is set the

When power is first applied the display will flash and shows 00:00.

The time of day is displayed in digital 24 hours format (e.g.: 18:00 is 6:00 pm). Press the reset

button to select manual mode and set clock as describe in section C.

Burning in

Before cooking in the appliance an initial pre-heating is required to burn off the fine oil film used to

protect the elements for shipping. The first time you heat up the oven (or grill) the oil will be given

off as smoke, which is perfectly normal.

Select a cooking mode and set the oven temperature to 180°C. With the oven door closed, leave

for approximately 5 minutes.

Repeat the above step for each cooking mode.

After completing the above make sure all controls are turned off. The oven is now ready for

cooking and grilling.

7

Page 7

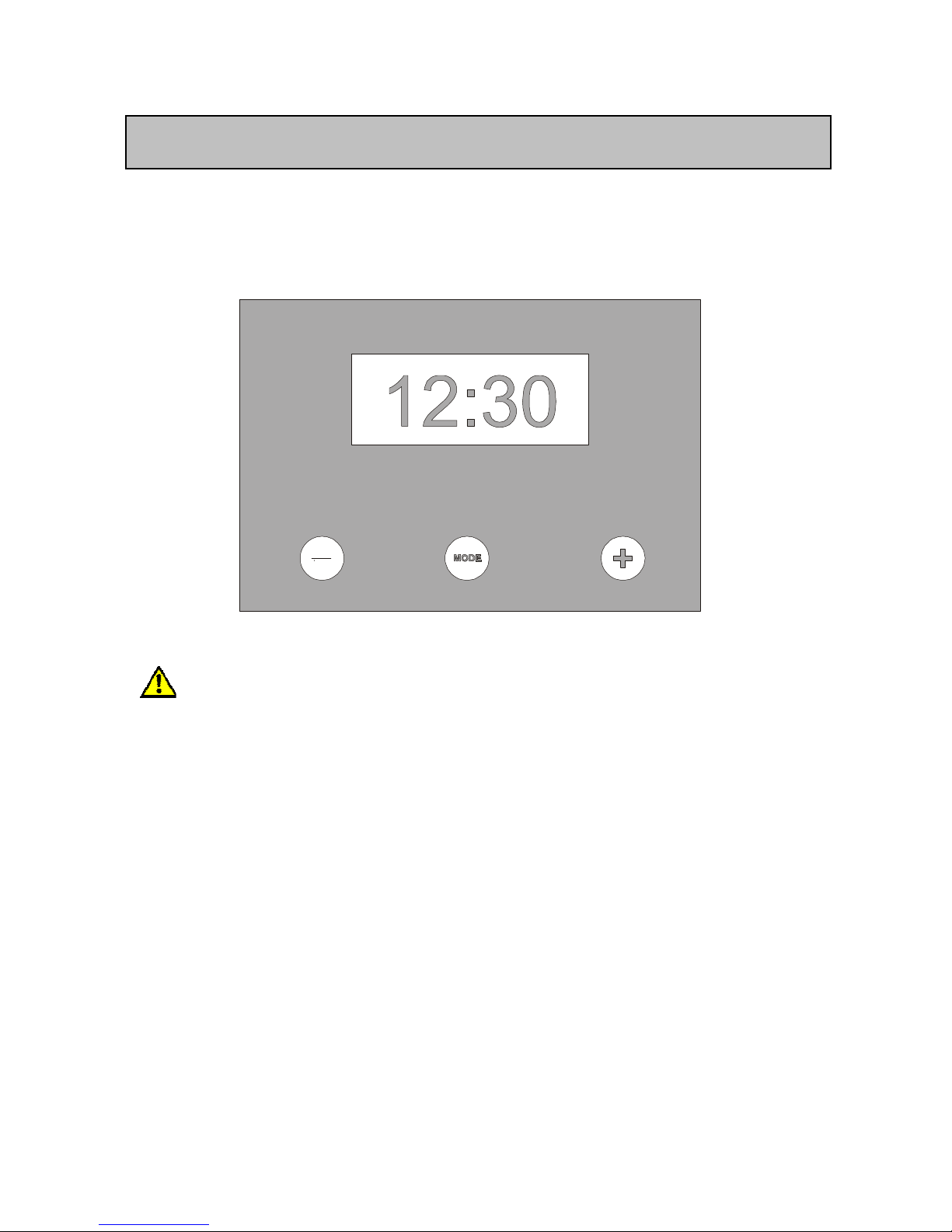

D - Electronic Programmer Operation

The 24 hour clock allows the setting of automatic cooking options up to 24 hours in

advance.

1 - Minus Time Button

2 Mode (Countdown Timer with Alarm, Cooking duration, Finish Cooking)

3 + Plus Time Button

Setting the time on the 24 hour clock

IMPORTANT – NOTE FOR NEW INSTALLATION AND FIRST OPERATION

1- The clock will require setting when you first turn on the power (or following a power

failure).

2- At power on, the relay contact is opened. The display and AUTO symbol flashes and

time of day starts from 0:00.

3- Press PLUS and MINUS button simultaneously for minimum 3 seconds. The AUTO

symbol goes out, POT symbol goes on the DOT is flashing. With the PLUS button the

time will advance slowly, and then speed up. If you over-shoot the desired time , use the

MINUS button)

4- Press the MODE button to select the time of day setting mode. The DOT will be

Conventional Oven

5- The oven is now ready for use and to accept the selected cooking functions

6- The timer can be set for countdown up to 24 hours and for automatic cooking mo des up

to 10 hours and will countdown to zero. When zero is reached the alarm will sound.

7- To set the countdown timer

8- Press the MODE button for minimum 3 seconds. The BELL symbol is flashing and the

display shows 0:00. Using the PLUS button advance the timer to the desired time.

9- Once the countdown timer is set, the normal time of day will return to the display within 7

seconds. If you wish to check how muc h time remains on the countdown, press the

10- MODE button for 3 seconds. The remaining time will be displayed. After 7 seconds the

normal time will return to the display.

11- To silence the alarm press the MODE button for minimum 4 seconds

8

Page 8

Adjusting the tone of the electronic timer alarm.

The tone is adjusted simply by pressing the minus button. There are 3 different tones from which

you can select. To change the tone you press the “+” and “-“ simultaneously, then press the Mode

button, ton will be displayed. Pressing the “-“ button while ton is in the display,will change the tone

to the desired setting

The electronic timer will store in its memory the last tone activated

Manual cooking

Once the time of day is set the POT symbol will be displayed. The oven is now in manual

operation mode ready for you to select the desired cooking function and temperature

Automatic cooking modes (Based on setting the duration “DUR”)

Set function and temperature to the desired position

For example: if you wish to cook for 45 minutes. Press the MODE button minimum for 4 seconds.

Press the MODE button again. The AUTO symbol is flashing and the display shows “dur”. The

display automatically switches over between "dur" display and 0:00. During this time you can set

the duration time of 45 minutes by pressing the PLUS button (use MINUS button should you overshoot the required time). Release and the display will return to the normal time of day after 7

seconds. The AUTO symbol will also appear indicating that you have set the automatic cooking

function.

The oven will operate for 45 minutes only, turn off automatically and the alarm will sound. The

AUTO symbol is flashing and the POT symbol will disappear. The alarm will turn off after pressing

the MODE button.

If you hold the MODE button down longer than 4 seconds the oven will return to the normal

cooking mode.

If further cooking is required, either leave on manual or repeat the above setting sequen ce.

Note: If you have not turned the function and thermostat setting off, your oven will now continue

to operate manually. The AUTO symbol will disappear and the POT symbol will reappear.

Based on setting a cook stop time

1 Set the function and thermostat control to the desired position

2 For example: if you commence cooking and decide you would like the oven to turn off at

6.00pm. Press the MODE button minimum for 4 seconds. Press the MODE button two

times again. The AUTO symbol is flashing and the display shows “End”. The display

automatically switches over between "End" and time of day. During this time you can set

the cooking stop time to 6.00pm, i.e.18:00 on the 24 hour clock, by pressing the PLUS

button (use MINUS button should you over-shoot the required time). Release and the

display will return to the normal time of day after 7 seconds. The AUTO symbol will also

appear indicating that you have set the automatic cooking function.

3 The oven will continue to cook until 18:00 (6.00pm) and then switch off and the alarm will

sound. The AUTO symbol is flashing and the POT symbol will disappear. The alarm will

turn off after pressing the MODE button.

4 If you hold the MODE button pressed longer then 4 seconds the oven will return to the

normal cooking mode.

If further cooking is required, either leave on manual or repeat the above setting sequen ce.

9

Page 9

Note: If you have not turned the function and thermostat setting off, your oven will now continue

to operate manually. The AUTO symbol will disappear and the POT symbol will reappear.

Fully automatic – (Start Later – Stop Later)

Your oven may be programmed to start, cook for the desired time and turn off automatically.

This function is particularly useful in the preparation of the evening meal, should you be out

during the day, it will be ready on your return home. For example if your cooking time is 45

minutes and you want the cooking to finish at 6.00 p.m.

Press the MODE button minimum for 4 seconds. Press the MODE button again. Set the cooking

duration time for say 45 minutes using the PLUS or MINUS button.

Press the MODE button again. Set the stop cooking time to 6.00pm (18:00). Release and the

display will return to the normal time of day after 7 seconds. The AUTO symbol will be displayed.

Using the above settings, the oven is now programmed automatically to commence cooki ng 45

minutes prior to 6.00 pm. Then automatically turn off.

When cooking is complete the AUTO symbol is flashing and the POT symbol will disappear and

the alarm will sound. The alarm will turn off after pressing the MODE button.

If you hold the MODE button pressed longer then 4 seconds the oven will return to the normal

cooking mode.

Canceling automatic settings

To cancel a program:

Press plus and minus button simultaneously for minimum 3 seconds.

NOTE:

On oven start up or possibly at other times, due to electricity supply deviations – the

programmer may freeze on a function – if this occurs we recommend that, after checking

other solutions without success, it is recommended that power supply be disconnected to

the appliance and allow it to be in this position for some minutes before reconnecting.

This may have a result of clearing the frozen position allowing you to reset the

programmer for normal operation.

Cooling Fan

The Ovens are provided with a cooling fan motor to reduce the heat around the oven. The fan

motor is controlled by a sensor, which will start when the temperature achieves the level pre-fixed

and stop working when the temperature is reduced accordingly.

This safeguards both the oven and the adjoining cupboards from the possibility of temperature

damage.

Safety Thermostat

Your oven is fitted with an over temperature sensor that will automatically shut down your oven

for a period if it is deemed to be overheating- this sensor is fitted to the rear wall of the oven,

inside the outer case – it will only activate in extreme circumstances and is provided as protection

to the appliance and the adjoining furnishings. If activated it will shut down the appliance for a

short time and will automatically reset allowing normal operations – you should consult your

service technician if the problem re-occurs.

10

Page 10

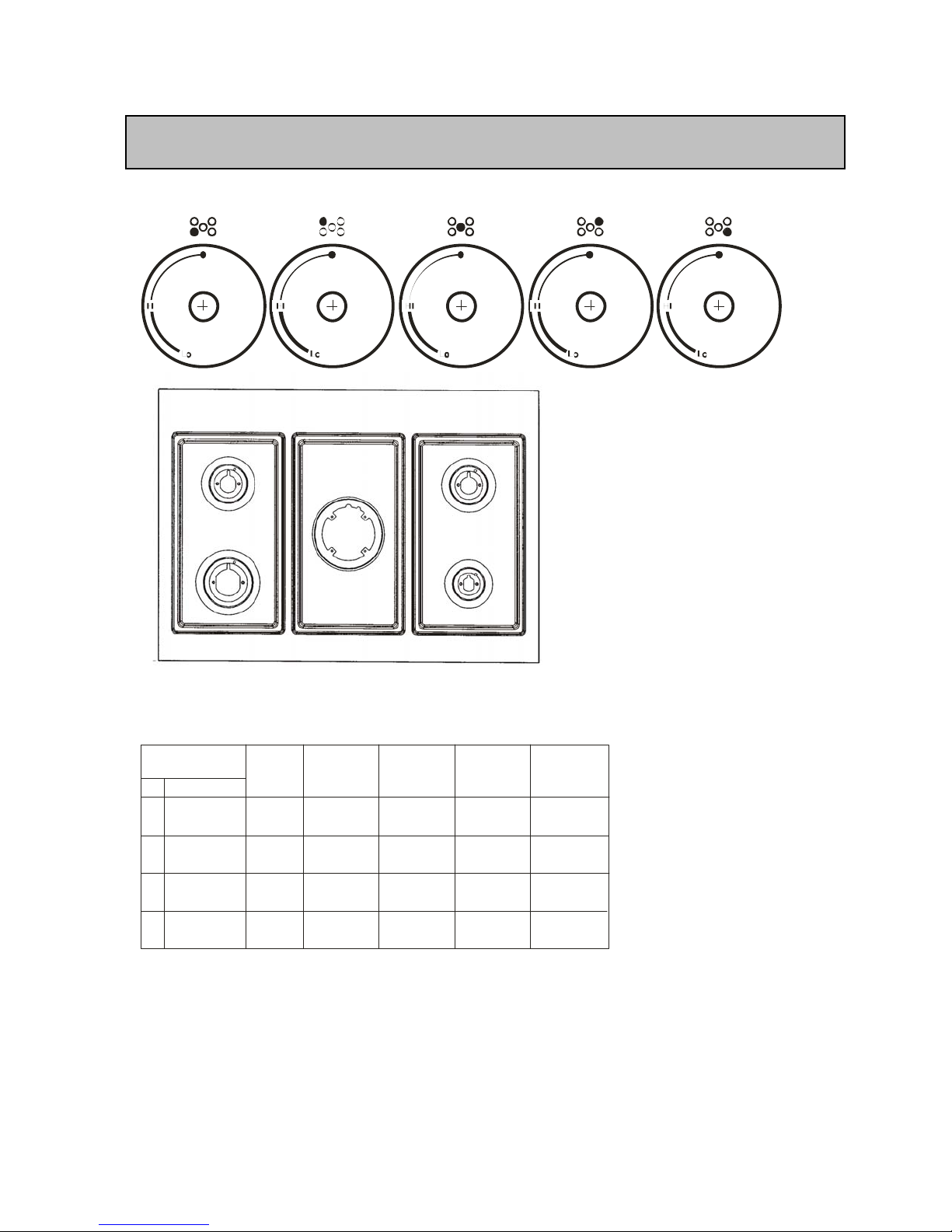

E - Gas Cooktop Control Panel

4

1

1

2

1= semirapid burner 2= rapid burner

3=auxiliary burner 4= wok burner

Technical Characteristic table

BURNERS

N° DESCRIPTION

1 SEMI-RAPID

2 RAPID

3 AUXILIAR Y

4 WOK

GAS

PROPANE 28 72 35

6.3(6000)

NATURAL 10 118 REG.

PROPANE 28 92 46

10.5(10000)

NATURAL 10 155 REG

PROPANE 28 55 35

3.7(3500)

NATURAL 10 90 REG.

PROPANE 28 105 65

13.7(12000)

NATURAL 10 160 REG.

NORMAL

PRESSURE

mbar

Table 1

INJECTOR

DIAMETER

1/100 mm

3

TAP BY PASS

DIAMETER

1/100mm

NOMINAL

HEAT INPUT

MAX.

MJ/h(bTU/H)

11

Page 11

F - Gas Cooktop Functions

B - Cooking Instructions

Automatic start-up with valves

Turn the corresponding knob anticlockwise up to the maximum position and press the knob.

Once the burner has been started up, keep the knob pressed for about 6 seconds.

Using the burners

In order to obtain the maximum yield without wasting gas, it is important that the diameter of

the pot is suitable for the burner potential (see the following table and fig.1). This is to avoid the

flame extremities being larger than the base of the pot. All of the operating positions must be

chosen between the maximum and the minimum ones, never between the minimum position and

the closing point.

The gas supply can be interrupted by turning the knob clockwise up to the closing position.

NOTE:

If there is no power supply, it is possible to light the burners with matches, setting the knob to the

startup

point (large flame, fig. 1).

BURNERS

Auxiliary 3.2

Semi-rapid 6.3

Rapid 11.6

Wok 17.9

NOTE:

When the equipment is switched off, always check that the knobs are in the closing position.

If the flame should blow out accidentally, the safety valve will automatically stop the gas supply,

after a few seconds. To restore operation, set the knob to the lighting point and press. While

cooking with fat or oil, pay the utmost attention as these substances can catch fire when

overheated.

WARNING:

-Do not use sprays near the appliance in operation.

-Do not place unstable or deformed pots on the burner, so as to prevent them from overturning or

overflowing.

-Always turn gas off if moving a pot away from the appliance

.

POWER (MJ/h)

POWER (Btu/h)

3000

6000

11000

17000

Ø of pots

10 - 14 cm

16 - 18 cm

20 - 22 cm

24 - 26 cm

12

Page 12

G - Ceramic Cooktop Control Panel

Ceramic Cooktop Controls:

Switch control ling

the left, front

Turning the knob cl ockwis e

activates the full hot plate.

Switch controlling the left,

back hot plate.

To operate Single (inner zone) and separate Dual (inner + outer zone) follow

this procedure:

a/ Inner Zone

The inner zone only will operate.

- rotate control knob in clockwise direction selecting power from positions 1 through 12.

Switch controlling

the right, back

hot plate.

Turning the knob clockwise

activates the full hot plate.

Switch controlling

the right, front

hot plate.

b/ Inner + Outer Zone = Full Power

through to the Dot on control panel only - a click will sound (do not Rotate control knob

- rotate control knob clockwise through position 12 as above, then

all the way to

OFF position as this will turn power OFF). Then rotate control knob backwards (anticlockwise) selecting

power level from 1 to 12 as before. This will activate both Inner and Outer zones concurrently for

maximum power.

c/ To deactivate (turn off)

Inner Zone or Inner + Outer Zone the control knob must be returned to the OFF

position

Important Note:

1/ DO NOT TURN CONTROL KNOB ANTICLOCKWISE FROM OFF

POSITION AS THIS

WILL DAMAGE THE CONTROL MECHANISM - OPERATE SINGLE AND DUAL ZONES

STRICTLY ACCORDING TO THE INSTRUCTIONS AS ABOVE.

13

Page 13

H - Ceramic Cooktop Functions

WARNING

All operations relative to installation and electric connection should be carried out by qualified

personnel in conformity with the regulations in force in your country.

The specific instructions are described in the booklet section for the installer

NOTICE

Use only flat pans with a sufficiently thick base, equal to or not much larger than the hot plate

selected (fig.1)

The containers should not have rough bottoms in order to avoid scratching the heat surface

of the top.

Do not switch the electric plate on without the pan over the plate.

Do not cook any food directly on the hot area. Avoid overflows of liquid and should they occur

clean away promptly.

Turn off the plate few minutes before the cooking end.

Switching on

Set the power by rotating the knob, taking into consideration that the highest number corresponds

with the maximum power.

The pilot light is switched ON when at least one element is on. The residual heat indicator will

light up when the temperature in any area is higher than 50OC.

Cleaning

Remove leftover and grease or spillage from the cooking surface with the special scraper (fig.3)

(optional).

Then clean the heating area thoroughly with a paper towel and ceramic cleaning products fo r the

correct care of your appliance. Never use abrasive sponge or irritating chemical detergents such

as over spray or spot removers.

14

Page 14

I - Oven Functions & Control Panel

Control Panel:

50

100

230

200

150

Warming Drawer & continuous warm function of main oven:

19 : 05

MODE

This switch controls the warming This switch controls the warming

element in the oven (200 Watt) drawer (200 Watt)

15

Page 15

The warming drawer and warming element of the main oven heats continuously until it reaches

75 Degrees C and this temperature will be maintained throughout the warming process as

required.

PREHEATING

Preheating the oven is not essential, but you will achieve better results if you do. Some foods,

particularly cakes and pastry, are better cooked in a preheated oven. Other foods, for example

casseroles, cook just as well when cooked in a non-preheated oven but may need longer cooking

times.

For faster preheating select pizza mode and the required temperature and on ce the oven has

reached the required level change to cooking mode/function for the task.

To preheat the oven:

1- Set the mode required for preheating.

2- Set the oven to the desired temperature.

Preheating guide (for 180°C settings)

Cooking Mode Preheat Time

CONVENTIONAL

15-20 MINUTES

OVEN

FAN OVEN 15-20 MINUTES

NOTE:

Any food or other cooking utensils placed in the oven during preheating will affect the preheating

time. The preheat time may also vary with installations.

WARNING

When using an alternative cooking mode for fast preheat, be sure to turn the cooking mode to

your required setting before placing food in the oven.

HINT:

To allow for heat loss while placing food into the oven, preheat the oven 10-20°C higher and then

reduce the temperature to your required cooking temperature.

Always preheat the oven when cooking multiple dishes at the same time.

Roasting guide. These cooking charts are intended as a guide only. Temperatu re and cooking

times may vary to suit individual tastes.

Type of Meat

Approx. 450 grams =

Cuts of Meat Time per lb

(allow)

Oven Temperature

0

C

1lb

Beef Prime Rib, rolled

sirloin bolar blade,

Top Loin, New York

60 minutes per 2lbs

40 minutes per 2lbs

1800 – 2000

0

- 2000

180

Strip Sirloin

Veal Shoulder or leg (with

bone or rolled)

40-50 minutes per

2lbs.

1800 - 2000

Lamb Leg, shoulder (loin or 40-50 minutes per 1800 - 2000

16

Page 16

rolled) 2lbs

Pork Leg loin 90 minutes per 2lbs. 2200-2300 / 1800-2000

Pork leg should be cooked at a higher temperature for the first 15-25 minutes then reduced to

lower temperature for remaining cooking time.

Type of Poultry Size of Meat Time per lb Oven Temperature

0

C

Chicken Whole or pieces 30 minutes per lb. 1800 - 2000

Duck 3lbs – 4.1lbs 30 minutes per lb.

1800 - 2000

+ 35 minutes extra

Turkey 5.4lbs – 21lbs 40-50 minutes per lb.

1800 - 2000

+ 35 minutes extra

Turkey should be well basted and turned during cooking

Type of Fish Cuts of Fish Time per lb Oven Temperature

0

C

Fish Whole or fillets 10 minutes per lb. 170-1900C

In Conventional Oven mode, fish should be covered for the first ¾ of the cooking time to help

retain moisture.

Baking guide. These cooking charts are intended as a guide only. Temperature and cooking

times may vary to suit individual tastes.

Oven Temperature

0

C General Times Foods Suitable

1300 – under Very slow Small meringues, pavlova, custard, reheating

1300 - 1500 Slow Rich fruit cake, light fruit cake

1500 - 1800 Moderate Casseroles, deep butter cake

1800 - 2000 Moderately hot Shallow butter cakes, sponges, biscuits, meat loaf,

baked fish

2000 - 2300 Hot Swiss roll, patty cakes, rock cakes, short crust pastry

2300 – and over Very Hot Scones, Choux pastry

17

Page 17

PIZZA

This function is also excellent as the fastest oven pre heat, engaging maximum power to heat the

oven to a selected temperature before selecting an appropriate function and temperature for a

task.

In this position the fan and fan element together with the under oven element are engaged

simultaneously. This is used for food that requires a concentration of cooking to the base, and

allows the top to gently cook at the same time.

For best results for pizza and similar items we recommend this fun ction an d may be combined

with our optional pizza stone for perfect outcomes.

STEAM CLEAN

CLEAN

Traditionally, oven enamels have been porous. This creates a surface that, over time, collect s

microscopic oil and grime deposits that build up within these pores and become nearly impossible

to remove.

Thanks to some of the latest technology, we have revolutionary new enamel which is much less

porous than predecessors and creates a surface that has glass-like characteristics.

Added to this breakthrough technology, we have incorporated a new compon ent into the enamel

that is non-stick. The two together creates a surface that is brilliantly effective and easy to clean.

To assist with easy cleaning, Porter and Charles have developed a Steam Clean function. Not

only is this environmentally friendly, it is also less severe on the oven surfaces as no harsh

chemicals are used. In addition to this, the power consumption normally needed by a traditional

Pyrolytic Oven have been minimized to reduce unnecessary energy use. This new enamel is also

acid resistant which ensures that stains around the walls of the oven liner are minimized, and

particularly if the new Steam Clean function is used regularly.

If the following simple Steam Cleaning procedure is adopted regularly, your oven should remain

in original condition for many years.

To activate Steam Cleaning follow these simple steps:

1. Remove the oven shelves and fittings. You can wash these either in your dishwasher

or by hand.

2. Add approximately ½ a litre (1 Pint) of clean water to an oven safe dish and place

either on the bottom of the oven or on the lowest rack.

3. Close the oven door and select the Clean function on the Mode selector.

4. Select Clean on the Temperature Selector

5. Run the oven in this mode for approximately 30 minutes (set timer if preferred to

remind)

18

Page 18

6. After 30 minutes of steaming, turn both the Clean Mode selection and Clean

Temperature selection off and wait for 5 to 10 minutes for oven to cool to a safe

temperature for you to access it.

7. With a warm damp cloth, simply wipe out grease from inside the oven. You should

apply a small amount of dish washing liquid to this cloth for further efficiency. It will

be noted that most grime has congregated on the base of the oven and is easily

wiped away.

8. Return all oven fittings.

NOTE: If stubborn stains remain after Steam Clean apply Ceramic Cooktop

Cleaner/Polish.

CONVENTIONAL OVEN

In this traditional mode, oven heat is provided from the top and under the oven compartment and

is most suitable when cooking on a single shelf. For best results, arrange the sh elves so the top

of the food is near the centre of the oven.

If cooking on more than one shelf, always preheat the oven and position the pans to allow as

much free circulation of heat as possible.

Depending on the food, you may need to rearrange the tray position during cooking.

1- Adjust oven shelves to desired position/s.

2- Select Conventional Oven mode.

3- Set the oven to the desired temperature.

4- When cooking is complete turn the oven off.

HINT:

If water is used in your cooking (such as water placed in a baking dish) the water will evaporate in

the oven in the form of steam. The level of condensation will be reduced when cooking in fan

oven mode where excess moisture is circulated and evaporates during the coo king cycle.

NOTE:

Stand clear of the oven when opening the oven door as steam may escape rapidly

FAN ASSIST (bottom of double oven)

This style of cooking provides traditional cooking heating from top and bottom elements with the

assistance of a circulation fan to ensure fast even results. This mode is most suitable for delicate

cooking such as cakes, pastries, gateaux, biscuits and yeast dough. Best results when

thermostat is set to 150-180 degrees – depending on recipe.

19

Page 19

CLASSIC BAKE (bottom of double oven)

In this mode, oven heat is provided from under the oven compartment. This is most suitable for

cooking food which requires a well cooked base or where minimal browning is required.

1- Adjust oven shelves to desired position/s.

2- Select CLASSIC BAKE.

3- Set the oven to the desired temperature.

4- When cooking is complete turn the oven off.

HIGH BAKE

The HIGH BAKE mode uses the oven fan to circulate air with heat from the under oven element.

Quick and consistent heat is evenly distributed throughout the oven.

The results are quick, not unlike a microwave oven. With the circulation of heat, foods cooked

with high bake mode retain a crisp, dry texture on the outside especially pizza, pastry and other

foods where you want the base to be well cooked. HIGH BAKE is also excellent for re-heating.

1- Adjust oven shelves to desired position/s.

2- Select HIGH BAKE mode.

3- Set the oven to the desired temperature.

4- When cooking is complete turn the oven off.

FAN FORCED CONVECTION – most commonly used function

In this mode the oven fan circulates heat from behind the fan cover to give a more even

temperature throughout the oven. The even heat provides similar cooking results for each portion

of food. Although temperatures for cooking foods in this type of oven are generally the same as

required by a conventional oven, when cooking foods that require lengthy cooking cycles a fan

forced oven normally cooks more quickly, saving time and energy.

Always place the food as near to the centre of the oven as possible. If cooking on more than one

level, arrange the pan positions to allow for free circulation of heat.

1- Adjust oven shelves to desired position/s.

2- Select FAN OVEN mode.

3- Set the oven to the desired temperature.

4- When the cooking is complete turn the oven off.

HINT:

Always preheat the oven when cooking on multiple shelves at the same time.

20

Page 20

Depending on the food, you may need to rearrange the tray positions during cooking.

FAN GRILL

NOTE: Door must be closed in Fan Grill Mode

Fan grilling is a combination of direct heat and circulated hot air which gives the appearance and

flavor similar to rotisserie cooking which is ideal for single level roasts. Direct infrared heat from

the grill element is circulated by the fan to cook the food, which should be positioned as near to

the centre of the oven as possible.

For best cooking results, it is recommended that food be turned once only.

1- Oven door must be closed

in Fan grill mode.

2- Place food on grill rack and pan supplied (ensure grill rack is inverted to the high position

to allow best circulation of air) as close to the centre of the oven as possible.

3- Select FAN GRILL mode.

4- Set the oven to the desired temperature. (see note below and refer to FAN GRILL

temperature guide).

5- When cooking is complete turn the oven off.

NOTE:

Large grill pans or roasting dishes can restrict the circulation of air in the oven. To prevent

moisture condensing in the cooler lower sections of the oven, preheat the oven for approximately

10 minutes, using CONVENTIONAL OVEN or HIGH BAKE modes, prior to fan grilling.

NOTE: The temperature setting in FAN GRILL mode must not exceed 200°C. The grill

element has a safety shutdown at approximately 200°C.

Fan grill guide

These cooking charts are intended as a guide only. Temperatures and cooking times may vary to

suit individual tastes.

Type of meat/poultry/fish Oven Temperature

Chicken – whole

pieces

Lamb - loin/rack

Chops - medium/rare

Chops – medium

Beef- Steak – rare

Steak – medium

Steak – well done

Pork Chops – medium/rare

Chops - medium

Chops – well done

Sausages- thin

thick

Fish fillets

Sliced vegetables

Tomato halves

Crumb Based dishes

1750 - 185

1850 - 1950

1750 - 185

1750 - 185

1750 - 1850

1750 - 185

1750 - 185

1750 - 185

1900 - 200

1750 - 185

1750 - 185

1750 - 185

1750 - 185

1750 - 185

1800 - 190

1900 - 2000

175

0

- 185

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

C Approximate Cooking Time

30 minutes per lb

15-20 minutes

25 minutes per lb

10-12 minutes

14-16 minutes

6-8 minutes

8-12 minutes

12-15 minutes

6-10 minutes

10-12 minutes

12-15 minutes

8-10 minutes

12-14 minutes

10-14 minutes

20-30 minutes

6-8 minutes

20-30 minutes

21

Page 21

Pasta dishes 1750 - 1850 20-30 minutes

FULL GRILL & HALF GRILL

This mode of cooking uses infrared heat from the top of the oven to cook foods to your

requirements. Half grill engages only the inner band of the top element and is sui t able for smaller

volumes and has a consequently lower energy usage.

This method of grilling in the oven is recommended for short duration (5 minutes or less)

grilling only, which is ideal for toasting (see note below). Foods with higher fat content or

foods, which require more than 5 minutes grilling time, should be grilled using the FAN

GRILL mode.

When in GRILL mode the oven door should be closed. If the door is not closed, over time

discoloration to the control panel may occur.

1- Commence grilling from a cold oven whenever possible.

2- Place food on grill rack and pan supplied.

3- Position the shelf to your preference.

4- Select GRILL mode and, turn to your desired heat setting.

5- When cooking is complete turn the oven off.

NOTE:

The grill element is controlled by the oven thermostat. Once the temperature in the oven has

reached the selected temperature the element will switch off, and then on again, when more heat

is required.

DEFROST

All foods may be defrosted using the Fan Forced Convection mode. It is important to note

that NO

As a general guide, the defrosting time for meat is approximately 15-20 minutes per

kilogram.

temperature (0 Degrees) is selected when using this function.

22

Page 22

L - Cleaning and Maintenance

NOTE: Your Porter&Charles oven comes with a Steam Clean function, please refer

to pages 18-19 for further instructions.

1. Cleaning and maintenance

Proper cleaning and care of your appliance is essential to maintain its appearance and durability.

NOTE:

People with sensitivity to cleaning chemicals must take the necessary precautions. It is

recommended that protective gloves be worn while cleaning the appliance. Routine cleaning of

the appliance should only be performed when the appliance is at room temperature.

Do not use any acid or caustic cleaners, abrasive powders or scourers on the interior or

exterior of the appliance. Substances or items with these properties may discolor or damage

the finishes of your appliance. If any abrasive, acidic or caustic substance or cleaning agent

should come into contact with the appliance, rinse off immediately with water, taking special care

to avoid injury if surfaces are hot.

When using the appliance, it may be soiled by food spills and spatters or foreign items such as

plastics accidentally coming into contact with warm or hot surfaces. Foods which contain acidic

substances or sugar can discolor or damage enamel finishes.

The enamel interior of the oven is a hard durable finish which is resistant to wear and

discoloration. However, to maintain the appearance and durability of the finish any spills must be

wiped off immediately. This should be done even if still hot and necessary precaution must be

taken to avoid injury. Once cool the affected area should be thoroughly cleaned and rinsed using

non-abrasive, mild cleaning detergents and water.

2. Care for stainless steel

No metal is indestructible and certain procedures should be followed to maintain the finish and

durability of stainless steel.

Never leave stainless steel items unwashed. The surface responds best to gentle cleaning

methods, scouring materials and harsh abrasives should not be used. Freq uent washing with

water (preferably hot) is the recommended treatment, followed by rinsing with fresh clean water

and wiping dry with a soft cloth or paper towel.

A little soap or detergent may be added to the washing water but too much can produce a cloudy

film over the appliance. Use of steel wool is not recommended but stainless steel wool (a fine

mesh pad) is an excellent cleaning aid. Oil or grease in the washing water can leave a rainbow

film when it dries. It can easily be removed by simply using polishing and cleaning methods

described previously. Thoroughly rinsing with clean water is the real secret and it a surprise how

easily stainless steel can be kept sparkling clean by using the above simple method.

Never leave stainless steel to dry by itself.

3. Only place cookware on oven shelves.

Other surfaces such as trims are not totally resistant to hard materials or direct heat and may be

permanently damaged by such use.

23

Page 23

Recommended cleaners

Mild detergents and warm water together with a clean, soft, non-abrasive cloth achieve goods

results for normal cleaning. Diluted washes with ammonia and water should rinse away any

adhesive residue or gummy deposits on the appliance surfaces. Eucalyptus oil (small am ounts) is

also good for removing adhesive residue. Alcohol based products (eg: methylated spirit, etc.) are

not recommended. Brand name cream cleansers and concentrates, without abrasive qualities,

can be used in small amounts to break down greasy deposits and dirt. After cleaning make sure

cleaned surfaces are thoroughly rinsed to prevent any risk of baked on cleaner residues a nd wipe

dry with a clean, soft cloth.

NOTE:

When cleaning stainless steel surfaces

stainless steel cleaner. Other reputable brand cleaners specifically formulated for cleaning

stainless steel may also be acceptable. Do not use steel soap pads or abrasive scourers of any

kind. The abrasive qualities of these pads will ruin the even brushed finish of the stainless steel

and any residual metal fibers may corrode causing a rusty/dull appearance. Metal polishes with

abrasive qualities are also not recommended.

WARNING:

Do not use any acid or caustic cleansers or abrasive powders or scourers on the interior

or exterior of the appliance.

Porter&Charles recommend 3M brand or Advance

Routine cleaning

Ensure all controls are in the off position and the appliance is cool before cleaning. When wiping

stainless steel surfaces with a brushed finish, wipe in the same directions as the bru shin g.

To clean the oven interior, fully open (side opening door/s) or remove the door/s (top opening

type, see opposite page) for better access while cleaning. The shelves and shelf guides can be

lifted out for cleaning by removing the relevant thumb screws. The shelves and shelf guides can

be washed manually but are also dishwasher safe.

If using commercial oven cleaners, choose only non-caustic cleaners and follow the

manufacturer’s instructions. Avoid contact with elements, rubber door seals and exterior surfaces.

After cleaning make sure all surfaces are thoroughly rinsed and wiped dry with a clean, soft cloth.

24

Page 24

Drop Down Grilling Element

The removal of a single screw at the front of the upper grill element allows the grill to drop down

to facilitate the cleaning of the oven ceiling. On completion of cleaning, simply replace the grill

element and secure with the screw.

To avoid smoking, use a clean, damp cloth to regularly clean oil and fat splatters from

the exposed drop down grilling element.

The fan cover can be lifted out for cleaning separately by removing the retaining screws. The fan

blade can also be removed for cleaning if necessary.

NOTE: that the fan blade nut has a left-handed thread.

Removing oven door (pull down door models only)

The oven door can be easily removed for better access while cleaning. To remove the oven door:

1. Open the door fully and fit the su pplied pin in the hole.

2. Raise the door slig htly, holding the sides of the door about half way up. Make sure

the pin stays in the hole the whole time. Lift the door gently. This should

disconnect the hinges from the oven frame.

3. Remove the door by continuing to raise it while pulling the door away from the oven.

When handling the door be careful not to dislodge the pin off the hole. If the pin does

dislodge, the hinge will have to be closed by hand and the pin re-fitted onto the hole

before re-fitting into the oven.

To re-fit the oven door:

i. Holding the door at an angle to the oven, slide the hinges into the oven frame,

making sure that on each side the top curved arm fits into the top slot and the lower

arm fits into the bottom slot.

ii. Make sure the hinges are pushed as far as they will go and the lower arm engages

into the plate mounted in the oven frame.

iii. Open the door fully and ensure the pin fully disengages from the hole. The door can

now be opened and as normal.

25

Page 25

Changing the light globe

The light globe is located behind the glass cover and is a screw-in type.

To change a light globe:

1- Gently lever out the glass cover only.

2- Pull the light globe and push in a replacement globe.

3- Replace the glass cover making sure it fits correctly into place.

NOTE:

Recommended globe: Halogen 25W

REMOVABLE BASEBOARD

The baseboard is provided with two clips to easy fit on to the legs.

To clean the floor under the ranges is easy removable the baseboard and refit after the

cleaning operations.

M - Trouble Shooting Guide

Symptom Remedy

No power supplied to appliance Has the power been disconnected? Check the meter

box. Has the main fuse or circuit breaker blown or

tripped?

Oven power is on but appliance does not

operate

Oven power is on but there is no heat Oven may be set on AUTO

Rubber seal has gap/s at bottom and

ends do not meet

Oven may be set on AUTO (see auto programmed

cooking)

Oven temperature may be set OFF

Mode may be on incorrect selection

Correct - doors are sealed this way for oven venting

purposes

Display is flashing, is only part

illuminated or is cycling through various

displays.

Turn power supply to appliance off, wait 30 seconds and

turn power on. Reset clock

26

Page 26

N - Installation instructions

INFORMATION FOR THE INSTALLER

THE GRAB HANDLES MUST BE USED TO MOVE THE OVEN.

WHEN THE OVEN IS HALF FITTED IN THE CABINET, IT IS POSSIBLE TO REMOVE THE

TWO HANDLES BY UNSCREWING THE FOUR FIXING SCREWS.

DO NOT LIFT OVEN BY THE FRONT DOOR AS THIS WILL DAMAGE THE OVEN

The operations indicated below must be followed by qualified personn el, in conformity with th e regula tions

in force.

The supplier refuses all responsibility for damages to person or property, resulting from

the failure to comply with such provisions.

All units are 230/240 power and 60h

The appliance is designed to be used near heat resistant pieces of furniture or kitchen cabinetry

only.

ELECTRICAL CONNECTIONS

Before carrying out electrical connection, be sure that the characteristics of the electrical system

meet the specifications located at the bottom of the cooktop and the electrical system is provided

with effective ground in compliance with the regulations and provision of the law in your country.

The ground is required in all circumstances.

If you wish a direct connection to the line, it is necessary to use a single pole switch, with a

minimum opening between the contacts of 3 mm. suitable for the purpose and in conformity with

the rules in your country (the green ground cable should not be interrupted by the switch).

ATTENTION

Disregard of this precaution could cause the incorrect operation of the touch control system of the

cooktop and effect the product warranty provisions.

WARNING:

Installation must comply with Standards North America (within North America) wiring rules, as

well as your local electrical and building codes and regulations and any other applicable

requirements. Your appliance must be properly installed and grounded by a qualified and

licensed technician.

Incorrect installation of the appliance, resulting from the kitchen maker not following the detailed

installation specifications, can affect the appliance performance. Ovens incorrectly installed may

invalidate the warranty and we strongly recommend that the oven cavity and venting be prepared,

as described, in the following specifications. This is critical to appearance, oven performance and

safety.

27

Page 27

CONNECTION TO THE GAS SUPPLY: CURRENT INSTALLATION STANDARDS

The cooker should be connected according to local regulations,

using either a rigid or flexible connections.

a) For building in: Use a continuous flexible stainless steel pipe, as

per current installation standards, which can be extended to a

maximum of 2000 mm.; the ends of the pipe must be fitted with

an ISO 228/1coupling and gasket or an ISO 7/1 threaded

coupling with mechanical gasket.

b) For free standing: A non-metallic flexible pipe can be used

as long as it complies with current standards and the

following installation instructions are observed: the pipe

must be longer than 400 mm and shorter than 1500 mm; it

must not exceed 50°C in any point; it is not pulled or

twisted; it cannot be choked and the entire edges, sharp

corners or other similar hazards.

Before connecting the non-metallic flexible pipe, the brass adapter and gasket supplied with

the cooker and/or available form the reseller must be fitted to the pipe/gas train on

the back of the cooker. The regulator provided should be positioned between the brass

adapter and the non metallic flexible pipe.

c) A certified gas plumber must complete the installation and meet with local regulation

requirements for gas connections. Where the unit has an armour cable a certified electricain

must complete the electrical connection. The white, or neutral wire will not be used and must

be capped using a marrette.

d)

Measurements

Please note that all dimensions provided are in millimeters (mm.) The sizes allow for only a small

degree of error so all cut-outs must be precise and square

Cooker Measurements

m

m

2

6

7

6

4

0

m

m

925 mm

m

m

2

6

7

6

4

0

m

m

925 mm

28

Page 28

O - Electrical wiring diagrams and instructions

WARNING:

All aspects of the installation must conform with the requirements of the standard North

America (within North America) wiring rules, as well as your local electrical and building

codes and regulations, and any other applicable requirements and conditions of your local

power supply authority.

A licensed electrician must perform the electrical work when installing this appliance. The

supply cable and fuse rating must be suitable for the appliance.

240 Volt 60hZ 40amp ( cooker with ceramic cooktop)

240 Volt 60hZ 30amp ( cooker with gas cooktop)

WARNING:

A licenced electrician must connect the armour cable and 3 wires into the electrical

connection box. The white, or Neutral wire is not used, and must be capped using a

marette.

To avoid power borne interference, this appliance must be installed individually on a separate and

distinct final sub-circuit.

Note:

To the electrician – please ensure sufficient supply cable is provided to allow the appliance to be

removed from the cavity should any servicing be necessary. This will also allow easy connection

of the supply.

Voltage supply connection

To connect the electrical supply:

1- Ensure the supply cable and fuse rating are suitable for the appliance (see the electrical

loading).

2- Remove the cover plate by undoing the screw.

3- Fit a suitable entry bush to the conduit entry on the rear left of the appliance (with the rear

toward you) and feed the fixed wiring through.

4- Connect the wiring to the terminal block using the screw connections provided. Ensure

the wires are properly secured to prevent any high resistance electrical connection.

5- Replace the cover plate making certain that the supply wiring is clear of any metal work

and the screws.

When connected to a sub circuit, protected by a circuit breaker, it is recommended the circuit

breaker be the same as the total rating of the appliance.

Electrical Loads

Oven 2350 W Oven 2350 W

Grill 2800 W Grill 2800 W

Oven fan and light 90 W Oven fan and light 90 W

Cearmic cooktop 6800 W Gas cooktop

TOTAL RATING 10.90 KW TOTAL RATING 3.70 KW

29

Page 29

30

Page 30

P

N = SPARK CANDLE

N

P = SPA RK GEN ERATOR

Green(Ground)

A = TERMIN AL BLOCK B = ELE CTR ONIC TI MER

C = OVEN THER MOSTAT D = OVEN SWITCH

E = OVEN LA MP F = R ED PI LOT LAMP

G = Y ELLOW PILOT LAMP H = FAN MOTOR

I = TOP ELEM ENT L = GRILL E LEMEN T

M = BOTTOM ELE MENT

Q = S WITCH CHAINE R = C OOLI NG FAN

T = SAFE TY TH ER MOSTAT S = COOLIN G FAN CLIXON

Y = DRAW ER HE ATIN G EL E M ENT

Red(L1)

A

O = FA N ELEMEN T

Z = SWI TCH E F OR W AR MIN G ELEME NT

Z

Y

I

L

Y

M

O

ELECTRICAL WIRING DIAGRAM FREE STANDING COOKER 90 CM. GAS COOKTOP

E

F

G

H

B

1A

1

C

D

Black(L2)

T

S

R

31

Page 31

P - Warranty

Porter&Charles products are designed and built to the highest standards.

We expect your appliances to provide many years of trouble free enjoyment.

In the event of an appliance requiring attention, each appliance is covered by a 2

year warranty from the date of purchase.

Refer to warranty policy for complete terms and conditions.

Coverage is for costs of parts and labor for appliances in capital cities &

metropolitan areas. We reserve the right to charge directly for handling

expenses outside the metropolitan region.

Porter&Charles products are supported by a national service support system.

Call our customer service department for attention.

Please retain your invoice Porter&Charles to quote should you require

service assistance. This will identify your product for our priority service

back-up. Please attach your invoice to this manual for easy future

reference.

PORTER & CHARLES INCORPORATED

2278 Speers Road

Oakville, Ontario,

Canada L6L2X8

Telephone: 1-866.699-4973

Telephone: 905-829.8389

Facsimile: 905-829.8409

For Service & Spares:

EURO-PARTS

1-800.678-8352

Important: Please record details of your purchase below and mail or fax to:

----------------------------------------------------------------------------cut along line --------------------------------------------------------------

Porter&Charles

Name:_____________________________ Tel no______________________________

Address:

______________________________________________________________________

City: ______________________ State:_______________ Zip Code: _______

Where purchased: _________________________ Purchase date ;________________

Items purchased:________________________________________________________

Serial No. (s): __________________________________________________________

32

Loading...

Loading...